moyno 1000 Service Manual

SERVICE MANUAL

MOYNO

®

1000 Pumps

TABLE OF CONTENTS

1-1. INTRODUCTION………………………………...

1-2. GENERAL…………………………………1

1-3. SCOPE…………………………………….1

1-4. NAMEPLATE DATA…...…………………1

1-5. Pump Rotation………………… 1

Page

1

4-21a. Mechanical Seals…………….. 7

4-22. Packing…………………………. 7

4-23. Rotor…………………………….. 7

4-24. Stator……………………………. 7

4-25. All Other Parts………………….. 7

1-6. Model Number………………… 1

2-1. INSTALLATION………………………………… 2

2-2. GENERAL…………………………………2

2-3. PIPING……………………………………. 2

2-4. Suction Piping………………… 2

2-5. Discharge Piping……………… 2

2-6. FOUNDATION…………………………… 2

2-7. SHAFT ALIGNMENT……………………. 2

2-8. Coupling Connected Units……3

2-9. Belt Drive Units……………….. 3

3-1. OPERATION…………………………………….. 3

3-2. INITIAL CHECK………………………….. 3

3-3. START-UP……………………………….. 3

3-4. PACKING LEAKAGE……………………. 3

4-1. MAINTENANCE……………………………………3

4-2. GENERAL…………………………………3

4-3. PACKING ADJUSTMENT……………….3

4-4. PACKING REPLACEMENT……………. 4

4-5. BEARING LUBRICATION…………….…4

4-6. DRIVE SHAFT AND ROTOR-

EXTENDED LIFE PROVISION….……... 4

4-7. DISASSEMBLY………………………….. 4

4-8. Disconnect Pump………….…. 4

4-9. Stator Removal……………….. 4

4-10. Suction Chamber Removal….. 5

4-11. Rotor Removal………………... 5

4-12. Connecting Rod or Auger

Assembly Removal ………….. 5

4-13. Packing Removal……………...5

4-14. Drive Shaft Removal………… 5

4-15. Bearing Removal……………... 6

4-16. Gearbox/Gearmotor Removal. 6

4-17. CLEANING……………………………… 6

4-18. INSPECTION…………………………… 6

4-19. Bearings……………………….. 6

4-20. Drive Shaft and Intermediate

Shaft……………………………. 6

4-21. Seals…………………………... 6

4-27. Two-Piece Shaft Models………………. 8

4-27a. Ball Bearing Models…………... 8

4-27b.Tapered Roller Bearing Models. 8

4-28. Close-Coupled Models………………… 8

4-29. Adjusting Bearing End Play ….... 8

4-30. Shaft Installation………………… 8

4-30a. Single Mechanical Seal... 9

4-30b. Double Mechanical Seal. 9

4-31. Connecting Rod or Auger

Assembly………………………… 9

4-32. Suction Chamber……………… 10

4-33. Stator……………………………... 10

4-34. Stator/Support/Discharge

Flange Assembly………………. 10

4-35. Packing…………………………... 10

4-36. Pump Connections……………… 10

4-37. STORAGE……………………………… 10

4-37a. Short-Term Storage……………10

4-37b. Long-Term Storage…………….11

4-38. STANDARD PACKING

SPECIFICATION…………………… 11

4-39. RECOMMENDED SPARE PARTS….. 11

4-40. HOW TO ORDER SPARE PARTS…... 11

4-41. STANDARD HARDWARE LIST STANDARD AND OPEN THROAT

MODELS……………………………….. 12

4-42. STANDARD HARDWARE LIST CLOSE-COUPLED MODELS………. 13

4-43. EXPLODED VIEWS…………………… 13

4-44. Standard Model-Ball Bearing

Design Drive End……………… 13

4-45. Standard Model-Roller Bearing

Design Drive End……………… 14

4-46. Close-Coupled Models…………. 15

4-47. Open Throat Models……………. 16

4-59. TROUBLESHOOTING CHART………. 28

Page

4-26. ASSEMBLY………………………………7

4-26a. One-Piece Shaft Ball Bearing Models…………... 7

4-26b. One-Piece Shaft Tapered Roller Bearing Models.7

4-48. PARTS LIST……………………………. 18

Section:

MOYNO 1000 PUMPS

Page: 1

Date: April 2002

SERVICE MANUAL

MOYNO

1-1. INTRODUCTION

1-2. GENERAL

The Moyno 1000 pump is the most versatile positive

displacement pump available. Its design parameters

have been proven in thousands of applications over the

past 60 years, and it is backed by this same half

century-plus of experience in application and

manufacturing know-how.

The Moyno 1000 pump is a progressing cavity pump.

The pumping action is created by a single helical rotor

rolling eccentrically in the double-threaded helix of the

stator. In its revolution, the rotor forms, in conjunction

with the stator, a series of sealed cavities 180 degrees

apart. As the rotor turns, the cavities progress from the

suction to the discharge. As one cavity diminishes, the

opposing cavity increases at exactly the same rate.

Thus, the sum of the two discharges is a constant

volume. The result is a pulsationless, positive

displacement flow.

1-3. SCOPE

This service manual covers the standard, close-

coupled, and open throat configurations of the Moyno

1000 pump line. Disassembly and assembly procedures

are also covered in this manual.

1-4. NAMEPLATE DATA

The pump nameplate, located on the bearing housing,

or drive adaptor, contains important information relative

to the operation and servicing of the pump. This

information includes the direction of rotation arrow and

the pump model and serial numbers.

The model and serial numbers must be used when

ordering spare parts. To facilitate parts ordering, the

nameplate data for your pump has been recorded

on the nameplate drawing on the front cover of this

manual.

1-5. Pump Rotation. The direction of rotation is

indicated by a rotation arrow on the nameplate.

Standard rotation of Moyno 1000 pumps is clockwise,

when viewed from the driven end of the pump. Close-

coupled models only, are not to be run in reverse.

1-6. Model Number. The pump model number is a

series of letters and numbers which identifies the

pump’s basic design and materials of construction. A

typical model number, for example, might be A2E

CDQ3AAA, as shown on the nameplate in Figure 1-1.

1000 PUMPS

Figure 1-1. Typical nameplate showing rotation arrow, model, and

manufacturing serial numbers.

The first three letters and numbers identify the pump’s

basic design characteristics.

In the first space, a letter designates the pump type.

Letters used and their corresponding design types are as

follows:

A = Standard D = High Abrasion, Standard

B = Close-coupled E = High Abrasion, Close-coupled

C = Open throat

The second position number identifies the number of

stages in the pumping elements. This will generally be a 1,

2, or 4.

The third position is a letter, A through K, which identifies

the pump’s capacity in terms of gallons (gal.) per 100

revolutions. Sometimes the third position is followed by the

letter “E” which denotes the pumping element is our Ultra

Pro 23 geometry.The letters, with their corresponding

capacities, are:

A – .38 gal./100 revs. G – 22.0 gal./100 revs.

