Moxa EXPC-1319-STS-W7E, EXPC-1319-STS-IHS-W7E, EXPC-1319-MTS-IHS-W7E, EXPC-1319-MTS-W7E User Manual

Page 1

EXPC-1319 Series Hardware User’s Manual

Edition 3.0, February 2017

www.moxa.com/product

© 2017 Moxa Inc. All rights reserved.

Page 2

EXPC-1319 Series Hardware User’s Manual

Moxa Americas

Toll

Tel:

Fax:

Moxa China (Shanghai office)

Toll

Tel:

Fax:

Moxa Europe

Tel:

Fax:

Moxa Asia

Tel:

Fax:

Moxa India

Tel:

Fax:

The software described in this manual is furnished under a license agreement and may be used only in accordance with

the terms of that agreement.

Copyright Notice

© 2017 Moxa Inc. All rights reserved.

Trademarks

The MOXA logo is a registered trademark of Moxa Inc.

All other trademarks or registered marks in this manual belong to their respective manufacturers.

Disclaimer

Information in this document is subject to change without notice and does not represent a commitment on the part of

Moxa.

Moxa provides this document as is, without warranty of any kind, e ither expre sse d or i mplie d, inclu ding, but not limited

to, its particular purpose. Moxa reserves the right to make improvements and/or changes to this manual, or to the

products and/or the programs described in this manual, at any time.

Information provided in this manual is intended to be accurate and reliable. However, Moxa assumes no responsibility for

its use, or for any infringements on the rights of third parties that may result from its use.

This product might include unintentional technical or typographical errors. Changes are periodically made to the

information herein to correct such errors, and these changes are incorporated into new editions of the publication.

Technical Support Contact Information

www.moxa.com/support

-free: 1-888-669-2872

+1-714-528-6777

+1-714-528-6778

+49-89-3 70 03 99-0

+49-89-3 70 03 99-99

+91-80-4172-9088

+91-80-4132-1045

-free: 800-820-5036

+86-21-5258-9955

+86-21-5258-5505

-Pacific

+886-2-8919-1230

+886-2-8919-1231

Page 3

Table of Contents

1. Introduction ...................................................................................................................................... 1-1

Overview ........................................................................................................................................... 1-2

Model Descriptions and Package Checklist .............................................................................................. 1-2

Appearance ........................................................................................................................................ 1-3

Features ............................................................................................................................................ 1-4

Hardware Specifications ...................................................................................................................... 1-5

LED Indicators and Buttons .................................................................................................................. 1-7

LCD Panel and Touch screen ................................................................................................................ 1-8

Moxa Intelligent Heating Solution ......................................................................................................... 1-8

2. Hardware Installation ....................................................................................................................... 2-1

Placement Options .............................................................................................................................. 2-2

Desktop ..................................................................................................................................... 2-2

Mounting .................................................................................................................................... 2-2

Wall Mounting ............................................................................................................................. 2-3

Other Mounting Solutions .................................................................................................................... 2-3

Yoke Mounting ............................................................................................................................ 2-4

Panel Mounting ........................................................................................................................... 2-4

VESA Mounting ........................................................................................................................... 2-5

Wiring Requirements ........................................................................................................................... 2-6

Connecting the Power Supply ............................................................................................................... 2-6

Connecting the Interfaces .................................................................................................................... 2-7

Connecting to a Display ....................................................................................................................... 2-7

Connecting USB Devices ...................................................................................................................... 2-8

Connecting Serial De vices .................................................................................................................... 2-9

Connecting LAN Ports ........................................................................................................................ 2-10

Replacing the SSD ............................................................................................................................ 2-11

Installing the CompactFlash Card ........................................................................................................ 2-12

3. Touch Screen Calibration .................................................................................................................. 3-1

Calibrating the Touch Screen................................................................................................................ 3-2

Standard Calibration .................................................................................................................... 3-3

Advanced Calibration ................................................................................................................... 3-3

PenMount Calibration Utility Parameters ................................................................................................ 3-4

Turn off EEPROM Storage ............................................................................................................. 3-4

Touch Screen Cursor Settings ....................................................................................................... 3-4

Edge Compensation ..................................................................................................................... 3-6

4. BIOS Setup ........................................................................................................................................ 4-1

Entering the BIOS Setup Utility ............................................................................................................ 4-2

BIOS Main Page .................................................................................................................................. 4-2

Modifying BIOS Settings ...................................................................................................................... 4-3

Advanced Settings ....................................................................................................................... 4-3

Security Settings ......................................................................................................................... 4-9

Power Settings .......................................................................................................................... 4-11

Boot Settings ............................................................................................................................ 4-13

Exit Settings ............................................................................................................................. 4-15

Upgrading the BIOS .......................................................................................................................... 4-16

A. Safety Installation Ins tr uctio n s ........................................................................................................ A-1

B. Statement of Regulatory Approval .................................................................................................... B-1

Page 4

1

1. Introduction

Thank you for purchasing the Moxa EXPC-1319 series x86 industrial panel computer.

This manual introduces the hardware installation, connector interfaces, and BIOS setup of the EXPC-1319. For

software configuration and management, please refer to the user’s manual for your operating system.

The following topics are covered in this chapter:

Overview

Model Descriptions and Pa ckage Checklist

Appearance

Features

Hardware Specifications

LED Indicators and Buttons

LCD Panel and Touch screen

Moxa Intelligent Heating Solution

Page 5

EXPC-1319 Series Hardware Introduction

1-2

Overview

The EXPC-1319 panel computers are f a n less, durable devices made for both indoor and outdoor hazardous

environments. The EXPC-1319 series features the dual core Intel Atom D525 1.8 GHz processor, with up to 4

GB of memory available to deliver high performance processing. The EXPC-1319 is Zone 2 certified, and comes

with two electrically isolated, software-selectable RS-232/422/485 serial ports alongside two Gigabit LAN ports,

providing reliable serial and high speed Ethernet LA N transmissions with full network redundancy.

The EXPC-1319 computers come with a patented, fanless, streamlined enclosure designed for highly efficient

heat dissipation, making this one of the most reliable industrial platforms available for harsh, hot outdoors

environments like oil and gas fields or drilling platforms. In addition, EXPC-1319 computers come with an

expanded set of self-health diagnostics that communicate over SNMP and may also be ordered with Moxa’s

Intelligent Heating Solution (IHS), a heating utility for use in extremely low temperature (-40°C) environments.

Finally, these computers feature capacitive touch screen controls with glass-film- glass bonding, making them

scratch- and glare-resistant and easy to read ev en during the peak daylight hours.

Model Descriptions and Package Checklist

The EXPC-1319 Series includes the following models:

• EXPC-1319-STS-W7E: Fanless, industrial-rugged Zone 2 19-inch 1000 nits LCD panel computer, single

point touch screen, IP66, d ual core Atom D525 1.8 GHz CPU, -20 to 60°C operating temperature

• EXPC-1319-STS-IHS-W7E: Fanless industrial-rug ged Zone 2 19-inch 1000 nits LCD panel computer,

single point touch screen, IP66, dual core Atom D525 1.8 GHz CPU, -40 to 60°C operating temperature,

with Intelligent Heating Solution (IHS )

• EXPC-1319-MTS-W7E: Fanless industrial-rugged zone 2 19-inch 1000 nits LCD panel computer, multi

point touch screen, IP66, dual core Atom D525 1.8 GHz CPU, -20 to 60°C operating temperature (available

on request)

• EXPC-1319-MTS-IHS-W7E: Fanless industrial-rugged Zone 2 19-inch 1000 nits LCD panel comp u ter,

multi point touch screen, IP66, dual core Atom D525 1.8 GHz CPU, -40 to 60°C operating temperature, with

Intelligent Heating Solution (IHS) (available on request)

Each model is shipped with following standard items:

• 1 EXPC-1319 panel computer

• Quick installation guide (printed)

