Moxa Technologies MGate MB3000, MGate MB3170, MGate MB3180, MGate MB3280, MGate MB3480 User Manual

...Page 1

MGate MB3000 Modbus G ateway

User Manual

Sixth Edition, July 2012

www.moxa.com/product

2012 Moxa Inc. All rights reserved.

Page 2

MGate MB3000 Modbus G ateway

User’s Manual

The software described in this manual is furnished under a license agreement and may be used only in accordance

with the terms of that agreement.

Copyright Notice

Copyright 2012 Moxa Inc.

All rights reserved.

Reproduction without permission is prohibited.

Trademarks

MOXA is a registered trademark of Moxa Inc.

All other trademarks or registered marks in this manual belong to their respective manufacturers.

Disclaimer

Information in th is doc um e nt is subject to ch ange without notice an d does not represent a commitment on the part

of Moxa.

Moxa provides this document “as is,” without warranty of any kind, either expressed or implied, including, but not

limited to, its particular purpose. Moxa reserves the right to make improvements and/or changes to this manual, or

to the products and/or the programs described in this manual, at any time.

Information provided in this manual is intended to be accurate and reliable. However, Moxa assumes no

responsibility for its use, or for any infringements on the rights of third parties that may result from its use.

This product might include unintentional technical or typographical err ors. Changes are periodically made to the

information herein to correct such errors, and these changes are incorporated into new editions of the publication.

Technical Support Contact Information

www.moxa.com/support

Moxa Americas:

Toll-free: 1-888-669-2872

Tel: +1-714-528-6777

Fax: +1-714-528-6778

Moxa China (Shanghai office):

Toll-free: 800-820-5036

Tel: +86-21-5258-9955

Fax: +86-10-6872-3958

Moxa Europe:

Tel: +49-89-3 70 03 99-0

Fax: +49-89-3 70 03 99-99

Moxa Asia-Pacific:

Tel: +886-2-8919-1230

Fax: +886-2-8919-1231

Page 3

Table of Contents

Chapter 1 Introduction .............................................................................................. 1-1

Overview .............................................................................................................................. 1-2

Package Checklist ................................................................................................................. 1-3

Product Features ................................................................................................................... 1-3

Chapter 2 Getting Started ......................................................................................... 2-1

Connecting Power ................................................................................................................ 2-2

Connecting Serial Devices.................................................................................................... 2-2

RS-485 Termination and Pull High/Low Resistors ...................................................... 2-3

Connecting to a Host or the Network ................................................................................... 2-3

Installing the Software .......................................................................................................... 2-3

Mounting the Unit ................................................................................................................ 2-3

Chapter 3 Hardware: MB3180 ................................................................................... 3-1

Panel Layout ......................................................................................................................... 3-2

LED Indicators ..................................................................................................................... 3-2

Dimensions ........................................................................................................................... 3-3

Jumpers ................................................................................................................................. 3-4

Pin Assignments ................................................................................................................... 3-5

DB9 (Male) ................................................................................................................... 3-5

DIN-Rail, Wall Mounting ..................................................................................................... 3-5

Specifications ....................................................................................................................... 3-6

Chapter 4 Hardware: MB3280 ................................................................................... 4-1

Panel Layout ......................................................................................................................... 4-2

LED Indicators ..................................................................................................................... 4-2

Dimensions ........................................................................................................................... 4-3

Jumpers ................................................................................................................................. 4-4

Pin Assignments ................................................................................................................... 4-5

DB9 (Male) ................................................................................................................... 4-5

DIN-Rail, Wall Mounting ..................................................................................................... 4-5

Specifications ....................................................................................................................... 4-6

Chapter 5 Hardware: MB3480 ................................................................................... 5-1

Panel Layout ......................................................................................................................... 5-2

LED Indicators ..................................................................................................................... 5-2

Dimensions ........................................................................................................................... 5-3

Jumpers ................................................................................................................................. 5-4

Pin Assignments ................................................................................................................... 5-5

DB9 (Male) ................................................................................................................... 5-5

DIN-Rail, Wall Mounting ..................................................................................................... 5-6

Specifications ....................................................................................................................... 5-7

Chapter 6 Hardware: MB3170, MB3170I................................................................... 6-1

Panel Layout ......................................................................................................................... 6-2

LED Indicators ..................................................................................................................... 6-2

Dimensions ........................................................................................................................... 6-3

Jumpers ................................................................................................................................. 6-4

Pin Assignments ................................................................................................................... 6-5

DB9 (Male) ................................................................................................................... 6-5

Page 4

Terminal Block (RS-422, RS-485) ............................................................................... 6-5

Power Input, Relay Output ........................................................................................... 6-6

DIN-Rail, Wall Mounting ..................................................................................................... 6-6

Specifications ....................................................................................................................... 6-7

Chapter 7 Hardware: MB3270, MB3270I................................................................... 7-1

Panel Layout ......................................................................................................................... 7-2

LED Indicators ..................................................................................................................... 7-2

Dimensions ........................................................................................................................... 7-3

Jumpers ................................................................................................................................. 7-4

Pin Assignments ................................................................................................................... 7-5

DB9 (Male) ................................................................................................................... 7-5

Power Input, Relay Output ........................................................................................... 7-5

DIN-Rail, Wall Mounting ..................................................................................................... 7-6

Specifications ....................................................................................................................... 7-7

Chapter 8 Typical Applications ................................................................................ 8-1

Ethernet Masters with Multiple Se r ia l Sla ves....................................................................... 8-2

Serial Masters with Multiple Ethernet Slaves....................................................................... 8-2

Modbus TCP Masters with ASCII and RTU Slaves ............................................................. 8-3

Serial Master with Serial Slaves over Internet ...................................................................... 8-3

Chapter 9 Configuring the Modbus Gateway .......................................................... 9-1

Installing the Software .......................................................................................................... 9-2

Starting MGate Manager ...................................................................................................... 9-5

Change Language Settin g ............................................................................................. 9-5

Connecting to the Unit .......................................................................................................... 9-6

Broadcast Search .......................................................................................................... 9-7

Specify by IP Address .................................................................................................. 9-8

Modifying the Configuration ................................................................................................ 9-9

Configure Serial Port for RTU or ASCII, Master or Slave ......................................... 9-10

What is ProCOM? ...................................................................................................... 9-11

How to Configure ProCOM for the MGate MB3000 ................................................. 9-11

Configure IP Address and Other Network Settings .................................................... 9-14

Configure Serial Communication Parameters ............................................................ 9-16

Set up Slave ID Mapping (Smart Routing) ................................................................. 9-17

Customize Modbus Settings ....................................................................................... 9-19

Set Up Priority Control ............................................................................................... 9-21

Accessible IP .............................................................................................................. 9-22

Miscellaneous Setup ................................................................................................... 9-24

Verifying the Locatio n o f the U nit ...................................................................................... 9-25

Monitoring Modbus Activity .............................................................................................. 9-26

Open Traffic Monitor Window ................................................................................... 9-27

Filter Traffic Information ........................................................................................... 9-28

Save Log to File .......................................................................................................... 9-29

Upgrading Fir m war e .......................................................................................................... 9-30

Chapter 10 Pin Assignments .................................................................................... 10-1

DB9 (Male) ......................................................................................................................... 10-2

Terminal Block (RS-422, RS-485) ..................................................................................... 10-3

Power Input, Relay Output ................................................................................................. 10-3

Chapter 11 Case Studies .......................................................................................... 11-1

Page 5

Introduction .........................................................................................................................11-2

Replace Serial Masters with Ethernet Master(s), Slave IDs are Configurable ....................11-2

Replace Serial Masters with Ethernet Master(s), Slave IDs are Fixed ................................11-3

Keep Serial Master and Add Ethernet Master(s) .................................................................11-3

Integrate Modbus RTU, ASCII, and TCP at the Same Time ...............................................11-4

Appendix A Modbus Overview ................................................................................... A-1

Introduction ......................................................................................................................... A-1

Devices are Either Masters or Slaves .................................................................................. A-1

Slaves are Identified by ID .................................................................................................. A-1

Communication is by Request and Response ...................................................................... A-2

Requests Need a Time Limit ............................................................................................... A-2

Modbus Ethernet vs. Modbus Serial .................................................................................... A-3

Integrate Mo dbus Serial and Ethernet with Gateways ......................................................... A-3

Appendix B Declaration of Conformity ...................................................................... B-1

Page 6

1

1

Chapter 1 Introduction

Welcome to the MGate MB3000 line of Modbus gateways. All models feature easy integration of

Modbus TCP to Modbus RTU/ASCII and feature RS-232/422/485 ports for Modbus serial

communication. One, two, and four-port models are available.

This chapter is an introduction to the MGate MB3000 and includes the following sections:

Overview

Package Checklist

Product Features

Page 7

MGate MB3000 User’s Manual Hardware Reference: MB3270, MB3270I

1-2

Overview

The MGate MB3000 is a line of protocol gateways that provid es users with

seamless integration of Ethernet and serial Modbus devices

powerful operation modes to handle almost any Modbus application

Windows utilities for easy setup and tr a ffic monitoring

Seamless integration of Ethernet and serial Modbus devices

Modbus is one of the most popular automation protocols in the world, supporting traditional

RS-232/422/485 devices and recently developed Ethernet devices. Many industrial devices, such as

PLCs, DCSs, HMIs, instruments, and meters, use Mo dbus as their communication stand a rd.

However, the Ethernet-based Modbus protocol is so different from the original serial-based

protocols that a communication gateway is needed as a bridge for integration.

In order to integ rat e Modbu s netw orks, t he MGate MB3000 includes an Ether net port an d up to f our

serial ports that support RS-232, RS-422, and RS-485 communication. It automatically and

intelligently translates between Modbus TCP (Ethernet) and Modbus ASCII/R TU (serial) protocols,

allowing Ethernet-based PLCs to control instruments over RS-485 without additional programmi ng

or effort.

Powerful operation modes to handle almost any Modbus application

With the Modbus protocol, devices must be clearly defined as either masters or slaves. Unlike other

Modbus gateways, the MGate MB3000’s operation modes allow users to select master or slave

operation for each serial port. Not only does the MB3000 allow Ethernet masters to control serial

slaves, it also allows serial masters to control Ethernet slaves. In additio n, the advanced models

(MGate MB3170) allow both Ethernet and ser ia l slaves to be controlled by both Ethernet and serial

masters. On multiport models, each serial port ’s operation mode is i ndepen dent of the oth er ports, s o

that one port may be configured for slave mode and another port configured for master mode.

Extra address mapping and exception parameters are provided to ensure that most situations can be

handled.

Windows utilities for easy setup and traffic monitoring

A W indows utility is provided to make configuration and operation of the MGate MB3000 as easy as

possible. The utility automatically connects to all available MGate MB300 0 units o n the LAN for

you. Traffic monitoring functions help you troubl eshoot Modbus communication problems by

tracking items such as connection status and address translation errors.