B – .75 gal./100 revs. H – 36.0 gal./100 revs.

C – 1.5 gal./100 revs. J – 48.0 gal./100 revs.

D – 3.0 gal./100 revs. K – 62.0 gal./100 revs.

E – 6.0 gal./100 revs. L – 115.0 gal./100 revs.

F – 12.0 gal./100 revs.

The next 3 positions, always letters, describe the

pump’s “Materials of Construction” in component

groups of parts.

The first letter in this group identifies the material of the

suction chamber casting.

The second letter indicates the material used in the

rotating parts, i.e., the drive shaft, connecting rod, rotor,

and other metallic parts in contact with the material

being pumped.

The third letter indicates the material of the stator. It

identifies only the stator material and not that of the tube

in which the stator is placed. The tube, a non-wetted

part, is always alloy steel.

A typical designation such as the CDQ used in our

example would result in the following:

C = Cast iron suction chamber

D = Hardened alloy steel internals including drive

shaft, connecting rod, pins, and rotor

Q = Nitrile (NBR) stator (70 durometer hardness)

The following letters identify the materials used in

standard construction:

C = Cast iron

D = Hardened alloy steel

S = Stainless steel, Type 316

Q = Nitrile (NBR), 70 durometer hardness

B = EPDM

F = Fluoroelastomer

The next position is a number identifying the current

pump revision, this manual corresponds to revision 3.

The last three letters indicate the trim code and

denote internal variations in a pump. The first letter

identifies sealing variations. The second letter indicates

internal variations. The third letter indicates rotor

variations.

A typical trim code is AAA, designating the following:

A = Standard black packing

A = Standard plated shaft

A = Standard size chrome-plated rotor

The variations available are:

Sealing:

A – Standard black packing

C – Teflon7 white packing (not food grade)

S – single mechanical seal

D – Double mechanical seal

Internal variations:

A – Standard plated shaft

B – Non-plated shaft

P – Two-piece shaft or pinned close coupled

Rotor variations:

A – Standard plated rotor

B – Non-plated rotor

C – Standard undersize

E – Standard oversize

X – Special to order

*Teflon is a registered trademark of E.I. duPont de Nemours & Co., Inc.

INSTALLATION

2-1.

2-2. GENERAL

Accessibility to the pump and adequate clearance should

be prime considerations in any installation. Enough space

should surround the unit so that maintenance can be

performed with ease.

2-3. PIPING

2-4. Suction piping should be as short as possible.

Normally, the suction line should be the same diameter as

the pump suction; however, conditions such as high

viscosity or required minimum flow velocities may dictate

otherwise. Long-sweep 90 degree elbows or 45 degree

elbows should be used instead of the standard elbow.

Avoid using suction piping loops which trap air.

2-5. Discharge piping diameter should generally be as

large as the discharge port unless fluid conditions indicate

otherwise.

An easily-removable section of piping, at least twice as

long as the stator, should be mated to the discharge port.

This will allow the rotor and stator to be removed without

having to remove the complete pump from the base.

2-6. FOUNDATION

For maximum pump-driver unit life, each unit should be

mounted on a strong steel baseplate. The baseplate should

be mounted on a firm foundation. The motors should be

supported on close-coupled configurations above 1 HP.

2-7. SHAFT ALIGNMENT

After the base has been bolted down to the foundation,

check the following conditions:

2-8. Coupling connected units. Be sure that the pump

and drive shafts are aligned before the coupling is

connected. Care should be exercised to ensure that all

components are level and mounted in a direct line.

Check the gap between coupling halves (refer to coupling

manufacture’s recommendations). Adjustment can usually

be made by loosening the mounting bolts on either the

pump or driver and moving the loosened component into

alignment with the fixed component. Do not use a hammer!

On couplings with equal diameter hubs, it may be helpful to

lay a straight edge across the coupling halves to check

alignment.

2-9. Belt drive units. Be sure that sheaves or sprockets

are in alignment. Check belts for proper tension. Tension

requirements will vary with type of belt, center distances,

and belt speeds. Consult belt manufacturer for specific

recommendations.

2

3-1. OPERATION

3-2. INTIAL CHECK

Before putting the pump into operation, the following

items should be checked to ensure that each piece of

equipment is installed correctly:

-Pump, driver, coupling, or sheave alignment.

-Electrical connections.

-Gauges and other instruments.

-Pump rotation. Rotation is indicated on the pump

nameplate.

-Belt tension on belt driven units. There should be no

appreciable deflection when first starting up.

-All valves should be open on both suction and

discharge sides of pump.

-Seal flush systems if required should be operational.

Double seals require flushing between faces.

CAUTION: This is a positive displacement pump. Do

not operate it against a closed valve.

3-3. START-UP

CAUTION: DRY OPERATION IS HARMFUL TO THE

PUMP! Never allow the pump to operate

without liquid, as dry operation will cause

premature wear of the stator and possible

damage. The stator is lubricated by the

liquid which is being pumped.

1. Before operating the pump for the first time, fill it

with liquid to lubricate the stator for the initial start-up.

Note: If the pump is shut down temporarily, enough

liquid will remain in the system to provide

lubrication upon restarting. It is advisable to

maintain the suction piping at a higher elevation

than the centerline of the pump in order to contain

some liquid in the pump at time of shutdown.

2. Once the pump has been filled with liquid, check for

direction of pump rotation by momentarily starting and

stopping the drive. See pump nameplate for correct

rotation.

3. Start seal flush water if so equipped.

4. Start pump.

3-4. PACKING LEAKAGE

The packed stuffing box is designed to control

leakage, not stop it completely. Leakage is necessary

to reduce friction and dissipate heat.

In a new pump, before the packing has had a

chance to seat properly, excessive leakage through

the stuffing box is common. Frequent adjustments of

the packing gland may be necessary during the first

few hours of operation in order to compress and seat

the packing. See Section 4-3.

4-1. MAINTENANCE

4-2. GENERAL

The Moyno 1000 pump has been designed for a

minimum of maintenance, the extent of which is routine

adjustment of the packing, and infrequent lubrication of

the bearings in tapered roller bearing models. The pump

is one of the easiest to work on because the main

elements are very accessible and require few tools to

disassemble.

