moyno G2, G3, Version 3 Service Manual

SERVICE MANUAL

®

MOYNO

2000 Pumps

G2 Open Throat Models

G3 Bridge Breaker Models

Version 3 Models

TABLE OF CONTENTS

Page

1-1. INTRODUCTION ...........................................1

1-2. GENERAL............................................... 1

1-3. NAMEPLATE DATA ............................... 1

1-4. Pump Rotation................................ 1

1-5. Model Number................................ 1

1-6. Frame Size Designation.................1

1-7. Type Designation............................ 1

1-8. Trim Code....................................... 2

1-9. Variation of Standard Parts............ 2

2-1. INSTALLATION............................................. 2

2-2. GENERAL............................................... 2

2-3. PIPING................................................... 2

2-4. Suction Hopper............................... 2

2-5. Discharge Piping ............................ 2

2-6. FOUNDATION........................................ 2

2-7. SHAFT ALIGNMENT.............................. 3

2-8. On Coupling Connected Units........ 3

2-9. On Belt Drive Units......................... 3

2-10. WATER FLUSH OF PACKING............. 3

3-1. OPERATION................................................... 3

3-2. INITIALCHECK....................................... 3

3-3. START-UP.............................................. 3

3-4. PACKING LEAKAGE.............................. 4

3-5.G3 DRIVE ASSEMBLY ADJUSTMENT..4

4-1. MAINTENANCE ............................................. 4

4-2. GENERAL............................................... 4

4-3. PACKING ADJUSTMENT ...................... 4

4-4. PACKING REPLACEMENT ................... 4

4-5. LUBRICATION........................................ 5

4-6. Bearings ......................................... 5

4-7. Gear Joints ..................................... 5

4-8. G3 Oilers ........................................ 5

4-9. DISASSEMBLY OF G2 OPEN THROAT

PUMP..................................................... 5

4-10. Disconnect Pump ......................... 5

4-11. Packing Removal.......................... 5

4-12. Stator Removal............................. 5

4-13. Rotor Removal.............................. 6

4-14. Gear Joints and Conveyor Assembly

Removal ...................................... 6

4-15. Drive Shaft and Bearings Removal6

4-16. DISASSEMBLY OF G3 BRIDGE

BREAKER............................................6

4-17. Disconnect Pump........................ 6

4-18. Chain Replacement .................... 6

4-19. Torque Limiter Removal ............. 6

4-20. Shaft Gears Removal.................. 6

4-21. Breaker End Shafts or Paddle

Assembly Removal..................... 7

4-22. Drive A s s e m b l y S h a f t s Re m o v a l... 7

4-23. Packing Removal........................ 7

Note: This service manual outlines installation, operation and maintenance proce-

dures for the open throat “G2” and bridge breaker “G3” models of the Moyno

2000 pump. For information on the flanged (G1) models of the Moyno 2000

pump, refer to the G1 Service Manual, or contact your nearest Moyno pump

representative.

4-24. CLEANING...................................................7

4-25. INSPECTION................................................7

4-26. Bearings..............................................7

4-27. Shafts..................................................7

4-28. Seals ................................................... 7

4-29. Packing................................................7

4-30. Rotor....................................................8

4-31. Stator...................................................8

4-32. All Other Parts.....................................8

4-33. ASSEMBLY OF G2 OPEN THROAT PUMP .....8

4-34. Lubrication During Assembly ..............8

4-35. Packing Installation.............................8

4-36. Bearing Housing/Suction Housing

Assembly ............................................9

4-37. Bearing/Drive Shaft Assembly ............9

4-38. Rotor/Stator Assembly........................9

4-39. Rotor Gear Joint and Conveyor

Assembly ...........................................10

4-40. Drive End Gear Joint Assembly.........11

4-41. Stator Support/Discharge

Assembly ...........................................11

4-42. Final Assembly...................................11

4-43. Packing Adjustment ........................... 11

4-44. ASSEMBLY OF G3 BRIDGE BREAKER.....11

4-45. Suction Flange Installation.................11

4-46. Packing Installation............................11

4-47. Mounting Bearings.............................11

4-48. Paddle Assembly Installation.............12

4-49. Drive Assembly Installation................ 12

4-50. Final Assembly...................................12

4-51. STORAGE....................................................12

4-52. Short Term Storage............................12

4-53. Long Term Storage ............................12

4-54. PACKING SPECIFICATION........................13

4-55. VARIATIONS OF STANDARD PARTS .......13

4-56. Rotors.................................................13

4-57. Drive Shafts........................................ 13

4-58. STANDARD HARDWARE FOR G2 OPEN

THROAT......................................................14

4-59. SELECTING THE CORRECT PART...........15

4-60. PARTS LIST FOR G2 OPEN THROAT.......16

4-61. STANDARD HARDWARE FOR G3 BRIDGE

BREAKER ................................................... 20

4-62. PARTS LIST FOR G3 BRIDGE BREAKER....20

4-63. CONVERSION FROM G2 TO G3................22

4-64. SHAFT SLEEVE ARRANGEMENT.............24

4-65. Disassembly.......................................24

4-66. Assembly............................................24

4-67. TROUBLESHOOTING.................................25

Page

SERVICE MANUAL

MOYNO® 2000 PUMPS

G2 Open Throat Models

G3 Bridge Breaker Models

1-1. INTRODUCTION

1-2. GENERAL

The Moyno

50 years of experience in manufacturing and marketing

fluids handling equipment. This rugged pump has

been engineered to be the most reliable product ever sold

under the Moyno name. The pump has been painstakingly

tested to assure consistent performance in the

most difficult of applications. It represents the next generation of the world’s most versatile pump.

