Page 1

2012 Moxa Inc. All rights reserved.

Reproduction without permission is prohibited.

P/N: 1802055100041

TN-5510-2GLSX-ODC

Hardware Installation Guide

Moxa ToughNet Switch

Second Edition, August 2013

Page 2

- 2 -

Overview

The ToughNet TN-5510-2GLSX-ODC series M12 managed Ethernet

switches are designed for industrial applications in harsh environments.

The TN series switches use M12 connectors to ensure tight, robust

connections, and guarantee reliable operation against environmental

disturbances, such as vibration and shock. The switch supports a power

input range 12/24/36/48 VDC.

TN-5510-2GLSX-ODC switches provide up to 8 Fast Ethernet M12 ports,

and 2 Gigabit Fiber ports on the bottom panel which allow cable lengths

up to 2 km. The TN-5510 Ethernet switch is compliant with the essential

sections of EN 50155 (railway applications), making it suitable for a

variety of industrial applications.

Package Checklist

Your ToughNet TN-5510-2GLSX-ODC switch is shipped with the following

items. If any of these items is missing or damaged, please contact your

customer service representative for assistance.

• 1 Moxa ToughNet switch.

• Hardware installation guide.

• CD-ROM with user’s manual, Windows utility, and SNMP MIB file.

• Moxa product warranty statement.

• M12 to DB9 console port cable.

• 2 protective caps for console and relay output ports.

• Panel mounting kit.

Features

Anti-Vibration Circular Connectors for Robust Links

• M12 D-coding 4 pins female connectors for Fast Ethernet

10/100BaseT(X) ports.

• Fiber-optic ODC connectors with embedded 2 km Gigabit Ethernet

1000BaseLSX.

• M12 A-coding 5 pins male connectors for console and relay output.

• M23 6 pins male connector for power input.

Dual Power Inputs

• Supports 12/24/36/48 VDC (8.4–60 VDC).

High Performance Network Switching Technology

• IEEE 1588 PTP (Precision Time Protocol) for precise time

synchronization of networks.

• DHCP Option 82 for IP address assignment with different policies.

• Modbus/TCP industrial Ethernet protocol.

• Turbo Ring, Turbo Chain,and RSTP/STP (IEEE802.1w/D).

• IGMP Snooping and GMRP for filtering multicast traffic from industrial

Ethernet protocols.

• Port-based VLAN, IEEE802.1Q VLAN, and GVRP protocol to ease

network planning.

• QoS (IEEE802.1p/1Q and TOS/DiffServ) to increase determinism.

• 802.3ad, LACP for optimum bandwidth utilization.

• IEEE802.1X and https/SSL to enhance network security.

• SNMP v1/v2c/v3 for different levels of network management.

• RMON for efficient network monitoring and proactive capability.

• Bandwidth management prevents unpredictable network status.

Page 3

- 3 -

• Lock port allows access by only authorized MAC addresses.

• Port mirroring for online debugging.

• Automatic warning by exception through email, relay output.

• Automatic recovery of connected device’s IP addresses.

• Line-swap fast recovery.

• LLDP for automatic topology discovery in network management

software.

• Configurable through Web browser, Telnet/Serial console, and

Windows utility.

Designed for Industrial-Specific Applications

• Three rotary switches for setting the last 3 digits of the IP address

makes maintenance even easier.

• Compliant with essential sections of EN 50155 (railway applications)

• -40 to 75°C operating temperature range.

• IP54, rugged high-strength case.

• Panel mounting or DIN-Rail mounting installation capability.

Recommended Optional Accessories

• CBL-M23(FF6P)Open-BK-100-IP67: 1-meter M23 to 6-pin power

cable with IP67-rated female 6-pin M23 connector.

• CBL-M12D(MM4P)/RJ45-100 IP67: 1-meter M12-to-RJ45 Cat-5E UTP

Ethernet cable with IP67-rated male 4-pin M12 D-coded connector.

• CBL-M12(FF5P)/OPEN-100 IP67: 1-meter M12-to-5-pin power cable

with IP67-rated female 5-pin M12 A-coded connector.

• M12D-4P-IP68: Field-installable M12 D-coded screw-in connector,

male 4-pin, IP68-rated.

• M12A-5P-IP68: Field-installable M12 A-coded screw-in connector,

female 5-pin, IP68-rated.

