mpec SA380-IT User Manual

SA380-IT User Guide

6 Pinnacle Way, Pride Park, Derby, UK, DE24 8ZS

Sales:

sales@mpec.co.uk

General Enquiries:

enquiries@mpec.co.uk

© MPEC Ltd. 2016 All rights reserved.

No part of this publication may be copied without the prior consent of MPEC.

www.mpec.co.uk

Contents

Contents

1) Safety Information

1.1) Explanation of Symbols

1.2) Intended Use

1.3) Warranty & Liability

1.4) Personnel

1.5) Handling Hazards

1.6) Safe Installation

2) General

2.1) Product Description

2.2) Principles of Operation

2.3) Modes of Operation

2.3.1 Normal Mode

2.3.2 Technicians Mode

2.3.3 Suspended Mode

2.3.4 Degraded Modes

2.4) System Voltage Measurement

2.5.1) AC and DC Circuits

2.5.2 DC Circuits Only

2.6) Core-to-Core Resistance Effects

2.7) Earth Integrity Measurement

2.8) Hardware Self-Test

2.9) Alert Conditions

2.8.1 Hysteresis:

2.8.2 Minimum Operation Time

2.10) Communications & Peripheral Outputs

2.9.1 Fault Indication (Volt-Free-Contact)

2.9.2 Auxiliary Power Supply

2.9.3 Serial RS485 Data Port

2.9.4 GSM & Ethernet Connection

2.11) Data Acquisition

2.10.1 Protocol Selection

2.10.2 The Rules of Acquisition

2.10.3 Buffering

2.10.4 Examples

3) Installation

3.1) Overview

3.2) Physical Installation

3.3) Termination of Wiring

3.4) Connection of SA380-IT Supply

3.5) Connection of Earth

3.6) Connection of Monitored Circuits

3.6.1 Via Resistive Cables

3.6.2 Via HI Z Outputs

3.7) Connection of Peripheral Equipment

3.7.1 GSM

3.7.2 Ethernet

3.7.3 Volt-Free Contact (VFC)

3.7.4 Auxiliary Power Output

3.7.5 RS485

3.8) Commissioning

4) Operation

4.2) SA380-IT Front Panel Indications

4.3) Connecting the SA380-IT with a Computer or Apple device

4.3.1 Connect to a Computer directly using an Ethernet Cable

4.3.2 Connect to an Apple Device directly using a Lightning to Ethernet Cable

4.4.4 Connect via a Local Area Network using Ethernet

4.4.5 Connect via GSM Network

4.4) Navigating the SA380-IT User Interface

4.4.1 Main Menu

4.4.2 Live Measurements

4.4.3 Technicians Modes

4.4.4 Device Status

4.4.5 Utilities

4.4.6 Upgrade Firmware

4.4.7 Settings

4.4.8 Monitored Circuit Settings

4.4.9 Auto Detect Circuits

4.4.10 Advanced

4.4.11 About

5) Faulting & Maintenance

5.1) Physical Inspection

5.2) Faulting Device Interlocks

6) Technical Data

6.1) Specification

6.2) Mechanical

6.3) Ordering Details

1) Safety Information

1.1) Explanation of Symbols

The following designations are used to bring important hazards and information to the attention of the user:

1.2) Intended Use

Correct use includes compliance with instructions from the operation and maintenance manual with regard to transportation, installation,all

operation and maintenance.

1.3) Warranty & Liability

Warranty and Liability claims due to injury to persons or damage to property are excluded if they can be attributed to any of the following

causes:

Improper use of the SA380-IT as defined in section 1.2.

Unauthorized modification to the SA380-IT, structural or electrical.

Unauthorized repair of the SA380-IT.

Disasters caused by foreign bodies, fire, or force majeure.

1.4) Personnel

Only personnel familiar with the installation, commissioning and operation of the SA380-IT may work with the SA380-IT. Such personnel mus

t:

Read and understand the safety chapter of this document.

Undertake appropriate training in the installation of electrical equipment.

Comply with all rules and regulations regarding safety for the given place of work.

1.5) Handling Hazards

The following precautions must be taken during storage and transportation:

Protection from prolonged rainfall.

Protection from immersion in water.

Ensure that the storage temperature is not exceeded.

Protection against crushing.

A real threat to human life. It must be adhered to at all times.

A possible dangerous situation. There could be a risk to human life is correct procedure is not followed.

A particularly useful application tip.

The intended use of the SA380-IT insulation monitor is to remotely monitor pole-to-pole voltage and resistance to earth

(insulation resistance) of IT (earth-free) power supply circuits. Any other use, or use beyond the product specification is

deemed improper. MPEC Tecnology Ltd shall not be liable for any loss or damage to life or property arising from

improper use.

Members of the public must never be permitted access to the SA380-IT.

Damaged enclosures can expose hazardous voltages and nullifies the SA380-IT Ingress-Protection.

1.6) Safe Installation

Detailed wiring instructions can be found in section 3. The purpose of this section is to reinforce critical safety information.

Prolonged exposure to, or immersion in water exceeds the SA380-IT Ingress-Protection rating. Under such conditions

dielectric withstand voltages cannot be guaranteed.

Never install or energise an SA380-IT that appears to be either physically damaged or suffering from water ingress.

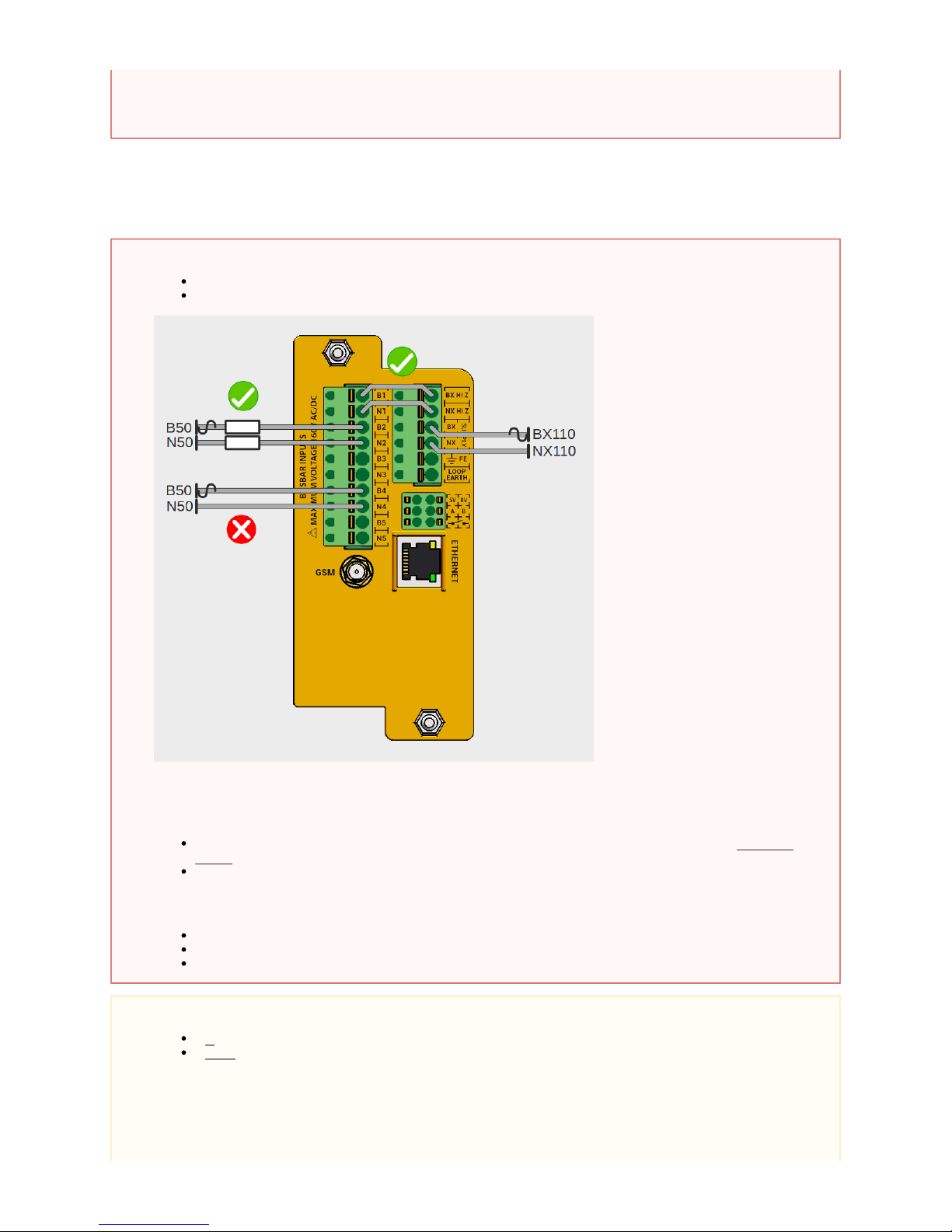

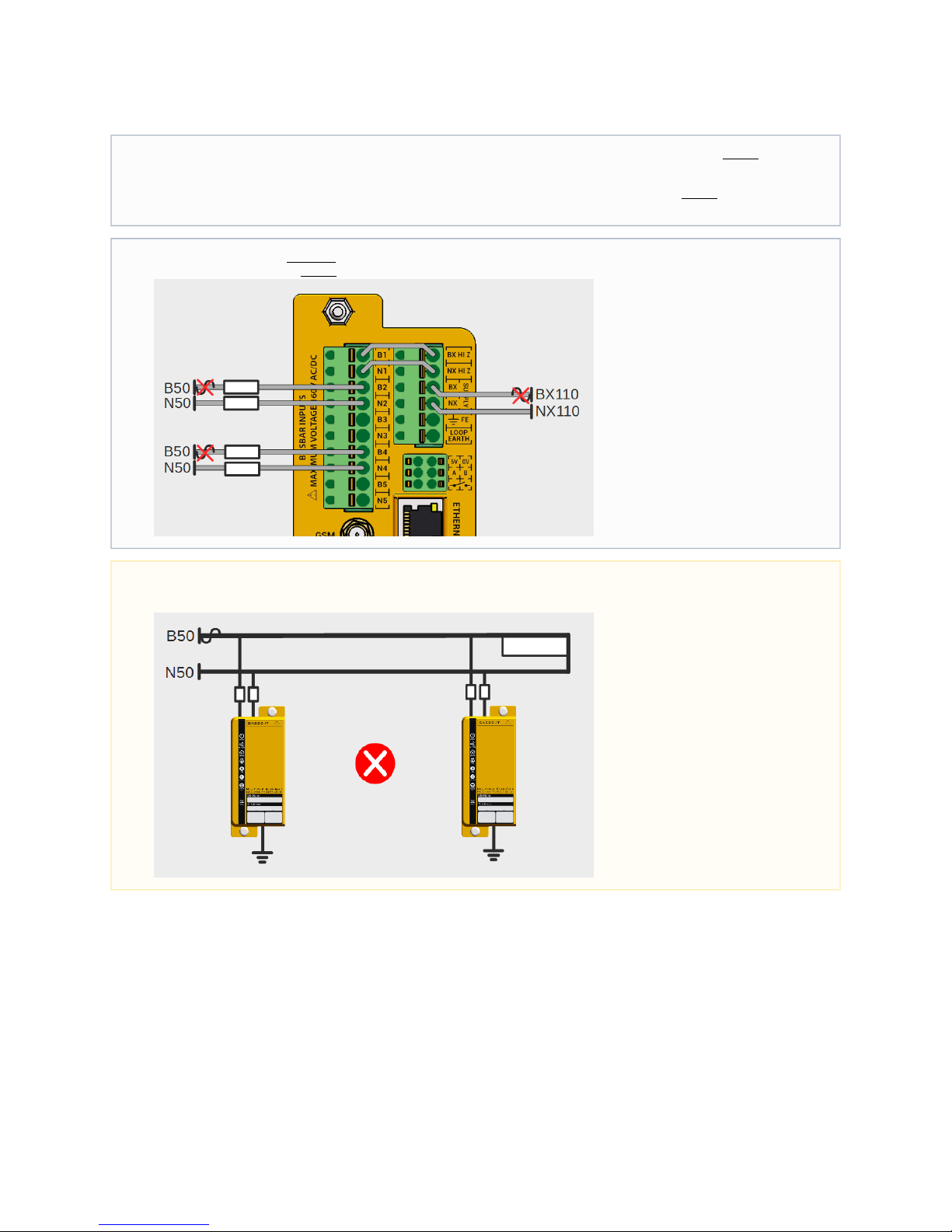

Never connect the SA380-IT directly to monitored circuits without:

Using the approved resistive cable (MPEC part No. SA380-IT-RC).

