Page 1

P/N: 1802059160011

*1802059160011*

TN-5916 Series

Quick Installation Guide

Moxa ToughNet NAT Router

Edition 2.0, February 2017

Technical Support Contact Information

www.moxa.com/support

Moxa Americas:

Toll

-free: 1-888-669-2872

Tel:

1-714-528-6777

Fax:

1-714-528-6778

Moxa China (Shanghai office):

Toll

-free: 800-820-5036

Tel:

+86-21-5258-9955

Fax:

+86-21-5258-5505

Moxa Europe:

Tel:

+49-89-3 70 03 99-0

Fax:

+49-89-3 70 03 99-99

Moxa Asia-Pacific:

Tel:

+886-2-8919-1230

Fax:

+886-2-8919-1231

Moxa India:

Tel:

+91-80-4172-9088

Fax:

+91-80-4132-1045

2017 Moxa Inc. All rights reserved.

Page 2

- 2 -

Overview

The ToughNet TN-5916 is a high performance M12 Layer 3 NAT Router

that supports Layer 3 routing functionality to facilitate the deployment of

applications across networks. The TN-5916 NAT router uses M12 and

other circular connectors to ensure tight, robust connections and

guarantee reliable operation against environmental disturbances, such as

vibration and shock. The TN-5916 NAT router supports is ola t ed p o we r in

the 24 to 110 VDC power input range, allowing the same model to be use d

at different sites around the globe, and provides up to 16 Fast Ethernet

M12 ports with 4 bypass relay ports. Furthermore, with a -40 to 75°C

operating temperature and IP54-rated waterproof enclosure, the router

can be deployed in harsh environments. The TN-5916 series Ethernet

routers are compliant with EN 50155/50121-4 requiremen ts, making the

router suitable for a variety of industrial applications.

Package Checklist

Your ToughNet TN-5916 NAT router is shipped with the following items. If

any of these items is missing or damaged, please contact your custo mer

service representative for assistance.

• 1 Moxa ToughNet NAT router

• M12 to DB9 console port cable

• 2 protective caps for console and relay output ports

• Panel mounting kit

• CD-ROM with user’s manual, Windows utility, and SNMP MIB file

• Quick installation guide (printed)

• Warranty card

Features

Anti-Vibration Circular Connectors for Robust Links

• M12 D-coding 4-pin female connectors for Fast Ethernet

10/100BaseT(X) ports.

• M12 A-coding 5-pin male connectors for console and relay output.

• M23 6-pin male connector for power input.

Dual Isolated Power Inputs

• 24 to 110 VDC (16.8 to 137.5 VDC), isolated.

Designed for Industry-specific Applications

• Bypass relay ensures non-stop data communication in the event the

router stops working due to a power failure.

• EN 50155/50121-3-2 compliant. See specs for details about

compliance with specific parts of the EN 50155 specifications.

• -40 to 75°C operating temperature range.

• IP54, rugged high-strength case.

• Panel mounting or DIN-rail mounting installation capability.

