Page 1

Simply Engineered Better

Technical Manual

Rotary

Glasswasher

October, 2003

P.O. Box 4183

Winston-Salem, North Carolina 27115-4183

Moyer Diebel, U.S.

336/661-1992

Fax: 336/661-1979

Manual P/N 0507371 REV. F

2674 N. Service Road

Jordan Station, Ontario, Canada L0R 1S0

Moyer Diebel, Ltd.

905/562-4195

Fax: 905/562-4618

Machine Serial No.

Model

DF-M6

DF1-M6

DF2-M6

Page 2

Complete the information below so it will be available for quick reference.

Model Number __________________________ Serial Number________________________

Voltage and Phase ______________________________________________________________

Moyer Diebel Parts Distributor _______________________________ Phone _____________

(if applicable)

_____________________________________________________________________________

Moyer Diebel Service Agency________________________________ Phone _____________

_____________________________________________________________________________

Moyer Diebel Service:

Moyer Diebel Limited Moyer Diebel, US

Phone: 1-905-562-4195 Phone: 1-336-661-1992

1-800-263-5798 1-800-228-8350

Fax: 1-905-562-4618 Fax: 1-336-661-1660

NOTE: When calling to order parts, be sure to have the model number, serial number, voltage,

and phase of your machine, along with your customer account number.

COPYRIGHT © 2003 by Moyer Diebel

Page 3

Revision History

Revision Revised Serial Number Comments

Date Pages Effectivity

09/07/90 All 16231 Issued manual and service parts list, Revision A

10/03/94 4 18354 Tank switch shuts down machine, revised the

schematic

05/03/95 4 18629 Changed to new style chemical injection board,

revised the schematic

06/07/95 — 18674 Changed to narrow control box, eliminated float rod

bearing

02/02/97 All — Reissue of manual and service parts lists, Revision C

02/28/00 39 — Revised wash down hose assy. parts list

06/18/00 33 G2147 Revised vacuum breaker parts

10/13/03 39 — Revise wash down hose assy. to options.

REVISIONS

Page 4

THIS PAGE

INTENTIONALLY

LEFT BLANK

2

Page 5

3

CONTENTS

Page

WARRANTY ............................................................................................................................. 4

INTRODUCTION...................................................................................................................... 5

INSTALLATION........................................................................................................................ 6

Unpacking .......................................................................................................................... 6

Measurements...................................................................................................................... 7

Utility Locations.................................................................................................................. 7

Electrical Connections......................................................................................................... 8

Plumbing Connections......................................................................................................... 8

OPERATION.............................................................................................................................. 9

General ................................................................................................................................ 9

To Fill The Wash Tank........................................................................................................ 9

Operating Instructions ......................................................................................................... 9

Approximate Chemical Settings .......................................................................................... 10

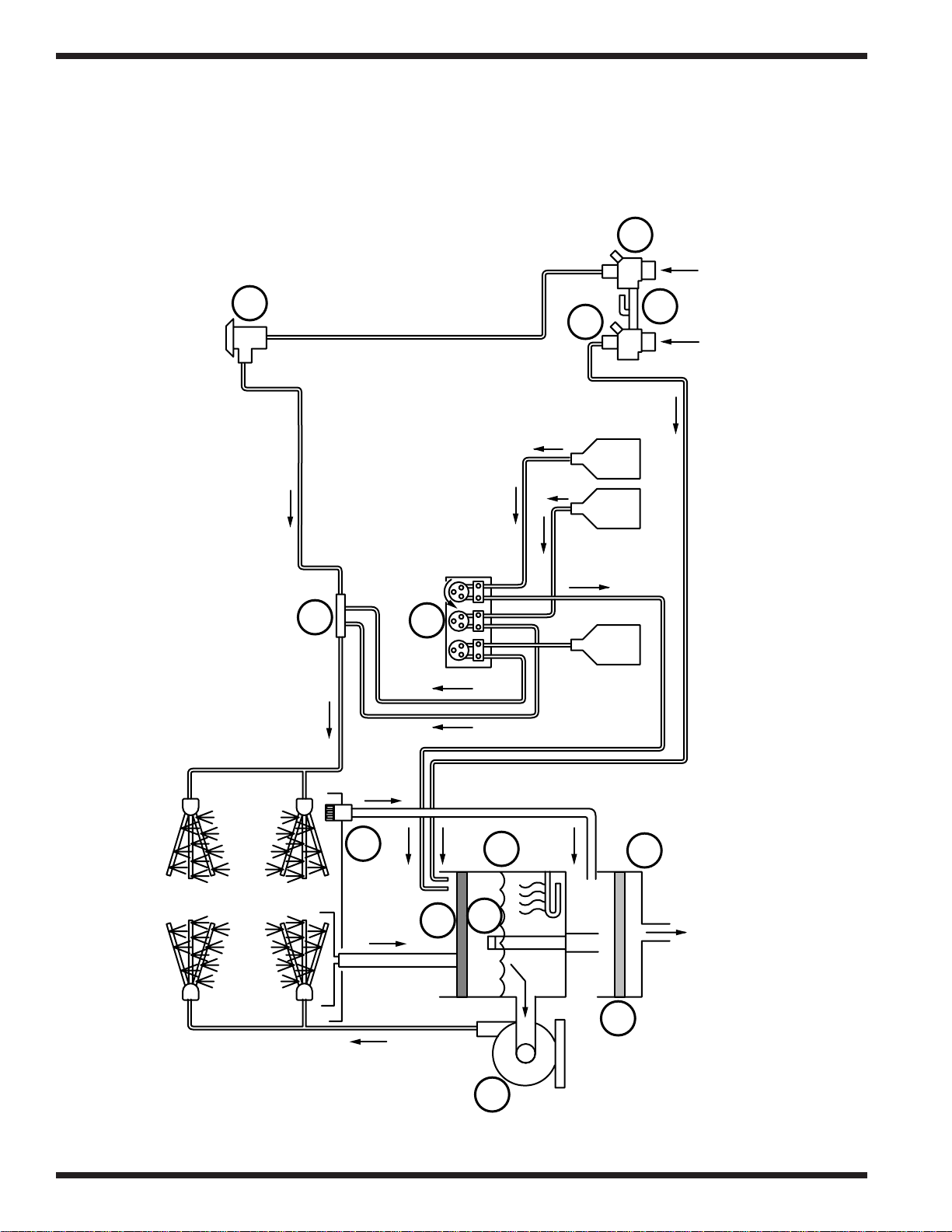

Plumbing Diagram............................................................................................................... 12

MAINTENANCE....................................................................................................................... 13

Daily Cleaning Instructions................................................................................................. 13

Weekly Cleaning Instructions.............................................................................................. 13

TROUBLESHOOTING ............................................................................................................. 14

REPLACEMENT PARTS .......................................................................................................... 17

ELECTRICAL SCHEMATICS ................................................................................................. 40

LIST OF FIGURES

Page

Figure 1 — Unpacking Parts................................................................................................... 6

Figure 2 — Machine Measurements ....................................................................................... 7

Figure 3 — Wash Tank............................................................................................................ 9

Figure 4 — Plumbing Diagram............................................................................................... 12

Figure 5 — Main Assembly.................................................................................................... 18

Figure 6 — Conveyor/Curtain/Switch Assembly.................................................................... 20

Figure 7 — Control Box ......................................................................................................... 22

Figure 8 — Control Box Cover/Chemical Injector Board...................................................... 24

Figure 9 — Detergent Tank..................................................................................................... 26

Figure 10 — Inlet Plumbing ...................................................................................................... 28

Figure 11 — Sanitizer Plumbing............................................................................................... 30

Figure 12 — Vacuum Breaker Plumbing Support .................................................................... 32

Figure 13 — Wash Pump .......................................................................................................... 34

Figure 14 — Drive Complete.................................................................................................... 36

Figure 15 — Cleaning Accessories........................................................................................... 38

Figure 16 — Optional Accessories ........................................................................................... 39

Figure 17 — Electrical Diagram (S/N 16211 through 18353).................................................. 40

Figure 18 — Electrical Diagram (S/N 18354 through 18628).................................................. 41

Figure 19 — Electrical Diagram (beginning with S/N 18629)................................................. 42

CONTENTS

Page 6

4

WARRANTY

LIMITED WARRANTY

Champion Industries/Moyer Diebel Limited, P.O. Box 4183, Winston-Salem, North Carolina 27115, and P. O. Box 301, 2674

North Service Road, Jordan Station, Ontario, Canada L0R 1S0 warrants machines, and parts, as set out below.