Connecting via the BX HI Z and NX HI Z terminals.

Never attempt to "common together" any conductors from differing monitored circuits.

Always check the voltage of the monitored and supply circuits:

Check each monitored or supply circuit does not exceed the specified maximum system voltage (160V RMS

).AC/DC

Ensure wiring of monitored or supply circuits is performed such that the cabling is not "live" until installation is

complete.

Attempting any of the above poses a risk of:

Circumvention if the inter-isolation of monitored circuits.

Short circuit of individual monitored circuits.

Electric shock.

The Functional Earth and Loop Earth must be connected to suitable earthing points using separate wires.

It acceptable to use a common earthing point if provision of a secondary earthing point is prohibitive.is

It acceptable to simply strap Functional Earth to Loop Earth.is not

An ineffective Earth Loop circuit is unable to verify correct connection of the SA380-IT, hence insulation readings may be incorrect.

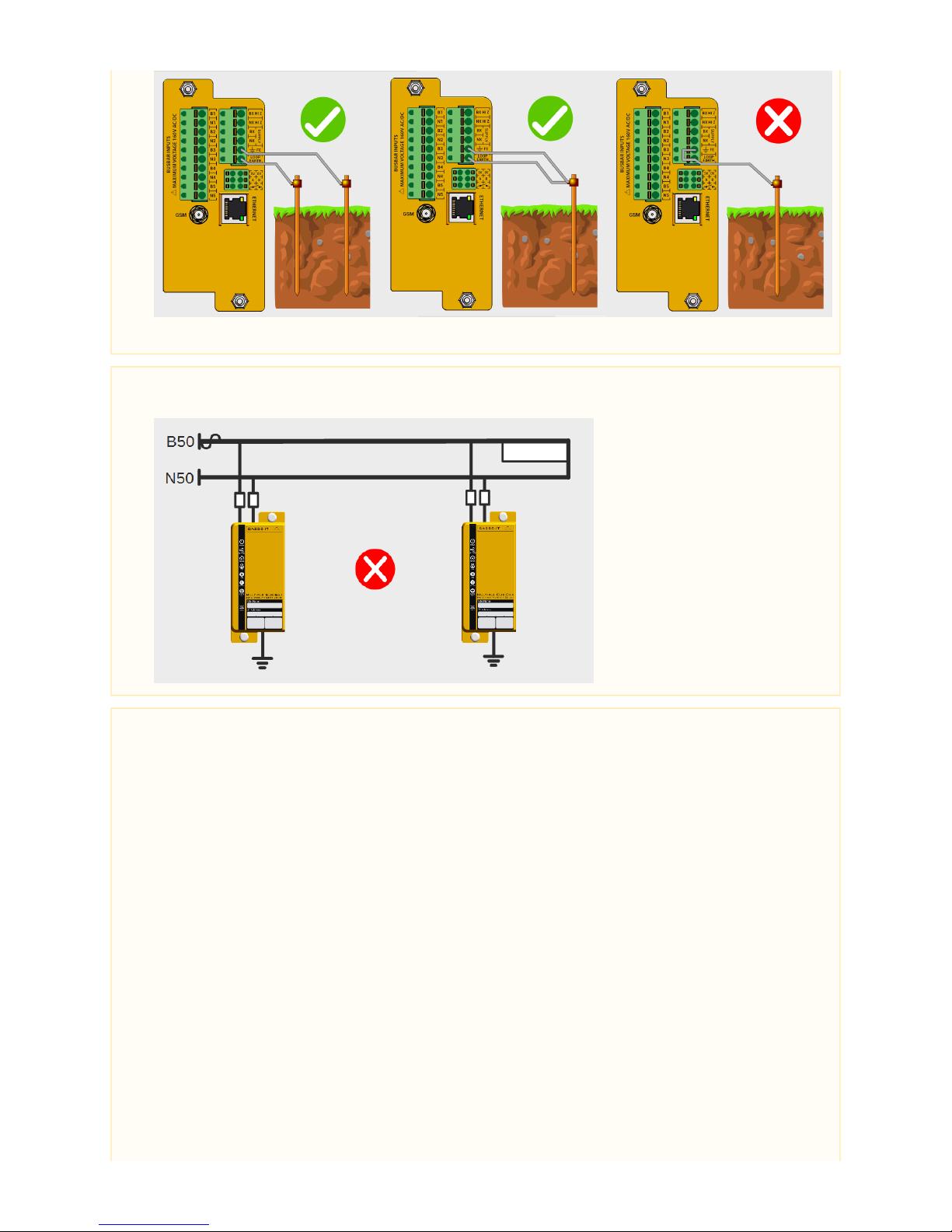

Only one insulation monitoring device may be used on a single interconnected circuit. Installation of additional monitoring devices

will cause each device to "fight" the other, resulting in incorrect readings on both devices.

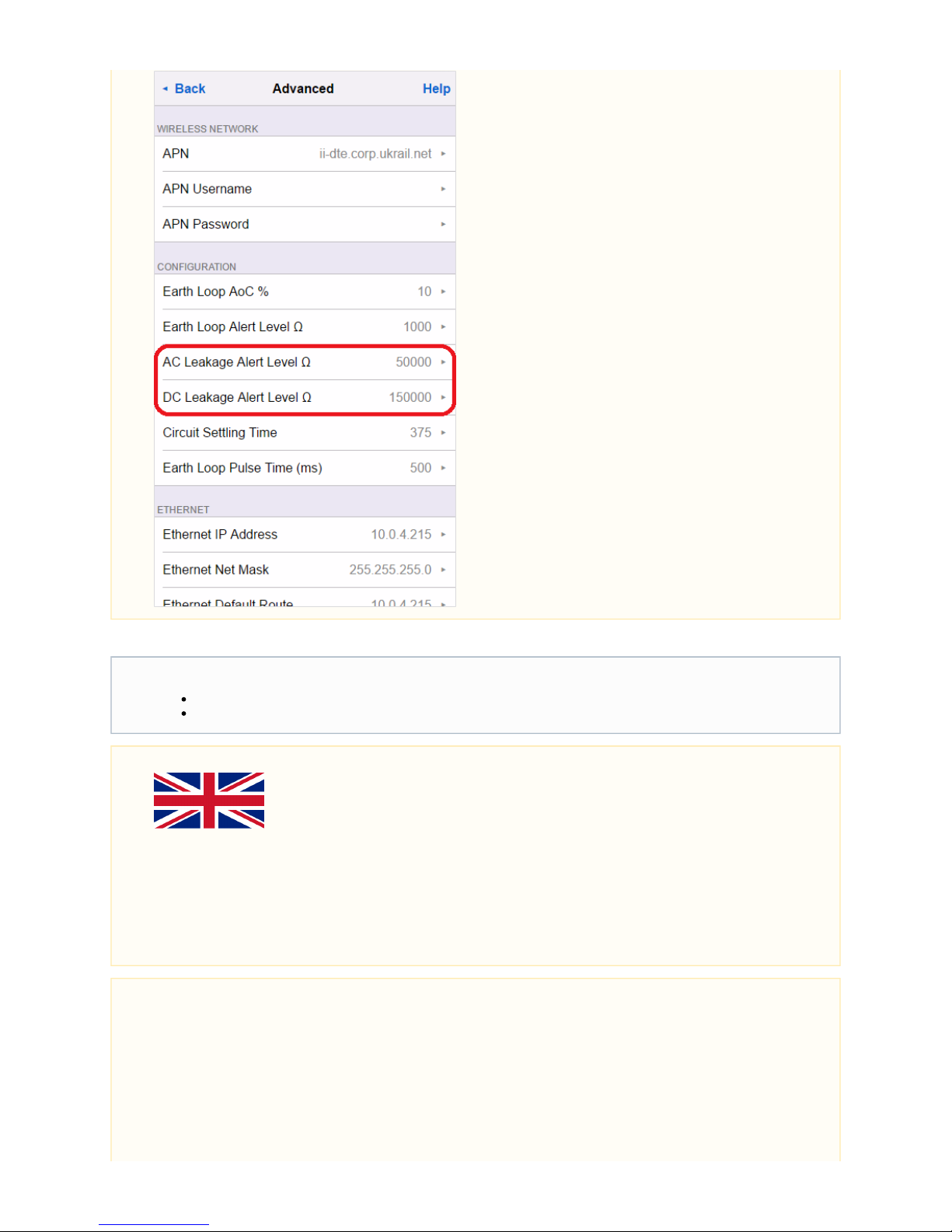

Check that the factory set earth loop and insulation resistance alarm levels are correct for your application. (See section 4.4.10)

REQUIRES NEW SCREENSHOT

The Ethernet port is sensitive to electrical surges:

Additional surge protection be fitted if the port is to be used continuously for data transmission. must

Surge protection is for temporary configuration and diagnostics activities.not required

Limitations of use in the United Kingdom

The following restrictions upon use must be observed when the SA380-IT is deployed on UK rail infrastructure:

Never attempt to power the SA380-IT from a DC power source

Never attempt to wire any conductors from differing monitored circuits into the same input channel.

Users in other countries may disregard this warning.

No hazards have been identified if the above advice is not followed, but these practices are against UK railway policy.

