Moyer Diebel MD44 Installation Manual

Rack Conveyor

Dishwasher

Installation/Operation Manual with Service Replacement Parts

Rack Conveyor Dishwasher

CH-44, MD-44

44" Single Tank with built-in electric booster

CH-66, MD-66

44" Single Tank with 22" Prewash

Single Tank

Model CH-44, MD-44

with built-in electric booster

www.championindustries.com

3765 Champion Boulevard

Winston-Salem, NC 27105

336/661-1556 Fax: 336/661-1660

Toll-free: 800.858.4477

Single Tank w/Prewash

Model CH-66, MD-66

Issue Date: 4.1.13

Manual P/N 115279 rev. -

For machines beginning with S/N RM13020073 and above

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Toll-free: 800.263.5798

Dishwasher serial no.

Printed in USA

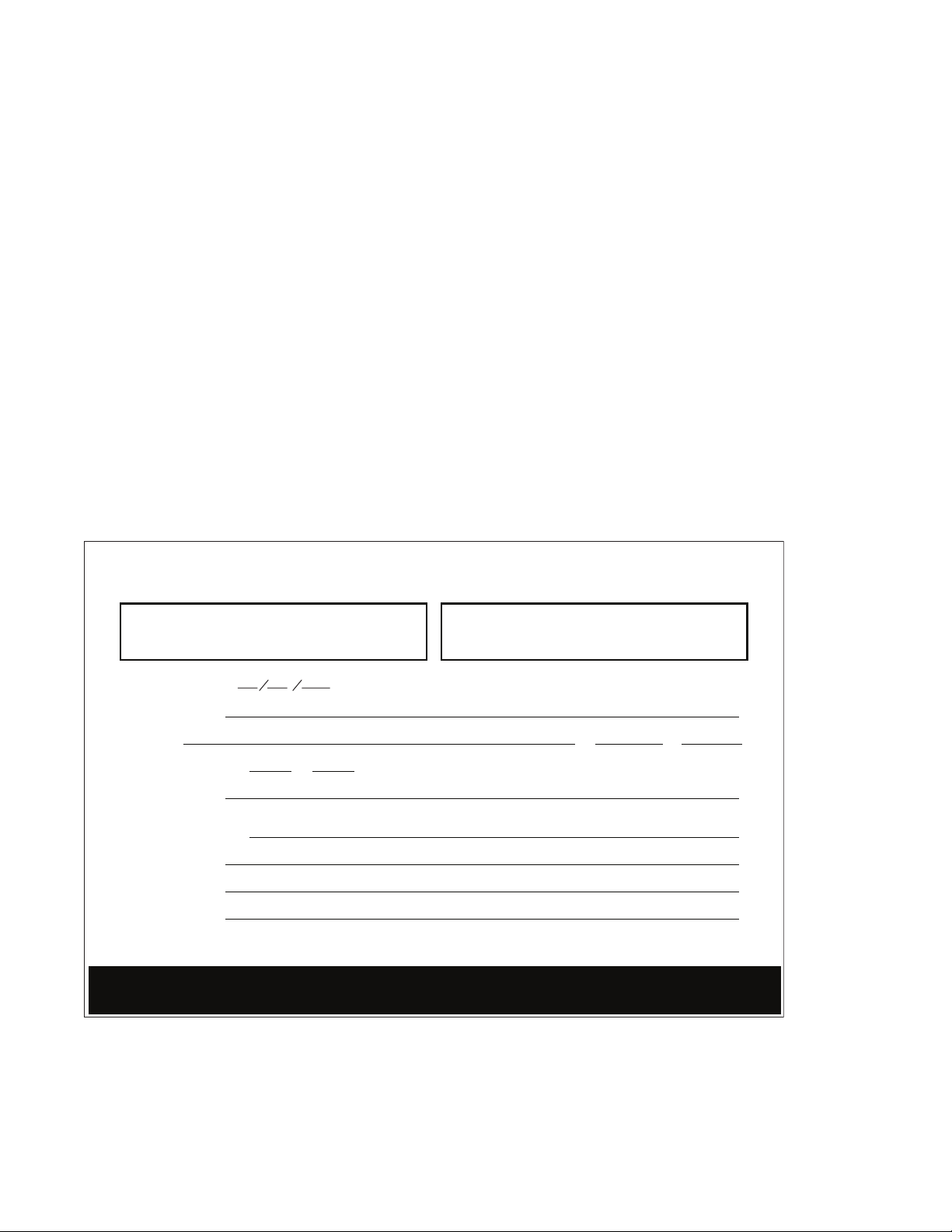

For future reference, record your dishwasher information in the box below.

Model Number__________________________ Serial Number_______________________

Voltage________________Hertz_____________ Phase__________________

Champion Service Agent __________________________________ Tel:______________________

Champion Parts Distributor _________________________________ Tel:______________________

National Service Department

In Canada: In the USA:

Toll-free: 800/ 263-5798 Toll-free: 800/ 858-4477

Tel: 905/ 562-4195 Tel: 336/ 661-1992

Fax: 905/ 562-4618 Fax: 336/ 661-1660

email: service@moyerdiebellimited.com email: service@moyerdiebel.com

ATTENTION:

The dishwasher model number,

serial number, voltage, hertz and phase

are needed to identify your machine and to

answer questions.

Please have this information on-hand

if you call for service assistance.

For all models:

The data plate mounts to

one side of the top-mounted

control cabinet.

The USGBC and the CaGBC Member Logos are trademarks owned by the U.S. Green Building Council and The Canadian Green

Building Council, respectively, and are used by permission. The logos signify only that Champion Industries, and Moyer Diebel

are USGBC members and CaGBC members respectively. USGBC and CaGBC do not review, certify nor endorse the products or

services offered by its members.

COPYRIGHT © 2013 All rights reserved Printed in the USA

REGISTER YOUR PRODUCT ONLINE

Make sure you are connected to the internet then enter the address below.

In the U.S.A

CHAMPION

http://www.championindustries.com/register

MOYER DIEBEL

http://www.moyerdiebel.com/register

In Canada

CHAMPION AND MOYER DIEBEL

http://www.championindustries.com/canada/register

PRODUCT REGISTRATION

BY FAX

COMPLETE THIS FORM AND FAX TO:

(336) 661-1660 in the USA

1-(800) 204-0109 in Canada

PRODUCT REGISTRATION CARD

Model

Date of Installation:

Company Name:

Address:

Telephone #: ( ) ---

(Street) Province Postal Code

Serial #

Contact:

Installation Company:

Address:

Telephone #:

Contact:

FAILURE TO REGISTER YOUR PRODUCT MAY VOID YOUR WARRANTY

IMPORTANT IMPORTANT

Revision History

Revision History

A revision might be a part number change, new instructions, or information that was not available

at print time. We reserve the right to make changes to this manual without notice and without

incurring any liability by making the changes. Dishwasher owners may request a revised manual,

at no charge, by calling (800) 858-4477 in the USA or (800) 263-5798 in Canada.

Revision Revised Serial Number Description

Date Pages Effectivity

4.1.13 All RM13020073 Released First Edition

i

Limited Warranty

LIMITED WARRANTY

Champion Industries and The Companies (The Companies), 3765 Champion Boulevard, Winston-Salem, North Carolina

27105, and P.O. Box 301, 2674 N. Service Road, Jordan Station, Canada, L0R 1S0, warrants machines, and parts,

as set out below.

Warranty of Machines: The Companies warrant all new machines of its manufacture bearing the name

"The Companies" and installed within the United States and Canada to be free from defects in material and workman

ship for a period of one (1) year after the date of installation or fteen (15) months after the date of shipment by

The Companies, whichever occurs rst. [See below for special provisions relating to glasswashers.] The online registration

or warranty registration fax must be returned to The Companies within ten (10) days after installation. If online registration

or warranty card fax is not returned to The Companies within such period, the warranty will expire after one year from the

date of shipment.

The Companies will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, The Companies, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided;

however, as to glasswashers, The Companies' obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs rst. In the event that The Companies

elect to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by The Companies' authorized service technician. Defective parts become the property of The Companies.

Use of replacement parts not authorized by The Companies will relieve The Companies of all further liability in connection

with its warranty. In no event will The Companies' warranty obligation exceed The Companies' charge for the machine.

The following are not covered by The Companies'' warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior nish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical

dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage

caused by labor dispute.

Warranty of Parts: The Companies warrant all new machine parts produced or authorized by The Companies to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period The Companies will replace the defective

part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. THE COMPANIES' WARRANTY IS ONLY TO THE

EXTENT REFLECTED ABOVE. THE COMPANIES MAKE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF MERCHANTABILITY, OR FITNESS OF PURPOSE. THE COMPANIES

SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN THE COMPANIES DISHWASHING MACHINES

AND THE COMPANIES PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING ANY LIABILITY FOR

INCIDENTALS OR CONSEQUENTIAL DAMAGES.

The Companies do not authorize any other person, including persons who deal in The Companies' dishwashing machines

to change this warranty or create any other obligation in connection with The Companies' Dishwashing Machines.

ii

Table of Contents

CH-44, MD-44 and CH-66, MD-66 Rack Conveyor Dishwashers

Revisions to this manual.............................................................................................. i

Limited Warranty ......................................................................................................... ii

Model Descriptions ...................................................................................................... iv

Installation ....................................................................................................... 1

Receiving ..............................................................................................................1

Plumbing Connections ..........................................................................................2

Drain Connections ................................................................................................3

Ventilation .............................................................................................................3

Electrical Connections ..........................................................................................4

Chemical Signal Connections ...............................................................................6

Vent Fan Signal Connection .................................................................................6

Running & Table Limit Switch Connections ..........................................................6

Curtain Locations ..................................................................................................7

Door Safety Switches ...........................................................................................8

Scrap Screens ......................................................................................................9

Installing Spray Arms ............................................................................................10

Installing the Curtains ...........................................................................................14

Initial Start-Up Check List .....................................................................................15

Operation ......................................................................................................... 17

Operation ...........................................................................................................17

Cleaning and Maintenance ...................................................................................21

Troubleshooting ....................................................................................................27

Service Replacement Parts ............................................................................ 29

Solid State Control Module Operation and Troubleshooting ..................... 77

Electrical Schematics ..................................................................................... 89

iii

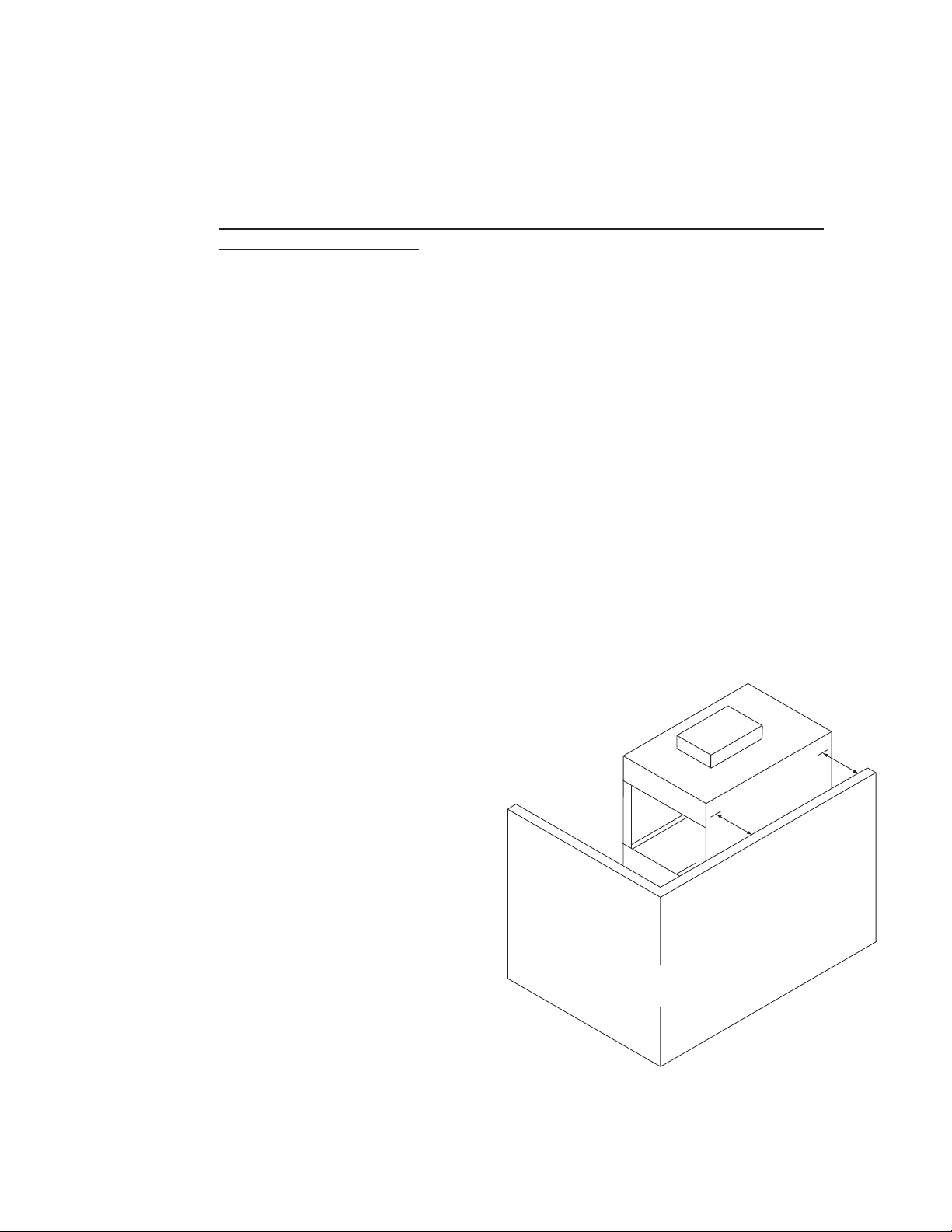

Model Descriptions

Model Descriptions

Models CH-44 and MD-44

Electric high temperature single tank rack conveyor dishwasher

with a built-in electric booster in 40°F/22°C rise or optional 70°F/39°C rise.

