Page 1

240 Series

Installation/Operation Manual with Service Replacement Parts

Moyer Diebel Model MD240

Batch-type

Glass Washer

Models:

MD240HT

High Temperature

Hot Water Sanitizing

MD240LT

Low Temperature

MD240HT

Chemical Sanitizing

MD240LT

3765 Champion Boulevard

Winston-Salem, NC 27105

336/661-1992 Fax: 336/661-1660

Toll-free: 800/ 858-4477

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Toll-free: 800/ 263-5798

Machine Serial No.

Issue Date: 10.08.15

Manual P/N 0513062 rev. B

For machines beginning with S/N W101013036 and above

Printed in the USA

Page 2

For future reference, record your dishwasher information in the box below.

Model Number__________________________ Serial Number_______________________

Voltage________________Hertz_____________ Phase__________________

Service Agent __________________________________ Tel:______________________

Parts Distributor _________________________________ Tel:______________________

National Service Department

In Canada: In the USA:

Toll-free: 800/ 263-5798 Toll-free: 800/ 858-4477

Tel: 905/ 562-4195 Tel: 336/ 661-1556

Fax: 905/ 562-4618 Fax: 336/ 661-1660

email: service@moyerdiebellimited.com email: service@championindustries.com

ATTENTION:

The model no., serial no., voltage, Hz

and phase are needed to identify your

machine and to answer questions.

The machine data plate is located

on the lower front panel.

Please have this information ready

if you call for service assistance.

The USGBC and the CaGBC Member Logos are trademarks owned by the U.S. Green Building Council and The Canadian Green Building Council,

respectively, and are used by permission. The logos signify only that Champion Industries, and Moyer Diebel are USGBC and CaGBC members;

USGBC and CaGBC do not review, certify nor endorse the products or services offered by its members.

COPYRIGHT © 2015 All rights reserved Printed in the USA

Page 3

REGISTER YOUR PRODUCT ONLINE

Make sure you are connected to the internet then enter the address below.

In the U.S.A

http://www.moyerdiebel.com/register

In Canada

http://www.championindustries.com/canada/register

Page 4

PRODUCT REGISTRATION

BY FAX

COMPLETE THIS FORM AND FAX TO:

(336) 661-1660 in the USA

1-(800) 204-0109 in Canada

PRODUCT REGISTRATION CARD

Model

Date of Installation:

Company Name:

Address:

Telephone #: ( ) ---

Serial #

(Street) Province Postal Code

Contact:

Installation Company:

Address:

Telephone #:

Contact:

FAILURE TO REGISTER YOUR PRODUCT MAY VOID YOUR WARRANTY

IMPORTANT IMPORTANT

Page 5

Revision History

Revision History

A revision might be a part number change, a new instruction, or other information that was

not available at print time. We reserve the right to make changes to these instructions without

notice and without incurring any liability by making the changes. Equipment owners may

request a revised manual, at no charge, by calling 1 (800) 858-4477 in the USA or by calling

1 (800) 263-5798 in Canada.

Revision Revised Serial Number Revision

Date Pages Effectivity Description

11.9.11 All

10.8.15

55

W101013036

All

Released First Edition

Added P/N 0512426, 2KW Heater

i

Page 6

Limited Warranty

LIMITED WARRANTY

Champion Industries and Moyer Diebel, (herein referred to as "The Company"), 3765 Champion Boulevard,

Winston-Salem, North Carolina 27105, and P.O. Box 301, 2674 N. Service Road, Jordan Station, Canada, L0R 1S0,

warrants machines, and parts, as set out below.

Warranty of Machines: The Company warrants all new machines of its manufacture bearing the name

"Champion" or "Moyer Diebel" and installed within the United States and Canada to be free from defects in material and

workmanship for a period of one (1) year after the date of installation or fteen (15) months after the date of shipment by

The Company, whichever occurs rst. [See below for special provisions relating to glasswashers.] The registration

card must be submitted by fax or online with The Company within ten (10) days after installation. If the registration is

not submitted to The Company within such period, the warranty will expire after one year from the date of shipment.

The Company will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, The Company, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided;

however, as to glasswashers, The Company's obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs rst.

elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by The Company's authorized service technician. Defective parts become the property of The Company.

Use of replacement parts not authorized by The Company will relieve The Company of all further liability in connection

with its warranty. In no event will The Company's warranty obligation exceed The Company's charge for the machine.

The following are not covered by The Company's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior nish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical

dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage

caused by labor dispute.

In the event that The Company

Warranty of Parts: The Company warrants all new machine parts produced or authorized by The Company to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in material and

workmanship is found to exist within the warranty period The Company will replace the defective part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. THE COMPANY'S WARRANTY IS ONLY TO THE

EXTENT REFLECTED ABOVE. THE COMPANY MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF MERCHANTABILITY, OR FITNESS OF PURPOSE. THE COMPANY

SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN THE COMPANY'S DISHWASHING MACHINES

AND THE COMPANY'S PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING ANY LIABILITY FOR

INCIDENTALS OR CONSEQUENTIAL DAMAGES.

The Company does not authorize any other person, including persons who deal in The Company's dishwashing machines

to change this warranty or create any other obligation in connection with The Company's Dishwashing Machines.

ii

Page 7

Table of Contents

Table of Contents

Model 240HT and 240LT Glasswasher

Revision History ................................................................................................................................... i

Limited Warranty ................................................................................................................................... ii

Model Descriptions ................................................................................................................................... iv

Receiving -All Models ................................................................................................................................... 1

Installation - 240HT..........................................................................................................................1

Electrical Connections - 240HT ........................................... 2

Water Connection - 240HT .................................................. 5

Drain Connection - 240HT ................................................... 5

Initial Start-up - 240HT ....................................................................................................................6

Filling the Booster - Booster Fill Switch ............................... 7

Chemical Dispensing Pumps ............................................... 8

Operation - 240HT............................................................................................................................13

Normal Wash Mode - 240HT ............................................... 13

Rinse Sentry Mode - 240HT ................................................ 14

Drain Mode - 240HT ............................................................ 14

Cleaning and Maintenance - 240HT ........................................................................................ 15

Cleaning -240HT.................................................................. 15

De-liming - 240HT ................................................................ 19

Maintenance - 240HT .......................................................... 20

Troubleshooting -240HT ...................................................... 21

Installation - 240LT .......................................................................................................................... 23

Electrical Connections - 240LT ............................................ 23

Water Connection - 240LT ................................................... 24

Drain Connection - 240LT .................................................... 25

Initial Start-up - 240LT ..................................................................................................................... 26

Chemical Dispensing Pumps ............................................... 27

Operation - 240LT ............................................................................................................................ 13

Normal Wash Mode - 240LT ................................................ 30

Drain Mode - 240LT ............................................................ 31

Cleaning and Maintenance - 240LT ........................................................................................15

Cleaning -240LT .................................................................. 32

De-liming - 240LT ................................................................ 35

Maintenance - 240LT ........................................................... 36

Troubleshooting -240LT ....................................................... 37

Service Replacement Parts ............................................................................................................ 39

Electrical Schematics......................................................................................................................74

Timer Charts ....................................................................................................................................76

iii

Page 8

Model Descriptions

Model Descriptions

240HT

High temperature hot water sanitizing dishwasher with built-in 40°F/22°C rise booster heater

208-240VAC/60/1

240LT

Low temperature chemical sanitizing dishwasher with three built-in chemical dispensers for

dtergent, sanitizer, and rinse-aid.

115VAC/60/1

Optional Equipment (consult factory)

70°F/39°C rise built-in booster heater

208-240V/60/1

Additional dish racks:

Flat-bottom dish rack - P/N 101273

Peg dish rack - P/N 101285

Casters, set of four: 2 locking, 2 regular - P/N 0701962

Low chemical alarm - P/N 0707258

Quick disconnect package (includes casters)

Site Glass Kit - P/N 0712993

Pressure Reducing Valve (unmounted) - P/N 107550

iv

Page 9

Installation

CAUTION:

Receiving - All Models

Be careful when lifting and moving the glasswasher to prevent damage to the machine.

NOTE:

The installation of your glasswasher must be performed by qualified service personnel who will

observe all applicable safety, electrical, plumbing, and health codes. Problems due to improper

installation are not covered by the Warranty.

1. Inspect the outside of the glasswasher carton for signs of damage.

2. Remove the carton and inspect the glasswasher for damage.

3. Check for any accessories that may have shipped with your glasswasher.

4. Turn to the front of this manual for the instructions to validate your machine warranty

online or by fax.

5. Move the glasswasher near its permanent location.

6. Compare the installation site utility connections with the glasswasher utility connections

and make sure they are the same.

7. The installation should provide storage space for the glasswasher chemical supply

containers. Containers must be placed on the oor and as close to the machine as

possible.

8. Place the glasswasher in its permanent location.

9. Level the glasswasher front-to-back and side-to-side.

The machine has 4 adjustable feet for leveling unless equipped with optional casters.

3

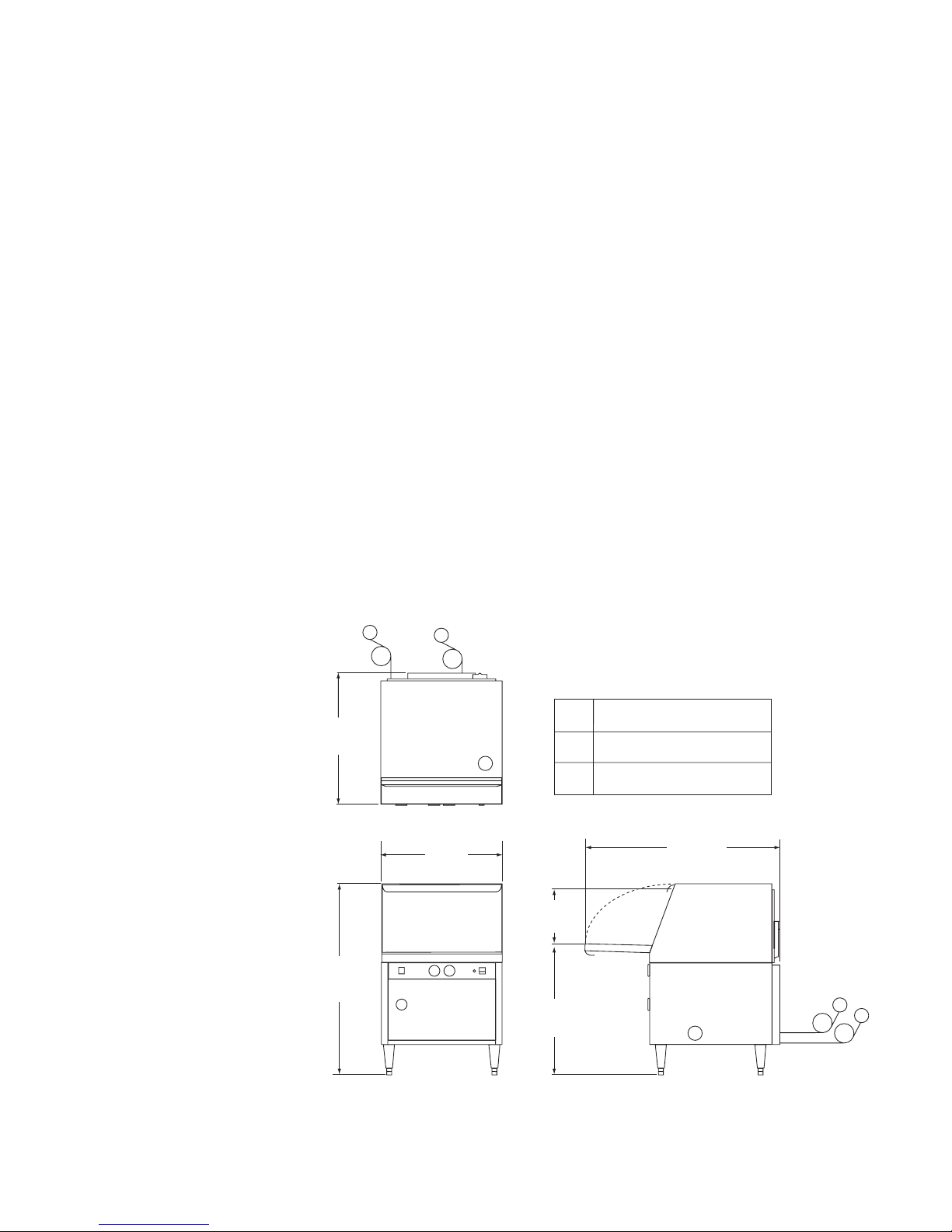

2

Model 240HT

26"

[660]

1

24"

[610]

38"

[965]

1 Electrical Connection

2 Water Connection

3 Drain Connection

11" [280]

clearance

26-1/2"

[673]

38-3/4"

[984]

1

2

3

Note: The 240LT has a flexible power cord and plug for 115VAC/60/1 operation.

