MovinCool Office Pro 63 Service Manual

SERVICE MANUAL

OFFICE PRO 63

SERIAL NUMBER FROM JANUARY 2008 (0108) TO PRESENT

DocID: 00G00017E

© 2008 DENSO SALES CALIFORNIA, INC.

All rights reserved. This book may not be reproduced or copied, in

whole or in part, without the written permission of the publisher . DENSO

SALES CALIFORNIA, INC. reserves the right to make changes without

prior notice. MovinCool is a registered trademark of DENSO

Corporation.

Table of Contents

Table of Contents

Operation Section

1. PRECAUTIONS FOR SAFETY

1.1 Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. GENERAL DESCRIPTION

2.1 Spot Cooler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Compact Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Easy Transportation and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Energy Conservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. CONSTRUCTION

3.1 Exterior Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Exterior Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Internal Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Basic Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Air Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.6 Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.7 Compressor and Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.8 Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.9 Condensate Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.10 Drain Tanks (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4. SPECIFICATIONS

4.1 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5. REFRIGERANT SYSTEM

5.1 Refrigerant System Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.4 Capillary Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.6 High Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table of Contents

6. ELECTRICAL SYSTEM

6.1 Circuit Diagram and Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Basic Operation of The Office Pro 63 Electrical Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4 Control Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.5 Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.6 Compressor Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.7 Condensate Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.8 Drain Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.9 Automatic Restart after Power Interruption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.10 Compressor Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.11 Temperature Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.12 Fan Mode Control Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.13 Temperature Scale Display Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.14 Warning Signal Connection (Outpu t Sign al Terminal L+ and L-) . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.15 Fire Alarm Control Panel Connection (Input Signal Terminal E+ and E-). . . . . . . . . . . . . . . . . . . . . 32

Table of Contents

Repair Section

7. TROUBLESHOOTING

7.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2 Self-Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.3 Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.4 Basic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8. DISASSEMBLY

8.1 Parts Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.2 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.3 Removal of Electrical Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.4 Removal of Blower Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.5 Removal of Condensate Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.6 Removal of Transformer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.7 Inspection of Capacitor (for Fan Motor and Compressor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.8 Inspection of Drain Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.9 Inspection of Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.10 Inspection of Compressor Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.11 Inspection of Transformer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.12 Inspection of Wiring Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.13 Inspection of Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.14 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9. REFRIGERANT SYSTEM REPAIR

9.1 Repair of Refrigerant System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.2 Removal of Refrigeration Cycle Compon e nts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

9.3 Charging the System with R-410A Refrigerant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.4 Refrigerant Charging Work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10. REASSEMBLY

10.1 Removal of Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.2 Compressor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.3 Blower Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.4 Wiring Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.5 Perform the Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.6 Caster Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.7 Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6

Operation Section

1. PRECAUTIONS FOR SAFETY

1.1 Foreword

• This manual has been published to service the MovinCool Office Pro 63. Please use this service

manual only when servicing the Office Pro 63.

1.2 Definition of Terms

WARNING

CAUTION

NOTE Provides additional information that facilitates installation or unit operation.

Describes precautions that should be observed in order to prevent injury to

the user during installation or unit operation.

Describes precautions that should be observed in order to prevent da mage to

the unit or its components, which may occur during installation or unit

operation if sufficient care is not taken.

1.3 General Precautions

WARNING

• All electrical work if necessary, should only be performed by qualified electrical

personnel. Repair to electrical components by non-certified technicians may result in

personal injury and/or damage to the unit. All electrical components replaced must be

genuine MovinCool parts, purchased from an authorized reseller.

• When handling refrigerant, always wear proper eye protection and do not allow the

refrigerant to come in contact with your skin.

• Do not expose refrigerant to an open flame.

• The proper electrical outlet for MovinCool units must be equipped with a “UL” approved

ground-fault breaker to prevent electrical shock from the unit.

• When brazing any tubing, always wear eye protection, and work only in a well ventilated

area.

• Disconnect power before servicing unit.

• Be careful of any sharp edges when working on unit.

2. GENERAL DESCRIPTION

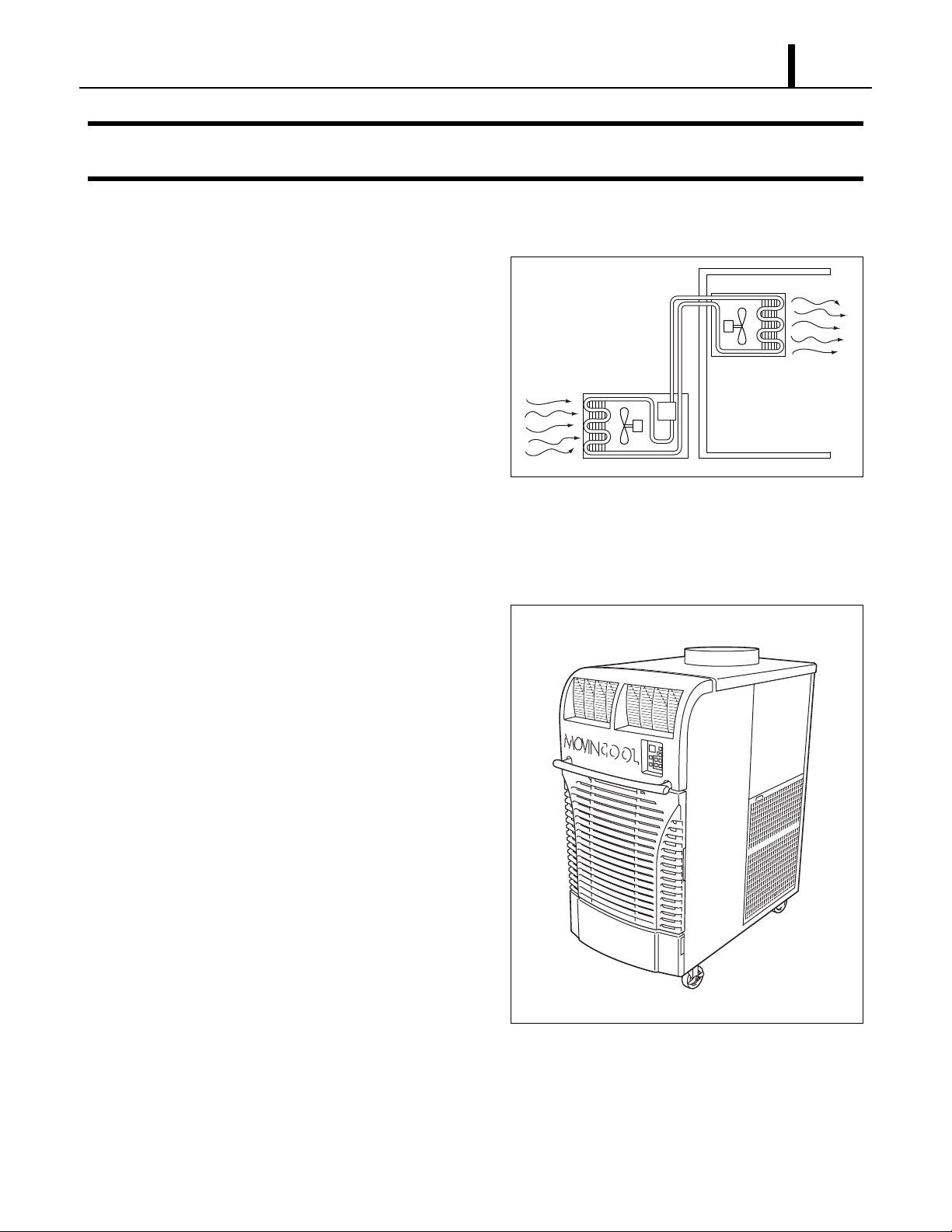

2.1 Spot Cooler

• In general, conventional air conditioners cool

the entire enclosed environment. They act as

“heat exchangers”, requiring an interior unit

(evaporator) to blow cool air into the interior

and an exterior unit (condenser) to exhaust

exchanged heat to the outdoors.

• Unlike conventional air conditioners, the

Condenser

(Outdoor Unit)

Operation Section

7

Evaporator

(Indoor Unit)

MovinCool Office Pro 63 is a spot cooler which

directs cool air to particular areas or objects.

MovinCool Office Pro 63 has the following features:

2.2 Compact Design

• The innovative design of MovinCool Office Pro

63 has resulted in one compact unit, replacing

the need for two separate units.

2.3 Easy Transportation and Installation

• With the whole cooling system built into one

compact unit, MovinCool Office Pro 63

requires no piping and can be easily

transported and installed.

I000501

2.4 Energy Conservation

• MovinCool Office Pro 63 is economical

because it cools only the area or objects which

need to be cooled.