• CAP-M12F-M: Metal cap for M12 female connector.

• DK-DC50131: DIN-Rail mounting kit, 50 x 131 mm.

• PLG-WPRJ-02: Field-installable circular connector kit for RJ45

twisted-pair cable, IP67-rated.

Page 4

- 4 -

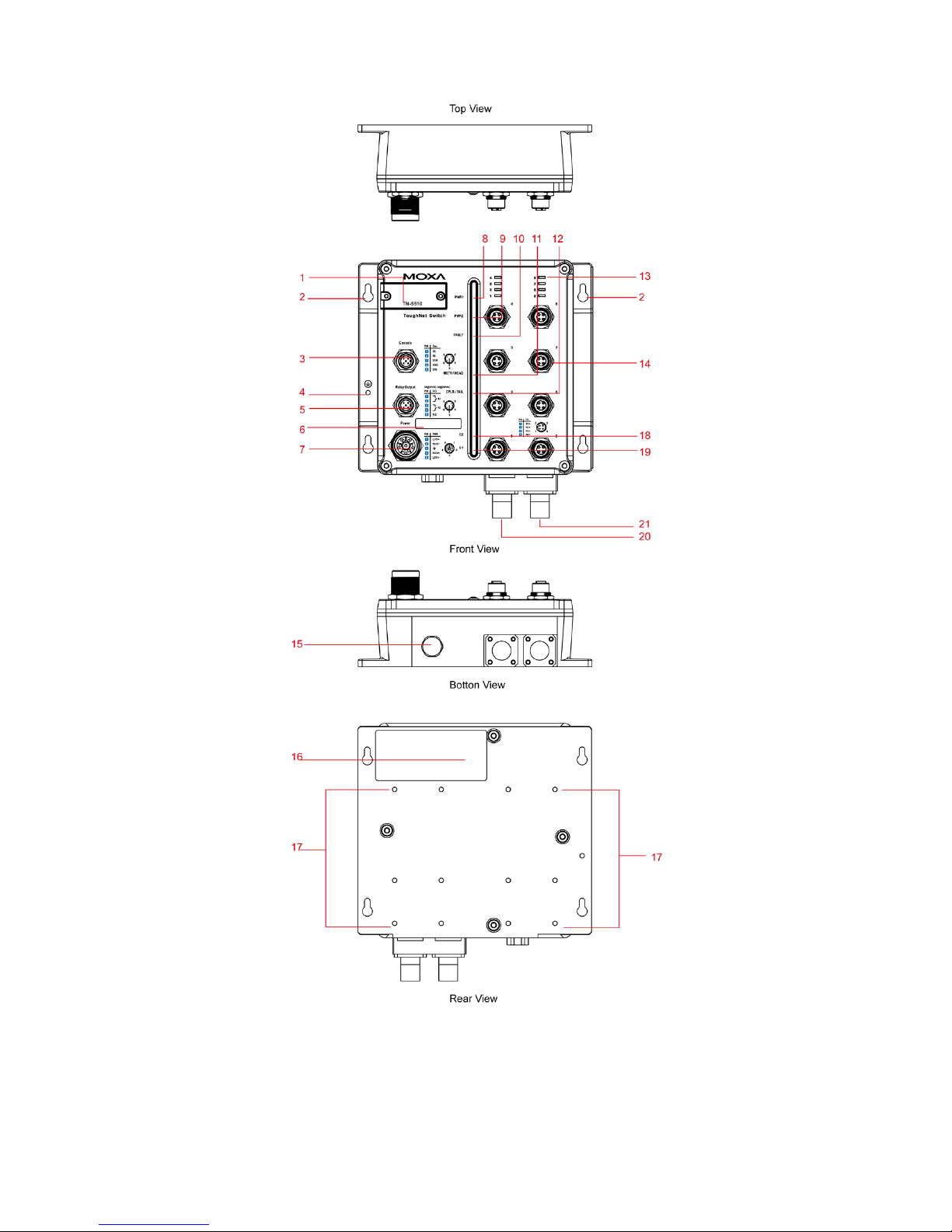

TN-5510-2GLSX-ODC Panel Layouts

1. 3 Rotary switches and protective cover with Model name.

