Page 1

2013 Moxa Inc. All rights reserved.

P/N: 1802012800011

Moxa ICF-1280I Series

Industrial PROFIBUS-to-Fiber

Converter

Hardware Installation Guide

First Edition, August 2013

Page 2

- 2 -

Introduction

The ICF-1280I series PROFIBUS-to-fiber converters are based on the

PROFIBUS DP standard, and are compliant with EN 50170. The converters

are mainly used to extend the transmission distance of PROFIBUS devices

over optical fiber, and provide redundant transmission. More specifically

the ICF-1280I series converts PROFIBUS signals between copper and

fiber wires, and extends PROFIBUS transmission up to 4 km (for

multi-mode models) or up to 45 km (for single-mode models). In addition,

the ICF-1280I series converters have dual fiber ports that can be used to

form a ring topology for redundant transmission, and avoid package lost

when a fiber path is broken. The ICF-1280I converter also provides 2 kV

isolation protection for the PROFIBUS system and dual power inputs to

ensure uninterrupted operation.

The ICF-1280I series converters are uniquely designed with Remote Fiber

Diagnosis that eliminates the need for a fiber optic sensor by using DIP

switch adjustments instead. Remote Fiber Diagnosis can detect fiber

connections for the overall topology from any individual converter, and

determine which side (Tx or Rx) is causing the problem for the converter.

Why Convert PROFIBUS to Fiber?

Optical fiber communication not only extends the communication

distance, but also provides the following advantages:

• Immunity to electrostatic interference: Fiber is immune to

electromagnetic interference and radio frequency interference. It

provides a clean communication path and is immune to cross-talk.

• Insulation: Optical fiber is an insulator interface; the glass fiber

eliminates the need for using electric currents as the communication

medium.

• Security: Fiber cannot be tapped by conventional electric means and

is very difficult to tap into optically while radio and satellite

communication signals can be captured easily for decoding.

• High reliability and low maintenance: Fiber wires are immune to

adverse temperature and moisture conditions. As a result, they do

not corrode or lose signals, and are not affected by short circuits,

power surges, or static electricity.

Auto/Manual Baudrate Settings

The ICF-1280I series converters simply convert the signal back and forth

between PROFIBUS and fiber at baudrates between 9.6 Kbps to 12 Mbps.

Engineers do not need to know the baudrate of the connected PROFIBUS

device; the ICF-1280I series converters can automatically detect the

baudrate of the PROFIBUS device and apply this baudrate directly. This is

an extremely convenient feature. If necessary, baudrates can be set to a

fixed value via DIP switches to shorten the baudrate detection period

when the system initializes.