I001905

8

Operation Section

3. CONSTRUCTION

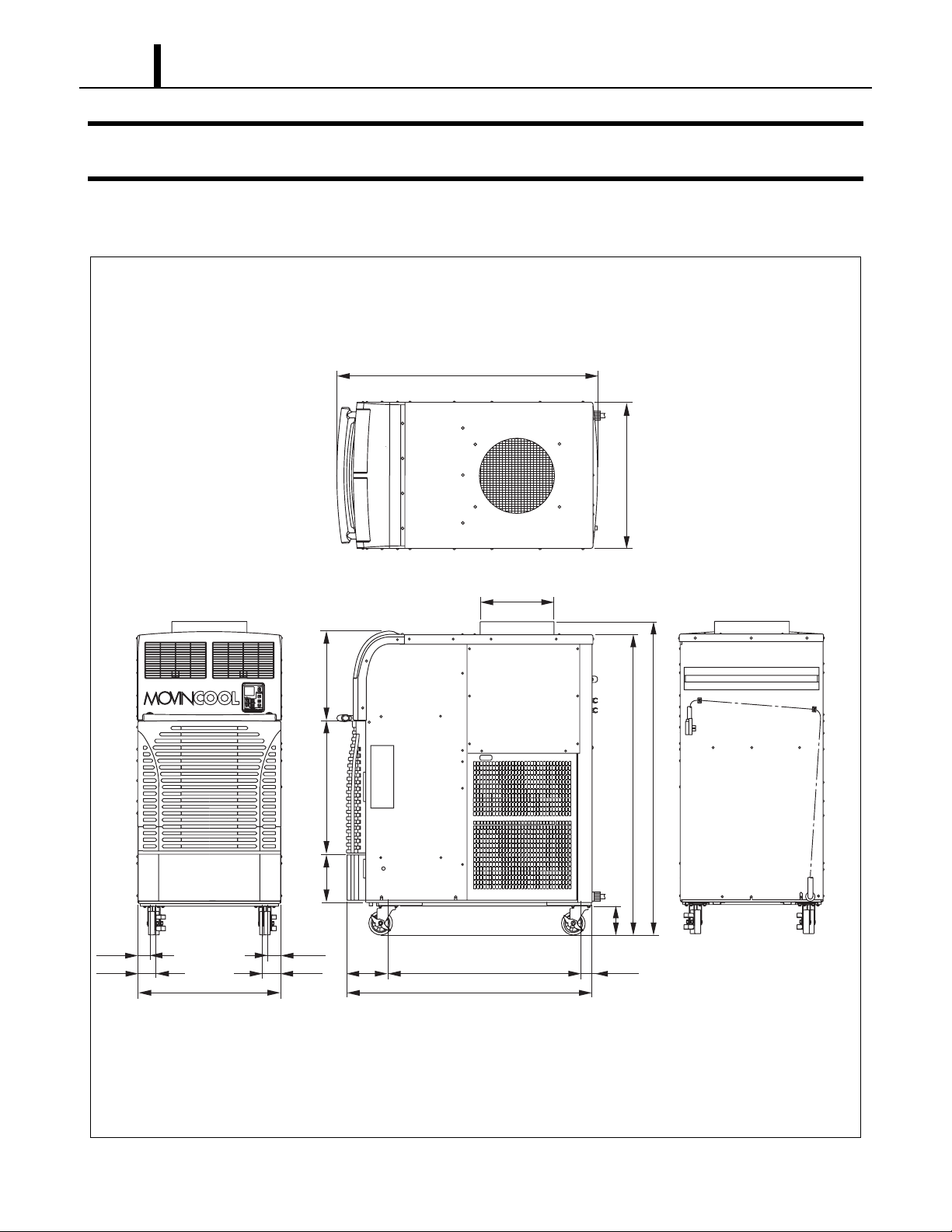

3.1 Exterior Dimensions

(55.0)

(30.2)

(2.6)

(3.6)

(29.9)

(2.6)

(3.6)

(18.7)

(27.6)

(10.0)

(8.5)

(40.8)

(51.6)

(DIA. 15.7)

(6.1)

(2.4)

(65.0)

(62.2)

(Unit: inch)

