Page 1

P/N: 1802005000022

Technical Support Contact Information

www.moxa.com/support

Moxa Americas:

Toll

Tel:

Fax:

Moxa China (Shanghai office):

Toll

Tel:

Fax:

Moxa Europe:

Tel:

Fax:

Moxa Asia-Pacific:

Tel:

Fax:

Moxa India:

Tel:

Fax:

2016 Moxa Inc. All rights reserved.

EDS-G500E Series

Quick Installation Guide

Moxa EtherDevice™ Switch

Edition 3.0, September 2016

-free: 1-888-669-2872

1-714-528-6777

1-714-528-6778

+49-89-3 70 03 99-0

+49-89-3 70 03 99-99

+91-80-4172-9088

+91-80-4132-1045

-free: 800-820-5036

+86-21-5258-9955

+86-21-5258-5505

+886-2-8919-1230

+886-2-8919-1231

*1802005000022*

Page 2

Package Checklist

The EDS-G500E is shipped with the following items . If any of these items

are missing or damaged, please contact your customer service

representative for assistance.

• 1 EDS-G508E or EDS-G512E-4GSFP or EDS-G516E-4GSFP Ethernet

switch

• Quick installation guide (printed)

• Documentation and software CD

• Warranty card

• USB cable

• Protective caps for unused ports

Features

• Up to 12 10/100/1000BaseT(X) ports and 4 100/1000BaseSFP ports

• Turbo Ring and Turbo Chain (recovery time < 50 ms @ 250 switches),

RSTP/STP, and MSTP for network redundancy

• RADIUS, TACACS+, SNMPv3, IEEE 802.1x, HTTPS, and SSH to

enhance network security

• EtherNet/IP, PROFINET, and Modbus/TCP protocols supported for

device management and monitoring

- 2 -

Page 3

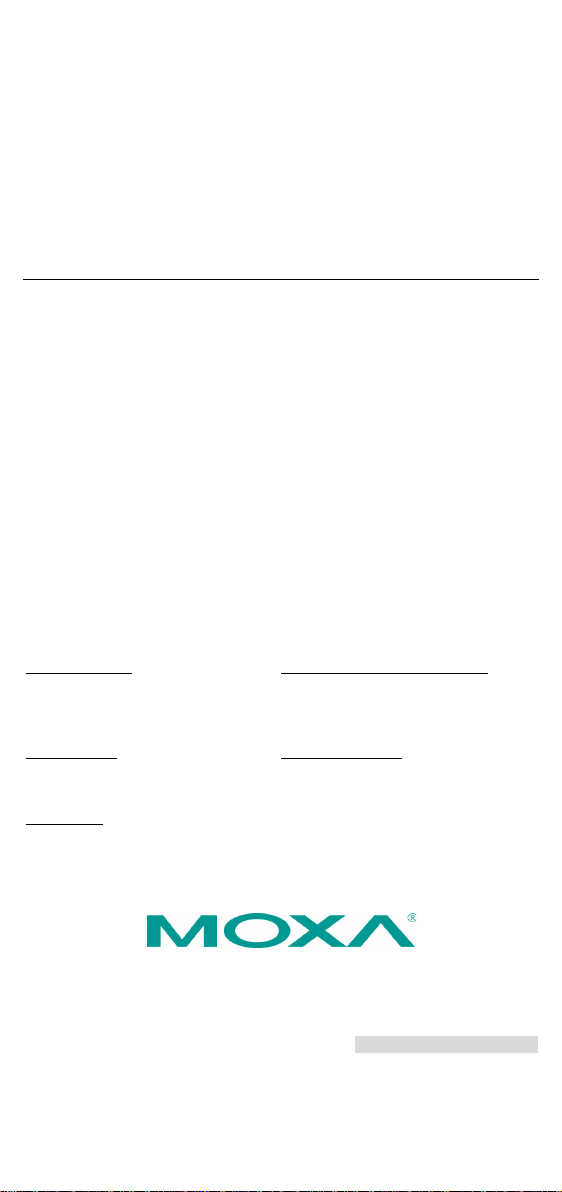

Panel Views of EDS-G500E Series

Front Panel

Front Panel

1.

