Page 1

EOM-G103-PHR-PTP Series Hardware

User’s Manual

Edition 2.0, February 2017

www.moxa.com/product

© 2017 Moxa Inc. All rights reserved.

Page 2

EOM-G103-PHR-PTP Series Hardware

Moxa Americas

Toll

Tel:

Fax:

Moxa China (Shanghai office)

Toll

Tel:

Fax:

Moxa Europe

Tel:

Fax

Moxa Asia

Tel:

Fax:

Moxa India

Tel:

Fax:

User’s Manual

The software described in this manual is furnished under a license agreement and may be used only in accordance with

the terms of that agreement.

Copyright Notice

© 2017 Moxa Inc. All rights reserved.

Trademarks

The MOXA logo is a registered trademark of Moxa Inc.

All other trademarks or registered marks in this manual belong to their respective manufacturers.

Disclaimer

Information in this document is subject to change without notice and does not represent a commitment on the part of

Moxa.

Moxa provides this document as is, without warranty of any kind, e ither expre ssed or impl ied , in cludin g, but not limit ed

to, its particular purpose. Moxa reserves the right to make improvements and/or changes to this manual, or to the

products and/or the programs described in this manual, at any time.

Information provided in this manual is intended to be accurate and reliable. However, Moxa assumes no responsibility for

its use, or for any infringements on the rights of third parties that may result from its use.

This product might include unintentional technical or typographical errors. Changes are periodically made to the

information herein to correct such errors, and these changes are incorporated into new editions of the publication.

Technical Support Contact Information

www.moxa.com/support

-free: 1-888-669-2872

+1-714-528-6777

+1-714-528-6778

+49-89-3 70 03 99-0

: +49-89-3 70 03 99-99

+91-80-4172-9088

+91-80-4132-1045

-free: 800-820-5036

+86-21-5258-9955

+86-21-5258-5505

-Pacific

+886-2-8919-1230

+886-2-8919-1231

Page 3

Table of Contents

1. Introduction ...................................................................................................................................... 1-1

Overview ........................................................................................................................................... 1-2

Package Checklist ............................................................................................................................... 1-2

Product Features ................................................................................................................................ 1-2

EOM-G103-PHR-PTP Hardware Specifications ......................................................................................... 1-3

EOM-G103-PHR-PTP Hardware Block Diagram ........................................................................................ 1-4

Appearance ........................................................................................................................................ 1-4

EOM-G103-PHR-PTP Embedded Module .......................................................................................... 1-4

EOM-G103-PHR-PTP Evaluation Board ............................................................................................ 1-5

Dimensions (unit: mm) ................................................................................................................ 1-5

2. EOM-G103-PHR-PTP Functionality ..................................................................................................... 2-1

EOM-G103-PHR-PTP Embedded Module Functions ................................................................................... 2-2

LAN Ports ................................................................................................................................... 2-2

Console Port ............................................................................................................................... 2-2

GPIO ......................................................................................................................................... 2-2

Pin Assignments ................................................................................................................................. 2-2

Pin assignment table for JP1 (2 x 40) ............................................................................................. 2-3

Pin assignment table for JP2 (2 x 10) ............................................................................................. 2-3

3. EOM-G103-PHR-PTP-ST Functionality ............................................................................................... 3-1

EOM-G103-PHR-PTP-ST Development Board .......................................................................................... 3-2

Combining the EOM-G103-PHR-PTP-ST with the Embedded Module ........................................................... 3-2

LED Indicators .................................................................................................................................... 3-3

Wiring Requirements ........................................................................................................................... 3-4

Connecting the Power ......................................................................................................................... 3-4

LAN Ports and Pin Assignments ............................................................................................................ 3-4

Reset Button ...................................................................................................................................... 3-5

4. PCB Layout and Design Guidelines .................................................................................................... 4-1

General Rules ..................................................................................................................................... 4-2

Power Ground Rules ............................................................................................................................ 4-2

Chassis Ground .................................................................................................................................. 4-2

Magnetic Noise Zone ........................................................................................................................... 4-3

Differential Signa l L ayout ..................................................................................................................... 4-3

USB Signal Layout .............................................................................................................................. 4-3

Heat Sink Requireme n rs ...................................................................................................................... 4-3

Design Guidelines ............................................................................................................................... 4-4

Page 4

1

1. Introduction

Thank you for purchasing the Moxa EOM-G103-PHR-PTP embedded module. The product’s features include

four 10/100 Mbps Ethernet ports and one UART serial port. The EOM-G103-PHR-PTP is ideal as the core module

of an industrial embedded system design.

The EOM-G103-PHR-PTP Evaluation Kit, which is d esigned for system and software program development at

the system evaluation stage, is also available. The kit includes the EOM-G103-PHR-PTP and

EOM-G103-PHR-PTP-ST, which is the carrier board used to evaluate the EOM-G103-PHR-PTP.

