Moxa Technologies ioLogik E1210, ioLogik E1211, ioLogik E1240, ioLogik E1212, ioLogik E1214 User Manual

Page 1

1

www.moxa.com

info@moxa.com

Industrial I/O

ioLogik E1200 Series

Introduction

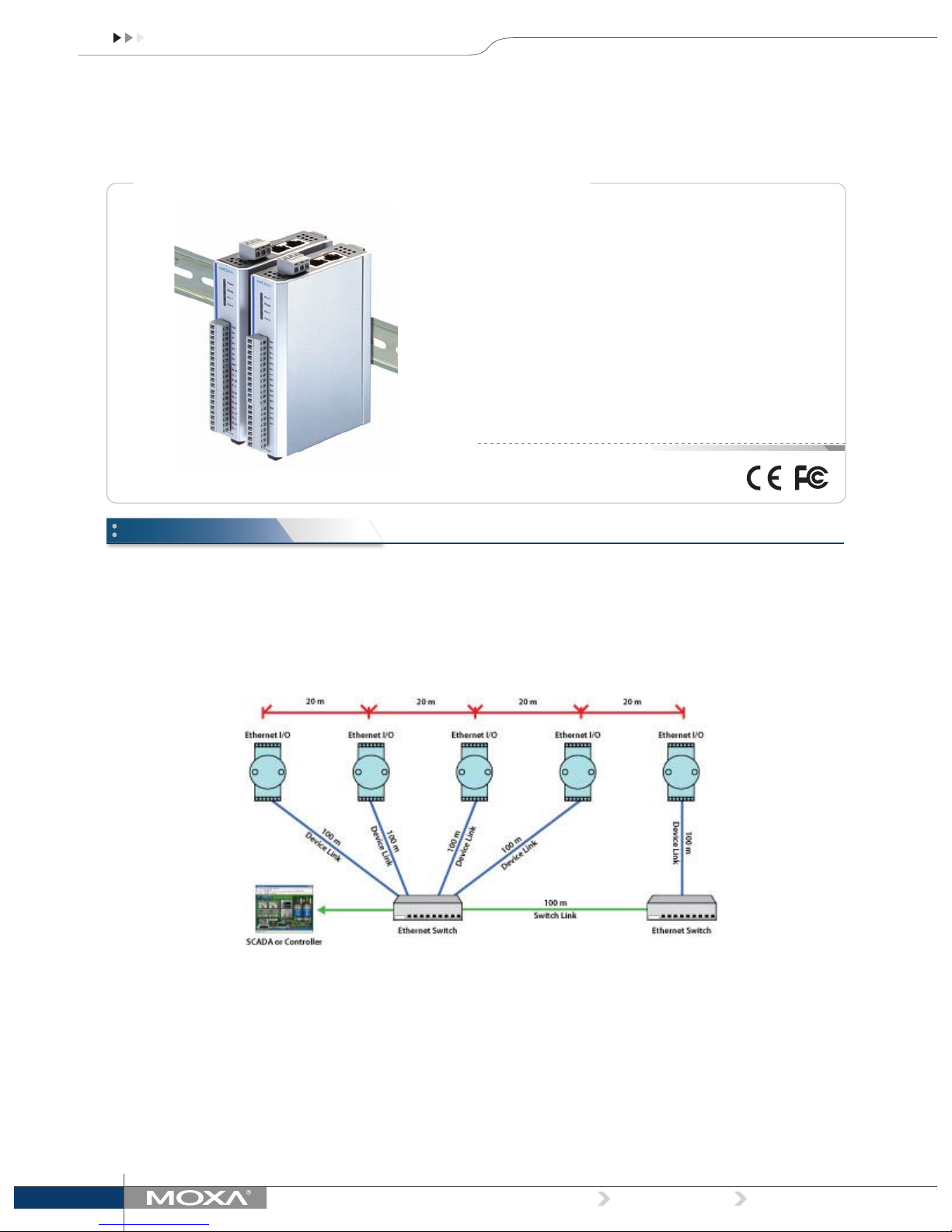

Star-topology for Ethernet Automation

Ethernet requires infrastructure equipment such as switches for

connecting a variety of different devices to the network. This is

unlike most field-bus automation networks that use a daisy-chain

topology, which presents a bit of a problem for Ethernet automation

applications since when connecting to Ethernet, meters and gauges

Remote Ethernet I/O with 2-port Ethernet Switch

Built-in 2-por t Ethernet switch for daisy-chain topologies ›

Free suppor t of Moxa’s push-based Active OPC Ser ver Lite ›

Seamlessly connect to any SCADA system ·

Save 80% on network bandwidth ·

I/O response that’s seven times fas ter ·

User-defined Modbus/TCP addressing ›

MXIO programming library for Windows and WinCE VB/ VC.NE T ›

and Linux C APIs

Web configuration with Import/Export function ›

must be formed in a “star” configuration. The ioLogik E1200 series

provides an alternative to spending the time and money needed to

figure out the best way to hook up your Ethernet switches. Since each

E1200 unit has two built-in Ethernet switches, the E1200 solution is

tailor-made for a daisy-chain type configuration.

Page 2

2

www.moxa.com

info@moxa.com

Industrial I/O

Efficient Ethernet Device Connectivity

The ioLogik E1200’s built-in Ethernet switch ports can be cascaded

to other Ethernet devices at the same location. A typical situation is a

remote site that has a few sensors, devices, and Internet connectivity.

Take a roadside cabinet as an example. The IP camera monitors

activity on the street and an Ethernet I/O device handles environmental

monitoring, intrusion, and alarms, and triggers the camera to take

snapshots when needed.

The traditional approach for this kind of remote monitoring application

requires an additional switch or hub for connecting the Ethernet I/O

device to the IP camera. A better approach is to connect another

Ethernet device such as a PLC controller or an IPC in the same cabinet

and use the industrial switch embedded in the ioLogik E1200. Not only

does this solution reduce the number of failure points associated with

an additional switch or hub, but it also reduces the amount of wiring

needed for power, signals, and the network. Space inside the cabinet

can also be saved.

