Page 1

Moxa PowerTrans Switch

PT-G7509 Series

Hardware Installation Guide

Fourth Edition, June 2010

© 2010 Moxa Inc. All rights reserved.

Reproduction without permission is prohibited.

Fl.4, No.135, Lane 235, Pao-Chiao Rd. Shing Tien City, Taipei, Taiwan,

R.O.C.

TEL: +886-2-8919-1230

P/N: 1802075090013

Page 2

- 2 -

Package Checklist

The Moxa PowerTrans switch is shipped with the following items. If any of

these items are missing or damaged, please contact your customer service

representative for assistance.

y 1 Moxa PowerTrans Switch

y Hardware Installation Guide

y CD-ROM with User’s Manual and SNMP MIB file

y Moxa Product Warranty Statement

y RJ45 to DB9 console port cable

y Protective caps for unused ports

y 2 rack-mount ears

Panel Layout

Front view (Front Cabling)

Front view (Rear Cabling)

Rear view (Front Cabling)

Rear view (Rear Cabling)

8

7

69

STAT

FAULT

PWR1

MASTER

PWR2

COUPLER

LNK/ACT SPEED FDX/HDX

RING PORT

COMUPLER

PORT

MODE

CONSOLE

STAT

FAULT

PWR1

MASTER

PWR2

COUPLER

LNK/ACT SPEED FDX/HDX

RING PORT

COMUPLER

PORT

MODE

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9

4

2

3

1

5

1. System status LEDs

2. Interface Module mode LEDs

3. 9 Gigabit Combo port LEDs

4. Push-button switch to select mode for Interface Module

5. Model Name

6. 9 Gigabit Combo ports

7. Serial Console port

8. 10-pin terminal block for power inputs, and relay output

9. Rack Mounting Kit

Page 3

- 3 -

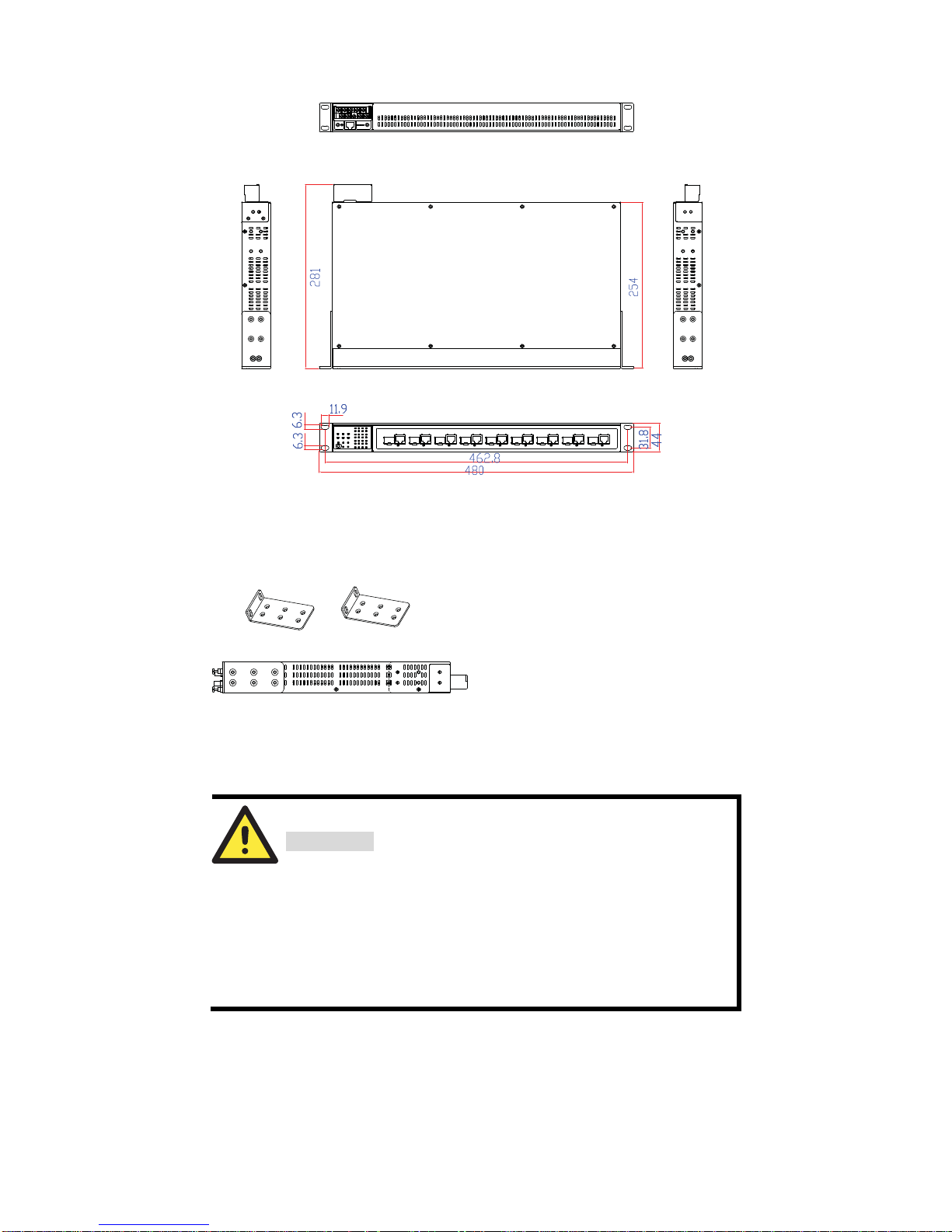

Dimensions (unit = mm)

Top View

Rear View

Side View Side View

Front View

Rack Mounting

Use four screws to attach the PT switch to a standard rack.

N

ote: Two additional

rack-mount ears can be

ordered as an option. Use

them to secure the rear of

the chassis in high-vibration

environments.

Wiring Requirements

WARNING

Safety First!

Be sure to disconnect the power cord before installing and/or

wiring your Moxa PowerTrans Switch.

Calculate the maximum possible current in each power wire and

common wire. Observe all electrical codes dictating the

maximum current allowable for each wire size.

If the current goes above the maximum ratings, the wiring could

overheat, causing serious damage to your equipment.

Grounding Moxa PowerTrans Switch

Grounding and wire routing help limit the effects of noise due to

electromagnetic interference (EMI). Run the ground connection from the