• Documentation & software DVD

• Ethernet Cable: RJ45 to RJ45 cross-over cable, 100 cm

• Waterproof USB connector pack x 2

• Waterproof DB9 connector pack x 2

• Waterproof LAN connector pack x 2

• Waterproof power connector pack x 1

• Wall mounting kit

• Warranty card

Page 6

EXPC-1319 Series Hardware Introduction

1-3

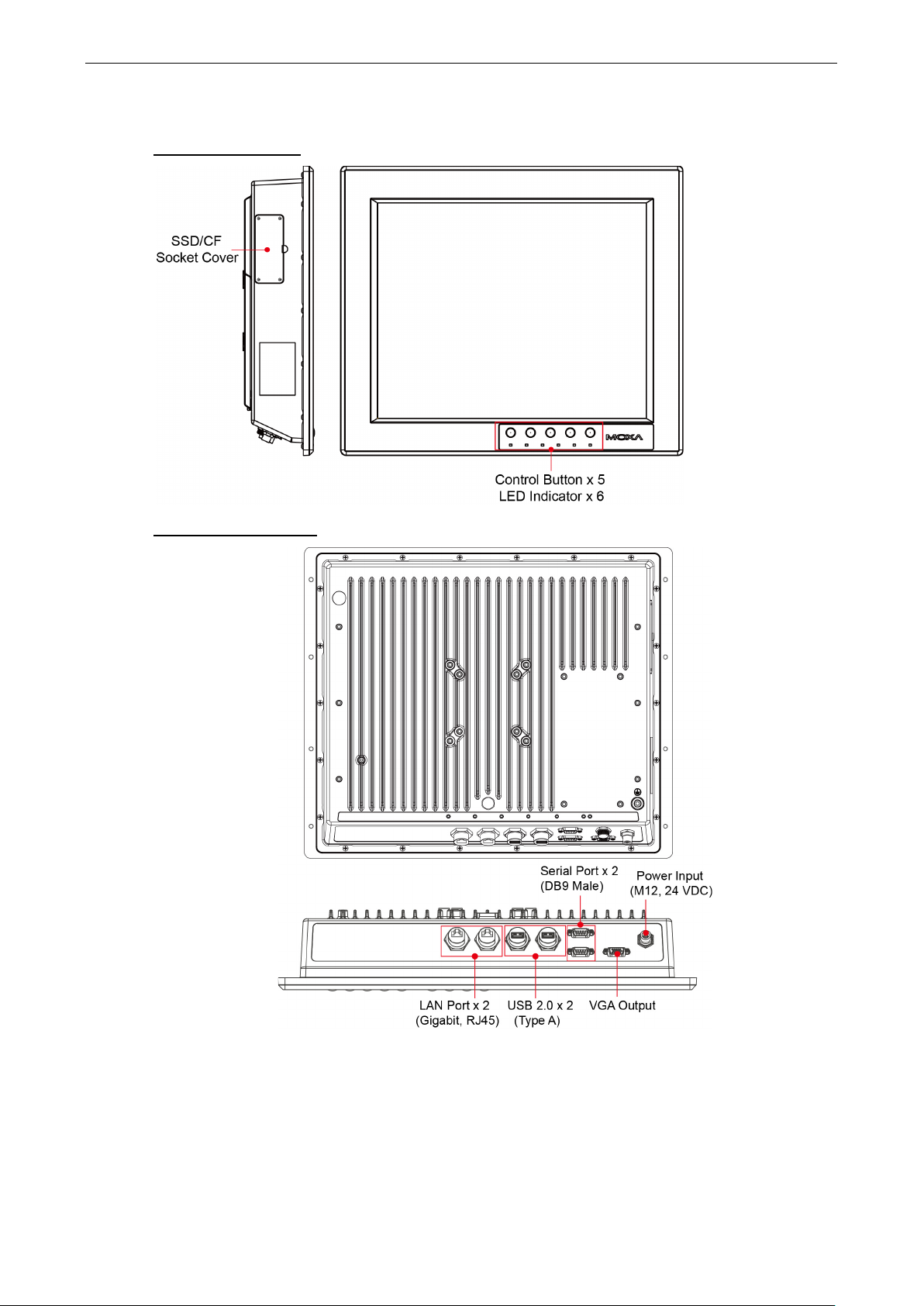

Appearance

Front and Side Views

Rear and Bottom Views

Page 7

EXPC-1319 Series Hardware Introduction

1-4

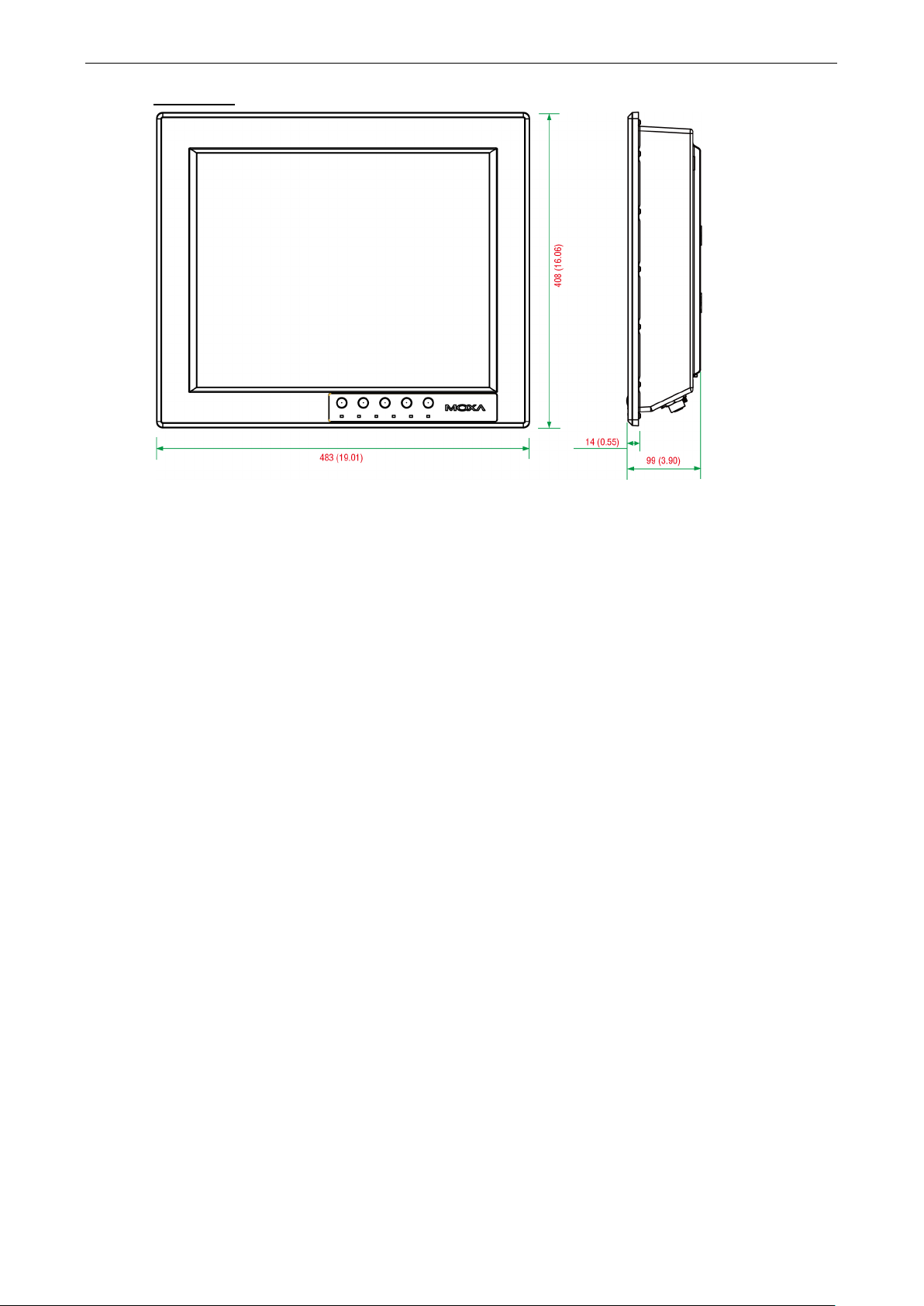

Dimensions

Features

• Zone 2 certified component for panel mounting in hazardous area applications

• High performance dual core Intel Atom D525 1.8GHz platform with low power consumption

• 19-inch scratch-resistant anti-glare 1000 nits LCD panel

• Self-health diagnostics software package for remote predictive maintena nce

• -40 to 60°C wide operating temperature (with built-in Intelligent Heater)

• Totally sealed IP66 / NEMA 4X panel computer (not for using in hazardous environments)

• Fanless, streamlined enclosure for highly efficient heat dissipation

• Touch screen control button to enable/disable touch screen

• Optional WLAN, 100M fiber optical interface

Page 8

EXPC-1319 Series Hardware Introduction

1-5

Computer

CPU:

OS:

System Chipset:

BIOS:

Graphics Controller:

Video Output:

System Memory:

Automatic Reboot Trigger:

in software programmable watchdog timer for system resets, configurable

from 1 to 255

Expansion Bus:

USB:

KB/MS:

, not for using in

hazardous en

Storage

Storage Expansion:

• On

• One extra on

Storage Support:

;

s

Display

Panel Size:

Aspect Ratio:

Response Time:

Contrast Ratio:

Viewing Angles:

• Horizontal: 170° (left to right)

• Vertical: 160° (up to down)

Max Colors:

Graphics Controller:

Video Output:

Resolution:

• VGA: 640 x 480

• SVGA: 800 x 600

• XGA: 1024 x 768

• SXGA: 1280 x 1024

Touch screen

EXPC

EXPC

Note: All EXPC

glare, suitable for use outdoors around heavy

equipm

Ethernet Interface

Hardware Interface:

LAN:

Optical Fiber Interface:

(available on

request

WLAN:

Magnetic Isolation Protection:

Serial Interface

Serial Standards:

Connector Type:

Hardware Specifications

Intel dual core Atom D525 1.8 GHz processor

Windows 7 for embedded systems

Intel Pineview-D+ ICH8M

16-Mbit Flash BIOS SPI type with ACPI

Integrated Intel GMA3150 graphics controller

VGA output, waterproof DB 15 (female) connector

4 GB capacity, 2 GB pre-installed: 2 slots of 2 GB DDR3-800 SO-DIMM SDRAM

Built-

second timeout intervals

1 PCI-104 slot, 1 mini PCIe socket

2 USB 2.0 hosts, waterproof circular type A connector

PS/2 keyboard/mouse inter face (Y-type cable) with waterproof connector (optional

vironments)

-board CompactFlash socket x 1

-board SATA interface, supporting configurable RAID 0/1

Removable 32 GB industrial grade SSD (operating temperature: -40 to 85°C) to store OS,

upports up to 256 GB

19-inch SXGA, 1000 nits LED backlit LCD

5:4

5 ms

1000:1

16.7 M colors

Integrated Intel GMA3150 graphics controller

VGA output, waterproof DB 15 (female) connector

-1319-STS: Resistive single point glass-film-glass

-1319-MTS: Capacitive multi point (available on requ est, not for using in hazardous environments)

-1319 t ouch screens are scratch resistant and anti-

ent.

2 auto-sensing 10/100/1000 Mbps ports

Waterproof RJ45 connector

2 multimode 100M fiber optic ports with wa terproof Q-ODC connector

)

1 802.11b/g/n interface (available on request)

1.5 kV built-in

2 RS-232/422/485 ports, software-selectable

Waterproof DB9 (male)

Page 9

EXPC-1319 Series Hardware Introduction

1-6

Baudrate:

Isolation Protection:

Serial Communication Parameters

Data Bits:

Stop Bits:

Parity:

Flow Control:

Serial Signals

RS

RS

RS

RS

LEDs and Buttons

LEDs:

commun

Control Buttons:

on/off, programmable "Fn" button

Physical Characteristics

Housing:

Weight:

• 10.7 kg (without Intelligent Heating Solution)

• 11.9 kg (with Intelligen

Dimensions:

Mounting:

Environmental Limits

Operating Temperature:

• Without Intelligent Heating Solution:

• With Intelligent Heating Solution:

Storage Temperature:

Ambient Relative Humid it y:

Anti

Anti

standard

Power Requirements

Input Voltage:

•

•

environments

Connector:

Power Consumption:

• Without Intelligent Heating Solution: 60 W

• With Intelligent Heating Solution: 120 W

Standards and Certifications

Hazardous Environments:

EMC:

Mechanical:

Green Product:

Warranty

Warranty Period:

Details:

Up to 38,400 bps

2 kV

5, 6, 7, 8

1, 1.5, 2

None, Even, Odd, Space, Mark

RTS/CTS, XON/XOFF, ADDC® (automatic data direction control) for RS-485

-232: TxD, RxD, DTR, DSR, R TS, CTS, DCD, GND

-422: TxD+, TxD-, RxD+, RxD-, GND

-485-4w: TxD+, TxD-, RxD+, RxD-, GND

-485-2w: Data+, Data-, GND

Power (on/off), heater (on/off), storage (blinking/off), LAN port communication x 2 (on/off), fiber

ication (reserved)

System on/off, brightness adjustment x 2, touch screen

Aluminum

t Heating Solution)