2.

3.

4.

5.

6.

7.

8.

1000BaseT(X) LED indicator

10/100BaseT(X) LED indicator

EDS-G508E

10/100/1000BaseT(X) ports

System status LED:

USB storage port

SFP port LED indicator

100/1000BaseSFP slots

Model Name

EDS-G508E: 1 to 8

EDS-G512E-4GSFP: 1 to 8

EDS-G516E-4GSFP: 1 to 12

• STATE LED indicator

• PWR1 LED indicator

• PWR2 LED indicator

• FAULT LED indicator

• MSTR/HEAD LED indicator

• CPLR/TAIL LED indicator

EDS-G512E-4GSFP: 9 to 12

EDS-G516E-4GSFP: 13 to 16

EDS-G512E-4GSFP

- 3 -

EDS-G516E-4GSFP

Page 4

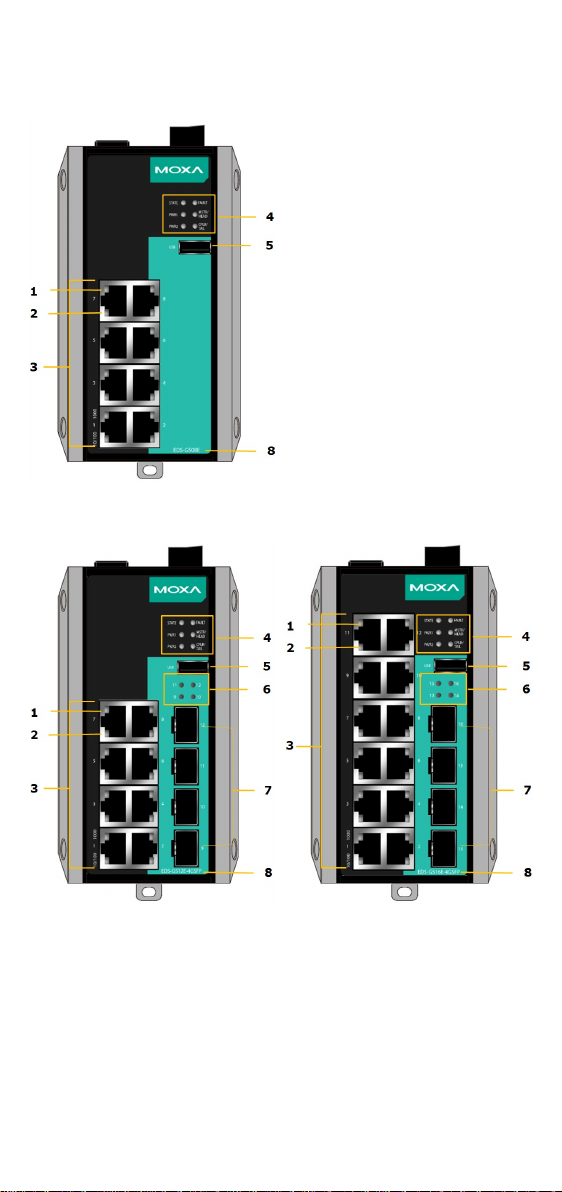

Top Panel

Top Panel

1.

Reset button

2.

3.

4.

5.

6.

Rear Panel

1.

2.

