Moyer Diebel 501HT Installation Manual

Installation/Operation Manual with Service Replacement Parts

Undercounter Dishwashers

M4 Series

501HT

High Temperature Wash

Refresh with built-in booster

and Pumped Final Rinse

501HT

501LT

Low Temperature Chemical

Sanitization Wash Refresh

with Pumped Final Rinse

501LT

3765 Champion Blvd.,

Winston-Salem, NC 27105

(336) 661-1556 Fax: (336) 661-1660

Toll-free: (800) 858-4477

Issue Date: 2.24.16

Manual P/N 115782 rev. A

For machines beginning with S/N W150350341 and above

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

(905) 562-4195 Fax: (905) 562-4618

Toll-free: (800) 263-5798

Printed in the USA

For future reference, record your dishwasher information in the box below.

Model Number__________________________ Serial Number_______________________

Voltage________________Hertz_____________ Phase__________________

Service Agent __________________________________ Tel:______________________

Parts Distributor _________________________________ Tel:______________________

National Service Department

In Canada:

Toll-free: (800) 263-5798

Tel: (905) 562-4195

Fax: (905) 562-4618

email: service@moyerdiebellimited.com

The model no., serial no., voltage, Hz

and phase are needed to identify your

machine and to answer questions.

Please have this information ready

ATTENTION:

The machine data plate is located

on the lower front panel.

if you call for service assistance.

The USGBC and the CaGBC Member Logos are trademarks owned by the U.S. Green Building Council and The Canadian Green

Building Council, respectively, and are used by permission. The logos signify only that Moyer Diebel is a USGBC member and a

CaGBC member; USGBC and CaGBC do not review, certify nor endorse the products or services offered by its members.

COPYRIGHT © 2016 All rights reserved Printed in the USA

PRODUCT REGISTRATION

ONLINE

Connect to the internet and enter the URL below to

register your machine.

IN CANADA:

http://www.championindustries.com/canada/register

PRODUCT REGISTRATION

BY FAX

COMPLETE THIS FORM AND FAX TO:

(336) 661-1660 in the USA

1 (800) 204-0109 in Canada

PRODUCT REGISTRATION CARD

Model

Date of Installation:

Company Name:

Address:

Telephone #: ( ) ---

(Street)

Serial #

State

or Province

Zip or

Postal Code

Contact:

Installation Company:

Address:

Telephone #:

Contact:

FAILURE TO REGISTER YOUR PRODUCT MAY VOID YOUR WARRANTY

IMPORTANT IMPORTANT

Revision History

Revision History

A revision might be a part number change, a new instruction, or other information that was

not available at print time. We reserve the right to make changes to these instructions without

notice and without incurring any liability by making the changes. Equipment owners may

request a revised manual, at no charge, by calling 1 (800) 858-4477 in the USA or by

calling 1 (800) 263-5798 in Canada.

Revision Revised Serial Number Revision

Date Pages Effectivity Description

10.9.15 --- W150350341 Released First 501HT Edition

W150350281 Released FIrst 501LT Edition

2.24.16 25 W150350341 Revised Varicycle illustration

i

Limited Warranty

LIMITED WARRANTY

Moyer Diebel. (herein referred to as The Company), 3765 Champion Blvd., Winston-Salem, North Carolina 27105, 2674 N.

Service Road, Jordan Station, Canada, L0R 1S0, warrants machines, and parts, as set out below.

Warranty of Machines: The Company warrants all new machines of its manufacture bearing the name "Moyer Diebel"

and installed within the United States and Canada to be free from defects in material and workmanship for a period of one (1)

year after the date of installation or fifteen (15) months after the date of shipment by The Company, whichever occurs first. [See

below for special provisions relating to glasswashers.] Warranty registration must be submitted to Moyer Diebel within ten (10)

days after installation either online on the Moyer Diebel website (http://www.moyerdiebel.com/register/) in the USA or

http://www.championindustries.com/canada/register in Canada or by fax on the form provided at the front of this manual.

If warranty registration is not returned to The Company within such period, the warranty will expire after one year from the

date of shipment. The Company will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions. If a defect in workmanship or material is found to exist within the warranty

period, The Company, at its election, will either repair or replace the defective machine or accept return of the machine for full

credit; provided; however, as to glasswashers, The Company's obligation with respect to labor associated with any repairs

shall end (a) 120 days after shipment, or (b) 90 days after installation, whichever occurs first. In the event that Moyer Diebel

elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular working hours

by The Company's authorized service technician. Defective parts become the property of The Company. Use of replacement

parts not authorized by The Company will relieve The Company of all further liability in connection with its warranty. In no event

will The Company's warranty obligation exceed The Company's charge for the machine. The following are not covered by The

Company's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or interior finish

as a result of the above, (2) Use with utility service other than that designated on the rating plate, (3) Improper connection to

utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from chemicals dispensed in excess of recommended

concentrations, (6) Failure of electrical components due to connection of chemical dispensing equipment installed by others, (7)

Leaks or damage resulting from such leaks caused by the installer, including those at machine table connections or by connection

of chemical dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage caused by

labor dispute.

Warranty of Parts: The Company warrants all new machine parts produced or authorized by The Company to be free from

defects in material and workmanship for a period of 90 days from date of invoice. If any defect in material and workmanship is

found to exist within the warranty period The Company will replace the defective part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. THE COMPANY'S WARRANTY

IS ONLY TO THE EXTENT REFLECTED ABOVE. THE COMPANY MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF MERCHANTABILITY,

OR FITNESS OF PURPOSE. MOYER DIEBEL SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE THE EXCLUSIVE REMEDIES FOR ANY

DEFECTS FOUND TO EXIST IN THE COMPANY'S DISHWASHING MACHINES AND THE COMPANY'S

PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING ANY LIABILITY FOR INCIDENTALS

OR CONSEQUENTIAL DAMAGES.

Moyer Diebel does not authorize any other person, including persons who deal in Moyer Diebel dishwashing machines to change this warranty

or create any other obligation in connection with Moyer Diebel Dishwashing Machines.

ii

Table of Contents

Table of Contents

Model 501HT

Revision History ........................................................................................................ i

Limited Warranty ...................................................................................................... ii

Installation - Model 501HT ..................................................................... 1

Receiving - 501HT .................................................................................................. 1

Placement - 501HT ................................................................................................. 1

Water Connections - 501HT .................................................................................... 2

Drain Connections - 501HT ..................................................................................... 3

Electrical Connections 501HT 1 Phase w/o Booster - 501HT ....................................... 6

Electrical Connections 501HT 1 and 3 PH Wiring Diagrams - 501HT ........................... 7

Connecting Incoming Power to the Main Terminal Block (1 and 3 PH) - 501HT .............. 8

Booster Heater Conversion from 1 to 3 PH - 501HT .................................................. 11

Booster Fill Switch - (Filling the booster for the first time) - 501HT ................................. 14

Chemical Connections - 501HT .............................................................................. 16

Pumps and Injection Points - Detergent and Rinse-aid Dispensing Pumps - 501HT ................... 17

Pump Priming - Detergent and Rinse-aid Dispensing Pumps - 501HT............................ 19

Fill Adjustments - Detergent and Rinse-aid Dispensing Pumps - 501HT ................................... 21

Operation - Model 501HT ................................................................................. 22

Loading Dish Racks - 501HT .................................................................................. 22

Normal Wash Mode - 501HT ................................................................................ 24

Varicycle Mode - 501HT ....................................................................................... 25

Rinse Sentry Mode - 501HT ................................................................................... 26

Drain Mode - 501HT ............................................................................................ 26

Cleaning - Model 501HT ....................................................................... 28

Cleaning the Wash Tank - 501HT ........................................................................... 28

Cleaning the Wash Arms - 501HT .......................................................................... 29

Cleaning Scrap Screen and Sump Strainer - 501HT.................................................. 31

Deliming - Model 501HT ....................................................................................... 32

Maintenance - Model 501HT .................................................................. 34

Daily, Weekly, Monthly ......................................................................................... 34

(continued on next page)

iii

Table of Contents

Table of Contents

Model 501LT

Installation - Model 501LT...................................................................... 37

Receiving - 501LT ................................................................................................. 37

Placement - 501LT ................................................................................................ 37

Single Phase Electrical Connections - 501LT ............................................................. 38

Water Connections - 501LT .................................................................................... 39

Drain Connections - 501LT ..................................................................................... 40

Pumps and Injection Points - Detergent and Rinse-aid Dispensing Pumps - 501LT .................... 42

Pump Priming - Detergent and Rinse-aid Dispensing Pumps - 501LT ............................. 44

Fill Adjustments - Detergent and Rinse-aid Dispensing Pumps - 501LT ..................................... 45

Operation - Model 501LT .................................................................................. 46

Loading Dish Racks - 501LT ................................................................................... 46

Normal Wash Mode - 501LT ................................................................................. 47

Vari-Cycle Mode - 501LT ....................................................................................... 48

Drain Mode - 501LT .............................................................................................. 49

Cleaning - Model 501LT ........................................................................ 50

Cleaning the Wash Tank - 501LT ............................................................................ 50

Cleaning the Wash Arms - 501LT ........................................................................... 50

Cleaning Scrap Screen and Sump Strainer - 501LT ................................................... 51

Deliming - Models 501LT ....................................................................................... 52

Maintenance - Model 501LT ................................................................... 54

Daily, Weekly, Monthly ......................................................................................... 54

Troubleshooting - Models 501HT, 501LT .............................................................. 57

Service Replacement Part - Models 501HT, 501LT

.......................................... 69

Electrical Schematics - Models 501HT, 501LT ................................................ 107

Timing Charts - Models 501HT, 501LT ................................................................. 110

iv

Receiving and Placement - Installation

Counter-top

Wall

3" [8cm] Min.

34"

[86cm]

Min.