483 x 408 x 99 mm (19.02 x 16.06 x 3.90 in)

Mounting holes for VESA 75/100, yoke mountin g , and pa nel mounting

-20 to 60°C (-4 to 140°F)

-40 to 60°C (-40 to 140°F)

-40 to 80°C (-40 to 176°F)

5 to 95% (non-condensing)

-Vibration: 2 g rms, 5-500 Hz frequency, compliant with IEC 60068-2-6 standard

-Shock: 20 g, half sine wav e un der system operating, 11 ms duration, compliant with IEC 60068-2-27

Typical 24 VDC

External 100 to 240 VAC isolated power supply unit (available on request, not for using in hazardous

)

M12, customizable

UL Class 1 Division 2, ATEX/IECEx Zone 2 certified componen t

EN 55032 Class B, EN 55024-4-2, EN 55024-4-3, EN 55024-4-4, FCC Part 15 Subpart B Class A

IP66, NEMA 4X

RoHS, cRoHS, WEEE

3 years for computer system, 1 year for LCD panel

See www.moxa.com/warranty

Page 10

EXPC-1319 Series Hardware Introduction

1-7

Press to turn on the computer. Press again to turn off the

ouch

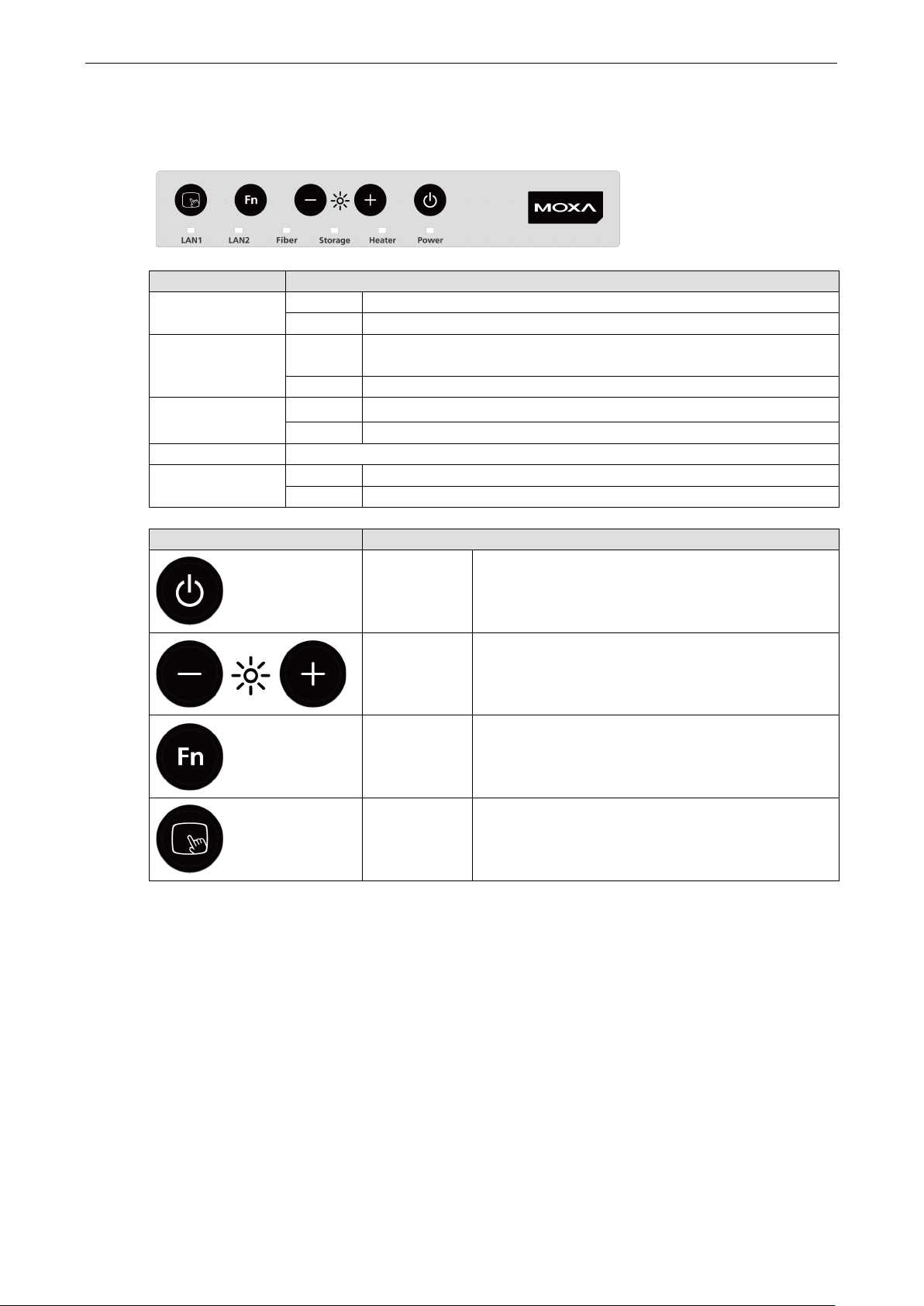

LED Indicators and Buttons

The EXPC-1319 comes with six LED indicators and five control buttons on the bottom of the front panel.

LED Function

Power

Heater

Storage

Fiber Reserved for optional function

LAN1 & LAN 2

Control Buttons Function

On Power is on.

Off Power is off.

On

Off

Blinking

Off Storage (SSD and CF) is not accessing.

On

Off Network is not transmitting or receiving data.

Heater is working. (Note that this function will be enabled when below

-20°C)

Heater is not working.

Storage (SSD or CF) is accessing.

Network is transmitting or receiving data.

Brightness

Function

Touch screen

Power

computer.

Press + button to increase the brightness of the panel.

Press – button to decrease the brigh tness of the panel.

Customizable function key, can be configu red by the

utility. The default value will enable a virtual keyboard

function. Refer to Software User’s Manual for

configuration details.

Touch to enable the touch screen function (default). T

again to disable.

Page 11

EXPC-1319 Series Hardware Introduction

1-8

NOTE

To ensure that the IHS

down the EXPC

LCD Panel and Touch screen

The EXPC-1319 comes with 1000 nits TFT LCD panel with touch screen bonding.

The 1000 nits TFT LCD panel means the panel’s brightness at its central point is 1000 cd/m

characteristics of liquid crystal in TFT LCD panels, even though the EXPC-1319 will work properly between -20

and 60˚C (-40 to 60˚C with Intelligent Heating Solution), to extend the panel’s life Moxa recommends

maintaining the working temperature between 0 and 50˚C whenever possible. Some areas on the LCD panel

might distort some colors to black at extremely high temperatures, or respond sluggishly at extremely low

temperatures.

The touch screen used on the EXPC-1319 includes hardened resistive glass-film-glass single point touch screen

(STS) or a capacitive type multipoint touch screen (MTS). Different touch screen technologies allow d if ferent

light transmission rates to decrease the brightness of L CD panel. Usually the light transmission rate of resistive

type touch screens is around 80%, while for capacitive types it is around 85% to 90%. Please note that the

screen is composed of hardened, scratch-resistant glass, and its anti-glare coating can still be scratched using

any abrasive with Mohs rating greater than 6. Please note that the capacitive type m ultipoint touch screen

(MTS) model cannot be used in the hazardous environments.

Notice: Please calibrate your touch screen every time you reboot the system to ensure the touch screen works

properly. To revie w touch screen calibration, please refer to the Touch screen Calibration section in Chapter

4 of the EXPC-1319 Windows Embedded Standard 7 User’s Manual.

2

. Due to the

Moxa Intelligent Heating Solution

The EXPC-1319 may be ordered with Moxa’s patented Intelligent Heating Solution, to ex tend the effective

range of the platform’s operating temperature, with the caveats below. EXPC-1319 computers equipped with

IHS feature the heating solution on th e display panel.

• The Intelligent Heatin g Solution will automatically initiate once the ambient temperature drops below

-20°C.

• It takes about 40 to 50 minutes for the Intelligent Heating Solution to warm up the display panel. Once IHS

has completed the heating cycle, the LED indicator for the Heater will turn off. Until the warming up cycle

is completed, the display may be distorted or otherwise function poorly.

• Moxa Intelligent Heating Solution remains (minimally) powered up and operating even after the computer

has been taken offline. This is to ensure its automated response when ambient temperature s d rop below

0°C.

• IHS may only be turned off by disconnecting the power supply.

• IHS requires a 120 W power supply.

-1319.

has been completely stopped, mak e sure to remove the power source after shutting

Page 12

2

2. Hardware Installation

The EXPC-1319 Series of panel computers are compact and r u g ged, making them suitable for any industrial

application that requires EMC Level 4 compliance. The LED indicators allow users to monitor performance and

identify trouble spots quickly, and multiple ports are provi ded for connecting a variety of different devices. The

EXPC-1319 hardware platform is stable, reliable, and easy to maintain, allowing you to spend your time on

application development rather than troubleshooting networking bugs. This cha pter describes the hardware

installation and interfaces of EXPC-1319 panel computers.

The following topics are covered in this chapter:

Placement Options

Desktop

Mounting

Wall Mounting

Other Mounting Solutions

Yoke Mounting

Panel Mounting

VESA Mounting

Wiring Requirements

Connecting the Power Supply

Connecting the Interfaces

Connecting to a Display

Connecting USB Devices

Connecting Serial Devices

Connecting LAN Ports

Replacing the SSD

Installing the CompactFlash Card

Page 13

EXPC-1319 Series Hardware Hardware Installation

2-2

ATTENTION!

For maximum safety, at least two persons should work together to lift, place, and

its

mounting point

is turned

off

Placement Options

. In addition, make sure you have prepared the correct screws for a wall mounting.

Desktop

Place your EXPC-1319 on a clean, flat, well-ventilated desktop. For better vent ilation, leave some space

between the EXPC-1319 and other equipment. Do not place e quipment or objects on top of the EXPC-1319, as

this might damage the computer’s internal components.