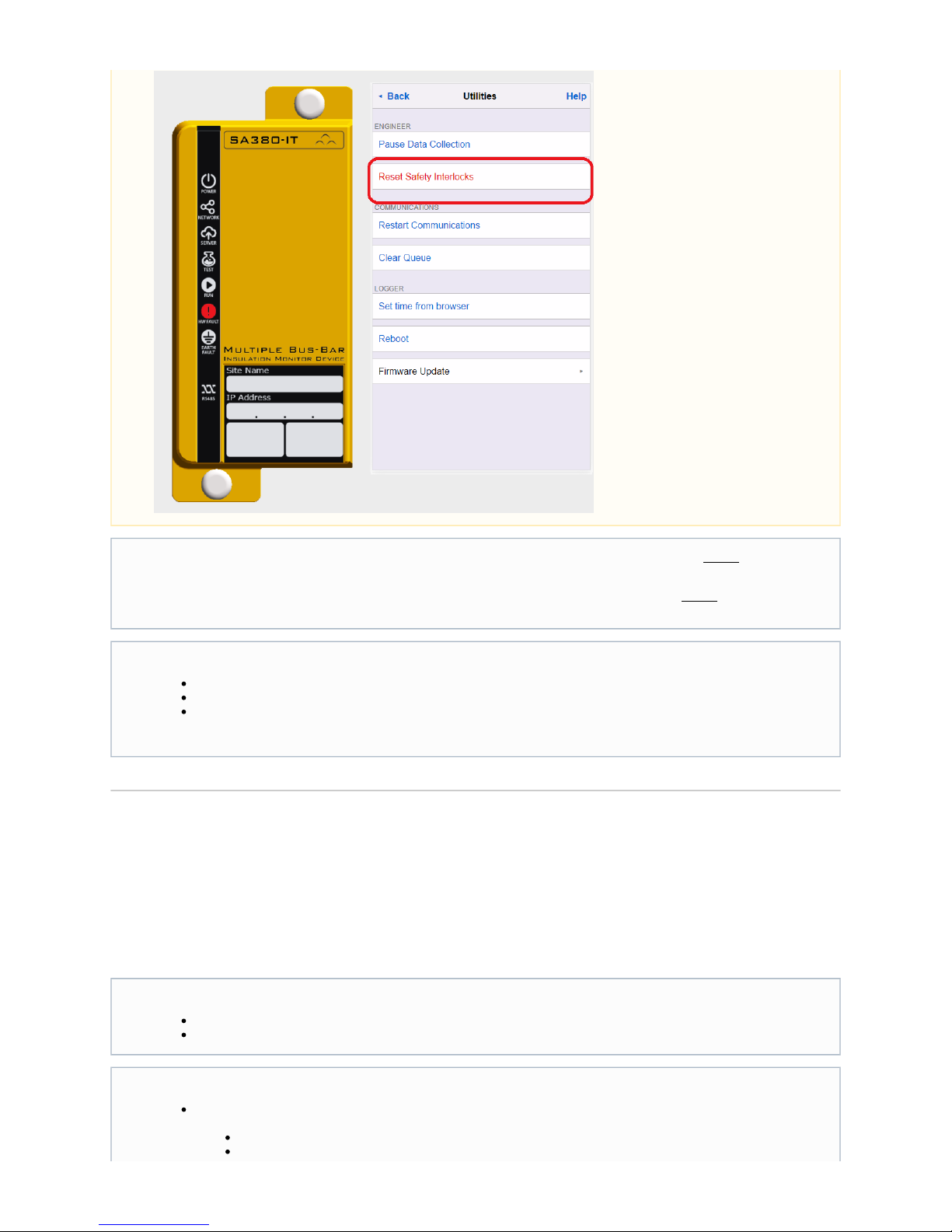

Ensure that you have exhausted all fault finding tasks prior to manually resetting any device interlock (see section 5.2 and section

4.4.5).

2) General

2.1) Product Description

The SA380-IT is designed to facilitate the continuous monitoring of circuit voltage and resistance to earth of up to 5 independent circuits.

The SA380-IT has built-in communications hardware in the form of a GSM modem and features Ethernet connectivity. This allows the

SA380-IT to connect to cloud-based Enterprise Asset Management Systems (EAMS).

It is wise to conduct a on monitored circuits both prior to, and after installation, but energising themanual insulation test before

SA380-IT. This will help verify correct installation of the measurement circuit wiring.

A between Functional Earth and Loop Earth connections after installation, but energising SA380-ITmanual continuity test before

will help verify correct installation of the earth-loop circuit wiring.

When conducting manual insulation testing on monitored circuits after commissioning, the SA380-IT must be either:

Prevented from attempting measurement (see section 4.4.5).

Physically disconnected from the monitored circuit.

Powered-down.

Failure to do so will result in incorrect readings.

ontinuous monitoring. It facilitates:Maintenance Reduction and Failure prevention are best realised through c

The removal of the requirement for time-consuming and dangerous physical inspection and measurement.

The ability to predict, schedule and fix developing earth faults they become an operational risk.before

Key Features:

Independent monitoring of up to 5 circuits, each circuit can be one of the following systems:

Single phase IT AC system up to 160 V RMS.

Single phase IT AC system up to 160 V RMS with galvanically connected rectifiers.

The SA380-IT has the ability to monitor and continuously report the following parameters:

For each monitored circuit:

System voltage.

For DC circuits, resistance to earth of individual circuit legs, R and R

B N.

For AC circuits, equivalent resistance to earth (R is measured. This is R and R in parallel.

L) B N

Resistance to earth alert status (resistance below pre-set threshold).

For each SA380-IT device:

Loop resistance between functional earth and loop earth terminals.

Earth Loop fault status.

Hardware fault status.

2.2) Principles of Operation

Monitored circuits remain galvanically isolated from one another at all times. Monitored circuits are only connected to measurement circuitry

and earth during measurement.

Periodic monitoring of the hardware and earth connection assures safe and reliable operation.

Inside the SA380-IT there is only one single instance of "measurement circuitry", however there are five instances of the "monitored circuit"

circuitry (switches and protection resistors).

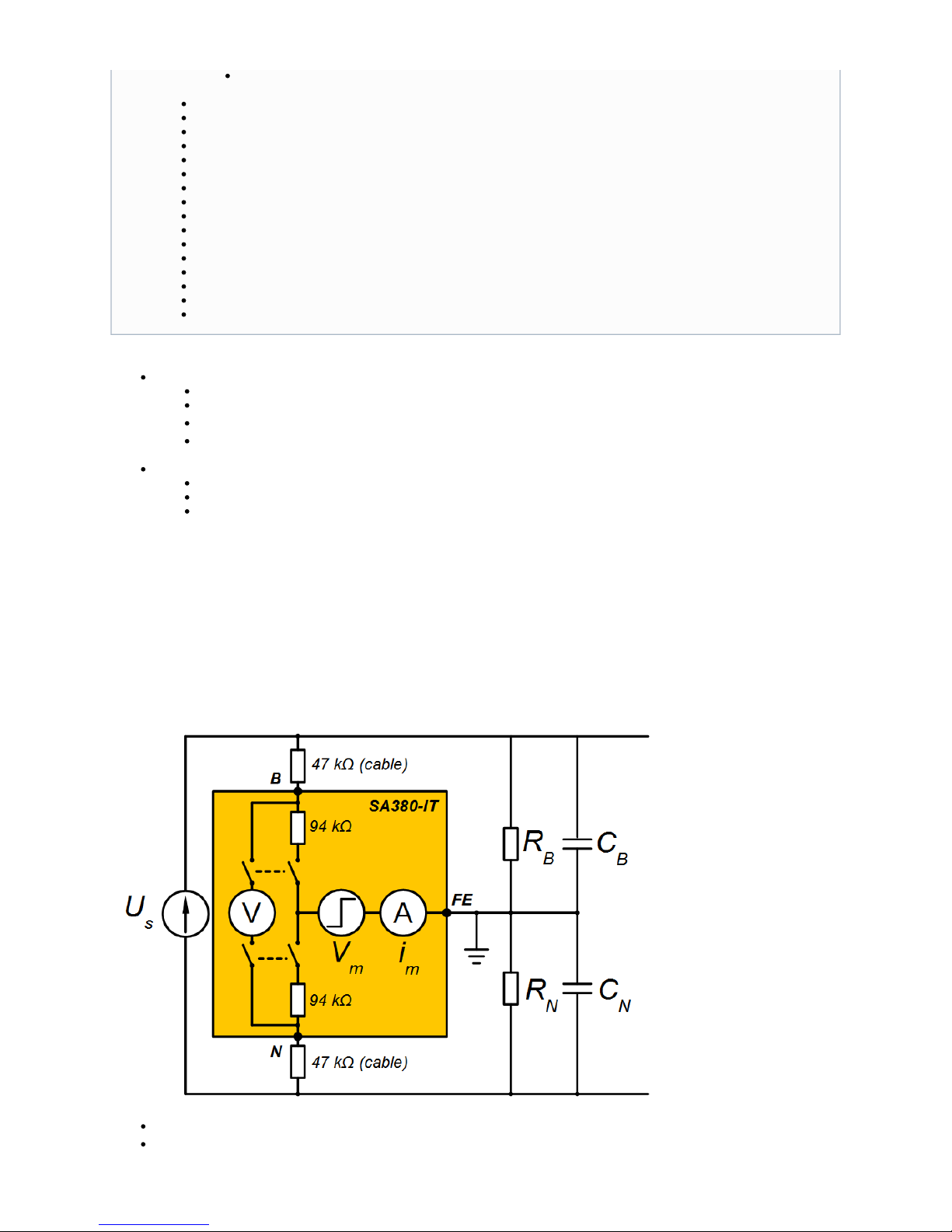

Simplified voltage and resistance to earth measurement circuitry for one monitored circuit.

U = Monitored circuit voltage.

s

B = B leg circuit connection.

IT DC system up to 160 V RMS.

Equivalent resistance to earth measurement of AC circuits.

Resistance to earth measurement of each circuit leg of DC circuits.

Automatic adaptation to system leakage capacitance.

Sub 1 second rapid response time.

Adjustable response values.

Captures long-term average, as well as fast transient faults to earth

Detection of core-to-core cables faults.

Monitored circuits supply voltage measurement.

Earth-loop continuity measurement.

Continual self-test for accuracy and safety.

Volt-free contact alarm output.

Auxiliary power supply output.

In-built GSM communication.

In-built Ethernet communication.

In-built RS485 communication.

Compatible with leading enterprise asset management systems.

N = N leg circuit connection.

FE = Functional earth circuit connection.

V = Internal voltmeter.

V = Measurement pulse voltage.

m

i = Resistance to earth ammeter.

m

R = Resistance to earth (B leg).

B

R = Resistance to earth (N leg).

N

C = System leakage capacitance (B leg).

B

C = System leakage capacitance (N leg).

N

An independent solid-state switch exists for each monitored circuit.

Independent internal protection resistors (94 k) exist for each monitored circuit.

Independent resistive cables (47 k) are provided for connection of each monitored circuit.

The modes of operation, and measurement principals of the SA380-IT are described in the following sections.

2.3) Modes of Operation

2.3.1 Normal Mode

Each monitored circuit (configured for measurement) is evaluated in turn, in a loop:

The monitored circuit is connected to the internal measurement circuitry and earth using a solid-state switch.