The Moyno 2000 Pump is a progressing cavity pump. The

pumping action is created by a single helical rotor rolling

eccentrically in the double helix of the stator. The rotor in

conjunction with the stator forms a series of sealed cavities

180 degrees apart. As the rotor turns, the cavities progress

from the suction to the discharge. As one cavity diminishes,

the opposing cavity increases at exactly the same rate. Thus

the sum of the two discharges is a constant volume. The

result is a pulsation-free positive displacement flo w utilizing

no valves.

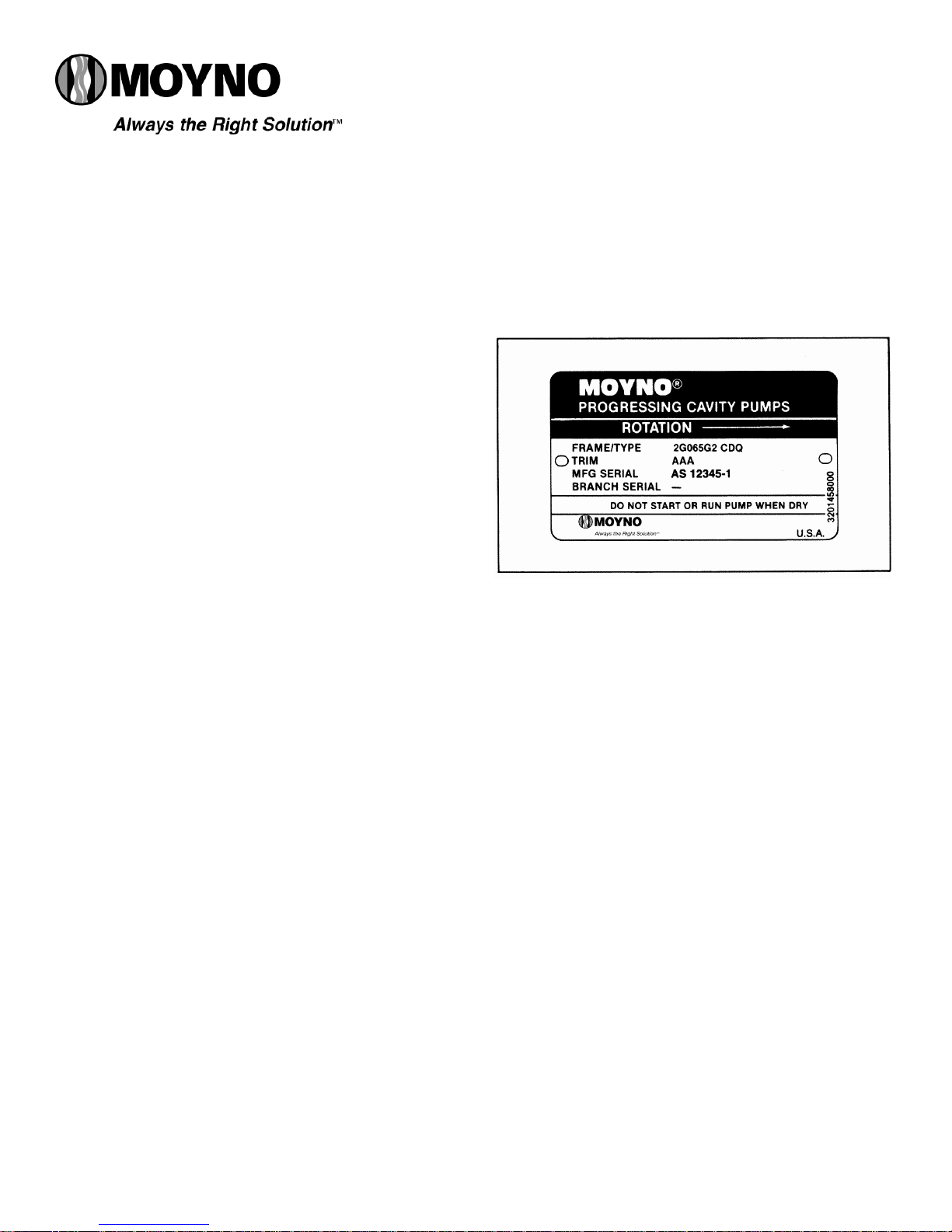

1.3. NAMEPLATE DATA

The pump nameplate, located on the bearing housing,

contains important information relating to the operation an d

servicing of the pump. This information includes the direction

of rotation arrow and the pump model and serial numbers

(see fig. 1-1).

The pump model number must be used for reference

when ordering spare parts. To simplify this procedure, the

model number for your pump has been recorded on the

nameplate drawing on the front cover of this manual. Please

carefully file this manual for further reference.

1.4. Pump Rotation. The direction of rotation is indicated by

a rotation arrow on the nameplate. Rotation of Moyno 2000

G2/G3 pumps is always clockwise, when viewed from the

driven end of the pump.

1-5. Model Number. The pump model number consists of

three component parts: Frame Designations, Type Designations and a Trim Code. A typical model number for example,

might be 2G065G2 CDQ AAA, as shown on the nameplate

in fig. 1-1.

1-6. Frame Designation. The Moyno 2000 is modular in

concept allowing for optimal matching of drive ends and

®

2000 Pump is the culmination of over

Section:

MOYNO® 2000 PUMPS

Page: 1

Date: October 2005

Figure 1-1. Typical nameplate showing rotation arrow,

model and manufacturing serial numbers.

pump elements (rotor and stator) to meet the requirements

of the application. The seven or more characters in the frame

designation describe the particular combination of drive end

and pump elements, as well as other construction details of

your pump.

The first character in the frame designation, always

a number, indicates the number of stages of the pumping

elements.

The second character is always a letter (E through K) and

indicates the drive end size.

The third, fourth and fifth characters are numbers indicating the theoretical capacity of the pumping elements per 100

revolutions.

The sixth character represents the type of universal joint

utilized. The letter G indicates a gear type joint. Other configurations may be indicated by the letters P or F.

