Moxa Technologies ioLogik 2542-GPRS, ioLogik 2512-GPRS, ioLogik 2512, ioLogik 2512-HSPA, ioLogik 2542-HSPA User Manual

...Page 1

ioLogik 2500 Series User’s Manual

Edition 7.0, March 2018

www.moxa.com/product

© 2018 Moxa Inc. All rights reserved.

Page 2

ioLogik 2500 Series User’s Manual

Moxa

Toll

Tel:

Fax:

Moxa China (Shanghai office)

Toll

Tel:

Fax:

Moxa Europe

Tel:

Fax: +49-89-3 70 03 99-99

Moxa As

Tel:

Fax: +886-2-8919-1231

Moxa India

Tel:

Fax:

The software described in this manual is fur nis he d und er a license agr eem e nt and may be used only in accor d ance

with the terms of that agreement.

Copyright Notice

© 2018 Moxa Inc. All rights reserved.

Trademarks

The MOXA logo is a registered trademark of Moxa Inc.

All other trademarks or registered marks in this manual belong to their res pec tive manufacturers.

Disclaimer

Information in this document is subject to c hange witho ut no ti c e and doe s not represent a commitment on the part of

Moxa.

Moxa provides this document as is, without warr anty of any kind, either expressed or implied, including, b ut not

limited to, its particular purpose. Mox a re serv e s the rig ht to mak e improv e ments and /or change s to this ma nual, or to

the products and/or the programs described in this manual, a t any time .

Information provided in this manual is intended to be accurate and reliable. However, Moxa assumes no responsibility

for its use, or for any infringements on the rights of third parties that ma y res ult from its use .

This product might include unintentional tec hnic al or typographical errors. Changes are periodic ally made to the

information herein to correct such errors, and these changes are incorporated into new editions of the public ation.

Technical Support Contact Information

www.moxa.com/support

Americas

-free: 1-888-669-2872

+1-714-528-6777

+1-714-528-6778

+49-89-3 70 03 99-0

-free: 800-820-5036

+86-21-5258-9955

+86-21-5258-5505

ia-Pacific

+886-2-8919-1230

+91-80-4172-9088

+91-80-4132-1045

Page 3

Table of Contents

1. Overview ........................................................................................................................................... 1-1

ioLogik 2500 Overview ........................................................................................................................ 1-2

Appearance ................................................................................................................................ 1-2

Dimensions Diagram .................................................................................................................... 1-3

Package Checklist ........................................................................................................................ 1-3

Product Features ......................................................................................................................... 1-3

I/O Channels Available on ioLogik 2500 Models ............................................................................... 1-3

Communication Interface ............................................................................................................. 1-4

ioLogik 2500 Ethernet Series Specifications ............................................................................................ 1-4

Common Specifications ................................................................................................................ 1-4

ioLogik 2512 Ethernet Specifications .............................................................................................. 1-5

ioLogik 2542 Ethernet Specifications .............................................................................................. 1-6

ioLogik 2500 HSPA/GPRS/WLAN Series Specifications.............................................................................. 1-7

Common Specifications ................................................................................................................ 1-7

ioLogik 2512 HSPA/GPRS/WLAN Specifications ................................................................................ 1-8

ioLogik 2542 HSPA/GPRS/WLAN Specifications ................................................................................ 1-9

2. Installation ....................................................................................................................................... 2-1

Hardware Installation .......................................................................................................................... 2-2

Installing the ioLogik 2500 on a DIN Rail ........................................................................................ 2-2

Removing the ioLogik 2500 from a DIN Rail .................................................................................... 2-2

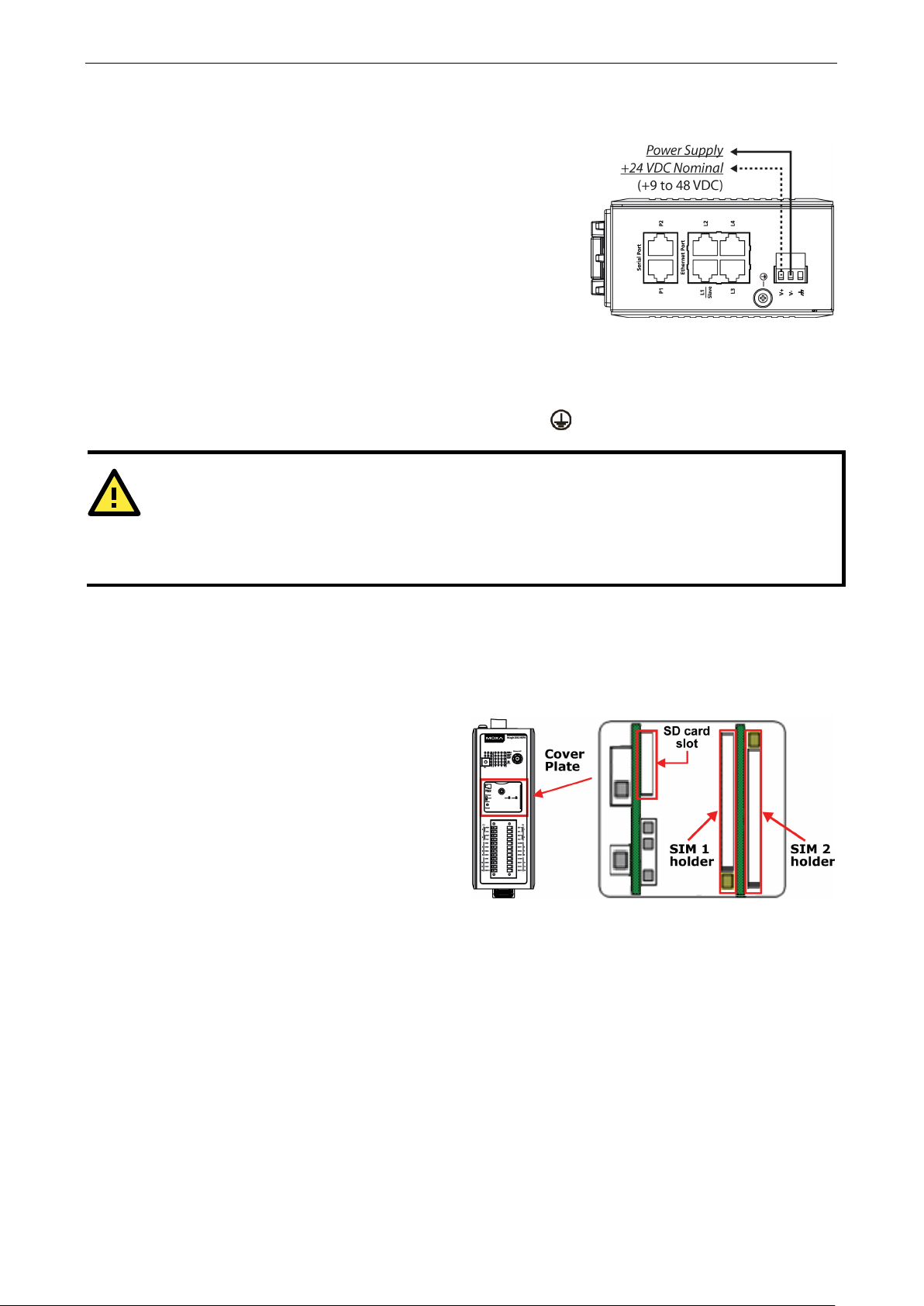

Powering on the ioLogik 2500 ............................................................................................................... 2-3

Grounding the Unit ............................................................................................................................. 2-3

Installing a microSD Card and SIM Cards (cellular m ode ls only) ............................................................... 2-3

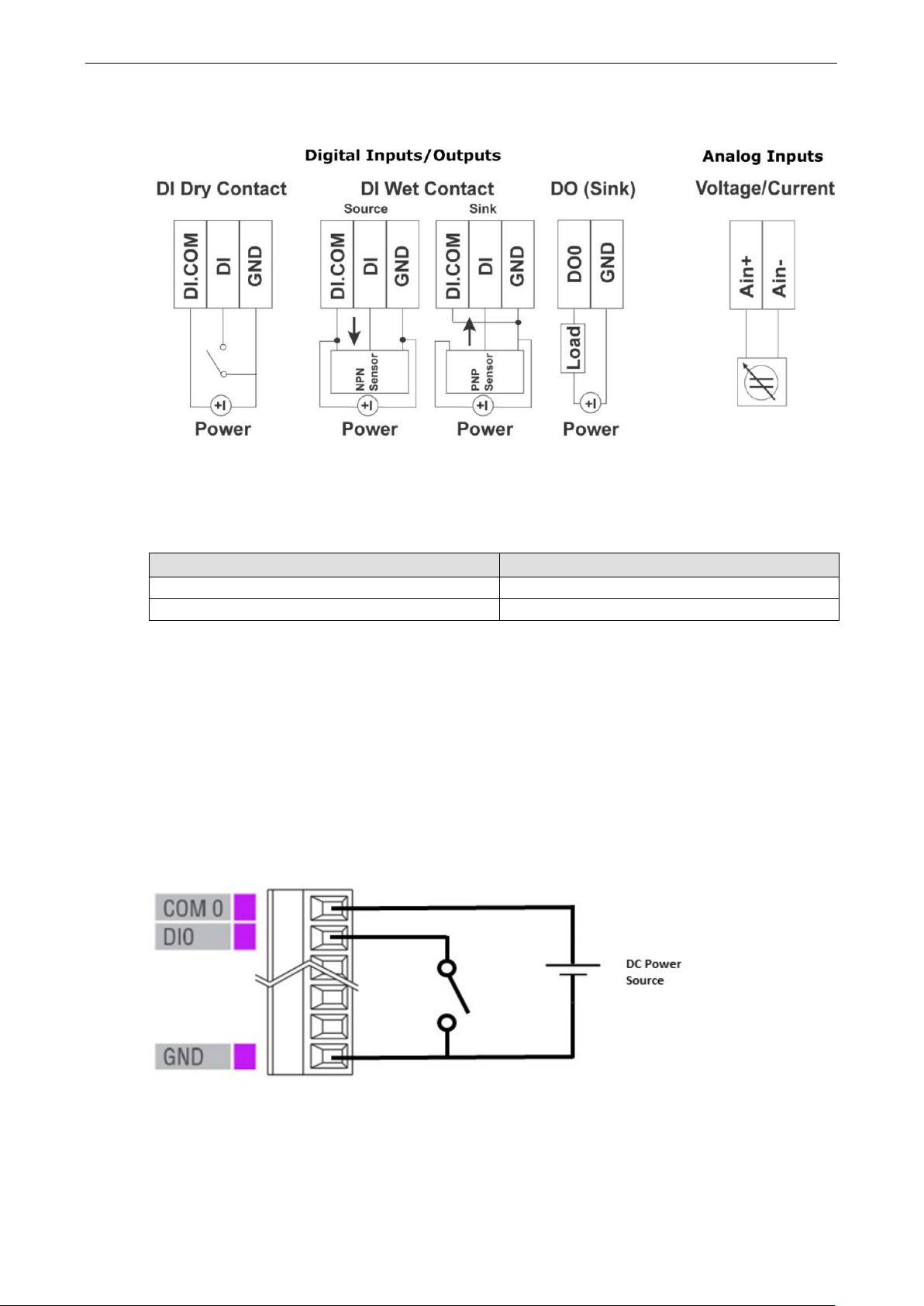

I/O Wiring Diagrams ........................................................................................................................... 2-4

I/O Wiring ......................................................................................................................................... 2-4

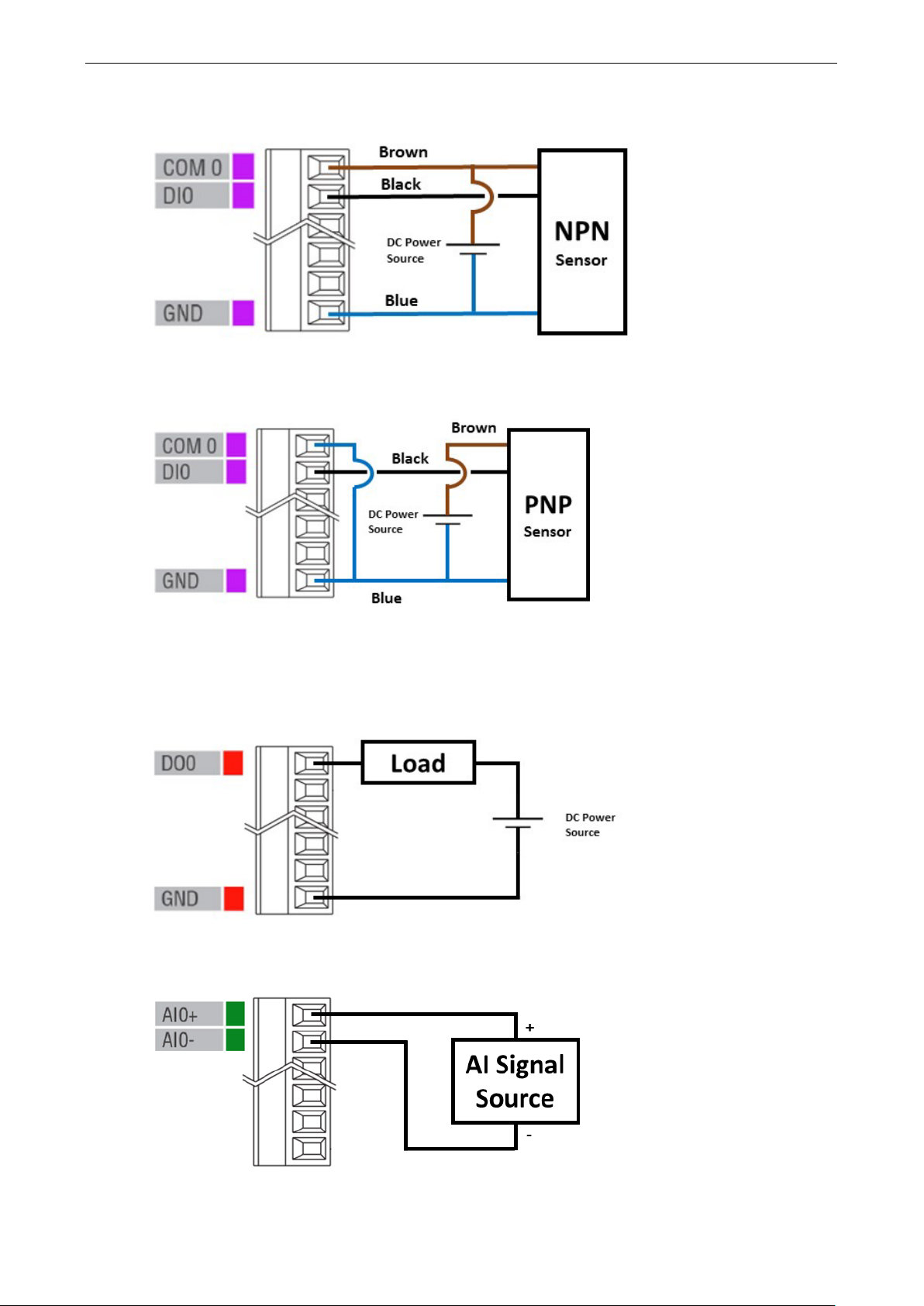

DI Channel ................................................................................................................................. 2-4

DO Channel (Sink Type) ............................................................................................................... 2-5

AI Channel ................................................................................................................................. 2-5

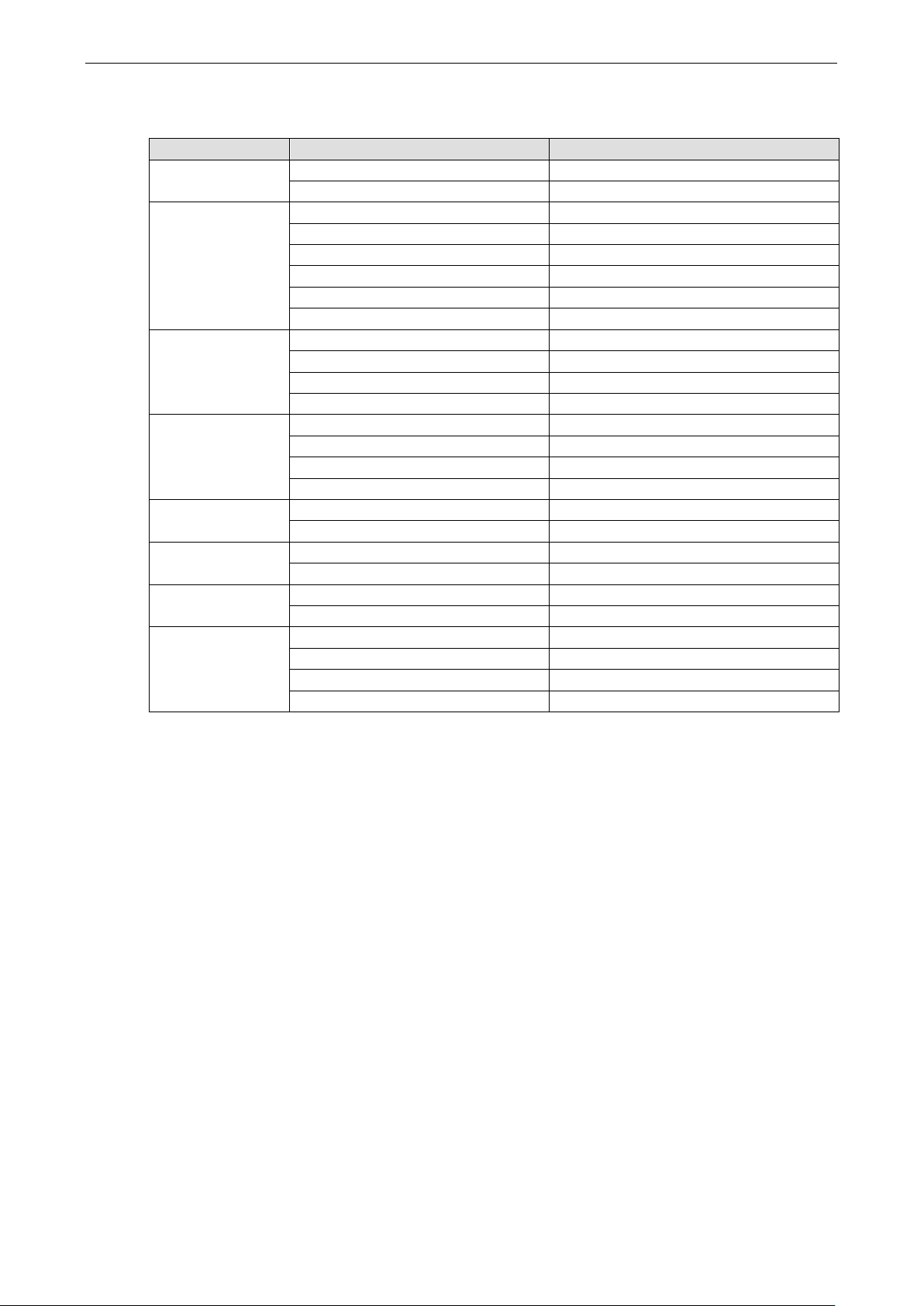

LED Indicators .................................................................................................................................... 2-6

Daisy-Chaining for I/O Expansion ......................................................................................................... 2-7

Reset to Factory Defaults ..................................................................................................................... 2-8

Network Installation ............................................................................................................................ 2-8

Ethernet Communication .............................................................................................................. 2-8

TCP/IP Settings ........................................................................................................................... 2-8

Serial Communication .................................................................................................................. 2-9

Software Installation—IO xp r ess U tility ................................................................................................. 2-10

System Requirements ................................................................................................................ 2-10

Installing IOxpress .................................................................................................................... 2-10

3. The IOxpress Utility .......................................................................................................................... 3-1

Application Interface ........................................................................................................................... 3-2

Main Screen................................................................................................................................ 3-2

Menu Bar ................................................................................................................................... 3-2

Using IOxpress ................................................................................................................................... 3-3

Configuration Flowchart ....................................................................................................................... 3-3

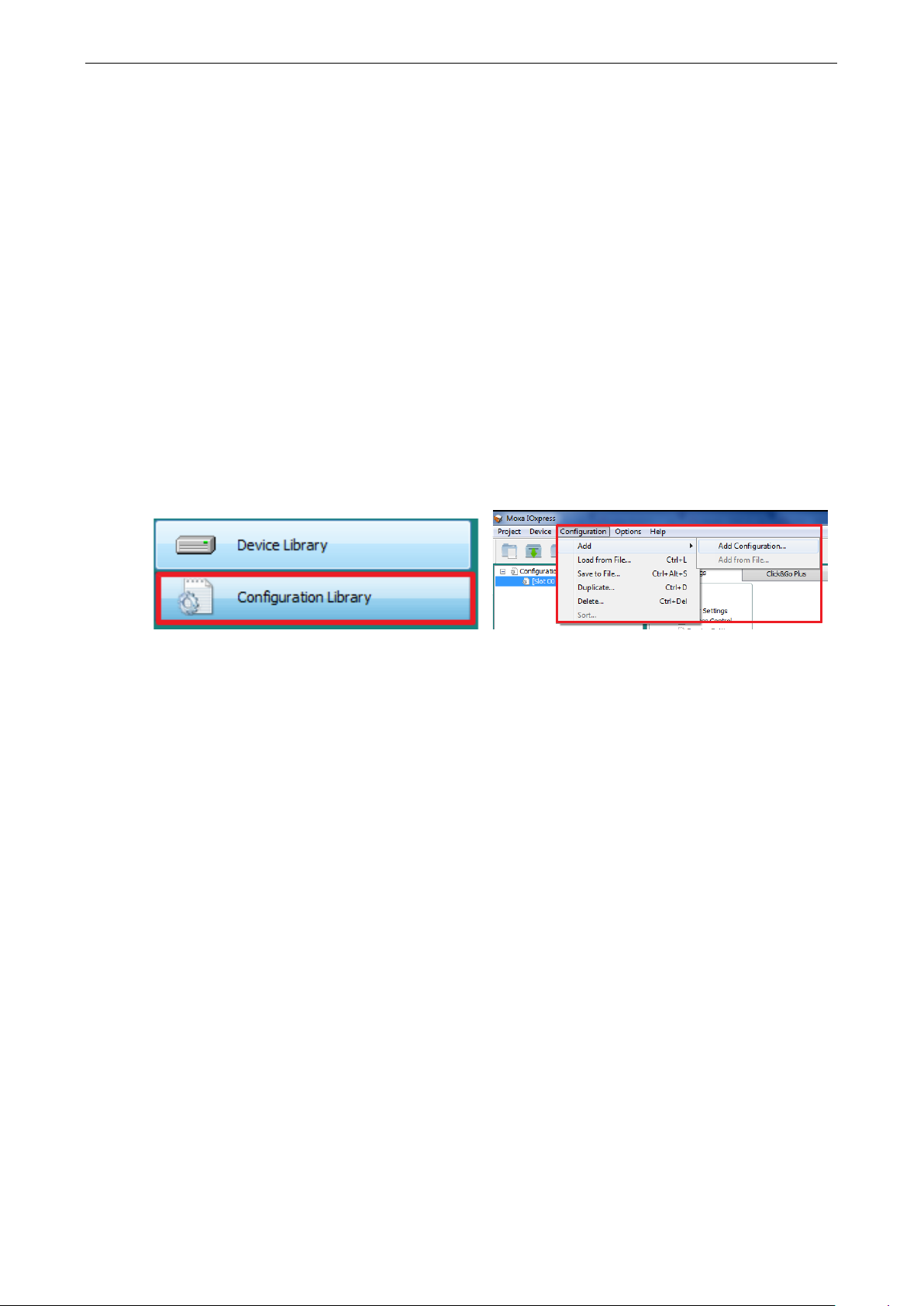

Configuration Library ................................................................................................................... 3-3

Device Library ............................................................................................................................. 3-3

4. Configuration Library ........................................................................................................................ 4-1

Introduction ....................................................................................................................................... 4-2

Saving Configurations as a Project ................................................................................................. 4-2

