Moxa Technologies ioLogik E2200, ioLogik E2210, ioLogik E2260, ioLogik E2262, ioLogik E2212 User Manual

...Page 1

ioLogik E2200 Series User’s Manual

Edition 6.5, November 2016

www.moxa.com/product

© 2016 Moxa Inc. All rights reserved.

Page 2

ioLogik E2200 Series User’s Manual

Moxa Americas

Toll

Tel:

Fax:

Moxa China (Shanghai office)

Toll

Tel:

Fax:

Moxa Europe

Tel:

Fax:

Moxa Asia

Tel:

Fax:

Moxa India

Tel:

Fax:

The software described in this manual is furnished under a license agreement and may be used only in accordance with

the terms of that agreement.

Copyright Notice

© 2016 Moxa Inc. All rights reserved.

Trademarks

The MOXA logo is a registered trademark of Moxa Inc.

All other trademarks or registered marks in this manual belong to their respective manufacturers.

Disclaimer

Information in this document is subject to change without notice and does not represent a commitment on the part of

Moxa.

Moxa provides this document as is, without warranty of any kind, either expressed or implied, including, but not limited

to, its particular purpose. Moxa reserves the right to make improvements and/or changes to this manual, or to the

products and/or the programs described in this manual, at any time.

Information provided in this manual is intended to be accurate and reliable. However, Moxa assumes no responsibility for

its use, or for any infringements on the rights of third parties that may result from its use.

This product might include unintentional technical or typographical errors. Changes are periodically made to the

information herein to correct such errors, and these changes are incorporated into new editions of the publication.

Technical Support Contact Information

www.moxa.com/support

-free: 1-888-669-2872

+1-714-528-6777

+1-714-528-6778

+49-89-3 70 03 99-0

+49-89-3 70 03 99-99

+91-80-4172-9088

+91-80-4132-1045

-free: 800-820-5036

+86-21-5258-9955

+86-21-5258-5505

-Pacific

+886-2-8919-1230

+886-2-8919-1231

Page 3

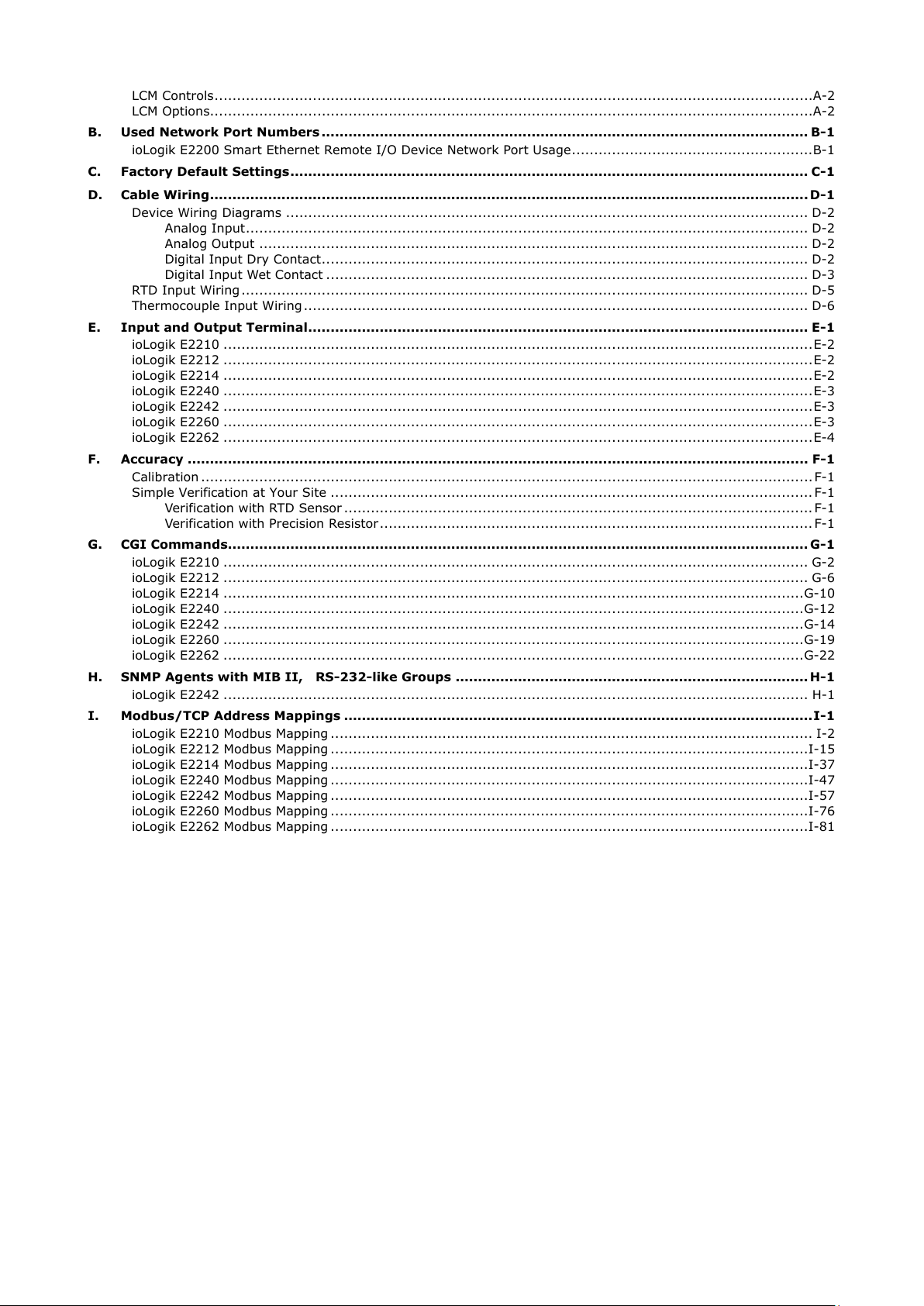

Table of Contents

1. Introduction ...................................................................................................................................... 1-1

Product Key Features and Highlights ..................................................................................................... 1-2

Package Checklist ............................................................................................................................... 1-2

Product Model Information ................................................................................................................... 1-2

Product Selection Guide ....................................................................................................................... 1-3

Product Specifications ......................................................................................................................... 1-4

Common Specifications ................................................................................................................ 1-4

ioLogik E2210 Specifications ......................................................................................................... 1-5

ioLogik E2212 Specifications ......................................................................................................... 1-6

ioLogik E2214 Specifications ......................................................................................................... 1-7

ioLogik E2240 Specifications ......................................................................................................... 1-8

ioLogik E2242 Specifications ......................................................................................................... 1-9

ioLogik E2260 Specifications ....................................................................................................... 1-10

ioLogik E2262 Specifications ....................................................................................................... 1-11

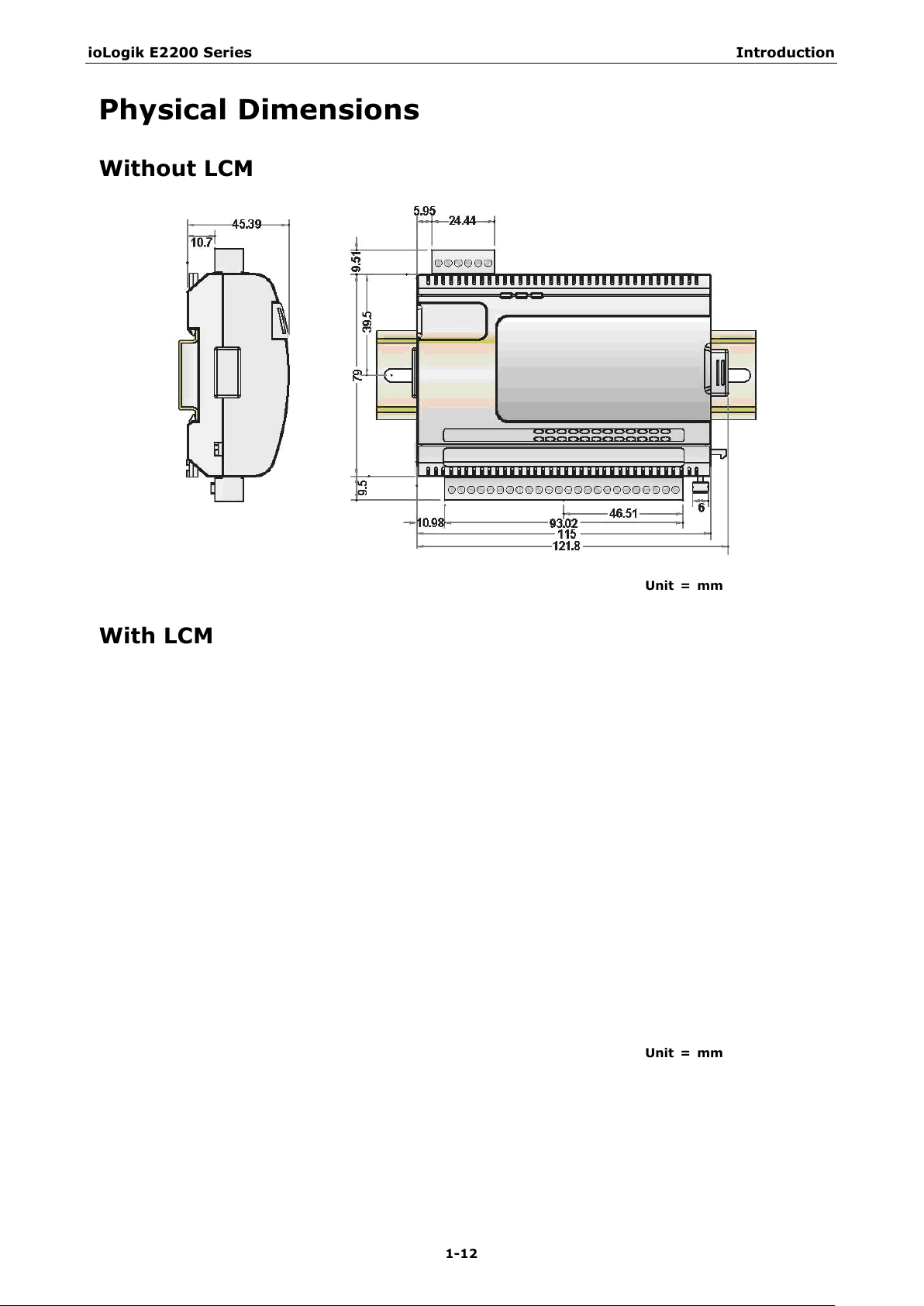

Physical Dimensions .......................................................................................................................... 1-12

Without LCM ............................................................................................................................. 1-12

With LCM ................................................................................................................................. 1-12

Hardware Reference .......................................................................................................................... 1-13

Panel Guide .............................................................................................................................. 1-13

Pin Assignments ........................................................................................................................ 1-13

LED Indicators .......................................................................................................................... 1-14

2. Initial Setup ...................................................................................................................................... 2-1

Hardware Installation .......................................................................................................................... 2-2

Connecting the Power .................................................................................................................. 2-2

Grounding the Unit ...................................................................................................................... 2-2

Software Installation ........................................................................................................................... 2-2

Restore Factory Defaults ...................................................................................................................... 2-4

Connecting to ioAdmin via Ethernet ...................................................................................................... 2-4

Configuring the Host Computer’s IP Address ................................................................................... 2-4

Activating ioAdmin and Connecting to the ioLogik ............................................................................ 2-5

Adding More I/O Channels ............................................................................................................ 2-8

Setting the RS-485 Baudrate ........................................................................................................ 2-9

I/O Wiring Diagrams ........................................................................................................................... 2-9

Using ioAdmin to Import/Export Configurations .................................................................................... 2-11

3. Using ioAdmin ................................................................................................................................... 3-1

System Requirements ......................................................................................................................... 3-2

Features of ioAdmin ............................................................................................................................ 3-2

ioAdmin Overview ............................................................................................................................... 3-3

Main Screen Overview .................................................................................................................. 3-3

Title ........................................................................................................................................... 3-4

Menu Bar ................................................................................................................................... 3-4

Quick Links ............................................................................................................................... 3-10

Navigation Panel ....................................................................................................................... 3-10

Main Window ............................................................................................................................ 3-12

Sync Rate Status ....................................................................................................................... 3-14

Status Bar ................................................................................................................................ 3-14

ioAdmin Administrator Functions ................................................................................................. 3-14

I/O Configuration Tab (Administrator) .......................................................................................... 3-15

Server Settings Tab (Administrator) ............................................................................................. 3-28

Network Tab ............................................................................................................................. 3-29

Firmware Update Tab ................................................................................................................. 3-30

Watchdog Tab ........................................................................................................................... 3-31

Click&Go Logic Tab .................................................................................................................... 3-32

Active Tags Tab ......................................................................................................................... 3-33

SNMP Settings Tab .................................................................................................................... 3-36

Message Monitor Panel (General) ................................................................................................ 3-37

Server Context Menu ........................................................................................................................ 3-38

Using ioEventLog .............................................................................................................................. 3-40

Installing ioEventLog ................................................................................................................. 3-40

Basic Functions ......................................................................................................................... 3-40

Configuration ............................................................................................................................ 3-41

Checking Connected Devices ...................................................................................................... 3-42

Opening Log Files ...................................................................................................................... 3-42

Clearing the Log ........................................................................................................................ 3-42

4. Click&Go ........................................................................................................................................... 4-1

Overview ........................................................................................................................................... 4-2

Features ............................................................................................................................................ 4-2

Page 4

Click&Go Logic Basics .......................................................................................................................... 4-3

Working with Rules ............................................................................................................................. 4-4

Click&Go Development Process ............................................................................................................. 4-4

I/O Configuration ................................................................................................................................ 4-5

Digital Input Mode Selection ......................................................................................................... 4-5

Digital Output Mode Selection ....................................................................................................... 4-6

Analog Input Mode Selection......................................................................................................... 4-6

Alias Name Configuration ............................................................................................................. 4-6

Testing the I/O Channels .............................................................................................................. 4-7

Defining Global Variables ..................................................................................................................... 4-8

Internal Register (Integer) Settings ............................................................................................... 4-8

Timer Settings ............................................................................................................................ 4-9

SNMP Trap Server ....................................................................................................................... 4-9

E-Mail Server ............................................................................................................................ 4-10

Active Message Server ............................................................................................................... 4-11

Working with Logic ........................................................................................................................... 4-12

Click&Go Logic Basics ................................................................................................................ 4-12

IF Conditions ............................................................................................................................ 4-14

THEN/ELSE Actions ........................................................................................................................... 4-18

Activating the Rule-set ...................................................................................................................... 4-27

Upload, Restart, and Run ........................................................................................................... 4-27

Rule-set Management Bar .......................................................................................................... 4-27

Import/Export Configuration .............................................................................................................. 4-27

More Information about Repeat Interval vs. Edge Detection ................................................................... 4-28

5. Using the Web Console ...................................................................................................................... 5-1

Introduction to the Web Console ........................................................................................................... 5-2

Overview ........................................................................................................................................... 5-3

Basic Settings .................................................................................................................................... 5-3

Network Settings ................................................................................................................................ 5-4

General Settings ......................................................................................................................... 5-4

Ethernet Configurations ............................................................................................................... 5-4

RS-485 Settings .......................................................................................................................... 5-4

I/O Settings ....................................................................................................................................... 5-5

DI Channels ................................................................................................................................ 5-5

DO Channels ............................................................................................................................... 5-6

AI Channels ................................................................................................................................ 5-8

Alias Name ................................................................................................................................. 5-8

AO Channels ............................................................................................................................... 5-9

Relay Output Channel .................................................................................................................. 5-9

Relay Count Motoring ................................................................................................................. 5-10

Alias Name set .......................................................................................................................... 5-11

RTD Channels ........................................................................................................................... 5-11

TC Channels ............................................................................................................................. 5-12

System Management ......................................................................................................................... 5-13

Accessible IP Settings ................................................................................................................ 5-13

SNMP Agent ............................................................................................................................. 5-14

