Page 1

P/N: 1802051110010

*1802051110010*

MGate 5111

Quick Installation Guide

Edition 1.0, December 2017

Technical Support Contact Information

www.moxa.com/support

Moxa Americas:

Toll

-free: 1-888-669-2872

Tel:

1-714-528-6777

Fax:

1-714-528-6778

Moxa China (Shanghai office):

Toll

-free: 800-820-5036

Tel:

+86-21-5258-9955

Fax:

+86-21-5258-5505

Moxa Europe:

Tel:

+49-89-3 70 03 99-0

Fax:

+49-89-3 70 03 99-99

Moxa Asia-Pacific:

Tel:

+886-2-8919-1230

Fax:

+886-2-8919-1231

Moxa India:

Tel:

+91-80-4172-9088

Fax:

+91-80-4132-1045

2017 Moxa Inc. All rights reserved.

Page 2

- 2 -

Overview

The MGate 5111 is an industrial Ethernet gateway for Modbus

RTU/ASCII/TCP, PROFINET and EtherNet/IP to PROFIBUS slave network

communications.

Package Checklist

Before installing the MGate 5111, verify that the package contains the

following items:

• MGate 5111 gateway

• Quick installation guide (printed)

• Warranty card

Please notify your sales representative if any of the above items is

missing or damaged.

Optional Accessories (can be purchased separately)