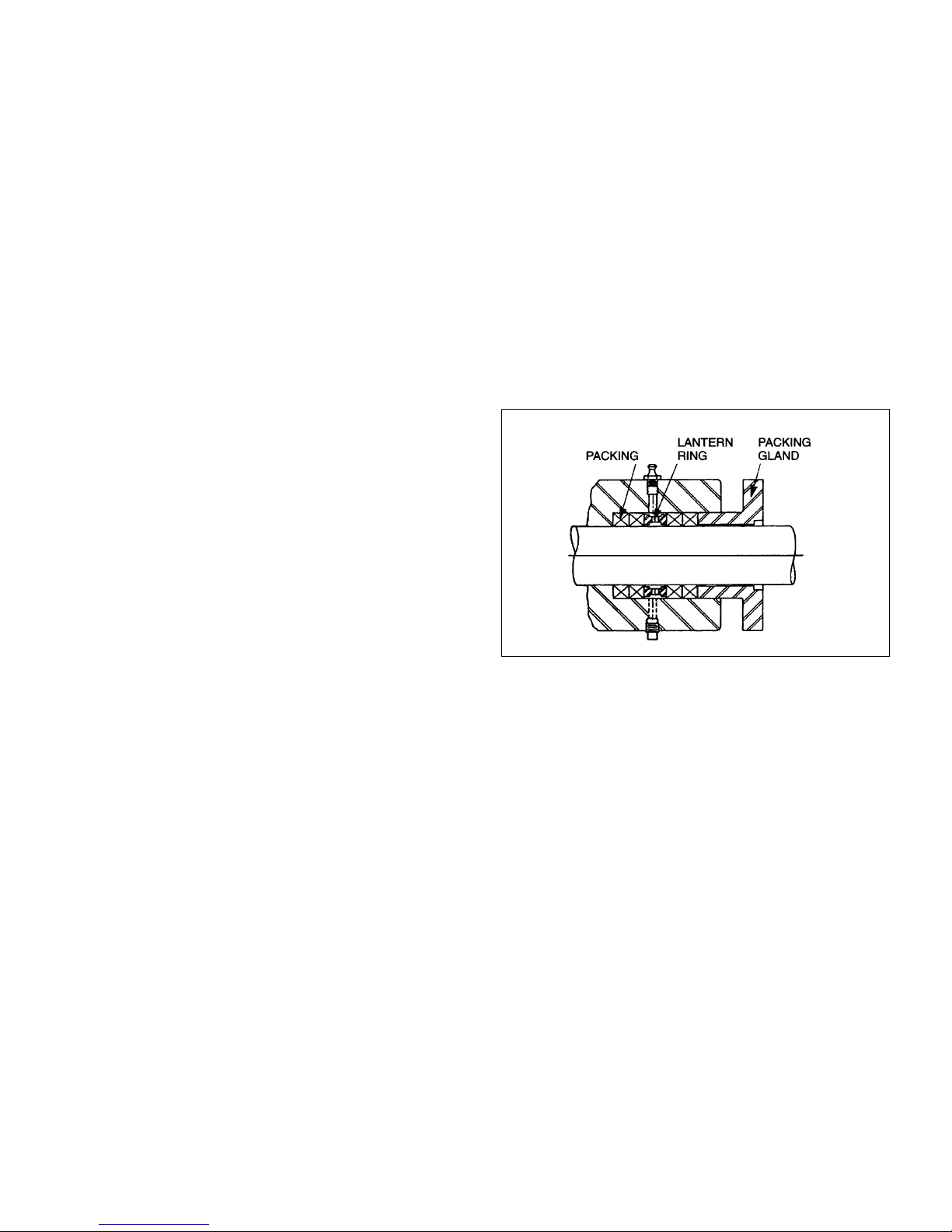

4-3. PACKING ADJUSTMENT

Packing gland nuts (see Figure 4-1) should be evenly

adjusted. Overtightening the packing gland may result in

premature packing failure and possible damage to the

shaft and gland.

Figure 4-1. Cross Section of Packing Retainer

When packing is new, frequent minor adjustments

during the first few hours of operation are recommended

in order to compress and seat the packing.

1. Upon initial start-up of the pump, adjust the gland

nuts for a leakage rate of 50-100 drops per minute until

the packing has seated and adjusted to the operating

temperature (approximately 10-15 minutes).

2. If leakage is excessive after 15 minutes of operation,

tighten the gland nuts ¼ of a turn.

3. Tighten the gland nuts ¼ of a turn after an additional

15 minutes if necessary and repeat this procedure until a

desired leakage of 1-2 drops per minute is obtained.

Adding grease may also reduce leakage by providing a

barrier at the lantern ring.

CAUTION: Do not tighten until zero leakage is obtained.

Overtightening the packing gland may result

in accelerated wear on the packing and

damage to the shaft. In those situations

where no packing leakage can be tolerated ,

consult your Moyno Authorized Service

Distributor.

3

4-4. PACKING REPLACEMENT

Note: In this section, the first reference to each pump

part will be followed by a number or a letter in

parentheses ( ). These numbers and letters are

those used to identify the pump parts and

hardware items in the Exploded Views in Section

4-43.

When leakage can no longer be regulated by

tightening the gland nuts, remove and replace the

packing. The entire pump need not be disassembled to

replace the packing. Briefly, replace as follows:

1. Remove packing gland nuts and lock washers and

slide gland (0900) and slinger ring (6800) back along

drive shaft (6000).