1

Page 10

Installation - 240HT

Electrical Connections - 240HT

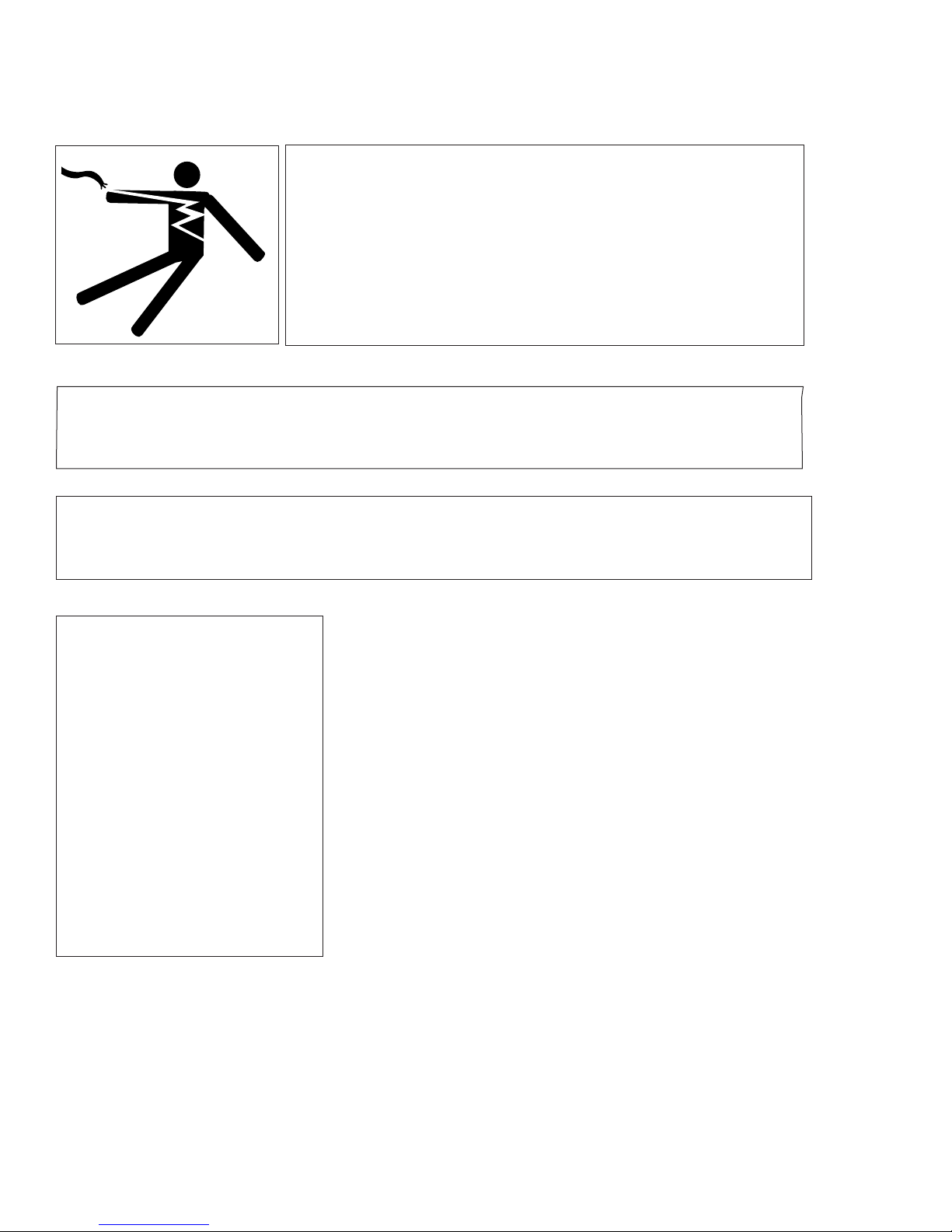

WARNING:

Electrocution or serious injury may result when working on an

energized circuit.

Disconnect power at the main breaker or service disconnect

switch before working on the circuit.

Lock-out and tag the breaker to indicate that work is being

performed on the circuit.

ATTENTION

A qualified electrician must connect the main incoming power to the glasswasher in accordance

with all local codes and regulations or in the absence of local codes

in accordance with the National Electrical Code.

NOTE

Model 240LT is equipped with a 4 ft. power cord and plug.

This model requires a 115VAC,15A receptacle.

Refer to the 240LT installation section beginning on page 23.

1. Power connections are made at the Main Terminal

Block (MTB) which is located at the lower right-hand

side of the glasswasher directly behind the lower

front access panel

2. Remove the MTB cover and 2 screws holding the

MTB to the machine base. Then, pull the MTB up

and forward to make the electrical connections.

3. Provide a 3 ft. service loop in the supply cable for

machine servicing.

4. Re-install the MTB and the lower front access panel

to complete the installation.

Main Terminal Block (MTB)

(shown extended from machine)

2

5. Refer to the connection diagrams on the next page

for wiring instructions.

Page 11

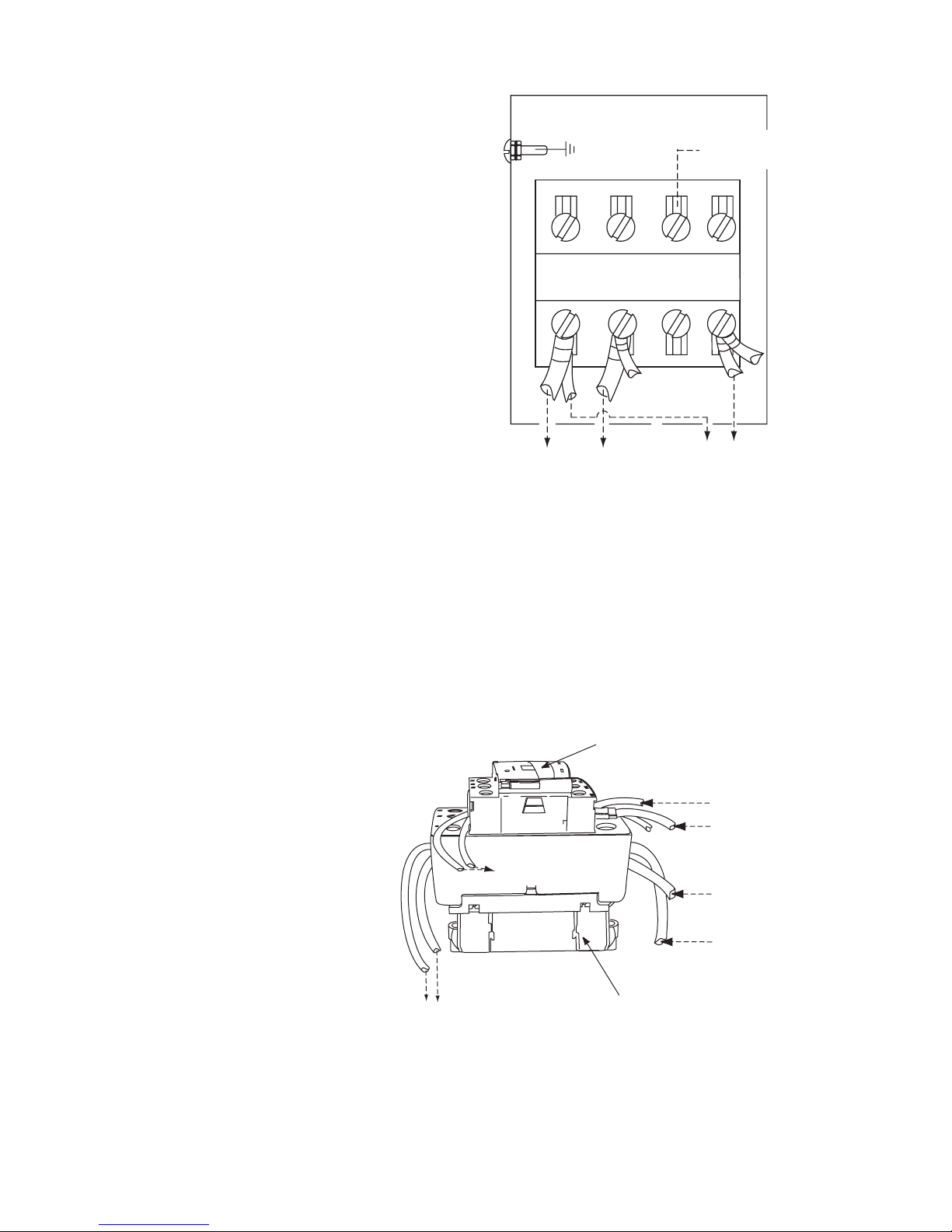

240HT - Installation

Electrical Connections - 240HT

See the diagram below and on the next page to connect main incoming power to the

Model 240HT glasswasher.

SINGLE PHASE POWER CONNECTION

Model 240HT

GND

L1 L2 N

115VAC

208-240

VAC

HOW TO CONNECT 1 PHASE POWER

1. Check the data plate on the front of the

dishwasher for the phase of the machine.

If the data plate says the machine is 1 Phase,

.

then connect a 1 PH power supply.

2. Remove the lower access panel.

3. Pull power connection box forward and out.

4. The Main Terminal Block has connections

for L1, L2, Neutral and Ground.

5. Connect ground, then connect

L1, L2 to 208-230VAC.

6. Connect a current carrying neutral to N.

7. Main Power connections are complete.

3

Page 12

Installation - 240HT

Auxiliary

Electrical Connections - 240HT (continued)

ATTENTION ELECTRICIAN:

The Main Terminal Block (MTB) is a 4-pole block.

The main incoming power is a 3-wire connection

which includes a current-carrying neutral. Connect

the 1PH power as shown on the previous page).

The diagram at right illustrates how power is

distributed to the booster heater contactor and the

auxiliary contactor contact.

The data plate on the lower front cover of the

glasswasher lists the correct power requirements.

heater contactor

208-240VAC

Booster Heater/Wash Tank Heater Interlock Circuit

Main Terminal Block (MTB)

Do not connect

power to L3

L1 L2 L3 N

To booster

1PH

To

auxiliary

contactor

contact

115VAC

The booster heater/wash tank heater interlock circuit removes power from the wash tank heater

whenever the booster heater contactor energizes. The illustration below shows how the booster

heater contactor is wired. The booster heater contactor is located on the backside of the control

panel bracket which is located behind the lower front access panel.

Interlock Circuit Operation

1. The glasswasher lls with water when the

main power switch on the glasswasher is

turned on. The booster heater thermostat

calls for heat which energizes the booster

heater contactor.

2. The auxiliary contact on the top of

the contactor opens and removes

power from the wash tank

heater.

3. When the booster heater thermostat

is satised, the booster heater

contactor deenergizes and the

auxiliary contacts close

applying power to the wash

1H2

To booster heater

1 PH 208-230VAC

tank heater.

1H1

To wash

tank heater

115VAC

Contactor

Contact

Booster Heater

Contactor

L1

N

L2

L1

From

main

terminal block

115 VAC

From

main

terminal block

1 PH

208-230VAC

4. This operation is repeated whenever

the booster thermostat calls for heat.

