Moxa Technologies ioLogik E1213, ioLogik E1212, ioLogik E1214, ioLogik E1210, ioLogik E1240 User Manual

...Page 1

ioLogik E1200 Series User’s Manual

Edition 15.4, October 2018

www.moxa.com/product

© 2018 Moxa Inc. All rights reserved.

Page 2

ioLogik E1200 Series User’s Manual

Moxa Americas

Toll

Tel:

Fax:

Moxa China (Shanghai office)

Toll

Tel:

Fax:

Moxa Europe

Tel:

Fax: +49-89-3 70 03 99-99

Mo

Tel:

Fax: +886-2-8919-1231

Moxa India

Tel:

Fax:

The software described in this manual is furnished under a license agreement and may be used only in accordance with

the terms of that agreement.

Copyright Notice

© 2018 Moxa Inc. All rights reserved.

Trademarks

The MOXA logo is a registered trademark of Moxa Inc.

All other trademarks or registered marks in this manual belong to their respective manufacturers.

Disclaimer

Information in this document is subject to change without notice and does not represent a commitment on the part of

Moxa.

Moxa provides this document as is, without warranty of any kind, either expressed or implied, including, but not limited

to, its particular purpose. Moxa reserves the right to make improvements and/or changes to this manual, or to the

products and/or the programs described in this manual, at any time.

Information provided in this manual is intended to be accurate and reliable. However, Moxa assumes no responsibility for

its use, or for any infringements on the rights of third parties that may result from its use.

This product might include unintentional technical or typographical errors. Changes are periodically made to the

information herein to correct such errors, and these changes are incorporated into new editions of the publication.

Technical Support Contact Information

www.moxa.com/support

-free: 1-888-669-2872

+1-714-528-6777

+1-714-528-6778

+49-89-3 70 03 99-0

-free: 800-820-5036

+86-21-5258-9955

+86-21-5258-5505

xa Asia-Pacific

+886-2-8919-1230

+91-80-4172-9088

+91-80-4132-1045

Page 3

Table of Contents

1. Introduction ...................................................................................................................................... 1-1

Product Features ................................................................................................................................ 1-2

Inside the Box .................................................................................................................................... 1-2

Product Model Information ................................................................................................................... 1-2

Product Specifications ......................................................................................................................... 1-3

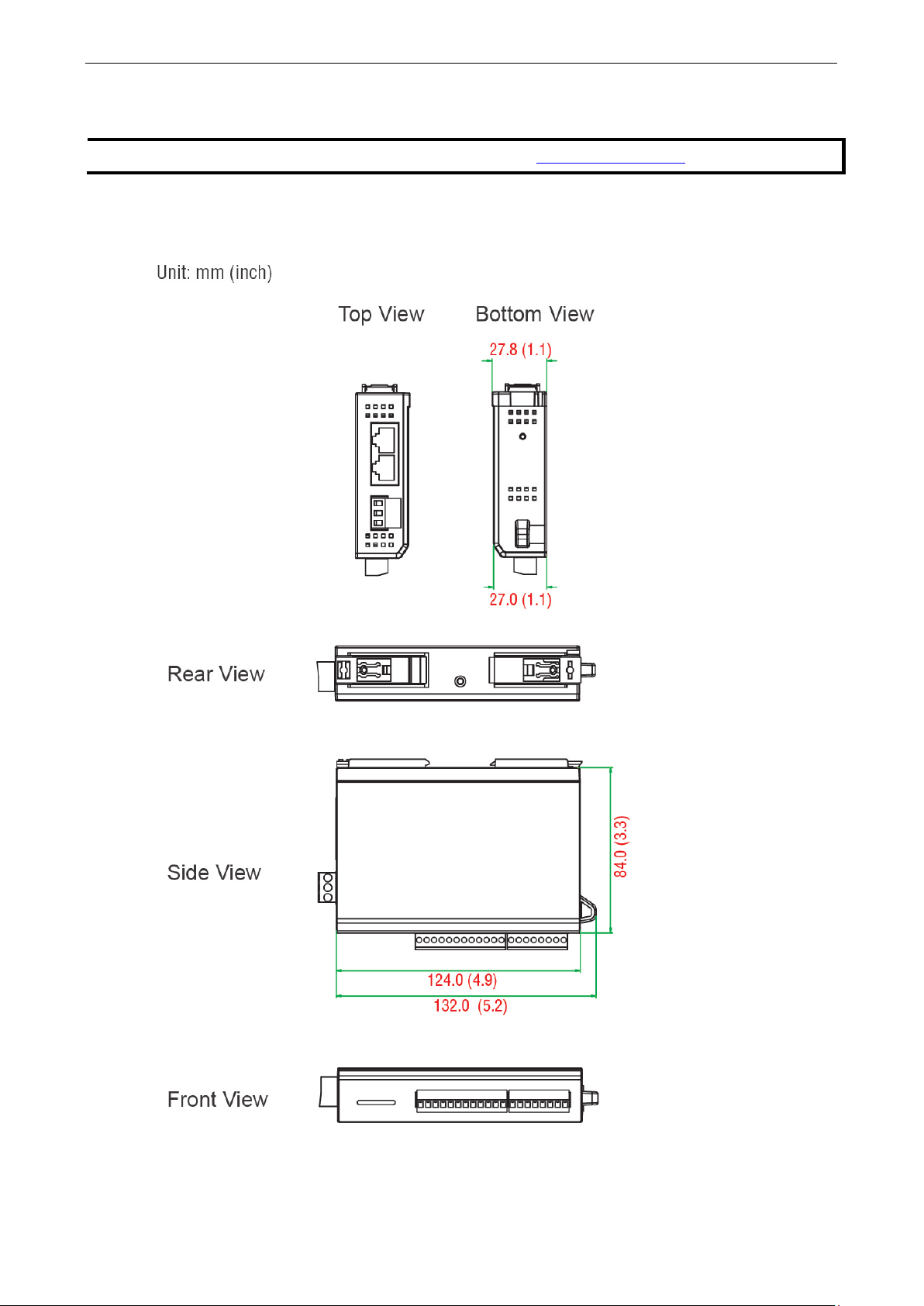

Physical Dimensions ............................................................................................................................ 1-3

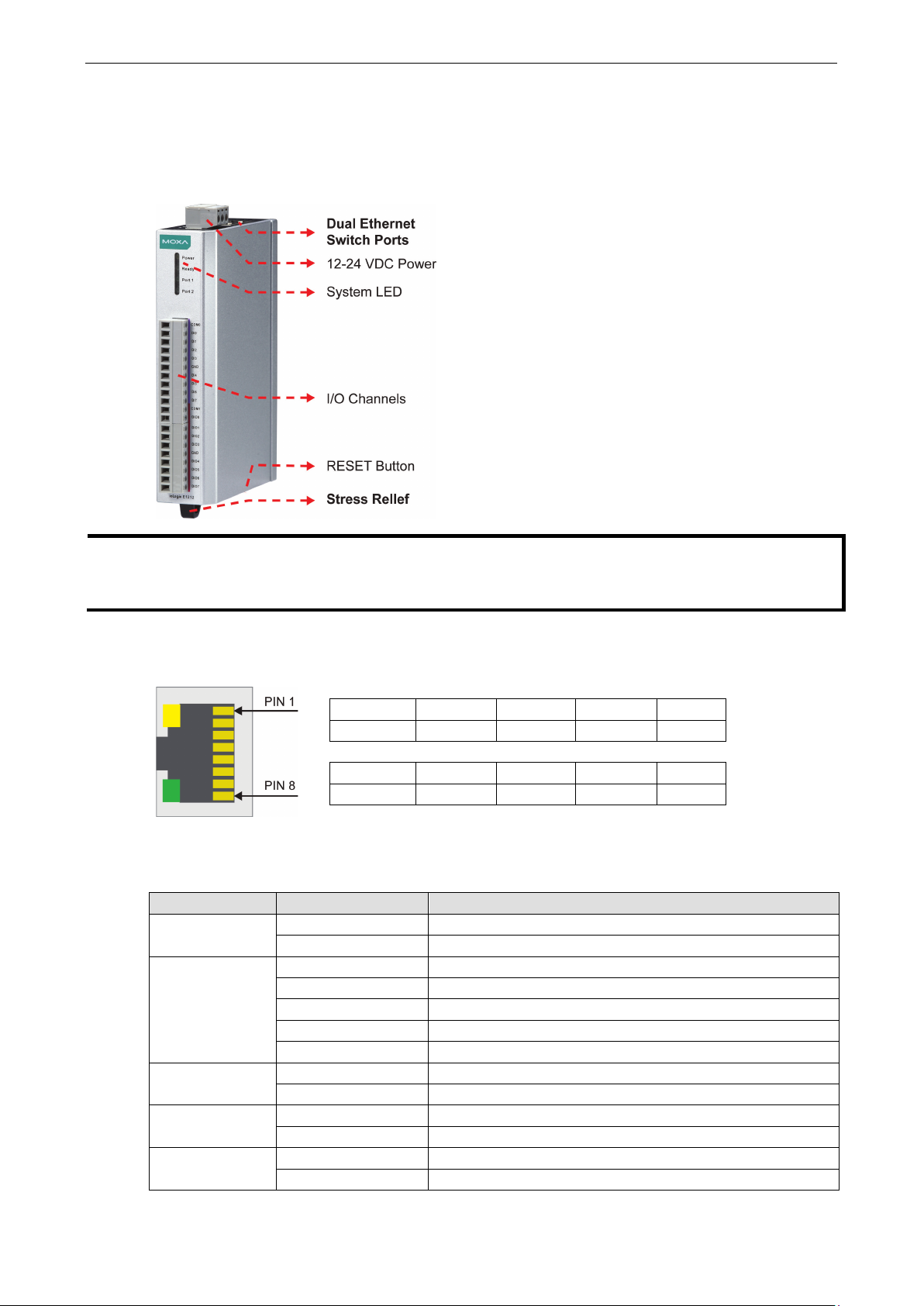

Hardware Reference ............................................................................................................................ 1-4

Panel Guide ................................................................................................................................ 1-4

Ethernet Port .............................................................................................................................. 1-4

LED Indicators ............................................................................................................................ 1-4

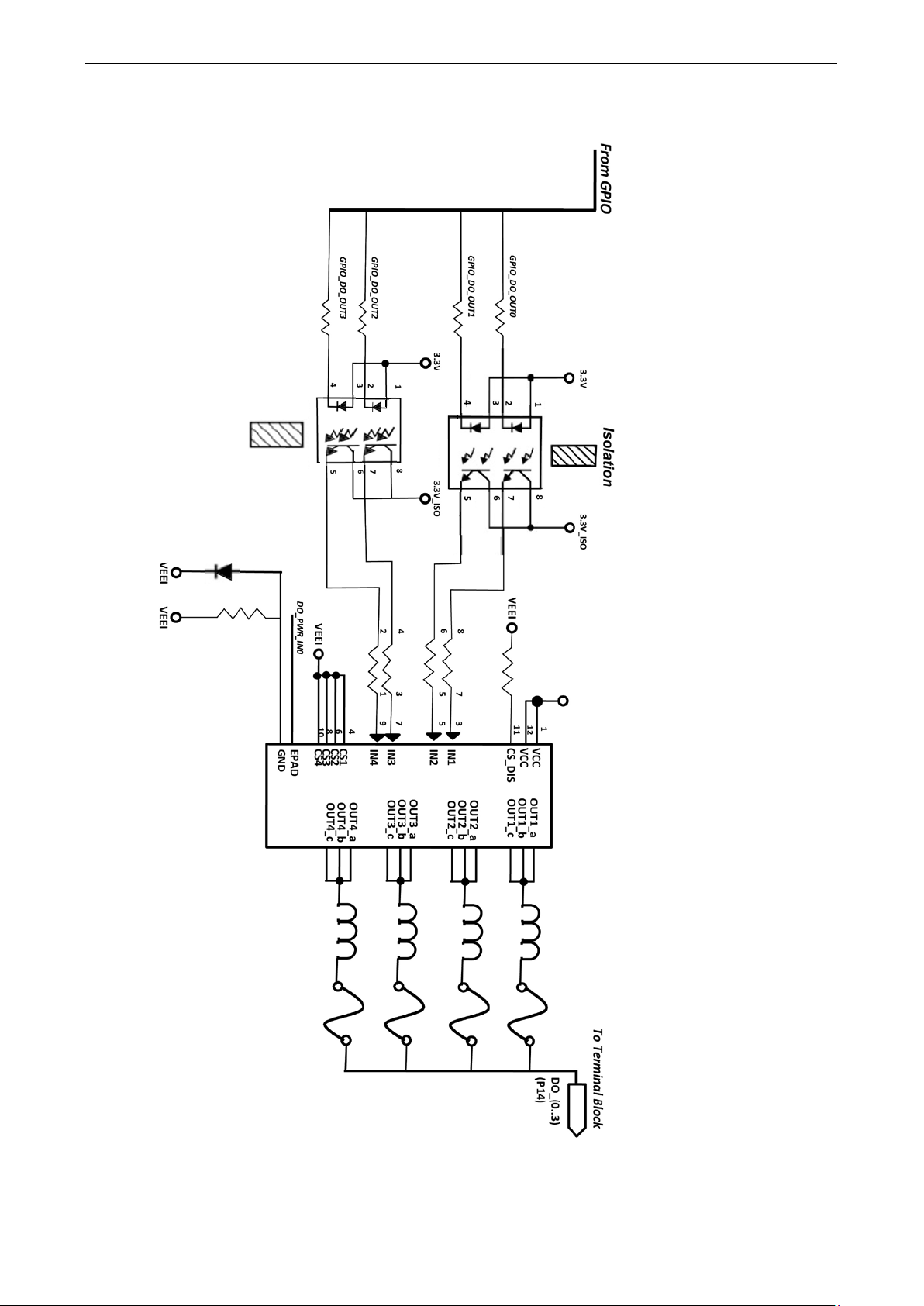

I/O Circuit Diagram ............................................................................................................................. 1-5

DI Circuit ................................................................................................................................... 1-5

Sinking DO Circuit ....................................................................................................................... 1-5

Sourcing DO Circuit ..................................................................................................................... 1-6

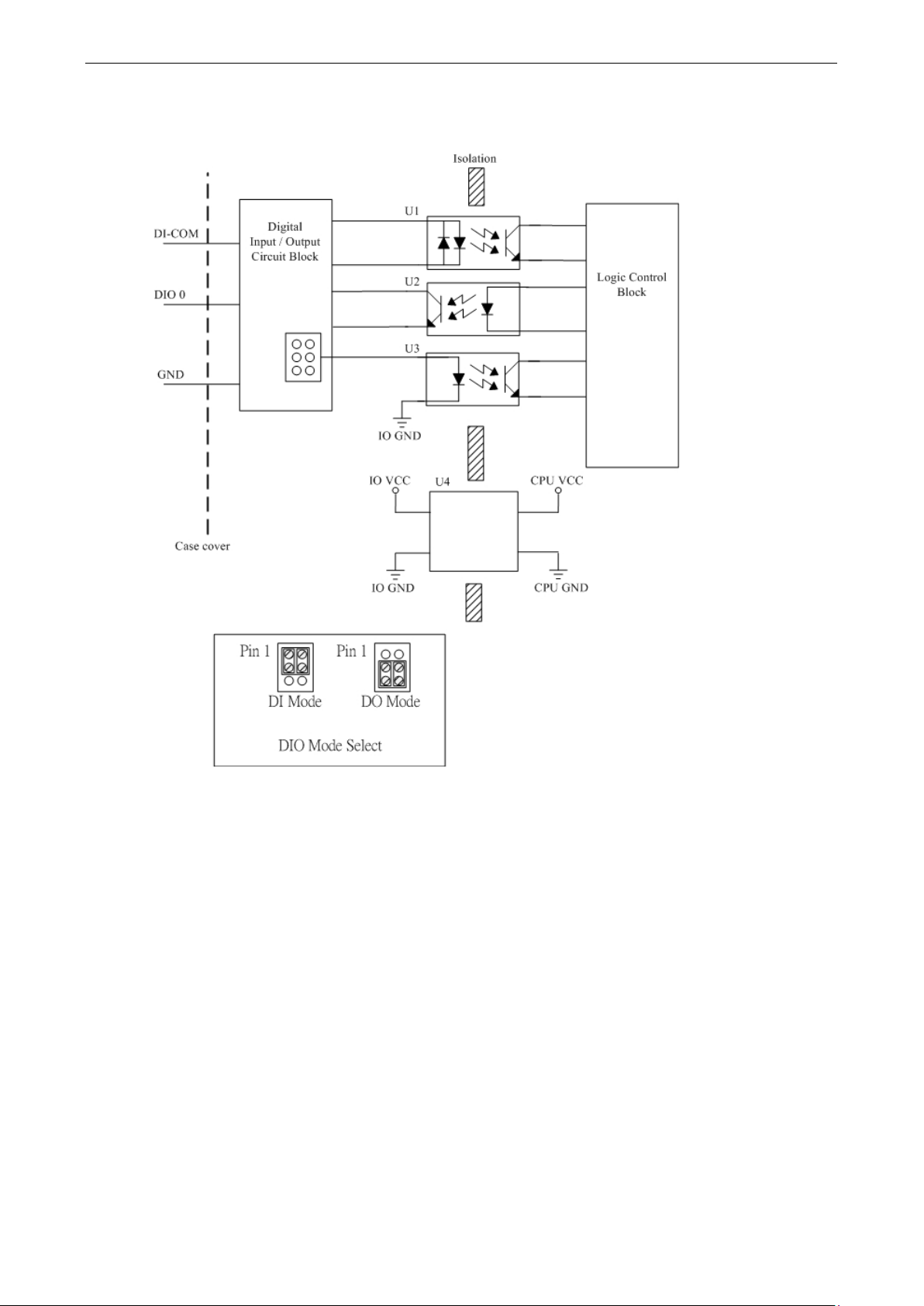

DIO Circuit ................................................................................................................................. 1-7

