MPS NB670GQ Schematic [ru]

NB670

The Future of Analog IC Technology

DESCRIPTION

The NB670 is a fully integrated high frequency

synchronous rectified step-down switch mode

converter with 3.3V fixed output voltage. It

offers very compact solution to achieve 6A

continuous output current and 9A peak output

current over a wide input supply range with

excellent load and line regulation. The NB670

operates at high efficiency over a wide output

current load range. Constant-On-Time (COT)

control mode provides fast transient response

and eases loop stabilization.

Under voltage lockout is internally set as 4.65 V.

An open drain power good signal indicates the

output is within its nominal voltage range.

NB670 also provides a 3.3V LDO, which can be

used to power the external peripheries, such as

the keyboard controller in the laptop computer.

A 300kHz CLK is also available; its output can

be used to drive an external charge pump,

generating gate drive voltage for the load

switches without reducing the main converter’s

efficiency.

Full protection features include OCP, OVP,

UVP and thermal shut down.

The converter requires minimum number of

external components and is available in QFN16

(3mmx3mm) package.

24V, High Current

Synchronous Buck Converter With LDO

FEATURES

• Wide 5V to 24V Operating Input Range

• 3.3V Fixed Output Voltage

• Built-in 3.3V, 100mA LDO with Switches

• 6A Continuous Output Current

• 9A Peak Output Current

• 300kHZ CLK for External Charge Pump

• Low R

(ON) Internal Power MOSFETs

DS

• Proprietary Switching Loss Reduction

Technique

• Internal Soft Start

• Output Discharge

• 500kHZ Switching Frequency

• OCP, OVP, UVP Protection and Thermal

Shutdown

APPLICATIONS

• Laptop Computer

• Tablet PC

• Networking Systems

• Personal Video Recorders

• Flat Panel Television and Monitors

• Distributed Power Systems

All MPS parts are lead-free and adhere to the RoHS directive. For MPS green

status, please visit MPS website under Products, Quality Assurance page.

“MPS” and “The Future of Analog IC Technology” are registered trademarks of

Monolithic Power Systems, Inc.