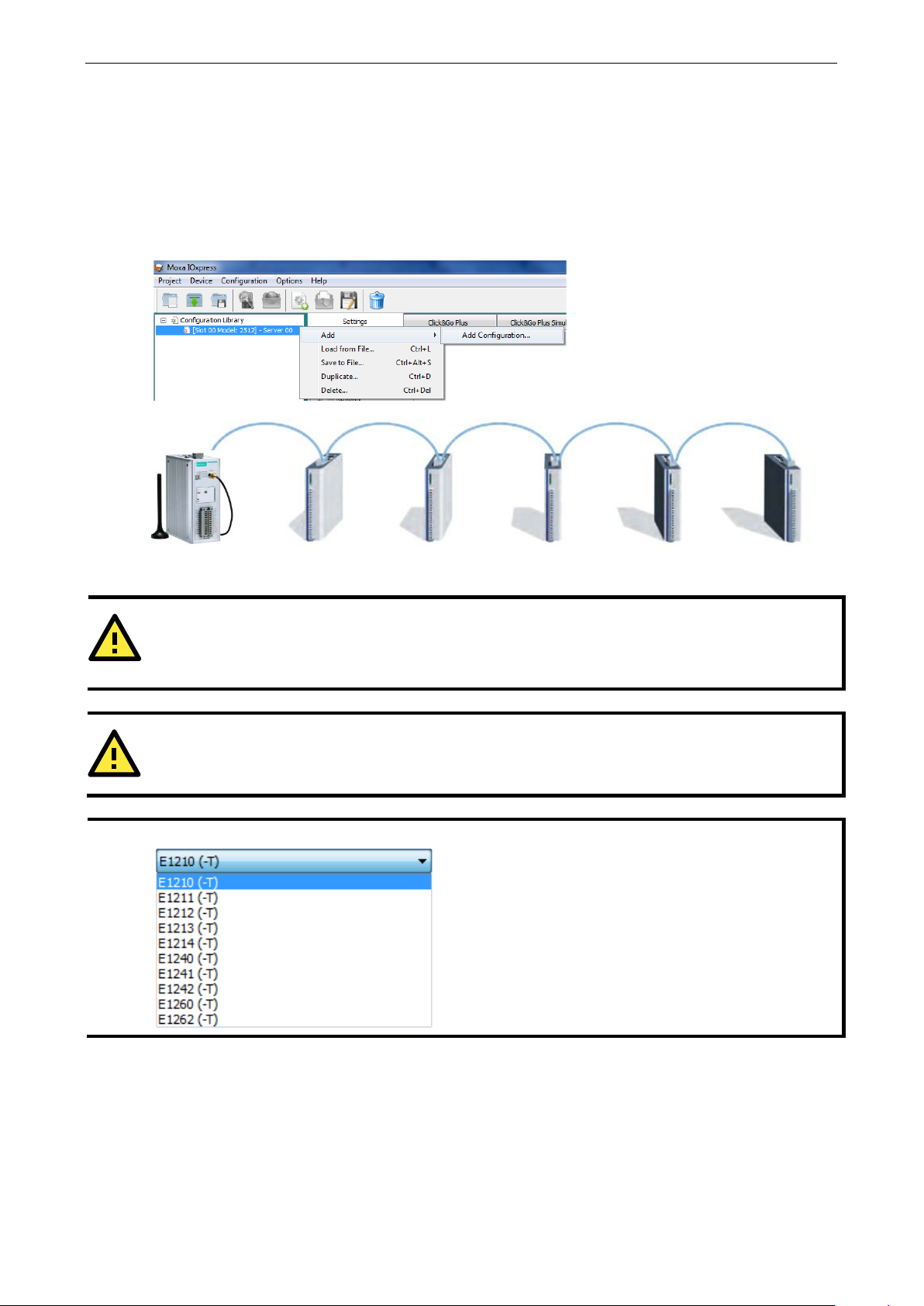

Adding an ioLogik 2500 Device to a Project .................................................................................... 4-2

Adding E1200 I/O Expansion Modules to a Project ........................................................................... 4-3

Duplicate Device Configuration for Mass Deployment ....................................................................... 4-4

Setting Up a Device ............................................................................................................................ 4-5

Settings Tab ...................................................................................................................................... 4-5

System ...................................................................................................................................... 4-5

Security ..................................................................................................................................... 4-6

Network ..................................................................................................................................... 4-8

I/O .......................................................................................................................................... 4-10

AOPC ....................................................................................................................................... 4-18

SNMP ....................................................................................................................................... 4-20

Modbus/TCP Slave ..................................................................................................................... 4-21

Modbus/TCP Master ................................................................................................................... 4-22

Serial Port (Port1/Port2)............................................................................................................. 4-25

Data Logging ............................................................................................................................ 4-28

Click&Go Plus ............................................................................................................................ 4-31

Click&Go Plus Tab ............................................................................................................................. 4-32

Click&Go Plus Simulator Tab .............................................................................................................. 4-32

Page 4

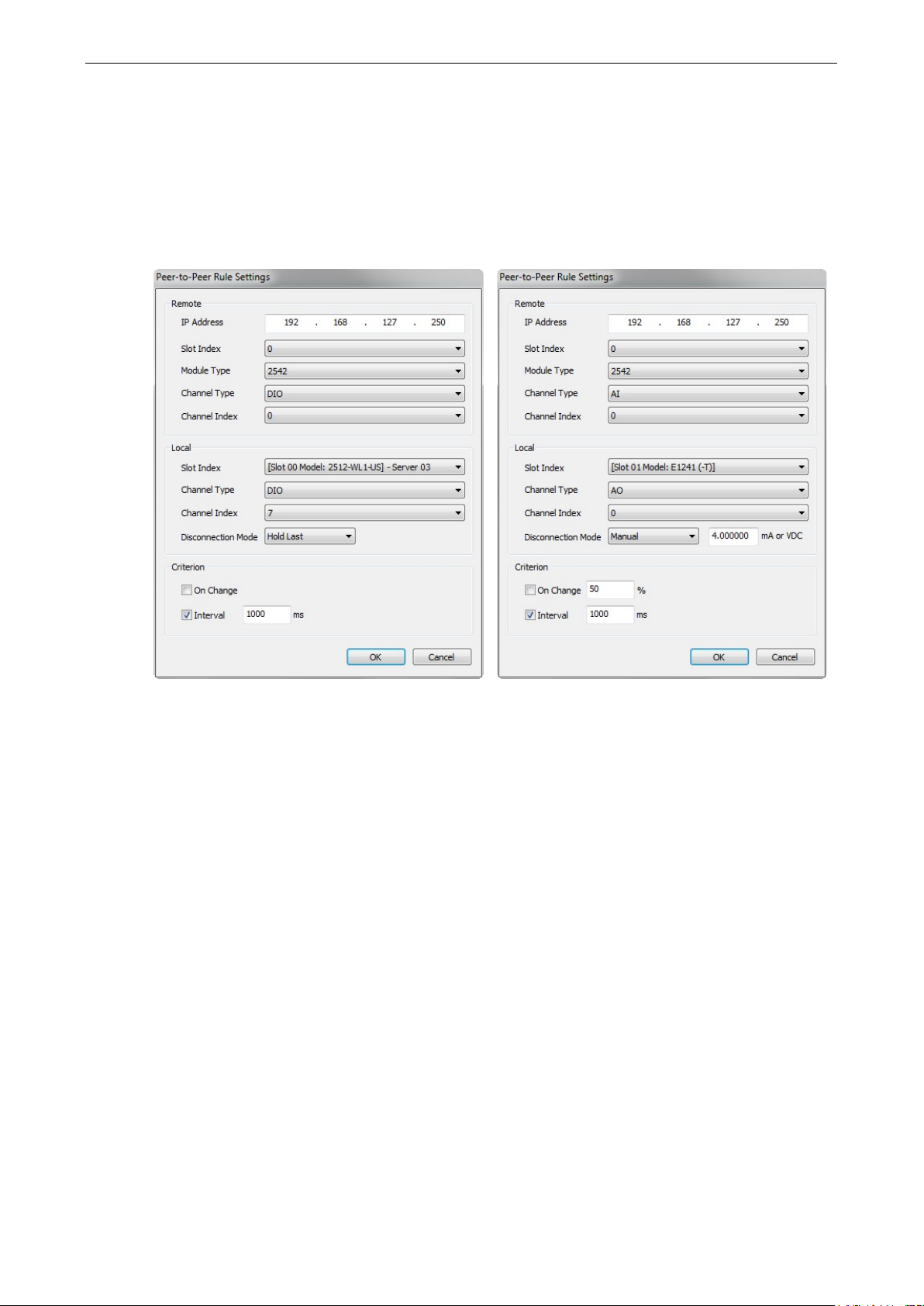

Peer-to-Peer Tab .............................................................................................................................. 4-32

General Settings ....................................................................................................................... 4-33

Peer-to-Peer Rule Settings ......................................................................................................... 4-34

5. Device Library ................................................................................................................................... 5-1

Introduction ....................................................................................................................................... 5-2

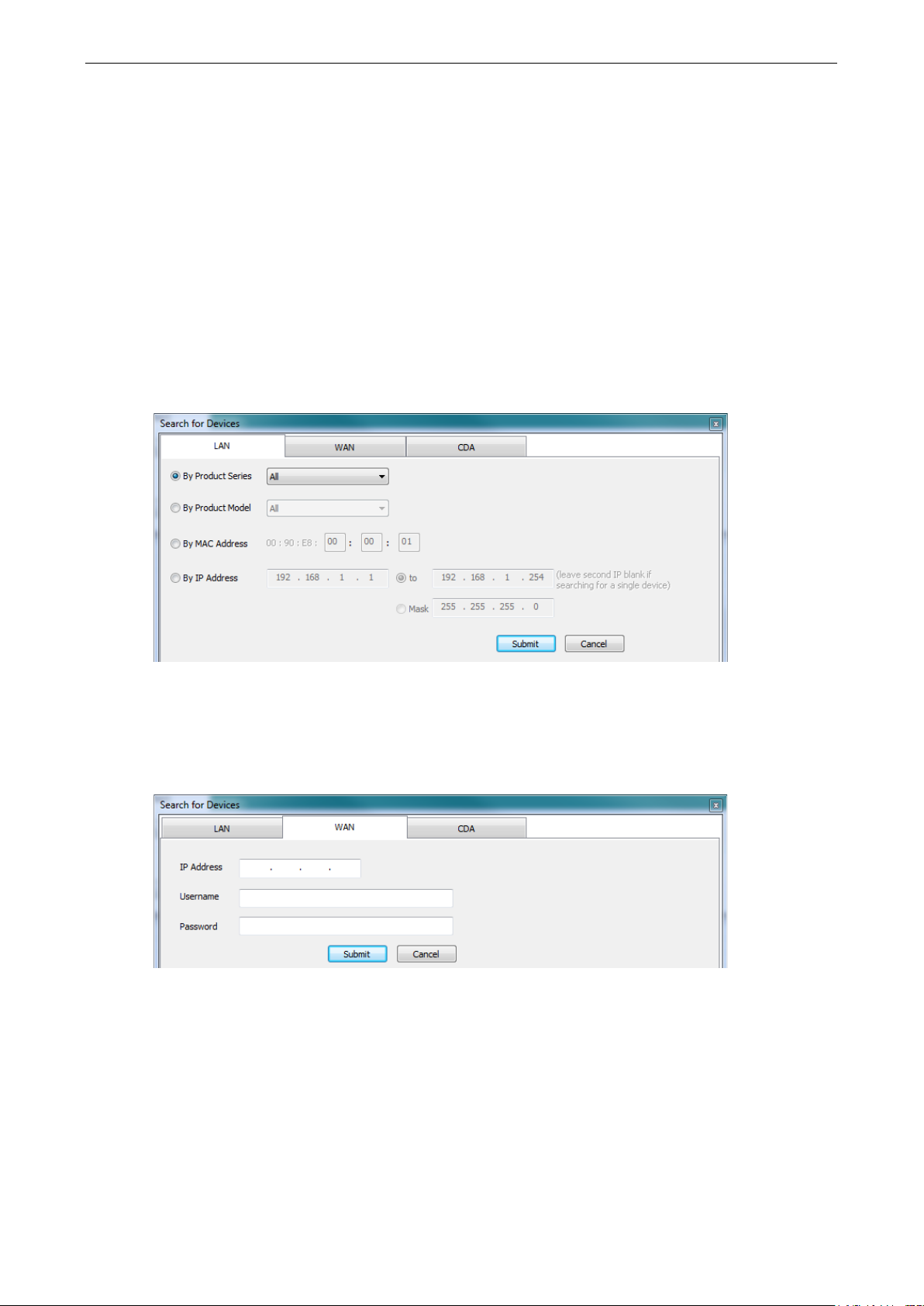

Auto-Searching for Online Devices ........................................................................................................ 5-3

First Time Searching for Devices ................................................................................................... 5-3

Conducting another Search for Online Devic e s ................................................................................ 5-3

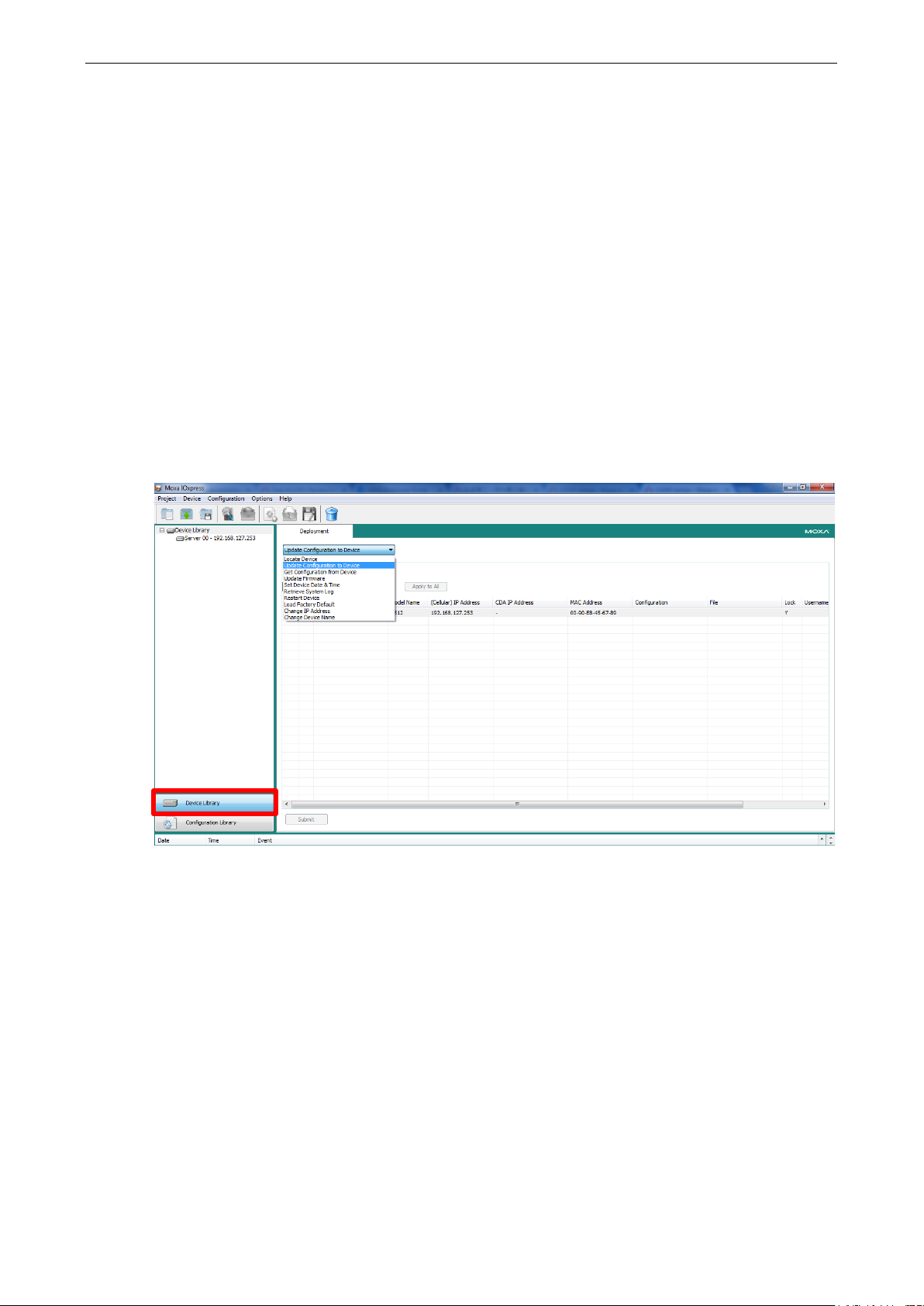

Deployment ....................................................................................................................................... 5-6

Update Configuration to Device ..................................................................................................... 5-7

Get Configuration from Device ...................................................................................................... 5-7

Update Firmware ......................................................................................................................... 5-7

Set Device Date & Time ............................................................................................................... 5-8

Retrieve System Log .................................................................................................................... 5-8

Restart Device ............................................................................................................................ 5-8

Load Factory Default .................................................................................................................... 5-8

Change IP Address ...................................................................................................................... 5-8

Change Device Name ................................................................................................................... 5-8

Web Console ...................................................................................................................................... 5-8

Web Console Functions ........................................................................................................................ 5-9

User Interface Introduction ........................................................................................................... 5-9

System Information Panel .......................................................................................................... 5-10

Menu Panel and Web Pages ........................................................................................................ 5-10

6. Cellular Network Setup and Configuration (for cellular models) ....................................................... 6-1

IOxpress Settings for a Cellular Network ................................................................................................ 6-2

Select Network Interface .............................................................................................................. 6-2

Cellular ...................................................................................................................................... 6-3

Cellular Network Connection .............................................................................................................. 6-10

MX-AOPC Server (for SCADA/HMI user s) ...................................................................................... 6-10

With DDNS (for SCADA/HMI users) .............................................................................................. 6-11

Moxa Cellular Data Access Utility (for mobile dev ic es/PCs) .............................................................. 6-11

7. Wireless LAN Networ k S et up and Conf i gur a tion (for wireless LAN m od els) ...................................... 7-1

Deploying the ioLogik 2500-WL1........................................................................................................... 7-2

IOxpress Settings for a Wireless LAN Network ........................................................................................ 7-2

Wireless LAN .............................................................................................................................. 7-2

A. Network Port Usage .......................................................................................................................... A-1

B. Modbus/TCP D efa ult Addre ss Mappings ............................................................................................ B-1

ioLogik 2512 Series Modbus Address and Register Map............................................................................ B-1

ioLogik 2542 Series Modbus Address and Regis ter Map............................................................................ B-2

C. RESTful API Default Add re ss Ma ppings ............................................................................................. C-1

API List ............................................................................................................................................. C-1

Response Code ................................................................................................................................... C-6

Page 5

1

1. Overview

The ioLogik 2500 is a smart remote I/O product with unique hard w are and softw are des igns, m ak i ng it an

ideal solution for a variety of industrial d ata acquis iti o n app lic ati o ns . The ioLogik 2500’s hardware design

includes a 4-port unmanaged Etherne t s w itc h and 2 ser ial ports , enab ling the ioLogik 2500 to seamlessly

connect to a variety of field devices. One of the Ethernet ports ca n be used to link to 8 daisy-chained

ioLogik E1200 expansion modules to provide more than 100 c hanne ls . The ioLogik 2500 acts as the “head”

unit, with Click&Go Plus logic used to control the entire I /O array. Mo st importantly, the ioLogik 2500’s

single IP is all that’s required to connect the entir e I/O arr ay to your netwo rk , providing the perfect solution

for industrial field sites that have an insuf f i c ie nt number of IP addre sse s .

For cellular connections, the ioLogik 2500 supports Moxa’s patented MX-AOPC Server with push

communications technology, and pr ov id es an econo mical solution for accessing multiple remote I/O devi ces

connected to the same private IP network, which itself links to the outside world over a cellular connection

using dynamic IP addresses.

The following topics are covered in this chapter:

ioLogik 2500 Overview

Appearance

D im e ns io ns D iagr am

Pac k a g e Checklist

Pr oduct Features

I/O Channels Available on ioLogik 2500 Models

Communication Interface

ioLogik 2500 Ethernet Seri es Specif ic a tio ns

Common Specifications

io Logik 2512 Ethernet Specifications

ioLogik 2542 Ethernet Specifications

ioLogik 2500 HSPA/GPRS/ WL AN S erie s Spec ific a tio n s

Common Specifications

ioLogik 2512 HSPA/GPRS/WLAN Specifications

ioLogik 2542 HSPA/GPRS/WLAN Specifications

Page 6

ioLogik 2500 Series Overview

1-2

The ioLogik

box, dramatically reducing the

devices from multiple vendors.

Micro SD card (supports cards with up to 32 GB of storage space), and the

ioLogik 2500

control logi

systems. As a rugged industrial device, the ioLogik 2500 operates reliably

at a wide range of temperatures, and is well suited for hard

wire remote

monitoring and

pipelines.

Top View

Front View

ioLogik 2500 Overview

2500 combines a remote I/O device and data logger into one

amount of effort required to integr a te

I/O and serial data can be logged onto a

can be programmed with Moxa’s convenient Click&Go™ Plus

c, which can be used to easily construct customized control

-to-

alarm applications at unmanned sites like riversides and

Appearance

Page 7

ioLogik 2500 Series Overview

1-3

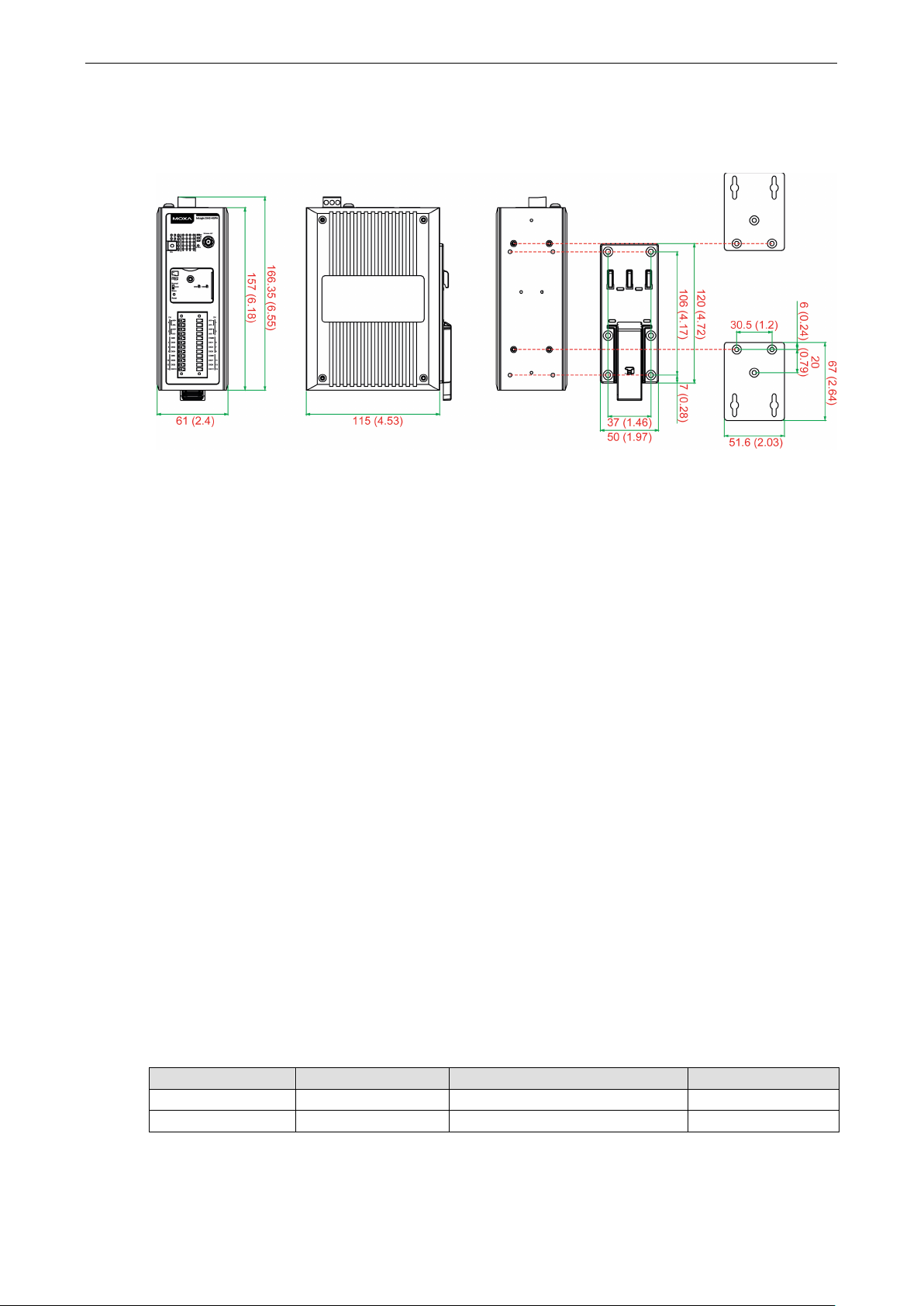

Dimensions Diagram

Units: mm (in)

Package Checklist

The ioLogik 2500 is shipped with the following ite ms :

• ioLogik 2500 device

• 2 RJ45-to-DB9 connection cables (CBL-RJ45M9-150)

• 1 antenna (only for wireless models)

• Quick installation guide (printed)

NOTE: Please notify your sales represe ntati v e if any of the above item s are missing or d amage d .

