Page 1

NE-4100 Series User’s Manual

Seventh Edition, September 2006

www.moxa.com/product

MOXA Technologies Co., Ltd.

Tel: +886-2-8919-1230

Fax: +886-2-8919-1231

Web:

MOXA Technical Support

Worldwide:

The Americas

www.moxa.com

support@moxa.com

support@usa.moxa.com

Page 2

NE-4100 Series User’s Manual

The software described in this manual is furnished under a license agreement and may be used only in

accordance with the terms of that agreement.

Copyright Notice

Copyright © 2006 MOXA Technologies Co., Ltd.

All rights reserved.

Reproduction without permi ssi on is pr ohibited.

Trademarks

MOXA is a registered trademark of The MOXA Group.

All other trademarks or registered marks in this manual belong to their respective manufacturers.

Disclaimer

Information in this document is subject to change without notice and does not represent a commitment on the

part of MOXA.

MOXA provides this document “as is,” without warranty of any kind, either expressed or implied, including, but

not limited to, its particular purpose. MOXA reserves the right to make improvements and/or changes to this

manual, or to the products and/or the programs described in this manual, at any time.

Information provided in this manual is intended to be accurate and reliable. However, MOXA assumes no

responsibility for its use or for any infringements on the rights of third parties that may result from its use.

This product may include unintentional technical or typographical errors. Changes are periodically made to th e

information herein to correct such errors, and these changes are incorporated into new editions of the

publication.

Page 3

Table of Contents

Chapter 1. Introduction ...............................................................................................1-1

Overview.............................................................................................................................. 1-2

Package Checklist................................................................................................................. 1-2

Product Features................................................................................................................... 1-2

Product Specifications.......................................................................................................... 1-3

Chapter 2. Panel Layout and Pin Assignments ........................................................2-1

NE-4100T, NE-4100-ST....................................................................................................... 2-2

Panel Layout................................................................................................................. 2-2

NE-4100-ST LED Indicators........................................................................................ 2-2

Pin Assignments........................................................................................................... 2-3

Block Diagrams............................................................................................................ 2-4

NE-4110S, NE-4110A, NE-4110-ST.................................................................................... 2-5

Panel Layout................................................................................................................. 2-5

NE-4110-ST LED Indicators........................................................................................ 2-6

Pin Assignments........................................................................................................... 2-6

Block Diagrams............................................................................................................ 2-8

NE-4120S, NE-4120A, NE-4120-ST................................................................................... 2-9

Panel Layout................................................................................................................. 2-9

NE-4120-ST LED Indicators...................................................................................... 2-10

Pin Assignments......................................................................................................... 2-11

Block Diagrams.......................................................................................................... 2-12

Chapter 3. Getting Started ..........................................................................................3-1

Wiring Precautions............................................................................................................... 3-2

Installing the NE-4100T onto the NE-4100-ST.................................................................... 3-3

Installing the NE-4110S, NE-4110A onto the NE-4110-ST................................................. 3-3

Installing the NE-4120S, NE-4120A onto the NE-4120-ST................................................. 3-4

Selecting the Serial Interface................................................................................................ 3-4

Circuit Pad for External Connection..................................................................................... 3-5

Connecting the Power........................................................................................................... 3-5

Connecting to the Network................................................................................................... 3-6

Connecting to a Serial Device.............................................................................................. 3-6

Digital I/O Channel Settings................................................................................................. 3-6

Digital Output LED Circuit Design.............................................................................. 3-8

Chapter 4. Choosing the Proper Operation Mode ....................................................4-1

Overview.............................................................................................................................. 4-2

TCP Server Mode................................................................................................................. 4-2

TCP Client Mode.................................................................................................................. 4-3

UDP Mode............................................................................................................................ 4-3

Real COM Mode .................................................................................................................. 4-4

Chapter 5. Initial IP Address Configuration...............................................................5-1

Static vs. Dynamic IP Address.............................................................................................. 5-2

Factory Default IP Address................................................................................................... 5-2

NE-4100 Series A dministration Suite................................................................................... 5-2

ARP...................................................................................................................................... 5-2

Telnet Console...................................................................................................................... 5-3

Serial Console (19200, n, 8, 1)............................................................................................. 5-5

Page 4

Chapter 6. Web Console Configuration.....................................................................6-1

Opening Your Browser ......................................................................................................... 6-2

Web Console Navigation...................................................................................................... 6-3

Basic Settings ....................................................................................................................... 6-4

Network Settings.................................................................................................................. 6-5

Serial Settings....................................................................................................................... 6-8

Operating Settings.............................................................................................................. 6-10

TCP Server Mode....................................................................................................... 6-10

Real COM Mode ........................................................................................................ 6-12

TCP Client Mode........................................................................................................ 6-15

UDP Mode.................................................................................................................. 6-18

Accessible IP Settings.........................................................................................................6-20

Auto W a rning Settings........................................................................................................ 6-21

E-mail and SNMP Trap.............................................................................................. 6-21

Event Type.................................................................................................................. 6-22

Digital IO............................................................................................................................ 6-23

DIO Settings............................................................................................................... 6-23

DIO Monitor............................................................................................................... 6-24

Serial Command Mode....................................................................................................... 6-24

Change Password................................................................................................................ 6-24

Load Factory Defaults........................................................................................................ 6-25

Save/Restart........................................................................................................................ 6-25

Chapter 7. Network Enabler Administrator ...............................................................7-1

Overview.............................................................................................................................. 7-2

Installing Network Enabler Administrator............................................................................ 7-2

Network Enabler Administrator Navigation......................................................................... 7-4

Configuration Functions....................................................................................................... 7-5

Broadcast Search .......................................................................................................... 7-5

Specify by IP Address .................................................................................................. 7-6

Locate........................................................................................................................... 7-6

Unlock .......................................................................................................................... 7-7

Configure...................................................................................................................... 7-9

Upgrade Firmware ...................................................................................................... 7-11

Import and Export Configuration ............................................................................... 7-12

Monitor Functions.............................................................................................................. 7-13

Add and Remove Target............................................................................................. 7-13

Load Configured COM Port....................................................................................... 7-14

Settings....................................................................................................................... 7-15

Go and Stop................................................................................................................ 7-16

Port Monitor Functions....................................................................................................... 7-18

COM Mapping Functions................................................................................................... 7-18

Add and Remove Target............................................................................................. 7-18

COM Settings............................................................................................................. 7-19

Enable and Disable..................................................................................................... 7-21

Apply and Discard Change ......................................................................................... 7-21

Import and Export COM Mapping............................................................................. 7-21

IP Address Report Functions .............................................................................................. 7-21

Chapter 8. Linux and UNIX Configuration .................................................................8-1

Linux Real TTY Drivers....................................................................................................... 8-2

Basic Procedures........................................................................................................... 8-2

Page 5

Hardware Setup ............................................................................................................ 8-2

Installing Linux Real TTY Driver Files .......................................................................8-2

Mapping TTY Ports...................................................................................................... 8-3

Removing Mapped TTY Ports......................................................................................8-3

Removing Linux Driver Files....................................................................................... 8-4

UNIX Fixed TTY Driver...................................................................................................... 8-4

Installing the UNIX Driver........................................................................................... 8-4

Configuring the UNIX Driver ...................................................................................... 8-5

Chapter 9. Serial Command Mode..............................................................................9-1

Overview.............................................................................................................................. 9-2

Serial Command Format and Command Set........................................................................ 9-2

Command Structure...................................................................................................... 9-2

Reply Structure............................................................................................................. 9-3

OP Codes and Parameters............................................................................................. 9-3

Operation Flow Chart........................................................................................................... 9-9

Configuring Trigger Type..................................................................................................... 9-9

Network Enabler Administrator..................................................................................9-10

Telnet Console............................................................................................................ 9-12

Web Console ..............................................................................................................9-13

Serial Console............................................................................................................. 9-13

Entering Serial Command Mode........................................................................................ 9-14

Trigger Type............................................................................................................... 9-14

Serial Port Parameters................................................................................................. 9-14

Comments................................................................................................................... 9-15

Exiting Serial Command Mode.......................................................................................... 9-15

Determining the Active Mode ............................................................................................9-16

Serial Command Examples ................................................................................................ 9-17

Example 1: Get Model Name Using HW Trigger...................................................... 9-17

Example 2: Change IP Address Using HW Trigger................................................... 9-17

Example 3: Get IP Mode Using SW Trigger.............................................................. 9-18

Example 4: Change TCP Port Number Using SW Trigger......................................... 9-18

Appendix A. Well Known Port Numbers ......................................................................A-1

Appendix B. NECI Library..............................................................................................B-1

Appendix C. Auto IP Report Protocol........................................................................... C-1

IP Address Report Structure .................................................................................................C-2

Hardware and AP ID.............................................................................................................C-2

Example................................................................................................................................C-2

Appendix D. DIO Commands ........................................................................................D-1

Overview............................................................................................................................. D-1

C Code Example .......................................................................................................... D-1

Read Single DIO.................................................................................................................. D-2

Command .................................................................................................................... D-2

Response...................................................................................................................... D-2

C Code Example .......................................................................................................... D-2

Write Single DIO................................................................................................................. D-3

Command .................................................................................................................... D-3

Response...................................................................................................................... D-3

C Code Example:......................................................................................................... D-3

Page 6

Read Multiple DIO.............................................................................................................. D-4

Command .................................................................................................................... D-4

Response...................................................................................................................... D-4

C Code Example:......................................................................................................... D-5

Write Multiple DIO............................................................................................................. D-5

Command .................................................................................................................... D-5

Response...................................................................................................................... D-6

C Code Example:......................................................................................................... D-7

Appendix E. SNMP Agent with MIB II & RS-232 Like Group ...................................... E-1

Appendix F. Service Information...................................................................................F-1

MOXA Internet Services......................................................................................................F-2

Technical Support E-mail Address...............................................................................F-2

Website for Product Information.................................................................................. F-2

Problem Report Form........................................................................................................... F-3

Product Return Procedure.....................................................................................................F-4

Page 7

1

1

Chapter 1. Introduction

The NE-4100 Series embedded device server is a line of compact modules that act as network

enablers. NE-4100 Series modules can be installed in or on a serial device to connect it to an

Ethernet network, allowing you to gain network access to any electronic device that has a serial

port. All NE-4100 Series modules come equipped with built-in TCP/IP protocols for fast

integration, saving you time and energy on programming.

The following topics are covered in this chapter.

Overview

Package Checklist

Product Features

Product Specifications

Page 8

NE-4100 Series User’s Manual Introduction

Overview

NE-4100 Series modules are a type of embedded device server or network enabler. An NE-4100

Series module may be installed in or attached to a serial device to make it accessible from a

network. There are three types of module offered: drop-in (NE-4100T), RJ45 (NE-4110S,

NE-4110A), and pin header (NE-4120S, NE-4120A). The last letter of the model number indicates

the serial signal supported by the module. T indicates a TTL connector, S indicates an RS-232

connector, and A indicates an RS-422/485 connector. Each module includes 4 digital input/output

channels, also known as DIO channels or GPIO channels.

NE-4100 Series modules are very compact—less than half the size of a credit card. At such a small

size, they can be installed into almost any serial device. Each NE-4100 Series module also comes

with a built-in TCP/IP stack for fast integration. Engineers can spend less time on TCP/IP

programming, and focus more on developing other major features, thereby shortening your

product’s time to market. Modules may be easily configured with a user-friendly Windows utility,

web browser, serial console, or Telnet console. In addition, a Windows-based NECI (Network

Enabler Configuration Interface) library is available to help you develop your own Windows

utilities.

Each module comes with a complete development kit containing an evaluation board, documents,

sample code, cables, and accessories.

Package Checklist

z 1 NE-4100 Series module

z 1 NE-4100-ST (the evaluation board )

z NE-4100 Series documentation & software CD

z 1 universal power adaptor

z 2 power cords

z 1 null modem cable

z 1 cross-over Ethernet cable

z Warranty statement

z Quick Installation Guide

NOTE: Please notify your sales representative if any of the above items is missing or damaged.

Product Features

All NE-4100 Series modules have the following features:

z 10/100 Mbps auto-sensing Ethernet interface

z Compact size and ready-to-go design (NE-4100T measures 45 × 36 mm, NE-4110/4120

measure 57 × 40 mm)

z Built-in TCP/IP firmware for fast integration

z TCP Server, TCP Client, UDP, Real COM driver operation modes

z Low power consumption (1.5W)

z Multiple user-friendly configuration options

z 4 dedicated digital input/output (DIO) channels for user applications

z Software reset

1-2

Page 9

NE-4100 Series User’s Manual Introduction

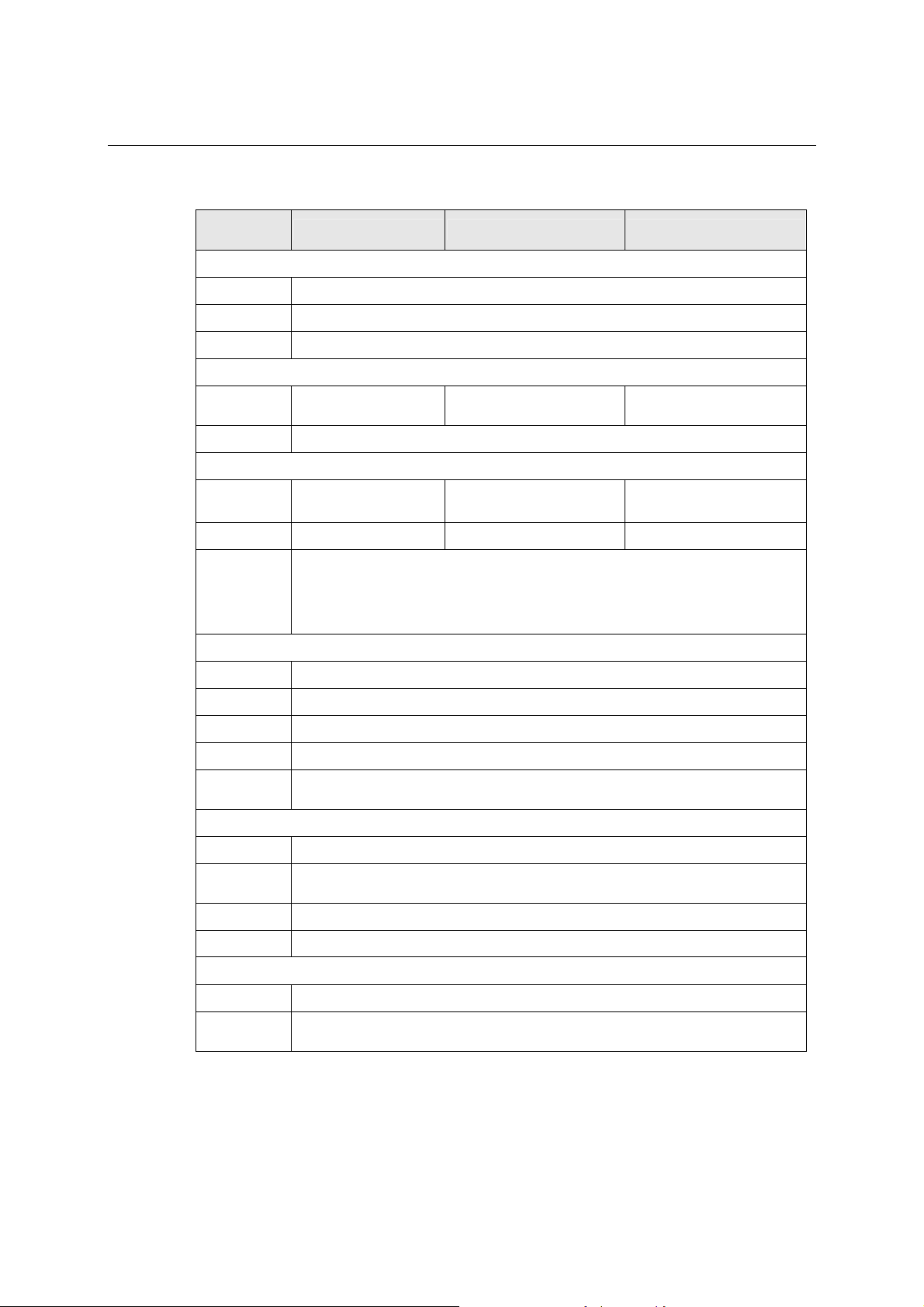

Product Specifications

System

CPU 16-bit MCU

RAM 1 MB

Flash 2 MB

LAN

Ethernet

Protection built-in transformer with 1.5 KV magnetic isolation

Serial

Interface TTL

Port Type pin header RJ45 pin header

Signals

Serial Communication Parameters

NE-4100T NE-4110S, NE-4110A NE-4120S, NE-4120A

10/100 Mbps, pin

headers

TTL, RS-232: TxD, RxD, RTS, CTS, DTR, DSR, DCD, GND

RS-422: TxD+, TxD-, RxD+, RxD-, GND

RS-485 (4-wire): TxD+, TxD-, RxD+, RxD-, GND

10/100 Mbps, RJ45 10/100 Mbps, pin headers

RS-232 (NE-4110S)

RS-422/485 (NE-4110A)

RS-485 (2-wire): Data+, Data-, GND

RS-232 (NE-4120S)

RS-422/485 (NE-4120A)

Parity None, Even, Odd, Space, Mark

Data Bits 5, 6, 7, 8

Stop Bit 1, 1.5, 2

Flow Control RTS/CTS, XON/XOFF

Transmission

Speed

Software Features

Protocols ICMP, ARP, IP, TCP, UDP, DHCP, HTTP, SNMP, SMTP

Operating

Mode

Utilities NE utility for Windows 95/98/ME/NT/2000/XP/2003(x64)/XP(x64)

Configuration web browser, serial console, Telnet console, or Windows utility

Power Requirements

Power Input 5 VDC

Power

Consumption

50 bps to 115.2 Kbps for PCB V1.x, 110 bps to 230.4 Kbps for PCB V2.x

TCP Server, TCP Client, UDP, Real COM mode

290 mA @ 5 VDC (Max.)