Voltage measurement is performed. (see 2.4)

If the voltage is in range, resistance to earth measurement is performed. (see 2.5)

The monitored circuit is disconnected from the internal measurement circuitry and earth.

the procedure is repeated for the next monitored circuit, and so on.

Every 60 seconds system integrity checks are performed:

Solid state switches are confirmed to be in the "open" state (all monitored circuits galvanically disconnected from each other,

measurement circuitry and earth).

The SA380-IT remains within its defined accuracy parameters (performs an internal calibration check).

Earth-loop resistance has not exceeded the alarm limit (resulting in inaccurate resistance to earth measurements).

2.3.2 Technicians Mode

For "on-site" use to aid a technician in locating and remedying monitored circuit faults. (see 4.4.3)

Forces the SA380-IT to make repeated measurements of a single monitored circuit.

Response time is increased as only the monitored circuit of interested is measured.

A large and clear read-out of measured values is reported to the technicians iPhone or computer display.

The technician can quickly verify if their actions are having the desired effect upon the monitored circuit.

Technicians mode can be cleared manually by the user at any time.

Technicians mode will automatically clear after a period of 4 hours, and the SA380-IT will resume "Normal mode".

Earth Loop resistance measurement and system safety tests are performed whilst in technicians mode.not

2.3.3 Suspended Mode

The user may suspend monitored circuit measurement to enable fault finding activities to take place. (See section 4.4.5). This prevents the

SA380-IT injecting a measurement pulse, or presenting resistances to earth across the monitored circuits.

During suspended mode, all monitored circuits remain galvanically isolated from each other, all internal measurement circuitry and

earth.

Suspended mode can be cleared manually by the user at any time.

Suspended mode will automatically clear after a period of 4 hours, and the SA380-IT will resume "Normal mode".

Earth Loop resistance measurement and system safety tests are performed whilst in suspended mode.not

2.3.4 Degraded Modes

There are instances when the SA380-IT may suspend some, or all measurements. Degraded modes are applicable in normal and

technicians mode and are often due to the activation of device safety interlocks. See section 5.2 for more information.

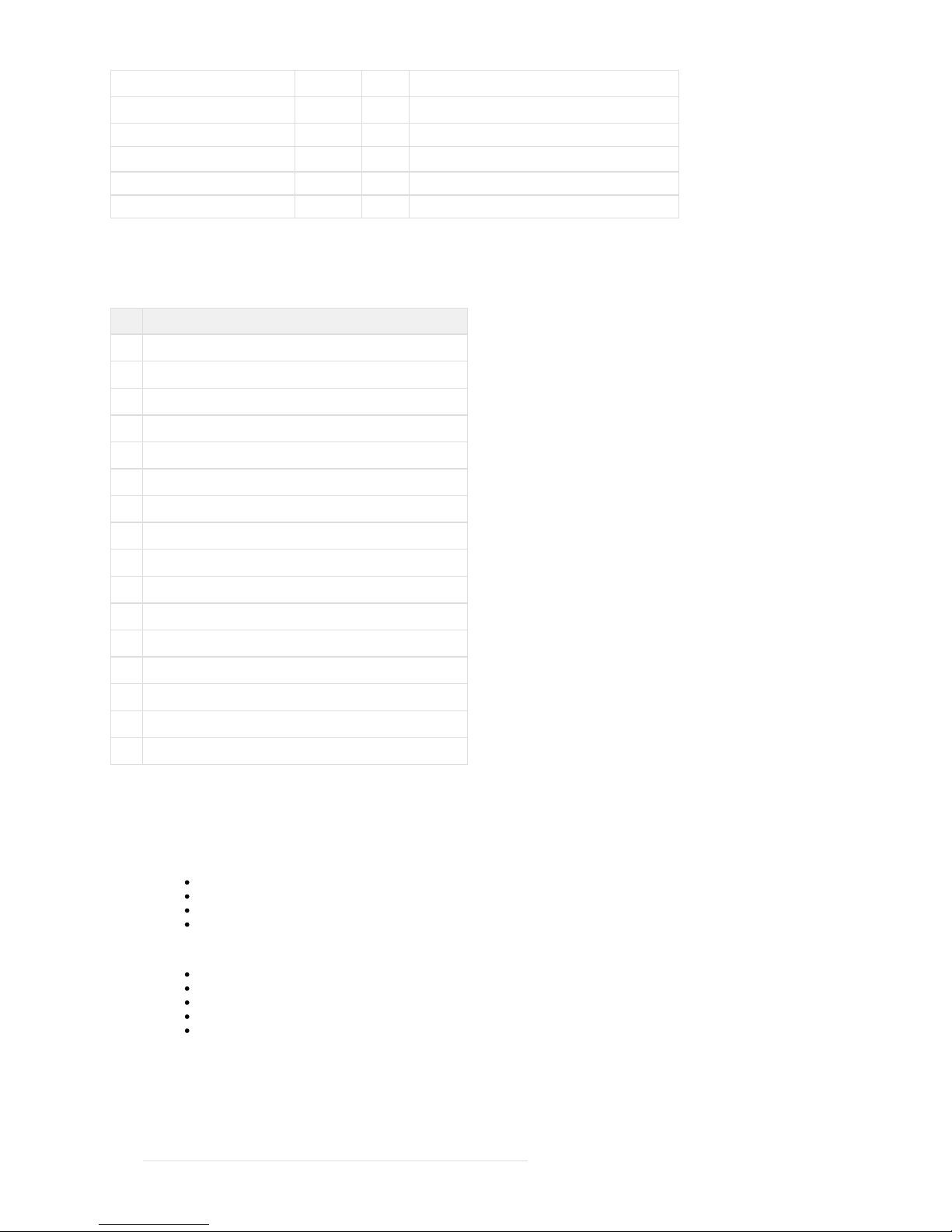

Scenario Voltage Measurement

of Monitored Circuits

Resistance to Earth

Measurement

of Monitored Circuits

Earth Loop &

Safety Tests

Device boot

No No No

Time not set

No No No

Earth loop resistance out of

tolerance

No No Yes

Monitored circuit under voltage

Yes No - Affected Circuits

Yes - Unaffected Circuits

Yes

Monitored circuit over voltage

Yes No - Affected Circuits

Yes - Unaffected Circuits

Yes

Solid state switch fault

No No No

Calibration test failure

No No No

2.4) System Voltage Measurement

Voltage is measured across the monitored circuit terminals after the monitored circuit is connected to the measurement circuitry, but prior to

resistance to earth measurement.

If the circuit is configured for measurement, the value of the voltage is calculated.AC RMS

If the circuit is configured for measurement, the value of the voltage is calculated.DC mean

2.5) Resistance to Earth Measurement

Only if the monitored circuits voltage measurement is within tolerable parameters will a resistance to earth measurement be attempted. This

is to ensure safe and reliable operation of the monitored circuit.

The SA380-IT utilises the "pulse test" method of resistance to earth measurement. A series of current limited rectangular pulses are injected

into the monitored circuit. This will cause a current to flow through any resistance and capacitance to earth.

Any capacitance to earth will eventually become fully charged by the test signal. once this occurs, a current measurement can be taken in the

steady state. The combined values of capacitance and resistance to earth will govern measurement time.

2.5.1) AC and DC Circuits

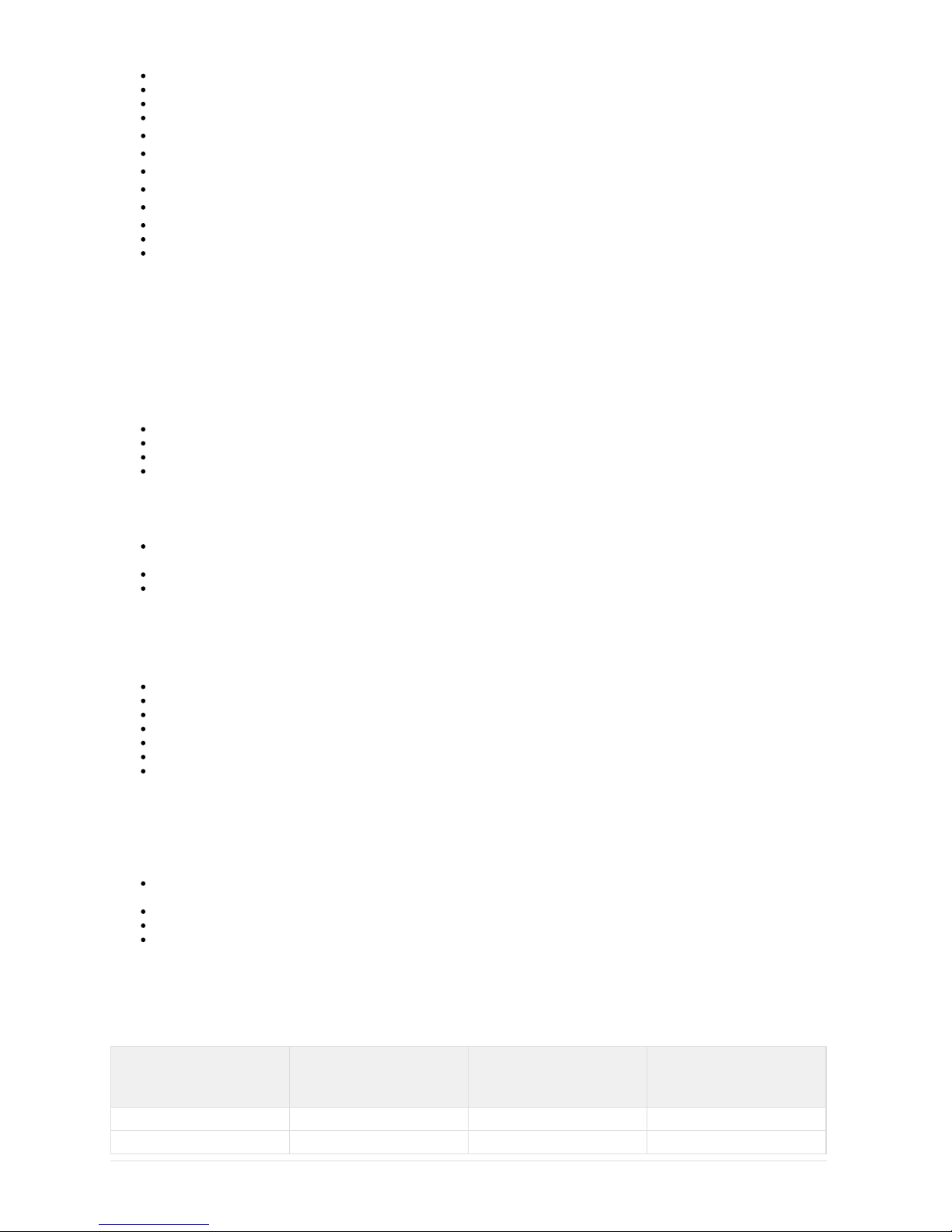

Equivalent Circuit for Measurement Pulse signal

R = Equivalent Resistance to Earth (R in parallel with R ).

