Moxa Technologies ioLogik R1210, ioLogik R1214, ioLogik R1212, ioLogik R1240, ioLogik R1241 User Manual

...Page 1

ioLogik R1200 Series User’s Manual

Edition 2.1, January 2016

www.moxa.com/product

© 2016 Moxa Inc. All rights reserved.

Page 2

ioLogik R1200 Series User’s Manual

Moxa Americas

Toll

Tel:

Fax:

Moxa China (Shanghai office)

Toll

Tel:

Fax:

Moxa Europe

Tel:

Fax:

Moxa Asia

Tel:

Fax:

Moxa In

Tel:

Fax:

The software described in this manual is furnished under a license agreement and may be used only in accordance with

the terms of that agreement.

Copyright Notice

© 2016 Moxa Inc. All rights reserved.

Trademarks

The MOXA logo is a registered trademark of Moxa Inc.

All other trademarks or registered marks in this manual belong to their respective manufacturers.

Disclaimer

Information in this document is subject to change without notice and does not represent a commitment on the part of

Moxa.

Moxa provides this document as is, without warranty of any kind, e ither expre sse d or i mplie d, inclu ding, but n ot limited

to, its particular purpose. Moxa reserves the right to make improvements and/or changes to this manual, or to the

products and/or the programs described in this manual, at any time.

Information provided in this manual is intended to be accurate and reliable. However, Moxa assumes no responsibility for

its use, or for any infringements on the rights of third parties that may result from its use.

This product might include unintentional technical or typographical errors. Changes are periodically made to the

information herein to correct such errors, and these changes are incorporated into new editions of the publication.

Technical Support Contact Information

www.moxa.com/support

-free: 1-888-669-2872

+1-714-528-6777

+1-714-528-6778

+49-89-3 70 03 99-0

+49-89-3 70 03 99-99

dia

+91-80-4172-9088

+91-80-4132-1045

-free: 800-820-5036

+86-21-5258-9955

+86-21-5258-5505

-Pacific

+886-2-8919-1230

+886-2-8919-1231

Page 3

Table of Contents

1. Overview ........................................................................................................................................... 1-1

Introduction ....................................................................................................................................... 1-2

Product Features ................................................................................................................................ 1-2

Package Checklist ............................................................................................................................... 1-2

Product Model Information ................................................................................................................... 1-2

Ordering Information ................................................................................................................... 1-2

Specifications ..................................................................................................................................... 1-3

Common Specifications ................................................................................................................ 1-3

ioLogik R1210 ............................................................................................................................. 1-4

ioLogik R1212 ............................................................................................................................. 1-4

ioLogik R1214 ............................................................................................................................. 1-5

ioLogik R1240 ............................................................................................................................. 1-6

ioLogik R1241 ............................................................................................................................. 1-6

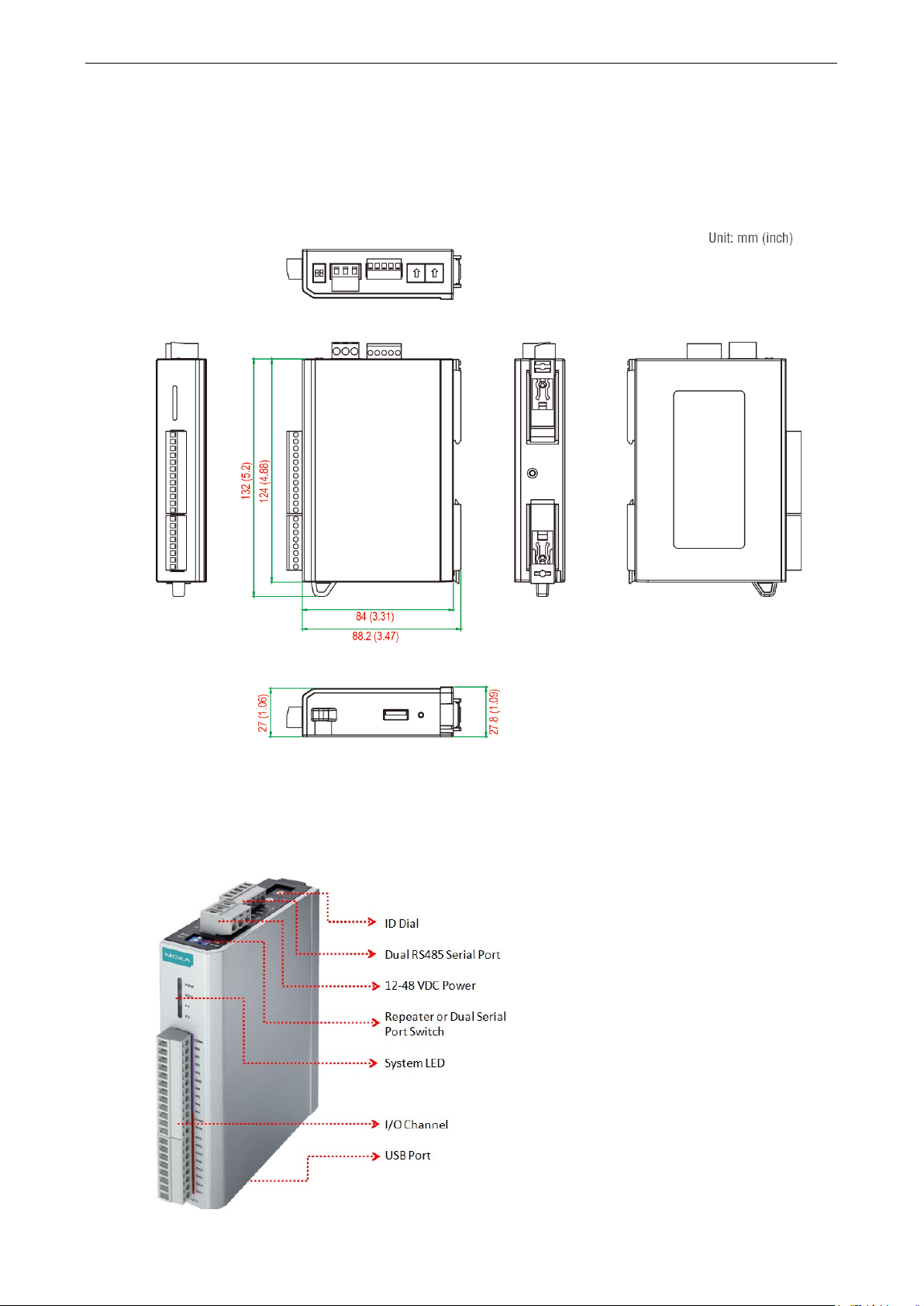

Physical Dimensions ............................................................................................................................ 1-7

Hardware Reference ............................................................................................................................ 1-7

Panel Guide ................................................................................................................................ 1-7

LED Indicators ............................................................................................................................ 1-8

Switch Settings ........................................................................................................................... 1-8

DI Circuit Diagram....................................................................................................................... 1-8

DIO Circuit Diagram .................................................................................................................... 1-9

Relay Circuit Diagram ................................................................................................................ 1-10

AI Circuit Diagram ..................................................................................................................... 1-10

2. Initial Setup ...................................................................................................................................... 2-1

Hardware Installation .......................................................................................................................... 2-2

Connecting the Power .................................................................................................................. 2-2

Grounding the ioLogik R1200 ........................................................................................................ 2-2

Mounting the ioLogik R1200 ......................................................................................................... 2-2

Connecting to Digita l Sensors and Devices ..................................................................................... 2-3

RS-485 Networks ........................................................................................................................ 2-4

Modbus/RTU Devices ................................................................................................................... 2-5

Dual RS-485 or Repeater Setting s ................................................................................................. 2-5

Jumper Settings (DIO and AI) ....................................................................................................... 2-6

Pull High/Low DIP Sw i tch Settings for the RS-485 Port ..................................................................... 2-6

Software Installation ........................................................................................................................... 2-7

ioSearch Installati on .................................................................................................................... 2-7

Initial Setup by USB .................................................................................................................... 2-9

Restore Factory Default Se ttings ................................................................................................. 2-10

3. Using ioSearch .................................................................................................................................. 3-1

Introduction to ioSearch ...................................................................................................................... 3-2

ioSearch Main Screen .......................................................................................................................... 3-2

Main Screen Overview ......................................................................................................................... 3-2

ioSearch Setup ................................................................................................................................... 3-3

System ...................................................................................................................................... 3-3

Sort ........................................................................................................................................... 3-5

Help .......................................................................................................................................... 3-6

Quick Links ........................................................................................................................................ 3-6

Main Functions ................................................................................................................................... 3-6

Locate ....................................................................................................................................... 3-6

Connect/Disconnect ..................................................................................................................... 3-6

Firmware Upgrade ....................................................................................................................... 3-7

Import ....................................................................................................................................... 3-7

Export ....................................................................................................................................... 3-7

Change Server Name ................................................................................................................... 3-7

Restart System ........................................................................................................................... 3-8

Delete ioLogik Device ................................................................................................................... 3-8

Reset to Default .......................................................................................................................... 3-8

Main Screen ....................................................................................................................................... 3-9

I/O Configuration Tab (General) .................................................................................................... 3-9

Configuring Digital Input Channels ................................................................................................ 3-9

Configuring Digital Output Channels ............................................................................................ 3-11

Configuring Analog Input Channels .............................................................................................. 3-13

AI Input Range ......................................................................................................................... 3-13

Configuring Analog Output Channels ............................................................................................ 3-14

Server Info Tab ................................................................................................................................ 3-16

Server Settings Tab (General) ..................................................................................................... 3-17

Watchdog ................................................................................................................................. 3-18

A. Modbus Mapping ............................................................................................................................... A-1

Page 4

R1210 Modbus Mapping ....................................................................................................................... A-2

0xxxx Read/Write Coils (Functions 1, 5, 15) ................................................................................... A-2

1xxxx Read Only Coils (Function 2) ............................................................................................... A-4

3xxxx Read Only Registers (Function 4) ......................................................................................... A-4

4xxxx Read/Write Registers (Fun ctions 3, 6, 16) ............................................................................. A-5

R1212 Modbus Mapping ....................................................................................................................... A-6

0xxxx Read/Write Coils (Functions 1, 5, 15) ................................................................................... A-6

1xxxx Read Only Coils (Function 2) ............................................................................................... A-9

3xxxx Read Only Registers (Function 4) ......................................................................................... A-9

4xxxx Read/Write Registers (Fun ctions 3, 6, 16) ........................................................................... A-10

R1214 Modbus Mapping ..................................................................................................................... A-12

0xxxx Read/Write Coils (Functions 1, 5, 15) ................................................................................. A-12

1xxxx Read Only Coils (Function 2) ............................................................................................. A-14

3xxxx Read Only Registers (Function 4) ....................................................................................... A-14

4xxxx Read/Write Registers (Fun ctions 3, 6, 16) ........................................................................... A-14

R1240 Modbus Mapping ..................................................................................................................... A-15

0xxxx Read/Write Coils (Functions 1, 5, 15) ................................................................................. A-15

3xxxx Read Only Registers (Function 4) ....................................................................................... A-16

4xxxx Read/Write Registers (Fun ctions 3, 6, 16) ........................................................................... A-17

R1241 Modbus Mapping ..................................................................................................................... A-18

4xxxx Read/Write Registers (Fun ctions 3, 6, 16) ........................................................................... A-18

B. Factory Defaults ................................................................................................................................ B-1

C. Pinouts .............................................................................................................................................. C-1

D. FCC Interference Statement .............................................................................................................. D-1

E. European Community (CE) ................................................................................................................ E-1

Page 5

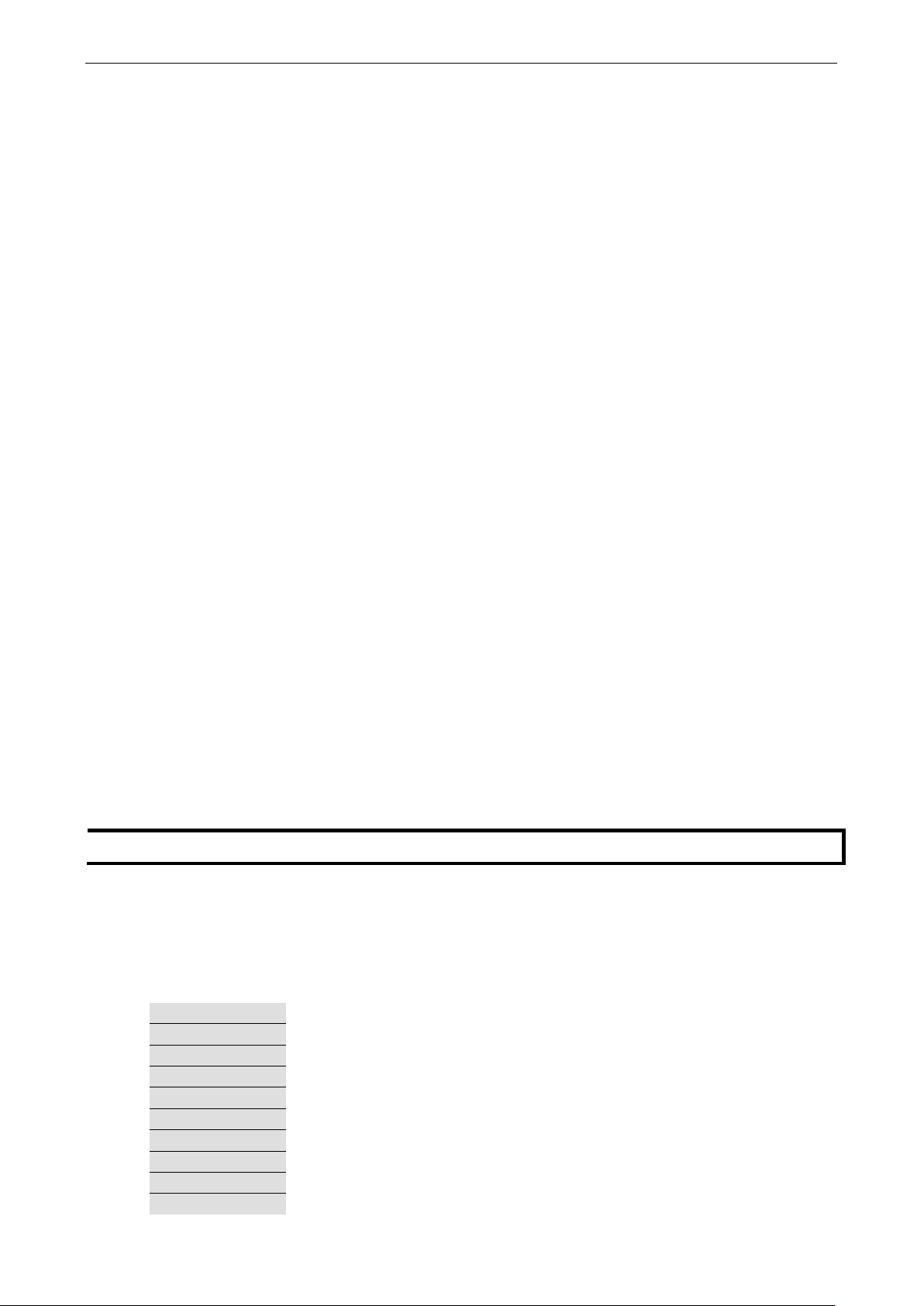

1

1. Overview

The following topics are covered in this chapter:

Introduction

Product Features

Package Checklist

Product Model Information

Ordering Information

Specifications

Common Specifications

ioLogik R1210

ioLogik R1212

ioLogik R1214

ioLogik R1240

ioLogik R1241

Physical Dimensions

Hardware Reference

Panel Guide

LED Indicators

Switch Settings

DI Circuit Diagram

DIO Circuit Diagram

Relay Circuit Diagram

AI Circuit Diagram

Page 6

ioLogik R1200 Series Overview

1-2

NOTE

Contact your sales representative if any of the above items are missing or damaged

Introduction

The ioLogik R1200 is an industrial grade, wide-temperature serial remot e I/O device equipped with dual

RS-485 ports that allow users to select between two RS -485 serial ports or sw itch to a built-in repeater.

Applications such as factory automation, security and surveillance systems, and tunnel monitoring can use the

RS-485 serial line to set up multi-drop device configurations through serial cables. Furthermore, a technician

with no serial background can upload device configurations and firmware via USB at the field site without

bringing a PC to the field site. The ioLogik R1200 lets you easily build an industrial grade, long distance

communication system with standard PC hardware, and extends the communication distance by 4,000 ft.

(1,200 m).

Product Features

• Upload and install device configurations and firmware via USB

• Multi-drop support for device configuration and firmware upgrade via RS-485

• Remote firmware updates via RS-485

• Dual RS-485 ports with built-in repeater

• Wide temperature (-40 to 85°C), 1 kV surge protection, and 3 kV I/O isolation between I/O channels,

networks and power circuits

• Multi-functional I/O support for DI, event counter, DO, and pulse output

• Modbus/RTU support for control by SCADA software, including Wonderware InTouch and GE Intellution

iFix32

• Monitoring and configuration via ioSearch Windows utility

• Hardware detection over RS-485 via ioSearch

Package Checklist

The ioLogik R1200 is shipped with the following items:

• 1 ioLogik R1200 remote I/O product

• Document and Software CD

• Quick Installation Guide (printed)

Product Model Information

Ordering Information

ioLogik R1210 RS-485 remote I/O, 16 DIs, -10 to 75°C operating temperature.

ioLogik R1210-T RS-485 remote I/O, 16 DIs, -40 to 85°C operating temperature.

ioLogik R1212 RS-485 remote I/O, 8 DIs, 8 DIO s, -10 to 75°C operating temperature.

ioLogik R1212-T RS-485 remote I/O, 8 DIs, 8 DIO s, -40 to 85°C operating temperature.

ioLogik R1214 RS-485 remote I/O, 6 DIs, 6 Relays, -10 to 75°C operating temperature.

ioLogik R1214-T RS-485 remote I/O, 6 DIs, 6 Relays, -40 to 85°C operating temperature.

ioLogik R1240 RS-485 remote I/O, 8 AIs, -10 to 75°C operating temperature.

ioLogik R1240-T RS-485 remote I/O, 8 AIs, -40 to 85°C operating temperature.

ioLogik R1241 RS-485 remote I/O, 4 AOs, -10 to 75°C operating temperature.

ioLogik R1241-T RS-485 remote I/O, 4 AOs, -40 to 85°C operating temperature.

.

Page 7

ioLogik R1200 Series Overview

1-3

Serial Communication

Interface:

Serial Line Protection:

Serial Communication Parameters

Parity:

Data Bits:

Stop Bits:

Baudrate:

Pull High/Low Resistor for RS

Protocols:

Physical Characteristics

Wiring:

Dimensions:

Environmental Limits

Operating Temperature:

Standard Models:

Wide Temp. Mo

Storage Temperature:

Ambient Relative Humid it y:

Standards and Certifications

Safety:

EMI:

EN 55022, EN 61000

EMS:

EN 55024, IEC 61000

Shock:

Freefall:

Vibration:

Warranty

Warranty Period:

Details:

Specifications

Common Specifications

RS-485-2w: Data+, Data-, GND (5-contact terminal block)

15 kV ESD for all signals, Level 2 surge, EN 61000-4-5 (1 kV)

None, Even, Odd (default = None)

8

1, 2 (default = 1)

1200 to 921.6 kbps (default = 9600)

-485: 1 kΩ, 150 kΩ

Modbus RTU

I/O cable max. 16 AWG

27.8 x 124 x 84 mm (1.09 x 4.88 x 3.31 in)

-10 to 75°C (14 to 167°F)

dels: -40 to 85°C (-40 to 185°F)

UL 508

-3-2, EN 61000-3-3, FCC Part 15 Subpart B Class A

-4, IEC 61000-6

IEC 60068-2-27

IEC 60068-2-32

IEC 60068-2-6

5 years (excluding t he ioLogik R1214)

See www.moxa.com/warranty

-40 to 85°C (-40 to 185°F)

5 to 95% (non-condensing)

Page 8

ioLogik R1200 Series Overview

1-4

Inputs and Outputs

Digital Inputs:

Isolation:

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

• On: short to GND

• Off: open

Wet Contact (DI to

• On:

• Of

Common Type:

Counter Frequency:

Digital Filtering Time Interval:

Power Requirements

Power Input:

Power Consumption:

Inputs and Outputs

Digital Inputs:

Configurable DIOs:

Isolation:

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

• On: short to GND

• Off: ope

Wet Contact (DI to

• On:

• Off: 0 to 3 VDC

Common Type:

Counter Frequency:

Digital Filtering Time Interval:

Digital Output

Type:

I/O Mode:

Pulse Output Frequency:

Over

Over

Over

Current Rating:

Power Requirements

Power Input:

Power Consumption:

ioLogik R1210

16 channels

3K VDC or 2K Vrms

Wet Contact (NPN or PNP), Dry Contact

DI or Event Counter

COM):

10 to 30 VDC

f: 0 to 3 VDC

8 points per COM

2.5 kHz, power off storage

Software selectable

24 VDC nominal, 12 to 48 VDC

154 mA @ 24VDC

ioLogik R1212

8 channels

3K VDC or 2K Vrms

Wet Contact (NPN or PNP), Dry Contact

DI or Event Counter

n

10 to 30 VDC

Sink

DO or Pulse Output

-voltage Protection: 45 VDC

-current Protection: 2.6 A (4 channels @ 650 mA)

-temperature Shutdown: 175°C (typical), 150°C (min.)

8 channels

COM):

8 points per COM

2.5 kHz, power off storage

Software selectable

5 kHz

200 mA per channel

24 VDC nominal, 12 to 48 VDC

187 mA @ 24VDC

Page 9

ioLogik R1200 Series Overview

1-5

Inputs and Outputs

Digital Inputs:

Relay Outputs:

Isolation:

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

• On: short to GND

• Off: open

Wet Contact (DI to

• On:

• Off: 0 to 3 VDC

Common Type:

Counter Frequency:

Digital Filtering Time Interval:

Relay Output

Type:

Contact Current Rating:

• Resistive Load: 5 A @ 30 VDC, 250 VAC, 110 VAC

Breakdown Voltage:

Relay On/Off Time:

Initial Insulation Resistance:

Mech

Electrical Endurance:

Contact Resistance:

Pulse Output:

Note: Ambient humidity must be non

e relays of the ioLogik

R1214 may malfunction when operating in high condensation environments below 0°C.

Power Requirements

Power Input:

Power Consumption:

ioLogik R1214

6 channels

6 channels

3K VDC or 2K Vrms

Wet Contact (NPN or PNP), Dry Contact

DI or Event Counter

COM):

10 to 30 VDC

6 points per COM

2.5 kHz, power off storage

Software selectable

Form A (N.O.) power relay

500 VAC

1500 ms (Max.)

anical Endurance: 5,000,000 operations

100,000 operations @ 5 A resistive load

100 m ohms (max.)

0.3 Hz at rated load

24 VDC nominal, 12 to 48 VDC

207 mA @ 24VDC

1000 M ohms (min.) @ 500 VDC

-condensing and remain between 5 and 95%. Th

Page 10

ioLogik R1200 Series Overview

1-6

Inputs and Outputs

Analog Input

Isolation:

Analog Input

Type:

Resolution:

I/O Mode:

Input Range:

Accuracy:

±0.1% FSR @ 25°C

±0.3% FSR @

±

Sampling Rate (all channels):

12 Hz

Input Impedance:

Built

Power Requirements

Power Input:

Power Consumption:

Inputs and Outputs

Analog Outputs:

Isolation:

Analog Output

Resolution:

Output Range:

Voltage Output:

Accuracy:

±0.1% FSR @ 25°C

±0.3% FSR @

Load Resistor:

•

• External 24V power: 1000 ohms

Power Requirements

Power Input:

Power Consumption:

ioLogik R1240

s: 8 channels

3K VDC or 2K Vrms

Differential input

16 bits

Voltage / Current

0 to 10 VDC, 0 to 20 mA, 4 to 20 mA (burn-out mode)

-10 and 60°C

0.5% FSR @ -40 and 75°C

10M ohms (min.)

-in Resistor for Current Input: 120 ohms

24 VDC nominal, 12 to 48 VDC

216 mA @ 24VDC

ioLogik R1241

4 channels

3K VDC or 2K Vrms

12 bits

0 to 10 VDC, 4 to 20 mA

10 mA (max.)

-40 and 75°C

Internal power: 400 ohms

24 VDC nominal, 12 to 48 VDC

343 mA @ 24VDC

Page 11

ioLogik R1200 Series Overview

1-7

Physical Dimensions

The dimensions of the ioLogik R1200 product are 27.8 x 124 x 84 mm. The connector for the two RS-485 ports

is a 5-pin 3.81 terminal block (2 RS-485 ports with 1 ground pin). The power connector is on the top and the

reset button is on the bottom of the product. There are also two dials for Board ID setup, and a 2-pin DIP switch

for “Initial/Run” mode and “Dual RS-485/Repeater” mode setup.

Hardware Reference

Panel Guide

Page 12

ioLogik R1200 Series Overview

1-8

NOTE

The RESET button restarts the server and resets all settings to factory defaults. Use a pointed object such as

a straightened paper clip to hold down the reset button for 5 seconds. The factor y defaults will load once the

READY LED turns green again. You may then release the RESET b utton.

LED Indicators

LED State Description

Power (PWR) Amber System power is ON

OFF System power is OFF

Read (RDY) Green System is ready

Flashing Flashes every 1 sec when the Locate function is triggered

Flashing Flashes every 0.5 sec when the firmwar e is being upgraded

Flashing Flashing USB upgrade is triggered

OFF System is not ready.