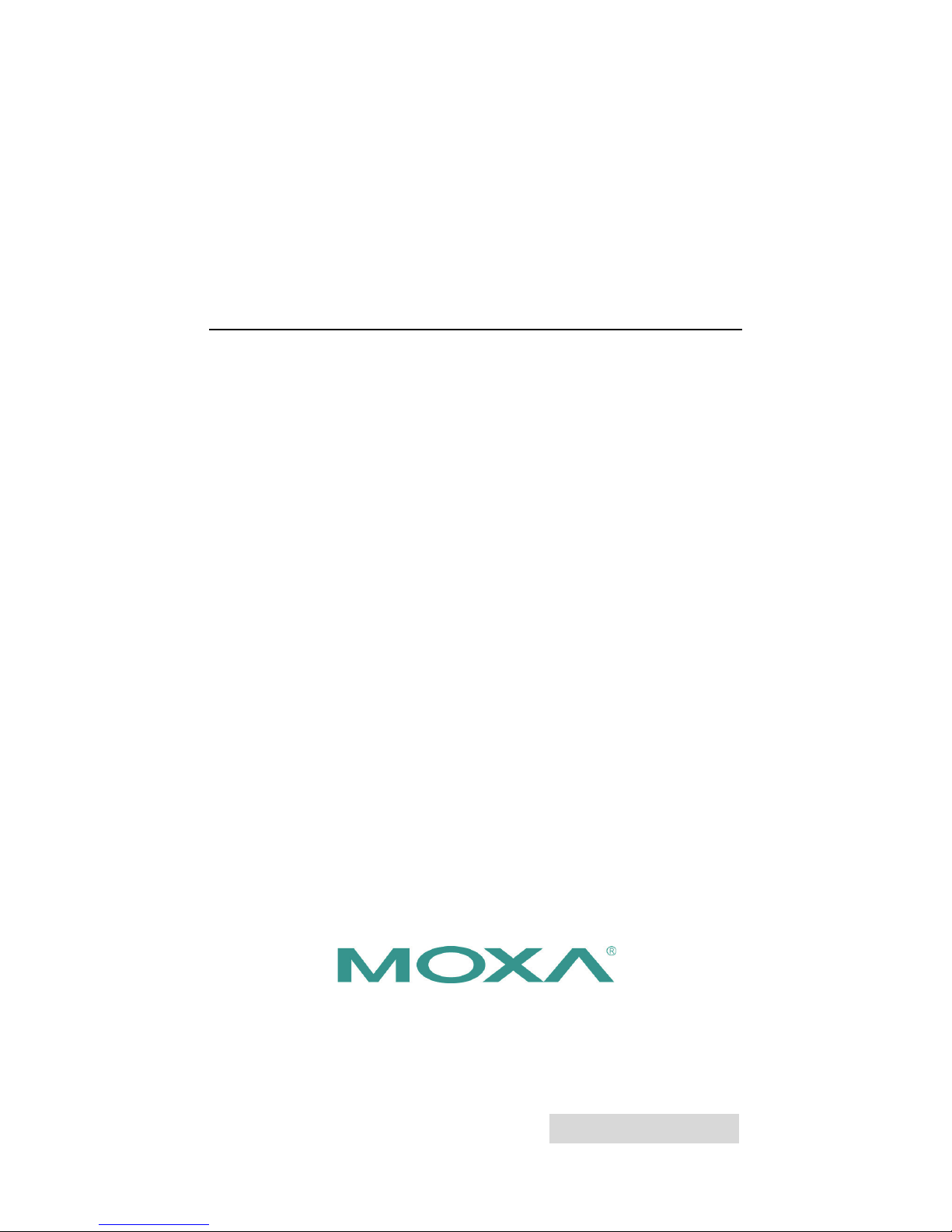

PROFIBUS Fail Safe

Electrical noise may be generated when a PROFIBUS device malfunctions

or the serial interface fails, resulting in bus failure. Traditional media

converters transmit noise signals through the fiber wire to the other

converter. This not only disrupts data communication between the two

buses, but will also bring communication across the entire system to a

Page 3

- 3 -

halt. When this occurs, the engineers will not be able to easily locate the

failed device because the entire PROFIBUS network is down. To avoid this

situation, the ICF-1280I series converter has a mechanism to detect and

recognize noise signals. If the bus fails on one side, the noise signal will

not propagate through the ICF-1280I converter and affect additional bus

segments. In addition, the ICF-1280I converter will also trigger an alarm

to provide the location of the failure to the field engineer.

Fiber Link Monitoring

The ICF-1280I series converter provides a fiber link monitoring function

to detect the communication errors on both sides of the fiber connection.

When a communication error occurs, a red LED status indicator (P1, P2,

or Fault LED) will turn on and the relay alarm will activate. If a fiber

abnormality occurs on a remote fiber segment, the Fault LED will flash.

Engineers can then use the Fiber Diagnosis function for troubleshooting.

Reverse Power Protection

The Reverse Power Protection feature protects against accidentally

connecting the power cables to the wrong terminal. The converter is

designed to detect automatically which power wire is positive and which is

negative, and then adjust the power supply accordingly.

Remote Fiber Diagnosis

Optical fiber cables are often deployed for long distance communication

and a fiber optic inspection pen is used by engineers to ensure proper

communication quality of the fiber cable. The ICF-1280I series converters

eliminate the need for a fiber optic inspection pen by providing a Remote

Fiber Diagnosis function that uses DIP switch adjustments. There are two

major functions provided by Remote Fiber Diagnosis: (1) determining

which side (Tx or Rx) is causing the problem on the converter; (2)

examining the fiber connections for the overall topology from any

individual converter. Fiber cable abnormalities can be automatically

detected and identified by the LED indicator even if it is not adjacent to

the converter. Remote Fiber Diagnosis facilitates fiber cable deployment

and management, and also significantly shortens troubleshooting time by

examining fiber connections for the overall topology from any individual

converter.

Page 4

- 4 -

Using Remote Fiber Diagnosis:

Set DIP switch SW8 to the ON position on any ICF-1280I converter and

see the Ready LED status. A flashing green Ready LED indicates that the

Fiber Diagnosis has finished. The Fault LED indicates the location of the

fiber connection abnormality. The P1 or P2 LED indicates which side (Tx

or Rx) is causing the problem.