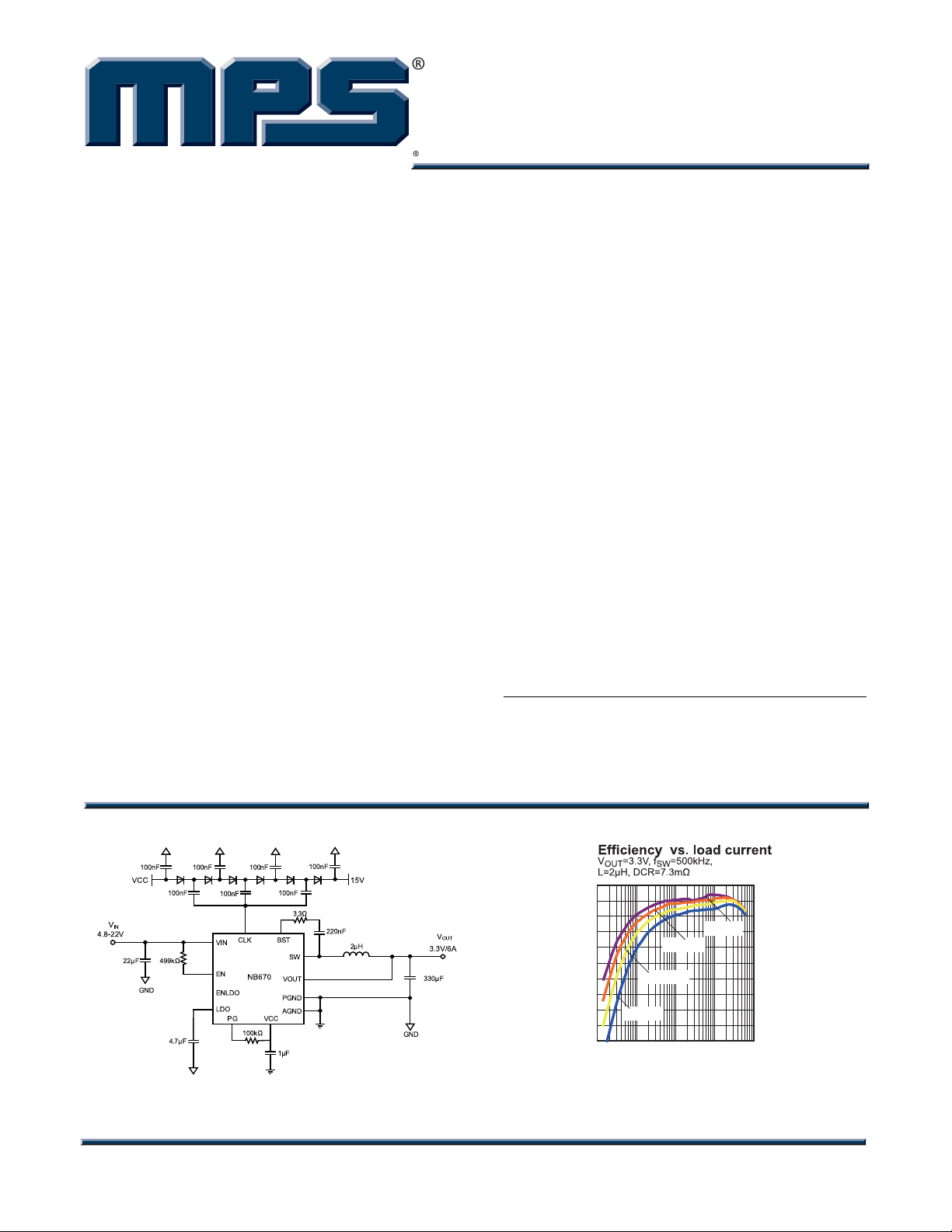

TYPICAL APPLICATION

100

95

90

85

80

75

70

65

EFFICIENCY (%)

60

55

50

NB670 Rev. 1.01 www.MonolithicPower.com 1

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

V

=12.6V

IN

VIN=19V

1 10 100 1000 10000

OUTPUT CURRENT (A)