Product Features

• Supports cellular (HSPA/GPRS), Ethernet, and serial communication (ioLog ik 2500-HSPA/GPRS only)

• New Click&Go Plus logic provides powerful front-end intelligence

• Supports wireless LAN communication (ioLo g i k 2500 -WL1 only)

• 4-port unmanaged switch built in for linking to Etherne t devices

• Optimized I/O expansion port for daisy chaining up to 8 ioLogik E1200 units

• 2 serial ports (RS-232/422/485) for connecting field devices

• Built-in data logger supports an FTP server/client and microSD™ card with up to a 32 GB

• Transforms Modbus RTU into Modbus TCP or Active Tags

• Active communication with patented MX -AOPC UA Server

• Smart alarm management: Email, SNMP traps, TCP, UDP, SMS

• Wide operating temperature: -40 to 75°C (-40 to 167°F)

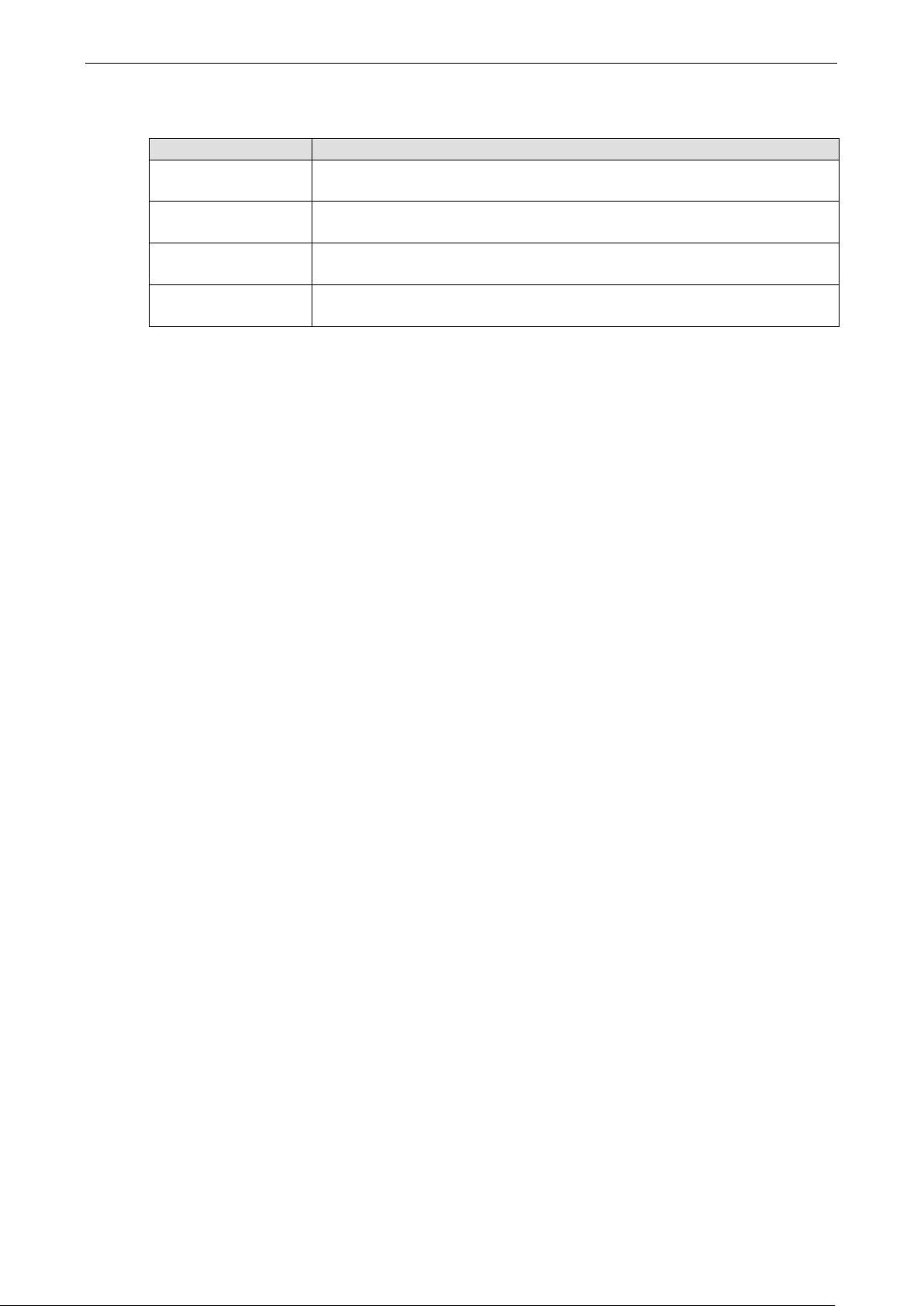

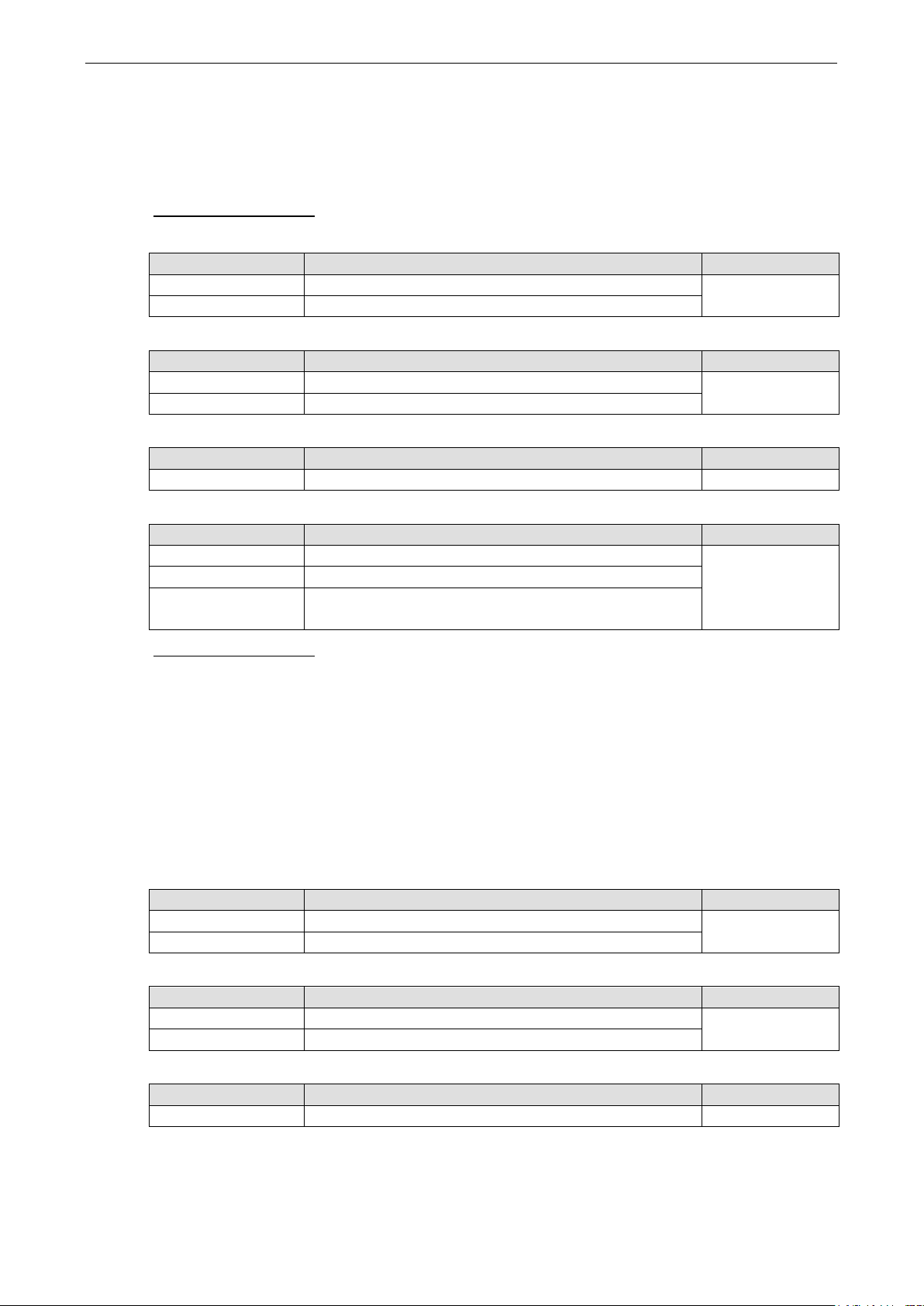

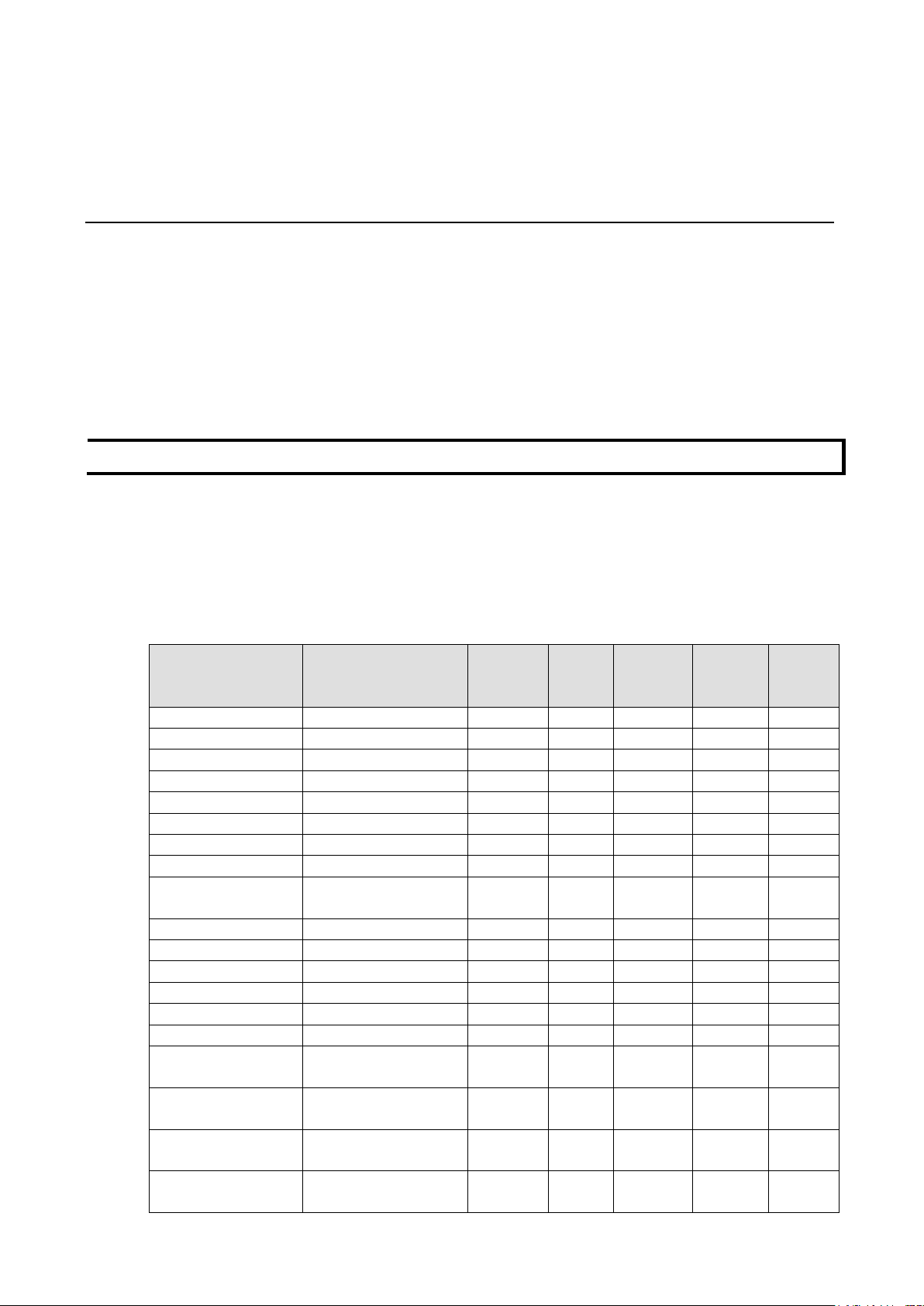

I/O Channels Available on ioLogik 2500 Models

Model Name Digital Inputs DI/DO (DIO) Configurable Analog Inputs

ioLogik 2512 8 8 –

ioLogik 2542 – 12 4

Page 8

ioLogik 2500 Series Overview

1-4

LAN

Ethernet:

• 4 switched 10/ 1 00 Mbps RJ45 ports

• 1 optimized port for faster

Note: The optimized daisy

Protection:

Protocols:

Serial

Interface:

Parity:

Data Bits:

Stop Bits:

Flow Control:

Baudrate:

Protocols:

Physical Characteristics

Wiring:

Dimensions:

Weight:

Mounting:

Storage

Expansion Slot:

Note: For units operating in extreme temperature s , ind us trial

required.

Environmental

Operating Temperature:

Standard Models:

Wide Temp. Models:

Storage Tem perature:

Ambient Relative Hu midity:

Shock:

Vibration

Altitude:

Note: Please contact Moxa if you require produc ts g uarante ed to f unc tion properly at higher altitudes.

Communication Interface

Model Name Communication Interfac e

ioLogik 2512

ioLogik 2542

ioLogik 2512-GPRS

ioLogik 2542-GPRS

ioLogik 2512-HSPA

ioLogik 2542-HSPA

ioLogik 2512-WL1

ioLogik 2542-WL1

Serial / Ethernet

Serial / Ethernet / GPRS (2G)

Serial / Ethernet / GPRS (2G) /HSPA (3G)

Serial / Ethernet / Wireless LAN

ioLogik 2500 Ethernet Series Specifications

Common Specifications

downstream communications with daisy-chaine d ioLogik E1200 units

-chain port is not supported by the ioLogik E1261W-T, E1261H-T, or E1263H-T.

1.5 kV magnetic isolation

Modbus/TCP (slave), TCP/IP, UDP, DHCP, BOOTP, SNMP, HT TP, C GI, SNTP, SMTP

2 RS-232/422/485 (software sele c t a b l e ) RJ45 ports

None , O dd, Even

5, 6, 7, 8

1, 2

None, RTS/CTS, XON/XOFF

300 to 11520 0 bps

Modbus/RTU (master/gateway), serial tunnel mod e (clie nt/s e rver)

I/O cable max. 14 AWG

61 x 157 x 115 m m (2.4 x 6.18 x 4.53 in)

Under 1265 g (2.79 lb)

DIN-rail (standard), wall (with o p tional kit)

Up to 32 GB microSD™ memory card (SDHC compatible)

-grade, wide-temperature SD cards are

Limits

-10 to 60°C (14 to 140°F)

-40 to 75°C (-40 to 167°F)

-40 to 85°C (-40 to 185° F)

5 to 95% (non-condensing)

IEC 60068-2-27

: IEC 60068-2-6

Up to 2000 m

Page 9

ioLogik 2500 Series Overview

1-5

Standards and Cer t ifications

Safety:

EMC:

EMI:

EMS:

IEC 61000

IEC 61000

IEC 61000

IEC 61000

IEC 61000

IEC 61000

Hazardous Location:

Green Product:

Note: Please check Moxa’s website for the most up

Warranty

Warranty Period:

Details: See www .mox a.com/warranty

Inputs and Outputs

Digital Inputs:

Configurable DIOs (by software): 8 channels

Isolation:

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

•

• Off: open

Wet Contact (DI to COM):

• On: 10 to 30 VDC

• Off: 0 to 3 VDC

Common Type:

Counter Frequenc y:

Digital Filtering Time Interval:

Digital Output

Type:

I/O Mode: DO or Pulse Output

Pulse Output Freq uenc y:

Over

Over

Over

Current Rating: 500 mA per channel @ 25°C

DIO Output Leakage Current:

Power Requirements

Input Voltage:

Input Curre nt:

MTBF (mean time between failures)

Time:

Standard:

UL 508

EN 61000-6-2/6-4

CISPR 32, FCC Part 15B Class A

-4-2 ESD: Contact: 4 kV; Air: 8 kV

-4-3 RS: 80 MHz to 1 GHz: 10 V/m

-4-4 EFT: Power: 1 kV; Signal: 0.5 kV

-4-5 Surge: Power: 1 kV

-4-6 CS: 3 V

-4-8

Class 1 Division 2; ATEX Zone 2

RoHS, C RoHS, WEEE

-to-date certification status.

5 years

ioLogik 2512 Ethernet Specifications

8 channels

3k VDC or 2k Vrms

Wet Contact (NPN or PNP) and Dry Contact

DI or Event Counter

On: short to GND

8 points per COM

2.5 kHz

Software configurable

Sink

5 kHz

-Voltage Protection: 45 VDC

-Current Protection: 1.5 A per channel @ 25°C

-Temperature Shutdown: 175°C (min.)

9 to 48 VDC

274 mA @ 24 VDC

467,032 hrs

Telcordia SR332

< 1 mA @ 30 VDC

Page 10

ioLogik 2500 Series Overview

1-6

Inputs and Outputs

Configurable DIOs

Analog Inputs:

Isolation:

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

• On: short to GND

• Off: open

Wet Contact (DI to

• On: 10 to 30 VDC

• Off: 0 to 3 VDC

Common Type:

Counter Frequenc y:

Digital Filtering Time Interval:

Digital Output

Type:

I/O Mode:

Pulse Output Freq uenc y:

Over

Over

Over

Current Rating:

DIO Output Leakage Current:

Analog Input

Type:

Resolution:

I/O Mode:

Input Ran g e:

Accuracy:

• ±0.1% FSR @ 25° C

• ±0.3% FSR @

• ±0.5% FSR @

Sampling Rate

• All channels: 400 samples/sec

• Per channel: 100 samples/sec

Input Impedance:

Built

Power Requirements

Input Voltage:

Input Curre nt:

MTBF (mean time between failures)

Time:

Standard:

ioLogik 2542 Ethernet Specifications

(by software): 12 channels

4 channels

3k VDC or 2k Vrms

Wet Contact (NPN or PNP) and Dry Contact

DI or Event Counter

COM):

6 points per COM

2.5 kHz

Software configurable

Sink

DO or Pulse Output

5 kHz

-Voltage Protection: 45 VDC

-Current Protection: 1.5 A per channel @ 25°C

-Temperature Shutdown: 175°C (min.)

500 mA per channel @ 25°C

< 1 mA @ 30 VDC

Differential input

16 bits

Voltage / Current (software selectable)

±10 V, 0 to 10 V, 0 to 20 mA, 4 to 20 mA, 4 to 20 mA (burnout detection)

-10 and 60°C

-30 and 70°C

:

1 mega-ohm (min.)

-in Resistor for Current Input: 120 ohms

9 to 48 VDC

358 mA @ 24 VDC

375,439 hrs

Telcordia SR332

Page 11

ioLogik 2500 Series Overview

1-7

Cellular

Standards:

HSPA Model Band Options:

• UMTS/HSPA+: five

•

GPRS Model Band Options:

SIM Control Voltage:

SIM Format:

Connector Type

WLAN

Standards:

• IEEE 802.11b/g for wireless LAN

•

Spread Spectrum and Modulation (typical):

• DSSS with DBPSK, DQPSK, CCK

• OFDM with BPSK, QPSK, 16QAM, 64QAM

• 802.11b: CCK @ 11/5.5 Mbps, DQPSK @ 2 Mbps, DBPSK @ 11 Mbps

• 802.11g: 64 QA M @ 54/48 Mbps, 16QAM @ 36/24 Mb p

Operating Channels (central frequency):

• US: 2.412 to 2.462 GHz (11 channels)

• EU: 2.412 to 2.472 GHz (13 channels)

Security:

• 64

• Full WPA/WPA2 Personal

Transmission Rates:

• 802.

• 802.11g: 6, 9, 12, 18, 24, 36, 48, 54 Mbps

TX Transmit Power:

• 802.11b: Typ . 18±1.5 dBm @ 1 to 11 Mbps

• 802.11g: Typ . 18±1.5 dBm @ 6 to 24 Mbps, Typ. 17±1.5 dBm @ 36 Mbps, Typ. 16± 1. 5 dBm @ 48 Mbps,

Typ. 16±1.5 dBm @ 54 Mbps

R

• 802.11b:

• 802.11g:

Connector Type:

LAN

Ethernet:

• 4 switched

• 1 optimized port for faster downstream communic ati o ns with dais y

Note: The optimized daisy

Protection:

Protocols:

Serial

Interface:

Parity:

Data Bits:

Stop Bits: 1, 2

ioLogik 2500 HSPA /GPRS/WLAN Series Specifications

Common Specifications

GSM/GPRS/EDGE/UMTS/HSPA+

-band 800/850/900/1900/2100 MHz

GSM/GPRS/EDGE: quad-band 850/900/1800/1900 MHz

GSM/GPRS/EDGE: quad-band 850/900/180 0/1900 MHz

3/1.8 V

Full size

: SMA female

IEEE 802.11i for wireless security

s, QPSK @ 18/12 Mbps, BPSK @ 9/6 Mbps

-bit and 128-bit WEP encryption

11b: 1, 2, 5.5, 11 Mbps

X Sensitivity:

-97 dBm @ 1 Mbps, -94 dBm @ 2 Mbps, -92 dBm @ 5.5 Mbps, -90 dBm @ 11 Mbps

-88 dBm @ 6 to 24 Mbps, -85 dBm @ 36 Mbps, -75 dBm @ 48 Mbps, -70 dBm @ 54 Mbps

RP-SMA Female

10/100 Mbps RJ45 ports

-chained ioLogik E1200 units

-chain port is not supported by the ioLogik E1261W-T, E1261H-T, or E1263H-T.

1.5 kV magnetic isolation

Modbus/TCP (slave), TCP/IP, UDP, DHCP, BOOTP, SNMP, HT TP, C GI, SNTP, SMTP

2 RS-232/422/485 (software sele c t a b l e ) RJ45 ports

None , O dd, Even

5, 6, 7, 8

Page 12

ioLogik 2500 Series Overview

1-8

Flow Control:

Baudrate:

Protocols:

Physical Characteristics

Wiring:

Dimensions:

Weight: Under 1265 g (2.79 lb)

Mounting:

Storage

Expansion Slot:

Note: For units operating in extreme temperature s , ind us trial

required.

Environmental Limits

Operating Temperature:

Standard Models:

Wide Temp. Models:

Storage Tem perature:

Ambient Relative Hu midity: 5 to 95% (non-condensing)

Shock:

Vibration:

Altitude:

Note: Please contact Moxa if you require produc ts g uarante ed to f unc tion properly at higher altitudes.

Standards and Cer t ifications

Safety:

EMC:

EMI:

EMS:

IEC 61000

IEC 61000

IEC 61000

IEC 61000

IEC 61000

IEC 61000

Radio:

Hazardous Location:

Green Product:

Note: Please check Moxa’s website for the most up

Warranty

Warranty Period:

Details: See www .mox a.com/warranty

Inputs and Outputs

Digital Inputs:

Configurable DIOs (by software): 8 channels

Isolation:

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

• On: short to GND

• Off: open

None, RTS/CTS, XON/XOFF

300 to 11520 0 bps

Modbus/RTU (master/gateway), serial tunnel mod e (clie nt/s e rver)

I/O cable, 14 AWG (max.)

61 x 157 x 115 m m (2.4 x 6.18 x 4.53 in)

DIN rail (standard), wall (optional)

Up to 32 GB microSD™ memory card (SDHC compatible)

-grade, wide-temperature SD cards are

-10 to 60°C (14 to 140°F)

-30 to 70°C (-22 to 158°F)

-40 to 85°C (-40 to 185° F)

IEC 60068-2-27

IEC 60068-2-6

Up to 2000 m

UL 508

EN 61000-6-2/6-4

CISPR 32, FCC Part 15B Class A

-4-2 ESD: Contact: 4 kV; Air: 8 kV

-4-3 RS: 80 MHz t o 1 GHz: 3 V/m

-4-4 EFT: Power: 1 kV; Signal: 0.5 kV

-4-5 Surge: Po wer 2 kV

-4-6 CS: 3 V

-4-8

R&TTE: EN 62311, EN 300 328, EN 301 489-1, EN 301 489-17, EN 301 893; NCC; VCCI

Class 1 Division 2; ATEX Zone 2

RoHS, C RoHS, WEEE

-to-date certification status.

5 years

ioLogik 2512 HSPA/GPRS/WLAN Specifications

8 channels

3k VDC or 2k Vrms

Wet Contact (NPN or PNP) and Dry Contact

DI or Event Counter

Page 13

ioLogik 2500 Series Overview

1-9

Wet Contact (DI to COM):

• On: 10 to 30 VDC

• Off: 0 to 3 VDC

Common Type:

Counter Frequenc y:

Dig

Digital Output

Type:

I/O Mode:

Pulse Output Freq uenc y:

Over

Over

Over

Current Rating:

DIO Output Leakage Current:

Power Requirements

Input Voltage:

Input Curre nt:

• HSPA Model: 390 mA @ 24 VDC

• GPRS Model: 416 mA @ 24 VDC

• WL1 Model: 328 mA @ 24 VDC

MTBF (mean time between failures)

Time:

• HSPA model: 378,154 hrs

• GPRS model: 403,452 hrs

• WL1 model: 400,469 hrs

Standard:

Inputs and Outputs

Configurable DIOs (by software):

Analog Inputs:

Isolation: 3k VDC or 2k Vrms

Digital Input

Sensor Type:

I/O Mode:

Dry Contact:

• On: short to GND

• Off: open

Wet Contact (DI to COM):

• On: 10 to 30 VDC

• Off: 0 to 3 VDC

Common Type:

Counter Frequenc y:

Digital Filtering Time Interval:

Digital Output

Type:

I/O Mode:

Pulse Output Freq uenc y:

Over

Over

Over

8 points per COM

2.5 kHz

ital Filtering Time Interval: Softw are configurable

Sink

DO or Pulse Output

5 kHz

-Voltage Protection: 45 VDC

-Current Protection: 1.5 A per channel @ 25°C

-Temperature Shutdown: 175°C (min.)

500 mA per channel @ 25°C

< 1 mA @ 30 VDC

9 to 48 VDC

Telcordia SR332

ioLogik 2542 HSPA/GPRS/WLAN Specifications

12 channels

4 channels

Wet Contact (NPN or PNP) and Dry Contact

DI or Event Counter

6 points per COM

2.5 kHz

Software configurable

Sink

DO or Pulse Output

5 kHz

-Voltage Protection: 45 VDC

-Current Protection: 1.5 A per channel @ 25°C

-Temperature Shutdown: 175°C (min.)

Page 14

ioLogik 2500 Series Overview

1-10

Current Rating:

DIO Output Leakage Current:

Analog Input

Type:

Resolution:

I/O Mode:

Input Ran g e: ±10 V, 0 to 10 V, 0 to 20 mA, 4 to 20 mA, 4 to 20 mA (burnout detection)

Accuracy:

• ±0.1% FSR @ 25° C

• ±0.3% FSR @

• ±0.5% FSR @

Sampling

• All channels: 400 samples/sec

• Per channel: 100 samples/sec

Input Impedance:

Built

Power Requirements

Input Voltage:

Input Curre nt:

• HSPA Model: 442 mA @ 24 VDC

• GPRS

• WL1 Model: 406 mA @ 24 VDC

MTBF (mean time between failures)

Time:

• HSPA model: 378,154 hrs

• GPRS model: 403,087 hrs

• WL1 model: 331,222 hrs

Standard: Telcordia SR332

500 mA per channel @ 25°C

< 1 mA @ 30 VDC

Differential input

16 bits

Voltage / Current (software selectable)

-10 and 60°C

-30 and 70°C

Rate:

1M ohms (min.)

-in Resistor for Current Input: 120 ohms

9 to 48 VDC

Model: 494 m A @ 24 VDC

Page 15

2

2. Installation

In this chapter, we provide instructions on how to instal l the io Log ik 2500 I/O ser ver to connect to the

network and serial devices.