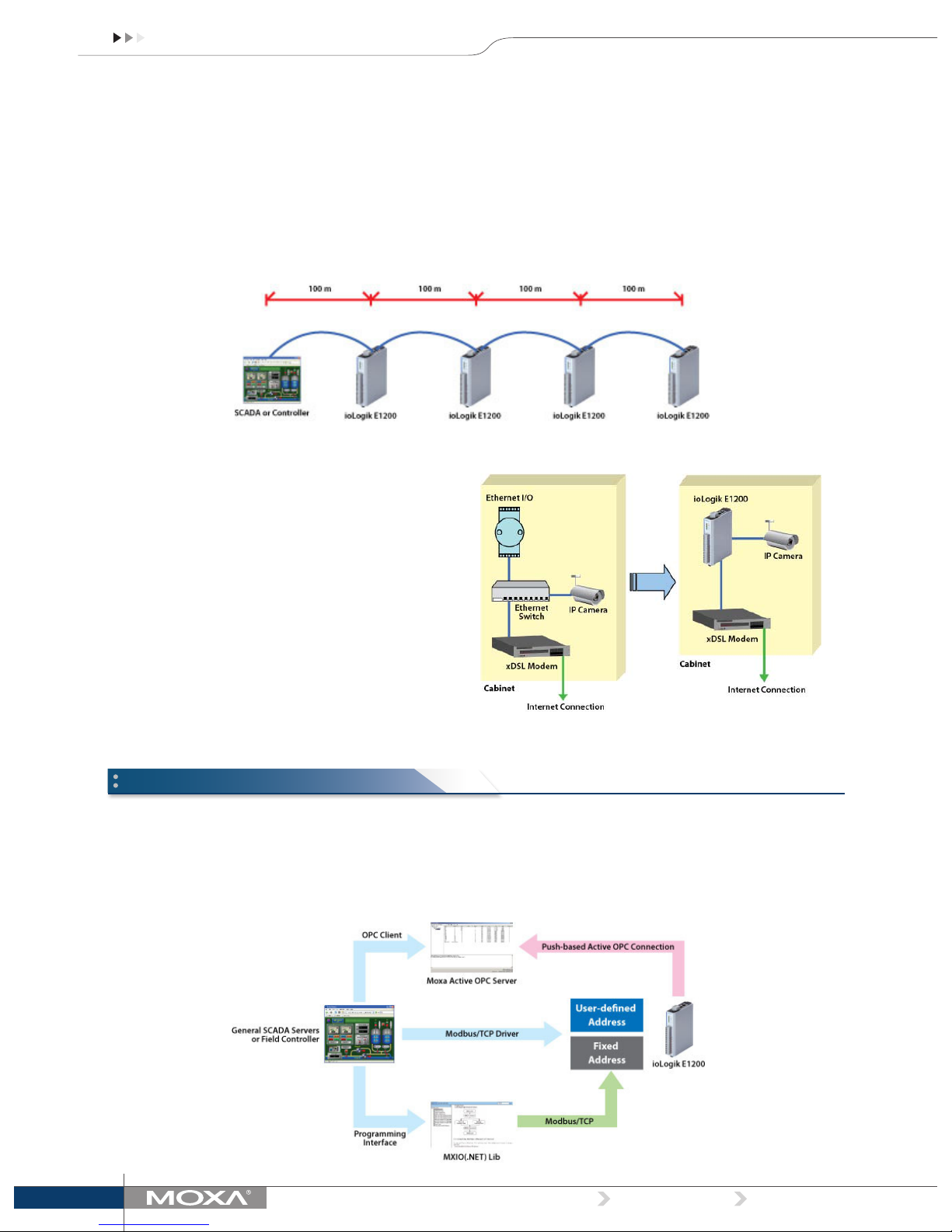

Daisy-chained Ethernet I/O Connection

A new daisy-chained Ethernet I/O concept is now available. The ioLogik

E1200 industrial remote Ethernet I/O has two embedded Ethernet

switch ports that allow information to flow to another local Ethernet

device or connect to the next ioLogik in the daisy-chain. Applications

such as factory automation, security and surveillance systems, and

tunnel monitoring, can make use of daisy-chained Ethernet for building

multi-drop I/O networks over standard Ethernet cables. Many industrial

automation users are familiar with the multi-drop configuration

typically used in fieldbus applications. The daisy-chain function on the

remote Ethernet I/O ioLogik E1200 not only increases the connection

between machines and panels, but also lowers the cost of buying

separate Ethernet switches, and at the same time reduces labor fees

and cabling by a large percentage. For example, if a production facility

contains 700 stations (20 points per station), the wiring cost reduction

can reach 15% of the total implementation cost.

Several approaches are available for controlling the ioLogik E1200

over an Ethernet network. As a traditional I/O solution, the ioLogik

E1200 allows a central SCADA system or field controller to poll the I/O

channel status via the standard, open Modbus/TCP protocol. Except

for the default fixed Modbus/TCP address, the ioLogik E1200 provides

the capability of letting users define the address by themselves. In

Smart I/O Connectivity

addition, the MXIO(.NET) library makes it easy for programmers to