USB console port

DIP switches for Turbo Ring,

Ring Master, and Ring Coupler

Grounding screw

4-pin terminal block for digital

input and power input 2

4-pin terminal block for relay

output and power input 1

Rear Panel

Screw holes for wall mounting

kit

DIN-rail mounting kit

- 4 -

Page 5

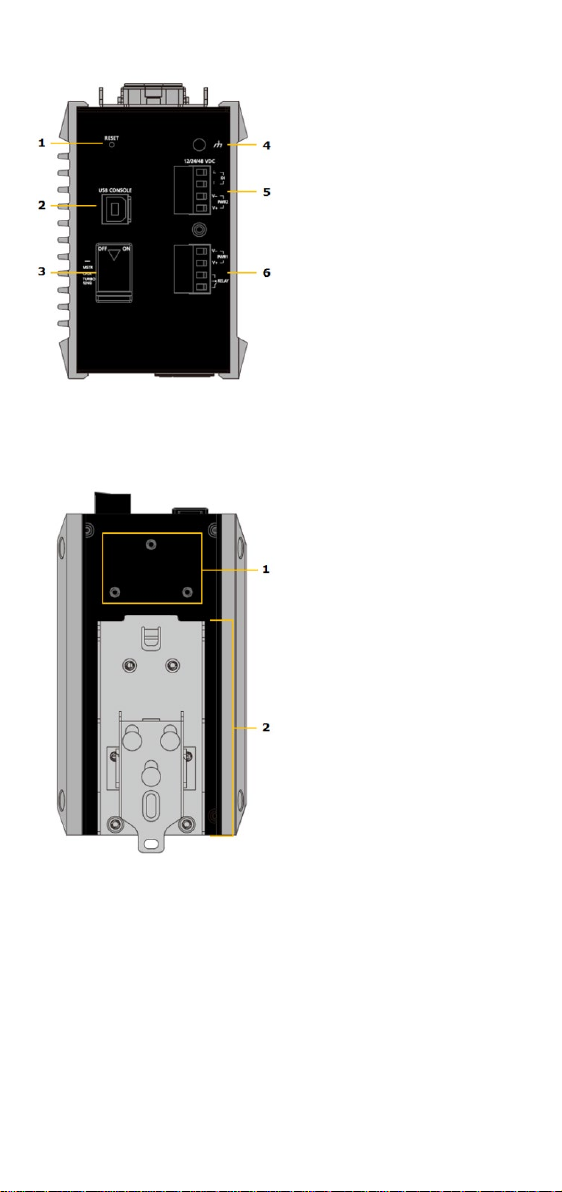

Mounting Dimensions

Unit = mm (inch)

- 5 -

Page 6

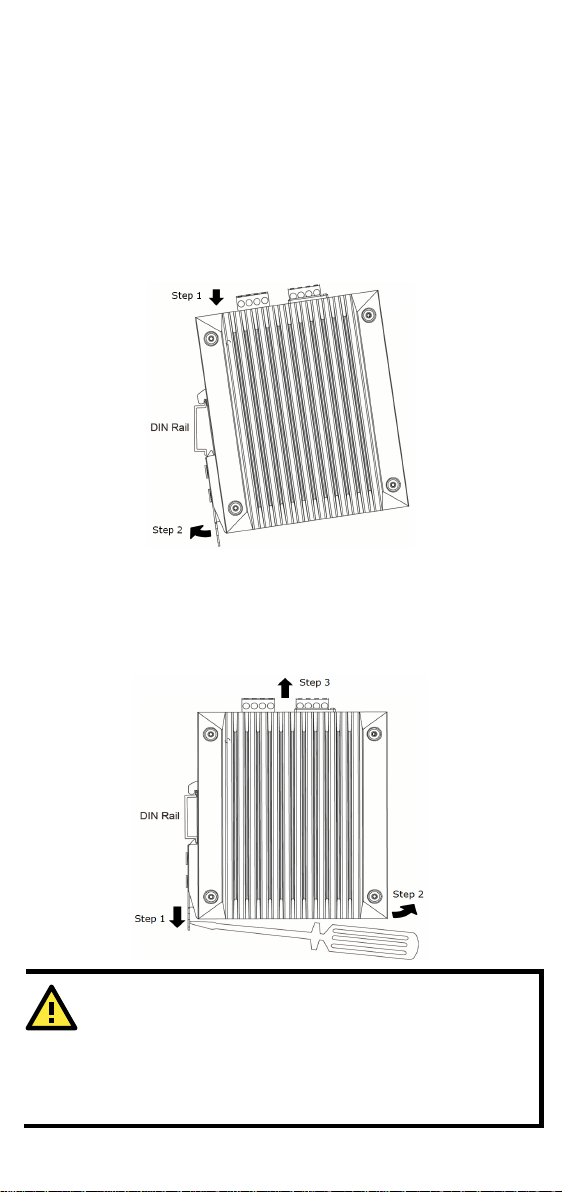

DIN-Rail Mounting

ATTENTION

installed

Groups A, B, C, and D or non-hazardous locations only.