Page 8

MGate MB3000 User’s Manual Hardware Reference: MB3270, MB3270I

1-3

Package Checklist

All models in the MGate MB300 0 line are shipped with the following items:

Standard Accessories

1 MGate MB3000 Modbus gateway

Document & software CD

Quick Installation G uide

Power adaptor (MB3180 only)

Product warranty statement

Optional Accessories

DK-35A: DIN-rail mounting kit (35 mm)

DR-4524: 45W/2A DIN-rail 24 VDC power supply with universal 85 to 264 VAC input

DR-75-24: 75W/3.2A DIN-rail 24 VDC power supply with uni ve rsal 85 to 264 VAC input

DR-120-24: 120W/5A DIN-rail 24 VDC power supply with 88 to 132 VAC/176 to 264 VAC

input by switch

NOTE: Notify your sales representative if any of the above items is missing or damaged.

Product Features

Integration of Modbus TCP and Modbus RTU/ASCII networks

Up to 31 Modbus RTU/ASCII slaves per serial port

Up to 32 Modbus TCP connections with Modbus RTU/ASCII masters

Configuration over Et hernet with e asy-to-use Windows utility

10/100M Fast Ethernet with automatic IP setting (DHCP)

Software-selectable RS-232/485/422 communication

High speed serial interface supporting 921.6 Kbps

Up to 16 Modbus TCP masters for Modbus RTU/ASCII slaves

Automatic slave ID routing on 2 and 4-port models

ProCOM: Virtual Serial Port for flexible Modbus to Modbus TCP communication

Page 9

2

2

Chapter 2 Getting Started

This chapter provides basic instructions for installing the MGate MB3000. The following topics are

covered:

Connecting Power

Connecting Serial Devices

RS-485 Termination and Pull High/Low Resistors

Connecting to a Host or the Network

Installing the Software

Mounting the Unit

Page 10

MGate MB3000 User’s Manual Getting Started

2-2

Connecting Power

The unit can be powered using the A C adaptor or by conn ecting a power source to the t erminal block,

depending on the model. The follo wing instructions are for the AC adaptor:

1. Plug the connector of the power adapter into the DC-IN jack on the back of the unit.

2. Plug the power adapter into an electrical outlet.

3. Follow these instructions to connect a power source to the terminal block:

4. Loosen or remove the screws on the terminal block.

5. Connect the 12~48 VDC power line to the terminal block.

6. Tighten the connections using the screws on the terminal block.

Note that the unit does not have an on/off switch. It automatically turns on when it receives power.

The PWR LED o n the top panel will glow to indicate that the unit is re c e iving power.

For power terminal block pin assignments, please refer to the hardware reference chapter for your

model.

Connecting Serial Devices

The unit’s serial port(s) are located on the back panel. There are two options for connecting serial

devices, depending on the serial interface:

You may use a DB9-to-DB9 cable to connect a serial device to the unit. Plug one end of the

cable into the port on the unit’s back panel and plug the other end of the cable into the device’s

serial port.

You may make your own customized serial cable to co nnect a serial device to the unit. For the

pin assignments of the unit’s serial port, please refer to Chapter 10. This information can then

be used to construct your own serial cable.

If you are connecting a RS-485 multidrop network with multiple devices, please note the following:

All devices that are connected to a single serial port must use the same protocol (i.e., either

Modbus RTU or Modbus ASCII).

Each master device must get its own port on the unit. If you are connecti ng a network with

both master and slave devices, the master must be connected on a separate port from the

slaves. Furthermore, the master will only be able to communicate to Modbus TCP slaves, not

to the ASCII or RTU slaves that are connected on a different serial port.

For serial port pin assignments, please refer to the hardware reference chapter for your model.

Page 11

MGate MB3000 User’s Manual Getting Started

2-3

RS-485 Termination and Pull High/Low Resistors

In some critical RS-485 environments, you may need to add termination resistor s to prevent the

reflection of serial signals. When using ter mination resistors, it is important to set the p ull high/low

resistors correctly so that the electrical signal is not corrupted. For each serial port, DIP switches or

jumper settings are used to set the pull high/low resistor values. For all models except the MB3180,

a built-in 120 Ω termination resistor can also be enabled.

To m odify the t ermination and pull high/low resistor settings, please refer t o the h ardware referen ce

chapter for your model.

ATTENTION

Do not use the 1 KΩ pull high/low setting on the MGate MB3000 when using the RS-232 interface.

Doing so will degrade the RS-232 signals and reduce the effective communication distance.

Connecting to a Host or the Network

A 10/100BaseT Ethernet port is located on the unit’s front panel. This port is used for the unit’s

connection to a host or Ethernet network, as follows:

For normal operation, use a standard straight-through Ethernet cable to connect the unit to

your Modbus TCP net work.

For initial configuration or for troubleshooting purposes, you may connect the unit directly to

a PC. In this case, use a crossover Ethernet cable to connect the unit to your PC’s Ethernet

connector.

The unit’s Link LED will light up to indicate a live Ethernet connection.

For advanced models (MB 3170, MB3170I, MB3270, and MB3270I), two Ethernet ports are

provided. One port can be used to connect to the network, and the other port can be used to connect

to another Ethernet device.

Installing the Software

The Windows management utility is installed from the Document and Software CD. Follow the

onscreen instructions after inserting the CD. For additional details, please refer to Chapter 9.

Mounting the Unit

The unit can be placed on a desktop, mounted on the wall, or mounted on a DIN-rail. The MB3180,

MB3280, and MB3480 require optional attachments for DIN-rail mounti ng. For a dditional details,

please refer to the hardware reference chapter for your model.

Page 12

3

3

Chapter 3 Hardware: MB3180

This chapter provides hardware information for the MGate MB3180.

The following topics are covered:

Panel Layout

LED Indicators

Dimensions

Jumpers

Pin Assignments

DB9 (Male)

DIN-Rail, Wall Mounting

Specifications

Page 13

MGate MB3000 User’s Manual Hardware: MB3180

3-2

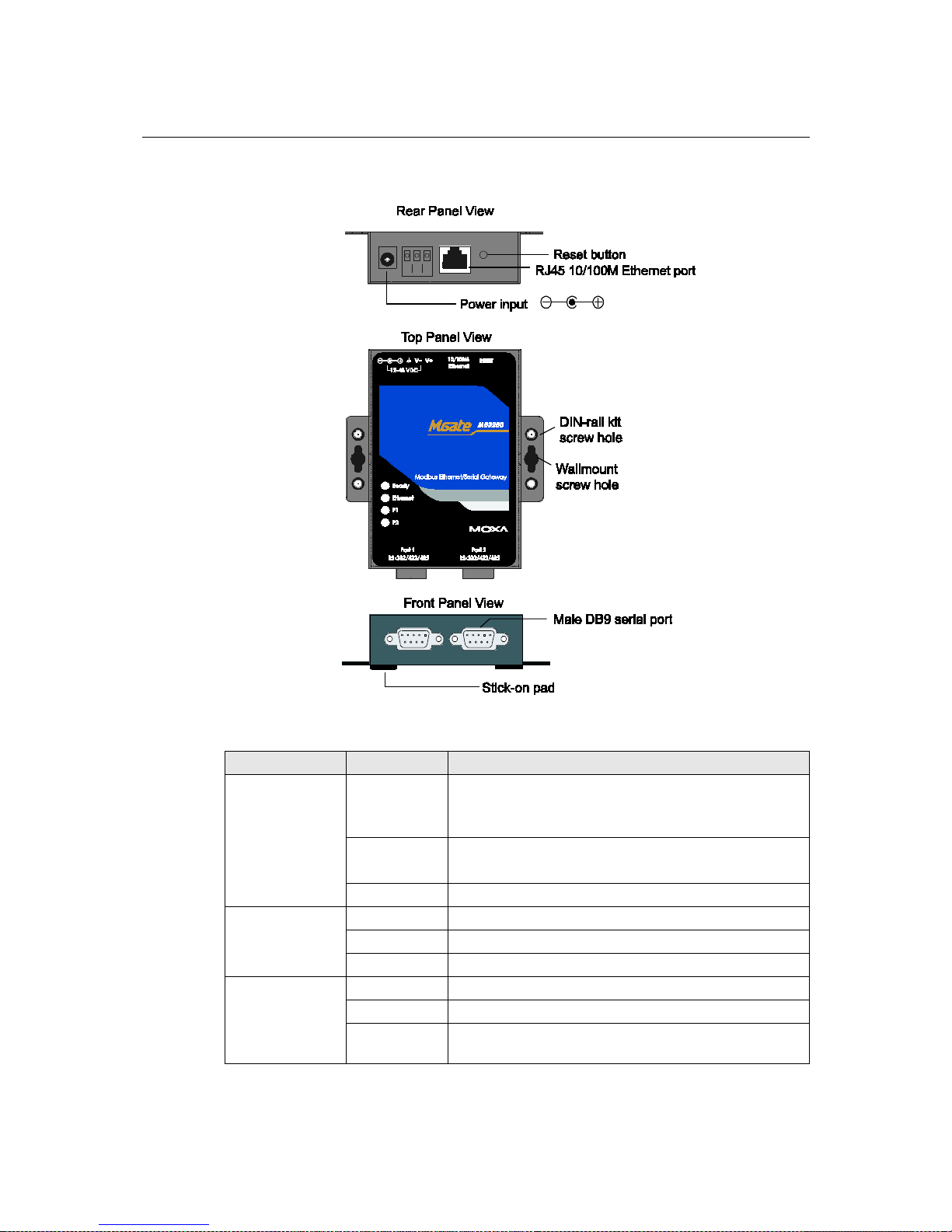

Panel Layout

LED Indicators

Name Color Function

Ready

Red

Steady on: Powe r is on and unit is booting up.

Blinking: Indicates an IP conflict, or DHCP or BOOTP

server is not responding properly.

Green

Steady on: Power is on and unit is functioning normally.

Blinking: U nit is responding to software Locate function.

Off Power is off, or power error condition exists.

Ethernet

Orange 10 Mbps Ethernet connection.

Green 100 Mbps Ethernet connection.

Off Ethernet cable is disconnected, or has a short.

P1 Tx/Rx

Orange Serial port is receiving data.

Green Serial port is transmitting data.

Off

No data is being transmitted or rec e ived through the serial

port.