integrate their own software to the ioLogik in the field. Moreover, the

ioLogik E1200 can leverage the benefits of the active technology of

the ioLogik E2000 series with the free Active OPC Server package to

seamlessly connect to any Windows-based SCADA system.

Page 3

3

www.moxa.com

info@moxa.com

Industrial I/O

Dynamic IP/WAN Connection

Active OPC Server Lite and ioLogik products provide the flexibility

of configuring the ioLogik E1200 to use dynamic IP addresses. The

ioLogik E1200 connects directly to the Active OPC Server Lite instead

of being polled, which makes dynamic IP addressing and WAN Access

Free Push-based Active OPC Server Lite Package

Active OPC Server Lite is a free software package provided by Moxa

that operates as an OPC driver for an HMI or SCADA system. General

OPC servers typically use the “poll/response,” or so-called “pull”

architecture, to connect to Ethernet I/O devices, which involves an

HMI/SCADA system continuously sending out commands to collect

relevant data. Moxa’s Active OPC Server Lite, with its non-polling

OPC Connection to SCADA

Critical T ests Say It BestCritical T ests Say It Best

Test 1: Network T raffic Comparison

This test used 32 ioLogik E2210 units with 640 DI/O points. As shown in the figure, Active Ethernet

I/O can save 80% on bandwidth consumption compared to passive Ethernet I/O.

Test 2: I/O Status Response Time

This test used 128 ioLogik E2210 units with 2,560 I/O points. As shown in the figure, the active

architecture is 7 times better than the passive architecture in response time when the I/O status

changes.