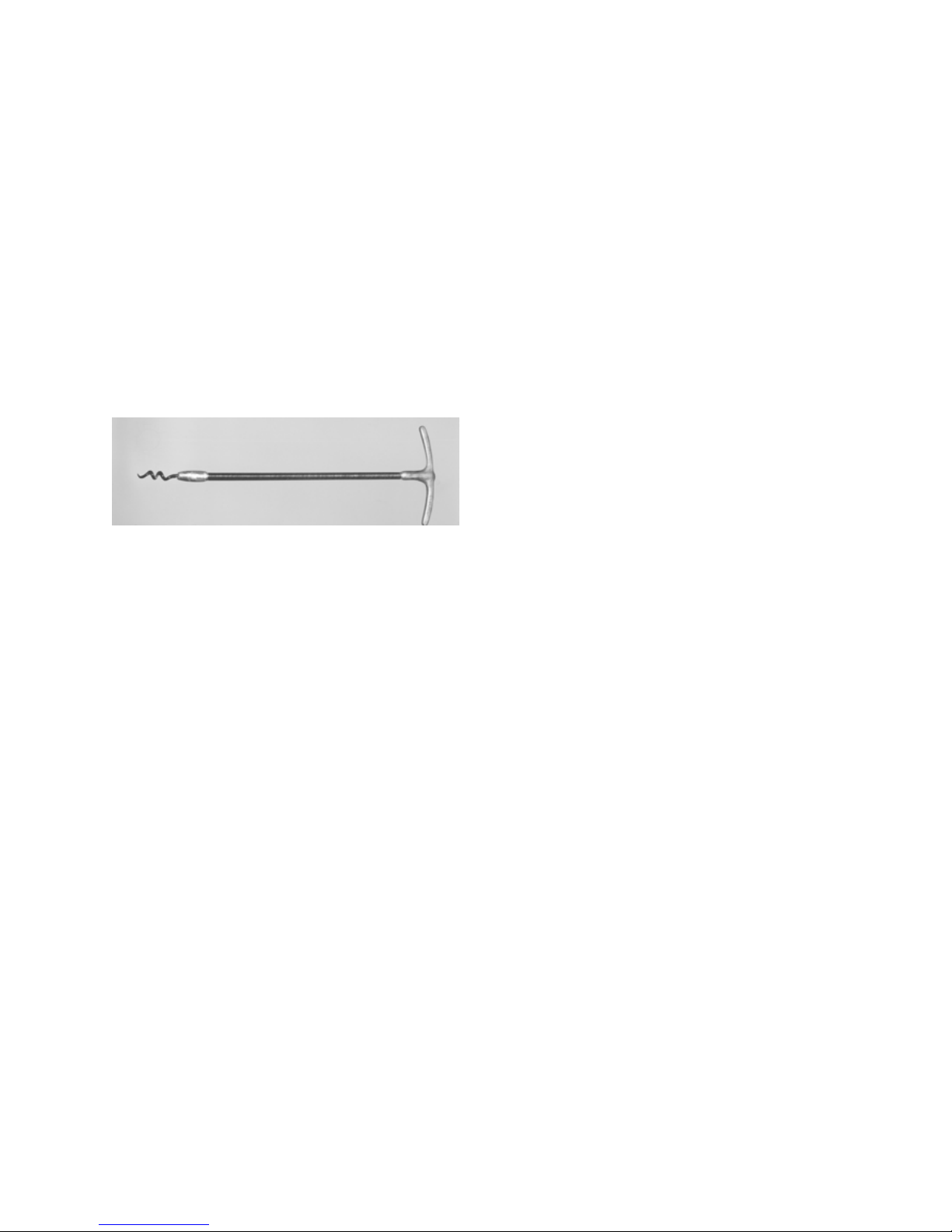

2. Use a packing puller tool (see Figure 4-2) to

remove the packing (6900).

Figure 4-2. Packing Removal Tool

3. Inspect surface of drive shaft for excessive wear or

grooves due to packing rub. If shaft is worn, or is badly

scored or grooved, it should be replaced.

4. If drive shaft is not worn, install a lantern ring and 4

packing rings, lubricating them before installation with a

good grade of packing grease. Be sure to stagger the

packing ring joints at 90 degrees increments.

Note: The stuffing box is supplied with 4 rings installed,

a fifth ring may be added after initial compression.

CAUTION: ALWAYS USE A PROPER PACKING

TAMPER TOOL TO INSTALL PACKING.

Do not use a pointed or sharp tool, as

damage to the packing material or drive

shaft could result. To assure proper shaft

lubrication, never use a one-piece spiral

wrap packing.

5. Replace packing gland and secure with packing

gland screws (H), lock washers, and nuts.

6. Adjust packing per Section 4-3.

4-5. BEARING LUBRICATION

(BEARING MODELS ONLY)

There are two types of bearings used in Moyno 1000

pumps. The smaller models utilize ball bearings which

are lubricated and permanently sealed by the bearing

manufacturer. These bearings cannot be lubricated in

service and generally, due to their low cost and

availability, are changed periodically during routine

maintenance operations.

The larger pumps, including all open throat models, utilize

tapered roller bearings which can be relubricated. Under

normal operating conditions, bearings should not require

replacement or relubrication for at least 15,000 hours or

every 2 years.

To lubricate tapered roller bearings:

1. Remove the drive shaft assembly and the bearings in

accordance with DESASSEMBLY instructions, Sections 414 and 4-15.

2. Clean bearing cups and cones and the shaft assembly

to remove all old grease.

3. Use a good grade of EP (Extreme Pressure) Lithium

soap-base grease such as Mobilux EP2 (Mobil Chemical

Co.), Shell Alvania EP2 (Shell Oil Co.), or equivalent, to

lubricate bearings.

4. Reassemble in accordance with the ASSEMBLY

instructions, Section 4-26.

4-6. DRIVE SHAFT AND ROTOR-EXTENDED LIFE

PROVISION

The heads on the drive shaft and rotor of Moyno 1000

pumps are manufactured with two sets of drive pin holes

located 90 degrees apart.

If, after many hours of service, pin hole wear is

encountered, the drive shaft and/or rotor may be rotated

90 degrees and the second set of pin holes utilized.

4-7. DISASSEMBLY

Note: In this section and in following sections on

CLEANING, INSPECTION, and ASSEMBLY, the

first reference to each pump part will be followed by

a number or letter in parentheses ( ). These

numbers and letters are those used to identify the

pump parts and hardware items in the Exploded

Views in Section 4-43.

4-8. Disconnect Pump

1. Disconnect the power source.

2. Close suction and discharge valves to isolate the pump

from the line.

3. Remove drain plug (N or P) in bottom of suction

chamber (1100) to drain any fluid remaining in pump and

suction line.

4-9. Stator Removal

1. Remove section of discharge pipe attached to

discharge flange (1400).

2. Remove discharge flange (1400) by unbolting from

stator clamp ring (1800) and remove stator gasket (1200).

Remove stator retaining ring (R) and stator clamp ring

(1800) from stator (6500).