2. Screw holes for panel mounting kit.

3. Console port.

4. Grounding screw.

5. Relay output port.

6. Power input voltage range indication.

7. Power input port (male 6-pin shielded M23 connector).

Page 5

- 5 -

8. PWR1 LED: for power input 1.

9. PWR2 LED: for power input 2.

10.

FAULT LED.

11.

MSTR/HEAD LED: for ring master or chain head.

12.

CPLR/TAIL LED: for ring coupler or chain tail.

13.

TP port’s 10/100 Mbps LED.

14.

10/100BaseT(X) port (female 4-

pin shielded M12 connector with D

coding).

15.

Waterproof vent.

16.

Product label.

17.

12 Screw holes for DIN-Rail mounting kit.

18.

E2 LED: Down-side E2 Gigabit port's 1000 Mbps LED.

19.

E1 LED: Down-side E1 Gigabit port's 1000 Mbps LED.

20.

Gigabit Fiber port E1 (corresponding to port 9 in the TN-

5510 User's

Manual).

21.

Gigabit Fiber port E2 (corresponding to port 10 in the TN-5510

User's Manual).

ATTENTION

Please DO NOT open or remove vent

15. The warranty will be

invalid if the seal is removed.

All exposed connectors, including

3, 5, 7, and 14, should be

tightly covered by protective caps when they are not in use to

ensure for

IP54 protection.

After setting rotary switch 1, the protective cover must be fixed

properly to ensure IP54 protection.