Network Connection .................................................................................................................. 5-14

Firmware Update ....................................................................................................................... 5-14

Import System Config ................................................................................................................ 5-15

Export System Config ................................................................................................................ 5-15

LCM ......................................................................................................................................... 5-15

Change Password ...................................................................................................................... 5-15

Load Factory Default .................................................................................................................. 5-16

Save/Restart............................................................................................................................. 5-16

6. Active OPC Server ............................................................................................................................. 6-1

Active OPC Server .............................................................................................................................. 6-2

OLE for Process Control ....................................................................................................................... 6-2

Introduction to Active OPC Server ......................................................................................................... 6-3

Active OPC Server—From Pull to Push ................................................................................................... 6-3

Features of Active OPC Server .............................................................................................................. 6-4

One Click to Create Active Tags ..................................................................................................... 6-4

Faster, More Accurate Data Collection than Traditional “Pull Technology” ............................................. 6-5

Active OPC Server Overview................................................................................................................. 6-5

Installing Active OPC Server ......................................................................................................... 6-5

Main Screen Overview .................................................................................................................. 6-6

Menu Bar ................................................................................................................................... 6-6

Tag Generation................................................................................................................................. 6-10

Configuring Push Tag from ioAdmin ............................................................................................. 6-10

Heartbeat Interval ..................................................................................................................... 6-11

Read/Write Privilege .................................................................................................................. 6-11

A. Liquid Crystal Display Module (LCM) ................................................................................................. A-1

Page 5

LCM Controls ...................................................................................................................................... A-2

LCM Options....................................................................................................................................... A-2

B. Used Network Port Numbers ............................................................................................................. B-1

ioLogik E2200 Smart Ethernet Remote I/O Device Network Port Usage ...................................................... B-1

C. Factory Default Settings .................................................................................................................... C-1

D. Cable Wiring ...................................................................................................................................... D-1

Device Wiring Diagrams ..................................................................................................................... D-2

Analog Input .............................................................................................................................. D-2

Analog Output ........................................................................................................................... D-2

Digital Input Dry Contact ............................................................................................................. D-2

Digital Input Wet Contact ............................................................................................................ D-3

RTD Input Wiring ............................................................................................................................... D-5

Thermocouple Input Wiring ................................................................................................................. D-6

E. Input and Output Terminal ................................................................................................................ E-1

ioLogik E2210 .................................................................................................................................... E-2

ioLogik E2212 .................................................................................................................................... E-2

ioLogik E2214 .................................................................................................................................... E-2

ioLogik E2240 .................................................................................................................................... E-3

ioLogik E2242 .................................................................................................................................... E-3

ioLogik E2260 .................................................................................................................................... E-3

ioLogik E2262 .................................................................................................................................... E-4

F. Accuracy ........................................................................................................................................... F-1

Calibration ......................................................................................................................................... F-1

Simple Verification at Your Site ............................................................................................................ F-1

Verification with RTD Sensor ......................................................................................................... F-1

Verification with Precision Resistor ................................................................................................. F-1

G. CGI Commands.................................................................................................................................. G-1

ioLogik E2210 ................................................................................................................................... G-2

ioLogik E2212 ................................................................................................................................... G-6

ioLogik E2214 .................................................................................................................................. G-10

ioLogik E2240 .................................................................................................................................. G-12

ioLogik E2242 .................................................................................................................................. G-14

ioLogik E2260 .................................................................................................................................. G-19

ioLogik E2262 .................................................................................................................................. G-22

H. SNMP Agents with MIB II, RS-232-like Groups ............................................................................... H-1

ioLogik E2242 ................................................................................................................................... H-1

I. Modbus/TCP Address Mappings ......................................................................................................... I-1

ioLogik E2210 Modbus Mapping ............................................................................................................ I-2

ioLogik E2212 Modbus Mapping ........................................................................................................... I-15

ioLogik E2214 Modbus Mapping ........................................................................................................... I-37

ioLogik E2240 Modbus Mapping ........................................................................................................... I-47

ioLogik E2242 Modbus Mapping ........................................................................................................... I-57

ioLogik E2260 Modbus Mapping ........................................................................................................... I-76

ioLogik E2262 Modbus Mapping ........................................................................................................... I-81

Page 6

1

1. Introduction

The ioLogik E2200 series is a standalone Smart Ethernet remote I/O device that can connect sensors and

on/off switches for automation applications over Ethernet and IP-based networks.

The following topics are covered in this chapter:

Product Key Features and Highlights

Package Checklist

Product Model Information

Product Selection Guide

Product Specifications

Common Specifications

ioLogik E2210 Specifications

ioLogik E2212 Specifications

ioLogik E2214 Specifications

ioLogik E2240 Specifications

ioLogik E2242 Specifications

ioLogik E2260 Specifications

ioLogik E2262 Specifications

Physical Dimensions

Without LCM

With LCM

Hardware Reference

Panel Guide

Pin Assignments

LED Indicators

Page 7

ioLogik E2200 Series Introduction

1-2

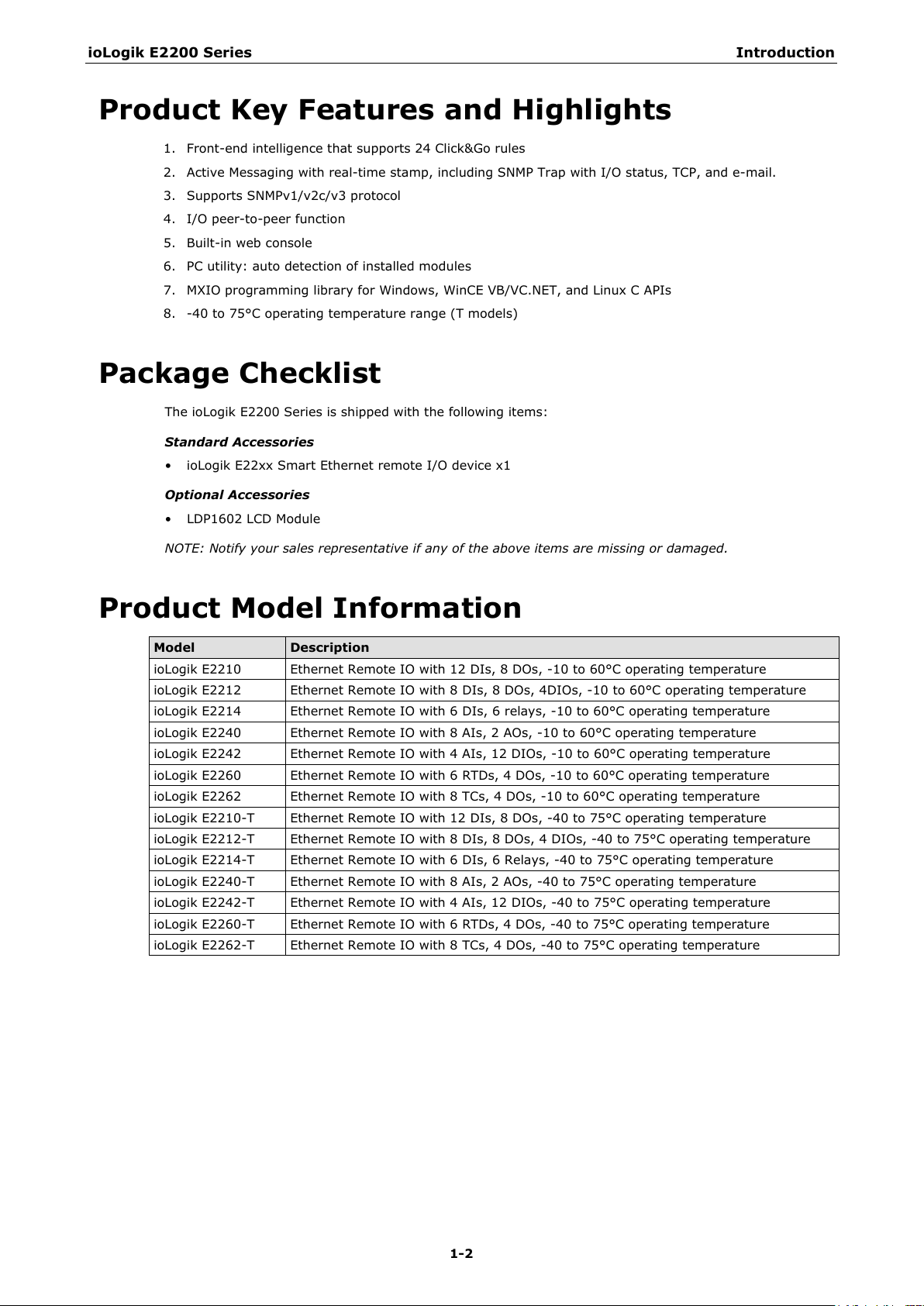

Product Key Features and Highlights

1. Front-end intelligence that supports 24 Click&Go rules

2. Active Messaging with real-time stamp, including SNMP Trap with I/O status, TCP, and e-mail.

3. Supports SNMPv1/v2c/v3 protocol

4. I/O peer-to-peer function

5. Built-in web console

6. PC utility: auto detection of installed modules

7. MXIO programming library for Windows, WinCE VB/VC.NET, and Linux C APIs

8. -40 to 75°C operating temperature range (T models)

Package Checklist

The ioLogik E2200 Series is shipped with the following items:

Standard Accessories

• ioLogik E22xx Smart Ethernet remote I/O device x1

Optional Accessories

• LDP1602 LCD Module

NOTE: Notify your sales representative if any of the above items are missing or damaged.

Product Model Information

Model Description

ioLogik E2210 Ethernet Remote IO with 12 DIs, 8 DOs, -10 to 60°C operating temperature

ioLogik E2212 Ethernet Remote IO with 8 DIs, 8 DOs, 4DIOs, -10 to 60°C operating temperature

ioLogik E2214 Ethernet Remote IO with 6 DIs, 6 relays, -10 to 60°C operating temperature

ioLogik E2240 Ethernet Remote IO with 8 AIs, 2 AOs, -10 to 60°C operating temperature

ioLogik E2242 Ethernet Remote IO with 4 AIs, 12 DIOs, -10 to 60°C operating temperature

ioLogik E2260 Ethernet Remote IO with 6 RTDs, 4 DOs, -10 to 60°C operating temperature

ioLogik E2262 Ethernet Remote IO with 8 TCs, 4 DOs, -10 to 60°C operating temperature

ioLogik E2210-T Ethernet Remote IO with 12 DIs, 8 DOs, -40 to 75°C operating temperature

ioLogik E2212-T Ethernet Remote IO with 8 DIs, 8 DOs, 4 DIOs, -40 to 75°C operating temperature

ioLogik E2214-T Ethernet Remote IO with 6 DIs, 6 Relays, -40 to 75°C operating temperature

ioLogik E2240-T Ethernet Remote IO with 8 AIs, 2 AOs, -40 to 75°C operating temperature

ioLogik E2242-T Ethernet Remote IO with 4 AIs, 12 DIOs, -40 to 75°C operating temperature

ioLogik E2260-T Ethernet Remote IO with 6 RTDs, 4 DOs, -40 to 75°C operating temperature

ioLogik E2262-T Ethernet Remote IO with 8 TCs, 4 DOs, -40 to 75°C operating temperature

Page 8

ioLogik E2200 Series Introduction

1-3

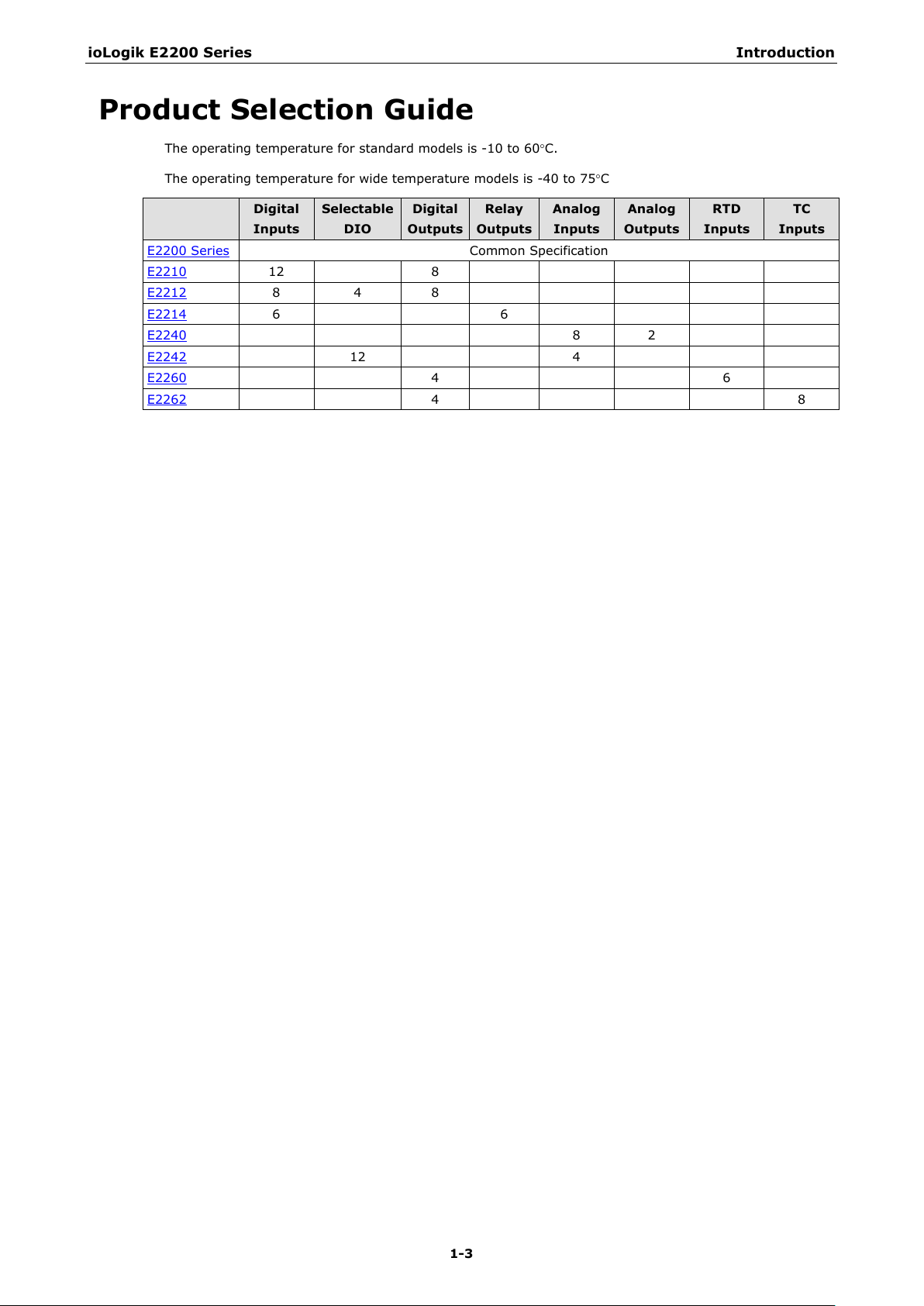

Product Selection Guide

The operating temperature for standard models is -10 to 60°C.