4

Page 13

240HT - Installation

Water Connections- 240HT

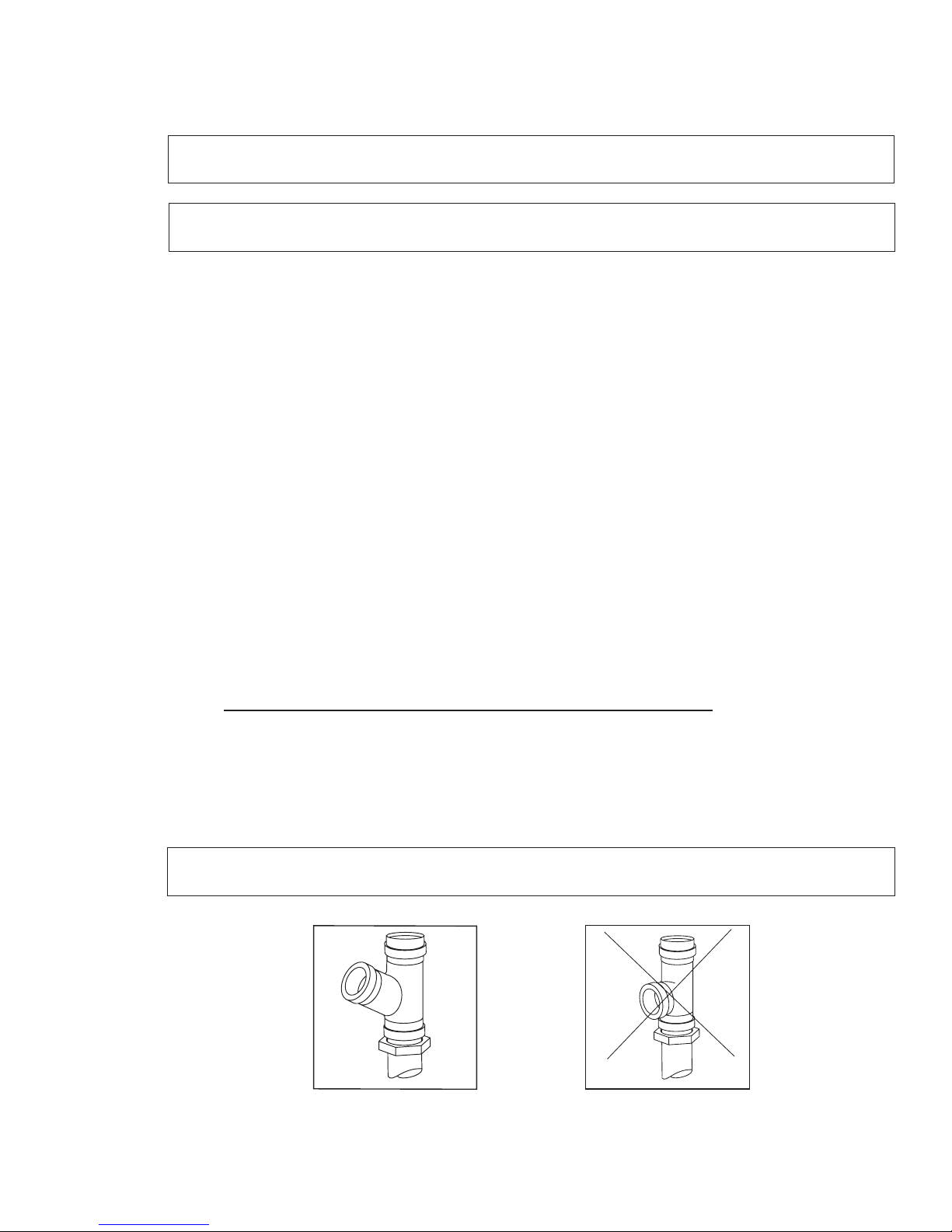

NOTE

Plumbing connections must comply with national, local plumbing and sanitary codes.

ATTENTION

Make sure that the flexible water supply and drain hoses are not kinked.

1. The 240HT has a 7ft. exible hot water ll hose with a 3/4" female garden hose connector.

2. A 1/2" or larger main incoming supply line should be installed to the glasswasher.

3. A 1/2" or larger shut-off valve should be installed in the water supply line as close possible

to the glasswasher for servicing.

4. A pressure regulating valve, PRV must be installed after the shut-off service valve if the

incoming ow pressure exceeds 20-22 psi.

5. The hot water supply must provide a minimum of 140°F/60°C, measured at the glasswasher

for the 40°F/ 22°C rise booster. For the 70°F/39°C rise booster the hot water supply must

provide a minimum of 110°F/43°C measured at the glasswasher.

Drain Connections - 240HT

1. All models have a 6ft. 5/8" I.D. drain hose. The maximum drain height connection must

not exceed 3 ft.[0.9 m].

2. The drain hose is located at the rear of the glasswasher.

3. The drain hose is secured to the rear of the machine by a clamp to maintain a gooseneck bend in the drain hose.

DO NOT KINK, STRETCH, OR LENGTHEN THE DRAIN HOSE.

4. Install the drain hose to a "WYE" drain tting.

Connection to a "TEE" tting will prevent the glasswasher from draining completely.

5. The maximum drain ow is 15 US gpm.

6. Make sure the drain hose does not kink. Kinks will prevent the glasswasher

from draining completely.

ATTENTION

The glaswasher will not drain correctly if the drain hose is connected to a disposer.

Connect the drain hose

to a WYE fitting.

Do not connect the drain

hose to a TEE fitting.

5

Page 14

Initial Start-up - 240HT

Check List

1. Make sure the glasswasher is permanently located.

2. Make sure all utility connections are complete.

3. Make sure the exible drain hose and the hot water ll hose are not kinked.

4. Remove any protective lm from glasswasher.

5. Check the interior for foreign material.

6. Remove the scrap screen and check the sump for foreign material.

7. Make sure the chemical supply containers are full and that the chemical pick-up tubes

are installed in the proper containers.

8. Make sure the scrap screen is in place.

9. Make sure the spray arms are in place and that they spin freely.

10. Close the glasswasher door.

11. Turn hot water supply on and check for leaks in the main water supply piping connected

to the glasswasher.

ATTENTION

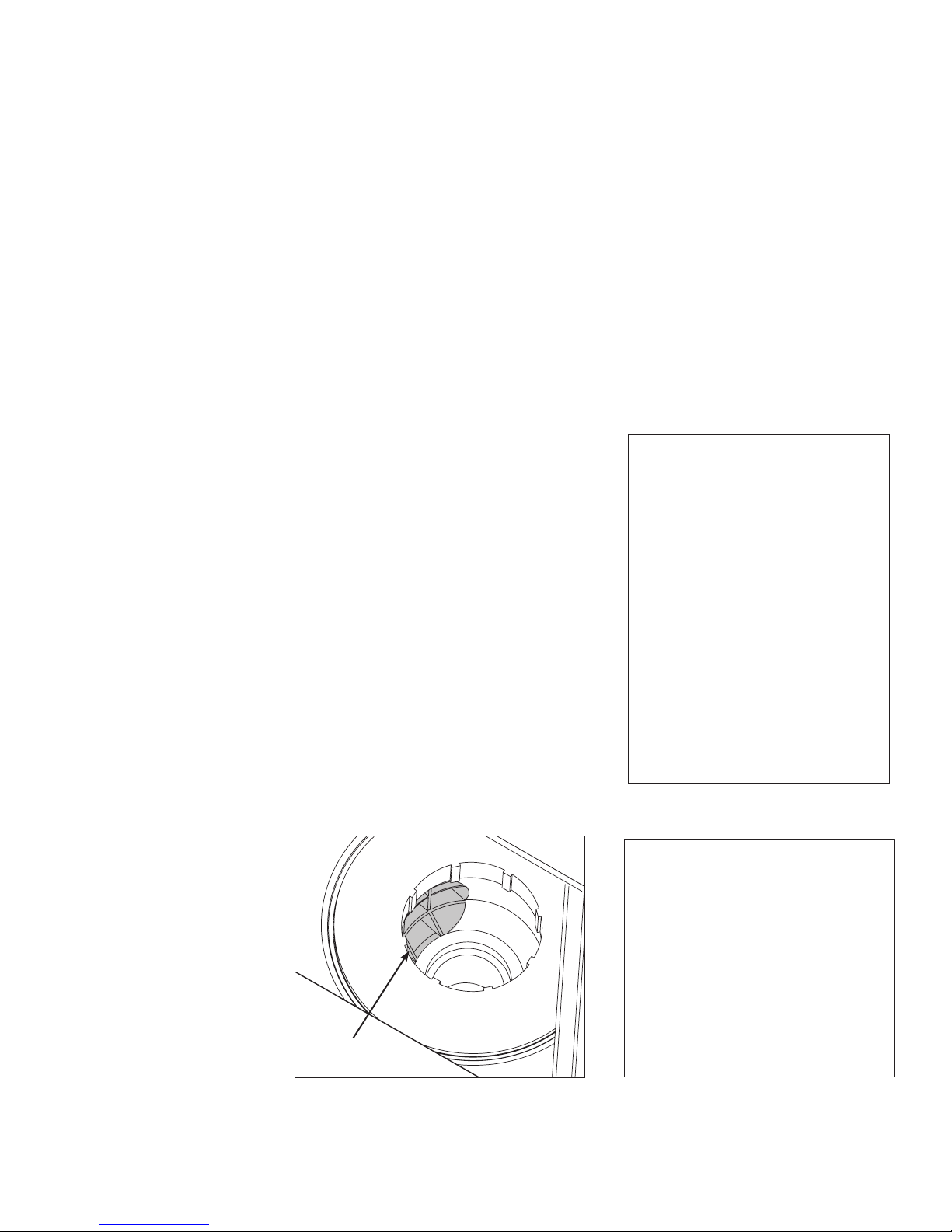

Make sure the overow guard is in place. Model 240HT only.

Make sure the overflow guard is in place.

6

Make sure the scrap screen is in place.

Page 15

240HT - Initial Start-up

Filling the Booster

Booster Fill Switch

ATTENTION

The built-in booster tank was drained prior to shipment and must be filled

before operating the machine.

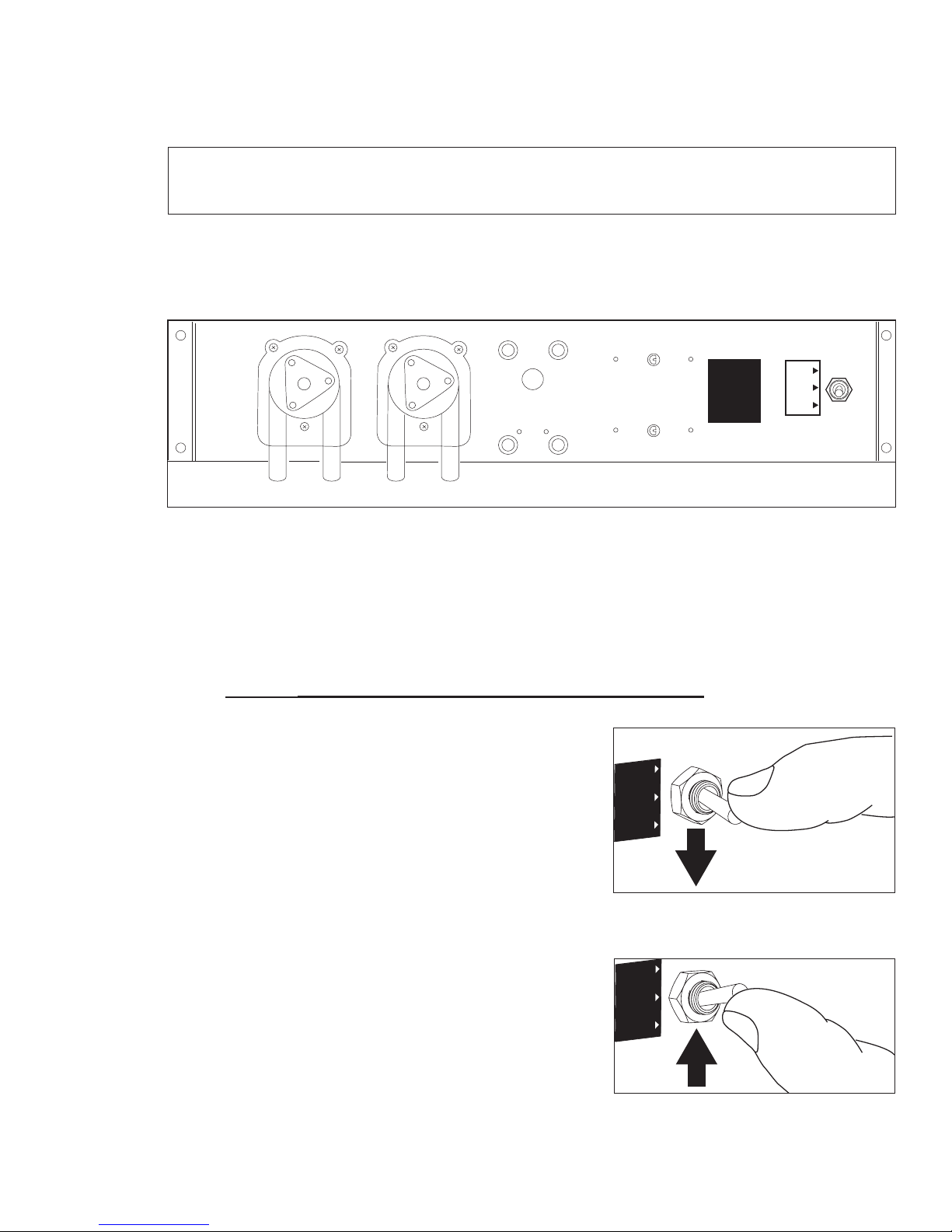

Booster Fill Switch

The booster tank is refilled using the Booster Fill Switch. It is located behind the lower front

access panel and on the right-side of the bracket that holds the chemical dispensing pumps.