L B N

C = System Leakage Capacitance (C in parallel with C ).

E B N

i = Ammeter current solely due to measurement pulse voltage.

Vm

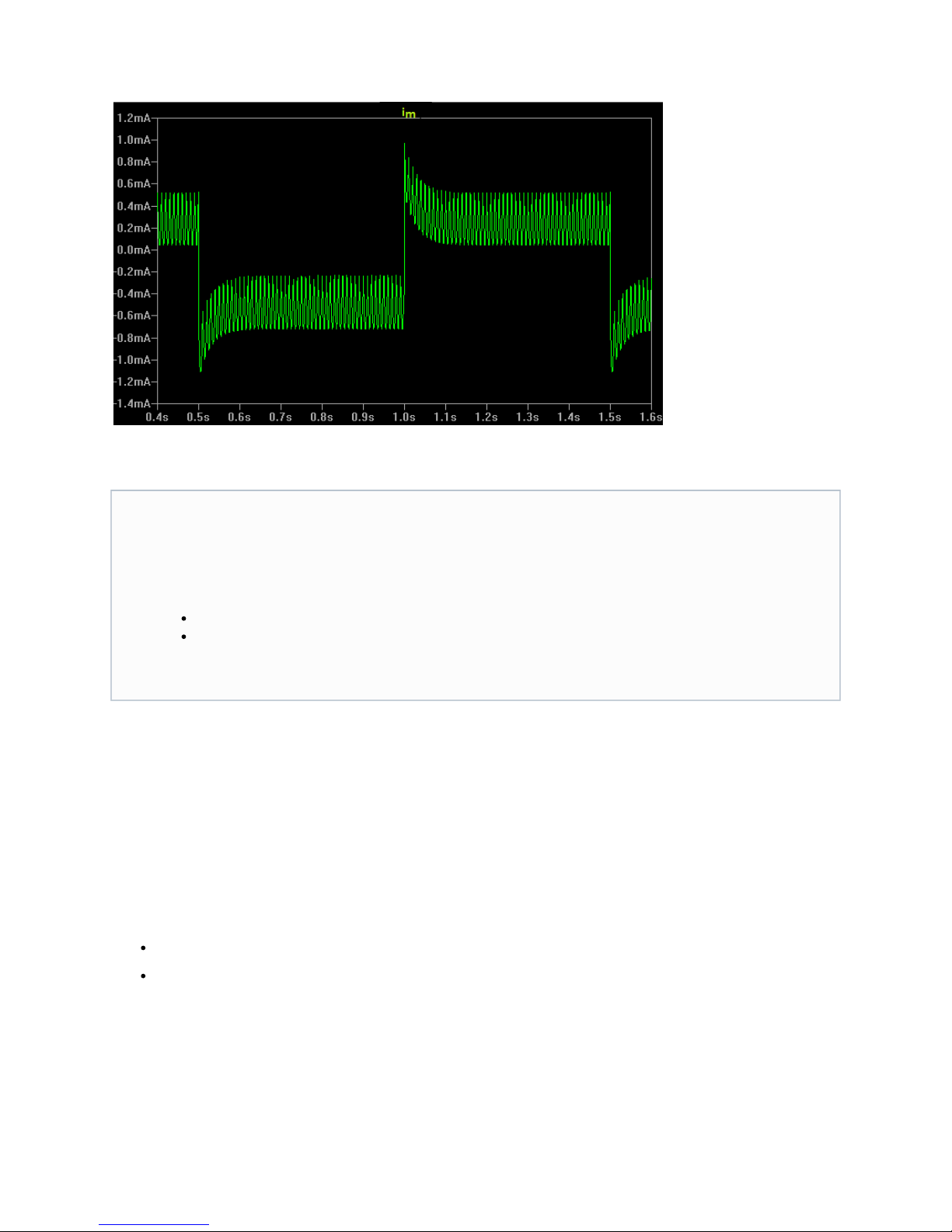

The graph below shows the application of measurement pulses, the transient charging current through the system capacitance and the

A voltage reading of less than 0.5 s regarded as an . times the configured nominal voltage i under-voltage (for example, a reading

Resistance to Earth will not be measured until the under-voltage is removed.of <=25 V on a circuit configured as 50 V).

A voltage reading of more than 1.45 times the configured nominal voltage is regarded as an (for example, a readingover-voltage

of >=72.5 V on a circuit configured as 50 V).

In the above scenarios, r Such an event be causedesistance to Earth will not be measured until the voltage error is removed. could

by hardware failure, but is often simply due to supply voltage variation.

eventual steady state condition:

Typical response to measurement pulses

The SA380-IT configurable "measurement timeout" parameters place limits on how long the device will wait for the steady state to be

achieved prior to taking a measurement. This time may be exceeded if:

The system capacitance and resistance are too high.

Transient signals present in the measurement loop prevent a steady state being achieved.

Transient signals may be due to sudden monitored circuit voltage variation, or transient resistance to earth events. Unstable circuit voltage

may also prevent the steady state being achieved.

Measurement Procedure:

Fast Scan

Rapid response time is achieved by performing resistance to earth measurements at high speed.

The timer setting (see section xxxx) governs how quickly the SA380-IT attempts measurement of each circuit. By default this fast scan

value is set to 1000 ms, meaning that measurement is performed within 1 second for each monitored circuit, giving a maximum cycle

time of 5 seconds for a fully utilised SA380-IT device.

If the steady-state can not be achieved in the fast-scan period, offending circuits are scheduled for a periodic slow scan. These slow

scans allow accurate measurement of high-resistance-to-earth, capacitive circuits, albeit a at a slower speed.

Slow Scan

Circuits that can not achieve steady state during the fast-scan period are measured during the slow-scan period. The timer slow scan

parameter control this frequency. (See section xxxx). By default this value is set to 5 minutes. Once every five minutes a slow scan is

performed on circuits that have repeatedly failed fast-scan readings. The period of time that the SA380-IT can spend performing

slow-scans is limited to 50% of total measurement time of the entire SA380-IT device, assuring that the fast-scan process still has time

to run.

If the slow scan fails, The SA380-IT still attempts measurement and displays one of the following:

If resistance-to-earth is estimated to be >= 5 M, then 5 M is displayed and the slow-scan is deemed to have succeeded.

If resistance-to-earth is estimated to be < 5 M, then the estimated reading is displayed on the user-interface alongside the

message "Unstable" and the slow-scan is deemed to have failed.

Spot-Readings

The successful result of a fast or slow scan is known as a spot reading. For circuits with little capacitance / low resistance-to-earth then

a spot-reading will be taken once every 1 to 5 seconds. A circuit with high capacitance / resistance-to-earth may record a spot reading

once every 5 minutes.

The latest Spot-readings are displayed on the user interface. If a spot-reading crosses an alert boundary (see section xxx), then the

latest average and spot-reading messages are sent to the EAMS to alert the maintainer of the transient fault condition.

Average Readings

Successful spot-readings are also used to calculate the long-term-mean resistance to earth of a circuit. The snapshot timer setting

governs how frequently these average readings are reported to the EAMS. By default, this period is set to 1 hour

The average is reset when the following occurs:

When the snapshot period elapses (default 1 hour)

When a transient spot-reading crosses an alert boundary (at any time)

Benefits

Through the balance of fast and slow scan, spot-reading and average readings the SA380-IT is able to achieve:

Rapid measurement and detection of transient earth faults.

Accurate measurement of high resistance / capacitive circuits

Stable Readings of circuits with a high resistance to earth

In addition to the above methods, the SA380-IT applies proprietary signal conditioning algorithms to improve measurement accuracy

under transient conditions, such as:

Unstable monitored circuit voltage.

Dynamic resistance to earth changes.

Transient events on monitored circuits.

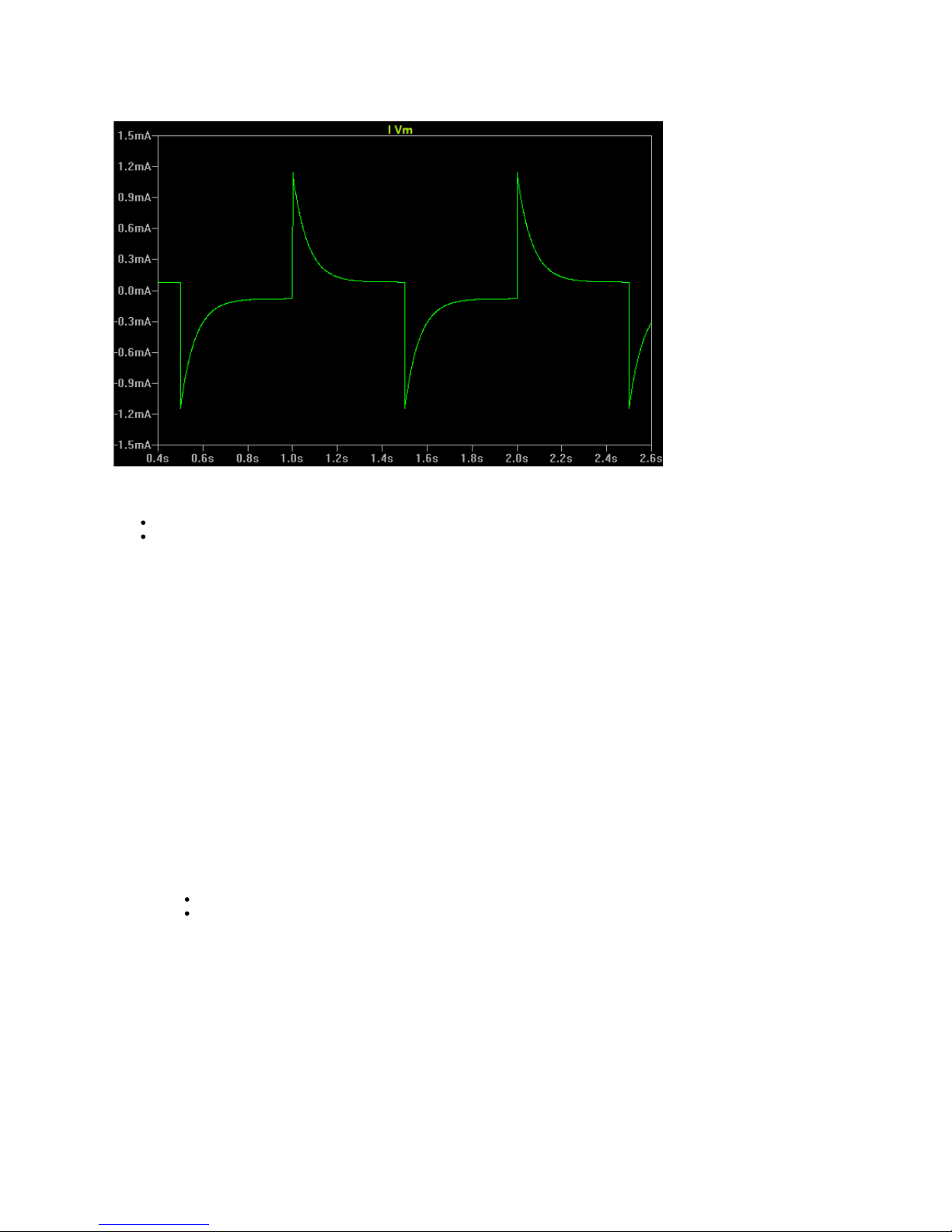

2.5.2 DC Circuits Only

In a DC circuit, the Resistance to earth of each circuit leg can cause current flow from the monitored circuits supply U , through SA380-IT

s

measurement circuitry. For DC sources, such a current will always appear to flow in the same "direction" through the measurement circuit,

regardless of measurement pulse polarity.