Page 6

- 6 -

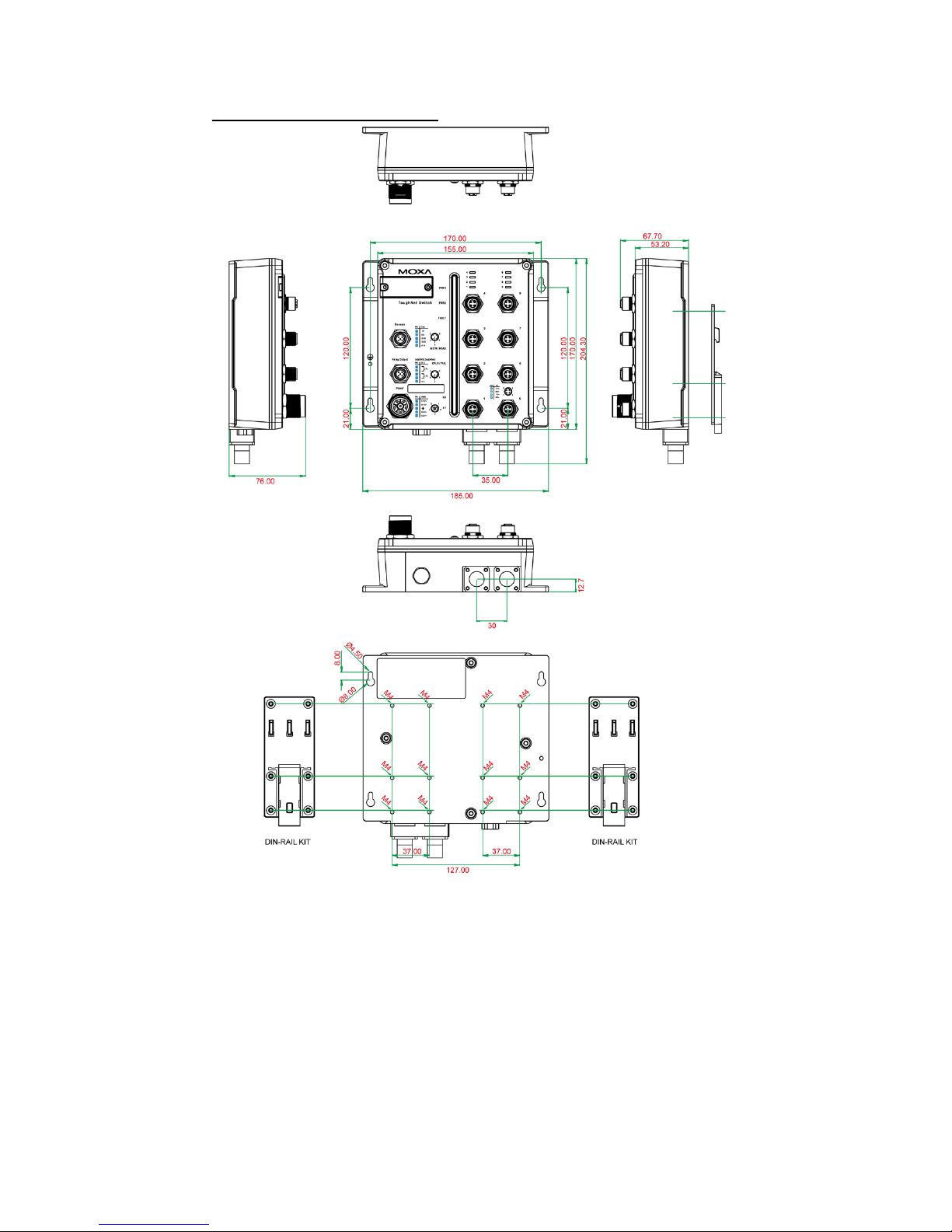

Mounting Dimensions (unit = mm)

TN-5510-2GLSX-ODC Series

Page 7

- 7 -

Panel/Wall Mounting

STEP 1:

Mounting the TN-5510 to a wall requires 4 screws. Use the ToughNet

switch as a guide to mark the correct positions of the 4 screws.

STEP 2:

Use the 4 screws in the panel mounting kit. If you

would like to use your own screws, make sure the

screw head is between 6.0 mm and 7.0 mm in

diameter and the shaft is less than 4.0 mm in

diameter, as shown at the right.

Do not screw the screws in all the way—leave a

space of about 2 mm to allow room for sliding the ToughNet switch

between the wall and the screws.

NOTE

Before tightening the screws into the wall, make sure the screw

head and shaft size are suitable by inserting the screw through

one of the keyhole-shaped apertures of the ToughNet switch.

STEP 3:

Once the screws are fixed in the wall, hang the ToughNet switch on the 4

screws through the large opening of the keyhole-shaped apertures, and

then slide the switch downwards. Tighten the four screws for added

stability.

NOTE

To provide greater protection from vibrations and shocks, use

screws with shaft diameter between 6.0 mm and 7.0 mm, and fix

the ToughNet switch onto the wall directly through the large

opening of the keyhole-shaped apertures.

Page 8

- 8 -

DIN-Rail Mounting (optional)

Use a pair of optional DK

-DC50131

DIN

-Rail mounting kits (must be

purchase

d separately) to mount the

TN

-5510 on a 35 mm DIN-Rail.

STEP 1:

Use 12 screws (6 screws per plate) to

attach the two DIN

-Rail attachment

plates to the rear panel of the switch

STEP 2:

If the spring-loaded bracket is locked in place, push the recessed button

to release it. Once released, you should feel some resistance from the

spring as you slide the bracket up and down a few millimeters in each

direction.

STEP 3:

Insert the top of the DIN

-Rail into

the top slot of the DIN

-Rail

attachment plates.

STEP

4:

The DIN-Rail attachment plates will

snap into position, as shown in the

figure below.

To remove the Moxa ToughNet Switch from the DIN-Rail, use a

screwdriver to pull down the bottom parts of the two spring-loaded

brackets until they are fixed in the “locked” position, and then reverse

Steps 3 and 4 above.

Page 9

- 9 -

Wiring Requirements

WARNING

Turn the power off before disconnecting modules or wires. The

correct power supply voltage is listed on the product label. Check

the voltage of your power source to make sure you are using the

correct voltage. Do NOT use a voltage greater than what is

specified on the product label.

These devices must be supplied by a SELV source as defined in

the Low Voltage Directive 2006/95/EC and 2004/108/EC.

ATTENTION

Safety First!

Observe all electrical codes dictating the

maximum current

allowable for each wire size. If the current

goes above the

maximum ratings, the wiring could overheat,

causing serious

damage to your equipment.

ATTENTION

Safety First!

Be sure to disconnect the power cord before installing and/or

wiring your Moxa switch.

This device has UL508 approval. Use copper conductors only,

60/75°C, and tighten to 4.5 poun

d-inches. For use in pollution

degree 2 environments.

Please read and follow these guidelines:

• Use separate paths to route wiring for power and devices. If power

wiring and device wiring paths must cross, make sure the wires are

perpendicular at the intersection point.

NOTE

Do not run signal or communications wiring and power wiring

through the same wire conduit. To avoid interference, wires with

different signal characteristics should be routed separately.