1-3

Page 10

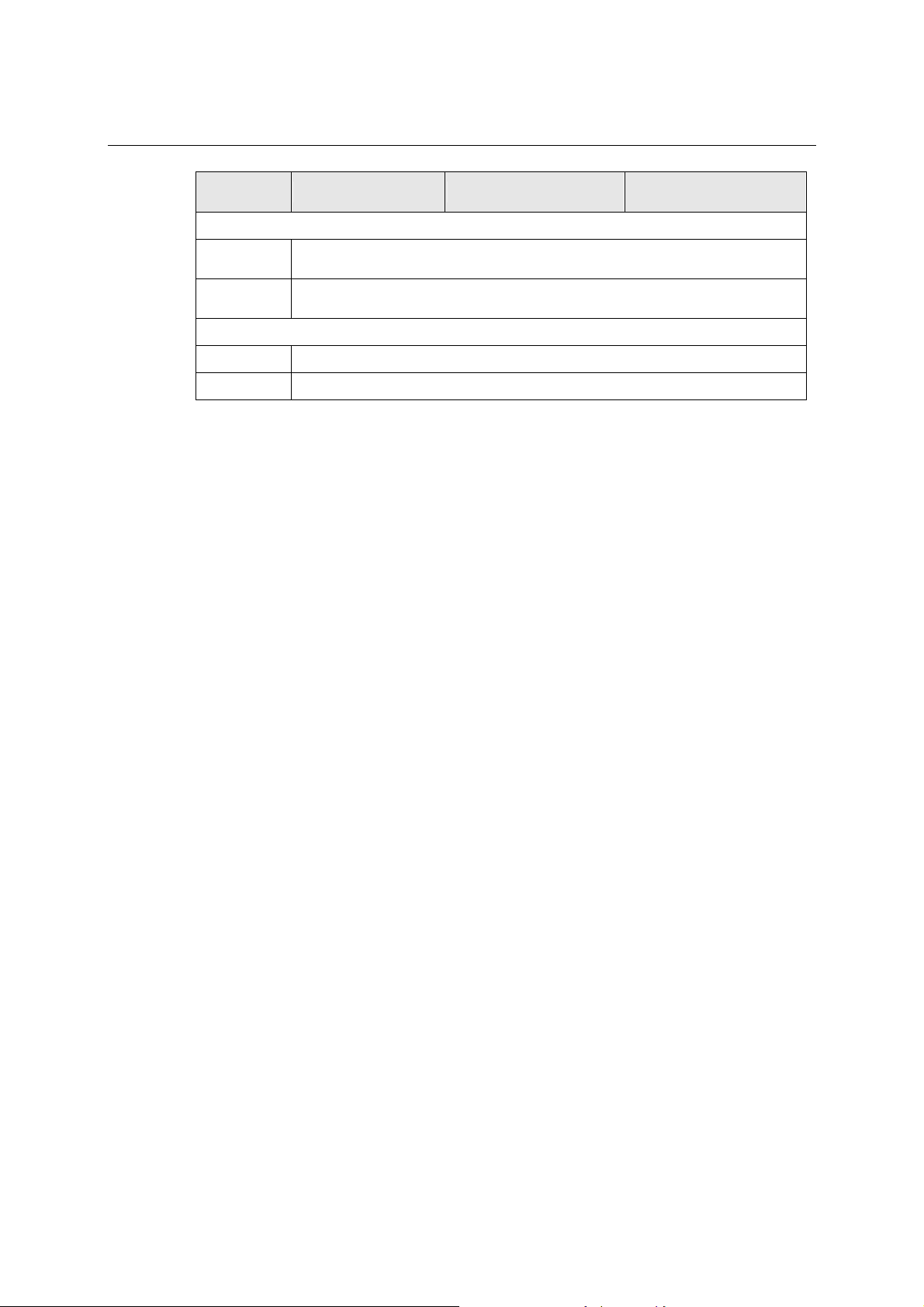

NE-4100 Series User’s Manual Introduction

Environmental

Operating

Temperature

Storage

Temperature

Regulatory Approvals

EMC FCC Class A, CE Class A

Warranty 5 years

NE-4100T NE-4110S, NE-4110A NE-4120S, NE-4120A

0°C to 70°C (32°F to 158°F), 5% to 95%RH

-20°C to 85°C (-4°F to 185°F), 5% to 95%RH

1-4

Page 11

2

2

Chapter 2. Panel Layout and Pin Assignments

This chapter includes information about the panel layouts and p in assignments for NE-4100 Series

modules. The layouts and reference circuit diagrams for the evaluation boards are also covered.

The evaluation boards are used for evaluation and development of applications for NE-4100 Series

modules.

The following topics are covered in this chapter:

NE-4100T, NE-4100-ST

¾ Panel Layout

¾ NE-4100-ST LED Indicators

¾ Pin Assignments

¾ Block Diagrams

NE-4110S, NE-4110A, NE-4110-ST

¾ Panel Layout

¾ NE-4110-ST LED Indicators

¾ Pin Assignments

¾ Block Diagrams

NE-4120S, NE-4120A, NE-4120-ST

¾ Panel Layout

¾ NE-4120-ST LED Indicators

¾ Pin Assignments

¾ Block Diagrams

Page 12

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

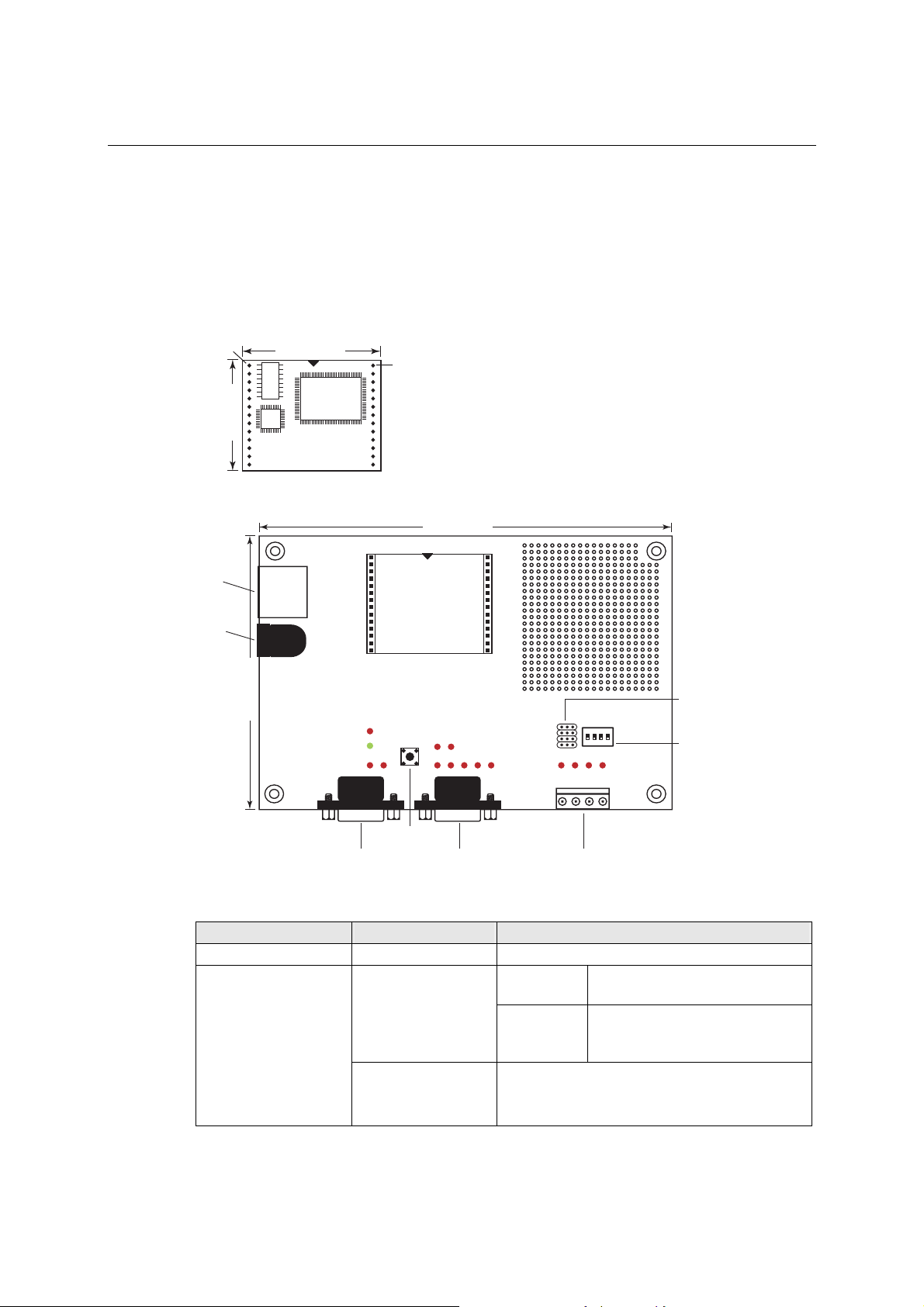

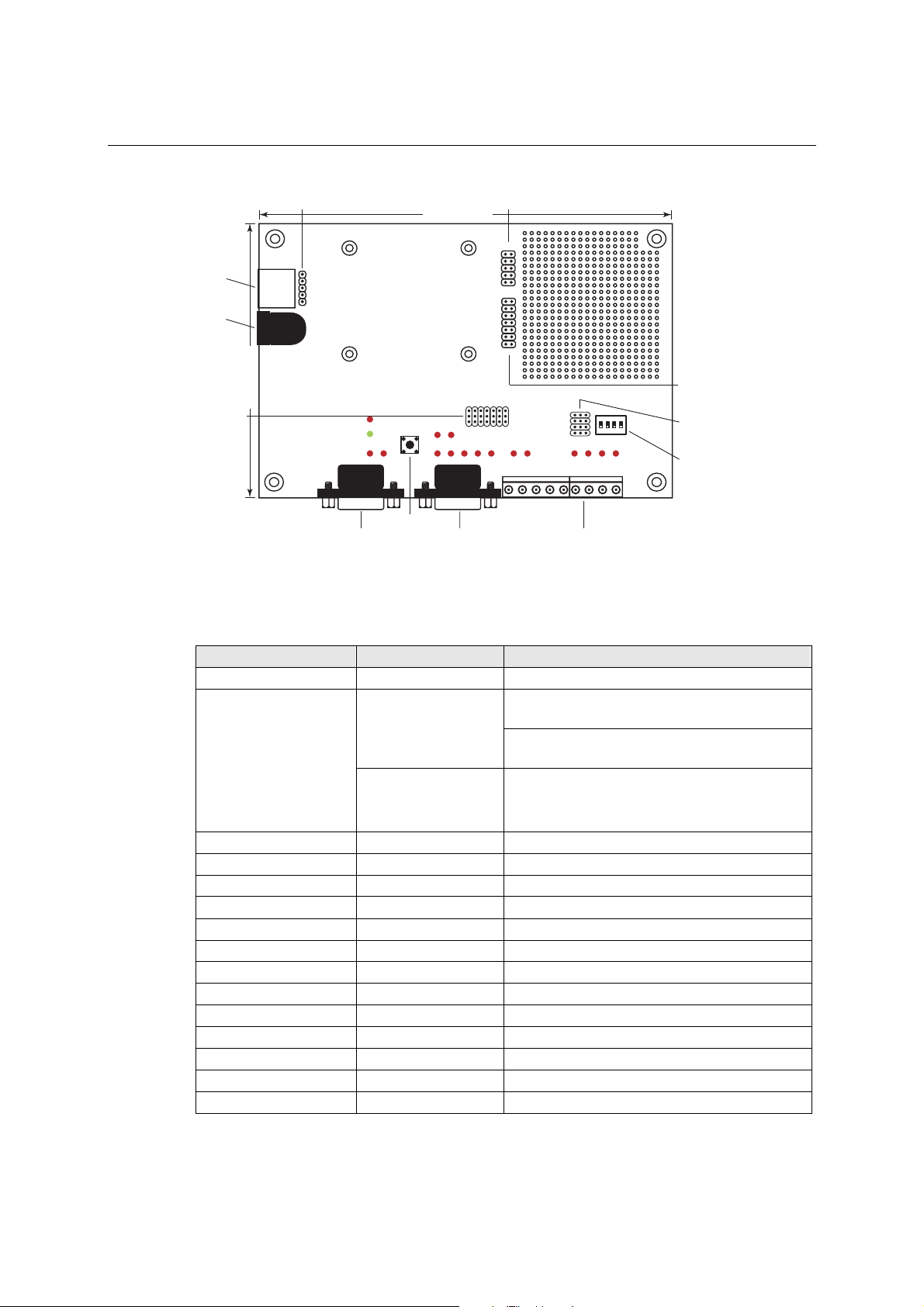

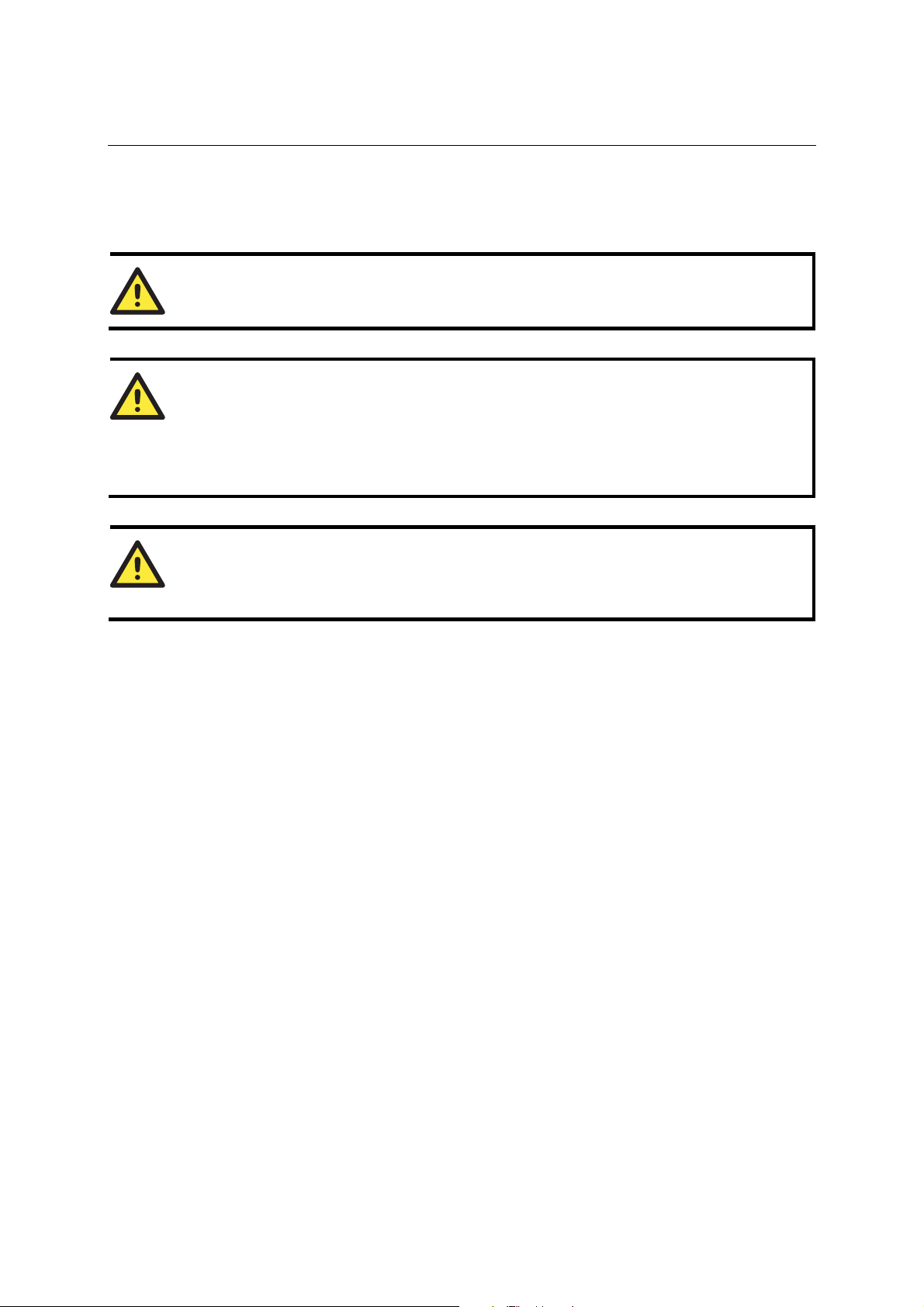

N

NE-4100T, NE-4100-ST

The NE-4100T is a TTL-to-Et her net dr op -in module. It measures 45 × 36 mm, and has a

dual-in-line, 26-pin design, making it easy to integrate with your serial devices. The NE-4100-ST

is the evaluation board for testing NE-4100T modules and developing your own applications.