Wash Thermo

ON

OFF

FILL

Booster

Fill

Booster Thermo

Detergent Rinse-aid

The booster fill switch is located on the right-side of the bracket holding the chemical dispensing pumps.

Switch

To fill the booster tank:

1. Remove the lower front access panel.

2. Locate the booster ll switch and note the 3 switch positions (ON - OFF - FILL).

3. Turn the main power supply on.

DO NOT TURN THE GLASSWASHER POWER SWITCH ON.

4. Push and hold the booster ll switch DOWN to the

booster ll position until water is heard spraying

inside the glasswasher wash compartment.

5. Release the booster ll switch and push it UP

to the ON position.

ON

OFF

BOOSTER

FILL

ON

OFF

BOOSTER

FILL

6. Booster ll is complete.

7

Page 16

Initial Start-Up - 240HT

Chemical Dispensing Pumps

ATTENTION

Contact a local chemical supplier for detergent and rinse-aid chemicals.

The detergent should be a non-chlorinated liquid detergent.

The chemical dispensing pumps must be adjusted by the chemical supplier.

Model 240HT Hot Water Sanitization:

1. The 240HT is equipped with a built-in detergent dispensing pump and rinse-aid dispensing pump.

(See the photographs below.)

2. The pumps are located on a center bracket behind the lower-front access panel.

3. Each pump is equipped with 6 feet [1.8 m] of pick-up supply tubing, a stiffener tube, and a strainer.

4. A red label marked DETERGENT is attached to the detergent pump inlet tubing.

5. A blue label marked RINSE-AID is attached to the rinse-aid pump inlet tubing.

6. The detergent enters the wash tank compartment through a tting at the right rear of the wash

compartment.

7. The detergent supply should be a non-chlorinated liquid detergent.

8. The rinse-aid enters the nal rinse piping through a tting located on the upper-right rear side of the

glasswasher. The tting is located near the vacuum breaker.

For Model 240HT, the dispensing pumps are located

on the center bracket behind the lower-front access

panel.

8

A stiffener tube, strainer and 6 ft. [1.8 m] of

pick-up tubing are supplied with the built-in

detergent and rinse-aid pumps.

Page 17

MD240-HT - Initial Start-Up

Chemical Dispensing Pumps

Model 240HT Hot Water Sanitization (continued)

9. The chemical supplier will choose the appropriate liquid rinse-aid.

10. The factory chemical dispensing pump settings are only approximations; therefore,

your chemical supplier must adjust the dispensers for the supplied product.

11. Place the chemical supply containers as close to the glasswasher as possible.

12. Do not elevate the chemical containers above the nished oor.

For Model 240HT detergent enters the wash tank

compartment through a fitting on the rear wall of the wash tank

compartment.

The rinse-aid enters the final rinse piping at the rear of

the glasswasher near the vacuum breaker.

9

Page 18

Initial Start-Up - 240HT

Chemical Dispensing Pumps

Priming the Chemical Dispensing Pumps

The chemical dispensing pump supply lines must be primed before they will pump the chemicals

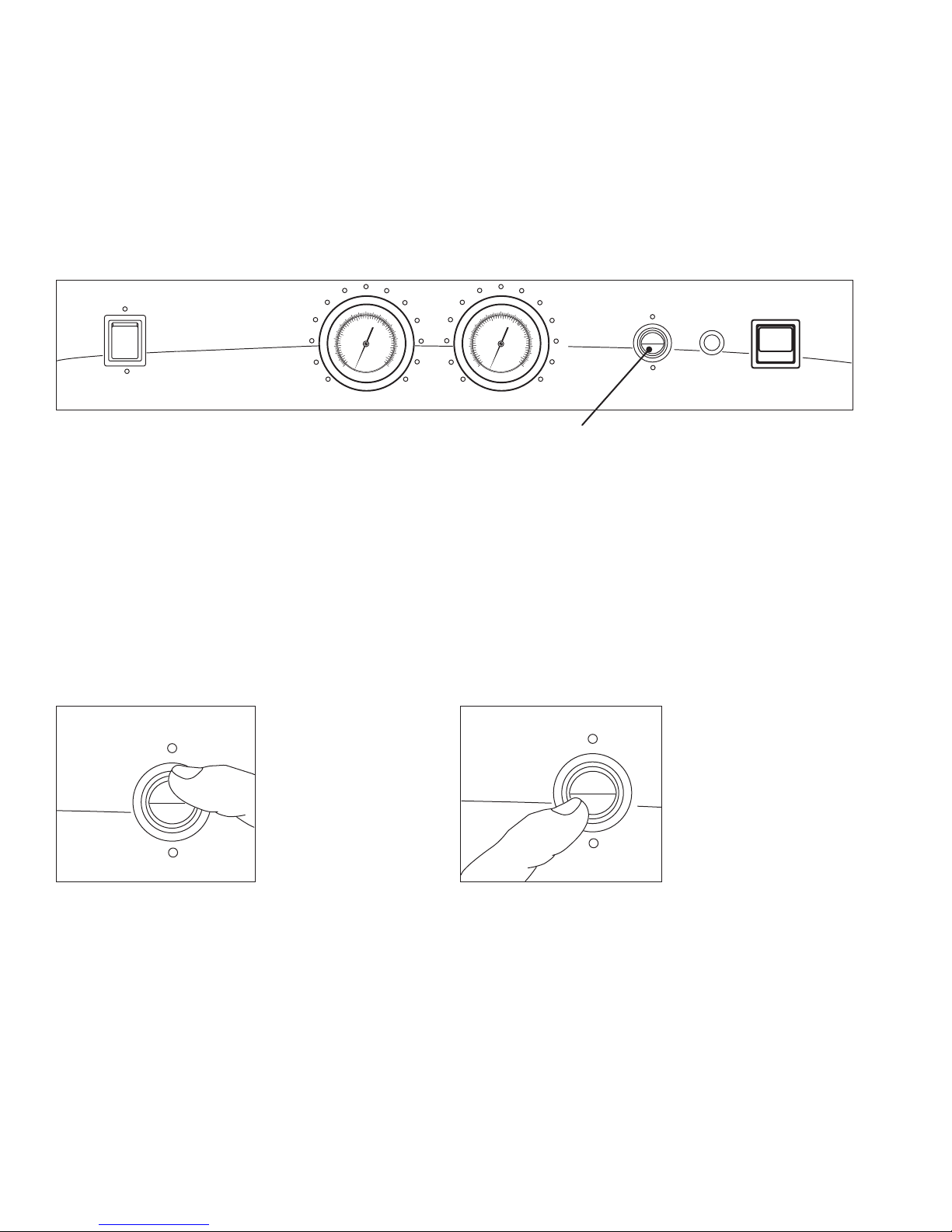

into the machine. The 240HT features a 2-position PRIME push button located on the front control

panel to prime the chemical dispensing pumps.

POWER

ON

I

O

OFF / DRAIN

120

100

40

80

20

60

40

0

20

WASH TEMP

140

160

60

180

80

100

200

220

100

40

80

20

60

40

0

20

RINSE TEMP

120

140

160

60

180

80

100

200

220

PRIME

DET

START

R/A

Prime Switch

To Prime the Dispensing Pumps:

1. Make sure the chemical containers are full and the correct pick-up tubes are in the containers.

2. Turn the glasswasher power switch ON.

3. The switch will illuminate and the glasswasher will ll with water.

4. Open the glasswasher door, then push and hold the prime push button UP to the DET position until

detergent is observed entering the wash tank compartment from the detergent injection point at the

right-rear of the wash tank.

5. Release the push button.

DET

DET

PRIME

PRIME

R/A

Push up to prime detergent. Push down to prime rinse-aid.

R/A

6. Push and hold the prime push button DOWN to the R/A position for 3 minutes.

7. Release the push button.

8. Run one empty wash cycle to remove accumulated chemicals from the wash compartment.

10

Page 19

MD240-HT - Initial Start-Up

Chemical Dispensing Pumps

Chemical Dispensing Pump Speed and Tank Fill Adjustments

The chemical dispensing pump speeds are not set at the factory. Variations in the

type of chemicals supplied by the chemical supplier always require that the supplier

make nal adjustments for the products supplied.

1. Adjustment screws are provided for the dispensing pumps and for the wash tank ll.

They are located on the right-side of the glasswasher behind the lower front access panel.

2. Make sure the chemical containers are full and the pick-up tubes are in the proper

containers.

3. Turn the glasswasher power switch ON. The switch will illuminate and the glasswasher

will ll with water.

4. Run a normal glasswasher cycle and test detergent and rinse-aid concentrations

according to the chemical supplier's instructions.

CAUTION

Excessive pressure to the potentiometers when adjusting

can result in bent or broken adjusting screws.

5. Each dispensing pump has a clearly marked

adjustment screw. Turn the screw CW to

increase the time of the dispensing pump

and CCW to reduce the dispensing pump

time.

6. The Fill adjustment screw will provide a

small change in the tank water level.

If a large adjustment is needed, then

check the incoming water pressure and

make sure the ll hose is not kinked. If these

items are okay, then the size of the incoming

water supply should be evaluated.

7. The 240HT uses detergent and rinse-aid

only, a sanitizer is not required.