• You can use the type of signal transmitted through a wire to

determine which wires should be kept separate. The rule of thumb is

that wiring that shares similar electrical characteristics can be

bundled together.

• Keep input wiring and output wiring separated.

• It is strongly advised that you label wiring for all devices in the system

when necessary.

Grounding the ToughNet Switch

Grounding and wire routing help limit the effects of noise due to

electromagnetic interference (EMI). Run the ground connection from the

grounding screw to the grounding surface prior to connecting devices.

Page 10

- 10 -

ATTENTION

This product is intended to be mounted to a well-grounded

mounting surface such as a metal panel.

Connecting the Power Supplies

The ToughNet TN-5510 switches support two sets of power

supplies—power input 1 and power input 2.The M23 6-pin male connector

on the TN-5510’s front panel is used for the dual power inputs. Use a

power cord with an M23 6-pin female connector to connect the power

inputs to the switch.

Pinouts for the power input port on the TN-5510

Pinouts for the power input port on the TN-5510.

Pin

Description

Usage

1

PWR1 Live / DC +

Connect “PWR1 Live / DC +” to the Live

terminal when using an AC power source

or to the positive (+) terminal when using

a DC power source.

2

PWR1 Neutral / DC -

Connect “PWR1 Neutral / DC –“to the

Neutral terminal when using an AC power

source or to the negative (-) terminal

when using a DC power source.

3

Chassis Ground

Connect the “Chassis Ground” to the

safety ground terminal for AC inputs or to

the equipment ground bus for DC inputs.

4

PWR2 Neutral / DC -

Connect “PWR2 Neutral / DC –”to the

Neutral terminal when using an AC power

source or to the negative (-) terminal

when using a DC power source.

5

PWR2 Live / DC +

Connect “PWR2 Live / DC +” to the (Live)

termi

nal when using an AC power source

or to the positive (+) terminal when using

a DC power source.

Page 11

- 11 -

STEP 1:

Plug your power cord’s M23 connector to the power input port of the

TN-5510 switch.

STEP 2:

Screw the nut on your power cord connector to the power input connector

on the switch to ensure a tight connection.

ATTENTION

Before connecting the TN

-5510 to the power input, make sure the

power source voltage is stable.

Connecting the Relay Outputs

Each TN-5510 switch has two sets of relay outputs—relay output 1 and

relay output 2. The M12 A-coded 5-pin male connector on the TN-5510’s

front panel is used for the two relay outputs. Use a power cord with an

M12 A-coded 5-pin female connector to connect the relay contacts from

the switch. You may purchase an M12 power cable from Moxa. The model

number of the cable, which must be purchased separately, is CBL-M12

(FF5P)/OPEN-100 IP67.

Pinouts for the relay output port on TN-5510.

N.C.: Not connected

FAULT:

The two sets of relay contacts of the M12 A-coded 5-pin male connector

are used to detect user-configured events. The two wires attached to the

fault contacts form an open circuit when a user-configured event is

triggered. If a user-configured event does not occur, the fault circuit

remains closed.

RS-232 Connection

The TN switch has one RS-232 (M12 5pin) console port, located on the

front panel. Use M12 to DB9 console cable to connect the TN switch

console port to your PC's COM port. you may than use a console terminal

program, such as Moxa PComm Terminal Emulator to access the TN

switch's configuration utility.

M12 Console Port Pinouts

Page 12

- 12 -

Connecting the Data Lines

10/100BaseT(X) Ethernet Port Connection

All TN-5510 models have 8 10/100BaseT(X) Ethernet ports (4-pin

shielded M12 connector with D coding). The 10/100Base-TX ports located

on the TN-5510 front panel are used to connect to Ethernet-enabled

devices. Most users configure these ports for Auto MDI/MDI-X mode, in

which case the port’s pinouts are adjusted automatically depending on

the type of Ethernet cable used (straight-through or cross-over), and the

type of device (NIC-type or HUB/Switch-type) connected to the port.

In what follows, we give pinouts for both MDI (NIC-type) ports and MDI-X

(HUB/Switch-type) ports. We also give cable wiring diagrams for

straight-through and cross-over Ethernet cables.

Pinouts for the 10/100BaseT(X) Ports on the TN-5510.