Panel Layout

NE-4100T

Pin #1

36.00 mm

NE-4100-ST

Ethernet

Port

45.00 mm

Pin #14

149.00 mm

Power

Jack

99.00 mm

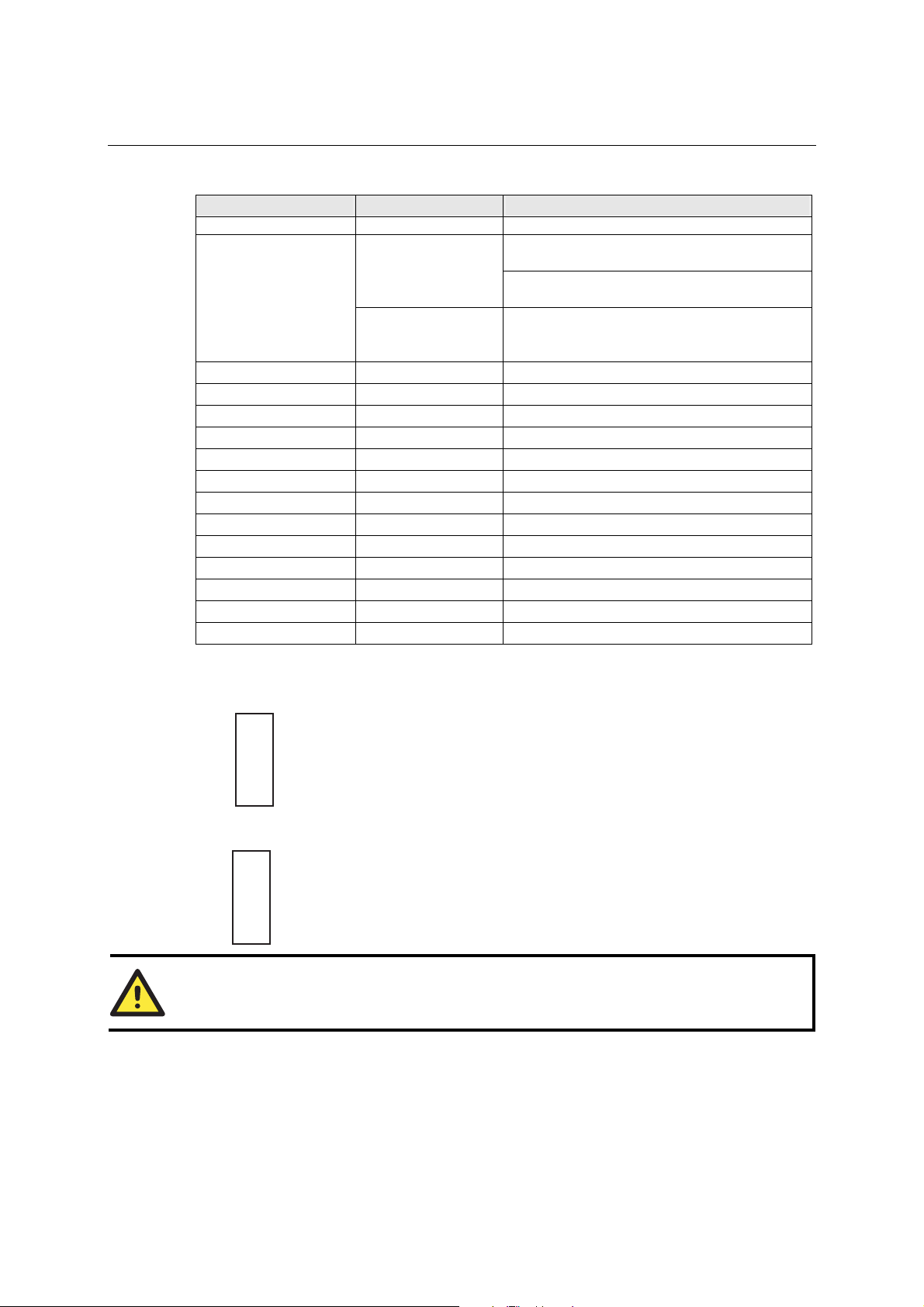

NE-4100-ST LED Indicators

LED Name LED Color LED Function

Power red Indicates the power is on.

Ready

Reset Button

Serial Port (RS-232)Debug Serial COM Port DI/O Terminal Block

Steady on:

green

Blinking:

y Power is off, or power error condition exists.

steady off

y IP address cannot be found in DHCP mode.

DI/O Selector

Jumpers

ON

DIP

1234

DI/O Signal

Setting

Switches

Power is on and NE-4100T is

functioning normally.

NE-4100T has been located by

etwork Enabler’s Administrator’s

Location function.

y IP address conflict.

2-2

Page 13

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

LED Name LED Color LED Function

DIO0 red Indicates that DIO is in “low” (0) status.

DIO1 red Indicates that DIO is in “low” (0) status.

DIO2 red Indicates that DIO is in “low” (0) status.

DIO3 red Indicates that DIO is in “low” (0) status.

TXD0 red Indicates that TXD0 has a signal.

RXD0 red Indicates that RXD0 has a signal.

DTR0 red Indicates that DTR0 has a signal.

CTS0 red Indicates that CTS0 has a signal.

DSR0 red Indicates that DSR0 has a signal.

DCD0 red Indicates that DCD0 has a signal.

RTS0 red Indicates that RTS0 has a signal.

TXD1 red Indicates that TXD1 has a signal.

RXD1 red Indicates that RXD1 has a signal.

Pin Assignments

NE-4100T

Pin Signal Pin Signal

1 ETx+ 14 PIO0

2 ETx- 15 PIO1

3 ERx+ 16 PIO2

4 ERx- 17 PIO3

5 10M LED 18 100M LED

6 TXD 19 DCD

7 RXD 20 DSR

8 RTS 21 DTR

9 CTS 22 GND

10 Reset 23 Ready LED

11 GND 24 +5V

12 GND 25 +5V

13 TXD1* 26 RXD1*

*Pins 13 and 26 control the NE-4100-ST Debug Serial COM Port’s TXD and RXD signals. The

location of the Debug Serial COM Port is shown on the pr evi o us page. This port is not needed

during normal operation. However, if the network fails and you need to configu re your NE-4100T,

you may connect the Debug Serial COM Port, and then use the serial console to config ure your

NE-4100T.

ATTENTION

NE-4100T Ethernet Signals: ETx+, ETx-, ERx+, ERx Serial Signals: TXD, RXD, RTS, CTS, DCD, DSR, DTR