Floor

Receiving - 501HT

NOTE:

The installation of your dishwasher must be performed by qualified service personnel familiar

with food service equipment and must comply with all local health codes.

Problems due to improper installation are not covered by the Limited Warranty.

NOTE:

The installation of the dishwasher must comply with all local electrical, plumbing, health and

safety codes or in the absence of local codes, installed in accordance with the applicable

requirements in the National Electrical Code, NFPA 70, Canadian Electrical Code (CEC),

Part 1, CSA C22.1; and the Standard for Ventilation Control and Fire Protection of

Commercial Cooking Operations, NFPA 96.

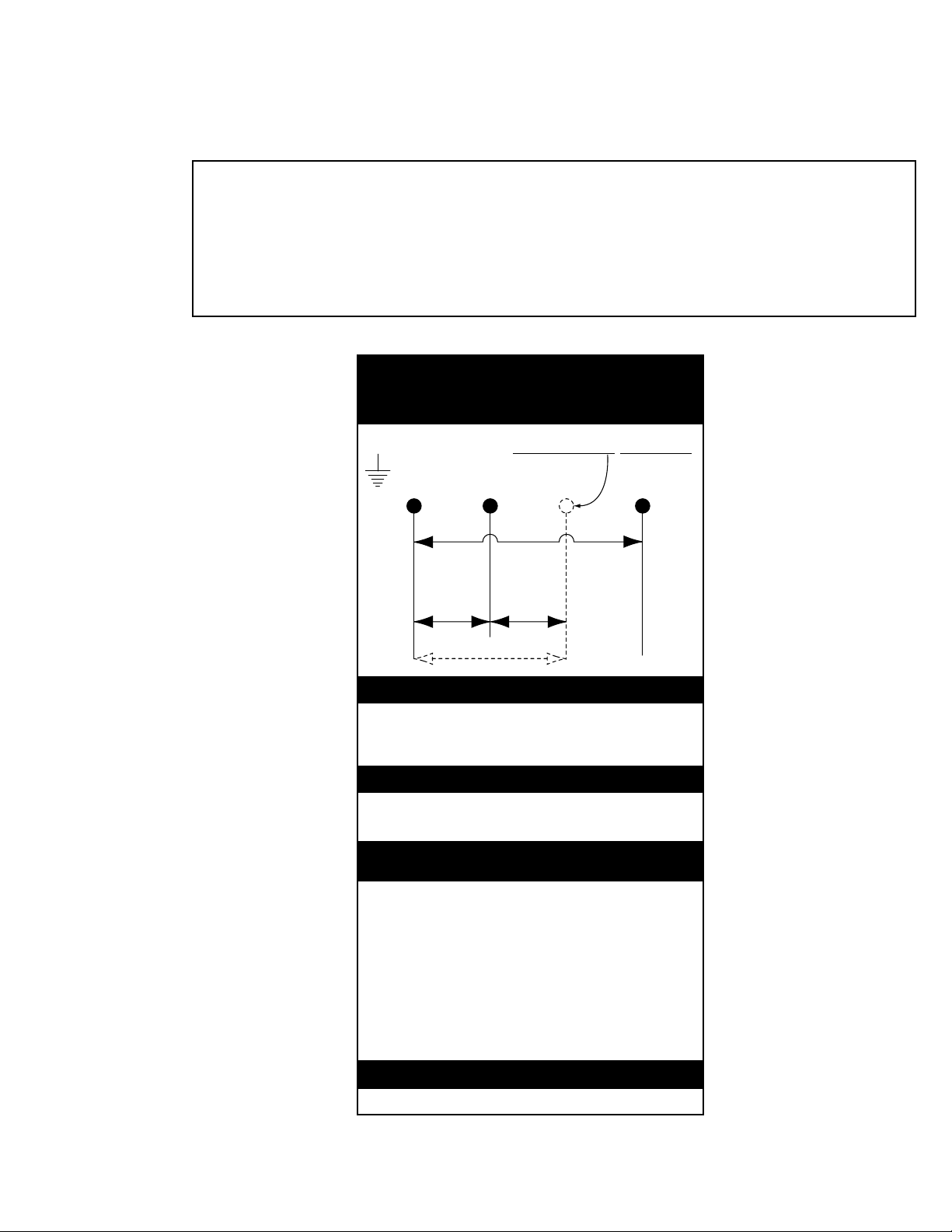

Placement - 501HT

CAUTION:

Be careful when lifting and moving the dishwasher to prevent damage to the machine.

1. Inspect the outside of the dishwasher carton for signs of damage.

2. Remove the carton and inspect the dishwasher for damage.

3. Check for any options or accessories that may have shipped with your dishwasher.

4. Compare the installation site utility connections with the dishwasher utility connections

and make sure they are the same.

