Page 1

C360

SuperPort System

A Super Professional

Intelligent Multiport Board

for IBM PC/AT and

Compatible System

Dec. 1996 (1st Edition)

All Rights Reserved

Page 2

Copyright Notice

This documentation is copyrighted by Moxa Technologies Co., Ltd. All

rights are reserved. Moxa Technologies reserves the right to make

improvements to the products described in this manual at any time without

notice.

Information provided in this manual is intended to be accurate and reliable.

However, Moxa Technologies assumes no responsibility for its use, nor for

any infringements of rights of the fourth parties which may result from its

use.

MOXA is a registered trademark of Moxa Technologies Co. Ltd. The other

trademarks in this manual belong to their manufacturers individually.

Moxa Technologies Co., Ltd. Moxa Tech USA (CA)

Tel: +866-2-8665-6373 Tel: (408)734-2224

Fax: +886-2-8665-6372 Fax: (408)734-4442

www.moxa.com.tw support @moxa.com.tw

Page 3

MoxaInternetService

s

Customer’s satisfaction is always our number one concern. To ensure

customers get the full benefit of our services, Moxa Internet Services (MIS)

have been built for technical support, product inquiry, new driver upgrade,

etc.

The followings are the services we provide.

E-mail for technical support

address: support@moxa.com.tw

Ftp site for free driver upgrade

address: ftp.moxa.com or ftp.moxa.com.tw

user ID: ftp

password: your_email_address

World Wide Web (WWW) for product info.

address: www.moxa.com or www.moxa.com.tw

Page 4

Table of Contents

. Chapter 1 Introduction 13 ~ 16

1.1 Overview 1

1.2 Features and Specifications 2

1.3 Check list 4

. Chapter 2 Hardware Installation¡@ 71 ~ 12

2.1 Installation of C360 7

2.2 Rack Mount Kit 9

2.3 Serial Number of the Async Concentrator 10

2.4 LED Indicators 10

2.5 Diagnostics 11

. Chapter 3 For DOS Users¡@ 13 ~ 18

3.1 Software Driver Installation and Setup 13

3.2 MOXA Serial Port Naming Convention 16

3.3 Dos API-232 Library and Programming Languages 17

3.4 Administrations 17

3.5 Data Scope 18

. Chapter 4 For UNIX Users¡@ 19 ~ 36

4.1 Driver Installation 19

4.2 MOXA TTY and Non-TTY Ports 21

4.3 Administrations 23

4.4 Programming the MOXA TTY Ports Using Standard UNIX API 27

4.5 Programming the MOXA Non-TTY Ports Using MOXA UNIX API-232 30

Page 5

Appendix A Troubleshooting 37 ~ 42

Problem Report Form 42

Appendix B Technical Reference 43 ~ 48

B.1 Ethernet Cabling 43

B.2 Async Concentrator and Serial Number 44

B.3 RS-232 Cable Wiring 45

Appendix C Example Program 49 ~ 52

Page 6

Page 7

hapter 1

C

Introduction

1.1 Overview

The C360 SuperPort System is a newly-designed 16 to 256 port serial

communication solution, which features high speed, large scale, distributed, and

easy layout. It is designed for industrial and office applications where an

AT/386/486/Pentium system needs to communicate with multiple terminals or

devices through serial interfaces. One C360 provides 16 to 256 full duplex

serial ports. Up to four C360 can be used in the same system and provide up to

1024 ports in total. However, each C360 Control Board must has its unique

IRQ.

The C360 SuperPort System consists of a Control Board, and Async

Concentrator(s). The switchless, jumperless and half-size Control Board links

from one up to 16 Async Concentrators via 10BASE-2 or 10BASE-T cable.

Each Async Concentrator contains 16 serial ports with RJ-45 connectors for

easier connection. Each serial port supports complete set of modem control

signals including RTS, CTS, DSR, DTR, and DCD.

The supported drivers are SCO UNIX and DOS initially. It is our commitment

to support more operating system platforms. Please call Moxa dealer for more

information about our newly available device drivers.

For DOS application programming, DOS API-232 library is provided which

supports most popular languages such as Microsoft C, Turbo C, QuickBasic,

Turbo Pascal, Assembly, and Clipper. For UNIX application programming,

UNIX standard API and MOXA UNIX API-232 are provided for controlling

standard TTY ports and MOXA specific non-TTY ports, respectively.

~1~

Page 8

Chapter 1 • • Introduction

1.2 Features and Specifications

Features

v ASIC-designed control board, compact size

v No switch, no jumper - easy configurable by software

v I/O mapped architecture - no shared memory wasted

v Low host CPU overhead

v RISC-based Async Concentrator

v Rack mountable - industry standard 19" rack

v High speed - up to 460.8K bps each port

v Reliable - 16550C UART with on-chip flow control, no data loss

v More serial ports - 256 ports per board, 1024 per system

v Longer distance - terminals/devices can be located 1000m away

v Suitable for large-scale or distributed application - terminals/devices can

be located at different places or buildings

v Ease of use - menu-driven utilities help ease the configuration, monitoring

and diagnostics

v Easy upgrade - firmware downloading

v Supports popular OSs - DOS and SCO UNIX/OpenServer

Specifications

The C360 SuperPort System consists of a PC Control Board and 1 to 16 Async

Concentrator(s). The Control Board and Async Concentrator(s) are linked

with Ethernet cable. The default shipment of Ethernet cable is 10BASE-2 with

T-type connectors and Terminators. If 10BASE-T cabling is desired, a Hub

and necessary 10BASE-T cables are required and should be prepared by the

user.

System

v 16 to 256 serial ports per Control Board

v Up to four Control Boards per PC system

~2~

Page 9

Introduction • • Chapter 1

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

Control Board

v 16-bit ISA bus (EISA compatible)

v I/O mapped address: 200H, 220H, 240H,260H, 280H, 2A0H,2C0H,2E0H,

300H, 320H, 340H, 360H 380H, 3A0H, 3C0H, 3E0H. (needs 32 bytes)

v IRQ: 2, 3, 4, 5, 10, 11, 12, 15

v Ethernet interface: BNC (for 10BASE-2/Coaxial) and UTP (for 10BASE-

T/Twisted pair), selectable by software IO-IRQ.EXE

v Transmission rate: 10M bps

v Dimensions: 15.8 cm x 6.3 cm

v Operating temperature: 0 °C ~ 55 °C

C360 Control Board

Async Concentrator

v Processor: RISC i80960CA-25 50 MIPS

v RAM: 1MB

v Ethernet interface: BNC (for 10BASE-2/Coaxial) and UTP (for 10BASE-

T/Twisted pair), auto-detection

v Transmission rate: 10M bps

v No. of serial ports: 16 RS-232 ports

v Serial connectors: RJ-45

v Serial port: Data bits - 5, 6, 7, 8

Stop bits - 1, 1.5, 2

Parity - none, even, odd, space, mark

UART - high speed 16550C, 16 byte FIFO

Speed (bps) - 50 ~ 460.8K

Signals - TxD, RxD, DTR, DSR, RTS, CTS, DCD, GND

v Serial number: Used by the driver for identification

v Rack Mount Kit: 2 L-type plates and 8 screws

v Dimension: 27 cm x 16 cm x 4.4 cm

3

Page 10

Chapter 1 • • Introduction

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

v Operating temperature: 0 °C ~ 55 °C

v 110V or 220V AC, auto-select

L-type Plate

Async

Async

Concentrator

Concentrator

BNC

UTP

S0 S1 Tx RX

P1

P8

P16

L-type Plate

Async Concentrator with Rack Mount Kit installed ( Front View )

L-type Plate

Serial NO :

100

Caution:No user serviceable

partsinside.Refer servicing

to qualified personnel.

AC POWER

90-260 V

47-63HZ

0.6Amp/110V

L-type Plate

Async Concentrator with Rack Mount Kit installed ( Rear View )

1.3 Check list

Upon unpacking the C360 SuperPort System, user should find the following

items included in the package:

C360 Control Board

v MOXA C360 Control Board

v 2 Ethernet terminators with a T-type connector

v Device driver diskettes for DOS and SCO UNIX

v C360 User's Manual

v API-232 Manual

Async Concentrator

v Async Concentrator with 16 serial ports

v Female RJ-45 to Male DB-25 RS-232 cable

v 1 meter 10BASE-2 Ethernet cable with a T-type connector

v Power cord

~4~

Page 11

Introduction • • Chapter 1

v Rack Mount Kit

5

Page 12

hapter 2

C

Hardware Installation

2.1 Installation of C360

Step 1: Choose a PC that has DOS system inside.