The Fault LED will shine a steady red to indicate an adjacent fiber

connection error, or flash red to indicate a non-adjacent fiber connection

error. If there are no fiber connection errors in the entire topology, the

related LEDs will shine green or remain OFF. If the fiber connection error

is adjacent to the converter, the status will also be indicated by the P1

(Port 1) or P2 (Port 2) LEDs. A flashing red light on P1 (or P2) means that

the Rx fiber cable connected to this port is broken. Similarly, a solid red

light on P1 (or P2) means that the Tx fiber cable in this port is broken. If

the fiber connection error is not adjacent to the converter (i.e., the fiber

cables connected to this converter are working properly), the Fault LED

will flash red. As a result, you should run Remote Fiber Diagnosis on every

other (second) converter in the topology to recursively troubleshoot the

problem. Further descriptions and troubleshooting can be found in the

Troubleshooting table.

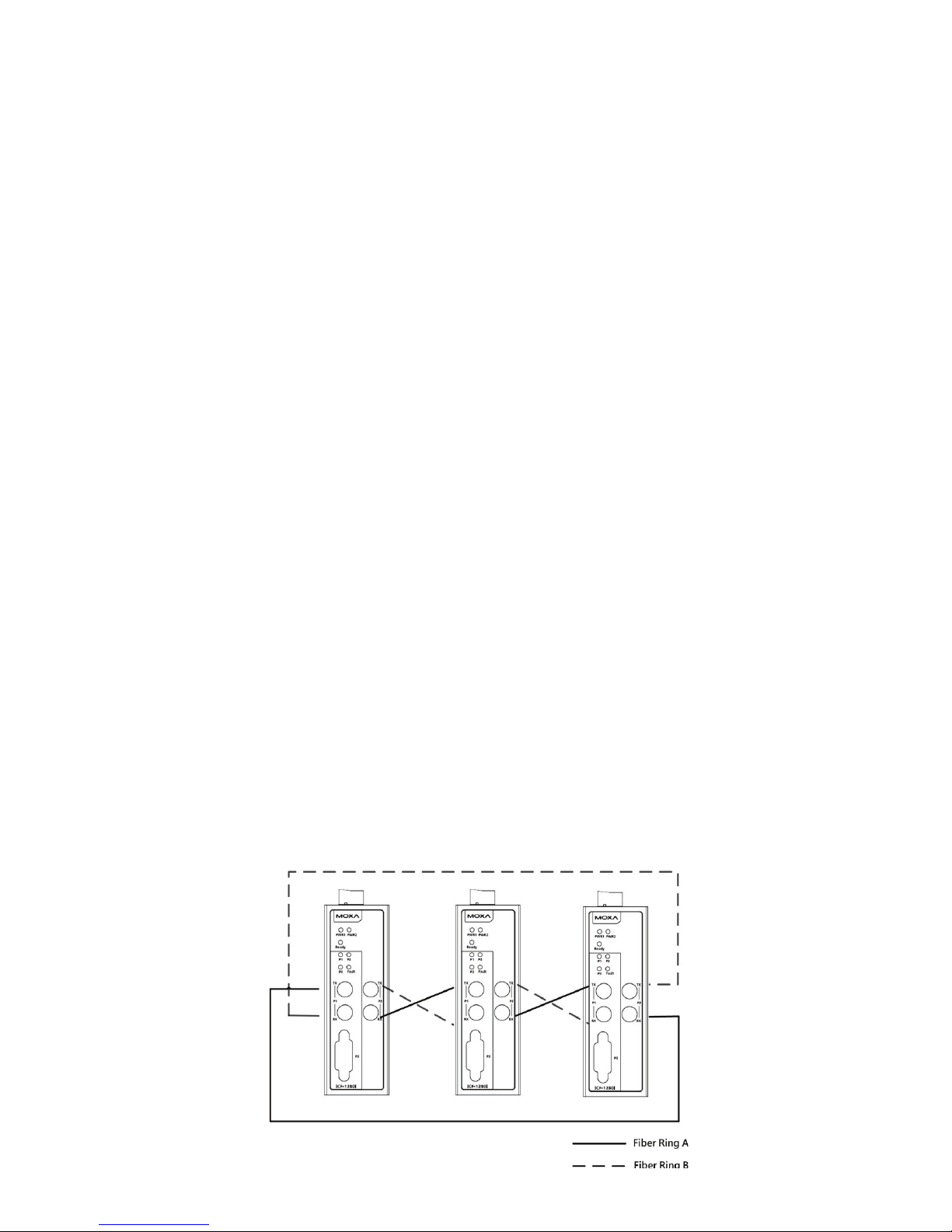

Redundant Ring

The ICF-1280I series converters can connect PROFIBUS devices in a

redundant ring topology. Use the DIP switch to configure all the ICF1280I converters to Redundant Ring mode. When a PROFIBUS master

transmits a signal from one converter to the PROFIBUS slave devices, this

signal will travel to all the converters around the ring until it returns to the

original converter and terminate.