Port 1 (P1) Green Serial connection enabled

Flashing Transmitting or receiving data

Port 2 (P2) Green Serial connection enabled

Flashing Transmitting or receiving data

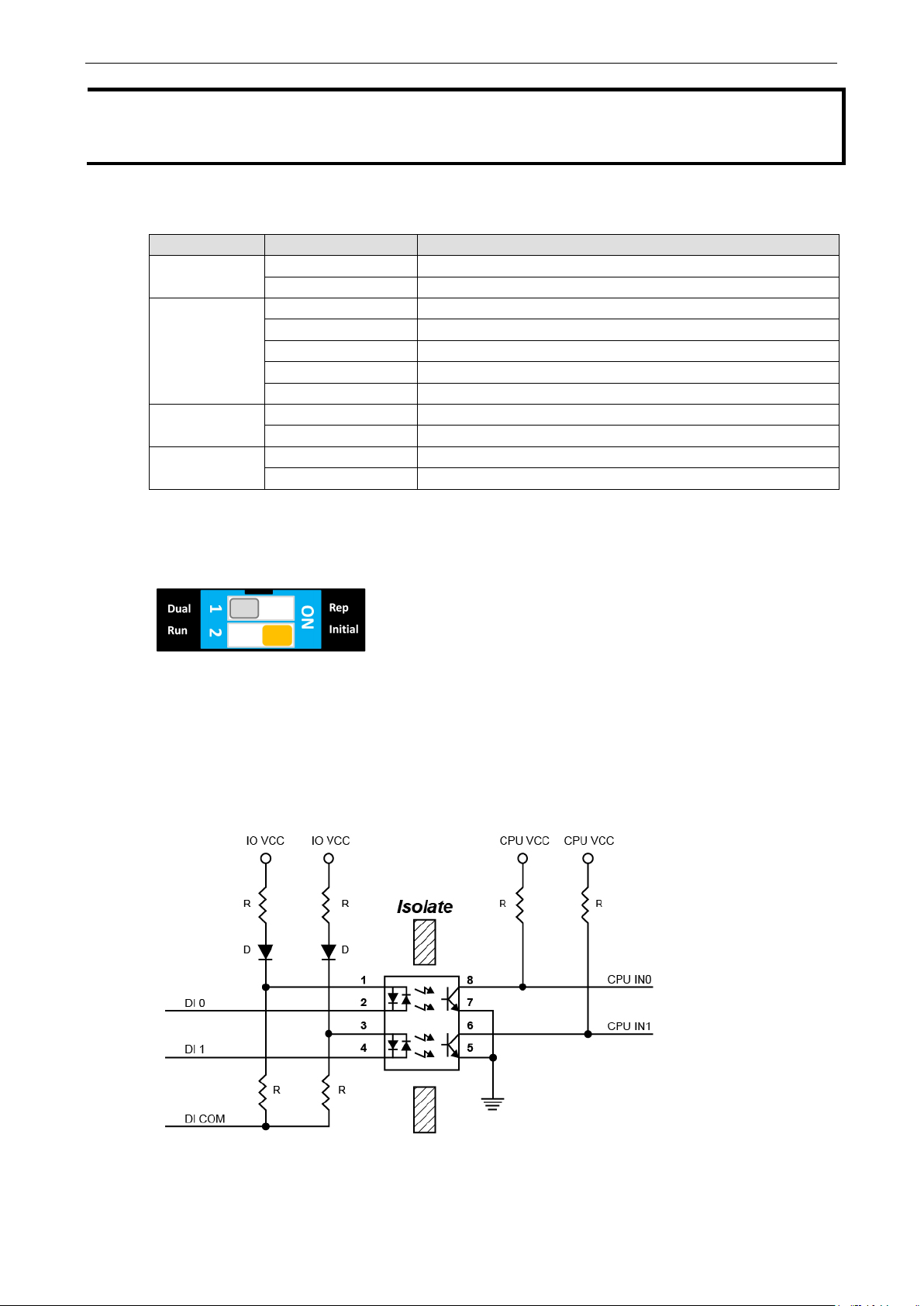

Switch Settings

The R1200 series provides Dual/Rep and Run/Initial switch settings for setting the communication mode.

Dual (Default) Dual RS-485 mode

Rep Repeater mode

Run User defined communication parameters

Initial (Default) Initial RS-485 communication parameters

DI Circuit Diagram

Page 13

ioLogik R1200 Series Overview

1-9

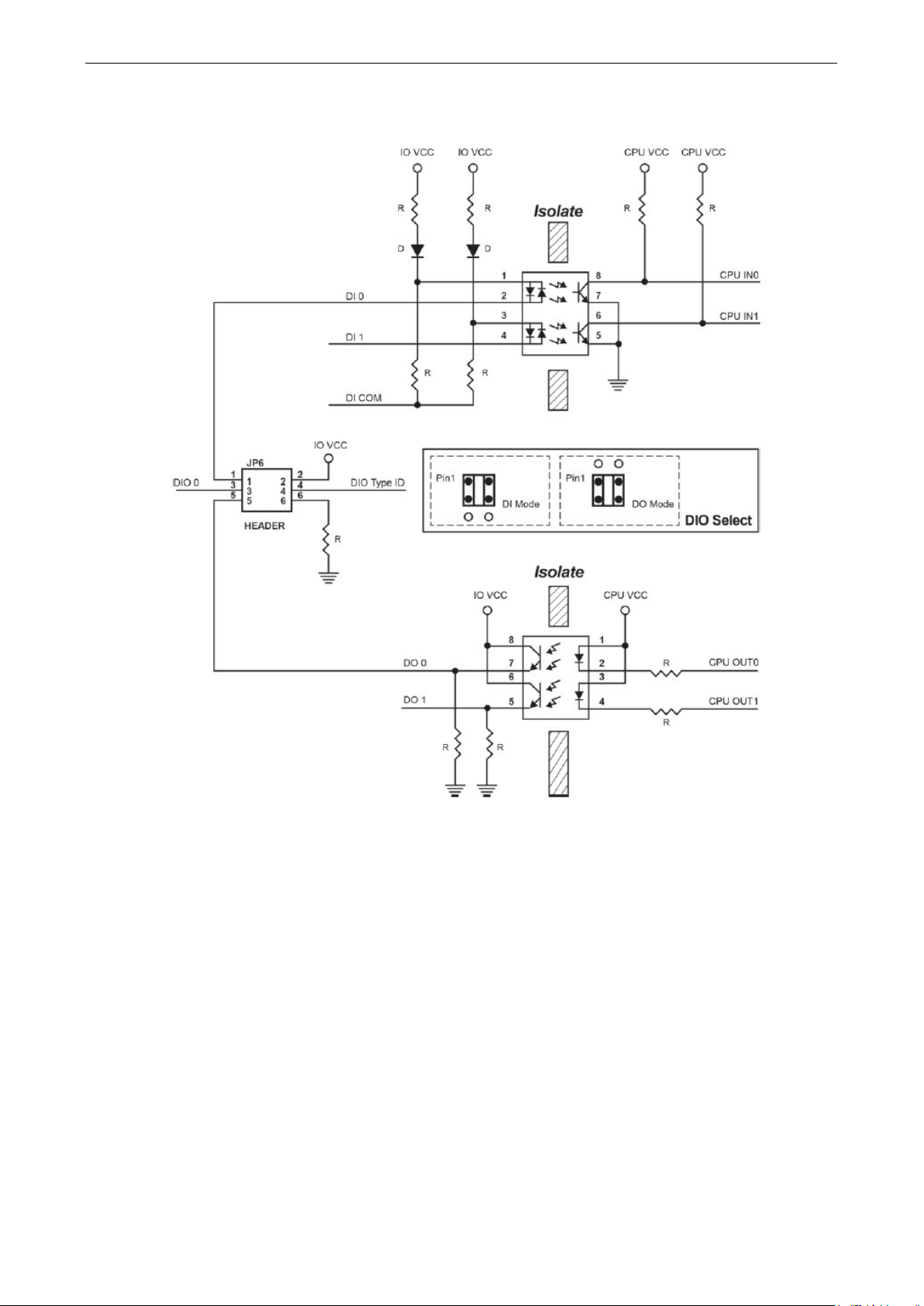

DIO Circuit Diagram

Page 14

ioLogik R1200 Series Overview

1-10

Relay Circuit Diagram

AI Circuit Diagram

Page 15

2

2. Initial Setup

The following topics are covered in this chapter:

Hardware Installation

Connecting the Power

Grounding the ioLogik R1200

Mounting the ioLogik R1200

Connecting to Digita l Sensors and Devices

RS-485 Networks

Modbus/RTU Devices

Dual RS-485 or Repeater Setting s

Jumper Settings (DIO and AI)

Pull High/Low DIP Sw i tch Settings for the RS-485 Port

Software Installation

ioSearch Installati on

Initial Setup by USB

Restore Factory Default Se ttings

Page 16

ioLogik R1200 Series Initial Setup

2-2

ATTENTION

Determine the maximum possible current for each power wire and common wire. Observe all electrical codes

dictating the maximum current allowable for each wire size. If the current exceeds the maximum rating, the

wiring could overheat, causing ser ious damage to your equipment. For safety reasons, we recommend an

average cable size of 22 AWG. However, depending on the current load, you may want to adjust your cable size

(the maximum

The ioLogik R1200 is equipped with a grounding point on the terminal block located on the top panel.

Connect the ground pin if an earth ground is available.

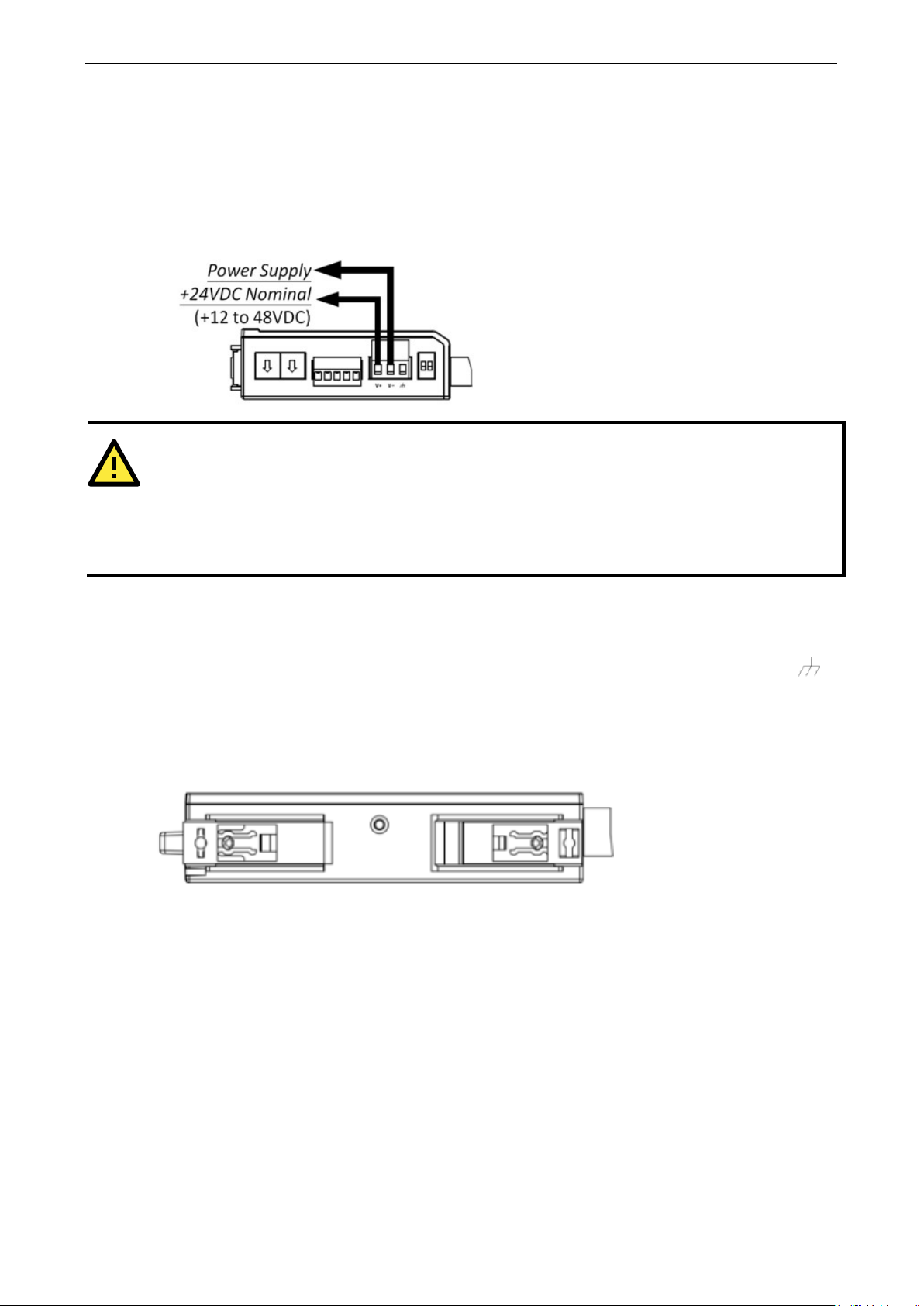

Hardware Installation

Connecting the Power

Connect the 12 to 48 VDC power line t o the ioLogik R1200’s terminal block on the top panel. If power is properly

supplied, the Power LED will glow a solid amber color.

wire size for power connectors is 2 mm).

Grounding the ioLogik R1200

Mounting the ioLogik R1200

The ioLogik R1200 can be used with both DIN rail and wall mounting applications.