NOTE: No matter what OS used, user has to configure the C360

Control Board via IO-IRQ.EXE under DOS.

Step 2: Power off the PC.

Step 3: Install the C360 Control Board(s) into a 16-bit slot(s).

NOTE: If installing more than one C360 Control Boards, insert ONE

AT A TIME and configure it using the IO-IRQ.EXE

program before inserting the next board. Each C360

Control Board must have unique base I/O address and IRQ.

The C360 Control Board has the following default (factory) settings:

BASE I/O address : 300H

IRQ : 2/9

Interface : BNC (10BASE-2)

Check if any existing board has the same I/O address or IRQ. If so,

user must try to avoid the conflict by doing either one of the

following:

a. Unplug the conflicting board temporarily if possible. Then

restore the board after changing the I/O address or IRQ of C360.

b. Change or disable the existing board's I/O address or IRQ in

advance.

~6~

Page 13

Hardware Installation • • Chapter 2

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

Step 4: Power on the PC and enter DOS system.

Step 5: Execute IO-IRQ.EXE which is included in the DOS API-232 software

driver diskette, and follow the on-line help to configure the C360.

Be careful not to conflict the I/O address and IRQ of the C360 Control

Board with any existing board's.

Step 6: After completing the configuration, the board is ready for use under

DOS or SCO UNIX.

Step 7: Connect the C360 Control Board and Async Concentrator(s) with the

shipped 10BASE-2 cables. Do not forget to put Terminators in place.

Please refer to Appendix B.1 Ethernet Cabling for more details.

Async

Async

Concentrator

Concentrator

Async

Async

Concentrator

Concentrator

BNC

S0 S1 Tx RX

P1

BNC

UTP

S0 S1 Tx RX

P1

UTP

P8

P16

P8

P16

C360 SuperPort System with 10BASE-2 Cabling

If 10BASE-T cabling is desired, remember to select UTP interface for

Control Board via executing IO-IRQ.EXE under DOS. Connect

Control Board and Async Concentrator(s) to the Hub with 10BASE-T

cables. Please refer to Appendix B.1 Ethernet Cabling for more

details.

7

Page 14

Chapter 2 • • Hardware Installation

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

Hub

Async

Async

Concentrator

Concentrator

Async

Async

Concentrator

Concentrator

BNC

S0 S1 Tx RX

P1

BNC

UTP

S0 S1 Tx RX

P1

UTP

P8

P16

P8

P16

C360 SuperPort System with 10BASE-T Cabling

2.2 Rack Mount Kit

To mount the Async Concentrator on the industry standard 19" rack, Rack

Mount Kit, including two L-type plates and eight screws, should be applied.

Async

Async

Concentrator

Concentrator

BNC

UTP

S0 S1 Tx RX

P1

L-type Plate

Async Concentrator with Rack Mount Kit installed ( Front View )

P8

P16

L-type Plate

L-Type Plate

AC POWER

90-260V

47-63HZ

0.6Amp/110V

Caution:Nouser serviceable

Serial NO :

100

Async Concentrator with Rack Mount Kit Installed ( Rear View )

partsinside.Refer servicing

to qualifiedpersonnel.

Screw

~8~

Page 15

Hardware Installation • • Chapter 2

2.3 Serial Number of the Async Concentrator

It is the unique number identifying an Async Concentrator and written on a

sticker which can be found at the left side of the rear panel of each Async

Concentrator.

User has to type in the serial number when setup the driver in the system.

Under DOS, user can use "Auto-Search Serial No." function of the setup

program to detect the serial number(s) of all the existing Async Concentrator(s)

for convenience without typing the serial number(s) one by one.

Under UNIX, "Auto-Search" function is not available at the time of driver

installation due to that the C360 driver is not in the UNIX system at that time.

2.4 LED Indicators

C360 Control Board

The green link LED labeled Lk lights up to indicate that a valid 10BASE-T link

beat is established. It should be ON under normal operating condition. If the

LED remains off after power is applied, check for a proper RJ-45 connection.

Async Concentrator

After powering on the Async Concentrator, red indicator S0 "ON" and S1

"OFF" means normal initialization status of the Async Concentrator. And

green indicator Tx and red indicator Rx will flash periodically and either more

frequently if C360 driver is not started or less frequently if C360 driver is

started.

Indicator Tx and Rx show the status of transmitting and receiving data. If the

indicator Tx is ON, then some data is transmitted from the Async Concentrator.

If the indicator Rx is ON, then some data is received by the Async Concentrator.

On the other hand, if indicators Tx and Rx are all OFF, then no data is

transferring at that time.

As to the signals' status of each serial port, please use "mini tester" to monitor.

2.5 Diagnostics

9

Page 16

Chapter 2 • • Hardware Installation

When hardware installation is complete, it is highly recommended to run

diagnostic program, SP-ADM.EXE, under DOS to check the Control Board, the

Ethernet cabling and Async Concentrator(s) as well as the compatibility

between the PC and C360 Control Board. Before running SP-ADM.EXE, user

has to run IO-IRQ.EXE to setup the Control Board, then run SETUP.EXE to

setup the DOS driver, then run SP-DRV.EXE to install the DOS driver.

For more information about SP-ADM.EXE, please refer to Section 3.5.

~10~

Page 17

Hardware Installation • • Chapter 2

11

Page 18

hapter 3

C

For DOS Users

The C360 is useful for office automation and industrial control as well as data

acquisition and communication. Because many users need to implement an

industrial control system or data acquisition system in the DOS environment,

but DOS did not has any better communication API, thus Moxa have developed

a device driver and library functions under DOS which are called API-232 for

DOS. User should find the API-232 driver diskette along with shipment in

addition to API-232 User's Manual.

See the README file on the API-232 driver diskette for the latest release notes

and other last-minute information.

3.1 Software Driver Installation and Setup

MOXA API-232 for DOS is a software package that assists users to develop

and/or debug programs for serial communications. It supports device drivers

for the MOXA boards such as C102/C104/C168 Service, standard PC COM

ports, and C360 SuperPort System.

Driver Installation

Insert the API-232 software diskette into the floppy drive, change directory (cd)

to the drive then type DOSINST.EXE to run the installation program. User

has to choose the C360 SuperPort Board and specify the target API-232

directory (e.g. C:\MOXA) to be installed.

Control Board Configuration

If have not executed IO-IRQ.EXE after installing C360 into the PC, please

change to API-232 directory and run the configuration program, IO-IRQ.EXE,

then choose C360 and specify the base I/O address, IRQ, and Interface for C360

Control Board. The settings of base I/O address and IRQ will be used when

~12~

Page 19

For DOS Users • • Chapter 3

running driver setup program, BIN\SETUP.EXE.

Driver Setup

Change to API-232 and run the setup program, BIN\SETUP.EXE, then choose

C360 and specify the base I/O address, IRQ, number of Async Concentrators,

port numbers range in board and system level, serial numbers in concentrator

level, and communication parameters in port level.

Noticeable fields and functions in "MOXA C360" dialog are explained below:

Async Concentrators: The number of Async Concentrators linked with

each C360 Control Board.

Port number: The range of port numbers for all ports of Async

Concentrators linked with each C360 Control Board.

Interrupt number: The IRQ number of C360 Control Board. Each

Control Board must use its own IRQ, not conflicting with others.

F3: Setup the serial numbers and range of port numbers for all Async

Concentrators linked with each C360 Control Board.

PgDn: Setup the initial values of communication parameters for all

ports of Async Concentrators linked with each C360 Control Board.

These values are used when driver is loaded.

Driver Loading

Having completed the setup, load the TSR driver, BIN\SP-DRV.EXE, at the

DOS prompt (or from within AUTOEXEC.BAT batch file). The driver will

detect the C360 automatically. If all the Control Board(s) and Async

Concentrator(s) are detected, a message similar to below will show:

13

Page 20

Chapter 3 • • For DOS Users

MOXA C360 SuperPort System Communication Driver (Ver. x.xx)

Setup driver ...

C360 Control Board 1: base I/O address [200] IRQ 10

Async Concentrator's serial no. : 101 102

Device Driver Setup O.K.

, which means the C360 driver is installed properly. At this point, user is ready

to execute application that supports API-232 functions, or start developing

applications.

If at least a pair of Control Board and Async Concentrator is detected, a

message similar to below will show:

MOXA C360 SuperPort System Communication Driver (Ver. x.xx)

Setup driver ...