In this manual, we introduce the hardware features and functions of the EOM-G103-PHR-PTP embedded

module and the EOM-G103-PHR-PTP Evaluation Kit. After a brief introduction to the hardware features, the

manual focuses on installation and hardware configuration with device interfaces.

The following topics are covered in this chapter:

Overview

Package Checklist

Product Features

EOM-G103-PHR-PTP Hardware Specifications

EOM-G103-PHR-PTP Hardware Block Diagram

Appearance

EOM-G103-PHR-PTP Embedded Module

EOM-G103-PHR-PTP Evaluation Board

Dimensions (unit: mm)

Page 5

EOM-G103-PHR-PTP Series Introduction

1-2

NOTE

Please notify your sales representative if any of the above items ar

Overview

The EOM-G103-PHR-PTP full Gigabit managed redundancy modules are designed for device manufacturers

who would like to embed and integrate the advanced functionality of IEC 62439-3 supported modules. The

EOM-G103-PHR-PTP embedded modules provide enhanced performance and reliability for certain

mission-critical a pplications, but with minimal effort.

IEC 62439-3 Clause 4 (PRP) and IEC 62439-3 Clause 5 (HSR) are the newest standardized redundancy

protocols for industrial automation networks where zero recovery time is needed. PRP and HSR are suit able for

electrical substation au tomation and other mission-critical applications that cannot tolerate any system

downtime.

The EOM-G103-PHR-PTP series modules are complia nt with the latest IEC 62439-3 standards and provide an

easy and cost-effective integrated solution for adding a redundancy module to a non-IEC 62439-3 supported

product. The modules support two IEC 62439-3 Ethernet ports (SGMII (MAC mode) or SERDES (1000Base-X)

interface) for constructing PRP or HSR networks and one standard Ethernet port (SGMII (MAC mode) or

SERDES (1000Base-X) interface) for connecting with standard IEEE 802.3 Ethern et devices. The

EOM-G103-PHR-PTP series also provide an extr a S GMII (MAC mode) or SERDES (1000Base-X) interface for

building up a local access Ethernet console port to easily maintain, contro l, and manage certain devices right

at the local site.

Package Checklist

The EOM-G103-PHR-PTP package includes t he EOM-G103-PHR-PTP embedded module only. The

EOM-G103-PHR-PTP Evaluation Kit is available separately for evaluation purposes. The EOM-G103-PHR-PTP

Evaluation Kit package contains the following items:

• One EOM-G103-PHR-PTP embedded module

• One EOM-G103-PHR-PTP-ST, the carrier board of the EOM-G103-PHR-PTP evaluation kit

• Ethernet cable

• USB-IF cable

• Universal power adapter

• Warranty card

Product Features

The EOM-G103-PHR-PTP embedded module has the following features:

• ARM9 32-bit 192 MHz processor

• On-board 32 MB RAM, 16 MB flash

• Two 10/100/1000Base Ethernet ports for PRP or HSR redundant networks and one 10/100/1000Base

Ethernet port for network switching

• One UART serial port for console control

• Compact size for easy integration at any field site

• Full-function evaluation kit for quick evaluation and application development

e missing or damaged.

Page 6

EOM-G103-PHR-PTP Series Introduction

1-3

Technology

Standards:

IEEE 802.3 for 10BaseT

IEEE 802.3u for 100BaseT(X) and 100BaseFX

IEEE 802.3ab for 1000BaseT(X)

IEEE 802.3z for 1000BaseX

Protocols:

Interface

Ethernet Ports:

Connectors:

Console Port:

GPIO:

Power Requirements

Input Voltage:

Input Current:

Physical Characteristics

Dimensions:

Weight:

Environmental Limits

Operating Temperature:

Note:

Storage Temperature:

Ambient Relative Humid it y:

Standards and Certifications

EMI:

Note: Please check Moxa’s website for the most up

Warranty

Warranty Period:

Details:

EOM-G103-PHR-PTP Hardware Specifications

PRP/HSR

3 10/100/1000Base ports

1 connector with 2 x 40 pins, and 1 connector with 2 x 10 pins

10/100/1000 Mbps Ethernet console port or USB console

3 programmable I/O pins

3.3 V

1.625 W @ 3.3 V

80 x 1.6 x 65 mm (3.15 x 0.06 x 2.56 in)

28.6 g (0.06 lb)

-40 to 60°C (-40 to 140°F)

Products with a a higher operating temperature are available by special request.

-40 to 85°C (-40 to 185°F)

5 to 95% (non-condensing)

FCC Part 15 Subpart B Class A, EN 55032 Class A, CE Class A

-to-date certification status.