The metal DIN-rail kit is fix ed to th e back panel of the EDS-G500E series

when you take it out of the box. Mount the EDS-G500E series on

corrosion-free mounting rails that meet the EN 60715 st andard.

Installation

STEP 1: Insert the upper lip of the DIN rail into the DIN-rail mounting kit.

STEP 2: Press the EDS-G500E series towards the DIN rail until it snaps

into place.

Removal

STEP 1: Pull down the latch on the mounting kit with a screwdriver.

STEP 2 & 3: Slightly pull the EDS-G500E series forward and lift up to

remove it from the DIN rail.

1. These devices are open-type dev ices that are to be

in an enclosure with tool removable cover or door that

suitable for the environment.

2. This equipment is suitable for use in Class I, Division 2,

- 6 -

Page 7

Wall Mounting (Optional)

STEP 1: Remove the

aluminum DIN r

attachment plate from the

rear panel

EDS

, and then

attach the wall mount plates

wi

in

the figure

STEP 2: Mounting the EDS-G500E series on the wall

requires 4 screws. Use the

wall mount plates attached, as a guide to mark the

correct locations of the 4 screws. The heads of the

screws should be less than 6.0 mm in d iameter, a nd

the shafts should be less than 3.5 mm in diameter, as

shown in the figure on at right.

NOTE

Before tightening the screws into the wall, make sure the screw

head and shank size are suitable by inserting the screw through

one of the keyhole-shaped apertures of the Wa ll Mounting Plates.

STEP 3: Once the screws are

fixed

four screw heads through the

wide parts of the

keyhole

and then slide

G500E

downwards, as i

the figure

the right. Tighten

the four screws for

stability.

WARNING

Do not disconnect equipment unless

Substitution of any components may

SEALING PROPERTIES OF MATERIALS USED IN THE RELAY.

For some applications, you will find it convenient to mount Moxa EDSG500E series on the wall, as shown in the following illustrations:

ail

of the

-G500E series

th M3 screws, as shown

at the right.

EDS-G500E series, with

Do not screw the screws in all the way—leave about 2 mm to allow room

for sliding the wall mount panel between the wall and the scre ws.

to the wall, insert the

-shaped apertures,

the EDS-

ndicated in

at

more

1. EXPLOSION HAZARD power has been removed or the area is known to be

non-hazardous.

2. EXPLOSION HAZARD impair suitability for Class I, Division 2.

3. EXPOSURE TO SOME CHEMICALS MAY DEGRADE THE

- 7 -

Page 8

ATEX Information

WARNING

D

switched off or the area is known to be non

devices may only be connected to the supply voltage shown on

the type plate. The devices are designed for operation with a

S

oltage. Thus, they may only be connected to

the supply voltage connections and to the signal conta ct with the

S

EN60950/ VDE0805.

ATTENTION

This unit is a built

type. When the unit is installed in another

piece of equipment, the equipment enclosing the unit must

comply with fire enclosure regulation IEC 60950/EN60950 (or

similar regulation).

ATTENTION

Safety First!

Be sure to disconnect the power cord before installing an d/or

wiring your Moxa EtherDevice Switch.

Calculate the maximum possible current in each power wire and

common wire. Observe all electrical codes dictating the

maximum current allowable for each wire

If the current goes above the maximum ratings, the wiring could

overheat, causing serious damage to your equipment.

1. Certificate number: DEMKO 14 ATEX 1212X

2. Certification string: Ex nA nC IIC T4 Gc

3. Standards covered:

EN 60079-0:2012+A11:2013, EN 60079-15:2010

4. These products are to be installed in an ATEX Certified IP54

enclosure and accessible only by the use of a tool.

5. These products are for use in an area of not more than pollution

degree 2 in accordance with IEC 60664-1.

Wiring Requirements

o not disconnect modules or wires unless power has been

afety Extra-Low V

afety Extra-Low Voltages (SELV) in compliance with IEC950/

-hazardous. The

-in

size.

- 8 -

Page 9

Please read and follow these guidelines:

ATTENTION

This product is intended to be mounted to a w

mounting surface such as a metal panel.