Page 3

- 3 -

Recommended Optional Accessories

• CBL-M23(FF6P)Open-BK-100-IP67: 1-meter M23 to 6-pin power

cable with IP67-rated female 6-pin M23 connector

• CBL-M12D(MM4P)/RJ45-100 IP67: 1-meter M12-to-RJ45 Cat-5E UTP

Ethernet cable with IP67-rated male 4-pin M12 D-coded connector

• CBL-M12(FF5P)/OPEN-100 IP67: 1-meter M12-to-5-pin power cable

with IP67-rated female 5-pin M12 A-coded connector

• M12D-4P-IP68: Field-installable M12 D-coded screw-in connector,

male 4-pin, IP68-rated

• M12A-5P-IP68: Field-installable M12 A-coded screw-in connector,

female 5-pin, IP68-rated

• CAP-M12F-M: Metal cap for M12 female connector

• DK-DC50131: DIN-rail mounting kit, 50 x 131 mm

Page 4

- 4 -

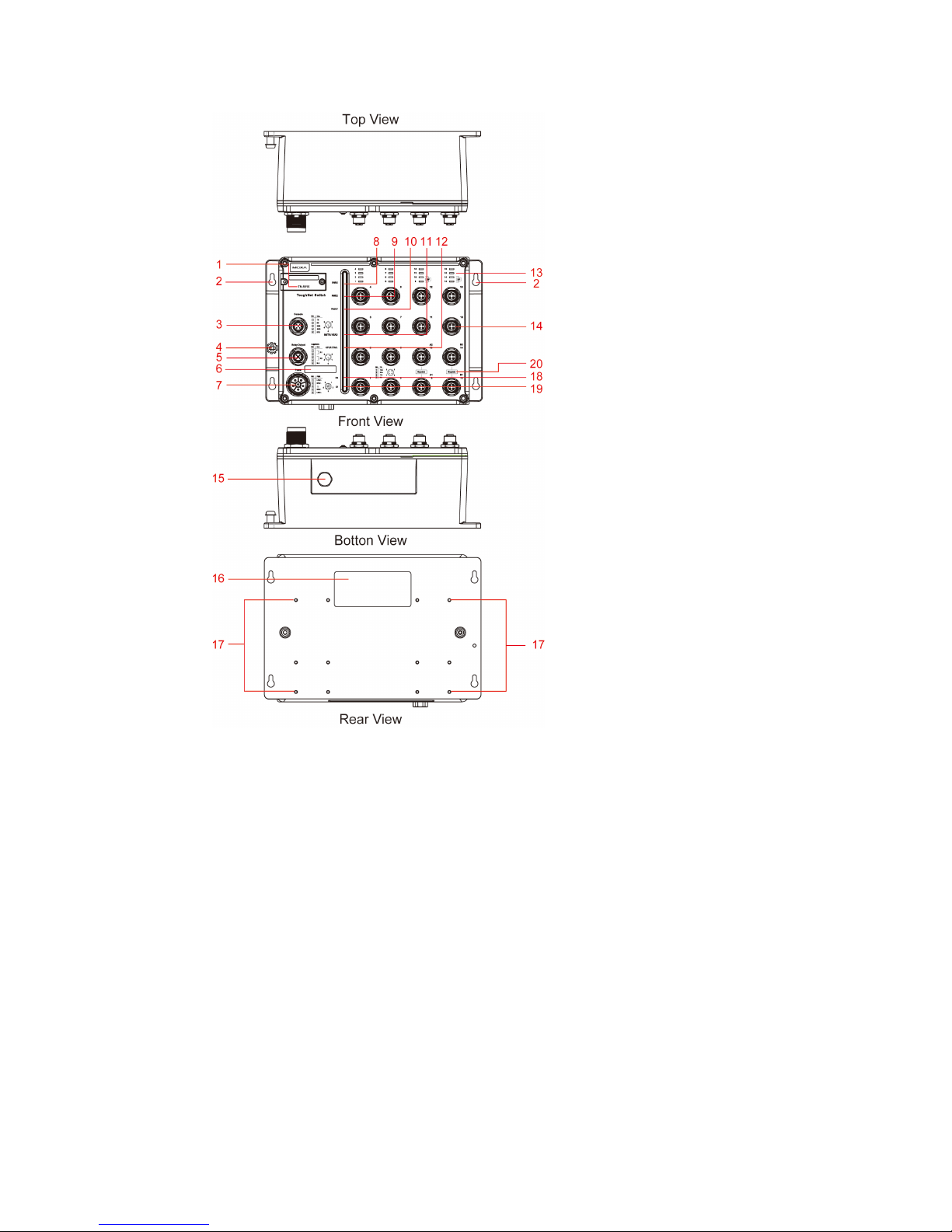

TN-5916 Panel Layouts

1. Model name

2. Screw holes for panel mounting kit

3. Console port

4. Grounding screw

5. Relay output port

6. Power input voltage range indicator

7. Power input port (male 6-pin shielded M23 connector)

8. PWR1 LED: for power input 1

9. PWR2 LED: for power input 2

10.