The seventh character, a number, indicates the type of

suction housing. Flanged suction port pumps are d esignated

by the numeral “1,” open throat pumps by the numeral “2”

and open throat pumps with a bridge breaker option by the

numeral “3.”

1-7. Type Designation. Following the Frame Designation is the Type Designation, a series of three letters describing the materials from which the pump is constructed.

Page 2

The first letter identifies the material of the suction

housing.

C — Cast Iron

E — Carpenter 20 Stainless Steel

H — Hastelloy “C”

M — Monel

S — 316 Stainless Steel

W — Cast Steel

X — Special to application

Note: The bearing housing of the pump is always made

of cast iron.

The second letter indicates the material used in the

drive shaft, connecting rod, rotor and other wettable parts.

D — Alloy Steel

E — Carpenter 20 Stainless Steel

G — 416 Stainless Steel

H — Hastelloy “C”

J — 17-4 PH Stainless Steel

M — Monel

S — 316 Stainless Steel

X — Special to application

The third letter indicates the material of the stator. It identifies only the stator material and not that of the tube in which

the stator is placed, which is always carbon steel. Standard

stator materials used in the Moyno 2000 pump are as follows:

B — EPDM 300, 70 Durometer

C — Nitrile 103, 50 Durometer

D — Tool Steel

E — Nitrile 110, 70 Durometer

F — Fluoroelastomer 500, 75 Durometer

G — 416 Stainless Steel

H — Hastelloy “C”

J — 17-4 PH Stainless Steel

K — Hypalon 800, 70 Durometer

M — Nitrile 100M 70 Durometer

P — Thiokol 70 Durometer

Q — Nitrile 100, 70 Durometer

R — Natural Rubber 200, 55 Durometer

T — Teflon 15% glass

U — Urethane 70 Durometer

X — Special to application

Z — White Nitrile 150,70 Dur ometer

A typical type designation such as CDQ, would identify the

following materials of construction:

C = Cast iron suction housing

D = Alloy steel rotor, drive shaft, connecting

Q = Nitrite (70 durometer) stator

1-8. Trim Code. Also included in the Model Number is the

three character Trim Code which is used to identify pump

construction. The letters “AAA” signify standard construction,

with letters other than “A” signifying variations. The first letter

identifies sealing variations; the second, internal variations;

and the third, rotor variations.

1-9. Variations of Standard Parts. Refer to Sections 4-55

thru 4-57 for variations available for modifying pumps to

meet specialized pumping conditions. If the trim code of your

pump is other than “AAA,” contact your nearest Moyno representative for clarification. Do not modify your pump with

any variation unless you have determined that it is compa tible with your application.

rod and other minor metallic parts in contact with the fluid being pumped.

2-1. INSTALLATION

2.2. GENERAL

Moyno pumps are lubricated and tested at the factory

prior to shipment and require minimum pre-start up

maintenance.

Accessibility to the pump and adequate clearance should

be a prime consideration in any installation . Enough space

should surround the unit so that maintenance can be carried out with ease.

2-3. PIPING

2-4. Suction hopper used with open throat and bridge

breaker pumps should have nearly vertical sides, or be ot herwise designed to enhance the flow of the material i nto the

pump.

2-5. Discharge piping diameter should generally be as

large as the pump ports unless fluid conditions indicate

otherwise.

An easily removable section of piping one-to-two times

longer than the connecting rod should be mated to the discharge port. This will allow the rotor and stator to be removed without having to remove the complete pump from

the base.