11

Page 20

Operation - 240HT

Operation

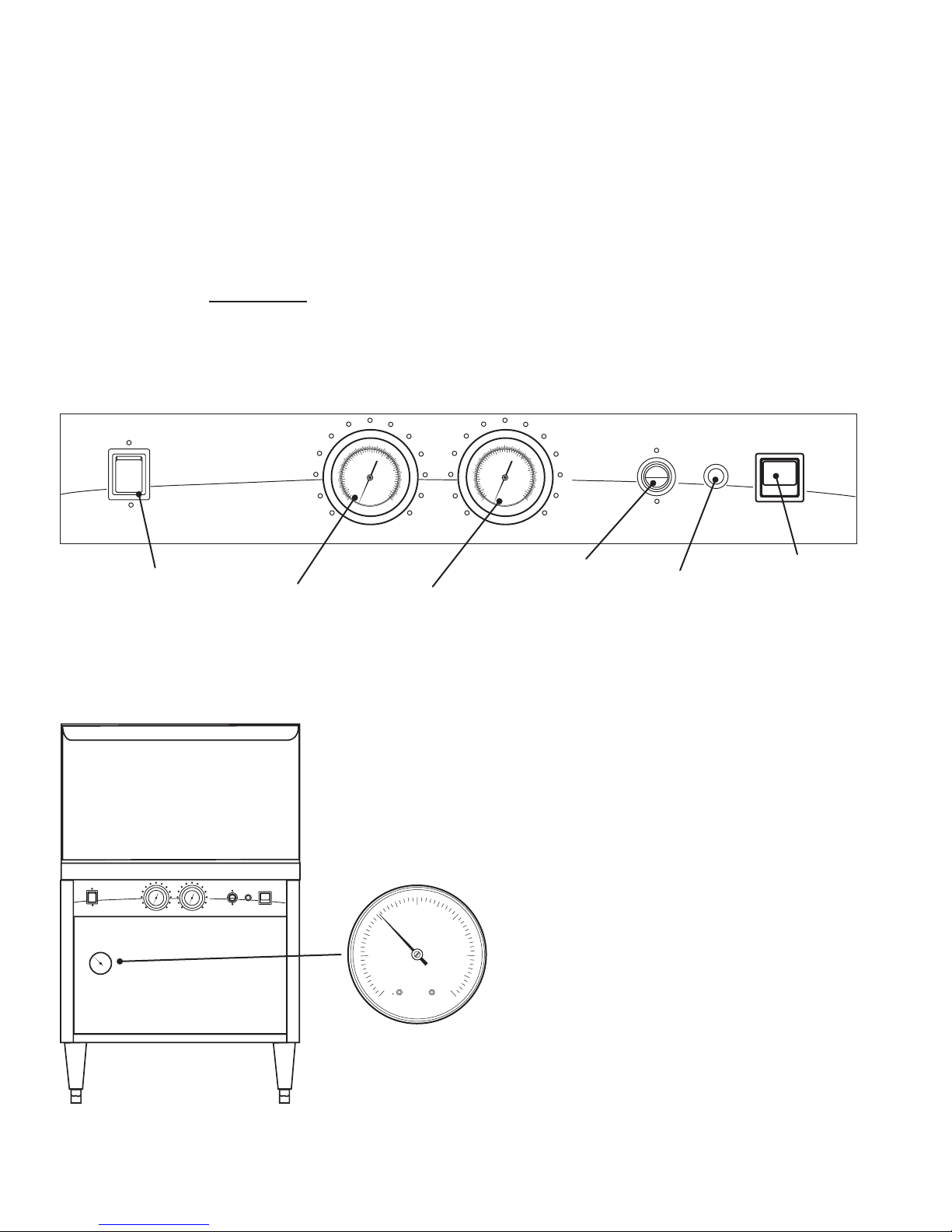

Model 240HT

Control Panel

The illustrations below show the layout of the 240HT control panel and the nal rinse pressure

gauge. Normal Wash Mode instructions are on the next page.

This machine has a Rinse Sentry feature to ensure the nal rinse water temperature is maintained

at a minimum of 180-195ºF/82-91ºC during the final rinse. The rinse sentry feature is explained on

page 14.

POWER

Power Switch

ON

I

POWER

O

OFF / DRAIN

ON

I

O

OFF / DRAIN

ON

OFF/DRAIN

WASH TEMP

Wash Temperature

DET

PRIME

R/A

RINSE TEMP

Gauge

START

120

140

100

160

40

80

60

20

60

40

0

20

180

80

100

200

220

WASH TEMP

Final Rinse Temperature

Gauge

30

20

10

40

PSI

60

40

50

120

100

40

80

60

20

0

20

RINSE TEMP

140

160

180

80

100

200

220

Prime Switch

PRIME

DET

R/A

In-cycle Light

START

Start

Push button

12

0

60

Final Rinse

Pressure Gauge

Page 21

240HT - Operation

Operation

Normal Wash Mode

1. Make sure the exible drain hose and the exible

ll hose are not kinked then turn the water supply on.

2. Close the glasswasher front door.

3. Turn the power on at the main circuit breaker.

4. Push the glasswasher Power Switch UP to turn the power ON.

5. The power switch will illuminate and the machine will ll.

6. Check the pressure gauge as the machine lls and make sure the incoming water

pressure is between 20-22 psi [138-152 kPa].

7. Open the front door and check the water level in the wash tank compartment. The

approximate water ll level should reach the top-left edge of the wash tank compartment

as shown in the photograph below.

Approximate water fill level.

8. Close the door.

9. Wait 10-minutes for the booster heater to reach temperature and for the WASH

temperature gauge to indicate a minimum of 150ºF/66ºC.

10. Load soiled wares into the dish rack. Place plates, glasses, cups and bowls in a peg

rack. Place utensils in a single layer in a flat-bottom rack.

Place pots and pans in a flat-bottom rack. Do not overload the dish racks

11. Slide 1 dish rack into the wash compartment making sure the wares do not interfere with

the rotating spray arms. Do not wash more than 1 dish rack at a time.

12. Close the front door then press the START BUTTON. The green in-cycle light will

illuminate and the wash cycle will begin. The wash cycle time runs for approximately

70-seconds.

13. Opening the door when the glasswasher is in-cycle will stop the glasswasher. The cycle

will restart automatically from the beginning of the wash cycle when the glasswasher

door is closed.

14. The nal rinse cycle begins at the end of the wash cycle and runs for approximately

16-seconds Check the RINSE temperature gauge during the nal rinse and make sure it

indicates a minimum of 180-195ºF/82-91ºC. The final rinse water is retained for the next

wash cycle.

13

Page 22

Operation - 240HT

Operation

Model 240HT

Rinse Sentry Mode

The nal rinse water temperature must be a minimum 180-195ºF/82-91ºC during the final rinse cycle to

ensure that all wares are sanitized. If for any reason, the hot water temperature in the booster tank cannot

provide this temperature, then the glasswasher will enter a Rinse Sentry Mode of operation.

The Rinse Sentry changes the Normal Operation Mode as described below:

1. The Rinse Sentry constantly monitors the water temperature inside nal rinse booster.

2. If the temperature inside the booster falls below 180-195ºF/82-91ºC then the Rinse Sentry

will extend the wash cycle time until the booster water temperature reaches the proper

temperature.

NOTE: LOW INCOMING WATER TEMPERATURE TO THE DISHWASHER OFTENS

CAUSES THE RINSE SENTRY TO OPERATE.

3. The in-cycle light will remain illuminated during the Rinse Sentry Mode.

4. The glasswasher will continue to wash for a maximum time of 5-minutes.

5. After 5-minutes the Rinse Sentry will stop and the glasswasher cycle will resume

normal operation.

6. The rinse water temperature gauge must be monitored to ensure that a minimum of

180-195ºF/82-91ºC is maintained. If the temperature is below the required minimum,

then the problem must be identied and corrected immediately to maintain sanitization.

Drain Mode

The 240HT drains automatically whenever the ON-OFF/DRAIN power switch is placed in

the OFF/DRAIN position.

To drain the machine:

1. Close the glasswasher door.

2. Press the lighted power switch down to the OFF/DRAIN position.

3. The power switch light will go out.

4. After a 4 second pause, the in-cycle light will illuminate and the glasswasher will drain,

ll with water, perform 3 short cycles and then drain completely.

DO NOT OPEN THE DOOR UNTIL THE IN-CYCLE LIGHT GOES OUT.

5. When the in-cyle light goes out, the drain cycle is complete.

14

Page 23

Cleaning - 240HT

After Each Meal Period or every 8 Hours of Operation

1. Close the glasswasher door.

2. Press the lighted power switch down to the OFF/DRAIN position.

3. The power switch light will go out.

4. The in-cycle light will illuminate and the glasswasher will drain, ll with water,

perform 3 short cycles and then drain completely.

5. The in-cycle light will go out indicating that the drain cycle is complete.

6. Remove the scrap screen carefully to keep the soil or waste particles from falling

into the sump.

7. Clean the scrap screen by rinsing with clean water.

Be sure to back-ush the screen.

Do not strike the screen against solid objects.

8. Check the sump for foreign material and clean as

required.

Cleaning

Model 240HT

9. Replace scrap screen. Make sure that spray arms

turn freely.

10. Check the chemical containers and rell as required.

11. Close the door and return to normal operation mode.

Remove the scrap screen

Pump Intake

Screen

Clean the pump intake screen

15

Page 24

240HT - Cleaning

Cleaning

Model 240HT

At the End of the Day

1. Perform Steps 1-9 on the previous page.

2. Remove the lower rinse and wash spray arms.

3. Disassemble the rinse arm, rinse arm pin and the retaining spacer.

4. Inspect the rinse arm hub for wear.

Contact a service agent to replace the hub if needed.

16

(continued on next page)

Page 25

Cleaning - 240HT

At the End of the Day (continued)

5. Using a small paper clip, clean the rinse arm nozzles.

6. If the rinse arm needs cleaning, Use a at blade screwdriver, remove the rinse arm end

plugs and set them aside.

7. Flush the inside of the rinse arm with fresh water and reassemble the rinse arm.

(continued on next page)

17

Page 26

Cleaning - 240HT

8. Remove the wash arm assembly and ush with clean water.

9. Inspect the wash arm bearings for wear.

Contact a service agent to replace the bearing if needed.

10. Inspect the wash tank heating element, and tank probes for scale build-up.

De-lime the machine in accordance with the chemical supplier instructions.

11. Using a small paper clip, clean the rinse nozzles in the rigid rinse piping located at the

top of the glasswasher wash compartment. The rinse piping is not removable.

12. Wipe the interior and exterior of the machine with a soft cloth and a mild detergent.

DO NOT HOSE THE EXTERIOR OF THE MACHINE WITH WATER.

13. Reassemble the glasswasher and leave the door open to aid in overnight drying.

18

Page 27

240HT - Cleaning

De-liming

Minerals accumulate on the interior surfaces of the glasswasher. The removal of lime

deposits is called de-liming and the glasswasher should be de-limed regularly. Inspect the

machine interior for lime deposits. If de-liming is required, a de-liming agent should be used in

accordance with the chemical supplier's instructions.

DANGER:

Death or serious injury may result when de-liming solution is mixed with sodium

hypochlorite sanitizing agent. Mixing may cause hazardous gases to form. De-liming

solution and other acids must never be mixed with chlorine, iodine, bromine, or fluorine.

CAUTION:

Skin contact with de-liming solutions can cause severe irritation and possible chemical

burns. Always wear eye protection, rubber gloves and protective clothing when handling

chemicals.

Follow the steps below to de-lime the 240HT glasswasher.

1. Open the glasswasher door and remove any dish racks. Close door.

2. Turn the power switch on the glasswasher to the ON position.

3. Remove the detergent and rinse-aid chemical supply tubing from their chemical supply.

4. Place the tubing in a container of hot water.

5. Press and hold the prime switch UP in the DET position for 2 minutes to ush the

detergent from the supply tubing. Release the switch.

6. Press and hold the prime switch DOWN in the R/A position for 4 minutes to ush the

rinse-aid from the supply tubing. Release the switch.

7. Turn the glasswasher power switch to OFF/DRAIN to drain the wash tank. The green

in-cyle light will go out when complete (90 seconds). Turn the power switch to ON to

rell the machine. Repeat 3 more times to completely ush any chemicals from the

machine.

8. Open the door and carefully add the de-liming chemical to the wash tank in accordance

with the chemical supplier's instructions. Be careful to avoid splashing.

9. Close the door and press the START button to begin a wash cycle.

10. The green in-cyle light will illuminate.

11. Turn the glasswasher power switch to OFF/DRAIN to drain the wash tank. The green

in-cyle light will go out when complete (90 seconds). Turn the power switch to ON to

rell the machine.

12. Repeat 3 more times to completely ush any chemicals from the machine.

13. Check the de-liming results and if scale is still present repeat steps 8-12.

14. Return chemical supply tubing to their containers and prime the chemical lines.

15. Return the glasswasher to normal operation.

19

Page 28

240HT - Maintenance

Maintenance

Follow the maintenance schedules below to keep the glasswasher operating most

efficiently.

Daily Maintenance

1. Make sure that the water supply is on and that the drain is not clogged.

2. Check the temperature gauges and/or displays to ensure that they are operating.

3. Make sure that dish racks are in good condition.

4. Check the chemical containers and rell as required.

5. Follow the cleaning procedures given above.

Weekly Maintenance

1. Perform Steps 1-5 in the Daily Maintenance.

2. Inspect water lines for leaks.

3. Check for water leaks underneath the glasswasher.

4. Make sure the exible water ll and drain hoses are not kinked.

5. Make sure that the glasswasher is level.

6. Clean accumulated lime deposits from the wash tank heating element.

7. Inspect the scrap screen and replace it if damaged.

8. Check the spray arms and replace or repair if damaged.

Monthly Maintenance

1. Perform the Daily and Weekly Maintenance listed above.

2. Clean the chemical dispenser pick-up tubing for the detergent and rinse-aid pumps by

ushing with hot water.

