Page 1

P/N: 1802075260022

*1802075260022*

ICS-G7526A/G7528A/

G7826A/ G7828A Series

Quick Installation Guide

Edition 2.1, August 2017

Technical Support Contact Information

www.moxa.com/support

Moxa Americas:

Toll

-free: 1-888-669-2872

Tel:

1-714-528-6777

Fax:

1-714-528-6778

Moxa China (Shanghai office):

Toll

-free: 800-820-5036

Tel:

+86-21-5258-9955

Fax:

+86-21-5258-5505

Moxa Europe

:

Tel:

+49-89-3 70 03 99-0

Fax:

+49-89-3 70 03 99-99

Moxa Asia

-Pacific:

Tel:

+886-2-8919-1230

Fax:

+886-2-8919-1231

Moxa India:

Tel:

+91-80-4172-9088

Fax:

+91-80-4132-1045

2017 Moxa Inc. All rights reserved.

Page 2

- 2 -

Package Checklist

The Moxa ICS-G7526A/G7528A/G7826A/G7828A Series industrial

rackmount switches are shipped with the following items. If any of these

items are missing or damaged, please contact your customer service

representative for assistance.

• ICS-G7526A/G7528A/G7826A/G7828A switch

• USB cable (Type A male to Type B male)

• Power cord

• 4 protective caps for unused ports

• 2 rackmount ears

• Documentation and software CD

• Quick installation guide (printed)