I001906

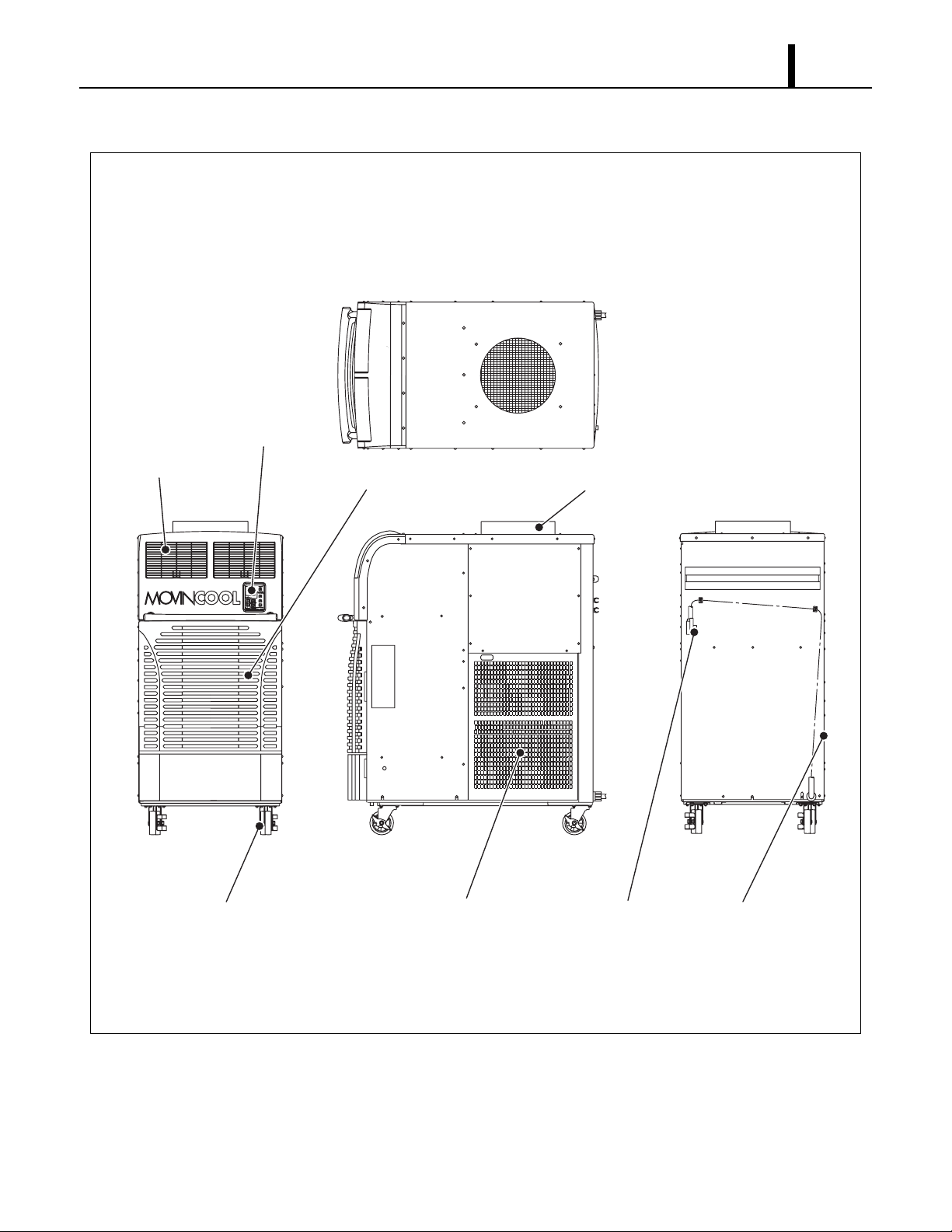

3.2 Exterior Components

Operation Panel

Operation Section

9

Cold Air Outlet Grill

Caster

Evaporator Air Inlet Grill

Condenser Air Outlet Duct

Service PanelPower CordCondenser Air Inlet Panel

I001907

10

Operation Section

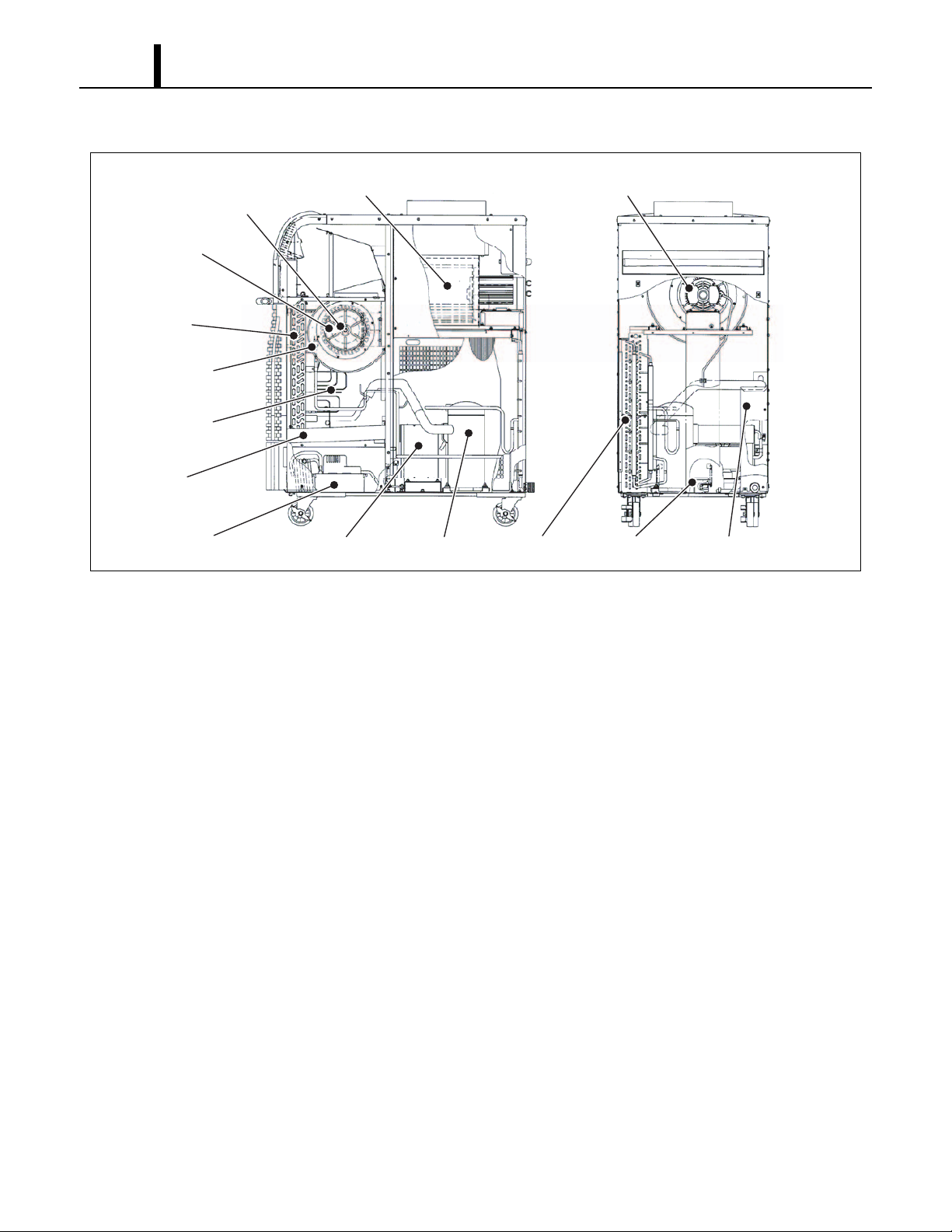

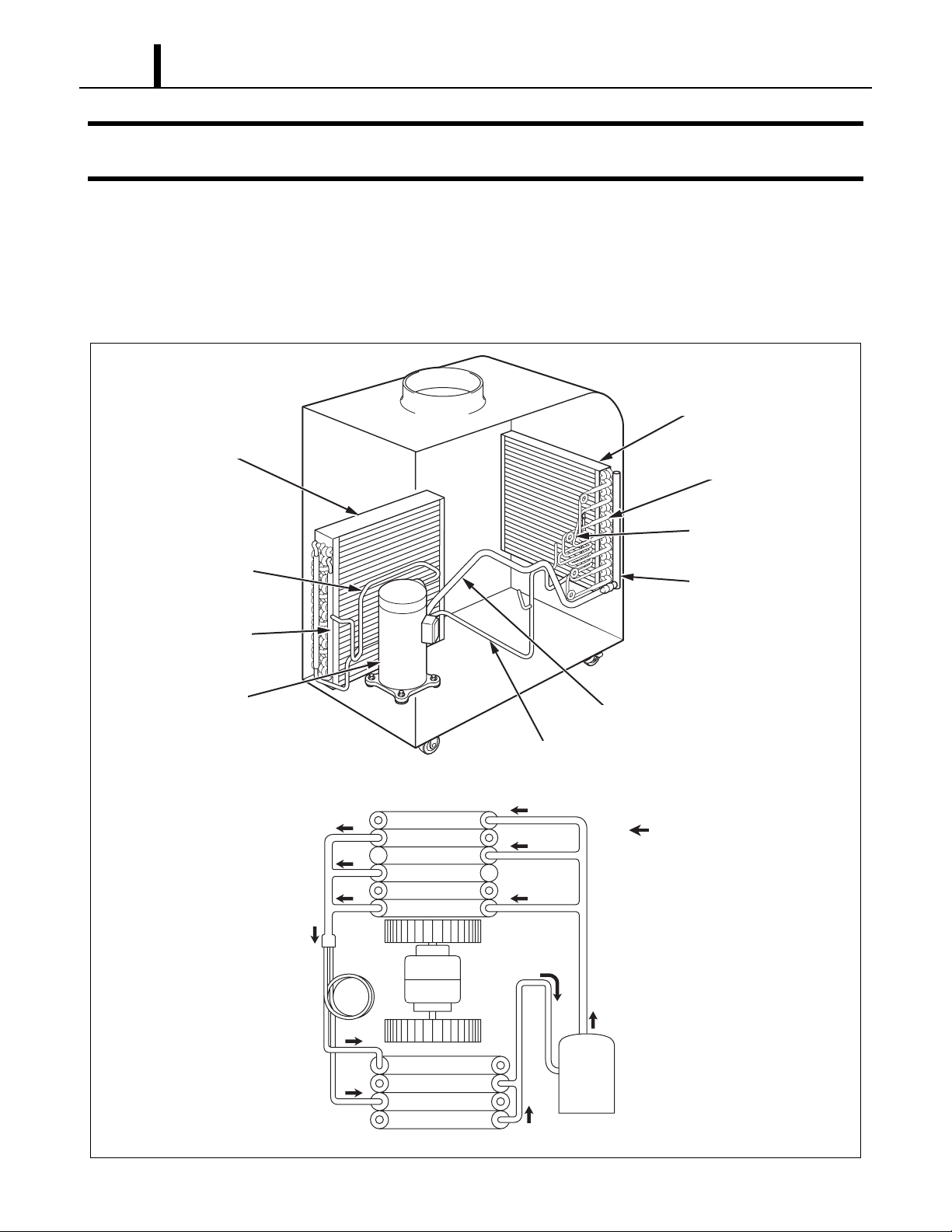

3.3 Internal Structure

Fan Motor

(Evaporator)

(Behind Fan)

Fan

(Evaporator)

Evaporator

High Pressure

Switch

Capillary Tube

Drain Pan

Fan

(Condenser)

TransformerCondensate Pump

3.4 Basic Construction

Compressor

Condenser

Fan Motor

(Condenser)

Drain Switch

Control Box

I001950

• The MovinCool Office Pro 63 is compact in construction because the condenser and the

evaporator are enclosed in one unit. The interior is divided into three sections. The upper front

face is equipped with the evaporator, and the lower front face contains the condensate pump

and optional drain tanks. The rear section contains the condenser, the compressor, the

transformer and the control box.

