moyno WA, WA036, WA050, WA022, WA065 Service Manual

...

WA Models

T

ABLE OF CONTENTS

PAGE

1-1. INTRODUCTION .................................................................................................................................................. 1

1-2. General.................................................................................................................................................. 1

1-3. Scope .................................................................................................................................................... 1

1-4. Nameplate Data..................................................................................................................................... 1

1-5. Pump Rotation ....................................................................................................................................... 1

1-6. Model Number ....................................................................................................................................... 1

2-1. INSTALLATION .................................................................................................................................................... 2

2-2. General.................................................................................................................................................. 2

2-3. Piping..................................................................................................................................................... 2

2-4. Foundation............................................................................................................................................. 2

3-1. OPERATION ........................................................................................................................................ 2

3-2. Initial Check ........................................................................................................................................... 2

3-3. Start-up.................................................................................................................................................. 2

3-4. Packing Leakage ................................................................................................................................... 2

4-1. MAINTENANCE................................................................................................................................................... 2

4-2. General.................................................................................................................................................. 2

4-3. Packing Adjustment ............................................................................................................................... 2

4-4. Packing Replacement............................................................................................................................ 3

5-1. DISASSEMBLY.................................................................................................................................................... 3

5-2. Disconnect Pump................................................................................................................................... 3

5-3. Stator Removal ...................................................................................................................................... 3

5-4. Suction Housing Removal ..................................................................................................................... 3

5-5. Rotor/Con Rod/Drive Shaft Assembly Removal..................................................................................... 3

5-6. Packing Housing Removal...................................................................................................................... 4

5-7. Seal Housing Removal ........................................................................................................................... 4

5-8. Rotor, Driveshaft, and Connecting Rod Disassembly ............................................................................. 4

5-9. Gear motor Removal ............................................................................................................................. 4

5-10. Bearing Housing Disassembly .............................................................................................................. 4

5-11. Cleaning ............................................................................................................................................... 4

6-1. INSPECTION ........................................................................................................................................................ 4

6-2. Drive Shaft and Packing/Seals .............................................................................................................. 4

6-3. Rotor...................................................................................................................................................... 4

6-4. Stator ..................................................................................................................................................... 5

6-5. All Other Parts ....................................................................................................................................... 5

7-1. ASSEMBLY.......................................................................................................................................................... 5

7-2. Lubrication During Assembly ................................................................................................................. 5

7-3. Driveshaft and Rotor Gear Joint Assembly ............................................................................................ 5

7-4. Bearing Housing Assembly.................................................................................................................... 6

7-5. Pumps with Single Mechanical Seal ...................................................................................................... 6

7-6. Pumps with Compression Packing ........................................................................................................ 6

7-7. Pumps with Double or Cartridge Mechanical Seals ............................................................................... 7

7-8. Rotor/Stator Assembly........................................................................................................................... 7

7-9. Gear motor installation ......................... ................... .................... .................... .................... ................... ............ 7

7-10. Pump Connections........ .................... ................... .................... .................... .................... .................... ............. 7

8-1. STORAGE ............................................................................................................................................................ 7

9-1. RECOMMENDED SPARE PARTS ....................................................................................................................... 7

10-1. HARDWARE LIST .............................................................................................................................................. 8

11-1. PARTS LIST ...................................................................................................................................................... 9

12-1. EXPLODED VIEW ............................................................................................................................................ 10

13-1. SEAL SET DIMENSIONS ................................................................................................................................. 12

14-1 TROUBLESHOOTING CHART........................................................................................................................ 13

Section:

SERVICE MANUAL

Moyno

2000 CC Pumps

WA Models

1-1. INTRODUCTION

1-2. General

The Moyno 2000 pump is a progressing cavity pump. A single

helical rotor rolling eccentrically in the double-threaded helix of

the stator creates the pumping action. In its revolution, the rotor

forms, in conjunction with the stator, a series of sealed cavities

180 degrees apart. As the rotor turns, the cavities progress

from the suction to the discharge. As one cavity diminishes, the

opposing cavity increases at exactly the same rate. Thus, the

sum of the two discharges is a constant volume. The result is a

pulsation-less, positive displacement flow.

1-3. Scope

This service manual covers the installation and maintenance

requirements for WA Model, close-coupled configuration of the

Moyno 2000 pump line. Disassembly and assembly procedures

are also covered in this manual.

1-4. Nameplate Data

The pump nameplate, located on the bearing housing, contains

important information relative to the operation and servicing of

the pump. This information includes the direction of rotation

arrow and the pump model and serial numbers.