FAULT:

The two contacts of the 6-pin terminal

block connector are used to detect

user-configured events. The two wires

attached to the fault contacts form an

open circuit when a user

event is triggered. If a us er-configured

event does not occur, the fault circuit

remains closed.

• Use separate paths to route wiring for power and devices. If power

wiring and device wiring paths must cross, make sure the wires are

perpendicular at the intersection point.

NOTE: Do not run signal or communications wiring and power wiring

through the same wire conduit. To avoid interference, wires with

different signal characteristics should be routed separately

• You can use the type of signal transmitted through a wire to

determine which wires should be kept separa te. The ru le of thumb is

that wiring that shares similar electrical characteristics can be

bundled together

• You should separate input wiring from output wiring

• We advise that you label the wiring to all devices in the system.

Grounding the Moxa EDS-G500E Series

Grounding and wire routing help limit the effects of noise due to

electromagnetic interference (EMI). Run the ground connect ion from the

ground screw to the grounding surface prior to connecting devices.

ell-grounded

Wiring the Relay Contact

The EDS-G500E series has one set of relay output. This relay contact uses

two contacts of the terminal block on the EDS-G500E’s top panel. Refer to

the next section for detailed instructions on how to connect t h e wires to

the terminal block connector, and how to attach the ter minal block

connector to the terminal block receptor. In this section, we illustrate the

meaning of the two contacts used to connect the relay contact.

- 9 -

-configured

Page 10

Wiring the Redundant Power Inputs

STEP 1:

DC wires into the V

respectively.

STEP 2:

pulling loose, use a small flat

screwdriver to tighten the wire-clamp

screws on the front of the terminal

block connector.

STEP 3:

block connector prongs into the

terminal block receptor, which is

located on the EDS-G500E’s top panel.

STEP 1: Insert the negative

(ground)/positive DI wires into the

┴

STEP 2:

pulling loose, use a small flat

screwdriver to tighten the wire-clamp

screws on the front of the terminal

block connector.

STEP 3:

block connector prongs into the

terminal block receptor, which i

located on the EDS-G500E’s top panel.

The EDS-G500E series has two sets of power inputs—power input 1 and

power input 2. The top and front views of one of the terminal block

connectors are shown here.

Insert the negative/positive

To keep the DC wires from

Insert the plastic terminal

-/V+ terminals,

-blade

Wiring the Digital Inputs

The EDS-G500E series has one set of digital input (DI). The DI consists of

two contacts of the 4-pin terminal block connector on the EDS-G500E's

top panel, which are used for the two DC inputs. The top and front views

of one of the terminal block connectors are shown here.

/I terminals, respectively.

To keep the DI wires from

Insert the plastic terminal

-blade

Communication Connections

Each EDS-G500E series switch has 4 types of communication ports:

• 1 USB console port (type B connector)

• 1 USB storage port (type A connector)

• 8 (EDS-G508E/EDS-G512E-4GSFP) or 12 (EDS-G516E-4GSFP)

10/100/1000BaseT(X) Ethernet ports

• 4 100/1000Base SFP slots (EDS-G512E-4GSFP/EDS-G516E-4GSFP)

USB Console Connection

The EDS-G500E series has one USB console port (type B connector),

located on the top panel. Use the USB cable (provided in the product

package) to connect the EDS-G500E's console port to your PC's USB port

and install the USB driver (available in the software CD) on the PC. You

may then use a console terminal program, such as Moxa PComm Terminal

Emulator, to access the EDS-G500E’s console configuration utility.

- 10 -

s

Page 11

USB Console Port (Type B Connector) Pinouts

Pin

Description

1

D– (Data -)

2

VCC (+5V)

3

D+ (Data+)

4

GND (Ground)

Plug the ABC-02-USB into the USB storage

on the wall with

Pin

Description

1

VCC (+5V)

2

D– (Data -)

3

D+ (Data+)

4

GND (Ground)

Pin

Signal

1

TRD(0)+

2

TRD(0)-

3

TRD(1)+

4

TRD(2)+

5

TRD(2)-

6

TRD(1)-

7

TRD(3)+

8

TRD(3)-

USB Storage Connection

The EDS-G500E series has one USB storage port (type A connector) on

the front panel. Use Moxa ABC-02-USB-T automatic backup configurato r

to connect the EDS-G500E's USB storage port for configuration backup,

firmware upgrade or system log file backup.