This model's direction of operation is convertible in the eld.

Models CH-66 and MD-66

Electric high temperature single tank with prewash tank

rack conveyor dishwasher with a built-in electric booster in 40°F/22°C rise

or optional 70°F/39°C rise.

The installation of your dishwasher must be performed by qualied electricians,

and plumbers and serviced by authorized service technicians trained in commercial

dishwashers.

Defects and repairs caused by unauthorized installers will not be covered by the

dishwasher warranty.

iv

Installation

Receiving

1. Inspect the outside of the dishwasher carton for signs of damage.

2. Remove the carton and inspect the dishwasher for damage.

3. Check for any options or accessories that may have shipped with your dishwasher.

4. Turn to the front of this manual and follow the instructions to register your

product online or by fax.

NOTE:

The installation of your dishwasher must be performed by qualified service personnel.

Problems due to improper installation are not covered by the Warranty.

NOTE:

The installation of the dishwasher must comply with all local electrical, plumbing, health and

safety codes or in the absence of local codes, installed in accordance with the applicable

requirements in the National Electrical Code, NFPA 70, Canadian Electrical Code (CEC),

Part 1, CSA C22.1; and the Standard for Ventilation Control and Fire Protection of

Commercial Cooking Operations, NFPA 96.

!!ATTENTION!!

Use caution when moving or lifting the dishwasher to prevent damaging the dishwasher

or the installation site. Check doorway and passageway clearance before moving the dishwasher.

Remove dishwasher front panels and check under the machine base for obstructions before moving.

1. Inspect the dishwasher for shipping damage.

2. Check the dishwasher interior for

curtains, panels and other supplies.

3. Lift the dishwasher off the shipping pallet

and move the machine near its

permanent location.

4. Leave a minimum of 6" between walls

and the rear of the dishwasher.

6"

6"

5. Level the dishwasher side-to-side and

front-to-back using a bubble level.

The dishwasher legs are adjusted by

screwing them in or out.

6. Do not remove tags attached to the

utility connections.

7. Remove the protective film from the

dishwasher exterior.

Wall Clearances

8. Remove any foreign material from the

dishwasher interior.

1

Installation

Utilities

Hot Water Connections

NOTE:

Only qualified personnel should make dishwasher plumbing connections.

Connections must meet local plumbing and sanitary codes.

Improper installation is not covered be the dishwasher warranty.

Hot Water Requirements:

1. Connect a 3/4" NPT hot water supply line to the line strainer located at the top rear of the

dishwasher. A water hardness of 3 grains/gal (US) [51.3 mg/L] or less is recommended.

2. For a dishwasher without a booster heater, the hot water connection must supply a

minimum of 180°F/82°C measured at the dishwasher.

3. For a 40°F/22°C rise booster heater, the hot water connection must supply a minimum of

140°F/60°C measured at the dishwasher.

4. For a 70°F/39°C rise booster heater, the hot water connection must supply a minimum of

110°F/43°C measured at the dishwasher.

5. Install a pressure regulating valve (PRV) before the dishwasher supply connection to

maintain a flowing pressure of 20-25 PSI/137.8-172.4 kPa.

6. Install a service shut-off valve in the supply line, as close to the dishwasher as possible.

The size of the valve must be the same size or larger as the supply line.

Cold Water Connections

Cold Water Requirements:

1. Connect a 1/2" NPT cold water supply line for a dishwasher equipped with a prewash cold

water tempering option. Connection is located at the top of rear of the dishwasher load end.

A water hardness of 3 grains/gal (US) [51.3 mg/L] or less is recommended.

2. Connect a 1/2" NPT cold water supply line for dishwashers required to have a drain water

temperature tempering option. A water hardness of 3 grains/gal (US) [51.3 mg/L] or less is

recommended. Request a P/N 452891 for a drain tempering water kit.

2

Installation

Drain Connections

1. The 1-1/2" drain line was removed and packed inside the dishwasher prior to shipping.

Install the drain line once the dishwasher has been placed in its final location.

2. Connect the 1-1/2" NPT drain line to above a drain sink or to a 1-1/2" or larger drain line

connection.

3. Observe all local plumbing and sanitary codes when installing.

Ventilation Connections

1. DO NOT VENT THE DISHWASHER INTO WALLS,

CEILINGS OR ENCLOSED PLACES.

2. Vent stacks with adjustable dampers are supplied with the dishwasher to connect house

vent.

3. Connect stainless steel water-tight duct inside the 4" x 16"/ 106mm x 407mm vent

stacks supplied with the dishwasher.

4. A minimum of 6 air changes per hour of kitchen is recommended

Ventilation Guidelines:

Dishwasher without a prewash tank option:

Load end- 200 CFM @ 1/4" SP/ 95 Liters/second

Unload end- 400 CFM @ 1/4" SP/ 189 Liters/second

Dishwasher with a Prewash tank option:

Load end- 150 CFM @ 1/4" SP/ 95 Liters/second

Unload end- 400 CFM @ 1/4" SP/ 189 Liters/second

3

Installation

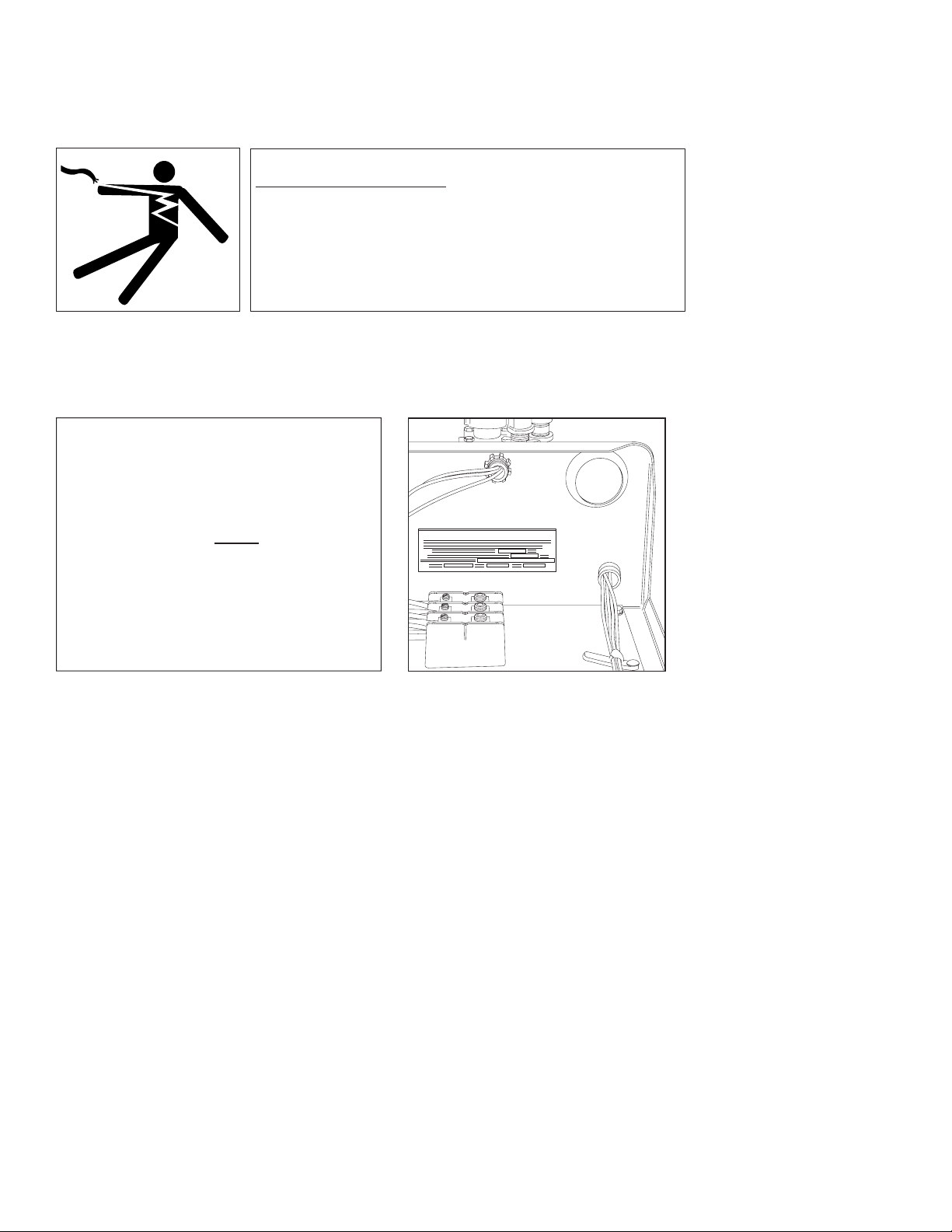

Electrical Connections

WARNING:

Electrocution or serious injury may result when working on an

energized circuit.

Disconnect power at the main breaker or service disconnect

switch before working on the circuit.

Lock-out and tag the breaker to indicate that work is being

performed on the circuit.

ATTENTION

A qualified electrician must connect the main incoming power to the dishwasher in accordance with all

local codes and regulations or in the absence of local codes in accordance with the National Electrical

Code.

!!ATTENTION!!

Electrical and grounding connections

must comply with the National Electrical Code

or in the absence of a National Code then

all Local Electrical Codes.

A qualified electrician MUST compare the

electrical power supply with the machine

electrical specifications stamped on the

MACHINE ELECTRICAL

CONNECTION PLATE

located inside the control cabinet before

connecting the main power to the dishwasher.

MACHINE ELECTRICAL CONNECTION

1. The main incoming power to the dishwasher is made at the top of machine

in the control cabinet.

2. The electrician must connect the incoming power based on the information

that is stamped on the Machine Electrical Connection Plate.

3. Any change to the Machine Electrical Connection Plate must be approved

by the factory in advance.

4. The dishwasher main power terminal block is located inside the top-mounted

control cabinet.

5. A knock-out plug is provided at the rear of the control cabinet for electrical

service connections.

6. Electric blower-dryers have a separate main power connection.

4

Installation

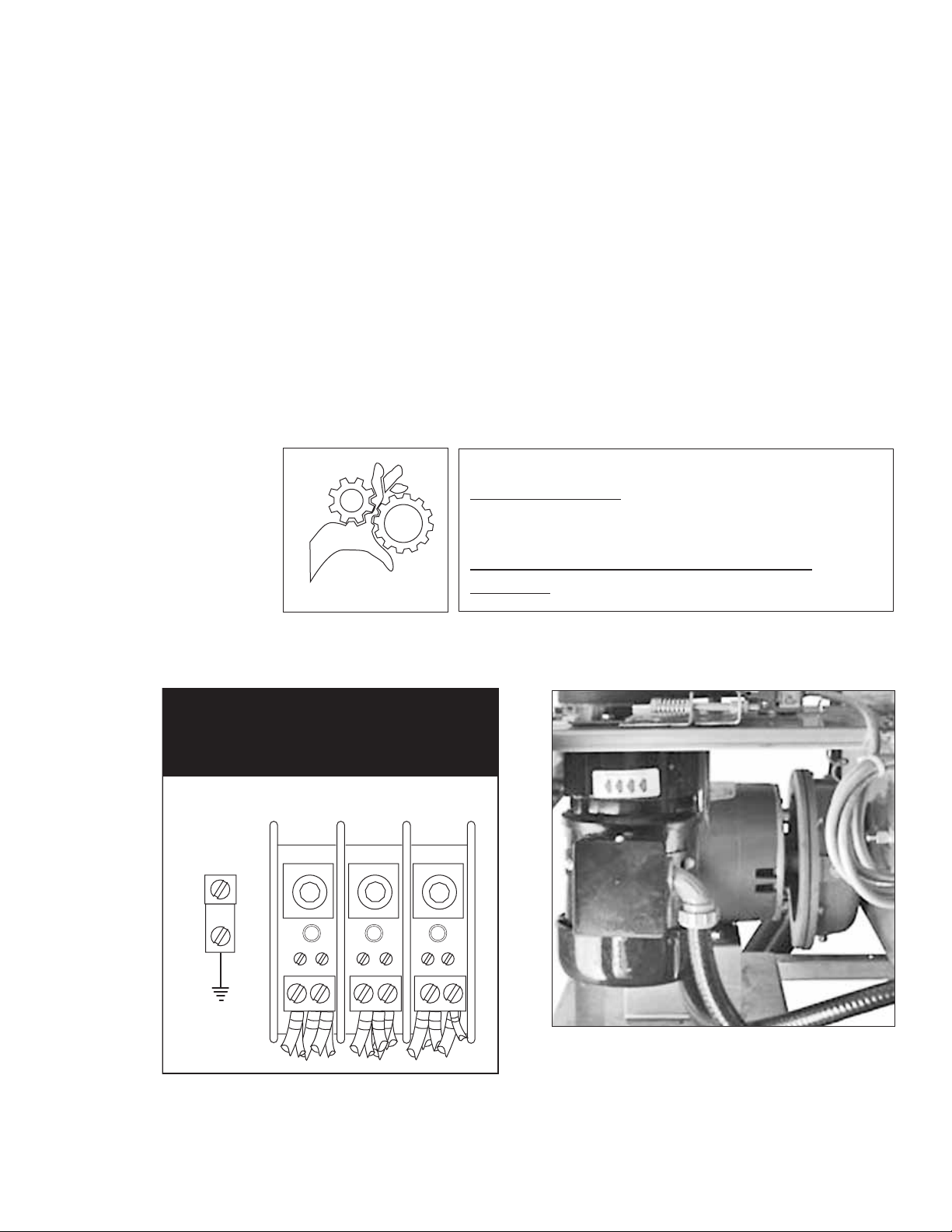

Electrical Connections (continued)

Motor Rotation

1. Motor rotation was set at the factory.

2. The conveyor drive motor rotation is indicated by a red arrow located on the side of

the motor.