Operation Section

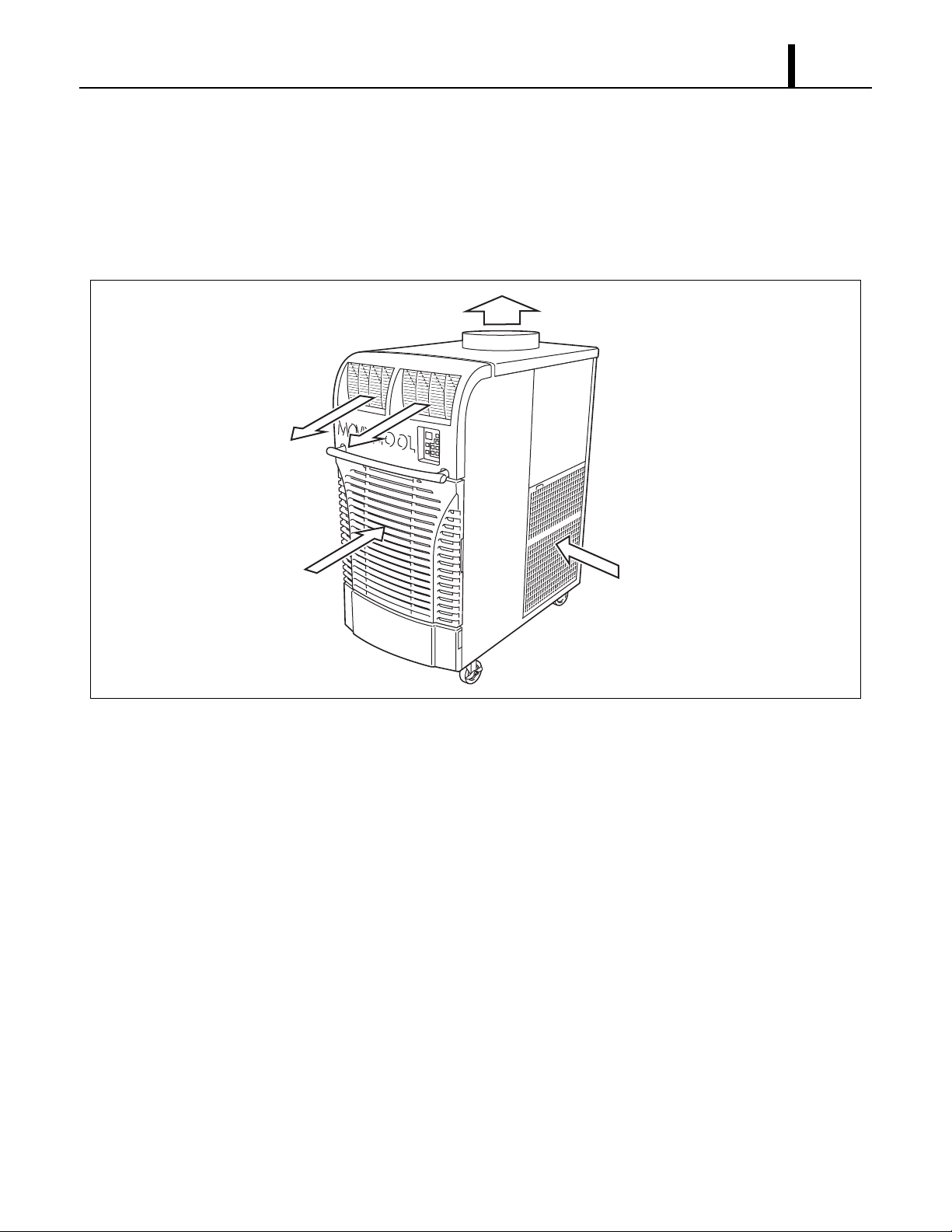

3.5 Air Flow

• Air drawn from the right side face passes through the condenser which extracts the heat. This

hot air is blown out through the upper exhaust air duct. Air taken in from the front face is cooled

by the evaporator and then blown through the cool air vent. All the air inlets are equipped with

filters, and the exhaust air duct is protected by metal grill.

Exhaust Air Out

Cool Air Out

11

Evaporator Air In

Condenser Air In

3.6 Electrical System

• The MovinCool Office Pro 63 is equipped with a compressor operated at 460 V, 3 phase and a

dry-type distribution transformer operated 460 V, single phase at primary side and 230 V single

phase at secondary side which supply power source for fan motors, relay board, and

condensate pump.

3.7 Compressor and Fans

• The compressor is hermetically sealed. Two sets of a two-speed fan motor with a centrifugal fan

are used to draw air across the evaporator and condenser.

I001909

3.8 Transformer

• The transformer is a dry-type distribution transformer rated 5 KVA at 460 V primary side and

230 V secondary side.

12

Operation Section

3.9 Condensate Pump

• The condensate pump and a 20 ft (6 m) drain hose are included with the Of fice Pro 63 to provide

continuous operation without the need of the drain tanks. The co ndensate pump has a maximum

head lift of 17 ft (5.2 m) at system operated voltage of 460 VAC.

3.10 Drain Tanks (optional)

• A set of two 5.0 gal (19 L) drain tanks are supplied as optional accessory for Office Pro 63. When

drain tanks are used instead of condensate pump , the condensate (water) is collected into both

tanks. The drain switch activates and stops the operation when tanks reach the level of

approximately 8.0 gal (30 L).

Operation Section

4. SPECIFICATIONS

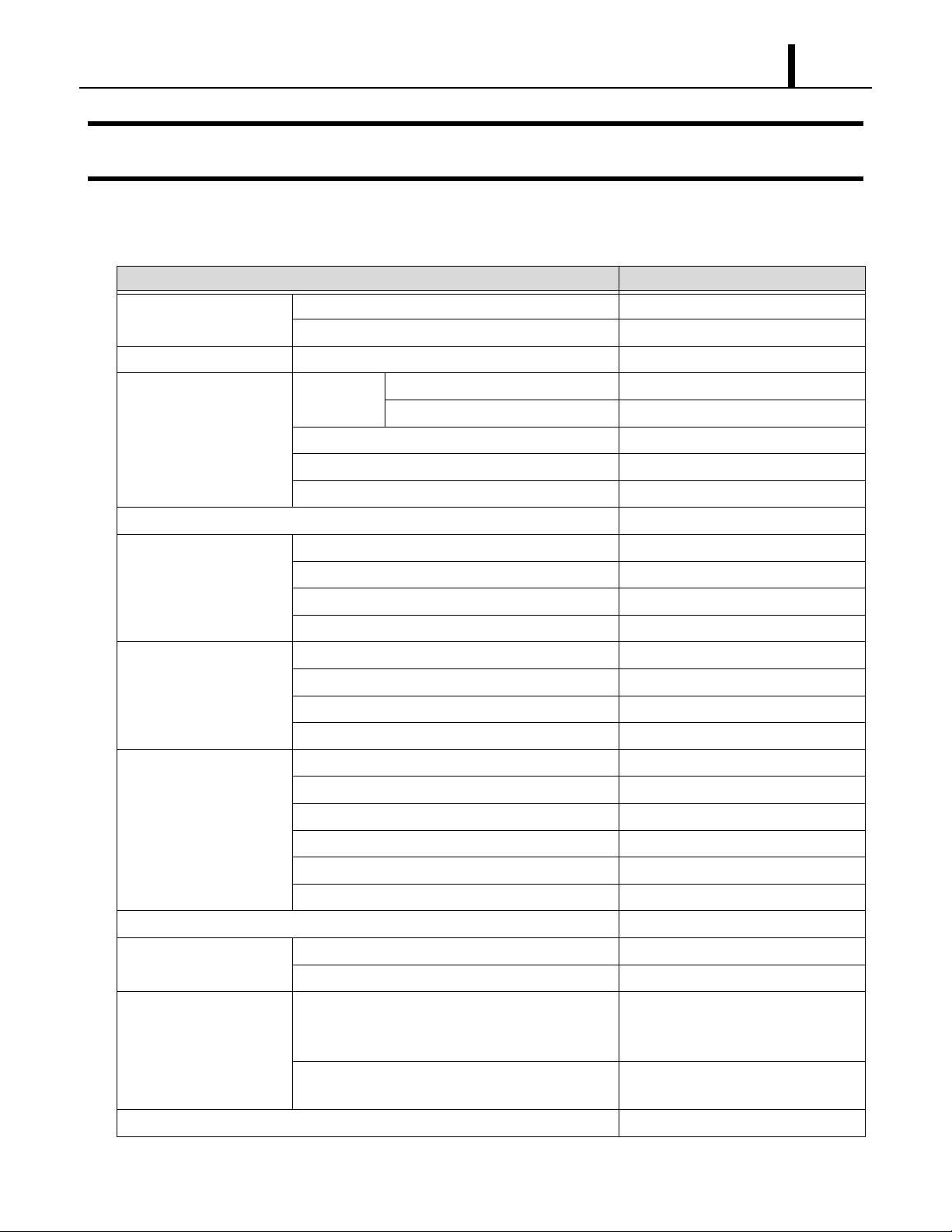

4.1 Technical Specifications

ITEM SPECIFICATIONS

Electronic Features Control Panel Electronic

Thermostat Control Electronic

Cooling Capacity

Refrigerant Circuit Compressor Compression Type Hermetic Scroll

*1

Capacity 60000 Btu/h (17585 W)

Motor Rated Output at 460 V 3.89 kW

Evaporator Plate Fin

Condenser Plate Fin

Refrigerant Control Capillary Tube

13

Refrigerant/Enclosed quantity R-410 A/4.41 lb (2.00 kg)

Ventilation Equipment For

Evaporator

Fan Type Centrifugal

Max. Air Flow-high/low 1940/1770 CFM (3300/3000 m

Motor Rated Output-high/low at 230 V 0.60/0.33 kW

Max. External Static Pressure 0.9 IWG (224 Pa)