The model and serial numbers must be used when

ordering spare parts.

1-5. Pump Rotation

A rotation arrow on the nameplate indicates the direction of

rotation. Standard rotation of Moyno 2000 pumps is clockwise,

when viewed from the driven end of the pump.

1-6. Model Number

The pump model number is a series of numbers and letters,

which identifies the pump’s basic design and materials of

construction. A typical model number, for example, might be

1WA065CDQ3SA1AAAC, as shown on the nameplate in

Figure 1-1.

MOYNO

PROGRESSING CAVITY PUMPS

ROTATION

MODEL NO. 1WA065CDQ3SA1AAAC

MFG. SERIAL AS123Q4

DO NOT START OR RUN PUMP WHEN DRY

→→→

U.S.A.

MOYNO 2000 PUMPS

Page: 1

Date: March 2011

Figure 1-1. Typical nameplate showing rotation arrow,

model, and manufacturing serial numbers.

The first six numbers and letters identify the pump’s basic design

characteristics.

In the first space, a number identifies the number of stages in the

pumping elements. This will generally be a 1 or 2.

In the second and third position, the letters designate the pump’s

drive train:

WA – Integral Bearing Design

WB – Traditional Close Coupled Design

The next three positions, always numbers, identify the pumping

element in terms of theoretical gallons per 100 revolutions.

The next 3 positions, always letters, describe the pump’s “materials

of construction” in component groups of parts.

The first letter in this group identifies the material of the suction

housing casting.

The second letter indicates the material used in the rotating parts,

i.e., the drive shaft, con rod, rotor, and other metallic parts in

contact with the material being pumped.

The third letter indicates the material of the stator. It identifies only

the stator material and not that of the tube in which the stator is

placed. The tube, a non-wetted part, is always alloy steel.

The standard designation such as the CDQ used in our example

would result in the following:

C = Cast iron suction chamber

D = Alloy steel internals including drive shaft, con rod, gear

joint, and rotor

Q = Nitrile (NBR) stator

The next position is a number identifying the version number. This

manual corresponds to Revision 3.

The next three letters indicate the sealing system of the pump. The

first letter identifies whether packing, a single seal, or a double seal

is being used. The second and third positions indicate specific seal

or packing model and type used.

A typical trim code is SA1, designating the following:

S = Single mechanical seal

A1 = John Crane type 2100 SiC/SiC/Viton/316

The next letter indicates rotor variations. The most common

designation is an A for standard size, chrome plated. Other

options are available including special coatings, under-sizing, and

over-sizing.

1

The next letter indicates whether there are any special options

being used in the pump; typically this is an A for no special

options.

The next letter indicates the suction configuration. For this

pump an A is used designating a standard flanged pump.

The last letter indicates the drive configuration and

flange/shaft/seal size. In our close coupled pump nameplate

the C designates a 250mm flange and 45mm shaft.

2-1. INSTALLATION

2-2. General

Accessibility to the pump and adequate clearance should be

prime considerations in any installation. Enough space should

surround the unit so that maintenance can be performed with

ease.

2-3. Piping

1. Suction piping should be as short as possible. Normally,

the suction line should be the same diameter as the pump

suction; however, conditions such as high viscosity or

required minimum flow velocities may dictate otherwise.

Long-sweep 90-degree elbows or 45-degree elbows

should be used instead of the standard elbow. Avoid using

suction piping loops, which trap air.

2. Discharge piping diameter should generally be as large as

the discharge port unless fluid conditions indicate

otherwise.

3. An easily removable section of piping, at least twice as

long as the stator should be mated to the discharge port.

This will allow the rotor and stator to be removed without

having to remove the complete pump from the base.

2-4. Foundation

For maximum pump-driver unit life, each unit should be

mounted on a strong steel base plate. The base plate should

be mounted on a firm foundation. The motors should be

supported on close-coupled configurations above 30 HP.

3-1. OPERATION

3-2. Initial Check

Before putting the pump into operation, the following items

should be checked to ensure that each piece of equipment is

installed correctly:

• Electrical connections.

• Gauges and other instruments.

• Pump rotation. Rotation is indicated on the pump

nameplate.

• All valves should be open on both suction and discharge

sides of pump.

• Seal flush systems if required should be operational.

Double seals require flushing between faces.

CAUTION: This is a positive displacement pump. Do not

operate it against a closed valve.