3. Check if all motors are running in the wrong direction.

4. Reverse the L1 and L2 wires on the output side of the dishwasher Main Terminal

Block (MTB) located inside the top-mounted control cabinet.

5. The photograph below shows the conveyor drive motor with its direction arrow.

6. A wash pump/motor assembly can be seen in the background of the photo.

WARNING:

Moving Conveyor Parts may cause INJURY OR DEATH.

Keep hands and clothing clear of the conveyor when the

conveyor is moving.

THREE PHASE

POWER CONNECTION

LINE IN

L1 L2 L3

GRD

USE EXTREME CAUTION WHEN THE CONVEYOR

IS MOVING.

Main Terminal Block Inside the Top-mounted Control

Cabinet.

Motor Direction Rotation Label on Motor Frame.

5

Installation

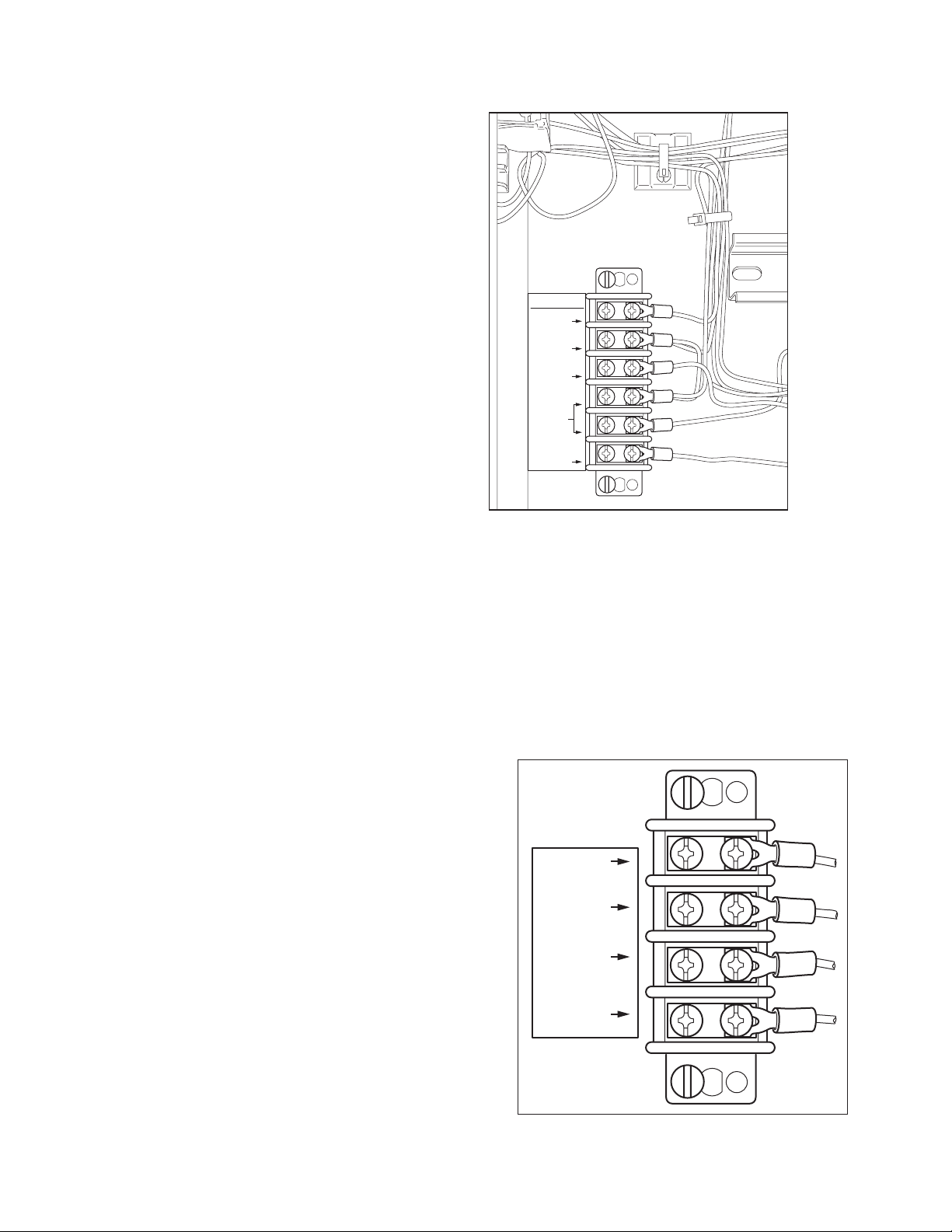

Chemical Signal Connections

1. Use a qualified detergent/chemical supplier

for detergent/chemical and dispensing

equipment needs.

2. Labeled detergent control circuit connection

terminals are provided in the control cabinet

for detergent and rinse agent/sanitizer

dispensing equipment (supplied by others).

3. The illustration at right, shows the

terminal board for the machine.

4. The signal connection points include:

•Detergentsignal120VAC,1Amaxload.

•Rinseaid/Sanitizersignal120VAC,1Aload.

5. A removable black plug is provided in the

load end side of the wash tank for installation

of the detergent conductivity cell.

SIGNAL ONLY

VENT FAN

120V

COMMON

RINSE AID

120V

COMMON

DETERGENT

120V

Vent Fan Signal Connection

NOTE:

The Vent Fan Signal Connection supplies 120VAC to a control relay (supplied by others)

when the dishwasher is ON and O VAC when the dishwasher is OFF. Power to operate

the vent fan (supplied by others) must be supplied separately.

6. The Vent Fan signal connection point is located

on the same terminal board as the chemical

connections (see illustration above). The

connection is:

•VentFan120VAC,1Ampmaxampload

Running Signal and

Table Limit Switch Connections

7. Connections are provided for systems that

require a signal to indicate the dishwasher

is running.

8. A signal connection is provided to indicate

that the dishwasher has stopped due to a

conveyor jam or when the clean dish table

is full of racks and additional racks cannot

exit the machine.

9. The table limit switch option installation is

recommended for all dishwashers and can be

ordered from the factory by P/N 407400.

6

SIGNAL ONLY

MACHINE

RUNNING

TABLE

LIMIT

SWITCH

Installation

Long Curtain

Long Curtain

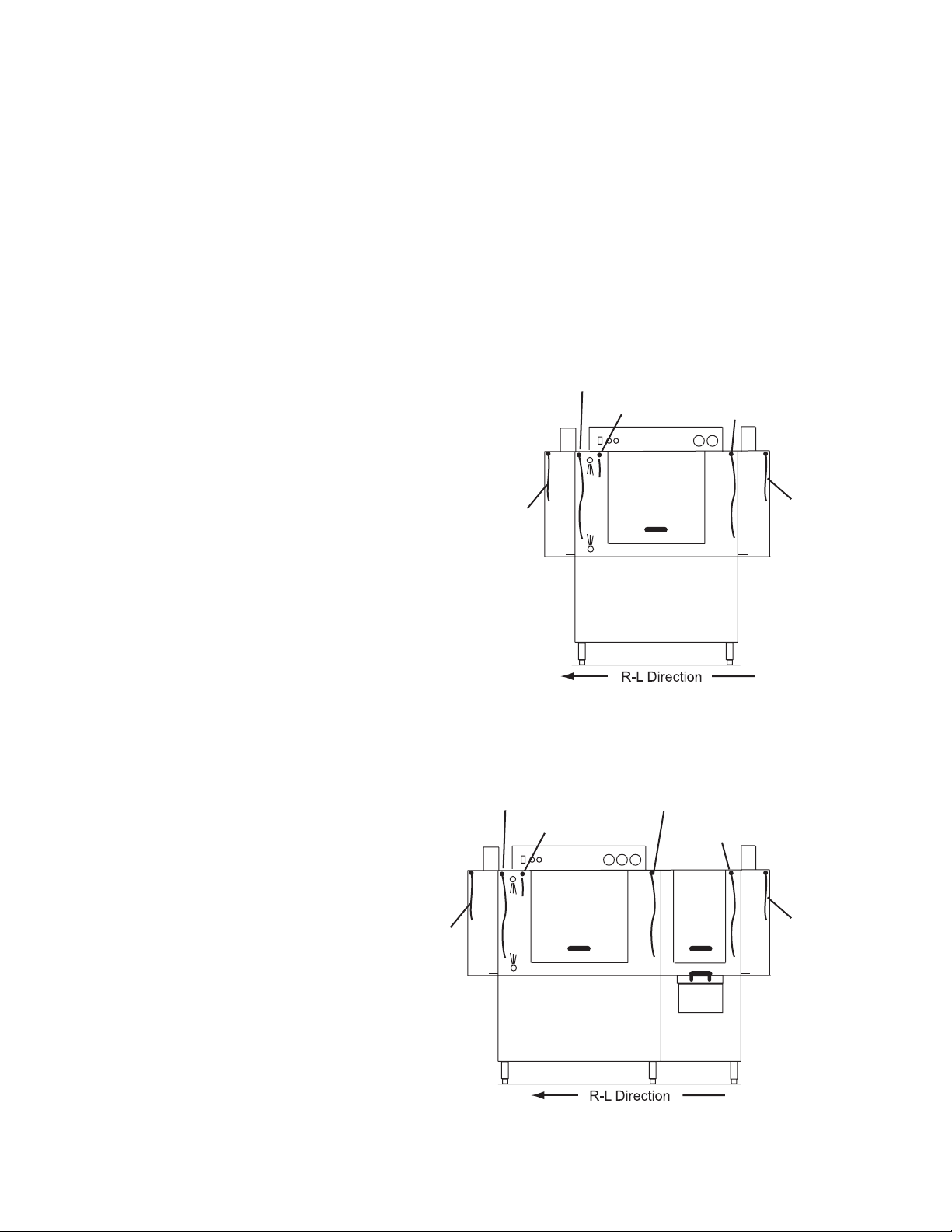

Curtain Locations

1. Refer to the illustrations below and hang the curtains as shown.

J-hooks are located in the corners of each section to accept the curtain rods.

• Standardlongcurtains 24"x20-1/4"

• Standardmediumcurtains 24"x13-/14"

• Standardshortcurtain 24"x6-1/4"

2. Make sure the that the short flaps of the curtains face the load end of the dishwasher.

Medium Curtain

NOTE:

Misplacing a curtain or failing to

install a curtain will adversely affect

the proper operation of the machine.