5 years

See www.moxa.com/warranty

Page 7

EOM-G103-PHR-PTP Series Introduction

1-4

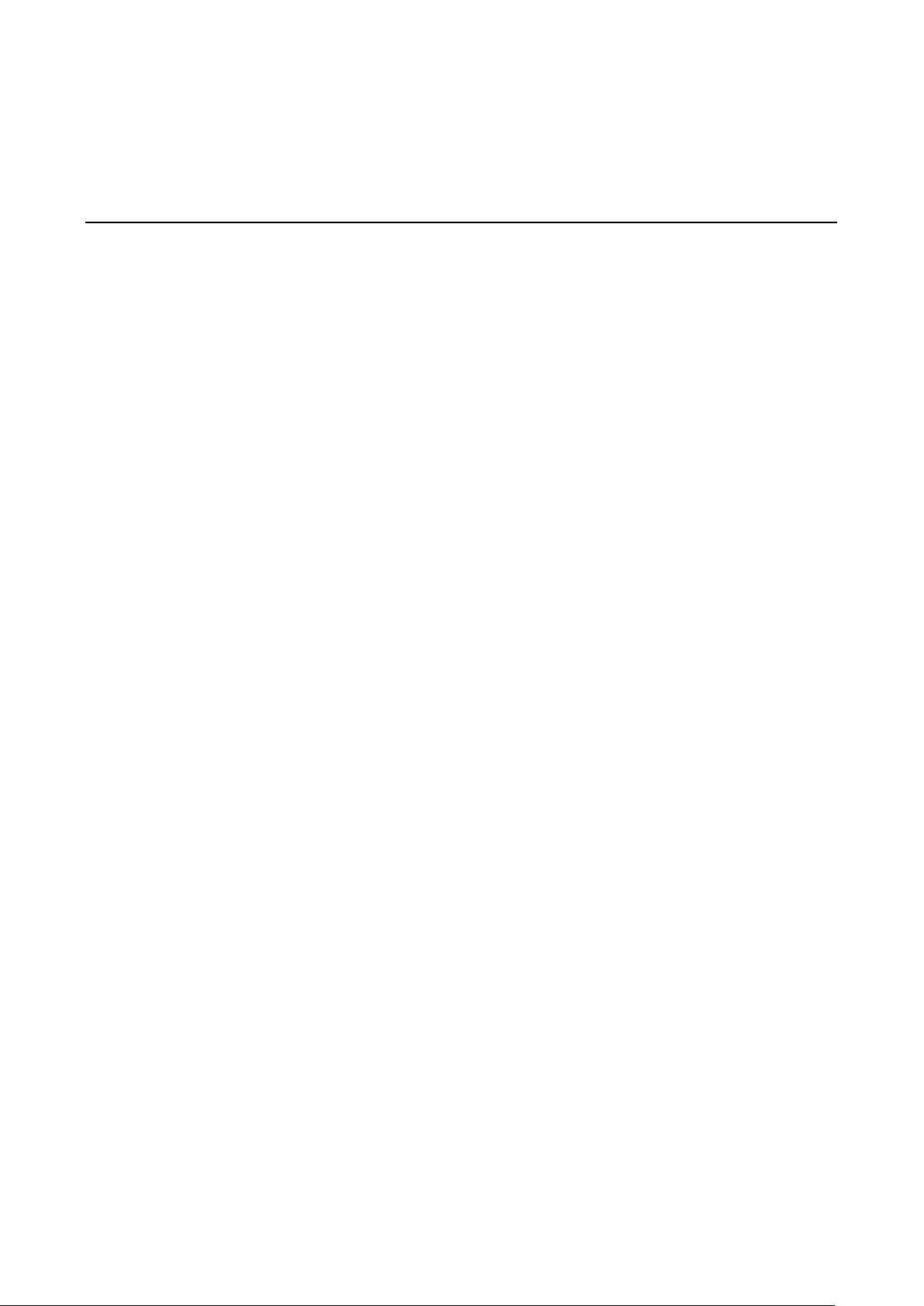

EOM-G103-PHR-PTP Hardware Block Diagram

Appearance

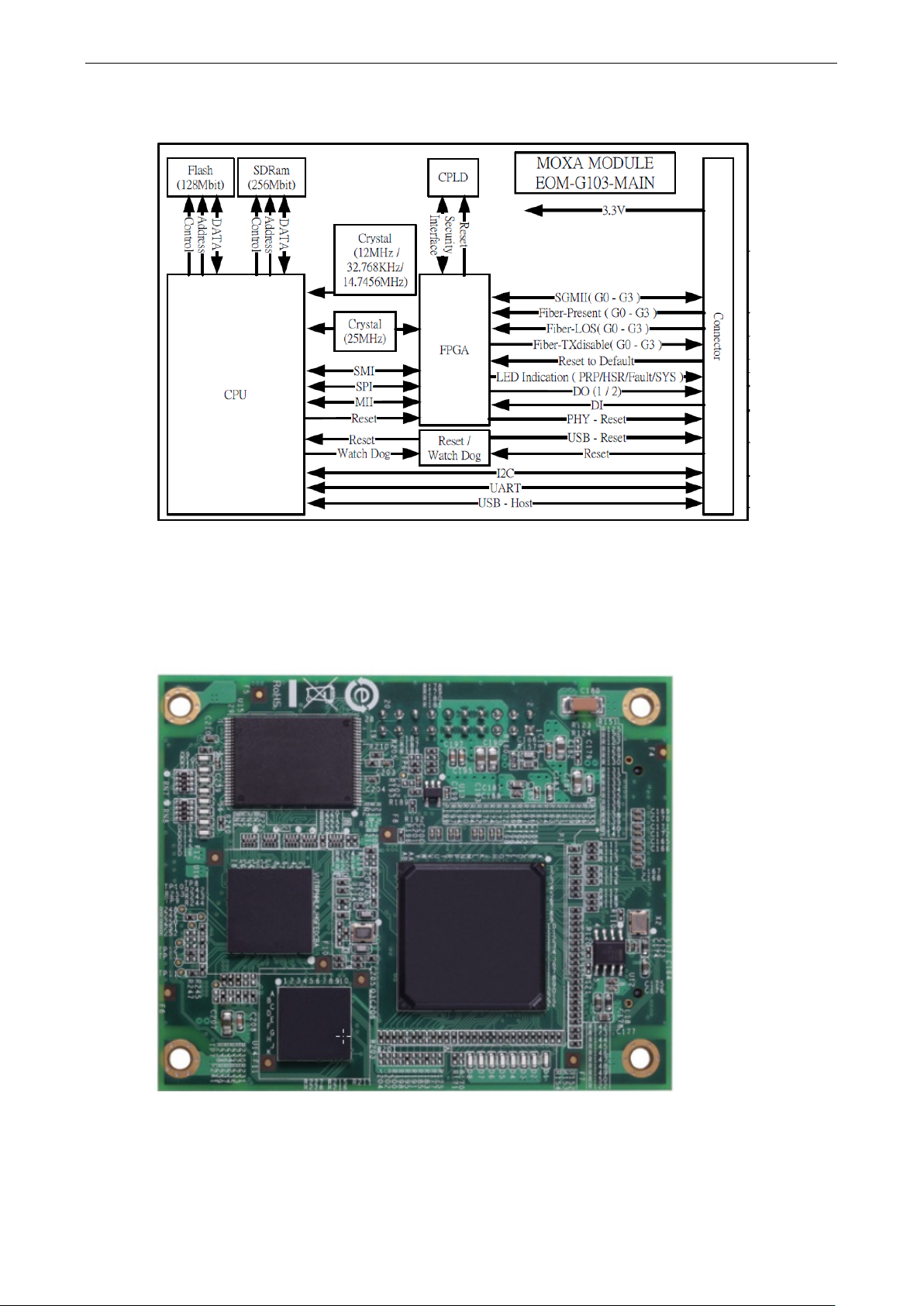

EOM-G103-PHR-PTP Embedded Module

Page 8

EOM-G103-PHR-PTP Series Introduction

1-5

EOM-G103-PHR-PTP Evaluation Board

Dimensions (unit: mm)

Page 9

2

2. EOM-G103-PHR-PTP Functionality

In this chapter, we introduce the basic features of the EOM-G103-PHR-PTP embedded module.

The following topics are covered in this chapter:

EOM-G103-PHR-PTP Embedded Module Functions

LAN Ports

Console Port

GPIO

Pin Assignments

Pin assignment table for JP1 (2 x 40)

Pin assignment table for JP2 (2 x 10)

Page 10

EOM-G103-PHR-PTP Series EOM-G103-PHR-PTP Functionality

2-2

EOM-G103-PHR-PTP Embedded Module Functions

LAN Ports

The EOM-G103-PHR-PTP embedded module has t hree 10/100/1000 Mbps SGMII (MAC mode) / SERDES

(1000Base-X) LAN ports that can be used to set up a redundant PRP/HSR network.

Console Port

The EOM-G103-PHR-PTP embedded module has 1 10/100/1000 Mbps Ethernet console port or USB console

port for onsite configuration.

GPIO

The EOM-G103-PHR-PTP embedded module provides 3 software-selectable GPIOs with one input and two

outputs. The GPIOs give users the ability to design customized functionality.

Pin Assignments

Page 11

EOM-G103-PHR-PTP Series EOM-G103-PHR-PTP Functionality

2-3

Pin assignment table for JP1 (2 x 40)