LED Controls: 10M LED, 100M LED, Ready LED

2-3

Page 14

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

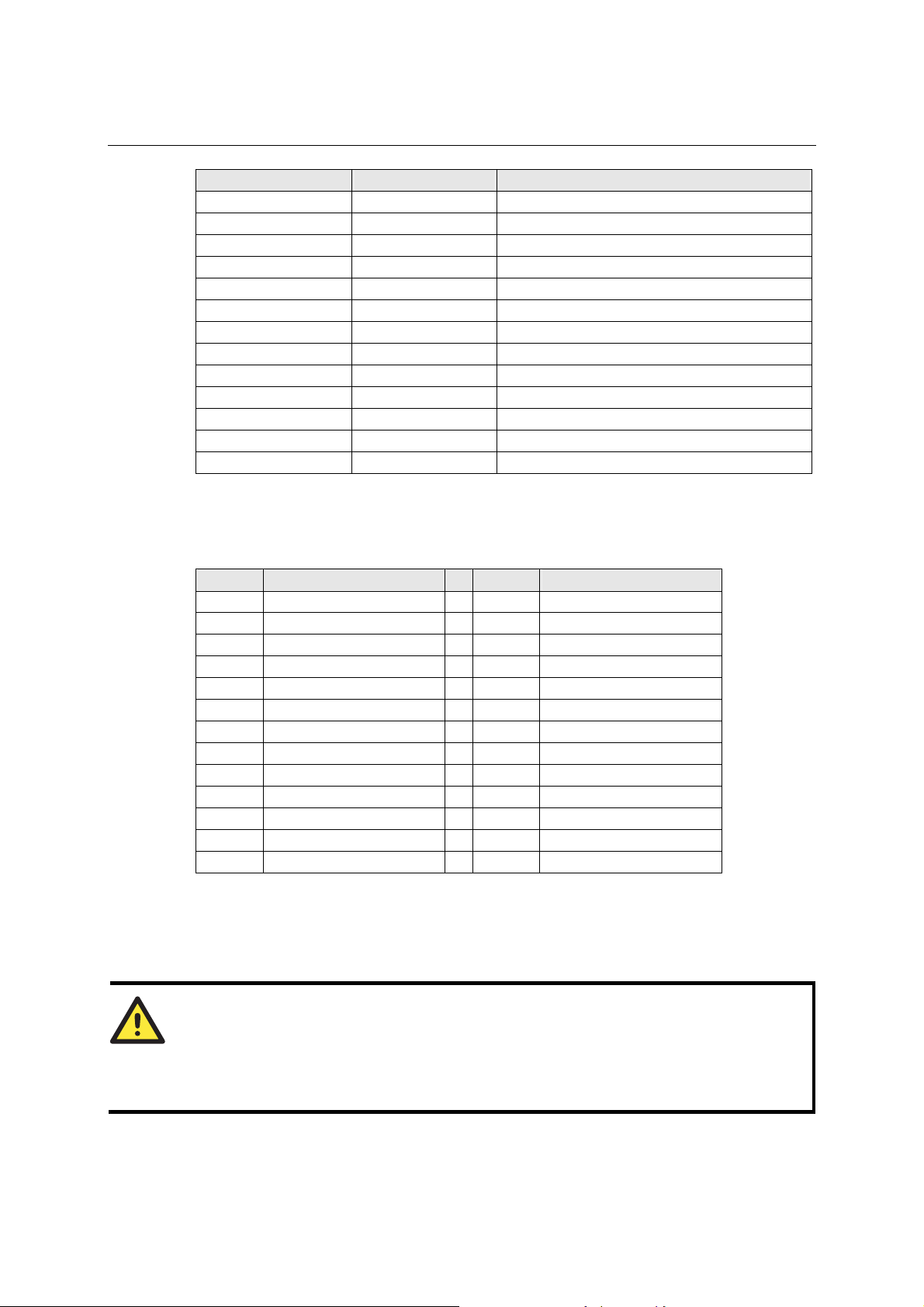

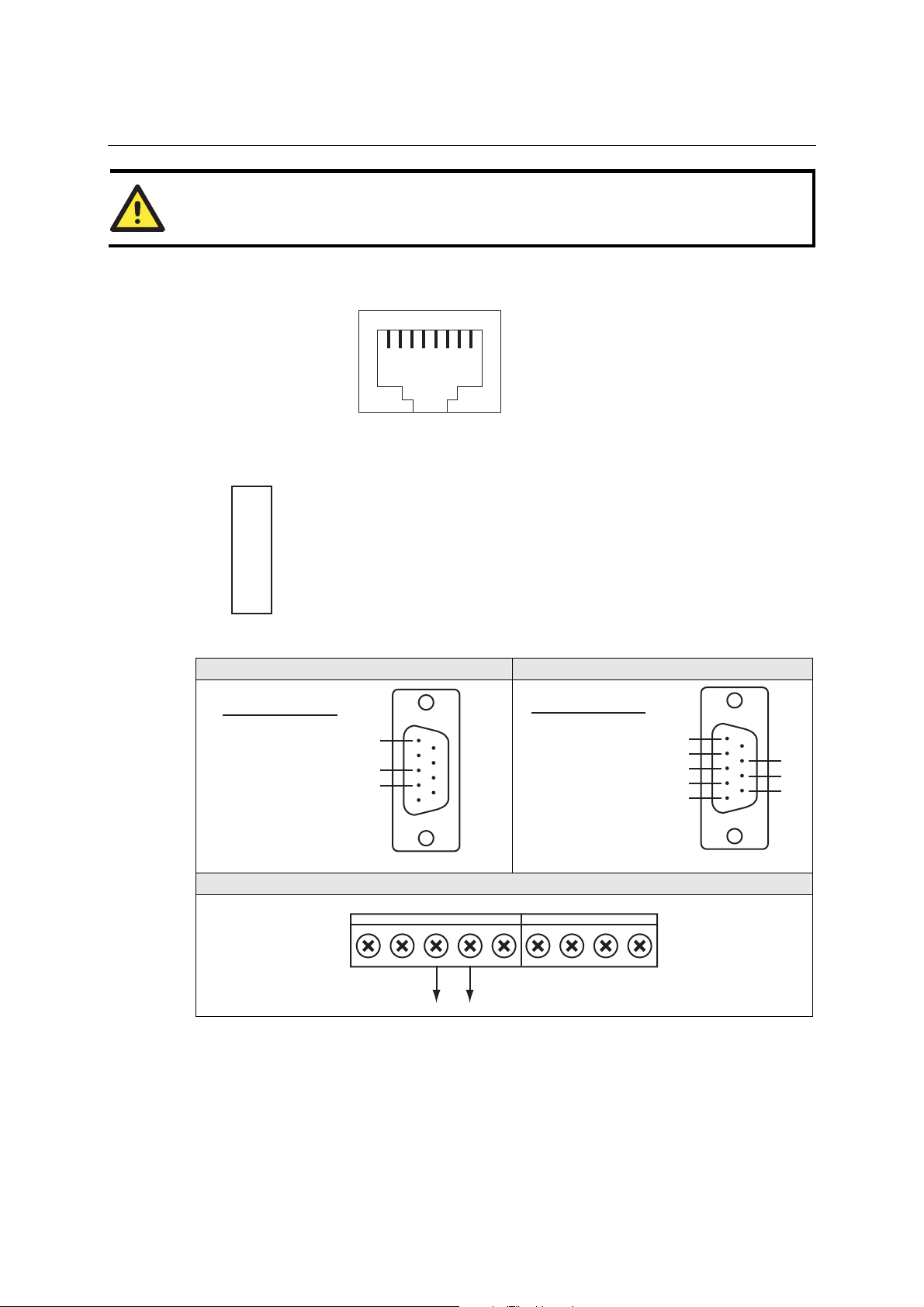

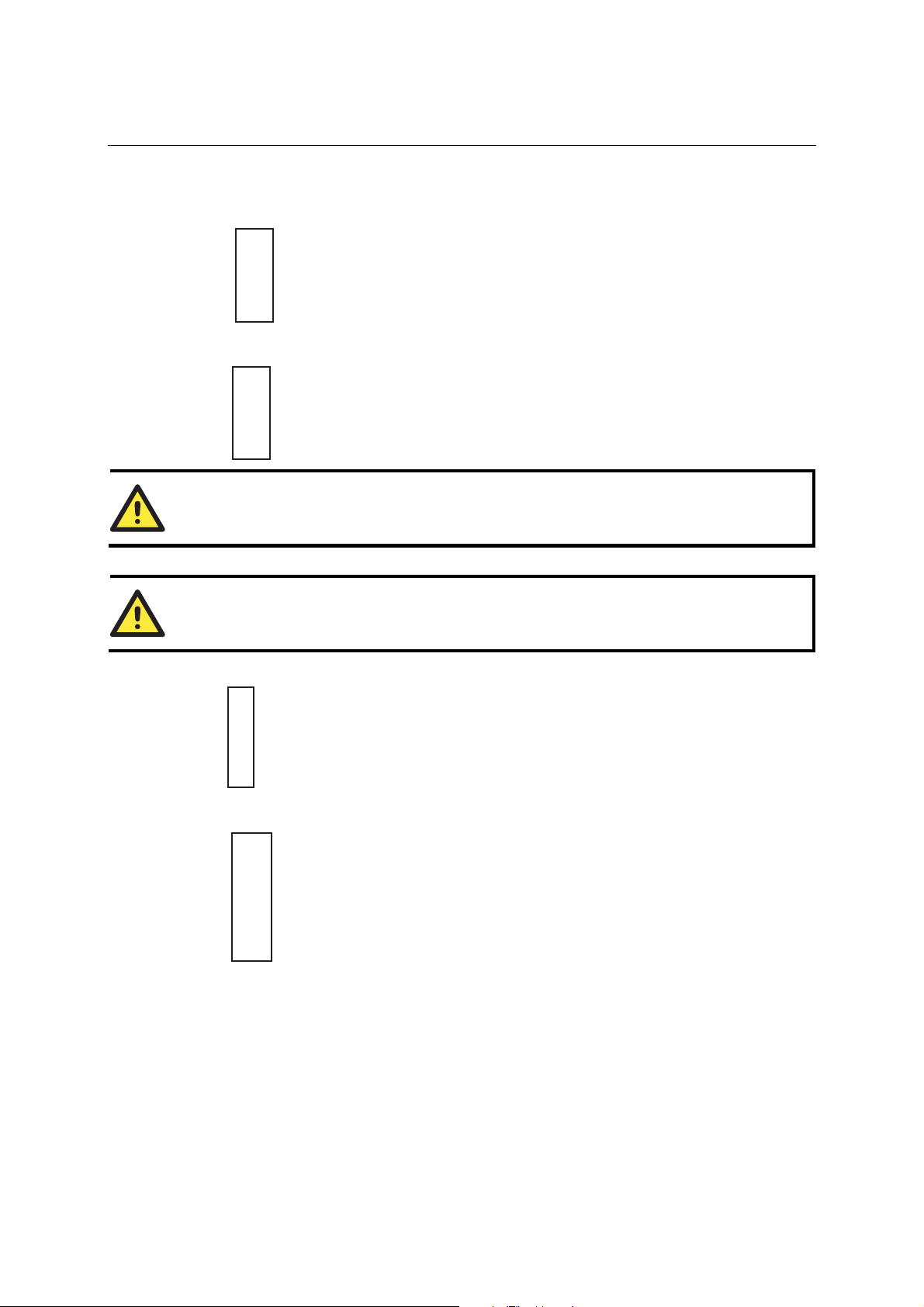

NE-4100-ST Serial Port Pinouts (DB9 Male)

Debug Serial Port for Serial Console RS-232 Port for Connecting Serial Devices

Pin

Signal

Pin

Signal

2

3

5

Block Diagrams

+5 VDC

10/100M

Ethernet PHY

RXD

TXD

GND

5

3

2

DIO Terminal Block

D0 D1 D2 D3

1 MB SDRAM 2 MB Flash

80186 CPU

UART0

MAC

1

2

3

4

5

6

7

8

TTL Serial data

(Tx, Rx, RTS, CTS,

DTR, DSR, DCD)

DCD

RXD

TXD

DTR

GND

DSR

RTS

CTS

Customer's Device

UART

5

4

3

2

1

8

7

6

Transformer

1.5 KV Isolation

RJ45

10M

LED

GPIO Port

PIO0 - PIO3

100M

LED

UART1

Line

Driver

Tx Rx

Serial Console

interface

2-4

Ready

LED

Page 15

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

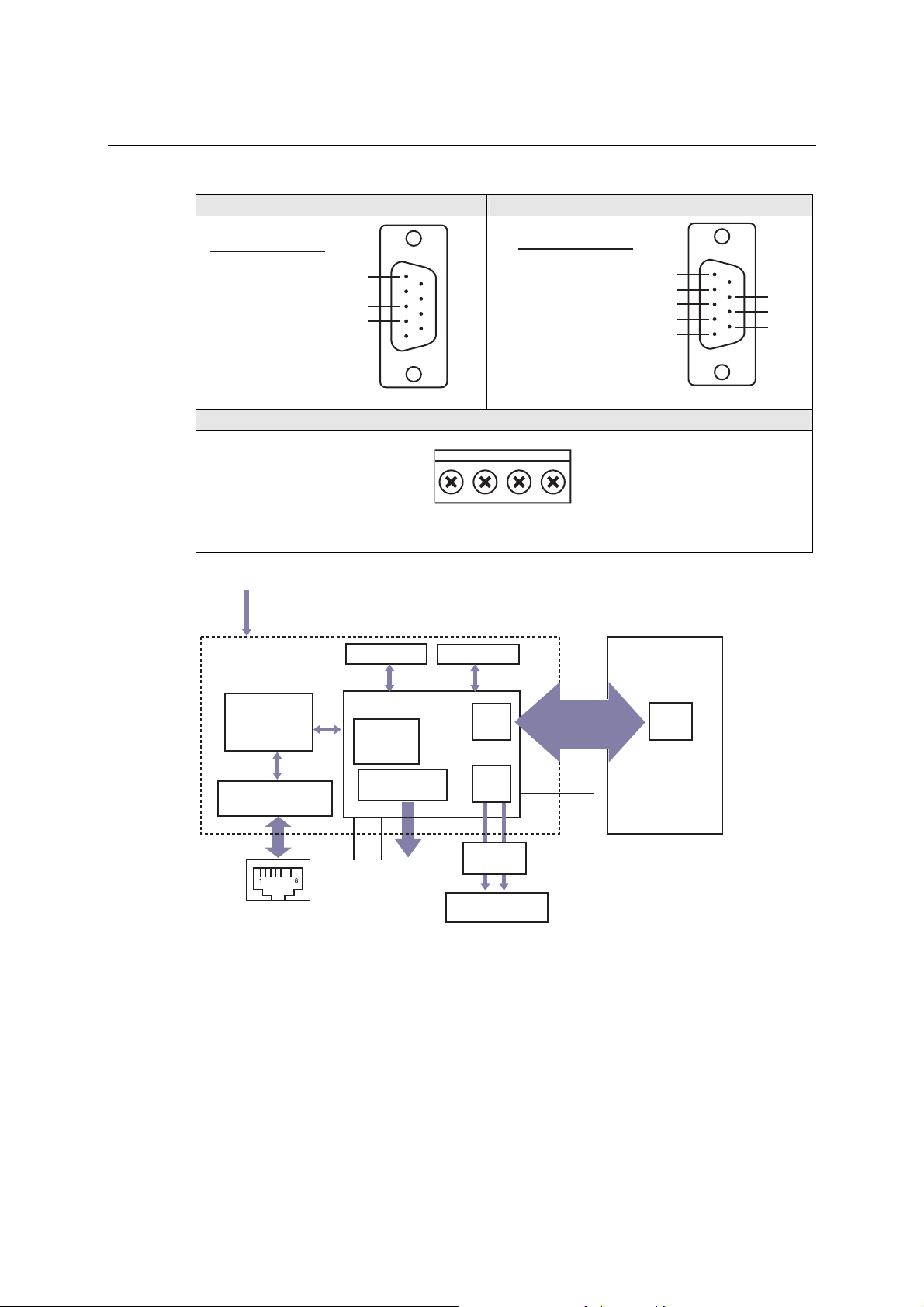

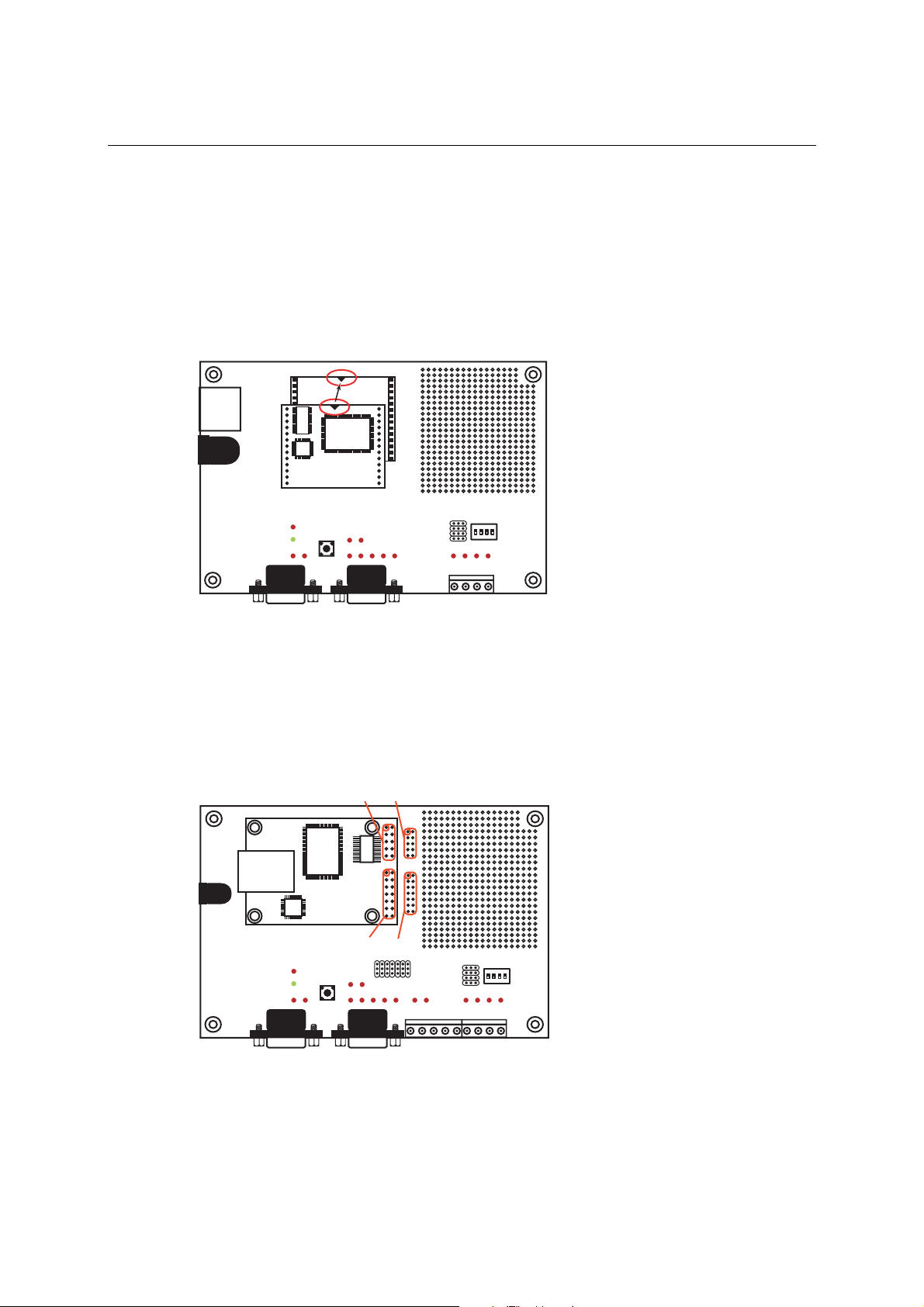

NE-4110S, NE-4110A, NE-4110-ST

The NE-4110S is an RS-232-to-Ethernet server, and the NE-4110A is an RS-422/485-to-Ethernet

server. Both models use an RJ45 connection and measure 57 × 40 mm. The NE-4110-ST is the

evaluation board for testing NE-4100S and NE-4110A modules and developing your own

applications.

Panel Layout

NE-4110S

57.00 mm

40.00 mm

NE-4110A

57.00 mm

JP2

40.00 mm

1

2

J1

9

10

1

2

J2

13

14

1

2

J1

9

10

1

2

J2

13

14

NE-4110-ST

149.00 mm

12

Jumper 9 (J9)

Power

Jack

99.00 mm

Interface

Selector

Jumpers

Reset Button

Serial Port (RS-232)Debug Serial COM Port DI/O Terminal Block

* JP2 is used to select RS-232 or RS-422/485 operation. Use the RS-232 position for RS-232

operation (NE-4110S); use the RS-485 position for RS-422 or RS-485 operation (NE-4110A).

910

12

13 14

ON

DIP

1234

Jumper 10

(J10)

DI/O Selector

Jumpers

DI/O Signal

Setting

Switches

2-5

Page 16

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

NE-4110-ST LED Indicators

LED Name LED Color LED Function

Power red Indicates the power is on.

Steady on: Power is on and NE-4110 is

green

Ready

steady off

DIO0 red Indicates that DIO is in “low” (0) status.

DIO1 red Indicates that DIO is in “low” (0) status.

DIO2 red Indicates that DIO is in “low” (0) status.

DIO3 red Indicates that DIO is in “low” (0) status.

TXD0 red Indicates that TXD0 has a signal.

RXD0 red Indicates that RXD0 has a signal.

DTR0 red Indicates that DTR0 has a signal.

CTS0 red Indicates that CTS0 has a signal.

DSR0 red Indicates that DSR0 has a signal.

DCD0 red Indicates that DCD0 has a signal.

RTS0 red Indicates that RTS0 has a signal.

TXD1 red Indicates that TXD1 has a signal.

RXD1 red Indicates that RXD1 has a signal.

functioning normally.

Blinking: NE-4110 has been located by

Network Enabler Administrator.

y Power is off, or power error condition exists.

y IP address cannot be found in DHCP mode.

y IP address conflict.

Pin Assignments

NE-4110S Serial Header Pinouts (J1)

9

10

NC

7

8

CTS0

5

6

DSR0

3

4

DTR0

1

2

RxD0

NE-4110A Serial Header Pinouts (J1)

9

10

NC

7

8

NC

5

6

NC

3

4

RxD-

1

2

TxD+

ATTENTION

The symbols “B” and “A” are often used in place of “+” and “-”, respectively.

NC

RTS0

GND

TxD0

DCD0

NC

NC

GND

RxD+

TxD-

2-6

Page 17

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

ATTENTION

For the 2-wire RS-485 interface, pin 3 is for Data+ (B) and pin 4 is for Data- (A).

