MPE XR III Operator's Manual

OPERATING AND SERVICE MANUAL

XR SERIES III

DC POWER SUPPLIES

MAGNA-POWER ELECTRONICS, INC.

39 ROYAL ROAD, FLEMINGTON, NJ 08822

February 20, 2012

SAFETY NOTICE

Before applying power to the system, verify that the unit is configured properly for the user’s

particular application.

CE recognition of XR Series power supplies is based on rack mounted applications only. Use of

these power supplies outside of a rack mount equipment enclosure will expose the user to high

voltage and/or high current sources. Extreme caution must be used under these circumstances.

Two or more XR Series power supplies may be connected in series. Regardless of the number

of units or the voltage ratings of the series connected power supplies, the voltage potential from

any output terminal to chassis ground should not exceed 1000 Vdc.

Installation and service must be performed only by properly trained and qualified personnel who

are aware of dealing with electrical hazards. Ensure that the ac power line ground is properly

connected to the power supply chassis. Furthermore, other power grounds, including those

connected to application maintenance equipment, must be grounded for both personnel and

equipment safety.

Always ensure that facility ac input power is de-energized prior to connecting or disconnecting

the input and output power cables.

Caution: Lethal voltages may be present inside the power supply even when the

ac input voltage is disconnected. Only properly trained and qualified personnel

should remove covers and access the inside of the power supply.

During normal operation, the operator does not have access to hazardous voltages within the

cabinet. Depending on the user’s application, high voltages hazardous to human safety may be

generated normally on the output terminals. Ensure that the output power cables are properly

labeled as to the safety hazards and that any inadvertent contact with hazardous voltages is

eliminated.

This power supply is designed to be permanently connected to the power source requiring a

readily accessible disconnect device incorporated in the fixed wiring.

These operating instructions form an integral part of the equipment and must be available to the

operating personnel at all times. All the safety instructions and advice notes are to be followed.

Neither Magna-Power Electronics, Inc. nor any of the associated sales organizations can accept

responsibility for personal injury, consequential injury, loss, or damage that results from

improper use of the equipment and accessories.

i

LIMITED WARRANTY

The following is made in lieu of all warranties expressed or implied.

Magna-Power Electronics, Inc. warranties its products to be free of manufacturing defects for a

period of two (2) years from date of original shipment from its factory. Magna-Power

Electronics, Inc. will repair, replace, or refund the purchase price at its discretion, which upon

examination by Magna-Power Electronics, Inc., is determined to be defective in material or

workmanship, providing such claimed defective material is returned upon written authorization

of Magna-Power Electronics, Inc., freight prepaid.

For products failing within the first 30 days of the warranty period, Magna-Power Electronics,

Inc. will return the repaired product at its expense using a standard shipping method; after 30

days of the warranty period, the repaired product will be returned at the customer’s expense

using the customer’s requested shipping method.

Damage due to corrosion, customer alterations, excessive dust, extreme environmental or

electrical conditions, and/or misuse will be evaluated upon inspection. If inspection reveals that

the cause of damage is not due to materials or workmanship, repair of the product will be treated

on a non-warranty basis.

All electrical, commercial supply parts, and items not manufactured by Magna-Power

Electronics, Inc. shall carry the warranty of the original manufacturer and no more, but under no

circumstances to exceed the warranty period. Replacement parts shall be warranted for a period

of 90 days.

Warranty labor shall only apply if the product, assembly, or part is returned to the factory freight

prepaid and insured. Damage or breakage while in transit is not covered by this warranty.

Magna-Power Electronics, Inc. assumes no responsibility to Buyer for labor to diagnose and

remove defective product and installation of replacement product. Furthermore, Magna-Power

Electronics, Inc. is not liable to Buyer or to any third party for consequential or incidental

damages under any circumstances, whether due to defect in the product, due to delay or failure

of delivery, due to a failure of the product to perform as specified, or for any other reason or

cause. Buyer and Magna-Power Electronics, Inc. agree that Buyer’s sole remedy and MagnaPower Electronics, Inc.’s sole liability to Buyer is limited to repair, replacement, or refund of

the purchase price of the product as described herein, whether Buyer’s claim arises out of

contract or in tort.

All claims against the warranty shall be the final determination of Magna-Power Electronics,

Inc.

ii

CLAIM FOR DAMAGE IN SHIPMENT

This instrument received comprehensive mechanical and electrical inspections before shipment.

Immediately upon receipt from the carrier, and before operation, this instrument should be

inspected visually for damage caused in shipment. If such inspection reveals internal or external

damage in any way, a claim should be filed with the carrier. A full report of the damage should

be obtained by the claim agent and this report should be forwarded to us. We will then advise

you of the disposition to be made of the equipment and arrange for repair or replacement. When

referring to this equipment, always include the model and serial number.

RETURNING EQUIPMENT

Before returning any equipment to the factory, the following steps should be taken:

1. Contact our technical service department. Give a full description of the difficulty and

include the model and serial number of the unit. On receipt of this information, we will

give you service information or shipping instructions.

2. Packaging and method of shipment must be coordinated with the factory to insure safe

delivery. All equipment returned for repair require a Return Authorization Number and

must be insured. No returns will be accepted without assignment of a Return

Authorization Number.

3. For non-warranty repairs, we will submit a cost estimate for your approval before

proceeding.