Ventilation Equipment For

Condenser

Fan Type Centrifugal

Max. Air Flow - high/low 2830/2650 CFM (4810/4500 m

Motor Rated Output-high/low at 230 V 1.2/0.92 kW

Max. External Static Pressure 0.85 IWG (212 Pa)

Electronic Characteristics Power Requirement 460 V, 3 PH, 60 Hz

MIN. MAX. Voltage MIN 414 V, MAX 506 V

Current Consumption

*1

Total Power Consumption

Power Factor

*1

*1

9.5 A

6.6 kW

87 %

Starting Current 65 A

Recommended Fuse size 20 A

Power Cord NEMA Plug Configuration L16-20

3

/h)

3

/h)

Gage x Length 12 AWG (4-core) x 6 ft

Signal Connection Fire Alarm Input • Dry contact type (recommended)

• No-Voltage Contact Input/Contact

resistance Less than 100 ohm

Warning Signal Output 2 A at 30 V (DC/AC) or less

(resistive load)

Net weight 705 lb (320 kg)

14

Operation Section

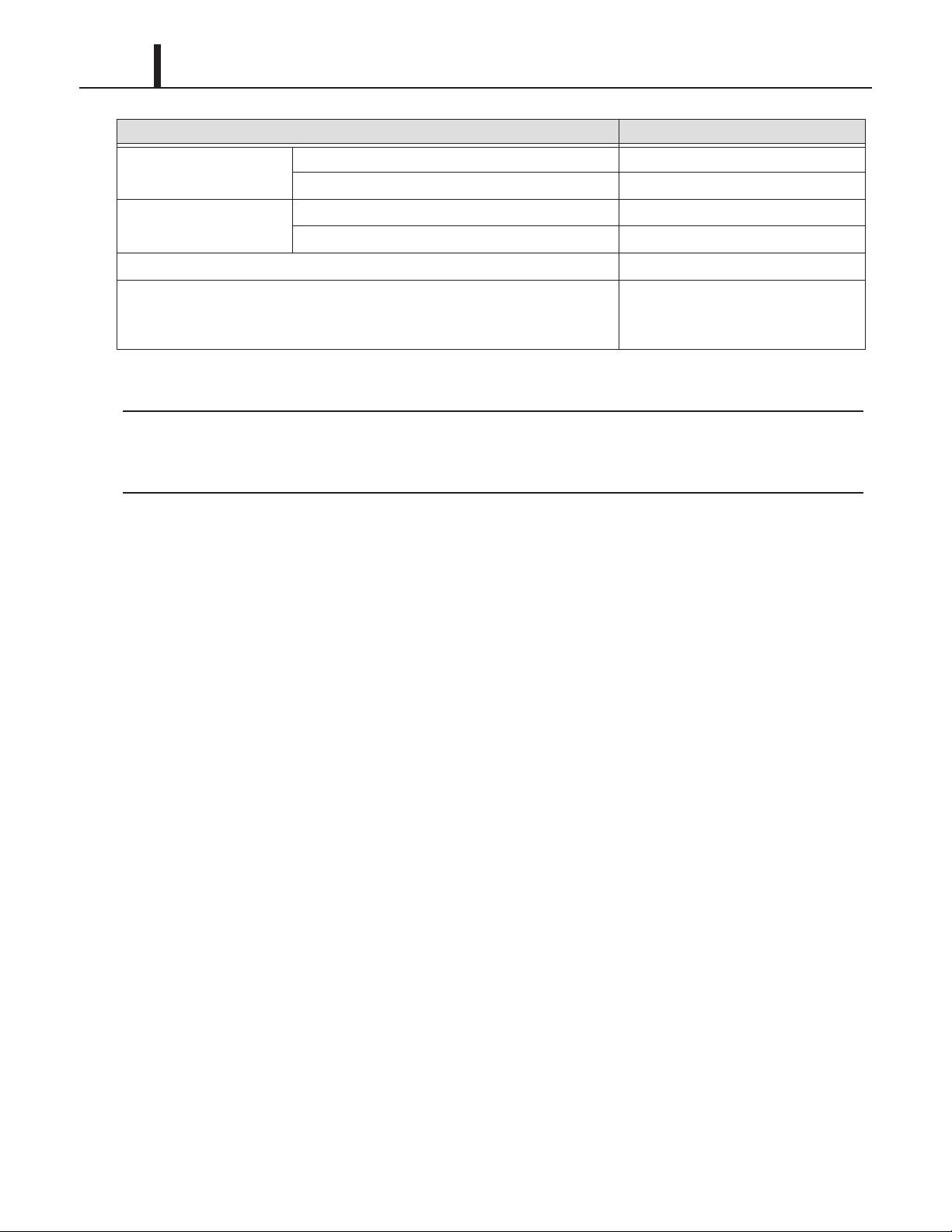

ITEM SPECIFICATIONS

Sound Level

Max. Duct Equivalent Length-Per Cold Duct )m 5.03/1.21( tf 001/04esoH tcuD toH/esoH

• Specifications are subject to change without notice.

< NOTE >

*1 :Rating Condition: 95 °F (35 °C), 60 %RH

*2 :Measured at 3.28 ft (1 m) from surface of unit.

*3 :Internal dry-type distribution transformer may produce a humming noise up to 31 dB(A) at maximum operated volt-

age (506 V) during stand-by state.

*2 *3

Discharge: 3/8 in (9.53 mm)

OD barbed

HR% 05 ,)C° 14( F° 501mumixaM :ria telnInoitidnoC gnitarepO

HR% 05 ,)C° 3.81( F° 56muminiM :ria telnI

)A(Bd 76/96wol/hgih-tcuD resnednoC htiW

)A(Bd 96/17wol/hgih-tcuD resnednoC tuohtiW

,W 57 ,A 5.0 ,V 032 ,PH 03/1pmuP etasnednoC

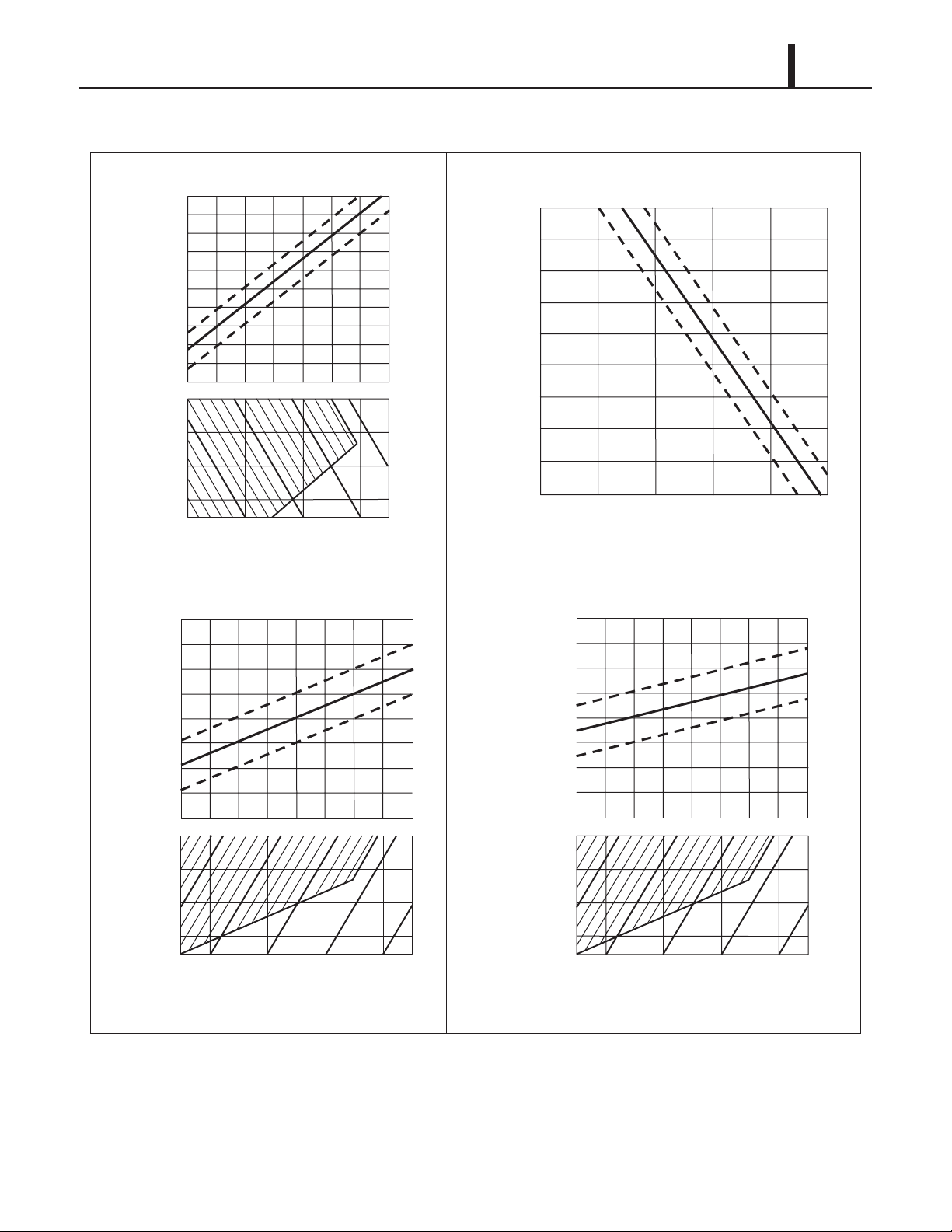

4.2 Characteristics

65

Btu/h)

