Page 1

2013 Moxa Inc. All rights reserved.

P/N: 1802075280030

PT-7528 Series

(8/12/16/20-Port Fiber Models)

Hardware Installation Guide

Moxa PowerTrans Switch

First Edition, December 2013

Page 2

- 2 -

Package Checklist

The Moxa PowerTrans switch is shipped with the following items. If any of

these items are missing or damaged, please contact your customer

service representative for assistance.

• 1 Moxa PowerTrans switch

• USB cable (Type A male to Type B male)

• Protective caps for unused ports

• 2 rackmount ears

• CD-ROM with user’s manual and SNMP MIB file

• Hardware installation guide

• Warranty card

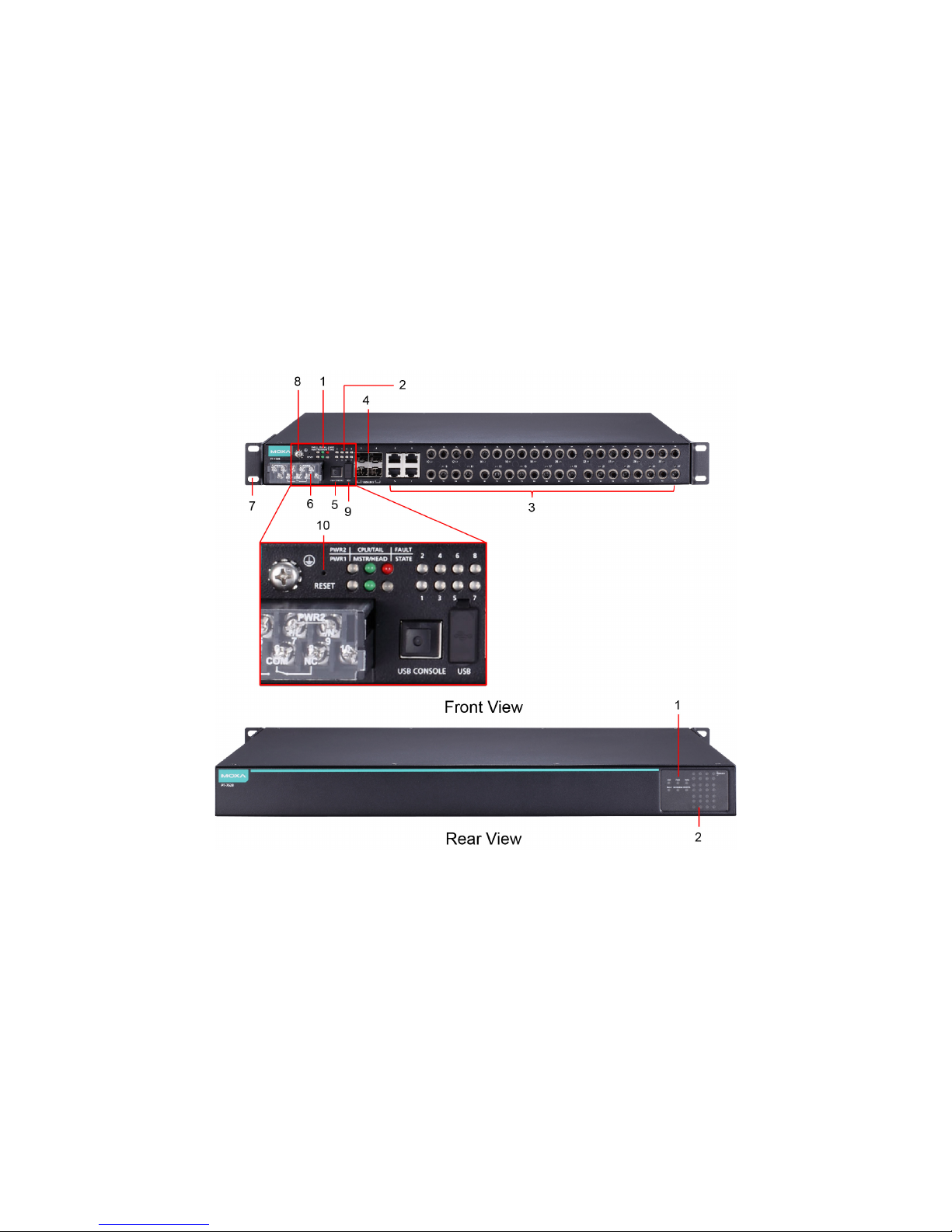

Panel Layout

1. System status LEDs

2. Ethernet port LEDs

3. Fast Ethernet ports and port LEDs

4. Gigabit SFP slots

5. USB console port

6. 10-pin terminal block for power inputs, and relay output

7. Rack mounting kit

8. Grounding screw

9. USB storage port (ABC-02-USB-T)

10. Reset button

Note: The model shown above is the PT-7528-20MST-4TX-4GSFP-HV

switch. For other models, the layout of Ethernet ports is different.