Relay Circuit ............................................................................................................................... 1-8

AI Circuit .................................................................................................................................... 1-8

RTD Circuit ................................................................................................................................. 1-8

TC Circuit ................................................................................................................................... 1-9

2. Initial Setup ...................................................................................................................................... 2-1

Hardware Installation .......................................................................................................................... 2-2

Mounting .................................................................................................................................... 2-2

Grounding the Unit ...................................................................................................................... 2-4

I/O Channel Jumper Setting.......................................................................................................... 2-4

I/O Wiring .................................................................................................................................. 2-6

Communication Port Wiring ........................................................................................................ 2-10

Use the Cable Tie Base to Securely Route a Connected I/O Cable .................................................... 2-11

Powering Up the Unit ................................................................................................................. 2-11

ioSearch™ Installation ....................................................................................................................... 2-13

Load Factory Default Settings ............................................................................................................. 2-13

3. Using the Web Console ...................................................................................................................... 3-1

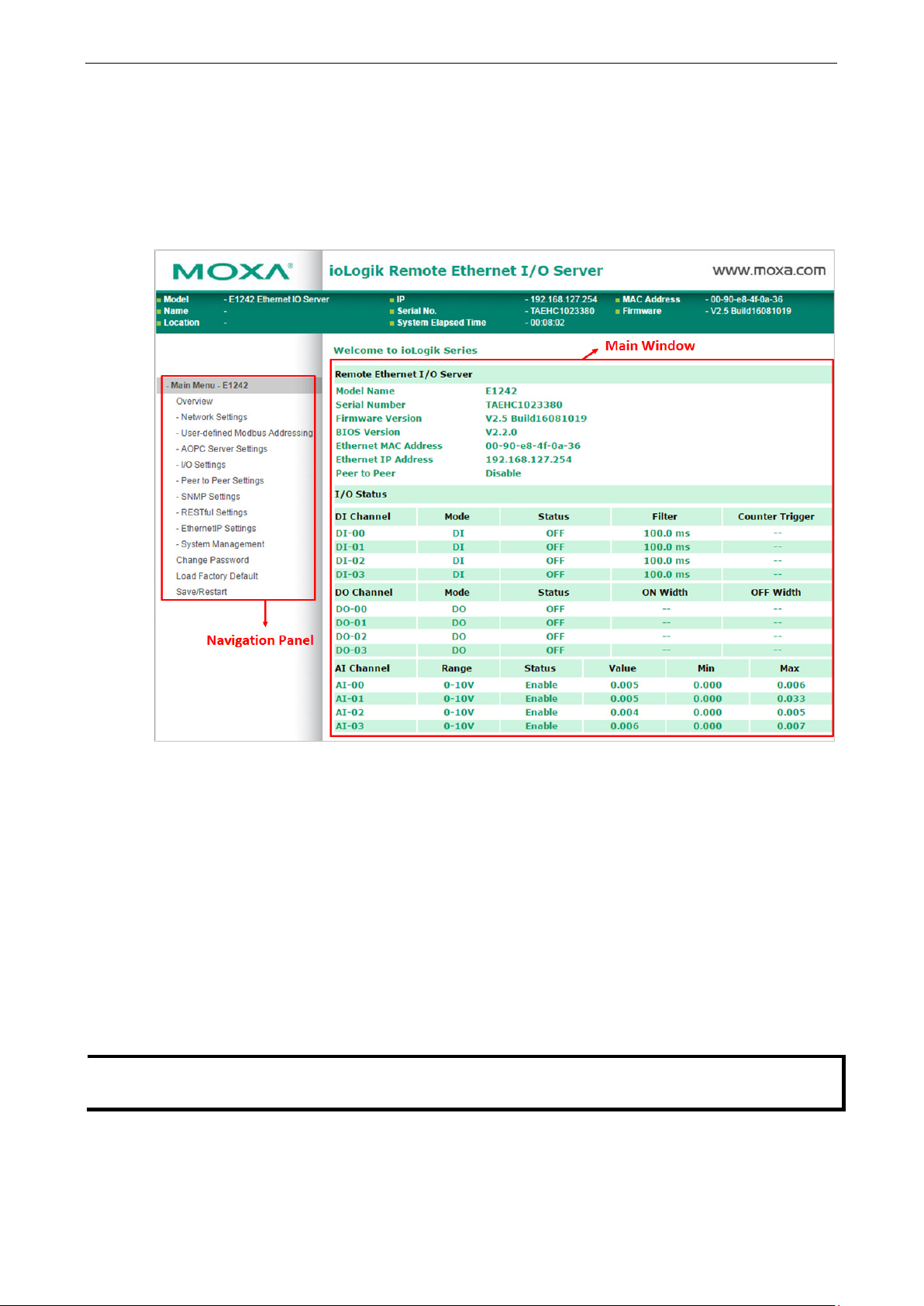

Introduction to the Web Console ........................................................................................................... 3-2

Overview ........................................................................................................................................... 3-3

Network Settings for the Web Console ................................................................................................... 3-4

General Settings ......................................................................................................................... 3-4

Ethernet Configuration ................................................................................................................. 3-4

User-Defined Modbus Addressing .......................................................................................................... 3-5

Default Modbus Address ............................................................................................................... 3-5

AOPC Server Settings .......................................................................................................................... 3-6

Tag Generation ........................................................................................................................... 3-6

I/O Settings ....................................................................................................................................... 3-8

DI Channels ................................................................................................................................ 3-8

DO Channels ............................................................................................................................. 3-10

AI Channels .............................................................................................................................. 3-12

AI Input Range ......................................................................................................................... 3-13

AO Channels ............................................................................................................................. 3-15

RTD Channels ........................................................................................................................... 3-16

TC Channels ............................................................................................................................. 3-17

Peer-to-Peer Networking.................................................................................................................... 3-19

Peer-to-Peer Settings (1-50)....................................................................................................... 3-19

Sample Peer-to-Peer Configuration .............................................................................................. 3-20

DO Safe Mode Settings .............................................................................................................. 3-21

AO Safe Mode Settings ............................................................................................................... 3-21

SNMP .............................................................................................................................................. 3-21

SNMP Trap ............................................................................................................................... 3-21

Using SNMP .............................................................................................................................. 3-22

Accessibility IP List .................................................................................................................... 3-27

RESTful API Setting........................................................................................................................... 3-28

EtherNet/IP Setting ........................................................................................................................... 3-28

System Management ......................................................................................................................... 3-28

Network Connection................................................................................................................... 3-28

Firmware Update ....................................................................................................................... 3-29

Import System Configuration Settings ......................................................................................... 3-29

Export System Settings .............................................................................................................. 3-29

Change Password ............................................................................................................................. 3-30

Load Factory Defaults ........................................................................................................................ 3-30

Save/Restart .................................................................................................................................... 3-30

Page 4

4. Using ioSearch™ ................................................................................................................................ 4-1

Introduction to ioSearch™ ................................................................................................................... 4-2

ioSearch™ Main Screen ....................................................................................................................... 4-2

Main Screen Overview .................................................................................................................. 4-2

ioSearch™ Setup ................................................................................................................................ 4-3

System ...................................................................................................................................... 4-3

Sort ........................................................................................................................................... 4-4

Quick Links ................................................................................................................................. 4-4

Main Function ..................................................................................................................................... 4-4

Locate ........................................................................................................................................ 4-5

Firmware Upgrade ....................................................................................................................... 4-5

Unlock ....................................................................................................................................... 4-6

Import ....................................................................................................................................... 4-6

Export ........................................................................................................................................ 4-6

Change IP Address ...................................................................................................................... 4-7

Batch TCP/IP Configuration on Multiple Devices ............................................................................... 4-7

Change Server Name ................................................................................................................... 4-8

Activate EtherNet/IP .................................................................................................................... 4-8

Restart System ........................................................................................................................... 4-9

Reset to Default .......................................................................................................................... 4-9

Mass Deployment (Import) ........................................................................................................... 4-9

Mass Deployment (Export) ......................................................................................................... 4-10

5. Activating the EtherNet/IP Function ................................................................................................. 5-1

6. How to Connect the ioLogik E1200 to an Allen-Bradley PLC .............................................................. 6-1

EDS Installation of the ioLogik E1200 Series in Rockwell Software RSLogix 5000 ........................................ 6-2

Establishing communication between the ioLogik E1200 device and the Allen-Bradley PLC ........................... 6-6

7. RESTful API Implementation ............................................................................................................. 7-1

Introduction ....................................................................................................................................... 7-2

Configuring RESTful API Settings .......................................................................................................... 7-2

Using RESTful API via a Web Service ..................................................................................................... 7-2

Troubleshooting Reference ................................................................................................................... 7-5

A. Modbus/TCP Default Address Mappings ............................................................................................ A-1

Supported Function Code ..................................................................................................................... A-2

ioLogik E1210 Modbus Address and Register Map ................................................................................... A-2

ioLogik E1211 Modbus Address and Register Map ................................................................................... A-3

ioLogik E1212 Modbus Address and Register Map ................................................................................... A-5

ioLogik E1213 Modbus Address and Register Map ................................................................................... A-7

ioLogik E1214 Modbus Address and Register Map ................................................................................... A-9

ioLogik E1240 Modbus Address and Register Map ................................................................................. A-11

ioLogik E1241 Modbus Address and Register Map ................................................................................. A-12

ioLogik E1242 Modbus Address and Register Map ................................................................................. A-14

ioLogik E1260 Modbus Address and Register Map ................................................................................. A-16

ioLogik E1262 Modbus Address and Register Map ................................................................................. A-18

B. EtherNet/IP Default Address Mappings............................................................................................. B-1

ioLogik E1200 EtherNet/IP Map ............................................................................................................ B-1

C. RESTful API Default Address Mappings ............................................................................................. C-1

ioLogik E1200 RESTful API Map ............................................................................................................ C-1

D. Network Port Numbers ...................................................................................................................... D-1

E. Factory Default Settings .................................................................................................................... E-1

F. Pinouts .............................................................................................................................................. F-1

G. FCC Interference Statement .............................................................................................................. G-1

H. European Community (CE) ................................................................................................................ H-1

I. Firmware Update Guidelines .............................................................................................................. I-1

Page 5

1

1. Introduction

The ioLogik E1200 industrial Ethernet remote I/O has two embedded Ethernet switch ports that allow

information to flow to another local Ethernet device or connect to the next ioLogik in a daisy-chain. Applications

such as factory automation, security and surveillance systems, and tunnel monitoring, can make use of

daisy-chained Ethernet for building multidrop I/O networks over standard Ethernet cables and familiar fieldbus

protocols. The daisy-chain function on the ioLogik E1200 Ethernet remote I/O not only increases the

connections between machines and panels, but it also lowers the cost of buying separate Ethernet switches,

and at the same time reduces labor fees and cabling by a large percentage. For example, if a production facility

contains 700 stations (20 points per station), the wiring cost reduction can reach 15% of the total

implementation cost.

The following topics are covered in this chapter:

Product Features

Inside the Box

Product Model Information

Product Specifications

Physical Dimensions

Hardware Reference

Panel Guide

Ethernet Port

LED Indicators

I/O Circuit Diagram

DI Circuit

Sinking DO Circuit

Sourcing DO Circuit

DIO Circuit

Relay Circuit

AI Circuit

RTD Circuit

TC Circuit

Page 6

ioLogik E1200 Series Introduction

1-2

NOTE

Notify your sales representative if any of the above items are missing or damaged.

ioLogik E1212

Remote Ethernet I/O with 2-port Ethernet switch, 8 DIs, and 8 DIOs

Ethernet remote I/O with 2-port Ethernet switch and 16 DIs, -40 to 75°C operating

temperature

temperature

Ethernet remote I/O with 2-port Ethernet switch, 8 DIs, and 8 DIOs, -40 to 75°C

operating temperature

type), -40 to 75°C operating temperature

Ethernet remote I/O with 2-port Ethernet switch, 6 DIs, and 6 Relays, -40 to 75°C

operating temperature

temperature

Ethernet remote I/O with 2-port Ethernet switch and 4 AOs , -40 to 75°C operating

temperature

40 to 75°C

operating temperature

Ethernet remote I/O with 2-port Ethernet switch and 6 RTDs, -40 to 75°C operating

temperature

temperature

Product Features

• Active communication with patented MX-AOPC UA Server

• 2-port Ethernet switch for daisy-chain topologies

• Easy mass deployment and configuration with ioSearch™utility

• User-friendly configuration via web browser

• Save time and wiring costs with peer-to-peer communication

• User-defined Modbus/TCP addressing

• Simplify I/O management with MXIO library on either Windows or Linux platform

• Wide operating temperature: -40 to 75°C (-40 to 167°F)

• Supports SNMPv1/v2c

• UL/cUL Class I Division 2, ATEX Zone 2 certification

Inside the Box

The ioLogik E1200 is shipped with the following items:

• ioLogik E1200 remote Ethernet I/O server

• Quick installation guide (printed)