60

3

Operation Section

15

>evruC ecnereffiD erutarepmeT riA looC<>evruC yticapaC gnilooC<

23.4(13)

21.6(12)

55

50

45

Cooling Capacity (x10

40

95(35)

86(30)

77(25)

68(20)

Dry Bulb Temp. °F (°C)

50

(10)

8.0

7.0

6.0

59

(15)

Wet Bulb Temp. °F (°C)

68

(20)

77

(25)

19.8(11)

18.0(10)

16.2(9)

14.4(8)

12.6(7)

Delta-T °F (°C)

10.8(6)

9.0(5)

7.2(4)

30 40 50 60 70 80

Relative Humidity (%)

>evruC noitpmusnoC tnerruC<>evruC noitpmusnoC rewoP<

12

10

8

5.0

Power Consumption (kW)

4.0

95(35)

86(30)

77(25)

68(20)

Dry Bulb Temp. °F (°C)

68

(20)

Wet Bulb Temp. °F (°C)

77

(25)

86

(30)

95

(35)

Current Consumption (A)

Dry Bulb Temp. °F (°C)

6

4

95(35)

86(30)

77(25)

68(20)

68

(20)

Wet Bulb Temp. °F (°C)

77

(25)

86

(30)

95

(35)

I001951

16

Operation Section

5. REFRIGERANT SYSTEM

5.1 Refrigerant System Construction

The component parts of the refrigerant system include the following:

• Compressor, Evaporator, Condenser, Capillary tube, High Pressure Switch

These parts are all connected by copper tubing. All the connections have been brazed.

Evaporator

Condenser

Evaporator Pipe

Compressor

Discharge Pipe

Condenser Inlet Pipe

Compressor

Capillary

Tubes

Condenser

Condenser

Fan

Evaporator

Fan

Capillary Tube

Evaporator Outlet Pipe

Compressor Suction Pipe

Condenser Outlet Pipe

Flow of Refrigerant

Evaporator

Compressor

I001952

Operation Section

5.2 Compressor

• The compressor used for the unit is hermetically sealed. The compressor and the compressor

motor are in one casing.

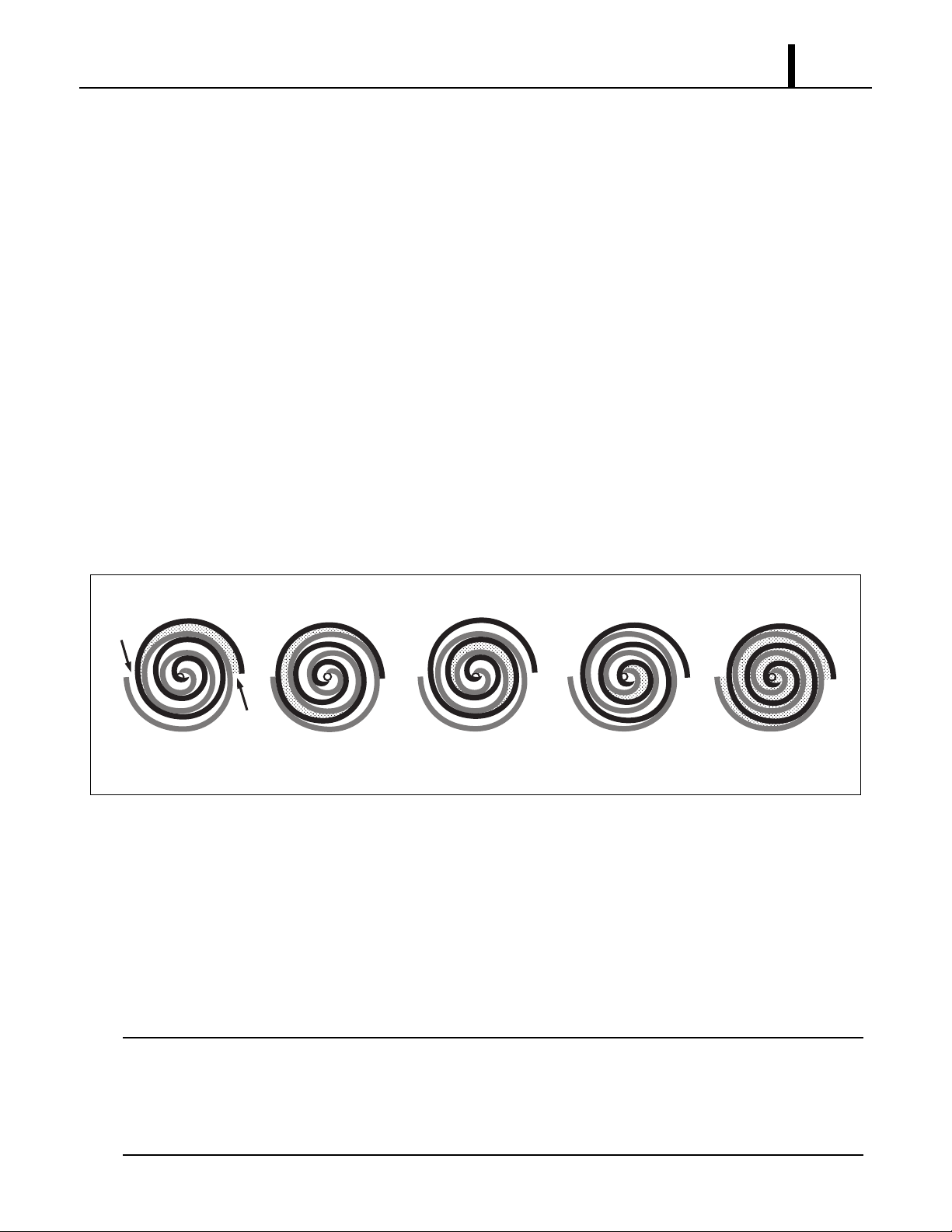

(1) Compressor theory of operation

• The scroll utilizes an involuted spiral which, when matched with a mating scroll form, generates

a series of crescent-shaped gas pockets between the two members. During compression, one

scroll remains stationary (fixed scroll) while the other form (orbiting scroll) is allowed to orbit (but

not rotate) around the first form. As this motion occurs, the pockets between the two forms are

slowly pushed to the center of the two scrolls while simultaneously being reduced in volume.

When the pocket reaches the center of the scroll form, the gas, which is now at a high pressure,

is discharged out of a port located at the center. During compression, several pockets are being

compressed simultaneously , resulting in a very smooth process. Both the suction process (outer

portion of the scroll members) and the discharge process (inner portion) are continuous.

17

(2) Compressor operation

1㧕 3㧕 4㧕 5㧕2㧕

I001767

1) Compression in the scroll is created by the interaction of an orbiting spiral and a stationary spiral.

Gas enters the outer openings as one of the spirals orbits.

2) The open passages are sealed off as gas is drawn into the spiral.

3) As the spiral continues to orbit, the gas is compressed into two increasingly smaller pockets.

4) By the time the gas arrives at the center port, discharge pressure has been reached.

5) Actually, during operation, all six gas passages are in various stag es of compression at all times,

resulting in nearly continuous suction and discharge.

< NOTE >

When the compressor shuts off, the compressor motor may run backward for a moment or two

until internal pressures is equalized. This has no effect on compressor durability but may cause

an unexpected sound after the compressor is turned off and should not be diagnosed as a

malfunction.

18

Operation Section

5.3 Condenser

• The condenser is a heat exchanger with copper tubes that are covered with thin aluminum

projections called plate fins.

• Heat is given off and absorbed by air being pulled across the condenser fins by the centrifugal

fan and then expelled through the exhaust air duct.