Page 3

- 3 -

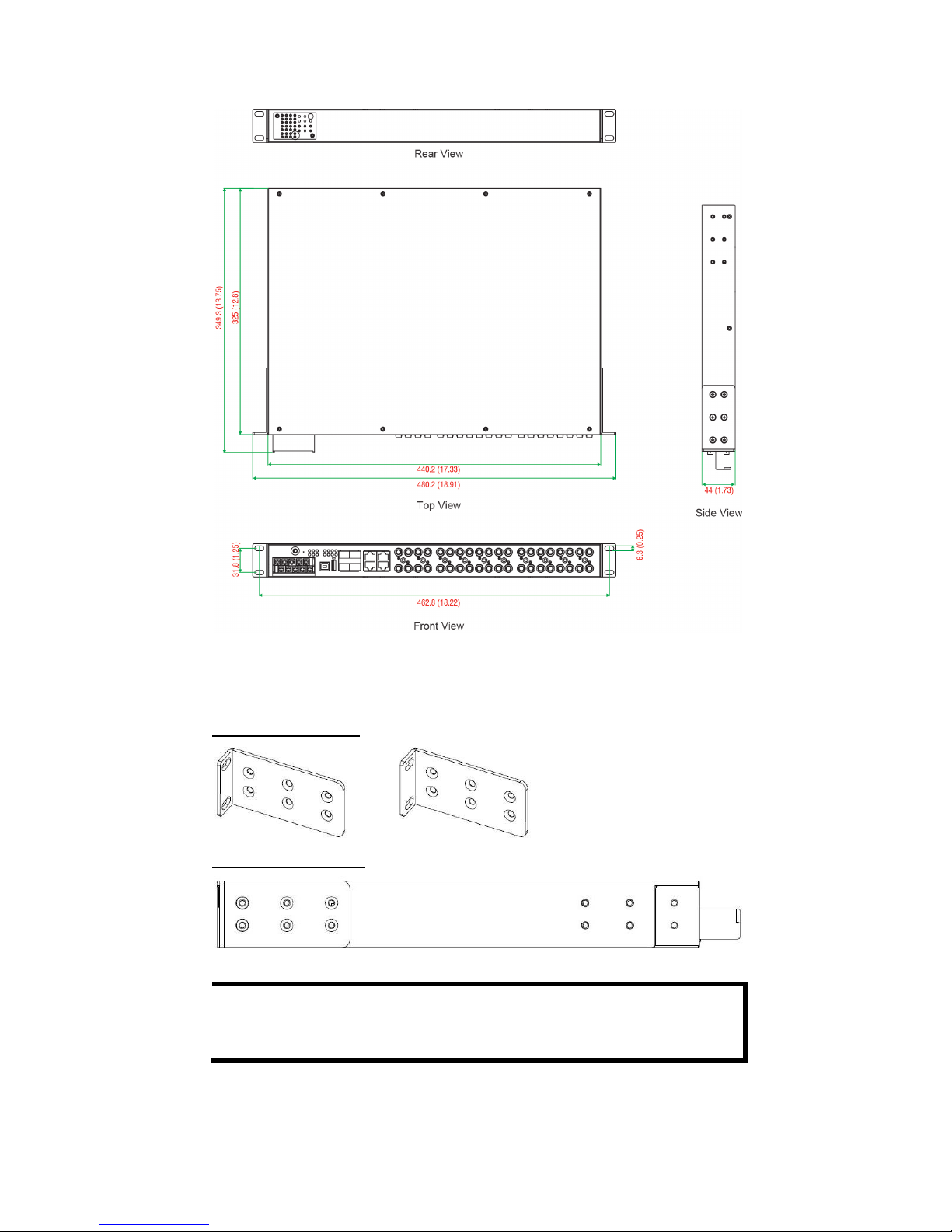

Dimensions; unit = mm (in)

Rack Mounting

Use six screws to attach the PT switch to a standard rack.

Rack Mounting Kit

PT-7528 Side View

NOTE

Two additional rack-mount ears can be ordered as an option. Use

them to secure the rear of the chassis in high

-vibration

environments.

Page 4

- 4 -

Wiring Requirements

WARNING

Safety First!

•

Be sure to disconnect the power cord bef

ore installing and/or

wiring your Moxa PowerTrans Switch.

• Calculate the maximum possible current in each power wire

and common wire. Observe all electrical codes dictating the

maximum current allowable for each wire size.

•

If the current goes above the maximum ratings, the wiring

could overheat, causing serious damage to your equipment.

Grounding the Moxa PowerTrans Switch

Grounding and wire routing help limit the effects of noise due to

electromagnetic interference (EMI). Run the ground connection from the

ground screw to the grounding surface prior to connecting devices.