Page 17

ioLogik R1200 Series Initial Setup

2-3

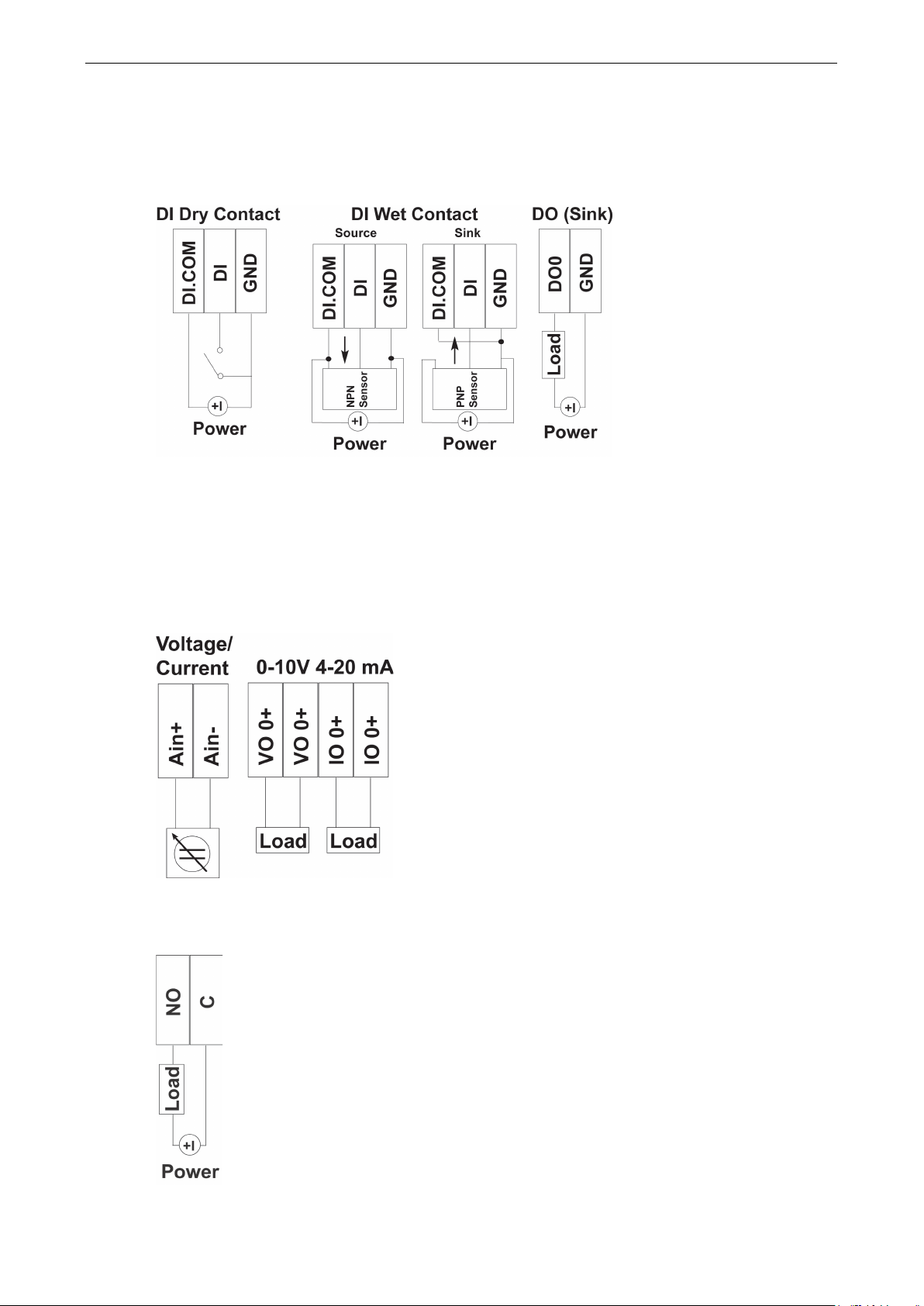

Connecting to Digital Sensors and Devices

Digital Input/Output (Sink Type)

A Dry Contact is a contact that does not provide voltage, e.g., the push-to-talk switch of a microphone, which

just closes a circuit without provid ing voltage.

A Wet Contact is a contact that will provide voltage when closed, e.g., a switch on the wall that acti vates a 110

VAC outlet to turn a lamp on in a room.

Analog Input/Output

Relay Output (Form A)

Page 18

ioLogik R1200 Series Initial Setup

2-4

NOTE

A “load” in a circuit schematic is a component or portion of the circuit that consumes electric power. For the

diagrams shown in this document, “load” refers to the devices or syste ms connected to the remote I/O unit.

NOTE

The tran

Termination is only required with high data

NOTE

The

RS-485 Networks

RS-485 permits a balanced transmission line to be shared in a party line or multi-drop configuration. As many

as 32 driver/receiver pairs can share a multi-drop connection on a single two-wire bus. The length of the

network is limited to 4,000 ft between the first node and the last node. You can use RS-485 in two-wire or

four-wire multi-drop network applications.

In an RS-485 four- wire network, one node must be a master node and all others slave nodes. The master does

not require tri-state output.

smission line is terminated on both ends of the line but not at drop points in the middle of the line.

rates or long wire runs.

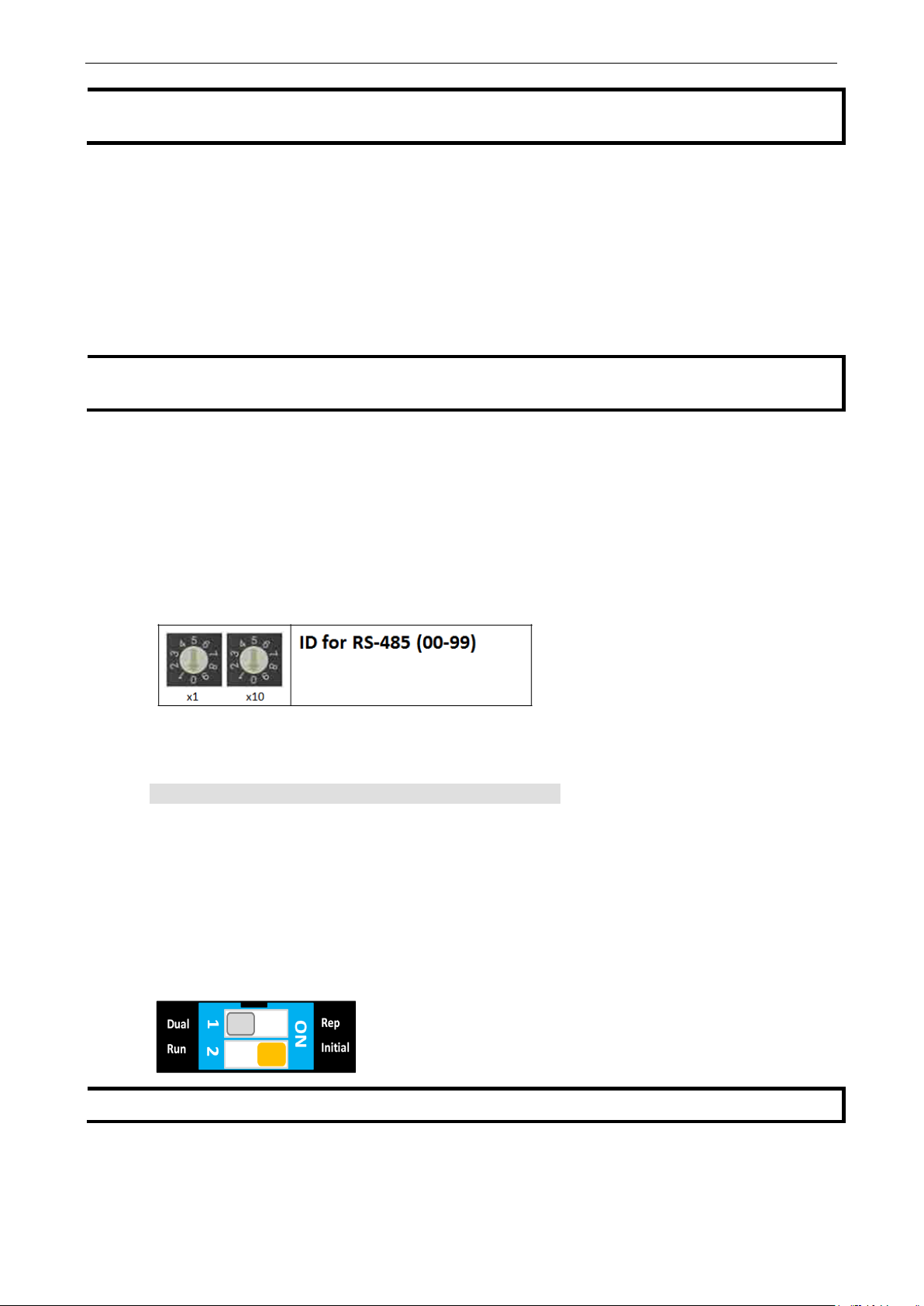

Setting the Device ID for RS-485 Serial Communication

The RS-485 port is used to communicate with other RS-485 devices or to link to another ioLogik RS-485 I/O

server. The RS-485 port can run M odbus/RTU or I/O command sets. The device ID for each ioLogik R1200

device can be set to any number from 01 to 99 by turning the two rotary dials on the back of the device. The

x1 dial (shown on the left in the figure below) represents the ones place and the x10 dial (shown on the right

in the figure below) represents the tens place. Settings such as the baud rate, parity check, data bits, and stop

bit are configured by software.

Serial Communication Parameters (Initial State)

Communication Parameters (Initial mode)

Parity None, Even, Odd (default = None)

Data Bits 8

Stop Bits 1, 2 (default = 1)

Baudrate 1200 to 921.6 kbps (default = 9600)

Serial Communication Initial Setup

During your initial setup, set the switch to “Initial” mode to configure your device, after configuration is done

flip the switch back to “Run” mode.

initial communication setting is: baudrate = 9600, n, 8, 1.

Page 19

ioLogik R1200 Series Initial Setup

2-5

NOTE

In

with a maximum

of

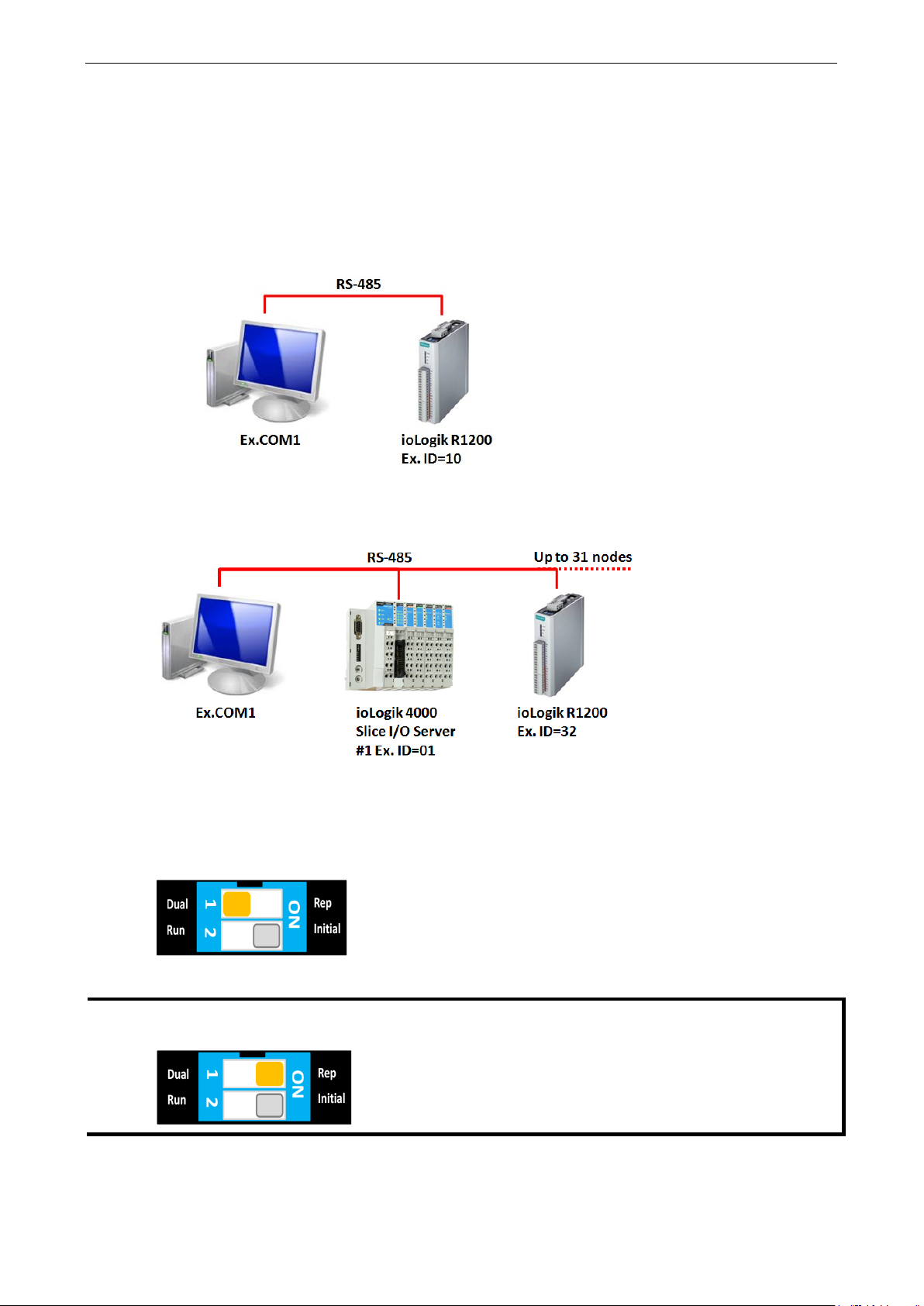

Modbus/RTU Devices

The RS-485 port runs Modbus/RTU and can connect to any Modbus device. You may use different methods to

connect different combinations of ioLogik R12000 servers and other Modbus devices. Some examples are

shown below:

Connecting One Modbus/RTU Device

Connecting Multiple Modbus/RTU Devices

Dual RS-485 or Repeater Settings

Dual RS-485: Switching the dial to “Dual” will divide the RS-485 port into two separate RS-485 po rts for users

to run dual RS-485 lines.

Repeater: Switching the dial to “Rep” will set the ioLogik R1200 to act as a repeater.

Repeater mode, when signals pass through one machine, the latency will increase by 1 byte

10 ms at 1200 bps baudrate.