FAULT LED

11.

MSTR/HEAD LED: for ring master or chain head

12.

CPLR/TAIL LED: for ring coupler or chain tail

13.

TP port’s 10/100 Mbps LED

14.

10/100BaseT(X) port (female 4-

pin shielded M12 connector with D

coding)

15.

Waterproof vent

16.

Product label

17.

12 screw holes for DIN-rail mounting kit

18.

E2 LED: Not used by the TN-5916 series

19.

E1 LED: Not used by the TN-5916 series

20. Ports 9-10, 13-14 with relay bypass function

Page 5

- 5 -

ATTENTION

DO NOT open or remove the vent (#15). Removing the seal will

invalidate the

warranty.

Ports (including 3, 5, and 14) that are not in use must b e tight ly

covered with protective caps (an optional accesso ry) to ensure

IP54/IP67

-rated protection.

Mounting Dimensions (unit = mm)

TN-5916 Series

Page 6

- 6 -

Panel/Wall Mounting

STEP 1:

Mounting the TN-5916 to a wall requires 4 screws. Use the ToughNet

router as a guide to mark the correct positions of the 4 screws.

STEP 2:

U

se the 4 screws in the panel

mounting kit. If you would like to

use your own screws, make sure

the screw head

is between 6.0

mm and 7.0 mm in diameter and

the shaft

is less than 4.0 mm in

diameter, as shown

at the right.

Do not screw the screws in all the way—leave a space of about 2 mm to

allow room for sliding the ToughNet router between the wall and the

screws.

NOTE

Before tightening the screws into the wall, make sure the screw

head and shaft size are suitable by inserting the screw through

one of the keyhole-shaped apertures of the ToughNet router.

STEP 3:

Once the screws are fixed in the wall, hang t he ToughNet router on the 4

screws through the large opening of the keyhole-shaped apertures, and

then slide the router downwards. Tighten the four screws for a dded

stability.

NOTE

To provide greater protection from vibration and shock, use

screws with shaft diameter between 6.0 mm and 7.0 mm, and fix

the ToughNet

router onto the wall directly through the large

opening of the keyhole-shaped apertures.

DIN-Rail Mounting (optional)

Use the optional DIN-rail mounting

kit

(DK-DC50131, must be

purchased separately)

to

mount the

TN

-5916 on a 35 mm DIN-rail.

STEP 1:

Use 12 screws (6 screws per plate)

to attach the two DIN

-rail

attachment plates to the rear panel

of the

router.

Page 7

- 7 -

STEP 2:

If the spring-loaded bracket is locked in place, push the recessed button

to release it. Once released, you should feel some resistance from the

spring as you slide the bracket up and down a few millimeters in each

direction.

STEP 3:

Position the ToughNet

router

on the

DIN

-rail, tilted, so the clamps hook

over the top edge of the rail.

STEP 4:

Swing the router down fully onto

the DIN-rail, until both clamps

completely latch.

To remove the Moxa ToughNet Router from the DIN-rail, use a

screwdriver to pull out the two spring-loaded brackets from the bottom

until they are fixed in a “locked” position. Then, reverse Steps 3 and 4

above.

Wiring Requirements

WARNING

Turn the power off before disconnecting modules or wires. The

correct power supply voltage is listed on the product label. Check

the voltage of your power source to make s ure you are using th e

correct voltage. Do NOT use a voltage greater than what is

specified on the product label.

These devices must be supplied by a SELV source as defined in

the Low Voltage Directive 2006/95/EC and 2004/108/EC.

Page 8

- 8 -

ATTENTION

Safety First!