Warranty of Machines: Champion Industries/Moyer Diebel Limited warrants all new machines of its manufacture bearing

the name “Champion” or "Moyer Diebel" and installed within the United States and Canada to be free from defects in

material and workmanship for a period of one (1) year after the date of installation or fifteen (15) months after the date of

shipment by Champion/Moyer Diebel, whichever occurs first. [See below for special provisions relating to Model Series DF

and SW.] The warranty registration card must be returned to Champion/Moyer Diebel within ten (10) days after installation.

If warranty card is not returned to Champion/Moyer Diebel within such period, the warranty will expire after one year from

the date of shipment.

Champion/Moyer Diebel will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion/Moyer Diebel, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided, however, as to

Model Series DF and SW, Champion/Moyer Diebel's obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs first. In the event that Champion/Moyer

Diebel elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by a Champion/Moyer Diebel authorized service technician. Defective parts become the property of

Champion/Moyer Diebel. Use of replacement parts not authorized by Champion/Moyer Diebel will relieve Champion/

Moyer Diebel of all further liability in connection with its warranty. In no event will Champion/Moyer Diebel's warranty

obligation exceed Champion/Moyer Diebel's charge for the machine. The following are not covered by Champion/Moyer

Diebel's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Adjustments to chemical dispensing equipment.

h. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

i. Performance of regular maintenance and cleaning as outlined in operator’s guide.

j. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or interior finish

as a result of the above, (2) Use with utility service other than that designated on the rating plate, (3) Improper connection to

utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to connection of chemical dispensing equipment installed

by others, (7) Leaks or damage resulting from such leaks caused by the installer, including those at machine table connections or by connection of chemical dispensing equipment installed by others, (8) Failure to comply with local building

codes, (9) Damage caused by labor dispute.

Warranty of Parts: Champion/Moyer Diebel warrants all new machine parts produced or authorized by Champion/Moyer

Diebel to be free from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion/Moyer Diebel will replace the defective

part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION/MOYER DIEBEL'S

WARRANTY IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION/MOYER DIEBEL MAKES NO

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY WARRANTY OF

MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION/MOYER DIEBEL SHALL NOT BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION/MOYER DIEBEL DISHWASHING

MACHINES AND CHAMPION/MOYER DIEBEL PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED,

INCLUDING ANY LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES.

Champion/Moyer Diebel does not authorize any other person, including persons who deal in Champion/Moyer Diebel

dishwashing machines, to change this warranty or create any other obligation in connection with Champion/Moyer Diebel

Dishwashing Machines.

rev. 8699

Page 7

INTRODUCTION

Welcome to Moyer Diebel...

and thank you for allowing us to take care of your glass washing needs.

This manual covers the Model DF glasswashers.

Your machine was completely assembled, inspected, and thoroughly tested at our factory before

it was shipped to your installation site.

This manual contains:

•Warranty Information

• Operation and Cleaning Instructions

• Maintenance Instructions

•Troubleshooting Guide

• Basic Service Information

•Replacement Parts Lists

• Electrical Schematics

Complete and return your warranty registration card within ten (10) days after the

installation of your machine.

All information, illustrations and specifications contained in this manual are based

upon the latest product information available at the time of publication. Moyer Diebel

constantly improves its products and reserves the right to make changes at any time

or to change specifications or design without notice and without incurring obligation.

For your protection, factory authorized parts should always be used for repairs.

Replacement parts may be ordered directly from Moyer Diebel authorized parts distributor or

authorized service agency. When ordering parts, please supply the model number, serial number,

voltage, and phase of your machine, the part number, part description and quantity.