Page 14

MGate MB3000 User’s Manual Hardware: MB3180

3-3

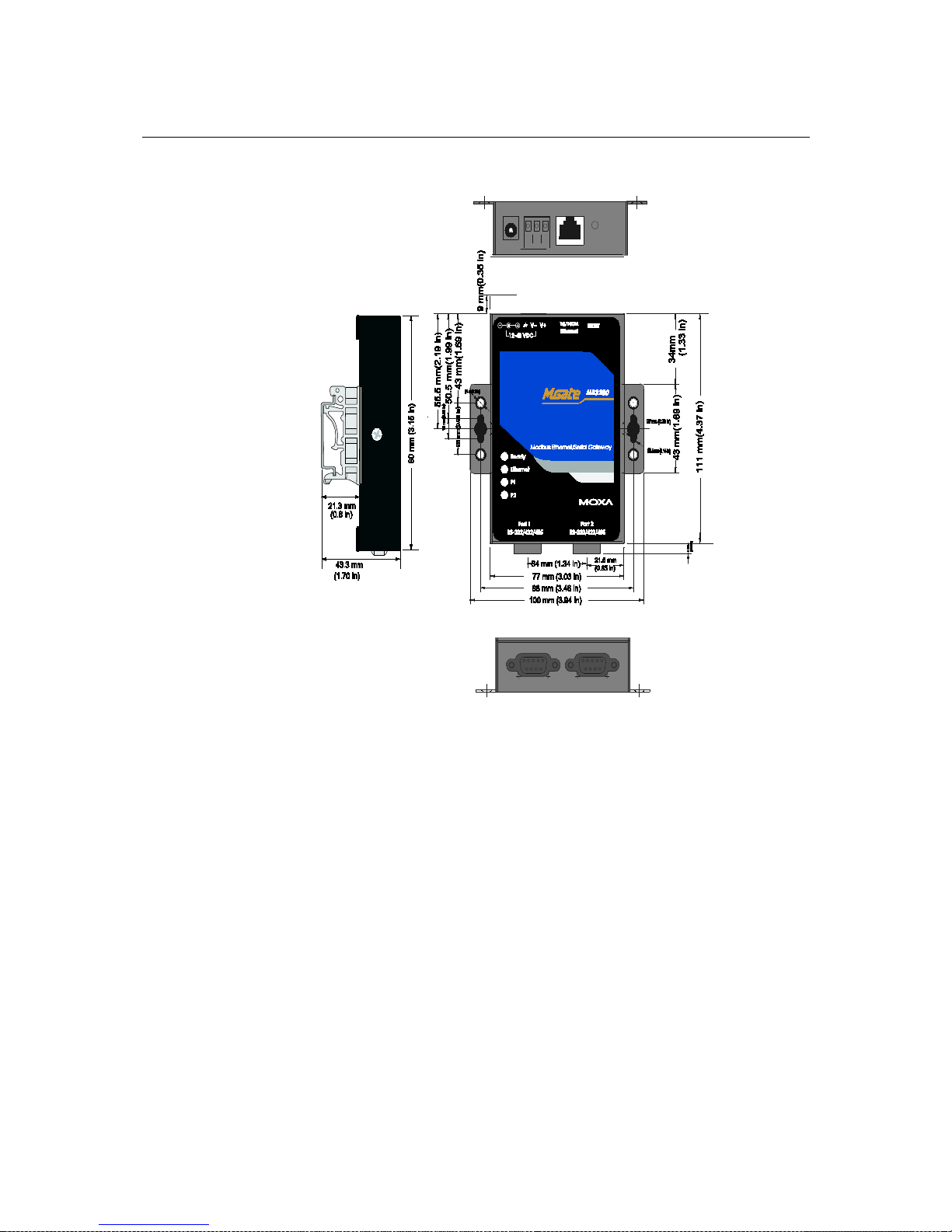

Dimensions

Page 15

MGate MB3000 User’s Manual Hardware: MB3180

3-4

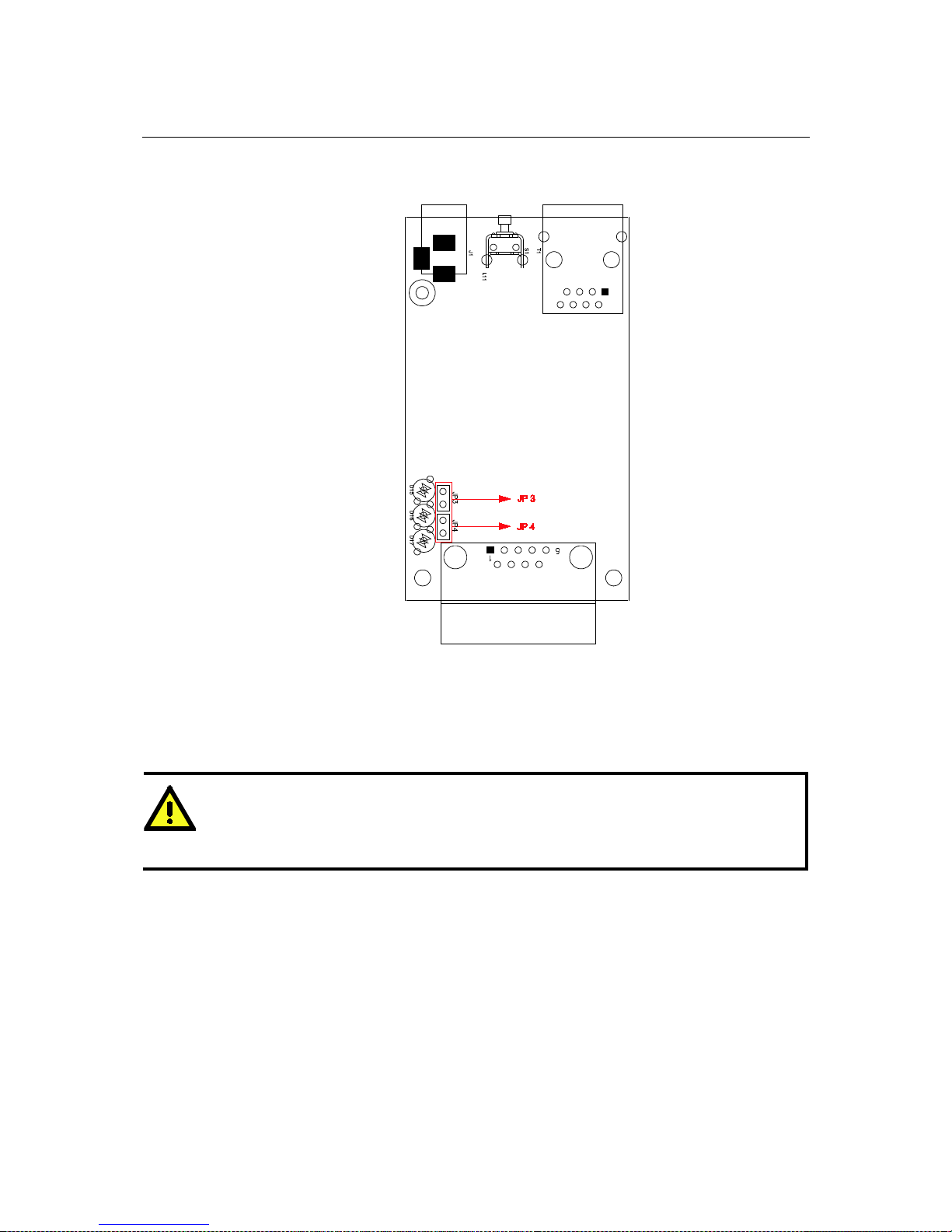

Jumpers

To set the pull high/low resistors to 150 KΩ, leave jumpers JP3 and JP4 open (not shorted). This

is the default setting.

To set the pull high/low resistors to 1 KΩ, short jumpers JP3 and JP4 with jumper caps.

ATTENTION

Do not use the 1 KΩ pull high/low setting on the MGate MB3000 when using the RS-232 interface.

Doing so will degrade the RS-232 signals and reduce the effective communication distance.

Page 16

MGate MB3000 User’s Manual Hardware: MB3180

3-5

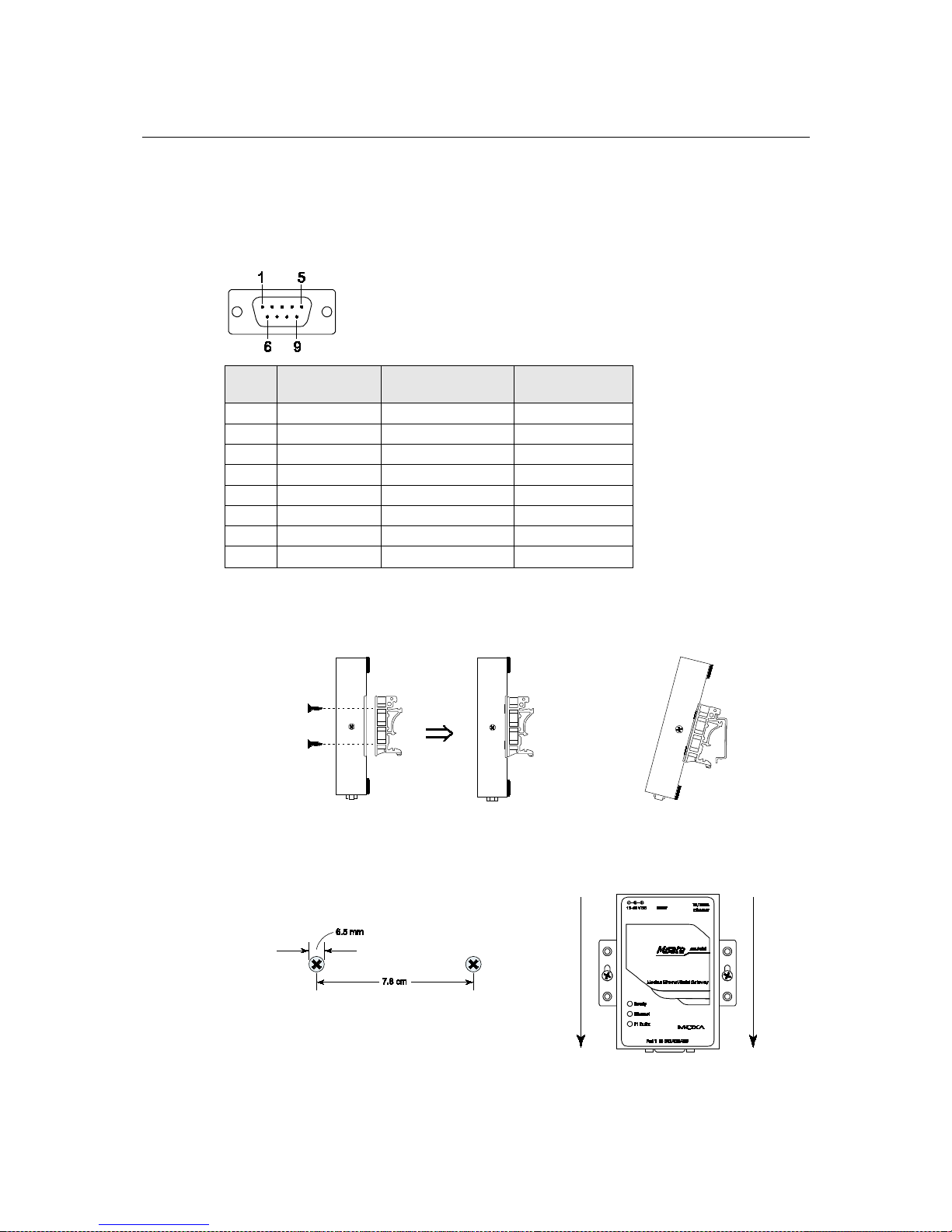

Pin Assignments

DB9 (Male)

The MGate MB3000 uses DB9 (male) serial ports to connect Modbus RTU or ASCII devices. Each

port supports three serial interfaces: RS-232, RS-422, and RS-485 (both 2 and 4-wire).