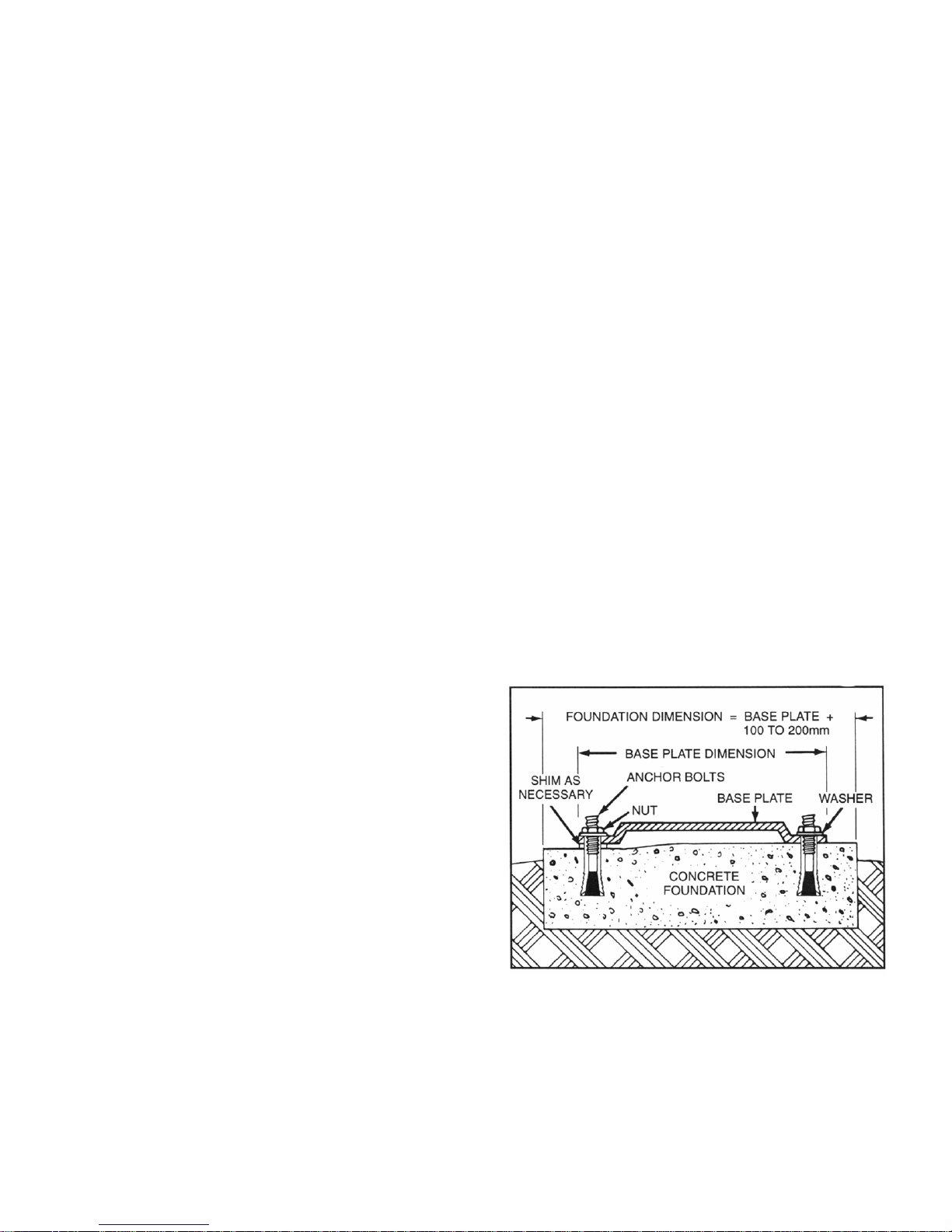

2-6. FOUNDATION

For maximum pump-driver unit life, each unit should be

mounted on a strong, fabricated-steel base plate which can

be ordered from Moyno. The base plate should be mounted

on a concrete foundation built on a solid base. The foundation

should be approximately 4” to 8” longer and wider than the

base for which it is buil t. (See fig. 2-1.) Anchor bolts for the

base plate should be located in the foundation.

Figure 2-1. Typical Foundation Example

Check the base plate surface with a carpenter’s level

and place shims under the base plate at the places

necessary to make it level. Then check the pump,

driver shaft and the pump ports to ensure that they are level.

Complete base mounted units supplied by Moyno including

pump and driver are leveled with respect to the base at the

factory. Shifting may occur during shipment. The pump and

driver should be realigned. Care should be exercised to ensure that all components are level and mou nted in a di rect line .

For maximum rigidity and lower noise levels the base

plate should be grouted to the foundation after the anchor

bolts have been evenly tightened. A good grade of nonshrink grout is recommended. The spaces between the base

plate and the foundation around the shims should also be

filled with grout. Allow the grout to dry according to manufacturer’s instructions, then fully tighten the anchor bolts.

2-7. SHAFT ALIGNMENT

Although the base-mounted units supplied by Robbi ns &

Myers are leveled with respect to the base before shipping,

most of the larger pump and driver units are shipped with the

flexible coupling disconnected.

After the base has been bolted down to the foundation,

check the following conditions:

2-8. On coupling connected units, be sure that the pump

and driver shafts are realigned before the coupling is connected. Care should be exercised to ensure that all compo nents are level and mounted in a direct line.

Check gap between coupling halves (refer to coupling

manufacturers recommendations). Adjustment can usually

be accomplished by loosening the mounting bolts on either

the pump or driver and moving the loosened component into

alignment with the fixed component. On couplings with equal

diameter hubs, it may be helpful to lay a straight edge axially

across the coupling halves to check alignment.

2-9. On belt drive units, check to ensure that sheaves or

sprockets are in alignment. Check belts for proper tension.

Tension requirements will vary with type of belt, center distances, and belt speeds. Consult belt manufacturer for specific recommendation.

2-10. WATER FLUSH OF PACKING

The packing may be either grease lubricated through a

grease fitting in the stuffing box or have plumbing connected

to the housing to allow a water flush. Packing is not grease

lubricated at the factory prior to shipping.

When the material being pumped is abrasive, water flushing the packing is recommended to extend shaft life.

Clean water can be injected through a 1/8” NPT tapped

hole that normally houses the grease fitting for lubricating the

packing. The water can be permitted to leak axially along the

shaft in either direction or can be removed from the second

tapped hole in the stuffing box. In both cases, the discharge

from the stuffing box should be throttled slightly to maintain

10-15 PSI higher pressure in the stuffing box than is present

in the suction housing. (See fig. 2-2.) Flow rate should be

approximately 1/2-2 gpm.

If mechanical seals are to be used on the unit, consult the

seal manufacturers’ instructions for seal flush requirements.

3-1. OPERATION

3-2. INITIAL CHECK

Before putting the pump into operation, the following items

should be checked to ensure that each piece of equipment is

installed correctly:

— Pump, driver, coupling or sheave alignment.