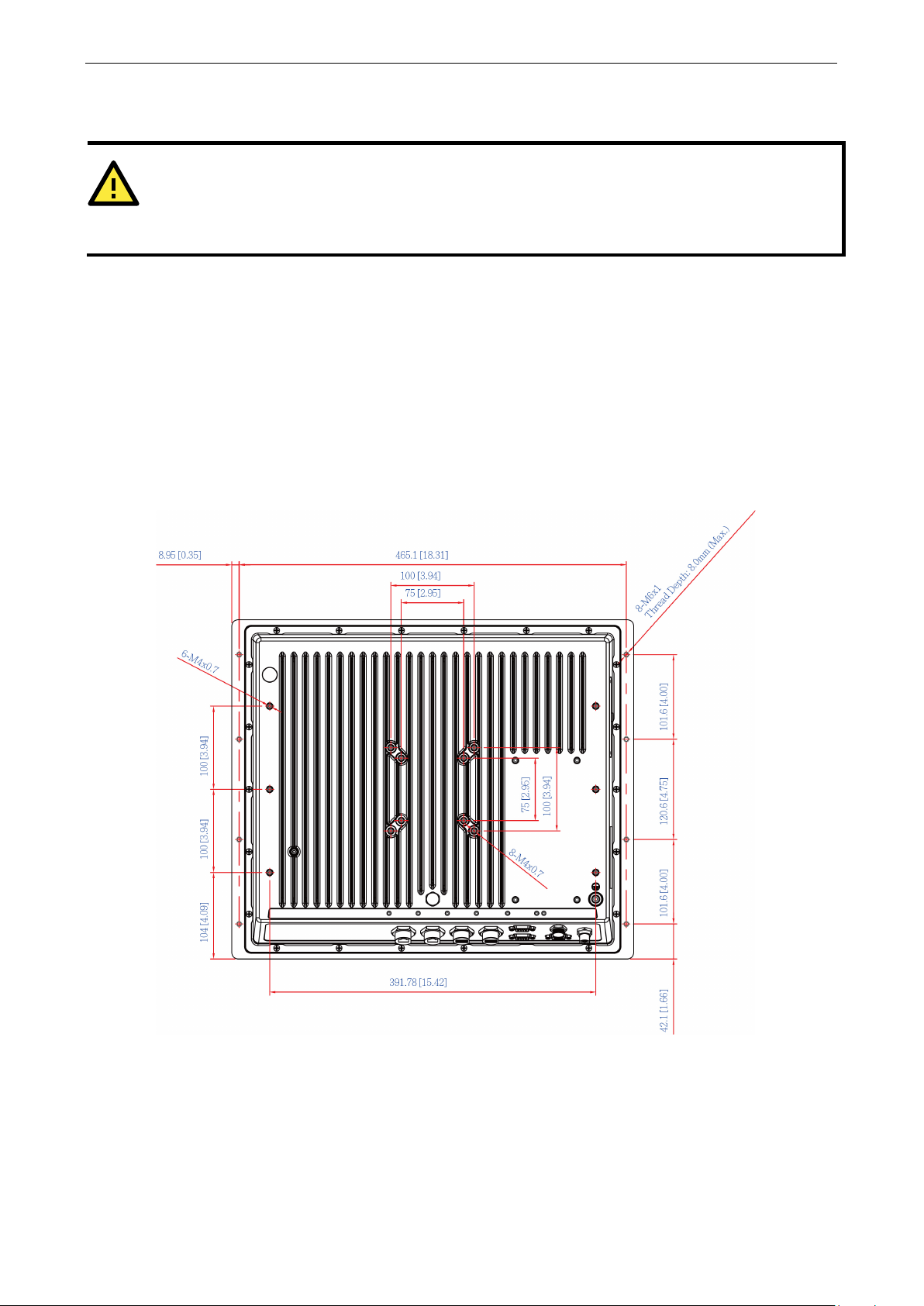

Mounting

The EXPC-1319 comes with a variety of mounting methods for different field sites. Before mounting, refer to

the following figure for the dimensions of the screw holes used for different mounting methods.

fasten the computer to

. Before you lift or move the computer, first verify both it and any power to the system

Page 14

EXPC-1319 Series Hardware Hardware Installation

2-3

NOTE

To make sure the panel computer will be securely installed on a wall,

of a

suitable length to guarantee the computer remains securely fastened to the mounting point

screw holes

penetrate

When choosing screws for installation, remember to account for the

thickness of the mounting surface.

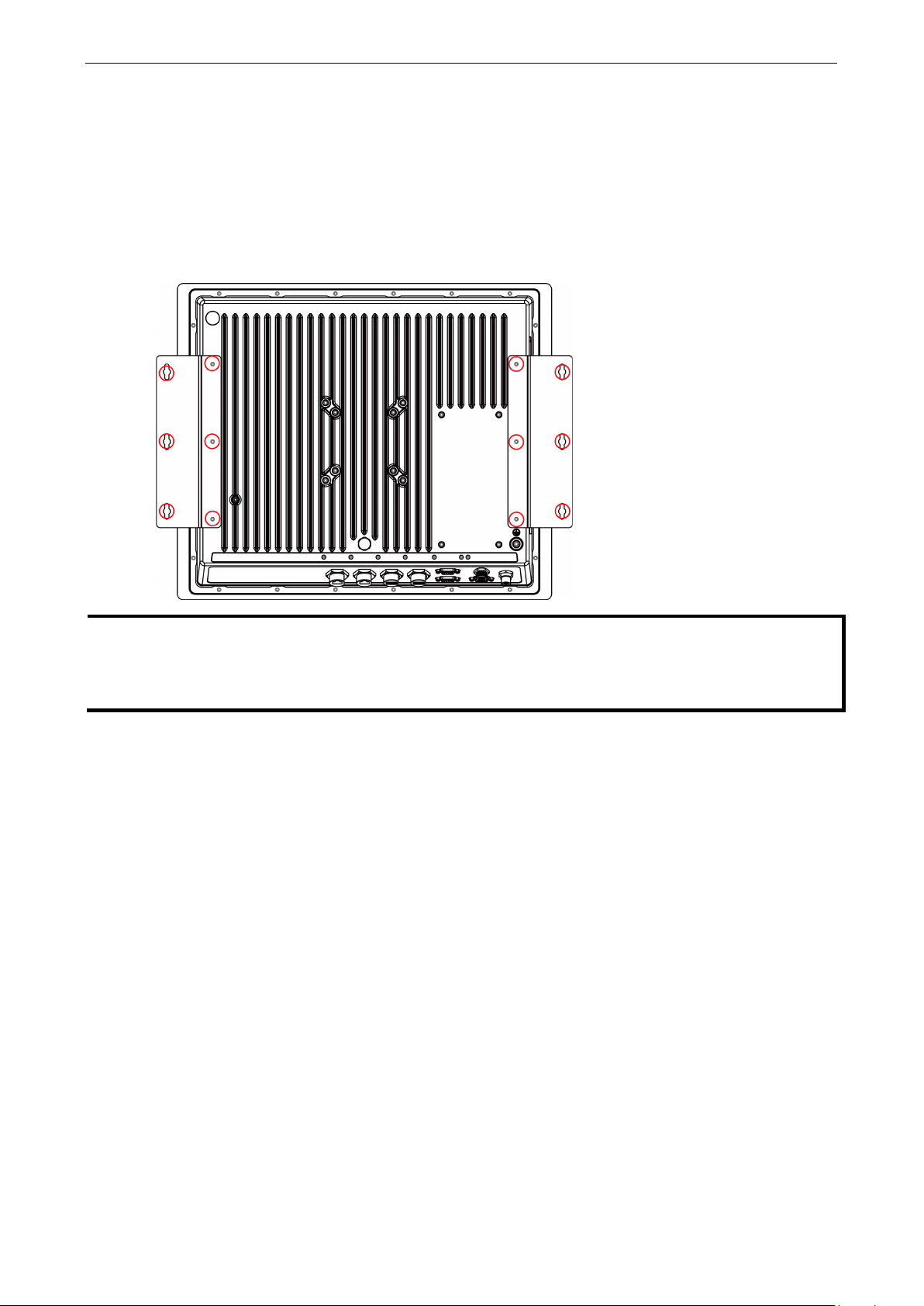

Wall Mounting

The EXPC-1319 comes with a wall mounting kit.

Follow these steps to mount the EXPC-1319 on a wall:

Step 1: Use screws to attach the mounting ears to the back of the computer. Each mounting ear requires three

screws.

Step2: Fasten the computer to the wall using three screws per ear.

8 mm into the computer’s case.

Other Mounting Solutions

The EXPC-1319 computers have reserved various mounting holes for users to mount the computer with

different solutions, including yoke mounting, panel mounting, and VESA mounting. See the following section

for detailed descriptions.

we suggest you to use M5 screws

. The

Page 15

EXPC-1319 Series Hardware Hardware Installation

2-4

NOTE

To make sure the pane

penetrate 8 mm into the computer’s case. When choosing screws for installation, remember to account for the

thickness of the mounting surface.

technical

NOTE

To make sure the panel computer will

length

remember to account for the thickness of the mounting surface.

Yoke Mounting

The EXPC-1319 comes with six screw holes for a yoke mount. These screws holes are the same size as those

for the wall mounting. Place the p a nel onto the mounting plate, fasten the computer using these holes.

details regarding regulation Class 1 Div. 2 devices.