The following topics are covered in this chapter:

Hardware Installation

Installing the ioLogik 2500 on a DIN Rail

R e moving the ioLogik 2500 from a DIN Rail

Powering on the ioLogik 2500

Grounding the Unit

Installing a microSD Card and SIM Cards (cellular models only)

I/O Wiring Diagrams

I/O Wiring

DI Channel

DO Channel (Sink Type)

AI Channel

LED Indicators

Daisy-Chaining for I/O Expansion

Reset to Factory Defaults

Network Install ati on

Ethe r ne t Co mm unic ation

TCP/IP Settings

Serial Communication

Software Install at ion —IOxpress Utility

System Requirements

Installing IOxpress

Page 16

ioLogik 2500 Series Installation

2-2

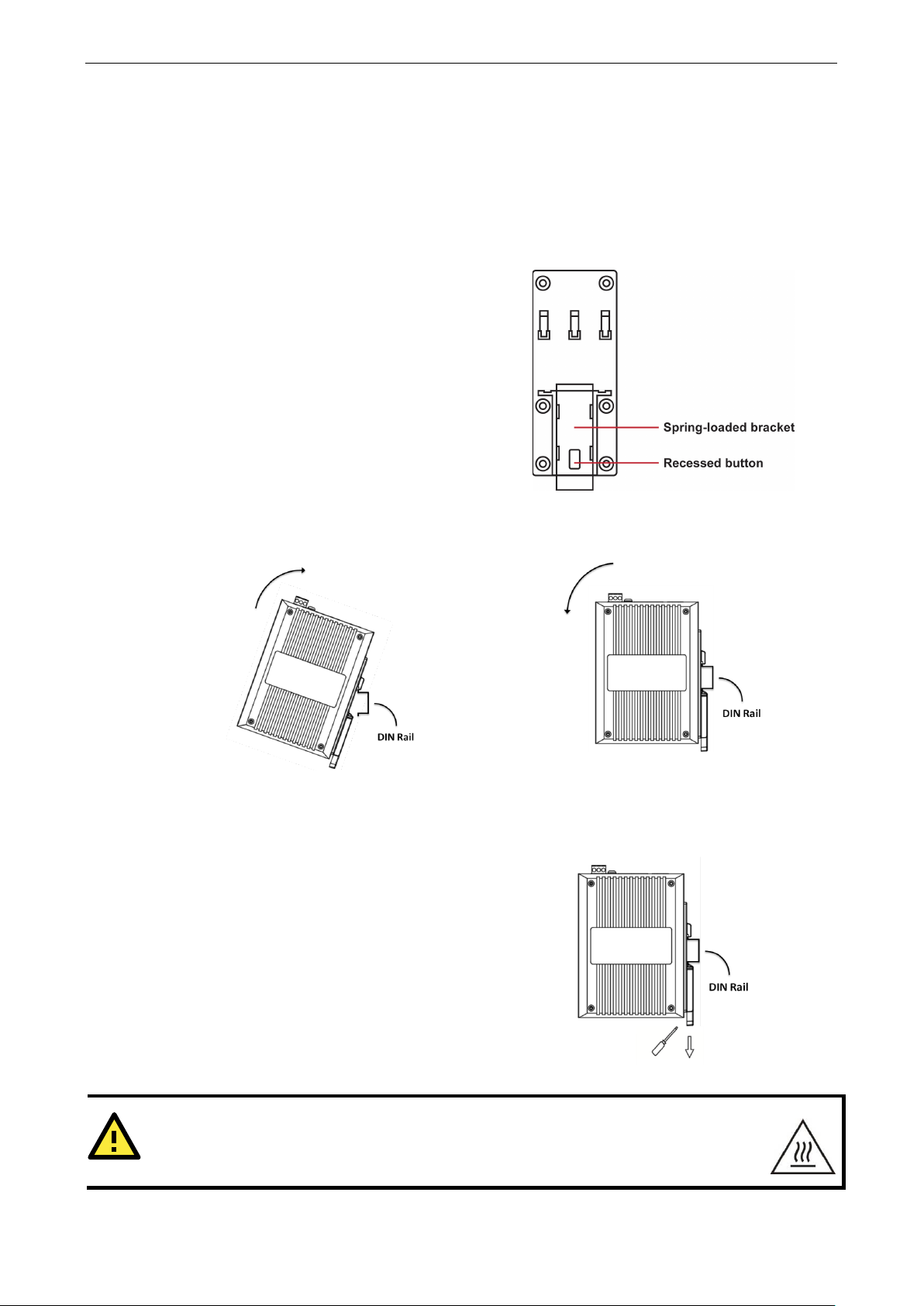

STEP 1:

place, push the recessed button to release it. Onc e

released, you should feel some resistance from the

spring as you slid

millimeters in each direction.

STEP 2:

of the attachment plate’s slot.

STEP 3:

place along the rail, as shown below.

To remove the ioLogik 2500 from a DIN rail, use a

screwdriver to pull down the spring

until it locks in place, as shown in the diagram at the

right. Next, rotate the bottom of the ioLogik 2500

upwards until y

WARNING

This equipment is intended to be used in Restricted Acc ess Lo c ations. External metal parts

be

Hardware Installation

Installing the ioLogik 2500 on a DIN Rail

The DIN-rail attachment plate should alr e ady b e fixed to the back panel of your ioLogik 2500. If you need

to reattach the plate, be sure the spring-loaded br ack e t is oriented tow ard s the bo tto m , as shown in the

figures below.

If the spring-loaded bracket is locked in

e the bracket up and down a few

Insert the top of the rail into the upper lip

The attachment unit should now snap into

Removing the ioLogik 2500 from a DIN Rail

-loaded bracke t

ou can remove it from the DIN rail.

hot! Maintenance personnel should wear protective gear before to uching the outside surface.

will

Page 17

ioLogik 2500 Series Installation

2-3

The ioLogik 2500 can re ceive power from a 9 to 48 VDC power

source. Input power is applied to the positive (V+) and negative

(V

After connecting the ioLogik 2500 to the power supply, it will take

30 to 60 seconds for the operating system to boot up. The green

Ready LED will illuminate continuously until the operating system

is ready.

ATTENTION

Be sure to note

codes dictating the maximum current allow able for each wire size. If current

the wi

connecting the power supply should be at least 2 mm in diameter (e.g., 12 gauge).

The ioLogik 2500 supports a single microSD card

and two SIM cards (cellular models only). The

card slots are located inside the ioLogik 2500 , as

shown here. The card slot is hidden

cover plate attached by a screw that must first

be removed before

After removing the screw holding the cover plate

in place you can insert or remove the

microSD/SIM cards. Be sure to refasten the

cover plate when you are done.

Powering on the ioLogik 2500

-) terminals on the connector.

Grounding the Unit

The ioLogik 2500 is equipped with a ground connector labeled .

res will overheat, and may cause serious damage to the equipment. For safety reasons, wires

the maximum possible current for each power wire and common wire. Observe a ll elec tr ic a l

s exceed the maximum rating

Installing a microSD Card and SIM Cards (cellular models only)

beneath a

the slot can be accessed.

Page 18

ioLogik 2500 Series Installation

2-4

I/O Wiring Diagrams

I/O Wiring

Follow the wiring guide for the I/O channels:

Item Suggestion

Wire range 16 to 26 AWG

Screw Torque 3 lb-inch

DI Channel

There are two categories of DI contact: Dry Contact and Wet Contact. Fo llow the wiring diagram for the

particular component you are using.

A Dry Contact is a contact that works without a power source: buttons, switches, etc.

A Wet Contact is a contact that requires a power source to work: proximity sensors, motion sensors, etc.

Check the sensor type (NPN, PNP) and follow the corresponding wiring sho wn belo w.

DI Dry Contact

Page 19

ioLogik 2500 Series Installation

2-5

DI Wet Contact (NPN)

DI Wet Contact (PNP)

DO Channel (Sink Type)

The DIO channels of this series can be used as DI channels or DO channels. The wiring diagram for DO

channels, which are sink type , is shown below:

AI Channel

Page 20

ioLogik 2500 Series Installation

2-6

Green

System is ready

LED Indicators

Type Color Description

Power

(PWR)

Ready

(RDY)

Ethernet Port

(L1/L2/L3/L4)

Serial Port

(P1/P2)

SD (Micro SD) Green SD card inserted

I/O Channel Status*

(0 to 15)

W.Link** Green Wireless connection established

Signal Status** Off No signal, or No SIM card

*Use the rotary switch to select which module’s I/O channe l s tatus is dis p laye d .

0 = ioLogik 2500

1 to 8 = E1200 expansio n

9 to F = Reserved

**Wireless models only

Green System power is ON

Off System power is OFF

Red System error

Green (blinking once per sec.) Locating device

Red (blinking once per sec.) Expansion Runtime Error

Green/Red (blinking once per 0.5 sec.) Safe Mode

Off System is not ready

Green Ethernet connection enabled at 100 Mbps

Amber Ethernet connection enabled at 10 Mbps

Blinking Data is being transmitted

Off Disconnected

Green Tx

Amber Rx

Blinking Data is being transmitted

Off Disconnected

Off SD card not inserted

Green Channel ON or Counter/Pulse signal

Off Channel OFF or No Counter/Pulse signal

Off Off

1 LED Weak or insufficient (SMS only)

2 LEDs Average (good for cellular connections)

3 LEDs Excellent signal

Page 21

ioLogik 2500 Series Installation

2-7

NOTE

Expansion units must be replaced with the same model of expans i o n unit. I

different expansion unit model, yo u must first change the relevant IOxpress settings.

ioLogik 2500

ioLogik E1200

ioLogik E1200

ioLogik E1200

ioLogik E1200

ioLogik E1200

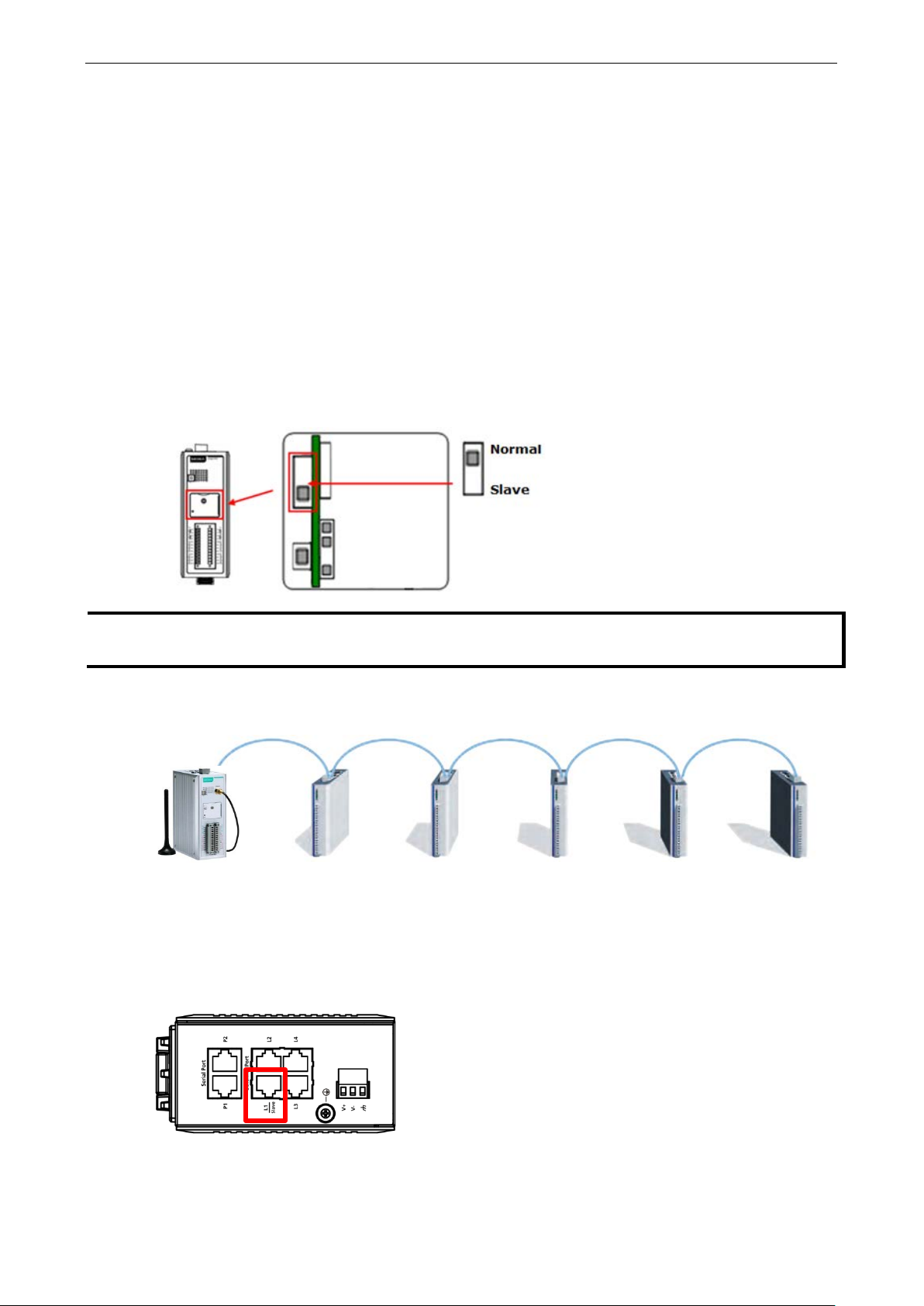

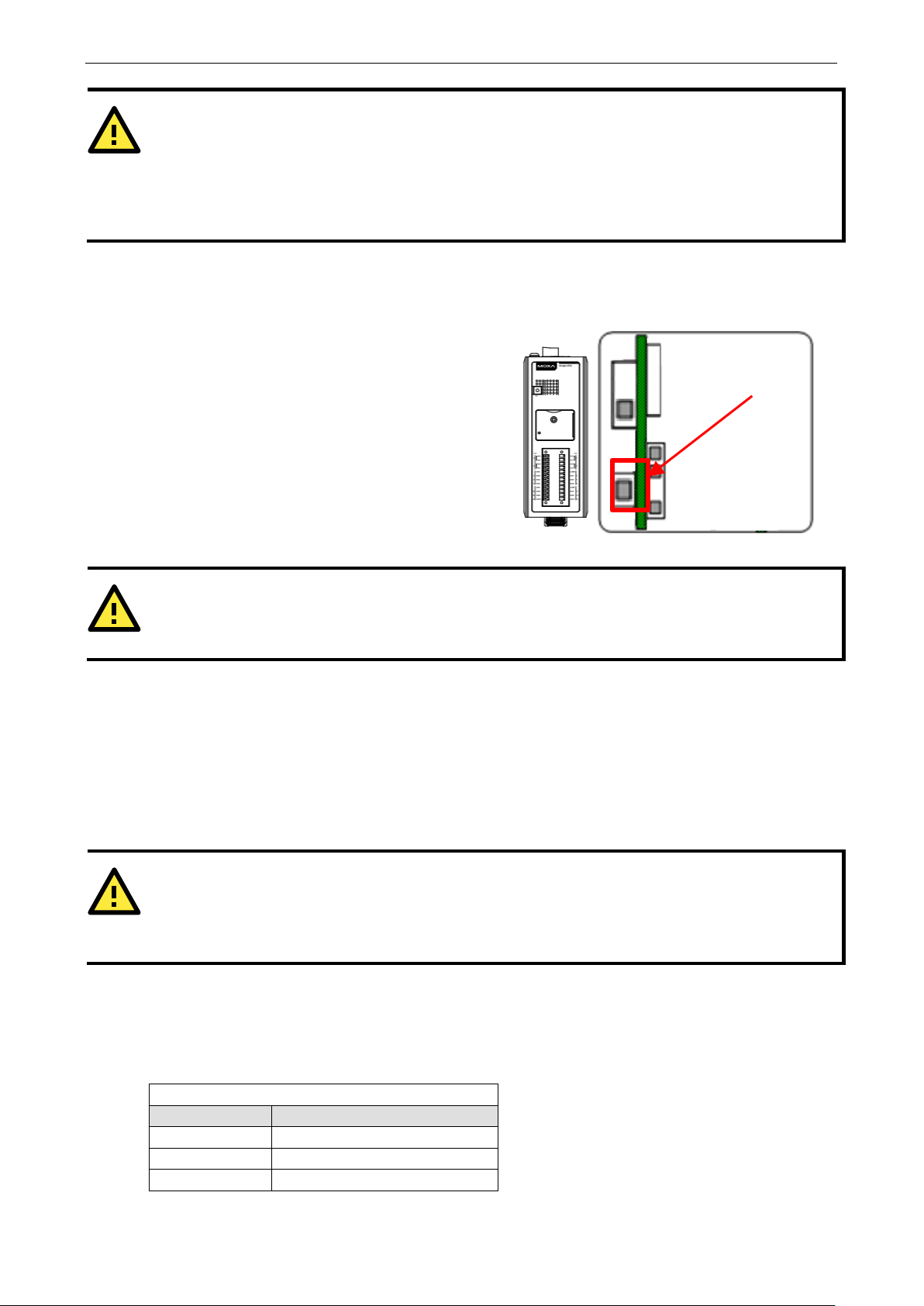

Daisy-Chaining for I/O Expansion

Up to 8 ioLogik E1200 devices can be connected in a daisy chain configuratio n to the ioLogik 2500 via the

L1/Slave port on the ioLogik 2500. An IOxpress configuration scheme is called a project. If the IOxpress

project includes expansion device s , the ioLog ik 2500 w ill a utomatic ally start running in expansion mode.

If the ioLogik 2500 is running, you can replace one of the expansion units w ithout powering down the

ioLogik 2500. Take the following steps to replace an expansio n unit:

1. Power-off the expansion unit.

2. Replace the unit with anothe r expansion unit of the same model.

3. Access the DIP switch bene a th the cover plate (a s shown below ).

4. Move the DIP switch from the down positio n to the up pos ition to tr igge r the ioLogik 2500 to refresh its

connection with the expansion units. If the DIP switch is already in the up position, move it down and

then back up again.

5. The expansion unit will sta r t running.

The following figure illustrates a s imple dais y -c hain of I/O modules using the ioL ogi k 2500 for w ire le s s

connectivity.

When daisy-chaining an array of devices, the first de v ice in the chain (after the ioLogik 2500) must be

connected to the L1 Slave port on the top of the ioLogik 2500 (outlined in red in the diagram).

When a network failure occurs between the ioLogik 2500 and expansion I/O units, the ioLogik 2500’s autorecovery mechanism will reestablish a connection onc e the network is back up and running.

f you would like to use a

Page 22

ioLogik 2500 Series Installation

2-8

ATTENTION

When using the ioLogik 2500 as the head of an array of ioLogik E1200 modules , make sure tha t:

If you need to reset the ioLogik 2500 to factory

defaults, press and hold the reset button (loc ate d

under the cover

more than

WARNING

Resetting your device to factory defaults w i ll res ult in the loss of all co nfig uration settings and any Click&Go

Plus logic settings that have

ATTENTION

The maximum cable length of a 10/100BaseT connection is 100 m (350 feet), but the a c tual limit co uld be

shorter depending on the amount of electr ic al nois e in the environment. To minimize the amount of noise,

Ethernet cables should not run parallel to power cable s or other cables tha t genera te el ectrical no is e .

1. You connec t the firs t E1200 expansion module in the array to the ioLogik 2500’s L1 Slave port.

2. A maximum of 8 ioLogik E1200 de v ices ar e connec te d in a single arra y.

3. You only use ioLogik E1200 devices in the array. Other devices cannot be used as part of the array.

Reset to Factory Defaults

-plate, as shown in the diagram) for

5 seconds.

Reset Button

Network Installation

Ethernet Communication

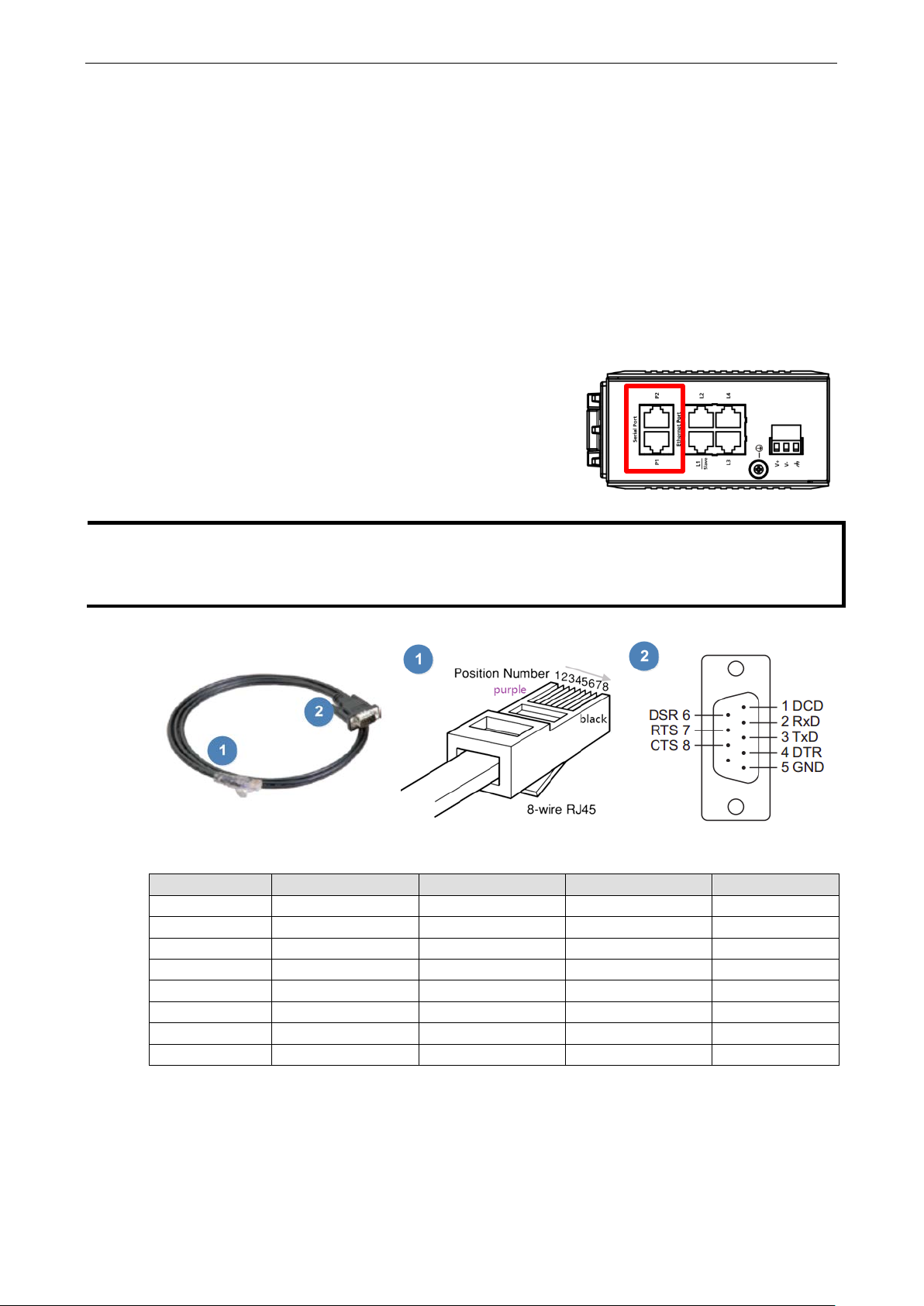

Connections to the LAN port are made through an RJ45 connector on the ioLog ik 2500 devic e . The wiring

and pin connections for these connectors ar e described in separate sections below.

TCP/IP Settings

The following table shows the TCP/IP parameter s suppor te d by the LAN por t. The io Log ik 2500 w ill reve rt to

these default values w he ne ver it is r ese t to factor y def a ults.

Parameter Supported Values

IP Address Defau lt: 192.168.127.253

Subnet Mask Default: 255.255.0.0

Gateway Default: 0.0.0.0

LAN Port

already been configured.

Page 23

ioLogik 2500 Series Installation

2-9

The ioLogik 2500 is equipped with two 3

selectable

RS

connect serial devices.

If required, the RJ45

used to connect to serial devices.

NOTE

The ioLogik 2500 is shipped with 2 RJ45 to DB9 connection cable s . If yo u need additional cables, contact

your Moxa sales representativ e.

The model name of the connection cable is

IP Address

The ioLogik 2500’s IP address.

Subnet Mask

Determines which subnet the device is connected to.

Gateway

The gateway IP address, which determines how the controller communicates with devices outs ide its subnet.

The IP address, subnet mask, and gateway are static; contact yo ur netw or k adminis trator to obtain these

addresses for the ioLogik 2500 device.

Serial Communication

-in-1 software-

-232/422/485 serial ports, making it more convenient to

to 8-pin male DB9 converter cab les can be

CBL-RJ45M9-150.