Reduce Bandwidth Consumption by 80%

Active Ethernet I/O

Passive Ethernet I/O

0 1 2 3 4 5

0 1 2 3 4 5 6 7

7 Times Faster

Active Ethernet I/O

Passive Ethernet I/O

architecture, supports the standard OPC protocol, but also offers active

(or “push”) communication with Moxa’s ioLogik series of Ethernet

I/O products to HMI/SCADA systems, providing instant I/O status

reports with “Active Tags.” The event-driven active tags result in an I/O

response time that is 7 times faster than other OPC Server packages,

and results in an apparent 80% reduction in network traffic.

to the Ethernet I/O device possible, and adds even greater flexibility by

allowing connections across firewalls. I/O devices for traditional data

acquisition applications are not capable of using this approach.

Push-based Active OPC Server

Active OPC Server Router

Remote I/O Remote I/O Remote I/O

ioLogikRouter

Internet and Dynamic IP

Connection

Pull-based OPC Server

General OPC Server

Local Network and Fixed IP Connection only

Polls continuously

No polling required

Page 4

4

www.moxa.com

info@moxa.com

Industrial I/O

Patented Automatic Tag Generation

Patented “Auto Tag Generation” eliminates the headache of specifying

target IP addresses, I/O channels, and data formats one by one, or

editing and importing configuration text files since Active OPC Server

Lite creates the tags for the target ioLogik automatically. One of the

biggest payoffs is that users will no longer need to be trained to install

and configure your OPC system, since setting up Active OPC Server

Lite is done automatically with a single click of the mouse.

ioLogik

It takes 5 seconds to create 20 or more tags

It takes 2.5 min.

to create only

1 tag

General OPC Server

Create Tags

Create Tags

5 steps for channels, interfaces, and protocol definition: takes 20 seconds.

13 steps for device, IP address, and other communication parameters: takes 30 seconds.

Select channels and press button to update configuration: takes 5 seconds.

1 step for looking up address table: takes 100 seconds.

Active OPC Server

To control an input or output channel of a remote Ethernet I/O device

running the most general Modbus/TCP protocol requires specifying

the Modbus address of those input and output channels. This can take

quite a bit of effort since you may need to look up the address and data

type in the user’s manual for address mapping, and can also cause

problems once the I/O channels change or a device is replaced.

User-defined Modbus Addressing

The ioLogik E1200’s user-defined Modbus addressing offers the

flexibility to make the Modbus address dynamic, and the address can

be configured to be compatible with other Modbus devices. When a

system is being replicated, or the filed I/O is being replaced, the userdefined Modbus eliminates the effort of reconfiguring the PC control

software or field controller.

Mechanical Design

DIN and Wall Mountable

The ioLogik E1200 is designed with a vertical form factor, and can be

used with both DIN-Rail and Wall Mounting.

Stress-relief for Solid Wiring

A stress-relief connector at the bottom of the ioLogik E1200 helps

prevent the wiring from being pulled out.

Page 5

5

www.moxa.com

info@moxa.com

Industrial I/O

Specifications

84

124

132

27

27.8

Dimensions (unit = mm)

Side ViewFront View Rear View

Top View

Down View

LAN

Ethernet: 2 x 10/100 Mbps switch ports, RJ45

Protection: 1.5 KV magnetic isolation

Protocols: Modbus/TCP, TCP/IP, UDP, DHCP, Bootp, HTTP

Analog Input (for ioLogik E1240)

Type: Differential input

Resolution: 16 bits

I/O Mode: Voltage / Current

Input Range: 0 to 10 VDC, 4 to 20 mA

Accuracy:

±0.1% FSR @ 25°C

±0.3% FSR @ -10 and 60°C

Sampling Rate (all channels): 12 samples/sec

Input Impedance: 10M ohms (minimum)

Built-in Resistor for Current Input: 120 ohms

Digital Input (for ioLogik E1210/E1212/E1214)

Sensor Type: NPN, PNP, and Dry contact

I/O Mode: DI or Event Counter

Dry Contact:

• Logic 0: short to GND

• Logic 1: open

Wet Contact:

• Logic 0: 0 to 3 VDC

• Logic 1: 10 to 30 VDC (DI COM to DI)

Isolation: 3K VDC or 2K Vrms

Counter/Frequency: 250 Hz, power off storage

Digital Output (for ioLogik E1211/E1212)

I/O Mode: DO or Pulse Output (up to 500 Hz)

Pulse Wave Width/Frequency: 1 ms/500 Hz

Over-voltage Protection: 45 VDC

Over-current Limit: 600 mA per channel

Over-temperature Shutdown: 175°C (typical), 150°C (min.)