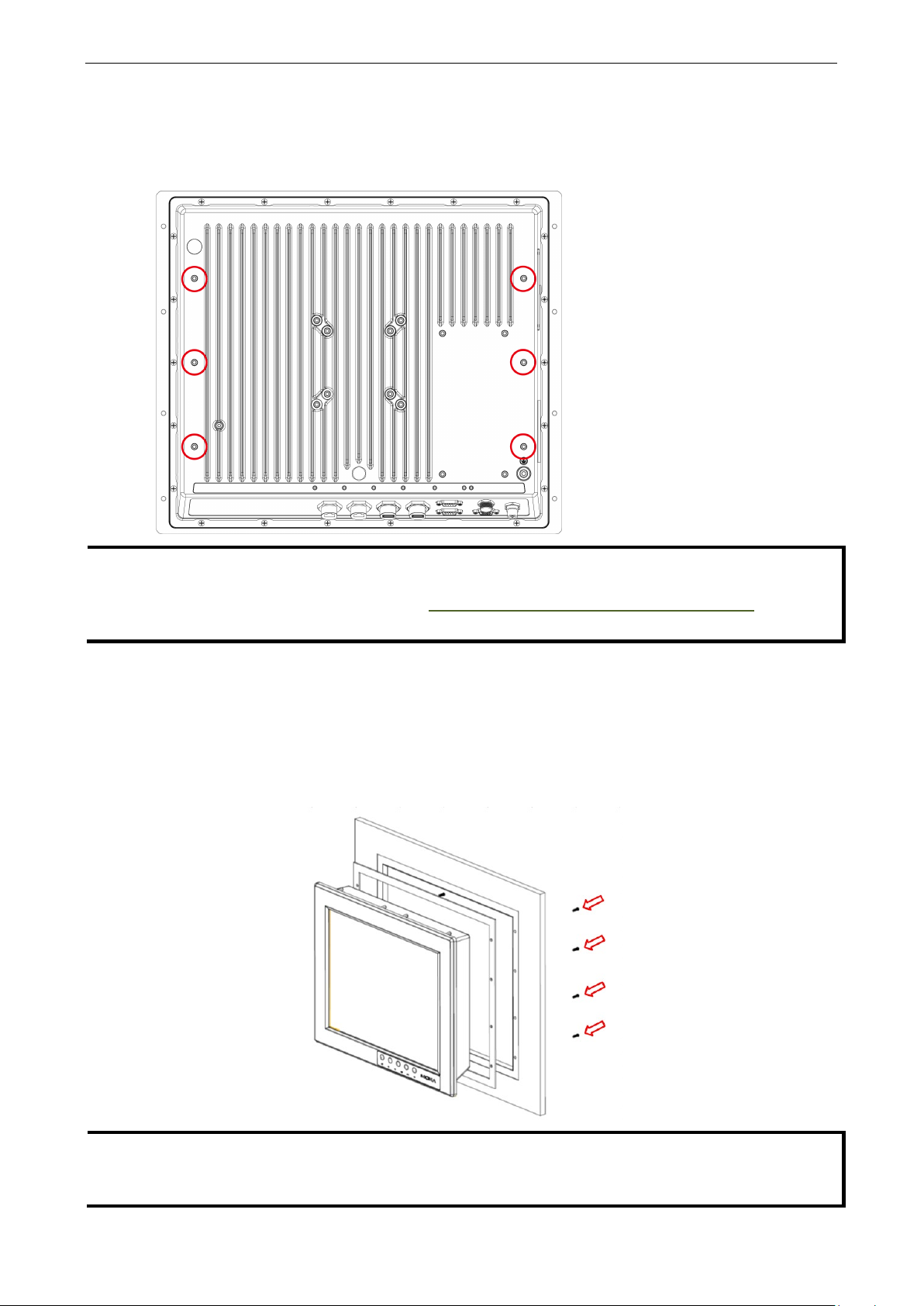

Panel Mounting

Follow these steps to install the EXPC-1319 on a panel cabinet.

1. Place the gasket between the EXPC-1319 and the enclosure, and use eight M6 screws to penetra te the

enclosure and gasket, so that the gasket can be securely fasten on two sides of the panel mounting holes

on the back of the EXPC-1319.

l computer will be secur ely ins ta lled on the yoke, use M4 screws. The screw holes

Refer to Appendix B: Statement of R egulatory Approval for the

. The screw holes penetrate 6 mm into the computer’s case. When choosing screws for installation,

remain securely installed in the cabinet, use M6 screws of a suitable

Page 16

EXPC-1319 Series Hardware Hardware Installation

2-5

NOTE

For the installation in hazardous environments, refer to

NOTE

To make sure the panel computer will be securely installed on a wall,

with the

specifications of

installation, remember to account for the thickness of the mounting surface.

dix B: Statement

of Regulatory Approval

2. Install the mounting brackets from inner part of the computer, and use M4 screws to fasten the brackets.

Four screws are required per side.

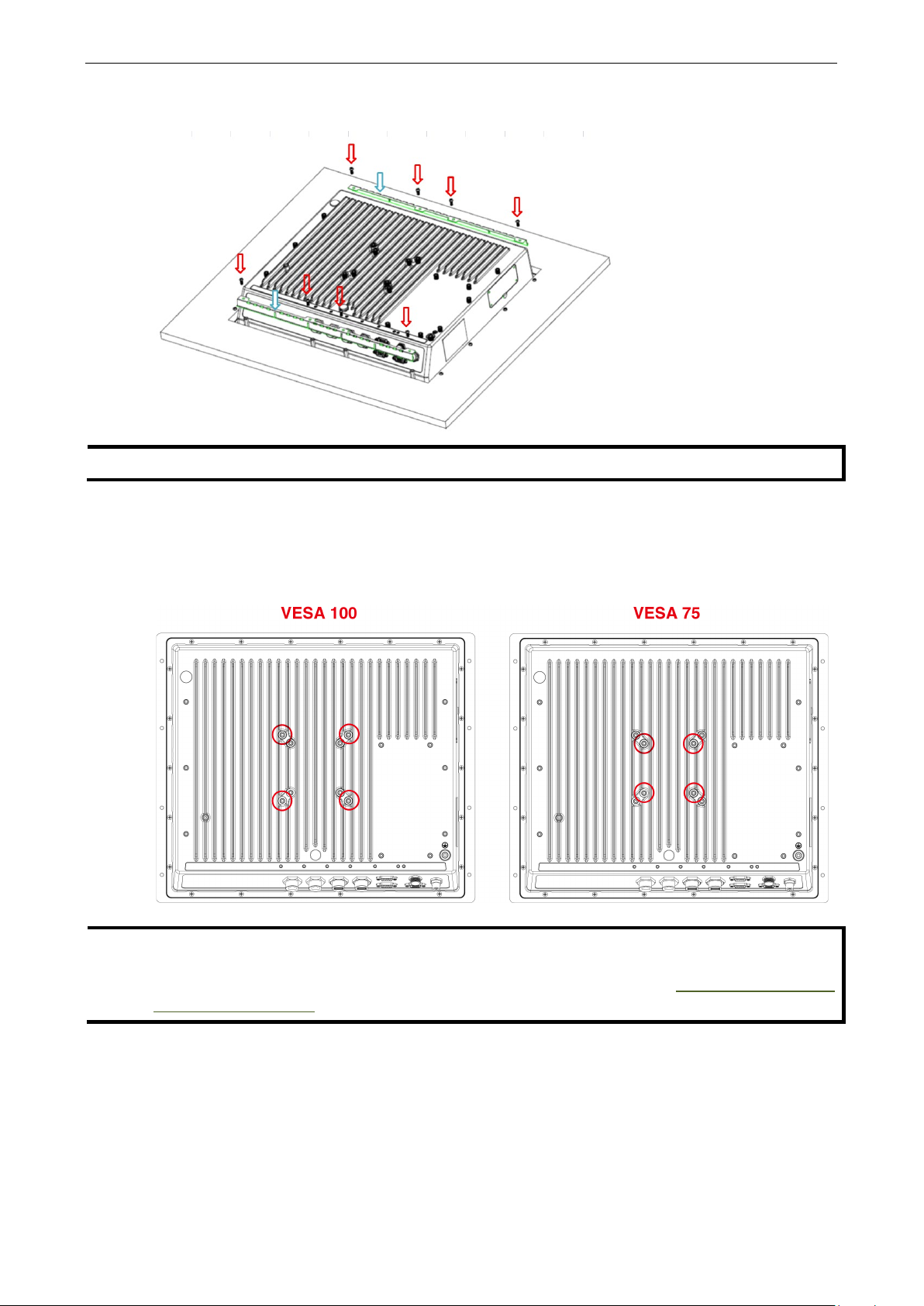

VESA Mounting

The EXPC-1319 comes with two sets of holes reserved for VESA mounts (FDMI): VESA 100 and VESA 75. Refer

to the following figures for the specific locations of the VESA mounting screw holes.

Explosion Hazard sect ion in Appendix B.

M4. The screw holes penetrate 6 mm into the computer’s case. When choosing screws for

for the technical details regarding regulation Class 1 Div. 2 devi c es.

we suggest you to use the screws

Refer to Appen

Page 17

EXPC-1319 Series Hardware Hardware Installation

2-6

ATTENTION

Do not run signal or communication wiring and power wiring in th e same conduit. To avoid int erference, wires

with different signal characteristics

ATTENTION

Safety First!

Be sure to disconnect the power cord before installing and/or wiring your device.

Caution!

Verify

rical

codes dictating the maximum curr ent allowable for each wire

If the current goes above the maximum ratings

, the wiring could overheat, causing serious damage to

your equipment.

Caution! High

Be careful when handling the un

heat

which may leave

Wiring Requirements

The following common safety precautions should be observed before installing any electronic device:

• Strive to use separate, non-intersecting paths to route power and networking wires. If power wiring and

device wiring paths must cross, make sure the wires are perpendicular at the intersection point.

• Keep the wires separated according to interface. The rule of thumb i s that wiring that sha res similar

electrical characteristics may be bundled together.

• Do not bundle input wiring with output wiring. Keep them separate.

• When necessary, it is strongly adv ised that you label wiring to all devices in the system.

the maximum possible current for each wire gauge, especially for the powe r cords. Observe all elect

High Electrical Current!

Temperatures!

the outer casing too hot to touch.

(i.e., different interfaces) should be routed separately.

gauge.

(120 W)

it. When the unit is plugged in, the internal components generate a lot of

Connecting the Power Supply

The power connector is located at the far left of the bottom panel. When wiring the machine for power, refer to

the following figure for the pinout of the M12 power connector. Please take care to guarantee your power cable

uses the correct pinout.

When power has been connected, press the power button on the front panel to turn on the computer.

Page 18

EXPC-1319 Series Hardware Hardware Installation

2-7

WARNING

When the

been

securely fasten

protective cap

rating.

regarding

regulation Class 1 Div. 2 devices

Connecting the Interfaces

The EXPC-1319 comes with various interfaces located on the bottom panel. All of these connectors have been

shipped with protective caps and tethers. If you wish to detach the tethers from the compu ter the screws

securing them to the rear panel will need to be removed. To keep water out of the enclosure and preserve the

life of the EXPC-1319, leave the protective caps in place (with their tethers) whenever the hardware interfaces

are not used.

Connecting to a Display

The EXPC-1319 comes with a 19-inch LED-backlit LCD display. Because the configuration of a 2nd or alternate

display may be required, the EXPC-1319 also comes with a VGA in ter f ace on its bottom panel. The VGA

hardware interface is a standard D-Sub 15-pin female connector; to ensure that the monitor image remains

clear, be sure to tighten the monitor cable after connecting it to the EXPC-1319 computer. The pin assignments

are shown below.

external VGA display is not in use, make sure that the protecti ve cap and the tether tail have

ed so that the waterproof function can work well. Please note that when reinst alling the

, it must be fully tightened to insure the unit is sealed correctly to meet the IP66 enclosure

You may refer to Appendix B: Statement of Regulatory Approval for the technical details

.

Page 19

EXPC-1319 Series Hardware Hardware Installation

2-8

Step 1:

c

wire you intend to connect through parts 4, 3, and

2, in that order.

Step 2:

according to

Step 3:

and connect the USB connector on the bottom

panel of the EXPC-1319. Make sure the connector

has been securely fastened to ensure the

waterproof function.