The operating temperature for wide temperature models is -40 to 75°C

Digital

Inputs

E2200 Series Common Specification

E2210 12 8

E2212 8 4 8

E2214 6 6

E2240 8 2

E2242 12 4

E2260 4 6

E2262 4 8

Selectable

DIO

Digital

Outputs

Relay

Outputs

Analog

Inputs

Analog

Outputs

RTD

Inputs

TC

Inputs

Page 9

ioLogik E2200 Series Introduction

1-4

LAN

Ethernet:

Protection:

Protocols:

Serial Communication

Interface:

Serial Line Protection:

Serial Communication Parameters

Parity:

Data Bits:

Stop Bits:

Flow Control:

Baudrate:

Protocol:

Power Requirements

Power Input:

Physical Characteristics

Wiring:

Dimensions:

Weight:

Mounting:

Environmental Limits

Operating Temperature:

• Standard Models:

• Wide Temp. Models:

Storage Temperature:

Ambient Relative Humidity:

Altitude:

Note: Please

Standards and Certifications

Safety:

EMI:

EN 61000

FCC Part 15, Subpart B, Class A

EMS:

EN 61000

EN 61000

EN 61000

Shock:

Freefall:

Vibration:

Green Product:

Note: Please check Moxa’s website for the most up

Warranty

Warranty Period:

*Because of the limited lifetime of power relays, products that use that component are covered by

a 2

Details:

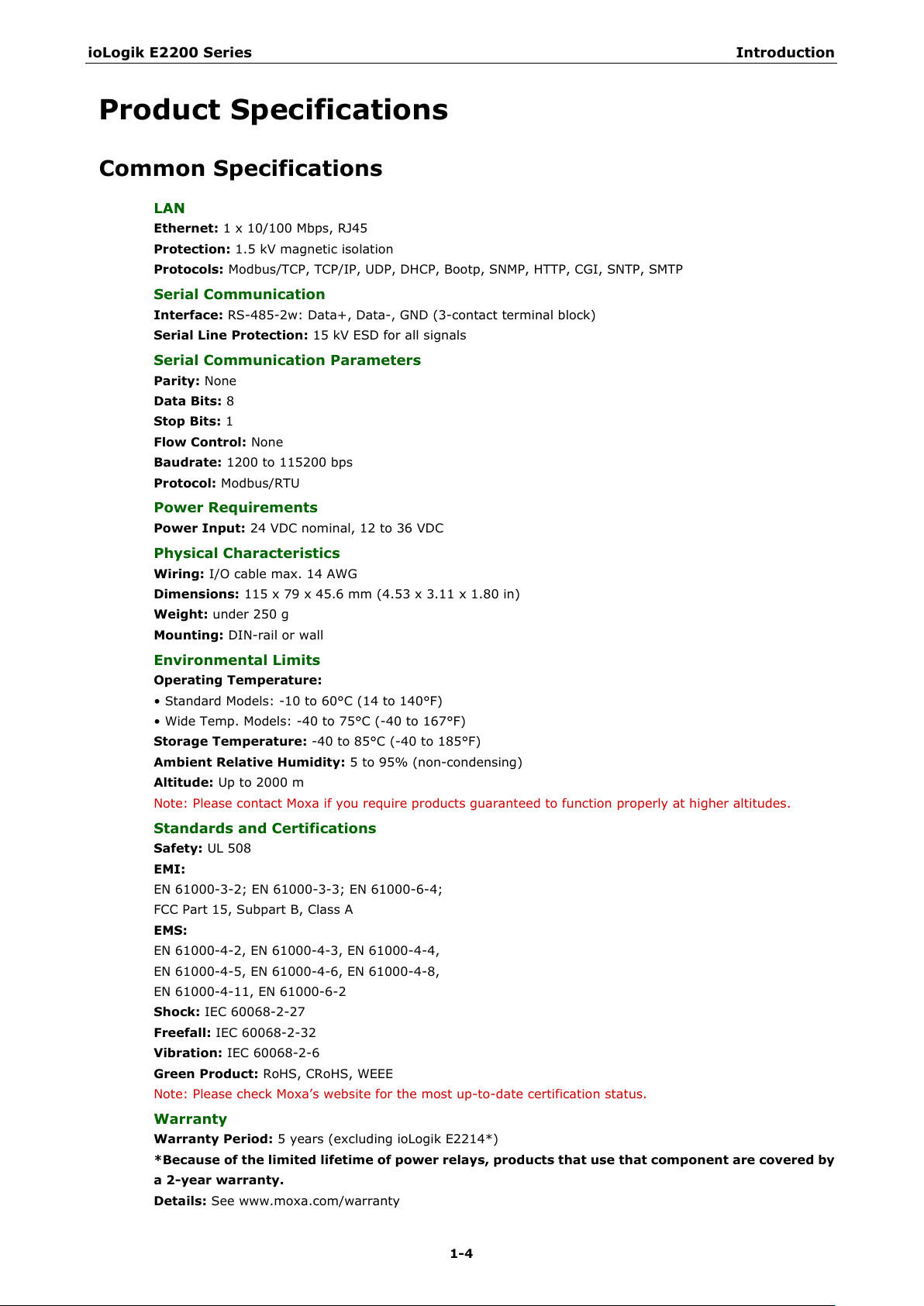

Product Specifications

Common Specifications

1 x 10/100 Mbps, RJ45

1.5 kV magnetic isolation

Modbus/TCP, TCP/IP, UDP, DHCP, Bootp, SNMP, HTTP, CGI, SNTP, SMTP

RS-485-2w: Data+, Data-, GND (3-contact terminal block)

15 kV ESD for all signals

None

8

1

None

1200 to 115200 bps

Modbus/RTU

24 VDC nominal, 12 to 36 VDC

I/O cable max. 14 AWG

115 x 79 x 45.6 mm (4.53 x 3.11 x 1.80 in)

under 250 g

DIN-rail or wall

-10 to 60°C (14 to 140°F)

-40 to 75°C (-40 to 167°F)

-40 to 85°C (-40 to 185°F)

5 to 95% (non-condensing)

Up to 2000 m

contact Moxa if you require products guaranteed to function properly at higher altitudes.

UL 508

-3-2; EN 61000-3-3; EN 61000-6-4;

-4-2, EN 61000-4-3, EN 61000-4-4,

-4-5, EN 61000-4-6, EN 61000-4-8,

-4-11, EN 61000-6-2

IEC 60068-2-27

IEC 60068-2-32

IEC 60068-2-6

RoHS, CRoHS, WEEE

-to-date certification status.

5 years (excluding ioLogik E2214*)

-year warranty.

See www.moxa.com/warranty

Page 10

ioLogik E2200 Series Introduction

1-5

Inputs and Outputs

Digital Inputs:

Digital Outputs:

Isolation:

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

• On: short to GND

• Off:

Wet Contact (DI to GND):

• On: 0 to 3 VDC

• Off: 10 to 30 VDC

Common Type:

Counter Frequency:

Digital Filtering Time Interval:

Digital Output

Type:

I/O Mode:

Pulse Output

Over

Over

Over

Current Rating:

Power Requirements

Power Consumption:

MTBF (mean time between failure)

Time:

Database:

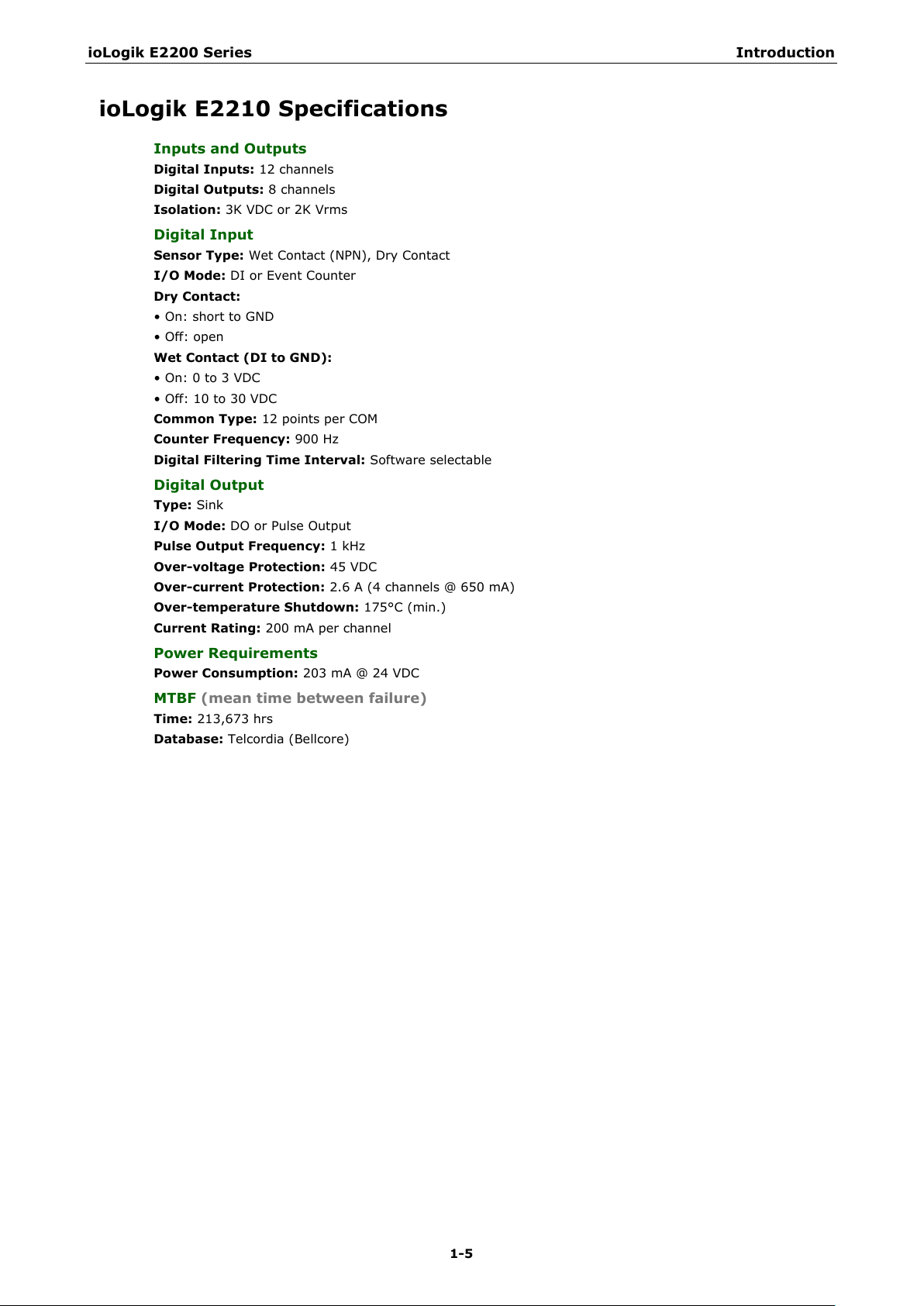

ioLogik E2210 Specifications

12 channels

8 channels

3K VDC or 2K Vrms

Wet Contact (NPN), Dry Contact

DI or Event Counter

open

12 points per COM

900 Hz

Software selectable

Sink

DO or Pulse Output

Frequency: 1 kHz

-voltage Protection: 45 VDC

-current Protection: 2.6 A (4 channels @ 650 mA)

-temperature Shutdown: 175°C (min.)

200 mA per channel

203 mA @ 24 VDC

213,673 hrs

Telcordia (Bellcore)

Page 11

ioLogik E2200 Series Introduction

1-6

Inputs and Outputs

Digital Inputs:

Digital Outputs:

Configurable DIOs:

Isolation:

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

• On: short to GND

• Off: open

Wet Contact (

• On: 0 to 3 VDC

• OFF: 10 to 30 VDC

Common Type:

Counter Frequency:

Digital Filtering Time Interval:

Digital Output

Type:

I/O Mode:

Pulse Output Frequency:

Over

Over

Over

Current Rating:

Power Requirements

Power Consumption:

MTBF

Time:

Database:

ioLogik E2212 Specifications

8 channels

8 channels

4 channels

3K VDC or 2K Vrms

Wet Contact (NPN or PNP) and Dry Contact

DI or Event Counter

DI to GND):

6 points per COM

900 Hz, power off storage

Software selectable

Sink

DO or Pulse Output

-voltage Protection: 45 VDC

-current Protection: 2.6 A (4 channels @650 mA)

-temperature Shutdown: 175°C (min.)

200 mA per channel

136 mA @ 24 VDC

(mean time between failure)

217,722 hrs

Telcordia (Bellcore)

1 kHz

Page 12

ioLogik E2200 Series Introduction

1-7

Inputs and Outputs

Digital Inputs:

Relay Outputs:

Isolation:

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

• On:

• Off: open

Wet Contact

• On: 0 to 3 VDC

• Off: 10 to 30 VDC

Common Type:

Counter Frequency:

Digital Filtering Time Interval:

Relay Output

Type:

Contact Current Rating:

• Inductive Load: 2 A @ 30 VDC, 250 VAC, 110 VAC

• Resistive Load: 5 A @ 30 VDC, 250 VAC, 110 VAC

Minimum permitted load:

Initial Insulation Resistance:

Mechani

Electrical endurance: 100,000 operations @ 5 A resistive load

Contact Resistance:

Pulse Output:

Power Requirements

Power Consumption:

MTBF (mean time between failure)

Time:

Database:

ioLogik E2214 Specifications

6 channels

6 channels

3K VDC or 2K Vrms

Wet Contact (NPN or PNP) and Dry Contact

DI or Event Counter

short to GND

(DI to GND):

3 points per COM

900 Hz, power off storage

Software selectable

Form A (N.O.) power relay

cal endurance: 1,000,000 operations

100 m ohms (max.)

0.3 Hz at rated load

170 mA @ 24 VDC

307,239 hrs

Telcordia (Bellcore)

1 A @ 5 VDC

1000 M ohms (min.) @ 500 VDC

Page 13

ioLogik E2200 Series Introduction

1-8

Inputs and Outputs

Analog Inputs:

Analog Outputs:

Analog Input

Type:

Resolution:

I/O Mode:

Input Range:

Accuracy:

±0.1% FSR @ 25°C

±0.3% FSR @

±0.5% FSR @

Sampling Rate:

All channels:

• 10 samples/sec for voltage

• 6 samples/sec for current

Per

• 1.25 samples/sec for voltage

• 0.75 samples/sec for current

Single channel:

• 1.25 samples/sec for voltage

• 0.75 samples/sec for current

Input Impedance:

Built

Isolation:

Analog Output

Resolution:

Output Range:

Drive Voltage:

Accuracy:

±0.1% FSR @ 25°C,

±0.3% FSR @

±0.5% FSR @

Load Resistor:

Power Requirements

Power Consumption:

MTBF (mean time between failure)

Time:

Database:

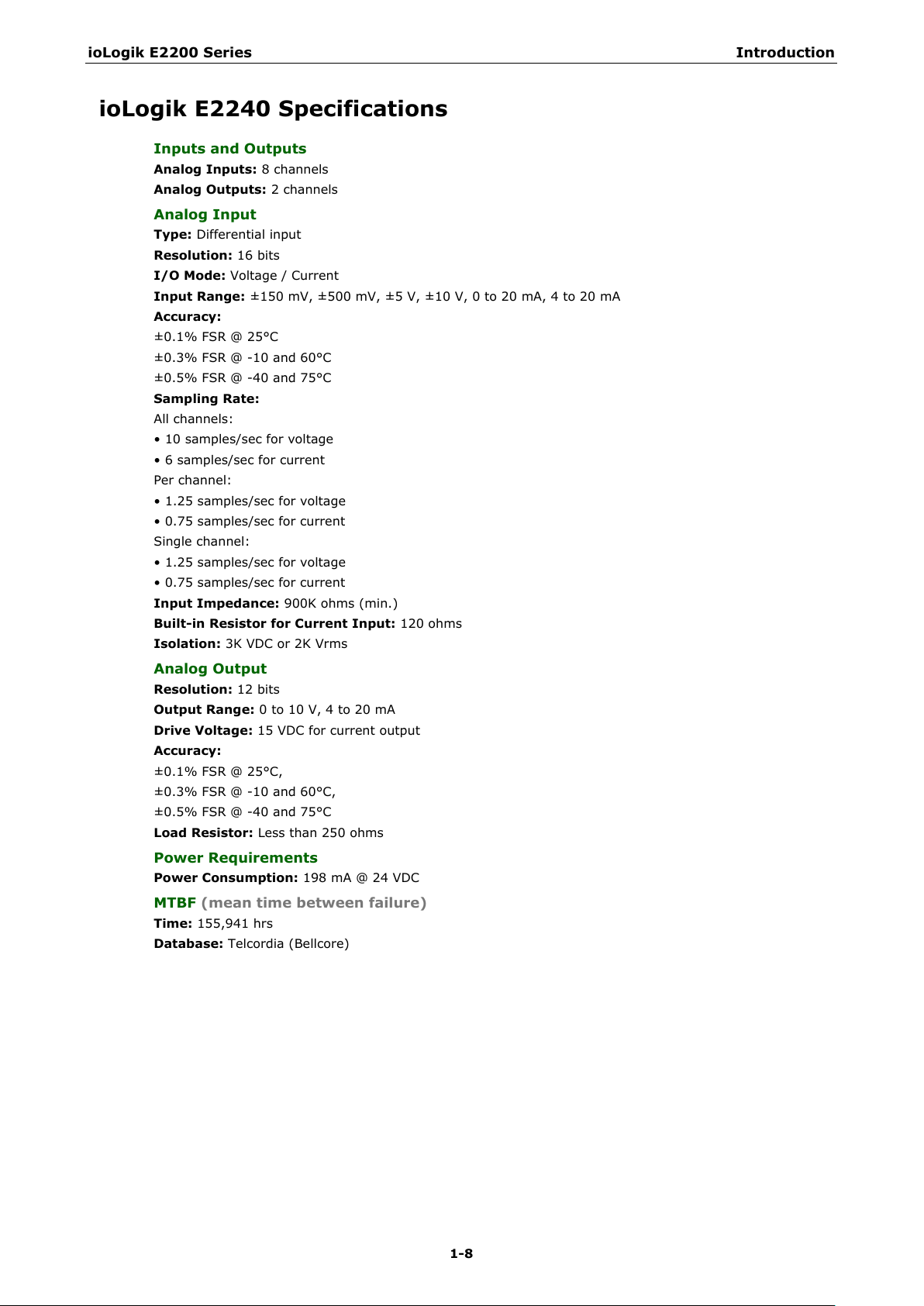

ioLogik E2240 Specifications

8 channels

2 channels

Differential input

16 bits

Voltage / Current

±150 mV, ±500 mV, ±5 V, ±10 V, 0 to 20 mA, 4 to 20 mA

-10 and 60°C

-40 and 75°C

channel:

900K ohms (min.)

