Page 1

MD-1000HT

Installation Manual with Service Replacement Parts

Door-type

Dishwasher

Models:

MD-1000HT

Pumped rinse high temperature sanitizing

w/built-in stainless steel electric booster

MD-1000LT

Pumped rinse low temperature sanitizing

w/3 built-in chemical dispensing pumps

www.moyerdiebel.com

P.O. Box 4183

Winston-Salem, NC 27115

336/661-1992 Fax: 336/661-1660

Toll-free: 800.858.4477

MD-1000LT

Issue Date: 3.14.06

Manual P/N 114156 rev.—

For machines beginning with S/N D2466 and above

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Toll-free: 800.263.5798

Dishwasher serial no.

File: DTMVC0214.6

Printed in the USA

Page 2

For future reference, record your dishwasher information in the box below.

Model Number__________________________ Serial Number_______________________

Voltage________________Hertz_____________ Phase__________________

Moyer Diebel Service Agent __________________________________ Tel:______________________

Moyer Diebel Parts Distributor _________________________________ Tel:______________________

For all models:

The data plate mounts to the

right-hand, side of the

top-mounted control cabinet.

National Service Department

In Canada: In the USA:

Toll-free: 800/ 263-5798 Toll-free: 800/ 858-4477

Tel: 905/ 562-4195 Tel: 336/ 661-1992

Fax: 905/ 562-4618 Fax: 336/ 661-1660

email: service@moyerdiebellimited.com email: service@moyerdiebel.com

ATTENTION:

The dishwasher model no., serial no.,

voltage, Hz and phase are needed to

identify your machine and to answer

questions.

We support

Please have this information on-hand

if you call for service assistance.

COPYRIGHT © 2006 All rights reserved Printed in the USA

Page 3

Revisions to this manual

_____________________ Revisions to this manual

This is where we record changes to the manual. A revision might be a part number

change, new instructions, or information that was not available at the time of printing.

We reserve the right to make changes to this manual without notice and without

incurring any liability by making the changes.

Dishwasher owners may request a revised manual, at no charge, by calling

1 (800) 858-4477 in the USA or 1 (800) 263-5798) in Canada.

Revision Revised Serial Number Revision

Date Pages Effectivity Description

3.14.06 All D2466 Released first edition

i

Page 4

Dear Owner:

Thank-you for choosing our dishwasher.

We appreciate your business.

This manual covers two models:

MD-1000HT Pumped rinse high temperature door -type dishwasher with standard

built-in booster in 40

MD-1000LT Pumped rinse low temperature chemical sanitizing door-type dishwasher with

built-in chemical dispensing pumps for detergent, rinse-aid, and sanitizer.

° F/22° C rise or an optional 70° F/39° C rise booster.

The installation, and initial start-up of your dishwasher

must be performed by qualified electricians, plumbers,

and authorized service technicians who are trained in

commercial dishwashers.

Defects and repairs resulting from the improper

installation of your dishwasher cannot be covered

by the dishwasher warranty.

Mr. or Ms. Installer:

Please read the installation guide before you begin.

Thank you,

Your Dishwasher!

ii

Page 5

Table of Contents

_____________ Table of Contents

Revisions to this manual _______________________________________________ iii

Limited Warranty ___________________________________________________ vi

Installation Guide

MD-1000HT: High temperature Door-type Dishwasher _________ pg.2

Unpack and Place ; Water Connection

;

;

Drain Connection ; Electrical Connection

;

Ventilation ; Chemical Dispensers

_____________________________________________________ Initial Start-up

______________________________________ How to Operate your dishwasher

________________________________________ How to Clean your dishwasher

_____________________________________ How to Maintain your dishwasher

_________________________________________________ The Troubleshooter

MD-1000LT: Low Temperature Door-type Dishwasher ________ pg.26

Unpack and Place ; Water Connection

;

;

Drain Connection ; Electrical Connection

;

Ventilation ; Chemical Dispensers

Initial Start-up

______________________________________ How to Operate your dishwasher

________________________________________ How to Clean your dishwasher

_____________________________________ How to Maintain your dishwasher

_________________________________________________ The Troubleshooter

All Models

Service Replacement Parts _______________________________________ pg.43

Appendix A: (Specification Sheets)

Electrical Schematics

iii

Page 6

Limited Warranty

R

Limited Warranty

Moyer Diebel, P.O. Box 4183, Winston-Salem, North Carolina 27115, and P. O. Box 301, 2674 North Service

Road, Jordan Station, Ontario, Canada L0R 1S0 warrants machines, and parts, as set out below.

Warranty of Machines:

“Moyer Diebel” and installed within the United States and Canada to be free from defects in material and workmanship for a period of one (1) year after the date of installation or fifteen (15) months after the date of shipment by

Moyer Diebel, whichever occurs first. [See below for special provisions relating to Model Series DF and SW.] The

warranty registration card must be returned to Moyer Diebel within ten (10) days after installation. If warranty card

is not returned to Moyer Diebel within such period, the warranty will expire after one year from the date of shipment.

Moyer Diebel will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Moyer Diebel, at its election, will either repair or replace the defective machine or accept return of the machine for full credit; provided,

however, as to Model Series DF and SW, Moyer Diebel’s obligation with respect to labor associated with any repairs shall end (a) 120 days after shipment, or (b) 90 days after installation, whichever occurs first. In the event that

Moyer Diebel elects to repair, the labor and work to be performed in connection with the warranty shall be done

during regular working hours by a Moyer Diebel authorized service technician. Defective parts become the property

of Moyer Diebel. Use of replacement parts not authorized by Moyer Diebel will relieve Moyer Diebel of all further

liability in connection with its warranty. In no event will Moyer Diebel’s warranty obligation exceed Moyer

Diebel’s charge for the machine. The following are not covered by Moyer Diebel’s warranty:

Moyer Diebel warrants all new machines of its manufacture bearing the name

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Adjustments to chemical dispensing equipment.

h. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

i. Performance of regular maintenance and cleaning as outlined in operator’s guide.

j. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior finish as a result of the above, (2) Use with utility service other than that designated on the rating

plate, (3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion

from chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due

to connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical dis-

pensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage caused by

labor dispute.

Warranty of Parts:

free from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in material and workmanship is found to exist within the warranty period Moyer Diebel will replace the defective part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. MOYER DIEBEL’S WARANTY

IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF

MERCHANTABILITY, OR FITNESS OF PURPOSE. MOYER DIEBEL SHALL NOT BE LIABLE FO

INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN MOYER DIEBEL

DISHWASHING MACHINES AND MOYER DIEBEL PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING ANY LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES.

Moyer Diebel does not authorize any other person, including persons who deal in Moyer Diebel Dishwashing

Machines to change this warranty or create any other obligation in connection with Moyer Diebel Dishwashing

Machines.

Moyer Diebel warrants all new machine parts produced or authorized by Moyer Diebel to be

iv

Page 7

Installation Guide

_____________ Installation Guide

; Unpack and Place MD-1000HT

1. Check the corrugated box that protected the dishwasher during shipment for

punched holes or impact marks.

2. Inspect the shipping pallet for splintered or broken boards.

3. Inspect the exterior of the dishwasher while still mounted on the pallet for signs

of damage.

4. Contact the freight company immediately if damage is found and save all packing

for inspection to verify your damage claim.

5. Report the damage to your equipment supplier. They will contact our factory

for repair or replacement of damaged components.

6. If no damage is found, proceed with lifting the dishwasher from its pallet.

Be careful to lift the dishwasher by the main frame if using a forklift.

7. Make sure the four legs are screwed firmly in place after landing the machine.

8. Check the packing list to ensure all accessories are with the dishwasher.

9. Open the doors and remove the dishracks inside the machine and locate

the postpaid warranty cards.

10. Complete the warranty card and drop in the mail immediately.

11. Move the dishwasher close to its permanent location.

12. Locate the Quick Check Installation Card glued on the front door of the

dishwasher. The card has a check list to familiarize the installer with the

dishwasher installation procedures detailed in this manual.

13. Remove the protective covering from the dishwasher and identify the

utility connections. Information cards and stickers must not be removed from

the dishwasher until the installation is complete.

14. Locate but do not remove the set of 2 keys attached to the back of the top-mounted

control cabinet.

v

1

Page 8

MD-1000HT • Unpack and Place

Installation Guide _____________

; Unpack and Place MD-1000HT

1. The installation of your dishwasher must be performed by qualified service personnel.

2. Problems due to improper installation are not covered by the Warranty.

3. Compare the utilities at the installation site with the specifications listed on each

model's specification sheets ( See Appendix A at the end of this manual)

4. The dishwasher data plate is located on the left, rear-corner of the top-mounted

control cabinet.