Pin Signal Pin Signal Pin Signal Pin Signal

1 GND 2 GND 41 PRP_LED 42 DI

3 DTR(UART) 4 DCD(UART) 43 FAULT_LED 44 Reserved

5 RTS(UART) 6 DSR(UART) 45 STAT_R_LED 46 Reserved

7 TXD(UART) 8 CTS(UART) 47 STAT_G_LED 48 Reserved

9 GND 10 RXD(UART) 49 TX_DIS_G3(SFP) 50 GND

11 GXB_RX_P_0(SGMII) 12 GND 51 PRESENT_G3(SFP) 52 Reserved

13 GXB_RX_N_0(SGMII) 14 GXB_TX_P0(SGMII) 53 LOS_G3(SFP) 54 Reserved

15 GND 16 GXB_TX_N0(SGMII) 55 TX_DIS_G2(SFP) 56 GND

17 GXB_RX_P_1(SGMII) 18 GND 57 PRESENT_G2(SFP) 58 SDA-(I2C)

19 GXB_RX_N_1(SGMII) 20 GXB_TX_P1(SGMII) 59 LOS_G2(SFP) 60 SCK-(I2C)

21 GND 22 GXB_TX_N1(SGMII) 61 TX_DIS_G1(SFP) 62 GND

23 GXB_RX_P_2(SGMII) 24 GND 63 PRESENT_G1(SFP) 64 MDIO-PHY(SMI)

25 GXB_RX_N_2(SGMII) 26 GXB_TX_P2(SGMII) 65 LOS_G1(SFP) 66 MDC-PHY(SMI)

27 GND 28 GXB_TX_N2(SGMII) 67 TX_DIS_G0(SFP) 68 GND

29 GXB_RX_P_3(SGMII) 30 GND 69 PRESENT_G0(SFP) 70 Reserved

31 GXB_RX_N_3(SGMII) 32 GXB_TX_P3(SGMII) 71 LOS_G0(SFP) 72 Reserved

33 GND 34 GXB_TX_N3(SGMII) 73 Reserved 74 GND

35 COUP_LED 36 GND 75 Reserved 76 USB-HOST-DP

37 QB_LED 38 DO(1) 77 Reserved 78 USB-HOST-DM

39 HSR_LED 40 DO(0) 79 Reserved 80 GND

Pin assignment table for JP2 (2 x 10)

Pin Signal Pin Signal

1 Reserved 2 Reserved

3 Reserved 4 Reserved

5 Reserved 6 Reserved

7 3.3V 8 3.3V

9 3.3V 10 3.3V

11 3.3V 12 GND

13 GND 14 GND

15 GND 16 GND

17 Reset_PHY 18 Reset

19 Reserved 20 Reset to Default

Page 12

EOM-G103-PHR-PTP Series EOM-G103-PHR-PTP Functionality

2-4

ended input

Signal JP1 pin# Pin Name Pin Type Description

SGMII/SerDes

UART

LED indication

FIBER_TX_DISA

BLE

FIBER_PRESENT

Fiber_LOS

11 GXB_RX_P_0

13 GXB_RX_N_0

14 GXB_TX_P_0

16 GXB_TX_N_0

17 GXB_RX_P_1

19 GXB_RX_N_1

20 GXB_TX_P_1

22 GXB_TX_N_1

23 GXB_RX_P_2

25 GXB_RX_N_2

26 GXB_TX_P_2

28 GXB_TX_N_2

29 GXB_RX_P_3

31 GXB_RX_N_3

32 GXB_TX_P_3

34 GXB_TX_N_3

4 DCD I Data carrier detect. It operate at 3.3V.

7 TXD O Serial output data. It operate at 3.3V.

10 RXD I Serial input data. It operate at 3.3V.

3 DTR O Data terminal ready. It operate at 3.3V.

6 DSR I Data set ready. It operate a t 3.3V.

5 RTS O Request to send. It operate at 3.3V.

8 CTS I Clear to send. It operate at 3.3V.

39 HSR_LED O

41 PRP_LED O

43 FAULT_LED O

45 STAT_R_LED O

47 STAT_G_LED O

67 TX_DIS_G0

61 TX_DIS_G1

55 TX_DIS_G2

49 TX_DIS_G3

69 PRESENT_G0

63 PRESENT_G1

57 PRESENT_G2

51 PRESENT_G3

71 LOS_G0

65 LOS_G1

59 LOS_G2

53 LOS_G3

I Port A.Receive pairs.Differential Input data.

O Port A.Transmit pairs.Differential Output data.

I Port B.Receive pairs.Differential Input data.

O Port B.Transmit pairs.Dif ferential Output data.

I InterLink.Receive pairs.Differential Input data.

O InterLink.Transmit pairs.Differential Output data.

Ethernet cosnsole.Receive pairs.Differential Input

I

data.

O

O

Ethernet cosnsole.Transmit pairs.Differential

Output data.

HSR Mode status LED. Active Low. It op erate at

3.3V.

PRP Mode status LED. Active High. It operate at

3.3V.

Fault indication LED. Active Low.The system is

operating abnormally. It operate at 3.3V.

System information LED. Active Low. The System

has passed self-diagnosis test on boot-up and is

ready to run. It operate at 3.3V.

System information LED. Active Low. The System

has failed self-diagnosis test on boot-up and is

ready to run. It operate at 3.3V.

The TX_DISABLE signal is high to turn off the laser

output. The laser will turn on when TX_DISABLE is

low.Active Low. G0(port A ). G1(port B).

G2(InterLink). G3(Ethernet Console).It oper ate at

3.3V.