Pin RS-232

RS-422

RS-485 (4W)

RS-485 (2W)

1

DCD

TxD-

---

2

RxD

TxD+

---

3

TxD

RxD+

Data+

4

DTR

RxD-

Data-

5

GND

GND

GND

6

DSR

---

---

7

RTS

---

---

8

CTS

---

---

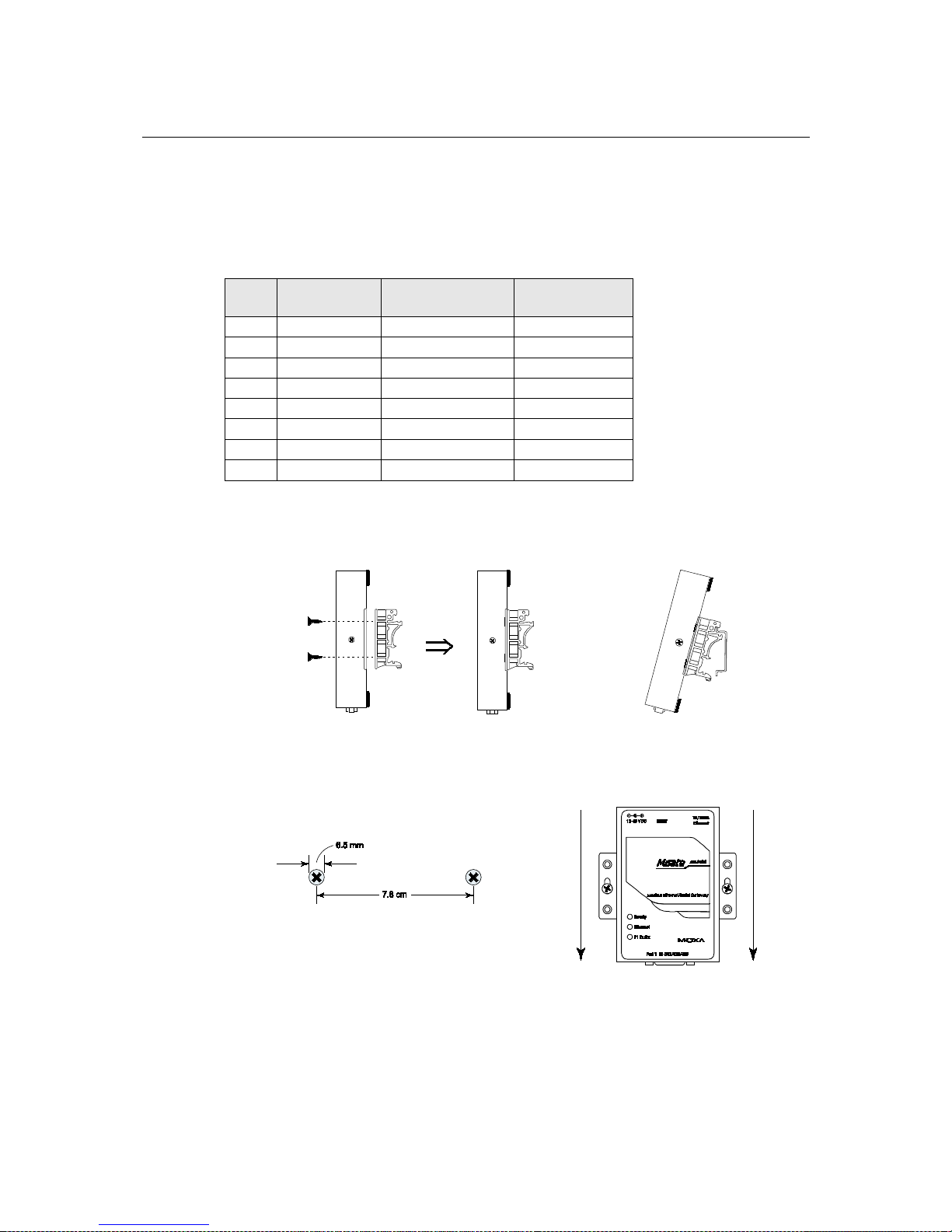

DIN-Rail, Wall Mounting

Mounting on a DIN-rail: Attach the DIN-rail accessories and latch the unit onto the DIN-rail as

shown. The DIN-rail kit is ordered separately.

Mounting on the wall: Place two screws in the wall and slide the unit onto the screws as shown. The

head of each screw 6.5 mm or less in diameter, and the shaft should be 3 mm or less in diameter.

Make sure to leave about 2 mm of space between the head and the wall.

Page 17

MGate MB3000 User’s Manual Hardware: MB3180

3-6

Specifications

LAN

Ethernet

10/100 Mbps, RJ45, Auto MDI/MDIX

Protection

Built-in 1.5 KV magnetic isolation

Serial Interface

Interface

RS-232/422/485

No. of Ports

1 port

Connector Type

DB9 (male)

Signals

RS-232:

TxD, RxD, RTS, CTS, DTR, DSR, DCD, GND

RS-422:

Tx+, Tx -, Rx+, Rx-, GND

RS-485 (2-wire):

Data+, Data-, GND

RS-485 (4-wire)

Tx+, Tx -, Rx+, Rx-, GND

Serial Line Protection

15 KV ESD for all signals

RS-485 Data Direction

Patented ADDC™

Serial Communication Parameters

Parity

None, Even, Odd, Space, Mark

Data Bits

7, 8

Stop Bits

1, 2

Flow Control

RTS/CTS, XON/XOFF

Transmission Speed

50 bps to 921.6 Kbps

Software Features

Operation Mode

RTU Slave, RTU Master, ASCII Slave, ASCII Master

Utilities

MGate Manager

Multi-Masters and

Multi-Request

16 simultaneous TCP masters, 32 simultaneous requests for ea ch TCP

master

Power Requirements

Power Input

12 to 48 VDC

Power Connector

Power jack

Power Consumption

200 mA@12 VDC, 60 mA@48 VDC

Environment

Operating Temperature

0 to 55°C (32 to 13 1°F), 5 to 95%RH

Storage Temperature

-20 to 85°C (-4 to 185°F), 5 to 95% RH

Warranty

Period

5 years

Page 18

4

4

Chapter 4 Hardware: MB3280

This chapter provides hardware information for the MGate MB3280.

The following topics are covered:

Panel Layout

LED Indicators

Dimensions

Jumpers

Pin Assignments

DB9 (Male)

DIN-Rail, Wall Mounting

Specifications

Page 19

MGate MB3000 User’s Manual Hardware: MB3280

4-2

Panel Layout

LED Indicators

Name Color Function

Ready

Red

Steady on: Power is on and unit is booting up.

Blinking: Indicates an IP conflict, or DHCP or BOOTP

server is not responding properly.

Green

Steady on: Power is on and unit is functioning normally.

Blinking: Unit is responding to software Locate function.

Off Power is off, or power error condition exists.

Ethernet

Orange 10 Mbps Ethernet connection.

Green 100 Mbps Ethernet connection.

Off Ethernet cable is disconnected, or has a short.

P1 and P2

Orange Serial port is receiving data.

Green Serial port is transmitting data.

Off

No data is being transmitted or rec e ived through the serial

port.

Page 20

MGate MB3000 User’s Manual Hardware: MB3280

4-3

Dimensions

Page 21

MGate MB3000 User’s Manual Hardware: MB3280

4-4

Jumpers

To add a 120 Ω termination resistor, set switch 3 on the port’s assigned DIP switch to ON; set

switch 3 to OFF (the d e fault setting) to disable the terminatio n re sisto r.

To set the pull high/low resistors to 150 KΩ, set swi tches 1 and 2 on the port’s assigne d DIP switch

to OFF. This is the default setting.

To set the pull high/low resistors to 1 KΩ, set switches 1 and 2 on the port’s assigned DI P switch to

ON.

Switch 4 on the port's assigned DIP switch is reserved.

ATTENTION

Do not use the 1 KΩ pull high/low setting on the MGate MB3000 when using the RS-232 interface.

Doing so will degrade the RS-232 signals and reduce the effective communication distance.

Page 22

MGate MB3000 User’s Manual Hardware: MB3280

4-5

Pin Assignments

DB9 (Male)

The MGate MB3000 uses DB9 (male) serial ports to connect Modbus RTU or ASCII devices. Each

port supports three serial interfaces: RS-232, RS-422, and RS-485 (both 2 and 4-wire).

Pin RS-232

RS-422

RS-485 (4W)

RS-485 (2W)

1

DCD

TxD-

---

2

RxD

TxD+

---

3

TxD

RxD+

Data+

4

DTR

RxD-

Data-

5

GND

GND

GND

6

DSR

---

---

7

RTS

---

---

8

CTS

---

---

DIN-Rail, Wall Mounting

Mounting on a DIN-rail: Attach the DIN-rail accessories and latch the unit onto the DIN-rail as

shown. The DIN-rail kit is order e d separately.

Mounting on the wall: Place two screws in the wall and slide the unit onto the screws as shown. The

head of each screw 6.5 mm or less in diameter, and the shaft should be 3 mm or less in diameter.

Make sure to leave about 2 mm of space between the head and the wall.

Page 23

MGate MB3000 User’s Manual Hardware: MB3280

4-6

Specifications

LAN

Ethernet

10/100 Mbps, RJ45, Auto MDI/MDIX

Protection

Built-in 1.5 KV magnetic isolation

Serial Interface

Interface

RS-232/422/485

No. of Ports

2 ports

Connector Type

DB9 (male)

Signals

RS-232:

TxD, RxD, RTS, CTS, DTR, DSR, DCD, GND

RS-422:

Tx+, Tx -, Rx+, Rx-, GND

RS-485 (2-wire):

Data+, Data-, GND

RS-485 (4-wire)

Tx+, Tx -, Rx+, Rx-, GND

Serial Line Protection

15 KV ESD for all signals

RS-485 Data Direction

Patented ADDC™

Serial Communication Parameters

Parity

None, Even, Odd, Space, Mark

Data Bits

7, 8

Stop Bits

1, 2

Flow Control

RTS/CTS, XON/XOFF

Transmission Speed

50 bps to 921.6 Kbps

Software Features

Operation Mode

RTU Slave, RTU Master, ASCII Slave, ASCII Master

Utilities

MGate Manager

Multi-Masters and

Multi-Request

16 simultaneous TCP masters, 32 simultaneous requests for ea ch TCP

master

Power Requirements

Power Input

250 mA@12 VDC, 90 mA@48 VDC

Power Socket

Power jack and terminal block

Power Consumption

250 mA (max.)

Environment

Operating Temperature

0 to 55°C (32 to 13 1°F), 5 to 95%RH

Storage Temperature

-20 to 85°C (-4 to 185°F), 5 to 95% RH

Warranty

Period

5 years

Page 24

5

5

Chapter 5 Hardware: MB3480

This chapter provides hardware information for the MGate MB3480.