DB15 Female VGA Connector

Pin No. Signal Definition Pin No. Signal Definition

1 Red 9 VCC

2 Green 10 GND

3 Blue 11 NC

4 NC 12 DDC2B Data

5 GND 13 HSYNC

6 GND 14 VSYNC

7 GND 15 DDC2B Clock

8 GND

Connecting USB Devices

The EXPC-1319 embedded computer has two USB 2.0 ports on the bottom panel. All of the ports are UHCI, Rev

2.0 compliant and support Plug & Play and hot swapping. These ports can be used to connect USB devices such

as a keyboard, mouse, USB flash disk, and USB CD-ROM. In addition, both USB ports support system boot up,

which can be activated by modifying the BIOS settings. BIOS configuration is described in detail in

BIOS Setup. Follow the steps below to wire up the USB connectors.

Chapter 4:

Disassemble the waterproof USB

onnector into four parts. Thread the end of the

Connect the wires to the USB head

the pinout shown in the table below.

When finished, assemble the USB parts,

Pin Number Assignment

1 VCC

2 DATA3 DATA+

4 Ground

Page 20

EXPC-1319 Series Hardware Hardware Installation

2-9

WARNING

To keep the EXPC

USB ports are not in use

and make sure they

the

unit is sealed to IP6

In addition,

supply

power accidents

shoks or electrocution, in damp conditions users

computer

dev

You may r

technical

Step 1: Disassemble the waterproof DB9 connector into

four parts.

Step 2: Connect the serial signal wires with the correct

pin definition. See the following figure and table.

Step 3:

parts, and connect to the DB9 connector on the bottom

panel of the EXPC

been securely fastened to ensure the wa terproof

function.

protective caps they must be tightened to 136 N-cm (12 in-lbs) to ensure the

of standard USB ports, care must be taken to protect the EXPC-1319 from

from its power source before conn ecting or disconnecting any USB

ices.

details regarding regulation Class 1 Div. 2 devices.

-1319 within the IP66 rating’s waterproof specifications, when the

operators must replace the protective caps and the tethers,

have been properly fastened. Please note that when reinstalling

6 specifications.

because of the danger posed by the maximum 5V @ 500 mA power

in damp environments. To guarantee safety from severe electrical

should disconnect the entire

efer to Appendix B: Statement of Regulatory Approval for the

Connecting Serial Devices

The EXPC-1319 comes with two RS-232/422/485 serial ports with DB9 male connector.

When finished, assemble the DB co nnector

-1319. Make sure the connector has

The pin assignments for RS-232/422/485 serial ports are shown in the following table:

DB-9 Male Port RS-232/422/485 Pinouts

Pin RS-232 RS-422 RS-485-4W RS-485-2W

1 DCD TxDA(-) TxDA(-) –

2 RxD TxDB(+) TxDB(+) –

3 TxD RxDB(+) RxDB(+) DataB(+)

4 DTR RxDA(-) RxDA(-) DataA(-)

5 GND GND GND GND

6 DSR – – –

7 RTS – – –

8 CTS – – –

Page 21

EXPC-1319 Series Hardware Hardware Installation

2-10

WARNING

When the

fasten

th

to IP6

detail

Step 1:

connector into four parts.

Step 2:

wire to

For pinouts, refer to

the figure and table

Step 3:

3, and 2, in that order, then c onnect it to the

RJ45 head

assemble the LAN

parts, and

the bottom

panel of the EXPC

connector

water

e screws which keep them in place must be tightened to 136 N-cm (12 i n-lbs) to ensure the unit is sealed

serial ports are not in use, make sure that the protective caps and the tethers have been securely

ed to keep water from entering the enclosure. Please note that when reinstalling the protective caps

6 specifications. You may refer to Appendix B: Statement of Regulatory Approval for the technical

s regarding regulation Class 1 Div. 2 devices.

Connecting LAN Ports

The EXPC-1319 has two 10/100/1000 Mbps LAN ports. These LAN ports come with waterproof RJ45 connectors.

Follow the steps below to connect the LAN ports.

By default, the LAN ports use DHCP addressing to assign network IP addresses. For detailed network

configuration, please refer to the EXPC-1319 Win 7 Embedded Software Manual.

Disassemble the waterproof RJ45 LAN

Users need to connect the twisted pair

the correct pinouts.

Pass LAN twisted pair thr ough parts 4,

. When finished, re

insert the RJ45 head into

-1319. Make sure the

is securely fastened to ensure full

resistance.

just below.

Pin No. 100 Mbps Signal 1000 Mbps Signal

1 ETx+ TRD (0)+

2 ETx- TRD (0)3 ERx+ TRD (1)+

4 – TRD (2)+

5 – TRD (2)6 ERx- TRD (1)7 – TRD (3)+

8 – TRD (3)-

Page 22

EXPC-1319 Series Hardware Hardware Installation

2-11

WARNING

When the

securely fastened to keep water from entering the enclo

protective cap

specifications

regarding

Ethernet LAN ports are not in use, make sure that the protective caps and tethers have been

s they must be tightened to 136 N-cm (12 in-lbs) to ensure the unit is sealed to IP66

. You may refer to Appendix B: Statement of Regulatory Approval for the technical details

regulation Class 1 Div. 2 devices.

Replacing the SSD

The EXPC-1319 comes with a removable 32 GB industrial SSD that can be upgraded to a maximum of 256 GB.

To replace the SSD, follow these steps.

sure. Please note that when reinstalling the

1. Remove the SSD cover, located on the left sid e of the computer (shown at rig ht).

2. Rem ove the SSD by pulling out the plastic plat e (shown at left).

3. Remove the screws on two sides of the SSD, and then remove the plastic plate.

Page 23

EXPC-1319 Series Hardware Hardware Installation

2-12

NOTE

Please note that the operating system is stored

will

may

about this procedure, please r

Embedded

NOTE

Please note that th

fastened to

pads

SSD and CF slots

waterproof

procedures when securing

4. Place the plastic plate on the new SSD, and fasten the screws on two sides of the SSD. When finished, insert

the SSD into the socket (shown a t left)

5. Set the SSD cover in place and fasten it using the original four screws.

perform a system recovery procedure to re-install the operating system on the new SSD. For de tails

efer to the System Recovery chapter in either the EXPC-1319 Win 7

(Chapter 9), or EXPC-1319 Win Linux (Ch a pter 5) software manuals,.

on the SSD. If you replace this SSD with a new model you

Installing the CompactFlash Card

The EXPC-1319 comes with an onboard CompactFlash socket located just beside the SSD socket. Follow these

steps to install.

1. Remove the SSD cover, located on the left side of the computer (shown at right).

2. The CompactFlash socket is located beside the SSD socket (shown at left).

3. Carefully insert the CompactFlash card into the socket, hardware interface first (s hown at right). To remove

the card, you may need to use a screwdriver or other long, slender tool.

4. When finished, place the cover back and fasten the screws.

the back plate, to help secu r e the SSD and CF cards. These

also help reduce vibration and assist in keeping the

, so take care to preserve them and follow suggested

e SSD/CompactFlash cover comes with rubber pads

the cover.

Page 24

3

3. Touch Screen Calibration

Calibrating the Touch Screen

Standard Calibration

Advanced Calibration

PenMount Calibration Utility Parameters

Turn off EEPROM Storage

Touch Screen Cursor Settings

Edge Compensation

Page 25

EXPC-1319 Series Hardware Hardware Installation

2-2

Calibrating the Touch Screen

This chapter describes the calibration process for the EXPC-1319 touch panel.

First, Open the PenMount control panel. This may be found under the Windows 7 Start Menu, in the

Programs list in the PenMount Windows Universal Driver(WHQL) folder. From the PenMount folder,

navigate to the Utility folder and open the PenMount Control Panel.

Next, the PenMount Control Panel should appear as in the screen shot to the right, with the Device tab as

its default display. Double-click on the device you want to calibrate, or select the device and click Configure.

If you do not see your device offered on the menu, click Refresh to refresh the list.

The final preparatory step is to choose what sort of calibration you want. Most will choose Standard

Calibration, which is a basic to uch screen calibration using five reference points. For most situations, a

standard calibration should be adequate. As the touch screen ages, users will find that the standard calibration

is not adequate for re-establishing screen accuracy and precision. If problems are still encountered following a

standard calibration, you may choose Advanced Calibration to calibrate the touch screen to a greater

number of reference points.

Page 26

EXPC-1319 Series Hardware Hardware Installation

2-3

Standard Calibration

For a standard five point calibration, five spots will appear one after another on the display. Use your finger or

stylus to touch the five points in order. After you have completed the sequence, hit ESC on your keyboard to

save the result and exit the calibration process.

Advanced Calibration

An advanced calibration uses 9, 16, or 25 points to calibrate touch panel linearity; select the number of

reference points from the drop-down menu offered on the calibration utility main dialog. You may also instruct

the calibration utility to plot detailed calibration data onto a graph. For more information about the data graph,

see the next section, Calibration Data Graph

Just as with the standard calibration, to complete the calibration use your finger or stylus to touch the points

in order, as they appear. After you have completed the sequence, hit ESC on your keyboard to save the result

and exit the calibration process.

.

Page 27

EXPC-1319 Series Hardware Hardware Installation

2-4

Advanced Calibration: Calibration Data Graph

If you performed an advanced calibration and ticked the Plot Calibration Data selection, then after you

complete an advanced calibration the calibration utility will provide you with a graph comparing ideal panel

linearity as assumed by the PenMount utility (the black lines) plotted against the approximate linearity derived

by the PenMount utility from the user calibration process (the blue lines).

Please note that this function is mainly used by the panel manufacturer for troubleshooting. To exit the graph,

simply touch the screen. If you feel you have discovered problems with calibration that you cannot solve using

the PenMount calibration utili ty, please contact Moxa’s Embedded Computing Technical Support staff.

PenMount Calibration Utility Parameters

Turn off EEPROM Storage

Ticking this box disables the storage of calibration data in the permanent EEPROM screen controller; instead,

the calibration data is saved to the system drive. If you turn off EEPROM storage, the value will be stored and

available from one restart to the next, but the changes will be lost should you perform a system software

recovery, forcing you perform a touch panel recalibration.

Touch Screen Cursor Settings

The Settings tab allows for configuration of four main touch screen cursor features: cursor behavior (mouse

emulation or stylus mode), a beep that sounds when contact with the touch screen is made or broken, a cursor

stabilizer, and press-and-hold in place of right clicking.

Page 28

EXPC-1319 Series Hardware Hardware Installation

2-5

The top drop-down may only be set to mouse emulation. No other modes are available.