How to form a redundant ring topology:

To form a redundant ring topology, connect the Tx Port (Port 1) on the

first ICF-1280I converter to the Rx Port (Port 2) on the following

converter. Then, connect the Tx Port (Port 2) on the first ICF-1280I

converter to the Rx Port (Port 1) on the preceding converter. Similarly,

connect the Rx Port (Port 1) on the first ICF-1280I converter to the Tx

Port (Port 2) on the following converter. Then, connect the Rx Port

(Port 2) on the first ICF-1280I converter to the Tx Port (Port 1) of the

preceding converter.

Page 5

- 5 -

Features

• Redundant Ring mode for fiber communication backup with zero

recovery time

• Remote Fiber Diagnosis

• Auto baudrate detection and data speeds up to 12 Mbps

• PROFIBUS bus fail safe

• Alarm by relay output

• Provide 2 kV galvanic isolation

• Power polarity protection

• Extend PROFIBUS transmission distance:

Up to 45 km with single-mode (ICF-1280I-S models)

Up to 4 km with multi-mode (ICF-1280I-M models)

• Point-to-point, linear (bus), star, and redundant ring topologies

• Dual power input for redundancy

• Wide operating temperature from -40 to 75°C (for “-T” models)

Package Checklist

Before installing the ICF-1280I converter, verify that the package

contains the following items:

• ICF-1280I PROFIBUS-to-fiber converter

• Hardware installation guide

• Warranty card

NOTE: Please notify your sales representative if any of the above items

are missing or damaged.

Mounting Dimensions (Unit: mm)

ICF-1280I

Page 6

- 6 -

Top View

Front View

ATTENTION

Electrostatic Discharge Warning!

To protect the

product from damage due to electrostatic

discharge, we recommend wearing a grounding device when

handling your ICF-1280I series converters.

Mounting

The aluminum DIN-rail attachment plate should be fixed onto the back

panel of the ICF-1280I converter when you take it out of the box. If you

need to reattach the DIN-rail attachment plate to the ICF-1280I

converter, make sure the stiff metal spring is situated towards the top, as

shown in the figures below.

STEP 1:

Insert the top of the DIN rail into the slot just below the stiff metal spring.

STEP 2:

The DIN-rail attachment unit will snap into place as shown below.

To remove the ICF-1280I series converter from the DIN rail, simply

reverse Steps 1 and 2 above.

Page 7

- 7 -

Fiber Cable

ST-Port Pinouts

ST-Port to ST-Port Cable Wiring

PROFIBUS Pin Assignment

PIN

Signal Name

1

N.C.

2

N.C.

3

PROFIBUS D+

4

RTS

5

Signal common

6

5 V

7

N.C.

8

PROFIBUS D-

9

N.C.

Federal Communications Commission Statement

This device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including

interference that may cause undesired operation.

Slot Time Settings

Although ICF-1280I series converters can be connected in different

topologies with a large number of units, the total cable length and

network topology can give rise to frame delays. A sufficient slot time is

required to prevent the PROFIBUS master from timing out. Engineers are

recommended to set the PROFIBUS master’s slot time according to the

following formulas.

For linear and star topologies:

Slot time = A + B × L + 13 × N

Transmission Speed (kbps)

A B 12000

811

120

6000

461

60

3000

261

30

1500

161

15

500

111

5

187.5

71

1.875

93.75

71

0.9375

45.45

411

0.4545

19.2

71

0.192

9.6

71

0.096

Page 8

- 8 -

For redundant ring topology:

Slot time = A + B × L + C × N

L: The length of the fiber optic in kilometer.

N: The number of converters in the system.

A, B, and C: Parameters set according to different baudrates.

*To avoid frame conflicts, it is recommended to set the PROFIBUS

command retry limit ≥ 3, and the slot time < 262128.

DIP Switch Settings

There are 8 DIP switches on the top panel of the ICF-1280I series

converter. All DIP switches except SW5 are set to the factory default OFF

position.