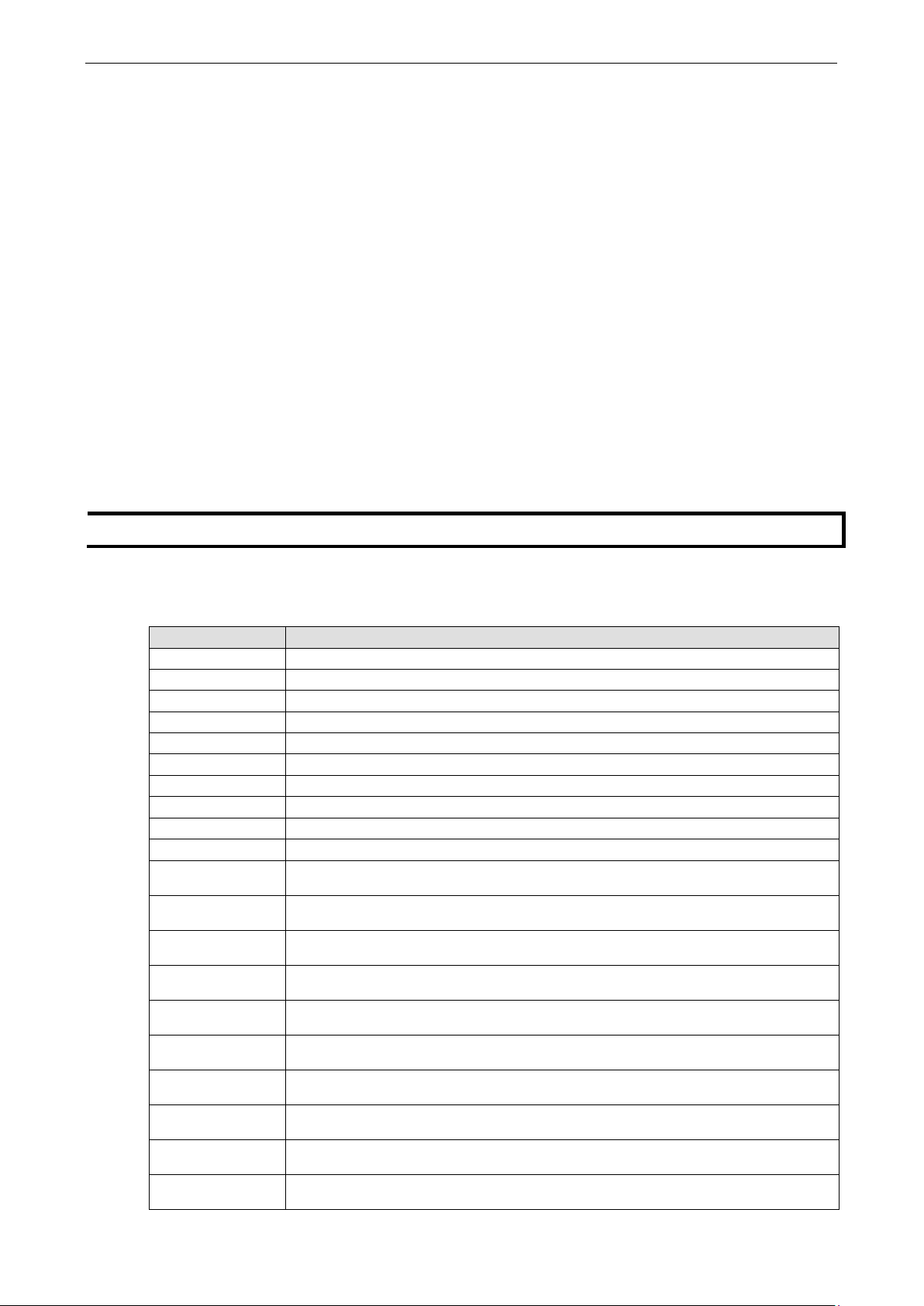

Product Model Information

Model Description

ioLogik E1210 Remote Ethernet I/O with 2-port Ethernet switch and 16 DIs

ioLogik E1211 Remote Ethernet I/O with 2-port Ethernet switch and 16 DOs

ioLogik E1213 Remote Ethernet I/O with 2-port Ethernet switch, 8 DIs, 4 DOs, and 4 DIOs (source type)

ioLogik E1214 Remote Ethernet I/O with 2-port Ethernet switch, 6 DIs, and 6 relays

ioLogik E1240 Remote Ethernet I/O with 2-port Ethernet switch and 8 AIs

ioLogik E1241 Remote Ethernet I/O with 2-port Ethernet switch and 4 AOs

ioLogik E1242 Remote Ethernet I/O with 2-port Ethernet switch and 4 AIs, 4DIs, and 4DIOs

ioLogik E1260 Remote Ethernet I/O with 2-port Ethernet switch and 6 RTDs

ioLogik E1262 Remote Ethernet I/O with 2-port Ethernet switch and 8 TCs

ioLogik E1210-T

ioLogik E1211-T

ioLogik E1212-T

ioLogik E1213-T

Ethernet remote I/O with 2-port Ethernet switch and 16 DOs, -40 to 75°C operating

Remote Ethernet I/O with 2 Port Ethernet switch, 8 DIs, 4 DOs, and 4 DIOs (source

ioLogik E1214-T

ioLogik E1240-T

ioLogik E1241-T

ioLogik E1242-T

ioLogik E1260-T

ioLogik E1262-T

Ethernet remote I/O with 2-port Ethernet switch and 8 AIs, -40 to 75°C operating

Ethernet remote I/O with 2-port Ethernet switch, 4 AIs, 4 DIs, and 4 DIOs, -

Ethernet remote I/O with 2-port Ethernet switch and 8 TCs, -40 to 75°C operating

Page 7

ioLogik E1200 Series Introduction

1-3

NOTE

The latest specifications for Moxa’s products can be found at

Product Specifications

Physical Dimensions

https://www.moxa.com.

Page 8

ioLogik E1200 Series Introduction

1-4

NOTE

The RESET button restarts the server and resets all settings to factory defaults. Use a pointed object such as

a straightened paper clip to hold down the RESET button for 5 seconds. The factory defaults will be loaded once

the READY LED turns green again. You

Hardware Reference

Panel Guide

Ethernet Port

LED Indicators

LED State Description

Power Amber System power is ON

Ready Green System is ready

Port 1 Green Ethernet connection enabled

Port 2 Green Ethernet connection enabled

EXT Green EXT field power input is connected

may then release the RESET button.

Pin 1 2 3 4

Signal TXD+ TXD- RXD+ ---

Pin 5 6 7 8

Signal --- RXD- --- ---

OFF System power is OFF

Flashing Flashes every 1 second when the “Locate” function is triggered

Flashing Flashes every 0.5 second when the firmware is being upgraded

Flashing ON/OFF cycle period of 0.5 second represents “Safe Mode”

OFF System is not ready

Flashing Transmitting or receiving data

Flashing Transmitting or receiving data

Off EXT field power input is disconnected

Page 9

ioLogik E1200 Series Introduction

1-5

I/O Circuit Diagram

DI Circuit

Sinking DO Circuit

Page 10

ioLogik E1200 Series Introduction

1-6

Sourcing DO Circuit

Page 11

ioLogik E1200 Series Introduction

1-7

DIO Circuit

Page 12

ioLogik E1200 Series Introduction

1-8

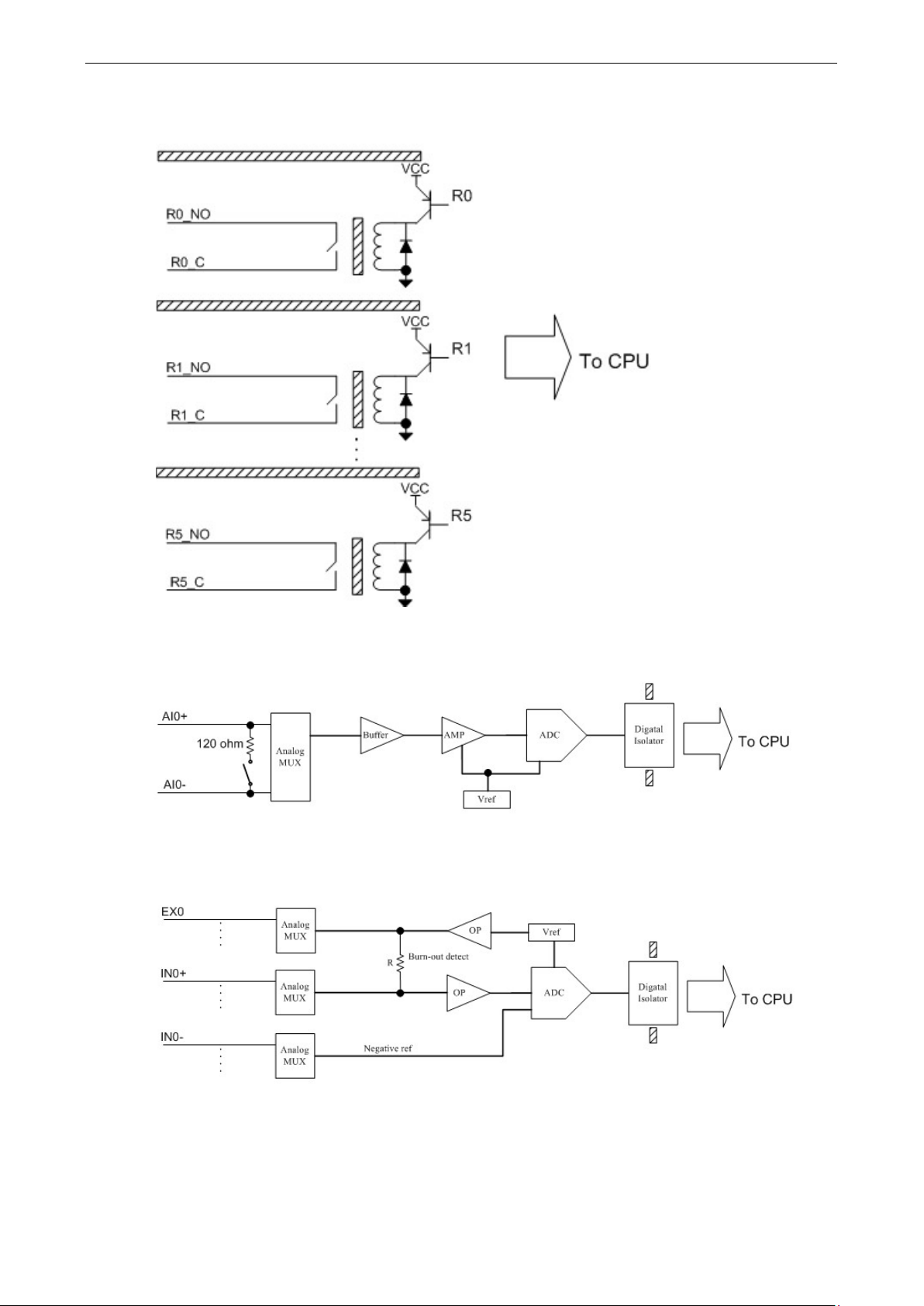

Relay Circuit

AI Circuit

RTD Circuit

Page 13

ioLogik E1200 Series Introduction

1-9

TC Circuit

Page 14

2

2. Initial Setup

This chapter describes how to install the ioLogik E1200.

The following topics are covered in this chapter:

Hardware Installation

Mounting

Grounding the Unit

I/O Channel Jumper Setting

I/O Wiring

Communication Port Wiring

Use the Cable Tie Base to Securely Route a Connected I/O Cable

Powering Up the Unit

ioSearch™ Installation

Load Factory Default Settings

Page 15

ioLogik E1200 Series Initial Setup

2-2

ATTENTION

This unit is sensitive to Electrostatic Discharge, which can cause internal damage and affect normal operation.

Follow the

•

•

•

•

•

•

WARNING

Disconnect

unless the

area is known to be free of ignitable

•

, an

sure

•

power is

•

STEP 1

Hardware Installation

Read all of the safety notifications and warnings below before installing the product.

Before handling the product, touch a grounded object to discharge static electricity from your body.

Wear an approved grounding wristband.

Do not touch connectors or pins on component boards.

Do not touch circuit components inside the equipment.

Use a static-safe workstation, if available.

Store the equipment in appropriate static-safe packaging when not in use.

If you connect or disconnect the Removable Terminal Block while field power is applied to the product

If you connect or disconnect wiring while the field-side power is applied to the product, an electrical arc

Do not disconnect the unit unless the power has been disconnected or the area is known to be

se guidelines when you handle this unit:

the power when you want to remove or replace components or disconnect equipment,

material.

electrical arc could occur. The arc could cause an explosion in hazardous location installations. Make

the power is disconnected, or the area is nonhazardous before starting the installation process.

could occur. The arc could cause an explosion in hazardous location installations. Make sure the

disconnected or the area is nonhazardous before starting the installation process.

nonhazardous. In a hazardous area, the unit must be powered down before removal.

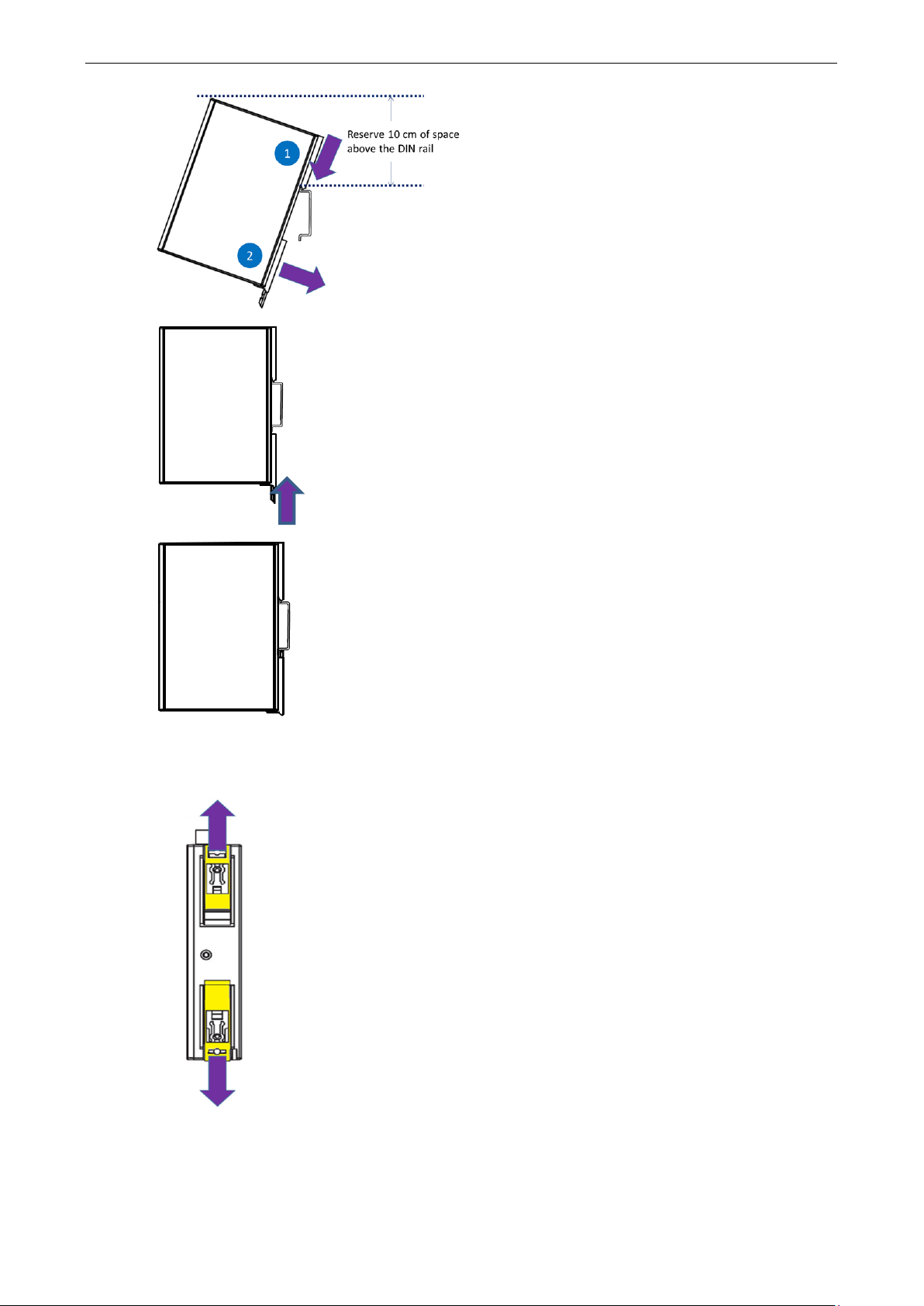

Mounting

The unit supports two types of mounting: DIN-Rail Mounting and Wall Mounting. While mounting the unit, be

sure to use the correct tools and accessories to ensure that the unit is property mounted.

DIN Rail

Take the following steps to mount the unit on a DIN rail:

. Pull down the bottom of the two sliders on the back of the unit.

Page 16

ioLogik E1200 Series Initial Setup

2-3

STEP 2

as

shown in the diagram.

above

that there is enough space to

complete the

STEP 3.

ush

the bottom slider

to lock the unit to

the DIN rail

STEP 4.

he unit

sh

STEP 1. There are two sliders

s out away from the

product

. Latch the top slider of the unit onto the DIN rail

Reserve at least 10 cm of space

the DIN rail to ensure

installation.

Rotate the unit down into a vertical position, and then p

back up to its original position

.

Wall Mounting

At this point, if the mounting was done correctly, t

ould be securely fixed to the DIN Rail.

on the back of the unit, pull out both slider

.

Page 17

ioLogik E1200 Series Initial Setup

2-4

STEP 2. Use screws to fix the unit to the wall, as shown in the

diagram.

the unit to ensure

STEP 3.

securely

The ioLogik E1200

panel

the terminal block. Connect the ground pin ( ) to earth

ground.

Reserve at least 1.5 cm of space above and below

that the installation can be done correctly.

At this point, if the mounting was done correctly, the unit should be

fixed to the wall.