The following topics are covered:

Panel Layout

LED Indicators

Dimensions

Jumpers

Pin Assignments

DB9 (Male)

DIN-Rail, Wall Mounting

Specifications

Page 25

MGate MB3000 User’s Manual Hardware: MB3480

5-2

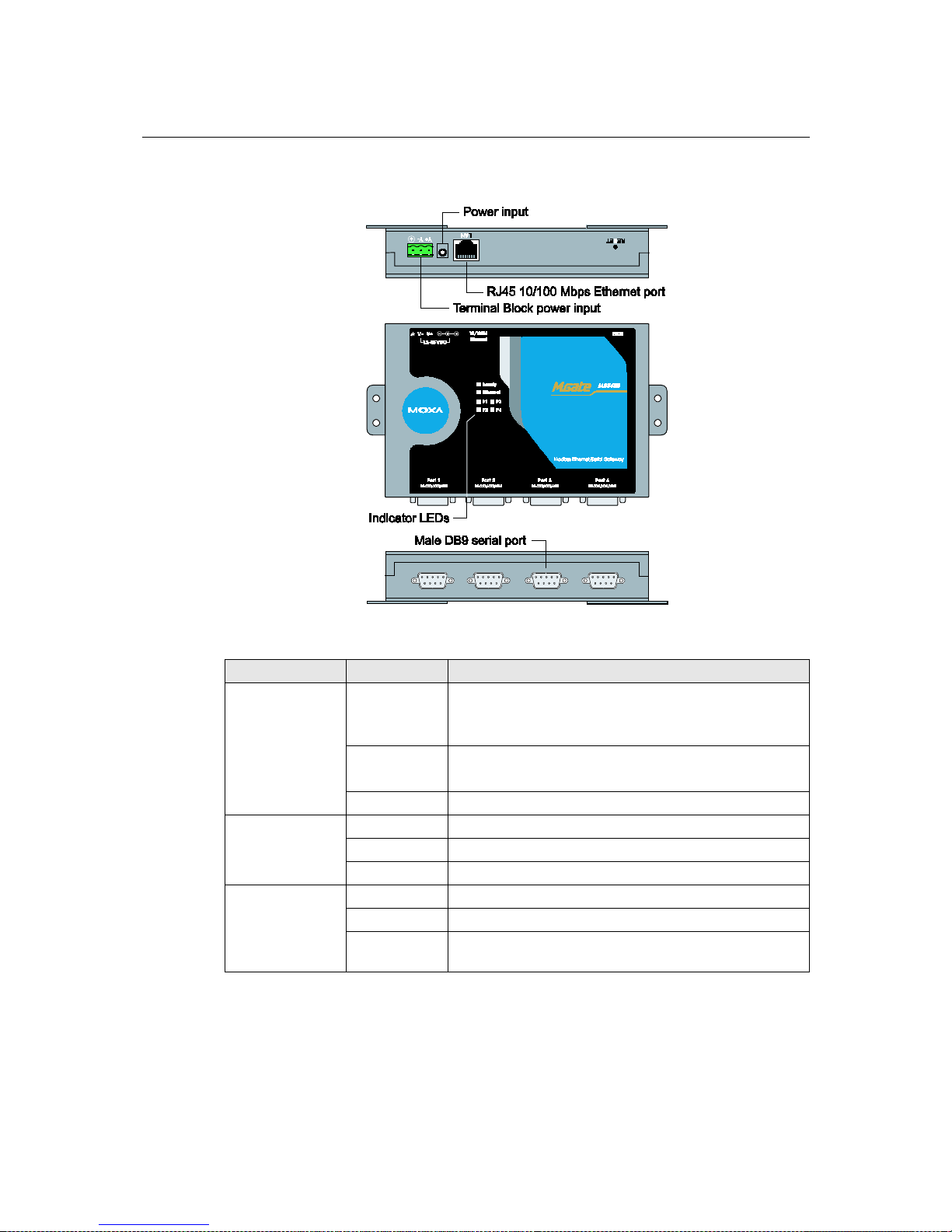

Panel Layout

LED Indicators

Name Color Function

Ready

Red

Steady on: Power is on and unit is booting up.

Blinking: Indicates an IP conflict, or DHCP or BOOTP

server is not responding properly.

Green

Steady on: Power is on and unit is functioning normally.

Blinking: U nit is responding to software Locate function.

Off Power is off, or power error condition exists.

Ethernet

Orange 10 Mbps Ethernet connection.

Green 100 Mbps Ethernet connection.

Off Ethernet cable is disconnected, or has a short.

P1, P2 P3, P4

Orange Serial port is receiving data.

Green Serial port is transmitting data.

Off

No data is being transmitted or rec e ived through the serial

port.

Page 26

MGate MB3000 User’s Manual Hardware: MB3480

5-3

Dimensions

Page 27

MGate MB3000 User’s Manual Hardware: MB3480

5-4

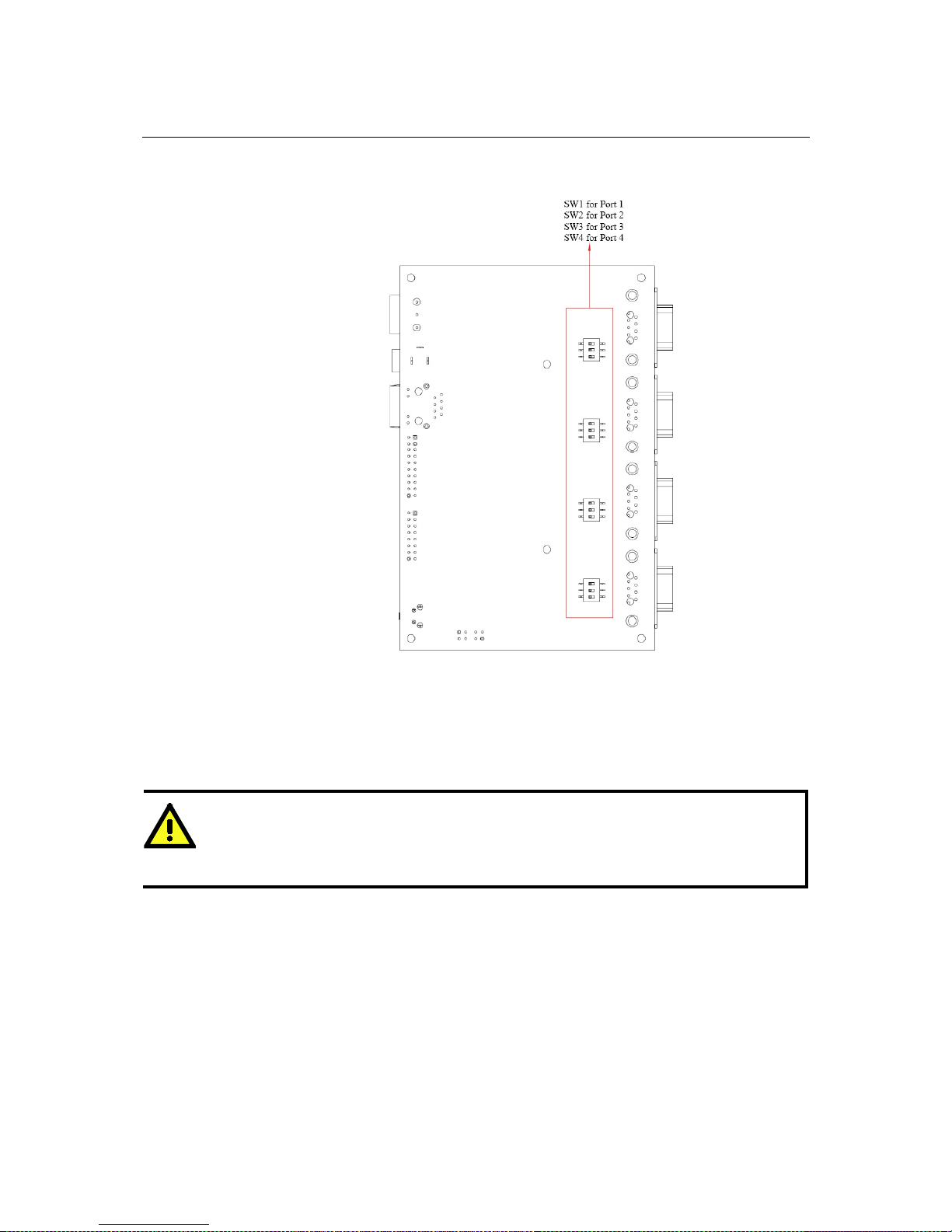

Jumpers

To add a 120 Ω termination resistor, set switch 3 on the port’s assigned DIP switch to ON; set

switch 3 to OFF (the default setting) to disable the termination resistor.

To set the pull high/low resistors to 150 KΩ, set swi tches 1 an d 2 on the port’s assigne d DIP switch

to OFF. This is the default setting.

T o set the pull high/low resistors to 1 KΩ, s et swit ches 1 and 2 on the port’ s assigned DIP switch to

ON.

ATTENTION

Do not use the 1 KΩ pull high/low setting on the MGate MB3000 when using the RS-232 interface.

Doing so will degrade the RS-232 signals and reduc e the effective communication d istance.

Page 28

MGate MB3000 User’s Manual Hardware: MB3480

5-5

Pin Assignments

DB9 (Male)

The MGate MB3000 uses DB9 (male) serial ports to connect Modbus RTU or ASCII devices. Each

port supports three serial interfaces: RS-232, RS-422, and RS-485 (both 2 and 4-wire).

Pin RS-232

RS-422

RS-485 (4W)

RS-485 (2W)

1

DCD

TxD-

---

2

RxD

TxD+

---

3

TxD

RxD+

Data+

4

DTR

RxD-

Data-

5

GND

GND

GND

6

DSR

---

---

7

RTS

---

---

8

CTS

---

---

Page 29

MGate MB3000 User’s Manual Hardware: MB3480

5-6

DIN-Rail, Wall Mounting

Mounting on a DIN-rail: You will first need to attach the mounting plates (included) to the unit.

Attach the DIN-rail accessories to the mounting plates and latch the unit onto the DIN-

rail as shown.

The DIN-rail kit is ordered separately.

Mounting on the wall: You will first need to attach the mounting plates to the unit. Place four

screws in the wall and slide the unit onto the screws as shown.

The head of each screw should be

6 mm or less in diameter, and the shaft should be 3 mm or less in

diameter. Make sure to leave about 5 mm of space between the head and the wall.