4

3. Remove top half of stator support (1700).

4. Unbolt stator clamp ring (1800) from suction

housing, remove stator from rotor, turning stator while

removing will ease disassembly. Use a screwdriver tip

to carefully remove the stator retaining ring. Remove

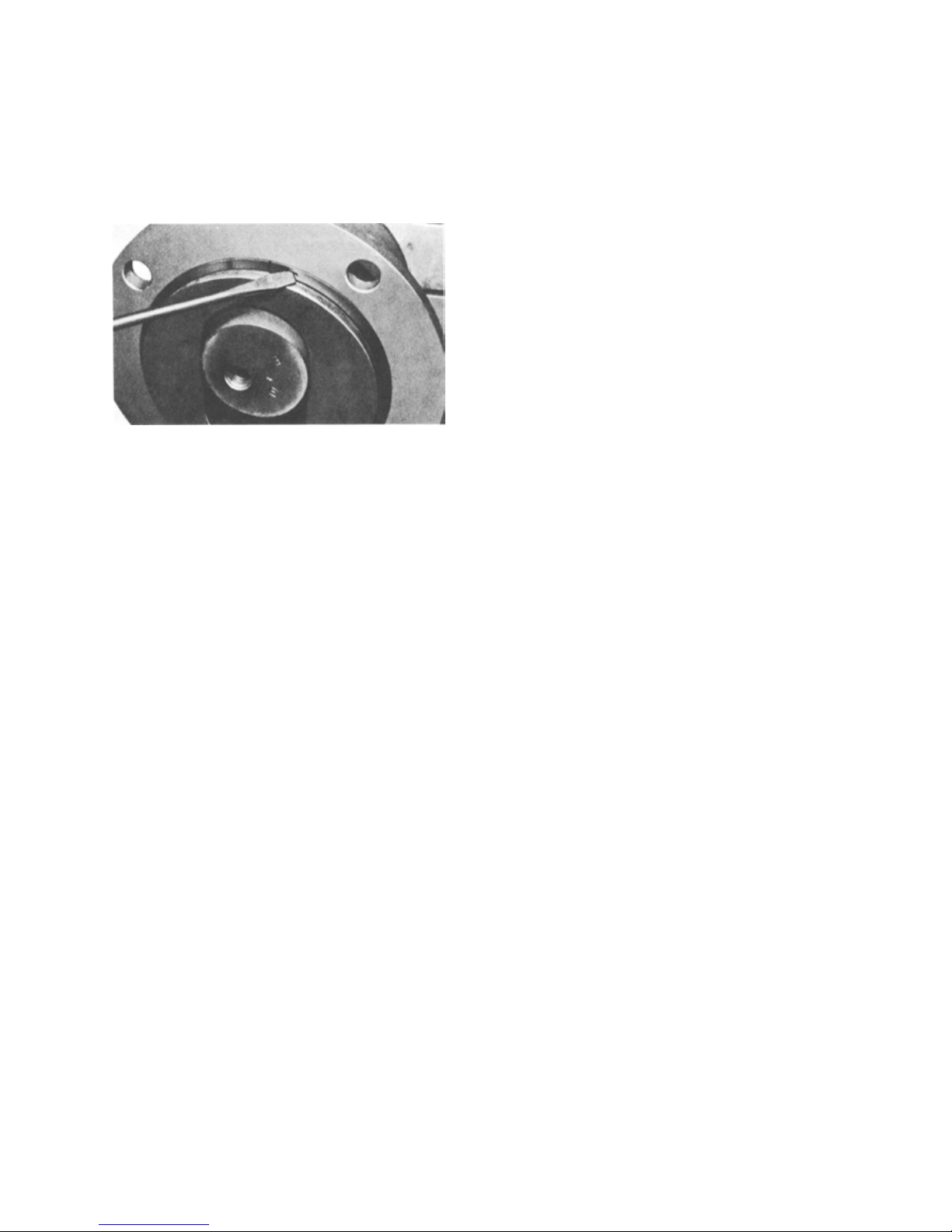

stator clamp ring (1800) from stator (6500). See Figure

4-3 for the typical retaining ring removal procedure.

Figure 4-3. Typical Retaining Ring Removal

Note: On some four-stage models, a stator adaptor

(1500) and gasket (1210) will be installed

between the stator and suction chamber.

4-10. Suction Chamber Removal

1. On standard and close-coupled models, remove

four suction chamber bolts and lock washers (M)

holding suction chamber to bearing housing (0100). On

open throat models, studs (O) screwed into the bearing

housing are used in place of the suction chamber bolts.

Remove four suction chamber nuts and lock washers

(O) holding suction chamber to bearing housing.

Remove stator gasket from housing.

2. Remove suction chamber and suction chamber

gasket (1220) over the connecting rod (6200) and rotor

on standard models or auger assembly (6200) and rotor

on open throat models.

4-11. Rotor Removal

1. With snap ring pliers, remove the rotor head snap

ring (J), sliding it down over the rotor. Some models

may use spiral type rings (see Figure 4-3).

2. Carefully tap the retaining ring (6100) towards the

rotor end exposing the edge of the universal joint seal

(6400).

3. Remove the edge of the universal joint seal from

the groove in the rotor head and fold the seal back.

4. Carefully tap the retaining ring back towards the

universal joint seal until the drive pin (6300) is exposed.

5. Push the drive pin through the rotor head and

remove the rotor.

6. Remove head O-ring (K) from rotor head.

4-12. Connecting Rod or Auger Assembly Removal

1. Remove the drive shaft head snap ring (J) sliding it

back towards the bearing housing. Some models may have

spiral type rings (see Figure 4-3).

2. Tap the retaining ring towards the bearing housing,

exposing the edge of the universal joint seal.

3. Remove the edge of the universal joint seal from the

groove and fold the seal back.

4. Slide the retaining ring back towards the seal until the

drive pin is exposed.

5. Push the drive pin through the drive shaft head and

remove the connecting rod or auger assembly from the

drive shaft (6000).

6. Remove head O-ring from drive shaft head.

4-13. Packing Removal

To remove packing without removing the drive shaft and

bearing assembly, refer to Section 4-4. If the drive shaft

and bearing assembly are to be removed, proceed directly

to Sections 4-14 and 4-15.

4-14. Drive Shaft Removal

Shaft Drive Models (one-piece shaft, not close-coupled)

The Moyno 1000 pump is designed so that the stuffing

box (1000), packing gland, packing, and bearings (D or E)

are removed as an assembly with the drive shaft. For

Close-Coupled models, skip to Step 17. For two-piece

Shaft Drive models, skip to Step 6.

1. Remove the drive shaft key (I).

2. Remove bearing cover screws and lock washers (A).

Note: Ball bearing models do not have a bearing cover. A

bearing housing snap ring (G), located at the drive

shaft end of the bearing housing, is used to position

the drive shaft and bearings. This snap ring need not

be removed.

3. Slide bearing cover (0300) with grease seal (B) and

bearing shims (6700) off of drive shaft.

4. Using snap ring pliers, remove the bearing housing

snap ring (G) located at the stuffing box end of the bearing

housing.

5. Slide drive shaft assembly from bearing housing.

Shaft Drive Models (two-piece shaft, not close-coupled)

The Moyno 1000 pump is designed with a two-piece drive

shaft available that allows for removal of the drive shaft

head for easy seal maintenance.

6. Remove drive shaft key (I).

7. Move slinger/pin retainer (6800) toward packing or seal

housing, exposing shaft pin.

5

8. Remove shaft pin (2000).

9. Pull intermediate shaft from bearing housing

assembly (2100).

10. Inspect the sealing O-ring (2200) and replace if

worn or damaged.

11. Remove mechanical seal and seal housing from

bearing housing, or remove packing stuffing box from

bearing housing.

12. Remove bearing cover screws and lock washers.

Note: Ball bearing models do not have a bearing cover.

A bearing housing snap ring, located at the drive

shaft end of the bearing housing, is used to

position the drive shaft and bearings. Remove this

snap ring.

13. Slide bearing cover (0300) with grease seal (B)

and bearing shims (6700) off of drive shaft.

14. Slide the drive shaft/bearing assembly out of the

bearing housing toward the bearing cover end.