C360 Control Board 1: base I/O address [200] IRQ 10

Async Concentrator's serial no. : 101

C360 Control Board 2: base I/O address [220] not found!!

C360 Control Board 3: base I/O address [240] found no concentrator!!

Device Driver Setup O.K.

Even though the C360 driver is installed, only the ports of the found pair(s) of

Control Board and Async Concentrator will work properly. Please refer to

Appendix A Troubleshooting for possible reasons and solutions.

If not a pair of Control Board and Async Concentrator is detected, one of the

error messages similar to below will show:

C360 Control Board 1: base I/O address [200] not found!!

C360 Control Board 2: base I/O address [220] found no concentrator!!

, which means the C360 driver is not installed properly. Please refer to

Appendix A Troubleshooting for possible reasons and solutions.

~14~

Page 21

For DOS Users • • Chapter 3

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

Driver Removal

To remove the C360 driver from memory, type SP-DRV/Q at the DOS prompt.

3.2 MOXA Serial Port Naming Convention

Each MOXA serial port are referenced as port number in terms of programming.

The port number is automatically assigned once the starting port number is

decided by user when configuring the Async Concentrators.

For example, if there is only one Async Concentrator configured and the

starting port number is 1, then the mapping of serial port numbers will be as

depicted.

8

7

6

5

4

3

2

1

Async

Async

Concentrator

Concentrator

9

10

11

12

13

14

15

16

BNC

UTP

S0 S1 Tx RX

15

P1

P8

P16

Page 22

Chapter 3 • • For DOS Users

3.3 DOS API-232 Library and Programming Languages

For DOS programming, API-232 includes powerful libraries supporting

languages like Microsoft C, Turbo C, Macro Assembly, QuickBasic, Turbo

Pascal, Clipper, etc. Sample programs for each supported language are

included. See the files in the sub-directory EXAMPLE\language of the API-232

directory.

For complete API-232 function description, see API-232 User's Manual or file

API-232.TXT in the API-232 directory for more details. The following

functions illustrated in C are for C360 only. Some language may vary in

function name and some does not support sio_getACs( ) due to its restriction.

1. sio_getACs( ) : Get C360 Async Concentrators' serial numbers

2. sio_ACstate ( ) : Get C360 Async Concentrator's status

3. sio_ACdiag ( ) : C360 Async Concentrator’s diagnostics

Function, sio_loopback(), is not available for C360. Function, sio_ACdiag( )

is recommended instead.

3.4 Administrations

The utility, BIN\SP-ADM.EXE, is for C360's status monitoring and hardware

diagnostics.

Async Concentrator Status Monitoring

This utility gives user a quick view about the status of all the Async

Concentrators linked with each Control Board. Status "Running" means the

Async Concentrator with corresponding serial number is working. Status "No

response" means the Async Concentrator is powered off or defective or the

Ethernet cabling goes wrong somewhere.

~16~

Page 23

For DOS Users • • Chapter 3

Async Concentrator Diagnostics

This utility gives user a quick view about all the Async Concentrators' and ports'

status. It will diagnose the C360 in the system and report the hardware status,

Good/Bad/No Response, of each port. It is strongly recommended to run this

for verifying hardware condition, especially as soon as received C360 package.

3.5 Data Scope

The Data Scope, BIN\SCOPE.EXE, is a set of utility programs that can help

user with system troubleshooting and serial communication debugging. There

are three major functions:

1. The Data Scope utility offers transparent monitoring of serial

communication lines and allows data to be streamed to disk storage for

later analysis.

2. The TTY terminal emulation utility allows user to view the signal

status and transfer data interactively or files using ASCII, XMODEM,

YMODEM, ZMODEM and KERMIT protocols.

3. The diagnostic test utility provides port connection test with two

MOXA ports connected via a properly-wired cable.

Please see on-line help as running BIN\SCOPE.EXE for more usage and

capability information.

17

Page 24

hapter 4

C

For UNIX Users

The C360 UNIX driver supports at most 256 TTY terminal ports in the UNIX

system which are called MOXA TTY ports. The rest of the ports are called

MOXA non-TTY ports. The differences between MOXA TTY and non-TTY

ports are described below.

In addition, C218/C320 Series can not co-exist with C360 in the UNIX system.

Please remove C218/C320 UNIX driver before installing C360 UNIX driver.

4.1 Driver Installation

Step 1. Boot the system and login from the console as a super user (root).

Step 2. Insert driver diskette into a 1.44MB floppy driver, A: or B:. If driver

files are obtained from MOXA FTP service, put them under

/tmp/moxa directory and skip the following “ tar ”command .

Step 3. Change to root directory by entering the following command:

# cd /

Step 4. Enter the following command to extract the install script file first.

# tar xvf /dev/fd0135ds18 /tmp/moxa/install (if 1.44MB A:)

# /tmp/moxa/install

Copyright (C) 199x Moxa Technologies Co., Ltd. All Rights Reserved.

MOXA C360 Device Driver Installation

( Ver. x.x )

Please select one of the devices where the driver diskette/files puts:

~18~

Page 25

For UNIX Users • • Chapter 4

1. /dev/fd0135ds18 (A: 1.44MB)

2. /dev/fd096ds15 (A: 1.2 MB )

3. /dev/fd1135ds18 (B: 1.44MB)

4. /dev/fd196ds15 (B: 1.2 MB )

5. /tmp/moxa (Hard Disk )

Select :

For ...

Tar files from driver diskette, please wait ...

Then the MOXA Multiport Board Installation Utility will show for

board installation.

Follow the instructions prompted to install.

Step 5. Now user may shutdown the system and reboot. If user has trouble

in booting the new UNIX kernel, use the backup kernel (/unix.moxa)

to boot the system. The system will work as before. Refer to

Appendix A Troubleshooting.

After the system starts up again, enter into the multiuser mode. The

following message will show:

MOXA C360 SuperPort System Communication Driver (Ver. x.xx)

Setup driver ...

C360 Control Board 1: base I/O address [200] IRQ 10

Async Concentrator's serial no. : 101

Device Driver Setup O.K.

If the following error message appears

C360 Control Board 1: base I/O address [220] not found!

C360 Control Board 2: base I/O address [240] found no concentrator!

Please see Appendix A Troubleshooting.

19

Page 26

Chapter 4 • • For UNIX Users

Step 6. Enable the "Terminal" port for login purpose.

Taking ttya11 as an example,

for SCO UNIX/OpenServer/Open Desktop,

# enable ttya11

Or refer to the UNIX system manuals for how to activate a tty port.