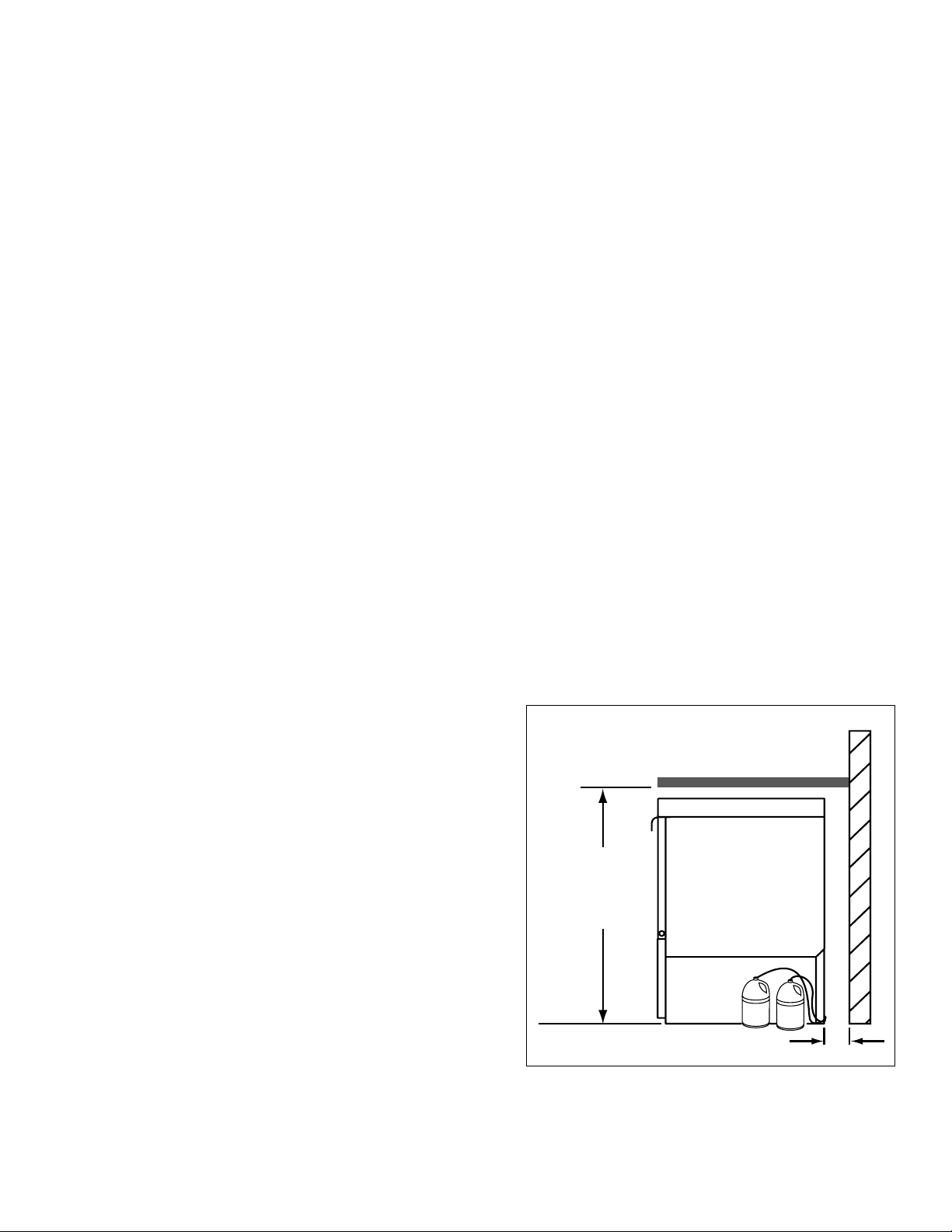

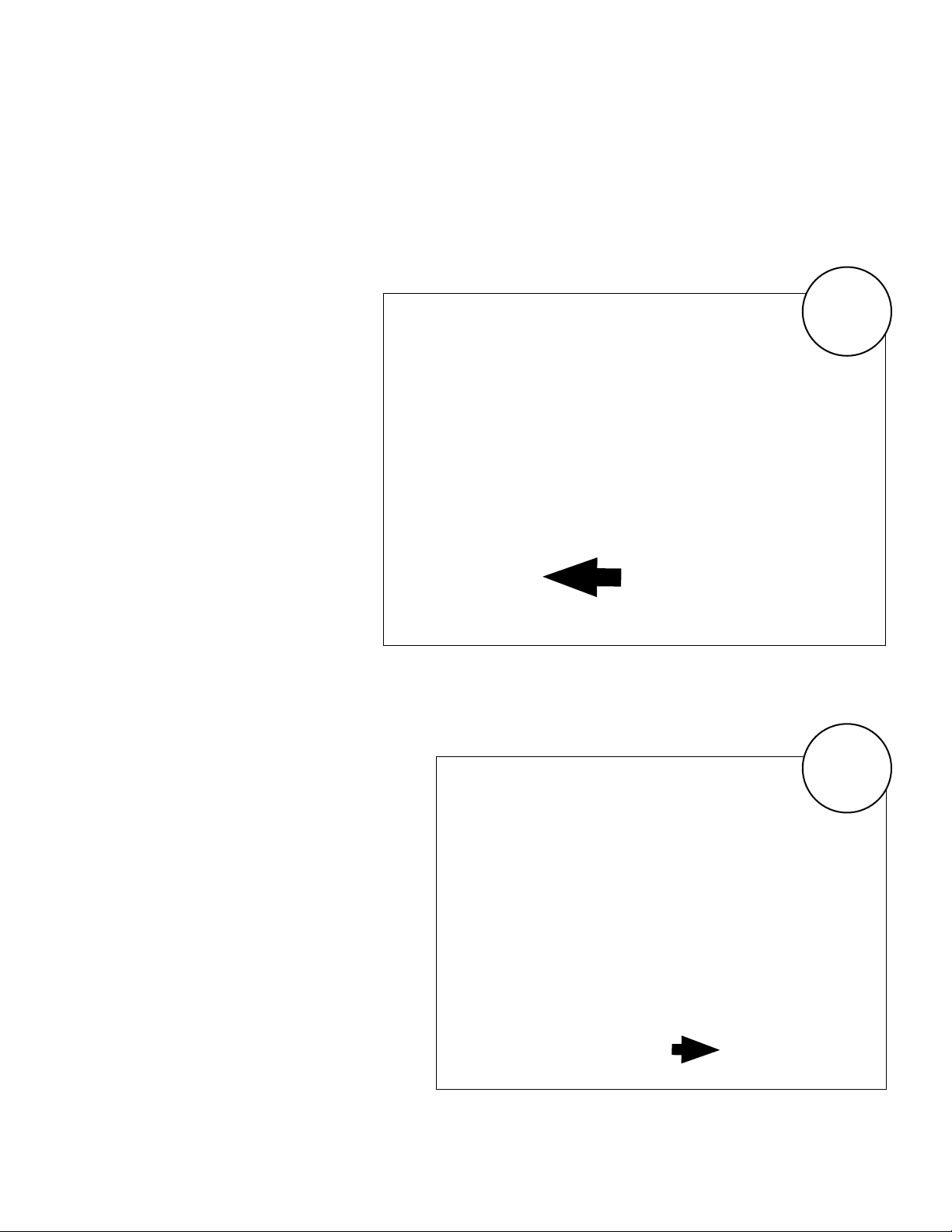

5. The dishwasher can be installed as a free-standing unit or under a counter-top.

The typical counter-top height in most locations is 34" [86cm].

6. It is highly recommended that the

underside of the counter-top be clad

in metal.

7. Under counter installations should

provide storage space for the

dishwasher chemical supply

containers. Do not elevate the

containers above the finished floor.

8. Chemical supply containers should

be placed as close to the machine

as possible and the chemical tubing

taped to the back of the machine

should be repositioned before

permanently placing the machine.

9. Place the dishwasher in its

permanent location.

10. The dishwasher has 4 adjustable

feet for leveling.

11. Level the dishwasher front-to-back

and side-to-side.

1

Installation - 501HT

Water Connections - 501HT

VERY IMPORTANT:

Make sure the flexible water supply and drain hoses are not kinked.

Plumbing connections must allow the machine to be pulled out for service and cleaning.

Plumbing connections must comply with national, provincial local plumbing and sanitary

codes. Only qualified service personnel familiar with food service equipment should install

the machine.

The installing plumber must thoroughly flush the water supply line to remove all debris

BEFORE connecting the water supply line to the machine.

CAUTION:

Plumbing connections must be made BEFORE the electrical installaion is performed.

Damage to the machine's water heaters will occur if the power is turned on to the

machine without an adequate water supply.

ATTENTION:

It is the installing plumber's responsibility to flush the incoming water line to remove debris

before connecting to the dishwasher. Failure to do so may void the machine warranty.

1. All models have a 6 ft. flexible hot water fill hose with a 3/4" female garden hose connector.

2. A 1/2" or larger main incoming supply line must be installed to the dishwasher.

3. A 1/2" or larger shut-off valve should be installed in the main water supply, as close to the

dishwasher as possible for servicing.

The 501HT with booster has a built-in flow control. The flowing incoming hot water supply

pressure must be between 25-95 psi. The hot water supply must provide a minimum of

140°F/60°C, measured at the dishwasher for 40°F/22°C rise booster or 110°F/43°C for

70°F/39°C rise booster.

4. A water hardness of 3 grains/gal (US) [5.3 mg/L] or less is recommended. Excessively hard

water may need a water softener or other means of water treatment to prevent lime build-up.

2

501HT - Installation

Drain Connections - 501HT

! VERY IMPORTANT !

Do not connect the drain hose to a disposer. The dishwasher will not drain correctly.

Refer to the photo below.

1. All models are equipped with a 6 ft.. 5/8" I.D. drain hose. The maximum drain

height connection must not exceed 3 ft.[1 m] and must be vented to prevent

the wash tank from siphoning.

2. The drain hose is located at the rear of the dishwasher, and is secured to the rear of

the machine by two clamps to maintain an anti-siphoning loop in the drain hose.

3. A 3/4" hose barb fitting is strapped to the drain hose prior to shipment.

The service part number for the hose barb is P/N 0512321.

4. Additional plumbing parts must be supplied by the plumbing installer.

5. The maximum drain flow is 15 US gpm/12.4 imp gpm/60 lpm.

! ATTENTION !

FAILURE TO FOLLOW THE DRAIN CONNECTION INSTRUCTIONS MAY VOID THE WARRANTY.

DO NOT REMOVE HOSE CLAMPS

NOR STRETCH HOSE

3/4" DRAIN HOSE BARB FITTING

STRAPPED TO DRAIN HOSE

3

Installation - 501HT

Drain Connection - 501HT (continued)

DO NOT REMOVE THE CLAMPS HOLDING THE DRAIN HOSE TO THE

BACK OF THE DISHWASHER.

DO NOT CONNECT THE DRAIN HOSE TO A DISPOSER.

DO NOT REDUCE THE SIZE OF THE DRAIN HOSE CONNECTION NOR USE A DOMESTIC

DRAIN FITTING.

DO NOT ADD ADDITIONAL LENGTH TO THE DRAIN HOSE.

DO NOT ALLOW THE DRAIN HOSE TO KINK.

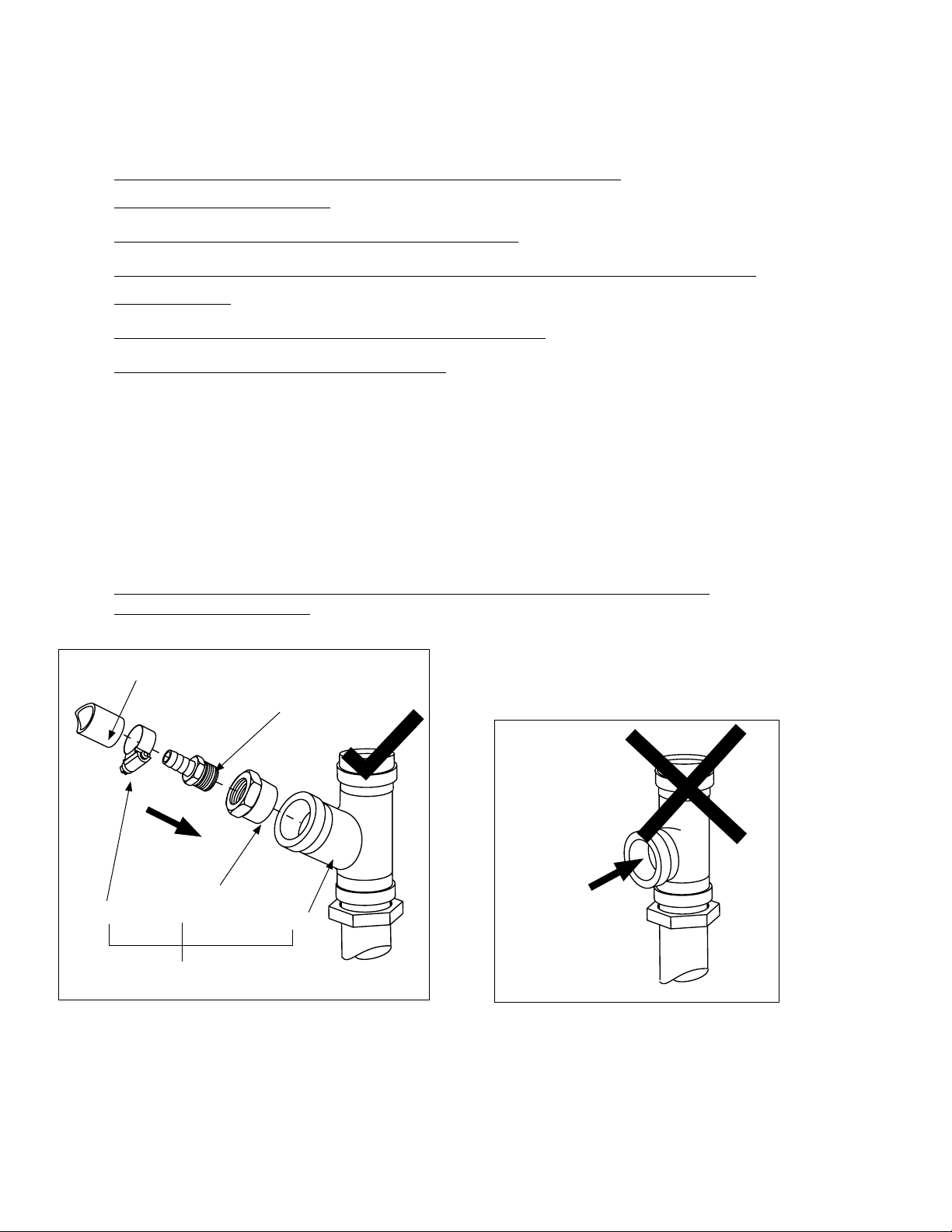

For a Direct Drain Connection:

1. Install the drain hose to an 1-1/2" or larger vented "WYE" drain fitting.

2. CONNECTION TO A "TEE" FITTING WILL PREVENT THE DISHWASHER FROM

DRAINING COMPLETELY.