Short Curtain

Short Curtain

Wash

Long Curtain

Long Curtain

Medium Curtain

Long Curtain

Medium Curtain

Medium Curtain

Wash Prewash

7

Installation

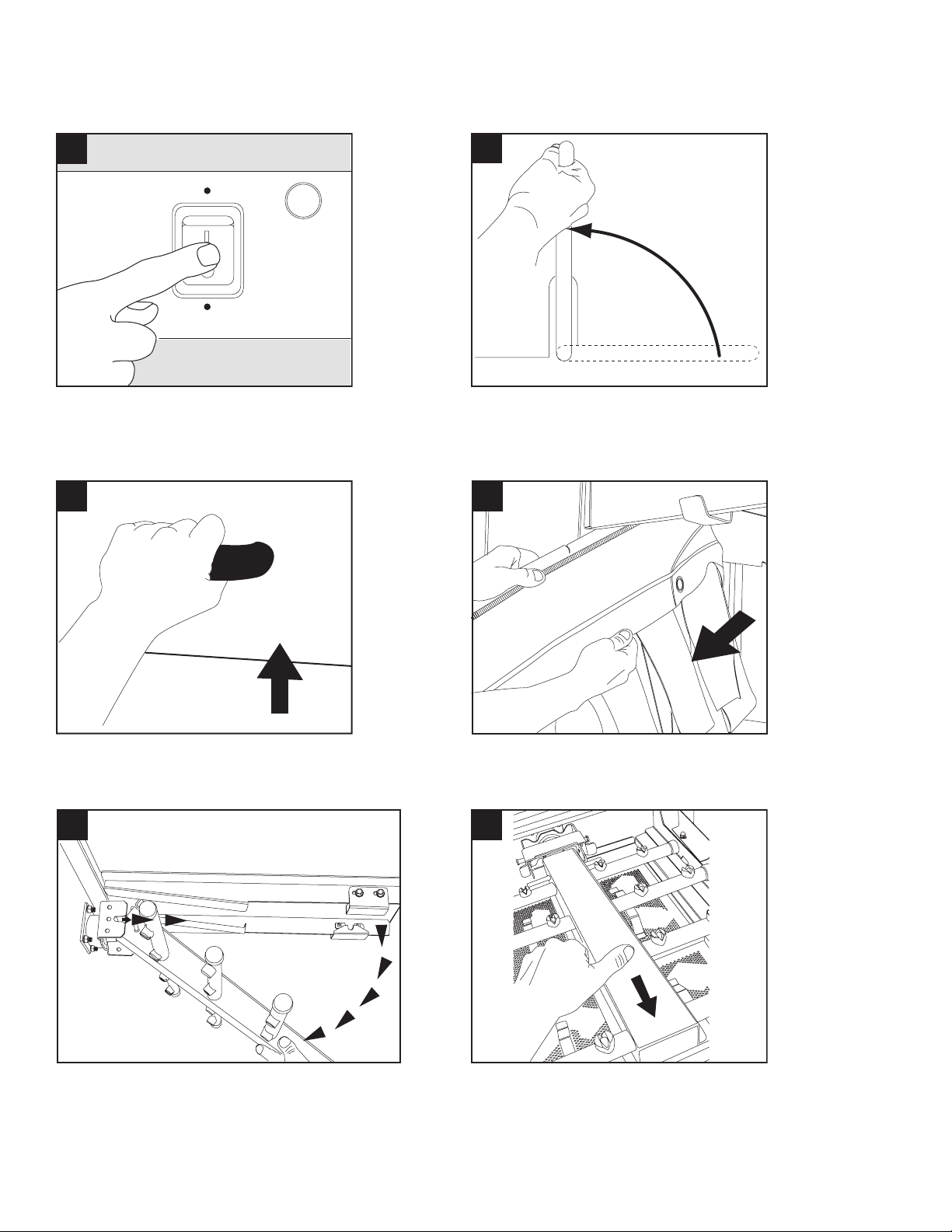

Door Safety Switches

Dishwasher access doors are equipped with a door safety switch that automatically

stops the dishwasher pumps and conveyor drive if a door is raised while the dishwasher

is running. In addition, the dishwasher will not start if a door is left open.

1. If the dishwasher is running and a door is raised, then lighted GREEN START

pushbutton goes out and the pumps and conveyor drive stop.

2. Check the interior of the dishwasher for any dish racks still in the machine.

These dish racks must be washed again to ensure they are washed and sanitized

completely.

3. To restart the dishwasher, make sure all doors are closed, then push the GREEN

START pushbutton.

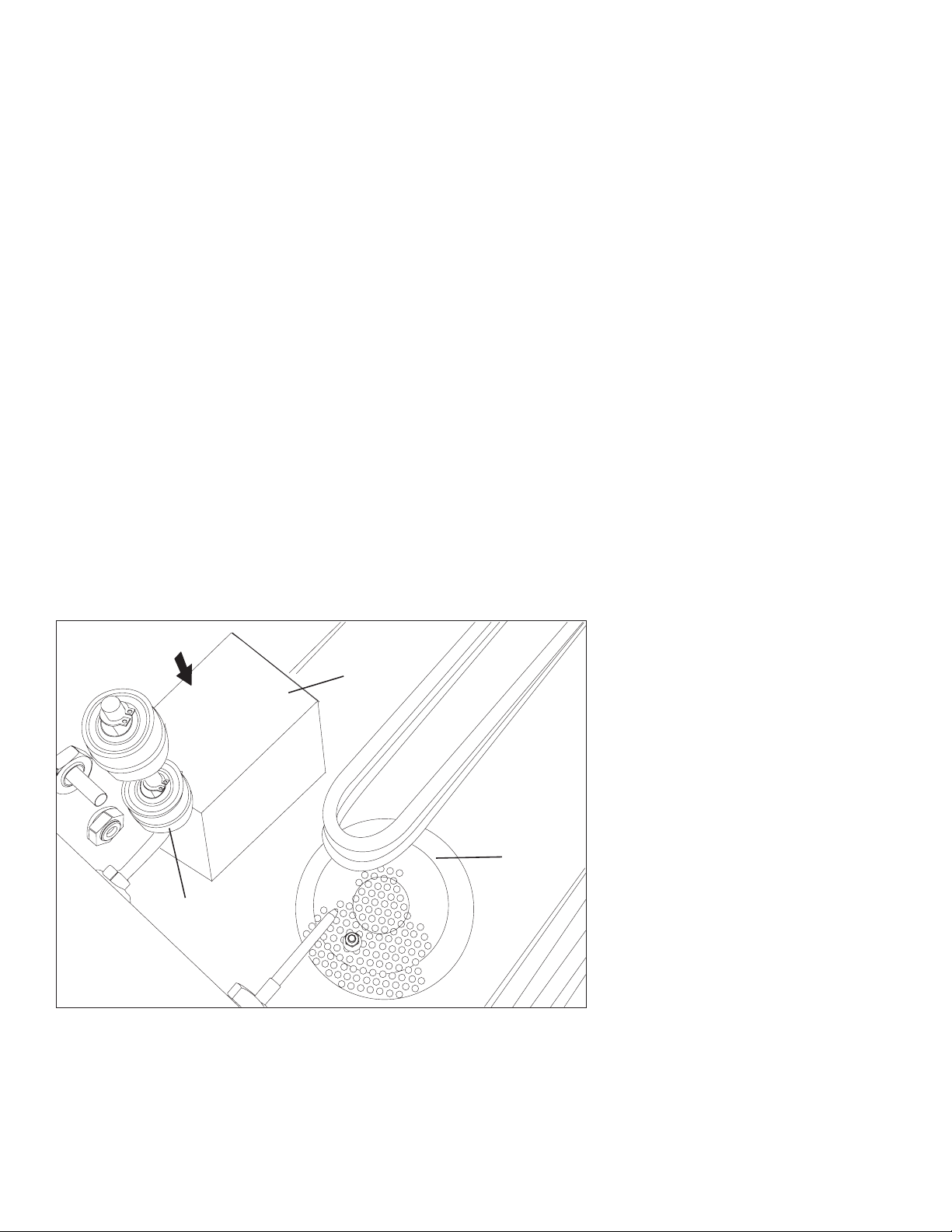

Pump Intake Screen and Dual Float Switch

Refer to the illustration below and note the location of the pump intake screen and dual float

switch.

1. Make sure the pump intake screen is installed by sliding it on the bracket located in front

of the wash pump intake.

2. Make sure the float balls on the dual float switch move freely on the float stem.

3. Check the interior of the tank for any foreign objects and make sure the drain screen is

clean.

Pump Intake

Screen

Drain

Screen

Dual Float

Switch

Make sure tank is clean, the pump intake screen is installed and the dual float switch

moves freely.