Grounding the Unit

Top View

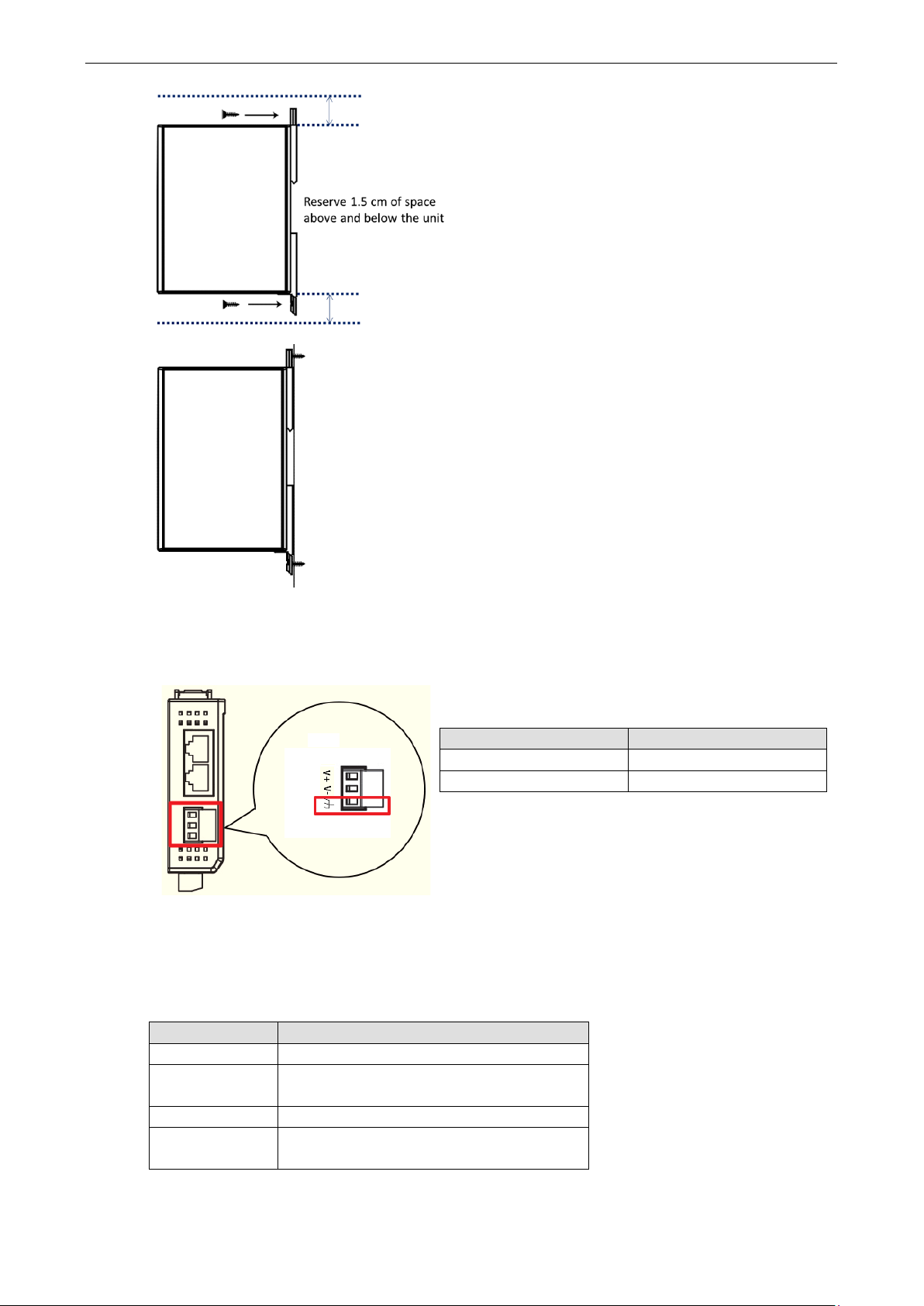

I/O Channel Jumper Setting

The following table shows jumper setting for each model of the ioLogik E1200 Series. We provide a more

detailed description of three different jumper settings.

Model Jumper Setting

E1212 DIO direction (DI, DO)

E1213 1. DIO direction (DI, DO)

2. EXT Power Configuration

E1240 AI mode (Voltage, Current)

E1242 1. DIO direction (DI, DO)

2. AI mode (Voltage, Current)

has a grounding point located on the top

of

Item Suggested Setting

Wire range 12 to 24 AWG

Screw Torque 7 lb-inch

Page 18

ioLogik E1200 Series Initial Setup

2-5

STEP 1. Remove the screw

(Suggested Torque: 3.9 ± 0.4 kg

STEP 2. Remove the Terminal Block and open the top cover as

shown in the diagram

STEP 3.

channels. Jumper settings for different modes of

operation are described below. In the diagrams,

a triangle is used to indicate the direction of the

setting.

Take the following to open up the unit.

Rear View

Top View

from the back panel.

-cm)

.

The jumpers are located near the IO

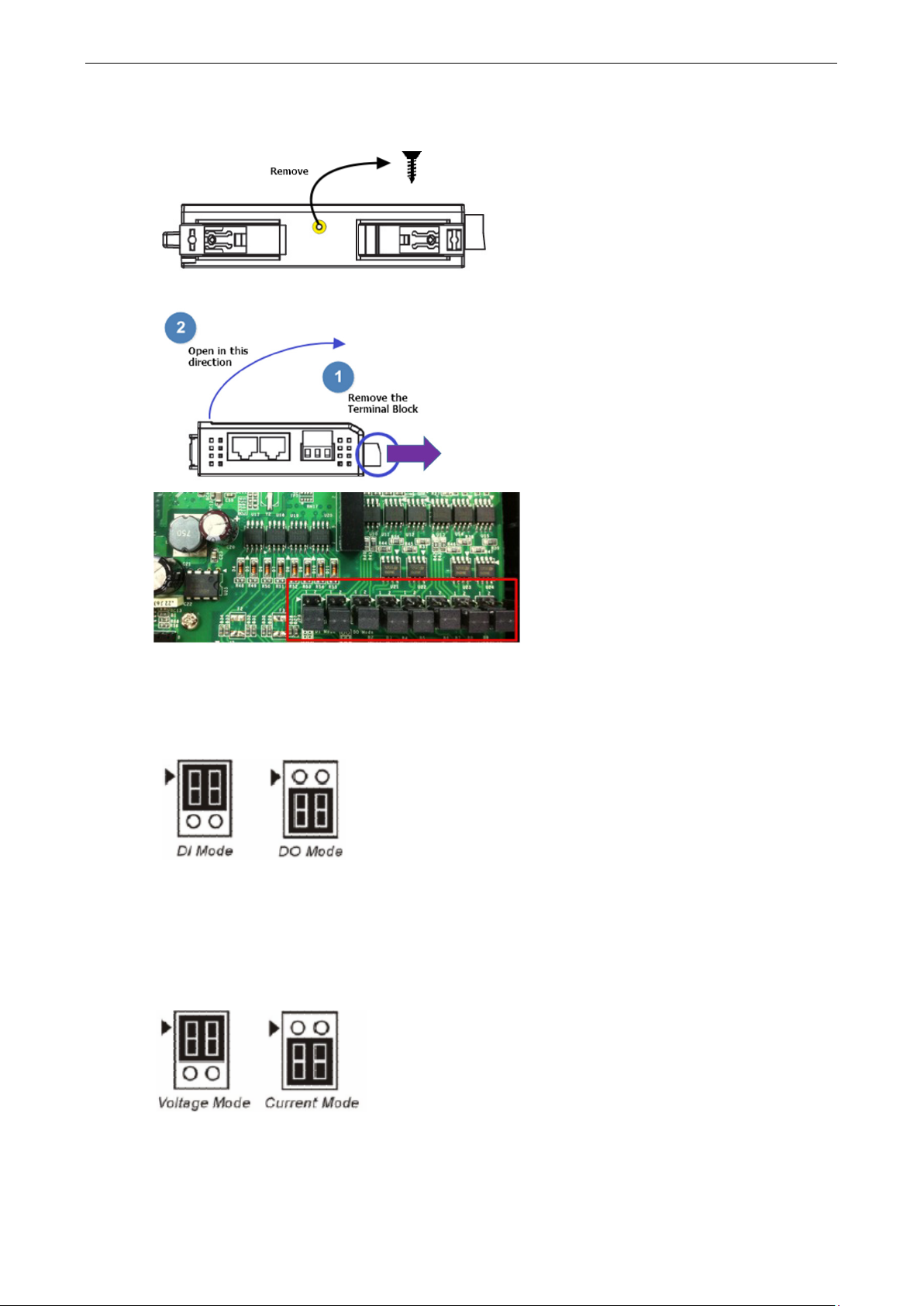

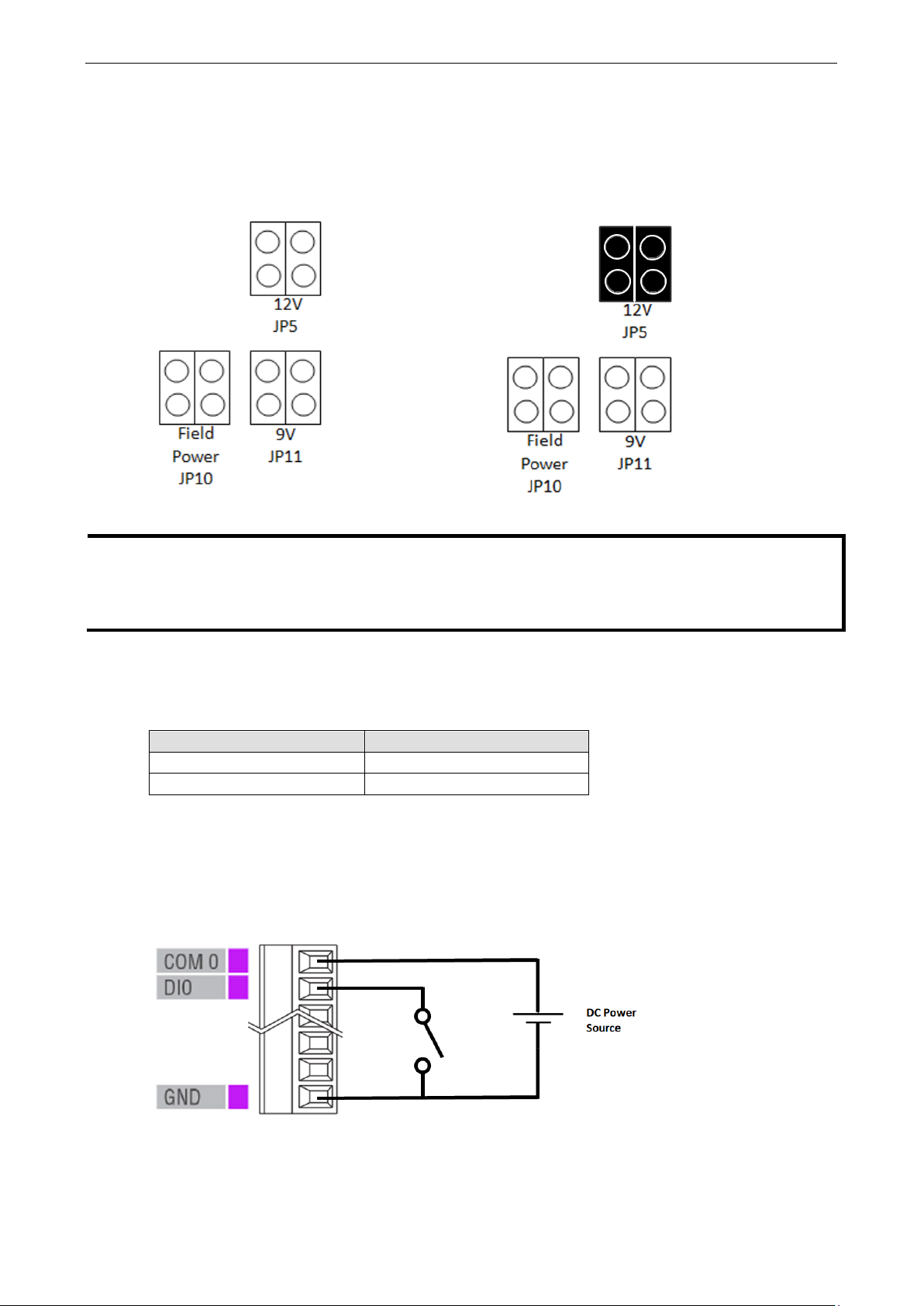

DIO Direction (DI, DO)

DIO mode configuration settings are shown below:

The default setting is DO Mode.

AI mode (Voltage, Current)

Analog mode configuration settings are shown below:

The default setting is Voltage Mode.

Page 19

ioLogik E1200 Series Initial Setup

2-6

Example:

If jumper is set to 12V,

EXT power will be 12V.

NOTE

The ioLogik E1213 has 4 pure DO channels and 4 hybrid DIO channels. For the 4 pure DO channels, you can use

the jumpers to select th

12 V, 9 V). But for the 4 hybrid DIO

channels, you cannot use the jumpers to select the power configuration output. Instead, you can only use the

jumpers to set the DIO channels to either DI mode or DO mode.

EXT Power Configuration

The ioLogik E1213 comes with a source type DO, which has three possible external (EXT) power configurations.

Only one field power configuration can be selected at a time (JP10 / 12V JP5 / 9V JP11), and the jumper must

be inserted vertically, not horizontally. EXT power configuration settings are shown below:

The default setting is Field Power JP10.

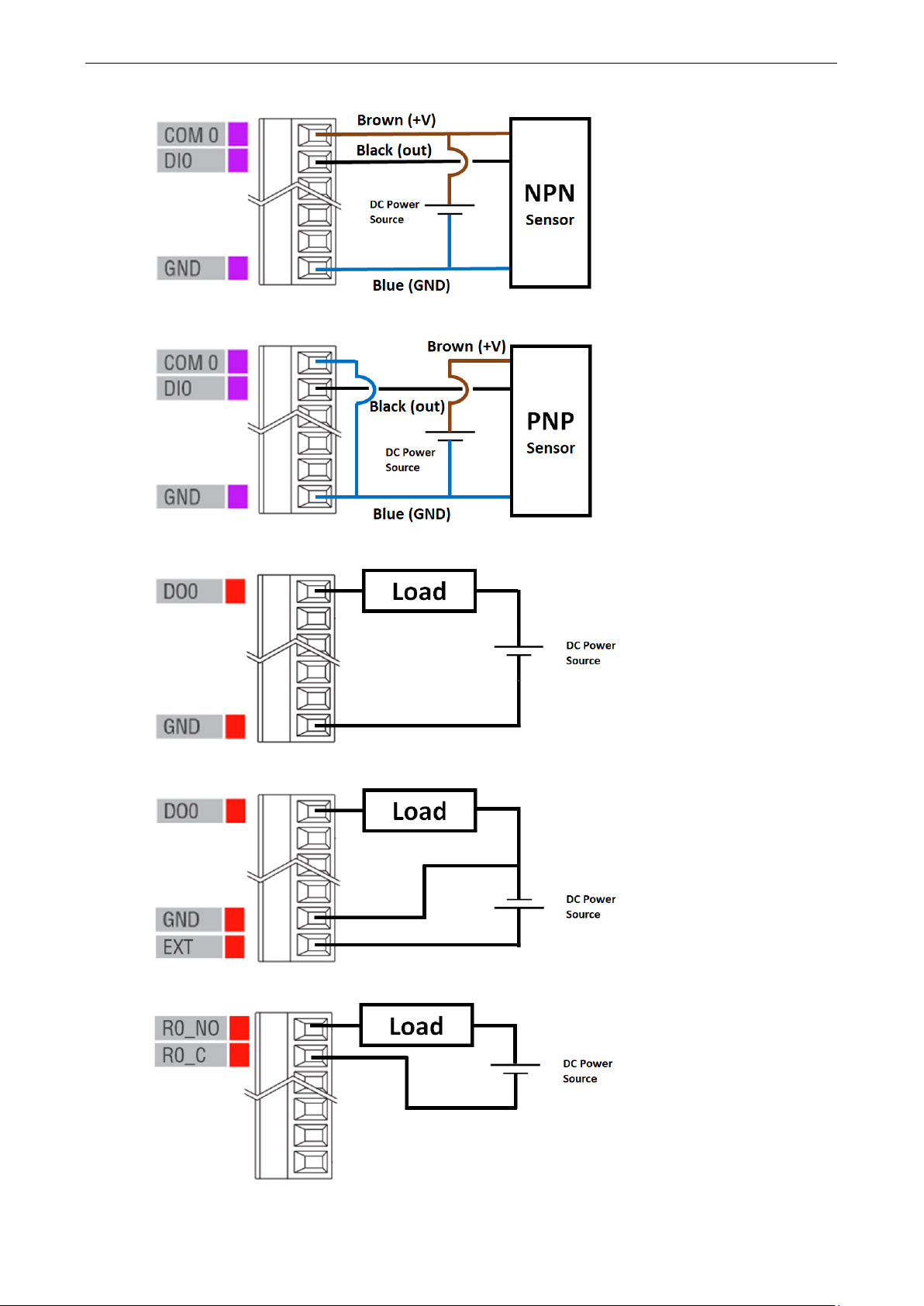

I/O Wiring

The following wiring guide explains how to configure seven different types of I/O channel:

Item Suggested Setting

Wire range 16 to 26 AWG

Screw Torque 3 lb-inch

A Dry Contact is a contact that works without a power source. This applies to buttons, switches, etc.