iii

TABLE OF CONTENTS

Section Title Page

1.0 GENERAL INFORMATION 1

1.1 Description 1

1.2 Features 1

1.3 IEC Symbols Used in Manual 4

1.4 Power Requirements 4

1.5 Specifications 4

2.0 INSTALLATION AND POWER ON CHECK 18

2.1 Cooling 18

2.2 AC Input Connections 18

2.3 DC Output Connections 19

2.4 General Operation 19

2.5 Controls and Indicators 21

2.6 Preparation for Use 21

2.6.1 Unpacking 21

2.6.2 Electrical Check 21

2.6.2.1 XR Series Models 21

2.6.2.2 XRC Series Models 22

3.0 OPERATION 25

3.1 Front Panel Commands 25

3.1.1 Run Mode Commands 25

3.1.2 Set Point Commands 26

3.1.3 Configuration Commands 28

3.1.4 Calibration Commands 31

3.2 Modes of Operation 33

3.2.1 Normal Mode 33

3.2.2 Constant Voltage 33

3.2.3 Constant Current 34

3.3 Remote Sensing 34

3.4 External Programming 35

3.4.1 Resistive Programming 37

3.4.2 Voltage Programming 37

3.4.3 Current Programming 38

3.5 Voltage and Current Monitoring 38

3.6 Digital Input and Output Lines 38

3.7 Diagnostic Functions 39

3.8 Parallel Operation 41

3.8.1 Parallel Operation - Direct 42

3.8.2 Parallel Operation - Master/Slave 42

iv

3.9 Series Operation 43

3.9.1 Series Operation - Direct 44

3.9.2 Series Operation - Master/Slave 44

3.10 Pulse Loading 45

3.11 Nomenclature 45

4.0 PROGRAMMING WITH SCPI COMMANDS 48

4.1 Command Features 48

4.2 Electrical Testing Using RS232 Communications 48

4.3 SCPI Subsystem Commands 49

4.3.1 Source Subsystem 49

4.3.1.1 VOLT and VOLT:TRIG 50

4.3.1.2 VOLT:PROT 51

4.3.1.3 CURR and CURR:TRIG 51

4.3.1.4 CURR:PROT 52

4.3.1.5 PER (not available for XR Series power supplies) 53

4.3.2 Measure Subsystem 53

4.3.2.1 MEAS:VOLT? 53

4.3.2.2 MEAS:CURR? 54

4.3.3 System Subsystem 54

4.3.3.1 SYST:VERS? 54

4.3.3.2 SYST:ERR? 54

4.3.4 Status Subsystem 55

4.3.4.1 Operation Register 55

4.3.4.2 Questionable Register 56

4.3.5 Output Subsystem 56

4.3.5.1 OUTP? 56

4.3.5.2 OUTP:ARM (not available for XR Series power supplies) 57

4.3.5.3 OUTP:START 57

4.3.5.4 OUTP:STOP 58

4.3.5.5 OUTP:PROT:CLE 58

4.3.6 Abort Subsystem 58

4.3.7 Trigger Subsystem 59

4.3.8 Initiate Subsystem 59

4.3.9 Calibrate Subsystem 60

4.3.9.1 CAL:IDN 60

4.3.9.2 CAL:PASS 60

4.3.9.3 CAL:POT 61

4.3.9.4 CAL:SCAL:VOLT 61

4.3.9.5 CAL:SCAL:CURR 61

4.3.9.6 CAL:SCAL:INP 62

4.3.9.7 CAL:DEF 62

4.3.9.8 CAL:STOP 62

4.3.10 Configure Subsystem 63

v

4.3.10.1 REM:SENS 63

4.3.10.2 CONT:INT 63

4.3.10.3 CONT:EXT 64

4.3.10.4 INTE 64

4.3.10.5 CONF:SETPT 64

4.3.11 GPIB Communications Subsystem 65

4.3.11.1 GPIB:VERS? (Optional GPIB only) 65

4.3.11.2 GPIB:ADDR (Optional GPIB only) 65

4.3.12 Ethernet Communications Subsystem 66

4.3.12.1 NET:VERS? (Optional Ethernet only) 66

4.3.12.2 NET:MAC? (Optional Ethernet only) 66

4.3.12.3 NET:SER? (Optional Ethernet only) 67

4.3.12.4 NET:ADDR (Optional Ethernet only) 67

4.3.12.5 NET:GATE (Optional Ethernet only) 67

4.3.12.6 NET:SUBN (Optional Ethernet only) 68

4.3.12.7 NET:PORT (Optional Ethernet only) 68

4.3.12.8 NET:HOST? (Optional Ethernet only) 69

4.3.12.9 NET:DHCP (Optional Ethernet only) 69

4.3.13 Recall Subsystem 69

4.3.14.1 MOD:TYPE:SEL 70

4.3.14.2 MOD:TABL 71

4.3.14.3 MOD:SAVE 72

4.3.14.4 MOD:TABL:LOAD 73

4.3.15 SCPI Data Formats 73

4.4 IEEE-488 Event Processing 74

4.5.1 Clear 74

4.5.2 Read Event Status Register 75

4.5.3 Read and Set Event Status Enable Register 77

4.5.4 Read Status Byte Register 77

4.5.5 Read and Set Service Request Enable Register 78

4.5.6 Read Model Number, Part Number, and Serial Number 78

4.5.7 Save 79

4.5.8 Recall 79

4.5.9 Reset 80

4.6 Error Messages 80

4.7 Restricted Command Set 81

5.0 INTERFACING USING THE REMOTE INTERFACE SOFTWARE 84

5.1 Application Setup 84

5.2 Virtual Control Panel 84

5.3 Command Panel 86

5.4 Register Panel 86

5.5 Calibration Panel 88

5.6 Firmware Panel 89

vi

5.7 Modulation Panel 89

6.0 PRINCIPLE OF OPERATION 92

7.0 MAINTENANCE AND TROUBLE SHOOTING 95

7.1 General 95

7.2 Trouble Shooting Guide 95

7.3 Calibration 96

7.3.1 Control Board 96

7.3.1.1 Reference Amplifier Calibration 96

7.3.1.2 Voltage Feedback Amplifier Calibration 96

7.3.1.3 Current Feedback Amplifier Calibration 96

7.3.2 Driver Board 96

7.3.2.1 Over Current Protection 97

7.3.2.2 Under Voltage Protection 97

8.0 APPLICATIONS 98

8.1 General 98

8.2 Leadless Remote Sensing 98

8.3 Photovoltaic Cell Simulator 98

8.4 Battery Charger 100

8.6 High-Slew Rate Option 104

APPENDIX A IEEE-488 COMMUNICATIONS 105

A.1 IEEE-488 Communications using the Remote Interface Software 105

A.2 IEEE-488 Communications with MAX 105

APPENDIX B ETHERNET COMMUNICATIONS 107

B.1 Ethernet Communications using the Remote Interface Software 107

B.2 Ethernet Communications using HyperTerminal 107

B.3 Ethernet Communications using a Web Page Browser 108

B.3.1 Connectivity 108

B.3.2 Discovery 109

B.3.2.1 Discovery using NI Measurement & Automation Explorer 109

B.3.2.2 Discovery using Agilent Connection Expert 109

B.3.2.3 Discovery using the Remote Interface Software 109

B.3.3 Web Interface 109

APPENDIX C USB COMMUNICATIONS 113

C.1 Edgeport/1 Setup 113

C.2 Edgeport/1 Communications using the Remote Interface Software 113

APPENDIX D RS485 COMMUNICATIONS 114

D.1 485DSS Initial Setup 114

vii

D.2 HyperTerminal Setup 114

D.3 485DSS Address Command 115

D.4 485DSS Communications using HyperTerminal 115

viii

1.0 GENERAL INFORMATION

1.1 Description

This manual contains operation and maintenance instructions for Magna-Power Electronics' XR

Series, current fed power supplies. These power supplies are constant voltage/constant current

sources suitable for a wide range of applications.

1.2 Features

Magna-Power Electronics’ XR Series combines the best of dc power processing with

multiprocessor embedded control. Magna-Power Electronics’ innovative power processing

technology improves response, shrinks package size, and reduces cost. XR Series power

supplies are current fed and are more tolerant to abusive loads than conventional switching

power supplies.

XR Series power supplies can operate as a voltage source or a current source depending on the

control settings and load conditions. If the power supply is operating as a voltage source and the

load increases to a point beyond the current command setting, the power supply automatically

crosses over to current mode control and operates as a current source at that setting.

XR Series power supplies incorporate an optically isolated feedback system. The result is that

all user interface circuitry is referenced to earth ground -- not the negative terminal of the power

supply. This enables users to connect external circuitry without concern of ground loops or

voltage breakdown.

XR Series power supplies offer both master/slave parallel and series operation. This enables two

or more power supplies to be placed in parallel for increased output current or in series for

increased output voltage. With master/slave operation, power supplies operate at near equal

voltage and current.

XR Series power supplies can be configured through the front panel for different applications.

The power supply can be programmed to have its control functions accessible from the front

panel, rear connector, or with RS232, optional IEEE-488, or optional Ethernet communications.

External RS485 to RS232 and external USB to RS232 converters are also available to echo

commands over the communications network. Communication options must be specified at time

of order. XR Series power supplies support a full set of SCPI commands. Drivers are available

for LabWindows/CVI, LabVIEW, and IVI.

Sensing can be established at the output terminal of the power supply or through a rear terminal

block for sensing at the load. A smart remote sense detector checks whether or not sense leads

are present eliminating the potential of uncontrolled operation. An external interlock can be set

to enable operation only when an external connection is made. Even calibration has been

simplified with front panel access to calibration digital potentiometers.

1

XR Series power supplies have three levels of over voltage/current protection: shutdown of

controlling insulated gate bipolar transistors (IGBT’s), disconnect of main power, and input

fuses. After an over voltage/current trip condition, the supply must be reset.

XR Series power supplies have push button start/stop controls. These controls are tied to a

mechanical contactor which operates with the electronic switches to break the ac mains when

stop is commanded. Unlike competing products, an off means both an electrical and mechanical

break in the power circuit — not a break in an electronic switch. Safety comes first at MagnaPower Electronics.

XR Series power supplies are available with two alternative front panels: XR Version for

analog/digital control and C Version for computer or programmable logic control. All XR Series

power supplies employ the same power processing engine. Table 1.1 shows a comparison

between the different models.

XR Series models utilizing the XR Version front panel provide stepless analog control from

front panel potentiometers. With simple configuration changes, voltage, current, over voltage

trip, and over current trip may be programmed from the rear connector or with RS232, optional

IEEE-488, or optional Ethernet communications. XR Series power supplies with XR Version

front panels are well suited for industrial and laboratory applications.

XR Series power supplies with XR Version front panels offer an analog input to modulate the

voltage or current setting using piecewise linear approximation. This feature enables the voltage

or current setting to be adjusted by a sensor input, such as a thermistor, or by monitoring its own

voltage or current. Modulation allows the output to be tailored for advanced process control

applications, battery charging, and source emulation.

XR Series models utilizing the C Version front panel only allow control from the rear connector

or with RS232, optional IEEE-488, or optional Ethernet communications. These models are

intended for process control applications where front panel controls and displays are not required

or desired.

Remote Interface Software is included to provide sophisticated computer control. This software

provides a virtual control panel to emulate the power supply’s front panel, a command panel to

send and monitor SCPI commands, a register panel to monitor registers, a calibration panel to

provide easy access to calibrate digital potentiometers, a firmware panel to upgrade the control

microprocessor, and a modulation panel to easily program modulation parameters.