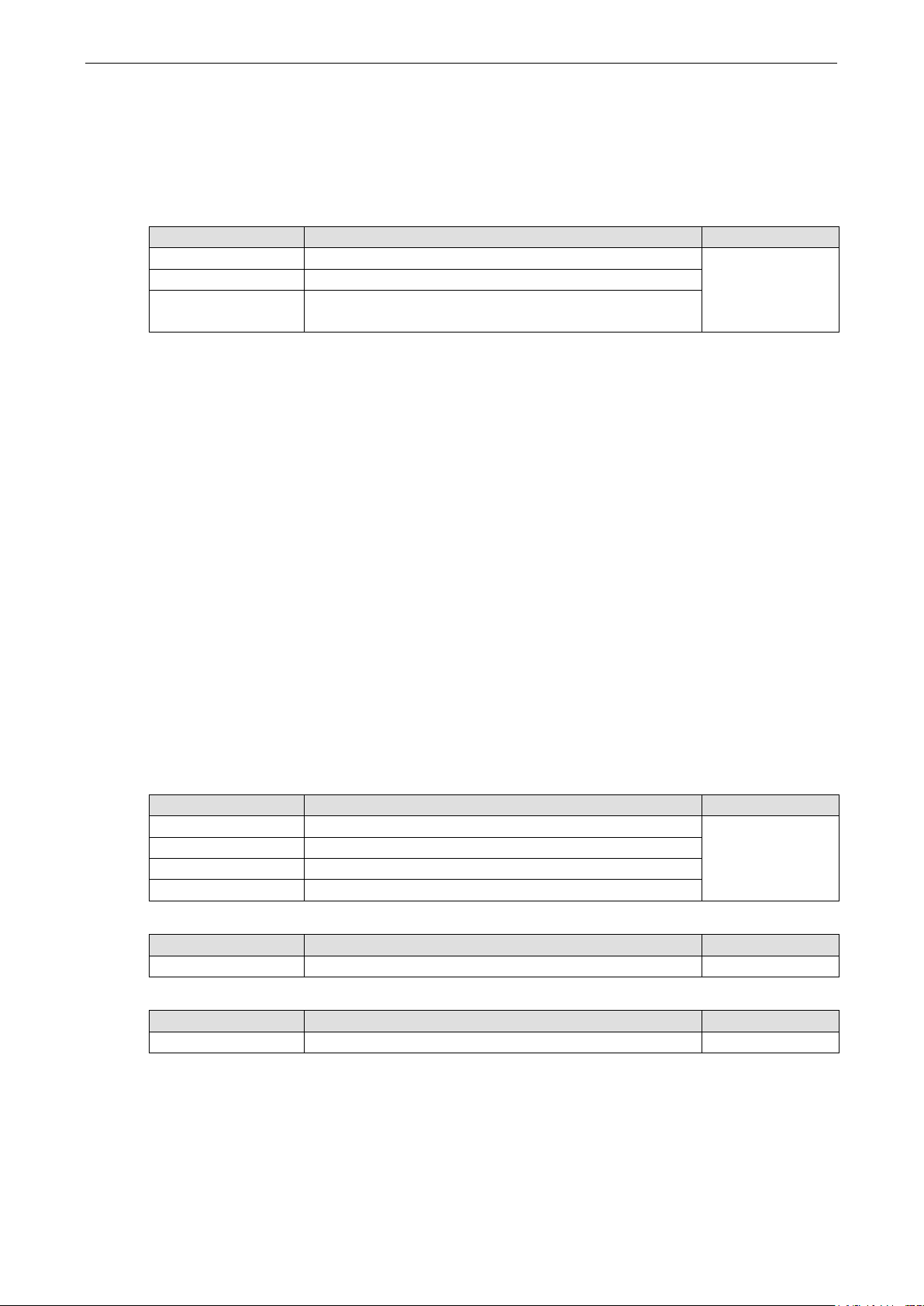

RJ45 to DB9 Conn ec ti o n Ca bl e RJ45 Connec t or Pinouts DB9M Connector Pinouts

DB9M Pin RS-232 RS-422 RS-485 RJ45 Pin

1 DCD RXD- DATA- 6

2 RXD RXD+ DATA+ 5

3 TXD TXD- – 4

4 DTR – – 8

5 GND GND GND 3

6 DSR – – 1

7 RTS TXD+ – 2

8 CTS – – 7

Page 24

ioLogik 2500 Series Installation

2-10

NOTE

Additional information on using IOXpr e ss c a n be found in

Software Installation—IOxpress Utility

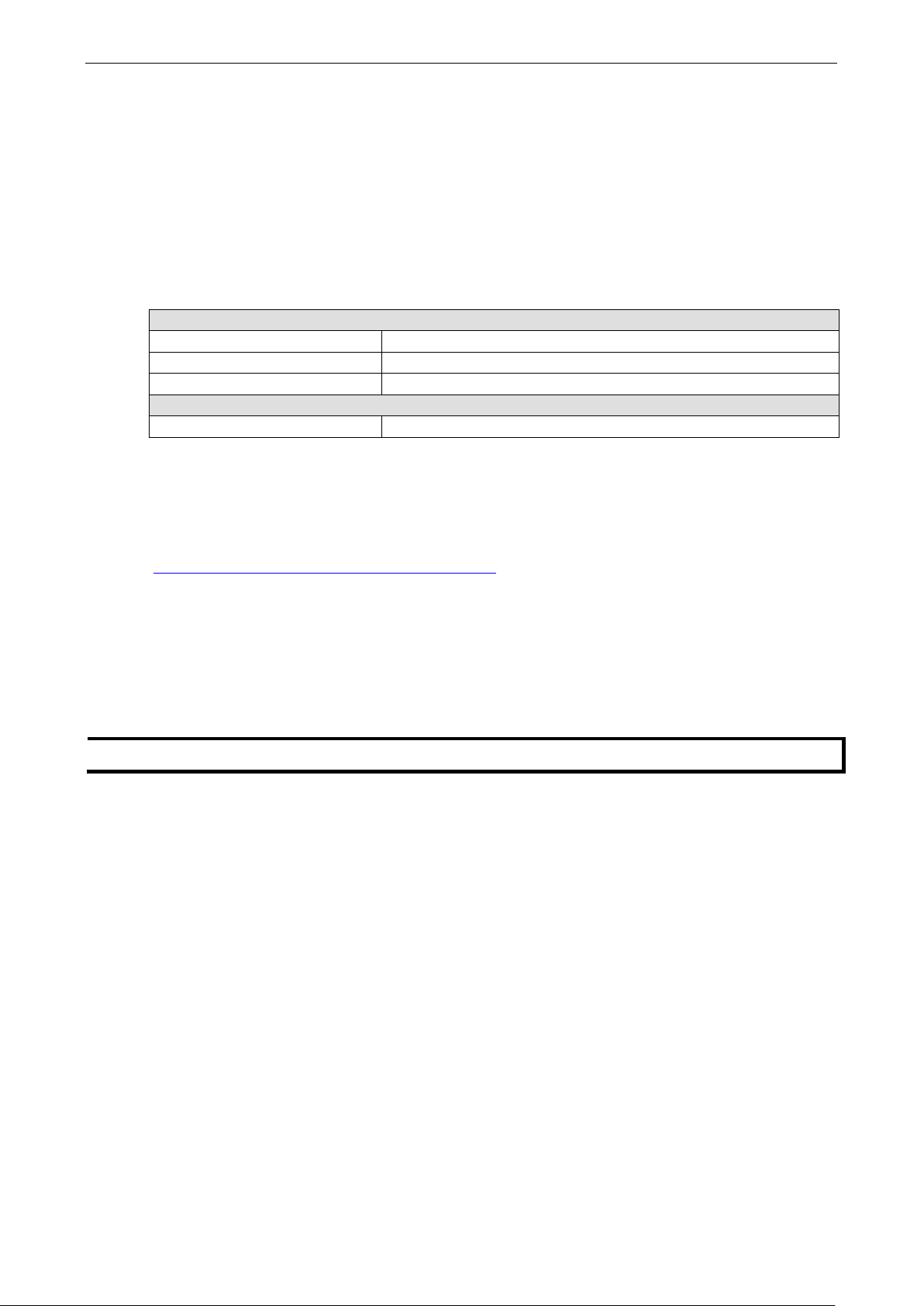

The ioLogik 2500 can be remotely managed and configured ov er a n Etherne t with Moxa’ s IOxpress utility.

IOxpress is a Windows utility provided for the conf iguration and management of the ioLogik 2500. IOxpress

can be used to remotely monitor and configure devices from any location on the network. The IOxpress

graphical user interface provides e asy acc ess to all status info rmation and configuration settings, and can

also be used to configure Click&Go Plus rules and handle front-e nd eve nts .

System Requirements

Hardware Requirements

CPU Intel Pentium 4 CPU or higher

RAM Min. 512 MB, 1024 MB is recommended

Network Interface 10/100 Ethernet

Software Requirements

Operating System Microsoft Windows 2000, XP or later

Installing IOxpress

The software can be downloaded from Moxa’s website. To do this, first click on the following link to access

the website’s search utility:

http://www.moxa.com/support/search.aspx?type=soft

When the web page opens, enter the model name of your product in the search box. Click the model name

to navigate to the product page, and then click on Utilities (in the middle of the pag e ), loc ate d in the box

titled Software.

Download and unzip the file, and then run SETUP.EXE from that location.

The installation program will guide you through the installation process and install the softwar e . After the

installation is finished , run the softw are fro m the Window s Start m e nu.

Chapter 3: The IOxpress Utility.

Page 25

3

3. The IOxpress Utility

In this chapter, we introduce Moxa’s IOxpress Utility. The ioLogik 2500 can be managed and configured

over an Ethernet using the IOxpress graphical user inte r face, which provides easy access to all status

information and settings. IOxpress can also be used to configure Click&Go Plus rules to handle fr o nt-end

events.

The following topics are covered in this chapter:

Application Interface

Main Screen

Menu B a r

Using IOxpress

Configuration Flowchart

C o nfiguration Library

D e vice Library

Page 26

ioLogik 2500 Series The IOxpress Utility

3-2

NOTE

If the host computer has multiple interfaces , be sure to select the corr e c t network inte rface before searching

for online devices. If you select the incorrect inte rf a c e or do not enable an interface, the search action will

not find any devices. The interface settings c an be found in the menu bar Options

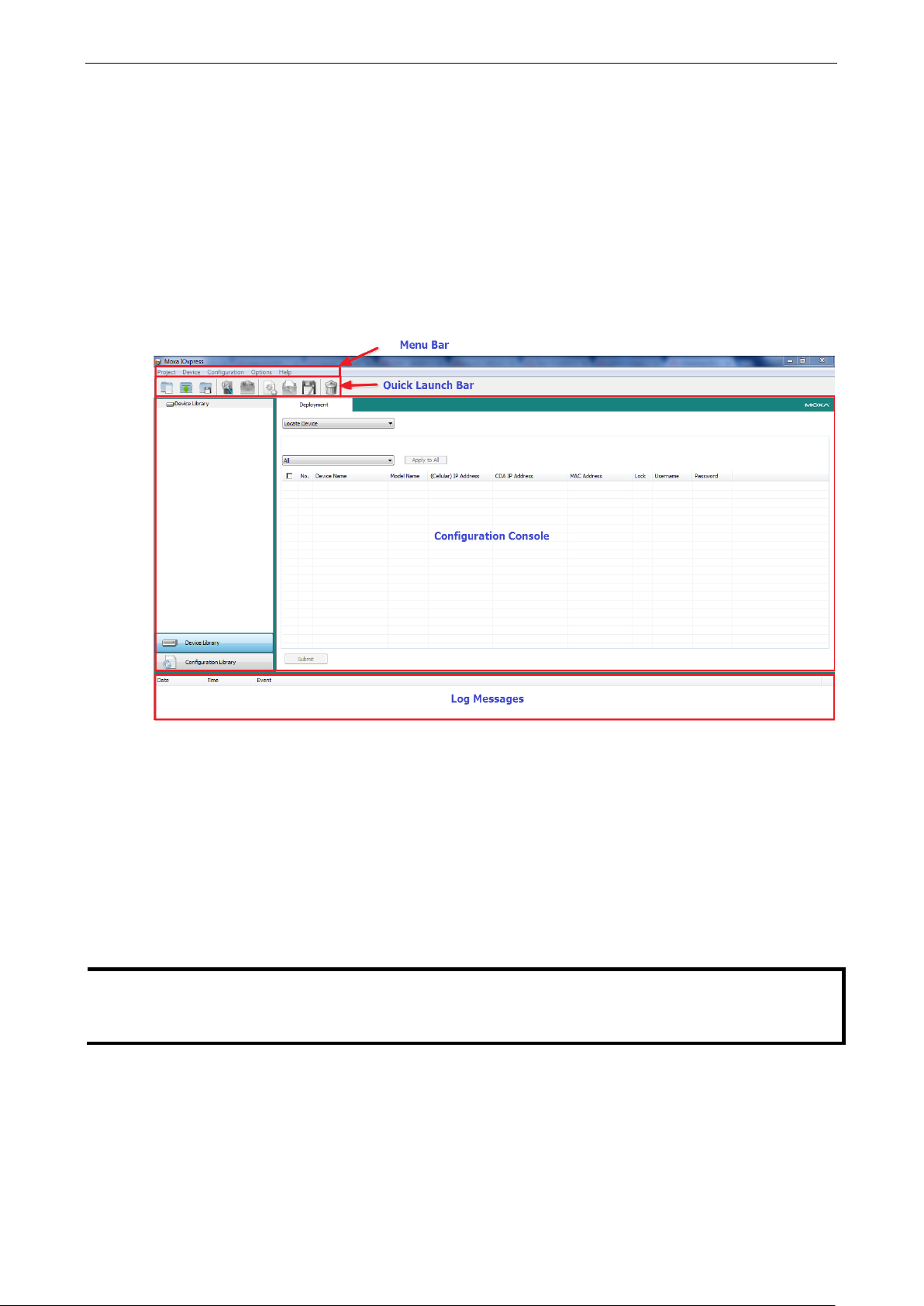

Application Interface

Main Screen

The following figure shows the main scree n of the IOxpress utili ty . The re are four main areas:

• Menu Bar

• Quick Launch Bar

• Configuration Console

• Log Messages

Menu Bar

There are five tabs on the menu bar:

• Project: For managing projects

• Device: For accessing functions to manage online devices

• Configuration: For performing configurations offline

• Options: Network interface and options

• Help: Version info rmation

Network Interfaces.

Page 27

ioLogik 2500 Series The IOxpress Utility

3-3

Using IOxpress

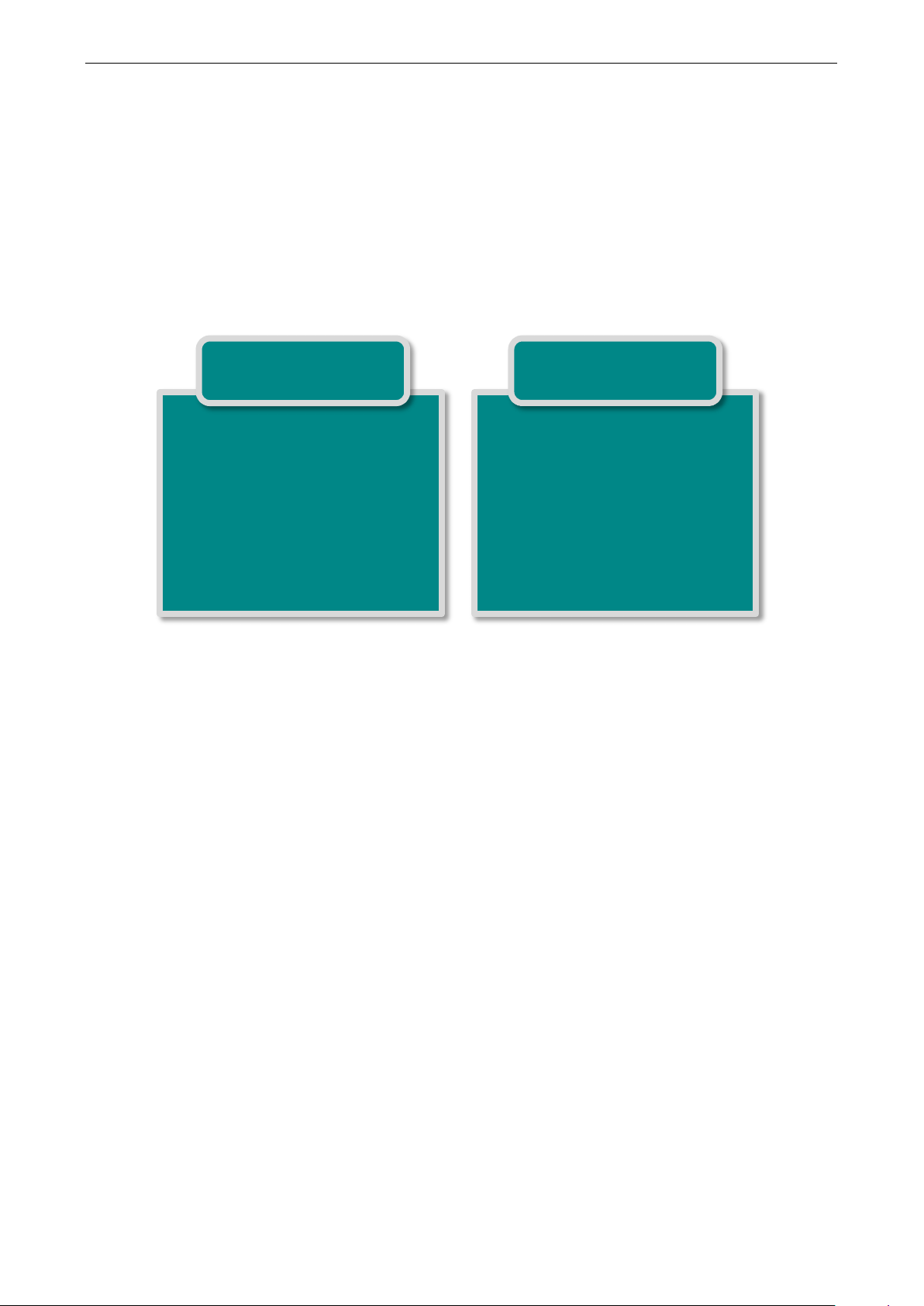

IOxpress sup po rts two configuration options: Config uratio n Libr ary and Device Library. Offline configuration

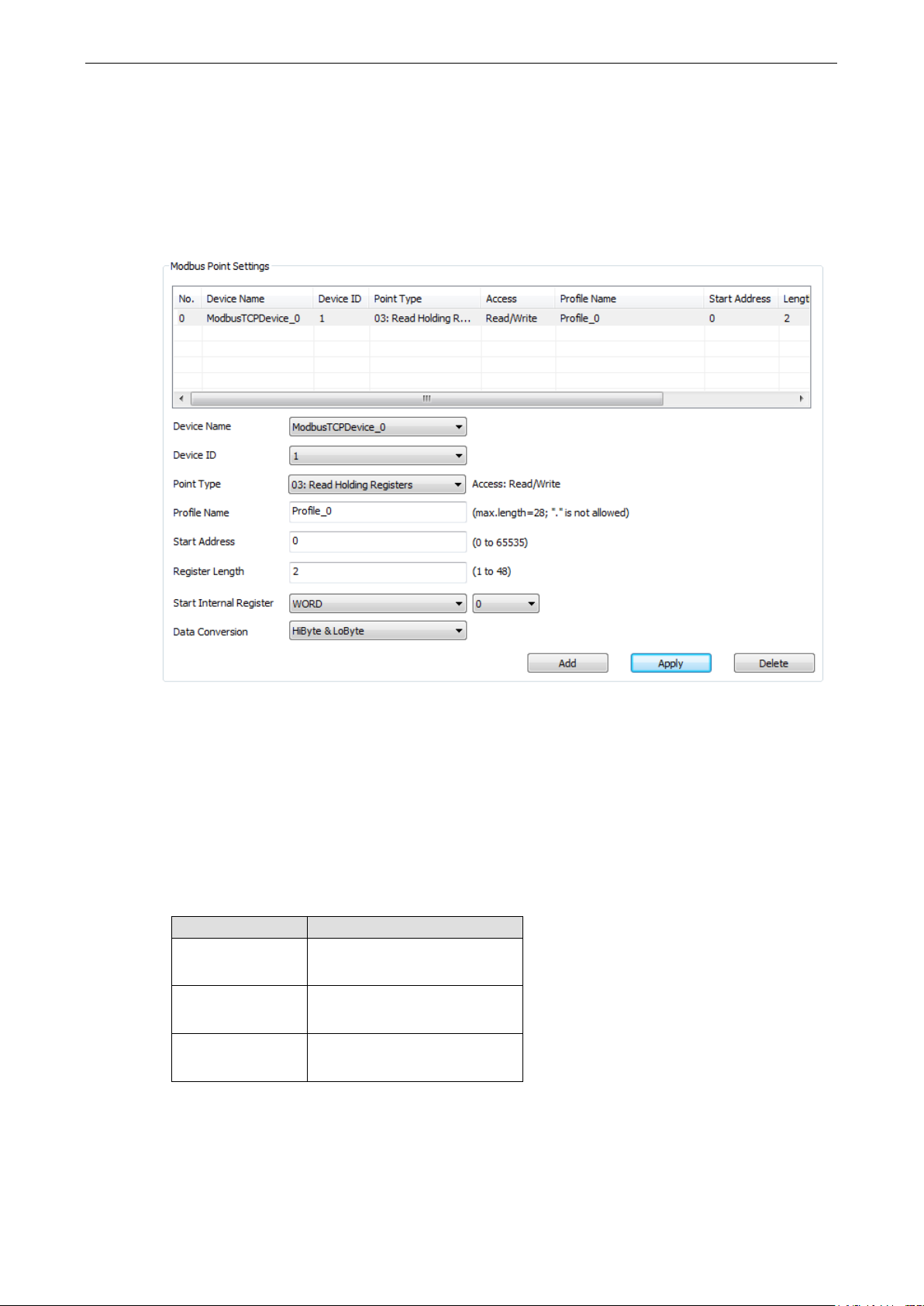

is usually completed first in the Config uration Library, and then the configurations are uplo ad ed over the

network to online devices.

Configuration Flowchart

The following flowchart gives an overview of the IOxpr e ss configuration process. Once offline config uration

is completed, you can start online configuration.

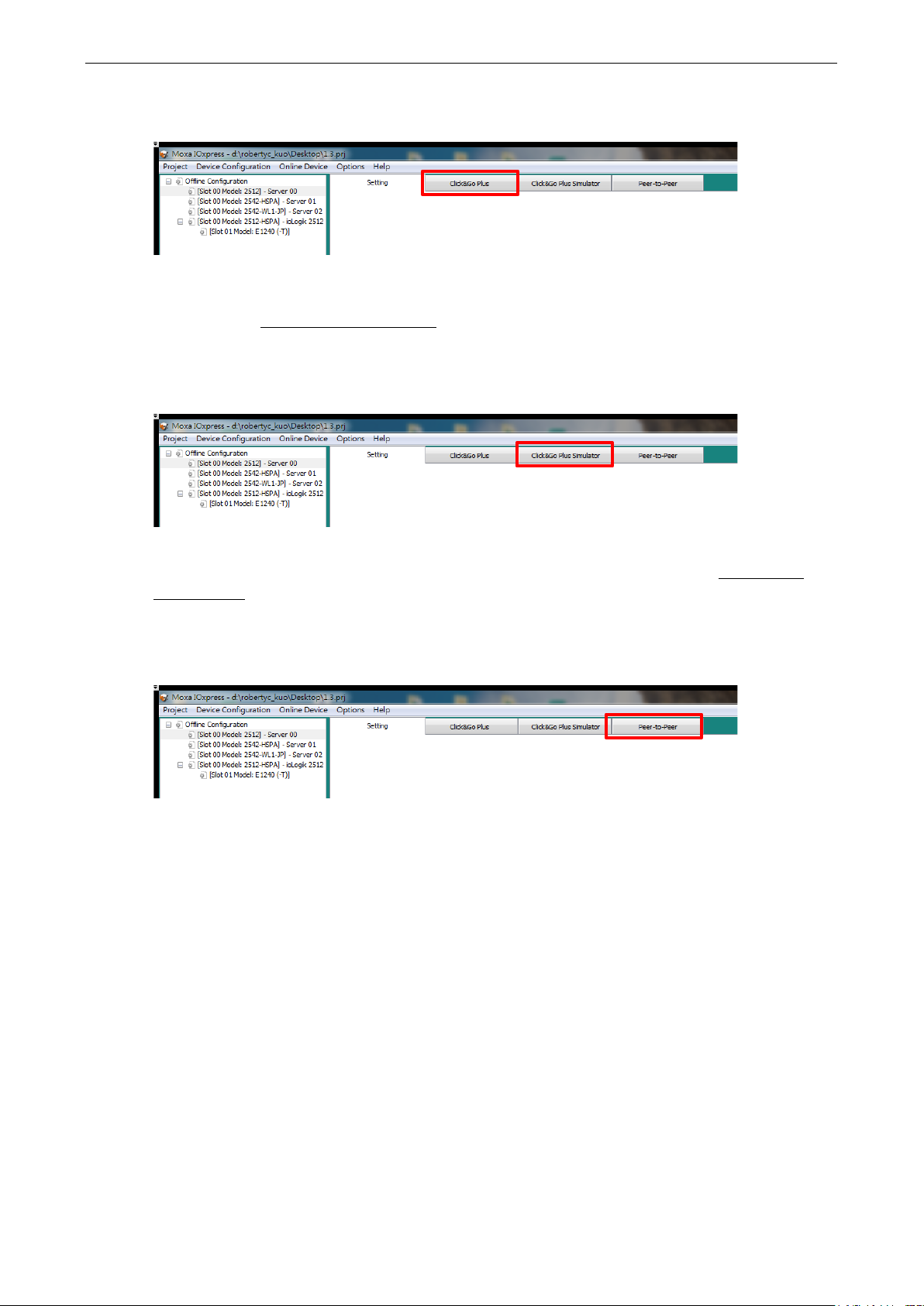

Configuration Library

1. Select Device Confi guration

Template

2500 + E1200

2. Detailed configuration

general settings

Click&Go Plus logic

Peer to Peer

Configuration Library

The operator uses IOxpress to store configuration options offline in IOxpress Projects. The configuration

settings are stored on the user’s computer.

See Chapter 4 for a detailed explanation.

Device Library

Device Library

1. Auto-search for online

devices

2500 + E1200

2. Select the functions to be

executed, and then

configure them

3. Deploy the configuration to

one or more devices

The operator uses IOxpress to export the configuration to devices on the network. That is, settings that

were configured offline are exported over the network to online de v ices . This can be done either in batch

mode, or on a case-by-case basis.

IOxpress can also be used to access online devices directly to check I/O status, upgra d e firm w are , expo r t

configurations, and restart devic e s.