Beep mode allows you to configure a beeping sound to play whenever contact is made (or broken) with the

screen. The beep may be configured for tone, frequency, and duration.

The cursor stabilizer removes jitter from the cursor when the computer is being used in high vibration

environments.

To enable right-click capability for the touch screen, users may enable the press-and-hold-as-right-click,

which allows users to press on the cursor and hold their finger in place, without moving, to call up the right-click

menu available in most Windows applications.

Back to defaults resets all of the touch screen interface settings to their factory defaults.

When finished, click OK.

Page 29

EXPC-1319 Series Hardware Hardware Installation

2-6

Edge Compensation

This page allows users to calibrate the touch scr een so that software features at the edges of the display are

easier to access. This is often a serio us problem when, for instance, users are touching the screen with

fingertips that are too thick to conv eniently access scroll bars, or to manipulate objects on the Windows task

bar, or in the system tray located on the bottom of the screen. The edge compensation interface consists of four

sliders one for each edge of the screen. The far right represents the largest possible edge area, while the far left

represents the smallest possible (unmagnified) edge area.

Page 30

4

4. BIOS Setup

This chapter describes the BIOS settings of the EXPC-1319 computer. The BIOS is a set of input/output control

routines for peripherals. The BI OS is used to initialize basic peripher als and loads the operating system. The

BIOS setup allows the user to modify the system configurations of these basic input/output peripherals. All of

the configurations will be stored in the NVRAM (flash memory), which retains the system in formation after

system reboots or the power is removed.

The following topics are covered in this chapter:

Entering the BIOS Setup Utility

BIOS Main Page

Modifying BIOS Settings

Advanced Settings

Security Settings

Power Settings

Boot Settings

Exit Settings

Upgrading the BIOS

Page 31

EXPC-1319 Series Hardware BIOS Setup

3-2

F1: General Help

F5/F6: Change Values

F9: Setup Defaults

F10: Save and

↑↓

← →

ESC: Exit

ENTER: Select or go to Submenu

Entering the BIOS Setup Utility

Before you start configuring BIOS settings, make sure the following notices have been confirmed.

1. The EXPC-1319 has been installed in the safe environment, such as office or lab.

2. The keyboard has been successfully con nected.

3. The pow er cable has been successfully co nnected.

To enter the BIOS setup utility, press the “F2” key while the system is booting up. The main BIOS Setup screen

will appear.

A basic description of each function key is listed at the bottom of the screen. Refer to these descriptions to learn

how to use them.

(in a drop down menu)

Exit

BIOS Main Page

The main page of the BIOS displays basic low-level information about system hardware, including things like

model names, CPU type, and BIOS version.

: Select Item

: Select Menu

Page 32

EXPC-1319 Series Hardware BIOS Setup

3-3

Modifying BIOS Settings

Navigate the BIOS menus using the arrow keys; up (↑) and down (↓) arrows navigate the menu, while left (←)

and right (→) arrows will open or close sub-menus from entries marked with a triangle (▲) at the beginning of

the line.

Advanced Settings

The Advanced Features scre en will appear when choosing the Advanced item from the main menu .

Page 33

EXPC-1319 Series Hardware BIOS Setup

3-4

Boot Configuration

This item allows users to toggle the number pad into “on” or “off” when first booting up.

Peripheral Configuration

This item allows you to configure the peripheral serial ports.

Serial Port A

This item allows you to configure the COM1 port.

Options: 3F8/IRQ4 (defa ul t), Di sa b led

Page 34

EXPC-1319 Series Hardware BIOS Setup

3-5

Serial Port B

This item allows you to configure the COM2 port.

Options: 2F8/IRQ3 (defa ul t) , Disa b led

Serial Port C

This item allows you to configure the control buttons.

Options: 3E8/IRQ5 (default), Disabled

Serial Port D

This item is reserved to configure the touch panel interface.

Options: 3E8/IRQ5 (default), Disabled

IDE Configuration

This item allows you to configure the storage drive controllers.

HDC Configure As

This item allows you to configure the storage drive type. The options are:

AHCI (default); PATA; SATA; and IDE Non-Combined

Channel Master 1 to 3

This setting displays the storage devices installed on the computer’s master bus. These storage devices may be

HDD, SSD, or a CF card.

Channel Slave 1 to 3

This setting displays storage devices installed on the computer’s slave bus. These storage drives may be HDD,

SSD, or a CF card.

Page 35

EXPC-1319 Series Hardware BIOS Setup

3-6

Video Configuration

This item allows you to configure the video settings.

IGD – Pre-Allocated

This item allows you to configure the pre-allocated capacity for the graphic memory capacity.

Options: 8 MB (default), 1 MB

IGD – DVMT Size

This item allows you to configure the capacity of the DVMT 5.0 used by th e internal graphics device.

Options: 64 MB (default) , 128 MB, 224 MB

IGD – Boot Type

This item allows you to select the video device which will be activated during POST.

Options: CRT+LCD (default), CRT, LCD

Please note that for the EXPC-1319, the LCD features the LCD panel, and the CRT features the VGA port at the

bottom of the computer.

IGD – LCD Panel Type

This item allows you to select the LCD panel type and the resolution.

Options: 1280x1024 LVDS (default), 1024x768 LVDS, 800x600 LVDS

Page 36

EXPC-1319 Series Hardware BIOS Setup

3-7

NOTE

Please note that USB Port 2 is reserved for touch panel function. Default value is Enabled.

USB Configuration

This item allows you to turn USB Legacy mode on or off. USB Legacy allows older USB devices to be accessed

from the earliest boot initialization, and/or DOS.

Options: Enabled (defau lt), Disabled

USB Port0

This item allows you to configure the USB Port 1.

Options: Enabled (defau lt), Disabled

USB Port1

This item allows you to configure the USB Port 2.

Options: Enabled (defau lt), Disabled

USB Port3-Port6

This item allows you to configure the USB Port 3 to 6. These ports are reserved on the main board.

Options: Enabled (defau lt), Disabled

Page 37

EXPC-1319 Series Hardware BIOS Setup

3-8

ACPI Table/Features Control

This item allows you to configure FACP and HPET fu nctions.

FACP – RTC S4 Wakeup

This item allows you to enable RTC wakeup, so the computer may pull itself out of sleep or hibernation mode

to perform specified tasks at a certain time each day.

Options: Enabled (defau lt), Disabled

HPET – HPET Support

This item allows you to enable/disable the HPET (High Precision Event Timer), which produces periodic

interrupts at a much higher resolution than the RTC and may be used to synchronize multimedia streams. HPET

can sometimes introduce system instability, so some users may wish to disable it.

Option: Enabled (default), Disabled

Base Address Select

This allows you to select the memory address range for the HPET.

Options: FED00000h (default), FED01000h, FED02000h, FED03000h

Page 38

EXPC-1319 Series Hardware BIOS Setup

3-9

Hardware Monitor

This item allows you to view various self-reported hardware states that include C PU temperature, system

temperature, and CPU voltage.

Security Settings

The section allows users to configure security settings like a system supervisor password and user password.

Page 39

EXPC-1319 Series Hardware BIOS Setup

3-10

WARNING

To guarantee yo

passwords in a secure place for future reference. If you set a security password on your hard disk you will

need to enter the same password whenever you access the hard drive, ev en i

computer.

Set Supervisor Password

This item allows you to set the supervisor password. Select and then enter the password, and then confirm the

password again.

Set User Password

This item allows you to set the user password. Select and then enter the password, and then confirm the

password again.

Set All HDD Password

This item allows you to set the password for all storage devices on your computers, including CF, D OM and hard

disk. You need to enter the password w hen booting up to use these stora g e d evices.

Please note that to update the password yo u need to first enter the current password, and then enter a new

password. If you wish to simply cancel the password and leave the system unprotected, you may leave the

password update box blank.

ur hard drive remains accessible, remember to record your hard disk drive

Set All Master HDD Password

This item allows you to set the password for the master storage drive on your computer. You ne ed to enter the

password when booting up to use the master hard disk.

f it is transferred to another

Page 40

EXPC-1319 Series Hardware BIOS Setup

3-11

Power Settings

The section allows users to configure power settings.

Page 41

EXPC-1319 Series Hardware BIOS Setup

3-12

Advanced CPU Control

Thermal Mode

This item enables Intel’s thermal throttling 1 technology in the CPU; it functions as a temperature trip that will

throttle the CPU (and thereby decrease p erformance) when a certain temperature is reached. Enabling this

function allows you to configure the thermal control circuit in the operating system userspace.

Options: TM1 (default), Disabled

HT Support

This item enables Hyper-Threading (HT) technology, so that the CPU may utilize simultaneous multithreading.

This improves performance for multi-threaded code and gives improved reaction and response time. However,

in some instances users may want to disable it to conserve power or r ed u ce CPU cache paging.

Options: Enable (default), Disabled

Use XD Capability

This item allows you to enable/disable the In tel XD function, which provides executable space protection by

toggling the NX bit in memory spaces designated as data. This gives a strong protection against buffer

overflows by preventing the execution of malicious code that has been delivered into memory space in a hidden

data packet. It is strongly advised to enable XD technology.

Options: Disabled (default), Enable

ACPI S3

This item allows you to enable/disable Processor Performance States (P-States) function; this technology is

primarily intended for power conservation on laptops. By default, it is enabled.

Options: Enabled (default) , D isa bled

PWRON After PWR-Fail (Power on after Power Fail)

This item allows you to configure the computer to turn itself back on after a power failure. If a power failure

occurs and Enabled is chosen, the computer will automatically power up, regardless if it was on or not when

the failure occurred. If Last State is chosen, the computer will power up if it had been on, or will remain of f if

it was not on when the failure occurred.

Options: Enabled (default) , D isa bled, Last State.

Wake on LAN

This feature is used to wake up the sys tem by a LAN device from a remote host.

Options: Enabled (default), Disable.

Page 42

EXPC-1319 Series Hardware BIOS Setup

3-13

Auto Wake on S5

This item allows you to configure the computer to wake from S5 status. S5 stands for Soft Off, where the PSU

remains engaged but power to all other parts of the system is cut. Auto-wake on S5 schedules a soft-reboot at

certain periodic times that may be sp ecified in the BIOS.

Options: Disabled (default); By Every Day (user specifies a regular daily time when the computer will power

up); By Day of Month (user specifies a regular day each month when the computer will power up)

Boot Settings

The section allows users to configure boot settings.