2

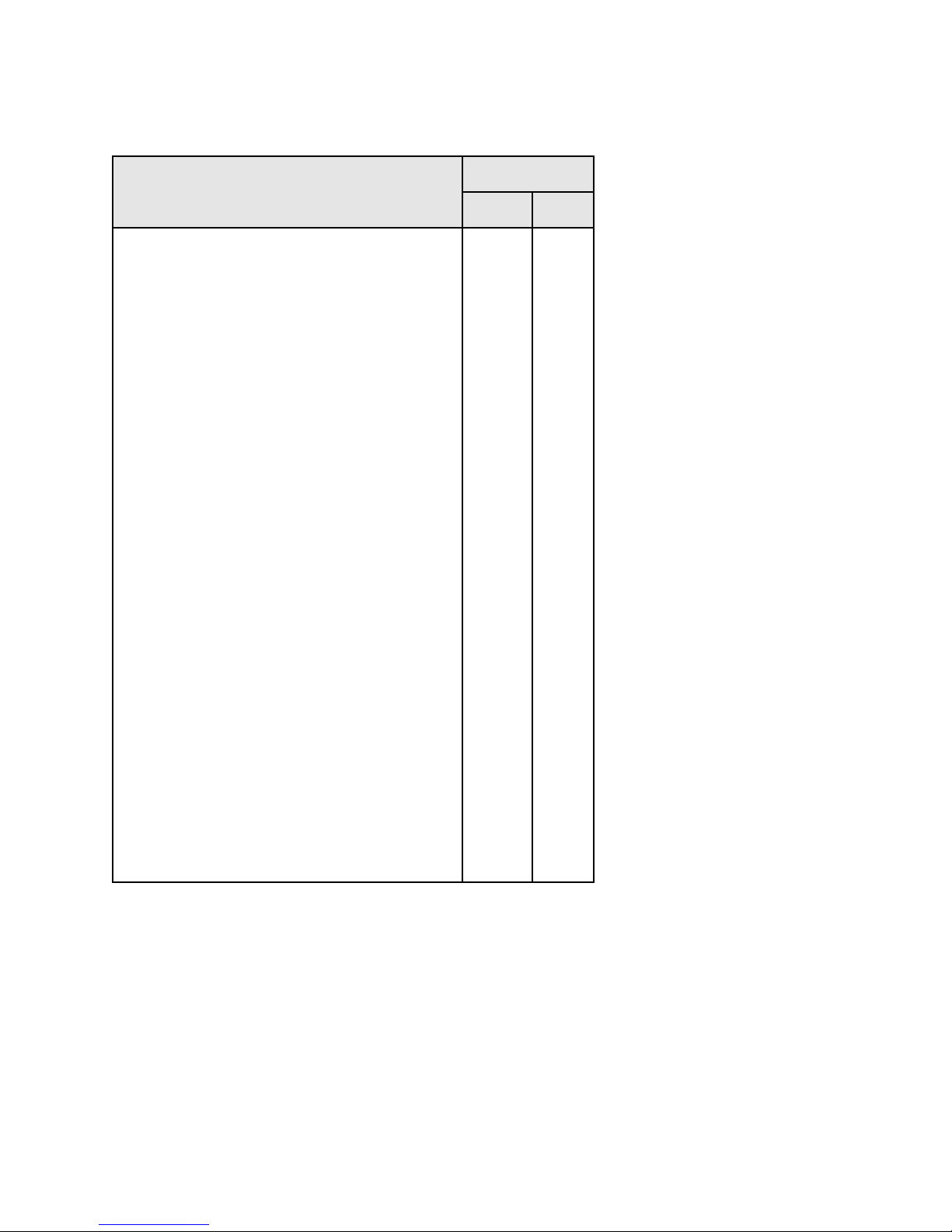

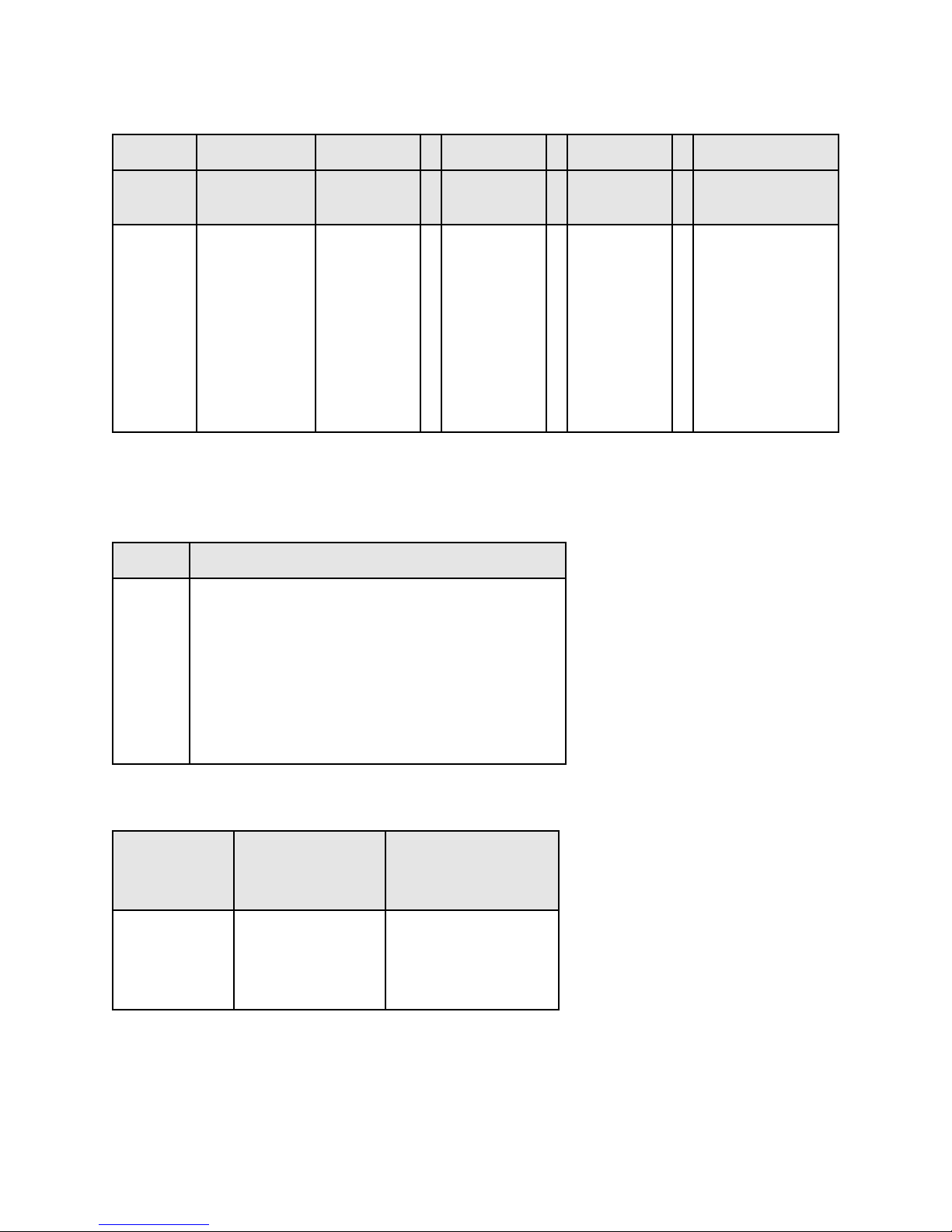

Table 1.1 COMPARISON CHART OF FRONT AND REAR

PANEL CONTROLS AND INDICATORS

MODELS

Features

XRC XR

FRONT PANEL CONTROLS

Power on/off

Start/Stop

Rotary voltage/current entry

Menu/Item

Display settings

Enter/Clear

!

!

!

!

!

!

!

INDICATORS

Voltage/current set point

OVT/OCT set point

Voltage/current output

Internal/external control

Alarms

Rotary/external/remote programming

Remote sense enabled

!

!

!

!

!

!

!

REAR PANEL CONTROLS

Voltage/current set point

OVT/OCT set point

Modulation set point

Voltage/current output

Internal/external control

Alarm outputs (8 lines)

Status outputs (6 lines)

Master/Slave connections

Remote sense inputs

RS232 inputs/outputs

Optional IEEE-488 inputs/outputs

Optional Ethernet inputs/outputs

Interlock enable

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

3

XR Series models have extensive diagnostic functions -- all of which when activated take

command to shut down the system. Diagnostic functions include phase loss, excessive thermal

conditions, over voltage trip, over current trip, and program line. Program line monitors

externally applied analog set point signals to insure they are within the specified range. Upon a

diagnostic fault condition, main power is disconnected and the diagnostic condition is latched

into memory. Pressing the clear key clears the memory. All diagnostic functions can be

monitored through a rear connector. Furthermore, control functions can also be set through the

rear connector to allow simultaneous control of one or more XR Series units.

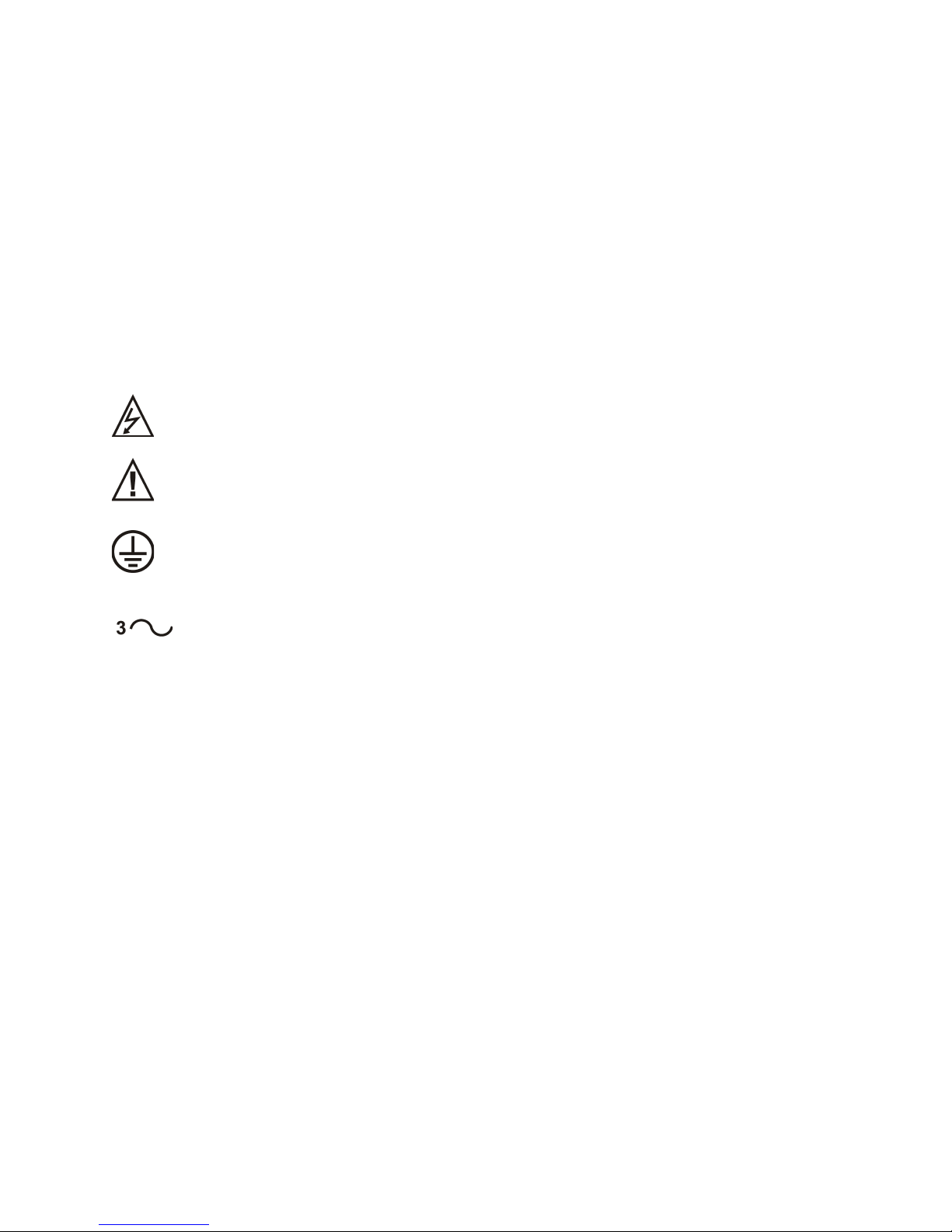

1.3 IEC Symbols Used in Manual

The following IEC symbols are used in this manual.