• Warranty card

Panel Layouts

ICS-G7526A/G7826A

ICS-G7528A/G7828A

1. Model Name

2. System status LEDs

3. 10/100/1000 BaseT(X) port status LEDs

4. 100/1000 Base SFP port status LEDs

Page 3

- 3 -

5. 10/100/1000 BaseT(X) port

6. 100/1000 Base SFP slot

7. 10/100/1000 BaseT(X) or 100/1000 Base SFP slot combo ports

8. 10 Gigabit Ethernet SFP+ slot

9. 10 Gigabit Ethernet SFP+ port status LEDs

10. Reset button

11. USB serial console port

12. USB storage port (ABC-02-USB)

13. Terminal block for Relay Output, Digital Input

14. AC power sockets for power inputs

15. Grounding screw

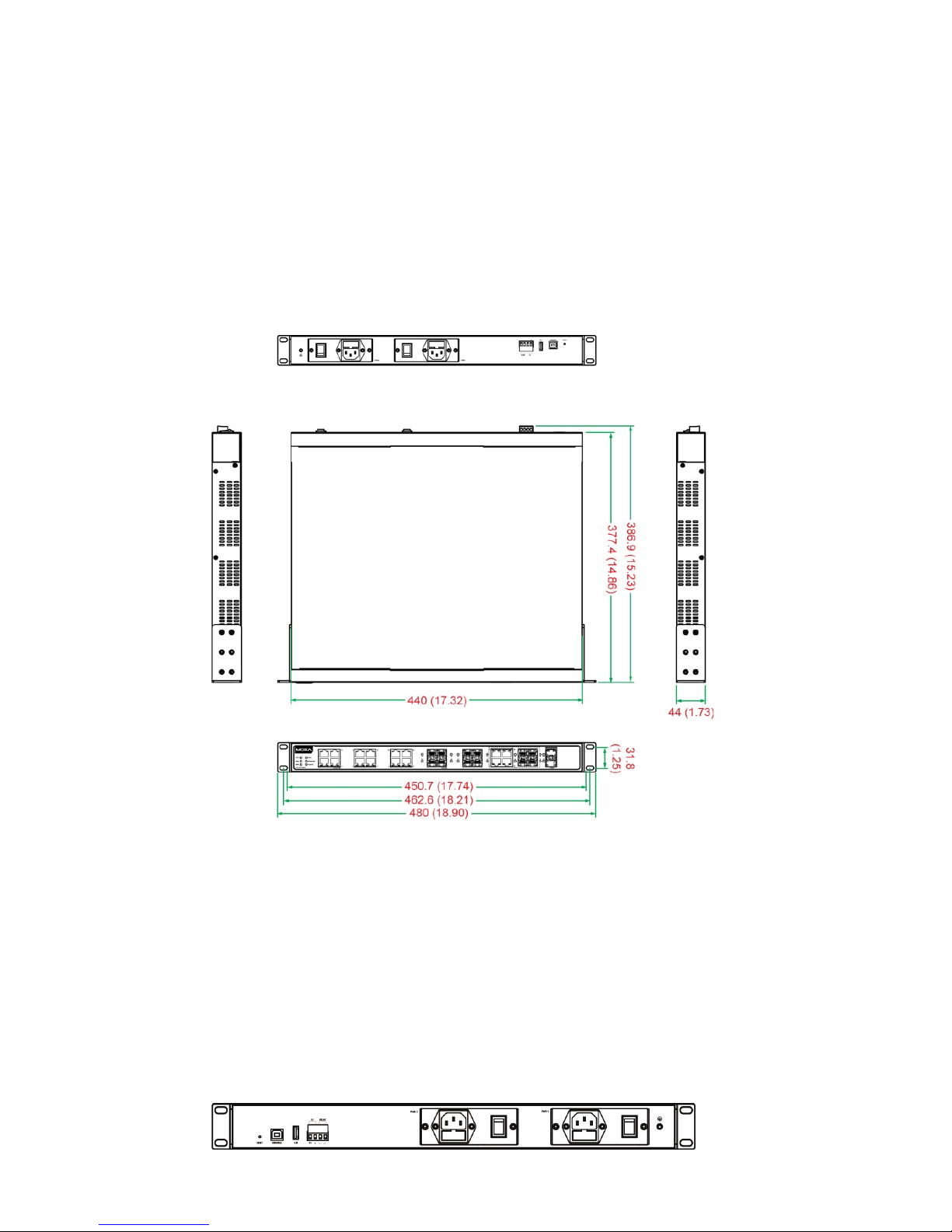

Dimensions (unit = mm)

Grounding the Industrial Rackmount Switch

Grounding and wire routing help limit the effects of noise due to

electromagnetic interference (EMI). Run the ground connection from the

ground screw to the grounding surface prior to connecting devices.

Connecting the Power Inputs

The ICS-G7526A/G7528A/G7826A/G7828A switches support dual

redundant power supplies: Power Supply 1 (PWR1) and Power Supply 2

(PWR2). The connections for PWR1 and PWR2 are located on the rear side

(shown below). Be sure to use a standard power cord with an IEC C13

connector, which is compatible with the AC power inlet.

Page 4

- 4 -

Wiring the Relay Contact

Each ICS-G7526A/G7528A/G7826A/G7828A switch has one relay output.

FAULT:

The relay contact of the 4-pin terminal block connector is used to detect

user-configured events. The two wires attached to the fault contacts form

an open circuit when a user-configured event is triggered. If a

user-configured event does not occur, the fault circuit remains closed.

USB Console Connection

The ICS-G7526A/G7528A/G7826A/G7828A series has one USB console

port (type B connector), located on the top panel. Use the USB cable

(provided in the product package) to connect the

ICS-G7526A/G7528A/G7826A/G7828A's console port to your PC's USB

port and install the USB driver (available in the software CD) on the PC.

You may then use a console terminal program, such as Moxa PComm

Terminal Emulator, to access the

ICS-G7526A/G7528A/G7826A/G7828A’s console configuration utility.

USB Console Port (Type B Connector) Pinouts

Pin

Description

1

D– (Data -)

2

VCC (+5V)

3

D+ (Data+)

4

GND (Ground)

USB Storage Connection

The ICS-G7526A/G7528A/G7826A/G7828A series has one USB storage

port (type A connector) on the front panel. Use Moxa ABC-02-USB

automatic backup configurator to connect the

ICS-G7526A/G7528A/G7826A/G7828A's USB storage port for

configuration backup, firmware upgrade or system log file backup.

USB Storage Port (Type A Connector) Pinouts

Pin

Description

1

VCC (+5V)

2

D– (Data -)

3

D+ (Data+)

4

GND (Ground)

NOTE

DO NOT

pull out USB Automatic Backup Configurator

ABC-02-USB while writing or reading data.