5

INTRODUCTION

Page 8

6

INSTALLATION

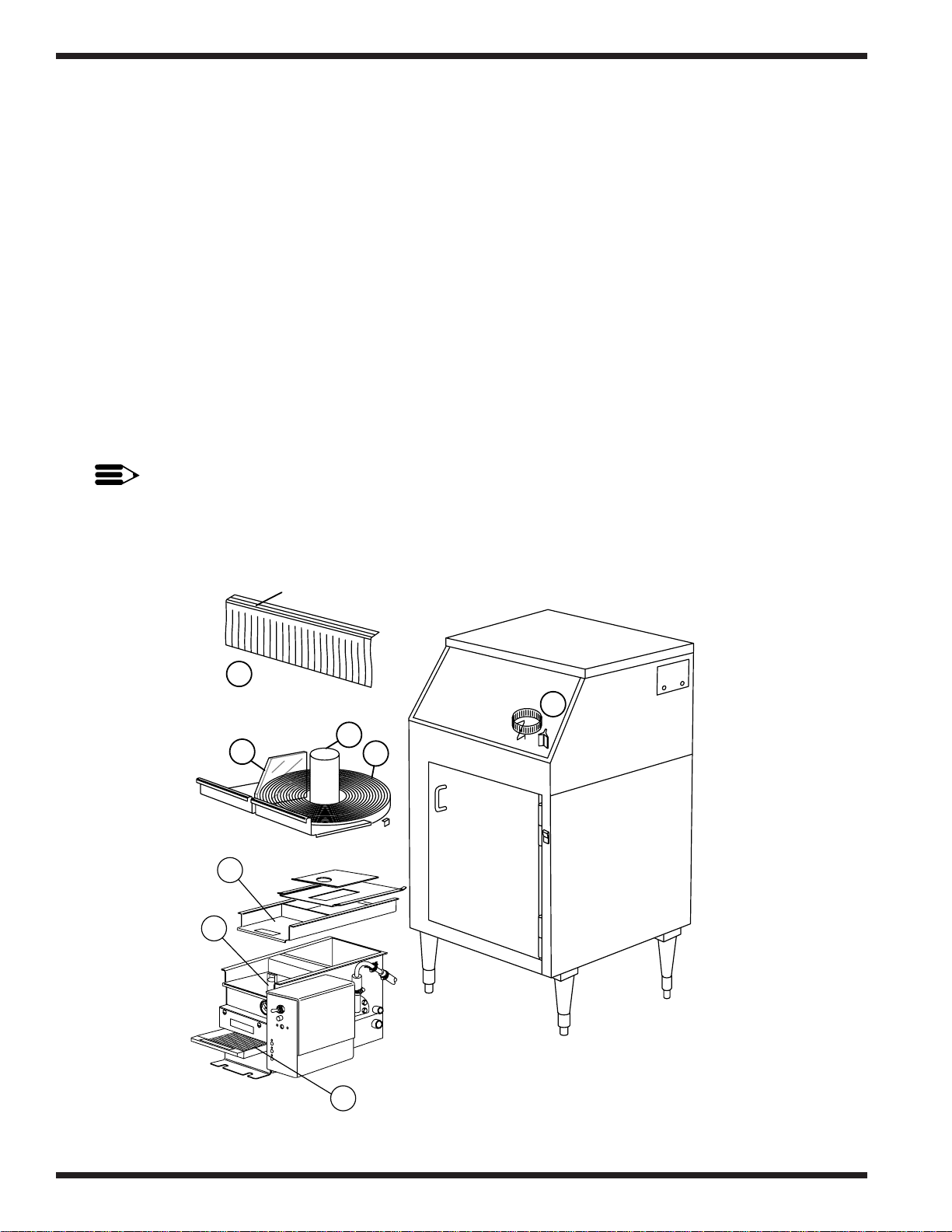

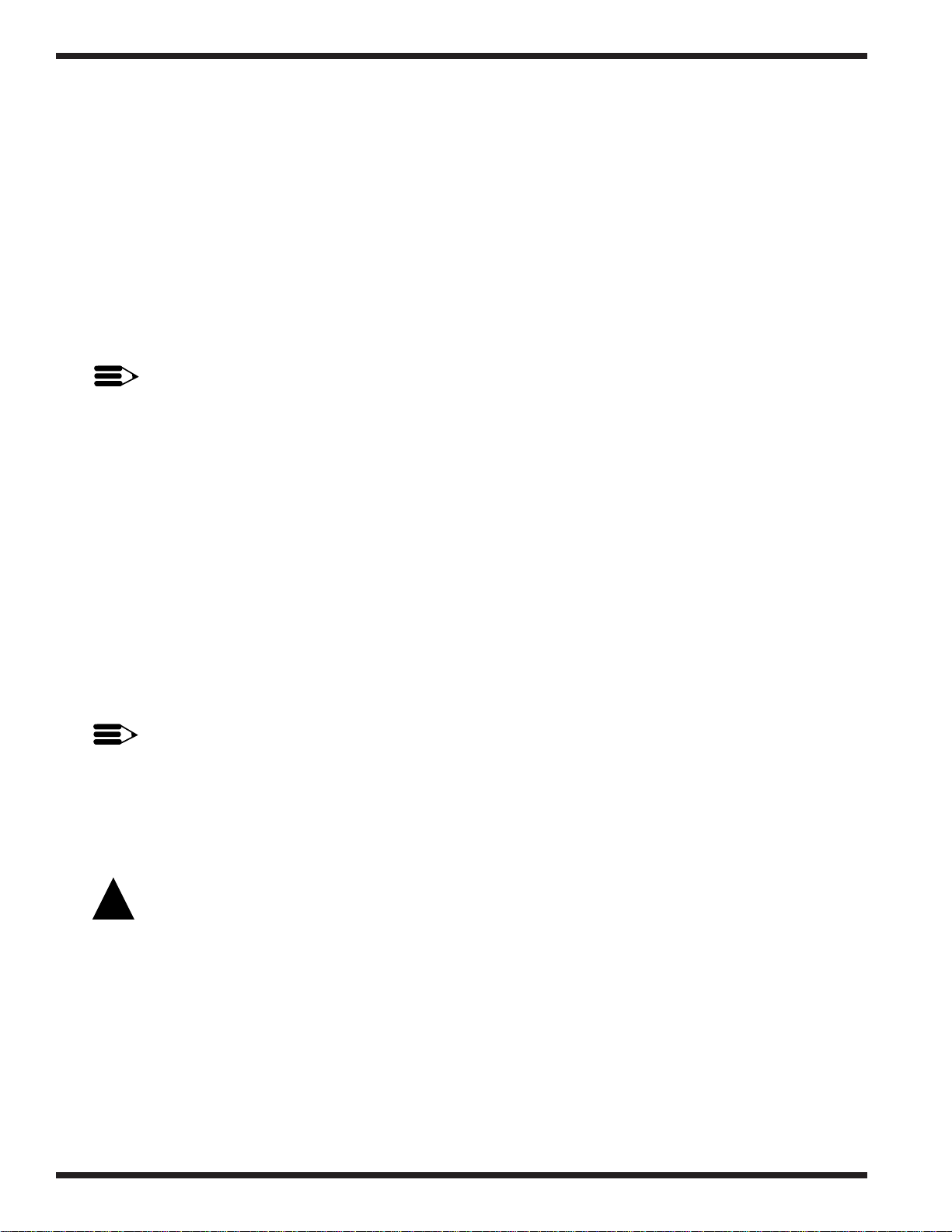

Unpacking

1. Remove the packing from the top of the conveyor stack.

2. Remove all packing from glass operated switch and right and left trays. Check that the

right and left hand trays are positioned properly.

3. Check that the drain deflector is secure in the rinse drain.

4. Check the position of the splash curtain.

5. Check that the conveyor is level and the drive gear is engaged in the conveyor’s outer rim

grooves.

6. Remove the packing from within and above the detergent tank.

7. Ensure the standpipe is in position in the detergent tank.

NOTE:

The standpipe is located inside the wash return screen for shipping.

8. Ensure that the wash return screen in the detergent tank is in position.

9. Check that the lower drain screen is in postion.

Figure 1 — Unpacking Parts

SPLASH CURTAIN

4

3

1

2

8

7

5

DETERGENT

TANK

9

Page 9

7

INSTALLATION (Cont’d)

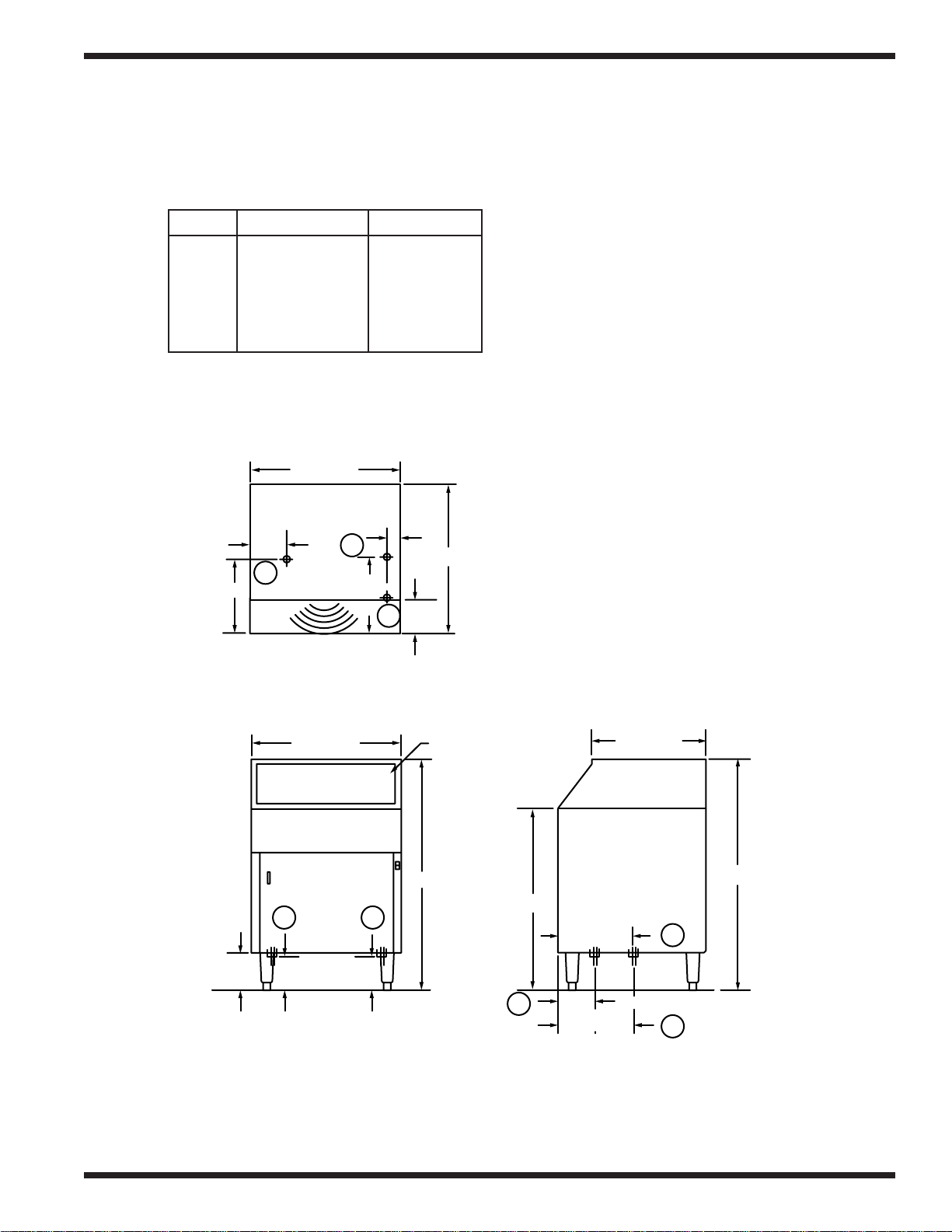

Measurements

Uncrated Crated

Height 39" (991) 40-1/2"(1181)

Width 25-1/4" (640) 27" (685)

Depth 25-1/8" (638) 27-1/2" (698)

Ship Wt. 154lb/70kg 176lb/80kg

*adjustable foot height 1-3/4" (45) max.

height 40-3/4" (1035)

Utility Locations

1.Hot Water

2.Cold Water

3.Drain

INSTALLATION

39" [991]

12 1/2" [317]

19 3/4" [502]

30 1/2" [775]

39" [991]

6"[152]

13" [330]

Side ViewFront View

Plan View

25 1/8" [638]

13"[330]

2 1/4" [57]

25 1/4" [641]

25 1/4" [641]

10" (254) VERTICAL

CLEARANCE

6"[152]

Front

5 1/2" [140]6" [152]

6"[152]

2

12 1/2" [317]

1

1

1

3

2

3

3

Figure 2 — Machine Measurements

Page 10

INSTALLATION (Cont’d)

Electrical Connections

1. The Glass Washer has a six foot power cord with a “U” ground tandem plug for connection

to a power receptacle.

2. Provide a nonlocking 250 volt, 15 ampere, 2 pole, 3 wire grounding receptacle within four

feet of the base of the Glass Washer(CSA TYPE 6-15R). This should be installed by a

qualified electrician to meet the specifications of the local electrical code.

3. This machine operates from 208 to 240 volts.

NOTE:

This machine is 50Hz and 60Hz compatible.

Plumbing Connections

Hot Water Connection

1. Connect a minimum 1/2" water line to the hot water solenoid valve. Supply temperature

must be minimun 140°F/60°C, with a flow pressure between 25-95 PSI/172-656 kPa.

2. Hot water consumption is approximately 10 Imp. gph./12 U.S. gph/45 litres/h.

Cold Water Connection

1. Connect a minimum 1/2" water line to the cold water solenoid valve. Flow pressure must

be between 25-95 PSI/172-656 kPa.