ABC-02-USB Installation

port of the Moxa EDS-G500E series.

Securing the ABC-02-USB

an M4 screw is suggested.

USB Storage Port (Type A Connector) Pinouts

1000BaseT Ethernet Port Connection

1000BaseT data is transmitted on differential TRD+/- signal pairs over

copper wires.

MDI/MDI-X Port Pinouts

- 11 -

Page 12

100/1000BaseSFP (mini-GBIC) Fiber Port

LC-Port Pinouts

LC-Port to LC-Port Cable Wiring

ATTENTION

This is a Class 1 Laser/LED product. To avoid causing serious

damage to your eyes, do not stare directly into the Laser Beam .

NOTE

Do NOT power off the Ethernet switch when loading default

settings.

The Gigabit Ethernet ports on the EDS-G500E series are

100/1000BaseSFP Fiber ports, which require using the 100M or 1G

mini-GBIC fiber transceivers to work properly. Moxa provides completed

transceiver models for different distance requirement.

The concept behind the LC port and cable is quite straightforward.

Suppose that you are connecting devices I and II; contrary to electrical

signals, optical signals do not require a circuit in order to transmit data.

Consequently, one of the optical lines is used to transmit data from device

I to device II, and the other optical line is used transmit data from device

II to device I, for full-duplex transmission.

Remember to connect the Tx (transmit) port of device I to the Rx (receive)

port of device II, and the Rx (receive) port of device I to the Tx (transmit)

port of device II. If you make your own cable, we suggest labeling the two

sides of the same line with the same letter (A-to-A and B-to-B, as shown

below, or A1-to-A2 and B1-to-B2).

Reset Button

There are two functions available on the Reset Button. One is to reset th e

Ethernet switch to factory default settings by pressing and holding the

Reset button for 5 seconds. Use a pointed object, s uch as a stra ightened

paper clip or toothpick, to depress the Res et but ton. This will cause the

STATE LED to blink once a second. After depressing the but t on for 5

continuous seconds, the STATE LED will start to blink rapidly. This

indicates that factory default settings have been loaded and you can

release the reset button.

When the ABC-02-USB is connected to the EDS-G500E Ethernet switch,

the reset button allows quick configuration and backs up log files to the

ABC-02-USB. Press the Reset button on top of the EDS-G500E, the

Ethernet switch will start backing up current system configuration files

and event logs to the ABC-02-USB.

- 12 -

Page 13

Turbo Ring DIP Switch Settings

NOTE

Please refer to the Turbo Rin g section in Communication

Redundancy

the setting and usage of Turbo Ring and Turbo Ring V2.

EDS-G500E Series DIP Switches

The default setting for each DIP Switch is OFF. The

following table explains the effect of setting the DIP

Switch to the ON position

DIP 1

DIP 2

DIP 3

DIP 4

Reserved for

ON: Enables this

ON: Enables the

ON: Activates

settings.

OFF: This EDS

OFF: Do not use

OFF: DIP switch

3 will be

DIP 1

DIP 2

DIP 3

DIP 4

ON: Enables the

enabled.

ON: Enables this

ON: Enables the

ON: Activates

OFF: Enables the

enabled.

OFF: This EDS

OFF: Do not use

this EDS as a ring

OFF: DIP switch

3 will be

EDS-G500E series are plug-and-play managed redundant Ethernet

switches. The proprietary Turbo Ring protocol was developed by Moxa to

provide better network reliability and faster recovery time. Moxa Turbo

Ring’s recovery time is less than 300 ms (Turbo Ring) or 50 ms (Turbo

Ring V2) —compared to a 3- to 5-minute recovery time for commercial

switches—decreasing the possible loss caused by network failures in an

industrial setting.

There are 4 Hardware DIP Switches for Turbo Ring on the top panel of

EDS-G500E series that can help setup the Turbo Ring easily within

seconds. If you do not want to use a hardware DIP switch to setup the

Turbo Ring, you can use a web browser, telnet, or conso le to disabl e this

function.