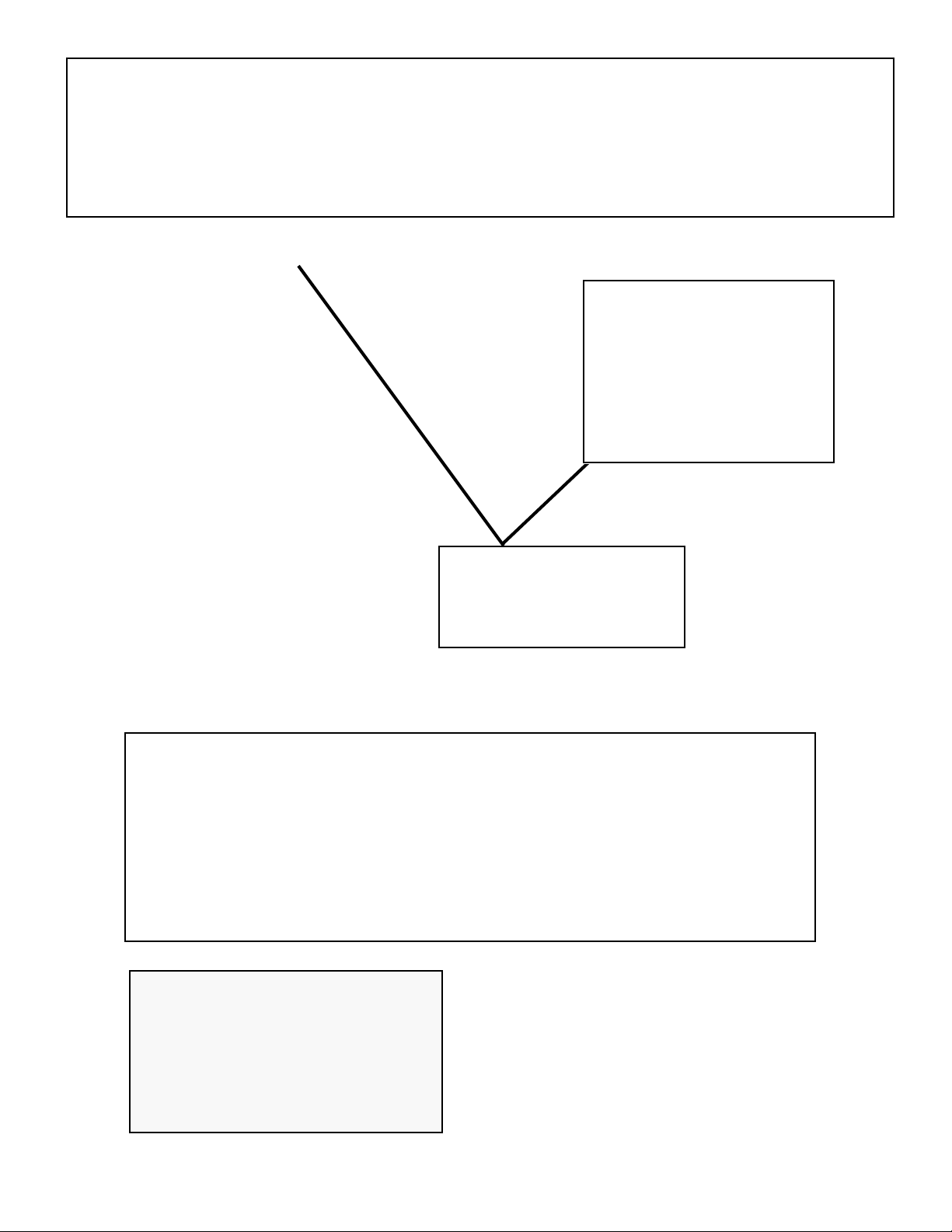

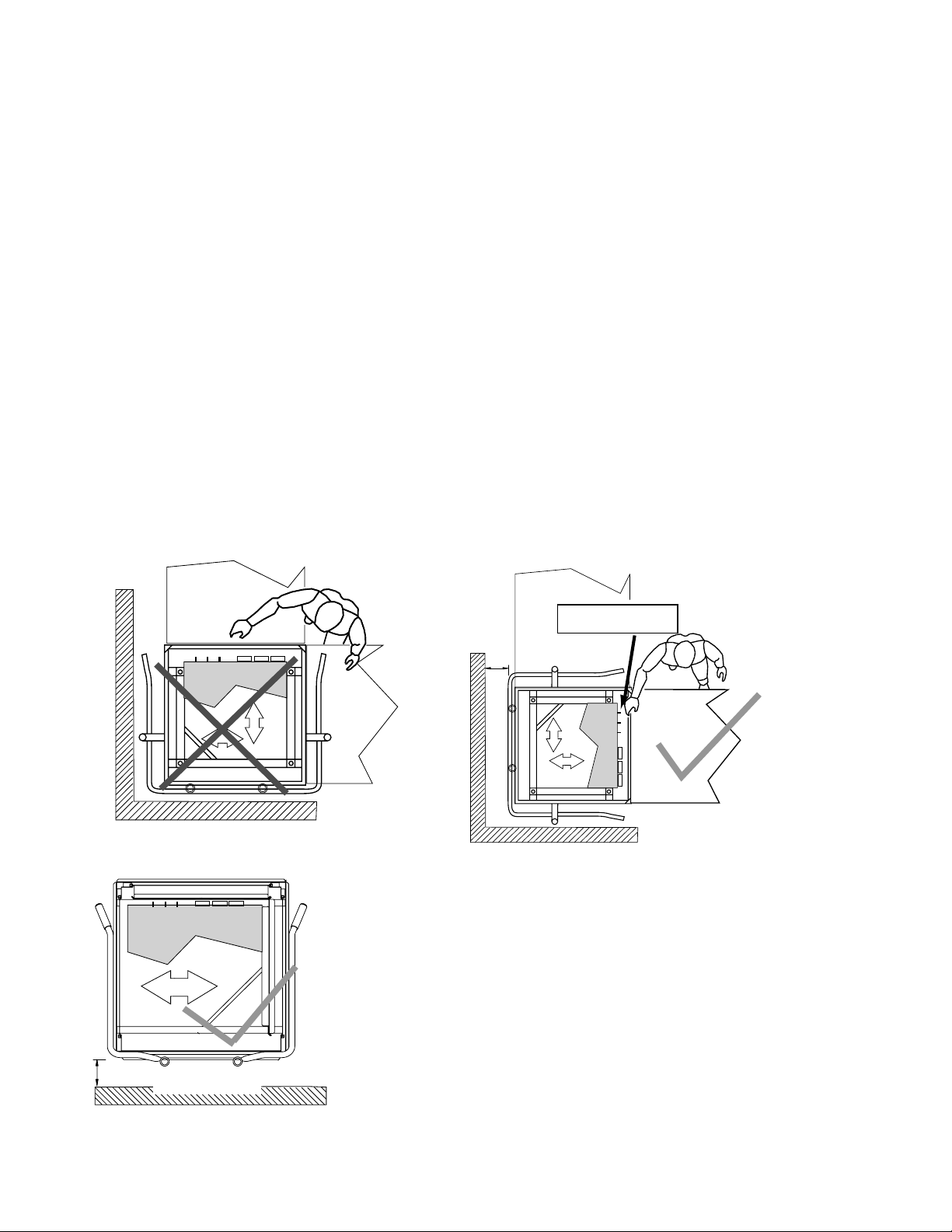

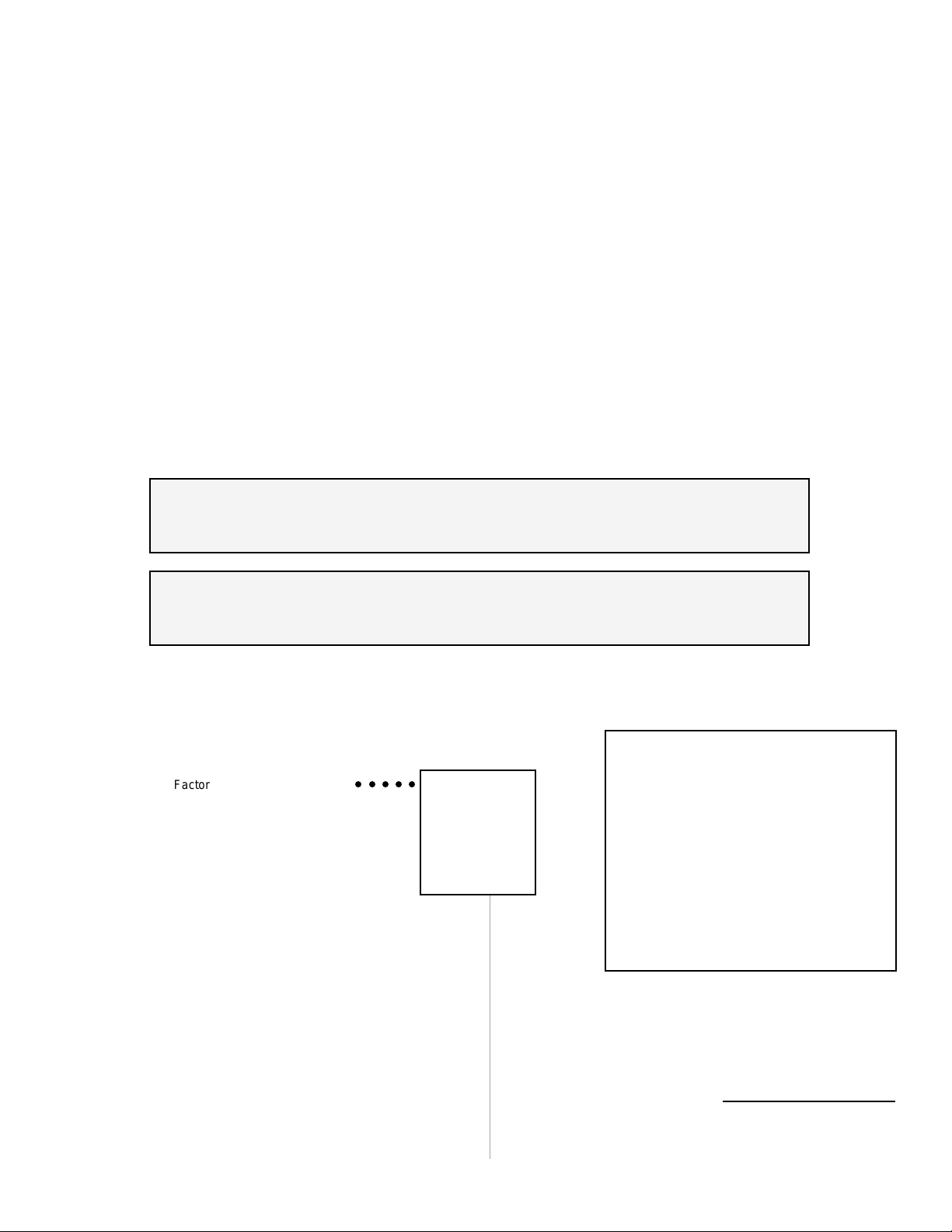

5. Study the configuration diagrams below. They show the 2 ways that the dishwasher may

be positioned.

Corner and straight-through dishwasher configurations

Dish table

Position dishwasher as shown

below so the controls are easy

to reach by the operator.

6" [152] Max.

Wall Clearance

Control Cabinet

Control Cabinet

Incorrect Corner Configuration

Correct Corner Configuration

Control Cabinet

Note:

The correct corner installation places the dishwasher

so the top-mounted controls are easy to reach.

Dish table

The minimum distance from wall to dishwasher

is 4" [103mm]. The maximum distance is

6" [129].

6" [152] Max.

Wall Clearance

Straight-through Configuration

The room ceiling height must be a minimum of

80" [2032mm] so the doors can be removed

completely.

2

Page 9

MD-1000HT • Unpack and Place

_____________ Installation Guide

; Unpack and Place MD-1000HT

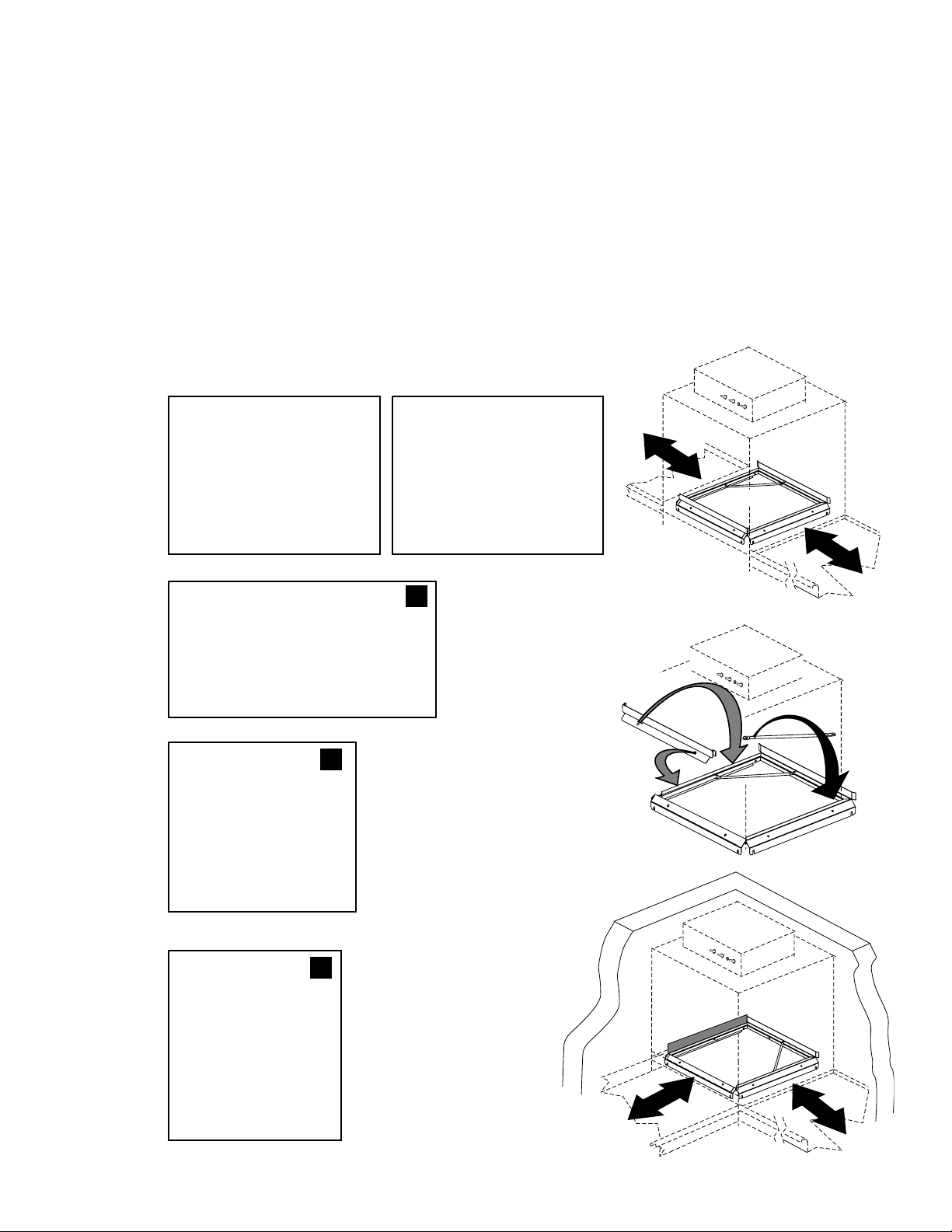

1. All dishwashers ship in the straight-through configuation.

2. Relocate the tracks and remove the wall-side door link components

to convert the dishwasher for corner operation.