NE-4110S and NE-4110A Ethernet Port Pinouts

Pin Signal

1

2

3

6

Tx+

TxRx+

Rx-

1

RJ45 Port

8

NE-4110S and NE-4110A DIO and LED Header Pinouts (J2)

14

10

8

6

4

2

VCC(+5V)

111312

VCC(+5V)

10M_LED

9

100M_LED

7

Ready_LED

5

Reset

3

RxD1

1

GND

GND

DIO0

DIO1

DIO2

DIO3

TxD1

NE-4110-ST Pinouts

Debug Serial Port for Serial Console RS-232 Port for Serial Devices

Pin

2

3

5

Signal

RXD

TXD

GND

5

3

2

Serial and DIO Terminal Blocks

TXD+ D0 D1 D2 D3TXD- RXD+ RXD-

SGND

Pin

1

2

3

4

5

6

7

8

Signal

DCD

RXD

TXD

DTR

GND

DSR

RTS

CTS

5

4

3

2

1

8

7

6

Data+ Data-

2-7

Page 18

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

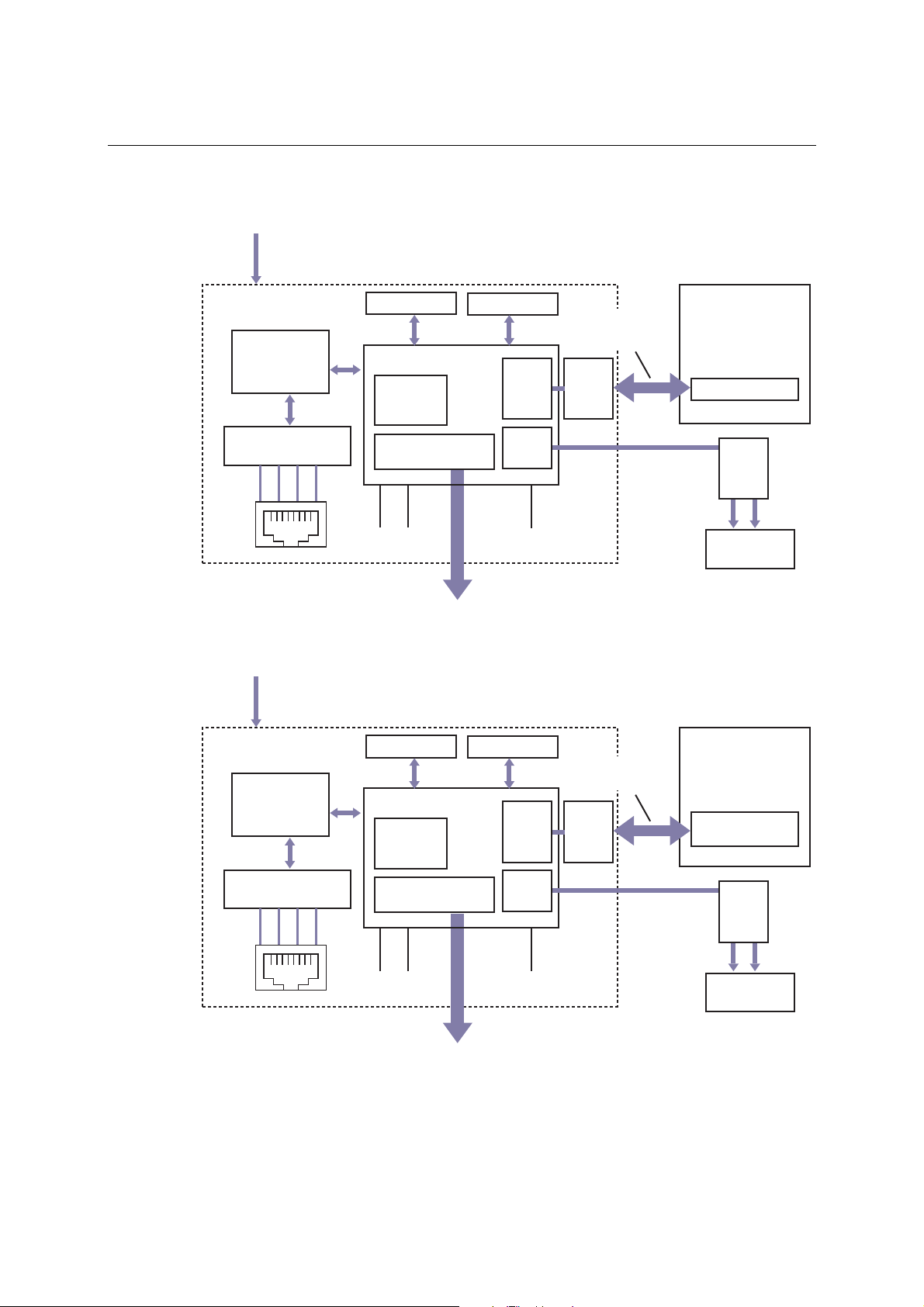

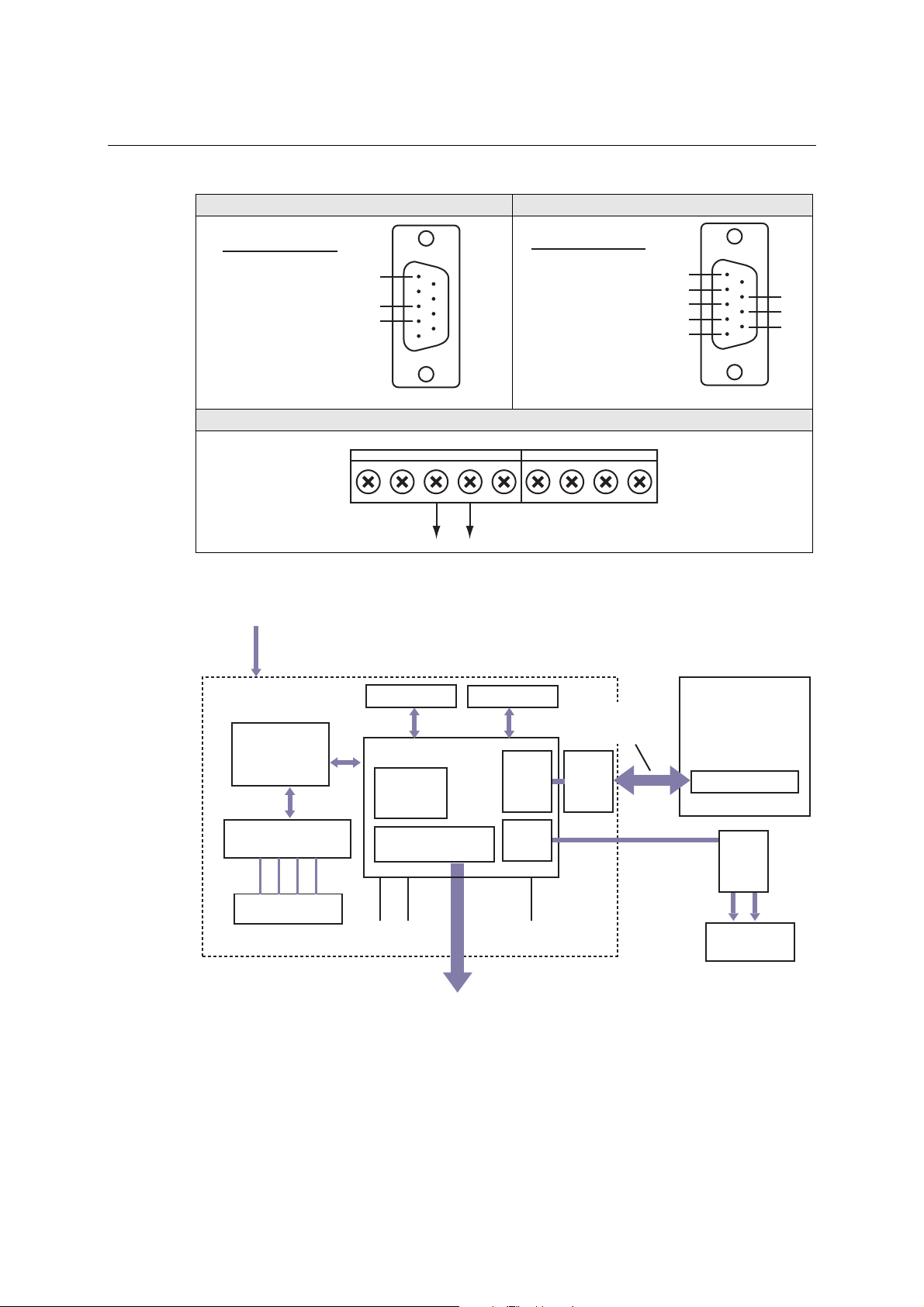

Block Diagrams

NE-4110S Block Diagram

+5 VDC

1 MB SDRAM

10/100 M

Ethernet PHY

Transformer

1.5 KV isolation

Tx+ Tx- Rx-Rx+

18

RJ45

10M

LED

NE-4110A Block Diagram

+5 VDC

1 MB SDRAM

10/100 M

Ethernet PHY

80186 CPU

MAC

GPIO Port

PIO0 - PIO3

100M

LED

80186 CPU

MAC

2 MB Flash

UART0

UART1

Ready

LED

2 MB Flash

UART0

Serial data

(Tx, Rx, RTS, CTS,

DTR, DSR, DCD)