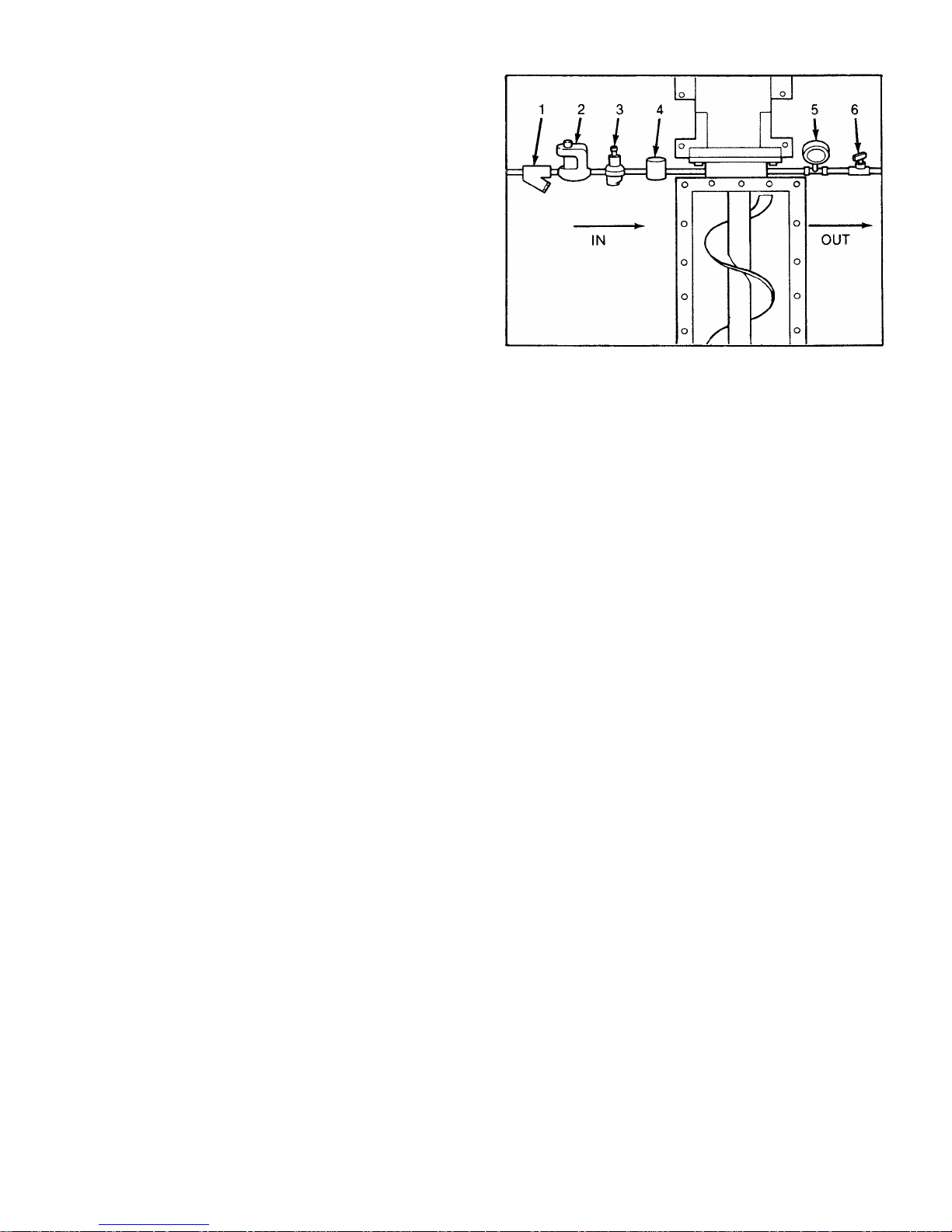

Figure 2-2. Typical water flush arrangement for units

with packing includes strainer valve (1), sigh t flow meter

(2), pressure regulating valve (3), solenoid valve (4),

pressure gauge (5), and needle valve (6).

— Electrical connections

— Gauges and other instruments.

— Water flush connection to the stuffing box.

— Pump rotation. Normal rotation is indicated on the

— All valves should be open on both suction and

CAUTION: This is a positive displacement pump. Do not

3-3. START-UP

CAUTION: DRY OPERATION IS HARMFUL TO THE PUMP!

Never allow the pump to operate w ithout liquid,

1. Before operating the pump for the first time, fill it with

liquid (the pipe plug tap on the suction housi ng may be used

for filling). If the liquid to be pumped is highly viscous, dilute

it before filling the pump. The liquid fill-up will lubricate the

stator for the initial start-up.

Note: If the pump is shut down temporarily, enough liquid

2. Once the pump has been filled with liquid, check for d irection of pump rotation by momentarily starting and stopping the drive. Check rotation arrow on pump nameplate for

correct rotation.

3. If applicable, turn on the seal water to packing.

4. Start pump.

3-4. PACKING LEAKAGE

A packed stuffing box is designed to control le akage, not

stop it completely. Leakage is generally necessary to reduce

friction and dissipate heat. The amount of leakage necessary

will depend on the fluid pumped, the install ation, and pump

speed and type. Refer to Section 4-3 for packing adjustment.

nameplate on the bearing housing.

discharge sides of pump.

operate it against a closed valve.

as dry operation will cause premature wear of

the stator and possible damage. The stator is

lubricated by the liquid which is pumped.

will remain in the system to provide lubrication upon

restarting. It is advisable to maintain the suction piping at a higher elevation than the centerline of the

pump in order to contain some liquid in the pump at

time of shutdown.

Page 3

Page 4

Moyno 2000 pumps have been designed for minimum

stuffing box leakage when properly maintained. If leakage

cannot be tolerated, then a mechanical seal should be used.

3-5. G3 DRIVE ASSEMBLY ADJUSTMENT

Ensure that the chain on the drive assembly has no bows.

The chain tension can be adjusted by loosening or tig htening

the idler adjusting screw (E, F,fig. 4-10).

The chain tension should be checked again and readjusted after the first 20 hours of operation.