V

=6V

IN

=8.4V

V

IN

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

y

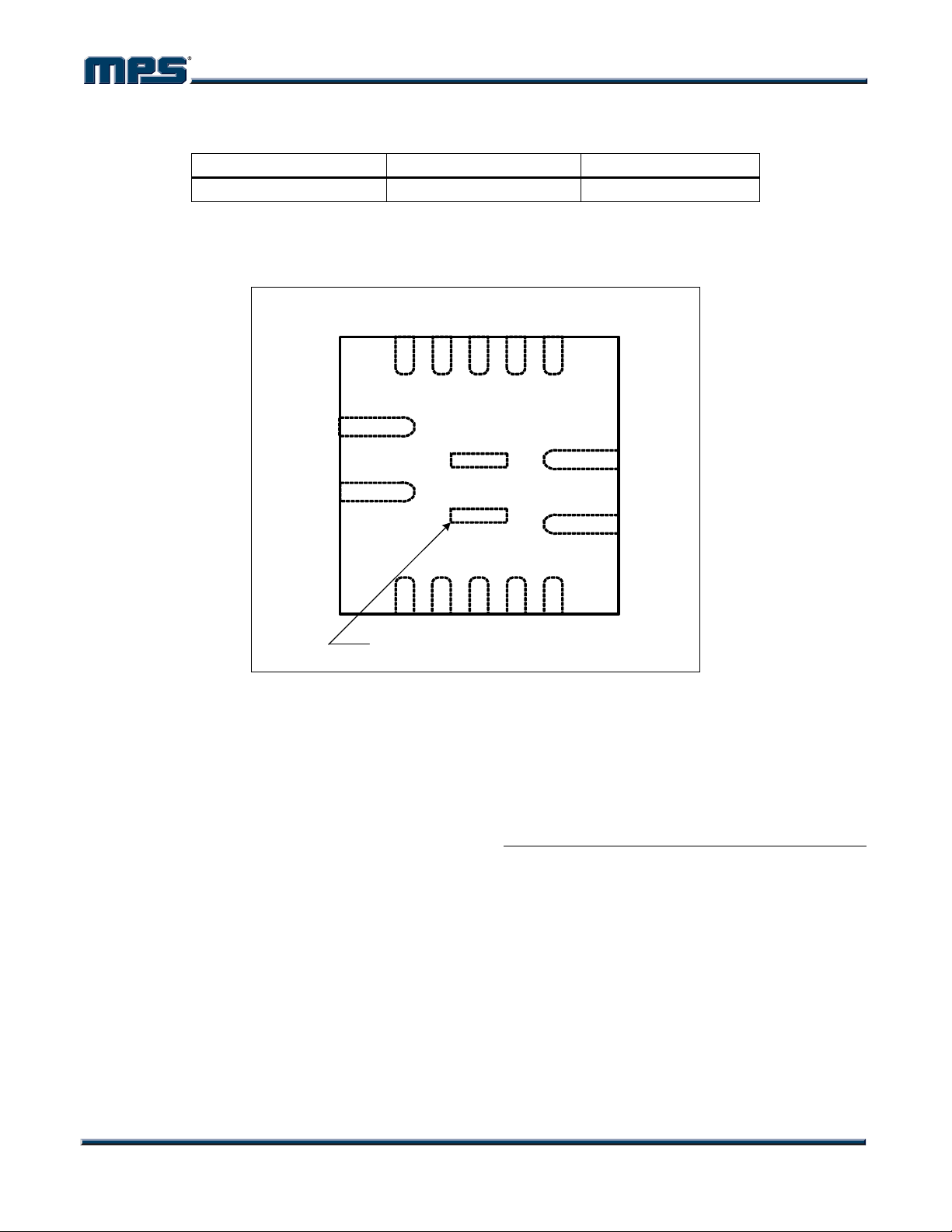

ORDERING INFORMATION

Part Number* Package Top Marking

NB670GQ QFN16 (3mmx3mm) ADZ

* For Tape & Reel, add suffix –Z (e.g. NB670GQ–Z)

PACKAGE REFERENCE

TOP VIEW

VCC

AGND EN

ENLDO

12 11

1314

BST

10

VIN

ABSOLUTE MAXIMUM RATINGS

1

2PGND

3

NC

EXPOSED PAD

ON BACKSIDE

(1)

Supply Voltage VIN....................................... 24V

V

...............................................-0.3V to 24.3V

SW

(30ns)..........................................-3V to 28V

V

SW

V

(5ns)............................................-6V to 28V

SW

V

................................................... VSW + 5.5V

BST

............................................................... 12V

V

EN

V

Enable Current I

........................................................... 12V

ENLDO

(2)

................................ 2.5mA

EN

All Other Pins...............................-0.3V to +5.5V

Continuous Power Dissipation (T

=+25°C)

A

(3)

QFN16……………………..….…..…………1.8W

Junction Temperature...............................150°C

Lead Temperature ....................................260°C

Storage Temperature............... -65°C to +150°C

15

SW

16

54 6 7

CLKPG VOUT

Recommended Operating Conditions

Supply Voltage VIN.............................. 5V to 22V

Output Voltage V

Enable Current I

Operating Junction Temp. (T

Thermal Resistance

QFN16 (3mmx3mm)............... 70...... 15... °C/W

Notes:

1) Exceeding these ratings may damage the device.

2) Refer to Page 19 of Configuring the EN Control.

3) The maximum allowable power dissipation is a function of the

4) The device is not guaranteed to function outside of its

5) Measured on JESD51-7, 4-layer PCB.

9

SWSW

SW

8

LDO

................................... 3.3V

OUT

...................................... 1mA

EN

)..-40°C to +125°C

J

(5)

θ

maximum junction temperature T

ambient thermal resistance

. The maximum allowable continuous power dissipation at

T

A

any ambient temperature is calculated by P

)/JA. Exceeding the maximum allowable power dissipation

T

A

will cause excessive die temperature, and the regulator will go

into thermal shutdown. Internal thermal shutdown circuitr

protects the device from permanent damage.

operating conditions.