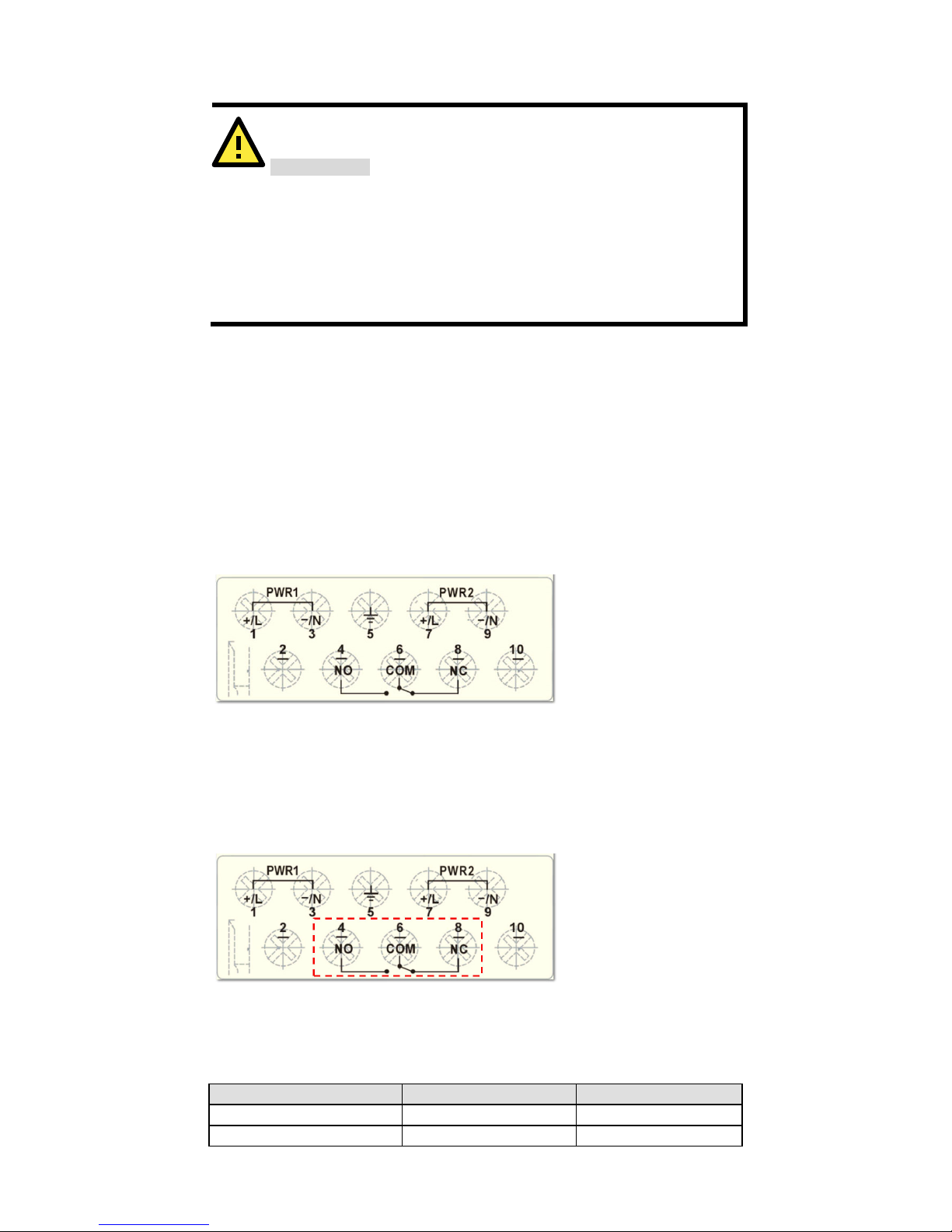

Wiring the Power Inputs

The PT-7528 switches support dual redundant power supplies: Power

Supply 1 (PWR1) and Power Supply 2 (PWR2). The connections for PWR1,

PWR2, and the RELAY are located on the terminal block. The front view of

the terminal block connectors are shown below.

Wiring the Relay Contact

Each PT-7528 switch provides two types of relay output, at the user’s

option. See below for detailed instructions on how to connect the wires to

the terminal block connector, and how to attach the terminal block

connector to the terminal block receptor.

Normal contact state

withou

t power applied

to device.

The relay contact is used to detect user-configured events. Two wires are

attached to the relay pins. The PT-7528 provides normal open and normal

closed circuits at the user’s option. For pin definitions, refer to the table

below:

Relay pin connection

Power on state

Event trigger

Pins 4 and 6

Closed circuit

Open circuit

Pins 8 and 6

Open circuit

Closed circuit

Page 5

- 5 -

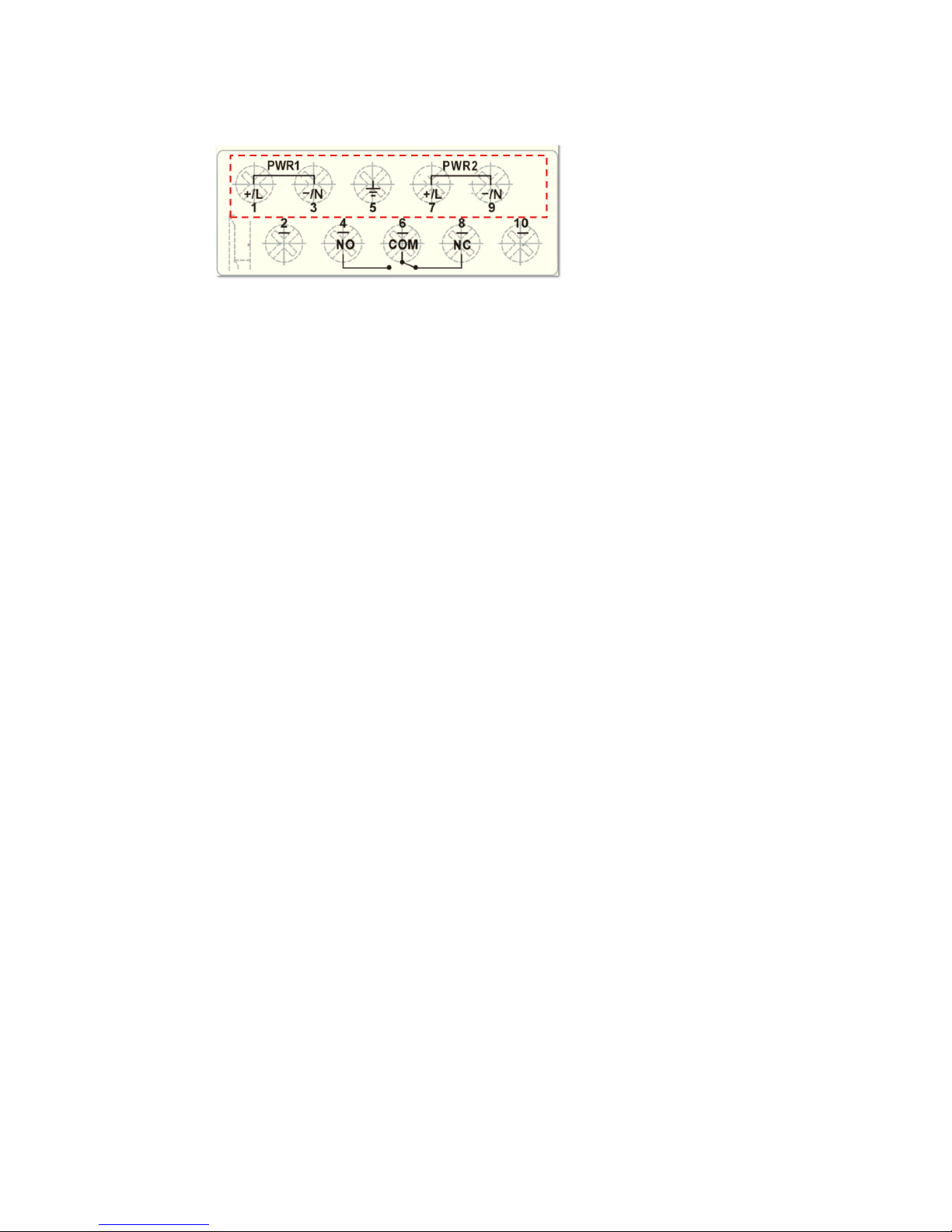

Wiring the Redundant Power Inputs

Each PT switch has two sets of power inputs: power input 1 and power

input 2.

STEP 1: Insert the dual set positive/negative DC wires into PWR1 and

PWR2 terminals (+ pins 1, 7; – pins 3, 9), or insert the L/N AC wires

into PWR1 and PWR2 terminals (L pins 1, 7; N pins 3, 9).

STEP 2: To keep the DC or AC wires from pulling loose, use a screwdriver

to tighten the wire-clamp screws on the front of the terminal block

connector.

Ethernet Ports

Fast Ethernet RJ45 Twisted-Pair Cabling

PT-7528 series switches are equipped with several 10/100BaseTX ports

for connecting to standard CAT-5 STP cables with RJ45 male connectors.

PT-7528 series switches feature auto-negotiation, auto-polarity, and

auto-crossover functions. For high EMC environment applications, we

suggest using shielded twisted-pair cables to avoid EMC interference to

retain compliance with the IEEE 1613 standard.

Gigabit Ethernet 1000BaseTX Cabling

The IEEE 802.3ab Gigabit Ethernet standard defines 1000 Mbps Ethernet

communications over distances of up to 100 meters using all 4 pairs in

category 5 (or higher) balanced unshielded twisted-pair cabling. For

wiring guidelines, system designers and integrators should refer to the

Telecommunications Industry Association (TIA) TIA/EIA-568-A wiring

standard that characterizes the minimum cabling performance

specifications required for proper Gigabit Ethernet operation. To ensure

reliable, error-free data communication, new and pre-existing

communication paths should be checked for TIA/EIA-568-A compliance.

• Data cable lengths should be as short as possible, ideally limited to 3

m (10 ft) in length. Copper data cables should not be used for

inter-building communications.

• Power and data cables should not be run in parallel for long distances,

and should be installed in separate conduits. Power and data cables

should intersect at 90° angles when necessary to reduce inductive

coupling.

• Optionally, shielded/screened cabling can be used. The cable shield

should be grounded at one single point to avoid the generation of

ground loops.

Page 6

- 6 -

USB Console Connection

The PT-7528 series has one USB console port (type B connector), located

on the top panel. Use the USB cable (provided in the product package) to

connect the PT-7528’s console port to your PC’s USB port and install the

USB driver (available in the software CD) on your PC. You may then use

a console terminal program, such as Moxa PComm Terminal Emulator, to

access the PT-7528’s console configuration utility.