-in Resistor for Current Input: 120 ohms

3K VDC or 2K Vrms

12 bits

0 to 10 V, 4 to 20 mA

15 VDC for current output

-10 and 60°C,

-40 and 75°C

Less than 250 ohms

155,941 hrs

Telcordia (Bellcore)

198 mA @ 24 VDC

Page 14

ioLogik E2200 Series Introduction

1-9

Inputs and Outputs

Analog Inputs:

Configurable DIOs:

Analog Input

Type:

Resolution:

I/O Mode:

Input Range: ±150 mV, 0 to 150 mV, ±500 mV, 0 to 500 mV, ±5 V, 0 to 5 V, ±10 V, 0 to 10 V, 0 to 20 mA,

4 to 20 mA

Accuracy:

±0.1% FSR @ 25°C

±0.3% FSR @

±0.5% FSR @

Sampling Rate:

All channels:

• 32 samples/sec

Per channel:

• 8 samples/sec

Single channel:

• 100 samples/sec

Input Impedance:

Built

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

• On: short to GND

• Off: Open

Wet Contact

• On: 0 to 3 VDC

• Off: 10 to 30 VDC

Common Type:

Isolation:

Counter

Digital Filtering Time Interval:

Digital Output

Type:

I/O Mode:

Pulse Output Frequency:

Over

Over

Over

Current Rating:

Isolation:

Power Requirements

Power Consumption:

MTBF (mean time between failure)

Time:

Database:

ioLogik E2242 Specifications

4 channels

12 channels

Differential input

16 bits

Voltage / Current

-10 and 60°C

-40 and 75°C

200K ohms (min.)

-in Resistor for Current Input: 120 ohms

Wet Contact (NPN or PNP) and Dry Contact

DI or event counter

(DI to GND):

6 points per COM

3K VDC or 2K Vrms

Frequency: 900 Hz, power off storage

Software selectable

Sink

DO or Pulse Output

1 kHz

-voltage Protection: 45 VDC

-current Protection: 2.6 A (4 channels @ 650 mA)

-temperature Shutdown: 175°C (min.)

200 mA per channel

3K VDC or 2K Vrms

178 mA @ 24 VDC

204,391 hrs

Telcordia (Bellcore)

Page 15

ioLogik E2200 Series Introduction

1-10

Inputs and Outputs

RTD Inputs:

Digital Outputs:

Isolation:

RTD Inputs

Input Type: PT50, PT100, PT200, PT500, PT1000; JPT100, JPT200, JPT500, JPT1000; NI100, NI120, NI200,

NI500, NI1000; Resistance of 310, 620, 1250, and 2200 ohms

Sampling Rate:

Resolution:

Accuracy:

±0.1% FSR @ 25°C

±0.

±0.5% FSR @

Input Impedance:

Digital Output

Type:

I/O Mode:

Pulse Output Frequency:

Over

Over

Over

Current Rating:

Power Requirements

Power Consumption:

MTBF (mean time between failure)

Time:

Database:

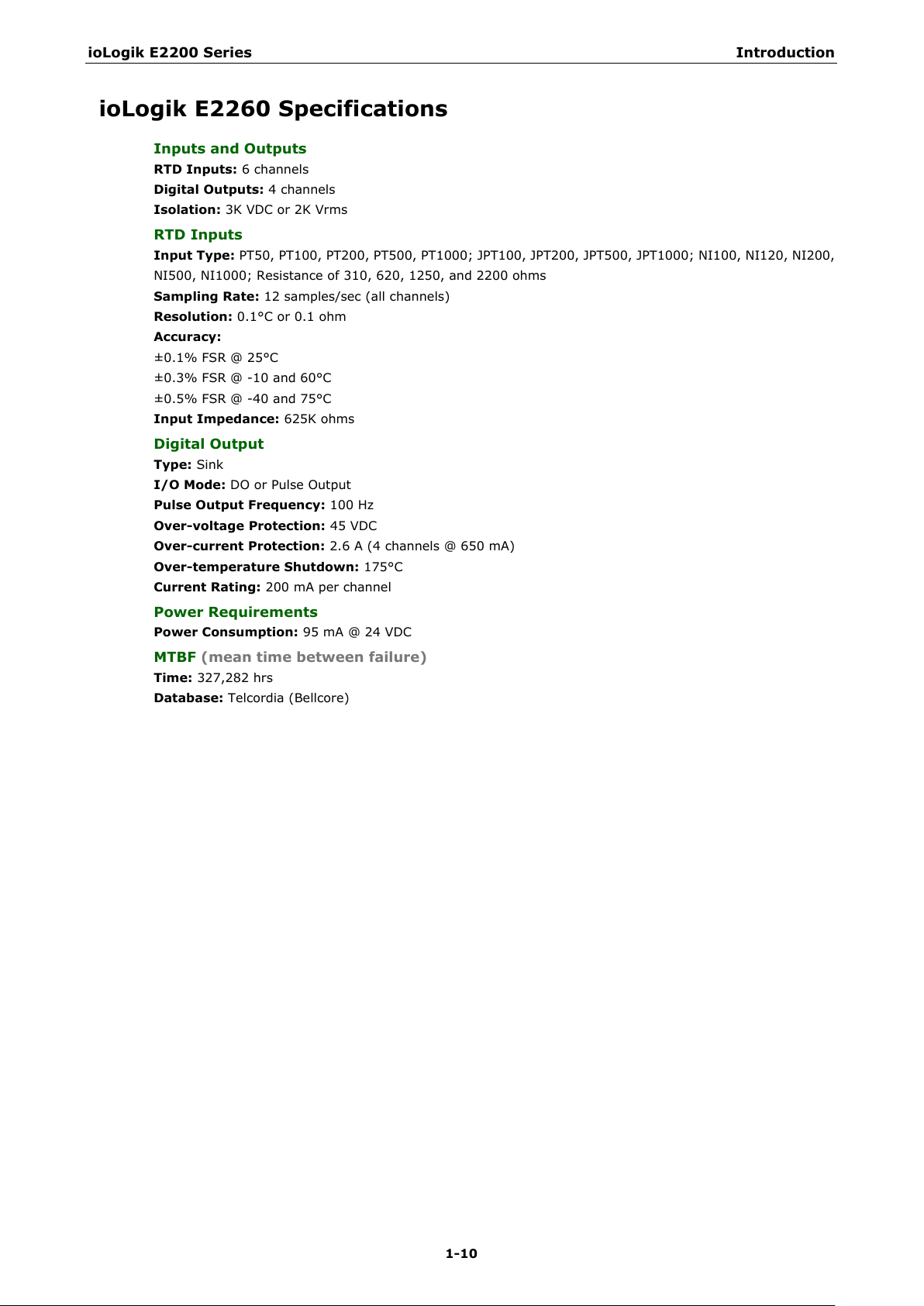

ioLogik E2260 Specifications

6 channels

4 channels

3K VDC or 2K Vrms

12 samples/sec (all channels)

0.1°C or 0.1 ohm

3% FSR @ -10 and 60°C

-40 and 75°C

625K ohms

Sink

DO or Pulse Output

100 Hz

-voltage Protection: 45 VDC

-current Protection: 2.6 A (4 channels @ 650 mA)

-temperature Shutdown: 175°C

200 mA per channel

95 mA @ 24 VDC

327,282 hrs

Telcordia (Bellcore)

Page 16

ioLogik E2200 Series Introduction

1-11

Inputs and Outputs

Thermocouple Inputs:

Digital Outputs:

Thermocouple Input

Sensor Type:

50 to 1600°C),

S (

Millivolt Type:

• Mode: ±78.126 mV, ±39.062 mV, ±19.532 mV

• Fault and over

Sampling Rate:

Resolution:

Accuracy:

±0.1% FSR @ 25°C

±0.3% FS

±0.5% FSR @

Input Impedance:

Digital Output

Type:

I/O Mode:

Pulse Output Frequency:

Over

Over

Over

Current Rating:

Isolation:

Power Requirements

Power Consumption:

MTBF

Time:

Database:

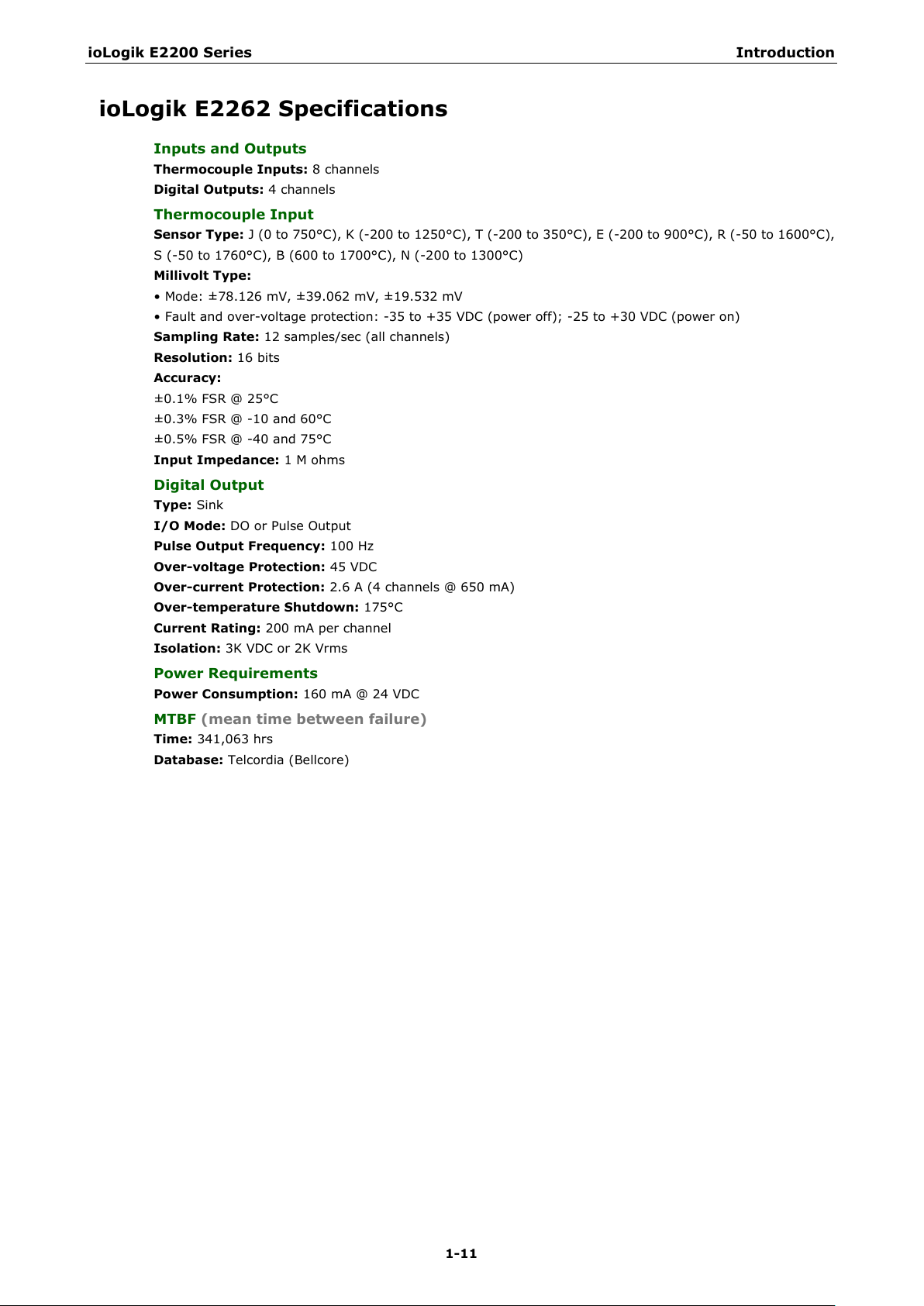

ioLogik E2262 Specifications

8 channels

4 channels

J (0 to 750°C), K (-200 to 1250°C), T (-200 to 350°C), E (-200 to 900°C), R (-

-50 to 1760°C), B (600 to 1700°C), N (-200 to 1300°C)

-voltage protection: -35 to +35 VDC (power off); -25 to +30 VDC (power on)

12 samples/sec (all channels)

16 bits

R @ -10 and 60°C

-40 and 75°C

1 M ohms

Sink

DO or Pulse Output

100 Hz

-voltage Protection: 45 VDC

-current Protection: 2.6 A (4 channels @ 650 mA)

-temperature Shutdown: 175°C

200 mA per channel

3K VDC or 2K Vrms

160 mA @ 24 VDC

(mean time between failure)

341,063 hrs

Telcordia (Bellcore)

Page 17

ioLogik E2200 Series Introduction

1-12

Physical Dimensions

Without LCM

With LCM

Unit = mm

Unit = mm

Page 18

ioLogik E2200 Series Introduction

1-13

NOTE

The RESET button restarts the device and resets all settings to factory defaults. Use a pointed object such as

a straightened paper clip to hold the RESET button down for 5 sec. The RDY LED will turn red as you are holding

the RESET button down. The factory defaults will be loaded once the RDY LED turns green again. At this point

you can release the RESET b

Hardware Reference

Panel Guide

TB1

TB2

Pin Assignments

System Bus

utton.