UEFI Boot

This item allows you to enable/disable the Unified Extensible Firmware Interface, which allows for remote

diagnostics and repair of computers even without an operating system. Users who are concerned about safety

or ownership issues may disable it .

Options: Enabled (defau lt), Disabled

Quick Boot

This item allows you to enable/disable quick book function to reduce OS loading times.

Options: Enabled (defau lt), Disabled

Page 43

EXPC-1319 Series Hardware BIOS Setup

3-14

PXE Boot to LAN

This item allows you to configure the Preboot eXecution Environment‘s boot-to-LAN function. PXE provides

an independent boot environment that may be initialized over a network interface, without intermediary

storage devices or local operating systems.

Options: Disabled (default), e n abl ed

USB Boot

This item allows you to enable/disable the system to bo ot from a USB storage device or network connection.

Options: Enabled (defau lt), Disabled

EFI

This item displays the boot selection for the UEFI boot function.

Legacy

Normal Boot Menu

This item allows you to configure the boot menu.

Options: Normal (defaul t), Advanced

Boot Type Order

This item allows you to select the order in which the computer will search storage devices for bootable images;

the highest device on the list will be searched first, then the second, and so on until the computer finds a

bootable image. F5/F6 will allow you to change the boot order. Use F5 to select the upper option, and F6 to

select the lower option.

Options: Hard Disk Drive (default), CD/DVD-ROM Drive, USB, Others.

Hard Disk Drive

This item allows you to view information returned by the storage device (SSD, HDD) installed in the computer.

USB

This item allows you to view information about any USB device connected to the computer.

Page 44

EXPC-1319 Series Hardware BIOS Setup

3-15

Exit Settings

The section allows users to exit the BIOS .

Exit Saving Changes

This item saves the values you have just configured and exits the BIOS.

Options: Yes (default), No

Save Change Without Exit

This item saves changes but does not exit t he BIOS.

Options: Yes (default), No

Exit Discarding Changes

This item allows you to exit the BIOS without saving any new settings fr om the user session.

Options: Yes (default), No

Load Defaults Setting

This item resets the entire BIOS to factory default values.

Options: Yes (default), No

Load Custom Defaults

This item loads custom defa ults across the entire BIOS.

Options: Yes (default), No

Page 45

EXPC-1319 Series Hardware BIOS Setup

3-16

Save Custom Defaults

This item saves the current BI OS settings as the new custom def a ults.

Options: Yes (default), No

Discard Changes

This item allows you to discard all settings you have just configured.

Options: Yes (default), No

Upgrading the BIOS

This section describes how to upgrade the BIOS. However, please note that it is easy to permanently damage

the computer when upgrading the BIOS. We strongly recommend that you contact Moxa’s technical support

staff for assistance in order to obtain all necessary tools and the most current advice before attempting to

upgrade the BIOS on any Moxa device.

Step 1: Create a Bootable USB Disk.

Before upgrading the BIOS every user should first create a bootable USB RAM drive as a system rescue device.

A useful software suite for building USB RAM drives may be found by searching for HP US B Disk Storage

Format Tool, which may then be downloaded and u sed to create a bootable RAM drive.

To create a rescue system, you will also need to download the FreeDos system files kernel.sys and

command.com from http://www.freedos.org/kernel/.

Copy the DOS files kernel.sys and command.com to a specified directory (C:\FreeDOS in this example).

Start the HP USB Disk Storage Format Tool and in the drop-down menu labeled Device select the USB device

that you want to use as a bootable disk.

Configure it to use a FAT file system from the File System drop-down.

Enter a drive name in the Volume Label field.

Check the option Create a DOS Startup Disk under Format Options.

Specify the directory where the system files are located (for example, C:\FreeDOS).

Click Start to format and create the bootable USB drive.

Page 46

EXPC-1319 Series Hardware BIOS Setup

3-17

ATTENTION

We suggest you use a USB drive with under 2 GB in disk space, as larger USB drives may not support the FAT

file format and

Step 2: Prepare the Upgrade File.

You must use the BIOS upgrade installation file to upgrade the BIOS. You can send your request to Moxa's

technical support team at support@moxa.com to get a n updated version of the BIOS.

1. Get the BIOS upgrade installation file. The file name should have following format: 139xxSyy.exe. (xx and

yy refers to the version number)

2. Copy the file to the Bootable USB Di sk .

Step 3: Run the upgrade program on the EXPC-1319 computer

1. Reboot the computer and go to the Boot Manager by pressing F12 while booting up, before the operating

system has begun to load.

2. Sel ect USB Disk as the first boot source. Press Enter to continue.

will consequently fail to boot.

Page 47

EXPC-1319 Series Hardware BIOS Setup

3-18

C:\ EXPC1319>13911S01.exe

ATTENTION

Do NOT switch off the power supply during the BIOS upgrade

permanent

da

1. Once the computer boots, a DOS screen will appear. Go to the directory where the upgrade file is located.

For example, if the upgrade file is stored in the EXPC-1319 folder, type:

#:/cd EXPC1319

C:\ cd EXPC1319

2. Run the upg rade program by typing 13911S01.exe.

Please note that the upgrade filename may vary depending on the firmware version.

3. The upgrade program will run. Wait until the procedure is finished before initiating any changes to the

system. Be patient; the upgrade will take quite a few minutes.

DO NOT ALLOW THE COMPUTER TO POWER DOWN! DO NOT REMOVE THE USB DRIVE!

4. Once the upgrade is finished, the computer will automatically reboot. To check and see if the upgrade was

successful, navigate to the BIOS Main Page and note the BIOS Version number.

mage to your system!

. Doing so will likely cause

Page 48

A. S afety Installation Instructions

A. RTC Battery Warning

Subjective devices can only utilize the Lithium Carbon-mono-fluoride (BR) Coin Cells battery-BR2032, rated 3

V, 195 mAh, manufactured by RAYOVAC Corp.

Caution:

1. Batteries must only be changed in an area known to be no n -hazardous.

2. Batteries must be installed with the positive (+) side facing as upper to avoid risk of shorting battery, fire

or explosion.

B. Fuse Warning

CAUTION: For continued protection against fire, replace only with same type and rating of fuse.

A

C. Rackmount Warning

The following or similar rackmount instructions are included with the installation instructions:

(1) Elevated Operating Ambient: If installed in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than the room ambient temper ature. Therefore,

consideration should be given to installing the equipment in an environment compatible with the max imum

ambient temperature (Tma) specified by the manufacturer.

(2) Reduced Air Flow: Installatio n of the equipment in a rack should be such that the air flow required for

safe operation is not obstructed.

(3) Mechanical Loading: Mounting of the equipment in the rack should no t create hazards that result from

uneven mechanical loading.

(4) Circuit Overloading: Consideration should be given to the connection of the equipment to the power

supply and the effect that overloading of the circuits might have on overcurrent protections or supply wiring.

Appropriate consideration of equipment nameplate ratings must be noted when evaluating this conc e rn.

(5) Reliable Grounding: Reliable grounding of rack-mounted equipme nt should be maintained. Particular

attention must be given to indirect power connections that do not directly link to the branch circuit (e.g., over

power strips).

D. High Temperature Warning

(1) This equipment is intended to be used in a Restricted Access location like a locked computer room.

Access to this equipment should only be granted to AUTHORIZED SERVICE PERSONNEL or to users who have

been instructed about the the potential heat hazard posed by the metal chassis. This computer can become so

hot that after a long period of operations users and service personnel must take special care to wear protective

clothing before touching it. Only AUTHORIZED PROFESSIONALS should be allowed direct access to an

operating device.

Page 49

EXPC-1319 Series Hardware Safety Installation Instructions

A-2

(2) External metal parts can get dangerously hot!! Before touching it, give special attention to device

temperature! Protective w ear will likely be necessary!

Page 50

B

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device m a y not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

European Community

N. A. Safety for Hazardous Locations

B. Statement of Regulatory Approval

Class A: FCC Warning! This equipment has be en tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This equipmen t

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Warning:

This is a Class A product. In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

In addition, please read the following descriptions for various approvals and certifications.

Description Agency Standard for Marking Comments

N. A. Safety for Information

Technology Equipment

Certification by Underwriter’s

Laboratories to UL60950-1, 2

standard and equivalent CSA C22.2

No

nd

Edition

60950-1-07, 2nd Edition

Standard

Certification by Underwriter’s

Class I, Div. 2, Groups A, B, C, D

Laboratories to

ANSI/ISA-12.12.01

Low Voltage Directive

European Safety for Industrial

Control Equipment

-2011 standard and equivalent CSA

C22.2 No 213-M1987 Standard

Self-Declaration in accordance with

European LVD Directive

2006/95/EC; Independent 3

assessment (Accredited by IEC

17025 )

rd

party

Page 51

EXPC-1319 Series Hardware Regulatory Statement Approval

B-2

Description Agency Standard for Marking Comments

Electromagnetic Compa tibility

Directive

European EMC for Industrial Control

Equipment

Explosive Atmospheres Directive

European Safety for Hazardous

Locations

Equipment Group II, Category 3,

Gas Group IIC

IEC Certification Scheme for

Explosive Atmospheres

Equipment Group II, Category 3,

Gas Group IIC

Self-Declaration in accordance with

EMC Directive 2004/108/EC;

Independent 3

rd

party assessment

(Accredited by IEC 17025 )

Certification with ATEX Directive

94/9/EC; Independent 3

rd

assessment (Notified Body: DEMKO)

IECEx Certificate of Conformity;

Independent 3

rd

party assessment

(Certified by UL)

Ex ic nA nC IIC Gc

IEC 60079-0, 60079-11, 60079-15

party

Explosion Hazard

• Component substitutions may impair suitability for UL Cla ss 1 Divisi on 2, ATEX Z one 2, EN 60079-15, a nd

IECEx.

• Do not connect or disconnect equip ment unless power has been switched off or the area is known to be

non-hazardous.

• Do not install or remove CompactFlash card, SSD, or HDD while circuit is alive.

• The battery used in this device may present a fire or chemical burn hazard if mistreated. Do not disassemble

or incinerate. Dispose of used batteries promptly. Keep away from children.

• The proper method for removing power from the unit is to switch off power at the circuit breaker.

• Enclosure Cover Warning - Explosion hazard - Do not remove cover unless area is know to be

non-hazardous. (Warning is applicable to any removable cover on the unit - HDD access door, etc.)

• I/O Cover Warning - For hazardous area installations reference manual for field wiring control drawing.

• The device is intended for mounting in a tool-accessible ATEX-certified or IECEx-certified IP54 enclosure

and used in an area of not more than pollution degree 2 as define by IEC 60664-1.

Loading...

Loading...