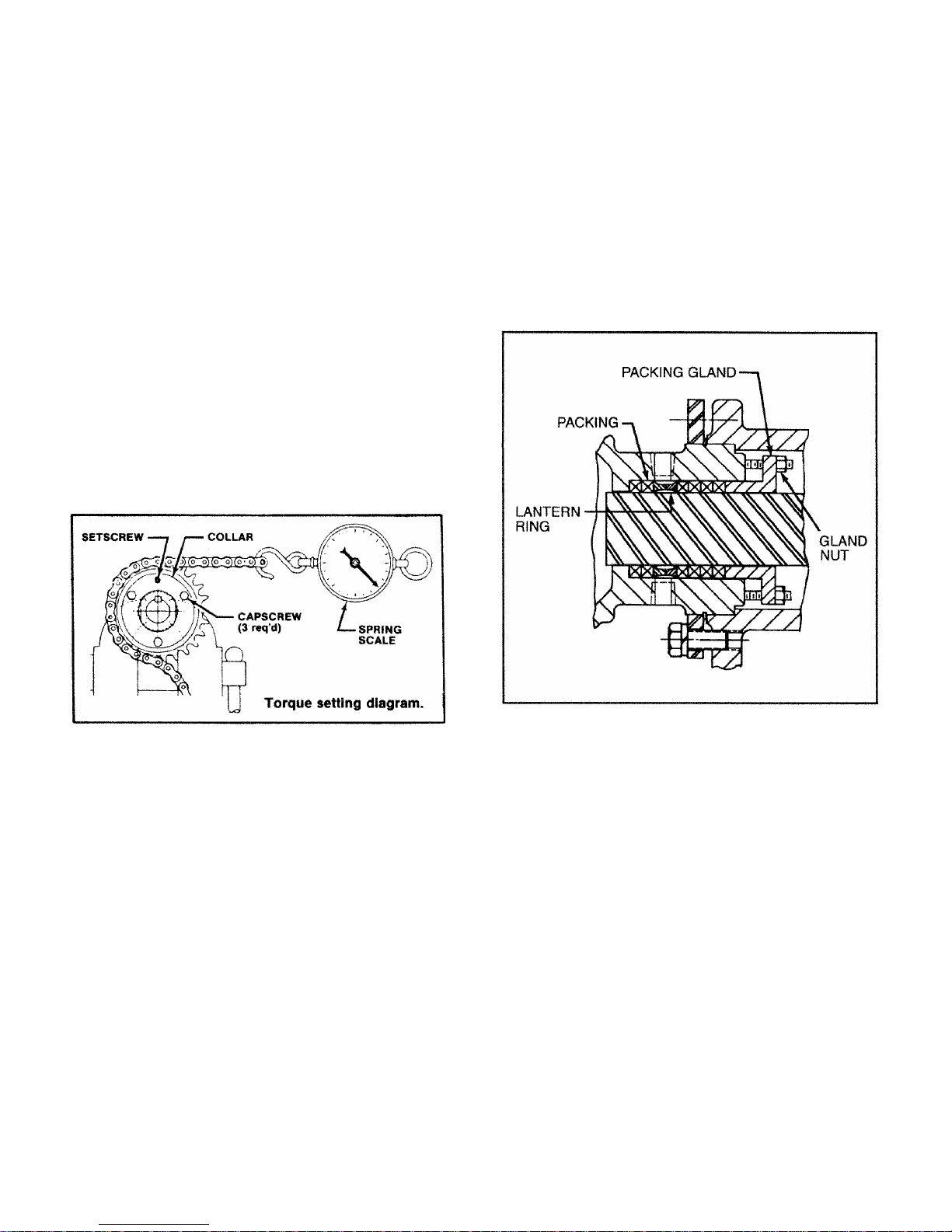

The assembled torque limiter (3) and sprocket (4) on the

bridge breaker assemblies are set at the factory to a reading

of 540 lbs on a spring scale. (See fig. 3-1.) If during operation the torque limiter slips, the torque should be checked

and if necessary, reset. To check the torque limiter setting,

use a spring scale as shown in the di agram with a properly

sized chain to fit the sprocket (4). Attach the scale to the

chain and pull, noting the value on the scale dial when the

torque limiter slips. To adjust the torque, loosen the three

capscrews on the torque limiter collar. Turn the collar clockwise to increase torque, or counter-clockwise to decrease it.

Tighten capscrews until heads bottom and again check the

torque setting. Repeat this process until the slipping point is

within 5 lbs of the 540 lb value. When the correct torque is

achieved, tighten setscrew to lock collar in position.

1. Upon initial start-up of the pump, adjust the gland nuts

for a leakage rate of 1-2 drops per second until the packing

has seated and adjusted to the operatin g temperature (approximately 10-15 minutes).

2. If leakage is excessive after 15 minutes of operation,

tighten the gland nuts until a desired leakage rate is obtained.

CAUTION: Do not tighten until zero leakage is obtained.

Over-tightening of the packing gland may

result in accelerated wear on the packing

and damage to the shaft. In those situations

where no packing leakage can be tolerated,

consult your Moyno Authorized Service

Representative.

Figure 3-1. Torque Setting Diagram

4-1. MAINTENANCE

Note: In this section, the first reference to each pump part

will be followed by a number or a letter in parentheses

( ). These numbers and letters are those used to identify the pump parts and hardware items in the foldout

Exploded Views (fig. 4-7 or 4-10 as indicated).

4-2. GENERAL

The Moyno 2000 pump has been designed for a minimum

of maintenance, the extent of which is routine adjustment

and lubrication of packing. The pump is one of the easiest to

work on, in that the main elements are very accessible and

require few tools to disassemble.

4-3. PACKING ADJUSTMENT

Pumps. Packing gland nuts should be evenly adjusted so

they are little more than finger tight. (See fig. 4-1.) Overtightening of the packing gland may result in premature

packing failure and possible damage to the shaft and gland.

When packing is new, frequent minor adjustments during

the first few hours of operation are recommended in order to

compress and seat the packing.

Figure 4-1. Cross Section of Stuffing Box

Bridge Breaker. Packing for the bridge breaker is ad-

justed by means of cylindrical packing glands (25, fig. 4-10)

which are threaded into the bearing retainers (28). Holes in

the packing gland allow the use of a punch to rotate the

gland. The packing is compressed by rotating the gland i n a

clockwise direction when viewed from the shaft end.

4-4. PACKING REPLACEMENT

When leakage can no longer be regulated by tightening

the gland nuts, remove and replace the packing. The entire

pump need not be disassembled to replace the packing.

Briefly, replace as follows:

1. Remove packing gland nuts (E, fig. 4-7), and slide

gland (12) and slinger ring (11) back along drive shaft (4).