Pin 1 2 3 4 5

Signal V+ V- V+ V- NC

Pin 6 7 8 9 10

Signal NC Data+ SYNC Data- GND

Ethernet Port

Pin 1 2 3 4

Signal TXD+ TXD- RXD+ ---

Pin 5 6 7 8

Signal --- RXD- --- ---

Page 19

ioLogik E2200 Series Introduction

1-14

(V+: 12 to

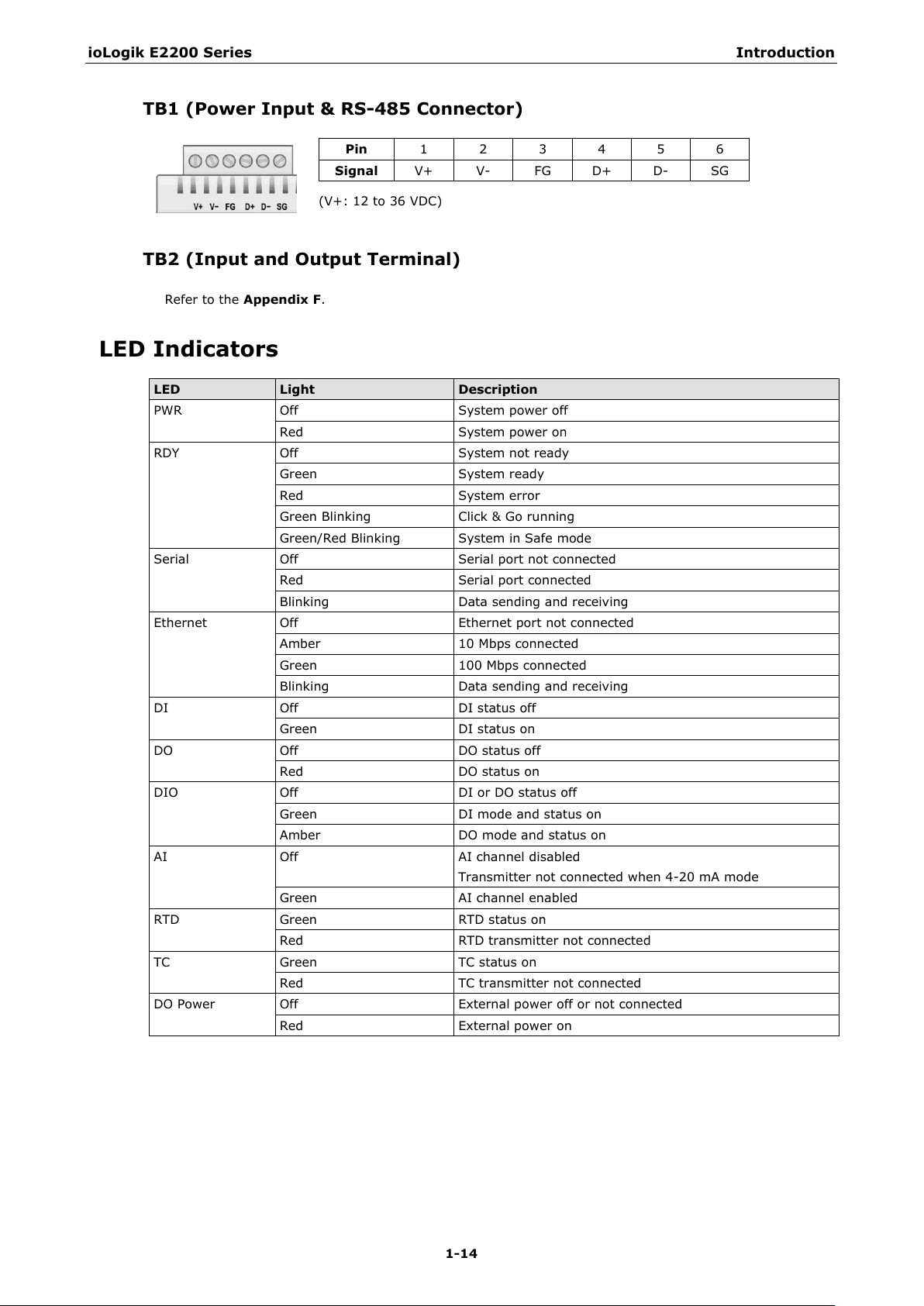

TB1 (Power Input & RS-485 Connector)

Pin 1 2 3 4 5 6

Signal V+ V- FG D+ D- SG

TB2 (Input and Output Terminal)

Refer to the Appendix F.

LED Indicators

LED Light Description

PWR Off System power off

Red System power on

RDY Off System not ready

Green System ready

Red System error

Green Blinking Click & Go running

Green/Red Blinking System in Safe mode

Serial Off Serial port not connected

Red Serial port connected

Blinking Data sending and receiving

Ethernet Off Ethernet port not connected

Amber 10 Mbps connected

Green 100 Mbps connected

Blinking Data sending and receiving

DI Off DI status off

Green DI status on

DO Off DO status off

Red DO status on

DIO Off DI or DO status off

Green DI mode and status on

Amber DO mode and status on

AI Off AI channel disabled

Green AI channel enabled

RTD Green RTD status on

Red RTD transmitter not connected

TC Green TC status on

Red TC transmitter not connected

DO Power Off External power off or not connected

Red External power on

36 VDC)

Transmitter not connected when 4-20 mA mode

Page 20

2

2. Initial Setup

This chapter describes how to install the ioLogik E2200 series.

The following topics are covered in this chapter:

Hardware Installation

Connecting the Power

Grounding the Unit

Software Installation

Restore Factory Defaults

Connecting to ioAdmin via Ethernet

Configuring the Host Computer’s IP Address

Activating ioAdmin and Connecting to the ioLogik

Adding More I/O Channels

Setting the RS-485 Baudrate

I/O Wiring Diagrams

Using ioAdmin to Import/Export Configurations

Page 21

ioLogik E2200 Series Initial Setup

2-2

ATTENTION

Determine the maximum possible current for each power wire and common wire. Observ

maximum current allowable for each wire size. If the current exceeds the maximum rating, the wiring could overheat, causing

serious damage to your equipment. For safety reasons, we recommend an average cable size of 22

depending on the current load, you may want to adjust your cable size (the maximum wire size for power connectors is 2

mm)..

Hardware Installation

Connecting the Power

Connect the 12 to 36 VDC power line to the ioLogik’s terminal block (TB1). If power is properly supplied, the

power LED will glow a solid red color.

Grounding the Unit

The ioLogik is equipped with two grounding points, one on the wall mount socket and the other on the

DIN-Rail mount. Both grounding points are connected to the same conducting pathway Connect the ground

pin if earth ground is available.

Software Installation

ioAdmin is a Windows utility provided for the configuration and management of ioLogik E2200 products and

connected I/O devices. ioAdmin can be used to monitor and configure ioLogik E2200 products from anywhere

on the network. Some settings may also be configured by web console or optional LCM.

ioAdmin can be downloaded from Moxa’s website.

1. Installing ioAdmin from website:

a. First click on the following link to access the website’s search utility:

http://www.moxa.com/support/search.aspx?type=soft

b. When the web page opens, enter the model name of your product in the search box.

c. Click the model name and navigate to the product page, and then click on Utilities, located in the box

titled Software.

d. Download and then unzip the file. Run SETUP.EXE from that location.

The installation program will guide you through the installation process and install the software.

2. Open ioAdmin: After installation is finished, run ioAdmin from the Windows Start menu: Start

Program Files

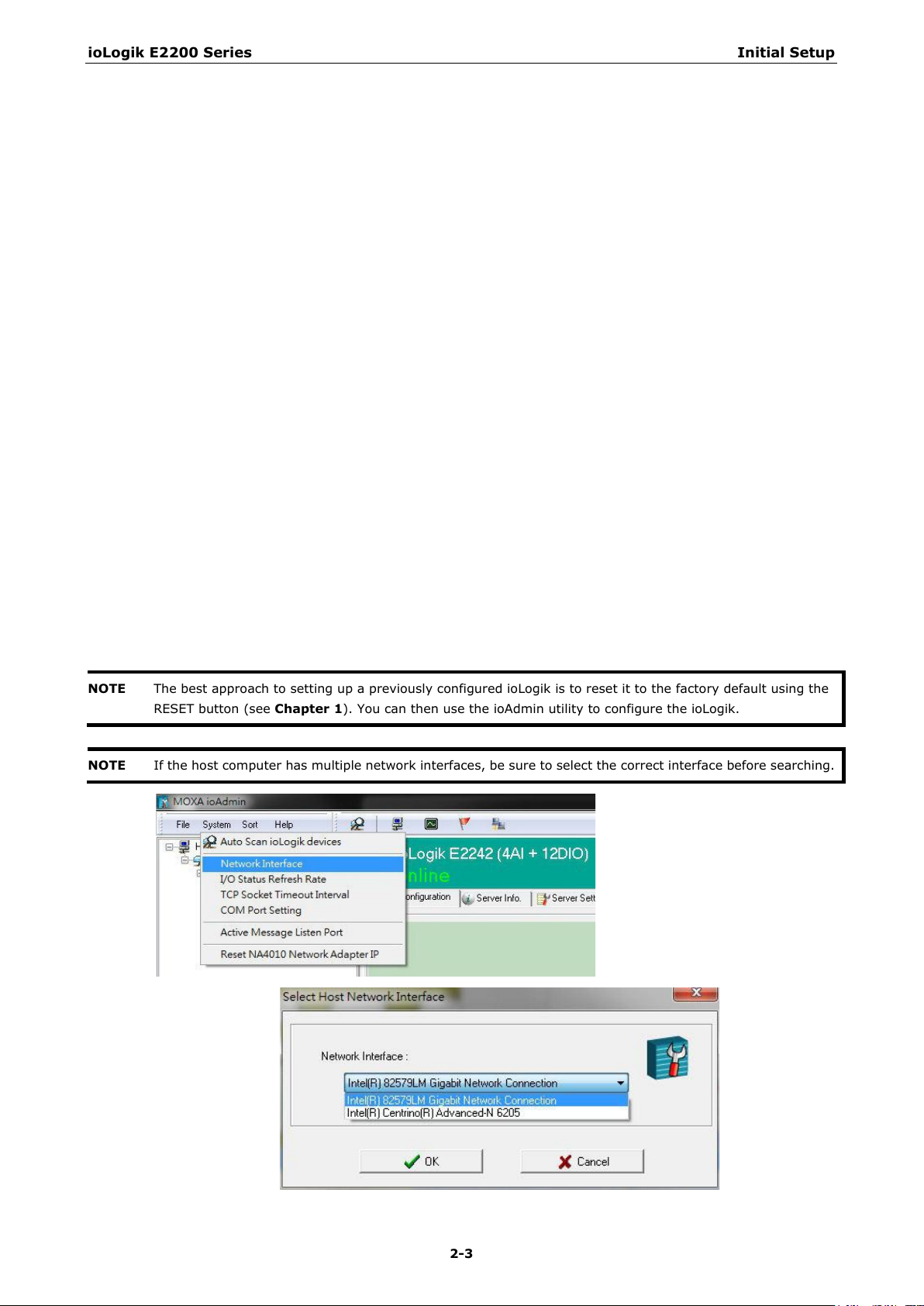

3. Search the network for ioLogik: When ioAdmin is started, it will automatically run the auto search

program. You can also find the program on the menu bar; select System

devices. A dialog window will appear. Click Start Search to begin searching for your unit.

MOXA IO Server Utility ioAdmin.

e all electrical codes dictating the

AWG. However,

Auto Scan Active ioLogik

Page 22

ioLogik E2200 Series Initial Setup

2-3

NOTE

The best approach to setting up

RESET button

NOTE

If the host computer has multiple network interfaces, be sure to select the correct interface before searching.

(see Chapter 1). You can then use the ioAdmin utility to configure the ioLogik.

a previously configured ioLogik is to reset it to the factory default using the

Page 23

ioLogik E2200 Series Initial Setup

2-4

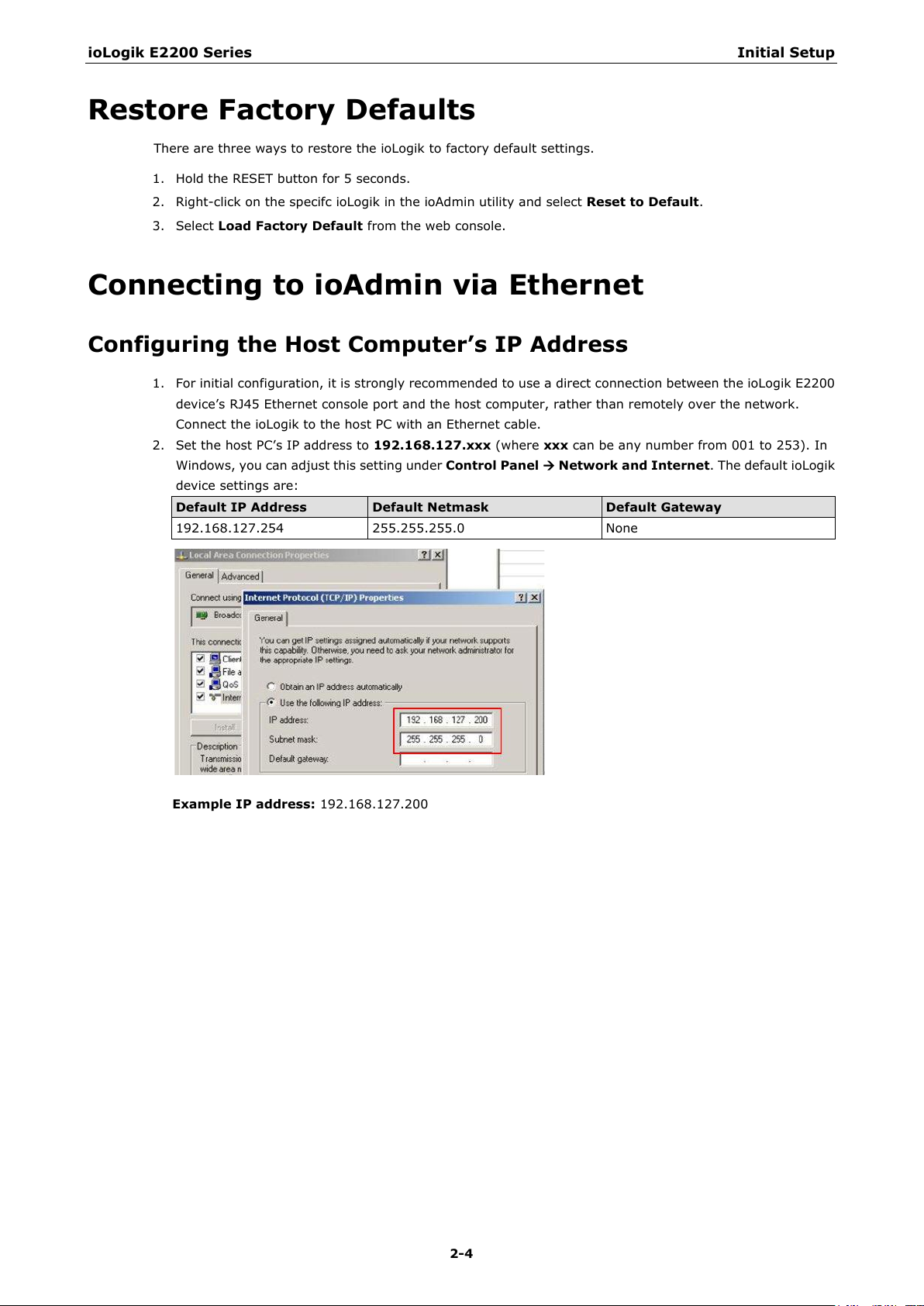

Restore Factory Defaults

There are three ways to restore the ioLogik to factory default settings.

1. Hold the RESET button for 5 seconds.

2. Right-click on the specifc ioLogik in the ioAdmin utility and select Reset to Default.

3. Select Load Factory Default from the web console.

Connecting to ioAdmin via Ethernet

Configuring the Host Computer’s IP Address

1. For initial configuration, it is strongly recommended to use a direct connection between the ioLogik E2200

device’s RJ45 Ethernet console port and the host computer, rather than remotely over the network.

Connect the ioLogik to the host PC with an Ethernet cable.