SFP module Detect. Active low. Singal-ended input

reference signal from fiber optical module. This

I

pins must be pull high 4.7K ohm. G0(port A).

G1(port B). G2(InterLink). G3(Ethernet

Console).It operate at 3.3V.

Fiber Signal Detect. Active low. Singalreference signal from fiber optical module. This

pins must be pull high 4.7K ohm.G0(port

I

A),G1(port B),G2(InterL ink ), G3 (E thernet

Console). It operate at 3.3V .

Page 13

EOM-G103-PHR-PTP Series EOM-G103-PHR-PTP Functionality

2-5

Signal JP1 pin# Pin Name Pin Type Description

Management data I/O. It operate at 3.3V. The

MII

Management

Interface

I2C

USB interface

Digatal output

Digatal input 42 DI I General Purpose Input. It operate at 3.3V.

POWER

Reserved

Signal JP2 pin# Pin Name Pin Type Description

Reset

Power

Reserved 1-6, 19 Reserved

Type Description

I Input

O Output

I/O Input/Output

PWR POWER

GND GROUND

PU Internal pull-up resistor

64 MDIO-PHY I/O PU

66 MDC-PHY O

58 SDA I/O PU Serial data line. It operate at 3.3V.

60 SCK O Serial data clock. It operate at 3.3V.

76

78

38 DO(1)

40 DO(0)

1,2,9,12,1

5,18,21,24

,27,30,33,

36,50,56,6

2,68,74,80

35,37,44,4

6,48,52,54

,70,72,73,

75,77,79

17 Reset_PHY O

18 Reset I

20

7-11 3.3V PWR PO WER. 3.3V.

12-16 GND GND Ground.

USB-HOST-DP

USB-HOST-D

M

GND GND Ground.

Reset to

Default

I/O USB Data +. Host side.

I/O USB Data -. Host side.

O General Purpose Output. It operate at 3.3V.

input data value on the MDIO pin is valid and

latched on the rising e dge of MDC.

Management data clock. It operate at 3.3V. The

chip sources a 2MHz clock to the external Phy

device

Do Not Connect. These pins should not be

connected. Do not connect these pins together.

Active Low. Reset the PHY chip. It operate at 3.3V.

Active Low. Reset the MOXA module. It operate at

3.3V.

Active Low. The low status for five continuous

I

seconds to load the factory default settings. It

operate at 3.3V.

Do Not Connect. These pins should not be

connected. Do not connect these pins together.

Page 14

3

3. EOM-G103-PHR-PTP-ST Functionality

This chapter includes information about the EOM-G103-PHR-PTP-ST (carrier board of the EOM-G103-PHR-PTP

Evaluation Kit).

The following topics are covered in this chapter:

EOM-G103-PHR-PTP-ST Development Board

Combining the EOM-G103-PHR-PTP-ST with the Embedded Module

LED Indicators

Wiring Requirements

Connecting the Power

LAN Ports and Pin Assignments

Reset Button

Page 15

EOM-G103-PHR-PTP Series EOM-G103-PHR-PTP-ST Functionality

3-2

EOM-G103-PHR-PTP-ST Development Board

The EOM-G103-PHR-PTP Evaluation Kit is a PCB board a with complete layout. The kit helps users evaluate,

develop, and integrate the EOM-G103-PHR-PTP embedded module into their systems and applications. Simply

combine the EOM-G103-PHR-PTP embedded module with the Evaluation Kit to start porting the relevant

software, and create a solution for the applications you wish to implement.

Number Description

1 Terminal block for DI and Relay

2 USB storage port(ABC-02-USB-T)

3 USB console port

4 Reset to factory default by pressing and hold the button for 5 seconds

5 Ethernet Console port: 10/100/1000BaseT(X)

6 Interlink port: 10/100/1000BaseT(X)

7 PRP/HSR redundant port A: 10/100/1000BaseT(X)

8 PRP/HSR redundant port B: 10/100/1000BaseT(X)

9 Interlink port: 100/1000BaseFX

10 PRP/HSR redundant port A: 100/1000BaseFX

11 PRP/HSR redundant port B: 100/1000BaseFX

24 System reboot

25 DO(1) (LED Display)

26 Power input

Combining the EOM-G103-PHR-PTP-ST with the Embedded Module

Insert the EOM-G103-PHR-PTP embedded module vertically onto the EOM-G103-PHR-PTP-ST. Note tha t the

Pin marked “JP1 and JP2” on the embedded module must be matched with the Pin marked “JP4 and JP5” on the

EOM-G103-PHR-PTP-ST. Be careful when installing the board to avoid damaging the pins.

Page 16

EOM-G103-PHR-PTP Series EOM-G103-PHR-PTP-ST Functionality

3-3

LED Indicators

Number LED Color State Description

Power is being supplied to the main system’s power input

PWR1

Power is not being supplied to the mai n system’s power

input PWR1

System has passed self-diagnosis test on boot-up and is

ready to run

1. Syste m is undergoing the self-diagnosis test

2. Syste m detects the ABC-02 USB plugged into the USB

storage port

3. Blinks once per second when pressing the reset button

for 5 seconds

4. Blinks rapidly when the reset button has b een pressed

continuously for 5 seconds, ind icating that the device

will be reset to factory defaults

System failed self-diagnosis on boot-up.