15. Remove, if desired, the bearing housing snap

ring (G) located at the stuffing box end of the bearing

housing.

16. This allows removal of the grease seal housing.

Inspect and replace grease seal if worn or damaged.

Close-Coupled Models Only

The Moyno 1000 close-coupled pump is designed so

that the stuffing box, packing gland, and packing are

removed as an assembly with the drive shaft.

17. Pull back slinger ring on pinned versions, and

push out the pin.

18. On keyed versions, remove set screws (D) in

locking ring (1600). Rotate locking ring 90

degrees. Slide drive shaft assembly from drive

adaptor, uncoupling from output shaft of drive.

Note: There is a flange on the gearbox side of the

locking ring that catches on the back end of the

drive shaft key. By rotating 90 degrees the set

screw holes should be 90 degrees from the key.

This will align a clearance in this locking ring for

removal.

4-15. Bearing Removal (Not Close-Coupled)

1. Remove shaft snap rings (F).

2. Use an arbor press to press bearings from drive

shaft. The first bearing is pressed off with its

accompanying grease retainer (0500). Slide the second

grease retainer off the shaft and then remove the

second bearing.

Note: When replacing drive shaft or bearings on tapered

roller bearing models, it is recommended that both

grease seals be replaced.

3. Remove the grease seal housing (0700) and grease

seal, bearing housing snap ring, slinger ring, packing gland,

packing, and stuffing box from drive shaft, on one-piece

shaft models.

4-16. Gearbox/Gearmotor Removal

Close-Coupled Models Only - Pinned and keyed

1. To remove the gearbox/gearmotor from the pump,

remove the bolts holding the gearmotor to the drive

adaptor.

2. Pull back slinger ring on pinned versions, and push out

the pin.

On keyed versions, loosen and remove two set screws

3.

in the locking ring. Rotate locking ring 90 degrees in

either direction.

4. Disengage gearmotor shaft from the pump drive shaft.

Note: Rotating locking ring aligns the slots in locking ring

with shaft key to allow disengagement.

4-17. CLEANING

Clean parts in a suitable cleaning solvent.

4-18. INSPECTION

4-19. Bearings. As described in Section 4-5 on Bearing

Lubrication, ball bearings (E) are sealed by the

manufacturer and are not designed to be relubricated and

reused. The following inspection procedure applies to

tapered roller bearings (D).

1. After cleaning, rotate bearings very slowly under

hand pressure to feel for smooth and even action. Never

spin a dry bearing. Check for cracks, galling, pitting, burns,

etc. Replace bearing if there is any doubt concerning

complete serviceability; bearings should be readily

available from any bearing source.

4-20. Drive Shaft and Intermediate Shaft. Inspect drive

shaft (6000) and intermediate shaft (2100) if so equipped

for scoring, burrs, cracks, etc. Replace as necessary. The

drive shaft head is equipped with two sets of pin holes.

When one set becomes worn, rotate shaft 90 degrees and

use second set.

4-21. Seals. It is sound practice to always replace grease

seals (B) whenever the drive shaft and tapered roller

bearings are removed.

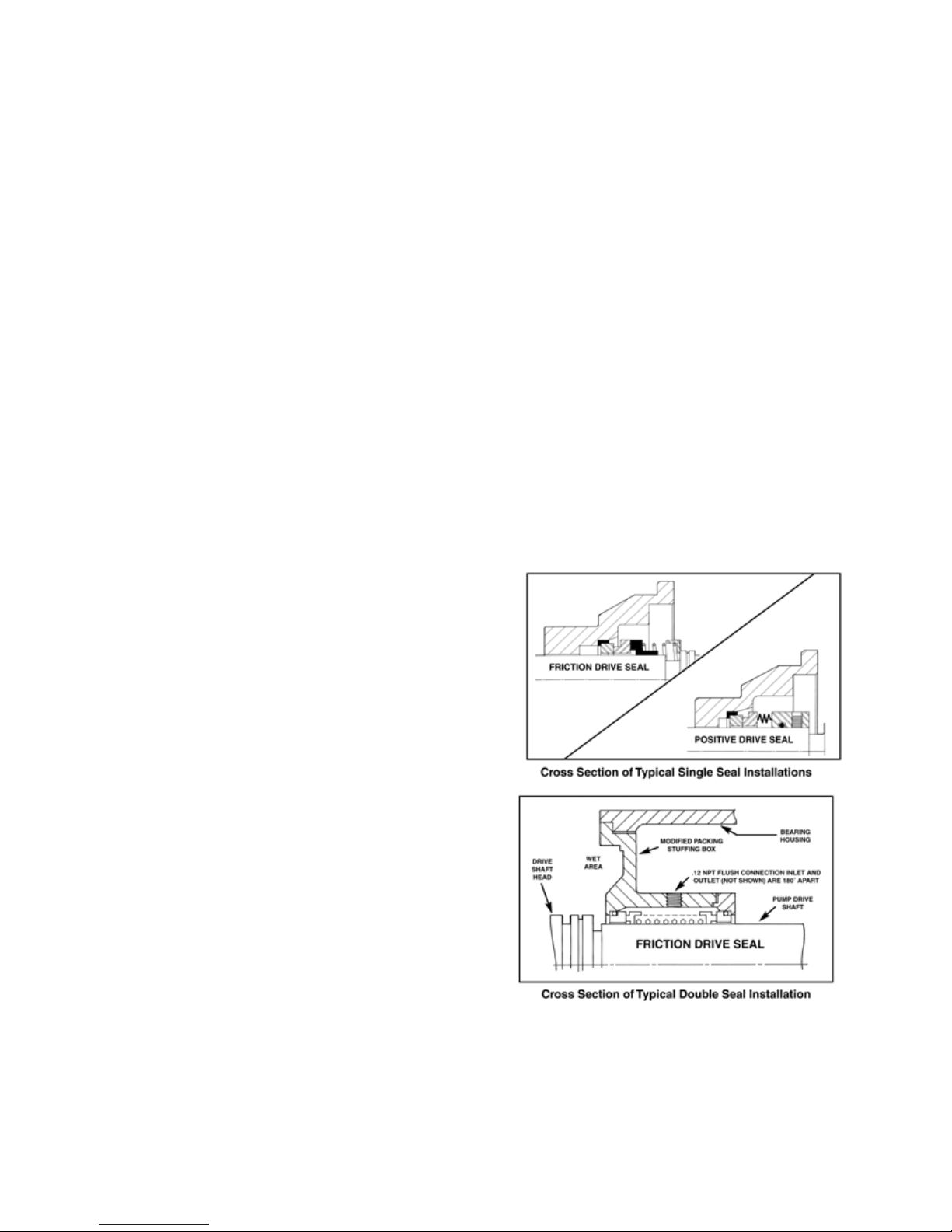

4-21a. Mechanical Seals. It is sound practice to replace

mechanical seals when the pump is disassembled. Extreme

care should be taken to protect the seal faces from

damage. These are fragile; avoid touching the faces and

keep them clean.