3-3. Start-Up

CAUTION: DRY OPERATION IS HARMFUL TO THE PUMP!

Never allow the pump to operate without liquid, as dry

operation will cause premature wear of the stator and possible

damage. The liquid being pumped lubricates the stator.

1. Before operating the pump for the first time, fill it with liquid

to lubricate the stator for the initial start-up.

Note: If the pump is shut down temporarily, enough liquid will

remain in the system to provide lubrication upon restarting. It

is advisable to maintain the suction piping at a higher

elevation than the centerline of the pump in order to contain

some liquid in the pump at time of shutdown.

2. Once the pump has been filled with liquid, check for direction

of pump rotation by momentarily starting and stopping the

drive. See pump nameplate for correct rotation.

3. Start seal flush water if so equipped.

4. Start pump.

3-4. Packing Leakage

The packed stuffing box is designed to control leakage, not stop

it completely. Leakage is necessary to reduce friction and

dissipate heat.

In a new pump, before the packing has had a chance to seat

properly, excessive leakage through the stuffing box is common.

Frequent adjustments of the packing gland may be necessary

during the first few hours of operation in order to compress and

seat the packing. See Section 4-3.

4-1. MAINTENANCE

4-2. General

The Moyno 2000 CC pump has been designed for a minimum of

maintenance, the extent of which is routine adjustment of the

packing. The pump is one of the easiest to maintain because the

main elements are very accessible and require few tools to

disassemble.