User's Manual for more detail information about

“Turbo Ring” DIP Switch Settings

future use.

“Turbo Ring V2” DIP Switch Settings

default “Ring

Coupling

(backup)” port

when DIP switch

3 is already

default “Ring

Coupling

(primary)” port

when DIP switch

3 is already

EDS as the Ring

Master.

will not be the

Ring Master.

EDS as the Ring

Master.

will not be the

Ring Master.

.

default “Ring

Coupling” ports.

this EDS as the

ring coupler.

default “Ring

Coupling” port.

coupler.

- 13 -

DIP switch 2 and

3 to configure

“Turbo Ring”

1, 2, and

disabled.

DIP switch 1, 2,

and 3 to

configure “Turbo

Ring V2”

settings.

1, 2, and

disabled.

Page 14

NOTE

You must enable the Turbo Ring function first before using the

DIP switch to activate the Master and Coupler functions.

NOTE

If you do not enable any of the EDS-G500E series s witches to be

the Ring Master, the Turbo Ring protocol will automatically

choose the EDS

range to be the Ring Master. If you accidentally enable more tha n

one EDS

E

series

negotiate to determine which one will be

the Ring Master.

LED

Color

Status

Description

The system passed the self-diagnosis test

on boot-up and is ready to run.

1. The switch is under reset progress (1

The system failed self-diagnosis on

RAM Test Fail / System Info. Read Fail /

(+ Green Coupler lit on: SW FAIL)

1. The signal contact is open.

The port being disabled because of the

5. Invalid Ring port connection.

Power is being supplied to the main

module’s power input PWR1.

Power is not being supplied to the main

module’s power input PWR1.

Power is being supplied to the main

module’s power input PWR2.

module’s power input PWR2.

-G500E series with the smallest MAC address

-G500E series to be the Ring Master, these EDS-G500

switches will auto-

LED Indicators

The front panel of the Moxa EDS-G500E series contains several LED

indicators. The function of each LED is described in the following table:

On

Green

Blinking

STATE

Red On

FAULT Red On

On

PWR1 Amber

Off

On

PWR2 Amber

Off

time/s).

2. Detect ABC-02-USB connect to the

switch (1 time/2s).

boot-up.

•

Switch Initial Fail / PTP PHY Error.

(+ Green MSTR lit on : HW FAIL)

• FW Checksum Fail / Uncompress Fail.

2. ABC Loading/Saving Fail.

3.

ingress multicast and broadcast

packets exceed the ingress rate limit.

4. Incorrect loop connection in a single

switch.

Power is not being supplied to the main

- 14 -

Page 15

LED

Color

Status

Description

On

1. The switch is set as the Master of the

Turbo Ring, or as the Head of the Turbo

blinking).

1. The switch has become the Ring Master

The Head of the Turbo Chain, after the

port is down.

1. The switch is not the Master of this

Turbo Chain.

1. The switch’s coupling function is

blinking)

1. Turbo Chain is down.

port is down.

1. This switch has disabled the coupling

Turbo Chain.

FAULT +

+ CPLR/TAIL

Rotate

Sequentially

STATE +

+ CPLR/TAIL

On

TP port’s 10 or 100 Mbps link is active.

Mbps.

Off

TP port’s 10/100 Mbps link is inactive.

1000M

On

TP port’s 1000 Mbps link is active.

Blinking

Data is being transmitted at 1000 Mbps.

Off

TP port’s 1000 Mbps link is inactive.

On

SFP port’s 100 Mbps link is active.

Blinking

Data is being transmitted at 100 Mbps.

Off

SFP port’s 100 Mbps link is inactive.

1000M

On

SFP port’s 1000 Mbps link is active.

Blinking

Data is being transmitted at 1000 Mbps.

Off

SFP port’s 1000 Mbps link is inactive.

Chain.

2. POST H.W. Fail (+Stat on and Fault

MSTR/

CPLR/

HEAD

TAIL

Green

Green

MSTR/HEAD

FAULT +

MSTR/HEAD

Blinking

Off

On

Blinking

Off

Blinking

Blinking

of the Turbo Ring.

2.

Turbo Ring or the Turbo Chain is down.