The rubber bellows (Type 43) or equal seals will adhere

to the shaft after assembly and must be replaces if

6

removed from the shaft. The (Type 680) metal bellows

seals or equal use O-rings to seal against the shaft and

may be reused if their condition does not dictate

replacement.

The rubber bellows (Type 43) or equal seals are

friction-driven which makes adhesion to the shaft a

necessity. The metal bellows (Type 680) seals or equal

are positive driven and locked to the shaft with set

screws that must be loosened to remove seal.

4-22. Packing. It is sound practice to always replace

packing (6900) whenever the pump is disassembled.

4-23. Rotor

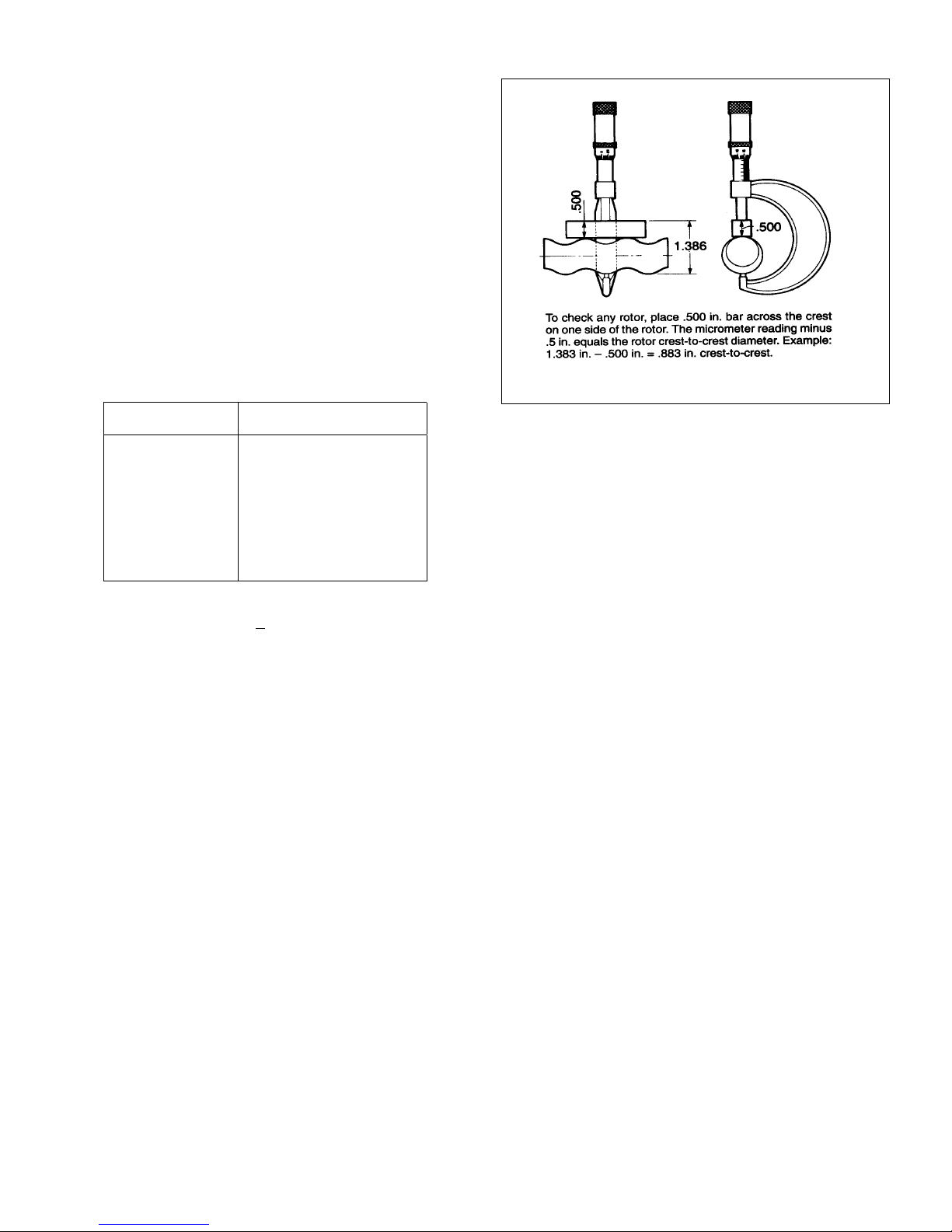

1. To check for excessive rotor (5000) wear, measure

the rotor crest-to-crest diameter (see Figure 4-4) and

compare with the following chart:

Rotor

Size

A

B

C

D

E

F

G

H, J, K

Crest-to-Crest Dia. (inches)

Standard

.886

1.061

1.327

1.671

2.100

2.676

3.428

4.015

The rotor size is designated by the third letter in the

Model Number (i.e., A2ECDQ3AAA).

2. If the measured crest-to-crest diameter is within

.010 in. of the standard value, the rotor is reusable

provided that:

a. the rotor pin holes are not excessively worn.

b. the rotor surface is not cracked, pitted or deeply

grooved (.030 in. or more).

3. Rotors with crest-to-crest diameters greater than

.010 in. under the standard value should generally be

replaced.

Figure 4-4. Measuring Rotor Diameter

4-24. Stator. The best indication of stator wear (6500) and

the need for replacement is a drop in pump performance.

Stators with interior surfaces that are pitted, grooved or

gouged should also be replace.

4-25. All Other Parts. Check for cracks, excessive wear,

damage to threaded holes, burrs, etc. Replace as

necessary. Replace O-rings (K) and all gaskets (1200,

1210, and 1220) at each disassembly and reassembly.

4-26. ASSEMBLY

Bearing Housing (One-Piece Shaft Models)

NOTE: For two-piece shaft models, go to 4-27. For close-

coupled models, go to 4-28.

1. Slide stuffing box (1000) on to drive shaft (6000), large

flanged end first.

2. Slide packing gland (0900) on to shaft so that the

round portion fits into the stuffing box.

3. Place slinger ring (6800) on shaft, adjacent to the

packing gland.

4. Place bearing housing snap ring (G) on the shaft.

4-26a. Ball Bearing Models

1) Press sealed bearing (E) on drive shaft.

2) Install shaft snap ring (F) in groove on shaft. Seat

bearing against snap ring.

3) Install second shaft snap ring.

4) Press second sealed bearing on shaft and seat against

snap ring.

5) If not already in place, install bearing housing snap ring

(G) in groove inside drive end of bearing housing (0100).

7

6) Place assembled drive shaft into bearing housing.

Secure by inserting second bearing housing snap ring in

groove in stuffing box end of bearing housing.