The Reset Button

Depress the Reset button for five continuous seconds to load the factory

default settings. Use a pointed object, such as a straightened paper clip or

toothpick, to depress the Reset button. When you do so, the STATE LED

will start to blink about once per second. Continue to depress the STATE

LED until it begins blinking more rapidly; this indicates that the button has

been depressed for five seconds and you can release the Reset button to

load factory default settings.

Page 5

- 5 -

NOTE

DO NOT power off the switch when loading default settings.

LED Indicators

The front panel of the ICS-G7526A/G7528A/G7826A/G7828A switches

contain several LED indicators. The function of each LED is described in

the table below.

LED

Color

State

Description

System LEDs

STATE

GREEN

On

The system passed the self-diagnosis test

on boot-up and is ready to run.

Blinking

1. System is undergoing the self-diagnosis

test

2. Blinks continuously when pressing the

reset button 5 seconds to reset to factory

default

3. Blinks slowly when an ABC-02

automatic backup device is detected

RED On

The system failed self-diagnosis on

boot-up.

PWR1 AMBER

On

Power is being supplied to the main

module’s power input PWR1.

Off

Power is not being supplied to the main

module’s power input PWR1.

PWR2 AMBER

On

Power is being supplied to the main

module’s power input PWR2.

Off

Power is not being supplied to the main

module’s power input PWR2.

FAULT RED

On

The system has failed, or is under quick

inspection.

Off

The system is operating normally.

MSTR/

HEAD

GREEN

On

The switch is set as the Master of the

Turbo Ring, or as the Head of the Turbo

Chain.

Blinking

The switch has become the Ring Master of

the Turbo Ring, or the Head of the Turbo

Chain, after the Turbo Ring or the Turbo

Chain is down.

Off

The switch is not the Master of this Turbo

Ring or is set as a Member of the Turbo

Chain

CPLR/

TAIL

GREEN

On

The switch’s coupling function is enabled

to form a back-

up path, or when it’s set as

the Tail of the Turbo Chain.

Blinking

Turbo Chain is down

Off

The switch disables the coupling function.

When the system is importing/exporting data from or to an ABC-02

automatic backup device, the FAULT, MSTR/HEAD, and CPLR/TAIL LEDs

will blink in sequence.

Page 6

- 6 -

LED

Color

State

Description

Port Status LEDs

10/100/

1000M

(TP ports)

GREEN

On

The corresponding port’s link is active.

Blinking

Data is being transmitted.

Off

The corresponding port’s link is inactive.

100/1000M

(Fiber Optic

ports)

GREEN

On

The corresponding port's link is active at

1000 Mbps.

Blinking

Data is being transmitted at 1000 Mbps.

Off

The corresponding port’s link is inactive.

AMBER

On

The corresponding port's link is active at

100 Mbps.

Blinking

Data is being transmitted at 100 Mbps.

Off

The corresponding port’s link is inactive.

10GbE

(Fiber Optic

ports)

GREEN

On

The corresponding port’s link is active.

Blinking

Data is being transmitted.

Off

The corresponding port’s link is inactive.

Specifications

Technology

Standards

IEEE 802.3 for 10BaseT

IEEE 802.3u for 100BaseT(X) and 100BaseFX

IEEE 802.3ab for 1000BaseT(X)

IEEE 802.3z for 1000BaseSX/LX/LHX/ZX

IEEE 802.3ae for 10 Gigabit Ethernet

IEEE 802.3x for Flow Control

IEEE 802.1D-2004 for Spanning Tree Protocol

IEEE 802.1w for Rapid Spanning Tree Protocol

IEEE 802.1s for Multiple Spanning Tree Protocol

IEEE 802.1Q for VLAN Tagging

IEEE 802.1p for Class of Service

IEEE 802.1X for Authentication

IEEE 802.3ad for Port Trunk with LACP

Protocols

IGMPv1/v2, GMRP, GVRP, SNMPv1/v2c/v3, DHCP

Server/Client, BootP, TFTP, SNTP, SMTP, RARP,

RMON, HTTP, HTTPS,Telnet, Syslog, DHCP Option

66/67/82, SSH, LLDP, IEEE 1588 PTP V2,

EtherNet/IP, Modbus/TCP, PROFINET, SNMP

Inform,

NTP Server/Client, IPv6 (ICS-G7500A series)

Layer 3 Switching

(ICS-G7800A)