8

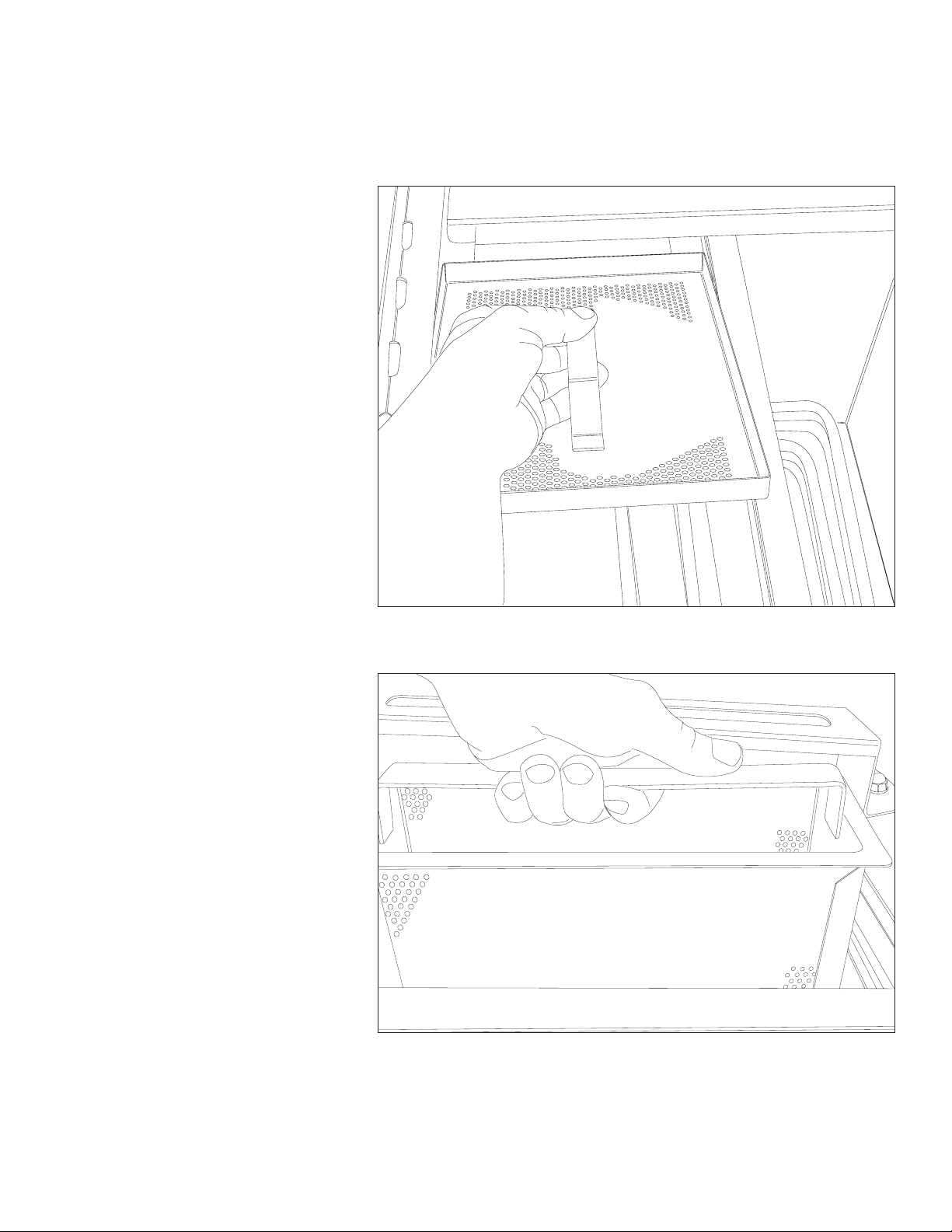

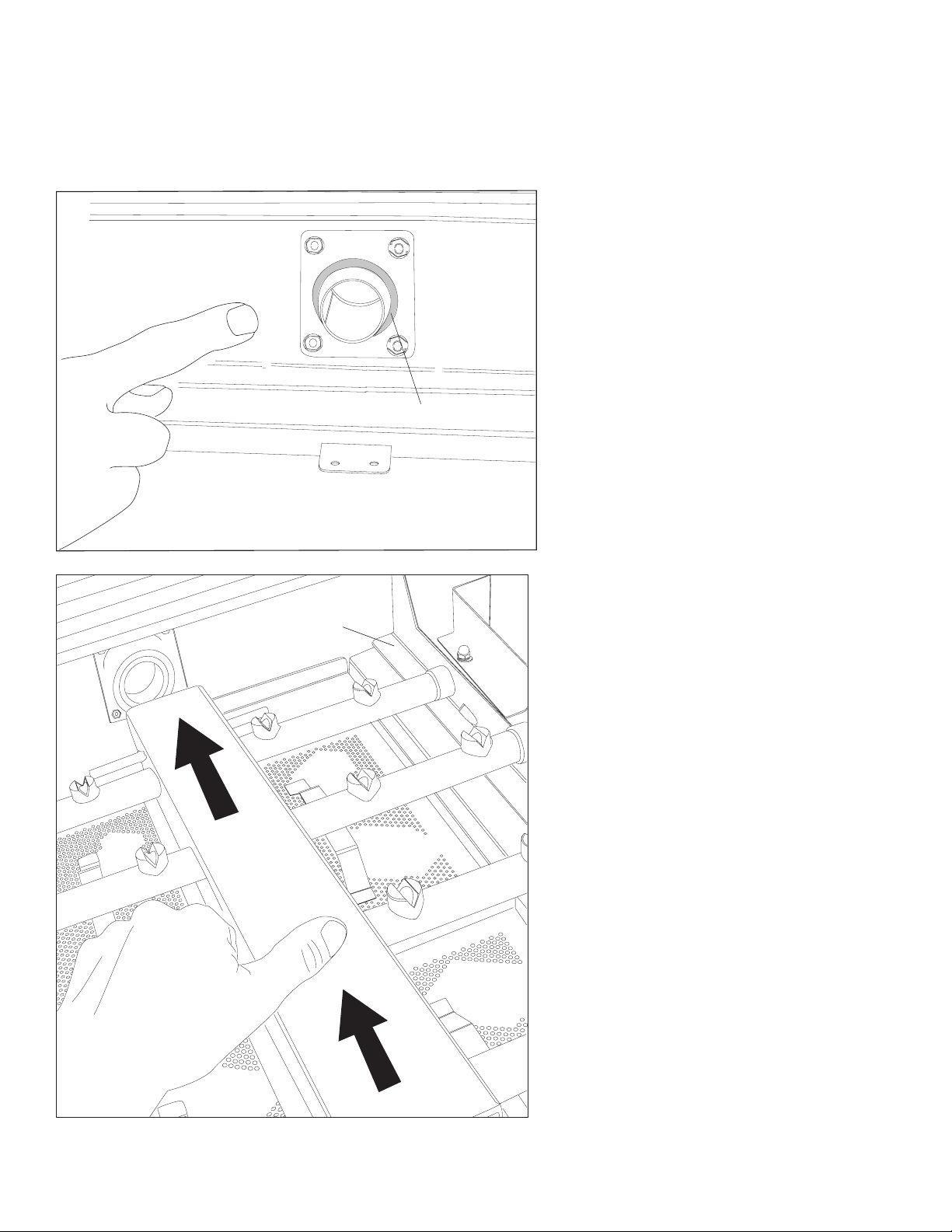

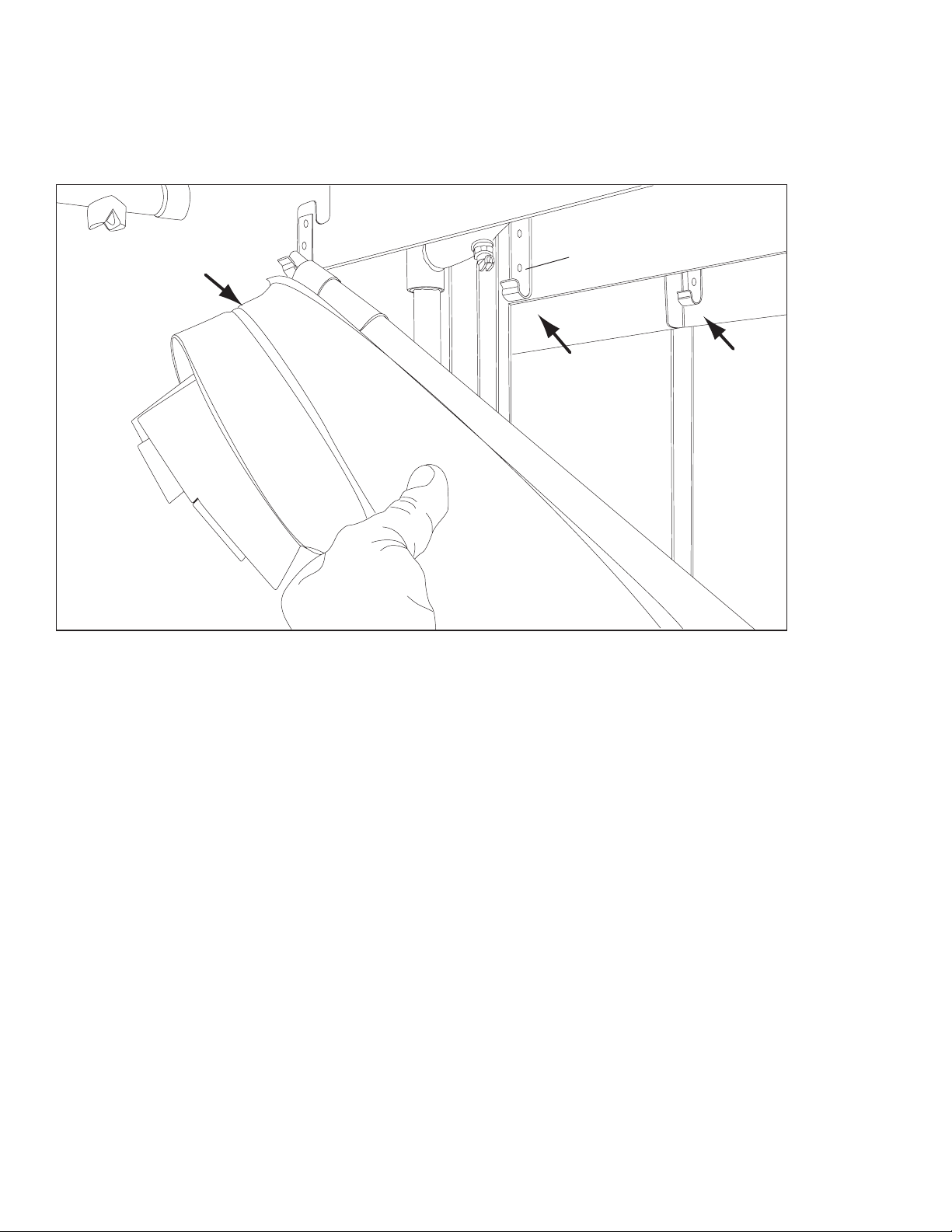

1. All models have scrap

screens in the top of the

wash tank.

Install four scrap screens in

the wash tank making sure

they fit securely without large

gaps between them.

Installation

Scrap Screens

2. The model CH-66 and the

MD-66 has a prewash tank

containing a single large

scrap screen which extends

from front to back in the

prewash tank.

The prewash screen also

holds a refuse basket to

facillitate cleaning when

the machine is off.

Install the large scrap screen

making sure the screen fits

securely in the front and back

of the tank then install the

refuse basket as shown in

the illustration to the right.

Never remove the prewash

scrap screen while the dishwasher is running.

All models have four scrap screens in the wash tank.

Model CH-66 and MD-66 has a scrap screen and refuse basket located in the

prewash tank.

9

Installation

Spray Arm O-ring

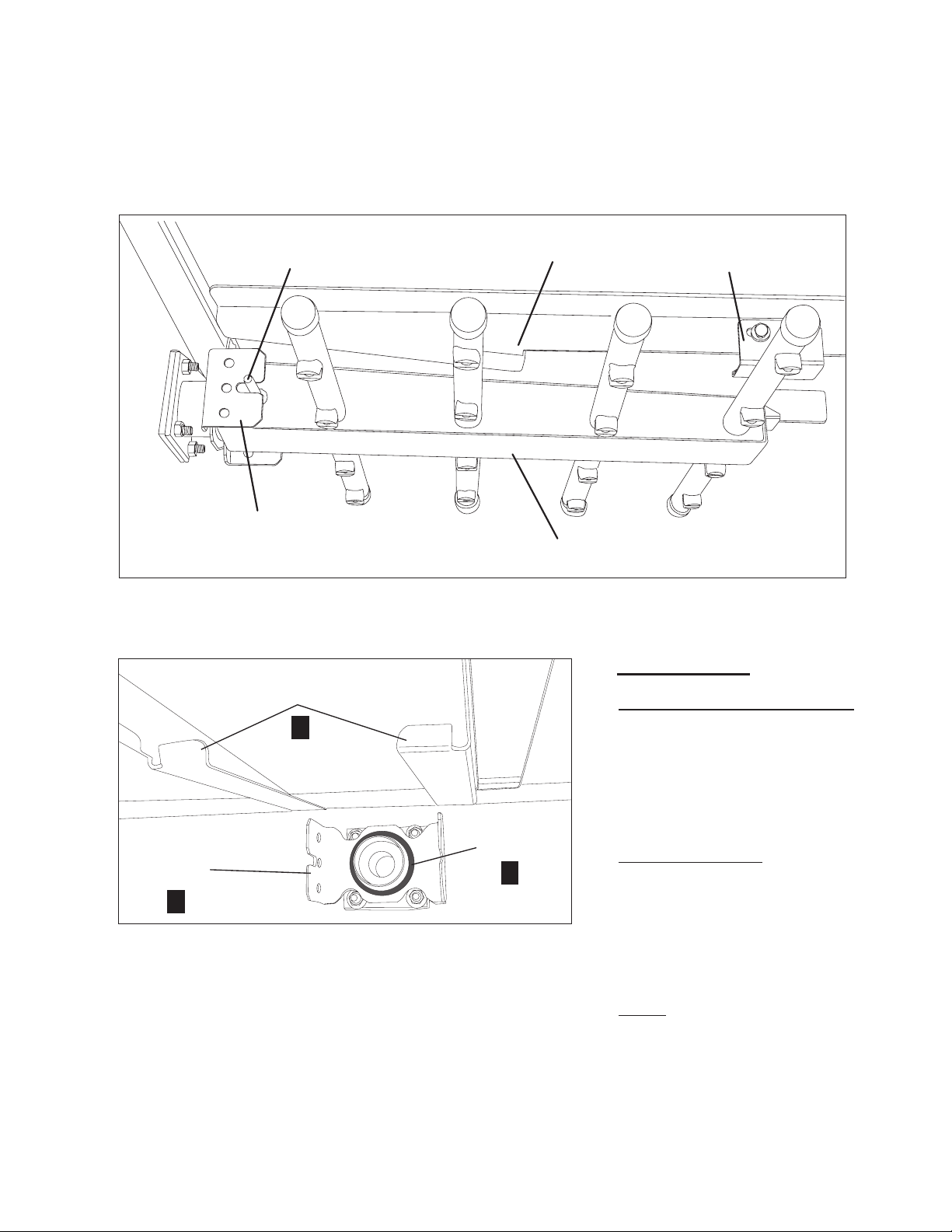

Installing the Lower Spray arm Assembly

1. The lower spray arm assembly is

connected to the rear wall of the

wash tank.

2. The spray arm o-ring makes a

water-tight seal when the spray

arm is properly seated.

Spray Arm Guide

3. Slide the lower arm into place

making sure the spray arm is

fully back and contacting the

spray arm o-ring.

4. The spray pipes are supported on

each side by the spray arm

guides and will lock the spray arm

securely in place.

10

Installation

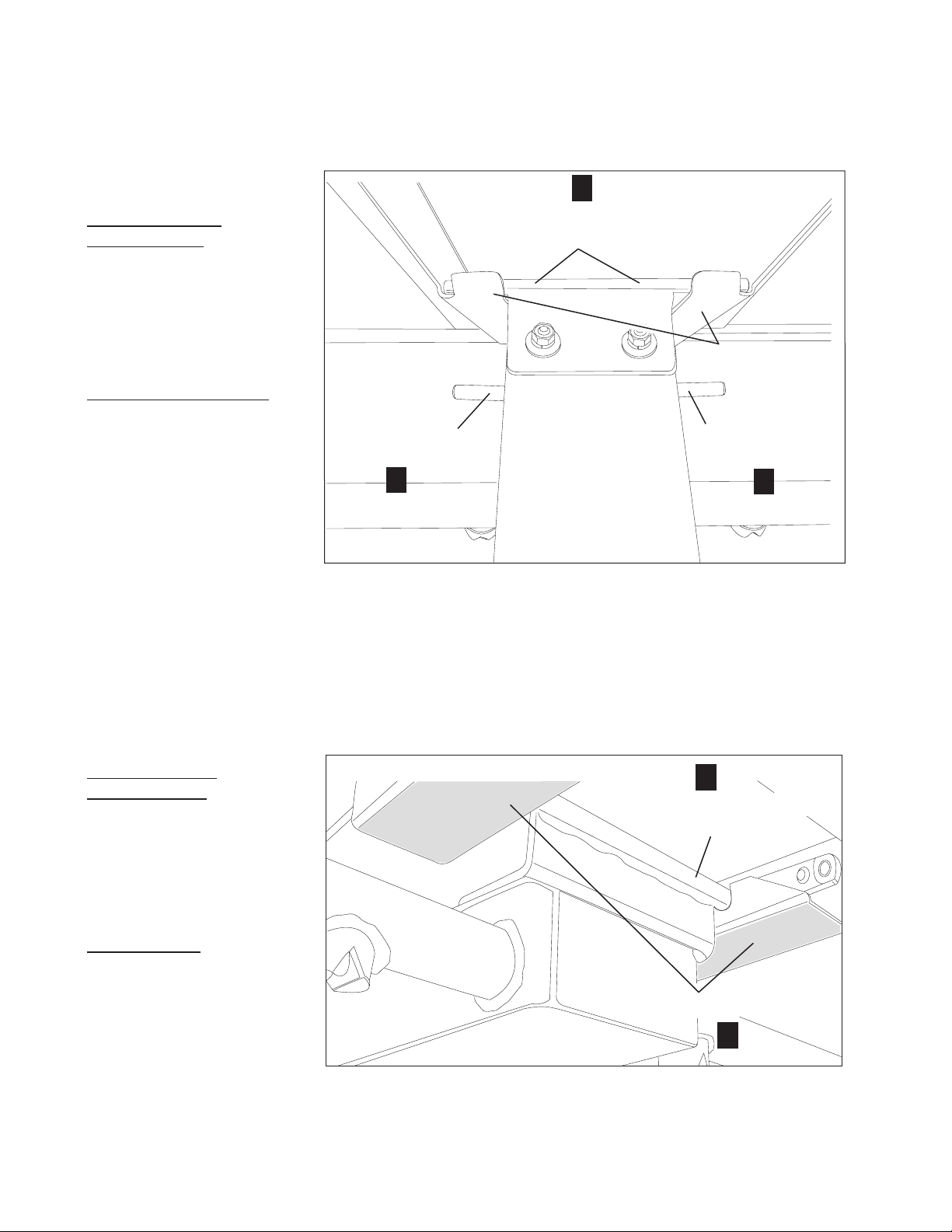

Installing the Upper Spray Arm Assembly

The upper wash arm assembly is suspended from the top of the dishwasher hood interior

by front and rear supports. Follow the instructions and illustrations below to install the

upper wash arm assembly.