4-26b. Tapered Roller Bearing Models

1) Press grease seal (B) into grease seal housing

(0700) and place assembly on shaft with chamfered

side of grease seal housing facing keyway end of shaft.

2) Pack the bearings (D) thoroughly with grease,

Mobilux EP2 or equal.

3) Place bearing cup on shaft and press bearing cone

on shaft approximately .150 in. beyond snap ring

groove.

4) Place grease retainer (0500) on shaft and install

shaft snap ring (F) in groove on shaft.

5) Seat bearing and grease retainer against snap ring.

6) Install second shaft snap ring in groove on shaft

and place second grease retainer on shaft.

7) Press bearing cone on shaft, and seat bearing and

grease retainer against snap ring.

8) Fill grease seal housing with grease.

9) Slide drive shaft assembly into bearing housing.

Secure by inserting bearing housing snap ring (G) in

groove in bearing housing at rear of stuffing box area.

10) Fill area around the bearing in the drive end of the

bearing housing with grease.

11) Complete bearing assembly by sliding bearing cup

into bearing housing.

12) Press grease seal in bearing cover (0300) and

place bearing cover on shaft. Secure with bearing cover

screws and lock washers (A). (see Section 4-29.)

4-27. ASSEMBLY (Two-Piece Shaft Models)

NOTE: For close-coupled models, go to 4-28.

4-27a. Ball Bearing Models

1) Press sealed bearing on drive shaft.

2) Install shaft snap ring in groove on shaft. Seat

bearing against snap ring.

3) Install second shaft snap ring.

4) Press second sealed bearing on shaft and seat

against snap ring.

5) If not already in place, install bearing housing snap

ring in groove inside stuffing box end of bearing

housing.

6) Place assembled drive shaft into bearing housing.

Secure by inserting second bearing housing snap ring

in groove in drive end of bearing housing. Proceed to 4-

30.

4-27b. Tapered Roller Bearing Models

1) Install bearing housing retaining ring in bearing

housing groove.

2) Press grease seal into grease seal housing and

assemble in housing with chamfered side of grease seal

housing facing bearing location.

3) Slide bearing cup into the bearing housing against the

seal housing.

4) Press bearing cone on shaft approximately .150 in.

beyond snap ring groove.

5) Place grease retainer on shaft and install shaft snap

ring in groove on shaft.

6) Seat bearing and grease retainer against snap ring.

7) Install second shaft snap ring in groove on shaft and

place second grease retainer on shaft.

8) Press bearing cone on shaft, and seal bearing and

grease retainer against snap ring.

9) Fill grease seal housing with grease.

10) Slide drive shaft assembly into bearing housing.

11) Fill area around the bearing in the drive end of the

bearing housing with grease.

12) Complete bearing assembly by sliding bearing cup

into bearing housing.

13) Press grease seal in bearing cover (0300) and

place bearing cover on shaft. Secure with bearing cover

screws and lock washers Proceed to 4-29.

4-28. Close-Coupled Models - Pinned versions are similar to

two piece shaft versions. Locking ring version is listed below.

1) Place locking ring on drive shaft with key clearance

slot aligned with keyslot in drive shaft.

2) Mount drive to the drive adaptor (0100) using four

bolts, lock washers, and nuts.

3) Install drive shaft assembly into the drive adaptor

while coupling drive shaft to output shaft of drive.

4) Rotate locking ring 90 degrees and secure one set

screw over the key and the other set screw at 180

degrees through the hole in the drive shaft, securing

on the output shaft of the drive.

4-29. Adjusting Bearing End Play

(Tapered Roller Bearings Only)

1. Tighten bearing cover screws around bearing cover

firmly, to the point the shaft will not turn. (Screws should be

tightened evenly, opposite each other.)

8

2. Measure the gap between the bearing cover and

the bearing housing.

3. Remove bearing cover and add shims (6700) to

equal gap measured in step 2 plus an additional .010 in.

4. Install bearing cover with shims and tighten screws

evenly, opposite each other.

5. Tap lightly on the shaft head or end using a soft

mallet. Rotate shaft to “free up” assembly. You should

be able to rotate the shaft by hand.

6. Shims may be added or subtracted to get the

proper setting.

7. Slide the rubber pin retainer on the drive shaft

pushing past the pin hole.

4-30. Intermediate Drive Shaft Installation (Mechanical

Seal Pumps Proceed to 4-30a.)

1. Position the packing in the stuffing box and install

the gland studs, if removed.

2. Position the stuffing box in the bearing housing,

sliding the packing gland on packed models onto the

gland studs. Rotate the stuffing box so that the zerk

fitting is on the side.

3. Install the intermediate shaft seal ring (2200) on

the intermediate shaft.

4. Insert the intermediate shaft through the stuffing

box, seating the end of the intermediate drive shaft into

the drive shaft. Rotate the shafts to align the pin holes

and insert the pin.

5. Slide the rubber pin retainer in place on the drive

shaft over the pin.

4-30a. Mechanical Seal Installation (Single Seal)

1. Install the stationary component (seat and O-ring)

of mechanical seal (6950) in seat of seal retainer

(1000).

2. Position the seal housing in the bearing housing

(1).

3. Slide the rotating component (spring and rotating

seat) onto the drive shaft. It may be necessary to wipe a

small amount of lubricant around inside diameter of

rotating component.

4. Lock mechanical seal set screws onto shaft if

mechanical seal is positively driven, locating the end of

the seal flush with the end of the drive shaft.

5. Install the intermediate shaft O-ring (2200) on the

intermediate shaft.

6. Insert the intermediate shaft into the drive shaft.

Rotate the shafts to align the pin holes and insert the

drive shaft pin, compressing the mechanical seal spring on

single spring friction drive seals.

7. Locate slinger/pin retainer on the shaft covering the

pin.

4-30b. Mechanical Seal Installation (Double Seal)

1. Press the stationary seat into the gland for a double

seal installation, taking care not to damage the face. Put

gland on shaft with care.

2. Install the seal on the shaft.

3. On double seal models the seal housing (modified

packing stuffing box) is slid on the shaft, with stationary

seat fitted into place. The seal assembly is then

compressed by bolting the gland to the seal housing. This

will bring the faces into contact.

4. Install the intermediate shaft O-ring (2200) on the

intermediate shaft.

5. Insert the intermediate shaft into the drive shaft.

Rotate the shafts to align the pin holes and insert the drive

shaft pin.

6. Locate the slinger/pin retainer on the shaft covering

the drive shaft pin.

4-31. Connecting rod or Auger Assembly

1. Install universal joint seal (6400) on connecting rod (or

auger assembly) (6200), making sure the raised ridge

inside the universal joint seal is placed in the matching

groove on the connecting rod.

9

Loading...

Loading...