Caution, risk of electric shock

Caution, risk of danger

Protective conductor terminal

Three-phase alternating current

1.4 Power Requirements

XR Series power supplies are manufactured to operate on 208/240 V, 380/415 V, or 440/480 V

50 to 400 Hz mains.

The standard operating voltage is 208 V, 3φ, 50 to 400 Hz unless otherwise specified at time of

order. For conversion from 208 V to 240 V operation, two internal wiring changes must be

made. The locations are not accessible to the user and the power supply must be returned to the

factory for modification.

XR Series power supplies are optionally available to operate on 380 V or 480 V, 3φ, 50 to 400

Hz mains. For conversion from 380 V to 415 V or from 480 V to 440 V operation, two internal

wiring changes must be made. The locations are not accessible to the user and the power supply

must be returned to the factory for modification.

1.5 Specifications

The following specifications describe the published operational characteristics of the XR Series

power supplies.

4

Input voltage:

208 Vac (operating range 187 - 229 Vac), 50 - 400 Hz (operating range 45 - 440 Hz), 3φ;

240 Vac (operating range 216 - 264 Vac), 50 - 400 Hz (operating range 45 - 440 Hz), 3φ;

380 Vac (operating range 342 - 418 Vac), 50 - 400 Hz (operating range 45 - 440 Hz), 3φ;

415 Vac (operating range 373 - 456 Vac), 50 - 400 Hz (operating range 45 - 440 Hz), 3φ;

440 Vac (operating range 396 - 484 Vac), 50 - 400 Hz (operating range 45 - 440 Hz), 3φ;

480 Vac (operating range 432 - 528 Vac), 50 - 400 Hz (operating range 45 - 440 Hz), 3φ.

208 Vac (operating range 187 - 229 Vac), 50 - 400 Hz (operating range 45 - 440 Hz), 1φ;

240 Vac (operating range 216 - 264 Vac), 50 - 400 Hz (operating range 45 - 440 Hz), 1φ.

Line regulation:

Voltage Mode: ±0.004% of full scale,

Current Mode: ±0.02% of full scale.

Load regulation:

Voltage Mode: ±0.01% of full scale,

Current Mode: ±0.04% of full scale.

Stability: 0.10 % for 8 hours after 30 minute warm up.

Maximum Slew Rate for standard models:

100 ms for an output voltage change from 0 to 63%,

100 ms for an output current change from 0 to 63%.

Maximum Slew Rate for optional high-slew rate models:

4 ms for an output voltage change from 0 to 63%,

8 ms for an output current change from 0 to 63%.

Bandwidth for standard models:

3 Hz with remote analog voltage programming,

2 Hz with remote analog current programming.

Bandwidth for optional high-slew rate models:

60 Hz with remote analog voltage programming,

45 Hz with remote analog current programming.

Load transient response:

2 ms to recover within ±1% of regulated output with a 50% to 100% or 100% to 50% step load

change.

Efficiency: greater than 86%, see Model and Ratings tables for details.

Temperature coefficient:

5

0.04 %/EC of maximum output voltage,

0.06 %/EC of maximum output current.

Isolation:

User inputs and outputs: referenced to earth ground,

Maximum input voltage to ground: ±2500 Vac,

Maximum output voltage to ground: ±1000 Vdc.

Power Factor: greater than 92% at maximum power, 3φ inputs,

greater than 70% at maximum power for 1φ inputs.

Ambient Temperature: 0 to 50EC.

Storage Temperature: -25 to +85EC.

Remote sense limits: 3% maximum voltage drop from output terminals to load.

Remote analog programming limits:

Voltage set point: 0 to 10.0 Vdc for 0 to 100% output,

Current set point: 0 to 10.0 Vdc for 0 to 100% output,

Over voltage trip set point: 0 to 10.0 Vdc for 0 to 110% output,

Over current trip set point: 0 to 10.0 Vdc for 0 to 110% output,

Modulation: 0 to 10 Vdc.

Remote analog input impedance: 10K for all inputs.

Remote analog programming accuracy of full scale:

Voltage set point: ±0.075%,

Current set point: ±0.075%,

Over voltage trip set point: ±0.075%,

Over current trip set point: ±0.075%.

Analog monitoring and reference:

Output voltage: 0 to 10.0 Vdc, 5 mA,

Output current: 0 to 10.0 Vdc, 5 mA,

+10V Ref: 10.0 Vdc, 5 mA,

Analog output impedances:

Voltage output monitoring: 100 ohm,

Current output monitoring: 100 ohm,

+10V Ref: 1 ohm.

Analog monitoring accuracy of full scale:

Output voltage: ±0.2%,

6

Output current: ±0.2%,

+10V Ref: ±.50%.

Digital programming accuracy of full scale:

Voltage set point: ±0.075%,

Current set point: ±0.075%,

Over voltage trip set point: ±0.075%,

Over current trip set point: ±0.075%.

Digital readback accuracy of full scale:

Output voltage: ±0.2%,

Output current: ±0.2%.

Digital control inputs and outputs limits:

Input voltage: 0 to 5 Vdc, 10K input impedance;

Output voltages: 0 to 5 Vdc, 5 mA drive capacity per line;

5 V supply: 25 mA.

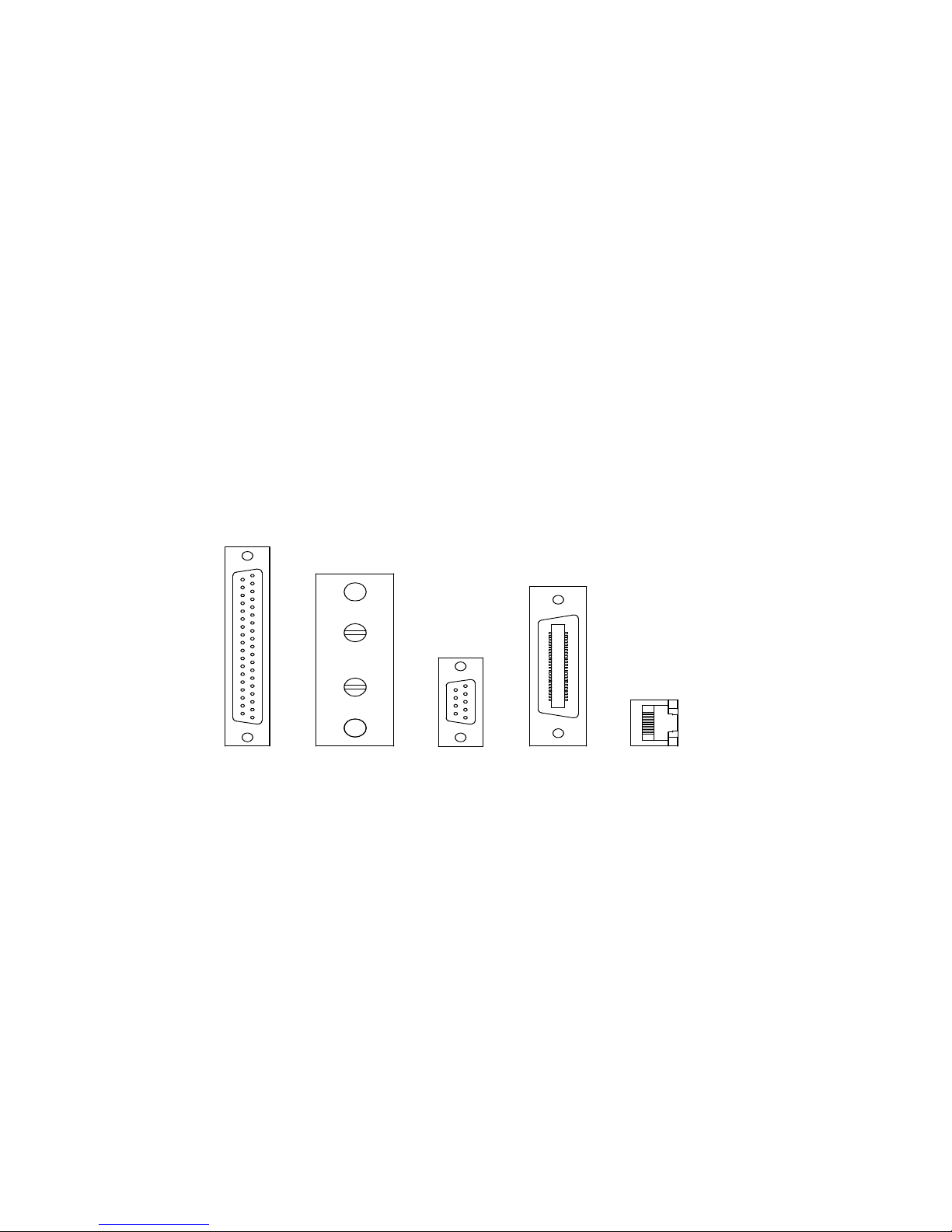

User interface connectors, see figure 1.1 and Tables 1.5, 1.6, 1.7, 1.8, and 1.9 for details:

JS1: 37 pin D-Subminiature, female;

JS2: 2 terminal 6-32 screw connector;

JS3: 9 pin D-Subminiature, female.

JS4: optional 24 pin IEEE-488, female.

JS5: optional 8 pin RJ45, female.

RS232 interface:

Baud Rate: 19200 Baud,

Data Size: 8-bit,

Parity: None,

Stop bits: 1.

Optional Ethernet Interface:

IP address: 169.254.x.x

Subnet Mask: 255.255.0.0

Default Getaway: 0.0.0.0

DNS Server: 0.0.0.0

Size and Weight: see figure 1.2 and Table 1.4 for details.