ground screw to the grounding surface prior to connecting devices.

Page 4

- 4 -

Wiring the Power Inputs

The PT series of switches supports dual redundant power supplies: “Power

Supply 1 (PWR1)” and “Power Supply 2 (PWR2)”. The connections for PWR1,

PWR2 and the RELAY are located on the terminal block. The front view of the

terminal block connectors are shown below.

Wiring the Relay Contact

Each PT switch has one relay output. Refer to the next section for detailed

instructions on how to connect the wires to the terminal block connector, and

how to attach the terminal block connector to the terminal block receptor.

FAULT: The relay contact of the 10-pin terminal block connector are used to

detect user-configured events. The two wires attached to the RELAY contacts

form an open circuit when a user-configured event is triggered. If a

user-configured event does not occur, the RELAY circuit will be closed.

Wiring the Redundant Power Inputs

Each PT switch has two sets of power inputs: power input 1 and power input 2.

STEP 1: Insert the dual set positive/negative DC wires into PWR1 and PWR2

terminals (+ → pins 1, 9; - → pins 2, 10). Or insert the L/N AC wires into

PWR1 and PWR2 terminals (L → pin 1, 9; N → pin 2,10)

STEP 2: To keep the DC or AC wires from pulling loose, use a screwdriver to

tighten the wire-clamp screws on the front of the terminal block connector.

Note 1: The PT switch with dual power supplies uses PWR2 as the first priority

power input by default.

Note 2: For dielectric strength (HIPOT) test, users must remove the metal

jumper located on terminals 3, 4, and 7, 8 of the terminal block to avoid

damage.

Page 5

- 5 -

LED Indicators

The front panel of the PT switch contains several LED

indicators. The function of each LED is described in the table

below.

LED Color State Description

System LEDs

STAT

GREEN

On

System has passed self-diagnosis test

on boot-up and is ready to run.

Blinking

System is undergoing the

self-diagnosis test.

RED On

System failed self-diagnosis on

boot-up.

PWR1 AMBER

On

Power is being supplied to the main

module’s power input PWR1.

Off

Power is not being supplied to the

main module’s power input PWR1.

PWR2 AMBER

On

Power is being supplied to the main

module’s power input PWR2.

Off

Power is not being supplied to the

main module’s power input PWR2.

FAULT RED

On

The corresponding PORT alarm is

enabled and a user-configured event

has been triggered.