3. The switch is set as Turbo Chain’s

Member and the corresponding chain

Turbo Ring.

2. This switch is set as a Member of the

enabled to form a back-up path.

2. When it’s set as the Tail of the Turbo

Chain.

3. POST S.W. Fail (+Stat on and Fault

2. The switch is set as Turbo Chain’s

Member and the corresponding chain

function.

2. This switch is set as a Member of the

ABC-02-USB is importing/exporting files.

Switch is being discovered/located by

MXview (2 times/s).

10M/

100M

Amber

Blinking

Data is being transmitted at 10 or 100

(TP)

Green

(TP)

100M

Amber

(SFP)

Green

(SFP)

- 15 -

Page 16

Specifications

Technology

Standards

IEEE 802.3 for 10BaseT

IEEE 802.3z for 1000BaseX

Protocols

IGMPv1/v2/v3, GMRP, GVRP, SNMPv1/v2c/v3,

DHCP Server/Client, DHCP Option 66/67/82, BootP,

V2, IPv6, NTP Server /Client

MIB

MIB-II, Ethernet-Like MIB, P-BRIDGE MIB,

Group 1, 2, 3, 9

Flow Control

IEEE 802.3x flow control, back pressure flow control

Interface

RJ45 Ports

8 (EDS-G508E/EDS-G512E-4GSFP) or

12 (EDS-G516E-4GSFP) 10/100/1000BaseT(X)

(EDS-G512E-4GSFP/EDS-G516-4GSFP only)

USB Ports

USB console port (type B connector)

USB storage port (type A connector)

Button

Reset button

LED Indicators

PWR1, PWR2, FAULT, STATE, 10/100M, 100/1000M,

MSTR/HEAD, CPLR/TAIL

Alarm Contact

1 relay output with current carrying capacity of 1 A

@ 24 VDC

• Max. input current: 8 mA

Power

Input Voltage

12/24/48/-48 VDC, redundant dual inputs

Input Current

EDS-G516E: 0.46 A @ 24 VDC

EDS-G508E: 0.33 A @ 24 VDC

Connection

2 removable 4-contact terminal blocks

Protection

Reverse Polarity

Protection

Present

Physical Characteristics

Housing

Metal, IP30 protection

Dimension

79.2 x 135 x 137 mm (3.1 x 5.3 x 5.4 in)

Installation

DIN-rail mounting, wall mounting (with optional kit)

IEEE 802.3u for 100BaseT(X) and 100BaseFX

IEEE 802.3ab for 1000BaseT(X)

TFTP, SNTP, SMTP, RARP, RMON, HTTP, HTTPS,

Telnet, SSH, Syslog, EtherNet/IP, PROFINET,

Modbus/TCP, SNMP Inform, LLDP, IEEE 1588 PTP

Q-BRIDGE MIB, Bridge MIB, RSTP MIB, RMON MIB

Fiber Ports 4-port 100/1000BaseSFP slot

Digital Input 1 input with the same ground, but electrically

Overload Current

isolated from the electronics.

• +13 to +30V for state “1”

• -30 to +3V for state “0”

EDS-G512E: 0.4 A @ 24 VDC

Present

- 16 -

Page 17

Environmental Limits

Operating

Temperature

-10 to 60°C (14 to 140°F) for standard models

-40 to 75°C (-40 to 167°F) for -T models

Storage

Temperature

-40 to 85°C (-40 to 185°F)

Ambient Relative

Humidity

Altitude

Up to 2000 m

Note: Please contact Moxa if you require products gua ranteed to function

properly at higher altitude.

Regulatory Approvals

Safety

UL 508

EMI

FCC Part 15 Subpart B Class A, EN 55022 Class A

EMS

EN 61000-4-2 (ESD) Level 4,

EN 61000-4-8

Shock

IEC 60068-2-27

Free Fall

IEC 60068-2-32

Vibration

IEC 60068-2-6

Warranty

Warranty

5 years

5 to 95% (non-condensing)

EN 61000-4-3 (RS) Level 3,

EN 61000-4-4 (EFT) Level 4,

EN 61000-4-5 (Surge) Level 4,

EN 61000-4-6 (CS) Level 3,

- 17 -

Loading...

Loading...