(MAX), the junction-to-

J

, and the ambient temperature

JA

θJC

JA

(MAX)=(TJ(MAX)-

D

(4)

NB670 Rev. 1.01 www.MonolithicPower.com 2

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

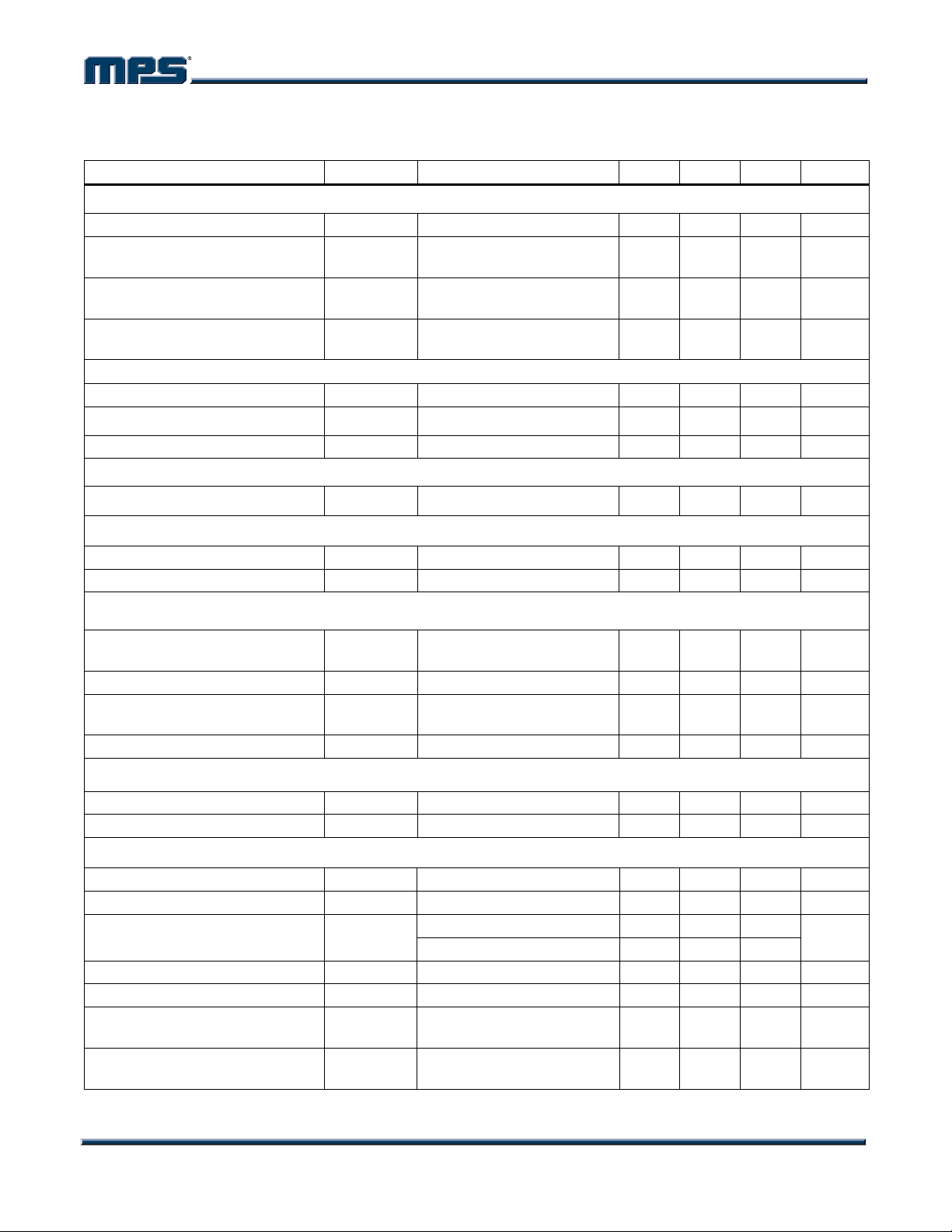

ELECTRICAL CHARACTERISTICS

VIN = 12V, TJ = 25°C, unless otherwise noted.