Output Current Rating: Max. 200 mA per channel

Isolation: 3K VDC or 2K Vrms

Relay Output (for ioLogik E1214)

Type: Form A (N.O.) relay outputs, 5A

Contact Rating: 5 A @ 30 VDC, 5 A @ 250 VAC, 5 A @ 110 VAC

Inductance Load: 2 A

Resistance Load: 5 A

Breakdown Voltage: 500 VAC

Relay On/Off Time: 1500 ms (Max.)

Initial Insulation Resistance: 1G min. @ 500 VDC

Expected Life: 100,000 times (Typical)

Initial Contact Resistance: 30 milli-ohms (Max.)

Pulse Output: 0.3 Hz at rated load

Power Requirements

Power Input: 24 VDC nominal, 12 to 36 VDC

Power Consumption: 130 mA typical @ 24 VDC

Physical Characteristics

Wiring: I/O cable max. 14AWG

Dimensions: 27.8 x 124 x 84 mm (1.09 x 4.88 x 3.31 in)

Weight:

ioLogik E1210: 171 g

ioLogik E1211: 187 g

ioLogik E1212: 171 g

ioLogik E1214: 177 g

ioLogik E1240: 179 g

Environmental Limits

Operating Temperature: -10 to 60°C (14 to 140°F)

Storage Temperature: -40 to 85°C (-40 to 185°F)

Ambient Relative Humidity: 5 to 95% (non-condensing)

Regulatory Approvals

EMI: FCC Part 15, CISPR (EN55022) class A

EMS: IEC 61000-4, IEC 61000-6

Shock: IEC 60068-2-27

Freefall: IEC 60068-2-32

Vibration: IEC 60068-2-6

Warranty

Warranty Period: 2 years

Details: See www.moxa.com/warranty

Page 6

6

Industrial I/O

© Moxa Inc. All Rights Reserved. Updated Oct. 22, 2009. Specifications subject to change without notice. Please visit our website for the most up-to-date product information.

I/O Pin Assignment

ioLogik E1211

(top to bottom)

1 COM 0

2 DI0

3 DI1

4 DI2

5 DI3

6 GND

7 DI4

8 DI5

9 DI6

10 DI7

11 COM 1

12 DI8

13 DI9

14 DI10

15 DI11

16 GND

17 DI12

18 DI13

19 DI14

20 DI15

ioLogik E1212

(top to bottom)

1

2 DO0

3 DO1

4 DO2

5 DO3

6 GND

7 DO4

8 DO5

9 DO6

10 DO7

11

12 DO8

13 DO9

14 DO10

15 DO11

16 GND

17 DO12

18 DO13

19 DO14

20 DO15

1 COM

2 DI0

3 DI1

4 DI2

5 DI3

6 DI4

7 DI5

8 GND

9 R0_NO

10 R0_C

11 R1_NO

12 R1_C

13 R2_NO

14 R2_C

15 R3_NO

16 R3_C

17 R4_NO

18 R4_C

19 R5_NO

20 R5_C

1 AI0+

2 AI03 AI1+

4 AI15 AI2+

6 AI27 AI3+

8 AI39 AI4+

10 AI411 AI5+

12 AI513 AI6+

14 AI615 AI7+

16 AI717

18

19

20

ioLogik E1214

(top to bottom)

ioLogik E1240

(top to bottom)

1 COM0

2 DI0

3 DI1

4 DI2

5 DI3

6 GND

7 DI4

8 DI5

9 DI6

10 DI7

11 COM1

12 DIO0

13 DIO1

14 DIO2

15 DIO3

16 GND

17 DIO4

18 DIO5

19 DIO6

20 DIO7

ioLogik E1210

(top to bottom)

Ordering Information

Available Models

ioLogik E1210: Remote Ethernet I/O with 2-port Ethernet switch and 16 DIs

ioLogik E1211: Remote Ethernet I/O with 2-port Ethernet switch and 16 DOs

ioLogik E1212: Remote Ethernet I/O with 2-port Ethernet switch, 8 DIs, and 8 DIOs

ioLogik E1214: Remote Ethernet I/O with 2-port Ethernet switch, 6 DIs, and 6 Relays

ioLogik E1240: Remote Ethernet I/O with 2-port Ethernet switch and 8 AIs

Loading...

Loading...