See Chapter 5 for a detailed explanation.

Page 28

4

4. Configuration Library

With Configuration Library, the operator uses IOxpress to store configuration options offline in IOxpress

Projects. The configuration settings are stored on the user’s computer.

The following topics are covered in this chapter:

Introduction

Saving Configurations as a Project

A d ding an ioLogik 2500 Device to a Project

A d ding E1200 I/O Expansion Modules to a Project

Duplicate Device Configuration for Mass Deployment

Setting Up a Device

Settings Tab

System

Security

Network

I/O

AOPC

SNMP

Modbus/TCP Slave

Mo d bus/TCP Master

S e r i al Por t (Port1/Port2)

D ata Log g ing

C lic k&Go Plus

Click&Go Plus Tab

Click&Go Plus Simulator Tab

Peer-to-Peer Tab

General Settings

Peer-to-Peer Rule Settings

Page 29

ioLogik 2500 Series Configuration Library

4-2

Introduction

With Configuration Library, the operator uses IOxpress to store configuration options offline in IOxpress

Projects. The configuration settings are stored on the user’s computer.

Saving Configurations as a Project

IOxpress configuration schem es a re cal led Projects (saved as *.prj files).

The first step to using IOxpress is to create a project for automating yo ur d evic e conf iguration processes.

This can be done offline, after which the project ca n be expor ted to o ther devic e s over the netwo rk dur ing

the online configuration phase (discussed in Chapter 5: Device Library).

Projects are automatically saved in the following folder:

C:\Users\Public\Documents\Moxa\IOxpress\Database

The first time you use offline configuratio n, create a new projec t by clicking New from the dropdown menu

under the Project tab.

Click Configuration Library and then select Configuration fro m the toolb ar. You may click on either

Add Configuration… or Load from File… to add a config uration to the new project.

Add

Adding an ioLogik 2500 Device to a Project

The ioLogik 2500 can be used as the head of a cascaded array of ioLogik E1200 modules , with C lic k &G o

Plus logic used to extend communication capability to the all of the expansion units.

Page 30

ioLogik 2500 Series Configuration Library

4-3

ioL

ATTENTION

If the IOxpress project includes expans ion devices, the

mode.

ATTENTION

The IP address of the ioLogik 2500 should not be the same as its E1200 expansion units.

NOTE

The following ioLogik E1200 models can be used for ioLog ik 2500 I/O arr ays:

Adding E1200 I/O Expansion Modules to a Project

Up to 8 ioLogik E1200 series devices can be connected to the ioLogik 2500 in a daisy -chain co nfiguration.

Right click on the ioLogik 2500 device you have just added, and then sele c t Add Add Configuration….

After adding an E1200, the settings for the added dev ice c an be found in the I/O settings, Tag selection,

and data logging – profile areas. The expansion status (0: disconnect; 1: Good) can be monitored via

Modbus, AOPC tag, SNMP, and RESTful API.

ogik 2500 ioLogik E1200 ioLogik E1200 ioLogik E1200 ioLogik E1200 ioLogik E1200

L1/slave port will automatically run in expans io n

Page 31

ioLogik 2500 Series Configuration Library

4-4

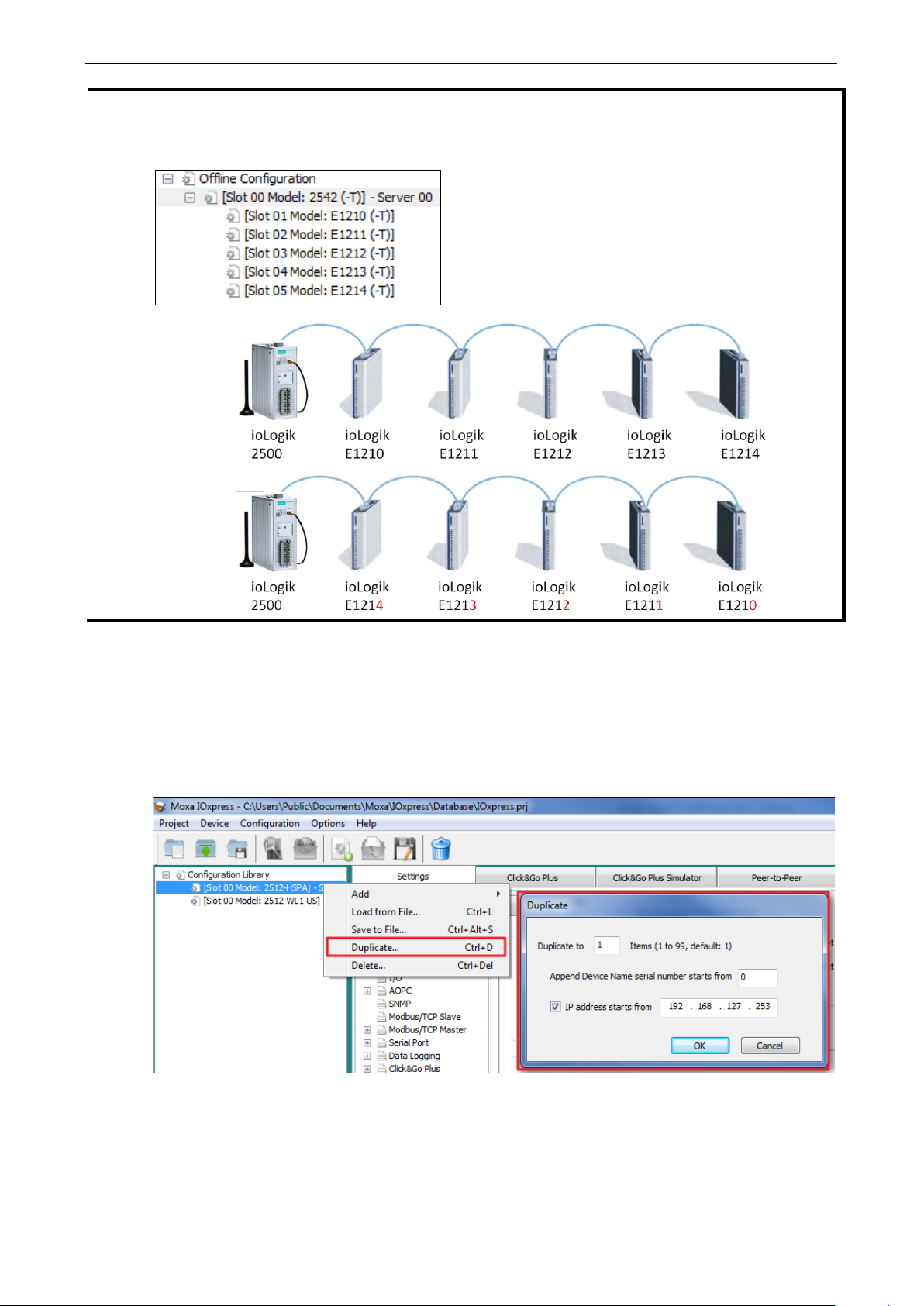

NOTE

The

If you would like to change a device in an E1200 array, make sure that the

order of the expansion modules is the same as in the Expansion Config uration list you just modified. An

example is shown below:

order of each model is fixed.

x

Duplicate Device Configuration for Mass Deployment

Use the Duplicate… function to quickly duplicate a configuration. First use Duplicate is to save your first

configuration as a template, and then use the duplicate function to duplicate the configuration template to

devices that have a different name, serial number, and IP address.

To do this, right click on a co nfig uration template and select Duplicate… from the dropdown list.

Page 32

ioLogik 2500 Series Configuration Library

4-5

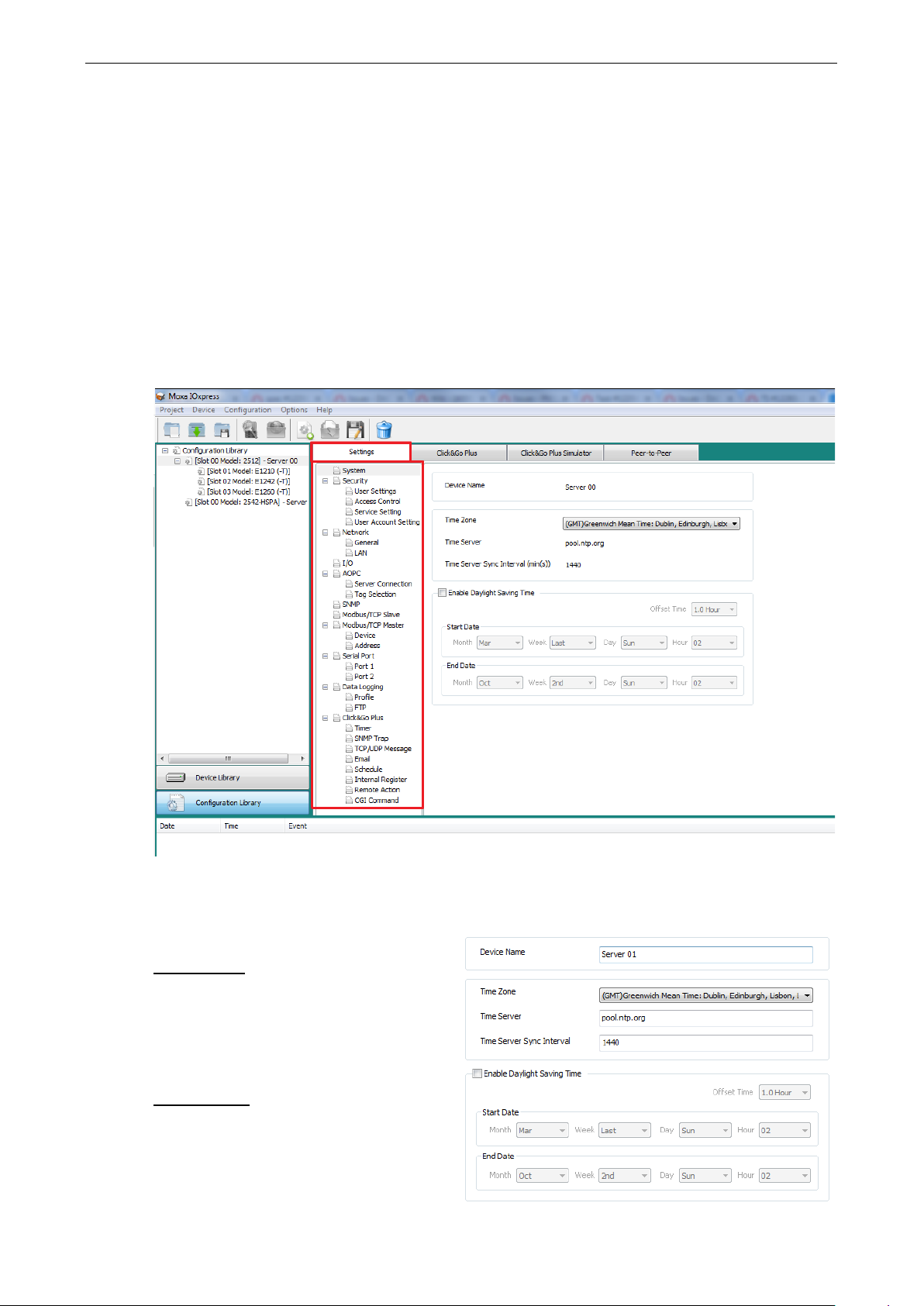

Click

Device Name

During

will

During online configuration, the device name will

appear in the

supports long

up to 30 characters.

Time Settings

The

the time server

box.

the

Setting Up a Device

After you have created the project, you can start to config ure each devic e in the pro ject. The configuration

window has four tabs:

• Settings

• Click&Go Plus

• Click&Go Plus Simulator

• Peer-to-Peer

Settings Tab

The Settings panel includes basic settings used to set up devices.

System

System to configure the fo llo wing items:

offline configuration, the device name

appear in the list of ioLogik 2500 units.

iologik 2500 will synchronize its time with

During online configuration, you can sync

PC’s time with the ioLogik 2500’s time.

mass deployment list. IOxpress

device names

indicated in the Time Server

Page 33

ioLogik 2500 Series Configuration Library

4-6

Daylight Saving Time

Select the

configure the

NOTE

Since the configuration is being done off line , the resul ts ar e stor ed in your compute r, and not in the ioLogik

device. Therefore, when updating this configuration to the ioLogik device, you will need to log

previous password.

Enable Daylight S avi ng Time c he ckbo x if your reg ion s upp or ts daylight saving time, and then

Offset Time, Start Date, and End Date.

Security

Configure the security settings to inc rease the security level of the device. Be sure to change the default

username/password the first time you configure this device, and then change it regularly thereaf ter .

User Settings

Each ioLogik 2500 is limited to precisely thre e users . Only the Username and Password of each user can

be modified. The No., Type, and Permission Level items cannot be changed. Use the Enable check box

(default: disable) to enable/disable Operator and User.

The factory defaults and access rights of the three user types are described below:

User Type Factory Default Access Right

Administrator admin Full control, including the ability to configure the device

Operator operator Can control I/O status through the web console

User user Can check I/O status through the web console

The characteristics of the username and password are described below:

Username:

Length: 1 to 30 characters

Acceptable characters: A to Z, a to z, 0 to 9, symbols; spaces are not allowed

Factory defaults: (see table above)

Password:

Length: 4 to 16 characters

Acceptable characters: A to Z, a to z, 0 to 9, Symbols, at least one number and one symbol

Factory default: moxa

in with the

Page 34

ioLogik 2500 Series Configuration Library

4-7

ATTENTION

To guard against cyber attacks,

when updating the password. Be sure to change the default password of each username before you start

using your ioLogik devices, and then change the passwo rd s at regular intervals.

NOTE

If all services are disabled, this device will no longe r be access ib le , and you will ne e d to load the fac tor y

default configuration to access the dev ice.

NOTE

MX

the password fields require at least one number and one symbol

Service Setting

Configure the service settings to enable/disable different services to prevent unintend e d acce s s . The

Default Configuration enables Web Server, Auto Search, and IOxpress Service. Enable other services (e.g.,

Modbus/TCP Slave) if additional serv ic e s are required.

-AOPC UA Serve r Service runs through the PC’s AOPC d ata co mmuni c ation ports 9500/9900.

User Account Settings

The user account settings include the following parameters.

• Idle Timeout: The system will log out idled users automatically when the idle timeo ut period is

surpassed.

• Retry Failure Threshold: Users will be locked out after this many unsuccessf ul log ins .

Page 35

ioLogik 2500 Series Configuration Library

4-8

• Lockout Time: The system will be locked for this period of time when the retry failure threshold is

surpassed.

• Login Failure Message: The system message that pops up when after an unsuccessful login.

• System Use Notification: The syste m messag e that wil l be displayed on the login page located below the

username and password field.

Access Control

Use IP Address / Netmask combinations to control which dev ic e s can use the Modbus/TCP protocol to

access your ioLogik device.

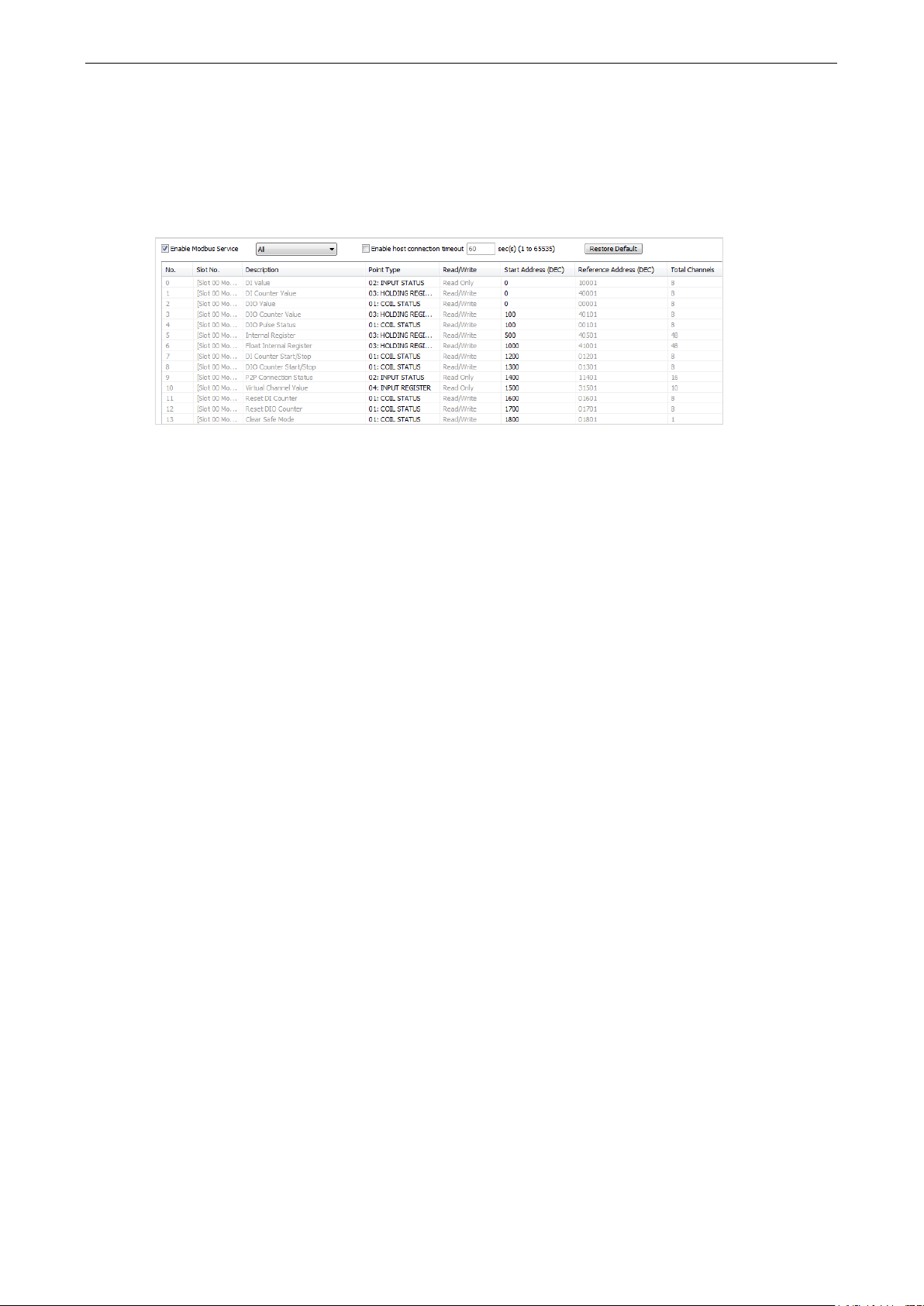

Network

There are three sub-pages under Network: General, LAN, Cellular (applies to the ioLogik 2500-

GPRS/HSPA only), and Wi-Fi (applies to the ioLogik 2500-WL1 only).

General

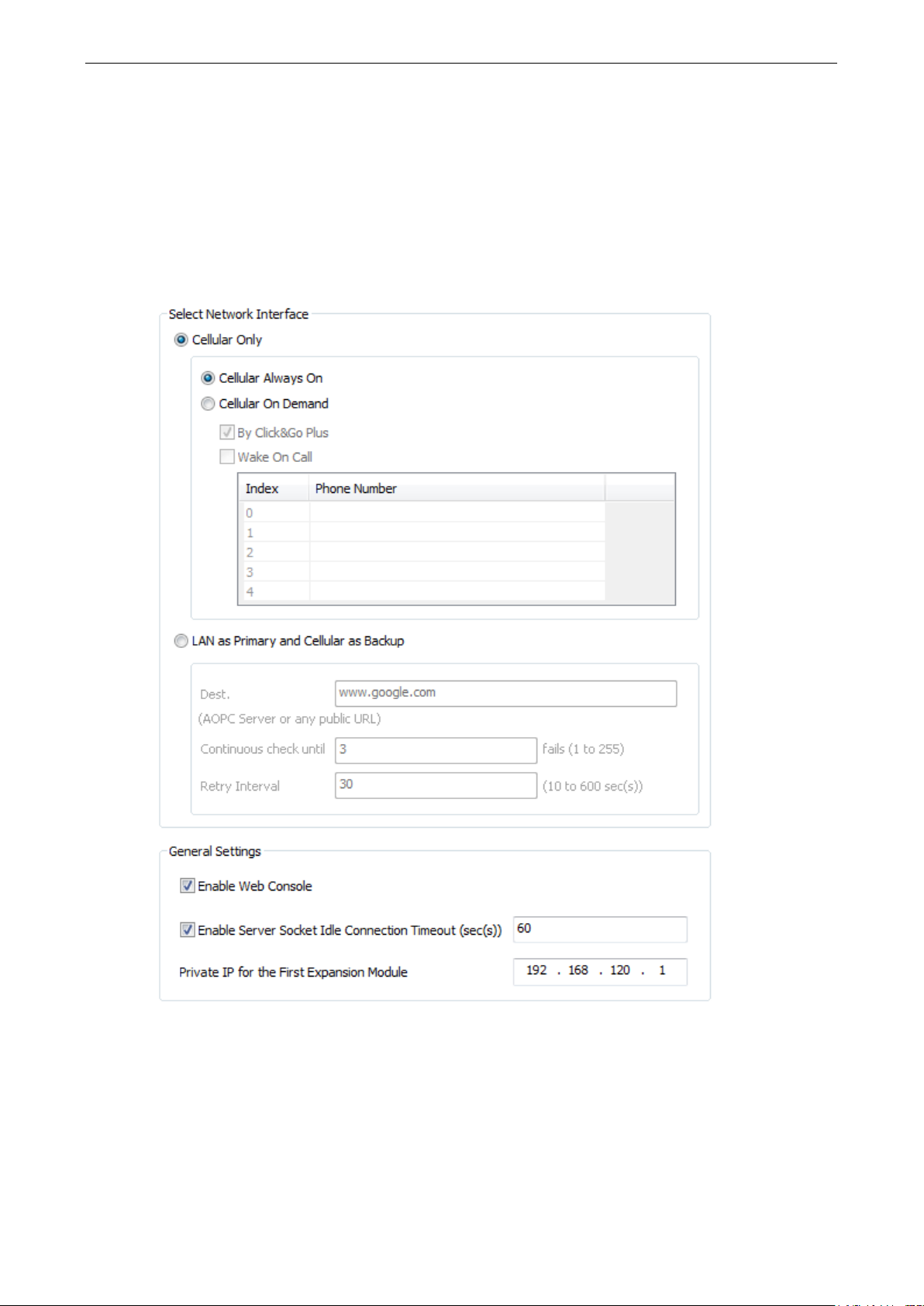

There are two columns under General: Select Network Interface and General Settings.

Select Network Interface

Select Network Interface is only available for the io Log ik 250 0 -GPRS/HSPA models. See Chapter 4:

Cellular Network Setup and Confi gura tio n for details.

General Settings

Page 36

ioLogik 2500 Series Configuration Library

4-9

An array of up to 8 modules can be connected to the

ioLogik 2500.

assigns an IP to the first E1200

subsequent

assigned consecutively. For example, if the IP of the first

E1200 device is set to 192.168.120.1, the IP of the second

E1200 will be 192.

192.168.120.3, and so on.

You can set up a static or dynamic IP address

for the ioLogik, as well as the subnet mask

and gateway address.

Use this field to specify the IP addresses of

one or two DNS servers. DNS servers ca n be

used to find available e-mail addresses when

setting up Click&Go

NOTE

The

Enable Web Console

Use this checkbox to enable or disable the web console. When enabled, the ioLogik can be configured from

a web browser. If not enabled, you will not be able to open the web console.

Enable Server Socket Idle Connection Timeout

Server Sock e t Id le Connect io n T imeout is designed to avoid TCP connection failures when the network

host is unable to respond due to a hardware failure or network prob le m.

If Server Socke t Idle Connection Timeout is enabled: When the server’s connection to the ioLogik 2500

exceeds the specified time period the device will auto m atic a lly re le as e its TCP connection to the server to

free up the port for the next connection.

If Server Socke t Idle Connection Timeout is not enabled: If the network host is unable to respond due

to a hardware failure or network problem, the ioLogik will continue to wait for a response from the host,

causing the TCP port to be occupied indefinitely by the host.

Private IP for the First Expansion Module

Private IP for First Expansion Module

module. The IPs for

modules in the chain will be automatically

LAN

168.120.2, the third IP will be

IP Settings

Plus rules.

Cellular (ioLogik 2500-GPRS/HSPA only)

ioLogik 2500-WL1 o nly supp or ts static I P addresses.

Cellular is only available for the ioLogik 2500-GPRS/HSPA models. See Chapter 4: Cellular Network

Setup and Configura tion for details.

Page 37

ioLogik 2500 Series Configuration Library

4-10

Channel No.

Sampling Time (min)

Wi-Fi (ioLogik 2500-WL1 Only)

Wi-Fi is only available for the ioLogik 2500-WL1 models. See Chapter 5: Wireless LAN Network S etup

and Configuration for details.

I/O

In the I/O section, you can configure I/O settings for ioLogik 2500 devices. Items that can be modified will

be shown in black. Items that cannot be modified will be shown in light gray. Because revising channel

type and name also changes each I/O setting, we recommend configuring the I/O Mode Settings first.