The equivalent circuit and associated current trace are shown below:

i = Ammeter current solely due to monitored circuit voltage "bleed through" in a DC circuit.

Us

The net current flow measured by the internal ammeter is the sum of the current produced by the test pulse voltage and the current caused

by the monitored circuit voltage "bleeding through" the SA380-IT.

The graph below shows a typical measurement current trace of the SA380-IT:

By applying a test pulse of alternating polarity, the test pulse current becomes a "differential" current reading, whilst the current due to the

supply circuit becomes a "common" current reading.

2.6) Core-to-Core Resistance Effects

2.7) Earth Integrity Measurement

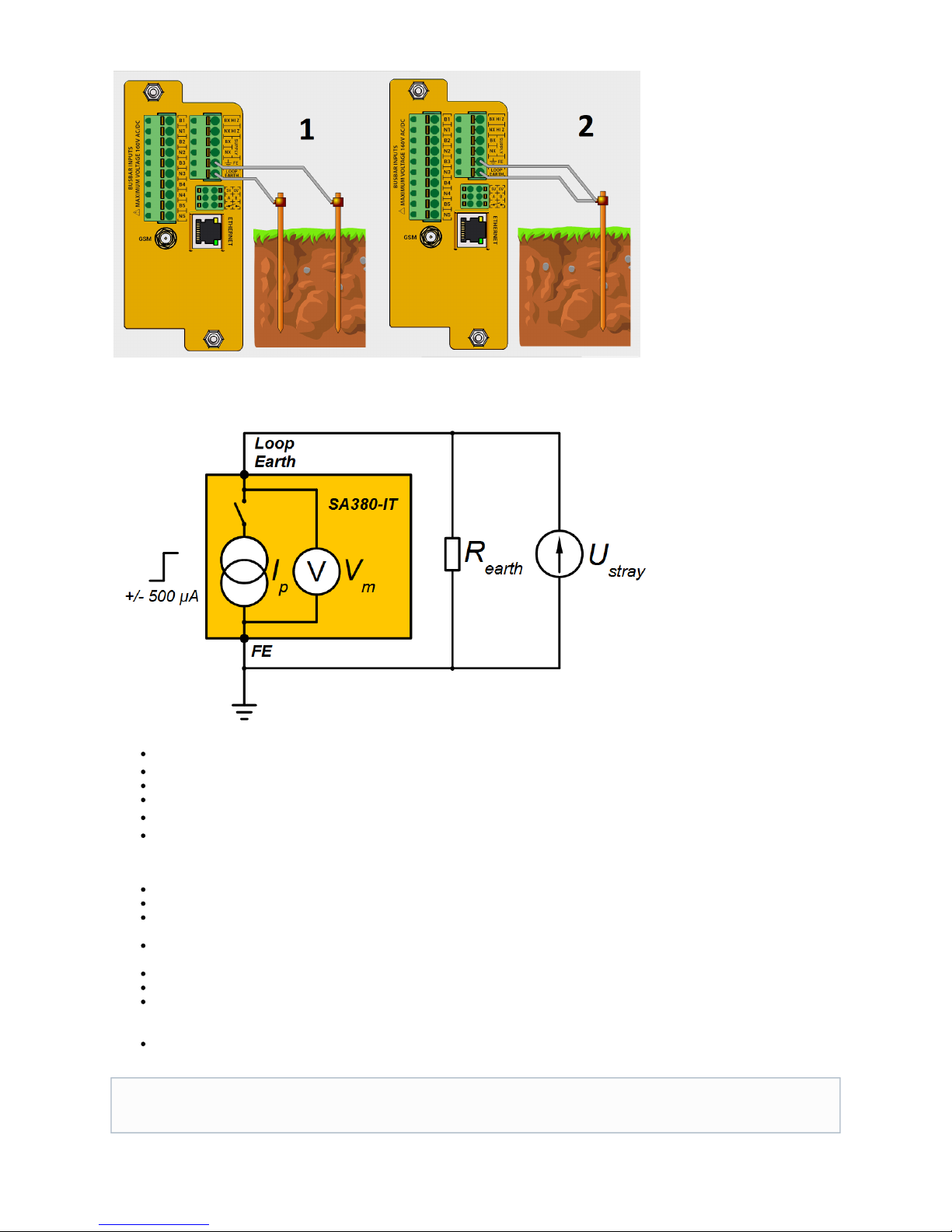

Every 30 seconds the integrity of the SA380-IT functional earth connection is validated by measuring the resistance between the primary

(Functional Earth) and secondary (Loop Earth) earth connections.

This gives confidence that the earth connection is "good" and therefore reliable Resistance to Earth measurement of monitored circuits can

be conducted.

In the case where two wholly independent earth points have been provided (1), it verifies that the functional earth connection is

intact, and that connection to the physical mass of the earth is also of sufficiently low resistance.

In the case where two independent wires have been run to a common earth point, (2) it verifies that the wiring of the functional earth

connection is intact.

Single & Double Earth Points:

By taking the difference of the measured current for the positive and negative measurement pulse signals, the "common" current is

eliminated allowing the calculation of equivalent resistance to earth (R ).

L

By taking the sum of the measured current for the positive and negative measurement pulse signals, the "differential" current is

eliminated. In the case of DC circuits, this allows the direct calculation of the resistance of each circuit leg R and R .

B N

Please note:

When R > 20 x R . Then the accuracy of

B N

R will B exceed +/-5%

When R > 20 x R . Then the accuracy of

N B

R will N exceed +/-5%

This is due to it becoming increasingly difficult to measure a large resistance to earth in one leg of a circuit, when the resistance to

earth in the other leg of the circuit becomes relatively small.

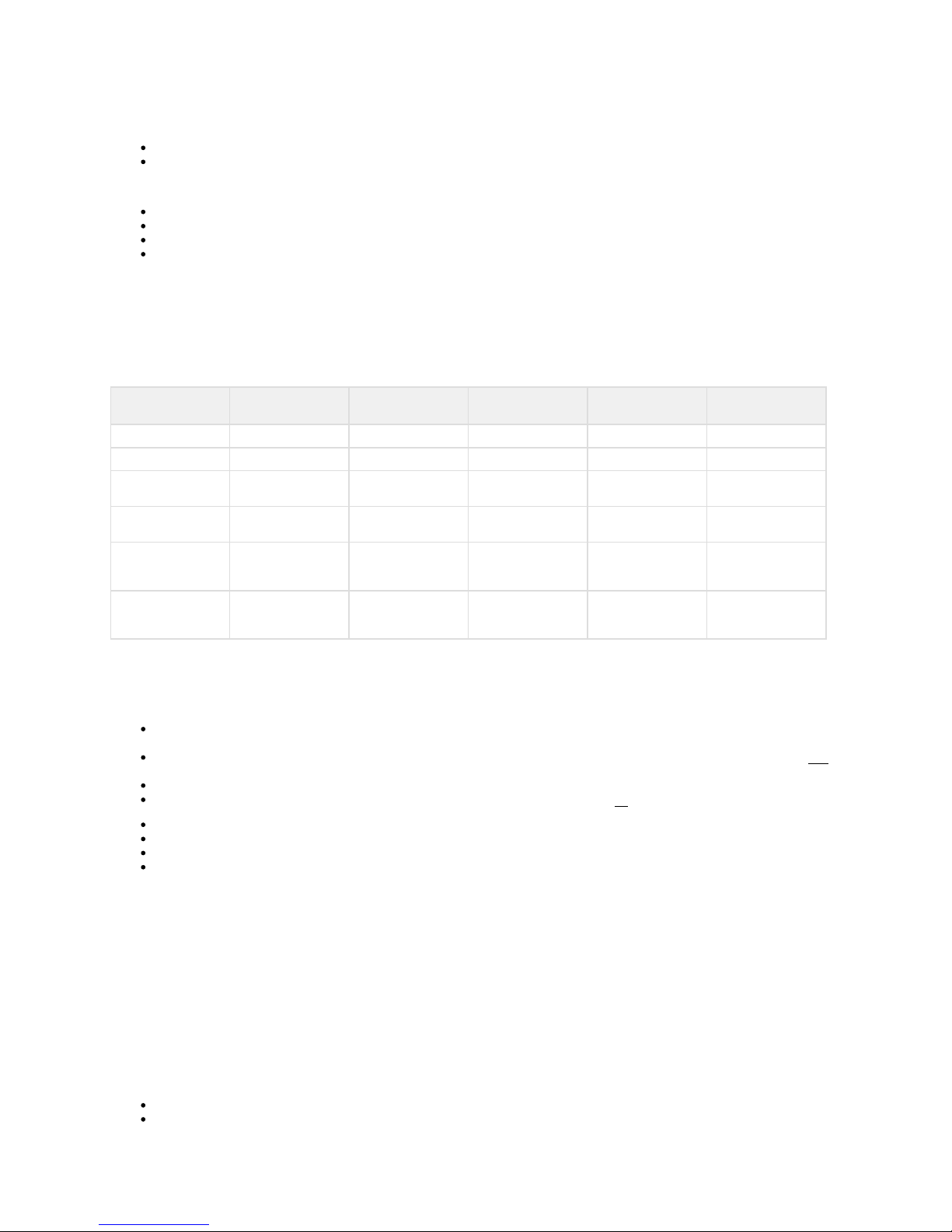

The Resistance of the earth loop is measured in a manner very similar to "Resistance to Earth of Monitored Circuits".

Equivalent Circuit for Earth Loop Measurement:

I = Measurement Pulse Current.

p

Loop Earth = Loop Earth terminal.

FE = Functional Earth circuit terminal.

V = Measured Voltage (High Impedance).

m

R = Earth Loop Resistance.

earth

U = Voltage due to stray Earth Currents.

stray

Measurement Procedure:

When the Earth Loop Resistance is not being measured, the current source is disconnected from the measurement circuit.

When measuring Earth Loop Resistance, a "pulse test" method of earth loop resistance measurement is employed.

A series of constant-current, rectangular pulses are injected into the monitored circuit. This will cause a constant current to flow

through any resistance in the earth loop path.

The constant current generates a voltage across the earth loop resistance. It is this voltage that is acquired by the measurement

circuitry. Voltage is limited to 3.5 V in the open circuit case.

Unwanted voltage will also be picked up by the measurement circuitry due to stray ground currents flowing in the earth loop.

Unwanted stray AC components above 3.5Hz are removed using digital filtering techniques.