2. Set the host PC’s IP address to 192.168.127.xxx (where xxx can be any number from 001 to 253). In

Windows, you can adjust this setting under Control Panel

device settings are:

Default IP Address Default Netmask Default Gateway

192.168.127.254 255.255.255.0 None

Network and Internet. The default ioLogik

Example IP address: 192.168.127.200

Page 24

ioLogik E2200 Series Initial Setup

2-5

NOTE

When setting up a previously configured ioLogik, first restore it to factory default settings by using the RESET

button

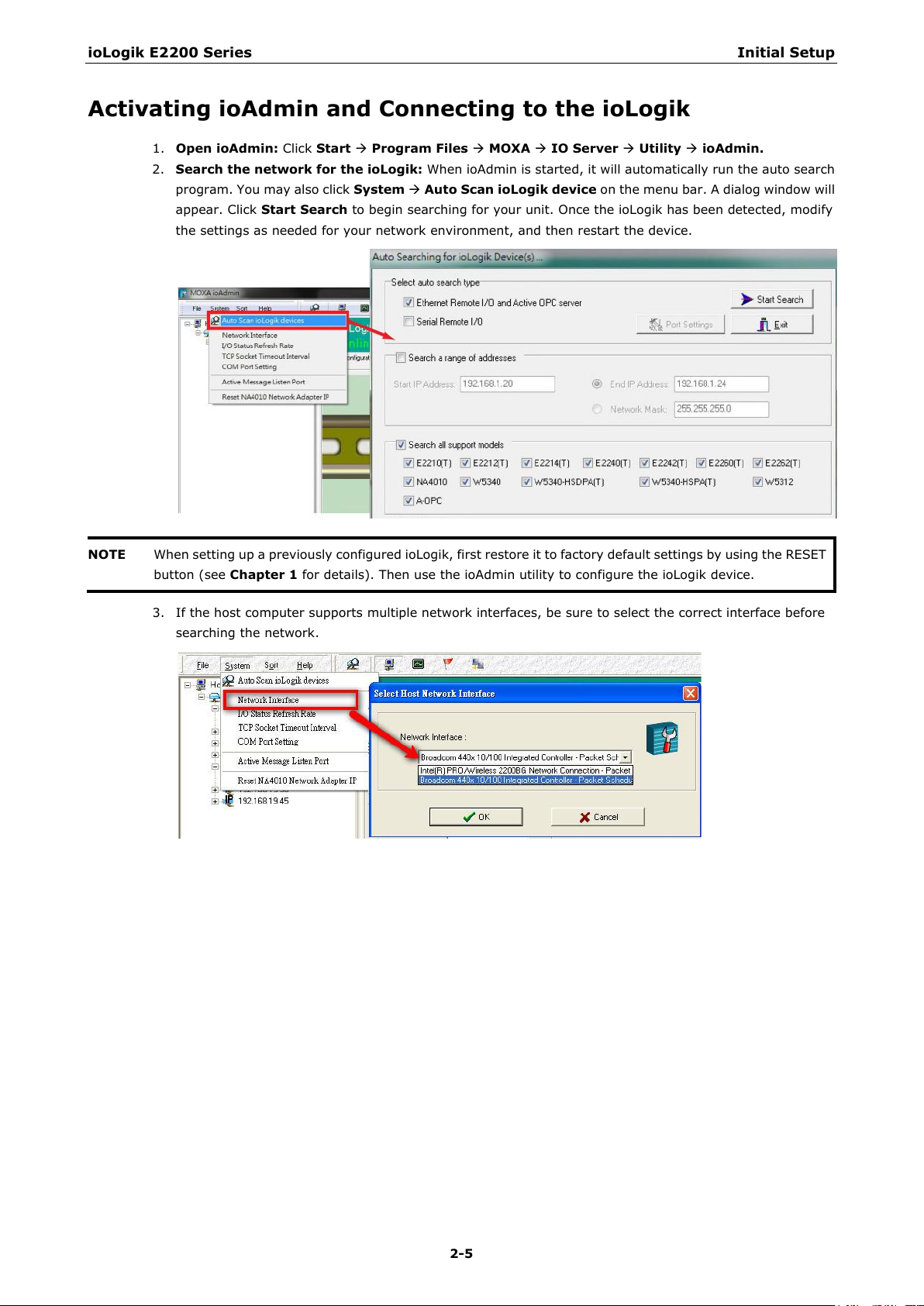

Activating ioAdmin and Connecting to the ioLogik

1. Open ioAdmin: Click Start Program Files MOXA IO Server Utility ioAdmin.

2. Search the network for the ioLogik: When ioAdmin is started, it will automatically run the auto search

program. You may also click System Auto Scan ioLogik device on the menu bar. A dialog window will

appear. Click Start Search to begin searching for your unit. Once the ioLogik has been detected, modify

the settings as needed for your network environment, and then restart the device.

(see Chapter 1 for details). Then use the ioAdmin utility to configure the ioLogik device.

3. If the host computer supports multiple network interfaces, be sure to select the correct interface before

searching the network.

Page 25

ioLogik E2200 Series Initial Setup

2-6

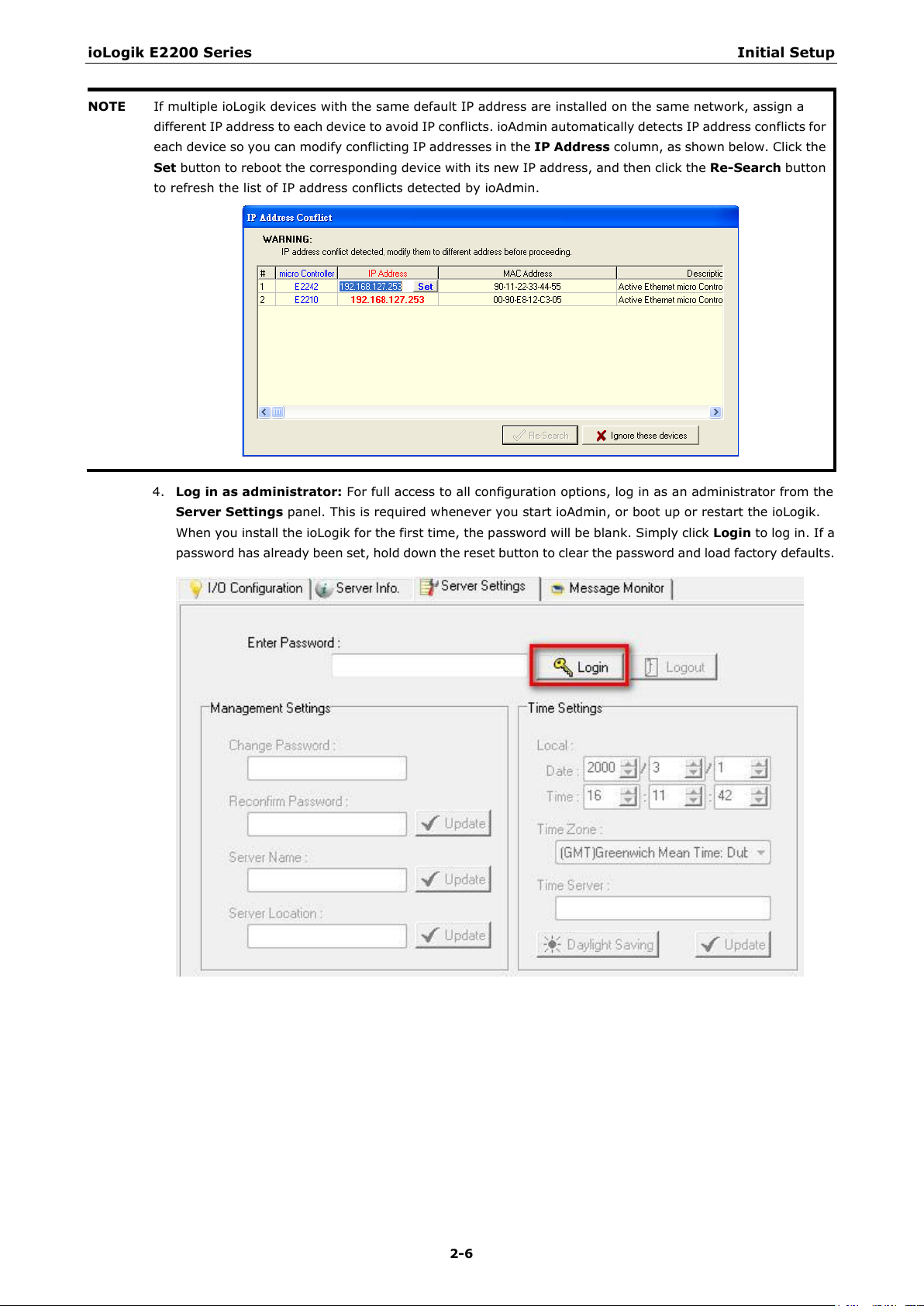

NOTE

If multiple ioLogik devices

different IP address to each device to avoid IP conflicts. ioAdmin automatically detects IP address conflicts for

each

column, as shown below. Click the

Set

button

to refresh the list of

device so you can modify conflicting IP addresses in the IP Address

button to reboot the corresponding device with its new IP address, and then click the Re-Search

4. Log in as administrator: For full access to all configuration options, log in as an administrator from the

Server Settings panel. This is required whenever you start ioAdmin, or boot up or restart the ioLogik.

When you install the ioLogik for the first time, the password will be blank. Simply click Login to log in. If a

password has already been set, hold down the reset button to clear the password and load factory defaults.

with the same default IP address are installed on the same network, assign a

IP address conflicts detected by ioAdmin.

Page 26

ioLogik E2200 Series Initial Setup

2-7

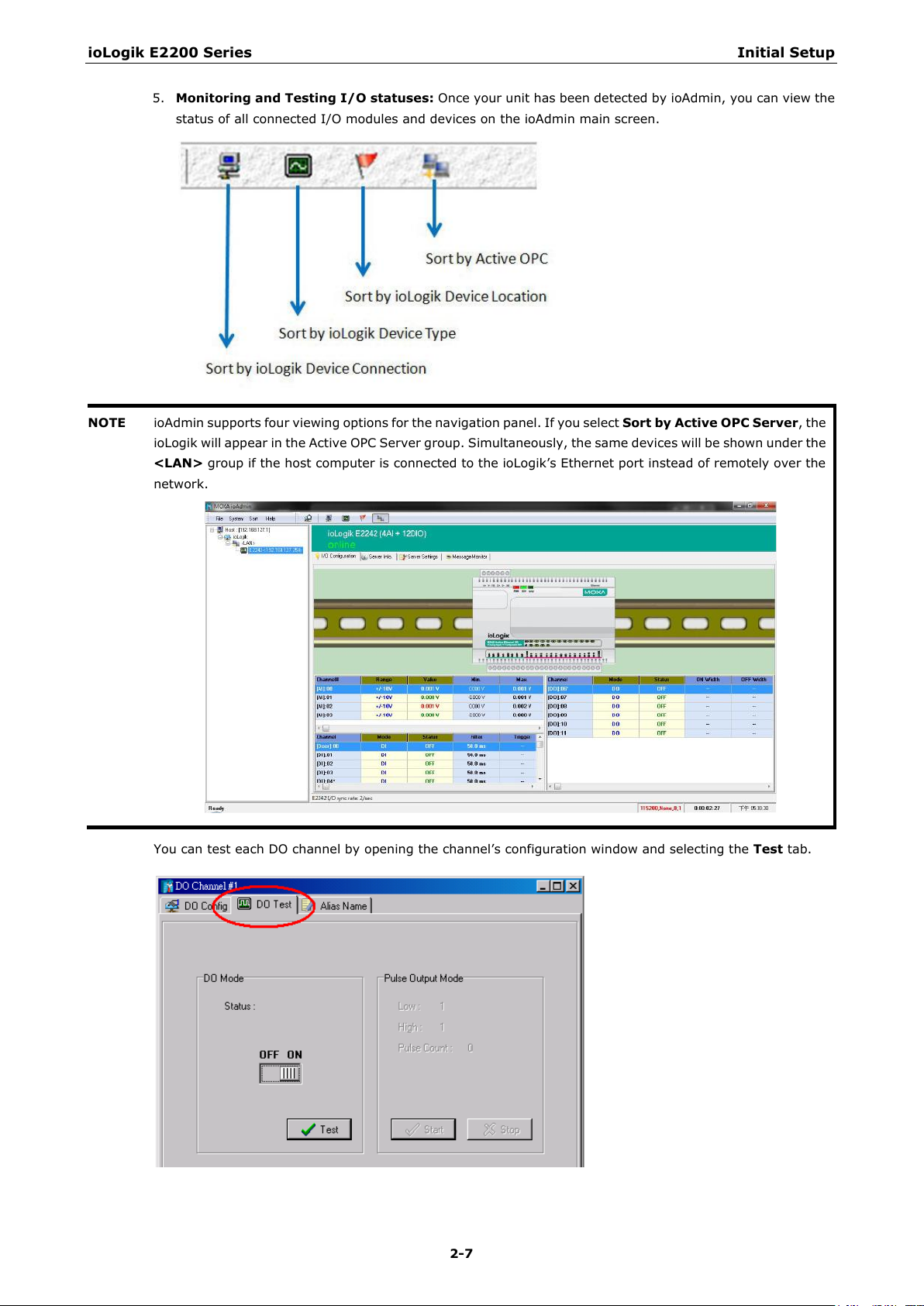

NOTE

ioAdmin supports four viewing options for the navigation panel. If you select

, the

ioLogik will appear in the Active OPC Server group. Simultaneously, the same devices will be shown under the

<LAN>

ly over the

network.

5. Monitoring and Testing I/O statuses: Once your unit has been detected by ioAdmin, you can view the

status of all connected I/O modules and devices on the ioAdmin main screen.

group if the host computer is connected to the ioLogik’s Ethernet port instead of remote

You can test each DO channel by opening the channel’s configuration window and selecting the Test tab.

Sort by Active OPC Server

Page 27

ioLogik E2200 Series Initial Setup

2-8

ATTENTION

Multiple ioLogik E2200/R21

485 network. But when

connecting the power, be sure to use the following steps in the order below:

ATTENTION

A total of 31 additional ioLogik R21

saving

arrangement is to use the TB1 terminal block for the cascaded RS-485 connections, instead of using the system

bus.

After clicking the Test tab, you can see how a channel’s status affects or is affected by the attached device. For

DO channels, you can set the ON/OFF status or START/STOP pulse output. For DI channels, you can monitor

the attached devices’ ON/OFF status, or monitor the counter.

You can now use ioAdmin to set up or configure your ioLogik E2200. For additional information on using

ioAdmin, see Chapter 3.