Parameters Symbol Condition Min Typ Max Units

Supply Current

Supply Current (Shutdown) I

Supply Current (Quiescent) IIN

Supply Current (No load) IIN

Supply Current (Standby) I

MOSFET

High-side Switch On Resistance HS

Low-side Switch On Resistance LS

Switch Leakage SW

Current Limit

VEN = 0V 1 2 A

IN_Shtdn

V

= 2V, V

EN

V

= 3.5V

OUT

V

= 2V, V

EN

V

= 3.35V, Io=0A

OUT

V

= 0V, V

EN

IN_Stby

RDS-ON

RDS-ON

LKG

I

= 0A

LDO

30 m

15 m

VEN = 0V, VSW = 0V 0 1 A

ENLDO

ENLDO

ENLDO

= 2V ,

= 2V ,

= 2V ,

140 220 300 A

240 A

40 80 120 A

Low-side Valley Current Limit I

8 8.5 9.5 A

LIMIT

Switching frequency and minimum off timer

Switching Frequency FSW 400 500 600 kHz

Minimum Off Time

(6)

T

350 ns

OFF

Over-voltage and Under-voltage Protection

OVP Threshold V

OVP Delay

(6)

T

UVP Threshold V

UVP Delay

(6)

T

OVP

OVPDEL

UVP

UVPDEL

125 130 135

2.5 s

55 60 65

8 s

%

V

OUT_Ref

%

V

OUT_Ref

Vout_Ref And Soft Start

Vout Ref Voltage Vout_Ref 3.285 3.35 3.415 V

Soft Start Time TSS 1.5 1.8 1.95 ms

Enable And UVLO

Enable Input Low Voltage VILEN 1.15 1.25 1.35 V

Enable Hysteresis V

Enable Input Current IEN

Enable LDO Input Low Voltage V

Enable LDO Hysteresis V

VCC Under Voltage Lockout

Threshold Rising

VCC Under Voltage Lockout

Threshold Hysteresis

ENLDO-HYS

VCC

VCC

100 mV

EN-HYS

VEN = 2V 5

V

= 0V 0

EN

1.15 1.25 1.35 V

ENLDO

A

100 mV

4.65 4.85 V

Vth

500 mV

HYS

NB670 Rev. 1.01 www.MonolithicPower.com 3

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

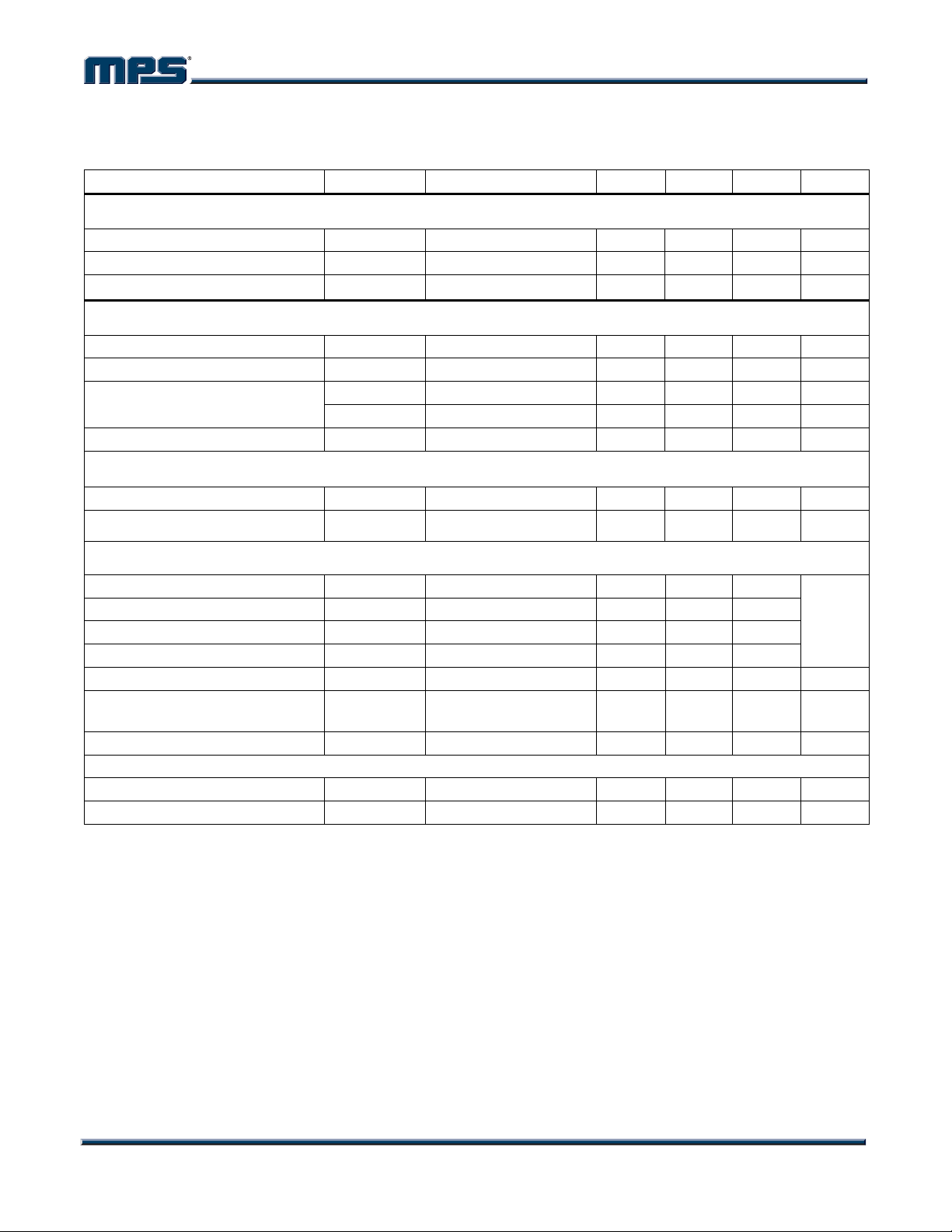

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

ELECTRICAL CHARACTERISTICS (continued)

VIN = 12V, TJ = 25°C, unless otherwise noted.