Drain Hose

Clamp

(Supplied by others)

3/4" NPT Hose Barb

Fitting

Drain

Adapter

Fitting

WYE

Fitting

DO

connect the dishwasher flexible drain

hose to a vented WYE drain fitting.

connect the dishwasher flexible

drain hose to a TEE drain fitting.

DO NOT

4

501HT - Installation

Drain Connection - 501HT

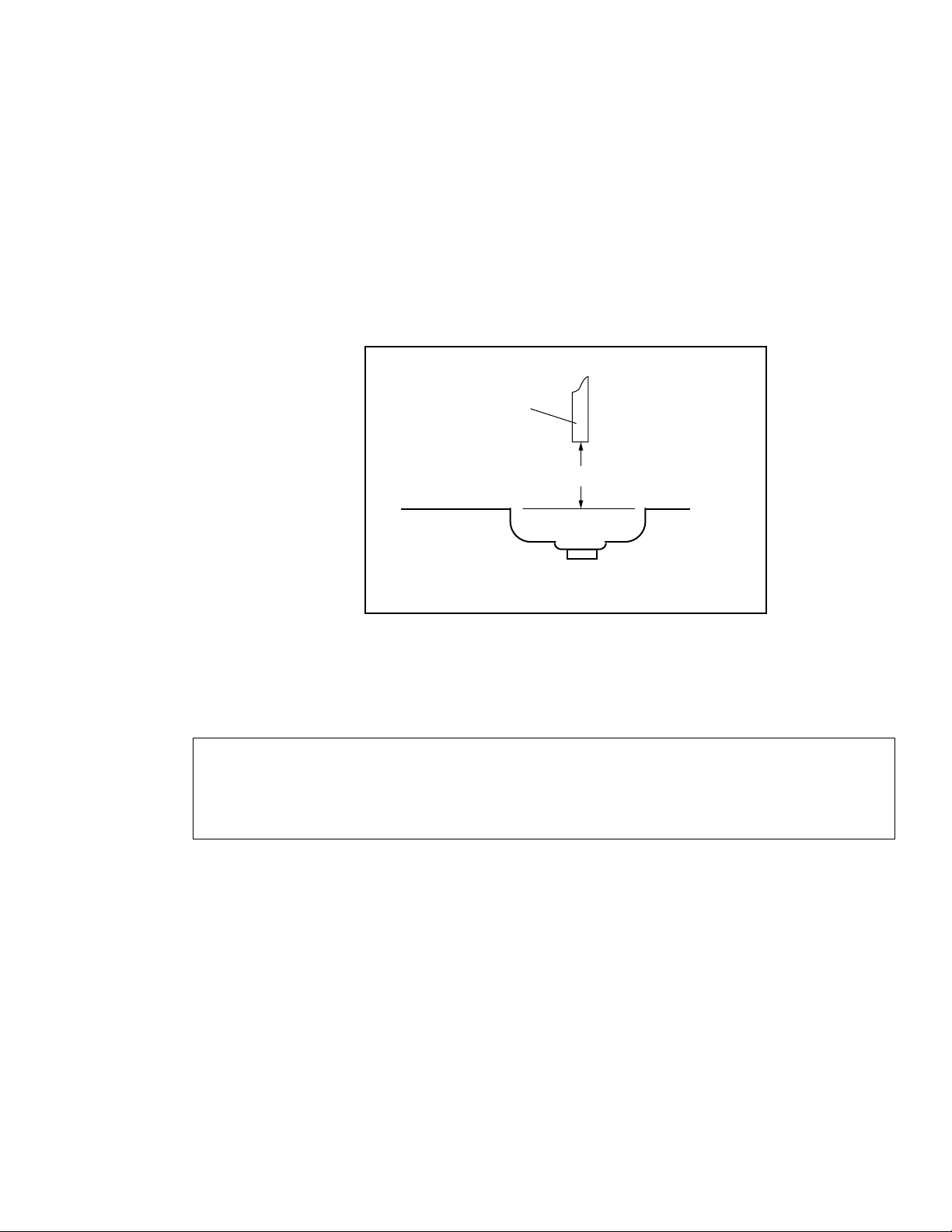

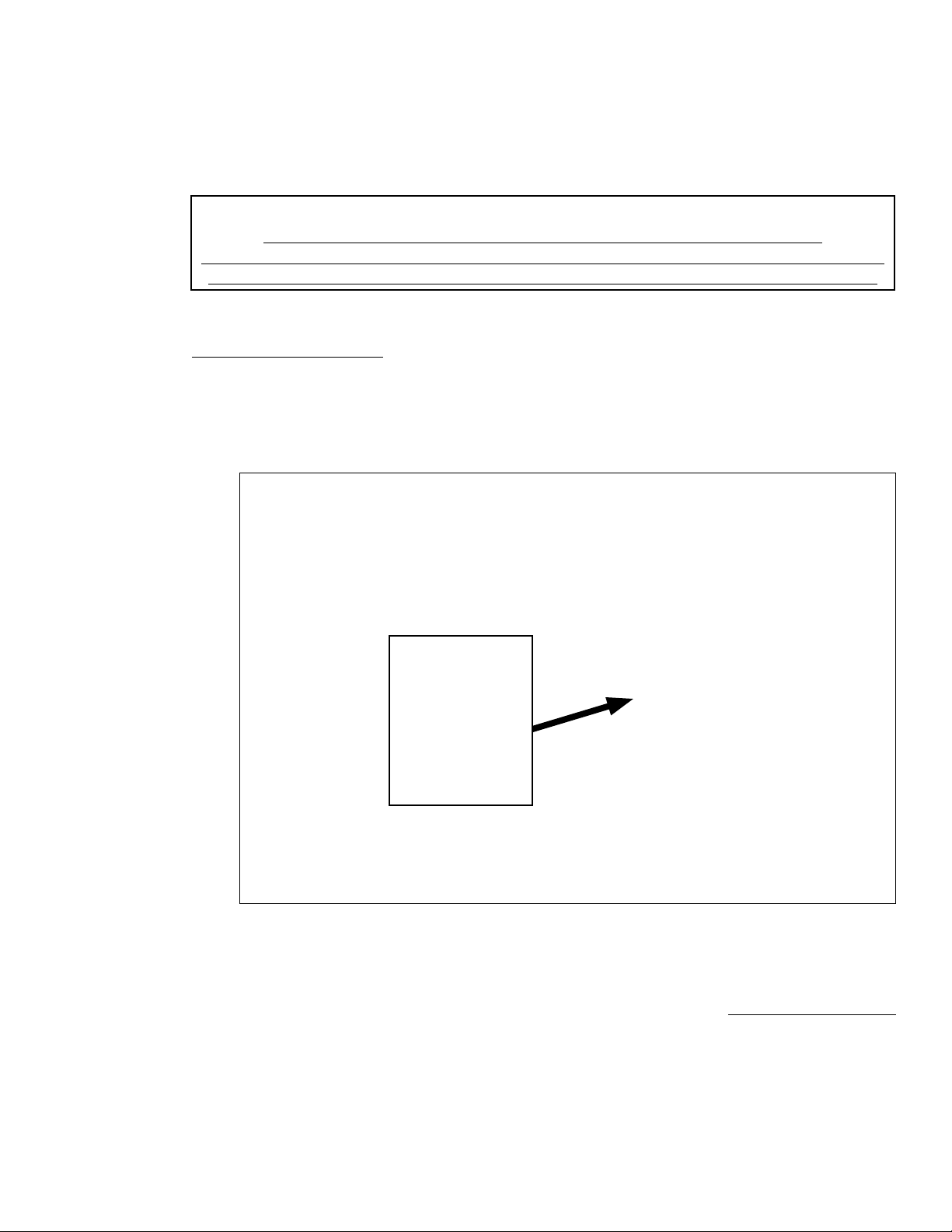

For an Indirect Drain Connection:

1. A 1" [25.4mm] minimum air gap must be provided between the outlet of the dishwasher

drain hose and the flood-level rim of the floor drain, floor sink or any other locally

approved drain receptacle. (See illustration below.)

Dishwasher

Drain Hose

Minimum

Air Gap

1” [25.4mm]

Floor

Floor Drain

! VERY IMPORTANT !

IMPROPER INSTALLATION OF MACHINE DRAIN HOSE.

Machine drain problems are often the result of improper installation and may not

be covered by the limited warranty.