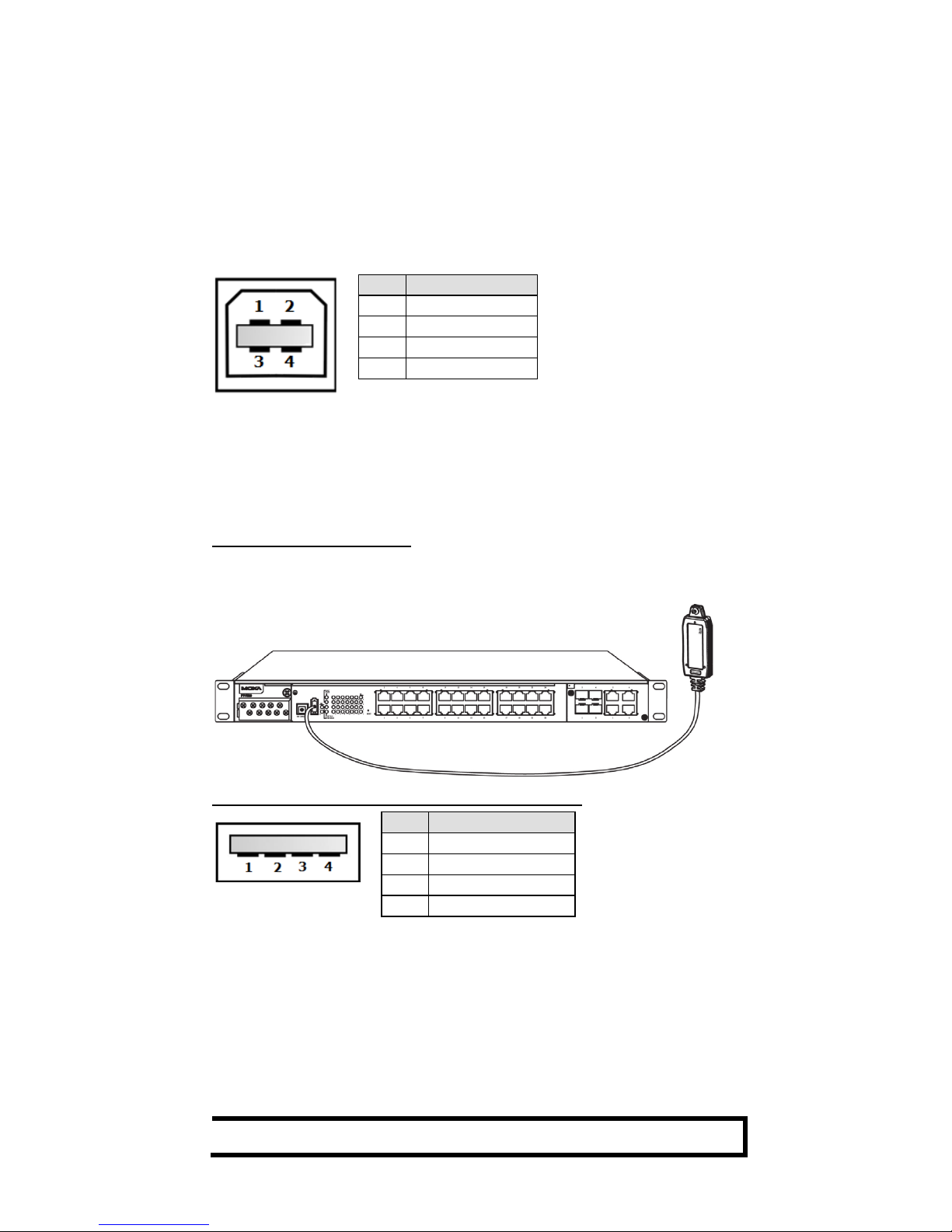

USB Console Port (Type B Connector) Pinouts

Pin

Description

1

D- (Data-)

2

VCC (+5V)

3

D+ (Data+)

4

GND (Ground)