Parameters Symbol Condition Min Typ Max Units

CLK Output

CLK Output High Level Voltage V

CLK Output Low Level Voltage V

CLK Frequency F

I

CLKH

I

CLKL

CLK

= -5mA 3.1 3.25 3.4 V

Vclk

= 5mA 0 0.05 0.1 V

Vclk

T

= 25°C

J

300 kHz

LDO Regulator

LDO Regulator V

LDO Load Regulation

LDO Load Capability

Switch Rdson R

3.25 3.35 3.45 V

LDO

I

Switch

=50mA 5 %

LDO

Before switch-over 70 90 120 mA

After switch-over 100 mA

I

=50mA 1.7 2.2

LDO

VCC Regulator

VCC Regulator V

VCC Load Regulation

CC

4.95 5.15 5.35 V

Icc=5mA 5 %

Power Good

PG Rising (Good) PG

PG Falling (Fault) PG

PG Rising (Fault) PG

PG Falling (Good) PG

95

Vth-Hi

85

Vth-Lo

115

Vth-Hi

105

Vth-Lo

%

V

OUT_Ref

Power Good Lower to High Delay PGTd 0.5 ms

Power Good Sink Current

Capability

Power Good Leakage Current I

Sink 4mA 0.4 V

V

PG

VPG = 3.3V 100 nA

PG_LEAK

Thermal Protection

Thermal Shutdown

(6)

T

150 °C

SD

Thermal Shutdown Hysteresis 25 °C

Note:

6) Guaranteed by design.

NB670 Rev. 1.01 www.MonolithicPower.com 4

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

PIN FUNCTIONS

PIN # Name Description

Supply Voltage. The VIN pin supplies power for internal MOSFET and regulator. The

1 VIN

2 PGND Power Ground. Use wide PCB traces and multiple vias to make the connection.

3 NC Not connected.

4 PG

5 CLK 300kHZ CLK output to drive the external charge pump

6 LDO

7 VOUT

8, 9

Exposed Pad

15, 16

10 BST

11 VCC

12 ENLDO

13 EN

14 AGND Analog ground. The internal reference is referred to AGND.

SW

NB670 operates from a +5V to +24V input rail. An input capacitor is needed to

decouple the input rail. Use wide PCB traces and multiple vias to make the

connection.