• RAM Test Fail/System Info. Read Fail/Switch In i tial

Fail/PTP PHY Error.

• FW Checksum Fail/Uncompress Fail (+ Green Coupler lit

on: SW FAIL)

1. Syste m has failed, or is under quick inspection

2. The relay signal contact is open

3. ABC-02 loading/saving failure

When there is a secure connection (or link) to a 1000 Mbps

device on any port.

When there is a secure connection (or link) to 10/100 Mbps

Ethernet device on any port.

22 PWR 1 amber

20 STATE

21 FAULT red

18 PRP green

19 HSR green

12 (Console)

13 (Interlink)

14(A)

15(B)

Link/Act/

Speed

green

blinking

red ON

green

blinking When data is being transmitted or received at 1000 Mbps.

amber

blinking When data is being transmitted or received at 10/100 Mbps.

ON

OFF

ON

ON

OFF The system is operating normally

ON PRP is working

OFF PRP is not enabled

ON HSR is working

OFF HSR is not enabled

ON

ON

OFF Link down or no link

Page 17

EOM-G103-PHR-PTP Series EOM-G103-PHR-PTP-ST Functionality

3-4

ATTENTION

Safety First!

Be sure to disconnect the power cord before installing and/or wiring your

.

Wiring Requirements

In this section, we describe how to connect the EOM-G103-PHR-PTP Evaluation Kit to devices.

Read the following safety precautions before proceeding with the in stallation of any electronic device :

• Use separate paths to route wiring for power and devices. If power wiring and device wiring paths must

cross, make sure the wires are perpend icular at the intersection point.

NOTE: Do not run signal or communication wiring and power wiring in the same wire conduit. To avoid

interference, wires with different signal characteristics should be routed separately.

• Use the type of signal transmitted through a wire to determine which wir es should be kept separate. The

rule of thumb is that wiring that shares similar electrical characteristics can be bundled together.

• Keep input wiring and output wiring separate.

• It is advisable to label the wiring to all devices in the system.

• Be sure to disconnect the power cord before installing and/or wiring your EOM-G103-PHR-PTP Evaluation

Kit.

Connecting the Power

You may use the power jack for connecting the power. The power input range of the EOM-G103-PHR-PTP

Evaluation Kit is from 12 VDC. If the power is properly suppli ed, the “Power” LED will light up in yellow after 3

to 5 seconds.

Power Ground Rules:

Do not split the ground plane into separate planes for analog, digital, and power pins. A single, contiguous

ground plane is recommended.

• Route high-speed signals above a solid and unbroken ground plane.

• Fill copper in the unused area of signal planes and connect these coppers to the ground plane through vias.

• Stagger the placement of vias to avoid creating long gap in the plane due to via voids.

LAN Ports and Pin Assignments

The EOM-G103-PHR-PTP Evaluation Kit has four 10/100/1000 Mbps LAN ports for connecting to a network . The

LAN ports use 8-pin RJ45 connectors. See the following diagram for the pinouts.

EOM-G103-PHR-PTP Evaluation Kit

8-pin RJ45 Pin Signal

1 TRD(0)+

2 TRD(0)3 TRD(1)+

4 TRD(2)+

5 TRD(2)–

6 TRD(1)7 TRD(3)+

8 TRD(3)–

Page 18

EOM-G103-PHR-PTP Series EOM-G103-PHR-PTP-ST Functionality

3-5

Reset Button

The EOM-G103-PHR-PTP Evaluation Kit has two reset buttons: Manual Reset and Reset to Default.

Press the Manual Reset button to reset the hardware of the EOM-G103-PHR-PTP Evaluation Kit and the

EOM-G103-PHR-PTP embedded module.

Press the Reset button continuously for at least 5 seconds to load the software factory default configuration.

After the factory default configuration has been loaded, the system will reboot automatically.

Page 19

4

4. PCB Layout and Design Guidelines

This chapter includes informatio n about using the EOM-G103-PHR-PTP embedded module to design products

that comply with the EMI standard.

The printed circuit board is the single most important factor that affects EMI and overall performance. In order

to meet these requirements, it depends on good design practices. The goal here is to minimize digital and

common mode noise as well as to provide shielding between the PCB’s internal circuitry and the external

environment. These PCB design pr a ctices should apply to the entire PCB design.

The following topics are covered in this chapter:

General Rules

Power Ground Rules

Chassis Ground

Magnetic Noise Zone

Differential Signal Layout

USB Signal Layout

Heat Sink Requiremenrs

Design Guidelines

Page 20

EOM-G103-PHR-PTP Series PCB Layout and Design Guidelines

4-2

General Rules

• Place components so as to avoid long loop traces.