Transmission Speed (kbps)

A B C

12000

1651

240

28

6000

951

120

24

3000

551

60

24

1500

351

30

24

500

251

10

24

187.5

171

3.75

24

93.75

171

1.875

24

45.45

851

0.909

24

19.2

171

0.384

24

9.6

171

0.192

24

Transmission Speed (kbps)

SW1

SW2

SW3

SW4

Auto (default)

OFF

OFF

OFF

OFF

12000

OFF

OFF

OFF

ON

6000

OFF

OFF

ON

OFF

3000

OFF

OFF

ON

ON

1500

OFF

ON

OFF

OFF

500

OFF

ON

OFF

ON

187.5

OFF

ON

ON

OFF

93.75

OFF

ON

ON

ON

45.45

ON

OFF

OFF

OFF

19.2

ON

OFF

OFF

ON

9.6

ON

OFF

ON

OFF

Setting

ON

OFF

SW5

Fiber Link Monitor

Disable

SW8

Remote Fiber Diagnosis*

Disable

Topology

SW6

SW7

Linear, Star (P1/P2 enable)

OFF

OFF

Linear, Star (P1 disable)

OFF

ON

Linear, Star (P2 disable) ON OFF

Redundant Ring

ON

ON

In Redundant Ring mode, the Fiber Link Monitor function is activated

automatically.

Page 9

- 9 -

LED Indicators

There are 7 LED indicators on the front panel of the ICF-1280I series

converter.

LED

Color

Description

Relay

Status

PWR1/PWR2

Solid

green

Power is on

Closed

Off

Power is off, or power error

condition exists

Open

Ready

Solid

green

Baud rate is detected, converter

is ready for communication

Closed

Flashing

green*

Fiber diagnosis is finished

Closed

Flashing

red*

Detecting baudrate.

Closed

Flashing

red and

green*

Slotting time setting error

Closed

Off

System power is off

Closed

P1/P2

(Fiber)

Flashing

/solid

green

Fiber port is receiving data

Closed

Solid

red*

Fiber cable linking to Tx is

abnormal

Open

Flashing

red*

Fiber cable linking to Rx is

abnormal

Open

Off

Fiber in idle state

Closed

P3

(PROFIBUS)

Flashing

green

PROFIBUS port is

communicating

Closed

Flashing

red

Inner transceiver IC defective;

PROFIBUS port Data

communication error;

Insufficient shielding of the bus

cable;

Echo package timeout

Open

Solid red

Echo package timeout,

PROFIBUS UART character error

Open

Off

PROFIBUS in idle state

Closed

Fau lt

Solid

green

Fiber connections are working

normally in Fiber Diagnosis

mode

Closed

Flashing

red*

Fiber abnormality occurred in

another segment

Closed

Solid

red*

Fiber abnormality occurred on

this converter

Closed

If both power inputs experience an outage, the relay will become an

open circuit for alarm purposes.

*Refer to the following table for troubleshooting.

*Refer to the Remote Fiber Diagnosis section for instructions.

If an ICF-1280I converter is deployed at the beginning

or at the end of the

topology in Linear mode or Star mode, the unused port should be

disabled. In such cases, it is recommended to use an ICF-1180I series

converter. Please use the ICF-1180I series with Rev. 1.3, or higher

versions, to connect with the ICF-1280I series.

Page 10

- 10 -

Troubleshooting LED Indicators and Fiber Diagnosis

LED

Status

Description

Status/Troubleshooting

Ready Flashing

green

Fiber diagnosis

finished

Check Fault LED;

At least one converter is in Fiber

Diagnosis mode;

Check PROFIBUS master settings;

Tx and Rx cables crossed

Flashing

red

Detecting

baudrate

No PROFIBUS node;

No PROFIBUS signal received;

Tx and RX crossed over;

Baudrate setting is incorrect.