1

Move Part 1

Remove Interior Door Bracket

4

2

Move Part 2

3

1

2

Remove Door Linkage

5

Adjust Door Spring Tension

wall

wall

3

Page 10

MD-1000HT • Unpack and Place

Installation Guide _____________

; Unpack and Place MD-1000HT

1. Compare the dishwasher and site utility connections.

2. Level the dishwasher by adjusting the bullet feet.

3. Raise the doors and check the door clearance to the ceiling.

4. Move the dishwasher to its permanent location.

Note:

Installers must follow applicable sanitation, safety, plumbing, and electrical codes and

regulations; and work in accordance with best practices for dishwasher installation.

Utility Connections - MD-1000HT

Power: 208-240V Single or Three Phase

Water supply: 3/4" NPT hot water supply (140°F/60°C minimum) for 40° F/22° C rise booster

(35 psi/241 KPa static pressure) 7-10 psi/63-69Kpa flow pressure

3/4" NPT hot water supply (110°F/43°C minimum) for 70° F/39° C rise booster

(35 psi/241 KPa static pressure) 7-10 psi/63-69Kpa flow pressure

Drain: 1-7/8" stainless steel, slip-fit hose connection

Max flow: 15 Us gal/min. (13.5 Imperial gal/min) 57liters/min.

Chemicals: Detergent and rinse-aid products are supplied by a chemical supplier

4

Page 11

MD-1000HT • Electrical Connection

_________________ Installation Guide

; Electrical Connection MD-1000HT

Warning:

The dishwasher must be electrically grounded according to all local codes

and regulations governing the installation of electrical service.

Warning:

Disconnect the main electric supply and place a tag at the fuse or disconnect switch

indicating that work is being performed on that circuit.

1. Locate the control cabinet keys on the rear of the control cabinet.

2. Remove 1 key to unlock the cabinet; do not remove the other key.

3. Unlock the control cabinet and remove the cover.

4. Locate the power cable knock out and main terminal block on the left-side of the cabinet.

5. Locate the Machine Electrical Connection Data Plate mounted near the terminal block.

The MACHINE ELECTRICAL CONNECTION DATA PLATE is the certified authority for the

dishwasher power requirement

unless an authorized factory represent

6. Connect the electric service to the dishwasher.

AA

TTENTIONTTENTION

A

TTENTION

AA

TTENTIONTTENTION

s. DO NOT use electrical data from any other source

ative instructs you to use other data.

Cable knock-out

Machine Electrical

Connection Data Plate

Main terminal block

ELECTRICIANELECTRICIAN

ELECTRICIAN

ELECTRICIANELECTRICIAN

The Model MD-1000HT dishwasher must not be turned ON at the dishwasher's

power switch located on the front of the top-mounted control cabinet

without performing an Initial Start-up at the same time.

Powering the dishwasher without performing the Initial Start-up

may damage the dishwasher's electrical circuits.

5

Page 12

MD-1000HT • Water Connection

Installation Guide _____________

; Water Connection MD-1000HT

1. Locate the built-in stainless steel booster on the left-side of the dishwasher.

Note:

The existing hot water supply lines to the dishwasher must be 3/4" NPT or larger. To the best of

your ability inspect, and verify that all supply piping meets the 3/4" NPT requirement.

Note:

The installing plumber must connect a water supply line to the dishwasher that is equal to or

greater than 3/4" NPT in size and a 3/4" pressure regulating valve, PRV (not supplied).

Dishwasher temperature

and water pressure requirements:

140°F/60°C minimum) for 40° F/22° C rise booster

(35 psi/241 KPa static pressure)

7-10 p

(110°F/43°C minimum) for 70° F/39° C rise booster

(35 psi/241 KPa static pressure)

7-10 p

2. Connect a 3/4” NPT hot water supply to the dishwasher at the line strainer.

Note:

The following components are not required for proper dishwasher operation, but are

highly recommended, because they make servicing of the dishwasher much faster.

Install the following components (not supplied) in the hot water supply line:

si/63-69Kpa flow pressure

si/48-69Kpa flow pressure

1) 3/4” or larger water shut-off valve near the machine in the water supply line.

2) ASSE 1010 Water hammer arrestor upstream from the shut-off valve.

3) Pressure gauge 0-60 PSI minimum downstream from the PRV.

4) Temperature gauge 0-180°F/82°C (not supplied) downstream from the gauge.

6

Page 13

Blank Page

This Page

Intentionally

Left Blank

7

Page 14

MD-1000HT • Drain Connection

Installation Guide _____________

; Drain Connection MD-1000HT

Continued from page 7

1. Locate the dishwasher drain connection underneath the machine frame.

2. Install a drain line conforming to local plumbing and health regulations.

Drain: 1-7/8" stainless steel, slip-fit hose connection

Max flow:

15 US gal/min.

13.5 Imperial gal/min

57liters/min.

; Ventilation MD-1000HT

1. The factory has no requirements for vent hoods; but, local codes and regulations in your

area supersede our suggestions. Consult your local building and health authorities for

local requirements.

2. Dishroom ventilation must provide sufficient airflow to prevent excessive humidity in the

work area. 200-400cfm/ 5.6 - 11.3 k Liters/min - is sufficient.

3. The dishwasher must not be subjected to continual drafts or cold air.

8

Page 15

MD-1000HT • Chemical Dispensers

_______________ Installation Guide

; Chemical Dispensers MD-1000HT

1. The MD-1000HT high temperature dishwasher sanitizes with 180-195° F/82-91° C

hot final rinse water.

2. Do not connect a sanitizer chemical dispenser to the MD-1000HT.

3. You may wish to contact a chemical supplier to supply the chemical dispensers

and chemicals for liquid detergent and liquid rinse-aid. (Consult your local listings).

4. The chemical supplier must adjust their dispensers to provide the proper dosages

for the installed dispensing system.

5. The factory may have supplied the chemical dispensing system as an option. Your

chemical supplier must adjust factory dispensers for the chemicals supplied also.

Note:

Manual dosing of detergent or rinse-aid is NOT RECOMMENDED for the MD-1000HT

dishwasher. Poor washing results may result if manual dosing is employed..

Note:

Cartridge detergent systems are NOT RECOMMENDED for the MD-1000HT

dishwasher. Poor washing results may result if installed on this model.

6. The factory recommends that the chemical injectors be installed in the right

front corner of the wash tank as shown below.

Factory installed injection points

○○○○○○

Recommended

locations

for chemical injectors

for dispensing

systems

supplied by others.

Continued on page 10

9

Page 16

MD-1000HT • Chemical Dispensers

Installation Guide _____________

; Chemical Dispensers MD-1000HT

Continued from page 9

115VAC Power Connections for Chemical Dispensers

FOR QUALIFIED INSTALLERS ONLY

Warning:

Chemical dispensers must be electrically grounded in compliance with applicable electric codes.

Warning:

Disconnect the main electric supply and place a tag at the fuse or

disconnect switch indicating that work is being performed on that circuit.

Caution:

Connecting chemical dispensers at points other than those recommended by the factory may

damage the dishwasher electrical system.

Damage caused by the installation of chemical equipment will not be covered by our WARRANTY.

1. Unlock the top-mounted control cabinet with the key. two keys should be stowed behind the

control cabinet. The installing electrician used one key during their installlation.

2. Locate the cycle timer mounted in the right-rear corner of the control cabinet.

3. Refer to the MD-1000HT electrical schematic located at the end of this manual.

10

Page 17

MD-1000HT • Chemical Dispensers

_________________ Installation Guide

; Chemical Dispensers MD-1000HT

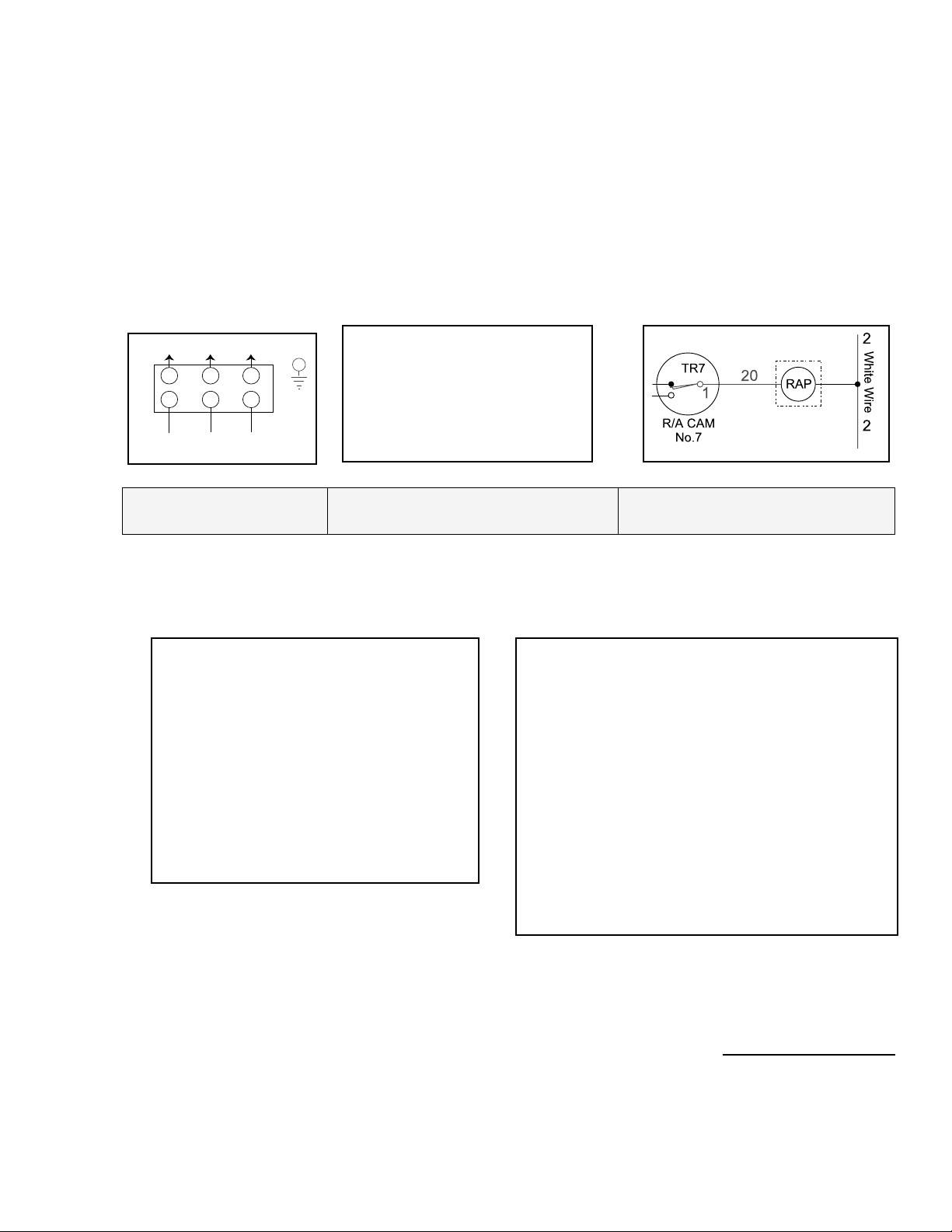

4. The diagrams below are taken from the electrical s chematic and are shown to help you

locate and focus on the steps necessary to connect the your dispensing pumps to the

dishwasher.