2. Open mixing valve located between hot and cold solenoid valves for areas with very cold

rinse water to heat the rinse water which will prevent glasses from cracking.

3. Cold water consumption is approximately 2.4 Imp. gpm/2.8 U.S. gpm/10.6 litres/min.

NOTE:

Install check valves on the hot and cold water lines as close as possible to the water inlet.

Drain Connection

1. This machine is gravity drain. Connect a 1-1/2" drain line where indicated.

2. PVC pipe is generally recommended as copper is prone to attack by the sanitizing

chemicals.

WARNING:

Plumbing and electrical connections should be made by a qualified workman who will

observe all the applicable plumbing, sanitary and safety codes. Before all utilities are

installed, ensure that all the bullet feet are in contact with the floor and at the desired

level.

8

INSTALLATION

!

Page 11

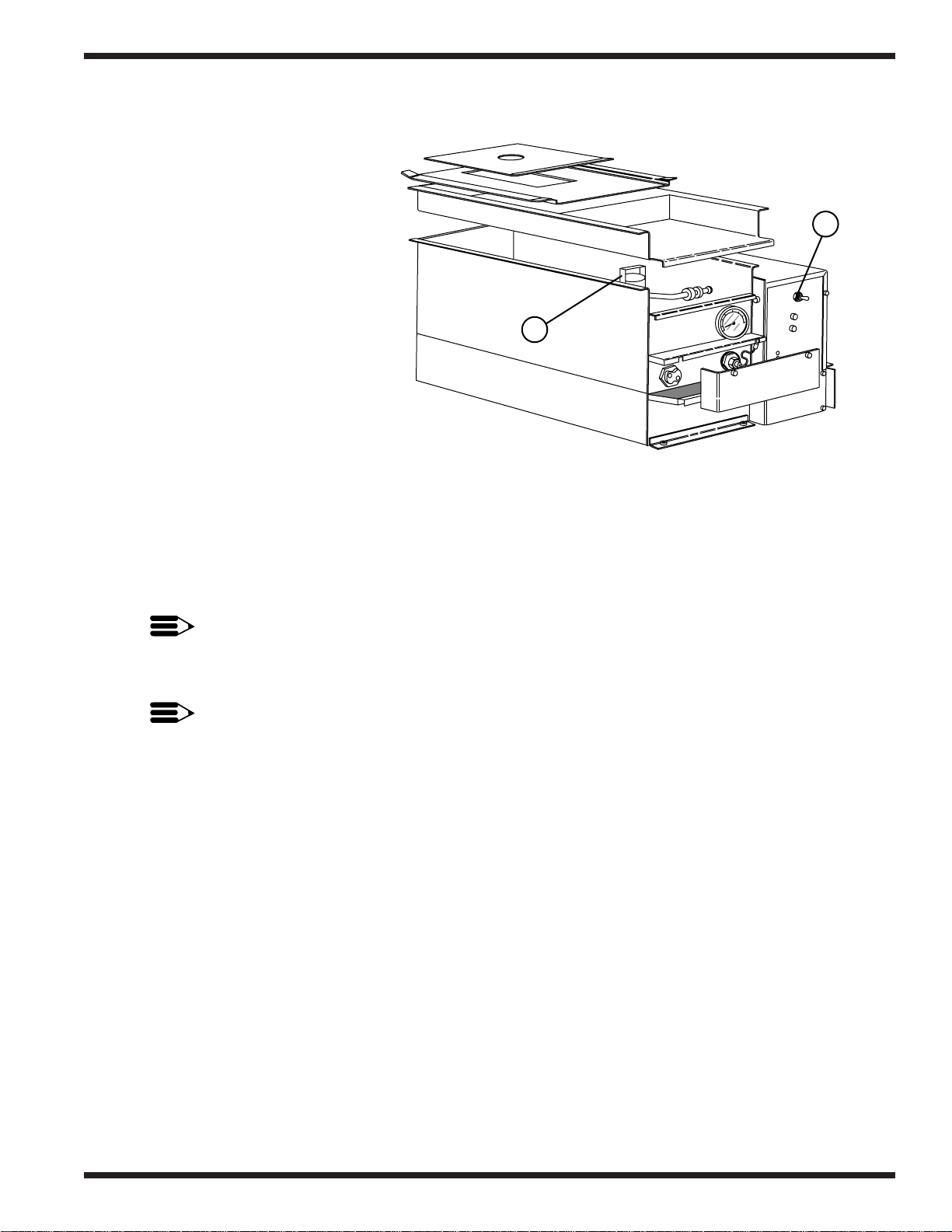

OPERATION

General

1. The wash tank is equipped

with a float assembly that

operates a single camoperated switch.

2. The water temperature is

controlled by a heater and

a thermostat. The

thermostat should be

between 140°F/60°C and

160°F/ 71°C.

To Fill the Wash Tank

Ensure that the standpipe (A) is in place. Put switch (B) to the “ON-FILL” position. The water

will fill until the proper level is reached then turn the heating element ON.

Detergent is fed from the supply container into the detergent tank in controlled amounts by the

detergent pump. Use detergent at a strength of 0.35% or as recommended by your chemical

supplier.

NOTE:

Use a commercial grade NON-CHLORINATED liquid detergent manufactured specifically

for glassware washing machines. Your chemical representative should test the solution to

ensure the proper strength to achieve the best cleaning results.

NOTE:

Many of the chemicals used in glass and dishwashers are harmful to the skin and eyes in

their concentrated form. Use extreme caution when handling containers to prevent

accidental exposure.

Operating Instructions

1. Open door, flip toggle switch located on wash tank to the “ON-FILL” position. Wash tank

will automatically fill.

2. Ensure there is product in the detergent, sanitizer and rinse agent containers.

3. Load glasses on the conveyor. Start machine with switch located on front right side of unit.

Machine will now stop and start with shut-off arm.

9

OPERATION

Figure 3 — Wash Tank

A

B

Page 12

10

OPERATION (Cont’d)

APPROXIMATE CHEMICAL SETTINGS

General

Approximate chemical settings can be obtained by counting the revolutions of the injector

rotors.

1. For detergent, one revolution per second equals approximately 0.35% concentration.

NOTE:

Detergent pump only operates when hot water tank is filling.

2. For sanitizer, one revolution in 5 seconds equals approximately 12.5 ppm Iodine or 50

ppm chlorine.

3. For rinse agent, one revolution in 8 seconds is recommended.

To Adjust Detergent Injector:

1. When a new detergent container is installed, push the prime button in and hold until the

detergent feed tube is full.

2. Install the detergent tank standpipe and switch tank fill toggle switch up to the “ON-FILL”

position. The detergent feeder will now feed detergent into the detergent tank with water

fill.

3. To increase detergent volume, turn the detergent adjustment screw clockwise.

4. To decrease the detergent volume, turn the detergent adjustment screw counter-clockwise.

To Adjust Sanitizer Injector:

1. When a new sanitizer container is installed, push the prime button in and hold until

sanitizer feed tube is full.

2. Start the washer with rocker switch located on the front of the machine. Take a sample

from the final rinse spray tube to check sanitizer level.

3. To increase the volume of sanitizer, turn the adjustment screw clockwise.

4. To decrease the volume of sanitizer, turn the adjustment screw counter-clockwise.

NOTE:

If Iodopher is being used as a sanitizer, it is not necessary to use a separate rinse agent. To

turn rinse agent injector “OFF” in this case, turn the adjustment screw counter-clockwise

until the pump stops turning.

NOTE:

If a sodium Hypochlorite (Chlorine) based sanitizer at a minimum concentration of

50PPM in the final rinse is used, use chlorine test papers to verify and monitor the 50PPM

chlorine level.

OPERATION

Page 13

11

OPERATION (Cont’d)

To Adjust Rinse Agent Injector:

1. When a new rinse agent container is installed, push the prime button in and hold until the

rinse injector feed tube is full.

2. Start the washer. Take a sample from the final rinse spray tubes.

3. To increase the volume of rinse agent, turn the adjustment screw clockwise.

4. To decrease the volume of rinse agent, turn the adjustment screw counter-clockwise.

NOTE:

To meet the requirements of N.S.F. standards, Iodophor in a concentration of 12.5 ppm or

chlorine at 50 ppm must be used in the final rinse.