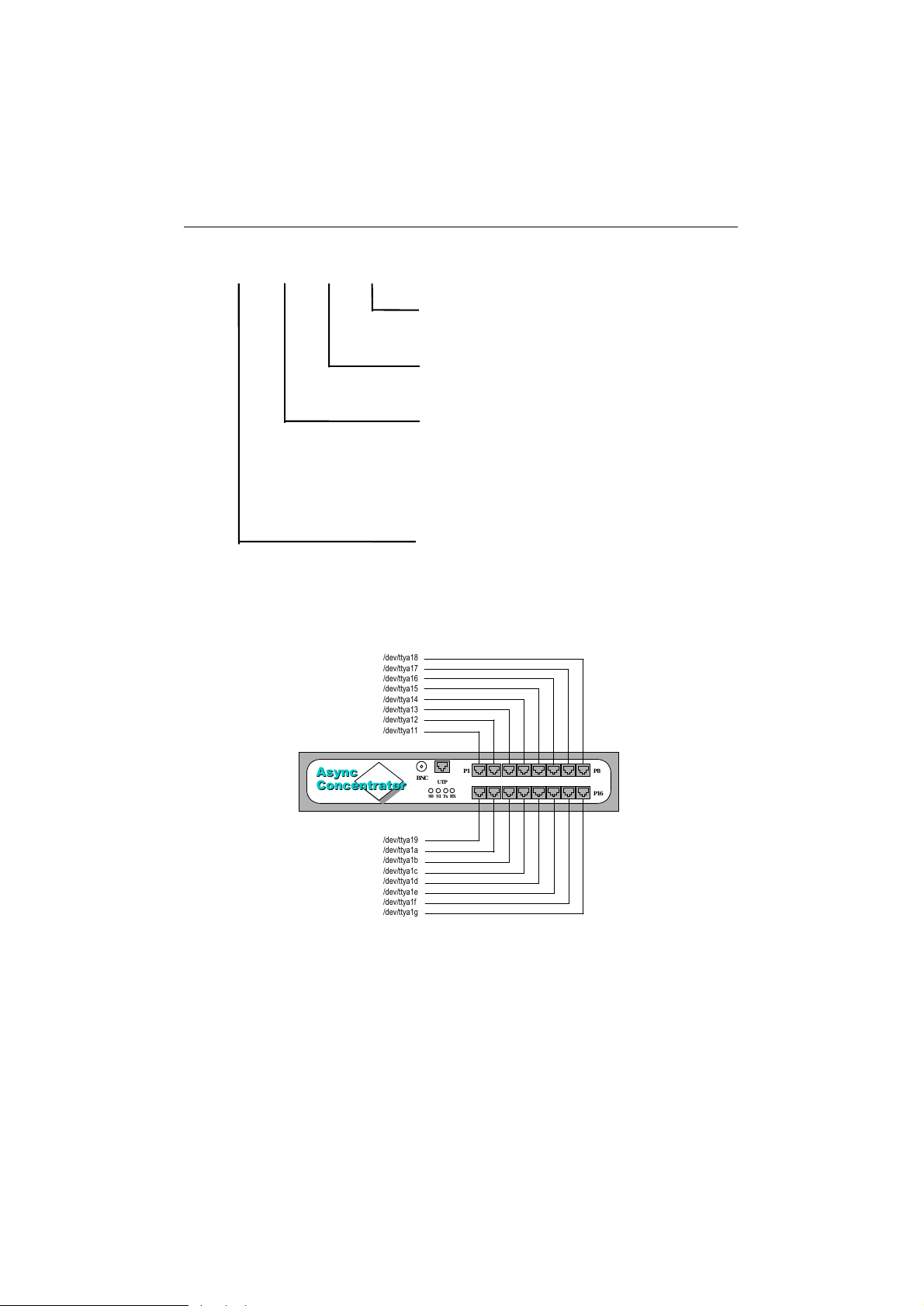

4.2 MOXA TTY and Non-TTY Ports

Even though C360 can provide up to 1024 serial port in a system, only 256

ports among 1024 ports can be configured as TTY ports, the rest ports as nonTTY ports.

MOXA TTY ports follow the standard of UNIX tty ports. But MOXA nonTTY ports do not. Instead, they follow the Moxa-defined rule which will be

stated below. In other word, the naming convention of MOXA TTY ports is

different from that of MOXA non-TTY ports. So is the programming rule.

MOXA TTY Ports

If the TTY ports of C360 are successfully configured, there will be two tty

devices created for each TTY port at /dev directory: one is non-MODEM tty

(e.g. ttya11), and the other is MODEM tty (e.g. ttyA11). The two devices are

actually accessing the same physical port except that the MODEM tty has to

check the ON status of DCD signal from remote site to be able to open device

and will close device automatically as DCD signal is OFF.

To be able to use speeds higher than 38400 bps in the UNIX system, the 50

baud rate will no longer stand for 50 bps instead it means 57600 bps, 75 baud

rate for 115.2K bps, 110 baud rate for 230.4K bps, and 134 baud rate for

460.8K bps.

The convention of the MOXA TTY device name is:

~20~

Page 27

For UNIX Users • • Chapter 4

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

"tty" + "A" + "B" + "C"

port ordinal number in an Async Concentrator

(from 1 to g)

Async Concentrator ordinal number1111111

(from 1 to g)

board ordinal number

"a" or "A" : 1st MOXA board

"b" or "B" : 2nd MOXA board

"c" or "C" : 3rd MOXA board

"d" or "D" : 4th MOXA board

Capitals indicate a MODEM port

Standard tty device prefix

For example, if there is only one Async Concentrator configured, then the

mapping of device names will be as depicted.

/dev/ttya18

/dev/ttya17

/dev/ttya16

/dev/ttya15

/dev/ttya14

/dev/ttya13

/dev/ttya12

/dev/ttya11

Async

Async

Concentrator

Concentrator

MOXA Non-TTY Ports

/dev/ttya19

/dev/ttya1a

/dev/ttya1b

/dev/ttya1c

/dev/ttya1d

/dev/ttya1e

/dev/ttya1f

/dev/ttya1g

BNC

UTP

S0 S1 Tx RX

21

P1

P8

P16

Page 28

Chapter 4 • • For UNIX Users

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

The MOXA non-TTY ports are simply referenced as port number in terms of

programming. The port number is automatically assigned when configuring

the Async Concentrators.

For example, if there is only one Async Concentrator configured, then the

mapping of device names will be as depicted.

8

7

6

5

4

3

2

1

Async

Async

Concentrator

Concentrator

9

10

11

12

13

14

15

16

BNC

UTP

S0 S1 Tx RX

P1

P8

P16

4.3 Administrations

User can use the administration utility, c360adm, to change the C360

configuration, to monitor the ports' activity, to diagnose the C360, to reset the

C360 driver, to restart the specified Async Concentrator or to remove the

installed MOXA driver from the UNIX system.

Configuration

~22~

Page 29

For UNIX Users • • Chapter 4

User can select base I/O address and interrupt at will as long as no conflict will

occurs. In [Concentrator Setting] dialog, there are several features that need

explanation which is as follows:

Async Concentrator Serial Number:

This is the unique number identifying an Async Concentrator. User has to

type in the serial number when installing the driver into the system at the very

first time. Otherwise, user can use "Auto Search Serial No." to detect the serial

number(s) of all the existing Async Concentrator(s) for convenience without

typing the serial number(s) one by one.

The unique serial number written on a sticker can be found at the left of the rear

panel of each Async Concentrator.

TTY or Non-TTY:

Specify TTY the for the Async Concentrator if all the 16 serial ports are to be

used for login or standard UNIX tty purpose. Otherwise, specify non-TTY for

MOXA port usage.

If TTY is specified for an Async Concentrator, user may enter [H/W Flow

Control Settings] dialog to specify "H/W Flow Control" feature: ON or OFF

(OFF is set as default).

This feature is for more flexible driver behavior. If set to OFF (default),

RTS/CTS hardware flow control function in driver will be disabled and CTS

signal from remote site is not needed for tty port to transfer data. On contrary,

if set to ON, RTS/CTS hardware flow control function in driver will be enabled

and CTS signal from remote site is needed for tty port to transfer data.

Any change of configuration, such as adding or deleting Async Concentrator(s),

changing from TTY to non-TTY or non-TTY to TTY, will cause kernel

rebuilding. Note that changing only the serial number will not cause kernel

rebuilding but "Concentrator Restart" or "Driver Reset" should be called for to

enable the newly configured Async Concentrator.

23

Page 30

Chapter 4 • • For UNIX Users

Monitoring

This utility gives user a quick view about all the Async Concentrators' and ports'

status. One can easily learn each port's total received/transmitted (Rx/Tx)

character count since the time when the monitoring is started. Rx/Tx

throughputs per second are also reported in interval basis (e.g. the last 5 seconds)

and in average basis (since the time the monitoring is started). User can reset

all ports' count by <HOME> key. <+> <-> (plus/minus) keys to change the

displaying time interval. Press <ENTER> on the port, that cursor stay, to view

the port's communication parameters, signal status, and input/output queue.

Besides, as entering [Port Status] dialog for highlighted port, parameters like

baud rate, parity, data bits, stop bits, CTS, DSR, DCD, input queue, and output

queue, are reported.

Diagnostics

The utility will diagnose the C360 in the system and report the hardware status

of each port of C360. However, user must make sure that

All MOXA TTY and non-TTY ports on the specified Async

Concentrator(s) must not be used by any applications (processes),

including getty or tty monitor, which should be stopped before the

utility is executed.

Driver Reset

The utility eliminates the need to shut down the UNIX system to re-initialize the

C360 with new configuration. However, user must make sure that

All MOXA TTY and non-TTY ports must not be used by any

applications (processes), including getty or tty monitor, which should

be stopped before the utility is executed.

Concentrator Restart

~24~

Page 31

For UNIX Users • • Chapter 4

The utility restarts the Async Concentrator(s) specified without shutting down

the UNIX system. This is especially useful for replacing a defective Async

Concentrator with a new Async Concentrator when any port of the original

Async Concentrator is mal-functional. In this case, even though the serial

numbers are different, "Driver Reset" is not suitable. However, user must

make sure that

All MOXA TTY and non-TTY ports on the specified Async

Concentrator(s) must not be used by any applications (processes),

including getty or tty monitor, which should be stopped before the

utility is executed.