L1 L2

123

208VAC/3PH/60/3

Main terminal block Detergent dispensing pump & cycle Rinse-aid dispensing pump & cycle

and ground lug Timer cam No.6 with timer microswitch timer cam No.7 with timer microswitch

L2

GND

Earth

Ground

also called

Chassis

Ground

Continued on page 12

11

Page 18

MD-1000HT • Chemical Dispensers

Installation Guide _____________

; Chemical Dispensers MD-1000HT

Continued from page 11

5. The main terminal board is the

termination point for the incoming power

and earth ground which is also called the

chassis ground.

6. Chemical dispensers (not supplied by

Factory) should be grounded to chassis

if possible.

7. The detergent signal and the rinse-aid signal

terminals for your chemical dispensing pump

are provided on the common terminal of each

Timer Cam microswitch (See diagrams above).

Cam No.6 operates the detergent microswitch

Cam No.7 operates the rinse-aid microswitch.

8. Look to the right for the photo of a timer cam

microswitch. Note the configuration of the

switch, do you see how the common terminal

is different than the Normally Closed (N.C.)

and the Normally Open (N.O.) terminals?

9. Look again at the Cycle Timer and

locate the Detergent Cam No.6 and

the Rinse-aid cam No.7.

10. There are 7 Cams on the cycle timer.

They are numbered 1-7 starting at

the timer motor side of the assembly.

11. Look at the underside of the detergent

and the Rinse-aid timer microswitches

and identify the common terminals.

s

12. Connect the hot lead for the detergent

pump to the common terminal of Cam

Switch No. 6. Make the connection using

a 12-14 slip-on terminal.

Do the same for the rinse-aid switch.

12

Page 19

MD-1000HT • Chemical Dispensers

________________ Installation Guide

; Chemical Dispensers MD-1000HT

Caution:

The NEUTRAL RETURN (#2 white wires) and Chassis Ground are

not the same point electrically. Improper wiring to these points may

result in unusual voltage readings and damage to the dishwasher's

electrical circuits.STOP WORKING ON THE DISHWASHER AT ONCE,

if you do not know the difference between a neutral return and chassis

ground.

Note:

You may void the dishwasher warranty if you connect the neutral wire

of your dispensing system anywhere else than at the main power

transformer.

13. Now you must connect your pumps to

the dishwasher neutral return. All white

wires marked with No. 2 are neutral wires;

however, you are not authorized to connect

to any #2 wire that you may identify.

14. Run a 12 gauge white wire with spade terminal connector (not supplied) from your

chemical dispensing pumps to the neutral #2 white wire located on the main power

transformer in the control cabinet.

AA

TTENTION TTENTION

A

TTENTION

AA

TTENTION TTENTION

DO NOT TURN ON the dishwasher power switch

located on the front of the top-mounted control cabinet

before the Initial Start-up is completed

Powering the dishwasher as described above, without knowing for

ain that the Initial Start-up was performed, may make you liable for any damages

cert

stemming from your actions.

INSTINST

INST

INSTINST

ALLERALLER

ALLER

ALLERALLER

13

Page 20

MD-1000HT • Chemical Dispensers

Installation Guide _____________

; Chemical Dispensers MD-1000HT

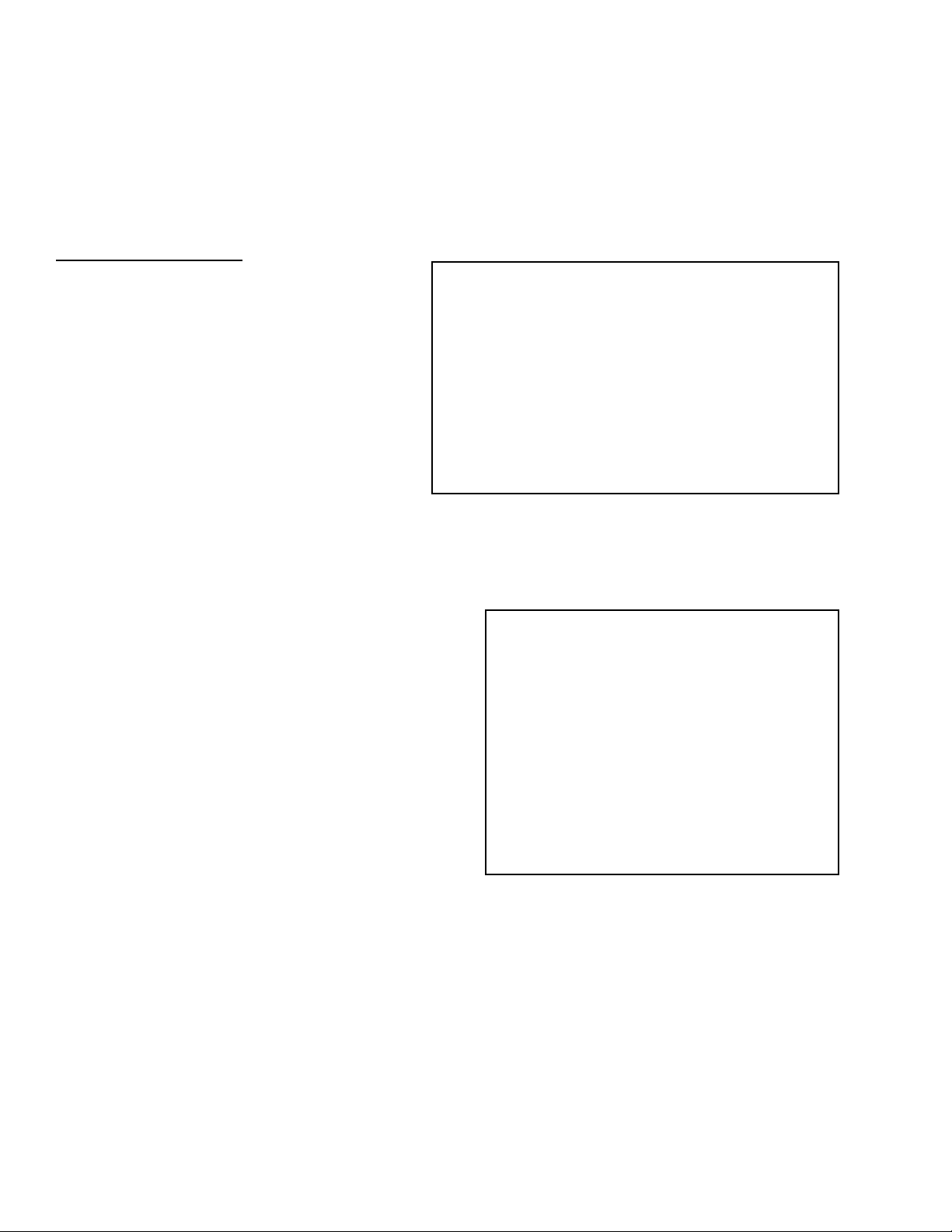

Priming the chemical dispensers (Factory dispensers only)

1. Factory dispensers are

optional equipment; however,

an automatic dispenser must

be installed by someone in

lieu of the factory.

2. The dispensers are mounted on

the right-hand side of the lower

wash tank.

From

Chemical

Containers

OUT OUT

IN IN

To wash tank

injection points

3. Chemical pick-up tubes are

inserted into their respective

containers.

4. Detergent and Rinse-aid chemical containers

can be placed a maximum of 11" [280 mm]

above the finished floor, (ABF).

5. Place the chemical containers as close

to the dishwasher as possible.

6. Each day check the detergent and rinse-aid

chemical containers to make sure they

are at least 1/2 full.

7. Push and hold the 2-position prime switch located on the front of the

top-mounted control cabinet. Push UP to prime the detergent

and DOWN to prime the rinse-aid.

8. Watch the chemical as it traveght-glass located on the

right-hand side, toprear corner of the

machine.

9. Release the switch

when the chemical

enters the sightglass.

Factory installed sight-glass

14

10. Chemicals should

reach the sightglass within 2

minutes of prime.

Page 21

MD-1000HT • Initial Start-up

_____________ Installation Guide

; Initial Start-up MD-1000HT

Caution:

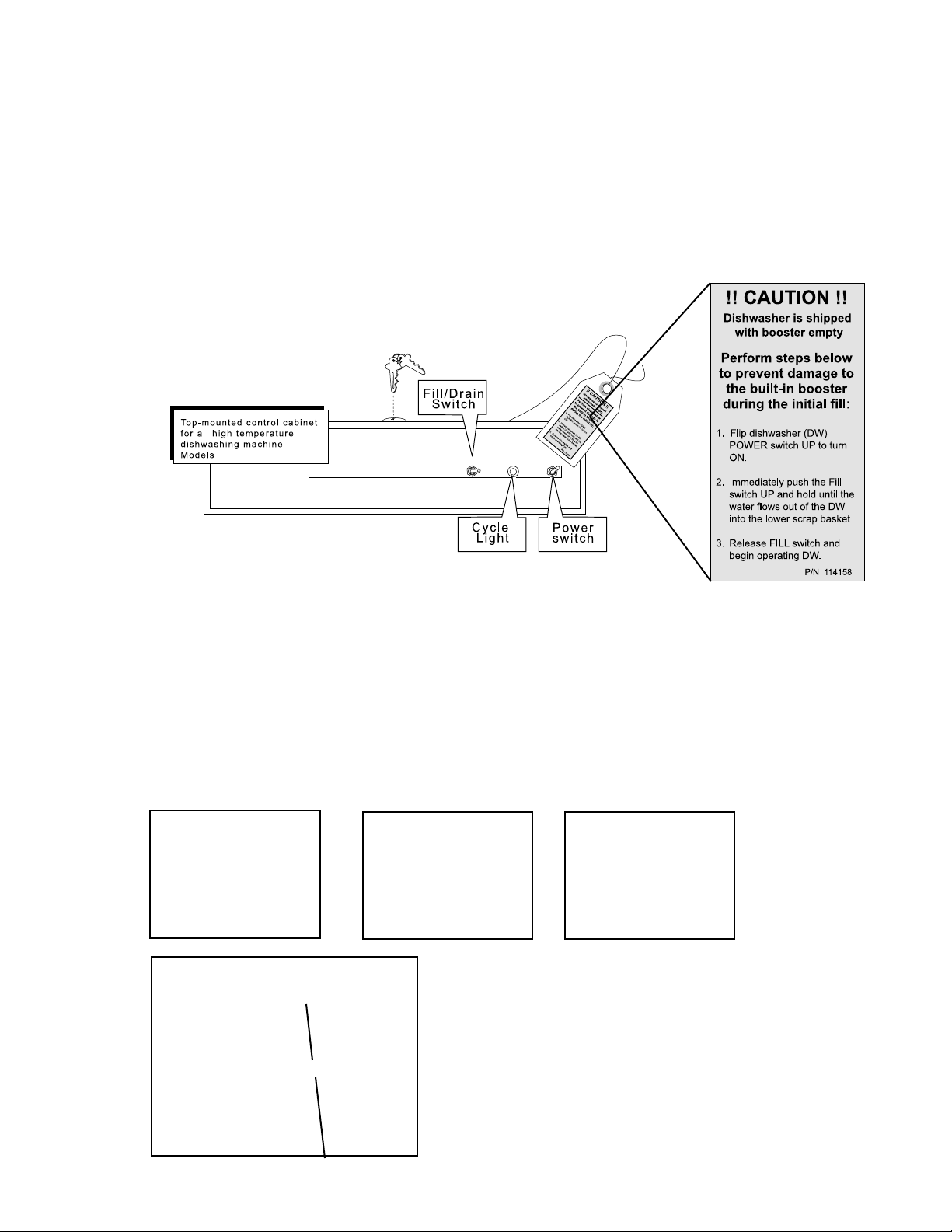

DO NOT flip the dishwasher power switch "ON"

until you read the instructions below.