Wash Arm Connection

Flange Pin

Rear Support

Front Support

Connection

Flange

Upper wash arm assembly shown installed.

(Note that the Wash Arm Connection Flange Pin is seated in the Connection Flange.)

Upper Wash Arm

Rear Support

1

Connection

Flange

2

Make sure the upper spray arm o-ring is in good condition and fits

securely in the connection flange before installing the upper

wash arm assembly.

Upper Wash Arm Assembly

O-ring

3

Components

1. Upper Wash Arm Rear Support

The rear support holds the wash

arm and serves as a guide when

the upper wash arm is pushed

to the toward the connection

flange at the rear of the

dishwasher.

2. Connection Flange

The connection flange holds the

wash arm securely in place when

the upper wash arm is placed in

position. In addition, the

connection flange holds the wash

arm o-ring in position.

3. O-ring

The wash arm o-ring rests in the

center of the connection flange

and forms a water-tight seal when

the upper wash arm is in place.

11

Installation

Upper Wash Arm

Upper Wash Arm

Rear Guide Pin

Connection

Flange Pin

Connection

Flange Pin

Rear Suppor

t

4

5

5

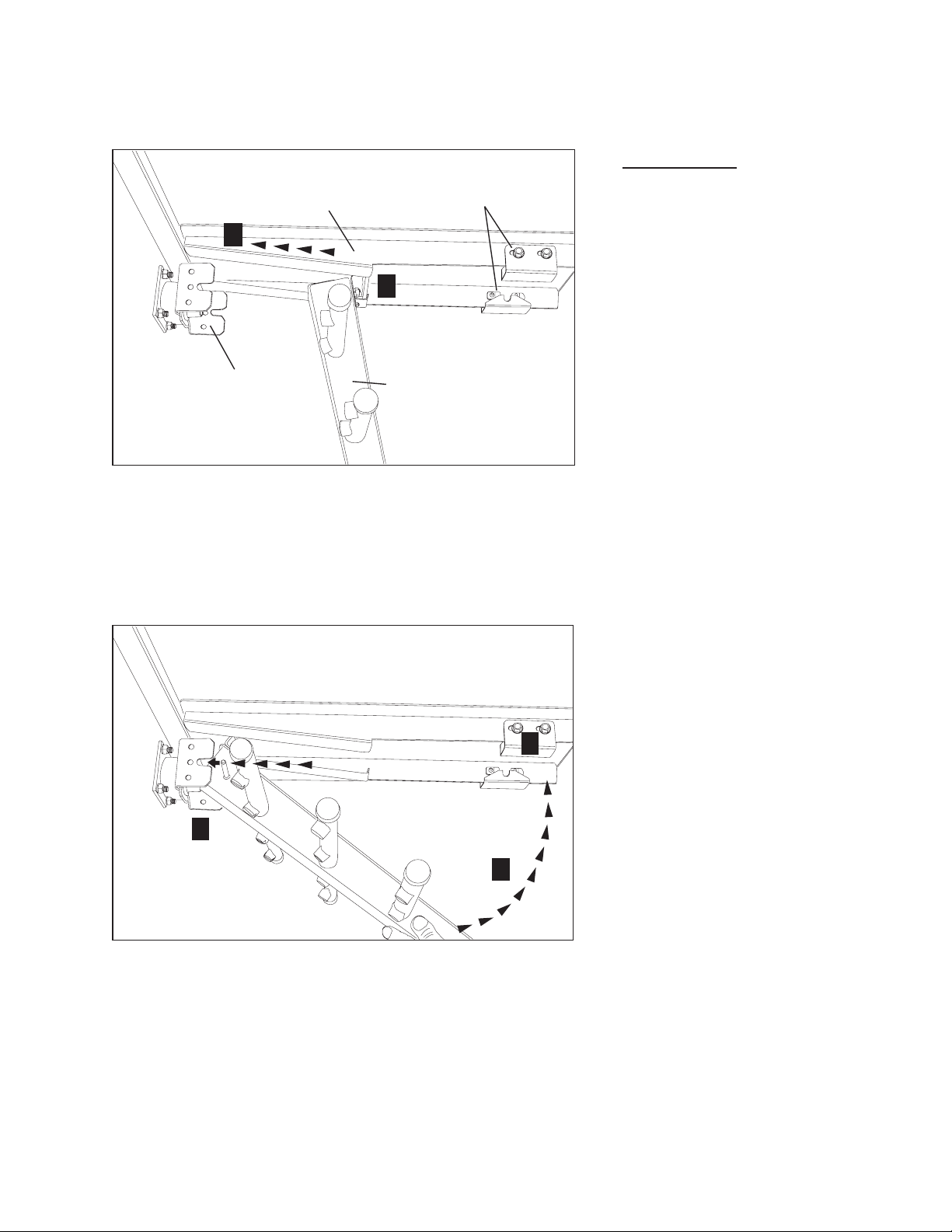

Installing the Upper Spray Arm Assembly (continued)

1. Upper Wash Arm

Rear Guide Pin

The rear guide pin is

attached to the rear of

the upper wash arm. It

mates with the upper

wash arm rear support.

2. Connection Flange Pins

The connection flange

pins are welded to the

sides of the upper wash

arm. These pins mate

with two slots in the

connection flange to

hold the wash arm in

place when installed.

The upper wash arm is shown with the rear guide pin placed on the rear support

before sliding the upper wash arm into position.

3. Upper Wash Arm

Front Guide Pin

The front guide pin is

attached to the front

of the upper wash arm.

It mates with the front

supports.

4. Front Supports

There are two fronts

supports which hold

the front of the upper

wash arm in place when

the wash arm is installed.

12

The upper wash arm is shown with the front guide pin resting in the front supports.

Upper Wash Arm

6

Upper Wash Arm Front

Guide Pin

Front Supports

7

Installing the Upper Spray Arm Assembly

Upper Wash Arm

Rear Support

2

Connection Flange

The upper wash arm assembly is shown resting on the

upper wash arm rear support as it slides toward the connection flange.

Upper Wash Arm

Front Supports

1

Upper Wash Arm Assembly

Installation

Installation

1. Open the dishwasher access

doors and check the location

and condition of the connection

flange o-ring. Replace the

o-ring if it is worn or damaged.

Place the upper wash arm rear

guide pin in the rear support so

the wash arm hangs in the

support.

2. Slide the upper wash

arm toward the rear of the

dishwasher making sure the

rear guide pin is centered in

the rear supports.

5

3

4

The upper wash arm assembly is shown resting on the

upper wash arm rear support as it slides toward the connection flange.

3. Raise the front of the wash

arm so the connection flange

pin mates with the connection

flange pin slots.

4. Swing the front of the wash

arm up toward the front of the

dishwasher.

The wash arm front guide pin

should be positioned close to

the door opening and before

the front wash arm supports.

5. Slide the upper wash arm

forward as far as it will go

making sure that the front

guide pin is above the front

support notched cut-out.

Lower the upper wash arm so

the front guide pin seats

securely in the front support

notch. Installation is complete.

13

Installation

Installing the Curtains

Short Curtain

J-hook

Long

Curtain

Curtain Installation Shown at the Final Rinse End of the Dishwasher

1. Curtain are equipped with curtain rods. The rods are hung on J-hooks located in

the top of the dishwasher.

2. Make sure that the short flaps on the curtains face the load end of the dishwasher.

Medium

Curtain

3. Refer to page 7, Curtain Locations, for additional information on curtain placement.

14

Check List

1. Remove white protective film from the dishwasher exterior.

2. Install lower panels to the dishwasher.

3. Remove any foreign material from inside of the machine.

4. Check dishwasher drain/overflows are closed and in securely seated.

5. Install scrap screens, spray arms.

6. Turn main utilities to the dishwasher ON. (Power, water).

7. Make sure doors are closed.

8. Turn dishwasher power switch ON. Machine fills with water and tank heat

comes on.

9. Check tank water temperatures reach proper levels.

10. Check for leaks.

11. Push the Start button. Green light comes on.

12. Insert an empty dish rack into the load end of the dishwasher.

The pumps and conveyor will run.

Installation

13. Allow the dish rack to travel to the unload end of the dishwasher. The final rinse

will run.

14. Allow the rack to exit the dishwasher. The dishwasher should have run for

90 seconds.

15. Place another dish rack in the machine to start another cycle.

16. Open each dishwasher door to make sure the safety switch stops the conveyor.

17. Immediately close the door, the dishwasher should restart.

18. Open the door and leave it open for 5 minutes. The machine should stop.

Push the Start button and the machine should restart when a rack is inserted into

the machine.

19. Push the Stop button when the machine is running and the dishwasher should stop.

20. Push the dishwasher Power Switch OFF. The dishwasher should shut down.

21. Drain the dishwasher and check that floor drains handle the water volume leaving

the dishwasher.

NOTE:

If the drain valve is open when the dishwasher is filling, the machine will

fill for 10 minutes, then the machine will shut-down and the green light

will blink on and off. Flip the dishwasher power switch off and close the

drain valve. Flip the power switch on and fill the machine.

15

Initial Start-Up

20-22 PSI

160°F/71°C

180-195°F

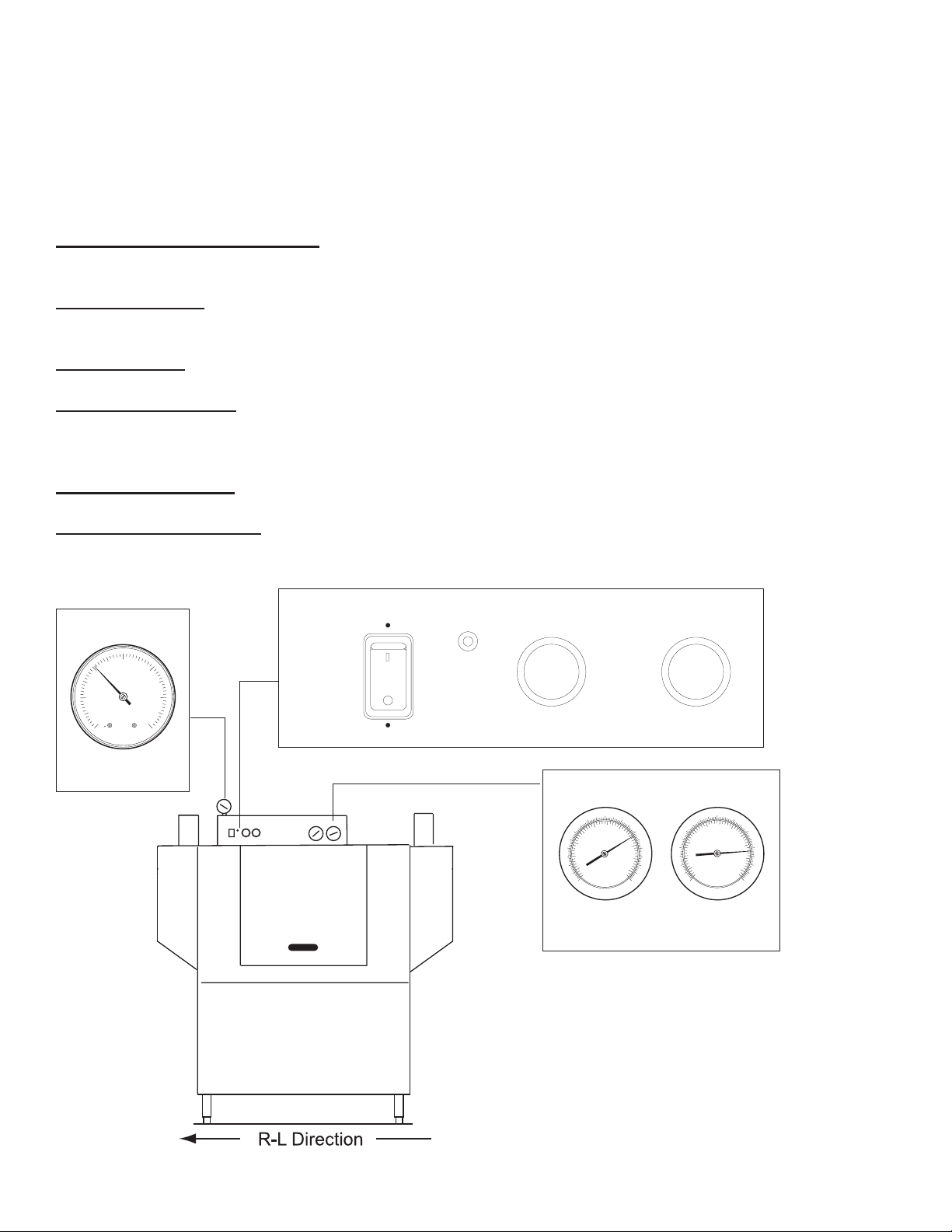

Control Panel Operation - CH-44, CH-66

The final rinse pressure gauge is located behind the control panel. The top-mounted control panel

contains the Power ON/OFF switch, start push button, stop push button, and the water temperature

gauges for the wash tank and the final rinse. The function of these controls are:

A Final Rinse Pressure Gauge - Indicates the flowing water pressure during the final rinse.