Terminal Emulation

This utility provides data sending and receiving ability of all tty ports, including

MOXA TTY ports (but not MOXA non-TTY ports). It is quite useful for

testing, for example, sending AT command to a modem connected to the port or

used as a terminal for login purpose. Note that this is only a dumb terminal

emulation without handling full screen operation. In addition, pattern/file

transfer function is provided.

Driver Removal

If user wants to remove the MOXA C360 device driver and return to the

original system configuration, just press Enter in this function entry and answer

"y" to confirm. Then the system will be rebuild. This may take some time.

If user answers "n", no action will be taken.

4.4 Programming the MOXA TTY Ports Using Standard UNIX API

The system services that apply to standard tty port can also be applied to

MOXA TTY port since they conforms to UNIX tty standard. For example,

25

Page 32

Chapter 4 • • For UNIX Users

open( ), ioctl( ) , read( ), write( ), close( ), etc. Please refer to the UNIX

Programmer's Reference manual. However, these system services only

provide a limited functions and thus may not satisfy the sophisticated

programmers' need. In order to meet the user's special needs, MOXA supports

extended services through ioctl( ) command which are listed below.

Note that UNIX system services can not be applied to MOXA Non-TTY ports

and please refer to the next Section for more details.

Extended Function List for MOXA TTY Ports :

1.MIBUFED (=0x401) To get byte count in input buffer.

2.MOBUFED (=0x402) To get byte count in output buffer.

3.MTCRTS (=0x403) To control RTS output signal.

4.MTCDTR (=0x404) To control DTR output signal.

5.MSTATUS (=0x407) To read modem line status (CTS/DSR/DCD).

6.MHWFLOW (=0x40e) To enable/disable the hardware flow control.

Function Description :

The following lists the syntax of MOXA extended functions for SCO UNIX.

The variable moxa_fd is the returned file descriptor by open( ) a specific

MOXA TTY port. For example,

int moxa_fd;

moxa_fd = open("/dev/ttya11",O_RDWR);

1. MIBUFED

This function let user know how many bytes queued in input buffer

when this function is issued.

#define MIBUFED 0x401

int count; /*number of bytes queued in the input buffer*/

ioctl(moxa_fd, MIBUFED, &count);

~26~

Page 33

For UNIX Users • • Chapter 4

2. MOBUFED

This function let user know the byte count queued in output buffer

when this function is issued.

#define MOBUFED 0x402

int count; /* number of bytes queued in the output buffer */

ioctl(moxa_fd, MOBUFED, &count);

3. MTCRTS

This function, only valid when hardware flow control is turned off

(see MHWFLOW), is used to drive RTS on or off.

#define MTCRTS 0x403

#define TurnON 1

#define TurnOFF 0

ioctl(moxa_fd, MTCRTS, TurnON);

ioctl(moxa_fd, MTCRTS, TurnOFF);

4. MTCDTR

This function is used to DTR on or off.

#define MTCDTR 0x404

#define TurnON 1

#define TurnOFF 0

ioctl(moxa_fd, MTCDTR, TurnON);

ioctl(moxa_fd, MTCDTR, TurnOFF);

5. MSTATUS

This function is used to know the RS-232 line status(CTS/DSR/DCD).

27

Page 34

Chapter 4 • • For UNIX Users

#define MSTATUS 0x407

int status; /* status = RS-232 line status */

/* bit0 - CTS (1:on, 0:off) */

/* bit1 - DSR (1:on, 0:off) */

/* bit2 - DCD (1:on, 0:off) */

ioctl(moxa_fd, MSTATUS, &status);

6. MHWFLOW

This function is used to enable/disable hardware flow control. The

first open() function of a port will set the MHWFLOW to

configuration setting. However, user might want to control the DTR

or RTS signal on their will, thus the RTS flow control bit should be

turned off in order to take over the control of DTR or RTS signal via

function MTCRTS or MTCDTR. MTCRTS and MTCDTR can be

effective only after the RTS flow control bit of MHWFLOW is turned

off.

#define MHWFLOW 0x40e

#define HWFlowControlOff 0x00

#define CTSFlowControlBitOn 0x01

#define RTSFlowControlBitOn 0x02

#define HWFlowControlOn 0x03

ioctl(moxa_fd, MHWFLOW, CTSFlowControlBitOn);

ioctl(moxa_fd, MHWFLOW, RTSFlowControlBitOn);

ioctl(moxa_fd, MHWFLOW, CTSFlowControlBitOn |

RTSFlowControlBitOn);

~28~

Page 35

For UNIX Users • • Chapter 4

4.5 Programming the MOXA Non-TTY Ports Using MOXA UNIX API-232

Even though C360 SuperPort system provides up to 1024 serial ports, maximum

of 256 ports can serve as standard UNIX TTY devices while the rest of the ports,

up to 768, can only be used as MOXA non-TTY devices.

To control MOXA non-TTY ports, MOXA proprietary functions in the MOXA

UNIX API-232 library should be used, which are listed below. Note that

UNIX system services, such as open( ), close( ), read( ), write( ), and ioctl( ),

can not be applied to MOXA non-TTY ports.

The MOXA UNIX API-232 functions are almost the same as those in MOXA

DOS API-232 library. Hence it is easier for porting applications from DOS

platform to UNIX one. One thing to notice is that all the MOXA non-TTY

ports can only be accessed in one UNIX application (process). In other word,

two or more applications accessing any MOXA non-TTY ports are not allowed.

Remember to include the header file, mxapi232.h, in the application program

and link with the library, mxapi232.o. User can use the example program

(example.c), header file (mxapi232.h), library (mxapi232.o) and makefile in the

directory, /usr/lib/moxa to shorten the learning curve.

Function List:

1. sio_open( ) Open a non-TTY port.

2. sio_close( ) Close a non-TTY port.

3. sio_read( ) Read data from a non-TTY port.

4. sio_write( ) Write a string of data to Rx buffer.

5. sio_putb( ) Put a block of data to Tx buffer.

6. sio_ioctl( ) Non-TTY port parameter setting.

7. sio_break( ) Send break signal.

8. sio_flush( ) Flush Tx/Rx buffer data.

9. sio_iqueue( ) Read the length of data queued in Rx buffer.

10. sio_oqueue( ) Read the length of data queued in Tx buffer.

11. sio_lstatus( ) Get modem line status.

12. sio_lctrl( ) Set modem line control.

13. sio_DTR( ) Set modem line control signal DTR.

29

Page 36

Chapter 4 • • For UNIX Users

14. sio_RTS( ) Set modem line control signal RTS.

15. sio_flowctrl( ) Setting CTS/RTS and XON/XOFF flow control.

16. sio_disableTx( ) Disable transmitting data.

17. sio_enableTx( ) Enable transmitting data.

Function Description:

The following lists the syntax of MOXA non-TTY port functions. The

variable port is the port number of a specific MOXA non-TTY port to be

controlled.

The return value -2 stands for Ethernet cabling problem or Async Concentrator

problem which may causes time out in function execution.

1. Open a non-TTY port.

int sio_open(int port)

return = 0 ok

-1 bad port

-2 time out

port = port number

2. Close a non-TTY port.

int sio_close(int port)

return = >=0 ok : bit 0 ON means Rx queue has data

bit 1 ON means Tx queue has data

-1 bad port

-2 time out

port = port number

3. Read data from a non-TTY port.

~30~

Page 37

For UNIX Users • • Chapter 4

int sio_read(int port, char *buf, int len)

return = >0 length of data received

0 no data received

-1 bad port

-2 time out

-5 port is not open

port = port number

buf = receive buffer pointer with required space

len = buffer length

4. Write a string of data to Tx buffer.

int sio_write(int port, char *buf, int len)

return = >0 length of data transmitted to Tx buffer

=0 buffer full

-1 bad port

-2 time out

-5 port is not open

port = port number

buf = transmit string pointer

len = transmit string length

5. Put a block of data to Tx buffer. If the Tx buffer free space is

smaller than block length, it will return zero.