1. The built-in stainless steel electric booster

was shipped without water.

2. A manilla card located above the power

switch explains how to turn the machine

on for the first time.

See step No. 10 on the next page for the first

DISHW

ASHER POWER UP procedure.

Let's begin the Initial Start-up:

1. Check the placement of the dishwasher:

; Compare the machine location with the

building plan or consult the owner or

the General Contractor for approval.

; Check that the dishwasher configuration

straight-through or corner operation

is correct (See page 2 for details).

2. Check that all options and/or accessories

are installed.

3. Remove protective white wrapping, tape,

and other packing materials and discard.

4. Remove any foreign materials from the

interior of the machine.

Continued on page 16

15

Page 22

MD-1000HT • Initial Start-up

Installation Guide _____________

; Initial Start-up MD-1000HT

Continued from page 15

5. Check that the following utilities are connected:

to the dishwasher and ready for use:

; Electrical service

; Hot water supply

; Drain

; Ventilation (if required by local regulations).

6. Check the chemical connections and chemical containers to

ensure that enough chemical supplies are available.

7. Turn on the water supply to the dishwasher.

8. Turn on the main power switch at the service disconnect switch.

9. Open the dishwasher doors fully.

10. Check upper and lower spray arms are in place and spin freely.

11. Check that the drain-overflow and pump screen are in place.

10

12. Check that the lower scrap screen is clean and in place.

11b11a

16

Page 23

_____________ Installation Guide

; Initial Start-up MD-1000HT

POWER UP THE DISHWASHER:

As stated on page 15, the dishwasher power switch must not

be turned without reading the instructions below

.:

MD-1000HT • Initial Start-up

CYCLE

POWER

OFF

ON

FILL

DRAIN

13. Turn on the main power switch at the service disconnect switch.

14. Flip the dishwasher power switch UP to turn on the dishwasher.

15. Immediately, push the fill switch up and hold it in the up position

until the water flows out of the wash tank and into the lower scrap screen.

16. Release the fill switch.

17. Open the dishwasher door fully and check the water level inside the tank.

The proper water level is just below the overflow tube and 3" [76 mm]

from the lower sprayarm support. Measure from the back of the support

up the tank toward the rear wall of the dishwasher.

14

15

16

3" [76mm]

Water line

17

Page 24

MD-1000HT • Initial Start-up

Installation Guide _____________

; Initial Start-up MD-1000HT

18. Operate the dishwasher for 10 cycles. Monitor

the wash and final rinse gauges located on the

lower front panel of the dishwasher to ensure the

machine is maintaining the proper temperatures.

In the USA, the NSF standards are:

150° F/66° C minimum wash temperature

180° F/82° C minimum final rinse temperature

Note:

In Canada, sanitary standards are regulated by each province.

Consult your provincial authorities for temperature requirements

and other sanitary standards.

19. Check the green cycle light. It should illuminate throughout

the 90-second cycle, then go out at the end of the cycle.

When the doors are raised, the cycle light should again

illuminate for 3-seconds and then go out. The 3-second

light indicates the timer is resetting. DO NOT CLOSE the

doors until the cycle light goes out.

2

0. Check the dishwasher piping for leaks.

21. Check the drain connection and make sure the house

drain piping handles the dishwasher drain flow.

Max flow is 15 USgpm/58 lpm or 1.7 US gals/6.6 Liters per rack.

22. Check the operation of the doors. They should go up and down smoothly.

Check the white door guides to ensure they move with the doors.

23. Inspect the table connections to the dishwasher making sure they

are secure and sealed with 100% silicon sealant on the mating flanges. The soiled

table

must slope away from the dishwasher and the clean table must slope

toward the dishwasher.

18

24. Remove the upper and lower sprayarms and

check the condition of the sprayarm

bearing O-rings.

25. The initial start-up is complete. Turn off power

to the dishwasher.

Page 25

How to Operate your Dishwasher • MD-1000HT

________________________Installation Guide

; How to Operate your Dishwasher MD-1000HT

1. Make sure there is adequate supply of liquid detergent and rinse-aid.

Check the chemical containers and refill if necessary.

2. Ensure internal circular tank screen, upper and lower spray arms and lower external

scrap screen are clean and in place.

3. Close door. Turn POWER switch to the “ ON ” position. Lift “FILL/DRAIN” switch to the “FILL”

position and hold for approximately 15-20 seconds, or until water flows from the wash tank

into the lower scrap pan.

4. Check the wash temperature gauge. Minimum reading must be 150°F/66°C.

Operate the dishwasher through 2 complete cycles to increase the wash temperature to

150°F/66°C. Check the temperature gauge reading on the front of the dishwasher to ensure

minimum temperatures are maintained.

5. Open doors completely and slide pre-scrapped rack of dishes into dishwasher.

Check that control panel green light is out.

6. Close doors to automatically start the cycle. Total cycle time is 90-seconds.

7. The RINSE SENTRY feature monitors the final rinse water temperature being generated in

the built-in booster. The rinse sentry will extend the wash cycle in the event that the

final rinse temperature is less than 180°F/82°C. Rinse Sentry deactivates when the final rinse

water in the built-in booster is a minimum of 180°F/82°C. Then the dishwasher timed cycle will

complete the wash cycle, drain and refill with the final rinse water and complete the cycle.

(See page 20 for an in-depth explanation of the Rinse Sentry feature.)

8. The final rinse cycle begins after the dishwasher washes and then drains.

The rinse-aid is automatically added to the wash tank.

9

. Cycle ends when green cycle light goes out. Opening the doors anytime during the

timed cycle will stop the dishwasher. The dishwasher will resume operation as soon as

the doors are closed. The timed cycle will begin at the place where it had stopped.

9. Open door. Remove the clean rack of dishes and insert another rack of soiled dishes.

10. Repeat steps 5-12 until all wares are clean.

Note:

Wash temperature must be a minimum of 150

Pumped final rinse temperature must be a minimum 180-195

o

F/66oC for optimum wash performance.

o

F/82-91oC for sanitizing.

19

Page 26

MD-1000HT • What is the Rinse Sentry Feature?

Installation Guide _____________

; What is the Rinse Sentry Feature? MD-1000HT

The MD-1000HT Rinse Sentry automatically monitors the final rinse water temperature in the

built-in stainless steel electric booster heater. If the final rinse water in the booster falls below

180°F/82°C, the Rinse Sentry will extend the dishwasher's wash cyle time in order to give

the booster heater additional time to provide the 180°F/82°C water temperature required.

Sanitization using hot final rinse water:

1. The MD-1000HT sanitizes dishware with a pumped hot final rinse water at a minimum

temperature of 180°F/82°C.

2. The MD-1000HT includes a built-in stainless steel electric booster heater which heats

incoming water temperatures to 180-195°F/82-91°C.

3. With Rinse Sentry, if the final rinse temperature inside the booster tank is below the

minimum 180°F/82°C, the timed cycle pauses the wash cycle until the minimum

temperature is available.

4. If something is defective and the final rinse water cannot reach the 180°F/82°C,

then the dishwasher will wash indefinitely.

5. This is usually the point where the operator realizes that the dishwasher has a

problem because the wash cycles are way too long.

Who is responsible for checking the final rinse water temperature?

1. The people operating the dishwasher, that's whom?

2. You are required to check to make sure that the final rinse water temperature gauge

always reads a temperature of 180-195°F/82-91°C during the final rinse cycle. And, It is

your job to immediately stop washing dishes if the temperature falls below the minimum

temperature of 180°F/82°C.

3. Guess what? Most people will forget to check the final rinse temperature at least once

in their careers! That's why the RInse Sentry is a part of your dishwasher.

20

Rinse Sentry constantly checks the final rinse water temperature

to ensure the minimum required temperature of 180°F/82°C is available

to sanitize the dishware for the health and safety of your guests.

Page 27

How to Clean your Dishwasher • MD-1000HT

_____________________ Installation Guide

; How to Clean the MD-1000HT

1. Leave the machine power switch in the ON position. Doors are fully closed.

2. Push and hold the “FILL/DRAIN” switch down in the “DRAIN” position for approximately

15-20 seconds. The water in the wash tank will drain completely.

3. Raise doors fully. Use caution, as metal surfaces may be hot. Allow interior to cool.

4. Rinse the interior of the dishwasher with fresh water. Wipe the interior with a soft cloth.

Do not scrub the interior with scouring pads, nor harsh detergents.

5. Close the doors fully; the dishwasher will begin a normal cycle. At the end of the cycle,

Push & hold the Fill/drain switch in the DRAIN position until the wash tank is empty

6. Flip the dishwasher power switch to the OFF position

7. Remove and clean circular wash tank screen.

8. Check the overflow /drain assembly . Ensure the drain seat is clean.

9. Loosen the upper and lower thumbscrews (Do not remove the screws)

Remove upper and lower sprayarms. Flush the sprayarm nozzles and check the

bearing o-rings.

10. Replace sprayarms (they are interchangeable) and tighten thumbscrews.

11. Replace circular tank screen.

12. Remove lower scrap screen. Empty debris and flush both sides with fresh water.

13. Check the drain pan and flush with clean water.

14. Wipe the exterior of the dishwasher with a soft cloth.

Do not hose the exterior with water nor scrub with scouring pads or harsh detergents.

15. Replace lower scrap screen, circular screen, and leave doors open for overnight drying.

16. Check the chemical supplies to ensure there are adequate supplies for the next shift.

21

Page 28

MD-1000HT • How to Maintain your Dishwasher

Installation Guide _____________

; How to Maintain the MD-1000HT

Thoroughly cleaning your dishwasher

every day is very best maintenance

you can do!!

Daily Maintenance

1. Keep your dishwasher and the surrounding area spotlessly clean.

2. Immediately report loose, broken or missing parts to your supervisor.

3. Check drains for flow restrictions.

4. Check the dishwasher for leaks.

5. Operate the dishwasher as explained in this manual.

Monthly Maintenance

1. Inspect pump hoses, door linkage, springs, and exterior of dishwasher for wear.

2. Inspect the wash arm bearings and O-rings.

3. Check the condition of scrap screens,. and dishracks for bent or broken pieces.

4. Check the toggle switches and indicator lights for damage.

5. Check the wash pump motor for loud bearings and leaking pump seal.

6. Create a simple Maintenance Tracking System as a guide for service.

Annual Maintenance

22

Call your authorized service agent or local service representative and schedule

a complete inspection of your dishwasher by a trained professional.

A Maintenance Tip -

Schedule your annual maintenance when you can give the service

agent unrestricted access to the dishwasher for at least 2 to 2-1/2 hours.

Page 29

MD-1000HT • The Trounbleshooter

The Troubleshooter

In order to find the cause of a breakdown or abnormal operating condition in your dishwasher please

ensure that:

1. All switches are ON

2. Drain overflow tube is in place and seated

3. Wash pipe and rinse nozzles are clean

4. Spray arms are in their proper positions

5. Round screen is properly positioned

6. Detergent, sanitizer and rinse additive dispensers are adequately filled

8. Doors are fully closed.

That wasn't it? Check for a solution below:

PROBLEM CAUSE SOLUTION

Cycle will not start Door not closed ........................... Make sure doors are fully closed

Door safety switch faulty ............. Contact your service agency

Main switch off............................. Check disconnect

Low or no water Main water supply is turned off ... Turn on house water supply

Drain/overflow tube is not

in place and seated ..................... Clean, replace and seat drain tube

..................................................... as needed.

Faulty fill valve ............................. Contact your chemcial supplier.