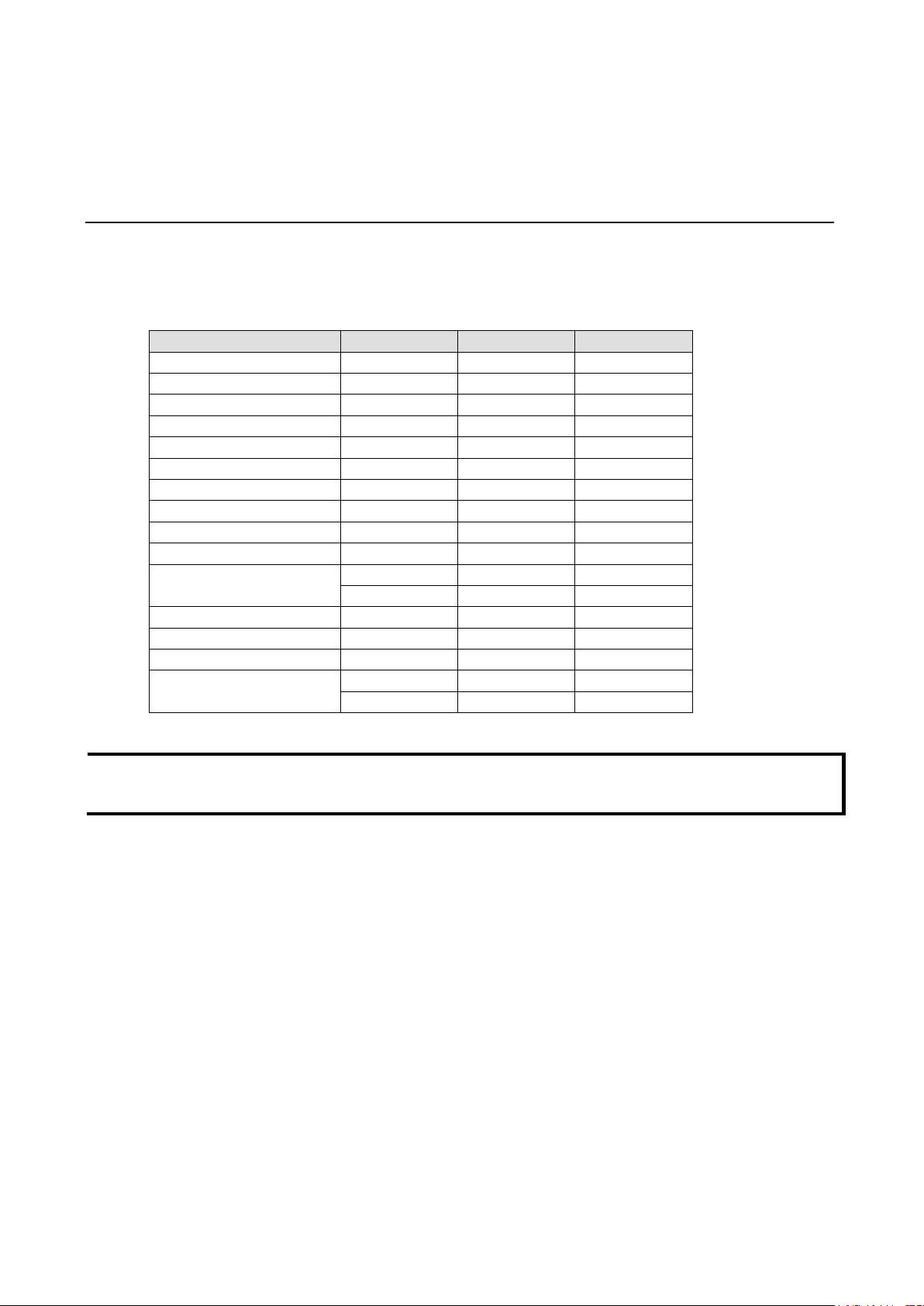

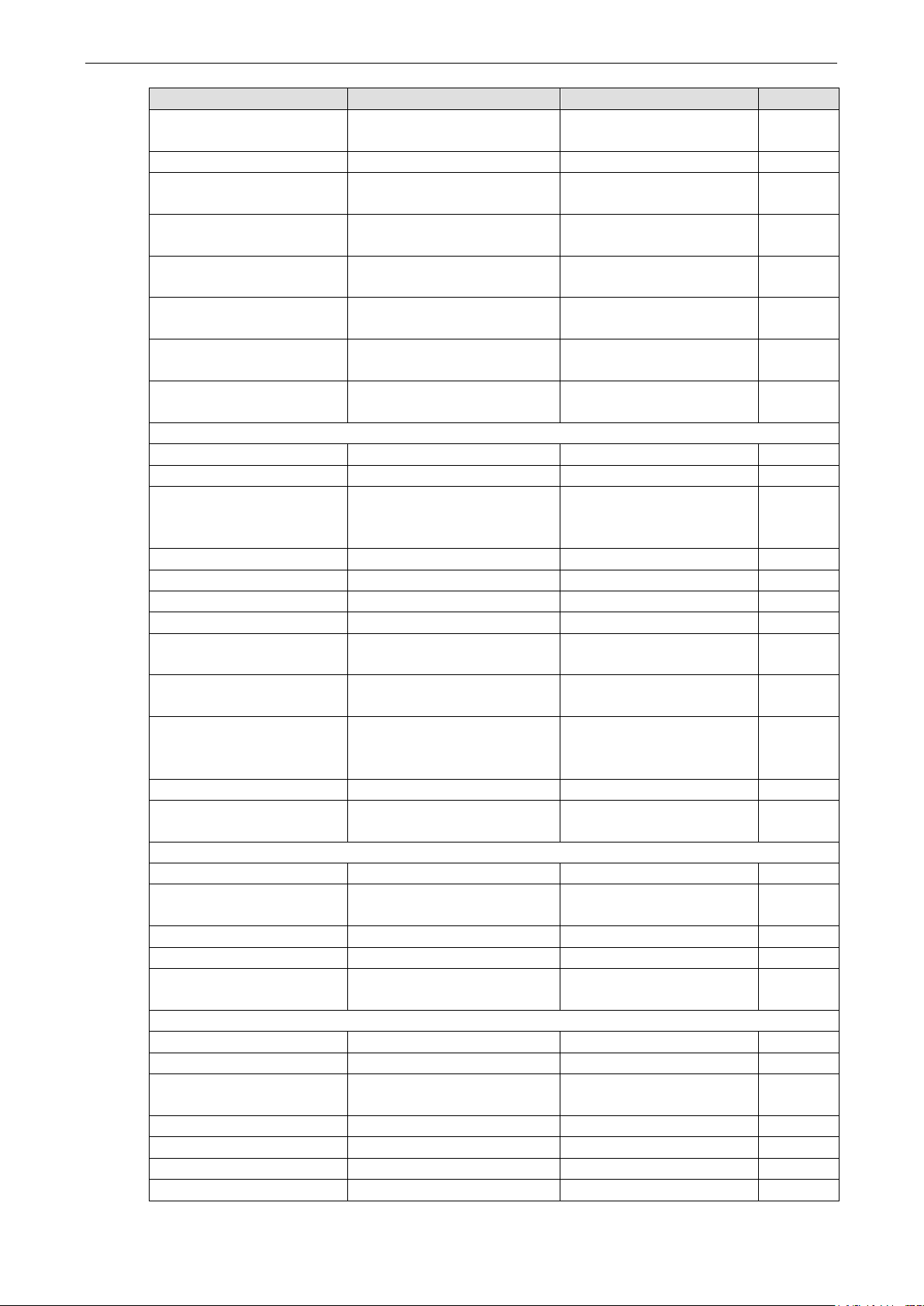

Setting Functions

IO Mode Setting Channel Mode

Name

DI Setting Filter

Counter Setting Filter

Initial Value

Trigger Mode

Power Off Storage

Power On Value

Power On Status

DO Setting Enab l e Com munic a tio n Wa tc hdo g for Safe Mode

Enable Auto Clear Safe Mode

Pulse Setting On Wid th

Off Width

Count

AI Setting Cha nne l Mo d e

Burnout Value

Scaling Slope

Virtual Channel Setting Enable

Slot No.

Scaling Enable

Scaling Slope

Scaling Offset

Scaling Interval

Power On Status

Power On Delay

Safe Mode Status

Power On Status

Power On Delay

Safe Mode Status

Scaling Offset

Scaling Unit

Function

Interval (min)

Page 38

ioLogik 2500 Series Configuration Library

4-11

NOTE

Since the ioLogik 2500 does not have AO

contains E1200 AO modules, such as the E1241.

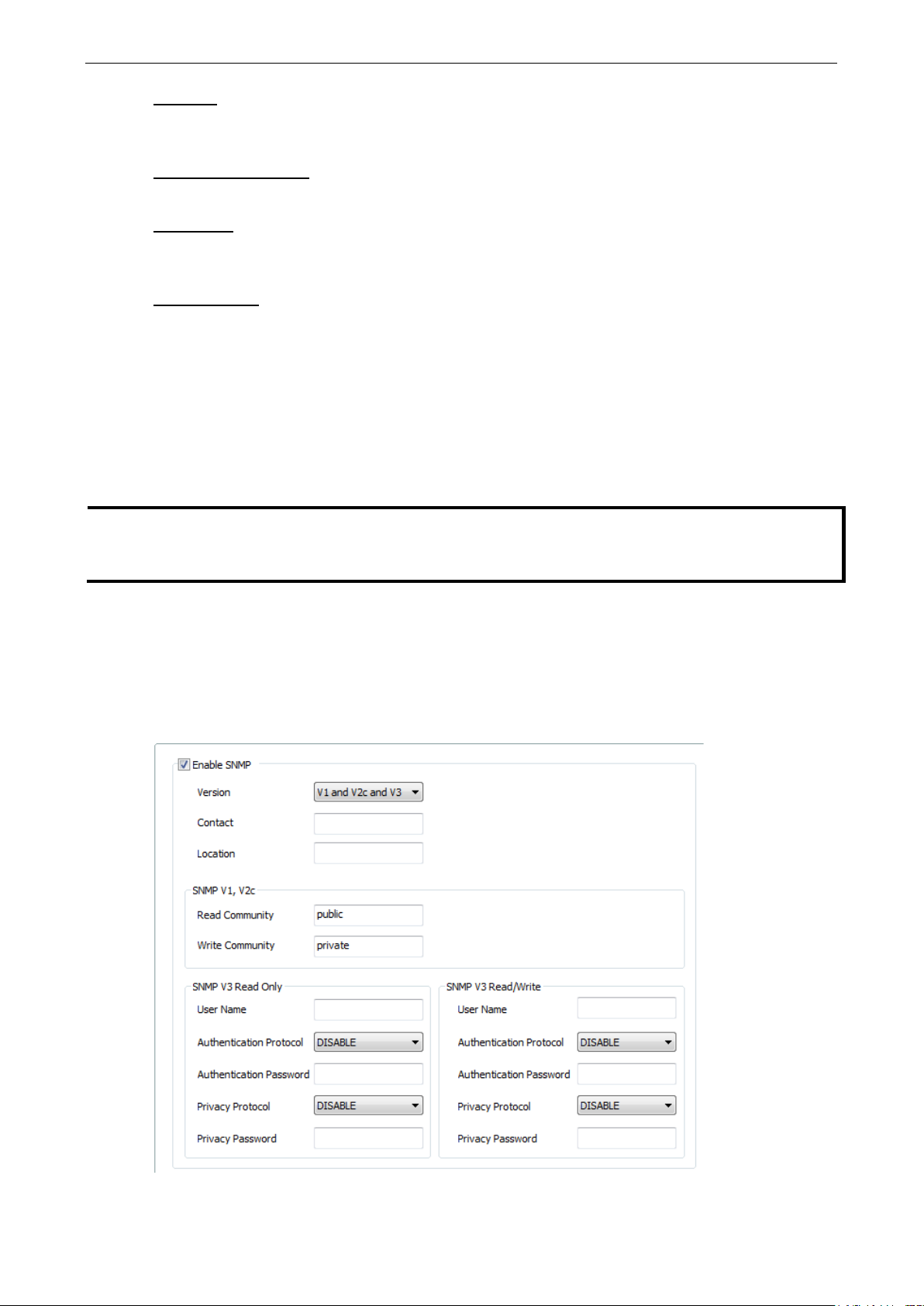

Select Module

Select the module that you would like to configure. Yo u may select All modules, in which case information

on all I/O channels in the project will be displayed .

IO Mode Setti n g

• Channel Mode

DIO channels can be set to one of four modes: DI, Event Counter , DO, or Pulse output. AI channels

can be set to one of five modes: ±10 V, 0 to 10 V, 0 to 20 mA, 4 to 20 mA, or 4 to 20 mA

(Burnout). AO channels can be set to one of two modes: 0 to 10 V and 4 to 20 mA.

• Name

The name will be attached to the AOPC tag to help users identify c hanne l infor m atio n in MX-AOPC.

DI Setting

Filter: Software filtering is used to avoid switch bounces. The filter is configurable in multiples of 100 μs

and accepts values between 1 and 65535.

channels, the AO setting will only show up when the project

Counter Setting

Counter refer s to an Event Counter channel. Co unts are stored inte rnally.

• Filter

Software filtering is used to avoid switch bounces. The filter is configurable in multiples of 100 μs and

accepts values between 1 and 65535.

• Initial Value

The initial value is the start value in counter mode.

Page 39

ioLogik 2500 Series Configuration Library

4-12

• Trigger Mode

In Trigger mode, the channel accepts limit or proximity switches and counts events according to the

ON/OFF status. When Rising edge is selected , the counte r value inc reases when the attached switch is

pushed. When Falling edge is selected, the counter value increases when the switch is released. When

Both is selected, the counter value increases when the attache d swi tc h is pus hed or rele ased .

• Power On Status

To enable the counter to resume counting immediate ly upon powering up, enable the Power On Status.

Stop: The counter star ts logging s i g nals o nly af ter config ured to do so by a Modbus or a Click&Go Plus

command.

Start: Counting begins automatically whenever the io Log ik is power ed on.

• Scaling Enable / Scaling Slope / Scaling Offset / Scaling Interval (sec)

Set the Slope & Offset to convert the Counter value to a new value. The scaled value = (original v alue

* Scaling Slope) + Scaling Offs e t.

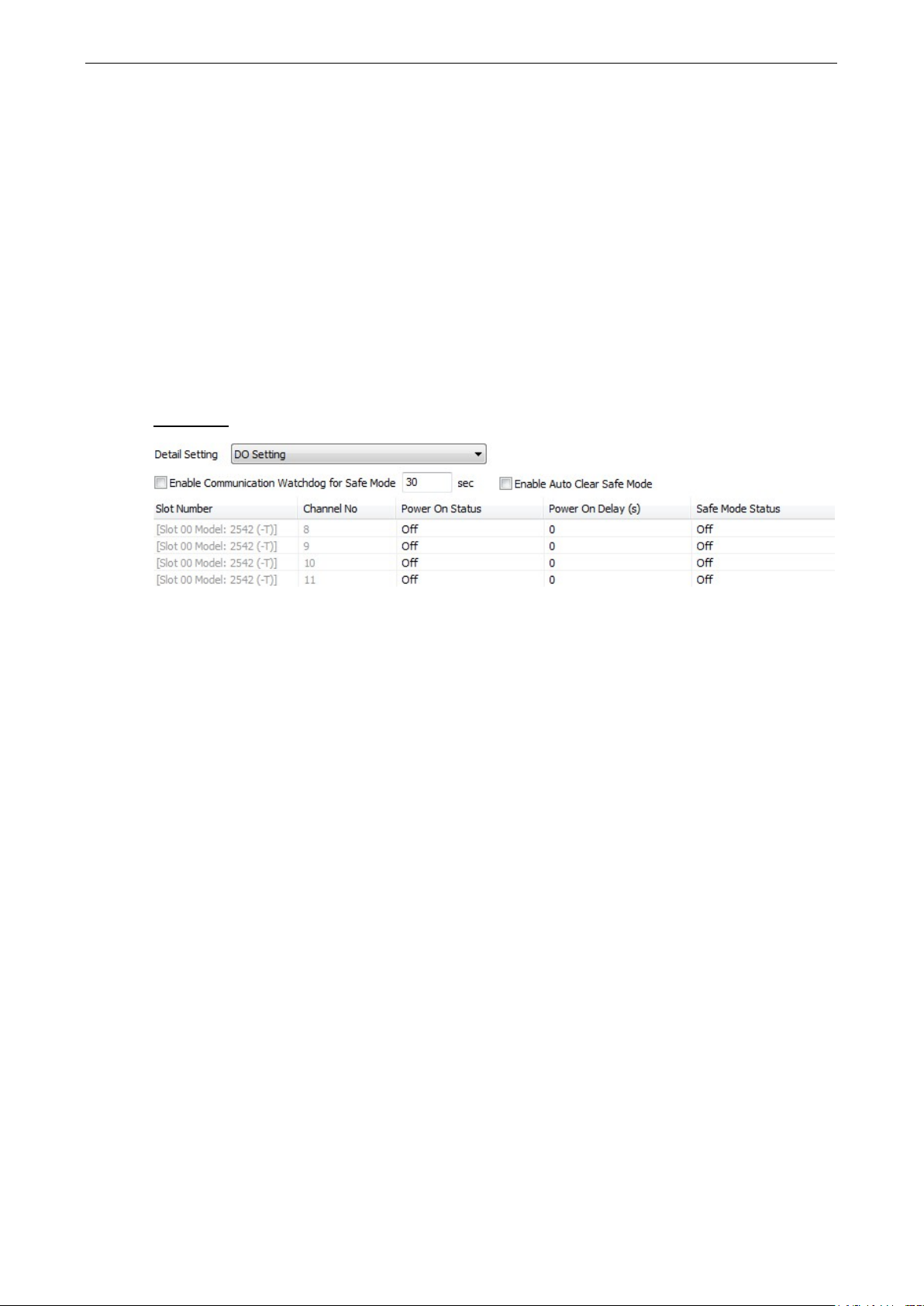

DO Setting

• Enable Communication Wa tchd og for Saf e Mo de

When the watchdog is enabled, any disconnection from the network will activate a safe state. In the

safe mode, DO channels can be configured to turn on, turn off, or commence puls e output d uring the

safe state. If the watchdog is not enabled, then DO channel sta tus w ill rem ain unc ha ng ed dur ing a

network disconnection.

To configure a DO for s afe mode , set the corresponding value in the Safe Mode Status column to ON.

• Enable Auto Clear Saf e Mo de

When detecting the reconnection of Ether net sig nal s , the devic e will auto c le ar the safe mode status.

• Power On Status

When the device is powered on, the status of each DO channel is set to OFF by default. This status can

be modified to ON.

• Power On Del a y

The time delay from tuning DO channels when the power is turned on.

• Safe Mode Status

Enable Communication Watchdog for Safe Mode allows you to control how DO and pulse output

channels act when the network is disconnected .

If the Communication Watchdog is enabled, a network disconnection will activate a safe state. The DO

channel can be configured to turn on / turn off during the safe state.

If the Communication Watchdog is not enabled, then the DO c hanne l status w ill rema in unchange d

during a network disconnection.

Page 40

ioLogik 2500 Series Configuration Library

4-13

Pulse Setting

• On Width / Off Width

In Pulse Output mode, the selec te d digital output channel will generate a square wave as specified in

the pulse mode parameters. The low and high level widths are specified in multiples of 100 μs, with a

maximum setting of 65,535.

• Count

You can specify between 1 and 4,294,967,295 pulses or enter “0” for continuous pulse output.

• Power On Status

When the device is first powered on, the status of each pulse o utp ut channel is set to OFF by default.

You can set a pulse output channel to turn ON when the ioLogik is powered on, or to commence pulse

output.

• Power On Del a y

The time delay from tuning Pulse channels when the pow er is tur ne d on.

• Safe Mode Status

If the Communication Watchdog is enabled, a network disconnection will activate a safe state. The pulse

output channel can be configured to turn on / turn off during the saf e state .

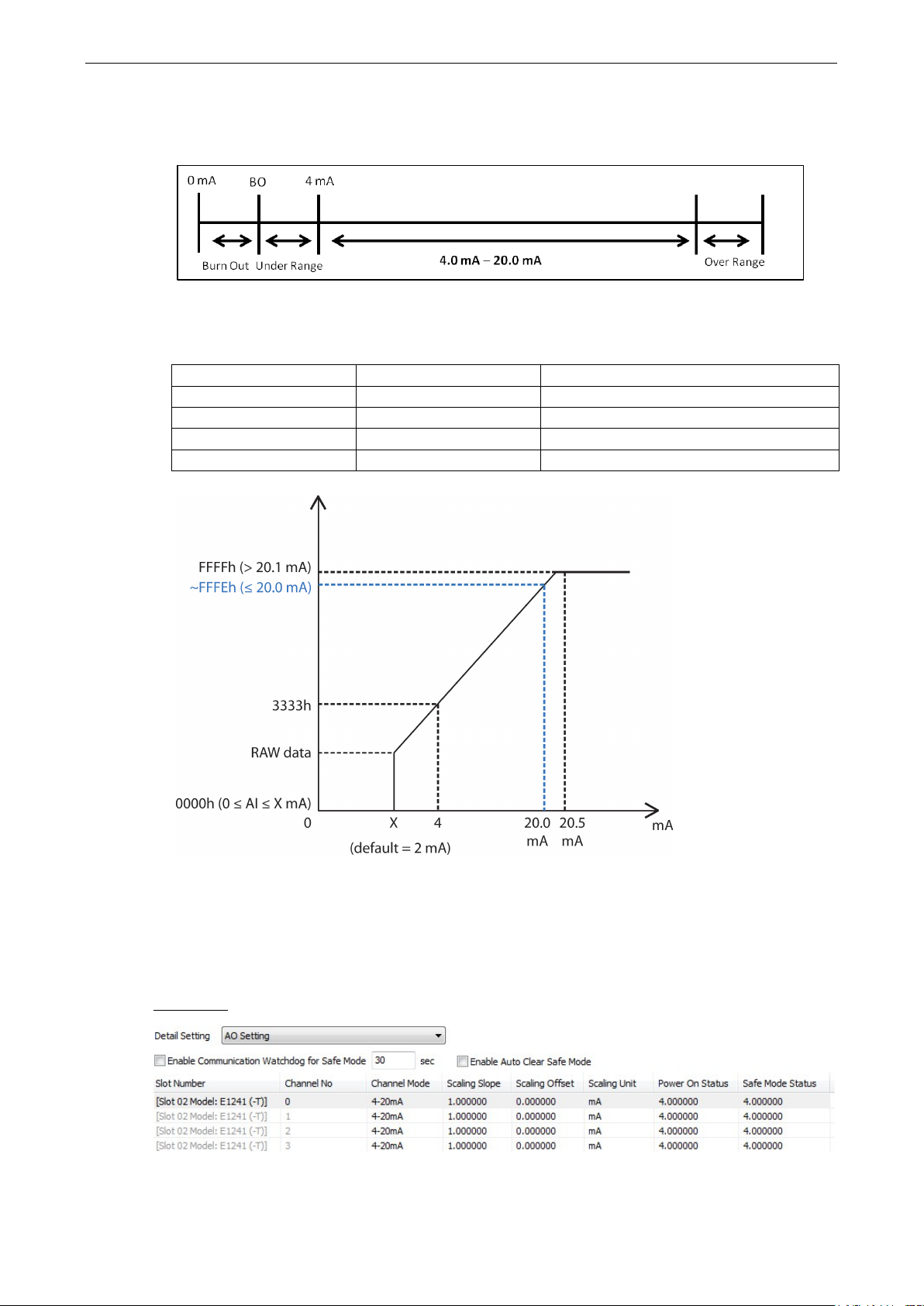

AI Setting

• Channel Mode

The input channels can be set individually to±10 V , 0 to 10 V, 0 to 20 mA, 4 to 20 mA, and 4 to 20 mA

(Burnout).

Page 41

ioLogik 2500 Series Configuration Library

4-14

• Burn-out Value

Burn Out mode indicates when the Current AI has burned out. For example , the 4–20 mA Burn-out

mode is defined in the following diagram:

Users can define Burn-out (BO) values (default = 2 mA) for selected ranges. When input values are in

the Burn Out range, raw data will register as 0000h to indicate that the analo g input has burned out.

The definition of raw data is as follows:

Burnout Value (BO) 0.0 < BO < 4.0 User defined (d ef ault 2 mA)

Burnout State 0 ≤ AI < BO mA Modbus output 0000h

Under Range BO ≤ AI < 4 mA Modbus output raw data

Normal Range 4 ≤AI ≤ 20.00 mA Modbus output raw data until FFFEh

Over Range XX > 20.00 mA Modbus output FFFFh

• Scaling Slope / Scali ng Of fse t /Sc aling Unit

Enabling the Scaling functions will line arly convert the actual current or voltage value into other userdefined units, such as percentage or ppm (parts per million).

Set the Slope & Offset to convert the AI value to a new value. The s c aled value = (or iginal v alue *

Scaling Slope) + Scaling Offset.

AO Setting

• Channel Mode

There are two modes for the AO channels: Voltage Mode (V) and Current Mode (mA).

Page 42

ioLogik 2500 Series Configuration Library

4-15

NOTE

Since the ioLogik 2500 does not have AO channels, the AO setting will o nly show up when the projec t

contains E1200 AO modules (such as the E1241).

• Scaling Slope / Scali ng Of fse t / Scal ing Unit

Enabling the Scaling functions will line arly convert the actual current or voltage value into other userdefined units, such as percentage or ppm (parts per million).

Set the Slope & Offset to convert the AO value to a new value. The scaled value = (original v a lue *

Scaling Slope) + Scaling Offset.

• Power On Status

When the device is first powered on, the status of each AO channel can be modif ied us ing the Power

On Status.

• Safe Mode Status

Enable Communication Wa tchd og for Saf e Mo de allows you to control how an AO channel acts

when the network is disconnected.

If the Communication Watchdog is enabled, a network disconnection will activate a safe state. The AO

channel can be configured to a defined value during the safe state .