OPERATION

Page 14

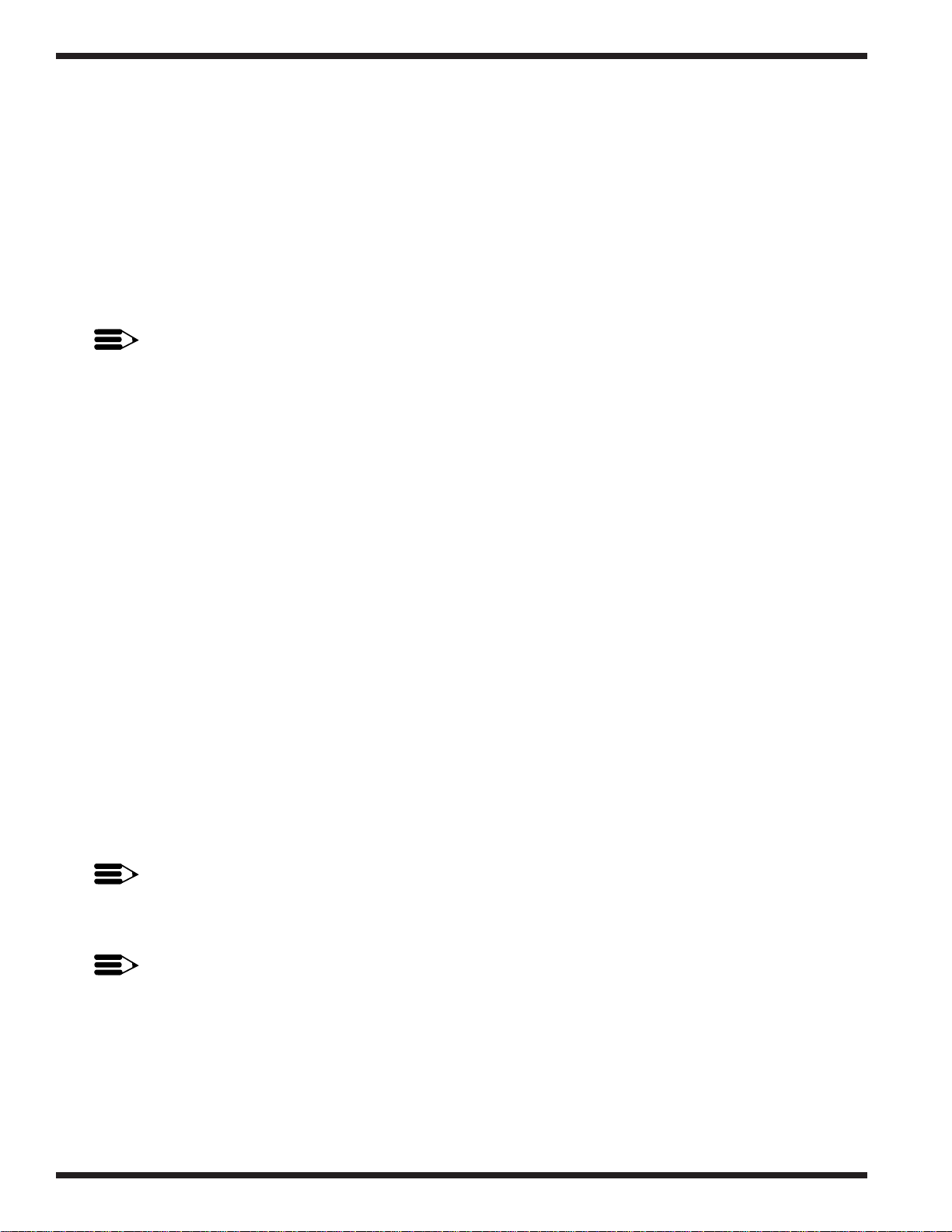

OPERATION (Cont’d)

12

OPERATION

Figure 4 — Plumbing Diagram

12

10

COLD

WATER IN

11

10

HOT

WATER IN

FLOW

8) CHEMICAL INJECTOR

9) INJECTION FITTING

10) WATER INLET VALVES

11) MIXING VALVE

7) MAIN TANK STANDPIPE

12) VACUUM BREAKER

9

1) WASH WATER TANK

2) STAND PIPE

3) WASH RETURN SCREEN

4) DRAIN PAN

5) DRAIN SCREEN

6) WASH PUMP

RINSE

WASH

8

RINSE SAN DET

7

3

1

4

2

TO DRAIN

5

6

Page 15

13

MAINTENANCE

MAINTENANCE

CLEANING

Daily Cleaning Instructions

1. Remove the drain tray/waste collector (if installed), from the front of your glasswasher.

2. Turn glasswasher off by flipping the toggle switch located on the wash tank to the “OFF”

position.

3. Remove right and left hand trays and splash curtain. Wash them with hot soapy water, rinse

thoroughly, then dry.

4. Remove the conveyor as follows: Remove cylinder in center of conveyor, flip shut-off rod

to the side, lift conveyor from center and pull out.

5. Remove lower wash and rinse arms. Clean wash and rinse areas with hot soapy water.

Rinse thoroughly, then dry.

6. Replace lower wash and rinse arms (they only fit one way). Replace conveyor as follows:

With back end of conveyor raised, mesh drive gear with side of conveyor, pull conveyor

towards you until center of conveyor drops onto pivot. Replace cylinder in center of

conveyor, flip shut-off bar back to normal position. Replace left hand tray ensuring shut-off

arm rests within the retainer, then replace right hand tray. Replace curtain.

7. Remove and clean upper and lower wash tank screens.

8. Remove stand pipe from the detergent tank, wash down the interior of the detergent tank.

Replace stand pipe and upper and lower wash tank screens.

NOTE:

Do not leave water in tank overnight!!!

9. Replace drain tray/waste collector (if installed) making sure hose is connected.

10. Ensure there is product in the detergent, sanitizer and rinse agent containers. Close door.

Weekly Cleaning Instructions

1. Remove upper and lower wash and rinse arms from the manifold and clean spray tubes

with reamer, tube brush, and tube scraper provided.

2. Remove detergent, sanitizer, and rinse agent feed lines from containers and place them in a

container of hot water. Hold prime buttons in until the feed lines have been thoroughly

flushed. Replace the feed lines to their proper container and prime product through lines.

Page 16

14

TROUBLESHOOTING

CONDITION CAUSE SOLUTION

Conveyor does not turn No power .............................................Check fuse panel

Turn power switch on

Drive motor burnt out .........................Replace

Obstruction in wash or rinse ..............Remove obstruction

Micro-switch on switch support..........Adjust or replace

bracket faulty or not making

contact

Conveyor not in position.....................Position properly

Excessive overspray Splash curtain not in position ............Install or adjust

from hood section Washer running without any ...............Keep conveyor loaded with glasses

glasses on conveyor

Spray tubes fallen off hub...................Ensure spray tube is pushed firmly on to hub

connection

Spray tubes plugged............................Clear and clean with reamer, scraper, and

brush

Lack of pressure at wash No water in detergent tank..................Ensure water supply is on

spray tubes Ensure detergent tank stand pipe is in postion

Ensure the tank fill switch is in “ON-FILL”

position and that tank fills with water

Ensure the float switch is activated by the float

cam

Ensure the tank fill solenoid valve is

operational

Obstruction in wash arm.....................Clear obstruction

Pump not operating.............................Check power supply to machine

Check pump capacitor

Replace pump if required

Pump operating but no pressure..........Check condition of impeller and stub shaft

Replace if needed

Lack of pressure in rinse Rinse spray tubes dirty........................Clean thoroughly with reamer, scraper, and

spray tubes brush provided

Shut-off valve on supply .....................Open valve

line closed

Low water pressure.............................Minimum 25PSI flow pressure required

Rinse solenoid valve will ...................Check coil

not operate Check and install rebuild kit

Replace if necessary

Rinse solenoid valve strainer .............Remove screen and clean

plugged

Water continues to flow to Solenoid valve not seating..................Clean seat

detergent tank or spray tubes Install diaphragm kit

with machine off Replace valve

TROUBLESHOOTING

Page 17

CONDITION CAUSE SOLUTION

Water temperature low Thermostat setting low........................Adjust thermostat

in detergent tank Thermostat defective ...........................Replace

Defective float switch .........................Replace

Heater burnt out ..................................Check and replace

Ensure water level is above element

Incoming water temp. low ..................Hot water supply min. 145°F/66°C

Water on floor around Pump seal leaking ...............................Replace

machine Rinse drain in wash area plugged.......Clear obstruction, clean machine

Wash return screen in detergent..........Clean

tank plugged

Drain screen under detergent .............Clean

tank plugged

Main drain plugged.............................Clean

Detergent tank covers are not .............Position all top covers to completely cover

positioned properly causing top of tank

condensation

Fill chute has lime build-up................De-scale detergent tank

Chemical containers filling Dirty rinse tubes..................................Refer to cleaning section

with water Element tube worn..............................Replace

Worn flow washer in solenoid ...........Replace

valve

Chemicals not feeding No product in containers .....................Refill container