To clean the pick-up tubing:

1. Remove the pick-up tubes from their containers.

2. Place each tube in a separate container of hot water.

3. Press and hold the PRIME button up in the DET position until water ows into the wash

tank compartment.

4. Press and hold the PRIME button down in the R/A position for 3 minutes.

5. Return the pick-up tubes to their containers.

6. Run 3 empty glasswasher cycles to ush any chemicals from the glasswasher

wash compartment.

20

Page 29

Troubleshooting

Troubleshooting

240HT

Follow the troubleshooting guide below in the event that your glasswasher does not

operate as expected. Perform the basic checks below before calling an authorized s

ervice agent:

Condition Cause Solution

Glasswasher will not run.

Low or no water.

Chemicals won’t feed into

Glasswasher.

Low water pressure

pumped from spray arms.

Poor wash results.

Door not closed.

Main power OFF.

Glasswasher OFF.

Main water supply off.

PRV defective.

Solenoid valve defective.

Solenoid strainer clogged.

Timer board defective.

Chemical supply low.

Supply tubing damaged.

Supply tubing kinked.

Pick-up tube clogged or

defective.

Timer board defective.

Clogged scrap screen.

Clogged spray arms.

Clogged pump intake

screen.

Water temperature low.

Thermostat defective.

(See chemicals won’t feed

above.)

(See low or no water

above.)

Detergent injector defective.

Wares incorrectly loaded.

in dishrack.

Close door completely.

Check breaker on panel.

Turn Glasswasher ON.

Open supply valve.

Adjust/replace PRV.

Install repair kit or replace.

Clean strainer.

Test/replace timer board.

Refill chemical container.

Replace tubing.

Straighten tubing.

Clean/replace tube.

Test/replace timer board.

Clean scrap screen.

Clean spray arms.

Inspect sump and clean

pump intake screen.

Raise incoming water

temperature.

Adjust/replace thermostat.

(See chemicals won’t feed

above.)

(See low or no water

above.)

Replace squeeze tube.

Replace injector motor.

Clean tubing. pick-up hoses

and strainer.

Reposition wares or reduce

amount of wares.

(HT models only)

Glasswasher stays in

wash cycle.

Booster high limit tripped.

Wash tank high limit tripped.

Rinse Sentry extends

wash mode for a maximum

time of 5-minutes to allow

final rinse water booster

temperature to reach

180˚F/82˚C.

Reset or replace high limit.

Reset or replace high limit.

Raise incoming water

temperature.

Adjust/replace final rinse

booster thermostat.

21

Page 30

Blank Page

This Page

Intentionally

Left Blank

22

Page 31

240LT - Installation

L1 L2

Electrical Connection

Model 240LT

WARNING:

Electrocution or serious injury may result when working on an

energized circuit.

Disconnect power at the main breaker or service disconnect

switch before working on the circuit.

Lock-out and tag the breaker to indicate that work is being

performed on the circuit.

ATTENTION

A qualified electrician must connect the main incoming power to the glasswasher in accordance

with all local codes and regulations or in the absence of local codes in accordance with the

National Electrical Code.

1. Model 240LT is equipped with

a 4 ft. power cord and plug.

2. The power cord is prewired at

the junction box located on the

front right side of the machine

behind the lower front access

panel.

3. This model requires a

115VAC,15A receptacle.

115VAC

15A

4 ft. power cord w/plug supplied

Model 240LT

ON

I

POWER

O

OFF / DRAIN

R/A

DET

START

PRIME

SANI

TEMPERATURE

The 240LT power cord is prewired to the junction box located at the

lower right-side of the machine behind the lower front access panel.

23

Page 32

Installation - 240LT

Water Connection

ATTENTION

Plumbing connections must comply with national, local plumbing and sanitary codes.

IMPORTANT

Make sure that the flexible water supply and drain hoses are not kinked.

1. The 240LT has a 7 ft./1.8 m exible hot water ll hose with a 3/4"

female garden hose connector.

2. A 1/2" or larger main incoming supply line should be installed to the glasswasher.

3. A 1/2" or larger shut-off valve should be installed in the main water supply as close to the

glasswasher as possible for service.

4. The machine has a built-in ow control. The incoming hot water supply pressure must be

between 25-95 psi/173-655 kPa.

5. The hot water supply must provide a minimum of 140°F/60°C, measured at the glasswasher.

24

Page 33

240LT - Installation

Drain Connection

ATTENTION

Do not connect the drain hose to a disposer. The glasswasher will not drain correctly.

1. This model has a 6ft. 5/8" I.D. drain hose. The maximum drain height connection

must not exceed 3 ft.[.09 m] above the nished oor.

2. The drain hose is located at the rear of the glasswasher.

3. The drain hose is secured to the rear of the machine by a clamp to maintain a

goose-neck bend in the drain hose.

DO NOT REMOVE THE DRAIN HOSE RETAINING CLAMP.

DO NOT KINK, STRETCH OR LENGTHEN THE DRAIN HOSE.

4. Install the drain hose to a "WYE" drain tting. Connection to a "TEE" tting will

prevent the glasswasher from draining completely.

5. The maximum drain ow is 15 US gpm/12.5 Imp gpm/57 Lpm.

6. Make sure the drain hose does not kink. Kinks will prevent the glasswasher

from draining completely, and the glasswasher will overow out the front door.

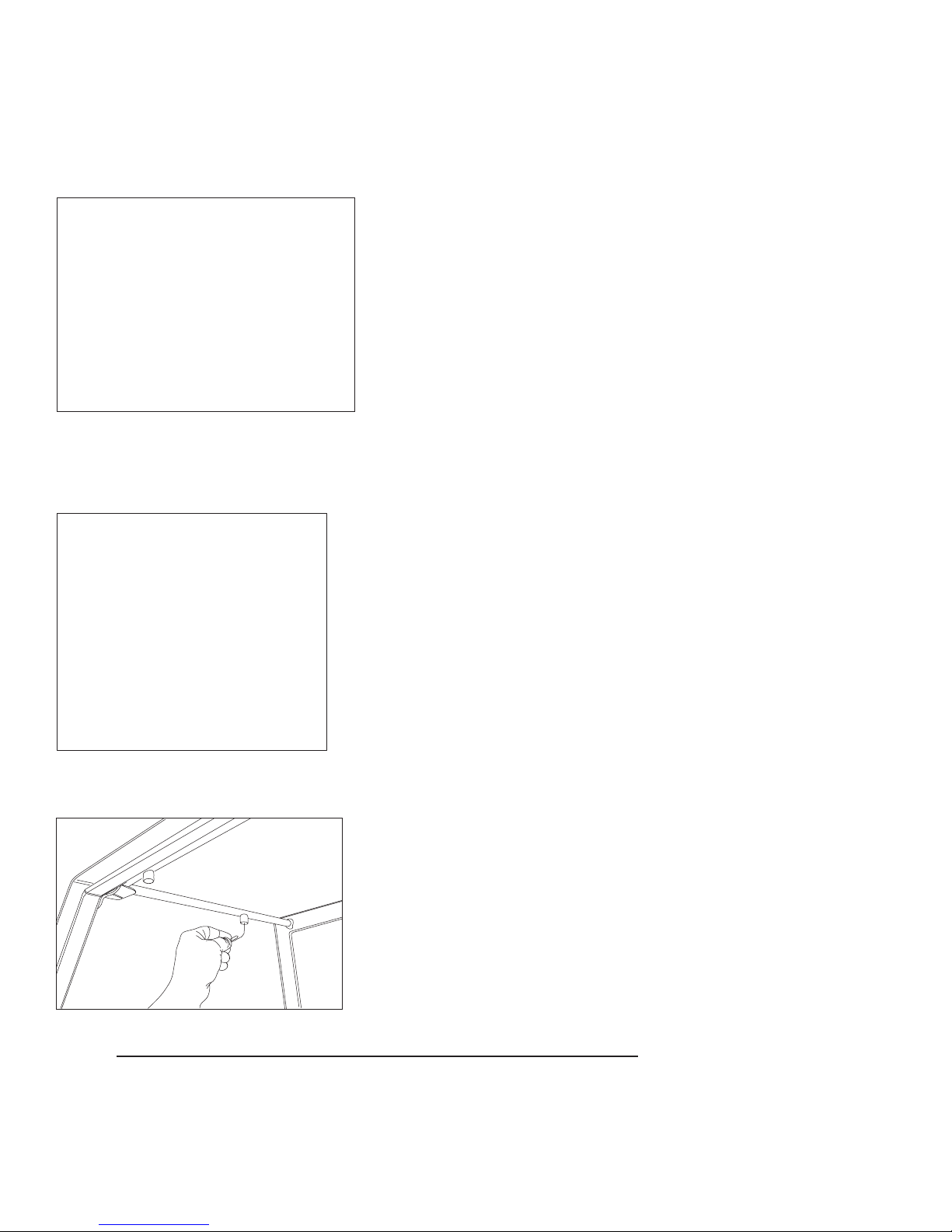

The glasswasher flexible drain hose

must be connected to a WYE fitting.

Do not connect the glasswasher

flexible drain hose to a TEE fitting.

25

Page 34

Initial Start-up - 240LT

Check List

Model 240LT

1. Make sure the glasswasher is permanently located.

2. Make sure all utility connections are complete.

3. Make sure the exible drain hose and the hot water ll hose are not kinked.

4. Remove any protective lm from glasswasher.

5. Check the interior for foreign material.

6. Remove the scrap screen and check the sump for foreign material.

7. Make sure the chemical supply containers are full and that the chemical pick-up tubes

are installed in the proper containers.

8. Make sure the scrap screen is in place.

9. Make sure the spray arm is in place and that it spins freely.

10. Close the glasswasher door.

11. Turn hot water supply on and check for leaks in the main water supply piping connected

to the glasswasher.

Scrap Screen

Spray Arm

Make sure the scrap screen and spray arm are in place.

26

Page 35

240LT - Initial Start-up

Chemical Dispensing Pumps

Model 240LT

ATTENTION

(For 240LT Model Only), 5.25% sodium hypochlorite (chlorine bleach) must be used as a

sanitizing agent to provide a minimum concentration of 50 ppm in the final rinse.

The 50 ppm concentration must be checked using chlorine test strips to make sure the proper

concentration is maintained

Wash Thermo

Detergent Rinse-aid Sanitizer

1. Model 240LT is equipped with built-in detergent, rinse-aid, and sanitizer dispensing

pumps. (See the illustration above).

2. The pumps are located on a center bracket behind the lower-front access panel.

3. The pick-up tubes are marked with colored labels that identify the type of chemical used:

RED = Detergent (Non-chlorinated)

BLUE = Rinse-Aid (Consult chemical supplier)

WHITE = Sanitizer (5.25% Sodium hypochlorite

(chlorine bleach) solution.

The chemicals enter the wash tank compartment through a tting on the right rear of the

wash compartment.

4. The detergent supply should be a non-chlorinated liquid detergent, the chemical supplier

will determine an appropriate rinse agent. Your chemical supplier must adjust the

dispensers for the supplied product.

5. Place the chemical supply containers as close to the glasswasher as possible.

6. Do not elevate the chemical containers above the nished oor.

Chemical Pick-up Tubes

Chemical Injection Point

27

Page 36

Initial Start-up - 240LT

Chemical Dispensers

Model 240LT

Priming the Chemical Dispensing Pumps

POWER

ON

I

O

OFF / DRAIN

120

140

100

160

40

80

60

20

60

40

0

20

TEMPERATURE

180

80

100

220

PRIME

200

Detergent and Sanitizer

Prime Switch

R/ADET

SAN

Rinse-aid

Prime Switch

1. There are two chemical dispenser prime push buttons on the 240LT. The rst is labeled

DET and SAN on the front control panel; the second is labeled R/A.

DET = Detergent

SAN = Sanitizer

R/A = Rinse-aid

2. Make sure the chemical containers are full and the correct pick-up tubes are in their

containers.

3. Turn the glasswasher power switch ON. The switch will illuminate and the glasswasher

will ll with water.

START

4. Open the glasswasher door, then push and hold the rst prime push button UP to the

DET position until detergent enters the wash tank compartment.