Power good output. The output of this pin is an open drain signal and is high if the

output voltage is higher than 95% of the nominal voltage. There is a delay from Vout

95% to PGOOD goes high.

Internal 3.3V LDO output. Decouple with a minimum 4.7µF ceramic capacitor as

close to the pin as possible. X7R or X5R grade dielectric ceramic capacitors are

recommended for their stable temperature characteristics.

Once the output voltage of the Buck regulator is ready, it will switch over the LDO

output to save the power loss.

Output voltage sense. For the NB670, the output of the Buck regulator is fixed to

3.3V. VOUT pin is used to sense the output voltage of the Buck regulator, connect

this pin to the output capacitor of the regulator directly. This pin also acts as the

input of the 3.3V LDO switch over power input.

Keep the VOUT sensing trace far away from the SW node. Vias should also be

avoided on the VOUT sensing trace.

Switch Output. Connect this pin to the inductor and bootstrap capacitor. This pin is

driven up to the VIN voltage by the high-side switch during the on-time of the PWM

duty cycle. The inductor current drives the SW pin negative during the off-time. The

on-resistance of the low-side switch and the internal diode fixes the negative

voltage. Use wide and short PCB traces to make the connection. Try to minimize the

area of the SW pattern.

Bootstrap. A capacitor connected between SW and BST pins is required to form a

floating supply across the high-side switch driver.

Internal 5V LDO output. The driver and control circuits are powered from this

voltage. Decouple with a minimum 1µF ceramic capacitor as close to the pin as

possible. X7R or X5R grade dielectric ceramic capacitors are recommended for their

stable temperature characteristics.

100mA LDO and VCC enable pin. ENLDO is internally pulled up to high. Leave this

pin open to enable the LDO. Drive it low to turn off all the regulators .

Buck regulator and charge pump clock enable pin. EN is a digital input that turns the

Buck regulator and CLK on or off. When the power supply of the control circuit is

ready, drive EN high to turn on the Buck regulator and charge pump clock, drive it

low to turn them off.