Product gelling or crystallizing ...........Flush all lines with hot water and use fresh

in chemical line supply of chemical

Chemical supply strainer plugged.......Clean with hot water

Speed adjustment set too low..............Increase by turning clockwise while machine

is running/filling

No power to pump ..............................Check power LED on chemical control board

Check signal LED for detergent, sanitize/rinse

on board

Replace board if necessary

Pump motor defective.........................Replace pump motor

Element tube stretched........................Replace

15

TROUBLESHOOTING

Page 18

THIS PAGE

INTENTIONALLY

LEFT BLANK

16

Page 19

17

REPLACEMENT PARTS

REPLACEMENT

PARTS

Page 20

18

REPLACEMENT PARTS

Figure 5 — Main Assembly

11

2

10

12

13

4

14

15

16

6

7

5

3

2

1

8

36

17

8

18

19

9

35

20

34

21

33

22

32

31

30

29

28

27

26

23

24

25

Page 21

19

REPLACEMENT PARTS

1 0501738 Rinse Arm DF, DF-1 .................................................................. 2

1 0501692 Wash Arm DF-2 (Counter-Clockwise units only)..................... 2

2 0501613 Wash Arm DF, DF-1 .................................................................. 2

2 0501740 Rinse Arm DF-2 (Counter-Clockwise units only) ..................... 2

3 0501608 “O” Ring..................................................................................... 4

4 0501610 Top Manifold.............................................................................. 1

5 0301622 Bottom Manifold........................................................................ 1

6 0300823 Flat Washer, 1/4"........................................................................ 1

7 0501422 Bolt, 1/4-20 x 1 1/2" .................................................................. 1

8 0501412 Screw, 10-32 x 3/8 ..................................................................... 4

9 0500813 Bottom Manifold Inlet Tube...................................................... 2

10 0502663 3/8 Braided Tubing (5" Long).................................................... 2

11 0503679 7/16" Gear Clamp ...................................................................... 4

12 0509478 Grommet..................................................................................... 2

13 0300908 Wash/Rinse Tube ........................................................................ 2

14 0700911 Deflector Screen Assembly (Rinse) .......................................... 1

15 0300841 Drain Deflector (Wash).............................................................. 1

16 0301003 Top Panel.................................................................................... 1

17 0300855 Access Cover for Vacuum Breaker............................................ 1

18 0307395 Side Trim Wrap.......................................................................... 1

19 0707692 Wash Tank .................................................................................. 1

20 0503574 Strain Relief Fitting.................................................................... 4

21 0503301 Label, Warning........................................................................... 1

22 0707413 Switch Box Assembly................................................................ 1

23 0501361 Rocker Switch............................................................................ 1

24 0501411 Screw, 10-32 x 1/4 ..................................................................... 2

25 0707690 DFM6 Base ................................................................................ 1

26 0501873 Cast Foot- Gray.......................................................................... 4

27 0707394 Front Trim Assembly (Right Hand)........................................... 1

28 0707399 Door Assembly........................................................................... 1

29 0507474 Wiring Schematic ....................................................................... 1

30 0507472 Label, Daily Cleaning................................................................ 1

31 0307396 Front Trim (Left Hand).............................................................. 1

32 0501464 Screw, 10-24 x 3/8 ..................................................................... 2

33 0501921 Door Handle............................................................................... 1

34 0501885 Magnetic Door Catch................................................................. 1

35 0307398 Front Trim.................................................................................. 1

36 0505111 Label, Machine Rating............................................................... 1

NS 0706923 Tank Support.............................................................................. 1

NS 0506442 Tank Insulation, Rear................................................................. 1

NS 0506443 Tank Insulation, Center.............................................................. 1

NS 0506444 Tank Insulation, Front................................................................ 1

MAIN ASSEMBLY

Fig. 5 Part Part Description Qty.

Item No. No.

Page 22

20

REPLACEMENT PARTS

Figure 6 — Conveyor/Curtain/Switch Assembly

4

1

3

5

2

6

9

10

11

8

7

13

12

15

16 17

14

18

19

22

21

20

13

Page 23

21

REPLACEMENT PARTS

CONVEYOR/CURTAIN/SWITCH ASSEMBLY

Fig. 6 Part Part Description Qty.

Item No. No.

1 0700354 Curtain Assembly Complete...................................................... 1

2 0700997 Curtain Support.......................................................................... 1

3 0501625 Spray Curtain ............................................................................. 1

4 0300998 Curtain Clamp............................................................................ 1

5 0501538 Nut, 8-32 .................................................................................... 5

6 0501408 Screw, 8-32 x 1/4 ....................................................................... 5

7 0301021 Right Hand Tray DF, DF1.......................................................... 1

7 0701128 Right Hand Tray DF2 ................................................................ 1

8 0707434 Left Hand Tray DF, DF1............................................................ 1

8 0701119 Left Hand Tray DF2................................................................... 1

9 0503810 Plexiglass Divider ...................................................................... 1

10 0307266 Ccnveyor Hub............................................................................. 1

11 0506885 Conveyor Moulded ..................................................................... 1

12 0307322 Glide Block ................................................................................ 4

13 0501412 Screw, 10-32 x 3/8 ..................................................................... 4

14 0701011 Shut-off Rod Assembly.............................................................. 1

15 0300848 Activator Assembly DF, DF1 ..................................................... 1

15 0706935 Activator Assembly DF2............................................................ 1

16 0501395 Set Screw, 1/4-20 x 5/16 ........................................................... 1

17 0301012 Nut Plate..................................................................................... 1

18 0501382 Tripswitch, Sealed ...................................................................... 1

19 0503574 Strain Relief ............................................................................... 1

20 0501483 Delrin Washer............................................................................. 2

21 0503723 Screw, 6-32 x 1"......................................................................... 2

22 0300980 Switch Support Bracket DF, DF1, DF2 (CW rotation) ............. 1

22 0301008 Switch Support Bracket DF2 (CCW rotation) ........................... 1

Page 24

22

REPLACEMENT PARTS

Figure 7 — Control Box

22

30

31

32

33

29

28

27

26

25

24

23

21

20

19

16

14

11

10

9

17

15

12 13

18

32

8

6

7

1

2

4

5

3

Page 25

23

REPLACEMENT PARTS

CONTROL BOX

Fig. 7 Part Part Description Qty.

Item No. No.

1 0707403 Control Box (prior to S/N 18673).............................................. 1

1 0709049 Control Box (starting @ S/N 18674)......................................... 1

2 0307405 Injector Motor Plate................................................................... 1

3 0501519 Tie, Nylon 4 in........................................................................... 6

4 0502666 1/8 x 1/4 OD Tubing.................................................................. AR

5 0706635 45CC Element Tube ................................................................... 2

6 0706634 15CC Element Tube ................................................................... 1

7 0707142 Rotor Assembly.......................................................................... 3

8 0506589 Screw, 6-32 x 7/8"...................................................................... 6

9 0504822 Screw, 8-32 x 1/2"...................................................................... 12

10 0501353 Chemical Injector Motor............................................................ 3

11 0507314 Start Capacitor (3 uF)................................................................. 1

12 0307422 Thermostat Bracket.................................................................... 1

13 0501450 Screw, 6-32 x 3/16".................................................................... 4

14 0507323 Thermostat.................................................................................. 1

15 0503592 Label, Ground ............................................................................ 1

15 0501403 Screw, Ground, 10-32 x 3/4" ...................................................... 2

15 0501533 Nut, Ground, 10-32.................................................................... 2

15 0501493 Washer, Lock, Ground, #10....................................................... 2

15 0501472 Washer, Flat, Ground ................................................................. 3

16 0503648 Screw, 8-32 x 5/16".................................................................... 2

17 0503647 Strain Relief Bushing (Medium)................................................ 1

18 0503574 Strain Relief Bushing (Small).................................................... 2

19 0501887 7/8" Button Plug......................................................................... 1

20 0507372 Power Cord................................................................................. 1

21 0503749 Terminal Board........................................................................... 2

22 0701933 Water/Heater Cam c/w Set Screw.............................................. 1

23 0501397 Set Screw, 6-40 x 3/16".............................................................. 1

24 0501379 Float Switch ............................................................................... 1

25 0307369 Nut Plate for Float Switch (starting @ S/N 18674)................... 1

26 0501433 Screw, 4-40 x 5/8"...................................................................... 2

27 0501411 Screw, 10-32 x 1/4".................................................................... 8

28 0309053 Float Switch Support (starting @ S/N 18674)........................... 1

29 0503642 Label, 2.5 Amp Fuse.................................................................. 1

30 0503693 Label, Switch Up........................................................................ 1

31 0501373 3-Position Switch....................................................................... 1

32 0501412 Screw, 10-32 x 3/8".................................................................... 8

