MPM 50 Overmolding Manual

Miniature Plastic Molding

Affordable Injection Molding Machinery

Model #50 – Hydraulic Molding Machine

OVERMOLDING MANUAL

6750 Arnold Miller Pkwy.

Solon, Ohio 44139

440-498-8465

Miniature Plastic Molding

Model #50

Overmolding Manual

Version 1.00

OVERVIEW

This manual is a supplement to the provided Operating Manual included with the Model 50

injection molding machine. The information in this manual is in addition to the information

provided in the other manuals.

The Model 50 machines have an optional base known as a 'C' frame. The optional base

takes the typical machine's 'V' mold base and rotates it 90º. The lower frame of the machine is

also shaped so that it leaves the front of the machine open. Thus, operators can perform molding

operations on long cables without having to feed the cable through the center of the machine.

The option was intended to allow the end-user to repair damaged cable jackets. The purpose of

this manual is to explain in more detail how to operate a Model 50 machine with the 'C' frame

option.

GENERAL SAFETY INFORMATION

(1) ALWAYS WEAR SAFETY GLASSES when running this or other types of machinery or

equipment. Make sure that the glasses are constructed of ANSI (American National Standards

Institute) approved material.

(2) Please READ THE PROVIDED MANUALS in their complete entirety before beginning any

work on the machine. Failure to review the provided manuals may result in damage to the

equipment or injury to the operator.

(3) NEVER OPERATE THE MACHINE WHILE GUARDS ARE REMOVED OR RENDERED INOPERATIVE. The Model 50 machine does not contain a moving clamping mechanism, but there

are moving parts, heater bands, and electrical devices that become potential safety hazards if the

guards are removed or the machine is operated in a careless manner.

(4) ALWAYS SHUT OFF THE POWER TO THE MACHINE when performing maintenance tasks.

An emergency stop button is provided on the operator’s panel that requires re-setting to operate

again. This button should not be used for shutting down the machine for maintenance. To shut

off power to the machine, use the rotary disconnect located on the main electrical enclosure. The

disconnect is also equipped with a lock-out feature for servicing the machine.

(5) NEVER REACH INTO THE MACHINE without taking safety precautions. There are potential

pinch points, high temperatures and voltages that would present hazards to the operator if the

machine were used in a careless manner.

(6) NEVER have more than one person operating the machine at any time.

(7) MAKE SURE THE MACHINE'S STAND IS SECURE BEFORE OPERATING. The machine

typically comes with a stand equipped with casters. Before operating the machine, make sure the

pads on the casters have been lowered. Failure to do so could cause the machine to move

around in an unsafe manner during operation. If the machine is positioned that permits access to

the rear of the unit, additional barrier guarding must be provided to prevent access.

(8) NEVER LEAVE THE MACHINE’S HEATERS ON FOR ANY EXTENDED LENGTH OF TIME

WHEN THE MACHINE IS NOT BEING OPERATED. It may overheat the material in the screw

barrel, possibly degrading it to the point where it could explode, expelling dangerous gases.

1

INTRODUCTION

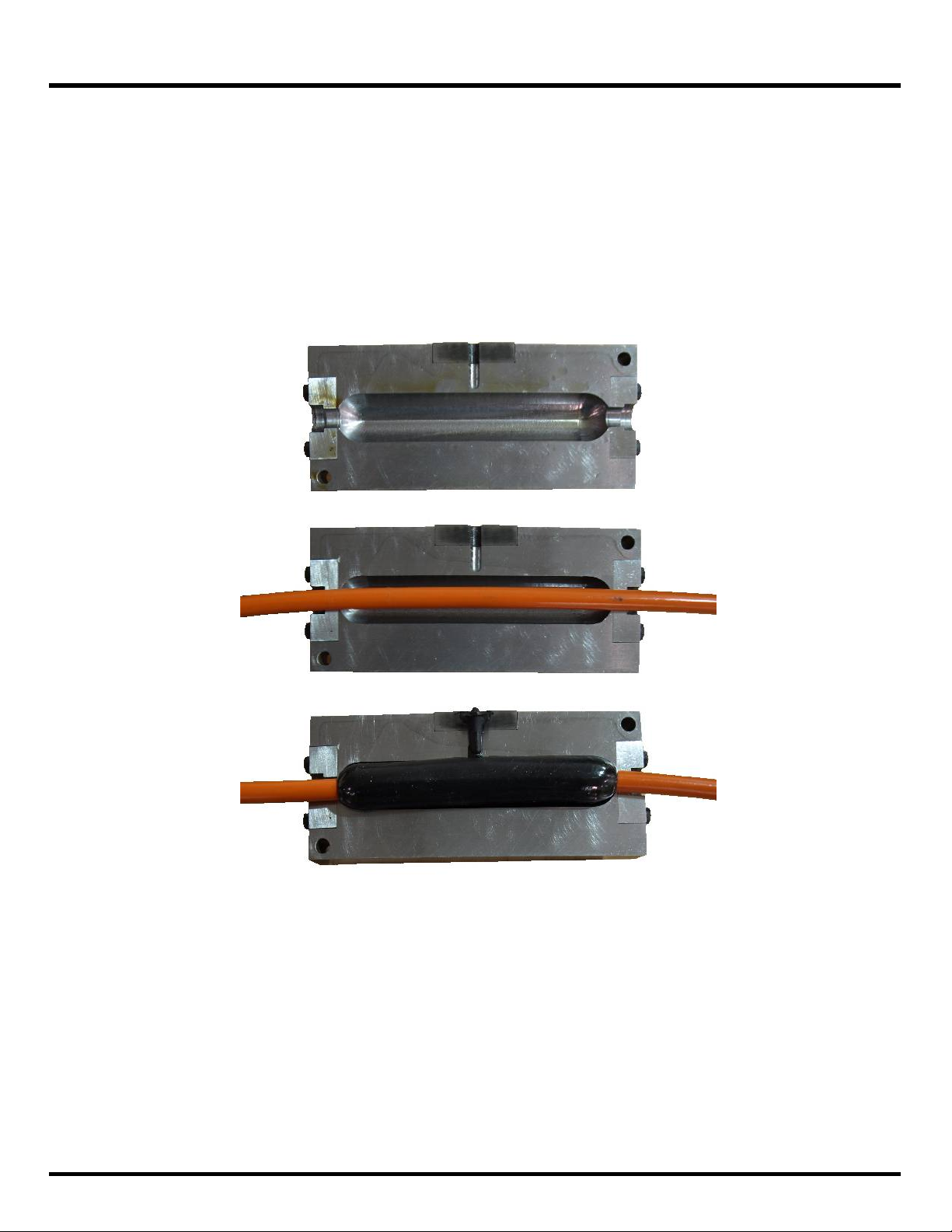

'V' Mold for Overmolding Cables

Miniature Plastic Molding offers a 'V' mold designed to overmold damaged jackets on

cables. The mold contains a large pocket to surround the damaged area. Either end of the mold

contains a groove large enough to hold the cable, but small enough to prevent material from

squirting out. The mold shown in the pictures below have interchangeable ends for different sized

cables.

2

Loading...

Loading...