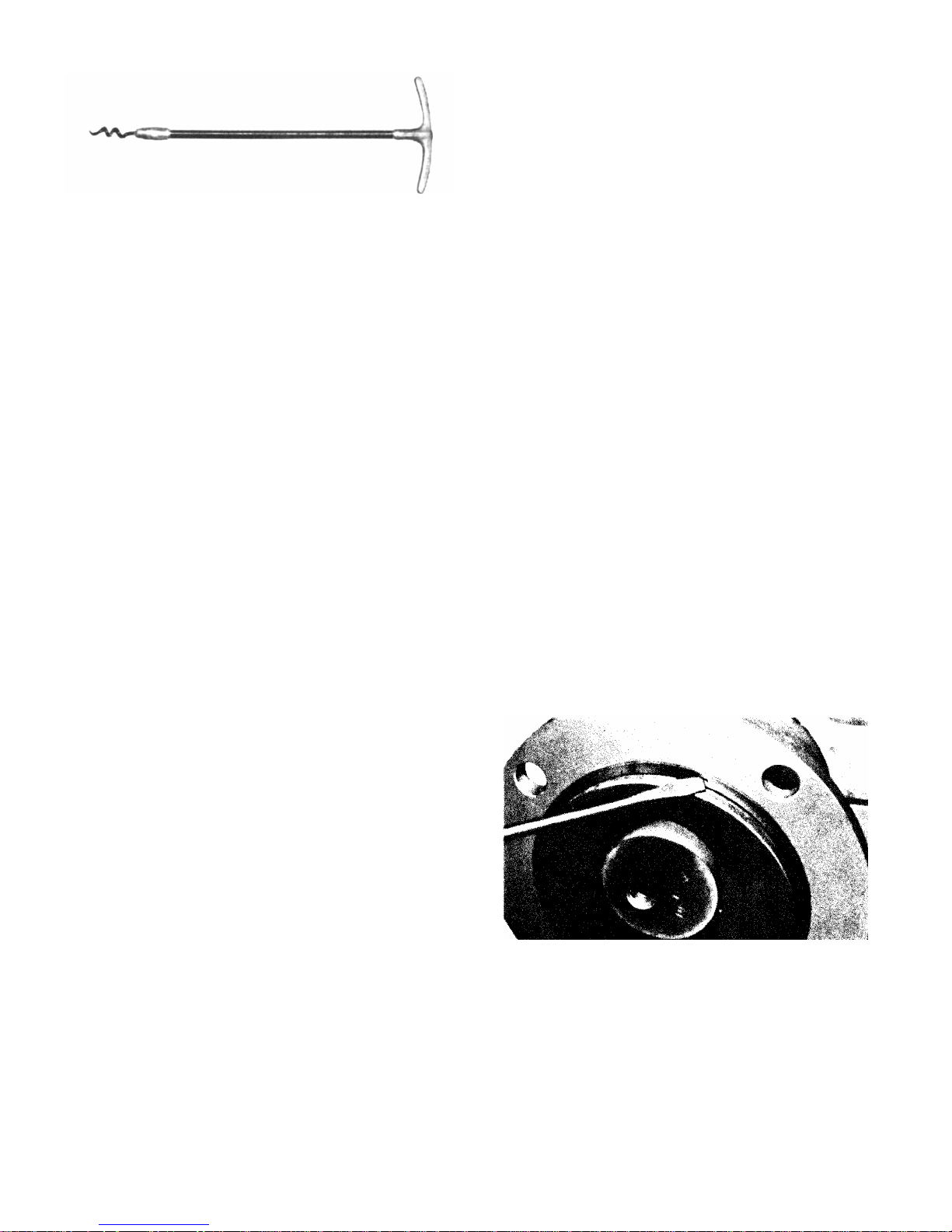

2. Use a pair of packing extractors (fig. 4-2) to remove

three packing rings (10), lantern ring halves (13) a nd three

additional packing rings (10).

3. Inspect surface of drive shaft for excessive wear or

grooves due to packing rub. If shaft is worn, or is badly

scored or grooved, it should be replaced.

Figure 4-2. Packing Removal Tool

4. If drive shaft is not worn, install three rings of packing,

the lantern ring halves, and four more rings of packing; lubricating them before installation with a good grade of packing

grease. Be sure to stagger the packing ring joints at 90° increments. (See Section 4-35.)

CAUTION: Always use a proper packing tamp er tool to

install packing. Do not use a pointed or

sharp tool, as damage to the packin g material or drive shaft could result. To assure

proper shaft lubrication, never use a onepiece spiral wrap packing.

5. Replace packing gland and secure with packing gland

nuts. (See fig. 4-1.)

6. Adjust packing per Section 4-3.

4.5. LUBRICATION

4.6. Bearings. The bearings are lubricated at the factory

and will only need to be re-lubricated when the shaft/bearing

assembly is removed from the pump. (See Section 4.34.)

4-7. Gear Joints. Both gear joints are packed with lubricant during assembly, and will only need to be re-lubricated

when gear joints are disassembled. (See Section 4-34.)

4-8. G-3 Oilers. Ensure that both oilers (item 1, fig. 4-10)

are filled with a suitable SAE 30 or 40 weight oil.

4-9. DISASSEMBLY OF G2 OPEN THROAT PUMP

Note: In the following G2 disassembly instructions, the part

reference numbers are from fig. 4-7.

Note: The following instructions cover ONE procedure for

disassembling all pump components. Major pump

components can be disassembled in various ways

since specific installation location limitations will determine method of component removal.

4-10. Disconnect Pump

1. Operate pump (preferably with clean water) to insure

rotor and stator are not dry.

2. Shut off pump.

3. Close suction and discharge valves.

4. Turn off flush water to packing or mechanical seal,

if used.