Agency Approvals:

CE-marked units meet the following standards:

EN61010-1:2001-02 Safety Requirements for Electrical Equipment for

7

Measurement, Control, and Laboratory Use

2004/108/EC EMC Directive

EN61000-6-3:2001 and EN61000-6-3:2001 General Emissions Standard

EN55022 Class A Product Specifications Emissions

EN61000-6-1:2001 Generic Immunity Standard

• EN61000-4-2 Electrostatic Discharge

• EN61000-4-3 Radiated Susceptibility

• EN61000-4-4 Electrical Fast Transient/Burst

• EN61000-4-6 Conducted Susceptibility

• EN61000-4-8 Magnetics

• EN61000-4-11 Voltage Dips & Interruptions

Optional Ethernet Interface units meet the following standards

LXI Class C, Revision 1.2

37

20

19

1

2

9

1

(b)

6

(c)(a)

24 12

5

1

113

8

1

(d) (e)

Figure 1.1 Connector (a) JS1, remote interface; (b) JS2, remote sense; ( c) JS3, RS232; (d)

JS4, IEEE-488; and (e) JS5, Ethernet (viewed from female end)

8

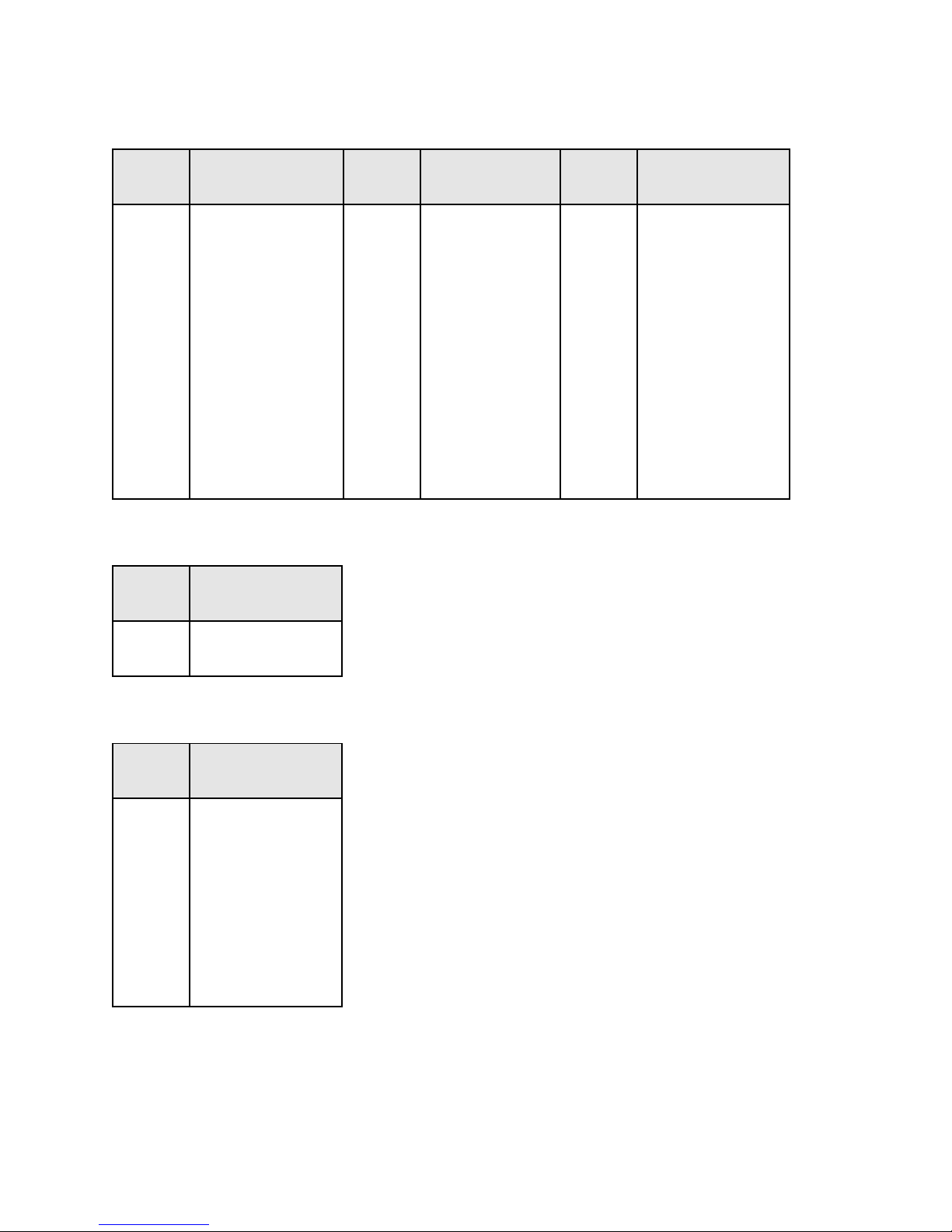

Table 1.2 MODEL ORDERING SYSTEM – Example XR500-16/208+WC+LXI

XR D 500 - 16 / 208 + WC+LXI

SERIES

NAME

XR

PQ

TS

MS

FRONT

PANEL

A: Analog

D: Digital

C: Computer

Blank: XR

OUTPUT

VOLTAGE

See Tables

1.11 and

greater

OUTPUT

CURRENT

See Tables

1.11 and

greater

MT

Note:

1) Multiple options can be specified as indicated.

Table 1.3 OPTIONS

TERM DEFINITION

EMI

WC

HS

LXI

GPIB

USB

RS485

EW

EMI Filter

Water Cooling

High-Slew Rate

LXI TCP/IP Ethernet Interface (Internal)

IEEE488.2 GPIB Interface (Internal)

USB Interface (External)

RS485 Interface (External)

Extended Warranty

INPUT

VOLTAGE OPTIONS

208 SP

See Table 1.3

240 SP

208

240

380

415

440

480

Table 1.4 SIZE AND WEIGHT MATRIX

POWER

kW

2.0

4.0

6.0

8.0

SIZE

H”xW”xD”