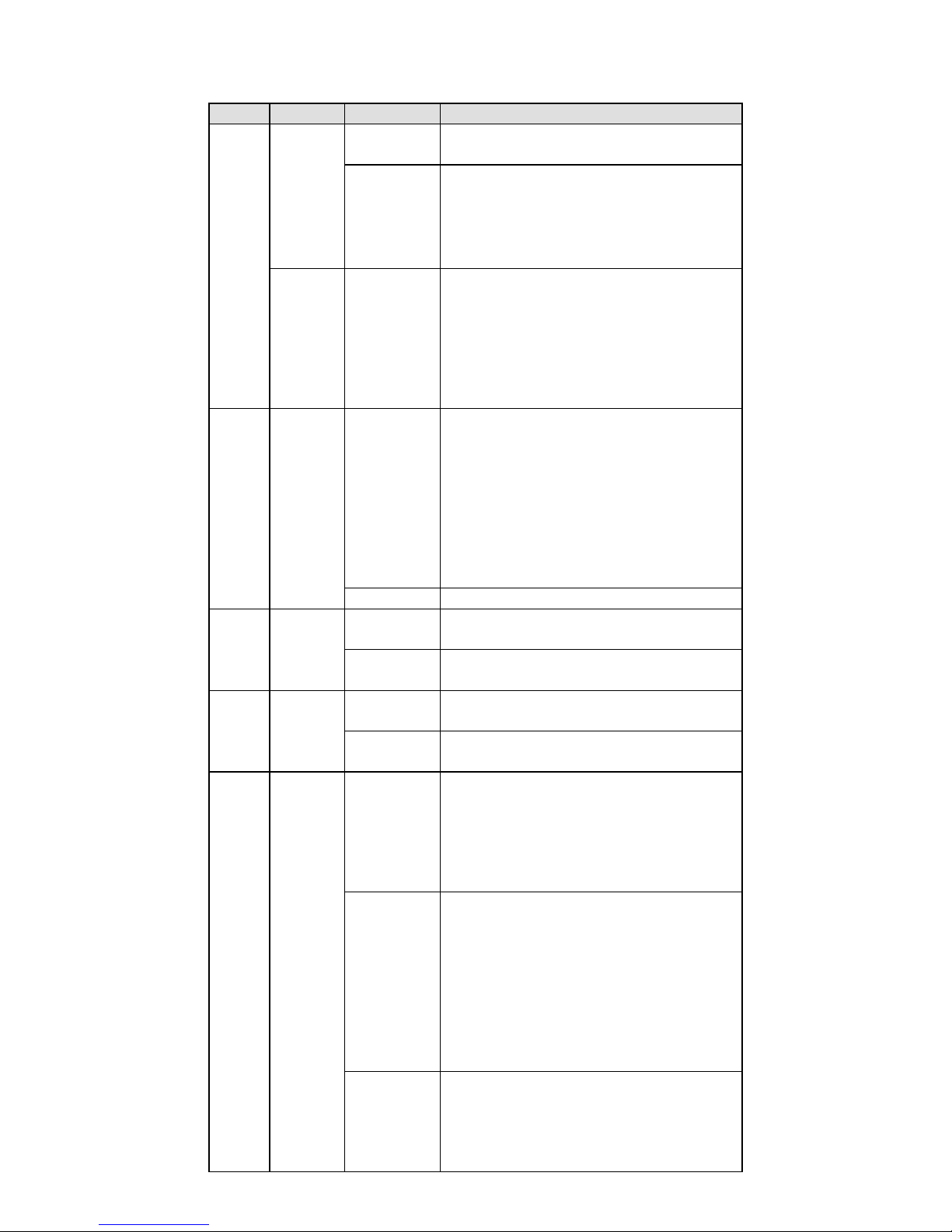

USB Storage Connection

The PT-7528 series has one USB storage port (type A connector) on the

front panel. Use Moxa’s ABC-02-USB-T automatic backup configurator to

connect the PT-7528’s USB storage port for configuration backup,

firmware upgrade, or system log file backup.

ABC-02-USB Installation

Plug the ABC-02-USB into the USB storage port of the Moxa PT-7528

series. We suggest attaching the ABC-02-USB to a wall with an M4 screw.

USB Storage Port (Type A Connector) Pinouts

Pin

Description

1

VCC (+5 V)

2

D- (Data-)

3

D+ (Data+)

4

GND (Ground)

The Reset Button

Depress the Reset button for five continuous seconds to load the factory

default settings. Use a pointed object, such as a straightened paper clip or

toothpick, to depress the Reset button. When you do so, the STATE LED

will start to blink about once per second. Continue to depress the STATE

LED until it begins blinking more rapidly; this indicates that the button has

been depressed for five seconds and you can release the Reset button to

load factory default settings.

NOTE

DO NOT power off the switch when loading default settings.