Pinouts for the 1000BaseLSX Q-ODC Gigabit Fiber port

Mating Sequence

Push plug slightly into

connector socket

Rotate to find keying

position

Unmated – push

connector to mate

Mated – connector snaps

in and is fully strain

relieved

Pull coupling ring to

unmate

M12 (4-pin, M) to M12 (4-pin, M) Cross-Over Cable Wiring

Page 13

- 13 -

M12 (4-pin, M) to M12 (4-pin, M) Straight-Trough Cable Wiring

M12 (4-pin, M) to RJ45 (8-pin) Cross-Over Cable Wiring

M12 (4-pin, M) to RJ45 (8-pin) Straight-Trough Cable Wiring

Rotary Switch IP Address Settings

The ToughNet TN-5510 switches have 3 rotary switches on the front

panel for configuring the IP address without using a PC, making onsite

configuration extremely convenient. This can be especially helpful when

you need to replace a faulty switch quickly.

STEP 1: Remove the protective cover by unscrewing the 2 screws with an

Allen wrench (also called an Allen key or hex key).

STEP 2: Use a flat-bladed screwdriver to rotate the 3 rotary switches to

point to the chosen numbers.

STEP 3: Replace the protective cover and then tighten the screws to the

proper torque.

STEP 4: Restart the ToughNet switch to enable the newly configured IP

address.

Page 14

- 14 -

NOTE

1. “Hardware-based IP configuration” only supports IPv4

address settings.

2. “Hardware-

based IP configuration” is enabled only when the

3 rotary switches are set to values ranging from 001 to 254.

The ToughNet switch’s IP address will be configured as

“192.168.127.xxx”, where “xxx” are valid value numbers

set by the rotary switches.

3. When enabled, “Hardware-based IP configuration”

overrides the “Auto IP Configuration” described in the “IP

Settings” section in the user’s manual.

4. Disable “Hardware-

based IP configuration” by setting the 3

rotary switches to 000 (the factory default).

5. If the rotary switch numbers are set to an invalid

combination (255 to 999), the ToughNet switch will use the

fixed IP address 192.168.127.253 by default.

ATTENTION

The protective cover must be fixed properly to ensure IP54

protection. Use a torque wrench set to a torque of 4 kgf-m when

tightening the screws. Note that applying a larger tor

que may

damage the plastic protective cover.

LED Indicators

Several LED indicators are located on the ToughNet switch’s front panel.

The function of each LED is described in the table below.

LED

Color

State

Description

System LEDs

PWR1 AMBER ON Power is being supplied to power input

PWR1.

OFF

Power is not being supplied to power

input PWR1

PWR2

AMBER

ON

Power is being supplied to power input

PWR2.

OFF Power is not being supplied to power

input PWR2.

FAULT

RED

ON

When the corresponding PORT alarm is

enabled, and a user-

configured event is

triggered.

OFF When the corresponding PORT alarm is

enabled and a user-configured event is

not triggered, or when the

corresponding PORT alarm is disabled.

MSTR/

HEAD

GREEN ON When the TN switch is either the

Master

of this Turbo Ring, or the Head of this

Turbo Chain.

Blinking

When the TN switch is Ring Master of

this Turbo Ring and the Turbo Ring is

broken, or it is Chain Head of this Turbo

Chain and the Turbo Chain is broken.

Page 15

- 15 -

OFF

When the TN switch is neither the

Master of this Turbo Ring, nor the Head

of this Turbo Chain.

CPLR/

TAIL

GREEN ON When the TN switch enables the

coupling function to form a back-

up path

in this Turbo Ring, or it is the Tail of this

Turbo Chain.

Blinking

When the Turbo Chain is down.

OFF When the TN switch disables the

coupling function of Turbo Ring, or it is

not the Tail of the Turbo Chain.

Ports LEDs

TP

(10/100M)

AMBER

ON

TP port’s 10 Mbps link is active.

Blinking

Data is being transmitted at 10 Mbps.

Off

TP port’s 10 Mbps link is inactive.

GREEN

On

TP port’s 100 Mbps link is active.

Blinking

Data is being transmitted at 100 Mbps.

off

TP port’s 100 Mbps link is inactive.

E1/E2

(1000M)

GREEN

On

TP port’s 1000 Mbps link is active.

Blinking

Data is being transmitted at 1000 Mbps.

Off

TP port’s 1000 Mbps link is inactive.