Page 20

ioLogik R1200 Series Initial Setup

2-6

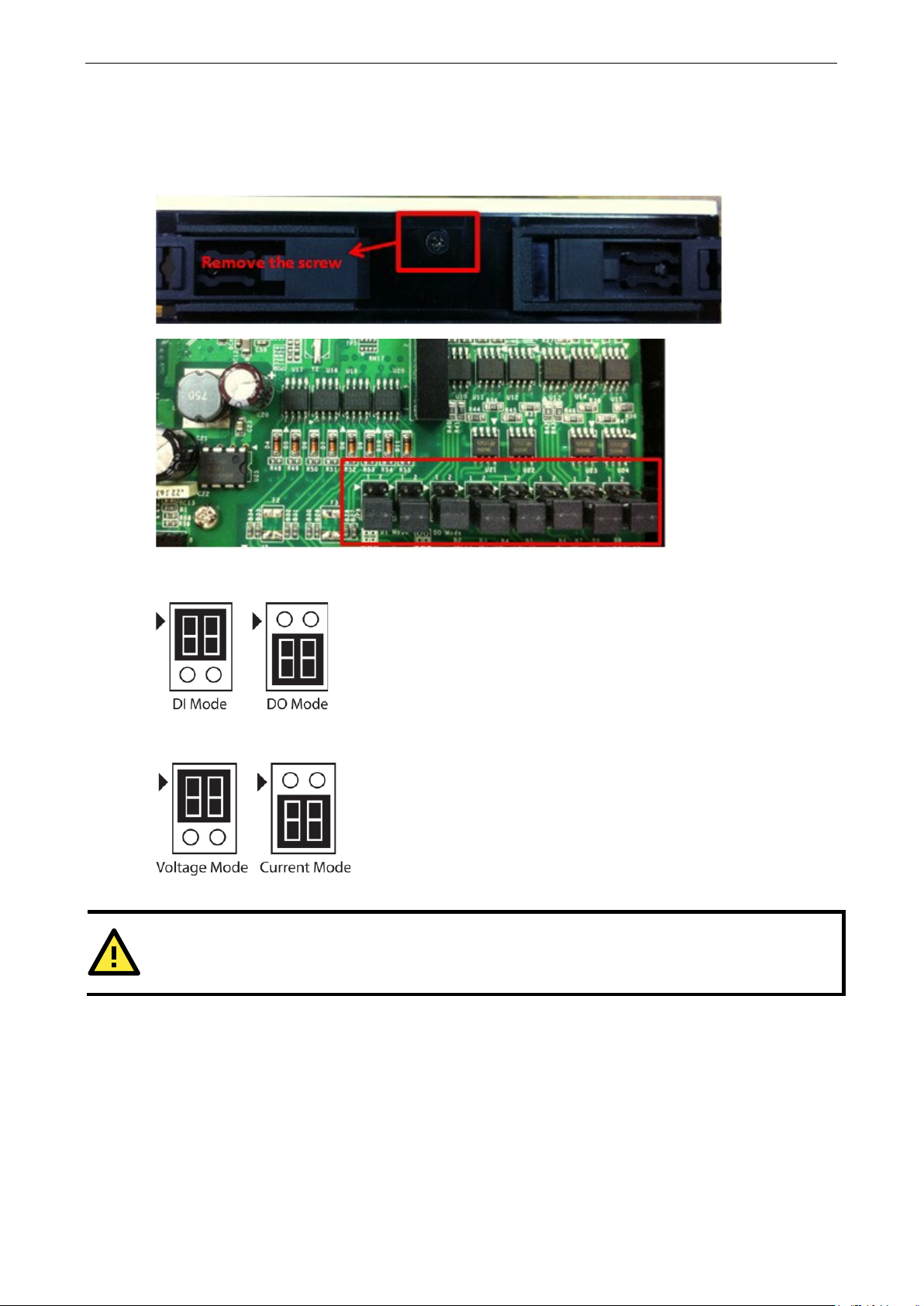

ATTENTION

Remove the screw on the back panel and o pen the cover to configure the jumpers.

Jumper Settings (DIO and AI)

The models with DIO or AI channels require configuring the jumpers ins ide the cover. Remove the screw

located on the back panel and open the cover to configure the jumpers.

DIO mode configuration is shown to the right (default: DO Mode).

Analog mode configuration is shown to the right (default: Voltage Mode).

Pull High/Low DIP Switch Settings for the RS-485 Port

In some critical environments, you may need to add termination resistors to prevent the reflection of serial

signals. When using termination resistors, it is important to set the pull high/low resistors correctly so that t he

electrical signal is not corrupted. Since there is no resistor value that works for every environment, DIP

switches are used to set the pull high/low resistor valve for each RS -485 port.

Page 21

ioLogik R1200 Series Initial Setup

2-7

DIP switches inside the cover of the ioLogik R1200 are used to set the pull high/low resistor values for each

serial port.

To set the pull high/low resistors to 150 kΩ, make sure both of the assigned DIP switches are in the OFF

position (default s e tting).

To set the pull high/low resistors to 1 kΩ, make sure bo th of the assigned DIP switches are in the O N

position.

Pull High/Low DIP switch settings for the RS-485 Port

Switch 1 2 3

Pull High/Low Pull High/Low Terminator

ON 1 kΩ 1 kΩ 120 Ω

OFF (default) 150 kΩ 150 kΩ ----

Software Installation

ioSearch Installation

ioSearch™ is a search utility that helps the user locate ioLogik R1200 devices on the local RS-485 network. Find

the ioSearch utility in the Document and Software CD under Software

version from Moxa’s website.

1. Ins t a ll th e Documents and Software CD: Insert the Documents and Software CD into the host

computer. In the root directory of the CD, locate and run SETUP.EXE. The installation program will guide

you through the installation process and install the ioSearch utility. You can also install the MXIO DLL library

separately.

2. Open ioSearch: After installation is complete, run ioSearch from Start Program Files MOXA IO

Server

3. Search for the server: On the menu bar, select System Auto Search Remote I/O Server. In the

dialog window, select “RS-232/485 I/O server” and click “Start Search.”

Utility ioSearch

ioSearch, or download the latest

Page 22

ioLogik R1200 Series Initial Setup

2-8

• If multiple ioLogik R1200 units are installed on the same network, remember to assign a unique device

ID to each unit to avoid conflicts.

• If ioSearch is unable to find the ioLogik R1200 device, there may also be a problem with your COM port

settings. Click “Port Settings” to view or modify the settings.

4. Monitor I/O status: Once the unit is found by ioSearch, you can view the status of all connected I/O

devices on the ioSearch main screen .

Page 23

ioLogik R1200 Series Initial Setup

2-9

NOTE

The USB format should be FAT or FAT32.

Initial Setup by USB

When setting up your ioLogik R1200 for the first time, you need to import the initial configurati on and firmware

files onto a USB drive. But before you connect the USB drive to the ioLogik R1200’s USB port to install and

upgrade configurations and firmware, you first need to place the configuration files under a designated folder.

The NTFS format is not supported.

Import Configuration File

To import configuration files via USB, follow these steps:

1. Create a new “config” folder on the USB drive

2. Use the ioSearch utility to export the configuration file from the device a nd place the file into the“config”

folder created in step 1 (above):

X:\config\R12YY.txt

(X represents the USB drive, and R12Y Y represents the model type)

Upgrade Firmware

To upgrade the firmware by USB, follow these steps:

1. Create a new "fwr" folder on the USB drive.

2. Place the firmware file under the folder created in step1:

X:\fwr\R12YY.1kp

(X represents the USB drive, and R12Y Y represent the model type)

Configure the Device

After you set up the USB drive, follow the steps below to configure your ioLogik R1200 device.

1. Power off the ioLogik R1200.

2. Set the DIP sw itch to “Ini t ial ” mo de .

3. Plug th e USB drive into the ioLogik R1200 device.

4. Power on the ioLogik R12 00 and the USB drive will automatically install the system files.

(Process: Rdy LED Red blinking 3s, then Green b linking,

Result: RdyLED Green: pass, Rdy Red: Failed)

5. Power off the ioLogik R1200 device.

6. Unplug t he USB drive.

7. Set the DIP s w it ch to “Ru n” mo de .

Page 24

ioLogik R1200 Series Initial Setup

2-10

Restore Factory Default Settings

There are two ways to restore the ioLogik R1200 device to the factory default settings.

1. Hold the reset button for 5 seconds.

2. Right-click on the ioLogik unit you want to restore in the ioSearch utility and change “Reset” to “Default.”

Page 25

3

3. Using ioSearch

The following topics are covered in this chapter:

Introduction to ioSearch

ioSearch Main Screen

Main Screen Overview

ioSearch Setup

System

Sort

Help

Quick Links

Main Functions

Locate

Connect/Disconnect

Firmware Upgrade

Import

Export

Change Server Name

Restart System

Delete ioLogik Device

Reset to Default

Main Screen

I/O Configuration Tab (General)

Configuring Digital Input Channels

Configuring Digital Output Channels

Configuring Analog Input Channels

AI Input Range

Configuring Analog Output Channels

Server Info Tab

Server Settings Tab (General)

Watchdog

Page 26

ioLogik R1200 Series Using ioSearch

3-2

Introduction to ioSearch

The ioSearch utility is used for locating or searching for an Logik R1200 unit on the physical network. The

following functions are supported by the ioSearch utility.

• Search for and locate ioLogik R1200 units

• Configure communication address

• Upgrade firmware for multiple ioLogik R1200 units

• Export configuration files from multiple ioLogik R1200 units

• Import a configuration file to multiple ioLogik R1200 units

• Reset to default

ioSearch Main Screen

The main screen of the ioSearch utility defaults to the I/O Configuration tab, which displays an image of the

ioLogik R1200 and the status of each I/O channel. The other tabs on the main screen take you to server and

network settings, and additional functions are available when you log on as an administrator. Note that

configuration options are not available until you log on as an administrator.

Main Screen Overview

ioSearch Main Screen

1 Title

2 Menu bar

3 Navigation panel

4 Quick link

5 Main window

6 Status Bar

Page 27

ioLogik R1200 Series Using ioSearch

3-3

ioSearch Setup

System

Several functions are available from the System menu.

Auto Search Remote Ethernet I/O Servers will search for ioLogik servers on the network. When connecting

for the first time or recovering from a network disconnection, you can use this command to find I/O servers that

are on the network.

Steps to Search for an ioLogik R1200 device:

1. Select the “RS-232/485 Remote I/O” checkbox.

2. Select the “R1000 Series” tab.

3. Sel ect the ioLogik R1200 model(s) for which you are searching.

4. Click and Select “Enab le sear c h range” and e nter the unit ID number, which ranges from 1 to 99.

5. Click the Port Settings button to configure, set, or verify the serial port settings. Select specific COM ports

under “Only Search”, or select “Search All System Com Ports” to configure COM port settings, the Modbus

protocol, and timeout interval.

Page 28

ioLogik R1200 Series Using ioSearch

3-4

Auto Search Timeout Interval: The timeout interval sets the preferred waiting time for an ioLogik R1200

device to respond to a search. After exceeding the preset time limit, ioSearch will proceed to the next device

on the network.

Connection Timeout Interval: The timeout interval sets the preferred waiting time for an ioLogik R1200

device to respond before it disconnects. After exceeding the preset time limit, ioSearch will disconnect the

ioLogik R1200 device.

6. When you click Start Search, ioSearch will begin searching up to 99 IDs for your ioLogik unit. The timeout

interval is for RS-485 communication and defaults to 2,000 ms. As soon as your screen looks like the figure

below, click Stop. Otherwise, ioSeach will continue to search all 99 ports.

Page 29

ioLogik R1200 Series Using ioSearch

3-5

ATTENTION

If io

matches the correct ioLogik

device. See the

Once the ioLogik R1200 device has been discovered by the ioSearch utility, you will be able to monitor the

I/O status from the first tab of the ioSearch utility. You will also be able to configure each DI and DO channel

from this tab after first logging in under the Management tab.

Search is unable to find your ioLogik R1200 device, confirm that the device ID

Auto Search Timeout allows users to set the timeout value for TCP socket communication, but only for

Ethernet remote I/O devices.

previous section for setting or viewing the device ID.

Sort

I/O Status Refresh Rate is used to adjust how often the I/O server is polled for device status. The current

rate is displayed on the sta tus bar at the bottom of the w indow. Note that higher sync rates result in higher

loads on the network.

The Sort menu allows the server list in the navigation panel to be sorted by ioLogik connection and server

model.

Page 30

ioLogik R1200 Series Using ioSearch

3-6

Help

In the Help menu, you can view vendor and version information.

Quick Links

Quick links are provided to search for I/O servers on the RS-485 network and sort the server list.

1. Automatically searches the local network

2. Sorts by ioLogik R1200 device ID (“By Connection”)

3. Sorts by ioLogik R1200 model number (“By I/O Server”)

Main Functions

Right click on a particular ioLogik R1200 device to view the ioSearch function menu.

Locate

The locate function helps users find a specific ioLogik on the network. When this function is triggered, the ready

LED on the selected unit will start to blink, indicating its location.

Connect/Disconnect

The Connect/Disconnect function connects or disconnects the ioLogik device from the ioSearch network.

Page 31

ioLogik R1200 Series Using ioSearch

3-7

Firmware Upgrade

The ioLogik R1200 supports a remote firmware upgrade function. Enter t he path of the firmware file or click on

the icon to browse for the file. The wizard will lead you through the process until the server restarts.

Import

Select this command to reload a configuration that was exported to a text file. You will need to restart the

ioLogik in order for the ne w configuration to take effect. This command may be used to restore a configurati on

after loading the factory defaults, or to duplicate a configuration to multiple ioLogik units.

Export

Select this command to export the configuration of the ioLogik to a text file. You will need to log in as an

administrator to use this function. It is strongly recommended you use this method to back up your

configuration after you have finished configuring the ioLogik for your application.