33 0507470 Label, Injector Prime.................................................................. 1

Page 26

24

REPLACEMENT PARTS

Figure 8 — Control Box Cover/Chemical Injector Board

7

8

6

5

4

1

2 3

9

20

10

11

12

13

14

1615

17

18

19

Page 27

1 0508433 Circuit Board (starting @ S/N 18629)....................................... 1

2 106695 Screw, 6-32 x 1/2"...................................................................... 4

3 0508710 Spacer, 5/16 lg............................................................................ 4

4 0309037 Support Bracket (starting @ S/N18629) .................................... 1

5 0503637 Fuse, 2.5 Amp ........................................................................... 1

6 0508920 Transformer (starting @ S/N 18629)......................................... 1

7 0501450 Screw, 6-32 x 3/16".................................................................... 4

8 0501411 Screw, 10-32 x 1/4".................................................................... 2

9 0503695 Label, Detergent......................................................................... 1

9 0505483 Label, Rinse................................................................................ 1

9 0503694 Label, Sanitizer .......................................................................... 1

10 0307408 Control Box Cover (prior to S/N 18674) ................................... 1

10 0309052 Control Box Cover (starting @ S/N 18674).............................. 1

11 0503301 Label, Warning........................................................................... 1

12 0509061 Label, Circuit Board (starting @ S/N 18629)............................ 1

13 0503343 Label, Warranty Void ................................................................. 1

14 0300986 Hinge, Cover ............................................................................. 2

15 0501408 Screw, 8-32 x 1/4"...................................................................... 4

16 0501538 Nut, 10-32 .................................................................................. 4

17 0307409 Injector Pump Cover.................................................................. 1

18 0306363 Dip Tube..................................................................................... 3

19 0502666 Hose, 1/8" I.D. x 1/4" O.D......................................................... AR

20 0501869 Strainer....................................................................................... 3

NS 0507370 Wiring Harness (Drive Motor, Solenoid Valves) ...................... 1

NS 0507578 Wiring Harness, Circuit Board (prior to S/N 18629) ................ 1

NS 0509039 Wiring Harness, Circuit Board (starting @ S/N 18629)............ 1

NS 0503739 Aluminum Spacer, Float Switch (prior to S/N 18674) .............. 2

NOTE:

The circuit board shown in this diagram started at S/N 18629. Prior units will require

circuit board conversion kit P/N 0708523. Once this kit has been installed, all replacement

parts except the wiring harness will be as shown. Replacement wiring harness for circuit

board kit is P/N 0509038.

25

REPLACEMENT PARTS

CONTROL BOX COVER/CHEMICAL INJECTOR BOARD

Fig. 8 Part Part Description Qty.

Item No. No.

Page 28

26

REPLACEMENT PARTS

Figure 9 — Detergent Tank

8

2

3

4

5

6

7

1

32

33

34

10

17

9

16

15

18

11

14

25

19

13

12

20

24

23

21

5

22

26

27

31

30

29

28

36

35

Page 29

27

REPLACEMENT PARTS

DETERGENT TANK

Fig. 9 Part Part Description Qty.

Item No. No.

1 0707415 Detergent Tank (up to S/N 18673)............................................. 1

1 0709054 Detergent Tank (starting @ S/N 18673) .................................... 1

2 0307379 Detergent Tank Cover Lid .......................................................... 1

3 0307378 Detergent Tank Rear Cover ........................................................ 1

4 0707375 Detergent Tank Screen Assembly .............................................. 1

5 0507471 Label, Clean Screens Daily ........................................................ 2

6 0700948 Standpipe Assembly................................................................... 1

7 0503670 Float Ball.................................................................................... 1

8 0507426 Float Rod .................................................................................... 1

9 0703673 Cam Bushing c/w Set Screw...................................................... 1

10 0501397 Set Screw 6-40 x 3/16" ..............................................................

11 0503701 Timer Shaft Bearing (not req’d after S/N 18673)...................... 2

12 0505112 Label, Data................................................................................. 1

13 0501896 Thermometer Seal...................................................................... 1

14 0501600 8" Thermometer ......................................................................... 1

15 0503588 Heater “O” Ring ......................................................................... 1

16 0507315 3 KW Heater c/w “O” Ring....................................................... 1

17 0507323 Thermostat (Capilary only shown) ............................................ 1

18 0501650 Thermostat Adaptor ................................................................... 1

19 0501836 Adaptor “O” Ring ...................................................................... 1

20 0501419 Bolt, 1/4-20 x 1/2" ..................................................................... 1

21 0707383 Drain Pan Screen Assembly....................................................... 1

22 0707380 Drain Pan Assembly................................................................... 1

23 0307423 Heater Cover .............................................................................. 1

24 0503301 Label, Warning........................................................................... 1

25 0501412 Screw, 10-32 x 3/8".................................................................... 2

26 107435 Nut, M6...................................................................................... 4

27 107886 Inlet Chute Gasket...................................................................... 1

28 108051 Elbow Flange.............................................................................. 1

29 0507431 Bolt, M6 x 25mm....................................................................... 4

30 0502563 1" Gear Clamp............................................................................ 1

31 0502668 1" I.D. Braided Hose .................................................................. AR

32 0307427 Inlet Water Tube......................................................................... 1

33 0503679 7/16" Gear Clamp ...................................................................... 2

34 0502665 1/2" I.D. Braided Hose............................................................... 1

35 0502662 1-1/2" Vac-U-Flex Hose............................................................. 19"

36 0502571 1-1/2" Gear Clamp..................................................................... 1

Page 30

28

REPLACEMENT PARTS

Figure 10 — Inlet Plumbing

8

7

6

TO VACUUM BREAKER

8

7

6

TO DETERGENT TANK

11

10

3

9

1

2

3

COLD WATER VALVE

4

1

2

2

5

3

12

13

25

16

14

15

24

17

18

19

HOT WATER VALVE

21

20

22

23

1

Page 31

29

REPLACEMENT PARTS

INLET PLUMBING

Fig. 10 Part Part Description Qty.

Item No. No.

1 0502783 230V 60HZ Solenoid Valve....................................................... 2

2 0503802 3/8" MPT Tee............................................................................. 3

3 0503801 3/8" Fem x 1/2" Fem Adapter .................................................... 2

4 0507324 3/8" Check Valve........................................................................ 1

5 0502768 Mixing Valve.............................................................................. 1

6 0502653 3/8" x 1/2" 90° Hose Barb ......................................................... 2

7 0503679 7/16" Gear Clamp ...................................................................... 2

8 0502665 1/2" I.D. Braided Hose............................................................... AR

9 0509659 Brass Cap ................................................................................... 1

10 0307688 Inlet Plumbing Clamp................................................................ 1

11 0501419 Bolt, 1/4-20 x 1/2" ..................................................................... 2

12 0504822 Screw, 8-32 x 1/2"...................................................................... 2

13 0306208 Cable Clamp Cover.................................................................... 1

14 0307373 Cable Clamp Assembly.............................................................. 1

15 0501404 Screw, 10-32 x 3/8", Brass......................................................... 2

16 0501493 Lock Washer, #10....................................................................... 2

17 0501533 Nut, 10-32, Brass ....................................................................... 2

18 0505229 Solenoid Guide........................................................................... 1

19 0502811 Diaphragm Kit............................................................................ AR

20 0502810 Flow Washer (2.6 GPM) ............................................................ 1

21 0502807 Washer, Brass............................................................................. 1

22 0502804 Washer, Brass............................................................................. 1

23 0502803 Screen......................................................................................... 1

24 0501406 Screw, 8-32 x 1/2"...................................................................... 2

25 0502806 Coil -230V 60HZ....................................................................... 1

Page 32

30

REPLACEMENT PARTS

Figure 11 — Sanitizer Plumbing

10

9

11

8 7

12

6

9

13

15

14

5

16

4

3

2

1

Page 33

31

REPLACEMENT PARTS

SANITIZER PLUMBING

Fig. 11 Part Part Description Qty.

Item No. No.

1 0503668 Thermometer.............................................................................. 1

2 0502583 3/8" FPT Cross Connector......................................................... 1

3 0502653 3/8" MPT x 1/2" 90° Hose Barb................................................ 1

4 0502645 1/8" Hose Barb........................................................................... 2

5 0502666 1/8" Hose .................................................................................... AR

6 0300918 Plumbing Clamp......................................................................... 1

7 0501501 Lock Washer, 1/4"...................................................................... 2

8 0501539 Nut, 1/4-20 ................................................................................. 2

9 0502665 1/2" I.D. Braided Hose............................................................... AR

10 0502663 3/8" I.D. Braided Hose............................................................... AR

11 0502652 1/2 x 1/2 x 3/8" Tee.................................................................... 1

12 0503679 7/16" Gear Clamp ...................................................................... 5

13 0503669 Injector Barb Fitting ................................................................... 1

14 0502781 Needle Valve .............................................................................. 1

15 0507100 0-30 PSI Pressure Gauge ........................................................... 1

16 0502577 3/8 x 1/4" Reducer Bushing....................................................... 1

Page 34

32

REPLACEMENT PARTS

Figure 12 — Vacuum Breaker Plumbing Support

TO SANITIZER

PLUMBING

4

5

9

6

3

2

1

8

7

10

Page 35

33

REPLACEMENT PARTS

VACUUM BREAKER PLUMBING SUPPORT

Fig. 12 Part Part Description Qty.