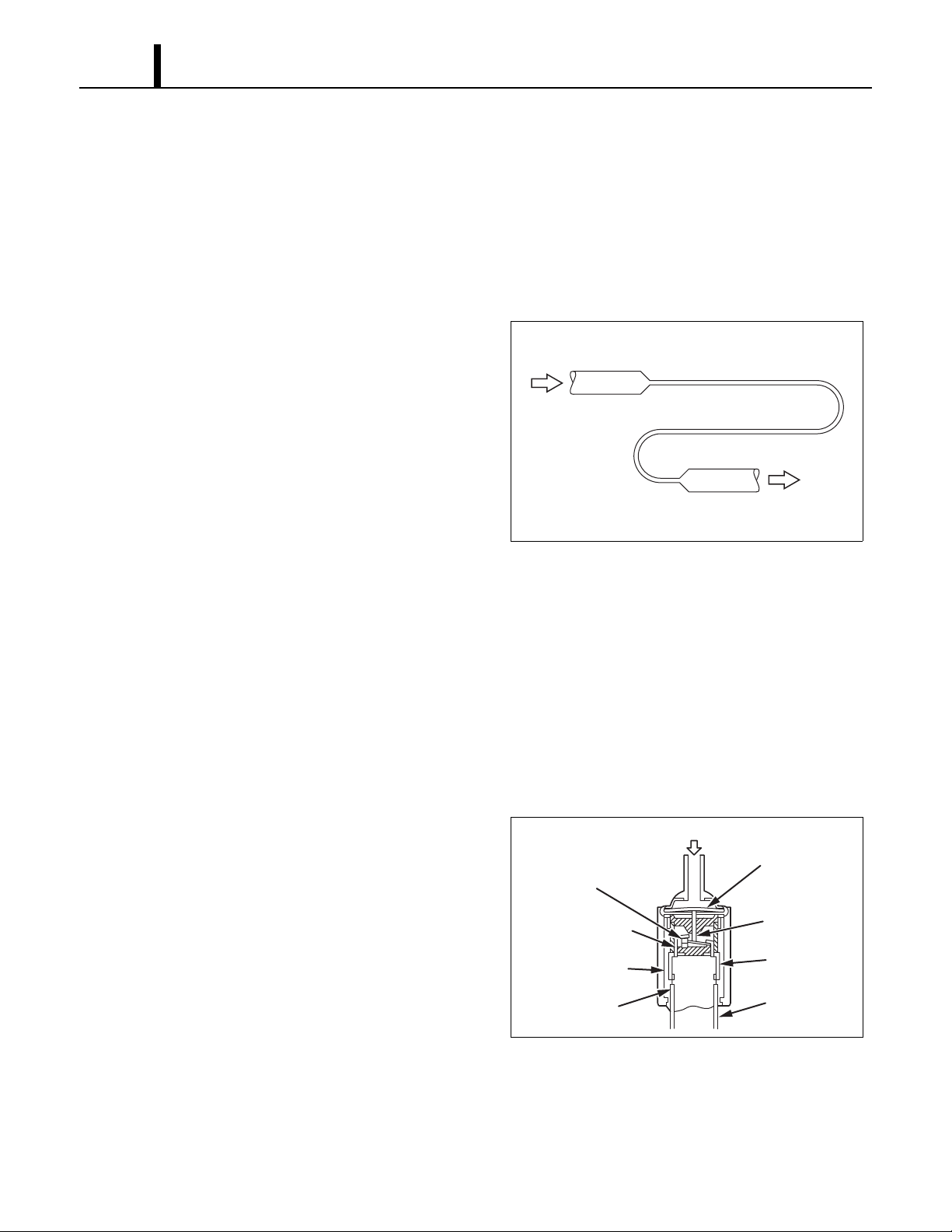

5.4 Capillary Tube

• The capillary tube is a long thin tube utilizing

line flow resistance to serve as an expansion

High Temp./High Pressure

Liquid Refrigerant

valve. The length and the inner diameter of the

capillary tube are determined by the capacity of

the refrigeration system, specified operating

conditions, and the amount of refrigerant. The

capillary tube causes the high pressure, high

temperature liquid refrigerant sent from the

Low Temp./Low Pressure

Gas and Liquid Mixture

condenser to expand rapidly as the refrigerant

is sprayed out through the fixed orifice in the capillary tube. As a result, the temperature and

state of the refrigerant becomes low and mist-like respectively, causing it to evaporate easily.

5.5 Evaporator

• The evaporator, like the condenser , is a heat exchanger covered with plate fins. Heat is removed

from the air being pulled across the evaporator by the centrifugal fan and the resulting cool air

is expelled through the cool air vent.

I001887

5.6 High Pressure Switch

• The high pressure switch prevents the

condenser and compressor from being

damaged by excessively high pressure in the

Movable Point

high pressure line of the refrigeration cycle.

The switch is normally closed. The snap disk

Stationary Point

responds to the variations in pressure and, if

pressure is abnormally high, the snap disk

moves down to push the pin down, causing the

Molding by Resin

internal contacts to open. This interrupts the

ground signal at the control board (J104 connector) which turns the compressor off.

• Possible causes of this trouble include:

- The condenser air filter is dirty, restricting air flow.

- The condenser blower is defective.