3½x19x24

3½x19x24

3½x19x24

3½x19x24

WEIGHT

LBS

45

47

48

48

9

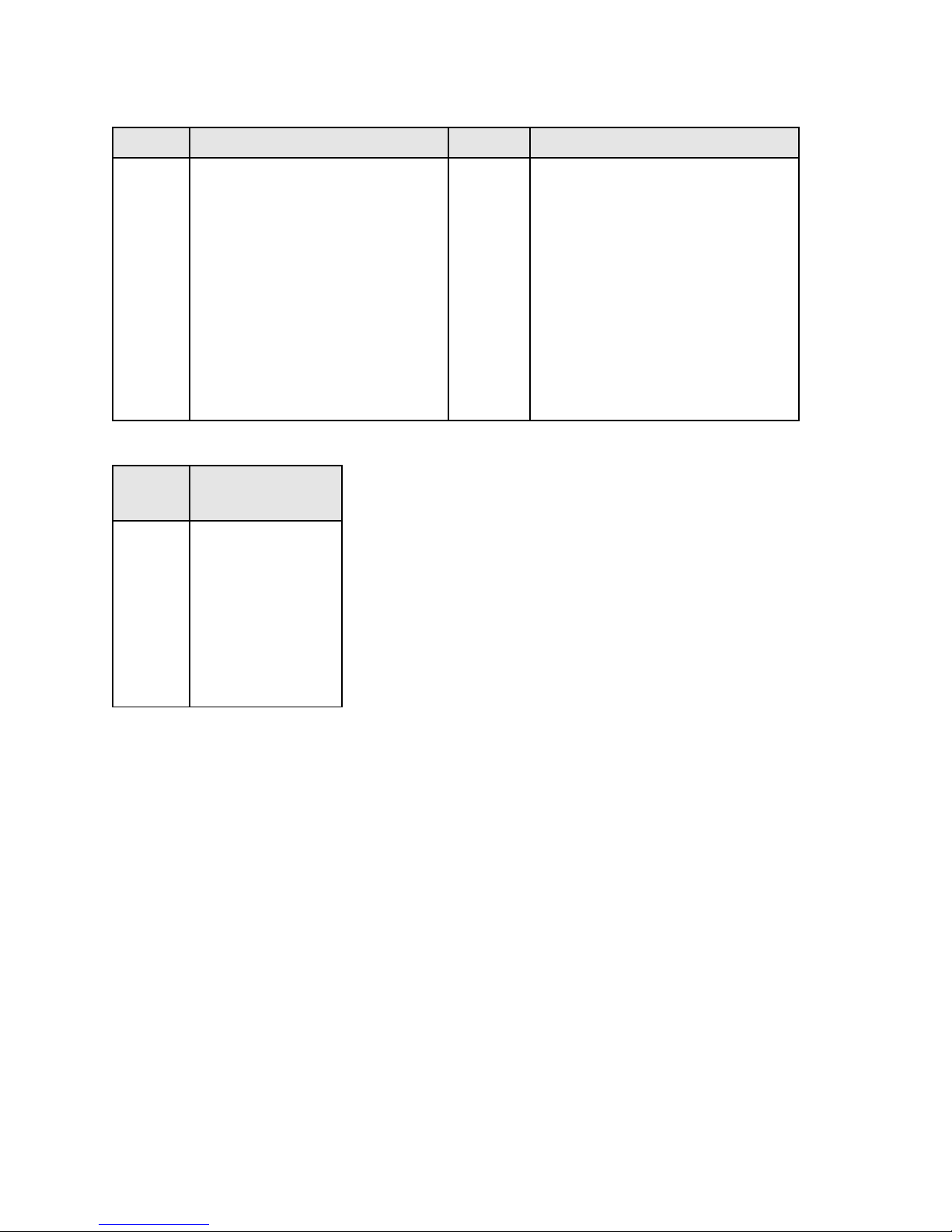

Table 1.5 TERMINAL DEFINITIONS FOR CONNECTOR JS1, REMOTE

INTERFACE

TERM PARAMETER TERM PARAMETER TERM PARAMETER

1

REF GND

2

REF GND

3

VREF EXT

4

TVREF EXT

5

VO2

6

+2.5V REF CAL

7

GND

8

POWER

9

THERMAL

10

INTERLOCK

11

CUR CTL

12

STANDBY/ALM

13

ALM

14

EXT CTL

15

RESERVE

16

RESERVE

17

START

18

CLEAR

19

STOP

20

REF GND

21

+10V REF

22

IREF EXT

23

TIREF EXT

24

IO2

25

VMOD

26

+5V

27

PGM LINE

28

STANDBY

29

PHASE LOSS

30

VOLT CTL

31

RESERVE

32

OCT

33

INT CTL

34

OVT

35

RESERVE

36

RESERVE

37

INTERLOCK

SET

Table 1.6 TERMINAL DEFINITIONS FOR CONNECTOR JS2, REMOTE SENSE

TERM PARAMETER

12VO1REM-

VO1REM+

Table 1.7 TERMINAL DEFINITIONS FOR CONNECTOR JS3, RS232

TERM PARAMETER

1

NC

2

RX

3

TX

4

DTR

5

GND

6

DSR

7

RTS

8

CTS

9

NC

10

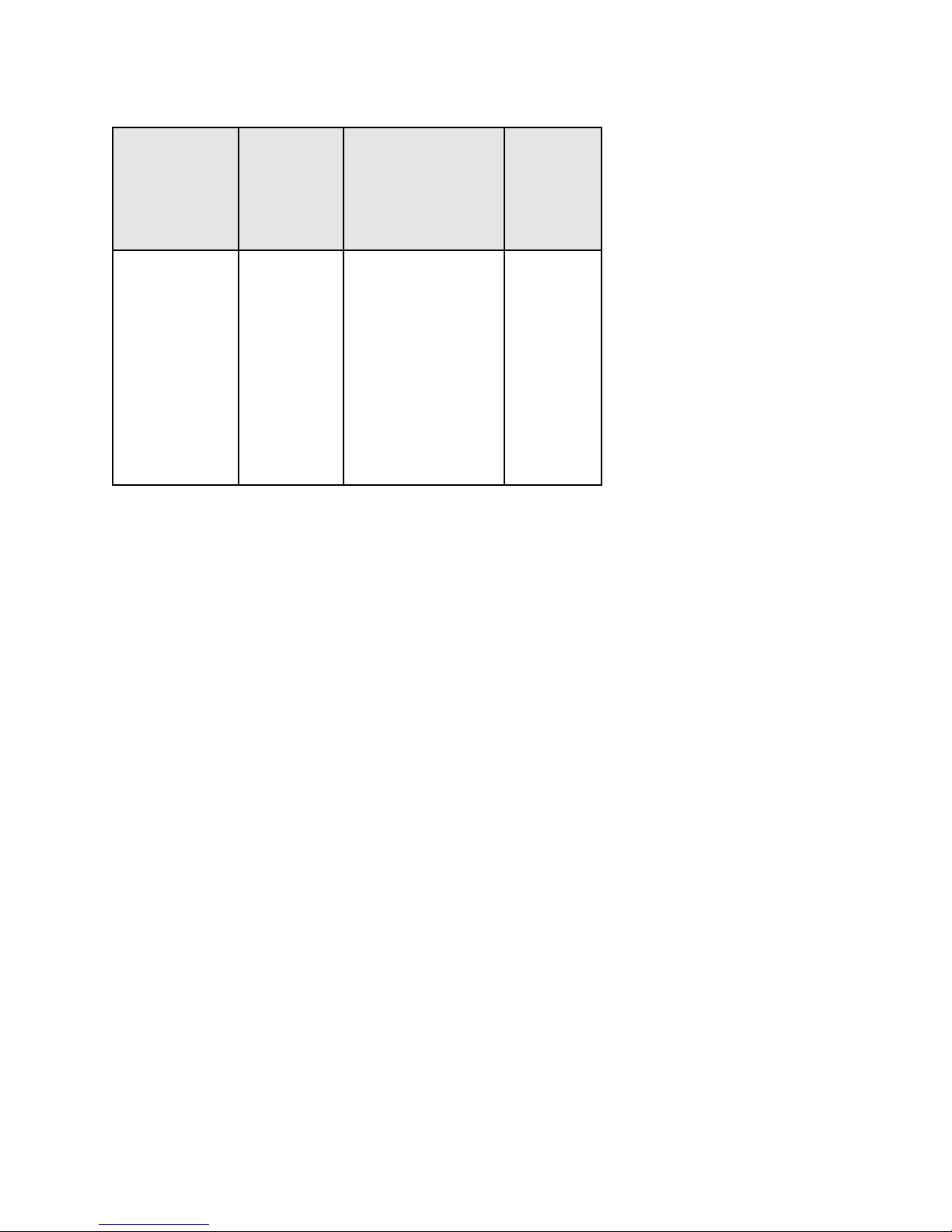

Table 1.8 TERMINAL DEFINITIONS FOR CONNECTOR JS4, IEEE-488

TERM PARAMETER TERM PARAMETER

1

2

3

4

5

6

7

8

9

10

11

12

DIO1/Data line

DIO2/Data line

DIO3/Data line

DIO4/Data line

EOI/End or Identify

DAV/Data Valid

NRFD/Not Ready For Data

NDAC/Not Data Accepted

IFC/Interface Clear

SRQ/Service Request

ATN/Attention

Shield

13

14

15

16

17

18

19

20

21

22

23

24

DIO5/Data line

DIO6/Data line

DIO7/Data line

DIO8/Data line

REN/Remote Enable

DAV/Gnd

NRFD/Gnd

NDAC/Gnd

IFC/Gnd

SRQ/Gnd

ATN/Gnd

Ground

Table 1.9 TERMINAL DEFINITIONS FOR CONNECTOR JS5, ETHERNET

TERM PARAMETER

1

TX+

2

TX-

3

RX+

4

NC

5

NC

6

RX-

7

NC

8

NC

11

Table 1.10 OPTIONAL HIGH-SLEW OUTPUT PARAMETERS

OUTPUT

VOLTAGE

RANGE

Vdc

5

10-16

20

32

40-80

100-400

500

600

800

1000

OUTPUT

POWER

RANGE

kW

2 - 8

OUTPUT

CAPACITANCEμFRIPPLE

Vrms

13200

4080

2340

1170

240

160

80

56

56

52

.50

.50

.70

1.4

1.5

1.6

2.1

2.3

2.5

3.0

12

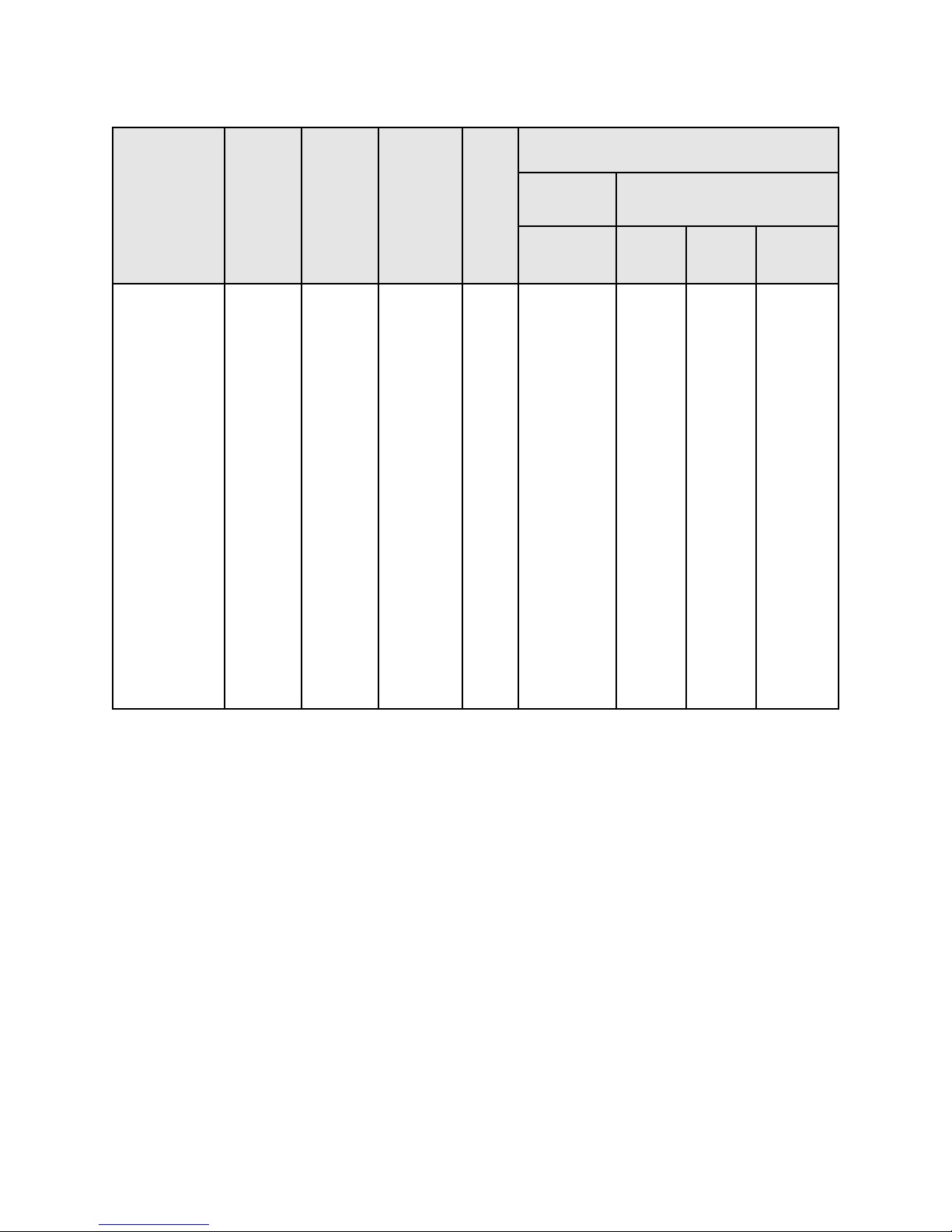

Table 1.11 2 KW MODELS AND RATINGS

MODEL

XR5-375

XR10-200

XR16-125

XR20-100

XR32-62

XR40-50

XR50-40

XR80-25

XR100-20