Item No. No.

1 0502665 1/2" x 3/4" Inner Braided Tubing.............................................. AR

2 0503679 7/16" Gear Clamp ...................................................................... 2

3 0502651 1/2" MPT x 1/2" Hose Barb....................................................... 1

4 0502751 1/2" Vacuum Breaker (prior to S/N G2147) .............................. 1

5 0502650 1/2" x 3/8" Reducer Bushing ..................................................... 1

6 0502653 3/8" MPT x 1/2" 90° Hose Barb................................................ 1

7 0508366 Vac Breaker Kit (prior to S/N G2147)....................................... AR

8 0307391 Plumbing Support....................................................................... 1

9 113220 1/2" Vacuum Breaker ................................................................. 1

(Beginning with S/N G2147 and above)

10 113221 Repair kit, vacuum breaker........................................................ 1

(Beginning with S/N G2147 and above)

NOTE:

Watts vacuum breaker repair kit is not available . . . use item #4.

Page 36

34

REPLACEMENT PARTS

Figure 13 — Wash Pump

9

8

7

5

6

5

4

8

3

10

1

2

17

11

12

13

14

15

18

16

Page 37

35

REPLACEMENT PARTS

WASH PUMP

Fig. 13 Part Part Description Qty.

Item No. No.

1 0507313 Wash Pump Complete................................................................ 1

2 0307410 Wash Pump Base........................................................................ 1

3 0501419 Bolt, 1/4-20 x 1/2" ..................................................................... 2

4 0507320 1" I.D. X 1-1/4" O.D. PVC Hose............................................... AR

5 0502563 1" Gear Clamp............................................................................ 4

6 0502668 1" I.D. Braided Hose .................................................................. AR

7 0501632 Pump Hose Connector ............................................................... 1

8 0503679 7/16" Gear Clamp ...................................................................... 2

9 0502665 1/2" I.D. Braided Hose............................................................... AR

10 0502663 3/8" I.D. Braided Hose............................................................... AR

11 0502734 Stub Shaft................................................................................... 1

12 0502730 Seal Kit c/w Spring.................................................................... AR

13 0502729 Impeller ...................................................................................... 1

14 0502731 Pump Housing ............................................................................ 1

15 0501635 “O” Ring, 5/16 I.D. X 1/16W.................................................... 1

16 0502732 Housing Seal Screw................................................................... 1

17 0503648 Screw, 8-32 x 5/16".................................................................... 4

18 0501406 Screw, 8-32 x 1/2"...................................................................... 4

NOTE:

Motor is not available as a separate item.

Page 38

36

REPLACEMENT PARTS

Figure 14 — Drive Complete

8

7

1

6

2

4

5

4

3

Page 39

37

REPLACEMENT PARTS

DRIVE COMPLETE

Fig. 14 Part Part Description Qty.

Item No. No.

1 0707388 Drive Motor Housing Assembly................................................ 1

2 0507145 Drive Motor................................................................................ 1

3 0307617 Drive Motor Housing Cover ...................................................... 1

4 0501412 Screw, 10-32 x 3/8 ..................................................................... 4

5 0503574 Strain Relief Bushing................................................................. 1

6 0501923 Extension Spring........................................................................ 1

7 0507264 Slinger Washer ........................................................................... 1

8 0506886 Drive Gear.................................................................................. 1

Page 40

38

REPLACEMENT PARTS

Figure 15 — Cleaning Accessories

1

2

3

4

5

6

5

7

8

Page 41

39

REPLACEMENT PARTS

CLEANING ACCESSORIES

Fig. 15 Part Part Description Qty.

Item No. No.

1 0708986 Tube Scraper ............................................................................. 1

2 0501826 Tube Brush................................................................................. 1

3 0501633 Jet Reamer c/w Drill .................................................................. 1

OPTIONAL ACCESSORIES (not shown)

Fig. 16 Part Part Description Qty.

Item No. No.

– 0707544 Drain Tray and Waste Collector (DF70A)

– 0700896 Screen

– 0708098 Drain pan

– 0503930 Drain hose, 48"

– 0501874 Caster, reg

– 0501876 Caster, locking

– 0507255 Hose, 1/2 female quick disconnect, 10'

– 0507256 Hose, 1/2 male quick disconnect, 16"

– 0707258 Quick Disconnect Package (including casters)

– 0701962 Caster Kit (2 Locking, 2 Regular)

– 0708453 Hand Sink and Wet Waste Receiver (SW46)

– 0701956 Wash Down Hose (includes items 4 - 8)

4 0703454 Wash Down Nozzle.................................................................... 1

5 0505320 1/2" Hose Washer....................................................................... 1

6 0502779 Nozzle......................................................................................... 1

7 0501833 1/2" x 10' Hose Assembly .......................................................... 1

8 0506643 Faucet......................................................................................... 1

Page 42

40

ELECTRICAL SCHEMATICS

Figure 17 — Electrical Diagram (S/N 16211 through 18353)

ON-OFF

SWITCH

GLASS SHUTOFF

ARM SWITCH

NO

NC

BLACK

RED

BLACK

RED

RINSE WATER

VALVE

CONV. DRIVE

MOTOR

WASH PUMP

MOTOR

START

CAPACITOR

WHITE

BLUE

GREEN

NO

WATER LEVEL

CAM SWITCH

NC

FLOAT OPERATED

FLUSH

OFF

AUTO

TANK FILL

TOGGLE SWITCH

2.5A FUSE

INJECTOR CONTROL BOARD

HEATER

THERMOSTAT

J1 1

J2

2

3

4

5

6

1

2

3

4

WASH WATER

DET PUMP

SANI PUMP

RINSE PUMP

VALVE

DET TANK

HEATER

DF M6

0507373

208/230V 12.8A 60HZ SINGLE PHASE

Page 43

41

ELECTRICAL SCHEMATICS

Figure 18 — Electrical Diagram (S/N 18354 through 18628)

RINSE WATER

VALVE

ON-OFF

SWITCH

GLASS SHUTOFF

ARM SWITCH

TANK FILL

TOGGLE SWITCH

FLUSH

OFF

AUTO

NO

NC

BLACK

2.5A FUSE

RED

BLACK

RED

CONV. DRIVE

WASH PUMP

J1 1

2

3

4

5

6

MOTOR

MOTOR

START

CAPACITOR

DET PUMP

SANI PUMP

RINSE PUMP

WHITE

BLUE

GREEN

NC

FLOAT OPERATED

DF M6

NO

WATER LEVEL

CAM SWITCH

J2

1

2

3

4

OFF

FLUSH

AUTO

TANK FILL

TOGGLE SWITCH

INJECTOR CONTROL BOARD

HEATER

THERMOSTAT

208/230V 12.8A 60HZ SINGLE PHASE

WASH WATER

VALVE

DET TANK

HEATER

0507474

Page 44

42

ELECTRICAL SCHEMATICS

Figure 19 — Electrical Diagram (beginning with S/N 18629)

RINSE WATER

VALVE

ON-OFF

SWITCH

GLASS SHUTOFF

240V PRIM.

18V SEC.

ARM SWITCH

NO

NC

TRANSFORMER

BLACK

DET PUMP

BLACK

RED

RED

SANITIZER PUMP

RINSE AID PUMP

POWER

LED 3

CONV. DRIVE

MOTOR

WASH PUMP

MOTOR

START

CAPACITOR

2.5A FUSE

WHITE

WHITE

BLUE

GREEN

NO

WATER LEVEL

CAM SWITCH

NC

FLOAT OPERATED

DF M6

TANK FILL

TOGGLE SWITCH

INJECTOR

CONTROL BOARD

DETERGENT

LED 2

R/S

LED 1

TANK FILL

FLUSH

TOGGLE SWITCH

OFF

AUTO

HEATER

THERMOSTAT

FLUSH

OFF

AUTO

208/230V 12.8A 60HZ SINGLE PHASE

SANI/RIN

RED

BLUE

DETERGENT

WASH WATER

VALVE

DET TANK

HEATER

0507474

Page 45

Page 46

Loading...

Loading...