• Mini DB9F-to-TB: DB9-female-to-terminal-block connector

• WK-51-01: Wall-mounting kit, 51 mm wide

Hardware Introduction

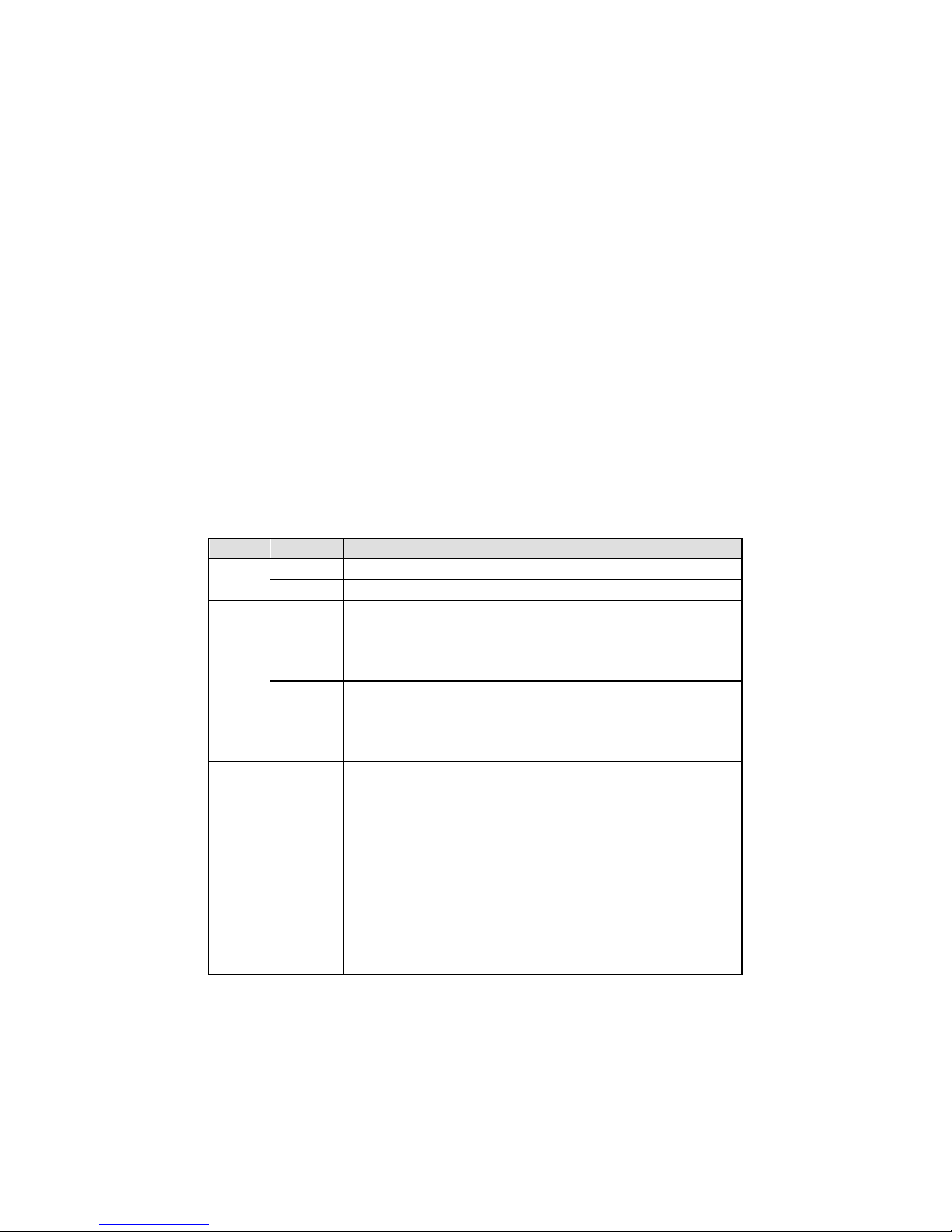

LED Indicators

LED

Color

Description

PWR 1,

PWR 2

Green

Power is on

Off

Power is off

Ready

Green

Steady on: Power is on, and the unit is functioning

normally

Blinking: The unit is responding to the software’s

Locate function

Red

Steady on: Power is on, and the unit is booting up

Blinking: Indicates an IP conflict, or the DHCP or

BOOTP server is not responding properly

Flashing quickly: the microSD card failed

LAN Green

(Flashing

only)

The Ethernet port is receiving or transmitting data

Modbus TCP Client:

Modbus communication in progress

Modbus TCP Server:

Modbus communication in progress

EtherNet/IP Adapter:

EtherNet/IP communication is exchanging data

PROFINET IO Device:

PROFINET communication is exchanging data

Page 3

- 3 -

LED

Color

Description

Red

(Flashing

only)

A communication error occurred

Modbus TCP Client:

1. Received an exception code or framing error

(parity error, checksum error)

2. Command timeout (slave device is not

responding)

3. TCP connection timeout

Modbus TCP Server:

1. Received an invalid function code or framing

error

(parity error, checksum error)

2. Accessed invalid register address or coil address

EtherNet/IP Adapter:

The connection was refused due to incorrect

configuration

Off

No communication

MB*

Green

(Flashing

only)

Modbus is receiving or transmitting data

Red

(Flashing

only)

A communication error occurred

Master Mode:

1. Received an exception code or framing error

(parity error, checksum error)

2. Command timeout (the slave device is not

responding)

Slave Mode:

1. Received an invalid function code or framing

error

(parity error, checksum error)

2. Accessed invalid register address or coil address

Off

No communication

PBS

Green

(Flashing

only)

PROFIBUS is receiving or transmitting data

Red

(Steady)

Error in the configuration or parameter data.

Off

PROFIBUS offline or Slave ID is wrong.

Eth1,

Eth2

Green

Indicates an 100 Mbps Ethernet connection

Amber

Indicates a 10 Mbps Ethernet connection

Off

The Ethernet cable is disconnected

*Only indicates serial communication status; for Modbus TCP status,

please refer to LAN LED indicator.

Page 4

- 4 -

Dimensions

Unit = mm (inch)

Reset Button

Restore the MGate to factory default settings by using a pointed object

(such as a straightened paper clip) to hold the reset button down until the

Ready LED stops blinking (approximately five seconds).

Pull-Up, Pull-Down, and Terminator for RS-485 (Modbus)

On the MGate 5111’s left side panel, you will find DIP

switches to adjust each serial port’s pull

-up resistor,

pull

-down resistor, and terminator.

SW

MODBUS

1 2 3

Pull-up

resistor

Pull-down

resistor

Terminator

ON

1 kΩ

1 kΩ

120 Ω

OFF

150 kΩ

(default)

150 kΩ

(default)

– (default)

Rotary Switch

Before communicating, you must assign a slave ID to the

PROFIBUS slave, If you would like to assign an address

between 0 to 99, you need to change the rotary switch to

the desired address. If you would like to assign an

address which is over 99, you must s

et it via web

console.

Page 5

- 5 -

Hardware Installation Procedure

1. Connect the power adapter. Connect the 12-48 VDC power line or

DIN-rail power supply to the MGate 5111’s terminal block.

2. Use a PROFIBUS cable to connect the MGate to a PROFIBUS PLC or

other PROFIBUS master.

3. Use an Ethernet cable to connect the MGate to the Modbus TCP client,

Modbus TCP server device, PROFINET IO controller, or EtherNet/IP

scanner device.

4. The MGate 5111 is designed to be attached to a DIN rail or mounted

on a wall. For DIN-rail mounting, push down the spring and properly

attach it to the DIN rail until it “snaps” into place. For wall mounting,

install the wall-mount kit (optional) first and then screw the device

onto the wall. The following figure illustrates the two mounting

options:

Software Installation Information

Please download the user's manual and DSU (Device Search Utility) from

Moxa’s website: www.moxa.com

. Insert the CD and follow the on-screen

instructions. Please refer to the User’s Manual for additional details on

using the Device Search Utility.

The MGate 5111 also supports login via a web browser.