A Wet Contact is a contact that must be connected to a power source to work. This applies to proximity

sensors, motion sensors, etc.

Check the sensor type (NPN, PNP) and follow the corresponding wiring instructions.

DI Dry Contact

e power configuration output (e.g., field power:

Page 20

ioLogik E1200 Series Initial Setup

2-7

DI Wet Contact (NPN)

DI Wet Contact (PNP)

DO (Sink Type)

DO (Source Type)

Relay

Page 21

ioLogik E1200 Series Initial Setup

2-8

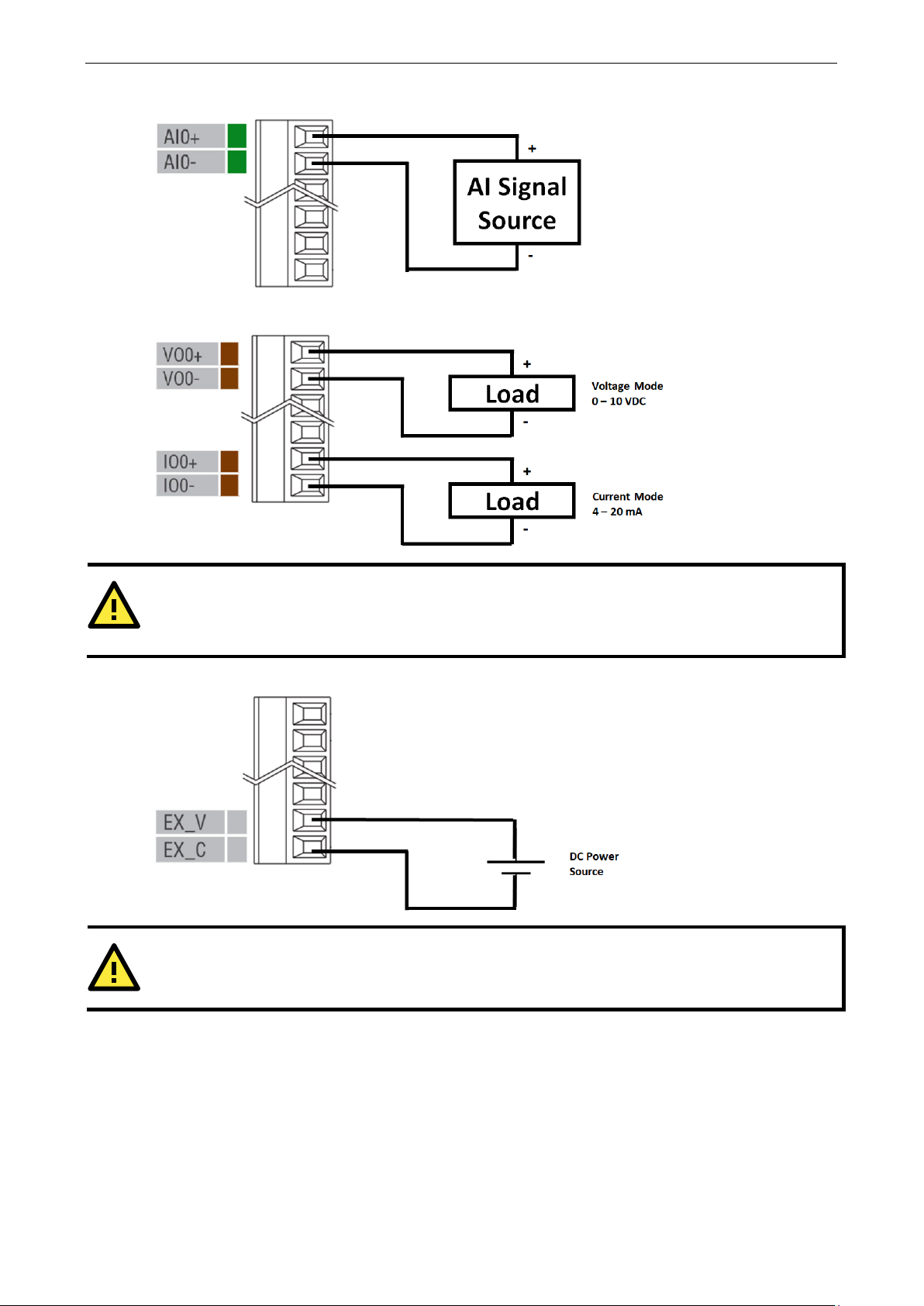

ATTENTION

Use

(

ATTENTION

24V of external power required in Analog output when loading exceeds 1000ohms.

AI

AO

the AO channel corresponding to the mode of operation you are using, as described above

e.g., voltage mode VO, current mode IO).

AO with external power

Page 22

ioLogik E1200 Series Initial Setup

2-9

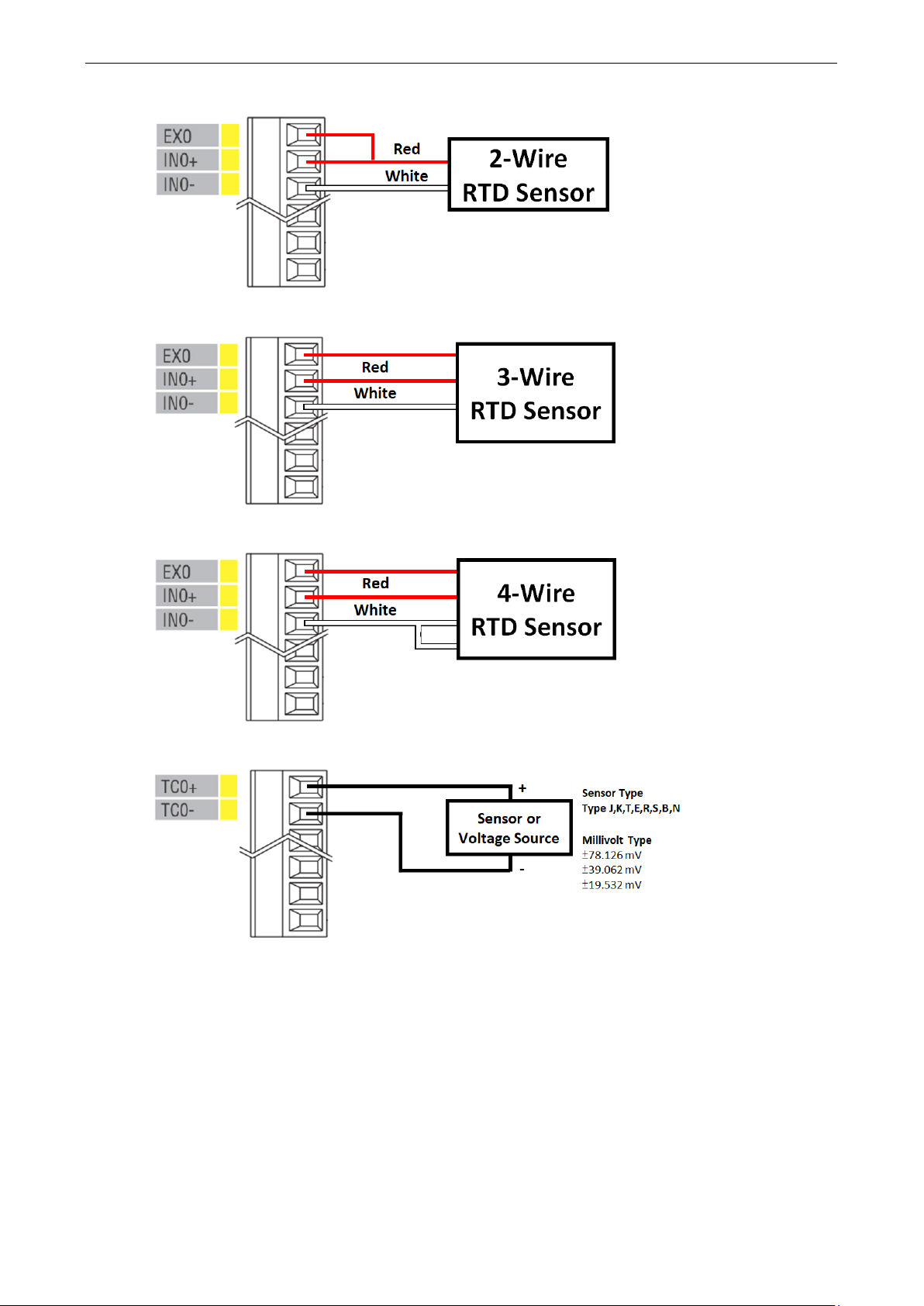

2-Wire RTD

3-Wire RTD

4-Wire RTD

TC

Page 23

ioLogik E1200 Series Initial Setup

2-10

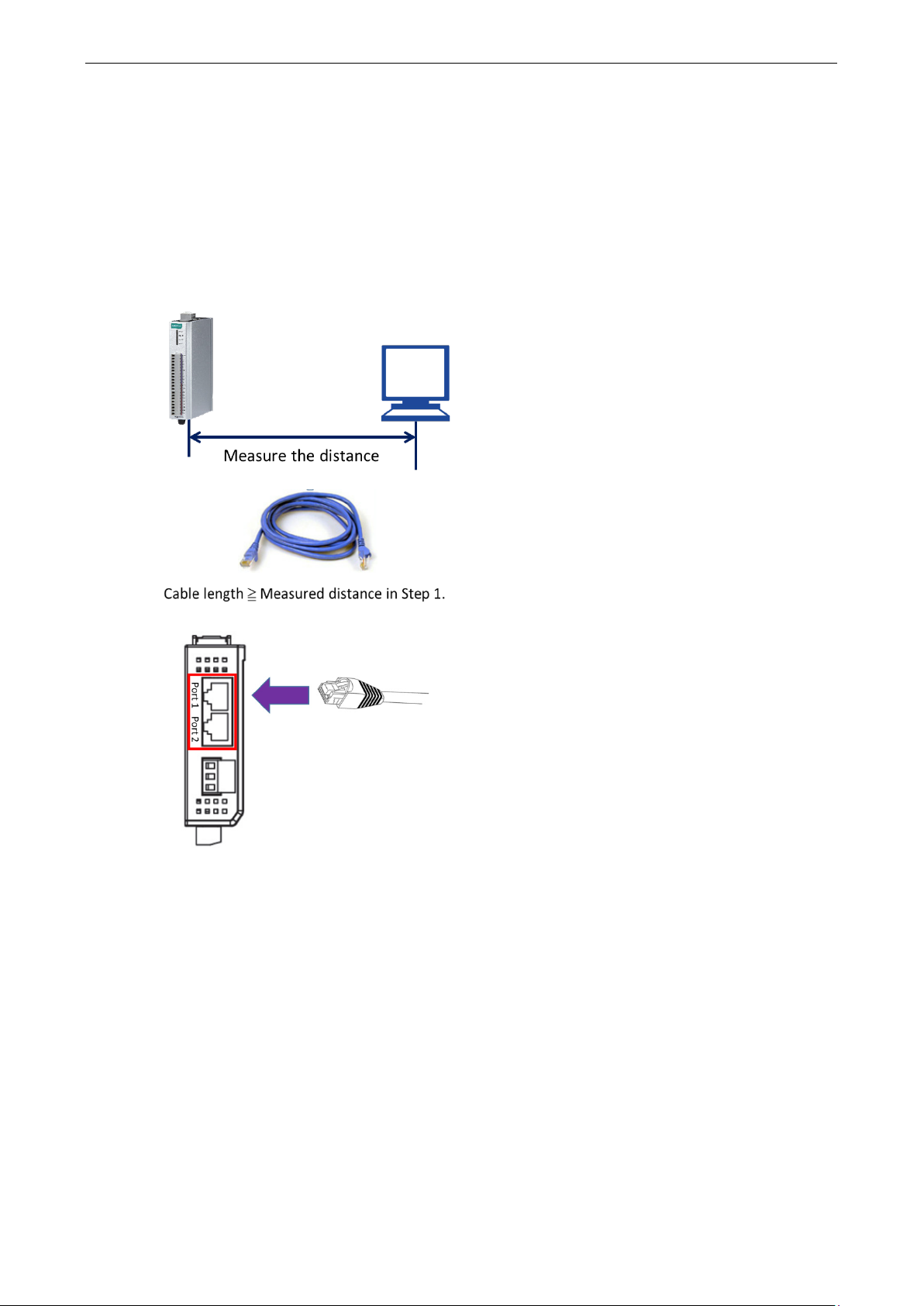

STEP 1. Measure the distance between the unit and your

workstation/ switch/ connected equipment.

STEP 2. Prepare

longer

than the distance m

STEP 3.

Port1/Port2.

Communication Port Wiring

The product series offers the communication ports described below:

RJ45: Ethernet

The Ethernet ports (Port1/Port2) on the unit are unmanaged switch ports. Each of the two ports function in

essentially the same way.

Take the following steps to wire the communication port correctly.

an Ethernet cable (RJ45 connector)

easured in Step 1.

Top View

Connect the RJ45 connector of the cable to

Page 24

ioLogik E1200 Series Initial Setup

2-11

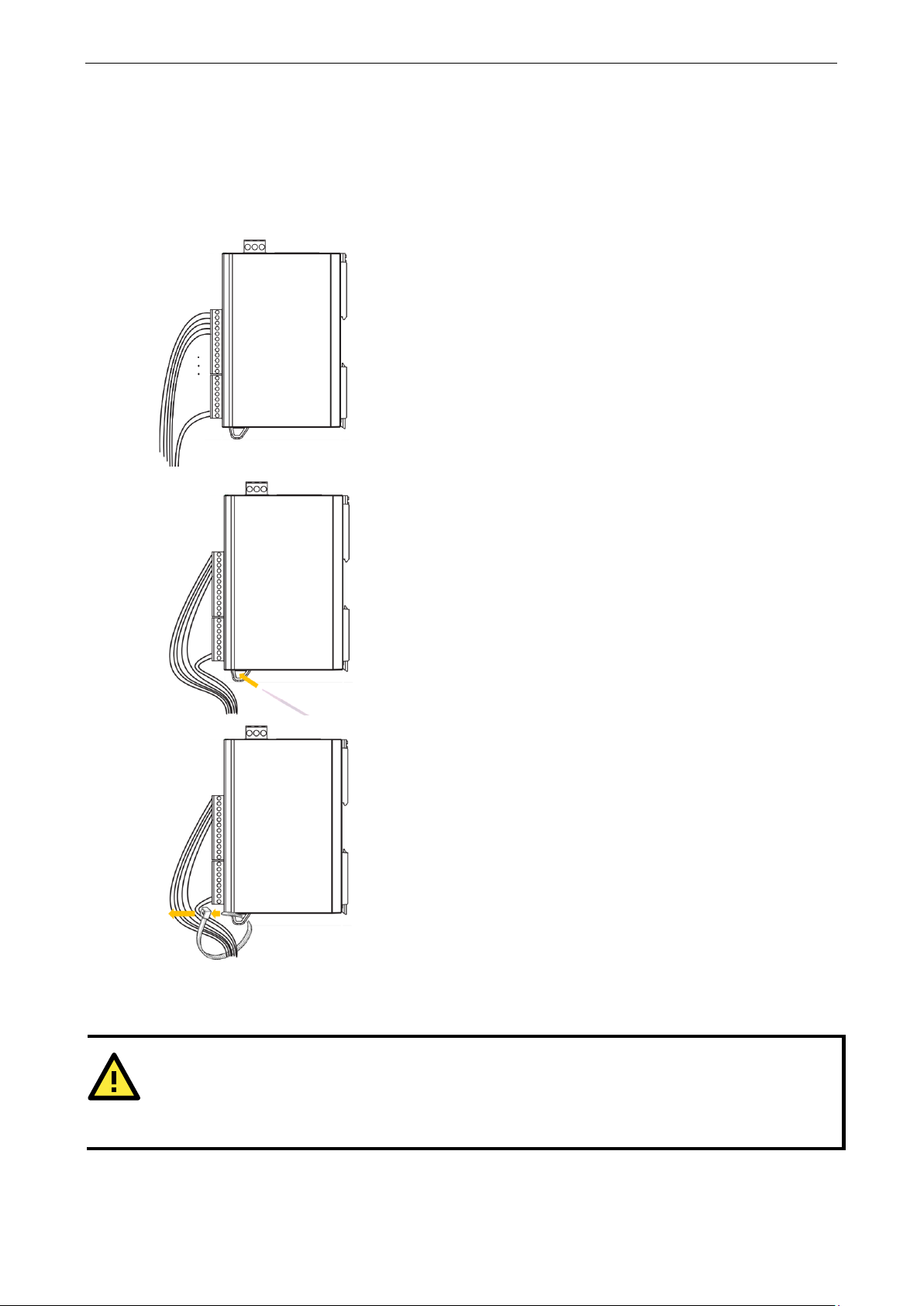

STEP 1.