Page 7

- 7 -

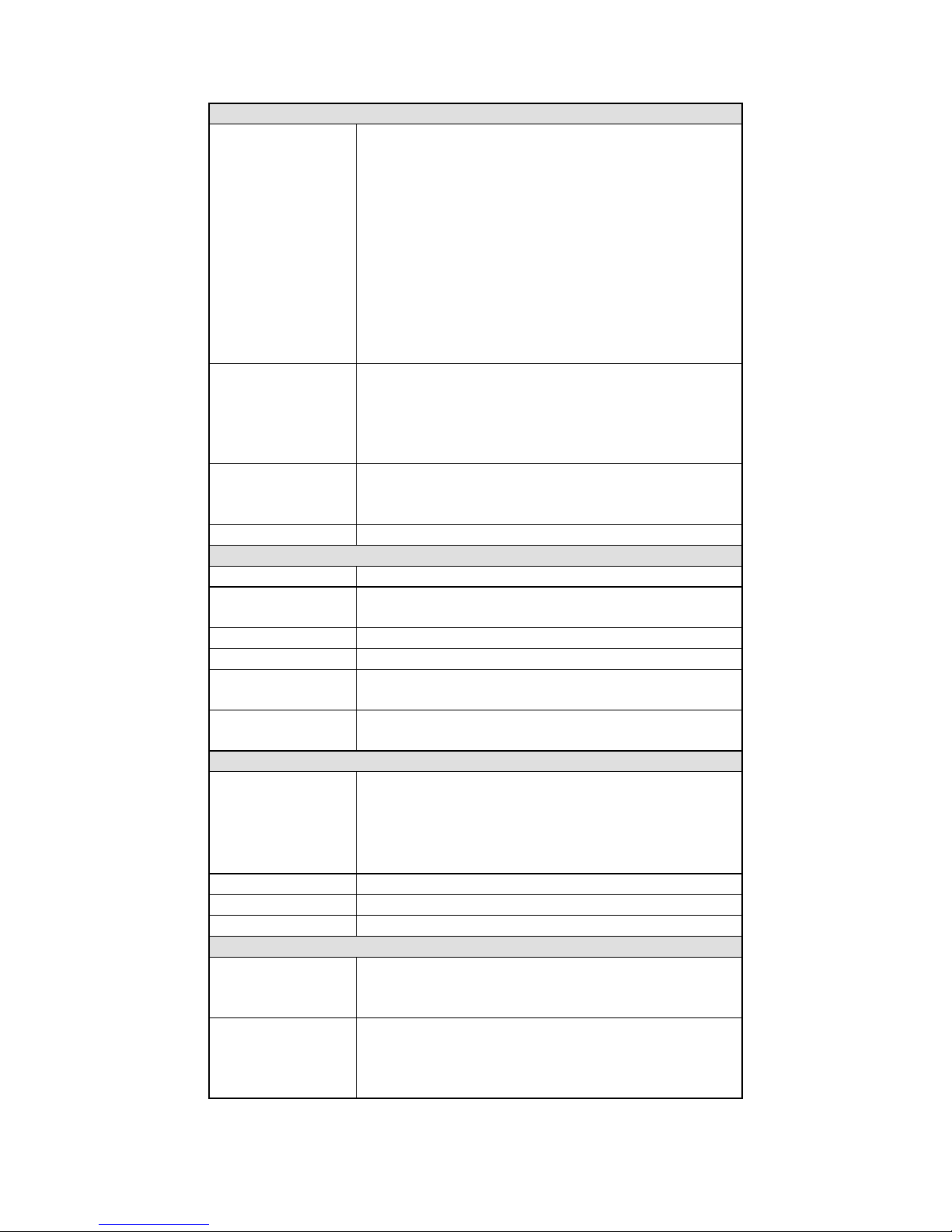

LED Indicators

LED

Color

State

Description

STATE

GREEN

On

System has passed self-diagnosis test on

boot-up and is ready to run.

Blinking

• 1 blink every sec:

The switch is being reset

• 1 blink every 2 sec:

The switch is connected to the

ABC-02-USB.

RED

On

The system failed self-diagnosis on

boot-up.

•

RAM Test Fail / System Info. Read Fail

/ Switch Initial Fail / PTP PHY Error.

(+

Green MSTR lit on : HW FAIL)

• FW Checksum Fail / Uncompress Fail.

(+ Green Coupler lit on: SW FAIL)

FAULT

RED

On

One of the following situations exists:

• The signal contact is open.

• ABC Loading/Saving Failure.

• The port has been disabled because

the ingress multicast and broadcast

packets exceed the ingress rate limit.

• Incorrect loop connection in a single

switch.

• Invalid Ring port connection.

Off

The system is operating normally.

PWR1

AMBER

On

Power is being supplied to the main

module’s power input PWR1.

Off Power is not being supplied to the main

module’s power input PWR1.

PWR2

AMBER

On

Power is being supplied to the main

module’s power input PWR2.

Off

Power is not being supplied to the main

module’s power input PWR2.

MSTR/

HEAD

GREEN

On

One of the following situations exists:

• The switch is set as the Master of the

Turbo Ring, or as the Head of the

Turbo Chain.

• POST H.W. Fail (+Stat on and Fault

blinking).

Blinking

One of the following situations exists:

• The switch has become the Ring

Master of the Turbo Ring.

• The switch has become the

Head of the

Turbo Chain after the Turbo Ring or

the Turbo Chain went down.

• The switch is set as a member of the

Turbo Chain and the corresponding

chain port is down.

Off

One of the following situations exists:

• The switch is not the Master of this

Turbo Ring.

• This switch is set as a member of the

Turbo Chain.

Page 8

- 8 -

CPLR/

TAIL

GREEN

On

One of the following situations exists:

• The switch’s coupling function is

enabled to form a back-up path.

• The switch is set as the Tail of the

Turbo Chain.

• POST S.W. Fail (+Stat on and Fault

blinking)

Blinking

One of the following situations exists:

• Turbo Chain is down.

• The switch is a member of the Turbo

Chain and the corresponding chain

port is down.

Off

One of the following situations exists:

• This switch has disabled the coupling

function.

• This switch is a member of the

Turbo Chain.

FAULT +

MSTR/HEAD

+ CPLR/TAIL

Rotate

Blinking

Sequentially

ABC-02-USB is importing/exporting files.

STATE +

FAULT +

MSTR/HEAD

+ CPLR/TAIL

Blinking

2 blinks per sec: The switch is being

discovered/located by MXview.

Ports

1 to 24

GREEN

On

Port’s 100 Mbps link is active

Blinking

Data is transmitting at 100 Mbps

Off

Port’s link is inactive

AMBER

On

Port’s 10 Mbps link is active

Blinking

Data is transmitting at 10 Mbps

Off

Port’s link is inactive

M1

Ports

1 to 4

GREEN

On

Port’s highest speed link is active

Blinking

Data is transmitting at the highest speed

Off

Port’s link is inactive

AMBER

On

Port’s non-highest speed link is active

Blinking

Data is transmitting at non-highest

speed

Off

Port’s link is inactive

Page 9

- 9 -

Specifications

Technology

Standards

IEEE 802.3 for 10BaseT

IEEE 802.3u for 100BaseT(X) and 100BaseFX

IEEE 802.3ab for 1000BaseT(X)