Default IP address: 192.168.127.254

Default account: admin

Default password: moxa

Pin Assignments

Ethernet Port (RJ45)

Pin

Signal

1

Tx+

2

Tx-

3

Rx+

6

Rx-

Page 6

- 6 -

Modbus Serial Port (Male DB9)

Pin RS-232

RS-422/

RS-485 (4W)

RS-485 (2W)

1

DCD

TxD-(A)

–

2

RXD

TxD+(B)

–

3

TXD

RxD+(B)

Data+(B)

4

DTR

RxD-(A)

Data-(A)

5*

GND

GND

GND

6

DSR – –

7

RTS – –

8

CTS – –

9 – –

–

*Signal ground

PROFIBUS Serial Port (Female DB9)

Pin

Signal

1 - 2 - 3

PROFIBUS D+

4

RTS

5

Signal common

6

5V 7 -

8

PROFIBUS D-

9

-

Console Port (RS-232)

The MGate 5111 Series can use an RJ45 serial port to connect to a PC to

configure the device.

Pin

Signal

1

DSR

2

RTS

3

GND

4

TXD

5

RXD

6

DCD

7

CTS

8

DTR

Power Input and Relay Output Pinouts

V2+ V2-

V1+ V1-

Shielded

Ground

DC

Power

Input 2

DC

Power

Input 2

N.O. Common N.C.

DC

Power

Input 1

DC

Power

Input 1

Page 7

- 7 -

Specifications

Power Requirements

Power Input

12 to 48 VDC

Power Consumption

416mA@12VDC, 195mA@24VDC,

110mA@48VDC

Operating Temperature

Standard model:

0 to 60°C (32 to 140°F)

Wide temperature model:

-40 to 75°C (-40 to 167°F)

Ambient Relative Humidity

5 to 95% RH

Dimensions

45.8 x 105 x 134 mm (1.80 x 4.13 x 5.28 in)

Reliability

Alert Tools

Built-in buzzer and RTC

MTBF

718,131 hrs

1. DEMKO Certificate number: 17 ATEX 1848X

IECEx Certificate number: IECEx UL 17.0019X

2. Ambient Temperature Range:

0°C to 60°C (for models without suffix –T)

-40°C to 75°C (for models with suffix –T only)

3. Certification String: Ex nA nC IIC T4 Gc

4. Standards Covered: EN 60079-0:2012+A11:2013/IEC 60079-0 6th

Ed. AND EN 60079-15:2010/IEC 60079-15 4th Ed.

5. The conditions of safe use:

a. Ethernet Communications Devices are intended for mounting in a

tool-accessible IP54 enclosure and use in an area of not more

than pollution degree 2 as defined by IEC/EN 60664-1.

b. Conductors suitable for use in an ambient temperature greater

than 86°C must be used for the power supply terminal.

c. A 4 mm

2

conductor must be used when a connection to the

external grounding screw is utilized.

d. Provisions shall be made, either in the equipment or external to

the equipment, to prevent the rated voltage from being exceeded

by the transient disturbances of more than 140% of the

peak-rated voltage.

When wiring the relay contact (R), digital input (DI), and power inputs

(P1/P2), we suggest using AWG (American Wire Gauge) 16-24 as a cable

and the corresponding pin-type cable terminals. The connector can

withstand a maximum torque of 5 pound-inches. The wire temperature

rating should be at least 105°C.

ATTENTION

For installations in hazardous locations (Class 1, Division 2):

These devices are to be installed in an enclosure with a

tool-removable cover or door, suitable for the environment.

Page 8

- 8 -

NOTE

This equipment is suitable for use in Class 1, Division 2, Groups A,

B, C, D or nonhazardous locations only

WARNING

EXPLOSION HAZARD

Do not disconnect the equipment unless the power has been

switched off, or the area is known to be nonhazardous.

WARNING

EXPLOSION HAZARD

The substitution of any components may impair suitability for

Class 1, Division 2.

WARNING

EXPOSURE TO SOME CHEMICALS MAY DEGRADE THE

SEALING

PROPERTIES OF MATERIALS USED IN THE FOLLOWING DEVICE:

Sealed Relay Device U21.

WARNING

EXPLOTION HAZARD

Indoor use and Pollution degree 2.

WARNING

EXPLOTION HAZARD

The equipment and label must be wiped by a dry cloth.

WARNING

EXPLOTION HAZARD

The device may only be connected to the supply voltage

connections

compliant with UL60950, or UL61010-1, or

UL61010-2-201 Safety Extra-Low Voltages (SELV).

Moxa Inc.

Fl. 4, No. 135, Lane 235, Baoqiao Rd.

Xindian Dist., New Taipei City, 23145

Taiwan, R.O.C.

Loading...

Loading...