Page 30

MGate MB3000 User’s Manual Hardware: MB3480

5-7

Specifications

LAN

Ethernet

10/100 Mbps, RJ45, Auto MDI/MDIX

Protection

Built-in 1.5 KV magnetic isolation

Serial Interface

Interface

RS-232/422/485

No. of Ports

4 ports

Connector Type

DB9 (male)

Signals

RS-232:

TxD, RxD, RTS, CTS, DTR, DSR, DCD, GND

RS-422:

Tx+, Tx -, Rx+, Rx-, GND

RS-485 (2-wire):

Data+, Data-, GND

RS-485 (4-wire)

Tx+, Tx -, Rx+, Rx-, GND

Serial Line Protection

15 KV ESD for all signals

RS-485 Data Direction

Patented ADDC™

Serial Communication Parameters

Parity

None, Even, Odd, Space, Mark

Data Bits

7, 8

Stop Bits

1, 2

Flow Control

RTS/CTS, XON/XOFF

Transmission Speed

50 bps to 921.6 Kbps

Software Features

Operation Mode

RTU Slave, RTU Master, ASCII Slave, ASCII Master

Utilities

MGate Manager

Multi-Masters and

Multi-Request

16 simultaneous TCP masters, 32 simultaneous requests for ea ch TCP

master

Power Requirements

Power Input

12 to 48 VDC

Power Socket

Power jack and terminal block

Power Consumption

460 mA@12 VDC, 170 mA@48 VDC

Environment

Operating Temperature

0 to 55°C (32 to 13 1°F), 5 to 95%RH

Storage Temperature

-20 to 85°C (-4 to 185°F), 5 to 95% RH

Warranty

Period

5 years

Page 31

6

6

Chapter 6 Hardware: MB3170, MB3170I

This chapter provides hardware information for the MGate MB3170 and MB3170I.

The following topics are covered:

Panel Layout

LED Indicators

Dimensions

Jumpers

Pin Assignments

DB9 (Male)

Terminal Block (RS-422, RS-485)

Power Input, Relay Output

DIN-Rail, Wall Mounting

Specifications

Page 32

MGate MB3000 User’s Manual Hardware: MB3170, MB3170I

6-2

Panel Layout

LED Indicators

Name

Color

Function

PWR1 Red

Power is being supplied to the power input.

PWR2 Red

Power is being supplied to the power input.

RDY

Red

Steady on: Power is on and unit is booting up.

Blinking: Indicates an IP conflict, or DHCP or BOOTP

server is not responding properly.

Green

Steady on: Power is on and unit is functioning normally.

Blinking: U nit is responding to software Locate function.

Off

Power is off, or power error condition exists.

Ethernet

Orange

10 Mbps Ethernet connection.

Green

100 Mbps Ethernet connection.

Off

Ethernet cable is disconnected, or has a short.

P1

Orange

Serial port is receiving data.

Green

Serial port is transmitting data.

Off

No data is being transmitted or rec e ived through the serial

port.

Page 33

MGate MB3000 User’s Manual Hardware: MB3170, MB3170I

6-3

Dimensions

Page 34

MGate MB3000 User’s Manual Hardware: MB3170, MB3170I

6-4

Jumpers

The DIP switches are located beneath the DIP switch panel on the side of the unit.

To add a 120 Ω termination resistor, set switch 3 to ON; set switch 3 to OFF (the default setting) to

disable the termination resistor.

To set the pull high/low resistors to 150 KΩ, set switches 1 and 2 to OFF. This is the default

setting.

To set the pull high/low resistors to 1 KΩ, set switches 1 and 2 to ON.

Switch 4 on the port’s assigned DIP switch is reserve d.

ATTENTION

Do not use the 1 KΩ pull high/low setting on the MGate MB3000 when using the RS-232 interface.

Doing so will degra d e the RS-23 2 signals and reduce the effective communication distance.

Page 35

MGate MB3000 User’s Manual Hardware: MB3170, MB3170I

6-5

Pin Assignments

DB9 (Male)

The MGate MB3170 and MB3170I use a DB9 (male) serial port for RS-232 connections to Modbus

RTU or ASCII devices.

Pin RS-232

1

DCD

2

RxD

3

TxD

4

DTR

5

GND

6

DSR

7

RTS

8

CTS

Terminal Block (RS-422, RS-485)

The MGate MB3170 and MB3170I use a terminal block connector for RS-422 and RS-485

connections t o Modbus RTU or ASCII devices.

Pin

RS-422

RS-485 (4W)

RS-485 (2W)

1

TxD+

---

2

TxD-

--- 3 RxD+

Data+

4

RxD-

Data-

5

GND

GND

Page 36

MGate MB3000 User’s Manual Hardware: MB3170, MB3170I

6-6

Power Input, Relay Output

V2+

V2- V1+

V1-

Shielded

Ground

DC Power

Input 1

DC Power

Input 1

Relay

Output

Relay

Output

DC Power

Input 2

DC Power

Input 2

DIN-Rail, Wall Mounting

There are two sliders on the back of the unit for DIN-rail and wall mounting.

Mounting on a DIN-rail: Pull out the bottom slider, latch the unit onto the DIN-rail, and push the

slider back in.

Mounting on the wall: Pull out both the top and bottom sliders and align the screws accordingly.

Page 37

MGate MB3000 User’s Manual Hardware: MB3170, MB3170I

6-7

Specifications

LAN

Ethernet

10/100 Mbps, RJ45, Auto MDI/MDIX

Protection

Built-in 1.5 KV magnetic isolation

Serial Interface

Interface

RS-232/422/485

No. of Ports

1 port

Connector Type

DB9 (male) for RS-232, terminal block for RS-422/485

Signals

RS-232:

TxD, RxD, RTS, CTS, DTR, DSR, DCD, GND

RS-422:

Tx+, Tx -, Rx+, Rx-, GND

RS-485 (2-wire):

Data+, Data-, GND

RS-485 (4-wire):

Tx+, Tx -, Rx+, Rx-, GND

Serial Line Protection

15 KV ESD for all signals

RS-485 Data Direction

Patented ADDC™

Serial Communication Parameters

Parity

None, Even, Odd, Space, Mark

Data Bits

7, 8

Stop Bits

1, 2

Flow Control

RTS/CTS, XON/XOFF

Transmission Speed

50 bps to 921.6 Kbps

Software Features

Operation Mode

RTU Slave, RTU Master, ASCII Slave, ASCII Master

Utilities

MGate Manager

Multi-Masters and

Multi-Request

16 simultaneous TCP masters, 32 simultaneous requests for ea ch TCP

master

Power Requirements

Power Input

12 to 48 VDC

Power Socket

Terminal block

Power Consumption

MB3170: 400 mA@12 VDC, 130 mA@48 VDC

MB3170I: 405 mA@12 VDC, 140 mA@48 VDC

Relay Output

1 digital relay output to alarm (normal close):

Current carrying capacity 1 A @ 30 VDC

Environment

Operating Temperature

0 to 55°C (32 to 13 1°F), 5 to 95%RH

-40 to 75°C (-40 to 167°F), 5 to 95%PH for “-T” models

Storage Temperature

-40 to 85°C (-40 to 185°F), 5 to 95% RH

Warranty

Period

5 years

Page 38

7

7

Chapter 7 Hardware: MB3270, MB3270I

This chapter provides hardware information for the MGate MB3270 and MB3270I. The following

topics are covered:

Panel Layout

LED Indicators

Dimensions

Jumpers

Pin Assignments

DB9 (Male)

Power Input, Relay Output

DIN-Rail, Wall Mounting

Specifications

Page 39

MGate MB3000 User’s Manual Hardware: MB3270, MB3270I

7-2

Panel Layout

LED Indicators

Name

Color

Function

PWR1 Red

Power is being supplied to the power input.

PWR2 Red

Power is being supplied to the power input.

RDY

Red

Steady on: Power is on and unit is booting up.

Blinking: Indicates an IP conflict, or DHCP or

BOOTP server is

not responding properly.

Green

Steady on: Power is on and unit is functioning normally.

Blinking: U nit is responding to software Locate function.

Off

Power is off, or power error condition exists.

Ethernet

Orange

10 Mbps Ethernet connection.

Green

100 Mbps Ethernet connection.

Off

Ethernet cable is disconnected, or has a short.

P1, P2

Orange

Serial port is receiving data.

Green

Serial port is transmitting data.

Off

No data is being tra nsmit ted or re ceiv ed th rough the serial port.

Page 40

MGate MB3000 User’s Manual Hardware: MB3270, MB3270I

7-3

Dimensions

Page 41

MGate MB3000 User’s Manual Hardware: MB3270, MB3270I

7-4

Jumpers

The DIP switches are located beneath the DIP switch panel on the side of the unit.

To add a 120 Ω termination resistor, set switch 3 on the port’s assigned DIP switch to ON; set

switch 3 to OFF (the default setting) to disable the termination resistor.

To set the pull high/low resistors to 150 KΩ, set swi tches 1 an d 2 on the port’s assigne d DIP switch

to OFF. This is the default setting.

To set the pull high/low resistors to 1 KΩ, set switches 1 and 2 on the port’ s assigned DIP switch to

ON.

Switch 4 on the port's assigned DIP switch is reserved.

ATTENTION

Do not use the 1 KΩ pull high/low setting on the MGate MB3000 when using the RS-232 interface.

Doing so will degrade the RS-232 signals and reduce the effective communication distance.

Page 42

MGate MB3000 User’s Manual Hardware: MB3270, MB3270I

7-5

Pin Assignments

DB9 (Male)

The MGate MB3000 uses DB9 (male) serial ports to connect Modbus RTU or ASCII devices. Each

port supports three serial interfaces: RS-232, RS-422, and RS-485 (both 2 and 4-wire).

Pin RS-232

RS-422

RS-485 (4W)

RS-485 (2W)

1

DCD

TxD-

---

2

RxD

TxD+

---

3

TxD

RxD+

Data+

4

DTR

RxD-

Data-

5

GND

GND

GND

6

DSR

---

---

7

RTS

---

---

8

CTS

---

---

Power Input, Relay Output

V2+ V2-

V1+ V1-

Shielded

Ground

DC Power

Input 1

DC Power

Input 1

Relay

Output

Relay

Output

DC Power

Input 2

DC Power

Input 2

Page 43

MGate MB3000 User’s Manual Hardware: MB3270, MB3270I

7-6

DIN-Rail, Wall Mounting

There are two sliders on the back of the unit for DIN-rail and wall mounting.

Mounting on a DIN-rail: Pull out the bottom slider, latch the unit onto the DIN-rail, and push the

slider back in.

Mounting on the wall: Pull out both the top and bottom sliders and align the screws accordingly.