Release the PRIME push button.

5. Push and hold the prime push button DOWN to the SAN position until sanitizer

is observed entering the wash tank compartment. Release the Prime push button.

6. Push and hold the second prime push button UP to the R/A position until rinse-aid

is observed entering the wash tank compartment. Release the Prime push button.

7. Run three empty cycles to remove chemicals in the wash tank.

8. Priming is complete.

28

Page 37

240LT - Initial Start-up

Chemical Dispensers

240LT

Chemical Dispensing Pump Speed and Tank Fill Adjustments

NOTE:

The chemical dispensing pump speeds are not set at the factory and variations in the

type of chemicals supplied by the chemical supplier always require that the supplier

make nal adjustments for the products supplied.

1. Adjustment screws are provided for the dispensing pumps and for the wash tank ll. They are

located on the right-side of the glasswasher behind the lower front access panel.

2. Make sure the chemical containers are full and the

pick-up tubes are in the proper containers.

3. Turn the glasswasher power switch ON.

The switch will illuminate and the glasswasher

will ll with water.

4. The chemical supplier should run a normal glasswasher

cycle and test detergent and rinse-aid concentrations

according to the chemical supplier's instructions.

CAUTION:

Excessive pressure to the potentiometers when adjusting can result

in bent or broken adjusting screws.

5. Each dispensing pump has a clearly marked

adjustment screw. Turn the screw CW to increase

the time of the dispensing pump and CCW to

reduce the dispensing pump time.

6. The Fill adjustment screw will provide a small

change in the tank water level. If a large adjustment

is needed, then check the incoming water pressure

making sure the ll hose is not kinked. If the above items

are okay then the size of the incoming water supply

should be evaluated.

7. For Model 240LT detergent, rinse-aid and sanitizer

are used.

5.25% sodium hypochlorite (chlorine beach) must be used

as a sanitizing agent to provide a minimum concentration

of 50 ppm in the final rinse. The 50 ppm concentration must

be checked using chlorine test strips to make sure that the

proper concentration is maintained.

Turning the chemical dispenser

adjusting Screws increase or

decrease the chemical dispensed.

Proper Water Level in the Wash Tank.

29

Page 38

Operation - 240LT

240LT Normal Wash Cycle

ON

POWER

O

OFF / DRAIN

OFF/Drain Switch

I

Power ON

Temperature

Gauge

120

140

100

160

40

80

60

20

60

40

0

20

TEMPERATURE

180

80

100

220

PRIME

200

Detergent and Sanitizer

Prime Switch

R/ADET

SAN

Rinse-aid

Prime Switch

In-cycle

Light

Cycle

Start Switch

240LT Control Panel

1. Push the POWER switch up to the ON position. The switch illuminates and water enters

the wash compartment.

2. Check the temperature gauge to ensure that it indicates a minimum of 140°F/60°C.

3. Prescrap and load wares into the appropriate dish rack. Do not overload dish rack.

Load wares in a peg rack; load silverware in a single layer in a at-bottom dish rack.

Overloading dish rack will result in poor washing results.

4. Open glasswasher door and slide dish rack into the machine. Load 1 dish rack per wash

cycle.

5. Close the glasswasher door. Press and hold START button for 1 second.

The cycle light illuminates and the wash cycle begins.

START

6. Check the temperature gauge during the nal rinse cycle to ensure the nal rinse

temperature indicates a minimum of 140°F/60°C during the nal rinse.

7. The green in-cycle light goes out completing the cycle. The nal rinse water

is held for the next wash cycle.

8. Open the glasswasher door and remove the dish rack of clean wares.

9. Repeat steps 2-8 for additional cycles.

NOTE:

Opening the door stops the cycle. When the glasswasher door is closed the cycle automatically

restarts from the beginning of the cycle.

30

Page 39

240LT - Operation

240LT Drain Operation

1. Push the glasswasher POWER switch up to the ON position.

2. The POWER switch illuminates and the machine lls with water.

3. Press and hold the green START button for 1 second.

4. Release the START switch.

5. The glasswasher starts and the green cycle light illuminates.

6. Check the temperature gauge to conrm that it displays the correct incoming hot water

temperature. This may take several minutes for the wash tank to reach temperature.

7. When the glasswasher stops, push the POWER switch down to the OFF/DRAIN position.

8. After a 4 second pause, the green cycle light will illuminate, the machine will drain, ll

with water; and perform 3 short cycles and then drain completely.

9. The green cycle light goes out when the machine has drained completely.

31

Page 40

Cleaning - 240LT

Cleaning

The best preventative maintenance is keeping the glasswasher as clean as possible

during regular use. A regular cleaning schedule will increase the life of the glasswasher

and ensure the best washing results.

CAUTION:

Damage to the unit or improper operation may occur if components are not

flushed and cleaned on a regularly scheduled basis.

After Each Meal Period or Every 8 hours of Operation

1. Remove the scrap screen and flush with clean water. Be sure to backflush the screen.

2. Inspect the sump and pump intake screen and clean as required.

3. Reassemble the machine and return to normal operation.

Daily-End of the Day

1. Push the POWER switch to the OFF/DRAIN position and close the door to drain the tank.

The green in-cycle light will illuminate indicating the machine is in the drain cycle.

2. After the green in-cycle light goes out, open the door and remove the lower spray arm.

3. Backush the spray arm with clean water to remove any debris from the spray nozzles.

Do not strike the spray arm against solid objects

Bearing

Nozzles

32

Page 41

240LT - Cleaning

4. Remove and clean the scrap screen by rinsing with clean water. Be sure to backush

the screen. Do not strike the screen on hard surfaces.

5. Inspect the sump and remove any foreign material.

6. Clean the pump intake screen. The pump intake screen is not removable.

7. Reinstall the scrap screen.

Pump Intake

Screen

Sump

continued on next page

33

Page 42

Cleaning - 240LT

Cleaning

Daily-End of the Day

8. Using a small paperclip, clean the nozzles in the upper rinse piping.

The rinse piping is not removable.

(continued)

9. Wipe the exterior of the glasswasher clean using a soft cloth and mild detergent.

10. Leave the glasswasher door open overnight to allow the inside to dry.

34

Page 43

240LT - De-liming

De-liming

Minerals accumulate on the interior surfaces of the glasswasher. The removal of lime

deposits is called de-liming and the glasswasher should be de-limed regularly. Inspect the

machine interior for lime deposits. If de-liming is required, a de-liming agent should be used in

accordance with the chemical supplier's instructions.

DANGER:

Death or serious injury may result when de-liming solution is mixed with sodium

hypochlorite sanitizing agent. Mixing may cause hazardous gases to form. De-liming

solution and other acids must never be mixed with chlorine, iodine, bromine, or fluorine.

CAUTION:

Skin contact with de-liming solutions can cause severe irritation and possible chemical

burns. Always wear eye protection, rubber gloves and protective clothing when handling

chemicals.

Follow the steps below to de-lime the 240LT glasswasher. Close the door.

1. Open the glasswasher door and remove any dish racks.

2. Turn the power switch on the glasswasher to the ON position.

3. Remove the detergent, sanitizer and rinse-aid chemical supply tubing from their

chemical supply containers.

4. Place the tubing in a container of hot water.

5. Press and hold the prime switch UP in the DET position for 2 minutes to ush the

detergent from the supply tubing. Release the switch.

6. Press and hold the prime switch DOWN in the SAN position for 4 minutes to ush the

sanitizer from the supply tubing. Release the switch.

7. Press and hold the prime switch UP in the R/A position for 4 minutes to ush the

rinse-aid from the supply tubing. Release the switch.

8. Turn the glasswasher power switch to OFF/DRAIN to drain the wash tank. The green

in-cyle light will go out when complete. Turn the power switch to ON to rell the

machine. Repeat 3 more times to completely ush any chemicals from the machine.

9. Open the door and carefully add the de-liming chemical to the wash tank in accordance

with the chemical supplier's instructions. Be careful to avoid splashing.

10. Close the door and press the START button to begin a wash cycle.

11. The green in-cyle light will illuminate and the machine will complete an automatic cycle.

12. Turn the glasswasher power switch to OFF/DRAIN to drain the wash tank. The green

in-cyle light will go out when complete (90 seconds). Turn the power switch to ON to

rell the machine.

13. Run 3 more empty wash cycles to completely ush any chemicals from the machine.

14. Check the de-liming results and if scale is still present repeat steps 8-13.

15. Return chemical supply tubing to their containers and prime the chemical lines.

16. Return the glasswasher to normal operation.

35

Page 44

Maintenance - 240LT

Maintenance Schedule

Follow the maintenance schedules below to keep the glasswasher operating most

efficiently.

Daily Maintenance

1. Make sure that the water supply is on and that the drain is not clogged.

2. Check the temperature gauge and ensure it is operating.

3. Make sure that dish racks are in good condition.

4. Check the chemical containers and rell as required.

5. Follow the cleaning procedures given above.

Weekly Maintenance

1. Perform Steps 1-5 in the Daily Maintenance.

2. Inspect water lines for leaks.

3. Check for water leaks underneath the glasswasher.

4. Make sure the exible water ll and drain hoses are not kinked.

5. Make sure that the glasswasher is level.

6. Clean accumulated lime deposits from the wash tank heating element.

7. Inspect the scrap screen and replace it if damaged.

8. Check the spray arm and replace or repair if damaged.

Monthly Maintenance

1. Perform the Daily and Weekly Maintenance listed above.

2. Clean the chemical dispenser pick-up tubing by ushing with hot water.

To clean the pick-up tubing:

1. Remove the pick-up tubes from their containers.

2. Place each tube in a separate container of hot water.

3. Press and hold the PRIME button up in the DET position until water ows into the wash

tank compartment.

4. Press and hold the PRIME button down in the SAN position for 3 minutes.

5. Press and hold the PRIME button up in the R/A position for 3 minutes.

6. Return the pick-up tubes to their containers.

7. Run 3 empty glasswasher cycles to ush any chemicals from the glasswasher

wash compartment.

36

Page 45

240LT - Troubleshooting

Condition Cause Solution

Dishwasher will not run.

Low or no water.

Chemicals won’t feed into

dishwasher.

Low water pressure

pumped from spray arms.

Poor wash results.

Door not closed.

Main power OFF.

Dishwasher OFF.

Main water supply off.

Solenoid valve defective.

Solenoid strainer clogged.

Flow washer defective.

Timer board defective.

Chemical supply low.

Supply tubing damaged.

Supply tubing kinked.

Pick-up tube clogged or

defective.

Timer board defective.

Clogged scrap screen.

Clogged spray arms.

Clogged pump intake

screen.

Water temperature low.

Thermostat defective.

(See chemicals won’t feed

above.)

(See low or no water

above.)

Detergent injector defective.

Close door completely.

Check breaker on panel.

Turn dishwasher ON.

Open supply valve.

Install repair kit or replace.

Clean strainer.

Replace flow washer.

Test/replace timer board.

Refill chemical container.

Replace tubing.

Straighten tubing.

Clean/replace tube.

Test/replace timer board.

Clean scrap screen.

Clean spray arms.

Clean sump and pump

intake screen.

Raise incoming water

temperature.

Adjust/replace thermostat.

(See chemicals won’t feed

above.)

(See low or no water

above.)

Replace squeeze tube.

Replace injector motor.

Clean pick-up tubing,.

hoses and strainer.

Wares incorrectly loaded.

in dishrack.

Reposition wares/reduce

amount of wares.