NB670 Rev. 1.01 www.MonolithicPower.com 5

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

NB670 ― 24V, HIGH CURRENT SYNCHRONOUS BUCK CONVERTER WITH LDO

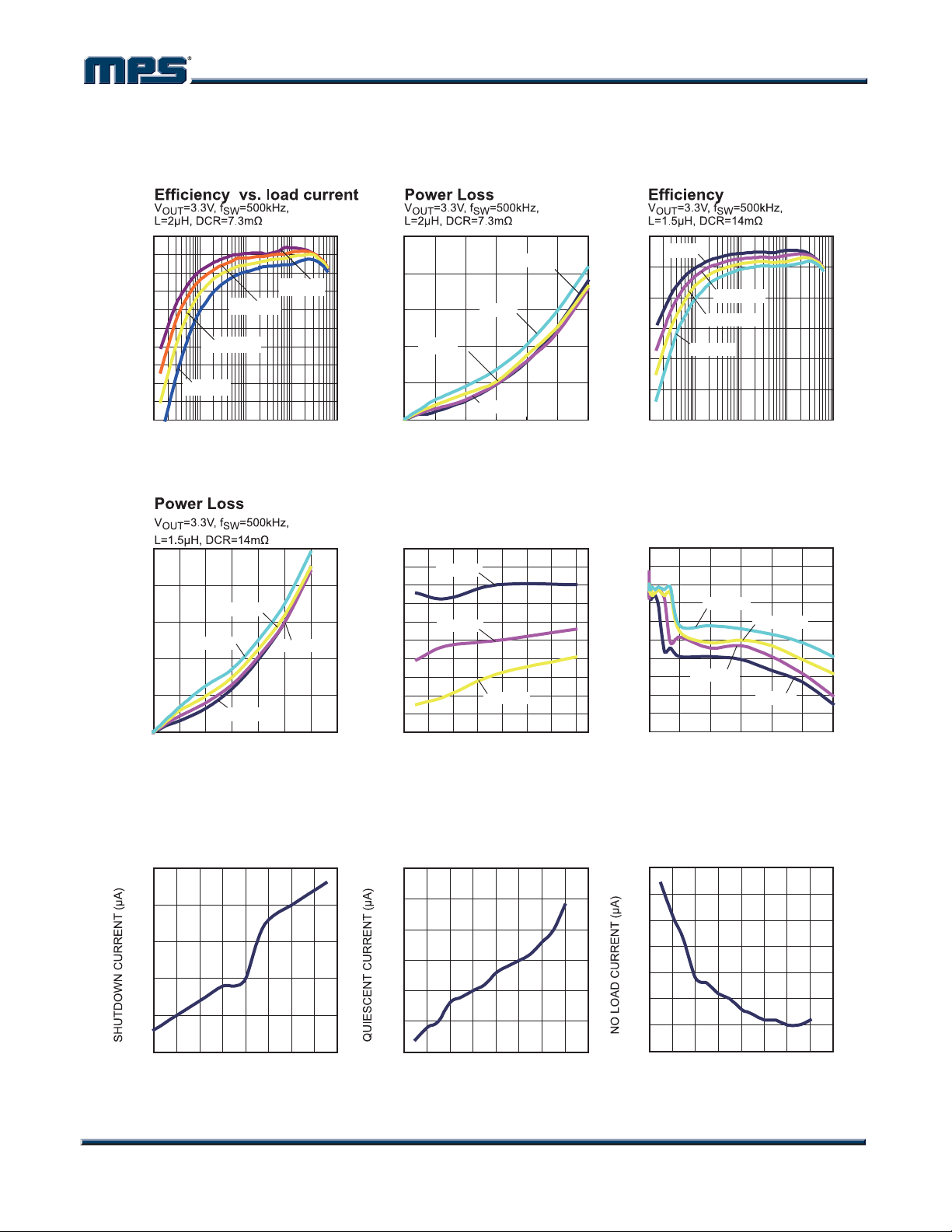

TYPICAL PERFORMANCE CHARACTERISTICS

Performance waveforms are tested on the evaluation board of the Design Example section.

=12V, V

V

IN

=3.3V, L=2µH, TJ=+25°C, unless otherwise noted.

OUT

100

95

90

85

80

75

70

65

EFFICIENCY (%)

60

VIN=19V

55

50

1 10 100 1000 10000

OUTPUT CURRENT (A) OUTPUT CURRENT (A)

2500

2000

1500

1000

POWER LOSS (mW)

500

0

01234567

OUTPUT CURRENT (A) OUTPUT CURRENT (A)

V

V

=12.6V

IN

V

=12.6V

IN

V

=19V

IN

V

IN

IN

=6V

=8.4V

VIN=6V

V

IN

=8.4V

2500

V

=6V

=19V

V

IN

VIN=8.4V

IN

2000

1500

1000

500

POWER LOSS (mW)

=12.6V

V

IN

0

0123456

100

VIN=6V

90

80

70

60

EFFICIENCY (%)

50

40

0.001 0.01 0.1 1 10

V

OUTPUT CURRENT (A)

Line Regulation Load Regulation

1

0.8

0.6

0.4

0.2

-0.2

-0.4

-0.6

LINE REGULATION (%)

-0.8

-1

I

=0A

OUT

I

=3A

OUT

0

=6A

I

OUT

5 7 9 11 13 15 17 19

INPUT VOLTAGE (V)

1

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

LOAD REGULATION (%)

-0.8

-1

VIN=8.4V

0123456

V

V

=12.6V

IN

=19V

IN

VIN=19V

IN

=8.4V

V

V

=12.6V

IN

=6V

IN

Supply Current(Shutdown)

vs. Input Voltage

2.5

2

1.5

1

0.5

0

5 7 9 111315171921

INPUT VOLTAGE (V) INPUT VOLTAGE (V)

Supply Current(Quiescent )

vs. Input Voltage

220

215

210

205

200

195

190

579111315171921

No Load Current vs.

Input Voltage

265

260

255

250

245

240

235

230

579111315171921

INPUT VOLTAGE (V)

NB670 Rev. 1.01 www.MonolithicPower.com 6

7/23/2013 MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

Loading...

Loading...