int sio_putb(int port, char *buf, int len)

return = >0 length of data transmitted to Tx buffer

0 free buffer not enough

-1 bad port

-2 time out

-5 port is not open

-6 len > Tx buffer size

port = port number

buf = transmit string pointer

len = transmit string length

6. Non-TTY port parameter setting.

31

Page 38

Chapter 4 • • For UNIX Users

int sio_ioctl(int port, int baud, int mode)

return = 0 ok

-1 bad port

-2 time out

-4 bad baud rate

port = port number

baud = 0 = 50 1 = 75 2 = 110

3 = 134.5 4 = 150 5 = 300

6 = 600 7 = 1200 8 = 1800

9 = 2400 10 = 4800 11 = 7200

12 = 9600 13 = 19200 14 = 38400

15 = 57600 16 = 115200 17 = 230400

18 = 460800

mode = bit_cnt OR stop_bit OR parity

bit_cnt ( bit 0, 1, 2 )

0x00 = bit_5 0x01 = bit_6 0x02 = bit_7

0x03 = bit_8

stop_bit ( bit 3 )

0x00 = stop_1 0x04 = stop_2

parity ( bit 4, 5 )

0x00 = none 0x08 = odd 0x18 = even

0x28 = mark 0x38 = space

7. Send break signal.

int sio_break(int port, int time)

return = 0 ok

-1 bad port

-2 time out

-4 xmit disable

-5 port is not open

port = port number

time = break time in tic ( 1/18.2 second )

8. Flush Tx/Rx buffer data.

~32~

Page 39

For UNIX Users • • Chapter 4

int sio_flush(int port, int func)

return = 0 ok

-1 bad port

-2 time out

-5 port is not open

port = port number

func = flush function (clear the assigned queue)

0 for input queue

1 for output queue

2 for input & output queue

9. Read the length of data queued in Rx buffer.

long sio_iqueue(int port)

return = >0 input queue size(bytes)

-1 bad port

-2 time out

-5 port is not open

port = port number

10. Read the length of data queued in Tx buffer.

long sio_oqueue(int port)

return = >=0 length of transmitted data which still

queued in Tx buffer

-1 bad port

-2 time out

-5 port is not open

port = port number

11. Get modem line status.

int sio_lstatus(int port)

return = >0 line status : bit 0 -- S_CTS

bit 1 -- S_DSR

33

Page 40

Chapter 4 • • For UNIX Users

bit 2 -- S_RI

bit 3 -- S_CD

-1 bad port

-2 time out

port = port number

12. Set modem line control.

int sio_lctrl(int port, int mode)

return = 0 ok

-1 bad port

-2 time out

port = port number

mode = C_DTR(bit 0), C_RTS(bit 1)

13. Set modem line control signal DTR.

int sio_DTR(int port, int mode)

return = 0 ok

-1 bad port

-2 time out

port = port number

mode = 0 set DTR off

1 set DTR on

14. Set modem line control signal RTS.

int sio_RTS(int port, int mode)

return = 0 ok

-1 bad port

-2 time out

-6 H/W flow control setting

port = port number

mode = 0 set RTS off

1 set RTS on

15. Setting CTS/RTS and XON/XOFF flow control.

~34~

Page 41

For UNIX Users • • Chapter 4

int sio_flowctrl(int port, int mode)

return = 0 ok

-1 bad port

-2 time out

port = port number

mode = bit 0 CTS flow control (0/1-off/on)

bit 1 RTS flow control (0/1-off/on)

bit 2 Tx XON/XOFF flow control (0/1-off/on)

bit 3 Rx XON/XOFF flow control (0/1-off/on)

16. Disable transmitting data.

int sio_disableTx(int port)

return = 0 ok

-1 bad port

-2 time out

-5 port is not open

port = port number

17. Enable transmitting data.

int sio_enableTx(int port)

return = 0 ok

-1 bad port

-2 time out

-5 port is not open

port = port number

35

Page 42

Appendix A Troubleshooting

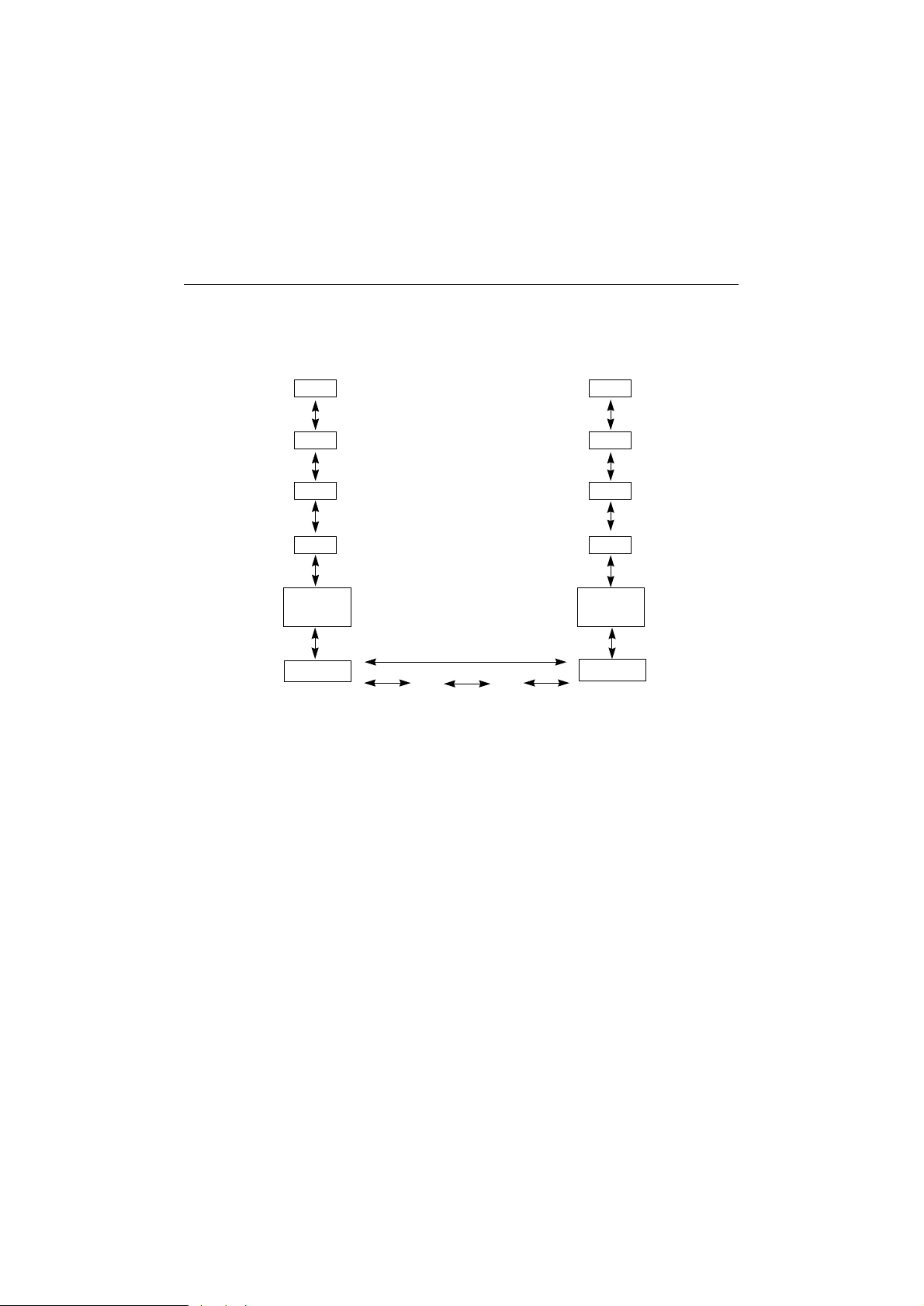

Basically, to have data communication work, many things are involved. The

following picture will help user to inspect where the problem is.

AP 1

API

OS

Driver

PC 1

With

Serial Board

Serial Port

or

MDMMDM

AP 2

API

OS

Driver

PC 2

With

Serial Board

Serial Port

The philosophy for quickly solving a communication problem lies in isolation

of the real question point. Communications would fail if any point on the way

from AP 1 to AP 2 went wrong. The error (messages) could only be the clue

to the solution but may not be the final answer. Even same error symptom

may result from totally different cause(s).

Common problems and possible solutions are listed below. If user still has

problems, contact the dealer or Moxa for help. Or report it using "Problem

Report Form" to the dealer at once for technical support.

~36~

Page 43

Technical Reference • • Appendix B

1 MOXA board not found.

Hardware causes and solutions:

a The I/O address user has selected for MOXA board conflicts with

that of other interface boards such as SCSI, LAN, or Sound boards.