STEP 2.

STEP 3. Fix the I/O channel cables to

WARNING

Confirm

power to the unit

operate in an

Use the Cable Tie Base to Securely Route a Connected I/O

Cable

The products in this series have a cable tie base at the bottom of the unit for securely routing connected I/O

cables, thereby decreasing the risk that the cable or terminal will be damaged accidentally.

Refer to the I/O wiring section to wire the I/O channel.

Insert the cable tie strap through the cable tie base.

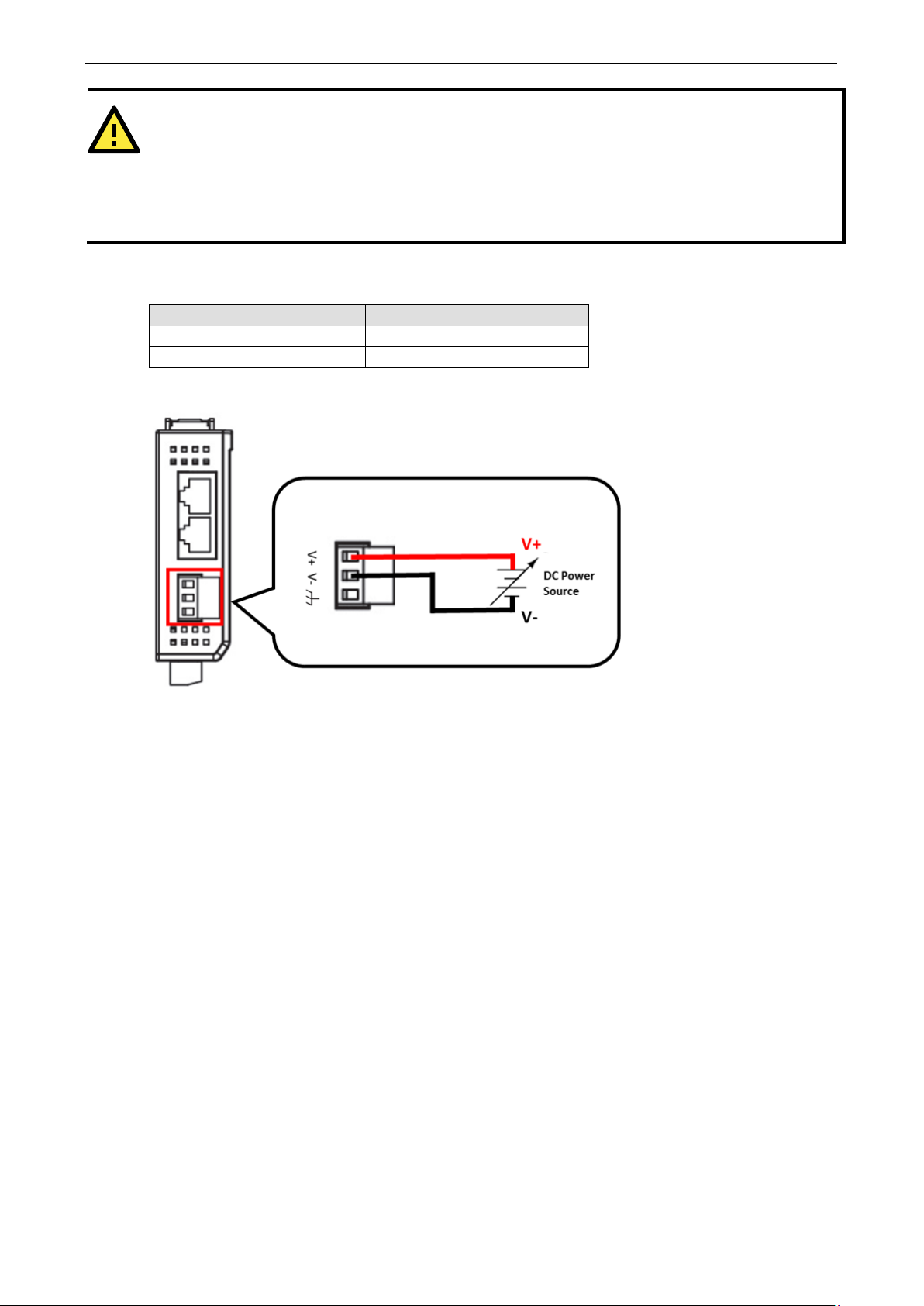

Powering Up the Unit

that the rated voltage of the connected DC Power Source is within 12 to 36 VDC to supply efficient

the cable tie base

; if the power source does not supply voltage in this range, your unit could be damaged or

unpredictable manner.

Page 25

ioLogik E1200 Series Initial Setup

2-12

ATTENTION

Determine the maximum possible current for each power wire and common wire according

maximum

causing serious damage to your equipment. For safety reasons, we recommend an average cable size of 22

AWG. However, depending on the current load, you may want to adjust your cable size (the maximum wire size

for power connectors is 2 mm).

The power terminal block is located on the top panel of the unit. Connect the unit to a 12 to 36 VDC power

source as shown below.

Item Suggested Setting

Wire range 12 to 24 AWG

Screw Torque 7 lb-inch

allowable current spec. If the current exceeds the maximum rating, the wiring may overheat,

Top View

to its size and

If power is properly supplied, the Power LED will glow a solid amber color. Continue to configure the software

after you have finished installing the hardware.

Page 26

ioLogik E1200 Series Initial Setup

2-13

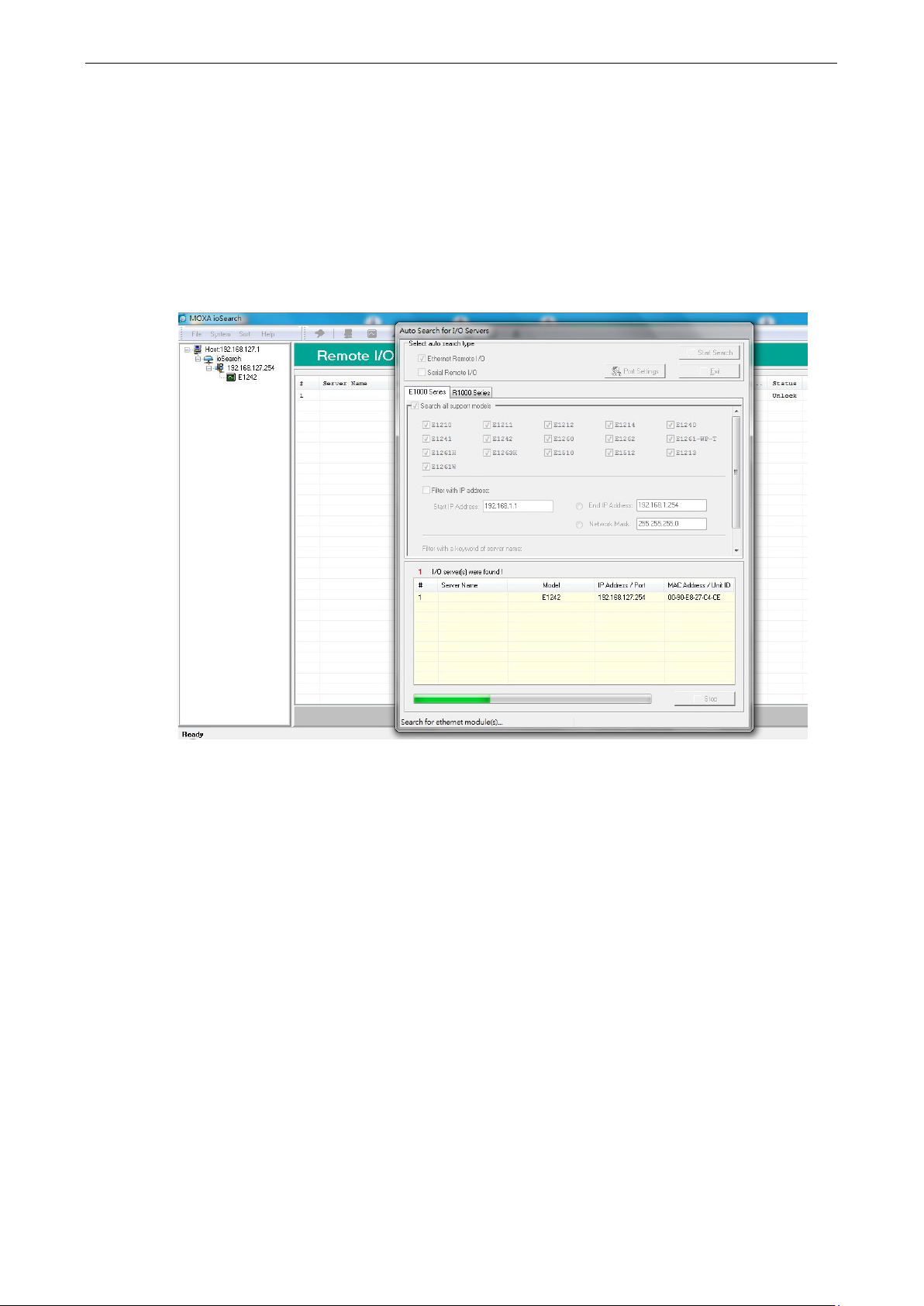

ioSearch™ Installation

ioSearch™ is a search utility that helps the user locate ioLogik E1200 devices on the local network. You may

download the latest version of ioSearch™ from Moxa’s website.

1. Installing the ioSearch™: Download the ioSearch™ utility from Moxa’s website, double click the

installation file, and then follow the installation wizard’s instructions to complete the installation.

2. Open ioSearch: After installation is finished, run ioSearch™ from Start Program Files MOXA IO

Server Utility ioSearch.

3. Search the network for the server: On the menu bar, select System Auto Scan Active Ethernet

I/O Server. A dialog window will pop up. Click Start Search to begin searching for the ioLogik E1200.

If multiple ioLogik E1200 units are installed on the same network, remember that each unit has the same

default IP address. You will need to assign a different IP address to each unit to avoid IP conflicts.

Load Factory Default Settings

There are three ways to restore the ioLogik E1200 to factory default settings.

1. Hold down the RESET button for 5 seconds

2. Right-click on the specific ioLogik device in the ioSearch™ utility and select Reset to Default

3. Select Load Factory Default from the web console

Page 27

3

3. Using the Web Console

The ioLogik E1200’s main configuration and management utility is the built-in web console, which can be used

to configure a wide range of options.

The following topics are covered in this chapter:

Introduction to the Web Console

Overview

Network Settings for the Web Console

General Settings

Ethernet Configuration

User-Defined Modbus Addressing

Default Modbus Address

AOPC Server Settings

Tag Generation

I/O Settings

DI Channels

DO Channels

AI Channels

AI Input Range

AO Channels

RTD Channels

TC Channels

Peer-to-Peer Networking

Peer-to-Peer Settings (1-50)

Sample Peer-to-Peer Configuration

DO Safe Mode Settings

AO Safe Mode Settings

SNMP

SNMP Trap

Using SNMP

Accessibility IP List

RESTful API Setting

EtherNet/IP Setting

System Management

Network Connection

Firmware Update

Import System Configuration Settings

Export System Settings

Change Password

Load Factory Defaults

Page 28

ioLogik E1200 Series Using the Web Console

3-2

NOTE

The web console is best viewed with Internet Explorer 9 or higher

supported

when using

Save/Restart

Introduction to the Web Console

The ioLogik E1200 web console is a browser-based configuration utility. When the ioLogik E1200 is connected

to your network, you may enter the server’s IP address in your web browser to access the web console.

The left panel is the navigation panel and contains an expandable menu tree for navigating among the various

settings and categories. When you click on a menu item in the navigation panel, the main window will display

the corresponding options for that item. Configuration changes can then be made in the main window. For

example, if you click on Network Settings in the navigation panel, the main window will show a page of basic

settings that you can configure.

You must click on the Submit button after making configuration changes. The Submit button will be located

at the bottom of every page that has configurable settings. If you navigate to another page without clicking the

Submit button, your changes will not be retained.

Submitted changes will not take effect until they are saved and the ioLogik E1200 is restarted! You

may save and restart the server in one step by clicking on the Save/Restart button after you submit a change.

If you need to make several changes before restarting, you may save your changes without restarting by

selecting Save/Restart in the navigation panel. If you restart the ioLogik E1200 without saving your

configuration, the ioLogik E1200 will discard all submitted changes.

other browsers.

; some functionality may not be

Page 29

ioLogik E1200 Series Using the Web Console

3-3

Overview

The Overview page contains basic information about the ioLogik E1200, including the model name, serial

number, firmware version, MAC address, and current IP address. Most importantly, you can see the current I/O

status by pressing the F5 key on the computer keyboard to refresh the page.

Page 30

ioLogik E1200 Series Using the Web Console

3-4

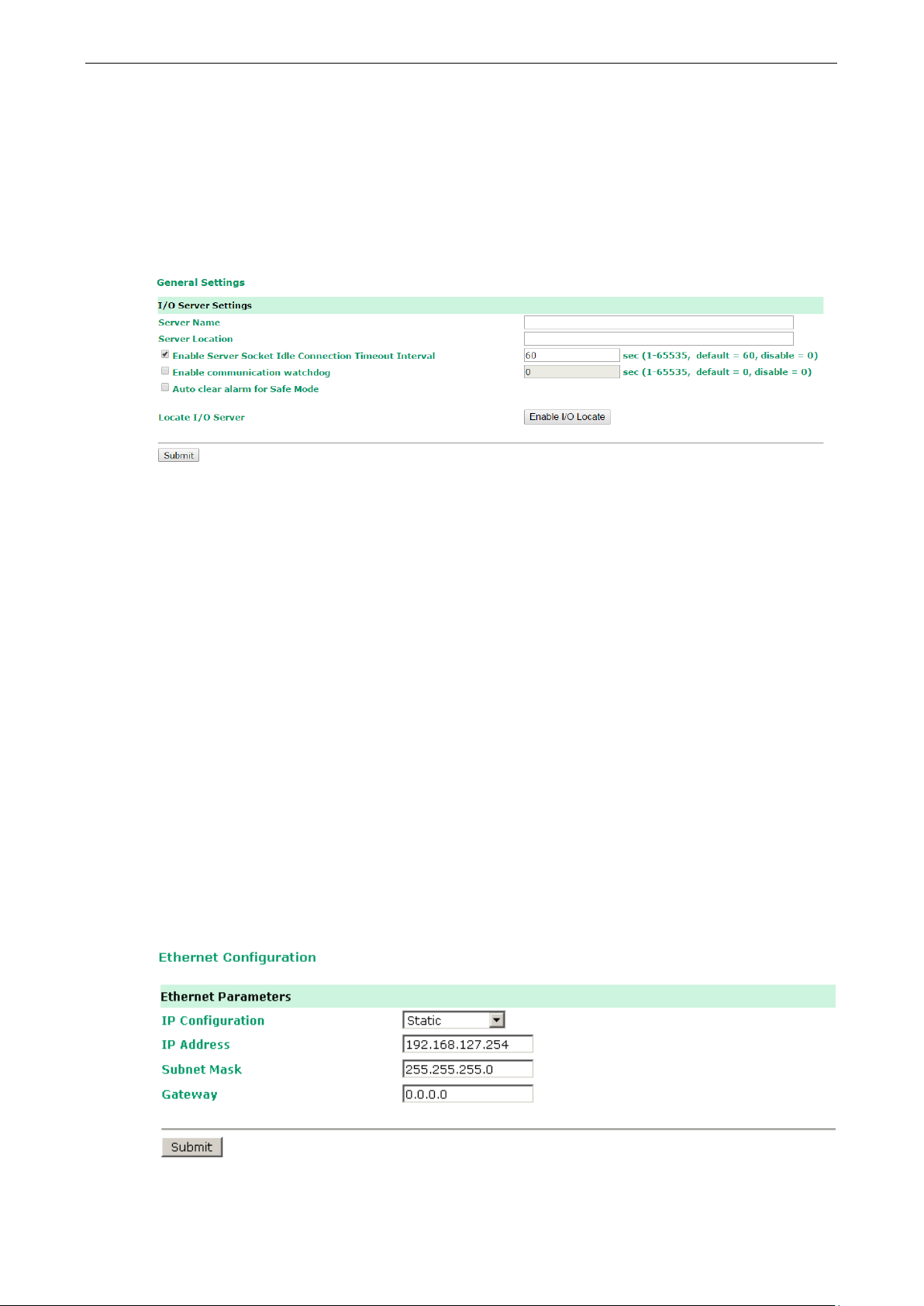

Network Settings for the Web Console

General Settings

On the General Settings page, you can assign a server name and location to assist you in differentiating

between different ioLogik E1200 units. You may also configure the Modbus/TCP timeout interval or enable the

Communication Watchdog function.