Line

Driver

RS-422/485

Signal

Line

Driver

Customer's device

RS-232 interface

Line

Driver

Tx Rx

Serial console

interface

Customer's device

RS-422/485

interface

Transformer

1.5 KV isolation

Tx+ Tx- Rx-Rx+

18

RJ45

10M

LED

GPIO Port

PIO0 - PIO3

100M

LED

2-8

UART1

Ready

LED

Line

Driver

Tx Rx

Serial console

interface

Page 19

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

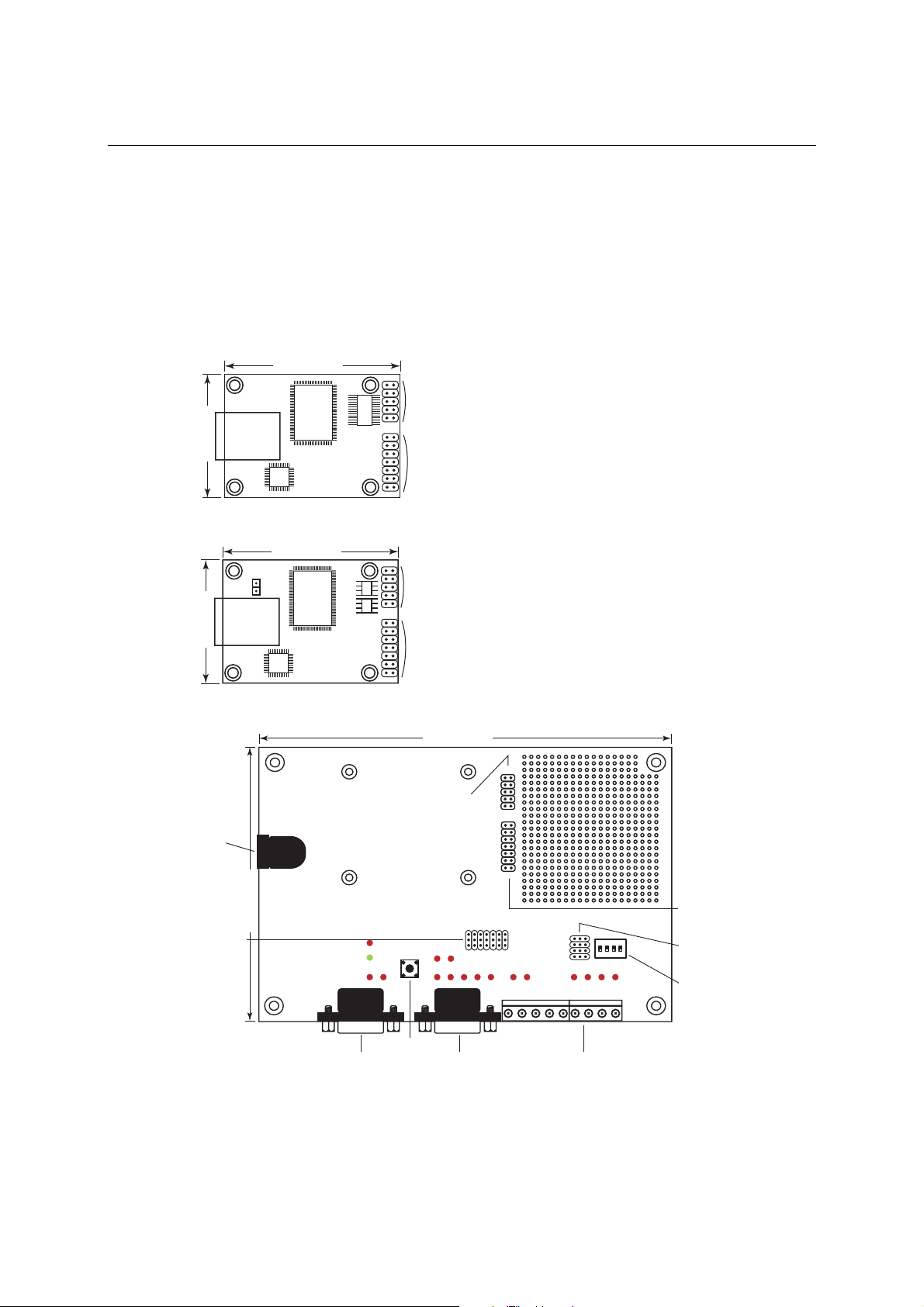

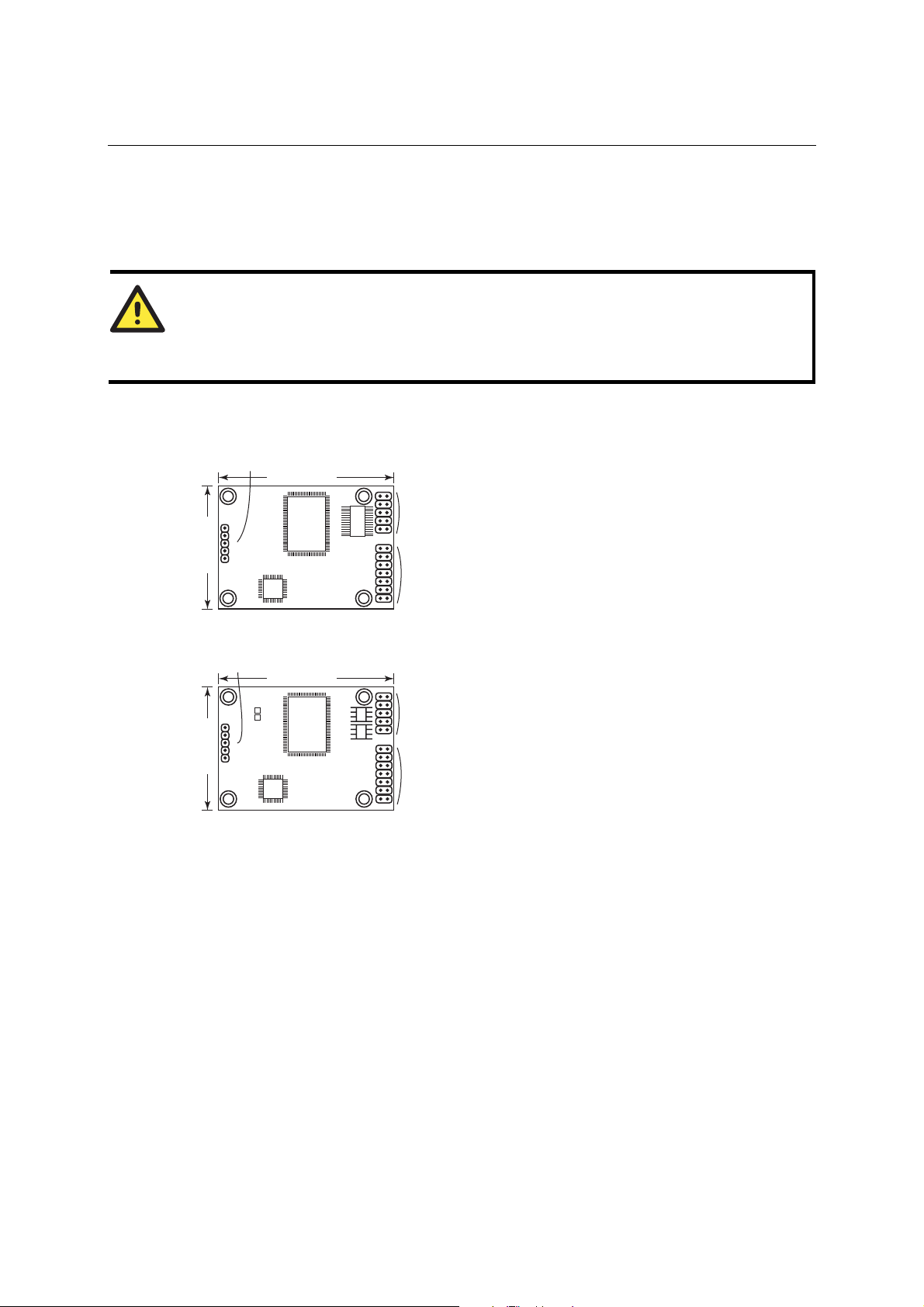

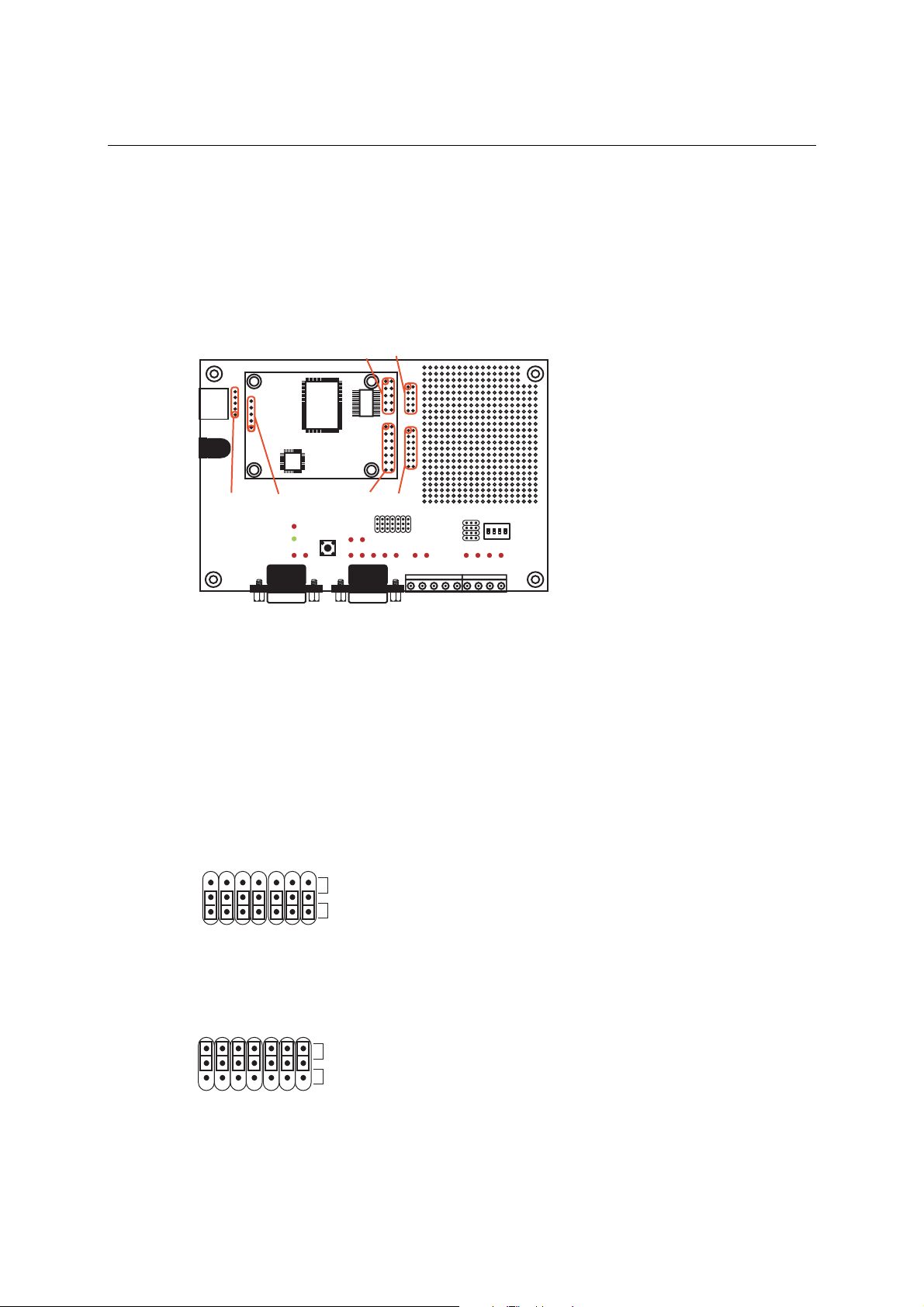

NE-4120S, NE-4120A, NE-4120-ST

The NE-4120S is an RS-232-to-Ethernet server, and the NE-4120A is an RS-422/485-to-Ethernet

server. Both models use pin headers instead of RJ45 connectors. The NE-4120-ST is the evaluation

board for testing NE-4120S and NE-4120A modules and developing your own applications.

ATTENTION

The NE-4120-ST is the same board as the NE-4110-ST but with an RJ45 jack and pin headers. If

your evaluation board has “NE-4110-ST” printed on the board but has the RJ45 jack and pin

headers, you have the NE-4120-ST board.

Panel Layout

NE-4120S

J3

5

4

3

2

1

40.00 mm

57.00 mm

1

2

J1

9

10

1

2

J2

NE-4120A

J3

JP2

5

4

3

2

1

40.00 mm

57.00 mm

13

14

1

2

J1

9

10

1

2

J2

13

14

2-9

Page 20

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

NE-4120-ST

Jumper 9 (J9)Jumper 7 (J7)

12

910

12

13 14

Ethernet

Port

Power

Jack

149.00 mm

5

3

3

2

1

99.00 mm

Interface

Selector

Jumpers

* JP2 is used to select RS-232 or RS-422/485 operation. Use the RS-232 position for RS-232

operation (NE-4120S); use the RS-485 position for RS-422 or RS-485 operation (NE-4120A).

NE-4120-ST LED Indicators

LED Name LED Color LED Function

Power red Indicates the power is on.

Ready

DIO0 red Indicates that DIO is in “low” (0) status.

DIO1 red Indicates that DIO is in “low” (0) status.

DIO2 red Indicates that DIO is in “low” (0) status.

DIO3 red Indicates that DIO is in “low” (0) status.

TXD0 red Indicates that TXD0 has a signal.

RXD0 red Indicates that RXD0 has a signal.

DTR0 red Indicates that DTR0 has a signal.

CTS0 red Indicates that CTS0 has a signal.

DSR0 red Indicates that DSR0 has a signal.

DCD0 red Indicates that DCD0 has a signal.

RTS0 red Indicates that RTS0 has a signal.

TXD1 red Indicates that TXD1 has a signal.

RXD1 red Indicates that RXD1 has a signal.

Reset Button

Serial Port (RS-232)Debug Serial COM Port DI/O Terminal Block

Steady on: Power is on and NE-4120 is

green

functioning normally.

Blinking: NE-4120 has been located by

Network Enabler Administrator.

y Power is off, or power error condition exists.

off

y IP address cannot be found in DHCP mode.

y IP address conflict.

ON

DIP

1234

Jumper 10

(J10)

DI/O Selector

Jumpers

DI/O Signal

Setting

Switches

2-10

Page 21

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

Pin Assignments

NE-4120S Serial Header Pinouts (J1)

NC

9

10

NC

RTS0

7

8

CTS0

GND

5

6

DSR0

TxD0

3

4

DTR0

1

DCD0

2

RxD0

NE-4120A Serial Header Pinouts (J1)

9

10

NC

7

8

NC

5

6

NC

3

4

RxD-

1

2

TxD+

ATTENTION

The symbols “B” and “A” are often used in place of “+” and “-”, respectively.

NC

NC

GND

RxD+

TxD-

ATTENTION

For the 2-wire RS-485 interface, pin 3 is for Data+ (B) and pin 4 is for Data- (A).

NE-4120S and NE-4120A Ethernet Header Pinouts (J3)

1

Tx+

2

Tx-

3

4

Rx+

5

Rx-

NE-4120S and NE-4120A DIO and LED Header Pinouts (J2)

14

10

8

6

4

2

VCC(+5V)

111312

VCC(+5V)

10M_LED

9

100M_LED

7

Ready_LED

5

Reset

3

RxD1

1

GND

GND

DIO0

DIO1

DIO2

DIO3

TxD1

2-11

Page 22

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

NE-4120-ST Pinouts

Debug Serial Port for Serial Console RS-232 Port for Serial Devices

Pin

Signal

Pin

Signal

2

3

5

Block Diagrams

NE-4120S Block Diagram

10/100 M

Ethernet PHY

+5 VDC

RXD

TXD

GND

5

3

2

Serial and DIO Terminal Blocks

TXD+ D0 D1 D2 D3TXD- RXD+ RXD-

Data+ Data-

1 MB SDRAM

80186 CPU

MAC

SGND

2 MB Flash

UART0

1

2

3

4

5

6

7

8

DCD

RXD

TXD

DTR

GND

DSR

RTS

CTS

5

4

3

2

1

8

7

6

Serial data

(Tx, Rx, RTS, CTS,

DTR, DSR, DCD)

Line

Driver

Customer's device

RS-232 interface

Transformer

1.5 KV isolation

Tx+ Tx- Rx-Rx+

Pin header

10M

LED

GPIO Port

PIO0 - PIO3

100M

LED

2-12

UART1

Ready

LED

Line

Driver

Tx Rx

Serial console

interface

Page 23

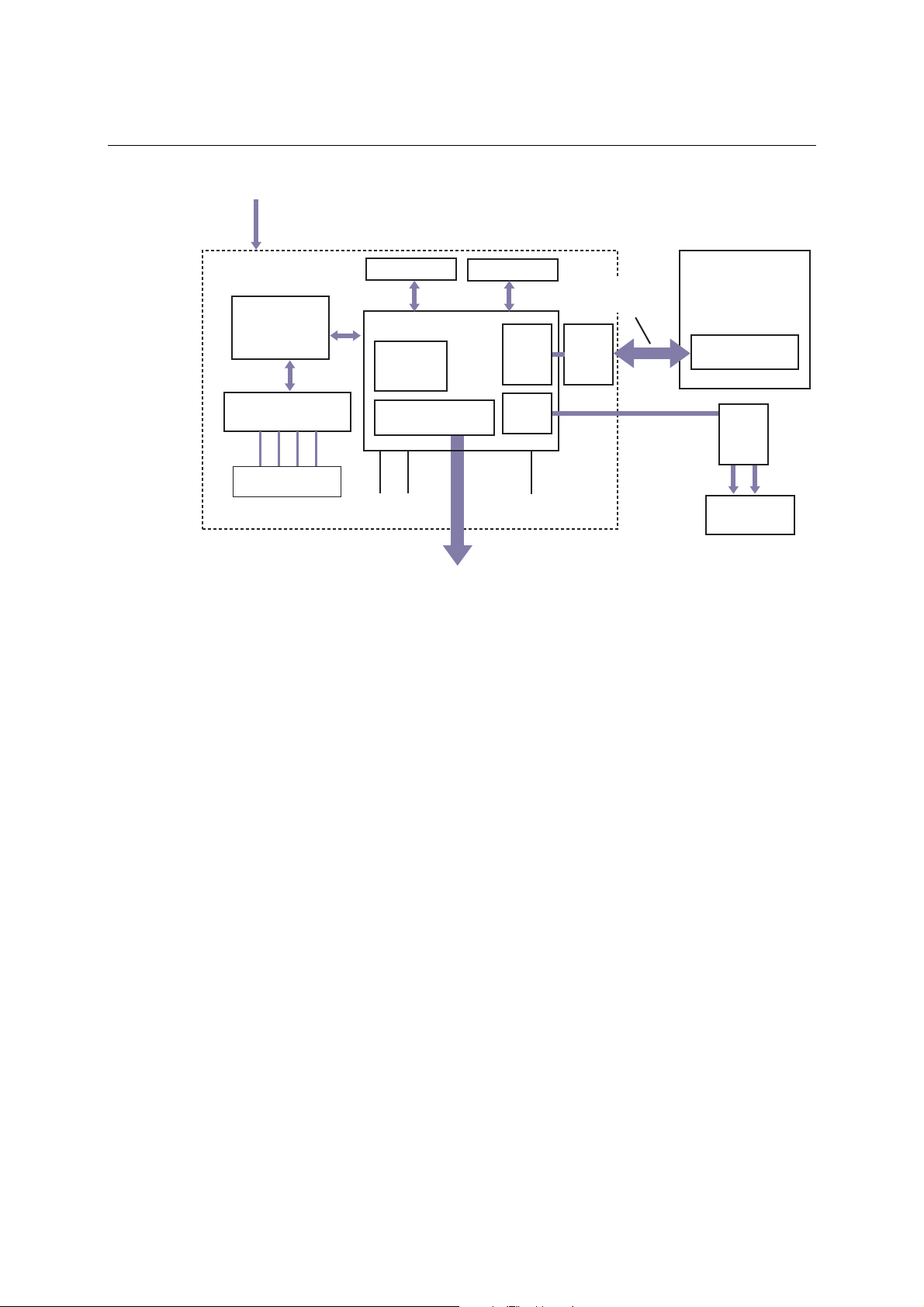

NE-4100 Series User’s Manual Panel Layout and Pin Assignments

NE-4120A Block Diagram

+5 VDC

10/100 M

Ethernet PHY

Transformer

1.5 KV isolation

Tx+ Tx- Rx-Rx+

Pin header

1 MB SDRAM

MAC

GPIO Port

PIO0 - PIO3

10M

100M

LED

LED

80186 CPU

2 MB Flash

UART0

UART1

Ready

LED

Line

Driver

RS-422/485

Signal

Customer's device

RS-422/485

interface

Line

Driver

Tx Rx

Serial console

interface

2-13

Page 24

3

3

Chapter 3. Getting Started

This chapter includes information about installation of NE-4100 Series modules for development

and testing.

The following topics are covered in this chapter:

Wiring Precautions

Installing the NE-4100T onto the NE-4100-ST

Installing the NE-4110S, NE-4110A onto the NE-4110-ST

Installing the NE-4120S, NE-4120A onto the NE-4120-ST

Selecting the Serial Interface

Circuit Pad for External Connection

Connecting the Power

Connecting to the Network

Connecting to a Serial Device

Digital I/O Channel Settings

¾ Digital Output LED Circuit Design

Page 25

NE-4100 Series User’s Manual Getting Started

Wiring Precautions

This section describes some important safety precautions that you should pay attention to before

proceeding with any installation.

ATTENTION

Be sure to disconnect the power cord before installing or wiring the evaluation board.

ATTENTION

Determine the maximum possible current in each power wire and common wire. Observe all

electrical codes dictating the maximum current allowable for each wire size.

If the current goes above the maximum ratings, the wiring could overheat, causing serious

damage to your equipment.

ATTENTION

Please take care when handling the evaluation boards. When plugged in, the evaluation boards’

internal components generate heat, and consequently the board may feel hot to the touch.

You should also pay attention to the following:

z Do not run signal or communication wiring and power wiring in the same wire conduit. To

avoid interference, wires with different signal characteristics should be routed separately.

Separate paths should be used to route wiring for power and devi ces. You can use the type of

signal transmitted through a wire to determ ine whi ch wires should be kept separate. The rul e

of thumb is that wires sharing similar electrical characteristics may be bundled together.

z Keep input wiring and output wirin g separate.

z If power wiring and device wiring paths must cross paths, make sure the wires are

perpendicular at the intersection point.

z All wiring should be clearly labeled.

3-2

Page 26

NE-4100 Series User’s Manual Getting Started

Installing the NE-4100T onto the NE-4100-ST

Before using the NE-4100-ST evaluation board with the module, disconnect the power supply,

network, and serial device. In the center of the evaluation board, there is a square with one white

inverted triangle (shown as black in the figure) on one of its sides, and 2 rows of female sockets on

the other two sides. The NE-4100T module also has a white inverted triangle on one of its sides.

When attaching the module to the evaluation board, make sure these 2 white inverted triangles are

facing the same direction, as shown in the following figure. After the module is installed, connect

the power supply, network, and serial device to the evaluation board.

NE-4100-ST Starter Kit

NE-4100T Series

Module

ON

DIP

1234

Installing the NE-4110S, NE-4110A onto the NE-4110-ST

The NE-4110S and NE -4110A modules are attached to the NE-4110-ST board using mounting

screws that are provided with the board. When attaching the module to the board, make sure that

the module is oriented so that the jumper banks on the module and the board are aligned as shown

below. Use the provided ribbon cables to connect jumper block J1 on the module to J9 on the

board, and jumper block J2 on the module to J10 on the board. When plugging in each ribbon

cable, make sure that the red key wire corresponds with pin 1 on each jumper block.

NE-4110-ST Starter Kit

NE-4110 Series

J1 J9

Module

J2

1

2

9

10

1

2

13

14

J10

12

910

12

13 14

ON

DIP

1234

3-3

Page 27

NE-4100 Series User’s Manual Getting Started

Installing the NE-4120S, NE-4120A onto the NE-4120-ST

The NE-4120S and NE -4120A modules are attached to the NE-4120-ST board using mounting

screws that are provided with the board. When attaching the module to the board, make sure that

the module is oriented so that the jumper banks on the module and the board are aligned as shown

below. Use the provided ribbon cables to connect jumper block J1 on the module to J9 on the

board, J2 on the module to J10 on the board, and J3 on the module to J7 on the board. When

plugging in each ribbon cable, make sure that the red key wire corresponds with pin 1 on each

jumper block.

NE-4120-ST Starter Kit

5

4

5

3

4

2

3

1

2

1

NE-4120 Series

J7

J3

J1 J9

Module

J2

1

2

9

10

1

2

13

14

J10

12

910

12

13 14

ON

DIP

1234

Selecting the Serial Interface

NE-4100 Series modules are available for different serial interfaces. The NE-4110S and NE-4120S

are designed for the RS-232 interface, and the NE-4110A and NE-4120A are designed for the

RS-422/485 interface. On the NE-4110-ST and NE-4120-ST evaluation boards, the Network

Enabler Interface jumper block is used to select the serial interface used for your particular

module.

For the NE-4110S and NE-4120S, the evaluation board should be configur ed for the RS-232

interface, as shown below.

JP2

Network Enabler

Interface

RS485

RS232

For the NE-4110A and NE-4120A, the evaluation board should be configured for the RS-485

interface, as shown below.