If so, adjust the I/O address to forestall the conflict.

b The MOXA board is not properly plugged in the system. If that is

the case, then re-install the board and make sure that it fits well in a

16-bit slot this time. Sometimes the slot for plugging MOXA

board is bad. In this case, please try other slots until a good one is

found.

c The MOXA board is not installed or missing (absent). Please

install it.

d The MOXA board is defective. Please check the MOXA board(s)

ONE AT A TIME in the system and find out the defective one. It

is also recommended to check it under DOS with F3 Diagnostics

function of utility "SETUP" to verify the hardware conditions.

Software Cause and Solution:

a The I/O address setting on board is not the same as the setting in

configuration software.

2 "Can not find any C360 Async Concentrator" error message.

This message shows that none of the configured Async Concentrator(s)

is found. The message will not show if AT LEAST ONE of the

configured Async Concentrator(s) is found.

37

Page 44

Appendix B • • Technical Reference

Hardware Causes and Solutions:

a Check if the Ethernet cable between the Async Concentrator and

the Control Board is working segment by segment and firmly

plugged and properly terminated.

b Run the board configuration program to check the board

configuration. Connect proper number of Async Concentrators as

configured in configuration program.

c If all the possible methods fail, the Async Concentrator might be

defective. It is recommended to check it under DOS with utility

"SETUP" to verify the hardware conditions one by one.

3 MOXA board found but can not transfer (transmitting/receiving)

data.

Hardware Causes and Solutions:

a Check if wrong cable wiring.

Refer to Appendix B.3 for precise pin assignment of the connector

type user is using and make sure the cable wiring is right.

b Cable or Async Concentrator is defective. Or only certain port of

the Async Concentrator is broken. Pleas check all the

components mentioned physically or using diagnostics utility

available.

c IRQ setting of the board does not match the setting in configuration

software and device driver. Please make sure they do match.

Software Causes and Solutions :

~38~

Page 45

Technical Reference • • Appendix B

a In the UNIX system, C360 will check line status (CTS/DSR)

before it sends data out if RTS/CTS flow control feature is set to

ON. In this case, if user is using 3-pin (TxD, RxD, GND) cable,

please run "moxaadm" and use configuration program to set the

RTS/CTS flow control feature to OFF (strongly recommended).

Or loopback (or short) the RTS with CTS and DTR with DSR on

MOXA port site as follows.

RTS DSR

CTS DTR

DCD

If RTS/CTS flow control feature is set to OFF, then leaving the

pins mentioned above open is fine.

b Perhaps the application controlling MOXA board is not correctly

written according to the corresponding API of the operating system.

To verify, please run existed and known good application or Moxaprovided utility.

For example, under UNIX, "stty", "cat", or "getty" is existed

program for testing tty port.

4 During operation, the host system with C360 is powered off but

the Async Concentrator(s) is(are) still on.

Solution:

Simply restart the host system, and normal C360 startup procedure

will be executed.

5 Under UNIX, MOXA port responds too slowly or abnormal key

operation.

39

Page 46

Appendix B • • Technical Reference

Hardware Cause and Solution:

a Wrong IRQ setting. If the hardware and software IRQ setting do

not match. MOXA driver will use a polling scheme and thus

causes slow operation. Try to match the IRQ settings.

6 Under UNIX, when respawning quite a few number of tty ports,

the following error messages appear: "Time out table overflow",

"File table overflow", "Region table overflow".

Software Cause and Solution:

The above error messages imply that the system resources are

exhausted. User should tune the kernel parameters to a larger value

and rebuild the kernel to be able to accommodate the new

configuration. Refer to UNIX system manual about how to tune the

parameters and rebuild kernel.

"Time out table overflow" : NCALL parameter too small.

"File table overflow" : NFILE or NINODE parameter too small.

"Region table overflow" : NREGION or NPROC parameter too small.

7 Under UNIX, the newly rebuilt kernel could not boot.

Software Causes and Solutions:

The C360 driver might not be built into the new kernel correctly.

a Please use the last good kernel backup to boot again. The kernel

backup in UNIX is /unix.moxa or /stand/unix.moxa.

b Then remove the C360 driver. Refer to Section 4.3 for driver

removal.

c Re-install the C360 driver once more.

~40~

Page 47

Technical Reference • • Appendix B

Appendix B Technical Reference

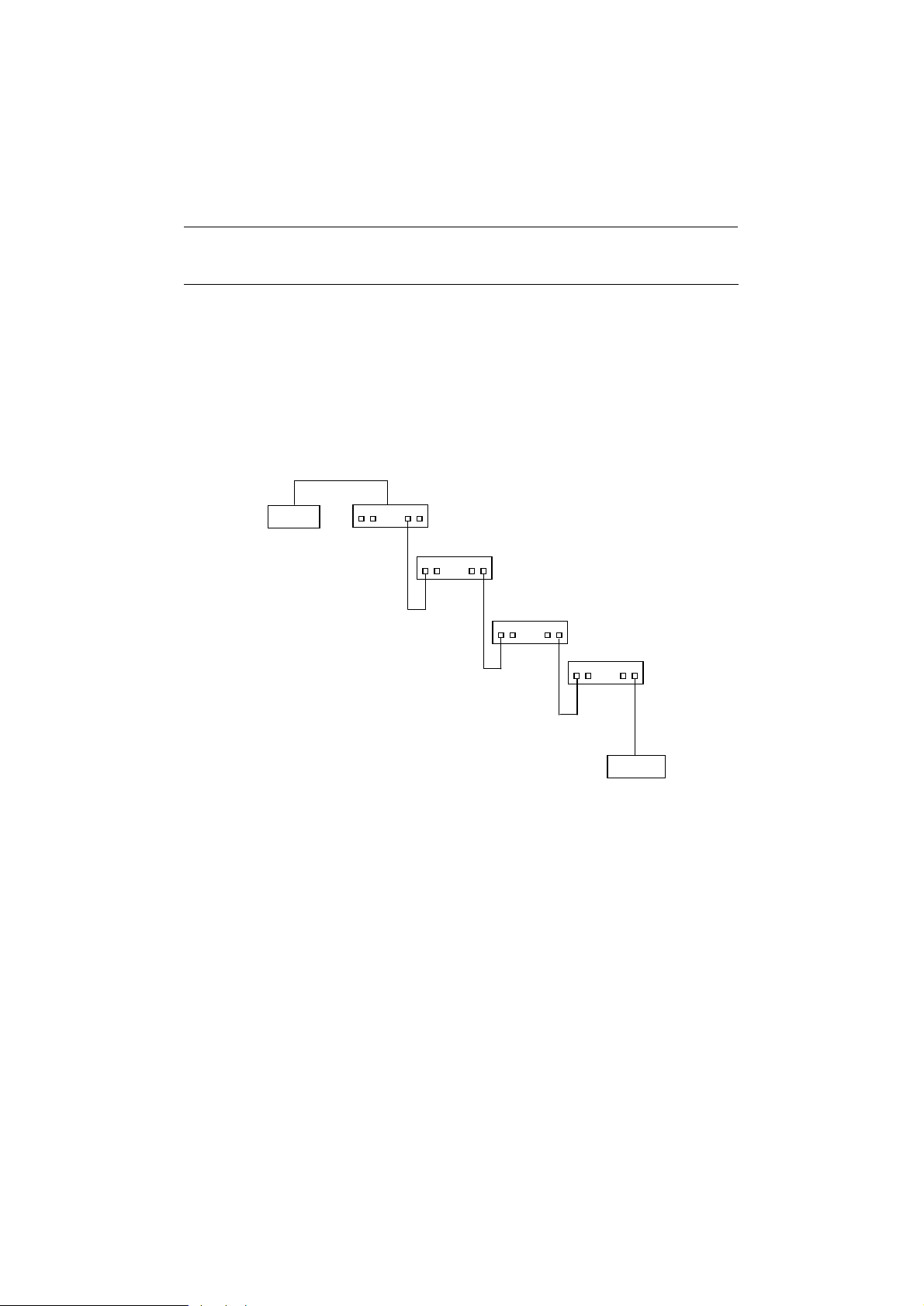

B.1 Ethernet Cabling

Async Concentrators' layout for C360 could be 10BASE-2 (BNC) and/or

10BASE-T (UTP) which conforming to Ethernet cabling rule.