Enable Server Socket Idle Connection Timeout Interval automatically disconnects the Modbus/TCP

connection from the server after a specified time period to free up the port for the next connection.

Enable Communication Watchdog activates Safe Mode when a specified period of time has passed and

there is a loss of Modbus/TCP network connectivity. Safe Mode is specially designed for products with output

channels to output a suitable value (see Chapter 3: AO Safe Mode Setting) or status (see Chapter 3: DO

Safe Mode Setting) when the ioLogik E1200 cannot be controlled by a remote PC (such as in the event of a

network failure). By default, the watchdog is disabled. Users can configure how each output channel responds

on the I/O Settings page.

To enable the Communication Watchdog function, select the Enable Communication Watchdog checkbox,

set the timeout value, and then restart the server. When the watchdog is enabled, the ioLogik E1200 will enter

Safe Mode after there is a disruption in communication that exceeds the specified time limit.

Auto clear alarm for Safe Mode automatically clears Safe Mode when the Modbus/TCP network

connectivity returns to normal. This function is only available in models with analog or digital output channels.

Enable I/O Locate enables remote toggling of the Ready LED from off to flashing to enable remote control

of LEDs for easier location of devices when troubleshooting.

Ethernet Configuration

On the Ethernet Configuration page, you can set up a static or dynamic IP address for the ioLogik E1200, and

configure the subnet mask and gateway address.

Page 31

ioLogik E1200 Series Using the Web Console

3-5

NOTE

The maximum number of Modbus TCP master connection

ATTENTION

Disable the user

Server

to control or monitor the ioLogik E1200’s I/O status.

User-Defined Modbus Addressing

The input and output addresses can be configured on this page. Select the Enable Modbus/TCP Slave

Protocol checkbox, and then configure the start address of each Modbus function. If you do not want to use

the Modbus function, deselect the Enable Modbus/TCP Slave Protocol checkbox.

Default Modbus Address

You can view the default Modbus address for all I/O devices on the Default Modbus Address settings page.

However, only the starting address will be displayed for each item with multiple reference addresses. For

example, if the reference addresses for DI Value start from 10001 and the second DI channel’s reference

address is 10002, only the first DI channel’s Modbus address of 10001 will be displayed. See the diagram

below.

s is 10.

-defined Modbus addressing function if using the MXIO (.NET) library or MX-AOPC UA

Page 32

ioLogik E1200 Series Using the Web Console

3-6

OPC Unified Architecture

1.01

NOTE

The

MX

, and to ensure that the ioLogik is connected and alive. If the heartbeat interval is set and

the network between the ioLogik E1200 and

will detect the

stopped heartbeat and the

connectivity.

AOPC Server Settings

Moxa’s MX-AOPC Server™ is a software package operated as an OPC driver of an HMI or SCADA system. It

seamlessly connects Moxa’s ioLogik products to a wide variety of SCADA systems, including the most popular:

Wonderware, Citect, and iFix. MX-AOPC UA Server™ conforms to the OPC UA standard to connect with other

standards-compliant devices and host OPC machines.

Hardware Requirements

CPU Intel Pentium 4 or above

RAM 512 MB (1024 MB recommended)

Communication Interface Ethernet or serial

Software Requirements

Operating System Microsoft Windows 7/8/10, Microsoft Windows Server 2003/2008/2012

Editor (optional) Microsoft Office 2003 (Access or Excel) or later

Database (optional) Oracle database, Microsoft SQL Server

OPC UA Server Specifications

OPC Data Access 1.0a, 2.0, 2.05a, 3.0

Device Protocols Moxa AOPC, Modbus/TCP (master), Modbus/RTU (master)

OPC UA Logger Specifications

OPC Unified Architecture 1.01

MX-AOPC UA Server can be downloaded from Moxa’s website support page at www.moxa.com/support/.

After downloading the MX-AOPC UA Server file, unzip the file and run Install.exe. The installation program will

guide you through the installation process and install the MX-AOPC UA Server Utility.

For more details on MX-AOPC UA Server installation and use, please check the user’s manual, which can be

downloaded from Moxa’s website.

Tag Generation

Use the web console to create AOPC tags for the ioLogik E1200 by opening your browser and navigating to the

AOPC Server Settings page.

Follow these steps to create the tags and send them from the ioLogik E1200 to MX-AOPC UA Server:

1. On the AOPC & I/O Settings page, select the Enable Active OPC checkbox and specify the IP address

where the MX-AOPC UA Server is installed.

2. Select the I/O channels that need to be created in MX-AOPC UA Server.

3. Configure the Heartbeat Interval, if necessary.

Heartbeat Interval can be used to determine the connection status between the ioLogik E1200 and

-AOPC UA Server

MX-AOPC UA Server is down, MX-AOPC UA Server

Quality column in the MX-AOPC UA will display BAD to indicate the loss of

Page 33

ioLogik E1200 Series Using the Web Console

3-7

4. Click the Submit button and then the Save/Restart button on the next page.

5. On the Create AOPC Tag page, click on the Create Tags button to “push” tag configurations to the

MX-AOPC UA Server utility.

6. Launch the MX-AOPC UA Server utility and the tags will be automatically created. Remember to save the

configuration of the MX-AOPC UA Server when exiting the program.

Page 34

ioLogik E1200 Series Using the Web Console

3-8

NOTE

Confirm that the Counter Filter is not set to 0; otherwise, the counter will never be activated.

I/O Settings

DI Channels

The status of each DI (digital input) channel appears on the DI Channel Settings page.

You can also configure each channel’s digital input mode and parameters by clicking on the channel. DI

channels can operate in DI mode or Event Counter mode.

Activate Event Counter mode by selecting the Counter Start field and configure the Counter Trigger by

selecting Lo to Hi, Hi to Lo, or Both from the dropdown menu. When the Counter Start field is not selected,

you can still activate the counter by using Modbus commands.

Page 35

ioLogik E1200 Series Using the Web Console

3-9

Power On Setting: You may configure DI channels in Event Counter mode whether or not counting begins

when powering up.

Save Counter On Power Failure: The ioLogik E1200 will automatically save the counter value when there is

a power failure if this function selected.

Reset Counter: Select this function to reset the counter.

Counter Overflow: If the value of the counter is over the maximum counter value of 4294967295, the word

Overflow will be displayed in the web console; the actual counter value will restart counting from 0. To display

the current counter value in the web console, check the Clear Overflow checkbox, as shown below.

Counter Scaling: Select the Enable Counter Scaling checkbox to enable the counter scaling function. To use

this function, define the gain and offset values, and define the update interval.

For example, if the gain is 5 and the offset is 10, the counter result will be (count difference x 5) + 10.

Page 36

ioLogik E1200 Series Using the Web Console

3-10

The DI channel’s Alias Name and logic definition can also be configured on this page. You can apply the alias

name to all channels by selecting the Apply to all DI channels checkbox.

DI Channel Specification:

DO Channels

On the I/O Setting: DO (Digital Output) Channels page; you can configure each DO channel by clicking on

the channel.

Page 37

ioLogik E1200 Series Using the Web Console

3-11

NOTE

Safe Status is controlled by the Co

s, which is disabled by default.

If the

Watchdog is disabled, the ioLogik E1200 will never enter Safe Mode and your Safe Status

settings

DO channels can operate in DO mode when the status is either ON or OFF.

If you select Pulse Output mode, you can specify the ON Width and OFF Width to generate a square wave.

Pulse Width unit = 1 ms, range = 1–65535

When configuring individual channels, if the Power On Setting is selected, the Pulse Output will start as soon

as the ioLogik E1200 is powered on. If the Safe Status Setting is selected, the Pulse Output will start only

when the E1200 has entered Safe Status mode. In contrast, when neither of these settings is selected and the

Pulse Start field is selected, the ioLogik E1200 will automatically stop the Pulse Output when the ioLogik

E1200 is either powered on or in Safe Status mode.

Communication

will have no effect.

mmunication Watchdog under General Setting

Page 38

ioLogik E1200 Series Using the Web Console

3-12

The DO channel’s Alias Name and logic definition can also be configured on this page. You can apply the alias

name to all channels by clicking on the Apply to all DO channels box.

AI Channels

The current status of each AI (analog input) channel can be viewed on the AI Channel Settings page.

Click on a specific AI channel to enable or disable it by selecting the Enable AI Channel field. There are two

modes available for the AI channels:

1. Voltage Mode (See the Jumper Settings (DIO and AI) in Chapter 2 for more details)

2. Current Mode (See the Jumper Settings (DIO and AI) in Chapter 2 for more details)

Page 39

ioLogik E1200 Series Using the Web Console

3-13

NOTE

Only i

Auto Scaling and Slope-intercept functions of the AI value can be defined on this page.

AI Input Range

Set the AI input ranges for each mode, as follows:

1. Voltage Mode (V) (See Jumper Settings (DIO and AI) in Chapter 2 for more details)

There is only one default analog Voltage input range: [0-10V]

2. Current Mode (mA) (See Jumper Settings (DIO and AI) in Chapter 2 for more details)

There are three modes in the analog Current input range: [4-20 mA], [0-20 mA], [4-20 mA (Burn Out)]

nput ranges [0-10 V] and [4-20 mA] support peer-to-peer networking.

AI Input: Current Mode

Burn Out mode indicates when the Current AI has burned out. For example, the 4–20 mA Burn Out mode is

defined in the following diagram:

Page 40

ioLogik E1200 Series Using the Web Console

3-14

ATTENTION

When configuring the jumpers to select voltage or current measurement for the AI channels, open the cover by

first removing the screw on the back panel. For details on jumper settings, see the

and AI)

NOTE

The scaled value’s

Users can define Burn Out (BO) values (default = 2 mA) for selected ranges. When input values are in the

Burn Out range, raw data will register as 0000h to indicate that the analog input has burned out. The definition

of raw data is as follows:

Burnout Value (BO) 0.0 < BO < 4.0 User defined (default 2 mA)

Burnout State 0 ≤ AI < BO mA S/W output 0000h

Under Range BO ≤ AI < 4 mA S/W output raw data

Normal Range 4 ≤AI ≤ 20.00 mA S/W output raw data until FFFEh

Over Range XX > 20.00 mA S/W output FFFFh

section in Chapter 2.

Selecting Enable Point-Slope formula on the Auto Scaling Settings page will linearly convert the actual

current or voltage value into other user-defined units, such as percentage or ppm (parts per million).

Modbus address differs from the original value.

Jumper Settings (DIO

Page 41

ioLogik E1200 Series Using the Web Console

3-15

NOTE

The scaled value’s

The slope-intercept function is used to compensate when the measurement requires a slight adjustment.

The AI channel’s Alias Name can also be configured on this page.

AO Channels

The current status of each AO (analog output) channel can be viewed on the AO Channel Settings page:

Click on a specific channel to access the AO channel settings, and then select the Enable AO Channel box. The

Auto Scaling function of the AO value can be defined on the same page.

There are two modes for the AO channels, Voltage Mode (V) and Current Mode (mA).

Enabling the Point-Slope Formula function on the Auto Scaling Settings page will linearly convert the

actual current or voltage value into other user-defined units, such as percentage or ppm (parts per million).

Modbus address differs from the original value.

Page 42

ioLogik E1200 Series Using the Web Console

3-16

The AO channel’s Alias Name can also be configured on this page.

RTD Channels

The current status of each RTD (Resistance Temperature Detector) channel can be viewed on the RTD

Channel page.

Click on a specific channel to access the RTD channel settings.

Select the Enable RTD Channel checkbox and then select the sensor type from the dropdown menu that

meets the physical attachment to the ioLogik E1200.

Page 43

ioLogik E1200 Series Using the Web Console

3-17

The ioLogik E1200 allows you to calibrate the temperature sensors. In each channel configuration section,

follow the instructions and click the Calibrate button to start the RTD sensor calibration. Each calibration

requires around 30 seconds per channel.

The ioLogik E1200 allows you to manually adjust the current temperature reading. In each channel

configuration section, select the channel, apply the offset value, and click the Submit button.

TC Channels

The current status of each TC (Thermocouple) channel can be viewed on the TC Channel page.

Page 44

ioLogik E1200 Series Using the Web Console

3-18

Click on a specific channel to enable or disable the TC channel. Select the Enable TC Channel checkbox and

then select the sensor type that meets the physical attachment to the ioLogik E1200.

The ioLogik E1200 allows you to calibrate the temperature sensors. In each channel configuration section,

follow the instructions and click the Calibrate button to start the TC sensor calibration. Each calibration

requires about 30 seconds per channel.

The ioLogik E1200 allows you to manually adjust the current temperature reading. In each channel

configuration section, select the channel, apply the offset value, and click the Submit button.

Page 45

ioLogik E1200 Series Using the Web Console

3-19

NOTE

If you select a DI or AI channel in the Local Channel field, the Remote Channel field will be disabled. You need

to configure the DO

Peer-to-Peer Networking

In some remote automation implementations, the control room and field sensors may be spread far apart from

each other, often with only a single remote I/O module to collect data from all the sensors. Peer-to-peer

communication has little or no limitation as it replaces cable by integrating multiple I/O signals over a single

network cable to transmit input-to-output controls without the aid of PLCs or controllers. Featuring

peer-to-peer communications and support for channel-to-channel mapping, the ioLogik E1200 allows

simultaneous multiple target transmissions. In addition, the ioLogik E1200 supports up to 16 channels for

transmission over Ethernet (based on an emitter and receiver I/O pair).

Peer-to-Peer Settings (1-50)

The ioLogik E1200 supports up to 50 peer-to-peer mapping rules. You can configure 10 channel settings at a

time. To enable the rules, either select the Enable All box to enable all 10 channels, or select the Enable box

individually for each rule. The Local Channel dropdown menu allows you to specify the channel of the ioLogik

E1200 to configure. Type the IP address and port number of a remote ioLogik E1200 in the Remote IP and

Remote Port fields, respectively. The Remote Channel field is for you to select input channels of the remote

ioLogik E1200 when you select output channels in the Local Channel field. Set the Interval Time and On

change percentage on the local ioLogik E1200 that will trigger the transmission of a mapping signal to the

remote ioLogik E1200. The default local listen port number is 9020; this value can be set from 1 to 65535.

or AO channel on the remote ioLogik E1200.

Page 46

ioLogik E1200 Series Using the Web Console

3-20

Heartbeat

The Heartbeat function can monitor packets being transmitted between a peer-to-peer client and peer-to-peer

server. When the peer-to-peer server does not receive a packet from the peer-to-peer client within a

predefined time interval, the peer-to-peer server will enter safe mode. The default value of heart beat interval

s 60 seconds; this value can be set to between 0 and 65535 (0 means the heartbeat function is disabled).