Specifications

Technology

Standards

IEEE 802.3 for 10BaseT

IEEE 802.3u for 100BaseT(X)

IEEE 802.3ab for 1000BaseT(X) (TN-

5510 series

only)

IEEE 802.3x for Flow Control

IEEE 802.1D for Spanning Tree Protocol

IEEE 802.1w for Rapid STP

IEEE 802.1Q for VLAN Tagging

IEEE 802.1p for Class of Service

IEEE 802.1X for Authentication

IEEE 802.3ad for Port Trunk with LACP

Protocols

IGMP v1/v2 device, GMRP, GVRP, SNMP

v1/v2C/v3, DHCP Server/Client, DHCP Option

66/67/82, BootP, TFTP, SNTP, SMTP, RARP,

RMON, HTTP, HTTPS, Telent, SSH, Syslog, LLDP,

IEEE 1588 PTP, Modbus/TCP, IPv6

MIB

MIB-II, Ethernet-like MIB, P-BRIDGE MIB,

Q-BRIDGE MIB, Bridge MIB, RSTP MIB, RMON

MIB Group 1, 2, 3, 9

Flow Control IEEE802.3x flow control, back pressure flow

control

Switch Properties

Priority Queues

4

Max. Number of

Available VLANs

64

VLAN ID Range

VID 1 to 4094

IGMP Groups

256

Page 16

- 16 -

Interface

Fast Ethernet

Front cabling, M12 connector, 10/100BaseT(X)

auto negotiation speed, F/H duplex mode, and

auto MDI/MDI-X connection

Gigabit Ethernet

Down cabling, M12 connector, 1000BaseLSX

Console Port

M12 A-coding 5-pin male connector

System LED Indicators

PWR1, PWR2, FAULT, MSTR/HEAD, CPLR/TAIL

Port LED Indicators

10/100M (Fast Ethernet port), 1000M (Gigabit

Ethernet port)

Alarm Contact Two relay outputs in one M12 A-coding 5-pin

male connector with current carrying capacity of

3 A @ 30 VDC or 3 A @ 240 VAC

Rotary Switches

For setting the last 3 digits of the IP address

Power Requirements

Input Voltage

LV: 12/24/36/48 VDC (8.4 to 60 VDC)

Input Current

0.507 A @ 24 VDC

Connection

M23, 6-pin male connector

Overload Current

Protection

Present

Reverse Polarity

Protection

Present

Physical Characteristics

Housing

Metal, IP54 protection (with protective caps on

unused ports)

Dimensions (W × H × D) 204.3 x 185 x 76 mm (8.04 x 7.28 x 2.99 in)

Weight

1700 g

Installation

Panel mounting, DIN-Rail mounting

(with optional kit)

Environmental Limits

Operating Temperature

-40 to 75°C (-40 to 167°F)

Storage Temperature

-40 to 85°C (-40 to 185°F)

Operating Humidity

5 to 95% (non-condensing)

Regulatory Approvals

Safety

UL508 (Pending)

Rail Traffic

EN50155, EN50121-3-2, EN50121-4

Road Traffic

NEMA TS2 (Pending), e-Mark (Pending)

EMI

FCC Part 15, CISPR (EN55022) class A

EMS EN61000-4-2 (ESD), level 3

EN61000-4-3 (RS), exceeds level 3

EN61000-4-4 (EFT), level 3

EN61000-4-5 (Surge), level 3

EN61000-4-6 (CS), level 3

EN61000-4-8

EN61000-4-11

EN61000-4-12

Shock

IEC61373

Freefall

IEC60068-2-32

Vibration

IEC61373

Note: Please check Moxa’s website for the most up-to-date certification

status.

WARRANTY

5 years

Details: See www.moxa.com/warranty

Page 17

- 17 -

Technical Support Contact Information

www.moxa.com/support

Moxa Americas:

Toll

-free: 1-888-669-2872

Tel:

1-714-528-6777

Fax:

1-714-528-6778

Moxa China (Shanghai office):

Toll

-free: 800-820-5036

Tel:

+86-21-5258-9955

Fax:

+86-21-5258-5505

Moxa Europe

:

Tel:

+49-89-3 70 03 99-0

Fax:

+49-89-3 70 03 99-99

Moxa Asia

-Pacific:

Tel:

+886-2-8919-1230

Fax:

+886-2-8919-1231

Loading...

Loading...