JP2

Network Enabler

Interface

RS485

RS232

3-4

Page 28

NE-4100 Series User’s Manual Getting Started

Note that the RS-485 interface is selected on the evaluation board for the NE-4110A and

NE-4120A modules, even when the module is operating in RS-422 mode. Please refer to

Panel Layout and Pin Assignments for additional details.

-

Chapter 2

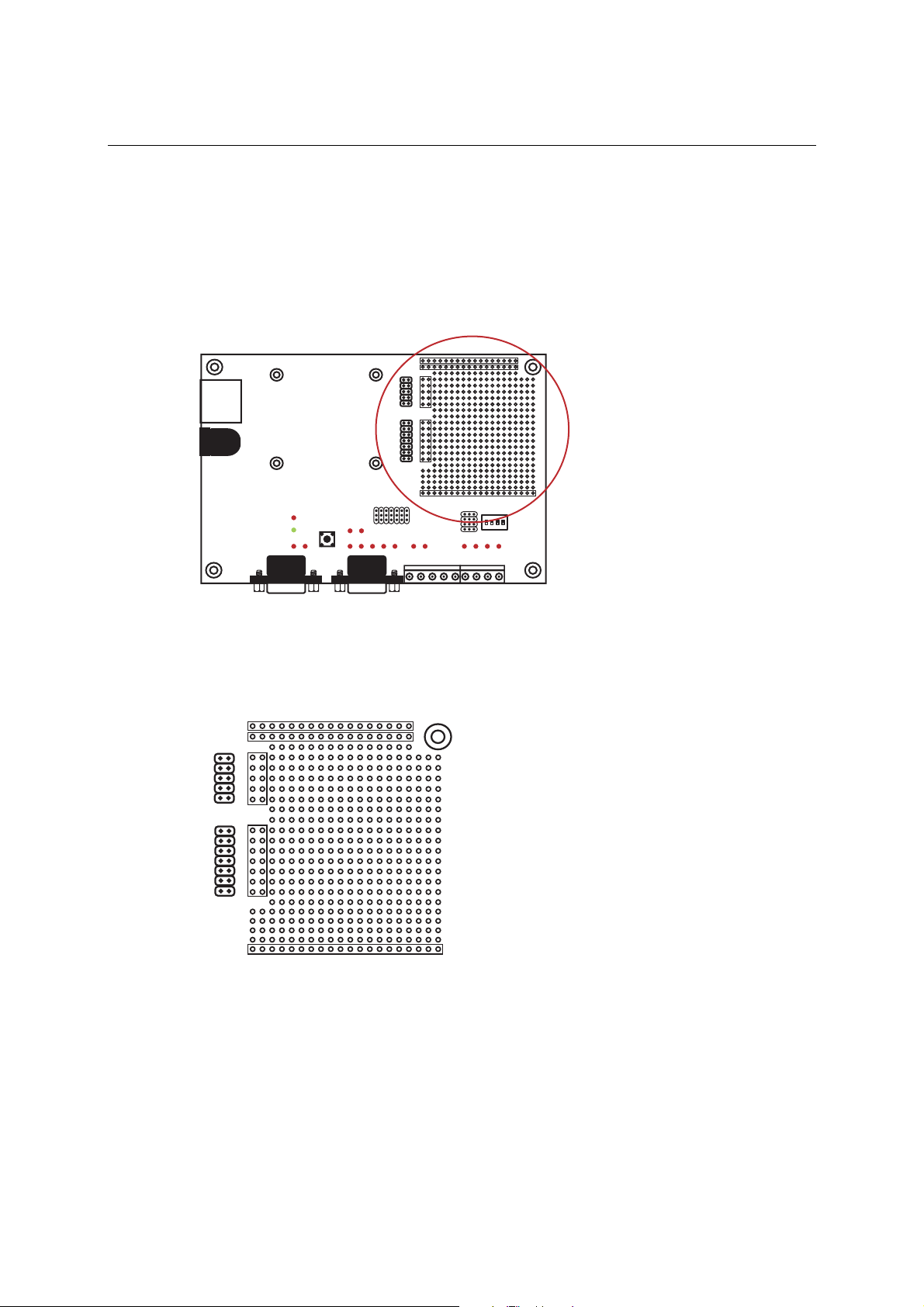

Circuit Pad for External Connection

A circuit pad is provided on the right side of each evaluation board for the development of

additional application circuits.

5V

3.3V

12

12

J3

J9

910

910

12

12

J4

J10

13 14

13 14

GND

ON

DIP

1234

The first row of the circuit pad is for connecting a 5V power supply; the second row is for

connecting a 3.3V power supply. The last row of the circuit pad is for grounding. Serial signals are

mapped to J3 as an extension of jumper block J9. DIO and LED signals are mapped to J4 as an

extension of jumper block J10. This means that pin assignments for J3 on the circuit pad are the

same as the pin assignments for jumper block J9; pin assignments for J4 on the circuit pad are the

same as the pin assignments for jumper block J10.

5V

3.3V

12

12

J3

J9

910

910

12

12

J4

J10

13 14

13 14

GND

Connecting the Power

Connect the 12 VDC power line with the evaluation board’s power jack. If the power is properly

supplied, the power LED will show a solid red color until the system is ready, at which time the

ready LED will show a solid green color.

3-5

Page 29

NE-4100 Series User’s Manual Getting Started

Connecting to the Network

To connect to the network for testing and development purposes, the module should be installed

onto its evaluation board. Make sure that the module is correctly installed onto the evaluation

board, then plug the Ethernet cable into the RJ45 jack. For models NE-4100T, NE-4120S, and

NE-4120A, the RJ45 jack is located on the evaluation board; for mode ls NE-4110S and NE-4110A,

the RJ45 jack is located on the module itself.

If the cable is properly connected, the RJ45 connector will indicate a valid connection to the

Ethernet as follows:

The green LED in the upper right corner blinks whe n t he cabl e is pr operly

LAN

LAN

When using a private IP address for the module, which is the factory default, make sure that

netmask and IP settings are configured appropriately in order to access the module from a host on

the network.

connected to a 100 Mbps Ethernet network, and data is being transmitted.

The yellow LED in the upper left corner blinks when the cable is properly

connected to a 10 Mbps Ethernet network, and data is being transmitted.

Connecting to a Serial Device

To connect to a serial device for testing and development purposes, the module should be installed

onto its evaluation board. The module’s serial signals are routed to and from the RS-232 COM port

on the evaluation board Use a serial data cable to connect the serial device to the COM port on the

evaluation board.

Digital I/O Channel Settings

Each module provides 4 digital I/O (DIO) channels. All 4 DIO channels may be configured by

software for either digital output or digital input mode. A DI channel is a channel that is operating

in digital input mode; a DO channel is a channel that is operating in digital output mode. You may

use the evaluation board’s Digital Output LEDs and Digital Input DIP switches as the digital input

and output devices, or you may connect digital input/output devices to the DI/O Terminal Block.

ATTENTION

When using a digital input device connected to the DI/O Terminal Block, the corresponding

Digital Input DIP switch must be set to “OFF” or “High”. Setting the DIP switch to “ON” or

“Low” will interfere with the signal from your digital input device.

3-6

Page 30

NE-4100 Series User’s Manual Getting Started

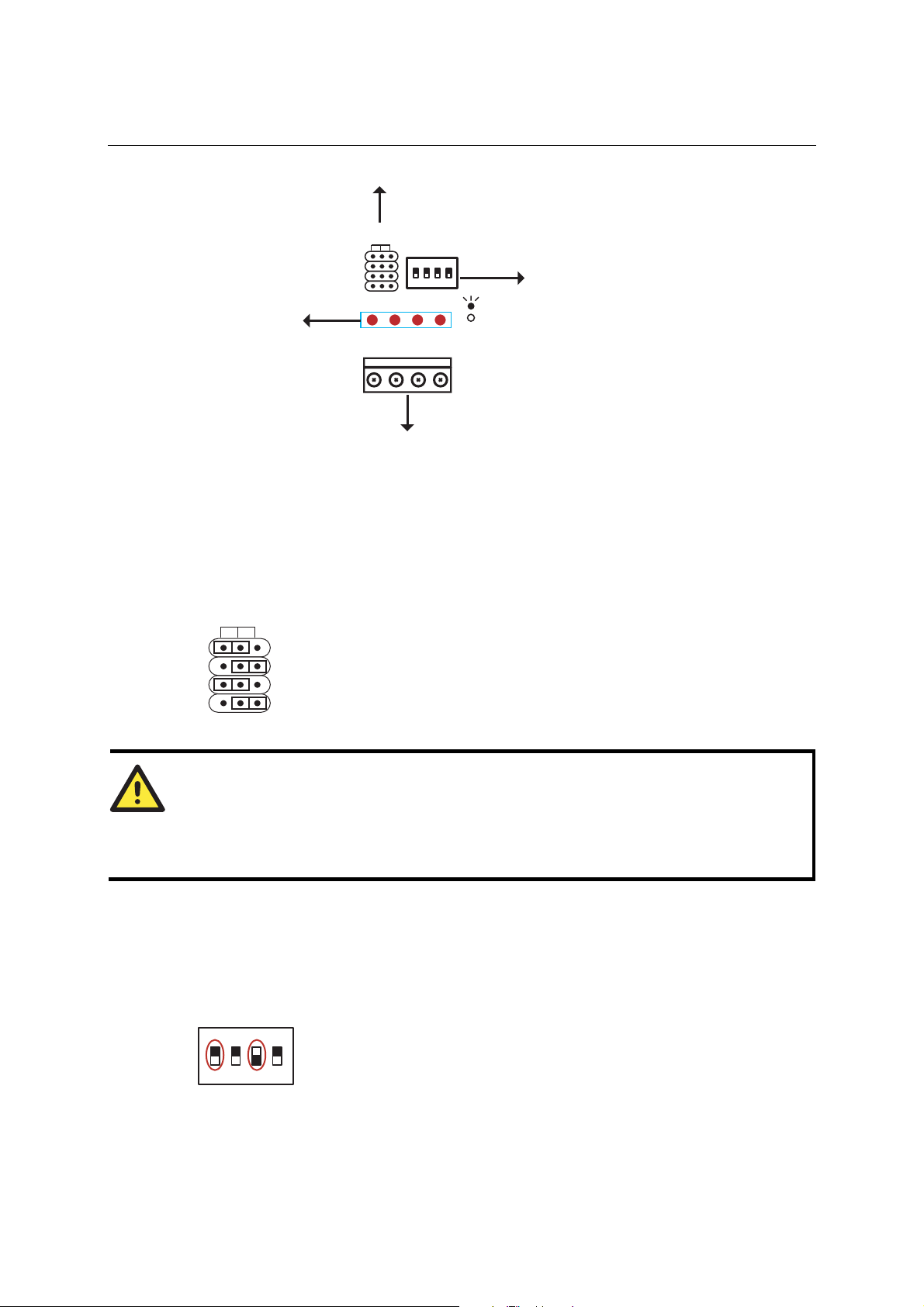

DI/O Selectable Jumper

DI/O Mode

DI DO

Digital Input

Digital Output LEDs

0

1

2

3

DO0 DO1 DO2 DO3

DO0 DO1 DO2 DO3

0123

ON

1234

Digital Output

DIP

ON: Low

OFF: High

: Low

: High

Digital Input Signal Setting Switch

DI/O Terminal Block

DI/O Mode jumpers 0 through 3 correspond with DIO channels 0 through 3. The jumper’s position

determines whether the corresponding channel is linked to a DIP switches or to an LED. When a

channel’s jumper is set to the DI position, the channel’s input signal is controlled by the

corresponding Digital Input DIP switch. When the jumper is set to the DO position, the channel’s

output signal is routed to the corresponding Digital Output LED. For example, if DIO channel 0 is

operating as a digital input channel, setting DI/O Mode jumper 0 to the DI position enables the use

of DIP switch 0 as that channels’ input device.

DI/O Mode

DI DO

0

1

2

3

ATTENTION

The DI/O Mode jumpers are used to tell the evaluation board whether to use the Digital Output

LEDs or the Digital Input DIP switches. The jumpers do not control the channel’s mode. Input

and output mode is configured through the web, serial, or Telnet console, or through Network

Enabler Administrator.

When using a Digital Input DIP switch as your input device, the “ON” position corresponds to

“Low” status and the “OFF” position corresponds to “High” status. The result can be monitored

with the Network Enabler Administrator or with the web console. Make sure all DIP switches are

set to “OFF” if you are using your own digital input device that is connected to the evaluation

board’s terminal block.

Digital Input

0123

ON

DIP

1234

ON: Low

OFF: High

3-7

Page 31

NE-4100 Series User’s Manual Getting Started

For channels in digital output mode, “Low” and “High” status is controlled from within the web

console. When using a Digital Output LED as your output device, “Low” status will be expressed

by the LED lighting up, and “High” status will be expressed by the LED turning off.

Digital Output

DO0 DO1 DO2 DO3

Digital Output LEDs

: Low

: High

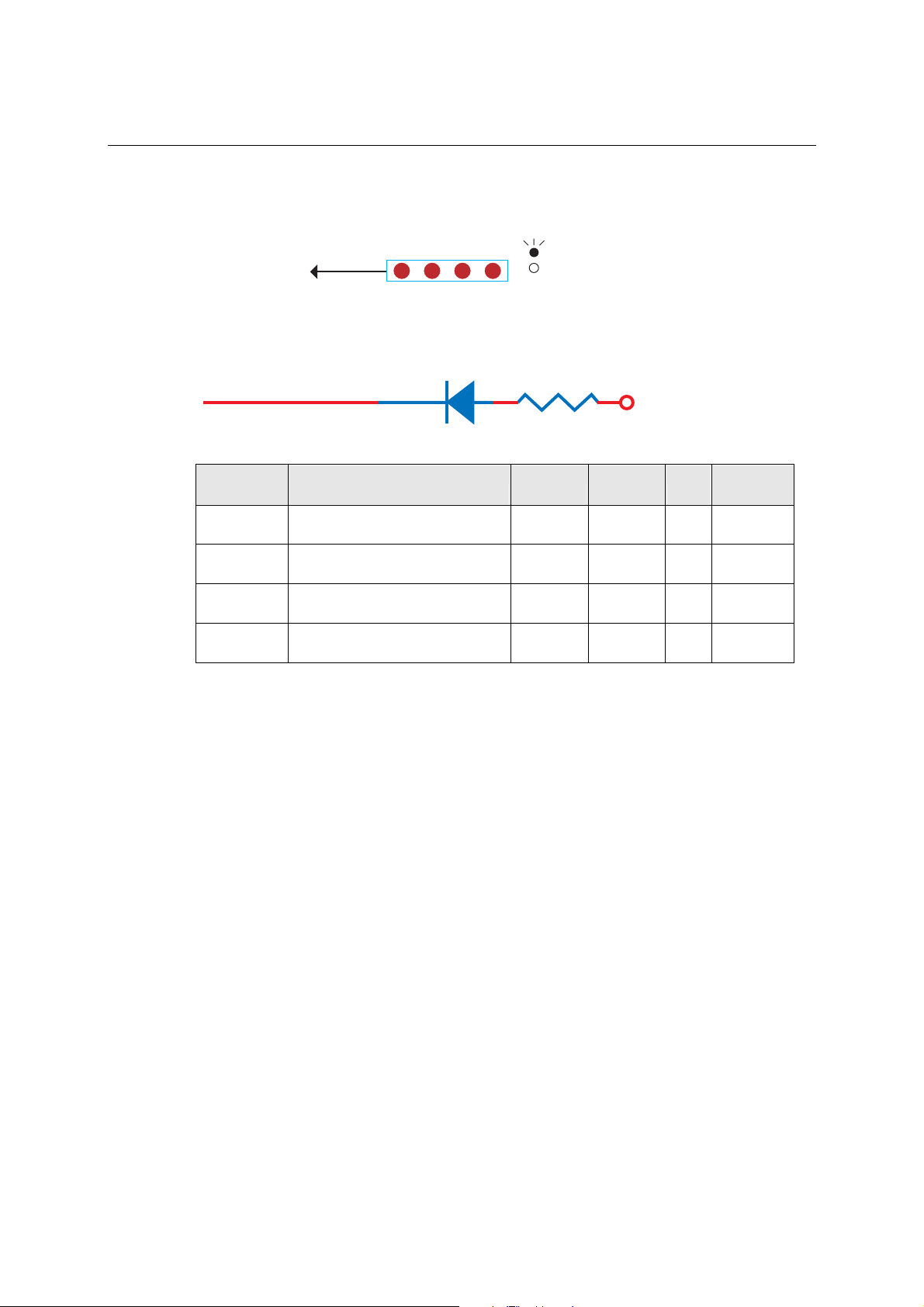

Digital Output LED Circuit Design

The figure shown below is the digital output LED circuit design. This is known as the “sink”

design.