Change Server Name

The Change Server name function can be used to directly modify the Server Name, especially for first time

installation.

Changing the Server Name for multiple ioLogik R1200 devices is allowed. Select the ioLogik R1200 and then

right click to process this function . After entering the desired server name, click Submit to apply changes.

Page 32

ioLogik R1200 Series Using ioSearch

3-8

Restart System

Select this command to restart the selected ioLogik R1200 device.

Restart multiple ioLogik R1200 units by right-clicking on an ioLogik R1200 and selecting this function.

Delete ioLogik Device

Select this function to remove an ioLogik R1200 unit from the tree manually.

Reset to Default

Select this function to reset all settings, including console passwor ds, to factory default values.

Reset multiple ioLogik R1200 units to default configurations by right-clicking the ioLogik R1200 and selecting

this function.

Page 33

ioLogik R1200 Series Using ioSearch

3-9

Main Screen

I/O Configuration Tab (General)

The I/O Configuration tab shows the status of every I/O channel. This is the default tab when you first open

ioSearch.

Configuring Digital Input Channels

The ioLogik R1200’s digital channel can be separately set to “DI” or “Event Counter Mode.” In “DI” mode, the

specifications are as follows:

Type Logic 0 (OFF) Logic 1 (ON)

Dry contact Open Close to GND

Wet contact (DI to COM) 0 to3 V 10 to 30 V

Page 34

ioLogik R1200 Series Using ioSearch

3-10

In “Event Counter” mode, the ioLogik R1200’s DI channel accepts data from limit or proximity switches, and

counts events according to the ON/OFF status. You may select from two modes, “Lo to Hi” or “Hi t o Lo.” When

“Lo to Hi” is selected, the counter value increases while the switch is pushed. When “Hi to Lo” is selected, the

counter value increases when the switch is pushed and released. The sampling rate of the counter is 2.5 kHz.

This function is designed for low speed switching, not for motor control.

To eliminate the problem of switch bouncing, the ioLogik R1200 provides software filtering that is configurable

in multiples of 0.2 ms. For example, a setting of 100 would mean a 20 ms filter (100 × 0.2 ms). The maximum

value allowed by the software filter is 65535. Setting the filter to “0” causes the system to filter all signals.

Power On Settings: You may configure DI channels in Event Counter mode whether or not counting begins

when powering up.

Safe Status Settings: For DI channels in Event Counter mode, you can configure whether or not counting

starts or continues when Safe Statu s has been activated. When the netwo rk connection is lost as specified in

the Host Connection Watchdog, the ioLogik R1200 will start or stop the counter according to the channel’s Safe

Status settings. Note that the Host Connection Watchdog is disabled by default, and must be enabled for Safe

Status settings to take effect.

Test I/O: You can test DI chan nels i n the Test tab to see how the status or counter value responds when the

attached input device is manipulated.

Page 35

ioLogik R1200 Series Using ioSearch

3-11

Configuring Digital Output Channels

Each ioLogik R1200 digital output channel can be set to “DO” or “Pulse Ou tput” mode. In DO mode, the

specifications are as follows.

Type Logic 0 (OFF) Logic 1 (ON)

DO mode Open Short

In “Pulse Output” mode, the selected digital output channel will generate a square wave as specified in the

pulse mode parameters. The Low and High parameters are in multiples of 0.1 ms, with a maximum setting of

65535. To set the low level width for 5 ms, you would enter 50 (because 50 × 0.1 ms = 5 ms). A setting of 100

for both Low and High would generate a square wave with a 20 ms cycle. The Output parameter specifies the

number of pulses to send. When set to 0, the system will send pulses continuously.

Page 36

ioLogik R1200 Series Using ioSearch

3-12

Power On Settings: Use this field to set the initial status for the DO channel when the ioLogik is powered on.

Safe Status Settings: Use this field to specify how the DO channel resp onds to a break in network

communication. When the network connection is lost as specified in the Host Connection Watchdog, the ioLogik

R1200 will reset all channels according to their Safe Status settings. Note that the Host Connection Watchdog

is disabled by default, an d must be enabled for Safe Status settings to have effect.

Test I/O: You can test the DO channel in the Test tab.

Page 37

ioLogik R1200 Series Using ioSearch

3-13

Configuring Analog Input Channels

The current status of each AI (analog input) channel can be viewed on the I/O Setting:

Click on a specific channel to enable or disable the AI channel by selecting the “Enable AI Channel” field.

There are two modes for the AI channels:

1. AI Input: Voltage Mode (V) (See Chapter 2, Jumper Settings (DIO and AI), for more information)

2. AI Input: Current Mode (mA) (See Chapter 2, Jumper Settings (DIO and AI), for more information)

AI Input Range

Set the AI input ranges for each mod e, as follows:

1. AI Input: Voltage Mode (V) (See Jumper Settings (DIO and AI) in Chapter 2 for more information)

There is only one default analog “voltage” input range: [0-10V]

2. AI Input: Current Mode (mA) (See Jumper Settings (DIO and AI) in Chapter 2 for more information)

There are two modes in the analog “ current” input range: [0-20 mA], [4-20 mA (burnout)]

Burnout mode indicates if the current analog input has burned out. For example, the 4–20 mA burnout mode

is defined in the following diagram:

Page 38

ioLogik R1200 Series Using ioSearch

3-14

ATTENTION

When configuring the jumpers to select voltage or current measurement for the AI channels, open the cover by

first removing the screw on the back panel. Details on jumper settings can be found in the Jumper Settings

(DIO and AI)

Users can define burnout values (BO, default 2 mA) for selected ranges. When input values are in the burnout

range, raw data will register as 0000h to indicate analog input burnout. The definition of raw data is as follows:

Burnout Value (BO) 0.0 < BO < 4.0 User defined (default 2 mA)

Burnout State 0 ≤ AI < BO mA S/W output 0000h

Under Range BO ≤ AI < 4 mA S/W output raw data

Normal Range 4 ≤AI ≤ 20.00 mA S/W output raw data until FFFEh

Over Range XX > 20.00 mA S/W output FFFFh

section.

Configuring Analog Output Channels

The current status of each AO (analog output) channel can be viewed on the I/O Setting:

Page 39

ioLogik R1200 Series Using ioSearch

3-15

Click on a specific channel to access the AO channel settings.

There are two modes for the AI channels, Voltage Mode (V) and Current Mode (mA). See Jumper Settings

(DIO and AI) in Chapter 2 for more information.

Power On Settings: For AO channels in Event Counter mode, you may configure whether or not counting

begins at power up.

Safe Status Settings: For AO channels in Event Counter mode, you can configure whether or not counting

starts or continues when Safe Statu s has been activated. When the netwo rk connection is lost as specified in

the Host Connection Watchdog, the ioLogik R1200 will start or stop the counter according to the channel’s Safe

Status settings. Note that the Host Connection Watchdog is disabled by default, and must be enabled for Safe

Status settings to have effect.

Page 40

ioLogik R1200 Series Using ioSearch

3-16

Test I/O: You can test AO channels in the Test tab. Yo u may see how the status or counter value responds

when the attached input device is manipulated.

Server Info Tab

The Server Information tab p rovides the Modbus addresses for all system configurations. This helps y ou

verify the access authority of each address. The screen also displays a c lear explanation of each item.

Page 41

ioLogik R1200 Series Using ioSearch

3-17

Server Settings Tab (General)

The Server Settings tab is where you log in as an administrator. This is required in order to gain access to the

ioLogik R1200 configuration options. If no administrator password h as been set u p, simply click on Login and

leave the Password for entry field blank. Additional information on ioSearch administrator functions is

provided later in this chapter.

Click “Serial Port1 Setting” or “Serial Port2 Setting” to define and set the serial communication ports.

Page 42

ioLogik R1200 Series Using ioSearch

3-18

Watchdog

The Watchdog tab is where you configure the Host Connection Watchdog, which is used with the Safe Status

settings to define each channel’s response to a lost connection. When the ioLogik R1200 loses its connection as

specified in the timeout, the Host Co nnection Watchdog will switch the ioLogik R1200 to Safe Status and all

channels will reset to their Safe Status settings. By default, the Watchdog is disabled. To enable the Watchdog,

make sure Enable Host Connection W a tchdog is checked, set the Timeou t v a lue, then click the Update

button.

After the Watchdog is enabled, the ioLogik R2110 will enter safe status if the RS-485 connection is lost. Once

the connection has been restored, you will need to return to the Watchdog tab in order to exit Safe Status.

There will be a message saying “Host Connection Lost” to indicate that the server is in safe status. Click Clear

Alarm to exit safe status and return to normal operation.

Page 43

A

A. Modbus Mapping

The following topics are covered in this appendix:

R1210 Modbus Mapping

0xxxx Read/Write Coils (Functions 1, 5, 15)

1xxxx Read Only Coils (Function 2)

3xxxx Read Only Registers (Function 4)

4xxxx Read/Write Registers (Functions 3, 6, 16)

R1212 Modbus Mapping

0xxxx Read/Write Coils (Functions 1, 5, 15)

1xxxx Read Only Coils (Function 2)

3xxxx Read Only Registers (Function 4)

4xxxx Read/Write Registers (Functions 3, 6, 16)

R1214 Modbus Mapping

0xxxx Read/Write Coils (Functions 1, 5, 15)

1xxxx Read Only Coils (Function 2)

3xxxx Read Only Registers (Function 4)

4xxxx Read/Write Registers (Functions 3, 6, 16)

R1240 Modbus Mapping

0xxxx Read/Write Coils (Functions 1, 5, 15)

3xxxx Read Only Registers (Function 4)

4xxxx Read/Write Registers (Functions 3, 6, 16)

R1241 Modbus Mapping

4xxxx Read/Write Registers (Functions 3, 6, 16)

Page 44

ioLogik R1200 Series Modbus Mapping

A-2

R1210 Modbus Mapping

0xxxx Read/Write Coils (Functions 1, 5, 15)

