User Manual

RAPID mini precision grinder

E106015.docx

ED: 16.01.17

SD: 02.12.19

Dieter Marx

- 1/2 -

Micro Präzision Marx GmbH D-91056 Erlangen 09131-9056-0 09131-9056-600

Observe safety

instructions:

IN SLEWED POSITION

ONLY GRIND TOWARDS

THE GAUGE BLOCK !

NEVER REMOVE THE

TIMING BELT COVER WHEN

MACHINE IS IN OPERATION

Applications:

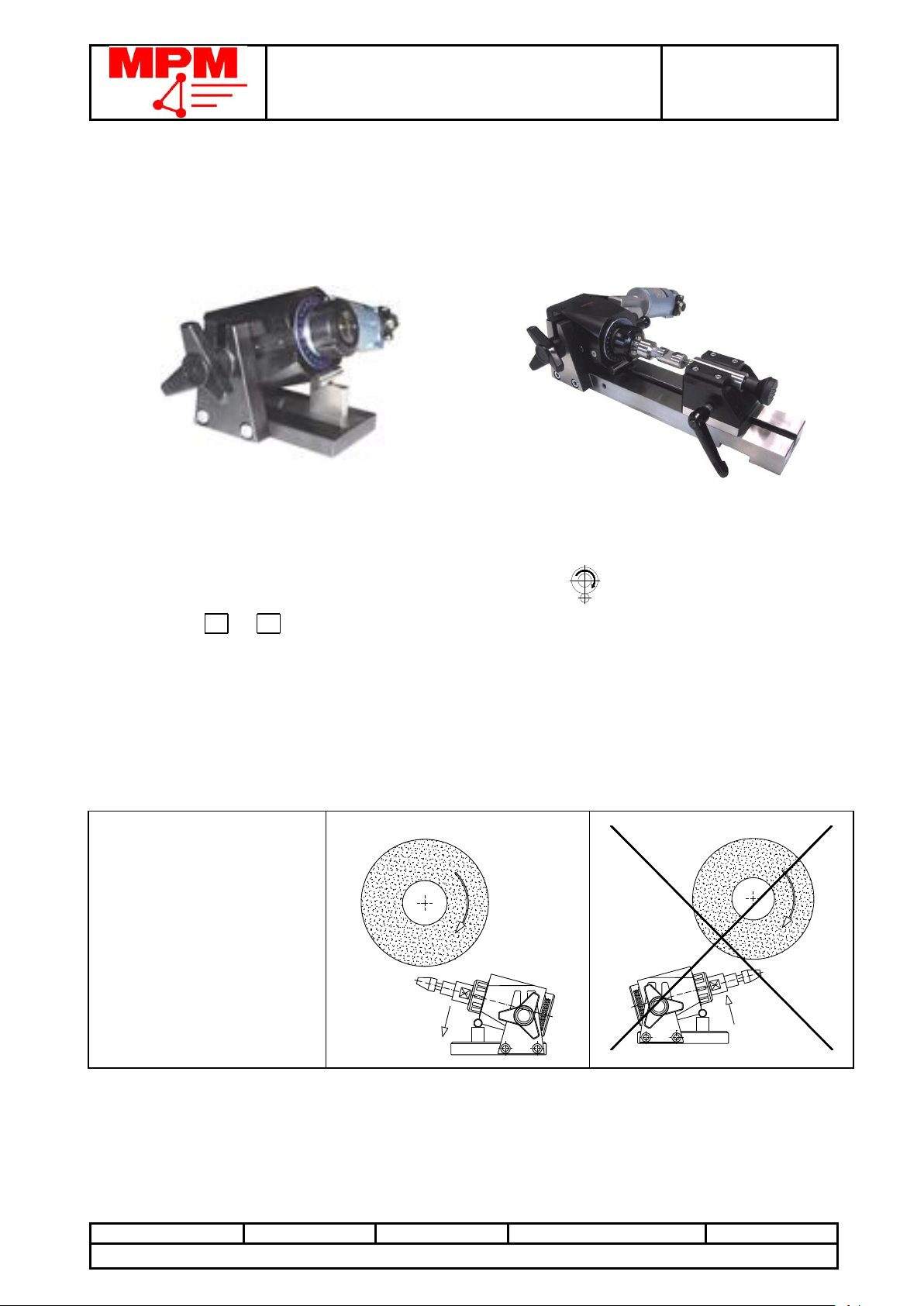

Cylindrical grinding --- taper grinding --- form grinding ---

polygon grinding --- plunge-cut grinding --- smallest diameter grinding

On your surface grinding machines!

Mode of use

1. Set the RAPID mini on the magnetic table of the surface grinder. Adjust the right-angled

groundplate to the stop ledge of the magnetic table and switch the magnet on.

2. Place the workpiece under the centre of the grinding wheel.

3. Select with or the sense of rotation and spindle start.

4. Determine the highest point of the workpiece by moving the machine-table.

5. When grinding cylindrical and taper parts, the timing belt must be tightened and the index bolt

must be unlocked!

Switch the motor on and let the workpiece rotate.

6. When grinding surfaces or polygons, the timing belt must be loosened.

For this, the clamping screw for the motor bracket must be released.This screw is on the

bottom of the block. Then you can move the motor along the slot.

7. The motor must be switched off and the index bolt must be locked.

Maintenance:

The RAPID mini grinder is sealed on the front and rear side with a shaft-sealing ring for

splash-water protection.

In case of heavy coolant use we recommend an additonal cover.

Cleanness and good care preserve the precision of the RAPID mini grinder .

User Manual

RAPID mini precision grinder

E106015.docx

ED: 16.01.17

SD: 02.12.19

Dieter Marx

- 2/2 -

Micro Präzision Marx GmbH D-91056 Erlangen 09131-9056-0 09131-9056-600

Ground plate ca.

125x100mm

Weight ca.

9 kg

Height (horizontal) ca.

110mm

Index-divider

15°

Height (vertical) ca.

175mm

Centre height ca.

45mm

Toolholder

E32

(for collets Ø 2-20mm)