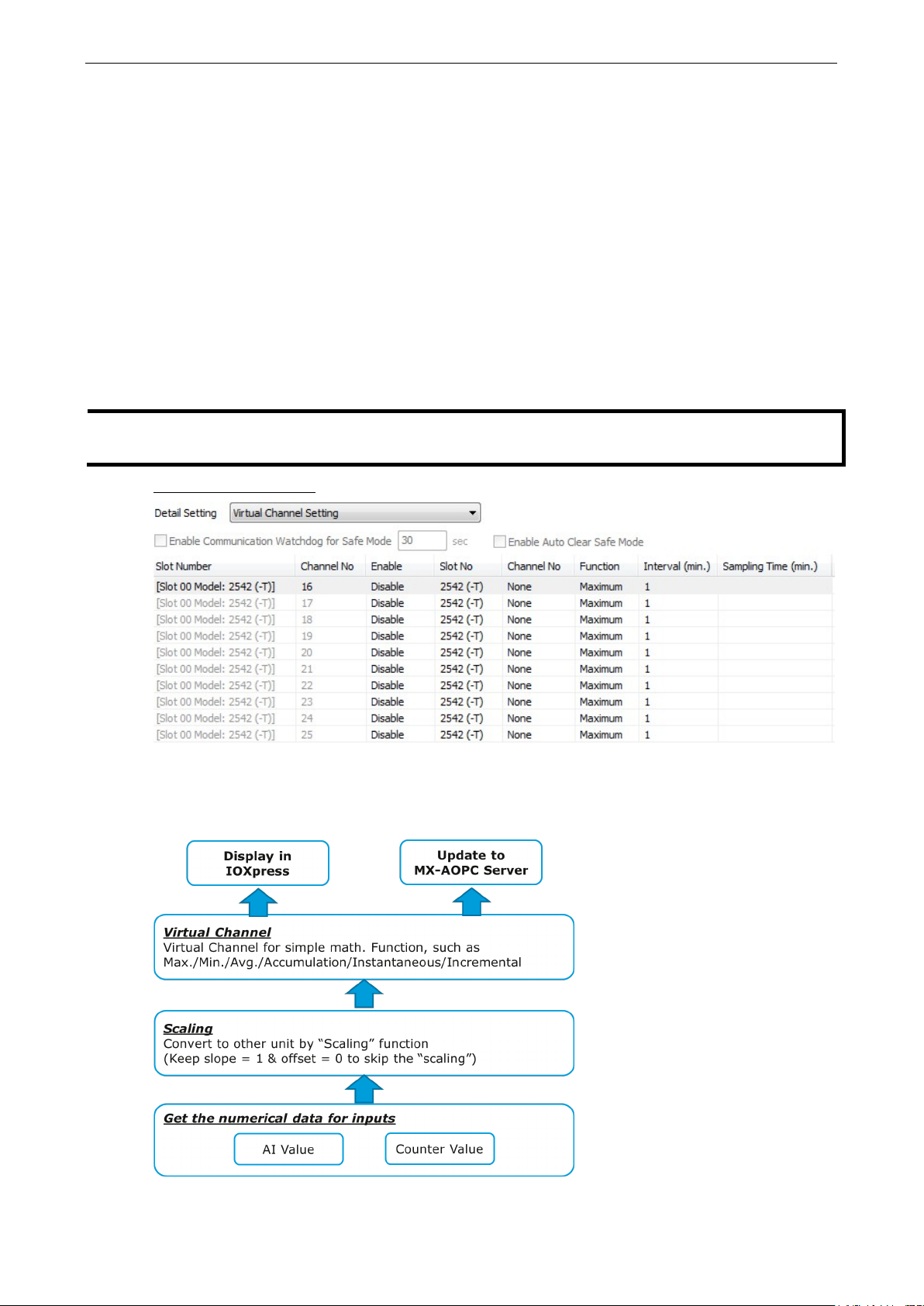

Virtual Channel Setting

The ioLogik 2500 has 10 internal virtual channels to s uppor t fro nt-end sta tis tic s functions.

The data source is the real I/O channel, such as AI and DI counters, some of whic h need to be converte d to

the appropriate time unit. The operation is illustrated below.

Page 43

ioLogik 2500 Series Configuration Library

4-16

NOTE

For AI/Counter scal

operations in the virtual channels.

If you have connected E1200 expansion modules, selec t the dev ic e you

would like to configure here.

For example, if you want to monitor the daily flow at a point in a pipeline, you can use a pulse output flo w

meter, where 1 pulse indicates 5 ml. You can set the virtual channel’s scaling function so that 1 tick of

counter input equals 5 ml. Next, set the Accumulation flag, and configure the Time Interval to 24 hours.

This will set up the virtual channel to log the total water flow vo lum e ove r a p er i od of 24 hours.

• Status

Enable/Disable virtual channels.

• Slot No.

• Channel No.

Virtual channels are required to config ure AI or counter c hannels.

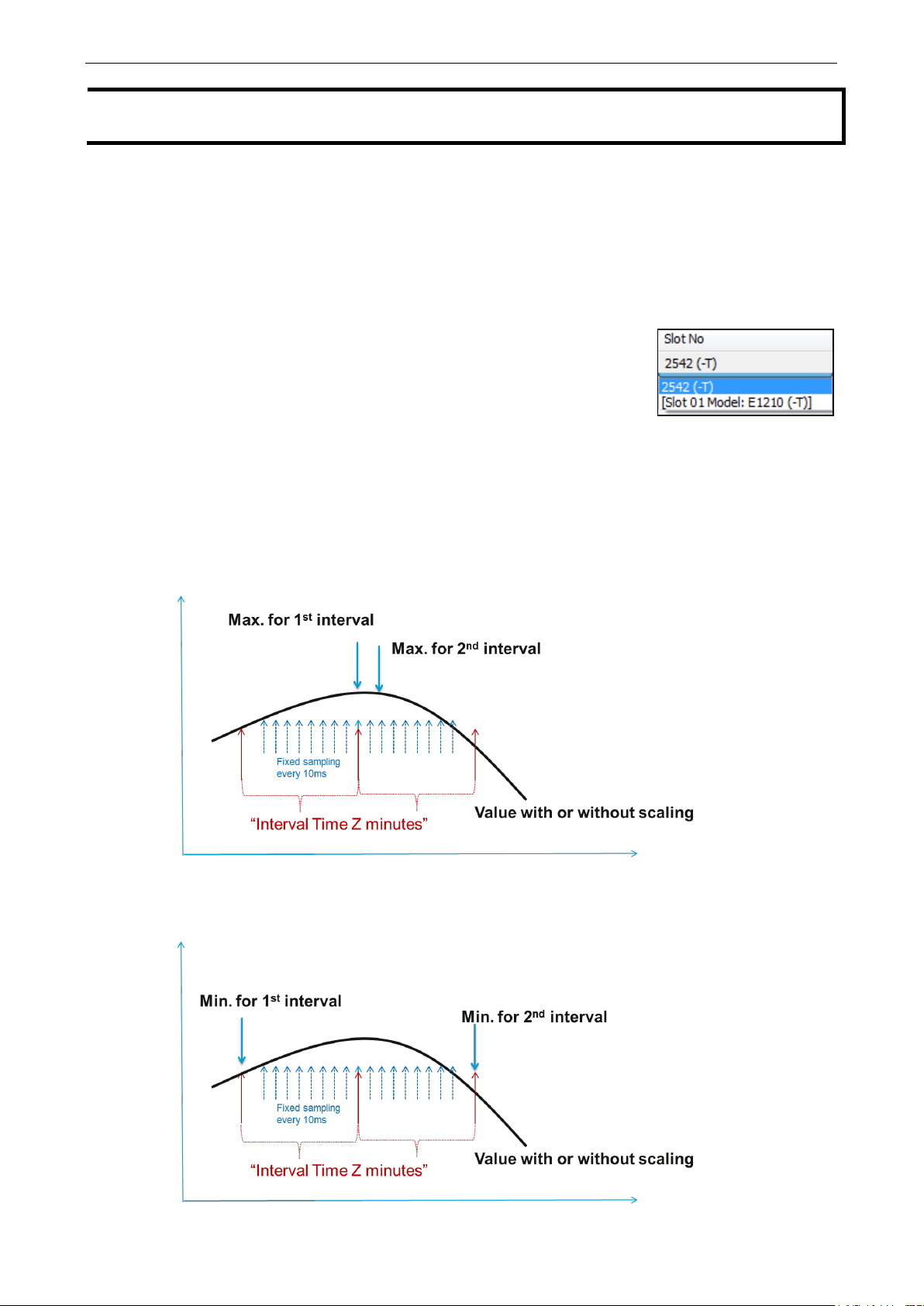

• Function

There are six functions: Max, Min, Average, Acc um ulation, Instantaneous, and Incremental.

Maximum:

The maximum value within Z sec, with sampling done every 10 ms.

ing, configure Scaling on the AI or Counter Configuration panel before selecting

Minimum:

The minimum value within Z sec, with sampling done every 10 ms.

Page 44

ioLogik 2500 Series Configuration Library

4-17

Average:

The average value within Z sec, with sampling done every 10 ms.

Instantaneous:

The instantaneous value when a sample is taken.

Incremental:

The difference (Δ) between two samples.

Page 45

ioLogik 2500 Series Configuration Library

4-18

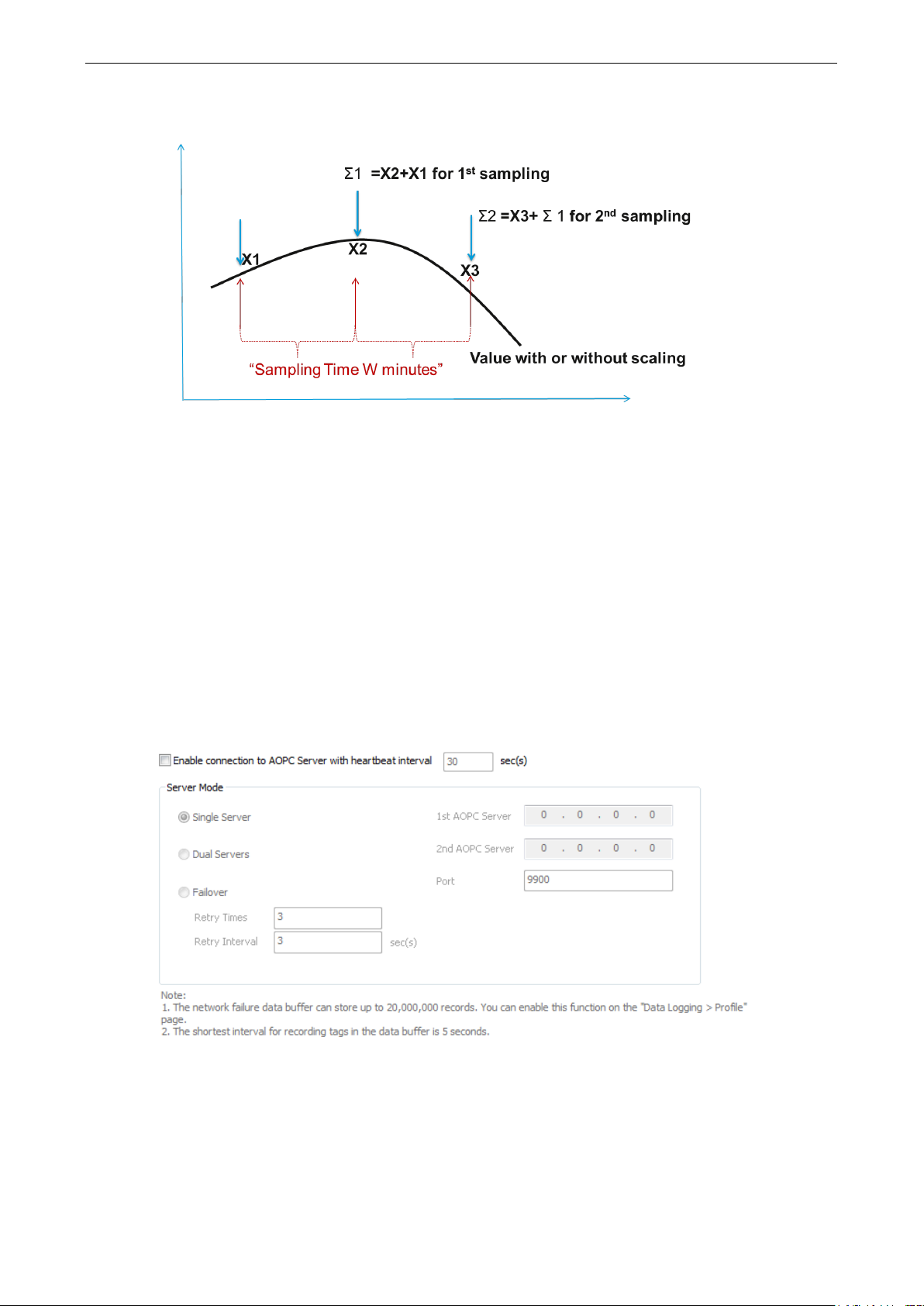

Accumulation:

The sum (Σ) of all sampling values.

• Interval (min.)

Set the interval time (Minutes) for Maximum, Minimum, and Average functions.

• Sampling Time (min.)

Set the sampling time (Minutes) for Instantaneo us and Incrementa l f unc ti o ns .

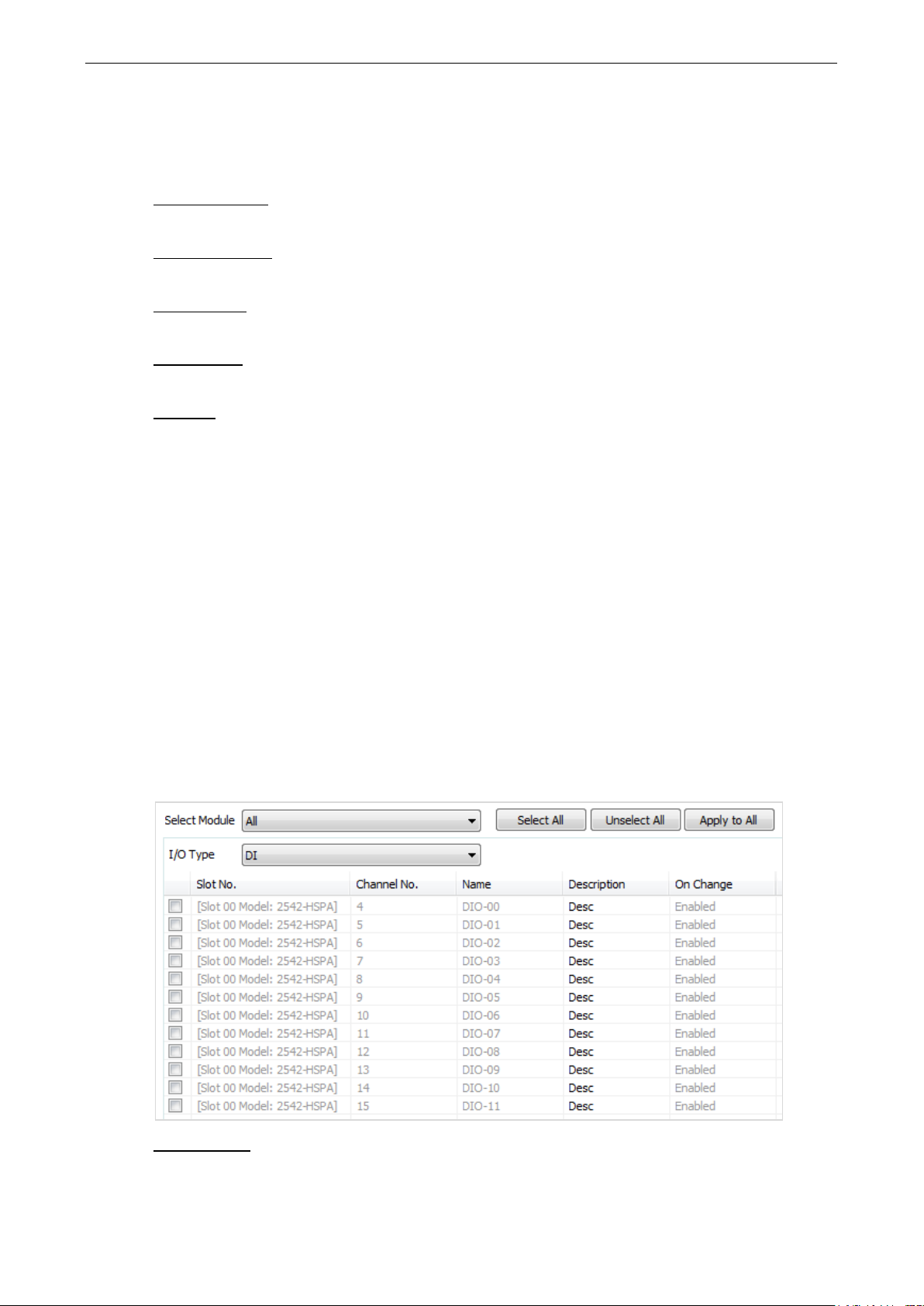

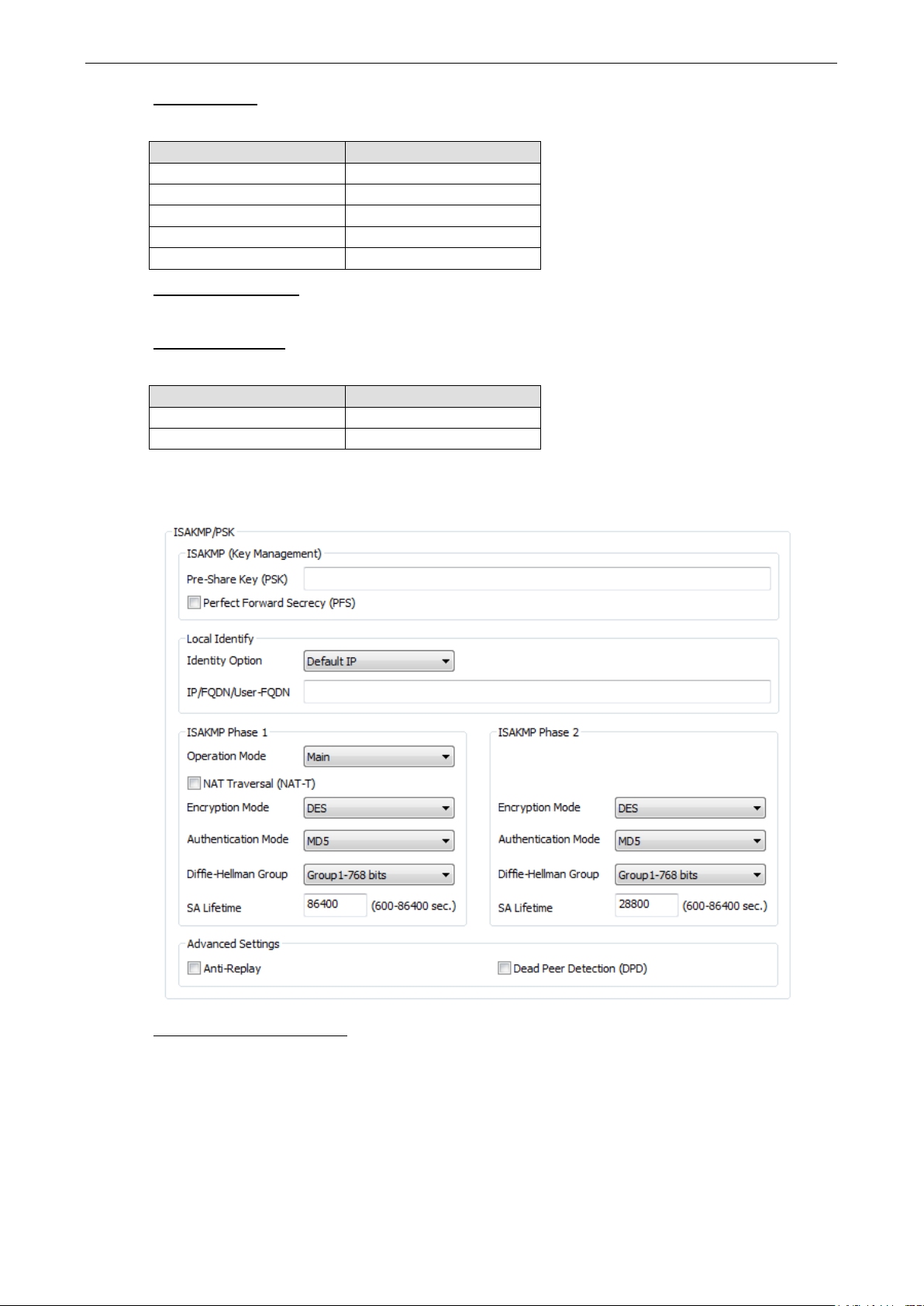

AOPC

Moxa MX-AOPC Server is a software package operated as an OPC driver of an HMI or SCADA syste m . I t

offers seamless connection from Moxa ioLogik series products to SCADA systems.

Server Connection

You can set the ioLogik 2500 to connect to MX-AOPC UA Server. Each ioLogik 2500 ser ie s can co nnect to

two MX-AOPC UA serv ers. You can also set different modes to send active tags.

Enable connection to AOPC Server with heartbeat interval

The Heartbeat Interval can be used to determine the connection status between the ioLogik 2500 and

MX-AOPC Server, and to ensure that the ioLogik 2500 is connected and aliv e . If the heartbeat inte rval is set

and the network between the ioLogik 2500 and MX-AOPC Server is down, MX-AOPC Server will detect the

stopped heartbeat and the Quality column in the MX-AOPC Server will d is play BAD to indicate the loss of

connectivity.

Page 46

ioLogik 2500 Series Configuration Library

4-19

Server Mode

The ioLogik 2500 can send active tags to one or two MX-AOPC UA servers. You ma y choose one of three

server modes.

1st AOPC Server

IP address of the 1st AOPC server.

2nd AOPC Server

IP address of the 2nd A OP C server.

Single Ser ver

The ioLogik 2500’s active tags will be sent to a single AOPC serv e r.

Dual Servers

The ioLogik 2500’s active tags will be sent to two AOPC server s .

Fail Over

The ioLogik 2500 will try to connect with the first MX-AOPC Server IP. If it cannot connect, it will

automatically connect with the seco nd IP, and w he n the connection to the second IP fails, it will switch back

to the first IP.

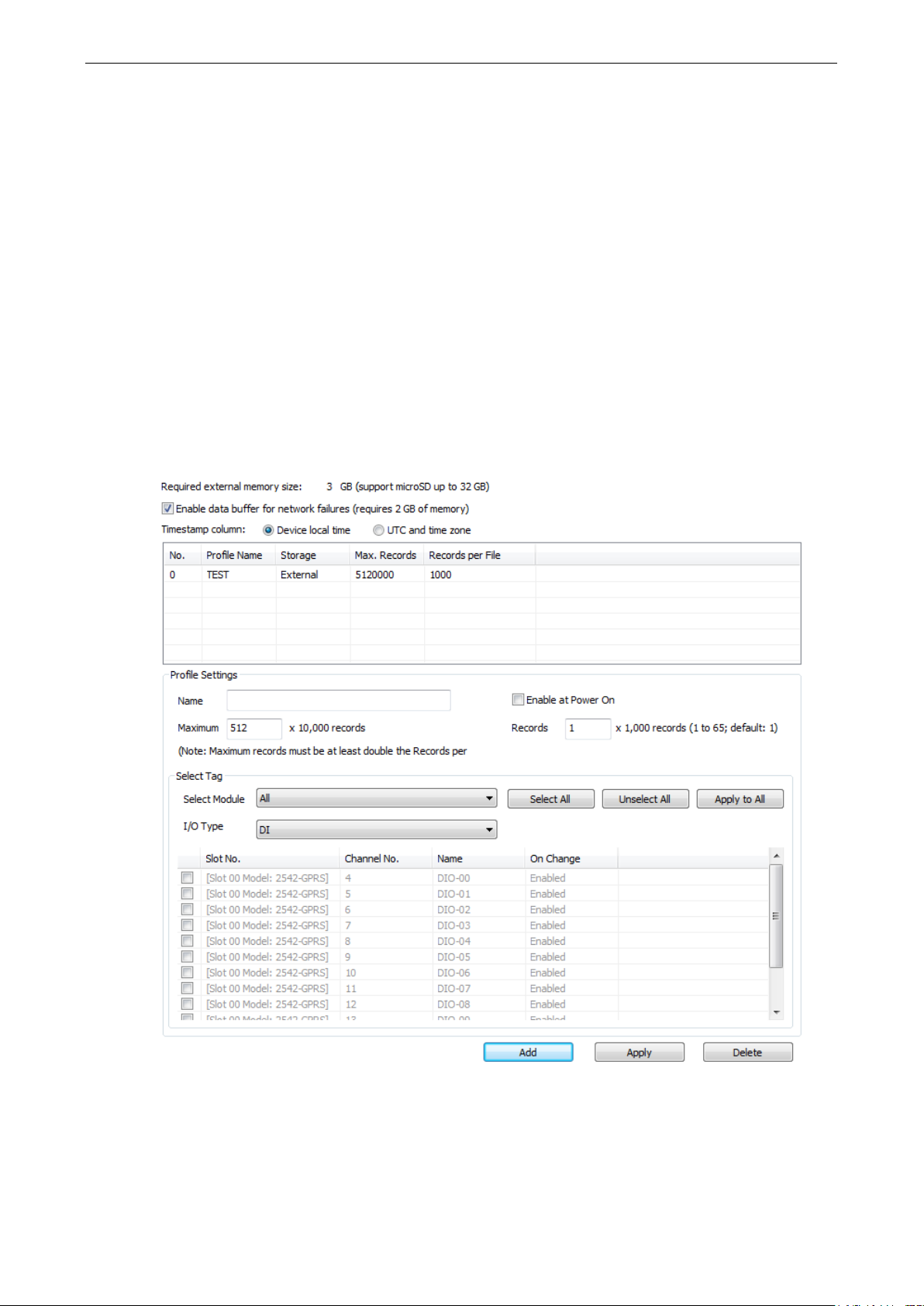

Data buffer for network failure

The ioLogik 2500 supports a data buffer function that stores transmitted data on an inserted SD card when

the connection between MX-AOPC UA Server and the ioLogik 2500 was down. MX-AOPC UA Logger will

automatically retrieve the buffering data after the connection b e twee n MX -AOPC UA Server and the ioLog ik