Be sure to disconnect the power cord before installing and/or

wiring your Moxa

router.

This device has UL

508 approva l. Use copper conductors only,

60

to 75°C

, and tighten to 4.5 inch-pounds. For use in pollution

degree 2 environments.

ATTENTION

Safety First!

Observe all electrical codes dictating the

maximum current

allowable for each wire size. If the current

goes above the

maximum ratings, the wiring could overheat,

causing serious

damage to your equipment.

Please Read and Follow These Guidelines:

• Use separate paths to route wiring for power and devices. If power

wiring and device wiring paths must cross, make sure the wires are

perpendicular at the intersection point.

NOTE: Do not run signal or communicat ions wiring and power wiring

through the same wire conduit. To avoid interference, wires with

different signal characteristics should be routed separately.

• You can use the type of signal transmitted through a wire to

determine which wires should be k ept separat e. The ru le of thumb is

that wiring that shares similar electrical characteristics can be

bundled together.

• Keep input wiring and output wiring separated.

• It is strongly advised that you label wiring for all devices in the system

when necessary.

Grounding the ToughNet NAT Router

Grounding and wire routing help limit the effects of noise due to

electromagnetic interference (EMI). Run the groun d connection from the

grounding screw to the grounding surface prior to connecting devices.

Page 9

- 9 -

ATTENTION

This product is intended to be mounted to a well

-grounded

mounting surface such as a metal panel.

Connecting the Power Supplies

The ToughNet TN-5916 series routers support two sets of power

supplies—power input 1 and power input 2. The M23 6-pin ma le

connector on the TN-5916’s front panel is used for the dual power inputs.

Pinouts for the Power Input Port on the TN-5916

Pin

Description

Usage

1 PWR1 Live / DC +

Connect “PWR1 Live / DC +” to the

positive (+) terminal when using a DC

power source.

2 PWR1 Neutral / DC -

Connect “PWR1 Neutral / DC –” to the

negative (-) terminal when using a DC

power source.

3 Chassis Ground

Connect the “Chassis Ground” to the

safety ground terminal for DC inputs.

4 PWR2 Neutral / DC -

Connect “PWR2 Neutral / DC –” to the

negative (-) terminal when using a DC

power source.

5 PWR2 Live / DC +

Connect “PWR2 Live / DC +” to the

positive (+) terminal when using a DC

power source.

STEP 1:

Plug the power cord connector into the TN-5916’s power input port.

STEP 2:

Screw in the nut on the power cord connector to the power input

connector (on the router) to ensure a tight connection.

ATTENTION

Before connecting the TN-5916 to the power input, make s ure the

power source voltage is stable.

Page 10

- 10 -

Connecting the Relay Outputs

Each TN-5916 router has two sets of relay outputs—relay output 1 and

relay output 2.The M12 A-coded 5-pin male connector on the TN-5916

front panel is used for the two relay outputs. Use a power cord with an

M12 A-coded 5-pin female connector to connect the relay contacts. You

can purchase an M12 power cable from Moxa; the model number is

CBL-M12 (FF5P)/OPEN-100 IP67.

Pinouts for the TN-5916’s Relay Output Port

N.C.: Not connected

FAULT:

The two sets of relay contacts of the M12 A-coded 5-pin male connector

are used to detect user-configured events. The two wires attached to the

fault contacts form an open circuit when a user-configured event is

triggered. If a user-configured event does not occur, the fault circuit

remains closed.

Connecting the Data Lines

10/100BaseT(X) Ethernet Port Connection

All TN-5916 models have 16 10/100BaseT(X) Ethernet ports (4-pin

shielded M12 connector with D coding). The 10/100TX ports located on

the TN-5916 front panel are used to connect to Eth ernet-enabled devices.

Most users configure these ports for Auto MDI/MDI-X mode, in wh ich case

the port’s pinouts are adjusted automatically depending on the type of

Ethernet cable used (straight-through or cross-over), and the type of

device (NIC-type or HUB/Switch/Router-type) connected to the port.