4-3. Packing Adjustment

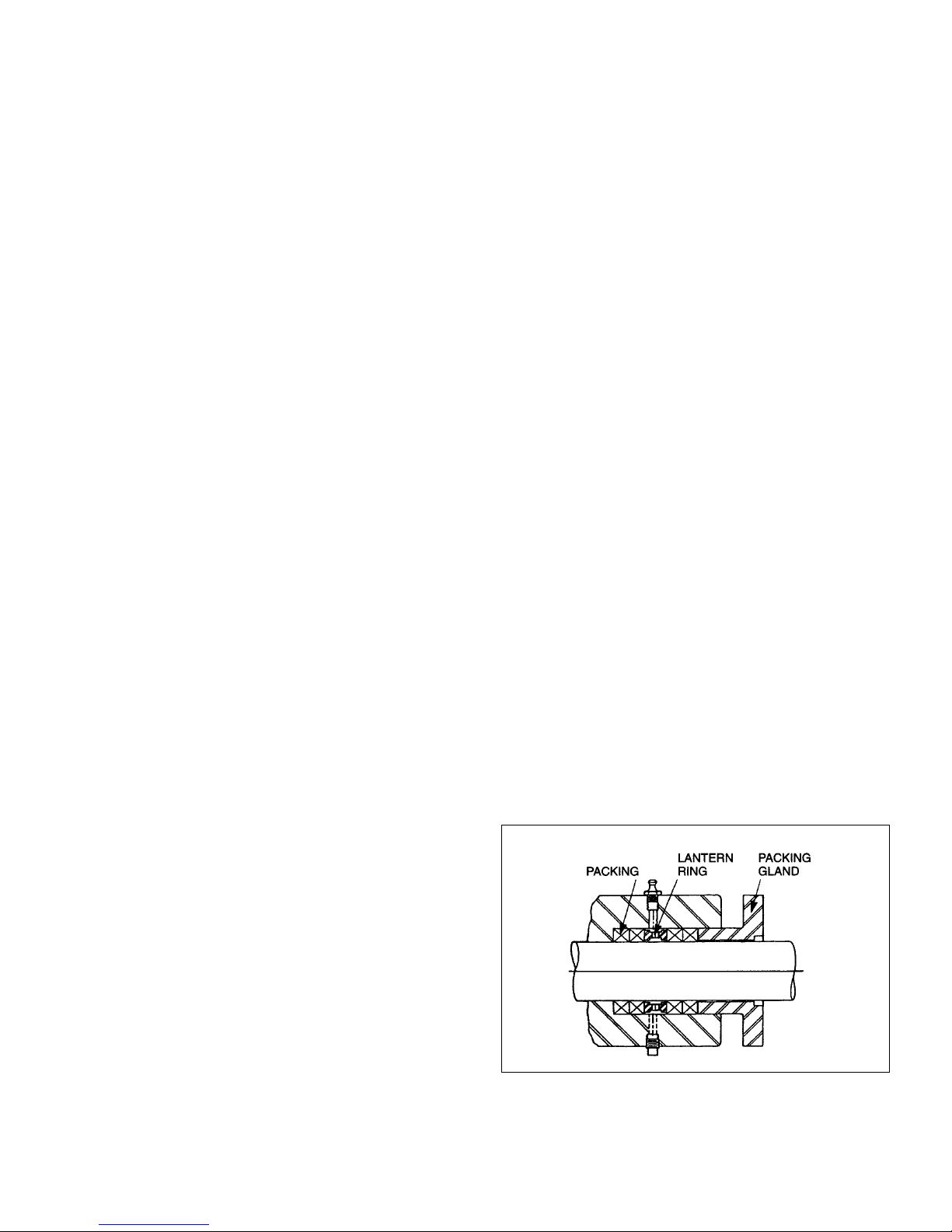

Packing gland nuts (see Figure 4-1) should be evenly adjusted.

Over-tightening the packing gland may result in premature

packing failure and possible damage to the shaft and gland.

Figure 4-1. Cross Section of Packing Housing

2

When packing is new, frequent minor adjustments during the

first few hours of operation are recommended in order to

compress and seat the packing.

1. Upon initial start-up of the pump, adjust the gland nuts

for a leakage rate of 50-11 drops per minute until the

packing has seated and adjusted to the operating

temperature (approximately 10-15 minutes).

2. If leakage is excessive after 15 minutes of operation,

tighten the gland nuts ¼ of a turn.

3. Tighten the gland nuts ¼ of a turn after an additional 15

minutes if necessary and repeat this procedure until a

desired leakage of 1-2 drops per minute is obtained.

Adding grease may also reduce leakage by providing a

barrier at the lantern ring.

CAUTION: Do not tighten until zero leakage is obtained. Overtightening the packing gland may result in accelerated wear on

the packing and damage to the shaft. In those situations where

no packing leakage can be tolerated, consult your Moyno

Authorized Representative.

Area To Lubricate

Packing

Approved Lubricant or

Equivalent

ACG-2

(Dubois Chemical, Inc.)

4-4. Packing Replacement

Note: In this section, the first reference to each pump part will

be followed by a number or a letter in parentheses ( ). These

numbers and letters are used to identify the pump parts and

hardware items in the Exploded Views in Section 12-1.

When tightening the gland nuts can no longer regulate leakage,

remove and replace the packing. The entire pump does not

need to be disassembled to replace the packing. Briefly,

replace as follows:

1. Remove packing gland nuts and slide gland halves (36)

back along drive shaft (26).