Page 44

MGate MB3000 User’s Manual Hardware: MB3270, MB3270I

7-7

Specifications

LAN

Ethernet

10/100 Mbps, RJ45, Auto MDI/MDIX

Protection

Built-in 1.5 KV magnetic isolation

Serial Interface

Interface

RS-232/422/485

No. of Ports

2 ports

Connector Type

DB9 (male)

Signals

RS-232:

TxD, RxD, RTS, CTS, DTR, DSR, DCD, GND

RS-422:

Tx+, Tx -, Rx+, Rx-, GND

RS-485 (2-wire):

Data+, Data-, GND

RS-485 (4-wire):

Tx+, Tx -, Rx+, Rx-, GND

Serial Line Protection

15 KV ESD for all signals

RS-485 Data Direction

Patented ADDC™

Serial Communication Parameters

Parity

None, Even, Odd, Space, Mark

Data Bits

7, 8

Stop Bits

1, 2

Flow Control

RTS/CTS, XON/XOFF

Transmission Speed

50 bps to 921.6 Kbps

Software Features

Operation Mode

RTU Slave, RTU Master, ASCII Slave, ASCII Master

Utilities

MGate Manager

Multi-Masters and

Multi-Request

16 simultaneous TCP masters, 32 simultaneous requests for ea ch TCP

master

Power Requirements

Power Input

12 to 48 VDC

Power Socket

Terminal block

Power Consumption

MB3270: 410 mA@12 VDC, 145 mA@48 VDC

MB3270I: 470 mA@12 VDC, 150 mA@48 VDC

Relay Output

1 digital relay output to alarm (normal close):

Current carrying capacity 1 A @ 30 VDC

Environment

Operating Temperature

0 to 55°C (32 to 13 1°F), 5 to 95%RH

-

40 to 75°C (-40 to 167°F), 5 to 95%PH for advanced models with “-

T”

option

Storage Temperature

-40 to 85°C (-40 to 185°F), 5 to 95% RH

Warranty

Period

5 years

Page 45

8

8

Chapter 8 Typical Applications

In this chapter, we introduce four typical Modbus applications.

Ethernet Masters with Multiple Serial Slaves

Serial Masters with Multiple Ethernet Slaves

Modbus TCP Masters with ASCII and RTU Slaves

Serial Master with Serial Slaves over Internet

Page 46

MGate MB3000 User’s Manual Ty pi cal Applications

8-2

Ethernet Masters with Multiple Serial Slaves

Connect all Modbus devices over an Ethernet network

Most modern PLCs and host computers support Modbus TCP over Ethernet. In order to access

discrete Modbus RTU/ASCII devices for data collection and control, they can rely on the MGate

MB3000 Modbus gateway.

The MGate MB3000 supports Modbus TCP with up to 16 simultaneous connections. The serial

interface support s both RS-232 an d RS-422/485, selectable through software. Each serial port can be

connected to one RS-232 or RS-422 serial device, or to 31 RS-485 serial devices.

Serial Masters with Multiple Ethernet Slaves

Link a serial master device with Ethernet slave devices

Many HMI (Human Machine Interface) systems use a serial interface to connect to a discrete DCS

(Data Control System). However, many DCSs are n ow Ethernet-based and operate as a Modbus TCP

slave device.

The MGate MB3000 Modbus gateway can link a serial-based HMI to distributed DCSs over an

Ethernet network. Up to 32 Modbus TCP slave devices are supported by each MGate MB3000.

Page 47

MGate MB3000 User’s Manual Ty pi cal Applications

8-3

Modbus TCP Masters with ASCII and RTU Slaves

Link TCP master devices with both ASCII and RTU serial devices

simultaneously

When integrating Modb us networks, you may encounter different Modbus serial networks that use

different baudrates or a different protocol. Modbus ASCII might be used by some devices, while

Modbus RTU is used by other devices.

The two and four-port MGate models can integrate serial Modbus networks that use different

parameters or protocols. You can configure each serial port to a specific Modbus serial environment,

set up a slave ID map. After configuration, only the gateway will be visible to Modbus TCP masters,

and all serial devices will be integrated behind it.

Serial Master with Serial Slaves over Internet

Let Modbus serial devices communicate over the Internet

Many Modbus devices communicate over RS-485, which lim its t h e number of devices in a network

to 32 and the transmission distance to 1.2 km.

With the MGate MB3000 Modbus gateway, you can lin k all Modbus devices over a n Ethernet

network. Up to 32 Modbus gateways can be installed in a single cont rol network, so each device can

now be accessed from anywhere the TCP/IP network can reach.

Page 48

9

9

Chapter 9 Configuring the Modbus Gateway

We discuss the following topics in this chapter:

Installing the Softwa re

Startin g MGate Mana ger

Change Language Settin g

Connecting to the Unit

Broadcast Search

Specify by IP Address

Modifying the Configuration

Configure Serial Port for RTU or ASCII, Master or Slave

Configure IP Address and Other Network Settings

Configure Serial Communication Parameters

Set up Slave ID Mapping (Smart Routing)

Customize Modbus Settings

Set Up Priority Control

Accessible IP

Miscellaneous

Verifying the Location of

the Unit

Monitoring Modbus Activity

Open Traffic Monitor Window

Filter Traffic Information

Save Log to File

Upgrading Firmware

Page 49

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-2

Installing the Software

The following instructions exp la in how to install MGate Manager, a utility for configuring and

monitoring MGate MB3000 units over t he network.

1. Insert the Document and Software CD int o the CD-ROM drive. Locate and run the following

setup program to begin the installation pr ocess:

MGM_Setup_[Version]_Build_[DateTime].exe

The latest version might be named MGM_Setup_Ver1.1.0_Build_xxxxxxxx.exe, for

example:

2. You will be greeted by the Welcome window. Click Next to continue.

3. When the Select Destination Location window appears, click Next to continue. You may

change the destination directory by fir st clic king on Browse....

Page 50

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-3

4. When the Select Additional T asks window appears, click Next to c ontinue. You may select

Create a desktop icon if you would like a shortcut to MGate Manager on your desktop.

5. Click Next to start copying the software files.

6. A progress bar will appear. The procedure should take only a few seconds to complete.

Page 51

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-4

7. A mes s age w ill indicate that MGat e Manager is successfully installed. You may choose to run it

immediately by selecting Launch MGate Manager.

8. You may also open MGate Manager through Start

Programs MGate Manager

MGate Manager, as shown below.

Page 52

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-5

Starting MGate Manager

MGate Manager is a Windows-based utility that is used to configure the MGate MB3000.

Before running MGate Manager, make sure that your PC and the MGate MB3000 are connected to

the same network. Alternatively, the MGate MB3000 may be connected directly to the PC for

configuration purposes. Please refer to Chapter 2 for more details.

You may open MGate Manager from the Windows Start menu by clicking Start

Programs

MGate Manager

MGate Manager. The MGate Manager window should appear as shown

below.

Change Language Setting

If you wish to run MGate Ma nager in a di fferent language , you may click Language to change the

language setting. A dialog box showing the available languages should a ppear as shown below.

Page 53

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-6

When you click OK, MGate Manager will immediately reflect your chosen language.

ATTENTION

Use “Default Language” before contacting Moxa Technical Support.

With support for multiple languages, MGate Manager is more user-friendly and accessible.

However, if you need assistance from Moxa Technical Support, please change the language to

“Default Language”. This will prevent any misunderstandings or confusion about MGate Manager

menu items and commands as our engineers assist you.

The default language is English and will only be active for the current MGate Manager session.

When you open MGate Manager again, t he language will revert to your original setting.

Connecting to the Unit

MGate Manager needs to connect to the unit before the unit can be configured. There are two

methods to connect to the unit. Broadcast Sear ch is used to find eve ry MGate MB3000 on the LAN.

Search by IP attempts to connect to a spec ific unit by IP address, which is useful if the unit is

located outside the LAN or can only be accessed by going through a router.

Page 54

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-7

Broadcast Search

Click Broadcast Search to begin searching the LAN for all MGate MB3000 units.

When the search is complete, every MGate MB3000 that is found on the LAN will app e a r in the

window with MAC address and IP address. Simply select the one that you wish to configure.

Page 55

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-8

Specify by IP Address

Click Specify by IP Addr ess if you know the IP address of the unit and wish to conn ect to it direct ly.

A dialog box will appear. Enter the unit’s IP address and click OK.

If the search is successful, the unit will be listed in MGate Manager. Click the unit to begin

configuration.

Page 56

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-9

ATTENTION

If Search by IP Address fails to locate the MGate MB3000, the IP address that you entered might

be incorrect. Try doing the search again and re-entering the IP address carefully.

Another possibility is that the MGate MB3000 is located on the same LAN as your PC, but on a

different subnet. In this case, you can modify your PC’s IP address and/or netmask so that it is on

the same subnet as the MGate MB3000. After your PC and the MGate MB3000 are on the same

subnet, MGate Manager should be able to find the unit.

Modifying the Configuration

Once your unit is displayed in MGate Manager , select it by clicking on it. The Configuration button

will become available. Click Configuration to open the configuration window.

Page 57

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-10

Configure Serial Port for RTU or ASCII, Master or Slave

The Mode tab is where each serial port’s operation mode is configured. The operation mode

determines whether the device(s) that are connected to the serial port will operate as a master or a

slave, and whether the Modbus RTU or Modbus ASCII protocol will be used. There are four

operation modes as follows:

Mode

Description

RTU Slave

Modbus RTU slave(s) will be connected to the serial port.

RTU Master

A Modbus RTU master will be connected to the serial port.

ASCII Slave

Modbus ASCII slave(s) will be connected to the serial port.

ASCII Master

A Modbus ASCII master will be connected to the serial port.

For entry-level models (MB3180, MB3280, and MB3480), Modbus TCP masters will control

Modbus RTU/ASCII slaves, and Modbus RTU/ASCII masters will control Modbus TCP slaves.

For advanced models (MB3170, MB3270), both Modbu s TCP and Modbus RTU/ASCII masters

can control Modbus TCP and Modbus RTU/ASCII slaves.

Use the radio buttons to select the desired operation mode for each serial port on the Modbus

gateway. Select the ProCOM Enable check box located in the center of the page to enable ProCOM.

For detailed information, refer to the ProCOM function description in this manual.

Page 58

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-11

What is ProCOM?

ProCOM is a Moxa proprietary function that creates virtual serial ports on the MGate MB3000

Series to make Fieldbus gateway communications more versatile. This intelligent Fieldbus gateway

mimics the behavior of a native serial port when transmitting data to the desired destination. PCs can

use ProCOM to communicate over the Ethernet with serial devices connected to the MGate MB3000

as if they were connected to the PC’s native COM ports. This advanced feature only works with the

MGate MB3x70 Series.

How to Configure ProCOM for the MGate MB3000

If your system uses remote PCs that only support COM port behavior to control remote Modbus

devices, then ProCOM is the best solution for your system. Before using ProCOM, your PC needs to

create virtual COM ports that connect to a specific ProCOM over an Ethernet network. B y us ing

ProCOM, the MGate MB3000 will treat your PC’s COM port as if it were an additional serial port on

the MGate MB3000.

To enable this function, ProCOM mapping must be completed as follows:

Locate the MGate MB3000 with the search function, and then select the MGate MB3000 device that

you want to set Pr oCO M for, and then click ProCOM Mapping to enter the mapping dialog box, as

illustrated by the following figure s.

Page 59

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-12

On the ProCOM mapping dialog box, you can map up to four ProCOM fun ctions for each Modb us

gateway to your PC’s COM ports. The driver will generate virtaul COM ports on your PC to connect

to the selected MGate MB3000s over the network.