Continuous water filling Fill valve will not close................. Clean or replace

Motor not running Defective contactor ..................... Contact your servicer

Defective motor ........................... Contact your servicer

Wash tank water temperature ..................................................... Incoming water temperature

is low when in use ..................................................... at machine too low

..................................................... Raise temperature to 140°F/60°C

Defective thermometer ................ Check or replace

Defective solenoid valve ............. Check or replace

Arms not rotating Rinse nozzles not clean .............. Clean

Bearings worn.............................. Replace

Water supply pressure low ......... Check incoming water pressure

Insufficient pumped spray Clogged intake screen ............... Clean

pressure Clogged spray pipe ..................... Clean

Low water level in tank ................ Check drain and overflow tube, timer may

..................................................... need adjustment, contact servicer

Defective pump seal .................... Contact service agent

Insufficient rinse or no Faulty pressure regulating valve. Clean or replace

rinse Improper setting on pressure

regulating valve ........................... Set static pressure to 35 psi

Clogged rinse nozzle and/or

pipe .............................................. Clean with paper clip/delime

Improper water line size .............. Have installer change to proper size 3/4" NPT

23

Page 30

MD-1000HT • The Troubleshooter

The Troubleshooter (continued)

PROBLEM CAUSE SOLUTION

Low final rinse temperature Low incoming water ..................... Check valve to be sure it is clean and

Machine leaking Leaking at chemical hose ........... Replace hoses

Water splashing out door Nozzles/End caps missing .......... Replace caps

..................................................... operating.

Defective thermometer ................ Check for proper setting or replace

Pump seal leaking....................... Replace seal

Leaking at pump hose ................. Contact your chemical supplier

Leaking at doors.......................... Check to make sure that doors are fully

..................................................... closed

Wash nozzles blocked ................ Clean

Arms not rotating ......................... Replace bearings

Door handle twisted .................... Adjust or replace handle

Poor washing results Detergent dispenser not

operating properly ....................... Contact detergent supplier

Insufficient detergents ................. Contact detergent supplier

Food Soil concentration too

high in wash tank ......................... Prescrap dishes throughly

Wash water temperature

too low ......................................... See condition “Wash Tank

Wash arm clogged ...................... Clean

Improperly scraped dishes .......... Check scraping procedures

Ware improperly

placed in rack .............................. Use proper racks. Do not overload racks

Improperly cleaned

equipment.................................... Unclog wash sprays and rinse nozzles

Water Temperature” above

to maintain proper pressure and flow

conditions. Overflows must be open.

Keep wash water as clean as possible.

24

Page 31

MD-1000LT • Installation Guide

Model MD-1000LT

Installation

Guide

25

Page 32

MD-1000LT • Unpack and Place

Installation Guide ____________

; Unpack and Place MD-1000LT

1. The installation of your dishwasher must be performed by qualified service personnel.

2. Problems due to improper installation are not covered by the Warranty.

3. Compare the utilities at the installation site with the specifications listed on each

model's specification sheets ( See Appendix A at the end of this manual)

4. The dishwasher data plate is located on the left, rear-corner of the top-mounted

control cabinet.

5. Study the configuration diagrams below. They show the 2 ways that the dishwasher may

be positioned.

Corner and straight-through dishwasher configurations

Dish table

Position dishwasher as shown

below so the controls are easy

to reach by the operator.

6" [152] Max.

Wall Clearance

Control Cabinet

Control Cabinet

Correct Corner Configuration

Control Cabinet

Dish table

Incorrect Corner Configuration

Note:

The correct corner installation places the dishwasher so the topmounted controls are easy to reach.

The minimum distance from wall to dishwasher

is 4" [103mm]. The maximum distance is

6" [129].

6" [152] Max.

Wall Clearance

Straight-through Configuration

26

The room ceiling height must be a minimum of

80" [2032mm] so the doors can be removed

completely.

Page 33

MD-1000LT • Unpack and Place

_____________ Installation Guide

; Unpack and Place MD-1000LT

1. All dishwashers ship in the straight-through configuation.

2. Relocate the tracks and remove the wall-side door link components

to convert the dishwasher for corner operation.

Move Part 1

Remove Interior Door Bracket

Remove Door Linkage

Move Part 2

1

2

wall

Adjust Door Spring Tension

wall

27

Page 34

MD-1000LT • Unpack and Place

Installation Guide ____________

; Unpack and Place MD-1000LT

1. Compare the dishwasher and site utility connections.

2. Level the dishwasher by adjusting the bullet feet.

3. Raise the doors and check the door clearance to the ceiling.

4. Move the dishwasher to its permanent location.

Note:

Installers must follow applicable sanitation, safety, plumbing, and electrical codes and

regulations; and work in accordance with best practices for dishwasher installation.

Utility Connections - MD-1000LT

Power: 115VAC 15Amp circuit

Water supply: 3/4" NPT hot water supply (140°F/60°C minimum)

(35 psi/241 KPa static pressure) 7-10 psi/63-69Kpa flow pressure

Drain: 1-7/8" stainless steel, slip-fit hose connection

Max flow: 15 Us gal/min. (13.5 Imperial gal/min) 57liters/min.

Chemicals: Detergent, rinse-aid, and sanitzer pumps are standard equipment.

Chemicals supplied by a chemical supplier

Chemical Dispensing Pumps - Factory Installed for MD-1000LT

• All pumps use liquid chemicals

• Detergent pump capacity = 350cc/min @ 108 RPM

Factory setting for detergent = 105cc in 18secs.

• Rinse-aid pump capacity = 35cc/min @ 14RPM

Factory setting for rinse-aid 14cc in 23 sec.

28

• Sanitizer pump capacity = 35cc/min @ 14RPM

Factory setting for Sanitizer= 14cc in 23 sec.

maintains 50PPM concentration of

5.25% sodium hypochlorite during

the final rinse cycle.

Page 35

MD-1000LT • Electrical Connection

_________________ Installation Guide

; Electrical Connection MD-1000LT

Warning:

The dishwasher must be electrically grounded according to all local codes

and regulations governing the installation of electrical service.

Warning:

Disconnect the main electric supply and place a tag at the fuse or disconnect switch

indicating that work is being performed on that circuit.

1. Locate the control cabinet keys on the rear of the control cabinet.

2. Remove 1 key to unlock the cabinet; do not remove the other key.

3. Unlock the control cabinet and remove the cover.

4. Locate the power cord on the left rear side of the control cabinet.

5. Locate the Machine Electrical Connection Data Plate mounted near the terminal block.

The MACHINE ELECTRICAL CONNECTION DATA PLATE is the certified authority for the

dishwasher power requirement

unless an authorized factory represent

6. Check the power cord terminal connections at the main terminal board.

s. DO NOT use electrical data from any other source

ative instructs you to use other data.

Machine Electrical

Connection Data Plate

Main terminal block

29

Page 36

MD-1000LT • Water Connection

Installation Guide ____________

; Water Connection MD-1000LT

Water supply: 3/4" NPT hot water supply (140°F/60°C minimum)

(35 psi/241 KPa static pressure) 7-10 psi/48-69Kpa flow pressure

Note:

Plumbing installer must connect a 3/4" NPT hot water supply line to the dishwasher.

A 3/4" pressure regulating valve (PRV) (not supplied) must be installed in the water

supply line and adjusted to (35 psi/241 KPa static pressure) 7-10 psi/48-69Kpa flow pressure

Note:

Under NO circumstances, may the installing plumber connect a water supply line to the

dishwasher that is less than 3/4" NPT in size.

Note:

The following components are not required for proper dishwasher operation, but are

highly recommended, because they make servicing of the dishwasher much faster.

Install the following components (not supplied) in the hot water supply line:

1) 3/4” or larger water shut-off valve near the machine in the water supply line.

2) ASSE 1010 Water hammer arrestor upstream from the shut-off valve.

3) Pressure gauge 0-60 PSI minimum downstream from the PRV.

4) Temperature gauge 0-180°F/82°C (not supplied) downstream from the gauge.

30

(3/4" NPT line strainer not supplied)

Page 37

MD-1000LT • Drain Connection

_____________ Installation Guide

; Drain Connection MD-1000LT

1. Locate the dishwasher drain connection underneath the machine frame.

2. Install a drain line conforming to local plumbing and health regulations.

Drain: 1-7/8" stainless steel, slip-fit hose connection

Max flow: 15 Us gal/min. (13.5 Imperial gal/min) 57liters/min.

; Ventilation MD-1000LT

1. The factory has no requirements for vent hoods; but, local codes and regulations in your

area supersede our suggestions. Consult your local building and health authorities for

local requirements.

2. Dishroom ventilation must provide sufficient airflow to prevent excessive humidity in the

work area. 200-400cfm/5.6- 11.3 k Liters/min - is sufficient.

3. The dishwasher must not be subjected to continual drafts or cold air.

31

Page 38

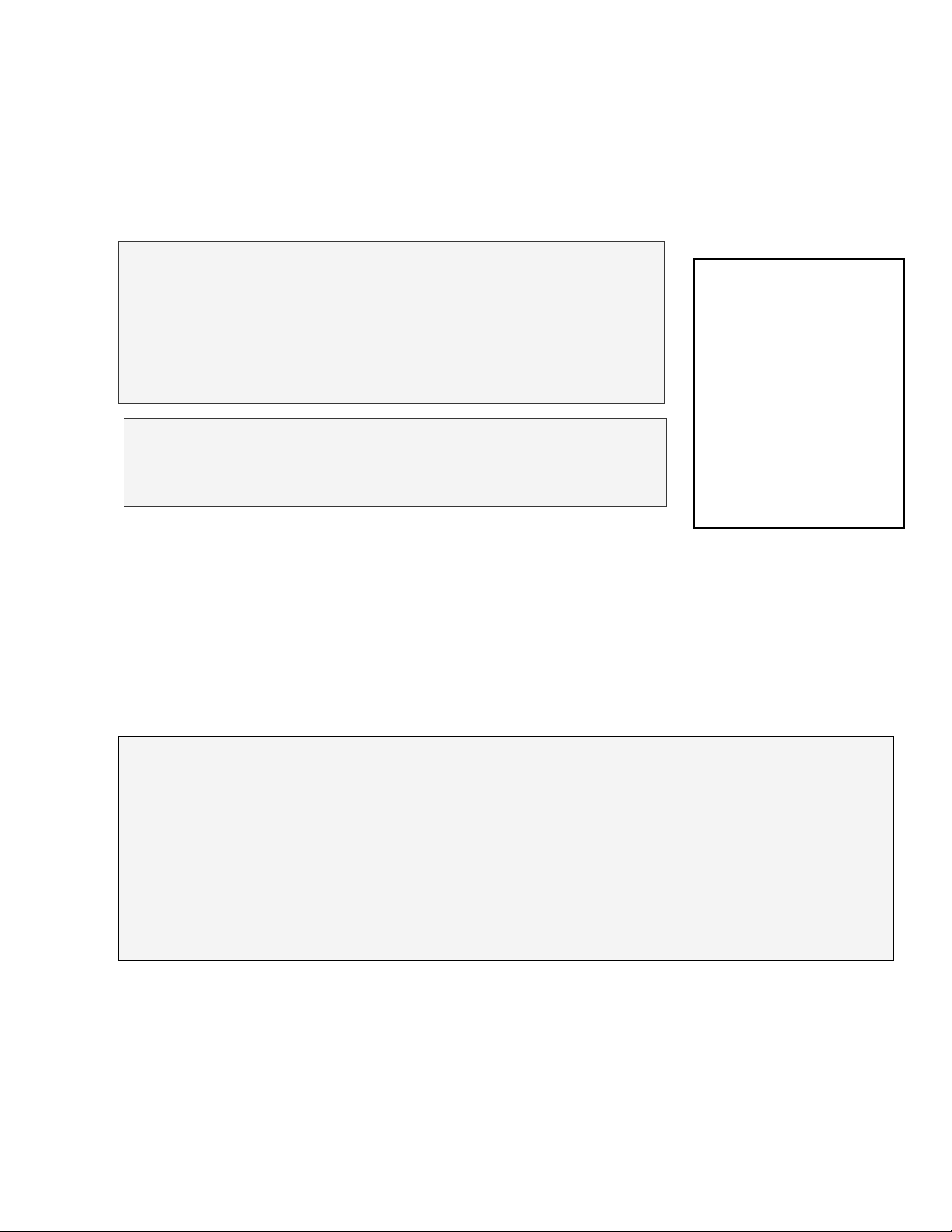

MD-1000LT • Chemical Dispensers

Installation Guide ____________

; Chemical Dispensers MD-1000LT

Note:

Manual dosing of detergent or rinse-aid is NOT RECOMMENDED for the MD-1000LT

dishwasher. Poor washing results may result if manual dosing is employed..