For 10BASE-T with HUBs, the longest distance from C360 Control Board to

the last Async Concentrator is 500 meters which is depicted as follows:

100 meters

C360

Hub #1

100 meters

Hub #2

100 meters

Hub #3

100 meters

Hub #4

100 meters

Async

Concentrator

Specifications for 10BASE-T thin coaxial cable are as follows:

v Cable characteristics: 0.4 - 0.6 mm (22 -26 AWG) 8-wire (Only 4 wires are

used for 10BASE-T)

v Max. segment length: 100 meters

41

Page 48

Appendix B • • Technical Reference

For 10BASE-2 with repeaters, the longest distance from C360 Control Board to

the last Async Concentrator is about 1000 meters which is depicted as follows:

200 m

AC

C360

200 m

200 m

AC

AC

: Repeater AC : Async Concentrator

200 m

AC

200 m

AC

Specifications for 10BASE-2 thin coaxial cable are as follows:

v Cable characteristics: 0.2 inch diameter RG-58A/U 50 ohm

v Max. segment length: 185 meters

v Min. distance between two nodes: 0.5 meter

v Max. number of nodes per segment: 30

B.2 Async Concentrator and Serial Number

Inside Async Concentrator, each 16550C chip controls one port. The 16550C

is an advanced asynchronous controller capable of on-chip hardware flow

control and higher speed up to 460.8K bps.

Each Async Concentrator has its own unique serial number for identification.

Serial Number is the only way to locate the Async Concentrator and then serial

ports.

~42~

Page 49

Technical Reference • • Appendix B

B.3 RS-232 Cable Wiring

Only RS-232 interface with RJ-45 female connector is supported.

RJ-45 Female Connector

1

10

C360 RJ-45 Female

Connector Pinouts Signals

1 DCD

2 DSR

3 RTS

4 GND

5 TxD

6 RxD

7 GND

8 CTS

9 DTR

10 _

43

Page 50

Appendix B • • Technical Reference

Type 1: To connect C360 to a DTE, e.g. terminal or PC COM1/2. (Please

check the precise DTE pinouts, the following DTE pinouts is just an

example)

C360 DTE C360 DTE

RJ-45 Female DB-25 Male RJ-45 Female DB-9 Male

1 DCD 8 DCD 1 DCD 1 DCD

2 DSR 20 DTR 2 DSR 4 DTR

3 RTS 5 CTS 3 RTS 8 CTS

5 TxD 3 RxD 5 TxD 2 RxD

6 RxD 2 TxD 6 RxD 3 TxD

7 GND 7 GND 7 GND 5 GND

8 CTS 4 RTS 8 CTS 7 RTS

9 DTR 6 DSR 9 DTR 6 DSR

Type 2: To connect C360 to a DCE, e.g. modem.

C360 DCE

RJ-45 Female DB-25 Female

1 DCD 8 DCD

2 DSR 6 DTR

3 RTS 4 CTS

5 TxD 2 RxD

6 RxD 3 TxD

7 GND 7 GND

8 CTS 5 RTS

9 DTR 20 DSR

~44~

Page 51

Technical Reference • • Appendix B

Type 3: To connect C360 to a DTE, e.g. terminal or PC COM1/2, with 3-pin

wiring if [Hardware flow control] feature is set to "ON".

C360 DTE C360 DTE

RJ-45 Female DB-25 Male RJ-45 Female DB-9 Male

5 TxD 3 RxD 5 TxD 2 RxD

6 RxD 2 TxD 6 RxD 3 TxD

7 GND 7 GND 7 GND 5 GND

3 RTS 5 CTS 3 RTS 8 CTS

8 CTS 4 RTS 8 CTS 7 RTS

2 DSR 20 DTR 2 DSR 4 DTR

9 DTR 6 DSR 9 DTR 6 DSR

1 DCD 8 DCD 1 DCD 1 DCD

User must loopback (or short) the RTS with CTS and DSR with DTR, DCD on

MOXA site if [Hardware flow control] feature is set to "ON".

Type 4: To connect C360 to a DTE, e.g. terminal or PC COM1/2, with 3-pin

wiring if [Hardware flow control] feature is set to "OFF".

C360 DTE C360DTE

RJ-45 Female DB-25 Male RJ-45 Female DB-9 Male

5 TxD 3 RxD 5 TxD 2 RxD

6 RxD 2 TxD 6 RxD 3 TxD

7 GND 7 GND 7 GND 5 GND

3 RTS 5 CTS 3 RTS 8 CTS

8 CTS 4 RTS 8 CTS 7 RTS

2 DSR 20 DTR 2 DSR 4 DTR

9 DTR 6 DSR 9 DTR 6 DSR

1 DCD 8 DCD 1 DCD 1 DCD

Users could just leave RTS, CTS, DSR, DTR, DCD open if [Hardware flow

control] feature is set to "OFF".

45

Page 52

Appendix C Example Program

/ *

* Example C program for controlling MOXA serial/Non-TTY ports

* using MOXA DOS/UNIX API-232 library

* /

#include "mxapi232.h"

void main()

{

int port_no, count, i;

char data[81];

/* Setting the port 9600, N, 8, 1, ... */

port_no = 1;

if (sio_ioctl(port_no, B9600, BIT_8 | P_NONE | STOP_1) != 0) {

printf("Port #%d sio_ioctl() error !\n", port_no);

exit;

}

sio_lctrl(port_no, 3); /* set DTR RTS on */

sio_flowctrl(port_no, 0); /* set NO flow control */

sio_open(port_no); /* Open Port */

/* Get line status from port. If CTS and DSR are ON, continue */

while (1) {

if ( sio_lstatus(port_no) & 3 )

break;

}

/* Read input queue status from port. If any input data, read it */

i = 5; /* execute for 5 times */

while (i) {

if ((count = sio_iqueue(port_no)) > 0) {

~46~

Page 53

Appendix C • • Example Program

if (count > 80)

count = 80;

/* Read data from port */

if ((count = sio_read(port_no, data, count)) < 0) {

printf("Port #%2d sio_read() error !\n", port_no);

exit;

} else if (count > 0) {

data[count] = 0;

printf("%s", data);

}

/* Write data ABCDEFGHIJ to port */

sio_putb(port_no, "ABCDEFGHIJ", 10 );

i--;

}

}

sio_flush(port_no, 2); /* Flush port's input & output queues */

sio_close(port_no); /* Close port */

}

47

Page 54

Problem Report Form

Customer name:

Company:

Email: Date:

Tel: Fax:

Moxa product: o C320 series o C218 series o C360

o C102 family o C104 family o C168 family

Moxa device driver version: _____________

Moxa hardware settings: memory (I/O) base address ____________ IRQ _________

Operating System: o DOS o Windows 3.x o Windows 95

(with version) o Windows NT o OS/2

o SCO UNIX 3.2.4 o SCO OpenServer Rel. 5 o SCO Xenix

o SVR4.2 UNIX o UnixWare o Solaris x86

o Linux o QNX o FreeBSD

o Others ______________

Which BIOS Shadow RAM Enabled: o C8000 o CC000 o D0000

o D4000 o D8000 o DC000

Memory management software under DOS CONFIG.SYS: o EMM386 o QEMM386

o None

PC Host CPU: o Pentium o 80486 o 80386

Speed: _____ MHz

LAN card: o None o Yes, memory base addr. _______ I/O base addr.___ IRQ ____

SCSI card: o None o Yes, memory base addr. _______ I/O base addr. ___ IRQ ____

SOUND card: o None o Yes, memory base addr. _______ I/O base addr. ___ IRQ ____

Others : o None o Yes, memory base addr. _______ I/O base addr. ___ IRQ ____

Problem description:

o Board not found. o Board found, but can't transfer data.

o Can transfer data, but lose data o Can transfer data but with garbled data.

o Others. Detailed error message description is recommended:

Page 55

WARRANTY

Moxa guarantees its products against defective materials and workmanship for a

period of one year from the day the original buyer receives the product. In the

event that this product fails to be in good working order during this twelvemonth warranty period, the Dealer and the manufacturer will repair or replace

this product at no additional cost to the customer.

This guarantee does not apply to products which have been repaired or altered

by other manufacturers. Moxa neither assumes nor authorizes any liability in

connection with the sale, installation or use of its products.

RETURN PROCEDURE

For product repair, exchange or refund, the customer must:

v Provide evidence of original purchase.

v Obtain a Product Return Agreement (PRA) from the sales representative or

dealer.

v Fill out the Problem Report Form (PRF) as detailed as possible for shorter

product repair time.

v Carefully pack the product in anti-static package, and send it, pre-paid, to

the dealer. The PRA should show on the outside of the package. Include a

description of the problem along with the return address and telephone

number of a technical contact.

Loading...

Loading...