The unwanted stray DC component is removed through the use of a bi-directional current source, similar to resistance to earth

measurement, the constant measurement pulse presents as a differential signal across the measuring element, whilst the stray DC

current appears as a common signal across the measuring element.

Measurement takes approximately 300 milliseconds.

By taking the difference of the measured voltage for the positive and negative measurement pulse signals, the "common" current is

eliminated allowing the calculation of Earth Loop Resistance (R )

earth

2.8) Hardware Self-Test

Hardware self-test is undertaken every 30 seconds. The SA380-IT will report a hardware-fault when the following conditions occur:

The SA380-IT is unable to make reliable measurements of insulation resistance.

The SA380-IT has detected an internal fault that could impact upon the safety or reliability of the monitored system.

The SA380-IT response to these scenarios is as follows:

Indicate to the cloud based supervisory system that a hardware fault has occurred.

Illuminate the light.HW FAULT

Open the volt-free contact output.

Disable the faulty hardware. (Device Interlock)

These "device interlocks" will prevent further measurements being conducted.

2.9) Alert Conditions

The SA380-IT raises alerts under the following scenarios:

Scenario Self-Clearing ? Locks Out: Lights HW Fault

Lamp?

Lights Earth Fault

Lamp?

Opens Volt-Free

Contact?

Under Voltage

Yes Channel No No No

Over Voltage

No Channel Yes No Yes

Calibration test

failure

No Device Yes No Yes

Solid state switch

fault

No Device Yes No Yes

Earth loop

Resistance above

Alert Threshold

Yes

5% Hysteresis

Device Yes No Yes

Resistance to Earth

below Alert

Threshold

Yes

5% Hysteresis

N/A No Yes Yes

2.8.1 Hysteresis:

Hysteresis is employed to prevent "chattering" alerts:

When the resistance to earth of a monitored circuit drops below the configured the SA380-IT will enter the alert threshold earth

state.fault

E.g. if the alert threshold is 100 k, an "earth fault" will be flagged as soon as resistance to earth drops below 100 k on any

monitored circuit.

The earth fault will remain until the resistance to earth of a monitored circuit exceeds the configured alert threshold +5%.

E.g. the earth fault would not "clear" until the resistance to earth exceeds 105 k on monitored circuits.all

When the earth loop resistance exceeds the configured the SA380-IT will enter the state. alert threshold hardware fault

E.g. if the alert threshold is 1 k, a "hardware fault" will be flagged as soon as earth loop resistance exceeds 1 k.

The hardware fault will remain until the earth loop resistance drops below configured alert threshold -5%.

E.g. the hardware fault would not "clear" until the earth loop resistance falls below 950 .

2.8.2 Minimum Operation Time

If any fault condition causes the volt-free contact to open, it shall remain open for a minimum period of 2 seconds to prevent the risk of

transient events being missed.

2.10) Communications & Peripheral Outputs

2.9.1 Fault Indication (Volt-Free-Contact)

The SA380-IT features a volt-free contact (relay) output. This can be utilised to:

Indicate fault conditions to external alarm circuits

Connect to external data-logging equipment.

The latter is particularly useful, as additional event data from the data logging device can be used to cross-check which sub-elements of a

monitored circuit are active in the event of transient earth faults.

Fault contact open Fault contact closed

SA380-IT powered down SA380-IT powered and fault free

Hardware fault

Earth fault

2.9.2 Auxiliary Power Supply

A external power supply is provided to power external sensors or equipment. The specification is:

5 Volts

1 Watt

Galvanically isolated from all other circuits except for RS485.

2.9.3 Serial RS485 Data Port

A serial RS485 port is provided to allow serial data communications between the SA380-IT and another device.

These features are yet to be implemented in software, but are envisioned to facilitate the following:

Connection to MPEC SA380TX data loggers

Connection to smaller down-stream earth continuity or earth leakage testers and sensors.

2.9.4 GSM & Ethernet Connection

The SA380-IT features an internal GPRS modem with factory fitted SIM, and an Ethernet controller. Configuration of the SA380-IT and

reporting of data is possible using both interfaces.

Both communication bearers allows continuous reporting of all measured values to an Enterprise Asset Management System (EAMS).

Operation and configuration of these Enterprise asset management systems is beyond the scope of this user guide.

On-site configuration via Apple devices, such as iPhone or iPad, is supported via a "Lightning to Ethernet" cable connected between Apple

device and SA380-IT.

A custom App named " " is available from the Apple AppStore that supports this cable. (See section 4.3.1 for details).SA380-IT

Configuration and interrogation is explored in depth in section 4.4.

2.11) Data Acquisition

The SA380-IT processes data before display to the user and transmission to an Enterprise Asset Management System. (EAMS)

The following quantities are sampled and sent back to the EAMS:

Name Quantity: Units: Notes

Monitored Circuit Voltage

U

m

V Reported for all five circuits

Resistance to Earth (Negative Leg)

R

N

k Reported for all five circuits

Enterprise asset management systems can be be utilised to monitor long term asset trends and forewarn of asset failure. Presently

two such systems are supported:

Product Vendor Web-Link

Centrix MPEC Centrix Documentation

Network Rail Intelligent Infrastructure Network Rail / Thales http://www.networkrailconsulting.com/s

ervice/remote-condition-monitoring

The Lightning to Ethernet Cable (MPEC part number SA380-IT-LE) is sold as a separate accessory and is not normally included

with the device (see section 6.3).

Resistance to Earth (Positive Leg)

R

B

k Reported for all five circuits

Earth Loop Resistance

R

E

Unit Status

Status NA Collection of binary status information (see table below)

Temperature

Temp

o

C

Internal temperature

Up-Time

Time minutes Period of time since last restart

Signal Strength

GSM Signal dB GSM modem signal strength

Note that for AC monitored circuits, R = R and R = R

B L N L.

The status message is a 16-bit integer. with '0' being false, and '1' being true. Each bit has the following meaning:

Bit Meaning

0

Calibration Fault

1

Internal Hardware Fault

2

Calibration or Hardware Fault; or device in suspended mode

3

Earth Loop Fault

4

Any Monitored Circuit has an Over voltage

5

Not used

6

Volt Free Contact State (0 closed, 1 open)

7

Not used

8

Not used

9

Not used

10

Internal Monitored Circuit Fault

11

Monitored Circuit 1 Fault

12

Monitored Circuit 2 Fault

13

Monitored Circuit 3 Fault

14

Monitored Circuit 4 Fault

15

Monitored Circuit 5 Fault

2.10.1 Protocol Selection

Two transmission protocols can be selected for sending data to an EAMS:

MIMOSA

Text based protocol compatible with the Network Rail Intelligent Infrastructure and MPEC Centrix systems.

Plain text, human-readable, but large data messages.

Lengthy back-off periods (up to 2 hours) in the event of loss of communications.

Does not support engineering units.

RailDAQ

Binary protocol compatible with the MPEC Centrix system.

Small, but unreadable binary messages (more than 10 times smaller than MIMOSA).

Minimal back-off periods (a few seconds) in the event of loss of communications.

Message size and back-off policy offer significant reliability improvements over MIMOSA.

Supports engineering units.

2.10.2 The Rules of Acquisition

Rounding and Truncation

After performing a measurement, the software will round and cap all data to make it simpler to interpret.

Quantity: Rounding: Capping:

Monitored Circuit Voltage

U

m

to the nearest 1 V 160 V

Resistance to Earth

R R

B N

down to the nearest 1 k 5 M

Earth Loop Resistance

R

E

to the nearest 0.5 1 k

It is the rounded and capped data is displayed on the web based user interface.

Sampling

Data is not continuously sampled and sent the EAMS as this would produce a vast amount of data.

The SA380-IT employs a sampling scheme that rationalises the amount of data buffered for transmission by employing the following

sampling rules.

State U

M

R

N

R

B

R

E

Status Temp Time GSM

Signal

Notes Factory

Default

Setting

At start-up

a

l

l

c

i

r

c

u

i

t

s

a

l

l

c

i

r

c

u

i

t

s

a

l

l

c

i

r

c

u

i

t

s

Sample

acquired as

soon as time

is set

NA

snapshot

time elapsed

since last

acquisition

a

l

l

c

i

r

c

u

i

t

s

a

l

l

c

i

r

c

u

i

t

s

a

l

l

c

i

r

c

u

i

t

s

snapshot

time is

configurable.

The snapshot

timer runs

"per channel"

1 hour

User clears

"comms

queue"

a

l

l

c

i

r

c

u

i

t

s

a

l

l

c

i

r

c

u

i

t

s

a

l

l

c

i

r

c

u

i

t

s

NA

% change in

Um

a

f

f

e

c

t

e

d

c

i

r

c

u

i

t

o

n

l

y

a

f

f

e

c

t

e

d

c

i

r

c

u

i

t

o

n

l

y

a

f

f

e

c

t

e

d

c

i

r

c

u

i

t

o

n

l

y

% change is

configurable

5%

% change in

R

L

a

f

f

e

c

t

e

d

c

i

r

c

u

i

t

o

n

l

y

a

f

f

e

c

t

e

d

c

i

r

c

u

i

t

o

n

l

y

a

f

f

e

c

t

e

d

c

i

r

c

u

i

t

o

n

l

y

% change is

configurable

5%

% change in

the lower

value of aR

B

nd R

N

a

f

f

e

c

t

e

d

c

i

r

c

u

i

t

o

n

l

y

a

f

f

e

c

t

e

d

c

i

r

c

u

i

t

o

n

l

y

a

f

f

e

c

t

e

d

c

i

r

c

u

i

t

o

n

l

y

% change is

configurable

5%

% change in

R

E

% change in

REis

configurable

5%

Any change

is Status

NA

% Change:

A acquisition is made when the last measurement made by the hardware differs by more than from the reading at the% change n%

time of the last acquisition.

For example, if at start up. a value of R = 100 k, and the change threshold is set to 5%, then a acquisition will not be take

N

% change

place until a reading <= 95 k, or >= 105 k is made.

Delayed acquisition:

60 seconds after any of the above acquisitions takes place, a further delayed acquisition is made to ensure that the EAMS knows that

the readings are stable and representative.

The 60 second time-out period is user configurable.

2.10.3 Buffering

Queue

Every time an acquisition takes place, if is placed in a first-in, first-out (FIFO) message queue. This message queue resides in

non-volatile memory and will not be erased when the SA380-IT powers-down.

The SA380-IT will attempt to empty this queue whenever a successful connection to an EAMS exists.

When the queue becomes full, the oldest entries are over-written.

The user can empty the queue at any time.

The queue has enough room for approximately 130,000 acquisitions. This is at least 1.5 days of data at absolute maximum

acquisition rates, or 9 months of data at a stable installation. Your mileage may vary.

Batching

When using MIMOSA communication the SA380-IT will hold-off the transmission of data until one of the following conditions becomes

true.

>= 1024 entries are pending in the queue.

>=60 seconds has elapsed since a message was last transmitted.

This is to economise transmission bandwidth and server resources.