37

Page 46

Blank Page

This Page

Intentionally

Left Blank

38

Page 47

Service Replacement Parts

Service Replacement Parts

Illustrations Page

Wash Pump/Motor Assembly ................................................................................................................................. 40

240HT - Booster Assembly ..................................................................................................................................... 42

Electrical Panel and Timer Board Assembly ........................................................................................................... 44

240HT - Control Panel Assembly ........................................................................................................................... 46

240LT - Control Panel Assembly ............................................................................................................................ 48

240HT - Wash, Rinse, and Drain Assemblies......................................................................................................... 50

240LT - Wash, Rinse, and Drain Assemblies ......................................................................................................... 52

Wash Tank, Heater, and Scrap Screen................................................................................................................... 54

240HT - Drain Manifold and Fill Solenoid Valve Assembly ..................................................................................... 56

240LT - Drain Manifold and Fill Solenoid Valve Assembly...................................................................................... 58

240HT - Vacuum Breaker and Rear Piping Assembly ............................................................................................ 60

240LT - Fill Chute and Rear Piping Assembly ........................................................................................................ 62

240HT/240LT - Panel Assembly ............................................................................................................................. 64

Door Assembly ....................................................................................................................................................... 66

240HT- Chemical Dispensing Pumps ..................................................................................................................... 68

240LT - Chemical Dispensing Pumps .................................................................................................................... 70

Dish Racks ............................................................................................................................................................. 72

Electrical Schematic - 240HT ................................................................................................................................. 74

Electrical Schematic - 240LT .................................................................................................................................. 75

Timer Chart ............................................................................................................................................................. 76

39

Page 48

Wash Pump/Motor Assembly

11

12

13

14

9

8

7

10

6

5

4

3

2

40

1

Page 49

Wash Pump/Motor Assembly

Item Part Description Qty.

No. No.

1 0512340 SCREW, M4, PHIL.PAN HD. 9

2 0512341 IMPELLER, HOUSING COVER 1

3 114144 NUT, M6 (LEFT-HAND THREADS) 1

4 0501501 WASHER, LOCK 1/4" 1

5 0501478 WASHER, PLAIN 17/64" 1

6 0512345 IMPELLER 1

7 114139 SEAL, PUMP 1

8 110285 GASKET, PUMP 1

9 114137 PLATE, PUMP BACKING 1

10 0512101 MOTOR, PUMP ASSEMBLY COMPLETE 115V/60/1 1

11 107337 NUT, M4 9

12 0512347 CAPACITOR,40μF 1

13 0313028 BRACKET, PUMP 1

14 0512185 BOLT, HEX FLANGE, 1/4-20 X 3/8" SST 2

41

Page 50

240HT - Booster Assembly

15

14

16

15

14

13

12

11

10

9

16

15

17

15

16

18

19

1

42

2

3

4

5

6

7

8

Page 51

Booster Assembly - 240HT

Item Part Description Qty.

No. No.

1 0509042 TANK, BOOSTER 1

2 0512185 BOLT, HEX FLANGE, 1/4-20 X 3/8" SST 2

3 0508817 PLUG, 1/8" HEX COUNTERSUNK 1

4 109985 SEAL, ELECTRIC HEATER FLANGE 1

5 111235-1 HEATER, 5/6.6KW 208-240V/60/1, 40ºF RISE 1

--- 111233 HEATER, 7.5/10KW 208-240V/1/60, 70ºF RISE 1

6 111885 INSULATION, FISHPAPER 1

7 100003 NUT, HEX 1/4-20 SST 6

8 H161123 COVER, HEATING ELEMENT 1

9 0512108 THERMOSTAT, BOOSTER 1

10 0512425 ADAPTER, THERMOSTAT (ORDER WITH ITEM 9) 1

11 110562 THERMOSTAT, HIGH LIMIT 1

12 108954 NUT, GRIP 6-32 WITH NYLON INSERT SST 2

13 0508840 BUSHING, 3/4" MPT X 3/8" FPT BRASS 2

14 0502653 ELBOW, 90º 3/8" MPT X 1/2" HOSE 2

15 0503679 CLAMP, SS GEAR, MIN. 5/16" MAX. 7/8" SST 4

16 107417 HOSE, RUBBER 1/2" ID X .84" OD A/R

17 0512857 TEE, RINSE THERMOMETER 1

18 0512941 FITTING, BOOSTER THERMOMETER 1

19 0512107 THERMOMETER, 2" DIAL 1

43

Page 52

Electrical Panel and Timer Board Assembly

LT M O D E L

12

13

14

H

18

T M

O

D

E L

10

19

15

1

2

3

4

5

6

6

17

4

16

15

14

13

12

11

10

7

4

8

4

9

44

Page 53

Electrical Panel and Timer Board Assembly

Item Part Description Qty.

No. No.

1 0503746 SCREW, 4-40 X 3/4" ROUND HEAD SST 2

2 113719 SWITCH, MAGNETIC REED 1

3 0313082 BRACKET, SWITCH ADJUSTMENT 1

4 100007 SCREW, 10-32 X 3/8" TRUSS HEAD 3

5 100778 SCREW, 1/4-20 X 3/8" TRUSS HEAD SST 2

6 0512373 FUSE, 4A, 250VAC 2

7 0512243 LABEL, ADJUSTMENT 1

8 0312189 COVER, TIMER ENCLOSURE 1

9 0312339 COVER, ENCLOSURE, ELEC. CONN. 1

10 0501472 WASHER, FLAT 1/8" X 1/2" BRASS 2

11 0312338 BASE, ENCLOSURE ELEC. CONN (240HT) 1

12 0503592 LABEL, GROUND (EARTH) 2

13 0501403 SCREW, RH 10-32 X 3/4" SLOTTED BRASS 2

14 0501493 WASHER, LOCK #10 EXT. TOOTH BRASS 4

15 0501533 NUT, 10-32 BRASS 4

16 0509527 BLOCK, TERMINAL 4-POLE 1

17 0312888 BASE, TIMER ENCLOSURE 1

18 0512292 CORD AND PLUG (240LT ONLY) 1

19 0512105-1 TIMER CKT. BOARD, SOLID STATE 1

45

Page 54

240HT - Control Panel Assembly

1

2

3

5

6

4

7

9

8

14

10

13

12

11

46

Page 55

Control Panel Assembly - 240HT

Item Part Description Qty.

No. No.

1 0313026 PANEL, LOWER FACIA 1

2 0513068 LABEL, FACIA 240HT 1

3 0512220 SWITCH, ROCKER DPST 125V NEON 1

4 0512107 THERMOMETER, 2" DIAL 2

5 0512226 SWITCH, ROCKER RND, SPDT MOMENTARY 1

6 0512232 LIGHT, INDICATOR, GREEN LED 2VDC 1

7 0512218 BUTTON, SWITCH GREEN 1

8 0512217 HOUSING, SWITCH 1

9 0512216 CONTACT, MOMENTARY, N.O. 1

10 0501540 SCREW, NIBS RH 8-32 X 1/2" PAN HD. PHIL. SST 4

11 0501373 SWITCH, 3-POSITION TOGGLE 1

12 0512432 CONTACTOR 25/40A, 3-POLE 115VAC 1

13 0512108 THERMOSTAT, BOOSTER 1

14 0507323 THERMOSTAT, WASH TANK 1

47

Page 56

240LT - Control Panel Assembly

2

3

1

11

4

10

5

6

9

8

7

48

Page 57

Control Panel Assembly - 240LT

Item Part Description Qty.

No. No.

1 0313027 PANEL, FACIA LOWER 1

2 0513067 LABEL, FACIA 240LT 1

3 0512220 SWITCH, ROCKER, DPST 125V NEON 1

4 0512107 THERMOMETER, 2" DIAL 1

5 0512226 SWITCH, ROCKER RND SPDT MOMENTARY 2

6 0512232 LIGHT, INDICATOR, GREEN LED 2VDC 1

7 0512218 BUTTON, SWITCH GREEN 1

8 0512217 HOUSING, SWITCH 1

9 0512216 CONTACT, MOMENTARY, N.O. 1

10 0501450 SCREW, NIBS RH 6-32 X 3/16" PHIL. SST 2

11 0507323 THERMOSTAT, WASH TANK 1

49

Page 58

240HT - Wash, Rinse, and Drain Assemblies

37

15

15

24

27

38

15

16

9

39

40

1

15

7

23

22

3

2

4

5

6

9

10

8

11

12

13

36

28

See illustration

on pg. 56-57

for detailed view

35

17

26

27

24

25

15

2815

21

14

15

20

17

19

18

See illustration

on pg. 56-57

for detailed view

29

30

31

34

50

33

32

Page 59

Wash, Rinse, and Drain Assemblies - 240HT

Item Part Description Qty.

No. No.

1 H36275 SPINDLE, RINSE ARM 1

2 H190663 BUSHING, RINSE ARM 2

3 H37149 NOZZLE, RINSE ARM 6

4 0512843 CAP, RINSE ARM, 5/16-24 2

5 H34998 NUT, SPACER 1

6 0712749 BEARING, ASSEMBLY, WASHARM 1

7 0512124 SHAFT, LOWER 1

8 0512066 HUB, LOWER WASHARM 1

9 0512322 CLAMP, HOSE 1-13/16" - 2-3/4" MAX SST 2

10 0512132 HOSE, OVERFLOW MOULDED 1

11 0502563 CLAMP, HOSE GEAR-TYPE 1" SST 1

12 0512227 PUMP, DRAIN 115V/60/1 1

13 0312145 BRACKET, DRAIN PUMP 1

14 0512352 SCREW, PHILLIPS PAN HEAD #10 X 3/4" 2

15 0503679 CLAMP, HOSE GEAR-TYPE SST 9

16 0508808 CLAMP, HOSE GEAR-TYPE SST 1

17 0509302 HOSE, 5/8" ID X 1" OD BRAIDED A/R

18 0512134 TEE, POLY 3/4" 1

19 108447 CAP, 1-1/4" PLASTIC 1

20 D80305 GASKET, ELBOW 1

21 D500603 ELBOW, PUMP SUCTION 1

22 D80208 GASKET, PUMP SUCTION 1

23 D500615 FLANGE, PUMP SUCTION 1

24 0502571 CLAMP, HOSE 1-1/2" GEAR-TYPE SST 4

25 0512118 HOSE, PUMP SUCTION 1

26 0512119 HOSE, PUMP DISCHARGE 1

27 107417 HOSE, RUBBER 1/2" ID X .84" OD A/R

28 0505320 WASHER, GARDEN HOSE 2

29 0313050 BRACKET, VALVE 1

30 0512185 BOLT, HEX FLANGE, 1/4-20 X 3/8" SST 2

31 0512936 WASHER, SILICON, 5/8" ID X 7/8" OD 1

32 0512926 HOSE, BOOSTER FILL, 1/2" ID X 12" LG. 1

33 107928 TUBING, 1/4" NATURAL A/R

34 109812 GAUGE, PRESSURE 0-60 PSI 1

35 111100 ELBOW, FEMALE 1/4" OD X 1/8" NPT 1

36 0509526 HOSE, 1/2" X 7 FT. LG. W/GARDEN HOSE ADAPTER 1

37 0713051 MANIFOLD, UPPER WASH 1

38 0512321 COUPLER, 3/4" MPT X 3/4" HOSE BARB, POLYPRO 1

39 0512120 HOSE 1

40 H420548 ASSEMBLY, WASHARM (INCLUDES ITEM 6) 1

51

Page 60

240LT - Wash, Rinse, and Drain Assemblies

3

1

17

23

17

20

25

26

14

24

18

19

17

4

See illustration

on pg. 58-59

5

for detailed view

16

15

2

6

7

52

23

22

21

14

17

13

11

11

10

12

See illustration

on pg. 58-59

for detailed view

8

9

Page 61

Wash, Rinse, and Drain Assemblies - 240LT

Item Part Description Qty.

No. No.

1 0512129 NUT, WASHARM 1

2 0712749 BEARING ASSEMBLY, WASHARM 1

3 H420548 WASHARM ASSEMBLY (INCLUDES ITEM 2) 1

4 0512125 SHAFT, LOWER F&D 1

5 0512066 HUB, LOWER WASHARM 1

6 D500615 FLANGE, PUMP SUCTION 1

7 D80208 GASKET, PUMP SUCTION 1

8 D500603 ELBOW, PUMP SUCTION 1

9 D80305 GASKET, ELBOW 1

10 108447 CAP, 1-1/4" PLASTIC 1

11 0512185 BOLT, HEX FLANGE, 1/4-20 X 3/8" SST 4

12 0300203 CLAMP, VALVE 1

13 0313050 BRACKET, VALVE 1

14 0502571 CLAMP, HOSE 1-1/2" GEAR-TYPE SST 4

15 0512118 HOSE, PUMP SUCTION 1

16 0509302 HOSE, 5/8" ID X 1" OD BRAIDED A/R

17 0503679 CLAMP, GEAR, MIN. 5/16" MAX. 7/8" SST 5

18 0512120 HOSE 1