Sample Peer-to-Peer Configuration

The following is an example of configuring DO (Server IP: 192.168.127.253) to DI (Client IP: 192.168.127.252)

peer-to-peer functionality with two ioLogik E1200 devices.

Server Settings:

Client Settings:

For client settings, the Interval Time setting and On Change percentage setting can be configured.

The following table shows the relationship between the number of rules and the maximum frequency with

which On Change percentage data can be transmitted.

Number of Rules DI max. On Change frequency

1 20 Hz

2 to 20 4 Hz

21 to 40 2 Hz

41 to 50 1 Hz

Page 47

ioLogik E1200 Series Using the Web Console

3-21

DO Safe Mode Settings

When a peer-to-peer rule on a local DO channel is not valid, or the peer-to-peer connection is down (e.g., the

Ethernet wire is unplugged or the device restarts), the local DO channel will enter Safe Mode. You can select

Hold Last, ON, or OFF from the Safe Mode Status dropdown menu for each DO channel. Once the DO

channel enters safe mode, the Safe Status will turn to ON. Click the Clear_Safe_Status button to change the

Safe Status back to NORMAL. Otherwise, it will remain in the ON position.

AO Safe Mode Settings

When a peer-to-peer rule on a local AO channel is not valid, or the peer-to-peer connection is down (e.g., the

Ethernet wire is unplugged or the device restarts), the local AO channel will enter Safe Mode. You can either set

the AO channel’s Safe Mode Value from 0–4095, or enable Hold Last Status during Safe Mode by selecting the

checkbox as shown in the following figure. Once the AO channel enters safe mode, the Safe Status will turn to

ON. Click the Clear_Safe_Status button to change the Safe Status back to NORMAL. Otherwise, it will

remain in the ON position.

SNMP

The ioLogik E1200 series remote I/O supports SNMPv1 and SNMPv2c for monitoring network I/O devices with

SNMP network management software, which is useful for building automation and telecommunications

applications.

SNMP Trap

The ioLogik E1200 series remote I/O provides standard SNMP traps and private SNMP traps for I/O devices.

Page 48

ioLogik E1200 Series Using the Web Console

3-22

SNMP manager

NOTE

You will

Standard Trap

The ioLogik E1200 series remote I/O provides the following standard SNMP traps:

Trigger Type Description

coldStart Sends SNMP trap when the agent reinitializes.

*Restart the measurement epochs because configuration data or MIB variables

may have changed.

warmStart Sends SNMP trap when the /etc/snmpd.conf file is reread and the agent

reinitializes.

*Do NOT restart the measurement epochs because configuration data or MIB

variable values have not changed. The configuration information in the

/etc/snmpd.conf file is for agent configurations that do not affect

databases.

Private Trap

The ioLogik E1200 series remote I/O provides the following private trap triggers:

Trigger Type Description

DI-change status Sends SNMP trap when DI status changes.

DO-change status Sends SNMP trap when DI status changes.

Relay-change status Sends SNMP trap when Relay status changes.

AI-burn-out Sends SNMP trap when AI reaches preset burn-out value.

AI-trigger Sends SNMP trap when AI reaches preset value.

AO-trigger Sends SNMP trap when AO reaches preset value.

RTD-trigger Sends SNMP trap when RTD reaches preset value.

TC-trigger Sends SNMP trap when TC reaches preset value.

need to load the correct MIB file to use Moxa’s private SNMP traps.

Using SNMP

Moxa has provided the ioLogik E1200 MIB file for easier analysis of SNMP data.

SNMP Agent

You can enable SNMP under SNMP Settings SNMP Agent. SNMP is used to monitor the network and I/O

devices with SNMP network management software. Use these fields to enable SNMP and set the read and write

community names, contact, and location for SNMPv1 and SNMPv2c.

Page 49

ioLogik E1200 Series Using the Web Console

3-23

NOTE

SNMP is not supported while using the peer

SNMP Trap Settings

On the SNMP Trap Settings page, you can enable SNMP and configure SNMP traps.

SNMP Trap Server

The SNMP Trap function sends an SNMP trap to up to two IP destinations. If both IP addresses are configured,

it will send to both addresses simultaneously when an SNMP trap is triggered.

SNMP Trap

To change the trap community name, type the new name in the input box located to the right of Trap

Community Name.

Enable Channel SNMP Trap by clicking on the SNMP Trap box, and then select the channel you would like to

enable.

-to-peer function.

Specific ID

The Specific ID (trap number) can be any number between 1 and 20. (You may need to consult with your

network administrator to determine how the trap numbers are used and defined on the network.)

Digital Input / Counter Trap Settings

For a digital input, the trap is triggered by the On Change function. When there is a change in the DI channel,

the SNMP will send a trap to the SNMP Server.

Page 50

ioLogik E1200 Series Using the Web Console

3-24

NOTE

SNMP Trap does not

NOTE

SNMP Trap does not

support the counter trap function.

Digital Output/Pulse Output Trap Settings

For digital output, the trap is triggered by the On Change function. When there is a change in the DO channel,

the SNMP will send a trap to the SNMP Server.

support the Pulse Output trap function.

Analog Input Trap Settings

For Analog Input, the trap is triggered when an analog input meets the preset conditions for Trigger, Value, and

Hysteresis. Refer to the AI Channel settings in Chapter 3 to set the mode.

Example:

For illustration purposes, consider the following example where we set the AI-00 channel’s trigger value to be

greater than 5 with a Hysteresis of 1 and also smaller than 5 with a Hysteresis of 1.

When Trigger = Greater, Value = 5, and Hysteresis = 1, the SNMP trap will only be triggered if the analog signal

fluctuates from 4 to 5, as depicted in Scenario 1 below. However, if we change the settings to Value = 5 and

Hysteresis = 2, the SNMP trap will only be triggered if the analog signal fluctuates from 3 to 5.

Page 51

ioLogik E1200 Series Using the Web Console

3-25

When Trigger = less, Value = 5, and Hysteresis = 1, the SNMP trap will only be triggered if the analog signal

fluctuates from 6 to 5, as depicted in Scenario 1 below. However, if we change the settings to Value = 5 and

Hysteresis = 2, the SNMP trap will only be triggered if the analog signal fluctuates from 7 to 5.

RTD Input Trap Settings

For RTD Input, the trap is triggered when the RTD input meets the preset conditions for Trigger, Value, and

Hysteresis. Refer to RTD Channel settings to set the Mode and Range.

Example:

When Trigger = Greater, Value = 400 and Hysteresis = 200, the SNMP trap will only be triggered if the RTD

signal fluctuates from 200 to 400, as depicted in Scenario 1 below. However, if we change the settings to Value

= 400 and Hysteresis = 400, the SNMP trap will only be triggered if the RTD signal fluctuates from 0 to 400.

When Trigger = less, Value = 400, and Hysteresis = 200, the SNMP trap will only be triggered if the RTD signal

fluctuates from 600 to 400, as depicted in Scenario 1 below. However, if we change the settings to Value = 400

and Hysteresis = 400, the SNMP trap will only be triggered if the RTD signal fluctuates from 800 to 400.

Page 52

ioLogik E1200 Series Using the Web Console

3-26

TC Input Trap Settings

For TC Input, the trap is triggered when the TC input meets the preset conditions for Trigger, Value, and

Hysteresis. Refer to the TC Channel settings to set the Mode and the Range.

Example:

When Trigger = Greater, Value = 400, and Hysteresis = 200, the SNMP trap will only be triggered if the TC

signal fluctuates from 200 to 400, like in scenario 1. If we change to Value = 400 and Hysteresis = 400, the

SNMP trap will only be triggered if the TC signal fluctuates from 0 to 400.

When Trigger = less, Value = 400, and Hysteresis = 200, the SNMP trap will only be triggered if the TC signal

fluctuates from 600 to 400, like in scenario 1. If we change to Value = 400 and Hysteresis = 400, the SNMP trap

will only be triggered if the TC signal fluctuates from 800 to 400.

Page 53

ioLogik E1200 Series Using the Web Console

3-27

Any host

Disable

Accessibility IP List

You can control network access to the ioLogik E1200 from the Accessibility IP List page by enabling access

only from specific IP addresses. When the Enable the accessibility IP list checkbox is enabled, a host’s IP

address must be provided and enabled in the list in order to gain access to the ioLogik E1200.

Enable access for a range of IP addresses by specifying the IP address and netmask, as follows:

To allow access for a specific IP address

Enter the IP address in the IP Address field and 255.255.255.255 in the Netmask field.

To allow access for hosts on a specific subnet

Enter 0 as the last digit in both the IP Address field and Netmask field (e.g., 192.168.1.0 and

255.255.255.0).

To allow unrestricted access

Deselect the Enable the accessible IP list option.

Refer to the following table for additional configuration examples.

Allowed Hosts IP Address/Netmask

192.168.1.120 192.168.1.120 / 255.255.255.255

192.168.1.1 to 192.168.1.254 192.168.1.0 / 255.255.255.0

192.168.0.1 to 192.168.255.254 192.168.0.0 / 255.255.0.0

192.168.1.1 to 192.168.1.126 192.168.1.0 / 255.255.255.128

192.168.1.129 to 192.168.1.254 192.168.1.128 / 255.255.255.128

Page 54

ioLogik E1200 Series Using the Web Console

3-28

NOTE

The

NOTE

The

allowed is

RESTful API Setting

The ioLogik E1200 supports RESTful API. To enable this API, select the Enable Restful API checkbox.

EtherNet/IP Setting

The ioLogik E1200 supports the EtherNet/IP protocol. To enable the protocol, select the Enable Ethernet/IP

Protocol checkbox.

EtherNet/IP function needs to be activated before it can be used. See Chapter 5 for details.

ioLogik E1200 series only supports EtherNet/IP adapter mode. The maximum number of connections

9 for read-only, and 1 for read/write.

System Management

Network Connection

TCP connections from other hosts appear on the Network Connection page. This information can assist you with

managing your devices.

Page 55

ioLogik E1200 Series Using the Web Console

3-29

WARNING

To avoid system failure while updating the firmware, follow the instructions

Firmware Update

Load new or updated firmware onto the ioLogik from the Firmware Update page.

Import System Configuration Settings

Import a configuration into the ioLogik server from the Import System Config page. This function can be used

to duplicate settings between ioLogik servers. You will be prompted for the location of the configuration file (i.e.,

“ik1212.txt”).

Export System Settings

given in Appendix I.

On the Export System Settings page, you can export a copy of the ioLogik’s configuration file for backup or

import into another ioLogik server.

Page 56

ioLogik E1200 Series Using the Web Console

3-30

NOTE

Password can only

ATTENTION

If you forget the password, the ONLY way to configure the ioLogik E1200 is by using the Reset button to load

the factory default settings.

Before you set a password

finished setting up your ioLogik E1200. Your configuration can then be easily imported back into the ioLogik

E1200 if you need to reset the ioLogik E1200 due to a forgotte

Change Password

To make any changes to the ioLogik E1200’s password protection settings, you will first need to enter the old

password. Leave the Old password field blank if you are setting up password protection for the first time. To

set up a new password or change the existing password, enter the new password (maximum of 16 characters)

in both the New password and Retype password fields. To remove password protection, leave the New

password and Retype password fields blank.

use English, numeric, or special characters e.g. ~!@#$%

for the first time, it is a good idea to export the configuration file when you have

Load Factory Defaults

This function will reset all of the ioLogik E1200’s settings to the factory default values. All previous settings,

including the console password, will be lost.

n password or for other reasons.

Save/Restart

If you change the configuration, do not forget to reboot the system.

Page 57

4

4. Using ioSearch™

This chapter describes ioSearch™, which is used to search for and locate ioLogik E1200 units.

The following topics are covered in this chapter:

Introduction to ioSearch™

ioSearch™ Main Screen

Main Screen Overview

ioSearch™ Setup

System

Sort

Quick Links

Main Function

Locate

Firmware Upgrade

Unlock

Import

Export

Change IP Address

Batch TCP/IP Configuration on Multiple Devices

Change Server Name

Activate EtherNet/IP

Restart System

Reset to Default

Mass Deployment (Import)

Mass Deployment (Export)

Page 58

ioLogik E1200 Series Using ioSearch™

4-2

3. Quick link

5

3

Introduction to ioSearch™

Moxa’s ioSearch™ utility is software tool that searches for ioLogik E1200 units on a physical network. The

following functions are supported by the ioSearch™ utility:

• Search for and locate ioLogik E1200 units

• Configure IP addresses

• Upgrade firmware for multiple ioLogik E1200 units (same model)

• Export configuration files from multiple ioLogik E1200 units

• Import configuration files from multiple ioLogik E1200 units (same model)

• Reset to default for multiple ioLogik E1200 units

• Activate the EtherNet/IP function for multiple ioLogik E1200 units (you will need to register the device

before activating it)

ioSearch™ Main Screen

Main Screen Overview

The main screen displays the results of a broadcast search for ioLogik E1200 units.

4

ioSearch™ Main Screen

1. Title

2. Menu bar

4. Navigation panel

5. Main window

Page 59

ioLogik E1200 Series Using ioSearch™

4-3

ioSearch™ Setup

System

Several operations are possible from the System menu.

Auto Scan Active Ethernet I/O Servers will search for ioLogik servers on the network. When connecting for

the first time or recovering from a network disconnection, you can use this command to find I/O servers that

are on the network.

Network Interface allows you to select a network to use, if the PC has multiple network adapters installed.

Page 60

ioLogik E1200 Series Using ioSearch™

4-4

4

Locate an ioLogik E1200

Sort

The Sort menu allows the server list in the navigation panel to be sorted by ioLogik connection and server

(model).

Quick Links

Quick links are provided to search for I/O servers on the network and sort the server list.

1 Automatically search the local network

2 Sort by ioLogik E1200’s IP address (connection)

3 Sort by ioLogik E1200 model

5 Upgrade Firmware

6 Import settings

7 Export settings

8 Unlock an ioLogik E1200 which is password protected

9 Change IP Address of an ioLogik E1200

Main Function

Right click on a particular ioLogik E1200 to view the ioSearch™ function menu.

Page 61

ioLogik E1200 Series Using ioSearch™

4-5

NOTE

If your product is using f

firmware version

ATTENTION

Do not interrupt the firmware update process! An interruption in the process may result in your device

becoming unrecoverable.

Locate

The locate function helps users find a dedicated ioLogik on the network. When this function is triggered, the

ready LED on the selected unit will start to blink indicating its location.

Firmware Upgrade

The ioLogik E1200 supports a remote firmware upgrade function. Enter the path to the firmware file or click on

the icon to browse for the file. The wizard will lead you through the process until the server is restarted.

.

irmware version V3.0 or higher, use ioSearch V2.0 or higher to upgrade to a newer

Batch Upgrades on Multiple Devices of the Same Model

Batch firmware upgrades are possible on multiple devices of the same ioLogik model. To upgrade multiple

models, press the “Shift” key, select “ioLogik”, and right click to process multiple firmware upgrades.

Page 62

ioLogik E1200 Series Using ioSearch™

4-6

Unlock

If an ioLogik E1200 is password protected, unlock the ioLogik E1200 by entering the password before using any

of the functions.

Import

Select this command to reload a configuration that was exported to a text file.

Importing one configuration file to multiple ioLogik E1200 units (same model) is allowed. To do this, press the

“Shift” key, select “ioLogik”, and then right click.

Export

The export function is used to export the current configuration file of an ioLogik E1200. The export file format

will be ik12xx.txt where “xx” represents the model type of the ioLogik E1200.

Exporting multiple files for different models of ioLogik E1200 is allowed. The file format is ik12xx_MAC

Address.txt, where the xx represents the model types of the ioLogik E1200.

e.g., ik1214_00-90-E8-66-32-19.txt

To export multiple configuration files, select the ioLogik and right click to process this function.

Page 63

ioLogik E1200 Series Using ioSearch™

4-7

Change IP Address

The Change IP Address function allows you to directly modify the IP address for one or multiple ioLogik E1200

series devices, and is especially useful for first time installation.

First, select the ioLogik E1200 device(s) you wish to modify. Then, right-click on the device(s) and select

Change IP Address from the dropdown menu to open the Change IP Address window. After changing the IP

address, click Set to complete setup, and search the network again to reveal the modified IP addresses.

Batch TCP/IP Configuration on Multiple Devices

Users can batch modify IP addresses, subnet masks, and gateways for devices of the same model from a single