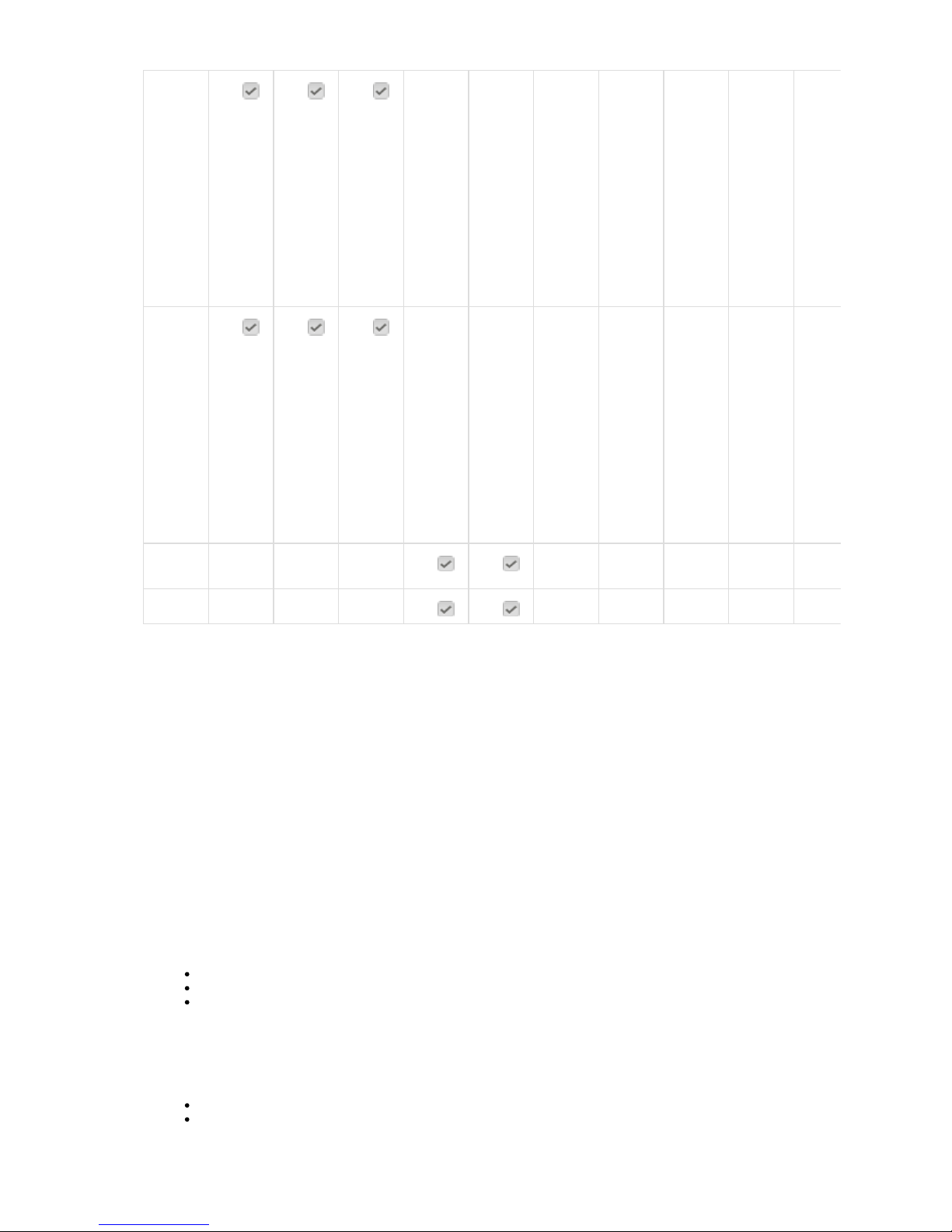

2.10.4 Examples

The diagram below shows examples of each type of acquisition:

In all cases two acquisitions take place for each event, the initial triggered acquisition, and the subsequent delayed acquisition 60 seconds

later.

Item Description

1

Acquisition on all channels due to device start-up

2

Acquisition on all channels due to user clearing the message

queue

3 Acquisition of Um, RN and RB due to a change in Um of >+/-5%

since the last acquisition of U

m

4 Acquisition of Um, RN and RB due to a change in RL of >+/-5%

since the last acquisition of RN and R

B

5 Acquisition of Um, RN and RB due to a change in RN (The lower of

RN & RB) of >+/-5% since the last acquisition of RN and R

B

6 Acquisition of RE and Status due to a change in RE of >+/-5%

since the last acquisition of R

E

7 Acquisition of RE and Status due to a change in Status since the

last acquisition of Status

8 Acquisition of Up-Time, Temp and GSM Signal due to a period of

1 hour elapsing since their last acquisition (snapshot)

9 Acquisition of Um, RN and RB due to a period of 1 hour elapsing

since their last acquisition (snapshot)

3) Installation

3.1) Overview

Before commencing installation please consider the following:

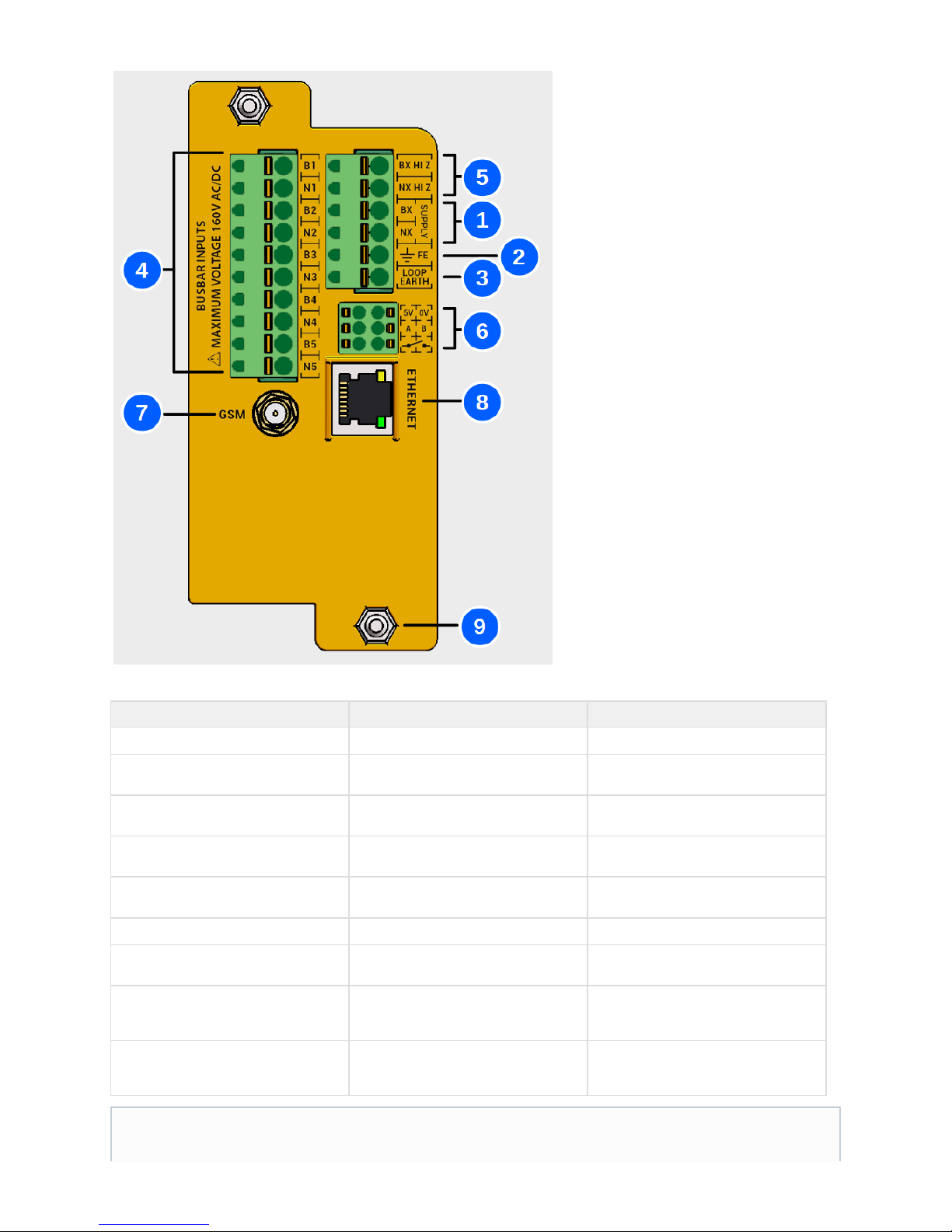

The SA380-IT back panel is reproduced below showing the connector layout:

It is wise to conduct a on the monitored circuits both prior to, and after installation, but energisingmanual insulation test before

the SA380-IT. This will help verify correct installation of the measurement circuit wiring.

A between Functional Earth and Loop Earth connections after installation, but energising SA380-ITmanual continuity test before

will help verify correct installation of the earth-loop circuit wiring.

Check all fuses / links are at the system termination point for each monitored circuit and the SA380-IT power supply priorremoved

to installation. Test all wiring re-inserting any fuses / links.before

Only one insulation monitoring device may be used on a single interconnected circuit. Installation of additional monitoring devices

will cause each device to "fight" the other, resulting in incorrect readings on both devices.

The principal connections are as follows:

No. Name Description

1 Supply

Power supply to the SA380-IT

2 Functional Earth

Common Earth point for all device

measurement

3 Loop Earth

Secondary Earth point for earth continuity

measurement

4 Monitored Circuits

The IT circuits that require insulation

monitoring

5 HiZ Outputs

A means of safely monitoring the insulation

of the supply circuit.

6 Auxiliary Outputs

I/O to other devices and alarm circuits

7 GSM Antenna

Facilitates GSM connection to an

Enterprise Asset Management System

8 Ethernet Jack

Allows local configuration and diagnostics,

or Ethernet connection to an Enterprise

Asset Management System

9 Fixing Stud

M5 mounting studs to fit BR930 / Q Style

relay mountings. Brackets are available to

allow alternate mounting arrangements

"Typical circuits" to Network Rail standards show the wiring arrangement of a typical installation.

3.2) Physical Installation

The following precautions must be taken during storage and transportation:

Protection from prolonged rainfall.

Protection from immersion in water.

Ensure that the storage temperature is not exceeded.

Protection against crushing

The SA380-IT is designed to be fitted to BR930 / Q Style relay bar. Alternative mounting arrangements can be made using the hinged

bracket (MPEC part no: BRK-HINGE)

Tool / Parts Required:

M5 (8 mm) nut spinner

Actions:

Install onto BR930 / Q Style relay racking. Feed the mounting studs through the pre-drilled holes on the mounting bar and secure

with the supplied spring washer and M5 nut. Take care not to over-tighten.

Damaged enclosures can expose hazardous voltages and nullifies the SA380-IT Ingress-Protection.

Prolonged exposure to, or immersion in water exceeds the SA380-IT Ingress-Protection rating. Under such conditions

dielectric withstand voltages cannot be guaranteed.

Never install or energise an SA380-IT that appears to be either physically damaged or suffering from water ingress.

Loading...

Loading...