Note:

Cartridge detergent systems are NOT RECOMMENDED for the MD-1000LT

dishwasher. Poor washing results may result if installed on this model.

Note:

The MD-1000LT chemical dispensers are standard equipment.

There are 3 built-in dispensers located on the front of the MD-1000LT

top-mounted control cabinet.

Consult a local commercial

dishwasher chemical supplier

for the set-up and operation

of the dispensing system.

32

Page 39

_____________ Installation Guide

; Initial Start-up MD-1000LT

1. Check that the following utilities are connected:

to the dishwasher and ready for use:

; Electrical service

; Hot water supply

; Drain

; Ventilation (if required by local regulations)

2. Check the chemical connections and chemical containers to

ensure that enough chemical supplies are available.

MD-1000LT • Initial Start-up

3. Turn on the water supply to the dishwasher.

4. Turn on the main power switch at the service disconnect switch.

5. Open the dishwasher doors fully.

6. Check upper and lower spray arms are in place and spin freely.

7. Check that the drain-overflow and pump screen are in place.

6

8. Check that the lower scrap screen is

clean and in place.

7b7a

33

Page 40

Blank Page

This Page

Intentionally

Left Blank

34

Page 41

MD-1000LT • Initial Start-up

_____________ Installation Guide

; Initial Start-up MD-1000LT

POWER UP THE DISHWASHER:

1. Flip the dishwasher power switch UP to turn on.

. Turn on the main power switch at the service disconnect switch.

2

3. Release the fill switch.

4. Open the dishwasher door fully and check the water level inside the tank.

The proper water level is just below the overflow tube and 3" [76 mm]

from the lower manifold measuring up the tank toward the rear of the

dishwasher.

5. Operate the dishwasher for 10 cycles

checking the temperature gauges to

ensure the machine is maintaining

the proper temperatures.

120°F/49°C minimum wash temperature

40°F/60°C recommended optimum

1

Water line

6. To drain the dishwasher, leave the machine

power switch in the ON position.

Doors are fully closed.

. Push and hold the “FILL/DRAIN” switch down in

7

the “DRAIN” position for approximately 15-20

seconds.

8. The water in the wash tank will drain completely.

9. Open the doors and check that all water has

drained for the machine.

120°F/49°C minimum final rinse temperature

140°F/60°C recommended optimum

10. The initial start-up is complete.

35

Page 42

How to Operate your Dishwasher • MD-1000LT

Installation Guide ____________

; How to Operate the MD-1000LT

1. Make sure there is adequate supply of liquid detergent and rinse-aid, and sanitizer.

Check the chemical containers and refill if necessary .

2. Ensure the overflow tube/drain ball are clean and in place, and the circular pump screen, upper and

lower spray arms and lower external scrap screen are clean and in place.

3. Close door. T urn POWER switch to the “ ON ” position. Lift “FILL/DRAIN” switch to the “FILL” position and

hold for approximately 15-20 seconds, or until water flows from the wash tank into the lower scrap pan.

4. Check the wash temperature gauge.

Minimum reading must be 120°F/49°C.

Recommended optimum temperature

is140°F/60°C.

5. Operate the dishwasher through 2

complete cycles to increase the wash

temperature

to 140°F/60°C optimum. Check the

temperature gauge reading on the front of

the dishwasher

6. Open doors completely and slide pre-scrapped rack of dishes into dishwasher.

7. Check that control panel green light is out.

8. Close doors to automatically start the cycle. Total cycle time is 90-seconds.

9. The final rinse cycle begins after the dishwasher washes and then drains.

The rinse-aid and sanitizer are automatically added to the wash tank.

10. Use a sodium hypochlorite (Chlorine) based sanitizer at a minimum concentration of 50PPM in the final

rinse. Routinely check the 50PPM chlorine level with test strips (supplied by chemical supplier).

Note:

Wash temperature should be a minimum of 140oF/60oC for optimum wash performance.

o

Final rinse temperature should be a minimum 120-140

F/49-60oC for optimum sanitizing.

11. Cycle ends when green cycle light goes out.

12. Open door. Remove the clean rack of dishes and insert another rack of soiled dishes.

13. Repeat steps 5-12 until all wares are clean.

36

Page 43

How to Clean your Dishwasher • MD-1000LT

________________________________Installation Guide

; How to Clean the MD-1000LT

1. Leave the machine power switch in the ON position. Doors are fully closed.

2. Push and hold the “FILL/DRAIN” switch down in the “DRAIN” position for approximately

15-20 seconds. The water in the wash tank will drain completely.

3. Raise doors fully. Use caution, as metal surfaces may be hot. Allow interior to cool.

4. Rinse the interior of the dishwasher with fresh water. Wipe the interior with a soft cloth.

Do not scrub the interior with scouring pads, nor harsh detergents.

5. Close the doors fully; the dishwasher will begin a normal cycle. At the end of the cycle,

Push & hold the Fill/drain switch in the DRAIN position until the wash tank is empty

. Flip the dishwasher power switch to the OFF position

6

7. Remove and clean circular wash tank screen.

8. Check the overflow /drain assembly. Ensure the drain seat is clean.

9. Loosen the upper and lower thumbscrews (Do not remove the screws)

Remove upper and lower sprayarms. Flush the sprayarm nozzles and check the

bearing o-rings.

10. Replace sprayarms (they are interchangeable) and tighten thumbscrews.

11. Replace circular tank screen.

12. Remove lower scrap screen. Empty debris and flush both sides with fresh water.

13. Check the drain pan and flush with clean water.

14. Wipe the exterior of the dishwasher with a soft cloth.

Do not hose the exterior with water nor scrub with scouring pads or harsh detergents.

15. Replace lower scrap screen, circular screen, and leave doors open for overnight drying.

6. Check the chemical supplies to ensure there are adequate supplies for the next shift.

1

37

Page 44

How to Clean your Dishwasher • MD-1000LT

Installation Guide ____________

; How to Clean the MD-1000LT

Deliming

Warning:

Electrocution or chemical burns may occur if untrained persons attempt the deliming

procedure.

Only qualified service personnel should delime the dishwasher.

1. The DL-1000 is equipped with a delime switch on the left front side inside

the top-mounted control cabinet.

2. After all necessary preparations have been performed in accordance with

the chemical supplier's instructions, the chemical supplier or qualified

service agent may operate the delime switch to lock the dishwasher in a

continuous wash mode.

3. Flip the delime switch down to the

wash position when the deliming is

complete.

38

Page 45

How to Maintain your Dishwasher

__________________________ Installation Guide

; How to Maintain your Dishwasher MD-1000LT

Thoroughly cleaning your dishwasher

every day is very best maintenance

you can do!!

Daily Maintenance

1. Keep your dishwasher and the surrounding area spotlessly clean.

2. Immediately report loose, broken or missing parts to your supervisor.

3. Check drains for flow restrictions.

4. Check the dishwasher for leaks.

5. Operate the dishwasher as explained in this manual.

Monthly Maintenance

1. Inspect pump hoses, door linkage, springs, and exterior of dishwasher for wear.

2. Inspect the wash arm bearings and O-rings.

3. Check the condition of scrap screens,. and dishracks for bent or broken pieces.

4. Check the toggle switches and indicator lights for damage.

5. Check the wash pump motor for loud bearings and leaking pump seal.

6. Create a simple Maintenance Tracking System as a guide for service

Annual Maintenance

Call your authorized service agent or local service representative and schedule

a complete inspection of your dishwasher by a trained professional.

A Maintenance Tip -

Schedule your annual maintenance when you can give the service

agent unrestricted access to the dishwasher for at least 2 to 2-1/2 hours.

39

Page 46

The Troubleshooter • MD-1000LT

The Troubleshooter

In order to find the cause of a breakdown or abnormal operating condition in your dishwasher please

ensure that:

1. All power switches are ON

2. Drain overflow tube is in place and seated

3. Wash pipe and rinse nozzles are clean

4. Spray arms are in their proper positions

5. Round screen is properly positioned

6. Detergent, sanitizer and rinse aid dispensers are adequately filled

8. Doors are fully closed.

That wasn't it? Check for a solution below:

PROBLEM CAUSE SOLUTION

Cycle will not start Door not closed ........................... Make sure doors are fully closed

Door safety switch faulty ............. Contact your service agency

Main switch off............................. Check disconnect

Low or no water Main water supply is turned off ... Turn on house water supply

Drain/overflow tube is not

in place and seated ..................... Clean, replace and seat drain tube

..................................................... as needed.

Faulty fill valve ............................. Contact your chemcial supplier.

Continuous water filling Fill valve will not close................. Clean or replace

Motor not running Defective contactor ..................... Contact your servicer

Defective motor ........................... Contact your servicer

Wash tank water temperature ..................................................... Incoming water temperature

is low when in use ..................................................... at machine too low

..................................................... Raise temperature to 140°F/60°C

Defective thermometer ................ Check or replace

Defective solenoid valve ............. Check or replace

Arms not rotating Rinse nozzles not clean .............. Clean

Bearings worn .............................. Replace

Water supply pressure low ......... Check incoming water pressure

Insufficient pumped spray Clogged intake screen ............... Clean

pressure Clogged spray pipe ..................... Clean

Low water level in tank................ Check drain and overflow tube, timer may

..................................................... need adjustment, contact servicer

Defective pump seal.................... Contact service agent

Insufficient rinse or no Faulty pressure regulating valve . Clean or replace

rinse Improper setting on pressure

regulating valve ........................... Set static pressure to 35 psi

Clogged rinse nozzle and/or

pipe .............................................. Clean with paper clip/delime

Improper water line size .............. Have installer change to proper size 3/4" NPT

40

Page 47

The Troubleshooter • MD-1000LT

The Troubleshooter (continued)

PROBLEM CAUSE SOLUTION

Low final rinse temperature Low incoming water ................... Check valve to be sure it is clean and

..................................................... operating.

Defectiv e therm ometer ............... Check for proper setting or replace

Machine leaking Leaking at chemical hose.......... Replace hoses

Pump seal leaking ...................... Replace seal

Leaking at pump hose ............... Contact your chemical supplier

Leaking at doors ......................... Check to make sure that doors are fully closed

Water splashing out door Nozzles /End caps m issing ........ Replace caps

Wash nozzles blocked ................ Clean

Arms not rotating ......................... Replace bearings

Door handle twisted

(pass through) ............................ Adjust or replace handle

Poor washing results Detergent dispenser not

operating properly ....................... Contact detergent supplier

Insufficient detergents ................ Contact detergent supplier

Food Soil concentration too

high in wash tank ........................ Prescrap dishes throughly

Wash water temperature

too low ......................................... See condition “Wash Tank

Water Temperature” above

Wash arm clogged ..................... Clean

Improperly scraped dishes ........ Check scraping procedures

Ware improperly

placed in rack .............................. Use proper racks. Do not overload racks

Improperly cleaned

equipment ................................... Unclog wash sprays and rinse nozzles

to maintain proper pressure and flow

conditions. Overflows must be open.

Keep wash water as clean as possible.