IEEE 802.3z for 1000BaseX

IEEE 802.3x for Flow Control

IEEE 802.1D-2004 for Spanning Tree Protocol

IEEE 802.1w for Rapid STP

IEEE 802.1s for Multiple Spanning Tree Protocol

IEEE 802.1Q for VLAN Tagging

IEEE 802.1p for Class of Service

IEEE 802.1X for Authentication

IEEE 802.3ad for Port Trunk with LACP

Protocols

IGMP v1/v2, GMRP, GVRP, SNMPv1/v2c/v3, DHCP

Server/Client, BootP, TFTP, SNTP, SMTP, RARP,

RMON, HTTP, HTTPS, Telnet, SSH, Syslog, DHCP

Option 66/67/82, EtherNet/IP, Modbus/TCP, LLDP,

IEEE 1588 PTP V2, IPv6, NTP Server/Client, MMS

MIB

MIB-II, Ethernet-like MIB, P-BRIDGE MIB,

Q-BRIDGE MIB, Bridge MIB, RSTP MIB,

RMON MIB Groups 1, 2, 3, 9

Flow control

IEEE 802.3x flow control, back pressure flow control

Interface

Fast Ethernet

10/100BaseT(X) or 100BaseFX (SC/ST connector)

Gigabit Ethernet

10/100/1000BaseT(X), 1000BaseSX/LX/LHX/ZX

(SFP slot, LC connector)

Console Port

USB-serial console (Type B connector)

Storage port

USB storage port (Type A connector)

System LED

Indicators

STAT, PWR1, PWR2, FAULT, MSTR/HEAD, CPLR/TAIL

Alarm Contact

One relay output with current carrying capacity of

3 A @ 30 VDC or 3 A @ 240 VAC

Optical Fiber (100BaseFX)

Distance Multi-mode:

0 to 5 km, 1300 nm (50/125μm, 800 MHz*km)

0 to 4 km, 1300 nm (62.5/125μm, 500 MHz*km)

Single-mode:

0 to 40 km, 1310 nm (9/125μm, 3.5 PS/(nm*km))

Min. TX Output

Multi-mode: -20 dBm; Single-mode: -5 dbm

Max. TX Output

Multi-mode: -10 dBm; Single-mode: 0 dbm

RX Sensitivity

Multi-mode: -32 dBm; Single-mode: -34 dbm

Power

Input Voltage

WV: 24/48 VDC (18 to 72 V)

HV: 110/220 VDC/VAC (88 to 300 VDC and 85 to 264

VAC)

Input Current

Max. 1.428 A @ 24 VDC

Max. 0.735 A @ 48 VDC

Max. 0.313/0.167 A @ 110/220 VDC

Max. 0.586/0.382 A @ 110/220 VAC

Page 10

- 10 -

Physical Characteristics

Housing

IP40 protection, metal case

Dimensions

(W x H x D)

440 x 44 x 325 mm (17.32 x 1.73 x 12.76 in)

Weight

4900 g

Installation

19” rack mounting

Standards and Certifications

Safety

UL 508

Power Automation

IEC 61850-3, IEEE 1613

Road Traffic

NEMA TS2

Rail Traffic

EN 50121-4

EMI

FCC Part 15 Subpart B Class A, EN55022 class A

Environmental Limits

Operating Temp.

-40 to 85°C (-40 to 185°F)

Cold start of min. 100 VAC at -40°C

Storage Temp.

-40 to 85°C (-40 to 185°F)

Ambient Relative

Humidity.

5 to 95% (non-condensing)

Warranty

Warranty Period

5 years

Details

See www.moxa.com/warranty

Rack Mounting Instructions

1. Elevated Operating Ambient: If installed in a closed or multi-unit

rack assembly, the operating ambient temperature of the rack

environment may be greater than room ambient. Therefore,

consideration should be given to installing the equipment in an

environment compatible with the maximum ambient temperature

(Tma) specified by the manufacturer.

2. Reduced Air Flow: Installation of the equipment in a rack should

be such that the amount of air flow required for safe operation of the

equipment is not compromised.

3. Mechanical Loading: Mounting of the equipment on the rack

should be such that a hazardous condition is not achieved due to

uneven mechanical loading.

4. Circuit Overloading: Consideration should be given to the

connection of the equipment to the supply circuit and the effect that

overloading of the circuits might have on overcurrent protection and

supply wiring. Appropriate consideration of equipment nameplate

ratings should be used when addressing this concern.

5. Reliable Grounding: Reliable grounding of rack-mounted

equipment should be maintained. Particular attention should be

given to supply connections other than direct connections to the

branch circuit (e.g., use of power strips).

NOTE

The rackmount ears can be attached to the front or rear of the

PT-7528 switch.

Page 11

- 11 -

Restricted Access Locations

• This equipment is intended to be used in Restricted

Access Locations, such as a computer room, with

access limited to SERVICE PERSONAL or USERS

who have been instructed on how to handle the

metal chassis of equipment that is so hot that

special protection may be needed before touching it. The location

should only be accessible with a key or through a security identity

system.

• External metal parts of this equipment are extremely hot!! Before

touching the equipment, you must take special precautions to protect

your hands and body from serious injury.

Technical Support Contact Information

www.moxa.com/support

Moxa Americas:

Toll

-free: 1-888-669-2872

Tel:

1-714-528-6777

Fax:

1-714-528-6778

Moxa China (Shanghai office):

Tel:

+86-21-5258-9955

Fax:

+86-21-5258-5505

Moxa Europe:

Tel:

+49-89-3 70 03 99-0

Fax:

+49-89-3 70 03 99-99

Moxa Asia-Pacific:

Tel:

+886-2-8919-1230

Fax:

+886-2-8919-1231

Loading...

Loading...