5. Disconnect power source.

6. Drain any fluid in pump.

7. Remove inspection plate (17) and gasket (18).

Page 5

4-11. Packing Removal

1. Stop pump.

2. Complete Section 4-10, steps 2 - 6.

3. Remove gland adjustment nuts (E) and gland halves

(12) from stuffing box.

4. Remove packing rings (10). This is best done by using

flexible packing extractors (see fig. 4.2). Use two extractors

simultaneously on opposite sides of each ring. Pull evenly.

5. Remove lantern rings (13) in similar fashion. Twist split

rings to remove from shaft.

6. Remove additional packing rings.

4-12. Stator Removal

1. Complete Section 4-10.

2. Remove section of discharge pipe attached to discharge flange (45).

3. Remove discharge flange (45) by unbolting from stator

clamp ring (40B) and remove stator gasket (42). Remove

stator retaining ring (43) and stator clamp ring (40B) from

stator (44).

Note: Omit above step 3 when using following method 6a to

separate rotor and stator.

4. Remove top half of stator support (41).

5. Unbolt stator clamp ring (40A) from adapter flange

(21) and suction housing (19). Remove stator gasket (42).

Use a screwdriver tip to carefully remove stator retaining

ring (43). (See fig. 4-3.) Remove stator clamp ring (40A)

from stator (44).

Figure 4-3. Typical Retaining Ring Removal

6. Pull stator (44) off rotor (37).

Note: On multiple stage pumps, or when also cleaning,

checking or changing stator (44), rotor (37) and/or

gear joint assembly, one of the following procedures

is suggested.

6a. Use winch-type device if anchored directly opposite

stator end. Attach cable to discharge flange (45) to pull stator (44) off rotor (37).

Page 6

6b.Hold stator (44) with pipe or strap wrench and turn

drive shaft (4) clockwise to force stator (44) off rotor (37).

7. Check rotor (37) and stator (44) for wear. See Rotor

(4-30) and Stator (4-31) for instructions.

4-13. Rotor Removal

1. Complete sections 4-9 and 4-11.

2. Remove stator adaptor (21) and O-ring (20) from suc-

tion housing (19).

3. Remove hopper or suction piping from suction

housing (19).

4. Remove socket head pipe plug (P) and set screw (Q)

from gear joint shell (36).

5. While supporting weight of rotor, remove six socket

head screws (N) from head ring (39), and slide head ring

(39) and O-ring (38) off rotor. Separate rotor from gear joint.

Note: If rotor-end gear joint is not accessi ble, disassemble

drive-end gear joint by following the procedure in section 4-14, steps 1-3. Then remove both the conveyor

assembly and rotor from suction housing as a single

unit.

4-14. Gear Joints and Conveyor Assembly Removal

1. Complete sections 4-9 thru 4-12.

2. Remove pipe plug (P) from gear joint shell (33).

Remove six socket head screws (N) from gear joint retainer

(34), and slide retainer and O-ring (24) toward conveyor

flight.

3. Pull conveyor assembly (35) from drive-end gear joint

until it is separated from gear joint shell (33) and completely

separated from suction housing (19).

4. Remove lock nut (28) from drive-end of conveyor assembly, and slide gear ball (29), secondary thrust plate (30) ,

seal support (31), gear joint seal (32), and gear joint retain er

(34) from conveyor assembly.

5. Remove two keys (26), ring gear (27), and primary

thrust plate (25) from gear joint shell (33).

6. The other gear joint is disassembled in a similar manner by first removing primary thrust plate (25) from rotor

head. Remove two keys (26) from gear joint shell.

7. Slide gear joint shell (36) toward flight on conveyor

assembly. Remove lock nut (28) from end of conveyor

assembly (35). Remove ring gear (27), gear ball (29),

secondary thrust plate (30), seal support (31), and gear

joint seal (32). Then slide gear joint shell (36) from conv eyor

assembly.

Note: It is recommended that each time a gear joint is dis-

assembled, the O-rings and grease seal should be

replaced.

4-15. Drive Shaft and Bearings Removal

1. Complete sections 4-9 thru 4-13.

2. Remove drive coupling or V-belts and pulleys

from drive shaft (4).

3. Remove four socket head screws (O) from shaft

adapter (23), and remove adapter and gear joint shell (33)

from end of drive shaft (4).

4. Remove six hex head screws (A) from bearing cover

plate (2). Slide bearing cover plate (2) along with radial

grease seal (1) and O-ring (3) off drive shaft.

5. Drive shaft (4) and bearings can now be pulled out of

bearing housing (14), taking steps to support the weight of

the assembly as the bearings clear the housing. Remove

grease seal (9) from bearing housing (14).

CAUTION: The bearings are pressed on the shaft during

assembly. Care must be taken during

disassembly to avoid damaging the

bearings or shaft.

6. Remove bearing lock screw (7) from bearing nut (8).

Using suitable spanner wrench or soft pun ch and hammer,

thread lock nut off drive shaft.

7. Remove both halv es of bearing spacer (6) from shaft,

and using suitable bearing press and adaptors, press bearings off shaft.

4-16. DISASSEMBLY OF G3 BRIDGE BREAKER

Note: In the following G3 disassembly instructions, the part

reference numbers are from fig. 4-10.

4-17. Disconnect Pump

1. Shut off pump.

2. Turn off flush water to packing or mechanical seal,

if used.

3. Disconnect power source.

4. Drain any fluid in pump.

4-18. Chain Replacement

1. Complete section 4-17, steps 1-3.

2. Remove oiler (1), oiler nozzle (1A), and guard (12).

3. Loosen idler arm adjusting screw (F) and remove

chain (9).

4. Install and connect chain (9). Tighten idler

adjusting screw (F). (See Section 3-5 for instructions

on chain tension.)

Loading...

Loading...