XR125-16

XR160-12

XR200-10

XR250-8.0

XR375-5.3

XR400-5.0

XR500-4.0

XR600-3.3

XR800-2.5

XR1000-2.0

VOLTS

Vdc

10

16

20

32

40

50

80

100

125

160

200

250

375

400

500

600

800

1000

AMPS

Adc

5

375

200

125

100

62

50

40

25

20

16

12

10

8.0

5.3

5.0

4.0

3.3

2.5

2.0

RIPPLE

mVrms

50

40

35

40

40

40

50

60

60

100

120

125

130

170

190

220

250

300

350

EFF

Notes:

1) Rating specified at 208, 380, and 440 V input.

2) Specifications subject to change without notice.

3) XR and XRC models all have identical ratings.

%

86

86

86

86

86

87

87

87

87

87

87

87

88

88

88

88

88

88

88

1φ UNITS

(Aac)

208/

240 V

18

18

18

18

18

18

18

18

18

18

18

18

18

18

18

18

18

18

18

INPUT CURRENT

3φ UNITS

(Aac)

208/

240 V

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

380/

415 V

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

440/

480 V

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

13

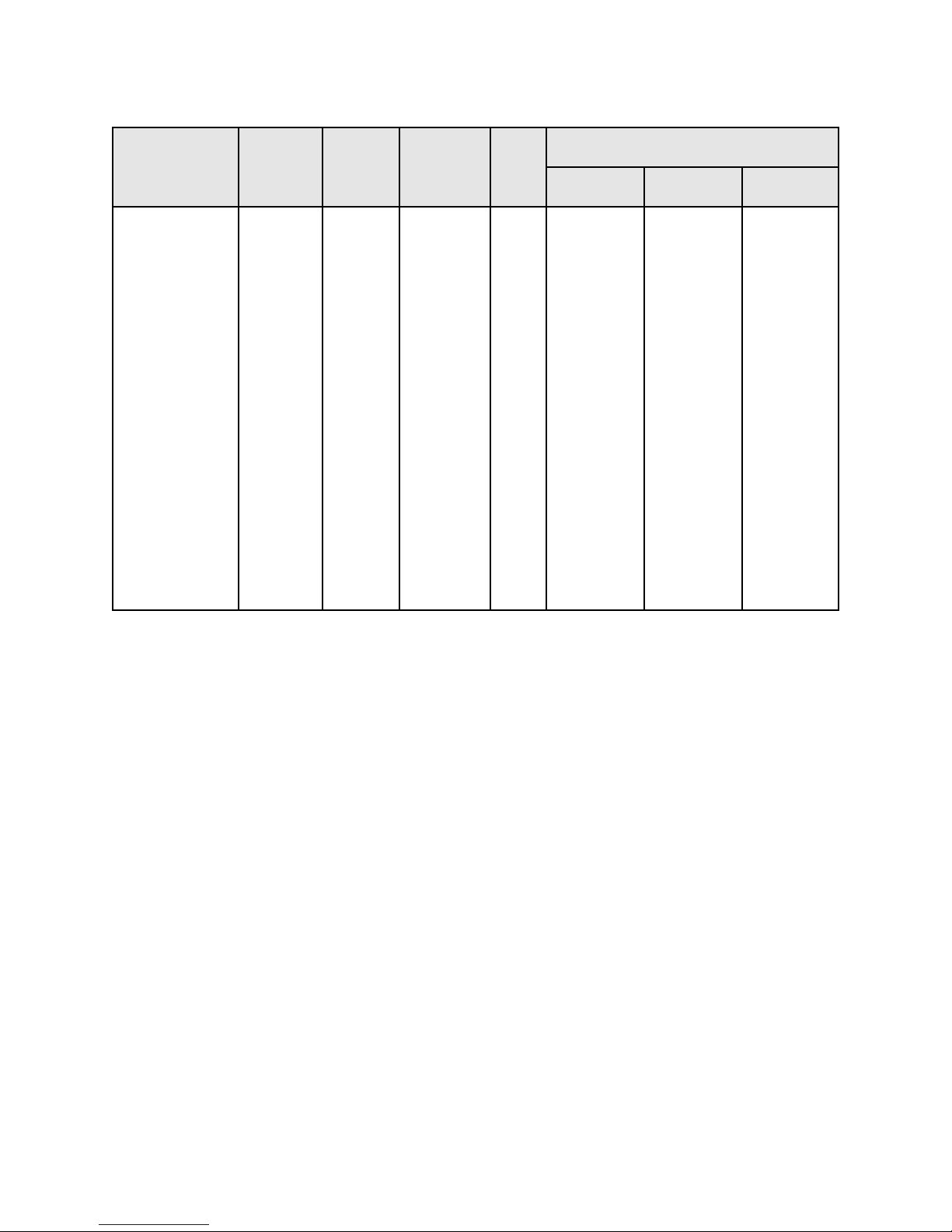

Table 1.12 4 KW MODELS AND RATINGS

MODEL

VOLTS

Vdc

AMPS

Adc

RIPPLE

mVrms

EFF

%

INPUT CURRENT (Aac)

208/240 V 380/415 V 440/480 V

XR10-375

XR16-250

XR20-200

XR32-124

XR40-100

XR50-80

XR80-50

XR100-40

XR125-32

XR160-24

XR200-20

XR250-16

XR375-10.6

XR400-10.0

XR500-8.0

XR600-6.6

XR800-5.0

XR1000-4.0

10

16

20

32

40

50

80

100

125

160

200

250

375

400

500

600

800

1000

375

250

200

124

100

80

50

40

32

24

20

16

10.6

10.0

8.0

6.6

5.0

4.0

40

35

40

40

40

50

60

60

100

120

125

130

170

190

220

250

300

350

Notes:

1) Rating specified at 208, 380, and 440 V input.

2) Specifications subject to change without notice.

3) XR and XRC models all have identical ratings.

86

86

86

86

87

87

87

87

87

87

87

88

88

88

88

88

88

88

15

15

15

15

15

15

15

15

14

14

14

14

14

14

14

14

14

14

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

14

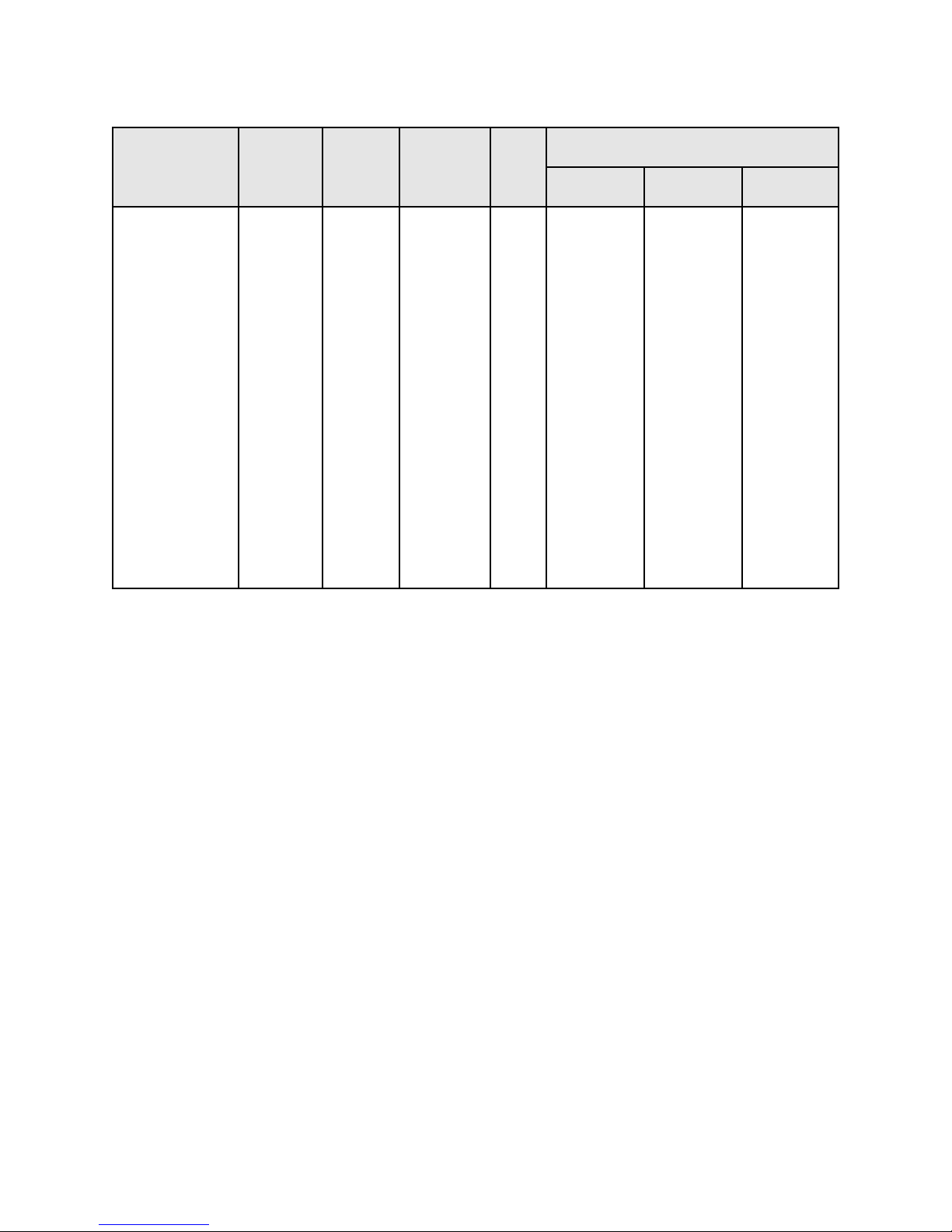

Table 1.13 6 KW MODELS AND RATINGS

MODEL

VOLTS

Vdc

AMPS

Adc

RIPPLE

mVrms

EFF

%

INPUT CURRENT (Aac)