41

Page 48

Blank Page

This Page

Intentionally

Left Blank

42

Page 49

MD-1000HT and MD-1000LT • Service Replacement Parts

___________ Service Replacement Parts

Models MD-1000HT • MD-1000LT

Illustrations Page

Wash pump/motor assembly _______________________________________________ 45

MD-1000HT • Built-in booster assembly ______________________________________ 47

MD-1000HT • Control cabinet enclosure ______________________________________ 49

MD-1000HT • Conrtol cabinet assembly ______________________________________ 51

MD-1000LT • Control cabinet enclosure with chemical dispensing pumps ____________ 53

MD-1000LT • Control cabinet assembly _______________________________________ 55

Top mounted assemblies __________________________________________________ 57

(water inlet airgap, chemical injection sight-glass, door safety switch)

Lower wash tank and drain assembly ________________________________________ 59

Hood assembly __________________________________________________________ 61

Front panel, temperature gauges, scrap screen covers___________________________ 63

Dishrack track assembly___________________________________________________ 65

Sprayarm assembly ______________________________________________________ 67

43

Page 50

Wash pump/motor assembly Service Replacement Parts

Item No. Part No. Description Qty. Unit

1 ----------- capacitor 50uf/240VAC, (VC1000-HT 240V/1) 1 ea

--- ----------- capacitor 15uf/450VAC, (VC1000LT 115V) 1 ea

2 0512015 complete motor/pump assy , 115VAC/60/1 1 ea

3 0512015-2 complete motor/pump assy , 220/60/1 1 ea

4 0512015-3 complete motor/pump assy , 220/60/3 1 ea

5 0512015-4 complete motor/pump assy , 220/50/3 1 ea

6 114134 water slinger 1 ea

7 114135 nut 10 ea

8 114136 screw 10 ea

9 114137 pump support 1 ea

10 114138 gasket 1 ea

11 114139 pump seal 1 ea

12 114140 washer 1 ea

13 114141 impeller 1 ea

14 114142 washer 1 ea

15 114143 lock washer 1 ea

16 114144 impeller nut 1 ea

17 114145 pump housing 1 ea

18 114146 o-ring 1 ea

19 114147 cap nut 1 ea

20 0310943 pump motor support 1 ea

21 107340 hose clamp 4 ea

22 0510942 discharge hose 1 ea

23 0510941 suction hose 1 ea

44

Page 51

Service Replacement Parts Wash pump/motor assembly

1/4-20 locknut

1/4" washer

1/4-20 x 3/4"

1/4 x 20 washer

1/4-20 locknut

1/4" washer

20

21

22

21

21

23

21

45

Page 52

Built-in booster assembly • MD-1000HT Service Replacement Parts

Item No. Part No. Description Qty. Unit

1 109985 booster element o-ring 1 ea

2 111233 booster heater, 220V/60/1 & 3 9kW, 40°F rise 1 ea

3 112059 booster heater, 220V/60/1 & 3 12kW, 70°F rise 1 ea

4 107908 booster element cover 1 ea

5 110768 3/4" brass line strainer 1 ea

6 100184 3/4" brass close nipple 4 ea

7 111437 3/4" solenoid valve 115VAC 1 ea

Nshown 108516 3/4" water solenoid valve coil 1 ea

Nshown 109903 3/4" water solenoid rebuild kit 1 ea

8 102444 3/4" brass street elbow 1 ea

9 113178 3/4" barb fitting 1 ea

10 113269 hose clamp 1 ea

11 114121 3/4" ID red hose 7 ft.

12 100571 3/4" brass union 1 ea

13 101525 Tee reducing 3/4" x 1/2" x 3/4" 1 ea

14 110562 fixed high limit thermostat 1 ea

15 113622 final rinse thermometer 4 ft. capilliary 1 ea

16 110929 high limit box 1 ea

17 100930 high limit box panel 1 ea

18 0509042 booster cannister 1 ea

19 101210 1/8" brass plug 1 ea

20 109069 temper ature control th ermostat 1 ea

21 0512027 bushing 1 ea

Nshown 107922 control thermostat metal box and base plate 1 ea

46

Page 53

Service Replacement Parts Built-in booster assembly • MD-1000HT

1

3

2

4

5

11

6-32 x 1/4" screw

6-32 washer

17

10-32 nylon insert nut

and washer

18

16

15

6

14

13

10

7

8

9

12

6

21

20

19

47

Page 54

Control cabinet enclosure • MD-1000HT Service Replacement Parts

Item No. Part No. Description Qty. Unit

1 0310962 control cabinet cover 1 ea

2 0510398 power switch 1 ea

3 0508551 green cycle light 1 ea

4 0510399 fill and drain switch 1 ea

5 0510399 detergent /rinse-aid prime switch (optional) 1 ea

6 0310959 control cabinet 1 ea

7 0510833-8 standard control panel decal w/o prime switch 1 ea

8 0510833-10 optional control panel decal w/ prime switch 1 ea

9 0510825-1 cycle counter 1 ea

10 0510824-1 control cabinet lock w/ 2 keys 1 ea

48

Page 55

Service Replacement Parts MD-1000HT • Control cabinet enclosure

w

1

10

3

2

6

1/4-20 x 1/4"

truss-head screw

4

1/4-20 x 1/4"

truss-head scre

5

9

7

8

Hood

49

Page 56

MD-1000HT • Control cabinet assembly Service Replacement Parts

Item No. Part No. Description Qty. Unit

1 0501403 brass screw 1 ea

---- 0501533 brass nut 1 ea

---- 0501472 brass 1/8” flat washer 1 ea

---- 0501493 brass lock washer 1 ea

2 0504951 terminal block 1 ea

3 105514 booster heat contactor 1 e a

4 106402 fuse block 1 ea

5 0503749 terminal board 1 ea

6 0512025 90-second timer assy 1 e a

7 0510825-1 cycle counter 1 e a

8 0510398 power switch 1 e a

9 0508551 green cycle light 1 e a

10 0510399 fill/drain switch 1 e a

---- 0510399 optional detergent/rinse-aid prime switch 1 e a

11 111036 relay socket 1 ea

12 111068 120VAC relay 1 e a

13 109604 step down transformer 1 e a

14 108122 12 Amp motor contactor 1 ea

15 110806 motor overload 1 ea

16 111026 door safety switch magnet 1 e a

17 111090 door safety reed switch 1 e a

18 112484 ADTR-1.5 Amp fuse 2 ea

50

Page 57

Service Replacement Parts MD-1000HT • Conrtol cabinet assembly

15

1

18

3

4

2

14

13

5

11

12

6

17

16

7

10

10

9

8

51

Page 58

Control cabinet enclosure • MD-1000LT Service Replacement Parts

with chemical dispensing pumps

Item No. Part No. Description Qty. Unit

1 0310962-1 control cabinet cover 1 e a

2 0510872-1 sanitizer & rinse aid pump mtr. 115VAC, 14RPM 2 e a

3 0510870-1 detergent pump motor, 115VAC, 108 RPM 1 e a

4 0510869-1 pump head assy. 3 e a

5 108412 tube clamp 14 e a

6 107928 clear sanitizer feed tubing 20 feet

7 107930 blue rinse-aid feed tubing 16 feet

8 107929 red detergent feed tubing 16 fee t

9 0312062 control cabinet leg 4 e a

10 0310959-1 control cabinet bottom 1 e a

11 0501398 power switch 1 ea

12 0508551 green cycle light 1 ea

13 0510399 momentary switch 3 ea

14 0501373-1 delime switch 1 ea

15 0510825-1 cycle counter 1 ea

16 0510833-5 decal 1 ea

17 0503695 detergent label 1 ea

18 0505483 rinse-aid label 1 ea

19 0503694 sanitizer label 1 ea

20 0306363 stiffener tube 3 ea

21 0501869 strainer 3 ea

22 108194 squeeze tube assy 3 ea

23 0510824-1 lock w/ 2 keys 1 ea

52

Page 59

Service Replacement Parts MD-1000LT • Control cabinet enclosure

with chemical dispensing pumps

23

1

13

14

10

1/4-20 x 1/4"

truss-head screw

2

3

9

11

12

Inner panel

cut-out

1/4-20 x 1/4"

truss-head screw

16

4

22

5

6

Rinse-aid = blue

7

15

20

Sanitizer = white

19

18

17

21

Hood

8

Detergent = red

53

Page 60

MD-1000LT • Control cabinet assembly Service Replacement Parts

Item No. Part No. Description Qty. Unit

1 0501403 brass screw 1 ea

---- 0501533 brass nut 1 ea

---- 0501472 brass 1/8” flat washer 1 ea

---- 0501493 brass lock washer 1 ea

2 0510635 terminal block 1 ea

3 107369 pump motor contactor 25 FLA 1 ea

4 111036 relay socket 1 ea

5 111068 120VAC relay 1 ea

6 0512018 90-second timer 1 ea

7 0501373-1 delime switch 1 ea

8 0510825-1 cycle counter 1 ea

8 0510398 power switch 1 ea

9 0503749 terminal board 1 ea

10 0501399 momentary toggle switch 3 ea

11 0508551 green cycle light 1 ea

12 0510398 power switch 1 ea

13 111090 door safety reed switch 1 ea

14 111026 door safety switch magnet 1 ea

54

Page 61

Service Replacement Parts MD-1000LT • Conrtol cabinet assembly

1

2

3

4

6

5

14

13

7

9

8

See page 52-53 for chemical dispenser

pumps

DETERGENT SANITIZER

RINSE AID

POWER

ON

12

OFF

FILL

101010

DRAIN

11

CYCLE

55

Page 62

Top mounted assemblies Service Replacement Parts

water inlet airgap chemical injection sight-glass,

door safety switch

Item No. Part No. Description Qty. Unit

1 102442 90 degree x 3/4" elbow 1 ea

2 102444 90 degree x 3/4" street elbow 1 ea

3 100156 3/4" locknut 1 ea

4 0310422-2 water inlet bracket 1 ea

5 0512021 air gap fitting 1 ea

6 0312014 water diverter 1 ea

7 0303590 sight-glass retaining plate 1 ea

8 0510987 sight-glass 1 ea

9 107930 blue rinse-aid feed tube 16 feet

10 107929 red detergent feed tubing 16 feet

11 107928 clear sanitizer feed tubing (MD-1000LT only) 20 feet

12 111026 door safety magnet 1 ea

13 111090 door safety switch 1 ea

14 0312046-2 splash guard (MD-1000HT only) 1 ea

15 0712046 valve mount bracket 1 ea

16 111437 3/4" solenoid valve (MD-1000LT top mounted) 1 ea

17 108516 3/4" solenoid coil 115VAC 1 ea

18 109903 3/4" solenoid valve rebuild kit 1 ea

56

Page 63

Service Replacement Parts Top mounted assemblies

water inlet airgap, chemical injection sight-glass,

door safety switch

18

17

16

Low Temp

15

2

1

14

3

4

9

8

5

6

11

15

10

11

12

13

7

57

Page 64

Lower wash tank and drain assembly Service Replacement Parts

Item No. Part No. Description Qty. Unit

1 0512012 drain overflow tube 1 ea

2 0510849 retaining ring 2 ea

3 202009 pin 2 ea

4 0510497 drain ball 1 e a

5 107440 thermometer w/ 8 ft. capillary (MD-1000HT) 1 ea

6 0510249 pump screen 1 ea

7 0510845-1 2" stem thermometer (MD-1000LT) 1 ea

8 0510846-1 reducing bushing 1 ea

9 0312017 drain solenoid cover 1 ea

10 0310771-3 drain lift rod 1 ea

11 0510773-1 lift rod guide 1 ea

12 0510400 drain solenoid 1 ea

13 0710739-2 drain sump 1 ea

14 0510202-3 sump gasket 1 ea

58

Page 65

Service Replacement Parts Lower wash tank and drain assembly

1

2

3

5

4

6

High Temp

Thermometer

7

Low Temp

Thermometer

and I DH200

9

12

Use Item 5

8

3

12

11

3

10

59

Page 66

Hood assembly Service Replacement Parts