Reference Address Data T ype Description

00001 0x0000 1Bit CH0 DI Counter start, 0=OFF, 1=ON

00002 0x0001 1Bit CH1 DI Counter start, 0=OFF, 1=ON

00003 0x0002 1Bit CH2 DI Counter start, 0=OFF, 1=ON

00004 0x0003 1Bit CH3 DI Counter start, 0=OFF, 1=ON

00005 0x0004 1Bit CH4 DI Counter start, 0=OFF, 1=ON

00006 0x0005 1Bit CH5 DI Counter start, 0=OFF, 1=ON

00007 0x0006 1Bit CH6 DI Counter start, 0=OFF, 1=ON

00008 0x0007 1Bit CH7 DI Counter start, 0=OFF, 1=ON

00009 0x0008 1Bit CH8 DI Counter start, 0=OFF, 1=ON

00010 0x0009 1Bit CH9 DI Counter start, 0=OFF, 1=ON

00011 0x000A 1Bit CH10 DI Counter start, 0=OFF, 1=ON

00012 0x000B 1Bit CH11 DI Count er start, 0=OFF, 1=ON

00013 0x000C 1Bit CH12 DI Counter start, 0 =OFF, 1=ON

00014 0x000D 1Bit CH13 DI Counter start, 0=OFF, 1=ON

00015 0x000E 1Bit CH14 DI Counter start, 0=OFF, 1=ON

00016 0x000F 1Bit CH15 DI Count er start, 0=OFF, 1=ON

00033 0x0020 1Bit CH0 DI Counter reset, 0=no effect, 1=reset

00034 0x0021 1Bit CH1 DI Counter reset, 0=no effect, 1=reset

00035 0x0022 1Bit CH2 DI Counter reset, 0=no effect, 1=reset

00036 0x0023 1Bit CH3 DI Counter reset, 0=no effect, 1=reset

00037 0x0024 1Bit CH4 DI Counter reset, 0=no effect, 1=reset

00038 0x0025 1Bit CH5 DI Counter reset, 0=no effect, 1=reset

00039 0x0026 1Bit CH6 DI Counter reset, 0=no effect, 1=reset

00040 0x0027 1Bit CH7 DI Counter reset, 0=no effect, 1=reset

00041 0x0028 1Bit CH8 DI Counter reset, 0=no effect, 1=reset

00042 0x0029 1Bit CH9 DI Counter reset, 0=no effect, 1=reset

00043 0x002A 1Bit CH10 DI Counter reset, 0=no effect, 1=reset

00044 0x002B 1Bit CH11 DI Counter reset, 0=no effect, 1=reset

00045 0x002C 1Bit CH12 DI Counter reset, 0=no effect, 1=reset

00046 0x002D 1Bit CH13 DI Counter reset, 0=no effect, 1=reset

00047 0x002E 1Bit CH14 DI Counter reset, 0=no effect, 1=reset

00048 0x002F 1Bit CH15 DI Count er reset, 0=no effect, 1=reset

00065 0x0040 1Bit CH0 DI Counter overflow, 0=no effect, 1=overflow

00066 0x0041 1Bit CH1 DI Counter overflow, 0=no effect, 1=overflow

00067 0x0042 1Bit CH2 DI Counter overflow, 0=no effect, 1=overflow

00068 0x0043 1Bit CH3 DI Counter overflow, 0=no effect, 1=overflow

00069 0x0044 1Bit CH4 DI Counter overflow, 0=no effect, 1=overflow

00070 0x0045 1Bit CH5 DI Counter overflow, 0=no effect, 1=overflow

00071 0x0046 1Bit CH6 DI Counter overflow, 0=no effect, 1=overflow

00072 0x0047 1Bit CH7 DI Counter overflow, 0=no effect, 1=overflow

00073 0x0048 1Bit CH8 DI Counter overflow, 0=no effect, 1=overflow

00074 0x0049 1Bit CH9 DI Counter overflow, 0=no effect, 1=overflow

00075 0x004A 1Bit CH10 DI Counter overflow, 0=no effect, 1=overflow

00076 0x004B 1Bit CH11 DI Counter overflow, 0=no effect, 1=overflow

00077 0x004C 1Bit CH12 DI Counter overflow, 0=no effect, 1=overflow

00078 0x004D 1Bit CH13 DI Counter overflow, 0=no effect, 1=overflow

Page 45

ioLogik R1200 Series Modbus Mapping

A-3

Reference Address Data T ype Description

00079 0x004E 1Bit CH14 DI Counter overflow, 0=no effect, 1=overflow

00080 0x004F 1Bit CH15 DI Counter overflow, 0=no effect, 1=overflow

00097 0x0060 1Bit CH0 DI Power on counter start, 0=OFF, 1=ON

00098 0x0061 1Bit CH1 DI Power on counter start, 0=OFF, 1=ON

00099 0x0062 1Bit CH2 DI Power on counter start, 0=OFF, 1=ON

00100 0x0063 1Bit CH3 DI Power on counter start, 0=OFF, 1=ON

00101 0x0064 1Bit CH4 DI Power on counter start, 0=OFF, 1=ON

00102 0x0065 1Bit CH5 DI Power on counter start, 0=OFF, 1=ON

00103 0x0066 1Bit CH6 DI Power on counter start, 0=OFF, 1=ON

00104 0x0067 1Bit CH7 DI Power on counter start, 0=OFF, 1=ON

00105 0x0068 1Bit CH8 DI Power on counter start, 0=OFF, 1=ON

00106 0x0069 1Bit CH9 DI Power on counter start, 0=OFF, 1=ON

00107 0x006A 1Bit CH10 DI Power on counter start, 0=OFF, 1=ON

00108 0x006B 1Bit CH11 DI Power on counter start, 0=OFF, 1=ON

00109 0x006C 1Bit CH12 DI Power on counter start, 0=OFF, 1=ON

00110 0x006D 1Bit CH13 DI Power on counter start, 0=OFF, 1=ON

00111 0x006E 1Bit CH14 DI Power on counter start, 0=OFF, 1=ON

00112 0x006F 1Bit CH15 DI Power on counter start, 0=OFF, 1=ON

00129 0x0080 1Bit CH0 DI Safe mode counter start, 0=OFF, 1=ON

00130 0x0081 1Bit CH1 DI Safe mode counter start, 0=OFF, 1=ON

00131 0x0082 1Bit CH2 DI Safe mode counter start, 0=OFF, 1=ON

00132 0x0083 1Bit CH3 DI Safe mode counter start, 0=OFF, 1=ON

00133 0x0084 1Bit CH4 DI Safe mode counter start, 0=OFF, 1=ON

00134 0x0085 1Bit CH5 DI Safe mode counter start, 0=OFF, 1=ON

00135 0x0086 1Bit CH6 DI Safe mode counter start, 0=OFF, 1=ON

00136 0x0087 1Bit CH7 DI Safe mode counter start, 0=OFF, 1=ON

00137 0x0088 1Bit CH8 DI Safe mode counter start, 0=OFF, 1=ON

00138 0x0089 1Bit CH9 DI Safe mode counter start, 0=OFF, 1=ON

00139 0x008A 1Bit CH10 DI Safe mode co u nter start, 0=OFF, 1=ON

00140 0x008B 1Bit CH11 DI Safe mode cou nter start, 0=OFF, 1=ON

00141 0x008C 1Bit CH12 DI Safe mode counter start, 0=OFF, 1=ON

00142 0x008D 1Bit CH13 DI Safe mode co u nter start, 0=OFF, 1=ON

00143 0x008E 1Bit CH14 DI Safe mode counter start, 0=OFF, 1=ON

00144 0x008F 1Bit CH15 DI Safe mode counter start, 0=OFF, 1=ON

00161 0x00A0 1Bit CH0 DI power failing counter storage, 0=OFF, 1=ON

00162 0x00A1 1Bit CH1 DI power failing counter storage, 0=OFF, 1 =ON

00163 0x00A2 1Bit CH2 DI power failing counter storage, 0=OFF, 1=ON

00164 0x00A3 1Bit CH3 DI power failing counter storage, 0=OFF, 1=ON

00165 0x00A4 1Bit CH4 DI power failing counter storage, 0=OFF, 1 =ON

00166 0x00A5 1Bit CH5 DI power failing counter storage, 0=OFF, 1 =ON

00167 0x00A6 1Bit CH6 DI power failing counter storage, 0=OFF, 1 =ON

00168 0x00A7 1Bit CH7 DI power failing counter storage, 0=OFF, 1=ON

00169 0x00A8 1Bit CH8 DI power failing counter storage, 0=OFF, 1 =ON

00170 0x00A9 1Bit CH9 DI power failing counter storage, 0=OFF, 1 =ON

00171 0x00AA 1Bit CH10 DI power failing counter storage, 0=OFF, 1=ON

00172 0x00AB 1Bit CH11 DI power failing counter storage, 0=OFF, 1=ON

00173 0x00AC 1Bit CH12 DI power failing counter storage, 0=OFF, 1=ON

00174 0x00AD 1Bit CH13 DI power failing counter storage, 0=OFF, 1=ON

00175 0x00AE 1Bit CH14 DI power failing counter storage, 0=OFF, 1=ON

00176 0x00AF 1Bit CH15 DI power failing counter storage, 0=OFF, 1=ON

Page 46

ioLogik R1200 Series Modbus Mapping

A-4

1xxxx Read Only Coils (Function 2)

Reference Address Data T ype Description

10001 0x0000 1Bit CH0 DI Bit value, 0=OFF, 1=ON

10002 0x0001 1Bit CH1 DI Bit value, 0=OFF, 1=ON

10003 0x0002 1Bit CH2 DI Bit value, 0=OFF, 1=ON

10004 0x0003 1Bit CH3 DI Bit value, 0=OFF, 1=ON

10005 0x0004 1Bit CH4 DI Bit value, 0=OFF, 1=ON

10006 0x0005 1Bit CH5 DI Bit value, 0=OFF, 1=ON

10007 0x0006 1Bit CH6 DI Bit value, 0=OFF, 1=ON

10008 0x0007 1Bit CH7 DI Bit value, 0=OFF, 1=ON

10009 0x0008 1Bit CH8 DI Bit value, 0=OFF, 1=ON

10010 0x0009 1Bit CH9 DI Bit value, 0=OFF, 1=ON

10011 0x000A 1Bit CH10 DI Bit value, 0=OFF, 1=ON

10012 0x000B 1Bit CH11 DI Bit va l u e, 0=OFF, 1=ON

10013 0x000C 1Bit CH12 DI Bit value, 0=OFF, 1=ON

10014 0x000D 1Bit CH13 DI Bit value, 0=OFF, 1=ON

10015 0x000E 1Bit CH14 DI Bit value, 0=OFF, 1=ON

10016 0x000F 1Bit CH15 DI Bit value, 0=OFF, 1=ON

3xxxx Read Only Registers (Function 4)

Reference Address Data T ype Description

30001 0x0000 1 Word CH0 DI value, 0=OFF, 1=ON

30002 0x0001 1 Word CH1 DI value, 0=OFF, 1=ON

30003 0x0002 1 Word CH2 DI value, 0=OFF, 1=ON

30004 0x0003 1 Word CH3 DI value, 0=OFF, 1=ON

30005 0x0004 1 Word CH4 DI value, 0=OFF, 1=ON

30006 0x0005 1 Word CH5 DI value, 0=OFF, 1=ON

30007 0x0006 1 Word CH6 DI value, 0=OFF, 1=ON

30008 0x0007 1 Word CH7 DI value, 0=OFF, 1=ON

30009 0x0008 1 Word CH8 DI value, 0=OFF, 1=ON

30010 0x0009 1 Word CH9 DI value, 0=OFF, 1=ON

30011 0x000A 1 Word CH10 DI value, 0=OFF, 1=ON

30012 0x000B 1 Word CH11 DI value, 0=OFF, 1=ON

30013 0x000C 1 Word CH12 DI value, 0=OFF, 1=ON

30014 0x000D 1 Word CH13 DI value, 0=OFF, 1=ON

30015 0x000E 1 Word CH14 DI value, 0=OFF, 1=ON

30016 0x000F 1 Word CH15 DI value, 0=OFF, 1=ON

30033 0x0020 2 Word CH0 DI counter value

30035 0x0022 2 Word CH1 DI counter value

30037 0x0024 2 Word CH2 DI counter value

30039 0x0026 2 Word CH3 DI counter value

30041 0x0028 2 Word CH4 DI counter value

30043 0x002A 2 Word CH5 DI counter value

30045 0x002C 2 Word CH6 DI counter value

30047 0x002E 2 Word CH7 DI counter value

30049 0x0030 2 Word CH8 DI counter value

30051 0x0032 2 Word CH9 DI counter value

30053 0x0034 2 Word CH10 DI counter value

30055 0x0036 2 Word CH11 DI counter value

30057 0x0038 2 Word CH12 DI counter value

Page 47

ioLogik R1200 Series Modbus Mapping

A-5

Reference Address Data T ype Description

30059 0x003A 2 Word CH13 DI counter value

30061 0x003C 2 Word CH14 DI counter value

30063 0x003E 2 Word CH15 DI counter value

4xxxx Read/Write Registers (Functions 3, 6, 16)

Reference Address Data T ype Description

40001 0x0000 1 Word CH0 DI Mode, 0=DI, 1=Counter

40002 0x0001 1 Word CH1 DI Mode, 0=DI, 1=Counter

40003 0x0002 1 Word CH2 DI Mode, 0=DI, 1=Counter

40004 0x0003 1 Word CH3 DI Mode, 0=DI, 1=Counter

40005 0x0004 1 Word CH4 DI Mode, 0=DI, 1=Counter

40006 0x0005 1 Word CH5 DI Mode, 0=DI, 1=Counter

40007 0x0006 1 Word CH6 DI Mode, 0=DI, 1=Counter

40008 0x0007 1 Word CH7 DI Mode, 0=DI, 1=Counter

40009 0x0008 1 Word CH8 DI Mode, 0=DI, 1=Counter

40010 0x0009 1 Word CH9 DI Mode, 0=DI, 1=Counter

40011 0x000A 1 Word CH10 DI Mode, 0=DI, 1=Counter

40012 0x000B 1 Word CH11 DI Mode, 0=DI, 1=Counter

40013 0x000C 1 Word CH12 DI Mode, 0=DI, 1=Counter

40014 0x000D 1 Word CH13 DI Mode, 0=DI, 1=Counter

40015 0x000E 1 Word CH14 DI Mode, 0=DI, 1=Counter

40016 0x000F 1 Word CH15 DI Mode, 0=DI, 1=Counter

40033 0x0020 1 Word CH0 DI filter value

40034 0x0021 1 Word CH1 DI filter value

40035 0x0022 1 Word CH2 DI filter value

40036 0x0023 1 Word CH3 DI filter value

40037 0x0024 1 Word CH4 DI filter value

40038 0x0025 1 Word CH5 DI filter value

40039 0x0026 1 Word CH6 DI filter value

40040 0x0027 1 Word CH7 DI filter value

40041 0x0028 1 Word CH8 DI filter value

40042 0x0029 1 Word CH9 DI filter value

40043 0x002A 1 Word CH10 DI filter value

40044 0x002B 1 Word CH11 DI filter value

40045 0x002C 1 Word CH12 DI filter value

40046 0x002D 1 Word CH13 DI filter value

40047 0x002E 1 Word CH14 DI filter value

40048 0x002F 1 Word CH15 DI filter value

40065 0x0040 1 Word CH0 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40066 0x0041 1 Word CH1 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40067 0x0042 1 Word CH2 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40068 0x0043 1 Word CH3 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40069 0x0044 1 Word CH4 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40070 0x0045 1 Word CH5 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40071 0x0046 1 Word CH6 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40072 0x0047 1 Word CH7 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40073 0x0048 1 Word CH8 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40074 0x0049 1 Word CH9 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40075 0x004A 1 Word CH10 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40076 0x004B 1 Word CH11 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

Page 48

ioLogik R1200 Series Modbus Mapping

A-6

Reference Address Data T ype Description

40077 0x004C 1 Word CH12 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40078 0x004D 1 Word CH13 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40079 0x004E 1 Word CH14 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

40080 0x004F 1 Word CH15 DI counter trigger type, 0:L2H, 1:H2L, 2: Both

R1212 Modbus Mapping

0xxxx Read/Write Coils (Functions 1, 5, 15)