In what follows, we give pinouts for both MDI (NIC-type) ports and MDI-X

(HUB/Switch/Router-type) ports. We also give cable wiring diagrams for

straight-through and cross-over Ethernet cables.

10/100BaseT(X) Port Pinouts

Housing: shield

Page 11

- 11 -

M12 (4-pin, M) to M12 (4-pin, M) Cross-Over Cable Wiring

M12 (4-pin, M) to M12 (4-pin, M) Straight-Through Cable Wiring

M12 (4-pin, M) to RJ45 (8-pin) Cross-Over Cable Wiring

M12 (4-pin, M) to RJ45 (8-pin) Straight-Through Cable Wiring

Page 12

- 12 -

Bypass Relay Function

The TN-5916 is equipped with a bypass re lay function. When the router is

operating normally, these bypass ports work in the same way as the other

ports. That is, frame ingressions are processed and then for warded. If the

router st ops working due to a power failure, the byp ass relay function will

be triggered to ensure non-stop data communication.

The figure below illustrates the bypass relay function. For example, if

Router B loses power, then the two bypass function al ports will be

bypassed through the relay circuit and the transm ission line from Router

A to B and the transmission line from Router B to C will interconnect

automatically, ensuring that power continues to be supplied.

The bypass relay function helps the network recover from single-node

failures in a linear topology.

Router A

Router B

Router C

Router D

Since the maximum segment length of category 5 twisted-pair cable is

100 meters, cable length must be considered when designing a network

that utilizes this function. For examp le, the total length of the cable s from

Router A to B and from B to C must be no more than 100 meters. Th is way,

if the two adjacent nodes (router B and C for example) encounter a power

failure, there will be no stoppage, provided that the total length of the

cables A-to-B, B-to-C, and C-to-D are no more than 100 meters.

The bypass relay function works best for networks with linear topologies.

ToughNet™ routers with bypass relay function are not recommended to

be used in networks that employ ring topologies because network loops

may occur when redundancy protocols such as RSTP or TurboRing™ are

applied.

Page 13

- 13 -

LED Indicators

Several LED indicators are located on the ToughNet router’s front panel.

The function of each LED is described in the table below.

LED

Color

State

Description

System LEDs

PWR1 AMBER

ON

Power is being supplied to power input

PWR1.

OFF

Power is not being supplied to power

input PWR1

PWR2 AMBER

ON

Power is being supplied to power input

PWR2.

OFF

Power is not being supplied to power

input PWR2.

FAULT RED

ON

When the corresponding PORT alarm is

enabled, and a user-

configured event is

triggered.

OFF

When the corresponding PORT alarm is

enabled and a user-configured event is

not triggered, or when the

corresponding PORT alarm is disabled.

MSTR/

HEAD

GREEN

ON

When the TN router is either the Master

of this Turbo Ring, or the Head of this

Turbo Chain.

Blinking

When the TN router is Ring Master of

this Turbo Ring and the Turbo Ring is

broken, or it is Chain Head of this Turbo

Chain and the Turbo Chain is broken.

OFF

When the TN router is neither the Master

of this Turbo Ring, nor the Head of this

Turbo Chain.

CPLR/

TAIL

GREEN

ON

When the TN router enables the

coupling function to form a back-

up path

in this Turbo Ring, or it is the Tail of this

Turbo Chain.

Blinking

When Turbo Chain is down.

OFF

When the TN router disables the

coupling function of the

Turbo Ring, or it

is not the Tail of the Turbo Chain.

Port LEDs

TP

(10/100M)

AMBER

ON

TP port’s 10 Mbps link is active.

Blinking

Data is being transmitted at 10 Mbps.

Off

TP port’s 10 Mbps link is inactive.

GREEN

On

TP port’s 100 Mbps link is active.