208/240 V 380/415 V 440/480 V

XR16-375

XR20-300

XR32-186

XR40-150

XR50-120

XR80-75

XR100-60

XR125-48

XR160-36

XR200-30

XR250-24

XR375-15.9

XR400-15.0

XR500-12

XR600-9.9

XR800-7.5

XR1000-6.0

16

20

32

40

50

80

100

125

160

200

250

375

400

500

600

800

1000

375

300

186

150

120

75

60

48

36

30

24

15.9

15.0

12.0

9.9

7.5

6.0

35

40

40

40

50

60

60

100

120

125

130

170

190

220

250

300

350

Notes:

1) Rating specified at 208, 380, and 440 V input.

2) Specifications subject to change without notice.

3) XR and XRC models all have identical ratings.

86

86

86

87

87

87

87

87

87

87

88

88

88

88

88

88

88

22

22

22

22

22

22

22

21

21

21

21

21

21

21

21

21

21

13

13

13

13

13

13

13

13

13

13

13

13

13

13

13

13

13

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

15

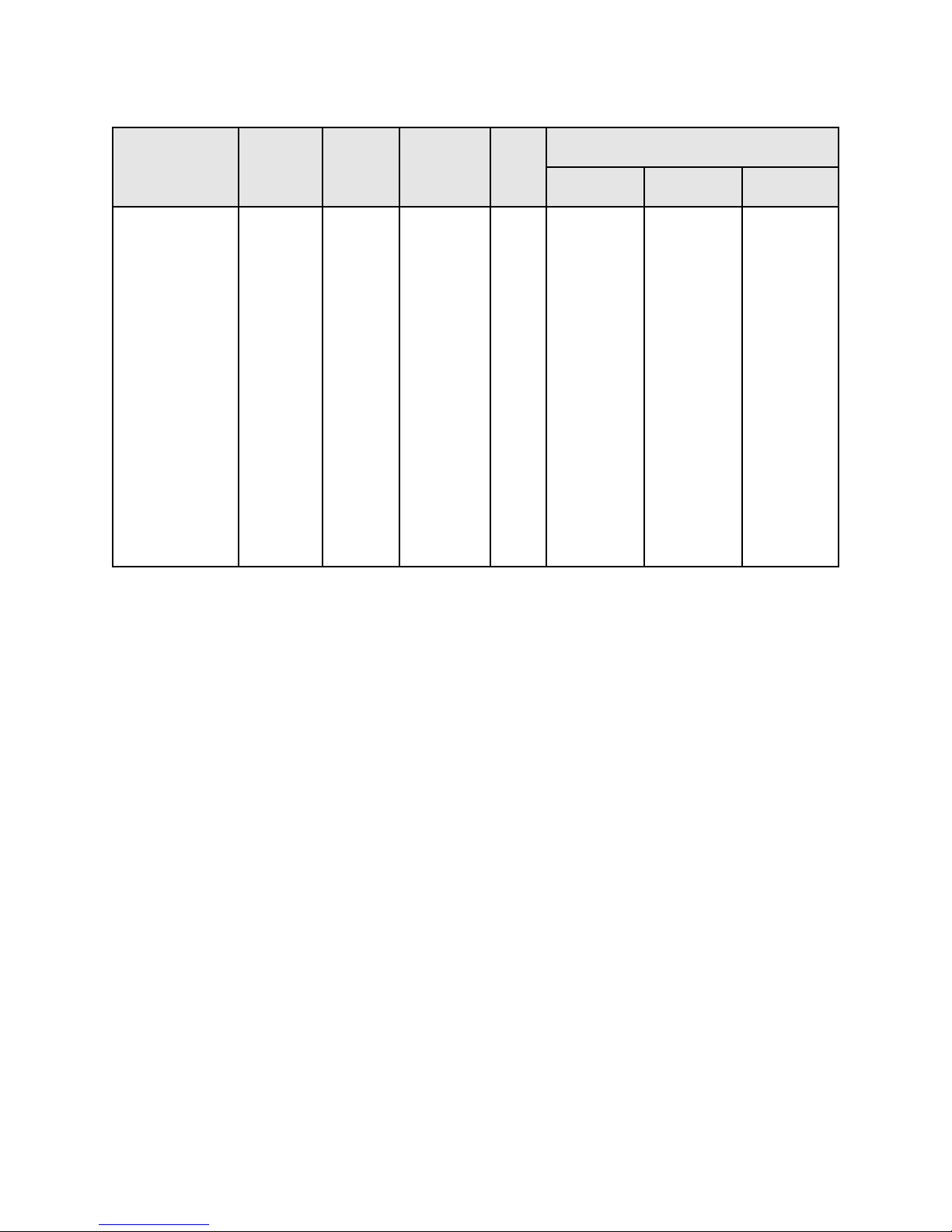

Table 1.14 8 KW MODELS AND RATINGS

MODEL

VOLTS

Vdc

AMPS

Adc

RIPPLE

mVrms

EFF

%

INPUT CURRENT (Aac)

208/240 V 380/415 V 440/480 V

XR20-375

XR32-250

XR40-200

XR50-160

XR80-100

XR100-80

XR125-64

XR160-50

XR200-40

XR250-32

XR375-21.3

XR400-20.0

XR500-16.0

XR600-13.3

XR800-10.0

XR1000-8.0

20

32

40

50

80

100

125

160

200

250

375

400

500

600

800

1000

375

250

200

160

100

80

64

50

40

32

21.3

20.0

16.0

13.3

10.0

8.0

60

60

60

70

80

80

120

125

120

140

200

220

240

280

320

380

Notes:

1) Rating specified at 208, 380, and 440 V input.

2) Specifications subject to change without notice.

3) XR and XRC models all have identical ratings.

86

86

87

87

87

87

87

87

87

88

88

88

88

88

88

88

29

29

29

29

29

29

28

28

28

28

28

28

28

28

28

28

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

15

15

15

15

15

15

15

15

15

15

15

15

15

15

15

15

16

Figure 1.2 XR Series package drawing with XR Version front panel

1.250

JS2

12

OCTOVTTHLPHLPGLLOC

CTLCTL

REM SEN

INT CT L

EXT CTL

ROTARY

EXT PGM

REMOTE

POWER

STANDBY MENU V/IDIS CLEAR

ITEM TRIPDIS ENTER

START STOP

CURRENTVOLTAGE

DC VOLTAGE DCCURRE NT

CONFIGURATON

MODE

PWR

ELECTRONICS

M

AGNA-POWER

B

3

INPUT

!

OUTPUT

NEG

A

CGND

POS

JS1

JS3

24.000

0.234

3.469

0.328

19.000

1.000

6.312

0.875

1.966

AIR INTAKE BOTH SIDES

0.250X1.000 SILVER PLATED COPPER BUS,

3/8-16 THREADED INSERT, QTY 2

AIR EXHAUST, BOTH SIDES

10-32 THEADED INSERTS, QTY 4

FRONT PANEL

REAR P AN E L

SIDE PANEL

OPTIONAL IEEE-488

INTERFACE

OPTIONAL ETHERNET

INTERFACE

JS1

JS5

JS3

RST LAN

JS1

JS4JS3

1.937

PROTECTIVESHIELD

17

2.0 INSTALLATION AND POWER ON CHECK

XR Series power supplies are intended for rack mount installations only and are designed to fit

in standard 19" equipment racks. Additional support, other than that provided by the front panel,

is required. Angle slides or cross beam supports securely fastened to the rack are recommended

for supporting the weight of the power supply. The unit should be horizontally mounted.

Caution: The power supply is too heavy for one person to safely lift and mount.

To avoid injury, ask a co-worker for assistance.

2.1 Cooling

Each power supply enclosure is cooled by suitable blowers exhausting warm air to the rear of the

cabinet. Fresh air intake is from the sides of the cabinet allowing two or more XR Series

supplies to be stacked. Equipment racks should be equipped with fans or blowers to remove heat

generated by the power supplies. The manufacturer recommends fresh air intake at the bottom

of the cabinet and exhaust at the top. Fans and blowers should be rated at 300 CFM for each XR

Series supply.

Caution: blocking ventilation will cause the power supply to overheat.

2.2 AC Input Connections

Caution: disconnect AC power from the mains before attempting any

installation procedure.

Caution: a safety ground wire must be connected to the unit as indicated by

the protective ground symbol at the rear of the power supply.

AC power is wired to the power supply by attaching three cables plus ground for 3-phase

installations and two cables and ground for single phase installations. The manufacture

recommends cables, as specified in Tables 2.1 or 2.2, be crimped to ring terminals and securely

fastened to the studs at the rear of the power supply. After connections are made, screw the four

standoffs into the back panel and place the protective shield over the connections.

18

Loading...

Loading...