Proper reading is 20-22 PSI.

B Power Switch - Turns power on and off to the dishwasher. The machine fills

automatically when the power is turned on.

C Cycle Light - Indicates when the dishwasher is ready for automatic operation.

D Start Push button - Pushing the Start push button sets the machine for automatic

operation. The conveyor and pumps start when a dish rack is

inserted into the machine.

E Stop Push button - Pushing the Stop push button stops the conveyor and pumps.

F Temperature Gauges - Temperature gauges indicate the water temperature in the wash

tank.The final rinse water temperature is indicated during the final

rinse.

ON

OFF

C

D

START

40

120

100

40

80

20

60

0

20

Wash

Temperature

E

STOP

82-91°C

120

140

160

60

180

80

100

60

40

200

220

100

40

80

20

0

20

Final Rinse

Temperature

140

160

60

180

80

100

200

220

A

30

20

PSI

10

CHAMPION INDUSTRIES, INC.

WINSTON-SALEM,NC

0

Final Rinse

Pressure

B

40

50

60

POWER

F

16

Model CH-44 Shown

Operation

20-22 PSI

160°F/71°C

180-195°F

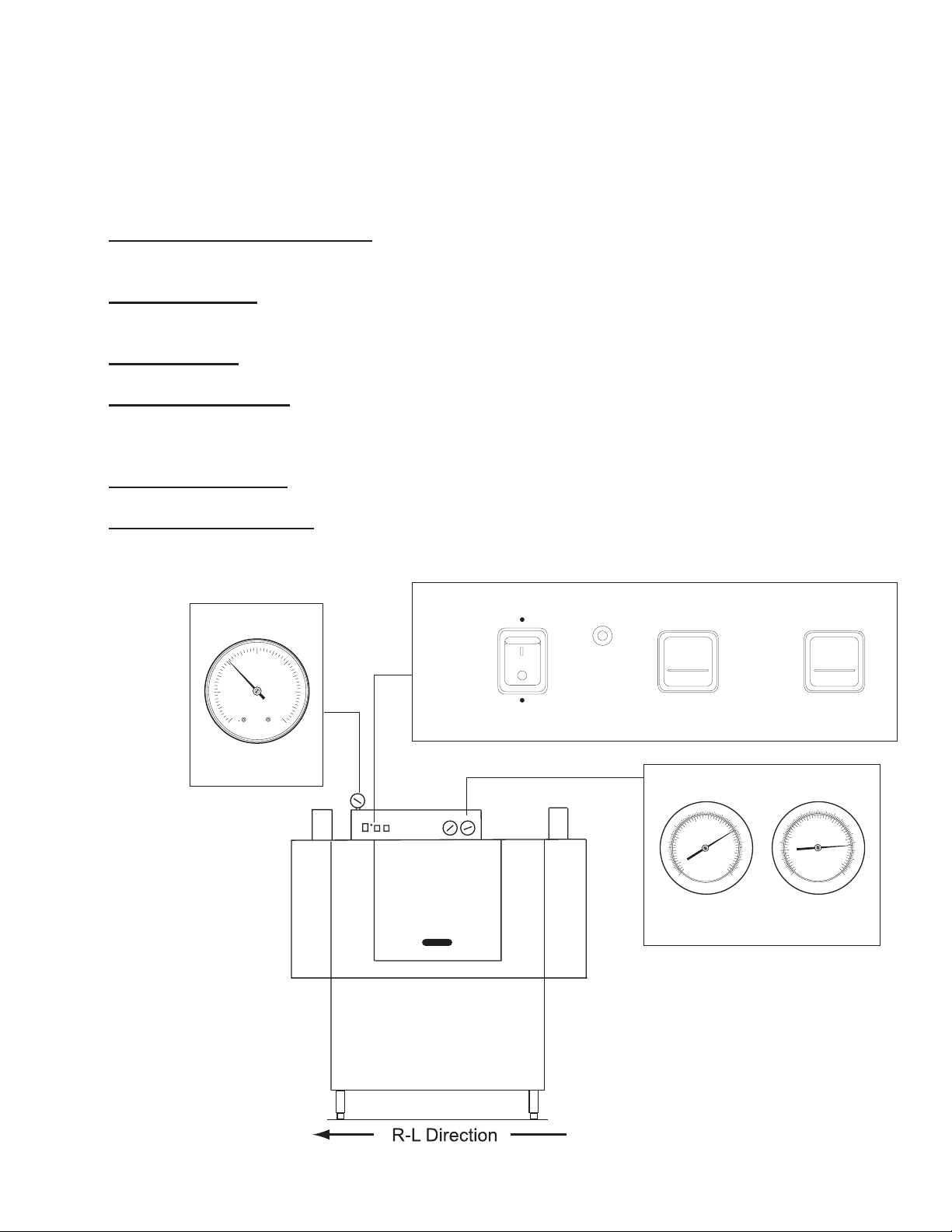

MD-44, MD-66 - Control Panel Operation

The final rinse pressure gauge is located behind the control panel. The top-mounted control panel

contains the Power ON/OFF switch, start push button, stop push button, and the water temperature

gauges for the wash tank and the final rinse. The function of these controls are:

A Final Rinse Pressure Gauge - Indicates the flowing water pressure during the final rinse.

Proper reading is 20-22 PSI.

B Power Switch - Turns power on and off to the dishwasher. The machine fills

automatically when the power is turned on.

C Cycle Light - Indicates when the dishwasher is ready for automatic operation.

D Start Push button - Pushing the Start push button sets the machine for automatic

operation. The conveyor and pumps start when a dish rack is

inserted into the machine.

E Stop Push button - Pushing the Stop push button stops the conveyor and pumps.

F Temperature Gauges - Temperature gauges indicate the water temperature in the wash

tank.The final rinse water temperature is indicated during the final

rinse.

ON

OFF

C

D

START

100

40

80

20

60

40

0

20

Wash

Temperature

E

STOP

82-91°C

120

140

160

60

180

80

100

200

220

100

80

20

60

40

0

20

Final Rinse

Temperature

120

140

160

40

60

180

80

100

200

220

A

30

20

PSI

10

CHAMPION INDUSTRIES, INC.

WINSTON-SALEM,NC

0

Final Rinse

Pressure

B

40

50

60

POWER

F

Model MD-44 Shown

17

Operation

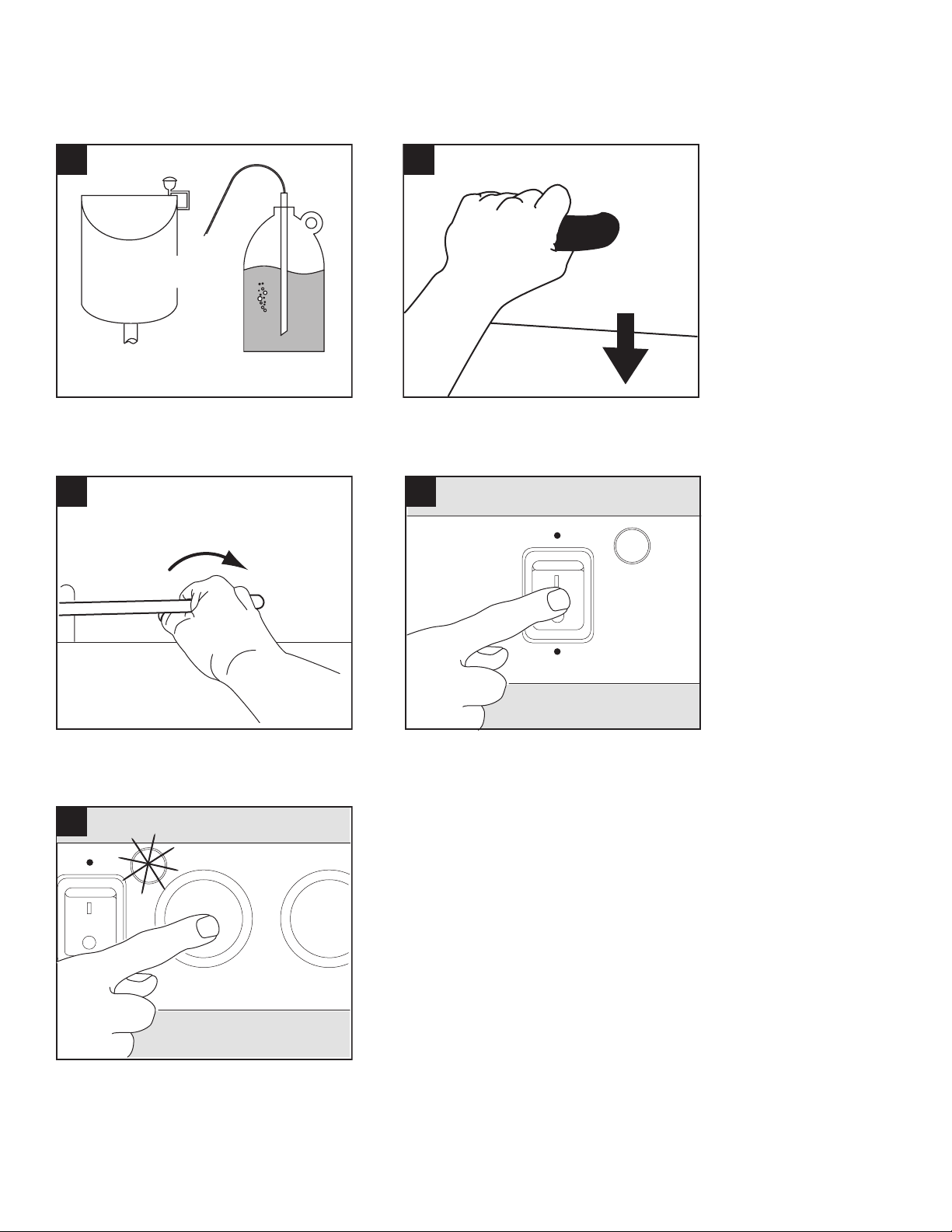

Operation

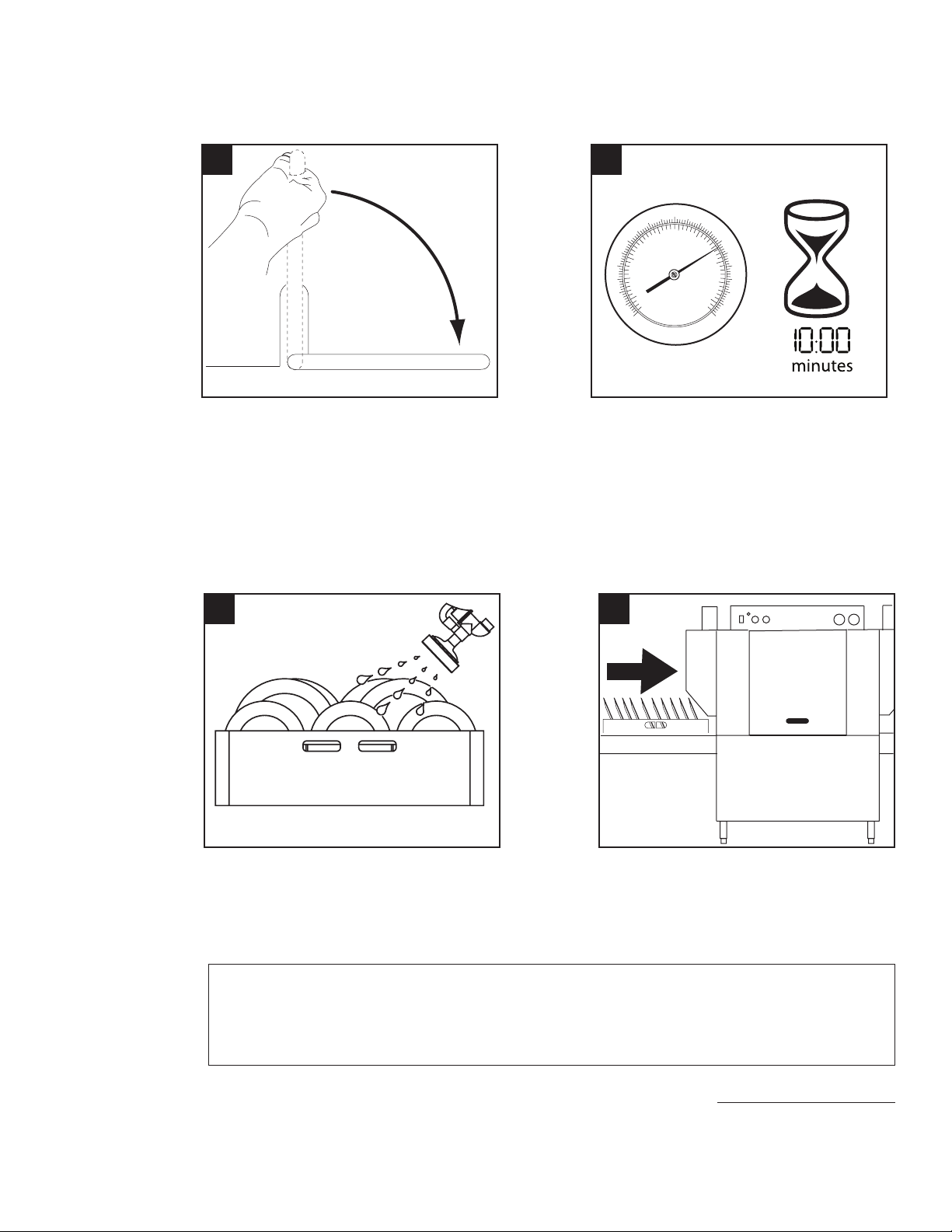

1

Detergent

Rinse-aid

Check the chemical containers and

rell as necessary.