Blinking

Data is being transmitted at 100 Mbps.

off

TP port’s 100 Mbps link is inactive.

Page 14

- 14 -

Specifications

Technology

Standards

IEEE 802.3 for 10BaseT

IEEE 802.3u for 100BaseT(X)

IEEE 802.3x for Flow Control

IEEE 802.1D for Spanning Tree Protocol

IEEE 802.1w for Rapid STP

IEEE 802.1Q for VLAN Tagging

IEEE 802.1p for Class of Service

IEEE 802.3ad for static Port Trunk

Protocols

IGMPv1/v2, SNMPv1/v2c/v3, DHCP Server,

TFTP, SNTP, SMT P, RMO

N, HTTP, HTTPS, T elnet,

Syslog, SSH, SNMP Inform, LLDP, RIP V1/V2,

VRRP

MIB MIB-II, Ethernet-like MIB, P-BRIDGE MIB,

Q-BRIDGE MIB, Bridge MIB, RSTP MIB, RMON

MIB Group 1, 2, 3, 9

Flow Control

IEEE802.3x flow control, back pressure flow

control

Router Properties

Priority Queues

4

Max. Number of

Available VLANs

16

VLAN ID Range

VID 1 to 4094

IGMP Groups

256

Interface

Fast Ethernet

Front cabling, M12 connector, 10/100BaseT(X)

auto negotiation speed, F/H duplex mode, and

auto MDI/MDI-X connection

Console Port

M12 A-coding 5-pin male connector

System LED Indicators

PWR1, PWR2, FAULT, MSTR/HEAD, CPLR/TAIL

Port LED Indicators

10/100M (fast Ethernet port)

Alarm Contact

Two relay outputs in one M12 A-coding 5-pin

male connector with current carrying capac ity of

1 A @ 30 VDC

Power Requirements

Input Voltage

WV: 24 to 110 VDC (16.8 to 137.5 VDC)

Input Current

0.85 A @ 24 VDC, 0.17 A @ 110 VDC

Connection

M23 6-pin male connector

Overload Current

Protection

Present

Reverse Polarity

Protection

Present

Physical Characteristics

Housing Metal, IP54 protection (with protective caps on

unused ports)

Dimensions (W × H × D)

250 × 175.8 × 116.3 mm (9.84 × 6.92 × 4.58 in)

Weight

4030 g

Installation Panel mounting, DIN-Rail mounting

(with optional kit)

Page 15

- 15 -

Environmental Limits

Operating Temperature

-40 to 75°C (-40 to 167°F)

Storage Temperature

-40 to 85°C (-40 to 185°F)

Operating Humidity

5 to 95% (non-condensing)

Regulatory Approvals

Safety

UL/cUL 508, EN 60950-1 (LVD)

EMC

EN 55032, EN 55024

EMI

CISPR 32, FCC Part 15B Class A

EMS

IEC 61000-4-2 ESD: Contact 6 kV; Air 8 kV

IEC 61000-4-3 RS: 80 MHz to 1 GHz: 20 V/m

IEC 61000-4-4 EFT: Power 2 kV; Signal 2 kV

IEC 61000-4-5 Surge: Power 2 kV; Signal 2 kV

IEC 61000-4-6 CS: 10 V

IEC 61000-4-8

Rail Traffic

EN 50155*, EN 50121-4, EN 45545-2

*This product is suitable for rolling stock railway applications, as defined

by the EN 50155 standard. For a more detailed statement, click here:

www.moxa.com/doc/specs/EN_50155_Compliance.pdf

Shock

EN 50155, EN/IEC 61373

Freefall

IEC 60068-2-32

Vibration

EN 50155, EN/IEC 61373

Note: Please check Moxa’s website for the most up-to-da t e certification

status.

MTBF (mean time between failures)

Time

556,025 hrs.

Standard

Telcordia SR332

Warranty

Warranty Period

5 years

Details

www.moxa.com/warranty

Loading...

Loading...