5

Installation - 501HT

Electrical Connections - 501HT with Built-in Booster1PH

and 3PH Wiring Diagrams

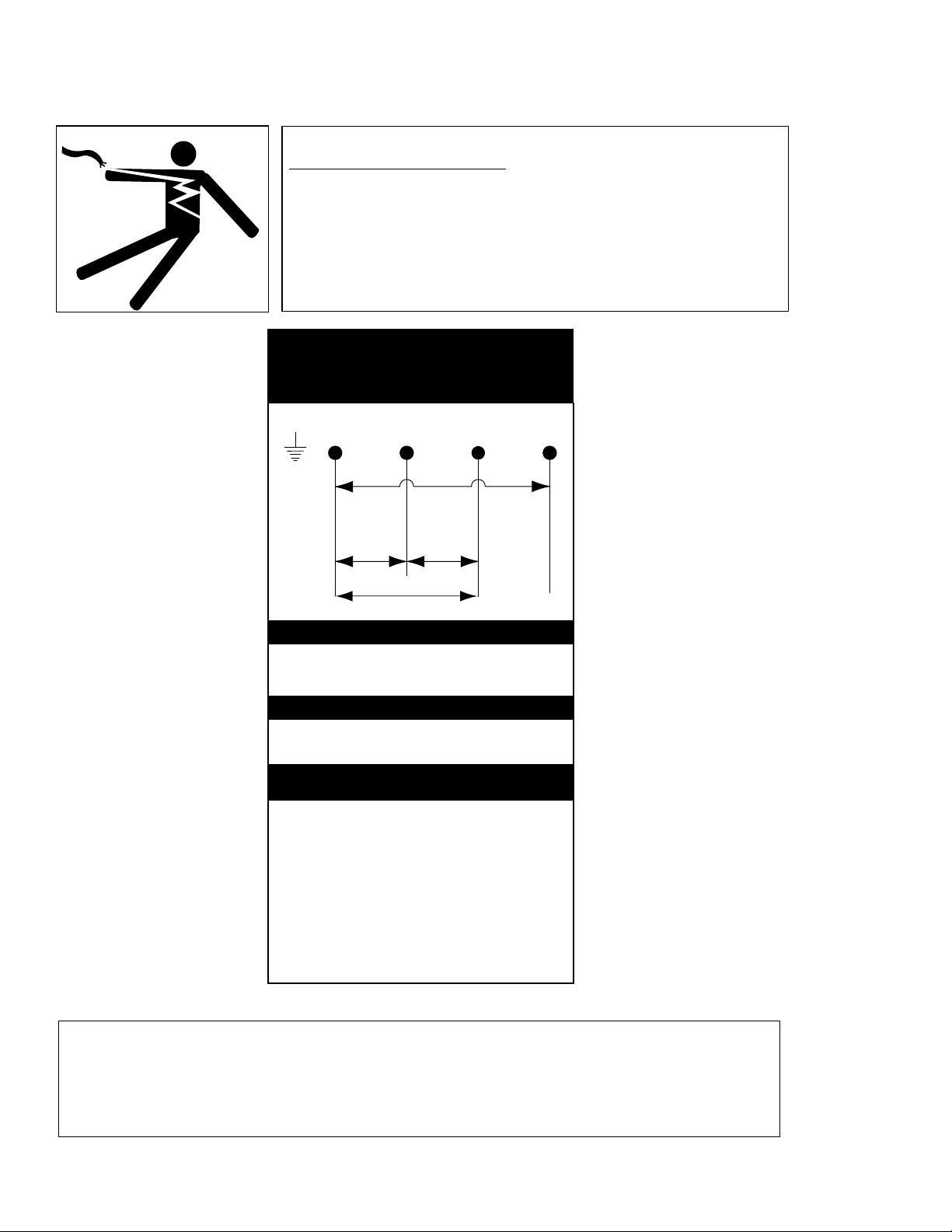

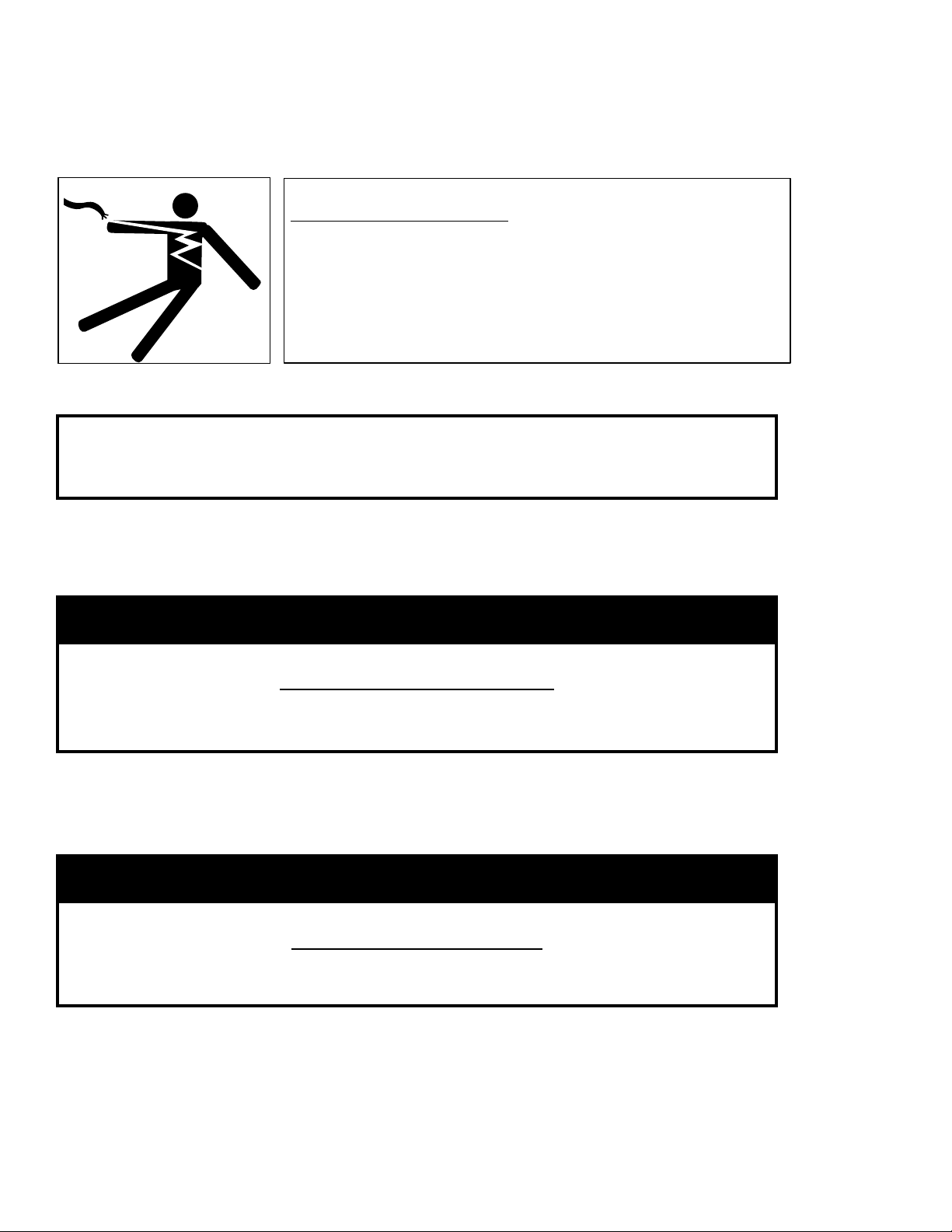

WARNING:

Electrocution or serious injury may result when working on an

energized circuit.

Disconnect power at the main breaker or service disconnect switch

before working on the circuit.

Lock-out and tag the breaker or service disconnect switch to

indicate that work is being performed on the circuit.

THREE PHASE POWER CONNECTION

GRD

L1 L2 L3 N

115VAC

208-230

VAC

208-230

VAC

208-230 VAC

! VERY IMPORTANT !

THE ELECTRICAL POWER MUST BE A

4-WIRE PLUS GROUND SUPPLY WHICH

INCLUDES A CURRENT CARRYING NEUTRAL.

HOW TO CONNECT 3 PHASE POWER

1. Check the data plate on the front of the

dishwasher for the phase of the machine.

If the data plate says the machine is 3 Phase,

.

then connect a 3 PH power supply.

2. Remove the lower access panel.

3. Pull power connection box forward and out.

4. The Main Terminal Block has terminals for

L1, L2, L3, Neutral and Ground.

5. Connect ground, then connect

L1, L2, L3 to 208-230VAC.

6. Connect a current carrying neutral to N.

7. Main power connections are complete.

! ATTENTION !

A qualified electrician must connect the main incoming power to the dishwasher in

accordance with all local codes and regulations or in the absence of local codes in

accordance with the National Electrical Code or the Canadian Electrical Code.

6

501HT - Installation

L1 L2 L3 N

208-230

VAC

0 VAC

0 VAC

115VAC

GRD

SINGLE PHASE POWER CONNECTION

Do not connect power to L3

HOW TO CONNECT 1 PHASE POWER

! VERY IMPORTANT !

1. Check the data plate on the front of the

dishwasher for the phase of the machine.

.

2. Remove the lower access panel.

3. Pull power connection box forward and out.

4. The Main Terminal Block has connections

for L1, L2, L3, Neutral and Ground.

5. Connect ground, then connect

L1, L2 to 208-230VAC.

6. Connect a current carrying neutral to N.

7. Main Power connections are complete.

If the data plate says the machine is 1 Phase,

then connect a 1 PH power supply.

DO NOT CONNECT POWER TO L3.

THE ELECTRICAL POWER MUST BE A

3-WIRE PLUS GROUND SUPPLY WHICH

INCLUDES A CURRENT CARRYING NEUTRAL.

Electrical Connections - 501HT with Built-in Booster1PH

and 3PH Wiring Diagrams

! ATTENTION !

The installation of the dishwasher must comply with all local electrical, plumbing,

health, and safety codes or in the absence of local codes, installed in accordance

with the applicable requirements in the National Electrical Code, NFPA 70,

Canadian Electrical Code (CEC), Part 1, CSA C22.1; and the Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations, NFPA 96.

7

Installation - 501HT

Connecting Incoming Power to the Main Terminal Block

for 1PH and 3PH Machines with Boosters- 501HT

WARNING:

Electrocution or serious injury may result when working on an

energized circuit.

Disconnect power at the main breaker or service disconnect switch

before working on the circuit.

Lock-out and tag the breaker or service disconnect switch to

indicate that work is being performed on the circuit.

! VERY IMPORTANT !

PROVIDE A 3 FEET/1 METER SERVICE LOOP IN THE POWER SUPPLY

CABLE TO SERVICE THE DISHWASHER.

! SINGLE PHASE POWER REQUIREMENT !

SINGLE PHASE 501HT

The electrical power must be a 3-wire plus ground supply which

includes a current carrying neutral.