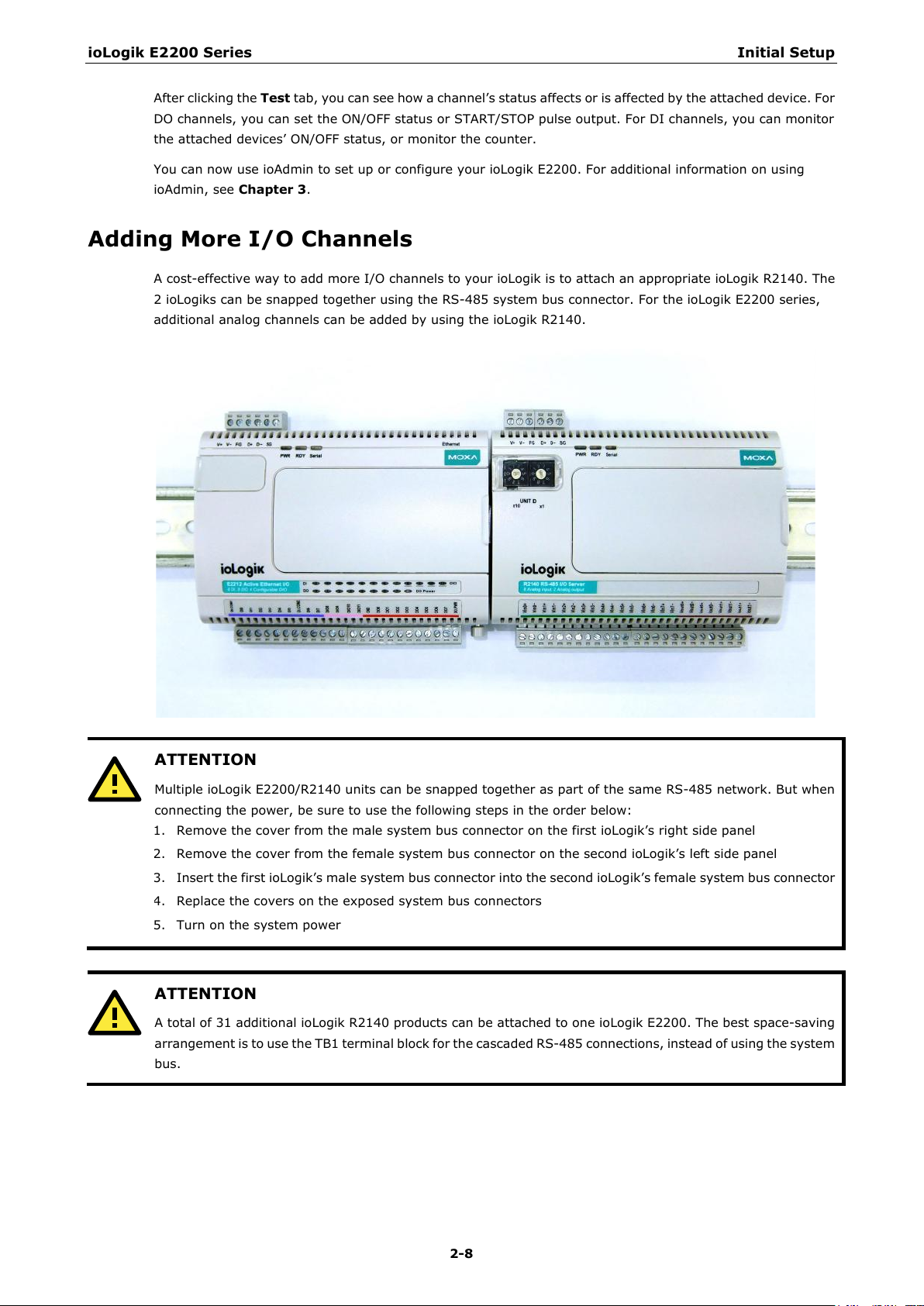

Adding More I/O Channels

A cost-effective way to add more I/O channels to your ioLogik is to attach an appropriate ioLogik R2140. The

2 ioLogiks can be snapped together using the RS-485 system bus connector. For the ioLogik E2200 series,

additional analog channels can be added by using the ioLogik R2140.

Remove the cover from the male system bus connector on the first ioLogik’s right side panel

Remove the cover from the female system bus connector on the second ioLogik’s left side panel

Insert the first ioLogik’s male system bus connector into the second ioLogik’s female system bus connector

Replace the covers on the exposed system bus connectors

Turn on the system power

40 units can be snapped together as part of the same RS-

40 products can be attached to one ioLogik E2200. The best space-

Page 28

ioLogik E2200 Series Initial Setup

2-9

ATTENTION

All I/O channels of the ioLogik E2200

ost PC, but Click&Go logic can

only be used with the ioLogik E2200 series. Currently, Click&Go local control logic is not supported by the

ioLogik R21

ATTENTION

When using the RS

485

Modbus devices, the ioLogik E2200 should always have an RS

ioLogik R21

E2200 series supports Unit IDs up to 247 for Modbus devices, the highest Unit ID on the ioLogik R2140 is 99.

40 series.

-485 cascading interface or system bus to add more I/O channels or to connect to RS-

40 or other devices should always be 2 or more, with an upper limit of 99. Although the ioLogik

+R2140 system can be polled by a remote h

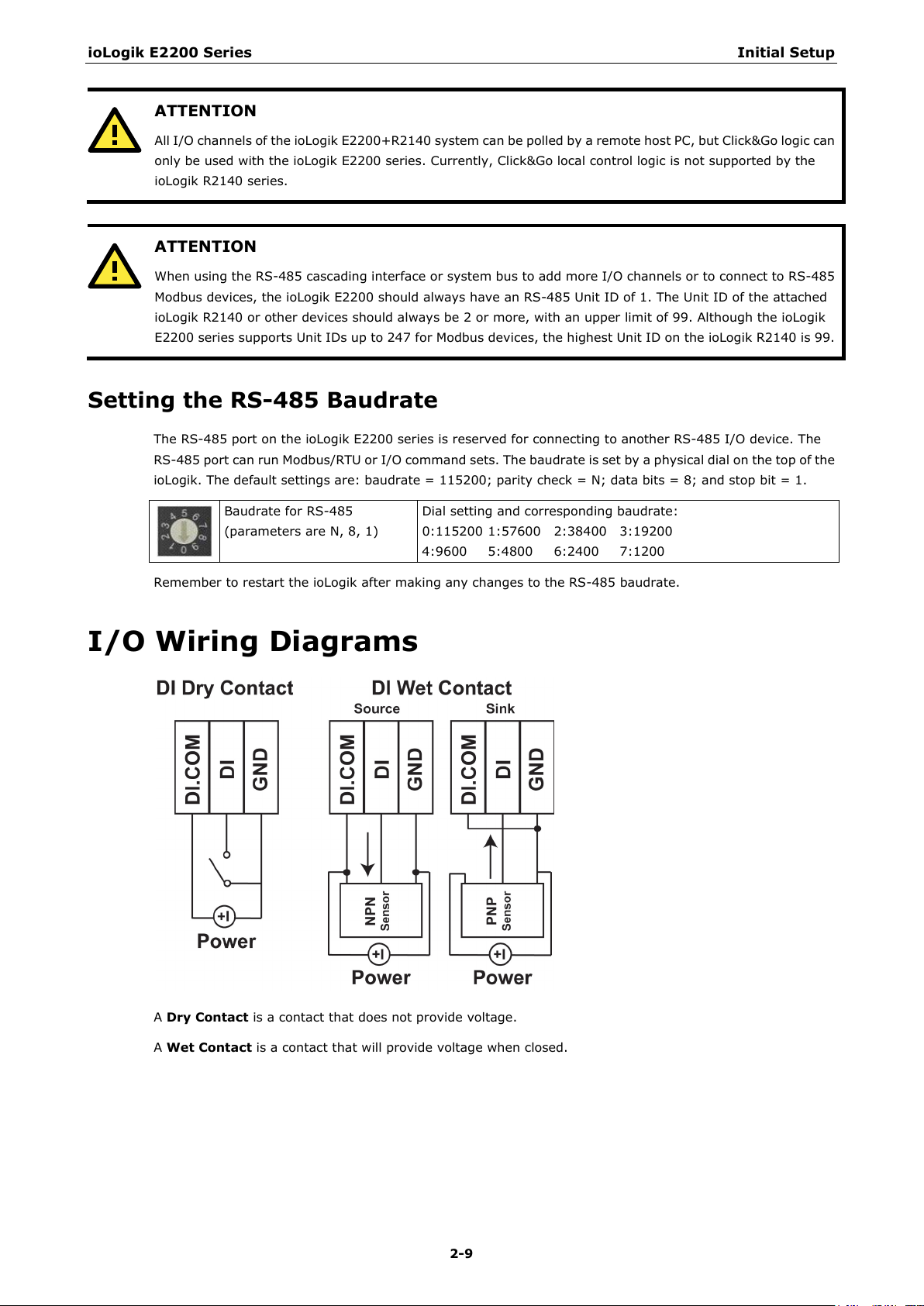

Setting the RS-485 Baudrate

The RS-485 port on the ioLogik E2200 series is reserved for connecting to another RS-485 I/O device. The

RS-485 port can run Modbus/RTU or I/O command sets. The baudrate is set by a physical dial on the top of the

ioLogik. The default settings are: baudrate = 115200; parity check = N; data bits = 8; and stop bit = 1.

Baudrate for RS-485

(parameters are N, 8, 1)

Remember to restart the ioLogik after making any changes to the RS-485 baudrate.

Dial setting and corresponding baudrate:

0:115200 1:57600 2:38400 3:19200

4:9600 5:4800 6:2400 7:1200

-485 Unit ID of 1. The Unit ID of the attached

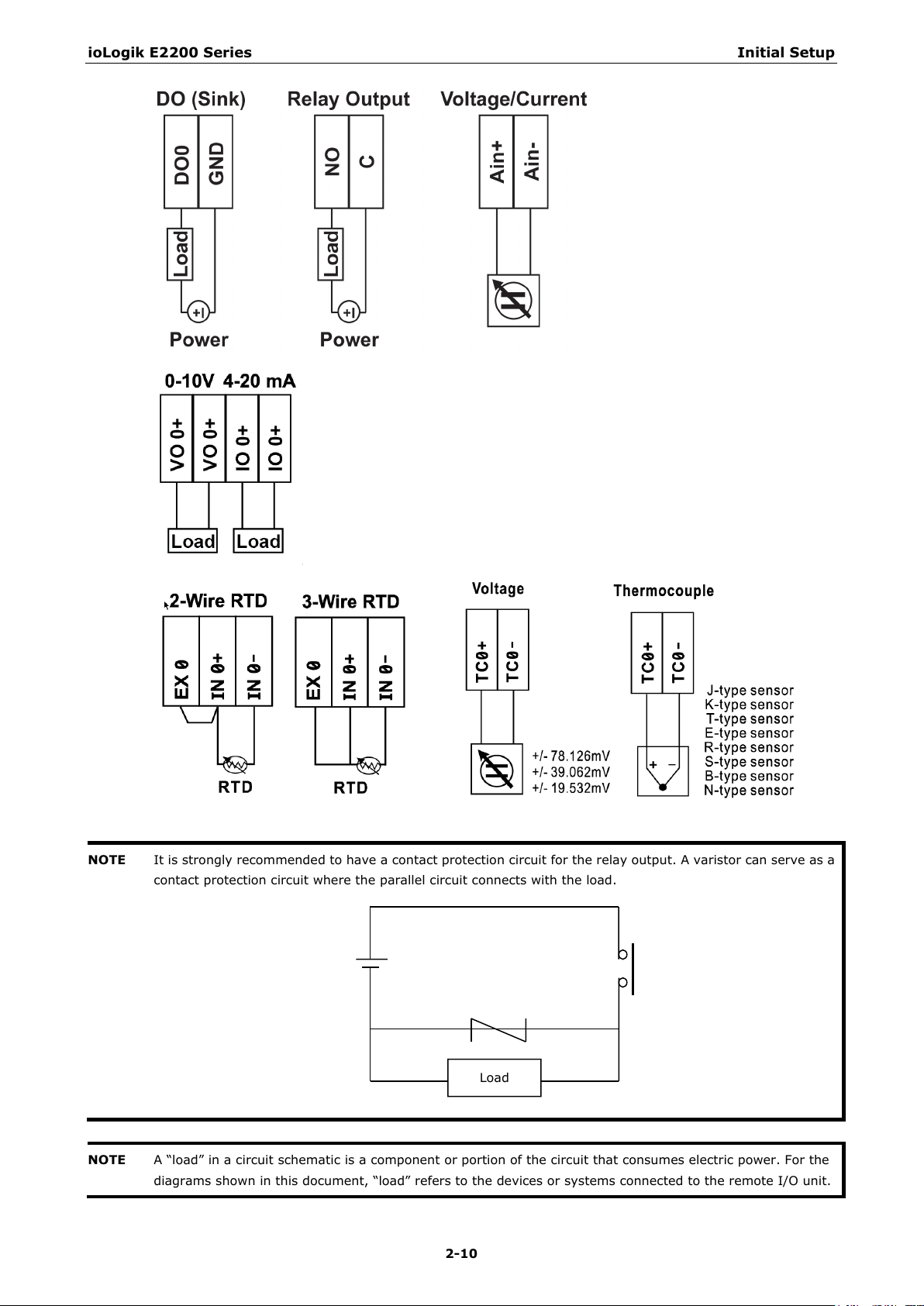

I/O Wiring Diagrams

A Dry Contact is a contact that does not provide voltage.

A Wet Contact is a contact that will provide voltage when closed.

Page 29

ioLogik E2200 Series Initial Setup

2-10

NOTE

It is strongly recommended to have a contact protection circuit for the relay output. A varistor can serve as a

contact pro

NOTE

A “load” in a circuit schematic is a component or portion of the circuit that consumes electric power. For the

diagrams shown in this document, “load” refers to the devices

tection circuit where the parallel circuit connects with the load.

Load

or systems connected to the remote I/O unit.

Page 30

ioLogik E2200 Series Initial Setup

2-11

ATTENTION—Dry Contacts

When connecting an I/O device to the ioLogik’s dry contacts, connect DI.COM

to the power of the external sensor to avoid affecting other channels.

DI.COM input power should be between 12 to 36 VDC.

ATTENTION—DIO Channels

Sensor types are grouped, with DI

group. If an NPN sensor is connected to DI-0, then only NPN sensors can be connected to the other DI channels

in the group (i.e., DI

, then only PNP sensors

can be connected to

O-4 and DIO-5). Likewise, if a PNP sensor is connected to DIO-6

the other DI channels in the group (i.e., DIO-10 and DIO-11).

O-0 to DIO-5 forming one group and DIO-6- to DIO-11 forming another

The

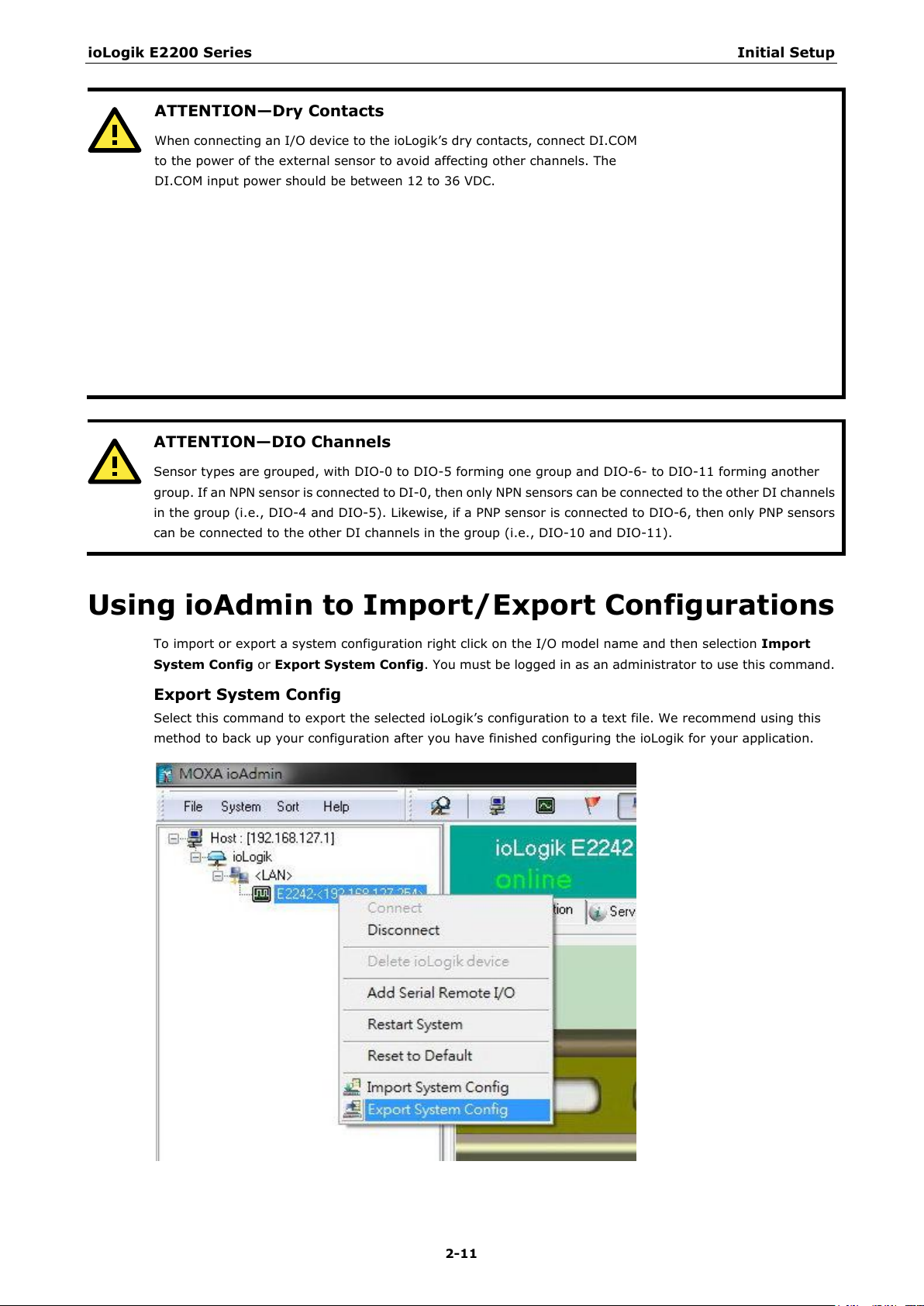

Using ioAdmin to Import/Export Configurations

To import or export a system configuration right click on the I/O model name and then selection Import

System Config or Export System Config. You must be logged in as an administrator to use this command.