Reference Address Data T ype Description

00001 0x0000 1Bit CH0 DI Counter start, 0=OFF, 1=ON

00002 0x0001 1Bit CH1 DI Counter start, 0=OFF, 1=ON

00003 0x0002 1Bit CH2 DI Counter start, 0=OFF, 1=ON

00004 0x0003 1Bit CH3 DI Counter start, 0=OFF, 1=ON

00005 0x0004 1Bit CH4 DI Counter start, 0=OFF, 1=ON

00006 0x0005 1Bit CH5 DI Counter start, 0=OFF, 1=ON

00007 0x0006 1Bit CH6 DI Counter start, 0=OFF, 1=ON

00008 0x0007 1Bit CH7 DI Counter start, 0=OFF, 1=ON

00009 0x0008 1Bit CH8 DI Counter start, 0=OFF, 1=ON

00010 0x0009 1Bit CH9 DI Counter start, 0=OFF, 1=ON

00011 0x000A 1Bit CH10 DI Counter start, 0=OFF, 1=ON

00012 0x000B 1Bit CH11 DI Counter start, 0=OFF, 1=ON

00013 0x000C 1Bit CH12 DI Counter start, 0 =OFF, 1=ON

00014 0x000D 1Bit CH13 DI Counter start, 0=OFF, 1=ON

00015 0x000E 1Bit CH14 DI Counter start, 0=OFF, 1=ON

00016 0x000F 1Bit CH15 DI Count er start, 0=OFF, 1=ON

00033 0x0020 1Bit CH0 DI Counter reset, 0=no effect, 1=reset

00034 0x0021 1Bit CH1 DI Counter reset, 0=no effect, 1=reset

00035 0x0022 1Bit CH2 DI Counter reset, 0=no effect, 1=reset

00036 0x0023 1Bit CH3 DI Counter reset, 0=no effect, 1=reset

00037 0x0024 1Bit CH4 DI Counter reset, 0=no effect, 1=reset

00038 0x0025 1Bit CH5 DI Counter reset, 0=no effect, 1=reset

00039 0x0026 1Bit CH6 DI Counter reset, 0=no effect, 1=reset

00040 0x0027 1Bit CH7 DI Counter reset, 0=no effect, 1=reset

00041 0x0028 1Bit CH8 DI Counter reset, 0=no effect, 1=reset

00042 0x0029 1Bit CH9 DI Counter reset, 0=no effect, 1=reset

00043 0x002A 1Bit CH10 DI Counter reset, 0=no effect, 1=reset

00044 0x002B 1Bit CH11 DI Counter reset, 0=no effect, 1=reset

00045 0x002C 1Bit CH12 DI Counter reset, 0=no effect, 1=reset

00046 0x002D 1Bit CH13 DI Counter reset, 0=no effect, 1=reset

00047 0x002E 1Bit CH14 DI Counter reset, 0=no effect, 1=reset

00048 0x002F 1Bit CH15 DI Count er reset, 0=no effect, 1=reset

00065 0x0040 1Bit CH0 DI Counter overflow, 0=no effect, 1=overflow

00066 0x0041 1Bit CH1 DI Counter overflow, 0=no effect, 1=overflow

00067 0x0042 1Bit CH2 DI Counter overflow, 0=no effect, 1=overflow

00068 0x0043 1Bit CH3 DI Counter overflow, 0=no effect, 1=overflow

00069 0x0044 1Bit CH4 DI Counter overflow, 0=no effect, 1=overflow

00070 0x0045 1Bit CH5 DI Counter overflow, 0=no effect, 1=overflow

00071 0x0046 1Bit CH6 DI Counter overflow, 0=no effect, 1=overflow

00072 0x0047 1Bit CH7 DI Counter overflow, 0=no effect, 1=overflow

Page 49

ioLogik R1200 Series Modbus Mapping

A-7

Reference Address Data T ype Description

00073 0x0048 1Bit CH8 DI Counter overflow, 0=no effect, 1=overflow

00074 0x0049 1Bit CH9 DI Counter overflow, 0=no effect, 1=overflow

00075 0x004A 1Bit CH10 DI Counter overflow, 0=no effect, 1=overflow

00076 0x004B 1Bit CH11 DI Counter overflow, 0=no effect, 1=overflow

00077 0x004C 1Bit CH12 DI Counter overflow, 0=no effect, 1=overflow

00078 0x004D 1Bit CH13 DI Counter overflow, 0=no effect, 1=overflow

00079 0x004E 1Bit CH14 DI Counter overflow, 0=no effect, 1=overflow

00080 0x004F 1Bit CH15 DI Counter overflow, 0=no effect, 1=overflow

00097 0x0060 1Bit CH0 DI Power on counter start, 0=OFF, 1=ON

00098 0x0061 1Bit CH1 DI Power on counter start, 0=OFF, 1=ON

00099 0x0062 1Bit CH2 DI Power on counter start, 0=OFF, 1=ON

00100 0x0063 1Bit CH3 DI Power on counter start, 0=OFF, 1=ON

00101 0x0064 1Bit CH4 DI Power on counter start, 0=OFF, 1=ON

00102 0x0065 1Bit CH5 DI Power on counter start, 0=OFF, 1=ON

00103 0x0066 1Bit CH6 DI Power on counter start, 0=OFF, 1=ON

00104 0x0067 1Bit CH7 DI Power on counter start, 0=OFF, 1=ON

00105 0x0068 1Bit CH8 DI Power on counter start, 0=OFF, 1=ON

00106 0x0069 1Bit CH9 DI Power on counter start, 0=OFF, 1=ON

00107 0x006A 1Bit CH10 DI Power on counter start, 0=OFF, 1=ON

00108 0x006B 1Bit CH11 DI Power on counter start, 0=OFF, 1=ON

00109 0x006C 1Bit CH12 DI Power on counter start, 0=OFF, 1=ON

00110 0x006D 1Bit CH13 DI Power on counter start, 0=OFF, 1=ON

00111 0x006E 1Bit CH14 DI Power on counter start, 0=OFF, 1=ON

00112 0x006F 1Bit CH15 DI Power on counter start, 0=OFF, 1=ON

00129 0x0080 1Bit CH0 DI Safe mode counter start, 0=OFF, 1=ON

00130 0x0081 1Bit CH1 DI Safe mode counter start, 0=OFF, 1=ON

00131 0x0082 1Bit CH2 DI Safe mode counter start, 0=OFF, 1=ON

00132 0x0083 1Bit CH3 DI Safe mode counter start, 0=OFF, 1=ON

00133 0x0084 1Bit CH4 DI Safe mode counter start, 0=OFF, 1=ON

00134 0x0085 1Bit CH5 DI Safe mode counter start, 0=OFF, 1=ON

00135 0x0086 1Bit CH6 DI Safe mode counter start, 0=OFF, 1=ON

00136 0x0087 1Bit CH7 DI Safe mode counter start, 0=OFF, 1=ON

00137 0x0088 1Bit CH8 DI Safe mode counter start, 0=OFF, 1=ON

00138 0x0089 1Bit CH9 DI Safe mode counter start, 0=OFF, 1=ON

00139 0x008A 1Bit CH10 DI Safe mode co u nter start, 0=OFF, 1=ON

00140 0x008B 1Bit CH11 DI Safe mode cou nter start, 0=OFF, 1=ON

00141 0x008C 1Bit CH12 DI Safe mode counter start, 0=OFF, 1=ON

00142 0x008D 1Bit CH13 DI Safe mode co u nter start, 0=OFF, 1=ON

00143 0x008E 1Bit CH14 DI Safe mode counter start, 0=OFF, 1=ON

00144 0x008F 1Bit CH15 DI Safe mode counter start, 0=OFF, 1=ON

00161 0x00A0 1Bit CH0 DI power failing counter storage, 0=OFF, 1=ON

00162 0x00A1 1Bit CH1 DI power failing counter storage, 0=OFF, 1 =ON

00163 0x00A2 1Bit CH2 DI power failing counter storage, 0=OFF, 1=ON

00164 0x00A3 1Bit CH3 DI power failing counter storage, 0=OFF, 1 =ON

00165 0x00A4 1Bit CH4 DI power failing counter storage, 0=OFF, 1 =ON

00166 0x00A5 1Bit CH5 DI power failing counter storage, 0=OFF, 1 =ON

00167 0x00A6 1Bit CH6 DI power failing counter storage, 0=OFF, 1 =ON

00168 0x00A7 1Bit CH7 DI power failing counter storage, 0=OFF, 1=ON

00169 0x00A8 1Bit CH8 DI power failing counter storage, 0=OFF, 1 =ON

00170 0x00A9 1Bit CH9 DI power failing counter storage, 0=OFF, 1 =ON

00171 0x00AA 1Bit CH10 DI power failing counter storage, 0=OFF, 1=ON

00172 0x00AB 1Bit CH11 DI power failing counter storage, 0=OFF, 1=ON

Page 50

ioLogik R1200 Series Modbus Mapping

A-8

Reference Address Data T ype Description

00173 0x00AC 1Bit CH12 DI power failing counter storage, 0=OFF, 1=ON

00174 0x00AD 1Bit CH13 DI power failing counter storage, 0=OFF, 1=ON

00175 0x00AE 1Bit CH14 DI power failing counter storage, 0=OFF, 1=ON

00176 0x00AF 1Bit CH15 DI power failing counter storage, 0=OFF, 1=ON

00321 0x0140 1Bit CH0 DO Bit value, 0=OFF, 1=ON

00322 0x0141 1Bit CH1 DO Bit value, 0=OFF, 1=ON

00323 0x0142 1Bit CH2 DO Bit value, 0=OFF, 1=ON

00324 0x0143 1Bit CH3 DO Bit value, 0=OFF, 1=ON

00325 0x0144 1Bit CH4 DO Bit value, 0=OFF, 1=ON

00326 0x0145 1Bit CH5 DO Bit value, 0=OFF, 1=ON

00327 0x0146 1Bit CH6 DO Bit value, 0=OFF, 1=ON

00328 0x0147 1Bit CH7 DO Bit value, 0=OFF, 1=ON

00353 0x0160 1Bit CH0 DO Power on value, 0=OFF, 1=ON

00354 0x0161 1Bit CH1 DO Power on value, 0=OFF, 1=ON

00355 0x0162 1Bit CH2 DO Power on value, 0=OFF, 1=ON

00356 0x0163 1Bit CH3 DO Power on value, 0=OFF, 1=ON

00357 0x0164 1Bit CH4 DO Power on value, 0=OFF, 1=ON

00358 0x0165 1Bit CH5 DO Power on value, 0=OFF, 1=ON

00359 0x0166 1Bit CH6 DO Power on value, 0=OFF, 1=ON

00360 0x0167 1Bit CH7 DO Power on value, 0=OFF, 1=ON

00385 0x0180 1Bit CH0 DO Pulse start, 0=OFF, 1=ON

00386 0x0181 1Bit CH1 DO Pulse start, 0=OFF, 1=ON

00387 0x0182 1Bit CH2 DO Pulse start, 0=OFF, 1=ON

00388 0x0183 1Bit CH3 DO Pulse start, 0=OFF, 1=ON

00389 0x0184 1Bit CH4 DO Pulse start, 0=OFF, 1=ON

00390 0x0185 1Bit CH5 DO Pulse start, 0=OFF, 1=ON

00391 0x0186 1Bit CH6 DO Pulse start, 0=OFF, 1=ON

00392 0x0187 1Bit CH7 DO Pulse start, 0=OFF, 1=ON

00417 0x01A0 1Bit CH0 DO Power Pulse start, 0=OFF, 1=ON

00418 0x01A1 1Bit CH1 DO Power Pulse start, 0=OFF, 1=ON

00419 0x01A2 1Bit CH2 DO Power Pulse start, 0=OFF, 1=ON

00420 0x01A3 1Bit CH3 DO Power Pulse start, 0=OFF, 1=ON

00421 0x01A4 1Bit CH4 DO Power Pulse start, 0=OFF, 1=ON

00422 0x01A5 1Bit CH5 DO Power Pulse start, 0=OFF, 1=ON

00423 0x01A6 1Bit CH6 DO Power Pulse start, 0=OFF, 1=ON

00424 0x01A7 1Bit CH7 DO Power Pulse start, 0=OFF, 1=ON

00449 0x01C0 1Bit CH0 DO Safe mode Pul se start, 0=OFF, 1=ON

00450 0x01C1 1Bit CH1 DO Safe mode Pulse start, 0=OFF, 1=ON

00451 0x01C2 1Bit CH2 DO Safe mode Pulse start, 0=OFF, 1=ON

00452 0x01C3 1Bit CH3 DO Safe mode Pulse start, 0=OFF, 1=ON

00453 0x01C4 1Bit CH4 DO Safe mode Pulse star t, 0=OFF, 1=ON

00454 0x01C5 1Bit CH5 DO Safe mode Pulse start, 0=OFF, 1=ON

00455 0x01C6 1Bit CH6 DO Safe mode Pulse start, 0=OFF, 1=ON

00456 0x01C7 1Bit CH7 DO Safe mode Pulse start, 0=OFF, 1=ON

Page 51

ioLogik R1200 Series Modbus Mapping

A-9

1xxxx Read Only Coils (Function 2)

Reference Address Data T ype Description

10001 0x0000 1Bit CH0 DI Bit value, 0=OFF, 1=ON

10002 0x0001 1Bit CH1 DI Bit value, 0=OFF, 1=ON

10003 0x0002 1Bit CH2 DI Bit value, 0=OFF, 1=ON

10004 0x0003 1Bit CH3 DI Bit value, 0=OFF, 1=ON

10005 0x0004 1Bit CH4 DI Bit value, 0=OFF, 1=ON

10006 0x0005 1Bit CH5 DI Bit value, 0=OFF, 1=ON

10007 0x0006 1Bit CH6 DI Bit value, 0=OFF, 1=ON

10008 0x0007 1Bit CH7 DI Bit value, 0=OFF, 1=ON

10009 0x0008 1Bit CH8 DI Bit value, 0=OFF, 1=ON

10010 0x0009 1Bit CH9 DI Bit value, 0=OFF, 1=ON

10011 0x000A 1Bit CH10 DI Bit value, 0=OFF, 1=ON

10012 0x000B 1Bit CH11 DI Bit va l u e, 0=OFF, 1=ON

10013 0x000C 1Bit CH12 DI Bit value, 0=OFF, 1=ON

10014 0x000D 1Bit CH13 DI Bit value, 0=OFF, 1=ON