Off

The corresponding PORT alarm is

enabled and a user-configured event

has not been triggered, or the

corresponding PORT alarm is

disabled.

MSTR/HEAD GREEN

On

This PT switch is set as the Master

of the Turbo Ring, or as the Head of

the Turbo Chain.

Blinking

This PT switch has become the Ring

Master of the T urbo Ring, or the

Head of the Turbo Chain, after the

Turbo Ring or the Turbo Chain went

down.

Off

This PT switch is not the Master of

this Turbo Ring

or is set as a

Member of the Turbo Chain.

CPLR/TAIL GREEN

On

When this PT switch enables the

coupling function to form a back-up

path.

Blinking

Turbo Chain is down.

Off

When this PT switch disables the

coupling function, or is set as a

Member of the Turbo Chain.

Mode LEDs

LNK/ACT GREEN On

The corresponding module port’s

link is active.

Page 6

- 6 -

Blinking

The corresponding module port’s

data is being transmitted.

Off

The corresponding module port’s

link is inactive.

SPEED GREEN

Off

The corresponding module port’s

data is bein

g

transmitted at 10 Mbps.

On

The corresponding module port’s

data is being transmitted at 100

Mb

p

s.

Blinking

The corresponding module port’s

data is being transmitted at

1000 Mb

p

s.

FDX/HDX GREEN

On

The corresponding module port’s

data is being transmitted in full

du

p

lex mode.

Off

The corresponding module port’s

data is being transmitted in half

du

p

lex mode.

RING/CHAIN

PORT

GREEN

On

The corresponding module’s port is

the ring or chainport of this PT

switch.

Off

The corresponding module’s port is

not the ring or chainport of this PT

switch.

COUPLER

PORT

GREEN

On

The corresponding module’s port is

the cou

p

ler port of this PT switch.

Off

The corresponding module’s port is

not the coupler port of this PT

switch.

Specifications

Technology

Standards IEEE 802.3, 802.3u, 802.3ab, 802.3z, 802.3x, 802.1D,

802.1W, 802.1Q, 802.1p, 802.1X, 802.3ad

Flow control IEEE 802.3x flow control, back pressure flow control

Interface

Fiber Ports 100/1000BaseSFP slot

RJ45 Ports 10/100/1000BaseT(X) auto negotiation speed

System LED

Indicators

STAT, PWR1, PWR2, FAULT, MSTR/HEAD,

CPLR/TAIL

Module LED

Indicators

LNK/ACT, FDX/HDX, SPEED, RING PORT,

COUPLER PORT

Alarm Contact One relay output with current carrying capacity of 3A

@ 30 VDC or 3A @ 240 VAC

Power

Input Voltage 24 VDC (18 to 36V)or 48 VDC (36 to 72V)or 110/220

VDC/VAC

(88 to 300 VDC and 85 to 264 VAC)

Input Current Max. 1.17A @ 24VDC

Max. 0.59A @ 48VDC

Max. 0.27/0.16A @ 110/220VDC

Max. 0.61/0.35A @ 110/220VAC

Physical Characteristics

Housing IP 30 protection, metal case

Dimensions

(W x H x D)

440 x 44 x 254 mm (17.32 x 1.73 x 10.00 in.)

Page 7

- 7 -

Weight 3800 g

Installation 19” rack mounting

Regulatory Approvals

Safety EN60950-1

Power Autom aton IEC61850-3, IEEE 1613

Rail Traffic EN50121-4, EN50155

EMI FCC Part 15, CISPR (EN55022) class A

Environmental Limits

Operating Temp. -40 to 85°C (-40 to 185°F)

Cold start of min. 100 VAC at -40°C

Storage Temp. -40 to 85°C (-40 to 185°F)

Ambient Relative

Humidity.

5 to 95% (non-condensing)

Warranty

5 years

Technical Support Contact Information

www.moxa.com/support

Moxa Americas:

Toll-free: 1-888-669-2872

Tel: +1-714-528-6777

Fax: +1-714-528-6778

Moxa China (Shanghai office):

Toll-free: 800-820-5036

Tel: +86-21-5258-9955

Fax: +86-10-5258-5505

Moxa Europe:

Tel: +49-89-3 70 03 99-0

Fax: +49-89-3 70 03 99-99

Moxa Asia-Pacific:

Tel: +886-2-8919-1230

Fax: +886-2-8919-1231

Loading...

Loading...