! THREE PHASE POWER REQUIREMENT !

THREE PHASE 501HT

The electrical power must be a 4-wire plus ground supply which

includes a current carrying neutral.

8

501HT - Installation

Connecting Incoming Power to the Main Terminal Block

for 1PH and 3PH Machines with Boosters- 501HT

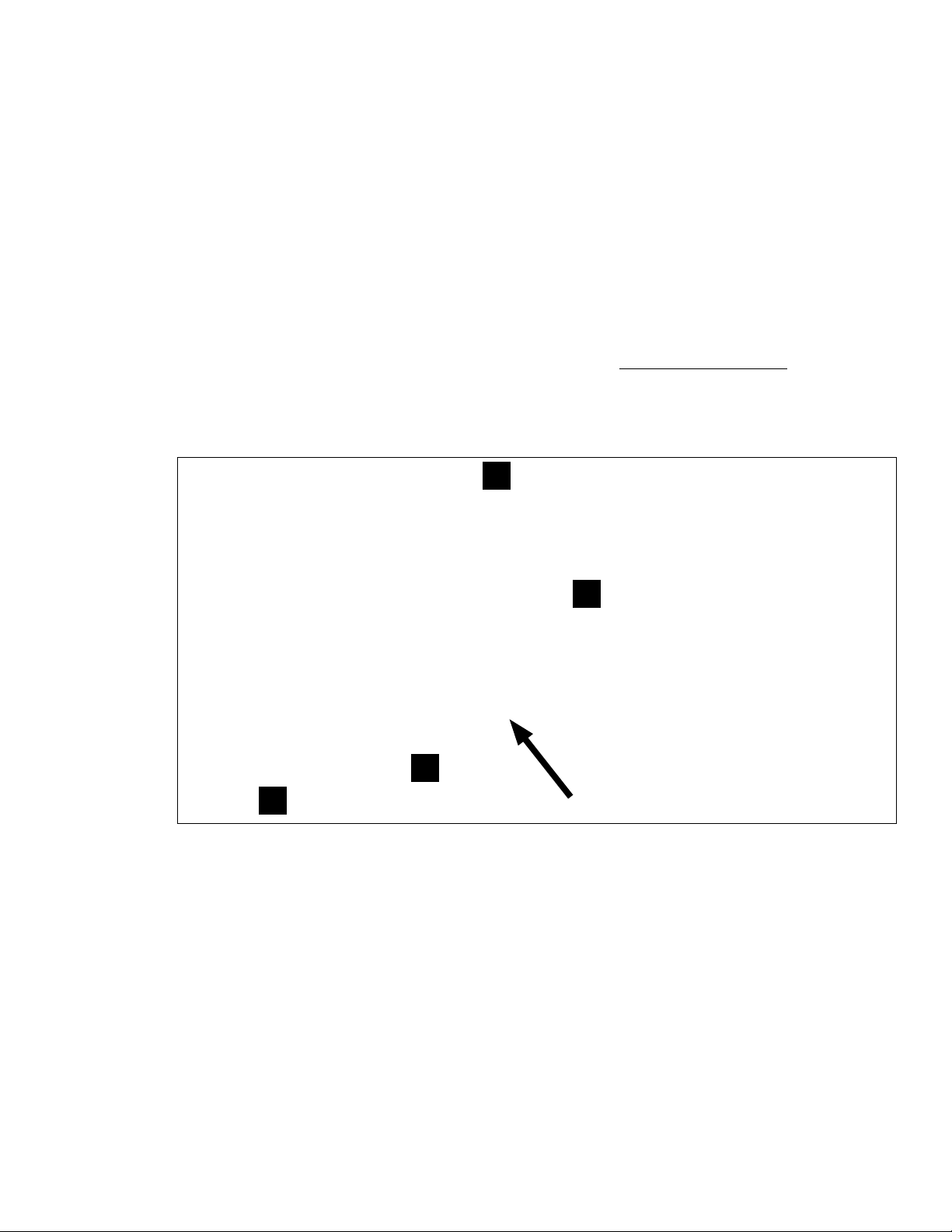

Refer to the photo below:

1. Remove the lower front dishwasher panel.

2. Remove the retaining fasteners (A) from the swing-out brackets and swing the chemical

pump bracket (B) and the chemical circuit board bracket (C) out of the way as shown.

(continued on next page)

A

B

C

A

Main Terminal Block Cover

9

Installation - 501HT

Connecting Incoming Power to the Main Terminal Block

for 1PH and 3PH Machines with Boosters

(continued from previous page)

Refer to the photo below:

3. Provide a 3 foot/1 meter service loop in the power supply cable to service the machine

4. Route the power cable from the rear of the machine to the terminal block making sure

the cable does not touch the booster tank.

5. Connect the power cable to the terminal block bracket using a suitable strain relief

connector.

6. Connect the power wires according to the wiring diagrams on page 3 for either

single phase or three phase operation.

7. Swing the chemical pump bracket and the chemical board back into position and

secure with the existing fasteners.

Main Terminal Block Cover Main Terminal Block

10

501HT - Installation

Booster Heater Conversion from 1PH to 3 PH Operation

! VERY IMPORTANT !

THE BOOSTER HEATER IS WIRED FOR 1PH OPERATION WHEN SHIPPED.

FOLLOW THE INSTRUCTIONS BELOW TO WIRE THE BOOSTER FOR 3PH.

WARNING:

Electrocution or serious injury may result when working on an

energized circuit.

Disconnect power at the main breaker or service disconnect switch

before working on the circuit.

Lock-out and tag the breaker or service disconnect switch to

indicate that work is being performed on the circuit.

1. To convert the booster heater from single phase to three phase operation, locate the

booster wire labeled 1H3 that is cable-tied to the booster hose.

2. Remove the shrink insulation from the terminal and connect to the booster heater

element as shown in the wiring diagram on page 12.

The three phase booster wire (1H3) is cable-tied to the hose adjacent to the booster tank.

11

Installation - 501HT

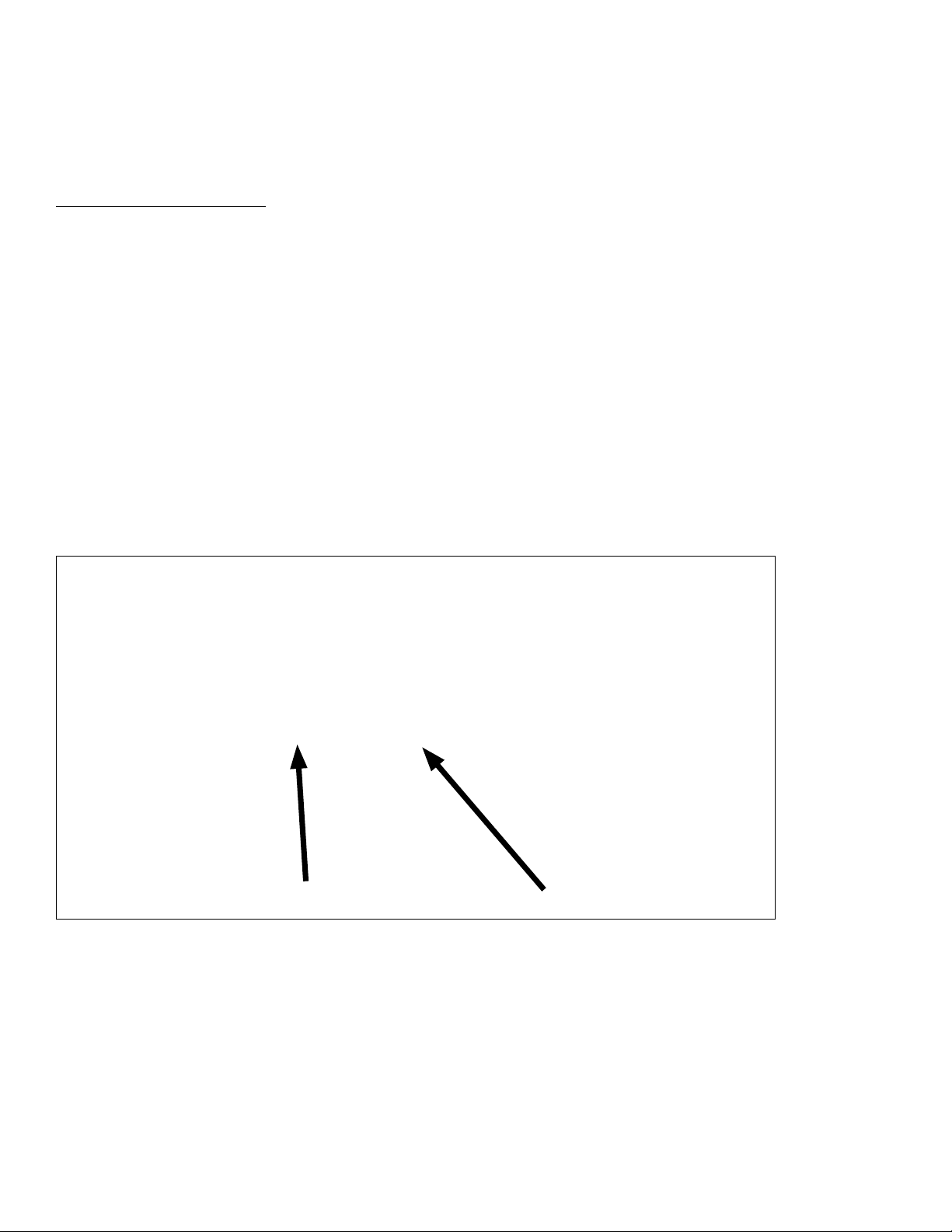

Booster Heater Conversion from 1PH to 3 PH Operation (continued)

! VERY IMPORTANT !

THE BOOSTER HEATER IS WIRED FOR 1PH OPERATION WHEN SHIPPED.