Export System Config

Select this command to export the selected ioLogik’s configuration to a text file. We recommend using this

method to back up your configuration after you have finished configuring the ioLogik for your application.

Page 31

ioLogik E2200 Series Initial Setup

2-12

ATTENTION

Since there are major functional differences between firmware versions, exporting the configuration file

requires a longer processing time.

ioAdmin 3.10 or above, especially if earlier versions of ioAdmin have been installed and then

Adjust the TCP Socket Timeout Interval to 30 seconds when using

removed.

Import System Config

Select this command to load a configuration for the selected ioLogik from a configuration text file. The new

configuration will not take effect until the ioLogik has been restarted. This command can be used to restore a

configuration after loading the factory defaults, or to duplicate a configuration to multiple ioLogik units.

Page 32

3

3. Using ioAdmin

In this chapter, we explain how to use ioAdmin to configure your ioLogik product.

The following topics are covered in this chapter:

System Requirements

Features of ioAdmin

ioAdmin Overview

Main Screen Overview

Title

Menu Bar

Quick Links

Navigation Panel

Main Window

Sync Rate Status

Status Bar

ioAdmin Administrator Functions

I/O Configuration Tab (Administrator)

Server Settings Tab (Administrator)

Network Tab

Firmware Update Tab

Watchdog Tab

Click&Go Logic Tab

Active Tags Tab

SNMP Settings Tab

Message Monitor Panel (General)

Server Context Menu

Using ioEventLog

Installing ioEventLog

Basic Functions

Configuration

Checking Connected Devices

Opening Log Files

Clearing the Log

Page 33

ioLogik E2200 Series Using ioAdmin

3-2

System Requirements

The ioLogik E2200 series device can be managed and configured by Ethernet with the ioAdmin Windows utility.

ioAdmin’s graphical user interface provides easy access to all status information and settings. ioAdmin can also

be used to configure Click&Go rules to handle front-end events.

Hardware Requirements

CPU Intel Pentium (Pentium 4 and above)

RAM 512 MB (1024 MB recommended)

Network Interface 10/100Mb Ethernet

Software Requirements

Operating System Microsoft Windows 2000, XP or later

Editor(Not necessary) Microsoft Office 2003 (Access 2003) or later

Features of ioAdmin

Remote management

Use ioAdmin to perform the following task over an Ethernet network:

• Search and configure multiple ioLogiks

• Monitor and control I/O statuses

• Use active message monitoring

• Configure Click&Go local control logic

• Upgrade the firmware

• Restart the ioLogik

• Restore factory default settings

On-line Wiring Guide

For added convenience, a wiring guide is available inside the ioAdmin utility to save time when troubleshooting

or expanding a network.

Configuration File

ioAdmin helps you save all ioLogik configurations as a file. The file is viewable in text format and can be used

as a:

• Record or backup of your configuration

• Template for configuring other ioLogik units

• Quick reference guide for configuring Modbus drivers in a SCADA system

The file includes the following information:

• File name, date, and time

• Model information

• System configuration

• I/O Modbus address

Device Management List

ioAdmin can import and export a list of ioLogik devices that are being managed. This file can make it easier to

manage all devices on the network, and includes the following information:

• Device name

• Module

• IP address

• Unit ID

Page 34

ioLogik E2200 Series Using ioAdmin

3-3

Server Management List

ioAdmin can import and export a list of ioLogik units

that are being managed. This file can make it easier

to manage all devices on the network, and includes

the following information:

•

•

•

•

1

2

4

6

5

7

3

Server name

Module

IP address

Unit ID

ioAdmin Overview

Main Screen Overview

The main screen of the ioAdmin utility defaults to the I/O Configuration tab, which displays a figure of your

ioLogik device with the status of each of its I/O channels. The other tabs on the main screen take you to server

and network settings, and further functions are available when you log on to the ioLogik. Note that

configuration options are not available unless you log on as an administrator.

ioAdmin Main Screen

1. Title

2. Menu bar

3. Quick link

4. Navigation panel

5. Main window

6. Sync. rate status

7. Status bar

Page 35

ioLogik E2200 Series Using ioAdmin

3-4

Title

The Title shows you which program is opened. In this case, it indicates that Moxa ioAdmin is running.

Menu Bar

The Menu bar has four items:

1.

File

2. System

3. Sort

4. Help

File

From the File menu, you can export the list of ioLogiks currently displayed in the navigation panel. You can also

import a list into ioAdmin.

When importing/exporting a device list, you will be prompted to select which ioLogik on the list needs to be

imported or exported. When a popup window appears, click the “folder” icon to select/key-in the file name to

save/import a specific file.

The file will have an .SLT extension and can be opened as a text file. The server list will provide the basic

information for each server, such as Device Name, Model, IP address, and Unit ID.

Page 36

ioLogik E2200 Series Using ioAdmin

3-5

Several operations can be accessed from the

System

System menu.

Auto Scan ioLogik Devices

The Auto Scan ioLogik Devices function searches for ioLogiks on the network automatically. When

connecting for the first time, or when recovering from a network disconnection, you can use this command to

find any ioLogik that is connected to the physical network.

You can search for ioLogik devices by type, IP address range, or model name. Click Start Search to start

searching and the search results will be shown at the bottom of the window.

Select auto search type

Search for an ioLogik device by whether it is an Smart Ethernet Remote I/O Device or RS-232/485

remote I/O.

Search a range of addresses

Search for ioLogik devices within a range of IP address addresses by defining a starting IP address and an

ending IP address, or by using the netmask.

Search all support models

Select the specific model number(s) of the ioLogik devices you wish to search for.

Page 37

ioLogik E2200 Series Using ioAdmin

3-6

Network Interface

Network Interface allows you to select a network interface to use (if the PC has multiple network adaptors

installed). The default network interface will be the same as the Windows setting. Make sure the interface is

correct when connecting to the ioLogik device; otherwise, no devices will be found.

I/O Status Refresh Rate

This operation is used to adjust how often the ioLogik is polled for device status by the ioAdmin utility. The

current rate is displayed on the status bar at the bottom of the window.

Note: The higher sync rates result in higher loads on the network.

TCP Socket Timeout Interval

This operation allows you to select the preferred timeout value for TCP socket communication. When the

ioLogik's E2200 connection to the server exceeds a specified time period the device will automatically release

its modbus/TCP connection to the server, to free up the port for the next connection (default: 30 seconds).

Page 38

ioLogik E2200 Series Using ioAdmin

3-7

COM Port Setting

This operation is used to set the default parameters for the ioAdmin utility to establish a Modbus connection,

such as baudrate, data bits, and timeout interval. For most applications, this will involve connecting to ioLogik

R-series devices.

Active Message Listen Port

This operation specifies the port number to use for Active Messages. If your network uses a firewall, you can

coordinate this setting with your firewall settings to ensure that active messages get through.

Reset NA4010 Network Adaptor IP

This operation is used to re-assign an IP address to the NA-4010 network as reported by the ioLogik W5300

series adaptor, for ioLogik 4000 systems.

Page 39

ioLogik E2200 Series Using ioAdmin

3-8

Sort

The Sort menu allows the Devices list in the navigation panel to be sorted by connection, model, location, or

Active OPC.

Help

In the Help menu, you can view wiring guides and information about ioAdmin.

Page 40

ioLogik E2200 Series Using ioAdmin

3-9

Wiring Guides

ioAdmin provides a wiring guide for the ioLogik E2200 series. You can access the wiring guide by right-clicking

the ioLogik figure in the I/O Configuration tab. Select “Wiring Guide” in the submenu to open a help file showing

the unit’s wiring information and electrical characteristics (or refer to cable wiring).

You can also access the On-line Wiring Guide through the Help menu on the menu bar.

Page 41

ioLogik E2200 Series Using ioAdmin

3-10

This icon provides a direct link to start running the

These icons allow you to sort the ioLogik devices viewed in the Navigation

Panel according to the following criteria:

NOTE

The default location is

00, the navigation panel

will group all

Quick Links

Quick Links toolbard contains a collection of commonly used functions, including the Search and the Sort

functions.

Auto Scan ioLogik Devices

Auto Scan ioLogik Devices function.

Sorting Methods

Icon Function Name Navigation Panel View

Sort by ioLogik Device Connection

Sort by ioLogik Device Type

Sort by ioLogik Device Location

Sort by Active OPC Server

Empty locations together.

Empty. If you do not specify the location for the ioLogik E22

Navigation Panel

The Navigation Panel shows an overview of the ioLogik devices on the network as defined by the sorting

method. The default sorting view is By Connection. You can choose a different sorting method by clicking on

a different quick link button. The Navigation Panel also includes additional functions, such as Connect and

Disconnect. More advanced functions require the administrator’s password.

Access the function menu by right-clicking on the ioLogik model name in the navigation panel. The menu lists

both basic functions and advanced functions:

Page 42

ioLogik E2200 Series Using ioAdmin

3-11

Basic Functions: Add, Connect, and Disconnect

Add ioLogik ioLogik device: Select ioLogik tag and right click the tag. Select the “Add ioLogik device”

command to add an ioLogik device or Active OPC server manually.

Connect: Select the “Connect” command to try connecting over the network to the selected ioLogik.

Disconnect: Select the “Disconnect” command to drop the network connection with the selected ioLogik.

Advanced Functions: Delete, Restart, Reset, Import/Export Config File

You must be logged in as administrator to use these commands.

Delete ioLogik device: Select this command to remove the selected ioLogik.

Note: The target must be disconnected first to use this command.

Restart System: Select this command to restart the selected ioLogik.

Reset to Default: Select this command to reset all settings on the selected ioLogik, including console

password, to factory default values.

Export System Config: Select this command to export the selected ioLogik’s configuration to a text file. We

strongly recommend that you use this method to back up your configuration after you have finished configuring

the ioLogik for your application.

Import System Config: Select this command to load a configuration for the selected ioLogik from a

configuration text file. The new configuration will not take effect until the ioLogik has been restarted. This

command can be used to restore a configuration after loading the factory defaults, or to duplicate a

configuration to multiple ioLogik units.

Page 43

ioLogik E2200 Series Using ioAdmin

3-12

Main Window

I/O Configuration Tab (General)

The I/O Configuration tab shows the status of every I/O channel. This is the default tab when you first open

ioAdmin. Input channels are listed on the left and output channels are listed on the right.

Server Info Tab

Server information, such as firmware version, is displayed in the Server Info tab.

Page 44

ioLogik E2200 Series Using ioAdmin

3-13

Server Settings Tab (General)

The Server Settings tab is where you log in as an ioAdmin administrator. This is required in order to gain

access to the ioLogik configuration options. If a password has not been configured, simply click Login and leave

the Password entry field blank. Refer to the ioAdmin Administrator Functions section later on in this chapter

for details.

Message Monitor Tab

The Message Monitor tab will display any TCP/UDP Active Messages reported by the ioLogik E2200 series.

When you install the unit for the first time, the ruleset will not have been defined yet, so there will be no

messages in the Message Monitor Tab. When a ruleset has been defined and activated, any TCP/UDP messages

that have been triggered by sensor events will be shown in the Message Monitor tab. Please refer to Chapter 5

for information on how to define rules for active I/O messaging.

Page 45

ioLogik E2200 Series Using ioAdmin

3-14

NOTE

The

ATTENTION

You MUST log in to access administrator functions, including Network, Communication Watchdog Timer, and

Firmware Update tabs. If you forget the password, hold down the reset button to clear the password and load

fac

This will result in the loss of all configuration settings and your Click&Go logic rules

that have already been configured.

Messages can be displayed in ASCII or in HEX. To display messages in HEX, make sure that “Toggle HEX” is

checked.

Sync Rate Status

The current sync rate is displayed on the bar at the bottom of the window. The number shows how often the

ioLogik is polled for device status from the ioAdmin utility. The rate can be adjusted by clicking Menu Bar

System I/O Status Refresh Rate

higher sync rates result in higher loads on the network.

Status Bar

The status bar shows ioAdmin status information, such as program ready, searching ioLogik I/O, time, etc.

ioAdmin Administrator Functions

For full access to all configuration options, log in as an administrator in the Server Settings tab. This is required

whenever you start up ioAdmin or boot up/restart the ioLogik. When you install the ioLogik for the first time,

the password will be blank and you can simply click Login. Additional functions will available after logging in,

including the following new tabs:

When making configuration changes, you will need to click Update or Apply to save the changes. Some

changes will require that the unit be restarted in order to take effect.

I/O Configuration

1.

2. Server Setting (Admin)

3. Network

4. Firmware Update

5. Click&Go Logic

6. Watchdog

7. Active Tag

8. SNMP Setting

9. Message Monitor

tory defaults.

Page 46

ioLogik E2200 Series Using ioAdmin

3-15

NOTE

To show or hide the image of the ioLogik device, right

View

will hide the

image.

I/O Configuration Tab (Administrator)

When logged in as an administrator, double-click on a channel in the I/O Configuration tab to configure that

channel’s settings. A window will open with configuration options for that channel. After configuraing the

channel as desired, click Apply to implement the new settings.

Configuring Analog Input Channels

1.

2. Configuring Analog Output Channels

3. Configuring DIO Channels

4. Configuring Digital Input and Event Counter Channels

5. Configuring Digital Output and Relay output Channels

6. Relay Count Monitoring

7. Testing DI and DO Channels

8. Configuring RTD Channels

9. Configuring TC Channels

from the dropdown menu will show the ioLogik’s picture, whereas selecting Vertical View

-click on the ioAdmin window. Selecting Horizontal

Page 47

ioLogik E2200 Series Using ioAdmin

3-16

Configuring Analog Input Channels

The ioLogik analog input channels can be configured individually, or you can set all channels at the same time

by selecting the Apply to all channels checkbox.

To increase the sampling rate, disable any unused AI channels by deselecting the Enable Channelcheckbox.

Select the Enable Auto Scaling checkbox to linearly convert the actual current or voltage value into other

user defined units, such as percentage or ppm (parts per million).

Page 48

ioLogik E2200 Series Using ioAdmin

3-17

Two math formulas are used to convert actual values and user-defined units: (1) the point-slope formula and

(2) the slope-intercept formula.

1. Auto Scaling by the point-slope formula

Auto Scaling by the point-slope formula can help eliminate high end and low end extremes. For example, a

temperature reading of 17 mA is already dangerously high, so there would be no need to wait for a higher

temperature reading before responding. Instead, you can cut off the values beyond 17 mA and convert it to

a proprietary level of danger, such as Level 5.

2. Auto Scaling by slope-intercept formula

Auto Scaling by the slope-intercept formula provides linear conversion between a ratio (M) and offset (D)

value. The offset (D) can be the initial value of the field device. The ratio (M) specifies the proportion by

which to enlarge or reduce the scale. It is also easy to modify the values in the database if you need to use

new ratios and offset values in the future.

Page 49

ioLogik E2200 Series Using ioAdmin

3-18