3

2

Close the doors.

4

ON

POWER

Turn drain handle clockwise to close

the drains.

5

ON

START

Push START switch. The green light

illuminates. The machine lls with

water and the tank heat comes on.

STOP

OFF

Flip power switch UP to the ON

position.

18

Operation

Operation

6

Open

Closed

If the drain is open or the ll runs for more

10 minutes then the dishwasher shuts down

& the green light blinks on and o. Close the

drain or check the ll, then push the power

switch o and back on to reset. Push the

Start switch to restart operation.

8

7

160°F/71°C

120

40

Wash

140

160

60

180

80

100

200

220

100

80

20

60

40

0

20

Temperature

Wait 10 minutes for the wash gauge to

indicate 160°F/71°C.

9

Prescrap & load wares into dish racks.

Plates and glasses go in peg rack, cups

and bowls go in a at rack. Place

Insert a dish rack of wares into the

dishwasher. The pumps and conveyor

will run.

silverware in a single layer in at rack.

NOTE:

Opening a door will stop the pumps and drive. If the door is closed within 5 minutes the

machine will resume operation where it left off. After 5 minutes the START switch must

be pressed and a dish rack inserted into the machine for normal operation.

continued on next page

19

Operation

Operation (continued)

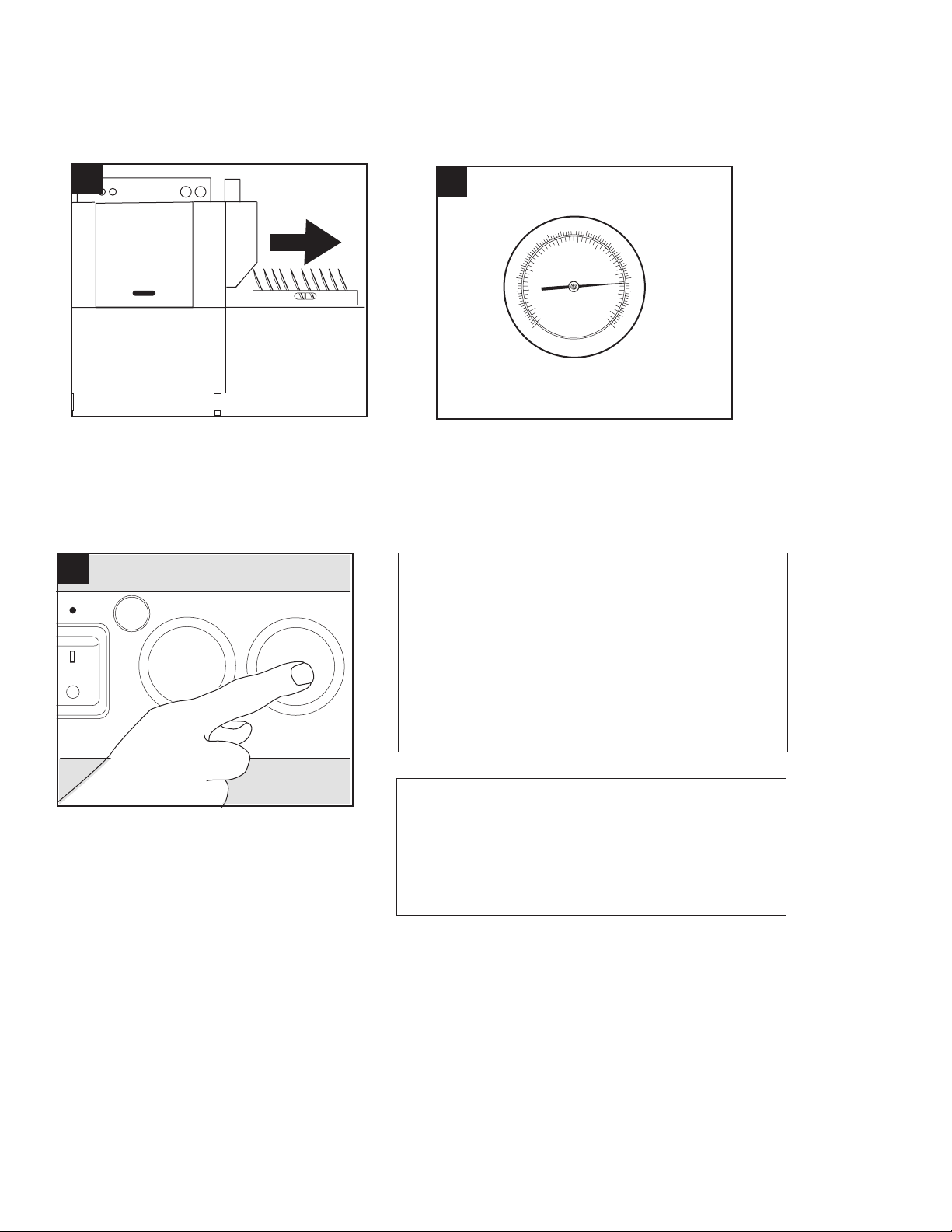

10

The dishwasher pumps and drive runs

90 seconds after the rack enters the machine. Loading additional racks before the

rst rack exits the machine resets the timer.

12

ON

STOP

11

180-195°F

82-91°C

120

100

80

20

60

40

0

20

140

40

160

60

180

80

100

200

220

Final Rinse

Temperature

Check the nal rinse temperature during

the nal rinse cycle to ensure the gauge

indicates 180-195ºF/82-91ºC.

NOTE:

In the event of a conveyor jam or a tripped table

limit switch, the dishwasher pumps and drive will

stop. The operator should check the conveyor

for articles stuck in the drive or in the case of

the table limit switch, remove dish racks from

the clean-end table. The START switch must

be pressed and a dish rack inserted into the

machine to resume normal operation.

Push the STOP switch to stop the pumps

and the drive. The green light goes out.

Push the START switch and insert a dish

rack to restart operation.

20

NOTE:

To shut the dishwasher down, press the stop

button. Flip the POWER switch down to the OFF

position. Open the doors and remove any dish

racks left in the machine. Open the drain to

drain the water from the tanks.

Cleaning

Cleaning

Cleaning your dishwasher is the best maintenance you can do.The cleaning intervals below are the

minimum requirements for most dishwashers.You may need to clean your dishwasher more

often when washing heavily soiled wares or during long periods of continuous operation.

Daily or every 2 hours of operation

1. Turn power switch to OFF.

2. Pull drain lever(s) to drain water. Remove scrap screens and scrap baskets.

Clean inside of the tanks and flush with clean water.

Back flush the scrap screens until clean.

DO NOT STRIKE SCREENS OR BASKETS AGAINST SOLID OBJECTS

3. Remove the spray arm assemblies. Remove the end cap from each spray arm.

4. Flush the spray arms and nozzles to remove any debris.

5. Replace the end caps. Check the condition of the manifold O-ring.

6. Reinstall the spray arms.

7. Remove and clean the curtains. Allow them to dry at the end of the day.

8. Leave the doors open between operations, allowing the machine to dry.

9. Make sure that the final rinse nozzles are clear of mineral deposits.

10. Straighten a metal paper clip to clean the nozzles.

11. Check the temperature and pressure gauge readings during operation.

12. Inspect the machine for signs of water leaks.

13. Check the chemical supplies and refill as necessary.

At the End of the Day

1. Perform Steps 1-10 on the previous page.

2. Remove the upper and lower rinse and wash spray arms and end plugs a

ndushwithfreshwater.

3. Cleanthenalrinsearmnozzlesusingasmallpaperclip.

4. Remove the curtains and clean with fresh water.

DO NOT USE STEEL WOOL TO CLEAN THE INTERIOR OF THE MACHINE.

5. Wipe the interior and exterior of the machine with a soft cloth and a mild

detergent.

DO NOT HOSE THE EXTERIOR OF THE MACHINE WITH WATER.

6. Reassemble the dishwasher and leave the door open to allow overnight

drying.

7. Contact the chemical supplier for de-liming if required.

continued on next page

21

Cleaning

Cleaning (continued)

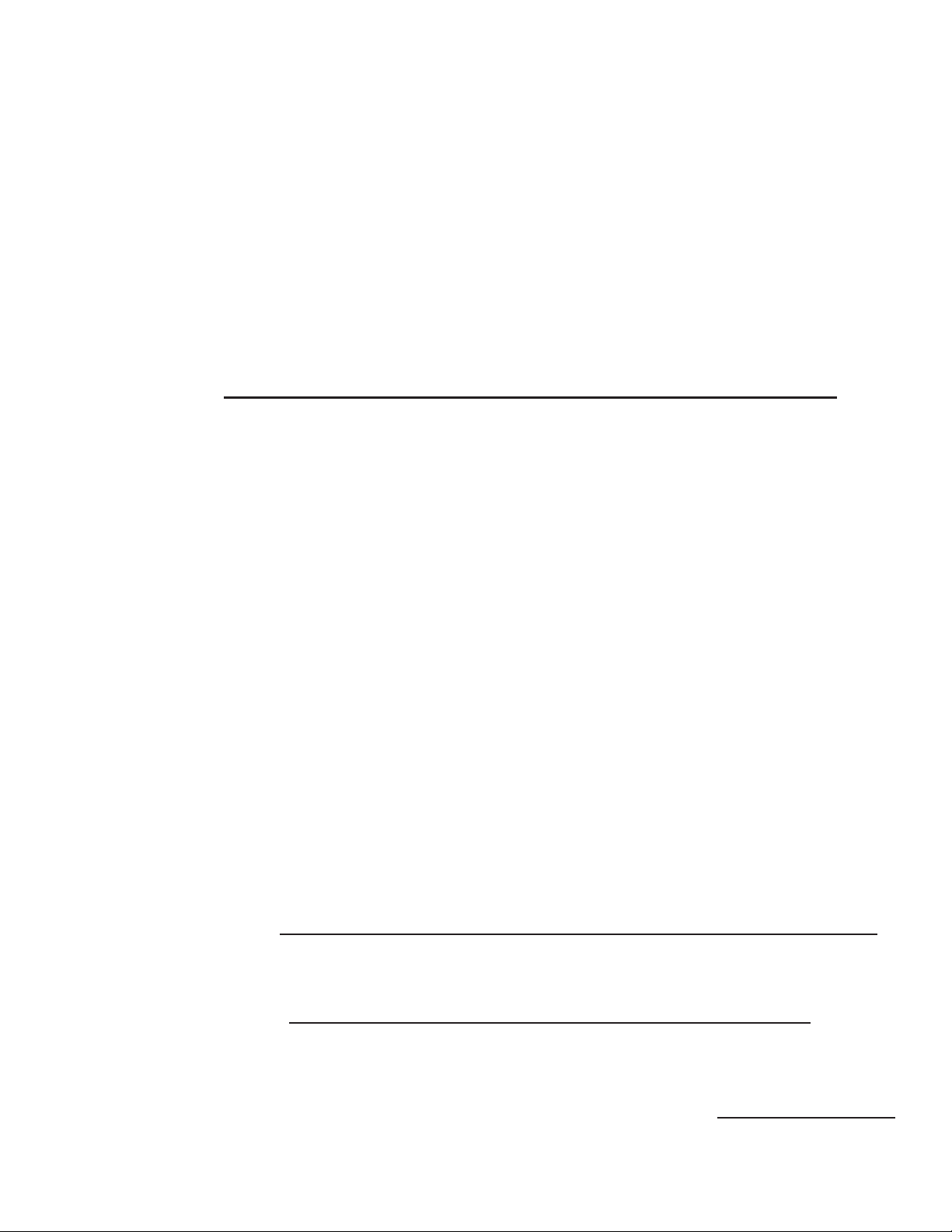

1

ON

POWER

OFF

Flip power switch down to the OFF

position.

3

2

Turn drain handle counter-clockwise

to the vertical position to drain the tanks.

4

Open doors.

5

Remove the upper wash arm assemblies and

ush clean in a sink.

22

Remove curtain assemblies and

rinse clean in a sink.

6

Remove lower wash arm assemblies

and ush clean in a sink.

Loading...

Loading...