FOLLOW THE INSTRUCTIONS BELOW TO WIRE THE BOOSTER FOR 3PH.

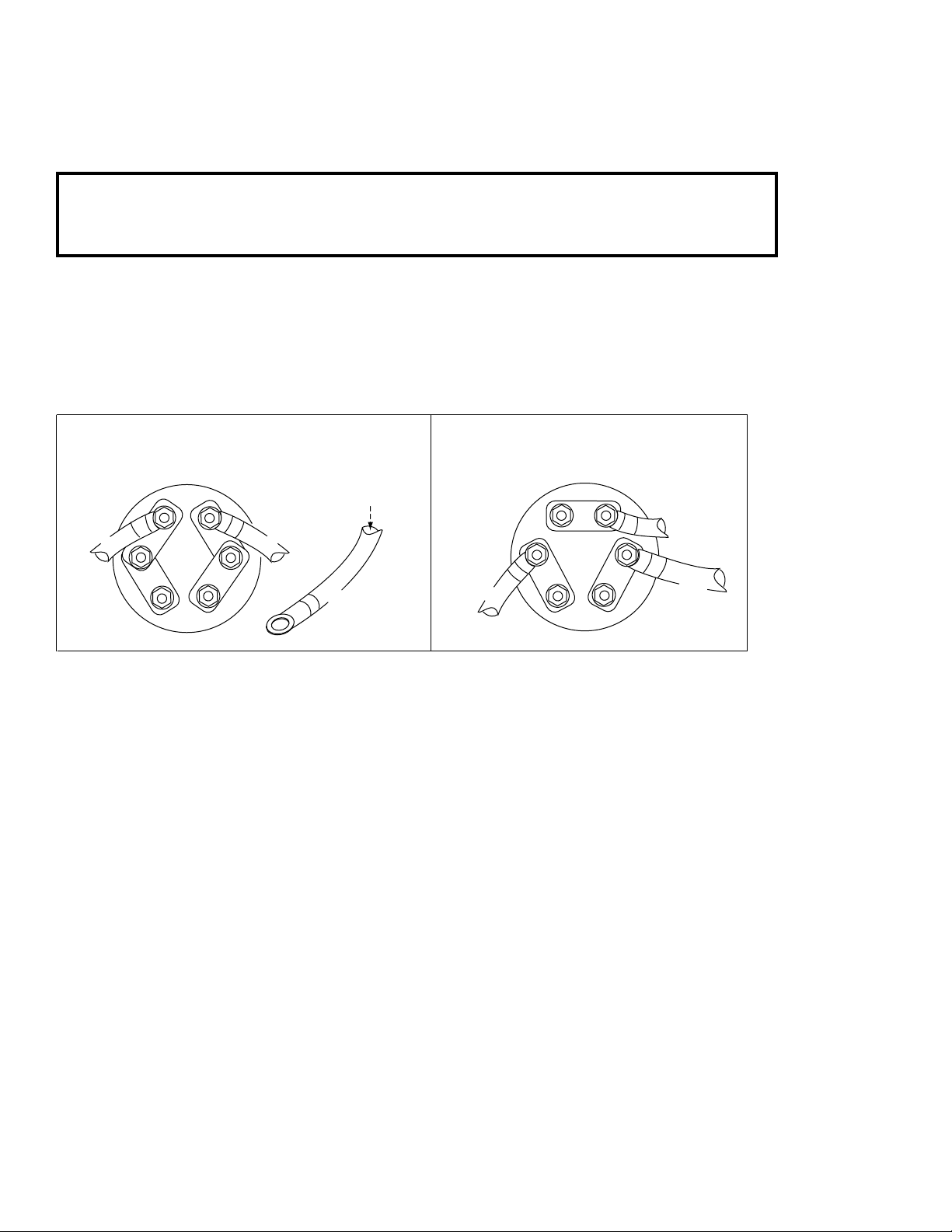

3. Disconnect the existing booster heater wires and change the booster heater element

jumpers as shown in the illustration below

4. Connect wires 1H1, 1H2, and 1H3 as shown below.

Booster Heater

Connected for 1PH

Wire not

connected

1H2

1H1

1H3

1H3

Wiring Diagram - Booster heater element connections shown for 1 phase and 3 phase operation.

Booster Heater

Connected for 3PH

1H1

1H2

12

501HT - Installation

Completing the 1PH to 3PH Electrical Conversion

! ATTENTION !

CHANGE THE DATA PLATE ON THE LOWER FRONT PANEL OF THE MACHINE

AFTER THE MACHINE IS WIRED FOR 3PH AND THE BOOSTER HEATER IS CONNECTED

FOR 3PH.

1. The data plate on the dishwasher lower front panel must be changed after the

machine is converted from single phase operation to three phase operation.

2. Locate the replacement data plate stowed on the back of the lower front panel.

3. Remove the paper backing from the label and carefully place it over the existing

data plate label making sure it covers the label completely.

4. Re-install the lower front panel to complete the conversion.

A three phase data plate is located on the back of the lower front panel.

13

Installation - 501HT

Booster Fill Switch - 501HT

(Filling the booster tank for the first time)

! CAUTION !

AVOID PERMANENT DAMAGE TO THE BOOSTER HEATER

DO NOT TURN THE DISHWASHER POWER SWITCH

ON WHEN FILLING THE BOOSTER FOR THE FIRST TIME.

THE BUILT-IN BOOSTER TANK WAS DRAINED BEFORE SHIPMENT AND

MUST BE REFILLED BEFORE OPERATING THE DISHWASHER.

THE BOOSTER FILL SWITCH IS LOCATED BEHIND THE LOWER FRONT PANEL ON THE

RIGHT SIDE OF THE MACHINE.

To refill the booster for the first time:

1. Turn the main breaker or disconnect switch to the dishwasher ON.

2. DO NOT PUSH THE DISHWASHER ON-OFF/DRAIN POWER SWITCH TO THE ON POSITION.

3. Locate the booster fill switch and note the switch is in the OFF position.

(continued on next page)

1

14

501HT - Installation

Booster Fill Switch - 501HT

(Filling the booster tank for the first time)

4. PUSH AND HOLD the booster fill switch in the FILL position until water starts filling

inside the wash compartment.

5. Release the FILL switch.

2

6. PUSH the booster fill switch to the ON position and release.

7. The booster fill operation is complete.

8. Replace the lower front panel on the machine.

3

15

Installation - 501HT

Chemical Connections - 501HT

! VERY IMPORTANT !

ALWAYS USE A COMMERCIAL-GRADE NON-CHLORINATED DETERGENT.

PLACE THE CHEMICAL SUPPLY CONTAINERS AS CLOSE TO THE MACHINE AS POSSIBLE.

DO NOT ELEVATE THE CHEMICAL CONTAINERS ABOVE THE FINISHED FLOOR.

! VERY IMPORTANT !

Contact a chemical supplier for detergent and rinse-aid chemicals. The chemical supplier must

adjust the chemical dispensing pumps for water hardness and food soil types.

Chemical Dispensing Pumps

1. The detergent and rinse-aid pumps are located on the lower left-side of the machine

behind the lower-front access panel.

2. Each pump is equipped with 6 feet [1.8 m] of pick-up tubes consisting of supply tubing,

stiffener tubes, and strainers.

3. The pick-up tubes are stowed on the back of the machine for shipping.

4. A red label marked DETERGENT and a blue label marked RINSE-AID identify the

chemical lines.

RINSE-AID

DETERGENT

16

The 501HT pumps are located on

the left-side behind the lower front panel

of the dishwasher.

501HT - Installation

Detergent and Rinse-aid Pumps and Injection Points - 501HT

! VERY IMPORTANT !

ALWAYS USE A COMMERCIAL-GRADE NON-CHLORINATED DETERGENT.

PLACE THE CHEMICAL SUPPLY CONTAINERS AS CLOSE TO THE MACHINE AS POSSIBLE.

DO NOT ELEVATE THE CHEMICAL CONTAINERS ABOVE THE FINISHED FLOOR.

Injection Point Locations

1. For 501HT, the detergent and rinse-aid enter the wash tank compartment

through a fitting on back right corner of the wash compartment.

501HT

DETERGENT

and

RINSE-AID

INJECTION

POINT

(continued on next page)

17

Blank Page

This Page

Intentionally

Left Blank

18

501HT - Installation

Detergent and Rinse-aid Pumps and Injection Points - 501HT

Priming the Dispensing Pumps

! VERY IMPORTANT !

The chemical dispensing pumps must be primed before operating the dishwasher and

whenever the chemical container is changed.