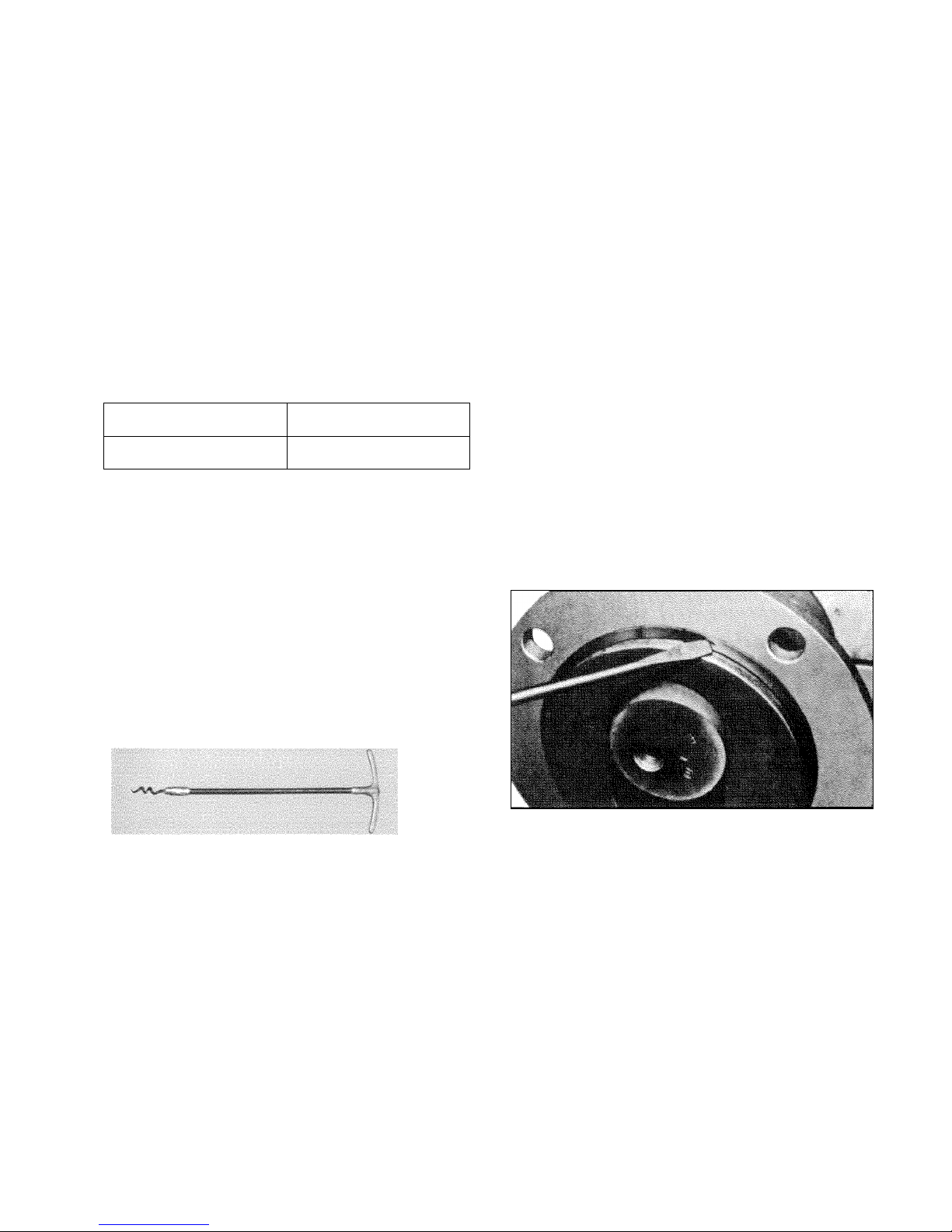

2. Use a packing puller tool (see Figure 4-2) to remove the

packing (34).

5. Replace packing gland halves and secure with packing gland

and nuts (T).

6. Adjust packing per Section 4-3.

5-1. DISASSEMBLY

Note: In this section and in following sections on CLEANING,

INSPECTION, and ASSEMBLY, the first reference to each pump

part will be followed by a number or letter in parentheses ( ). These

numbers and letters are those used to identify the pump parts and

hardware items in the Exploded Views in Section 13-1.

5-2. Disconnect Pump

1. Disconnect the power source.

2. Close suction and discharge valves to isolate the pump from

the line.

5-3. Stator Removal

1. Remove section of discharge pipe attached to discharge

flange (1).

2. Remove pump support (5) from discharge flange (1).

3. Unbolt stator clamp ring (4) from suction housing and remove

stator from rotor (turning stator clockwise while removing will

ease disassembly). Remove the stator retaining ring. Remove

stator clamp ring from stator. See Figure 5-1. for the typical

retaining ring removal procedure.

4. Remove discharge flange (1) by unbolting it from stator clamp

ring (4) and remove stator gasket (2). Use a flat-headed

screwdriver tip to remove stator retaining ring (3) and stator

clamp ring (4) from stator (6).

Figure 4-2. Packing Removal Tool

3. Inspect surface of drive shaft for excessive wear or

grooves due to packing rub. If shaft is worn, or is badly

scored or grooved, it should be replaced.

4. If drive shaft is not worn, install a lantern ring and four

packing rings, lubricating them before installation with a

good grade of packing grease. Be sure to stagger the

packing ring joints at 90-degree increments.

Note: The stuffing box is supplied with four rings installed; a

fifth ring may be added after initial compression.

CAUTION: ALWAYS USE A PROPER PACKING TAMPER

TOOL TO INSTALL PACKING. Do not use a pointed or sharp

tool, as damage to the packing material or drive shaft could

result. To assure proper shaft lubrication, never use a onepiece spiral wrap packing.

Figure 5-1. Typical Retaining Ring Removal

5-4. Suction Housing Removal

1. Remove four bolts (U) and lock washers (Y) holding the

suction housing (11) to the bearing housing (35).

2. Pull the suction housing (11) toward the rotor and away from

the bearing housing (35). Place a block of wood under the

suction housing to prevent it from dropping as you pull it away

from the bearing housing.

5-5. Rotor / Con Rod / Drive Shaft Assembly Removal

1. Slide the slinger ring (31) along the drive shaft (26), towards

the gear reducer, exposing the drive pin (25).

2. With a punch and hammer, tap the drive pin (25) from the

drive shaft.

3

Loading...

Loading...