Flashing

green/red

Slot time setting

error

Recalculate the slot time; Set

TSDR ≥ 11;

Set HAS = greatest PROFIBUS

node address + 1;

Check consistency of operation

mode for DIP switch 6/7;

Check consistency of Fiber Link

Monitor Mode for DIP switch 5

Fault

Flashing

red

Fiber

abnormality

occurred in

another segment

Use Fiber Diagnosis on another

converter that is not adjacent to

this converter

Solid red

Fiber

abnormality

occurred on this

converter

Check P1 and P2 LEDs

P1/P2

Flashing

red

Rx fiber cable

abnormality

Check the Rx fiber cable

connecting to this port*;

Tx and Rx cables crossed over;

Partner module is powered OFF

or

defective

Solid red Tx fiber cable

abnormality

Check the fiber cable linking to Tx

of this port*

P3

OFF

PROFIBUS is idle

Check the PROFIBUS device

connection

Flashing

red

PROFIBUS side

error

RS-485 cable is not terminated or

only terminated at one end;

Open bus cable;

PROFIBUS D+ and D- crossed

over;

Short circuit on PROFIBUS cable;

RS-485 driver is defective;

Check slot time setting, baudrate,

and operation mode

If the abnormality indicated by the LED disappears in Fiber Diagnosis

mode, check the consistency of the DIP switch settings on all the

converters.

If the Tx and Rx cables are both abnormal, the

P1/P2 LED will shine red.

Check the Rx cable first for troubleshooting.

*If the Fault LED, P1 LED, and P2 LED are all lit/flashing red

simultaneously, the Tx and Rx cables of P1 and P2 may be crossed over.

Page 11

- 11 -

ATTENTION

This is

a Class 1 laser/LED product. Do not stare into the laser

beam.

Specifications

PROFIBUS Communication

PROFIBUS Interface

PROFIBUS DP

Number of Ports

1

Connector

DB9 female

Isolation Protection

2 kV

Baudrate

9.6 Kbps to 12 Mbps

Auto Baudrate

Yes

Compliant with EN 50170

Fiber Communication

Connector type

ST

Number of Ports

2

Distance

Single-mode fiber for 45 km

Multi-mode fiber for 4 km

Support Cable:

Single-mode

Multi-mode

8.3/125, 8.7/125, 9/125 or 10/125 μm

50/125, 62.5/125, or 100/140 μm

Wavelength

ICF-1280I-S: 1310 nm

ICF-1280I-M: 820 nm

Tx Output

ICF-1280I-S: -7 dBm

ICF-1280I-M: -14 dBm

Rx Sensitivity

ICF-1280I-S: -29 dBm

ICF-1280I-M: -28 dBm

Link Budget

ICF-1280I-S: 21 dBm

ICF-1280I-M: 14 dBm

Transmission

Half duplex

Signal delay time

(any input/output)

6.5 t

bit

Environmental

Operating Temperature

0 to 60°C (32 to 140

°F)

-40 to 75°C (-40 to 167 °F) for T Models

Storage Temperature

-40 to 75°C (-40 to 167 °F),

Ambient Relative Humidity

5 to 95% (non-condensing)

Atmospheric pressure

Up to 2000 m (795 hPa), higher altitudes

on demand

Page 12

- 12 -

Power

Input Power Voltage

12 to 48 VDC

Connector

Terminal block

Power Line Protection

IEC 6000

-4-5 Level 3 (2 kV) Surge

Protection

Power Polarity Protection

Protects against V+/V- reversal

Support over Currents

Protection

1.1 A

Power Consumption

Single mode: 165 mA

@24 V

Multi mode:140 mA @24 V

Relay Output

Supports 1 digital output relay to alarm

(

Normal: close)

Current carrying capacity: 2 A@30 VDC

Mechanical

Dimensions (W × H × D)

39 × 115 × 70 mm

Material

Aluminum (1 mm)

Gross Weight

225 g

Regulatory Approvals

Safety

UL 508; EN 60950-1

EMC

CE; FCC Part 15, sub part B, Class A

EMI

EN 55022, Class A; EN 55024

EMS

EN 61000

-4-2 (ESD), Level 2

EN 61000

-4-3 (RS), Level 3

EN 61000

-4-4 (EFT), Level 4

EN 61000

-4-5 (Power Surge), Level 3

EN 61000

-4-6 (CS), Level 3

EN 61000-4-8(PFMF), Level 1

Freefall

IEC 60068-2-32

MTBF

792,085 hrs

Green product

RoHS, CRoHS, WEEE

Technical Support Contact Information

www.moxa.com/support

Moxa Americas:

Toll

-free: 1-888-669-2872

Tel:

1-714-528-6777

Fax:

1-714-528-6778

Moxa China (Shanghai office):

Toll

-free: 800-820-5036

Tel:

+86-21-5258-9955

Fax:

+86-21-5258-5505

Moxa Europe

:

Tel:

+49-89-3 70 03 99-0

Fax:

+49-89-3 70 03 99-99

Moxa Asia

-Pacific:

Tel:

+886-2-8919-1230

Fax:

+886-2-8919-1231

Loading...

Loading...