REQUIRED

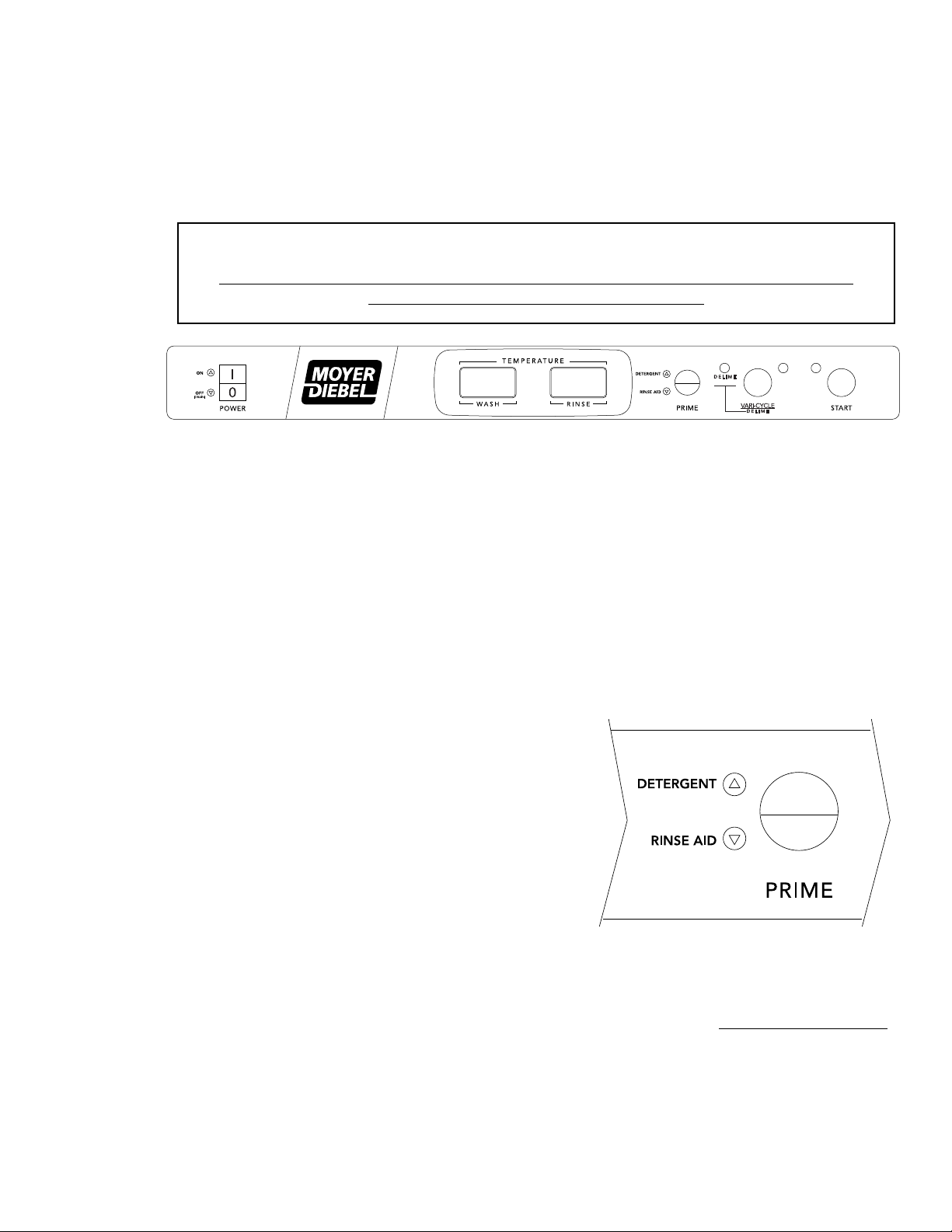

501HT Control Panel

1. The chemical dispensing pump supply lines must be primed before they will pump the

chemicals properly.

2. Make sure the chemical containers are full and the correct pick-up tubes are in their

containers.

3. Turn the dishwasher power switch ON. The switch will illuminate and the dishwasher

will fill with water.

4. Open the dishwasher door, then push and hold the prime push button UP to the

DETERGENT position until detergent is observed entering the wash tank compartment

through the fitting located on the back right

corner of the tank. Release the push button.

5. Push and hold the prime push button DOWN

to the Rinse-aid position until you see air

bubbles moving through the rinse-aid tubing,

then hold the button for another 2 minutes.

Release the push button.

6. Close the door to complete the priming

operation.

(continued on next page)

19

Installation - 501HT

Detergent and Rinse-aid Pumps and Injection Points - 501HT

! ATTENTION !

The amount of dispensed chemical is determined by the run time of the dispensing pump.

Refer to the photo below:

1. The chemical dispensing pump run and the tank fill adjustment screws are located on the

end of the chemical circuit board swing-out bracket.

2. It is not necessary to swing the bracket out to make adjustments, but if desired, remove

the mounting nut (A) and swing the bracket (B) out and to the right.

3. Refer to the next page for adjustment instructions.

! VERY IMPORTANT !

INSPECT & REPLACE THE CHEMICAL DISPENSING PUMP SQUEEZE TUBES EVERY SIX MONTHS.

A

B

B

! VERY IMPORTANT !

Contact a chemical supplier for detergent and rinse-aid chemicals. The

chemical supplier must adjust the chemical dispensing pumps for water

hardness and food soil types.

20

Detergent and Rinse-aid Pumps and Injection Points - 501HT

Refer to the photo below:

To adjust the amount of chemicals dispensed

by the pumps:

1. Make sure the chemical containers are full and

the pick-up tubes are in their proper containers.

3. Turn the dishwasher power switch ON.

The switch will illuminate and the dishwasher

will fill with water.

4. Run a normal dishwasher cycle and test

detergent and rinse-aid concentrations

according to the chemical supplier's

instructions.

CAUTION:

Excessive pressure to the potentiometers when

adjusting can result in bent or broken adjusting

screws.

501HT - Installation

5. Each dispensing pump has a clearly marked

adjustment screw. Turn the screw CW to

increase the run time of the dispensing pump

and CCW to reduce the run time.

Fill Adjustments

To adjust the tank fill:

1. The fill adjustment screw will provide a

small change in the tank water level.

2. If a large adjustment is needed, check the

incoming water pressure and make sure the fill

hose is not kinked.

3. If the above items are okay then the size

of the incoming water supply should be

checked. The incoming water supply line must

be a minimum of 1/2" or larger.

Use a 4mm

blade

screwdriver

Fill Adjustment

For 501HT

21

Operation - 501HT

Operation - 501HT

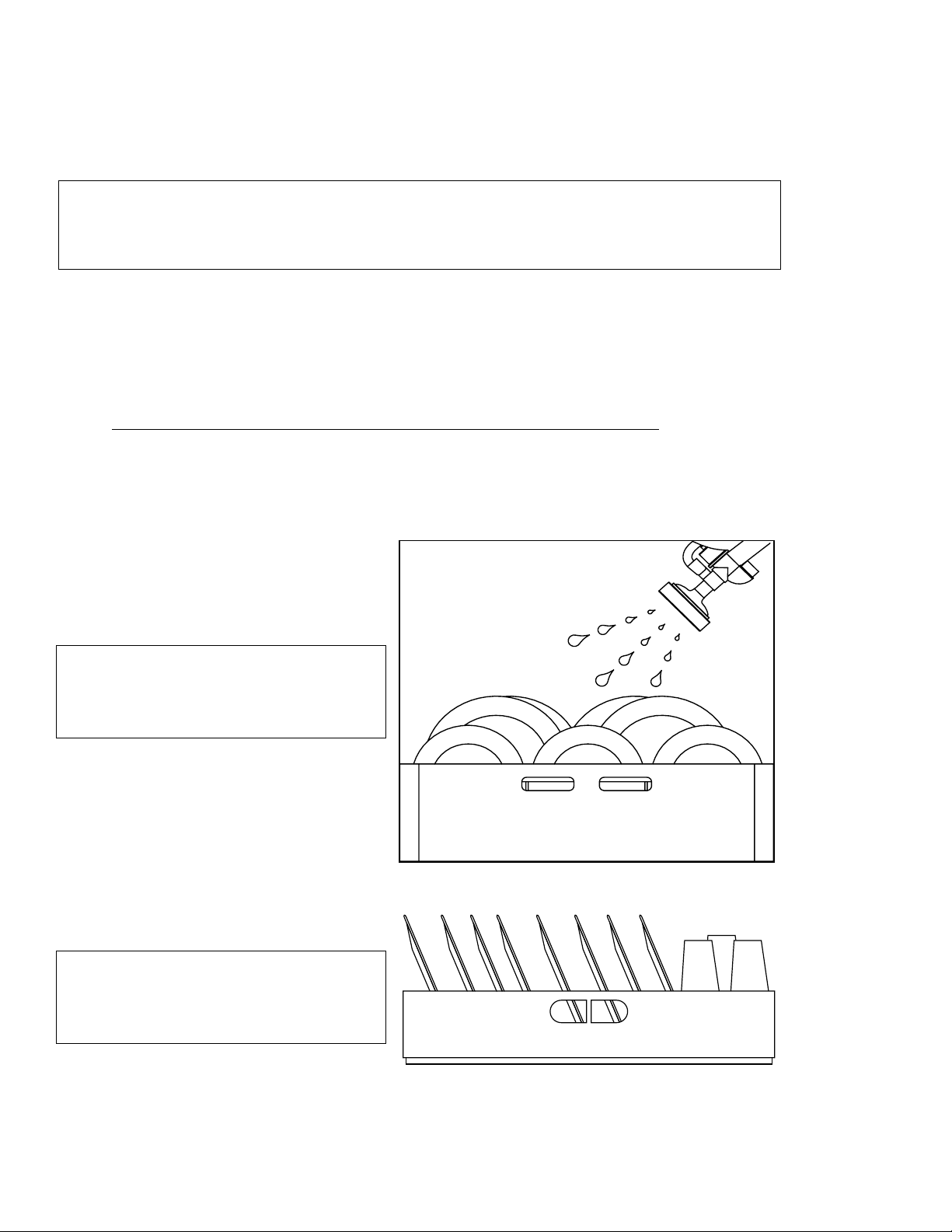

Loading Dish Racks

! VERY IMPORTANT !

DO NOT OVERLOAD THE DISH RACK.

LOAD ONE DISH RACK INTO THE MACHINE AT A TIME.

1. Prescrap and rinse the wares before loading to remove large food particles.

2. Load soiled wares into the dish rack. Place plates and glasses in a peg rack. Place

cups and bowls in a flat bottom rack. Place utensils in a single layer in a flat-bottom rack.

Place pots and pans in a flat-bottom rack.

Do not overload the dish rack. Wash one dish rack at a time.

3. Slide one dish rack into the wash compartment making sure that wares do not interfere

with the rotating spray arms. Do not wash more than one dish rack at a time.

Prescrap and rinse wares before

loading into the machine.

Load plates and glasses in a peg

rack.

22

Loading...

Loading...