Spindle true running

0,002mm

Drive

E-Motor,

continiously adjustable

up to 300min-1

sense of rotation selectable

Mains supply

115-230V

50-60Hz

70W

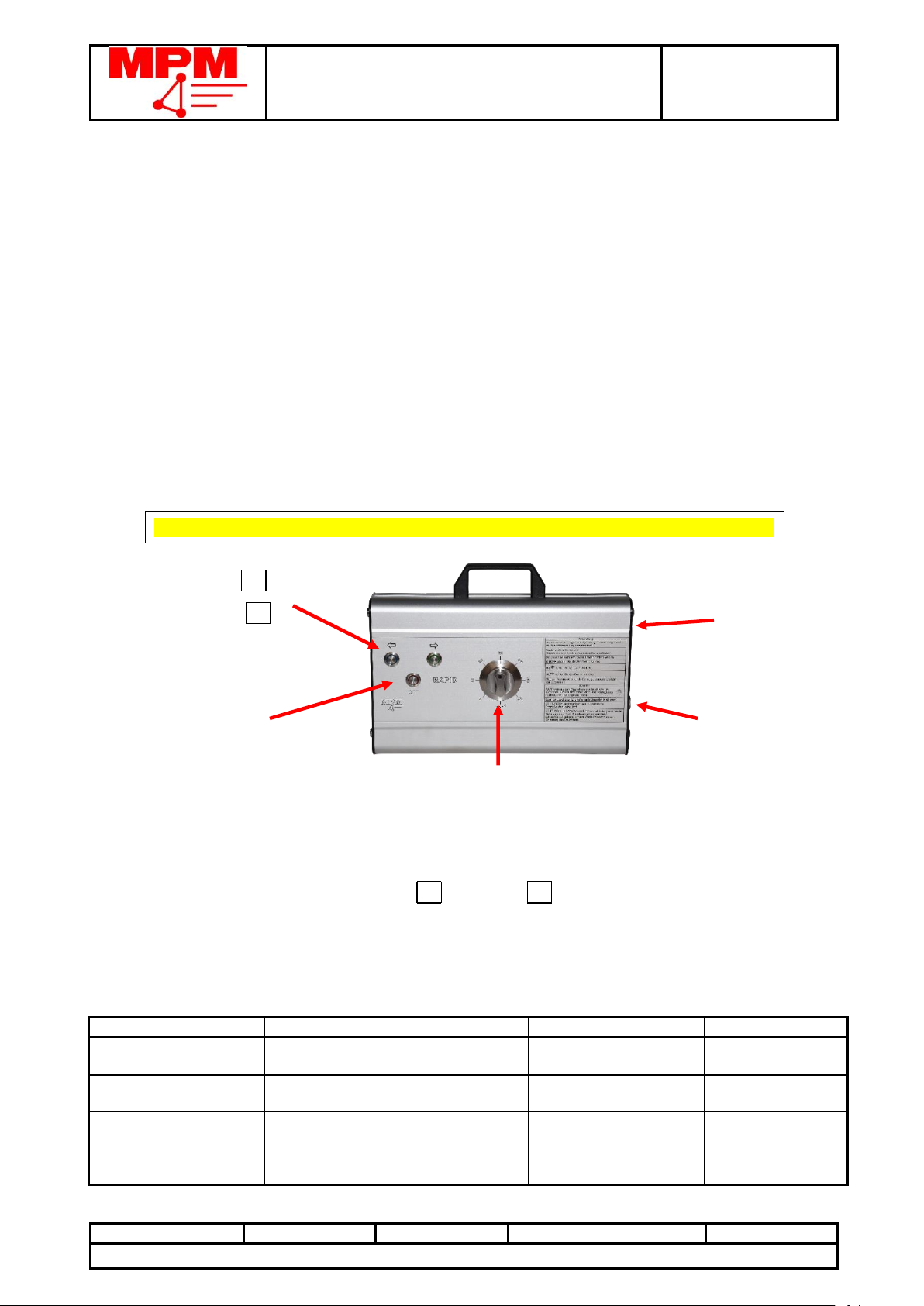

Rotation left

Rotation right

The OFFbutton

illuminates after

mains connection.

It must be actvated

at every change of

direction (left/right)!

Potentiometer for

speed regulation

Connection

line voltage

Cable connection

grinding device

Please compare set voltage on the main switch with your line voltage.

Taper grinding:

Slewable up to 45° (relative 90°). Use gauge block according attached sine table.

Up to +45° angle position place the gauge block underneath the front sine axle.

When minus degrees are necessary, position the gauge block underneath the rear sine axle.

At an angle +90°, adjust both sine axles vertically.

Grinding with tailstock and rigid center punch:

Please observe heat development, thin workpieces may bend.

Motor-temperatures up to ca. 60° are harmless.

Workpiece change:

Lock the spindle with the index bolt. Loosen, respectively tighten the collet chuck with the hook

spanner.

The spindle cone (toolholder) is suitable for collets Ø-range 2-20mm.

High precision collets, reduction sleeve ER11, reduction sleeve DECKEL S20, three-jaw chuck

Ø80mm, magnet chuck Ø60 and Ø100mm are optional.

1. Connect mains supply and 5-pole lead. The device is on.

2. The OFF button is illuminated.

3. Select the sense of rotation. Right with , left with

4. The active rotation button is illuminated

5. With the potentiometer is the spindle speed adjustable up to ca. 300min-1

6. Stop the spindle rotation with OFF

Technical details:

Subject to change w ithout prior notice., MPM

Loading...

Loading...