Static routing, RIP V1/V2, OSPF, DVMRP, PIM-DM,

PIM-SM, PIM-SSM

Layer 3 Switching

Redundancy

(ICS-G7800A)

VRRP

MIB

MIB-II, Ethernet-like MIB, P-BRIDGE MIB, Q-BRIDGE

MIB,

Bridge MIB, RSTP MIB, RMON MIB Groups 1, 2,

3, 9

Flow Control

IEEE 802.3x flow control, back pressure flow control

Page 7

- 7 -

Interface

Gigabit Ethernet

10/100/1000BaseT(X) or 100/1000BaseSFP slot

10 Gigabit Ethernet

10GbE SFP+ slot

Console Port

USB-serial console (Type B connector)

Storage Port

USB storage (Type A connector for ABC-02-USB)

LED Indicators

STATE, PWR1, PWR2, FAULT, MSTR/HEAD,

CPLR/TAIL

Alarm Contact

1 relay output with current carrying capacity of

2 A @ 30 VDC

Digital Inputs

1 input with the same ground, but electrically

isolated from the electronics.

• +13 to +30V for state “1”

• -30 to +1V for state “0”

• Max.input current: 8 mA

Power Requirements

Input Voltage

110/220 VAC (85 to 264 VAC)

Input Current

ICS-G7526/G7826:

Max. 0.98/0.55 A @ 110/220 VAC

ICS-G7528/G7828:

Max. 1.16/0.65 A @ 110/220 VAC

Overload Current

Protection

Present

Reverse Polarity

Protection

Present

Physical Characteristics

Housing

IP30 protection

Dimensions

440 x 44 x 386.9 mm (17.32 x 1.73 x 15.23 in)

Installation

19” rack mounting

Environmental Limits

Operating Temp.

-10 to 60°C (14 to 140°F)

Storage Temp.

-40 to 85°C (-40 to 185°F)

Ambient Relative

Humidity.

5 to 95% (non-condensing)

Standards and Certifications

Safety

UL 60950-1, EN 60950-1

EMI

FCC Part 15 Subpart B Class A, EN 55032 Class A

EMS

EN 61000-4-2 (ESD) Level 3

EN 61000-4-3 (RS) Level 3

EN 61000-4-4 (EFT) Level 3

EN 61000-4-5 (Surge) Level 3

EN 61000-4-6 (CS) Level 3

EN 61000-4-8

EN 61000-4-11

Rail Traffic

EN 50121-4

Shock

IEC 60068-2-27

Freefall

IEC 60068-2-32

Vibration

IEC 60068-2-6

Warranty

Warranty Period

5 years

Details

See www.moxa.com/warranty

Page 8

- 8 -

Rack Mounting Instructions

1. Elevated Operating Ambient: If installed in a closed or multi-unit

rack assembly, the operating ambient temperature of the rack

environment may be greater than room ambient. Therefore,

consideration should be given to installing the equipment in an

environment compatible with the maximum ambient temperature

(Tma) specified by the manufacturer.

2. Reduced Air Flow: Installation of the equipment in a rack should be

such that the amount of air flow required for safe operation of the

equipment is not compromised.

3. Mechanical Loading: Mounting of the equipment in the rack should

be such that a hazardous condition is not achieved due to uneven

mechanical loading.

4. Circuit Overloading: Consideration should be given to the

connection of the equipment to the supply circuit and the effect that

overloading of the circuits might have on overcurrent protection and

supply wiring. Appropriate consideration of equipment nameplate

ratings should be used when addressing this concern.

5. Reliable Earthing: Reliable earthing of rack-mounted equipment

should be maintained. Particular attention should be given to supply

connections other than direct connections to the branch circuit (e.g.

use of power strips)."

Restricted Access Locations

• This equipment is intended to be used in Restricted Access Locations,

such as a computer room, with access limited to SERVICE PERSONAL

or USERS who have been instructed on how to handle the metal

chassis of equipment that is so hot that special protection may be

needed before touching it. The location should only be accessible with

a key or through a security identity system.

• External metal parts of this equipment are extremely hot!! Before

touching the equipment, you must take special precautions to protect

your hands and body from serious injury.

Loading...

Loading...