Dout

3.3V

When developing your own applications, you need to be aware of the voltage limits shown below.

Min. Max. Unit Conditions

Low-level

Input Voltage

High-level

Input Voltage

Low-level

Input Voltage

High-level

Input Voltage

Maximum voltage when DI is set

to “Low” status.

Minimum voltage when DI is set

to “High” status. 0.7xVCC ----- V

Maximum voltage when DO is set

to “Low” status. ----- 0.4 V

Minimum voltage when DO is set

to “High” status

----- 0.3xVCC V

2.4 ----- V

The output current for digital output channels carries only 1 mA.

3-8

Page 32

4

4

Chapter 4. Choosing the Proper Operation Mode

In this section, we describe the various operation modes of NE-410 0 Seri es modules. Depending

on your intended use, the operation mode will determine how serial communication is handled by

the network. There is an operation mode for COM port mapping from the host computer as well

operation modes for TCP/IP protocols. After choosing the proper operating mode in this chapter,

please refer to subsequent chapters for details on configuration parameters.

The following topics are covered in this chapter:

Overview

TCP Server Mode

TCP Client Mode

UDP Mode

Real COM Mode

Page 33

NE-4100 Series User’s Manual Choosing the Proper Operation Mode

Overview

NE-4100 Series modules act as a bridge to connect your serial devices to the Ethernet. The built-in

TCP/IP stack means less time spent on programming networking protocols. With one step you may

choose the proper operation mode, then use your computer to access, manage, and configure your

serial device from anywhere in the world over the Internet.

Traditional SCADA and data collection systems rely on serial ports (RS-232/422/485) to collect

data from various kinds of instruments. Since NE-4100 Series modules convert between serial and

Ethernet signals, your SCADA and data collection system can be made accessible from every

device connected to a standard TCP/IP network, regardless of whether the devices are used locally

or at a remote site.

Three different socket modes—TCP Server, TCP Client, and UDP Server/Client—are available, as

well as a Real COM mode. The main difference between the TCP and UDP protocol is that TCP

guarantees delivery of data by requiring the recipient to send an acknowledgement to the sender.

UDP does not require this type of verification, making it possible to offer speedier delivery. UDP

also allows multicasting of data to groups of IP addresses.

ATTENTION

The figures in this chapter use the NE-4110S as an example, but they apply to all models in the

NE-4100 Series.

TCP Server Mode

In TCP Server mode, the module is assigned a unique IP

address and port number on the TCP/IP network. The

module waits passively to be contacted by the host

computer, allowing the host computer to establish a

connection with and obtain data from the serial device.

This operation mode also supports up to 4 simultaneous

connections, so that multiple hosts can collect data from

the same serial device—at the same time.

As illustrated in the figure, data transmission proceeds as

follows:

1. The host connects to the module configured for TCP

Server mode.

2. Once the connection is established, data can be

transmitted in both directions—from the host to the

module, and from the module to the host.

4-2

Page 34

NE-4100 Series User’s Manual Choosing the Proper Operation Mode

TCP Client Mode

In TCP Client mode, the module can actively

establish a TCP connection to a pre-defined host

computer when serial data arrives.

After the data has been transferred, the module can

automatically disconnect from the host computer by

using the “TCP alive check time” or “Inactivity

time” settings. Please refer to the following chapters

for more details.

As illustrated in the figure, data transmission

proceeds as follows:

1. The module actively establishes a connection

based on the conditions set in the firmware.

You may let the module connect to a remote

host on startup, or connect later when data

from serial device arrives.

2. Once the connection is established, data can be

transmitted in both directions—from the host

to the module, and from the module to the host.

UDP Mode

UDP mode is faster and more efficient than

TCP modes. In UDP mode, you can multicast

data from the serial device to multiple host

computers, and the serial device can also

receive data from multiple host computers,

making this mode ideal for message display

applications.

4-3

Page 35

NE-4100 Series User’s Manual Choosing the Proper Operation Mode

Real COM Mode

Real COM mode allows users to continue using

software that was written for pure serial

communications applications. Each module

comes equipped with COM drivers for

Windows systems (95 and above). The serial

module’s serial port is mapped by the driver to

an IP address and port number. The driver

intercepts data sent to the host’s COM port,

packs it into a TCP/IP packet, and then

redirects it through the host’s Ethernet card. At

the other end of the connection, the module

accepts the Ethernet frame, unpacks the TCP/IP

packet, and then transparently sends the data to

the attached serial device. The driver thus

establishes a transparent connection between

the host and serial device, allowing the host to

treat the networked device as if it were directly

attached.

ATTENTION

The Real COM driver comes with Network Enabler Administrator, which is part of the NE-4100

Series Administration Suite.

ATTENTION

Real COM mode can allow several hosts to have simultaneous access to the module. The driver

controls host access to attached serial devices by checking the host’s IP address against the

Accessible IP list.

Use the Accessible IP table to restrict access to the module when a public IP address is required

for your application.

4-4

Page 36

5

5

Chapter 5. Initial IP Address Configuration

When setting up your NE-4100 Series module for the first time, the first thing you should do is

configure the IP address. This chapter introduces the methods that can be used to configure the

module’s IP address. For more details about network settings, please refer to the

section from

This chapter includes the following sections:

Chapter 6 - Web Console Configuration.

Network Settings

Static vs. Dynamic IP Address

Factory Default IP Address

NE-4100 Series Administration Suite Å recommended configuration method

ARP

Telnet Console

Serial Console (19200, n, 8, 1)

Page 37

NE-4100 Series User’s Manual Initial IP Address Configuration

Static vs. Dynamic IP Address

Determine whether the module will use a Static IP or Dynamic IP (either DHCP or BOOTP

application).

z If the module is used in a Static IP environment, you will configure the IP address directly.

z If the module is used in a Dynamic IP environment, you will configure the module to obtain

an IP address dynamically with DHCP, DHCP/BOOTP, or BOOTP.

ATTENTION

Consult your network administrator on how to reserve a fixed IP address for the module in the

MAC-IP mapping table when using a DHCP Server or BOOTP Server. For most applications, you

should assign a fixed IP address to the module.

Factory Default IP Address

The module is configured with the following default private IP address:

192.168.127.254

Please note that IP addresses of the form 192.168.xxx.xxx are referred to as private IP addresses,

since it is not possible to directly access a device configured with a private IP address from a

public network. For example, you would not be able to ping such a device from an outside Internet

connection. Applications that require sending data over a public network, such as the Internet,

require setting up the server with a valid public IP address, which can be leased from a local ISP.

NE-4100 Series Administration Suite

The NE-4100 Series Administration Suite consists of some useful utilities that are used to

configure and manage the module. Please refer to

Series Administration Suite to set up the module’s IP addresses.

Chapter 7 for details on using the NE-4100

ARP

You can use the ARP (Address Resolution Protocol) command to set up the module’s IP address.

The ARP command tells your computer to associate the module’s MAC address with the intended

IP address. You must then use Telnet to access the module, at which point the module’s IP address

will be reconfigured.

ATTENTION

In order to use ARP, both your computer and the module must be connected to the same LAN.

You may also use a cross-over Ethernet cable to connect the module directly to your computer’s

Ethernet port.

Your module must be configured with the factory default IP address before executing the ARP

command.

5-2

Page 38

NE-4100 Series User’s Manual Initial IP Address Configuration

To configure the IP address using ARP, follow these instructions:

1. Obtain a valid IP address for the module from your network administrator.

2. Obtain the module’s MAC address from the label on the module.

3. Execute the ‘arp -s’ command from your computer’s MS-DOS prompt by typing:

arp –s <new IP address> 00-90-E8-xx-xx-xx

For example,

arp –s 192.168.200.100 00-90-E8-00-00-00

In the example above, 192.168.200.100 is the new IP address and 00-90-E8-00-00-00 is the

module’s MAC address, as obtained in steps 1 and 2.

4. Execute a special Telnet command by typing:

telnet <new IP address> 6000

For example.

telnet 192.168.200.100 6000

After issuing this command, a Connect failed message

will appear, as shown here. After the module reboots, its

IP address will be updated to the new address, and you can

reconnect using Telnet, web, or Network Enabler

Administrator to verify that the update was successful.

Telnet Console

Depending on how your computer and network are configured, you may find it convenient to use

network access to set up your module’s IP address. This can be done using the Telnet program,

which requires that the module have a network connection and an IP address.

1. From the Windows desktop, click on Start and then select Run.

2. Telnet to the module’s current IP address. If this

is the first time configuring the module, you

will telnet to the default IP address by typing

telnet 192.168.127.254

in the Open text box, then clicking OK.

5-3

Page 39

NE-4100 Series User’s Manual Initial IP Address Configuration

3. Select Network settings by pressing 2 and then Enter.

4. Select IP address by pressing 1 and then Enter.

5. Use the Backspace key to er ase the current IP address,

then type in the new IP address and press Enter.

5-4

Page 40

NE-4100 Series User’s Manual Initial IP Address Configuration

6. Press any key to continue.

7. Press M and then Enter to return to the main menu.

8. Press S and then Enter to Save/Restart the system.

9. Press Y and then Enter to save the new IP address and

restart the module.

Serial Console (19200, n, 8, 1)

If you wish to configure the IP address of the module without going through the network, you may

use the serial console, which involves connecting a serial terminal directly to the RS-232 console

port on the evaluation board. Moxa offers a free utility called PComm Terminal Emulator that can

5-5

Page 41

NE-4100 Series User’s Manual Initial IP Address Configuration

be used for this purpose, although you are free to choose among other terminal emulators that are

widely available. PComm Lite may be downloaded at www.moxa.com.

The following instructions show the procedure using PComm Lite. If you are using another utility,

the instructions may vary slightly.

1. Plug one end of a serial cable into the RS-232 DEBUG (P1) serial port on the evaluation

board; plug the other end directly into your computer’s male RS-232 serial port.

2. From the Windows desktop, click on Start Æ Programs Æ PComm Lite Æ Terminal

Emulator.

3. When the PComm T erminal Emulator window

opens, select Open from the Port Manager

menu, or simply click on the Open icon.

4. The Property window opens automatically. On

the Communication Parameter tab, select the

appropriate COM port for the connection, COM1

in this example. The parameters should be set to

19200 for Baud Rate, 8 for Data Bits, None for

Parity, and 1 for Stop Bits.

5. On the Terminal tab, select ANSI or VT100 for

Terminal Type and then click OK.

If you select Dumb Terminal as the terminal

type, some of the console functions—especially

the Monitor function—may not work properly.

6. Enter any character to switch automatically from data mode to console mode.

7. The serial console will open up. At this point, it

will look exactly the same as the Telnet console.

Please continue to step 3 in the previous Telnet

Console section for the rest of the instructions on

setting up the IP address.

5-6

Page 42

6

6

Chapter 6. Web Console Configuration

The web console is the most user-friendly way to configure your NE-4100 Series module. This

chapter introduces the web console function groups and function definitions.

This chapter includes the following sections:

Opening Y our Browser

Web Console Navigation

Basic Settings

Network Settings

Serial Settings

Operating Settings

¾ TCP Server Mode

¾ Real COM Mode

¾ TCP Client Mode

¾ UDP Mode

Accessible IP Settings

Auto Warning Settings

¾ E-mail and SNMP Trap

¾ Event Type

Digital IO

¾ DIO Settings

¾ DIO Monitor

Serial Command Mode

Change Password

Load Factory Defaults

Save/Restart

Page 43

NE-4100 Series User’s Manual Web Console Configuration

Opening Your Browser

1. Open your browser with the cookie function enabled. (To enable your browser for cookies,

right click on your desktop Internet Expl o rer i c on, select Properties, click on the Security tab,

and then select the three Enable options as shown in the figure below.)

2. Type 192.168.127.254 in the Address box (use the correct IP addres s if different from the

default), and then press Enter.

ATTENTION

If you use other web browsers, remember to enable the functions to “allow cookies that are stored

on your computer” or “allow per-session cookies.”

NE-4100 Series modules only use cookies for password transmission.

ATTENTION

Please refer to

The examples in this chapter use the factory default IP address (192.168.127.254).

Chapter 5 - Initial IP Address Configuration for instructions on IP configuration.

6-2

Page 44

NE-4100 Series User’s Manual Web Console Configuration

3. The web console will open. On this page, you can see a brief description of the web console’s

eleven function groups.

Note: “Serial Command Mode” is supported in firmware version 3.0 and above.

ATTENTION

If you can’t remember the password, the ONLY way to configure the module is to load factory

defaults by using the reset button located near the DB9 male serial port on the evaluation board.

Remember to use Network Enabler Administrator to export the configuration file when you have

finished the configuration. After using the reset button to load factory defaults, your configuration

can be easily reloaded into the module. Please refer to

and importing configuration settings.

Chapter 7 for more details about exporting

Web Console Navigation

On the web console, the left panel is the navigation panel and contains an expandable menu tree

for navigating among the various settings and categories. When you click on a menu item in the

navigation panel, the main window will display the corresponding options for that item.

Configuration changes can then be made in the main window. For example, if you click on Basic

Settings in the navigation panel, the main window will show a page of basic settings that you can

configure.

You must click on the Submit button to keep your configuration changes. The Submit button will

be located at the bottom of every page that has configurable settings. If you navigate to another

page without clicking the Submit button, your settings will not be retained.

Changes will not take effect until they are saved and the module is restarted! You may

complete this in one step by clicking on Save/Restart after you submit a change. If you restart the

module without saving your configuration, the module will discard all submitted changes.

6-3

Page 45

NE-4100 Series User’s Manual Web Console Configuration

Basic Settings

Note: “Serial Command Mode” is supported in firmware version 3.0 and above.

Server name

Setting Factory Default Necessity

1 to 39 characters NP[model name]_[Serial No.] Optional

This option can be used to specify the location or application of the module, which may be useful

when managing more than one module on the network.

Time

The module has a built-in Real-Time Clock for time calibration functions. Functions such as Auto

warning e-mail or SNMP trap can add real-time information to the message.

ATTENTION

Always select and submit the time zone before modifying the time. The console will display the

real time according to the time zone compared to GMT.

If you would like to modify the real time clock, select Local T i me. The module’s firmware will

modify the GMT time according to the Time Zone.

Time zone

Setting Factory Default Necessity

User selectable time zone GMT (Greenwich Mean Time) Optional

Local time

Setting Factory Default Necessity

User adjustable time. GMT (Greenwich Mean Time) Optional

Click on the Modify button to open the Modify time

settings window to input the correct local time.

6-4

Page 46

NE-4100 Series User’s Manual Web Console Configuration

Time server

Setting Factory Default Necessity

IP or domain address

(E.g., 192.168.1.1, time.stdtime.g ov.tw, or

time.nist.gov)

NE-4100 Series modules use SNTP (RFC-1769) for auto time calibration.

Enter the Time Server IP address or domain address. When the Time Server IP address is provided,

the module will request time information from the Time Server every 10 minutes.

None Optional

Console

Web console, Telnet console

Setting Factory Default Necessity

Enable or Disable Enable Required

The web console and Telnet console can be disabled for security reasons. In some cases, you may

want to disable one or both of these console utilities as an extra precaution to prevent unauthorized

users from accessing the module. The factory default for both web console and Telnet console is

Enable.

ATTENTION

If you disable both the web console and Telnet console, you can still use the serial console or

Network Enabler Administrator to configure the module.

Network Settings

Note: “Serial Command Mode” is supported in firmware version 3.0 and above.

You must assign a valid IP address to the module before it will work in your network environment.

Your networ k system administrator should provide you with an IP address and related settings for

your network. The IP address must be unique within the network; otherwise the module will not

have a valid connection to the network. First time users can refer to

Configuration for more information.

Chapter 5 - Initial IP Address

6-5

Page 47

NE-4100 Series User’s Manual Web Console Configuration

IP configuration

Method Function Definition

Static User defined IP address, Netmask, Gateway.

DHCP DHCP Server assigned IP address, Netmask, Gateway, DNS, and Time Server

DHCP Server assigned IP address, Netmask, Gateway, DNS, and Time

DHCP/BOOTP

BOOTP BOOTP Server assigned IP address

IP configuration is a required field. The default setting is Static.

ATTENTION

In Dynamic IP environments, the module will attempt to obtain an IP address from the DHCP or

BOOTP server 3 times at 30-second intervals. The timeout for the first try will be 1 second, the

second try will be to 3 seconds, and the last try will be 5 seconds.

If the DHCP/BOOTP Server is unavailable, the module will use the default IP address