• Use a metal box to shield the printed circuit board.

• Use a ferrite core on the DC power cord to reduce EMI.

• Provide controlled impedance on all high-speed digital signal traces with the right terminat io n sch emes to

prevent reflection and ringing.

• Ensure that the power line is rated for the application and optimized with decoupling capacitors.

• Keep power and ground noise under 100 mV peak to peak.

• Ensure that the switching DC-DC converter is filtered and properly shielded as the DC-DC power converter

can produce a great deal of EMI noise.

• Avoid via and pad in the path on any critical signal as via and pad will induce unwanted capacitance and

inductance which can cause reflection and distortion.

Power Ground Rules

• Do not split the ground plane into separate planes for analog, digital, and power pins. A single, contiguous

ground plane is recommended.

• Route high-speed signals above a solid and unbroken ground plane.

• Fill copper in the unused area of signal planes and connect these coppers to the ground plane through vias.

• Stagger the placement of vias to avoid creating long gap in the plane due to via voids.

Chassis Ground

The chassis ground and magnetics serve two purposes: they help to reduce EMI noise emissions from the signal

ground plane to the PCB’s external environment, and act as a shield to protect the PCB components from ESD.

Place the chassis ground on all PCB layers and use conne ction mounting holes to join the chassis ground on

different PCB layers The chassis ground on the PCB is directly connected to the metal shield of the equipment

through the connection mounting holes. Use a trench/moat to isolate the chassis ground plane from the signal

ground plane. The chassis ground region extends from the front edge of the PCB board (RJ45 connectors) to the

magnetics and around the edge of the board as shown below.

Page 21

EOM-G103-PHR-PTP Series PCB Layout and Design Guidelines

4-3

Magnetic Noise Zone

• Void both power and ground planes on all PCB layers directly u n d er the magnetics.

• The chassis ground should extend from the magnetics to the RJ45 connector.

• Do not route any digital signals between the PHY and RJ45 connector.

• Add transformer to Port 1 and Port 2 as shown in figure 3 when connecting to external cable is required.

Differential Signal Layout

• Differential pair (GXB_TX_P/N or GXB_RX_P/N) should be routed away from all other signals and keeps 100

ohms differential Impedance.

• Keep both traces of each differential pair as identical to each other as possible.

• Route each differential pair on the sa me PCB layer.

• Route both (GXB_TX_P/N or GXB_RX_P/N) pairs far away from each other at least 20 mil s pace as sh own

below.

• The transmit, receive, and clock signals should be kept away from each other.

• Do not space single-ended and differential pair traces close than threes the height above the nearest plane

USB Signal Layout

The following layout guidelines apply to the USB_DP and USB_DM differential pair signals:

• Route the signals close to each other as parallel traces on the PCB, and not parallel with other non-USB

signal traces to minimize crosstalk.

• Doubling the space from the USB_DP/USB_DM signal pair to adjacent signal traces helps prevent crosstalk.

Do not worry about crosstalk between the two USB_DP/USB_DM signal traces. Also can adopt the ground

guard get up the USB_DP/USB_DM signal pair wrapping to decrease crosstalk and EMI.

• The USB_DP/USB_DM signal traces must also be the same length . This mi nimiz es the ef fect of com mon

mode current on EMI. Lastly do not route over plane splits.

• The trace impedance for the USB_DP/USB_DM signals should be 45W±10% (to ground). The impedance is

90W±10% between the differential signal pairs USB_DP and USB_DM to match the 90W±10% USB twisted

pair cable impedance. The trace impedance can be controlled by carefully selecting the line width, trace

distance from power or ground planes, and physical proximity of nearby traces.

• Do not forget the USB data line must be make the impedance matching finally, to avoid the signal reflection.

• Minimize the length of high-speed clock and periodic signal traces that run parallel to high speed USB signal

lines to minimize crosstalk.

• Based on EMI testing experience, the minimum suggested spacing to clock signals is 50 mils.

• Based on simulation data, use 20-mil minimum spacing between high-speed USB signal pairs and other

signal traces for optimal signal quality. This helps to prevent crosstalk

Heat Sink Requiremenrs

Chip Part reference TC (case temperature)

MOXA ART U16 109°C (228.2°F)

FPGA EP4CGX75CF23I7N P1 90°C (194°F)

Page 22

EOM-G103-PHR-PTP Series PCB Layout and Design Guidelines

4-4

Design Guidelines

You may quickly enable the PRP/HSR function on the System by integrating the EOM-G103-PHR-PTP Series to

the main system board. The configuration and communication interfaces between the system main board and

EOM-G103-PHR-PTP module are UART and SGMII (MAC mode) and SERDES (1000Base-X), respectively. All

management and IP-based functions are activated by the System main board and the EOM-G103-PHR-PTP

series provide several functions, including PRP/HSR redundancy pr otocols, VLAN filtering, Multica st filtering,

and time zone settings (refer to the user’s manual for details).

Loading...

Loading...