This way, when you send a Modbus request to ProCOM, the driver will forward your request to the

MGate MB3000 and then the MGate MB3000 will forward the request to the target Modbus device

using the pre-set Modbus device mode and Slave ID. For example, the Modbus request from

ProCOM can be redirected to a Modbus RTU/ASCII device that is behind the MGate MB3000's

serial interface, or to a Modbus TCP device through the MG ate MB3000's Ethernet port. In addition,

it can be redirected to another ProCOM port on the MGate MB3000.

Page 60

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-13

If you would l ike to change the COM port numbers, double click on the items as follows:

Page 61

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-14

Configure IP Address and Other Network Settings

The Network tab is where the unit’s network settings are configured. You can modify the Name,

Network Config uratio n, IP Address, Netmask, Default Gatew ay, and DNS. You may also

select a Password to protect the unit from unauthorized access.

Page 62

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-15

Parameter

Value

Notes

Name (an alphanumeric string)

You can enter a name to help you identif y the

unit, such as the location, function, etc.

Network

Configuration

Static IP, DHCP, BootP, or

DHCP/BootP

Select “Static IP” if you are using a fixed IP

address. Select one of the other options if the IP

address is set dynamically.

IP Address

192.168.127.254

(or other 32-bit number)

The IP (Internet Protocol) address identifies the

server on the TCP/IP network.

Netmask

255.255.255.0

(or other 32-bit number)

This

identifies the server as belonging to a Class

A, B, or C network.

Gateway

0.0.0.0

(or other 32-bit number)

This is the IP address of the router that provides

network access outside the server’s LAN.

DNS1

0.0.0.0

(or other 32-bit number)

This is the IP address of the primary domain

name server.

DNS2

0.0.0.0

(or other 32-bit number)

This is the IP address of the secondary domain

name server.

Password (an alphanumeric string)

You can set a password to prevent unauthorized

users from co nfiguring the unit. The password

will be required when anyone atte mpts to

configure the unit over the network. M odbus

operation is not affected by the password.

Confirm password

(an alphanumeric string)

Re-type the password again for confirmation.

ATTENTION

To erase an existing password, leave both the New Password and Confirm Password text input

boxes blank. The password will be erased when you click OK in the bottom right corner.

Page 63

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-16

Configure Serial Communication Parameters

The Serial tab is where each serial port’s communication parameters are configured. You can

configure Baud Rate, Parity, Stop Bit, Flo w Con trol, FIFO, and Interface Mode.

Parameter

Value

Interface Mode

RS-232

RS-422

RS-485, 2W

RS-485, 4W

Baud Rate

50 bps to 961200 bps

Parity

None, Odd, Even, Space, Mark

Stop Bits

1, 2

Flow Control

None, Xon/Xoff, RTS/CTS

UART FIFO

Enable, Disable

Page 64

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-17

Set up Slave ID Mapping (Smart Routing)

The Slave ID Map tab is where slave IDs are managed. The definitions on this tab determine how

requests will be routed by the unit.

Page 65

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-18

How Slave IDs are Mapped on the MGate MB3000

When a Modbus master requests information from a Modbus slave, the request is addressed to the

desired slave's ID, which must be unique on the network. When Modbus networks are integrated by

a Modbus gateway, complications can arise if the same slave ID is being used on dif ferent netw orks.

If this is not properly addres sed, a request sent to that slave ID would receive more than one response,

causing communication problems.

With the MGate MB3000, this situation is addressed by using a slave ID map. While configuring the

MGate, users set up a range of "virtual" slave IDs that are mapped to slave devices on a specific

Modbus network. To send a request to a s lave th at is on a dif feren t Modbus network, a master would

address the request to the appropriate virtual slave ID. The MGate then routes that request as

specified by the slave ID map.

For example, if a TCP master needs information from an ASCII slave, it addresses the request to the

correspo nding virtual slave ID as defined on the MGate's slave ID map. The MGate identifies the

request as within its virtual slave ID range and forwards the request to the Modbus ASCII network,

this time addressed to the device's actual slave ID.

Virtual slave IDs must not conflict with each other or with other TCP slave IDs.

ATTENTION

The MGate MB3000 will disregard any request that is not addressed to a virtual slave ID on its

slave ID map. If a device has not been assigned a virtual slave ID, it will not be accessible by

masters on the other side of the Modbus gateway.

With the slave ID map, smart routing is achieved for units w ith multiple serial ports. Since each

virtual slave ID is routed to a specific Modbus network, requests are not broadcast over all serial

ports. This keeps communication efficient and prevents devices on one port from slowing down the

whole system.

How Slave ID Map is Defined

The slave ID map consists of entries (channels) that specify a range of virtual IDs, the destination,

and the offset value. The offset value is used to convert the virtual ID to the actual ID.

Setting

Value

Notes

Virtual Slaves ID Range

(numeric range from

1 to 254)

This specifies the range of IDs that will be

routed to the selected set of slave devices.

For example, you can specify that IDs

between 8 and 24 be routed to the devices

on Port 3. The ID 255 is reserved for the

gateway itself

Slave ID Offset

(number between

-253 and 253)

This specifies the difference between the

virtual slave ID and the actual slave ID.

If a

slave's virtual ID is 16 and the actual ID is

5, you would set the offset to -11. This

offset is applied to the entire range of

virtual slave IDs.

When a serial port is set to RTU slave or ASCII slave mode, a virtual ID range will already be

created for you. Simple select the entry in the table and modify the range and offset as needed. For

TCP slaves, you can add an entry that assigns a range of virtual IDs to a specific IP address, using the

Remote TCP Slave IP setting.

Page 66

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-19

Slave ID Map Example

Suppose you have two ASCII slave devices on port 1 assigned to slave IDs 3 and 5. The MGate will

automatically create a virtual ID range for port 1, which you will need to modify. If slave IDs 3 and

5 are already in use by TCP slaves, the virtual ID range should be set to IDs that are not in use, such

as 20 through 22. In that case, you would specify a slave ID offset of -17, since that is the difference

between the virtual ID range and the actual slave IDs. The formula is as follows:

(Real Slave ID)

-

(Virtual Slave ID)

=

(Slave ID Offset)

3 - 20 = -17

With the slave ID map configured, a master that wants information from one of the ASCII slaves

would add ress the request to slave ID 20 or 22. The MGate would identify that the request was

addressed to a virtual slave ID in the slave ID map. The MGate would then forward the request to

port 1, applying the -17 offset to obtain the actual ID of the desired device.

Customize Modbus Settings

The Modbus tab is where certain adjustments can be made to fine tune the communication between

different Modbus networks. You can configure Initial Delay, Modbus TCP Exception, Slave

Channel, and Response Time-out.

Parameter

Value

Initial Delay

Numeric

Modbus TCP Exception

Enable or Disable

Slave Channel

Radio button

Response Time-out

Numeric

Initial Delay

Some Modbus slaves may take more time to boot up than other devices. For certain environments,

this may cause the entire system to suffer fro m repea te d exceptions during the initial boo t-up. Y ou

can force the MGate to wait af ter b oo tin g up b e fore s e ndi ng t he fir st request with the “Ini tia l

Delay” setting.

Modbus TCP Exception

The MGate MB3000 is a protocol gateway that transparently passes requests and responses between

the Ethernet and serial interfaces. In some situations, it may be necessary for the gateway to return an

exception in response to a request from a Modbus TCP master. This is enabled or disabled with the

“Modbus TCP Excep t ion” setting. When enabled, t he unit can return two types of exceptio n:

Exception

Conditions

Timeout

There is no response from the slave. Maybe the device is off-line

or the serial cable is broken.

Request dropped

There are two situations that will resul t in this exception:

The request queue is full (32 request queue for each master)

The destinat ion ID not included in the slave ID map.

Not all Modbus TCP masters require this exception, so it is up to you to dete rmine if this setting

should be enabled.

Page 67

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-20

Slave Channel and Response Timeout

According to th e Modbus standard, the time that it takes for a sl ave dev ice t o respond to a requ est is

defined by the device manufacturer (please refer to Appendix A for details). Based on this response

time, a master can be configured to wait a certain amount of time for a slave’s response. If no

response is received within the specified time, the master will disregard the request and continue

operation. This allows the Modbus system to continue operation even if a slave device is

disconnected or faulty.

On the MGate MB3000, the “Response Time-out” field is used to configure ho w long the gateway

will wait for a response from a Modbus A SCII or RTU slave. This field is s et independent ly for each

serial port, which is selected through the “Slave Channel” field. Please refer to your device

manufacturer’s documentation to manually set the response time-out.

The MGate MB3000 also provides automatic calibration of the response timeout. Instead of

manually figuring out the appropriate setting, you can click “Auto Detection” to have the MGate

figure out the setting for you. Once a value has been recommended, you can fine-tune it for best

performance.

Page 68

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-21

ATTENTION

Please note the following regard ing automatic calibration of response ti meo uts:

When automatically detecting the response timeout, the MGate will use the slave ID map to

determine which ports and which IDs to search. Make sure that you have defined the slave ID map

for your system before clicking “Auto D e te c tion”.

The automatic calibration will take some time to complete. We recommend that you save this step

for last and take a break as the MGate does its work.

Set Up Priority Control

The Priority Contr ol tab is where emergency requests are enabled and conf igured. This is available

for advanced models only (MB3170, MB3170I, and MB3270).

Page 69

MGate MB3000 User’s Manual Configuring the Modbus Gateway

9-22

Priority control is designed for requests that are sent to Modbus RTU/ASCII slaves. Since Modbus

RTU/ASCII slaves cannot handle multiple requests, the Modbus gateway must send each request

individually and wait for the response before sending the next request. As requests stack up, the

response time can suffer. This can cause problems for certain critical requests that require an

immediate response.

With priority control, y ou can specify that certain requests are sent to the f ront of th e queue for m ore

immediate response times. Priority requests can be specified by master (IP address or serial port),

TCP port, or comm and type (slave ID, function code, or data). When the Modbus gateway identifies

a priority request, the request will immediately be placed at the front of the queue.

To define a priority request, enable the appropriate priority scheme (i.e., Specified Masters,

Specified TCP Port, or Specified Re que sts). Then, specify the parameter(s) tha t will indicate a

priority request. Finally, click Add/Modify to apply this defi nitio n. ( This last step is not necessary

for Specified TCP Port.)

For example, if you want all requests from 192.168.32.161 to be considered a priority request, you

would follow these steps:

1. Enable Specified Masters.

2. Enter 192.168.32.161 as the IP.

3. Click Add/Modify.

Accessible IP

The MGate MB3000 uses an IP address-based filtering method to control access to itself.

The Accessible IP List function allows you to add or block remote host IP addresses to prevent

unauthorized access. Access to the MGate MB3000 is controlled by IP a ddress. That is, i f a host’s IP

address is in the accessible IP t able, th en th e host will be allow ed to access the MGate MB3000. The

following descriptions illustrate how to configure the accessibility parameters:

• Only one host with a specific IP address can access the MGate MB3000

Enter “IP address/255.255.255.255” (e.g., “192.168.1.1/255.255.255.255”) and activate the item by

selecting the checkbox.

• Hosts on a specific subnet can access the MGate MB3000