Pressure of Refrigerant

Case

Snap Disk

Pin

Terminal

Lead Wires

I001768

6. ELECTRICAL SYSTEM

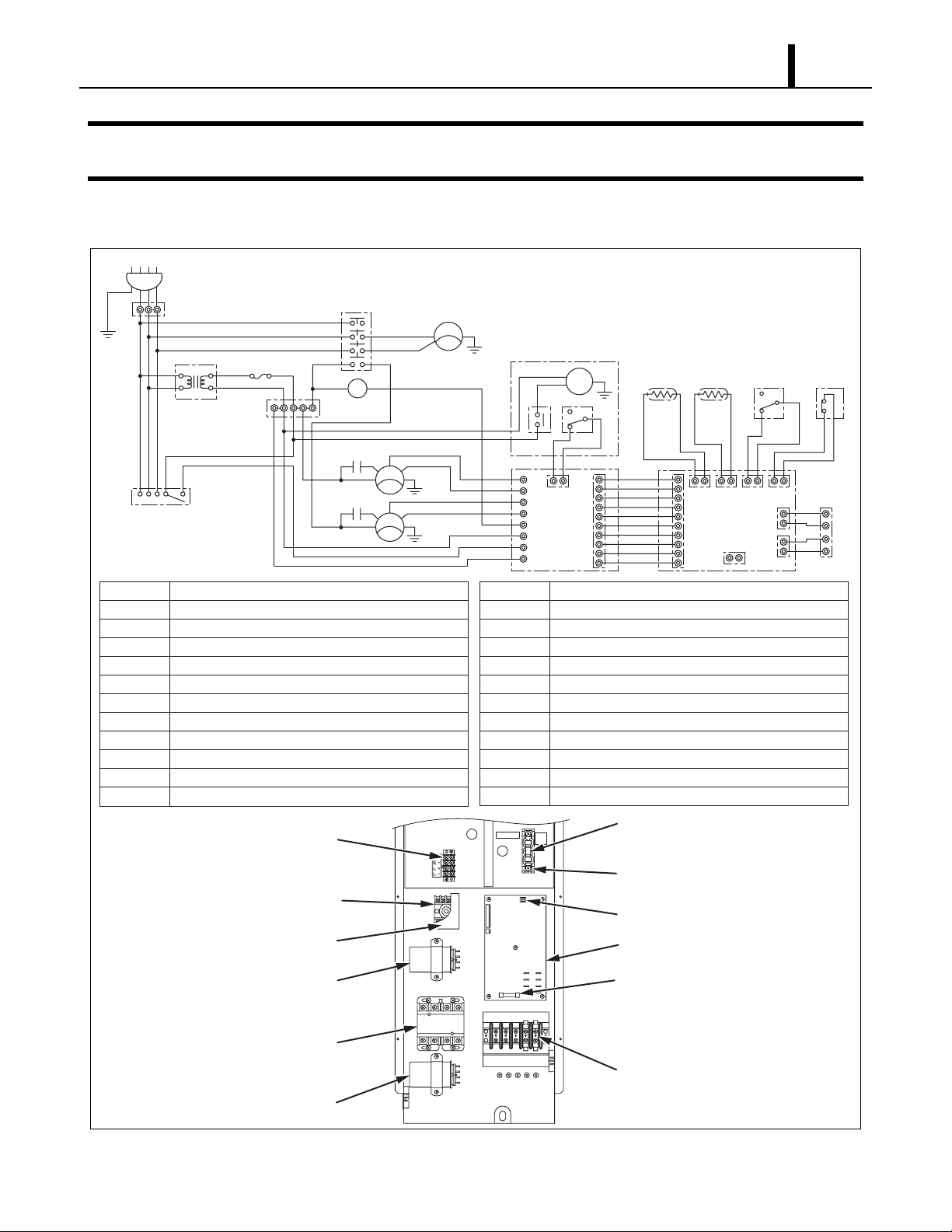

6.1 Circuit Diagram and Control Box

AC460 V 3 φ 60 Hz

AP

TSR

G

G

TB1

460 V 230 V

HI

H4 X1

345 1 8

RPHR

TNS

X4

F

1

2

S1 R1

1L1

3L2

5L3

7L4

A1 A2

TB1

MCC

MCC

CF2

12

CF1

12

2T1

4T2

6T3

8T4

HI

MF2

IOLF

HI

MF1

IOLF

LO

LO

MC

IOLC

G

G

G

J8

J7

J6

J5

J4

J3

J2

J1

Condensate Pump

MDP

ODS

FDS

J9

J10

RB

Operation Section

19

G

RTH THS

J101 J102 J103 J104

J201

CB

DS HPRS

3

2

J106

J108

J105

1

TB2

LL+

EE+

AP

TB1

TB2

CB

RB

MF1

MF2

MC

CF1

CF2

RPHR

TNS

Attachment Plug

Terminal Block

Terminal Block

Control Board

Relay Board

Condenser Fan Motor

Evaporator Fan Motor

Compressor Motor

Capacitor for Condenser Motor

Capacitor for Evaporator Motor

Phase Reversal Relay

Transformer

Terminal Block

(Signal Connection)

Terminal Block

(Reverse Phase Protector)

Reverse Phase Protector

Fan Capacitor

(Evaporator)

TB2

TB1

IOLF

IOLC

DS

THS

RTH

G

HPRS

MCC

MDP

FDS

ODS

F

FUSE 25A

Inner Overload Relay of Fan Motor

Inner Overload Relay of Compressor

Full Drain Warning Switch

Freeze Protection Thermistor

Room Thermistor

Grounding

High Pressure Switch

Relay for Compressor and Condenser Fan Motor

Condensate Pump Motor

Drain Float Switch

Drain Overflow Switch

Fuse (25 A)

Fuse

(for Transformer)

Fuse Holder

Dip Switch

Relay Board

Relay Board Fuse

Relay

Fan Capacitor

(Condenser)

G

Terminal Block

I001953

20

Operation Section

6.2 Basic Operation of The Office Pro 63 Electrical Circuit

• There are three basic components used to control the operation of the Office Pro 63 electrical

system:

- Transformer

- Control panel assembly

- Control box

• The control panel assembly contains the control panel, control board (with inputs for the freeze

and room temperature thermistors), drain switch, high pressure switch and a microprocessor.

(1) Fan mode

High Fan Mode

• When the FAN MODE button on the control panel is pressed, the microprocesso r turns on “F AN

HI” “COOL OFF” indication of LCD and activates both the fan on relay and fan mode relay. This

sends line voltage (230 VAC) from the fan on relay to the N.O. (normally open) contacts of the

fan mode relay. This output is connected to the J8 terminal (relay board) where the high speed

wire of the fan motor is connected.

• When this button is pressed again, fan turns to low mode (see below). Press again, fan stops.

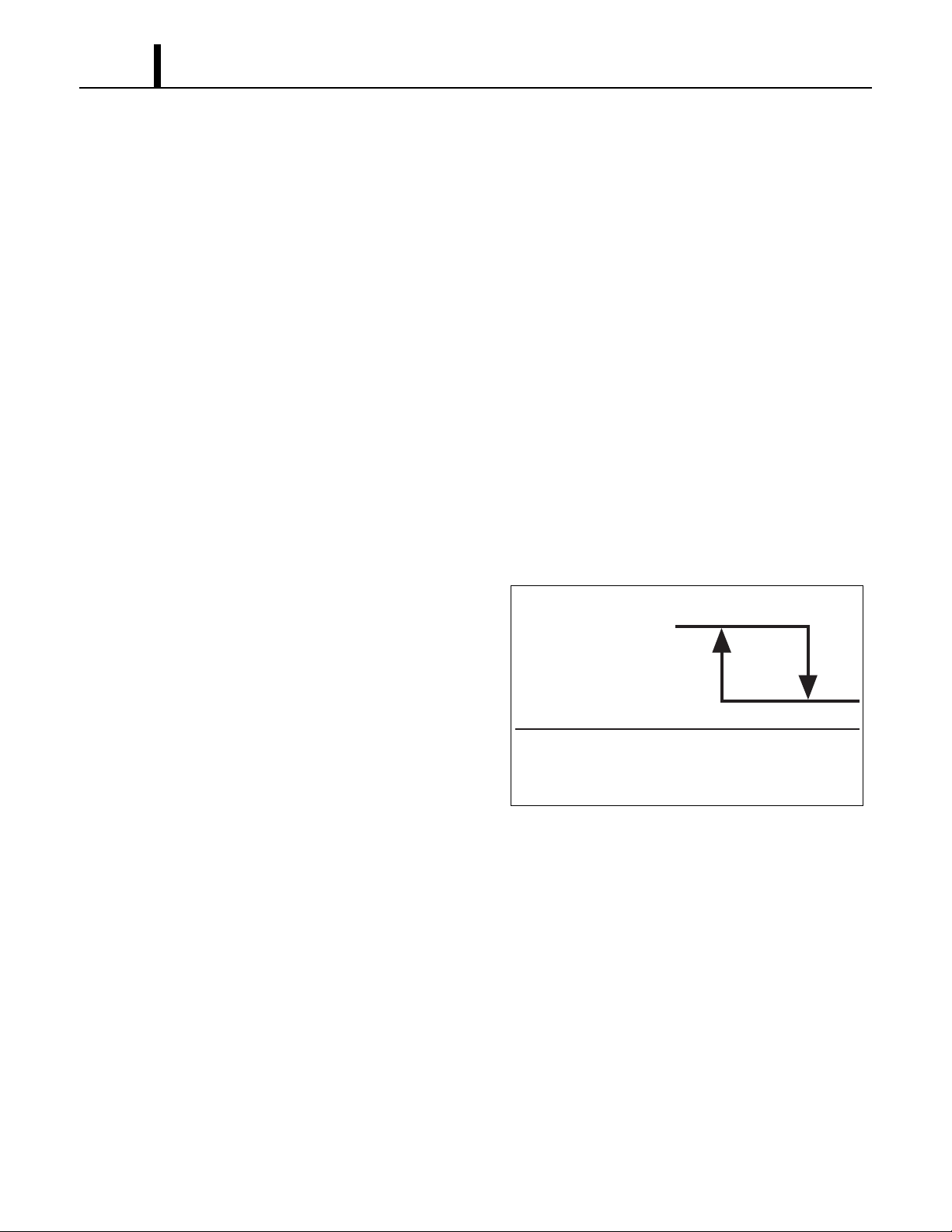

• High fan mode is automatically switched

depending on room temperature. When room

(High)

temperature is decreased down to 80 °F

(27 °C) or below, fan mode is switched to

Condenser Fan

HIGH. When room temperature is increased to

88 °F (31 °C) or higher, fan mode is switched

from HIGH to LO.

Room Temperature

(LO)

80 °F

(27 °C)

88 °F

(31 °C)

I001914

Low Fan Mode

• When the FAN MODE button on the control panel is pressed again, th e microprocessor turns on

“FAN LO” “COOL OFF” indication of LCD and activates both the fan on relay and fan mode relay.

This sends line voltage (230 VAC) from the fan on relay to the N.C. (normally closed) contacts

of the fan mode relay. This output is connected to the J7 terminal (relay board) where the low

speed wire of the fan motor is connected.

• When this button is pressed again, fan stops.

Operation Section

(2) Cool mode

• In addition to fan mode (as described above), when the COOL ON/OFF button on the control

panel is pressed, the microprocessor turns on “COOL ON” indication of LCD and if the

temperature set point is less than the current room temperature, activate s the compressor relay

(relay board) after 120 sec delay. This sends line voltage (230 VAC) to the J4 terminal (relay

board) and compressor auxiliary relay is excited. Then compressor and condenser fan motor

turn on (Cooling Operation).

• Condenser fan mode is automatically switched

21

depending on room temperature. When room

temperature is approximately. 100 °F (38 °C)

or greater, fan mode is switched LO to HIGH.

When room temperature is approximately.

95 °F (35 °C), fan mode is switched HI to LO.

(LO)

Condenser Fan

(High)

Room Temperature

95 °F

(35 °C)

100 °F

(38 °C)

I001915

22

Operation Section

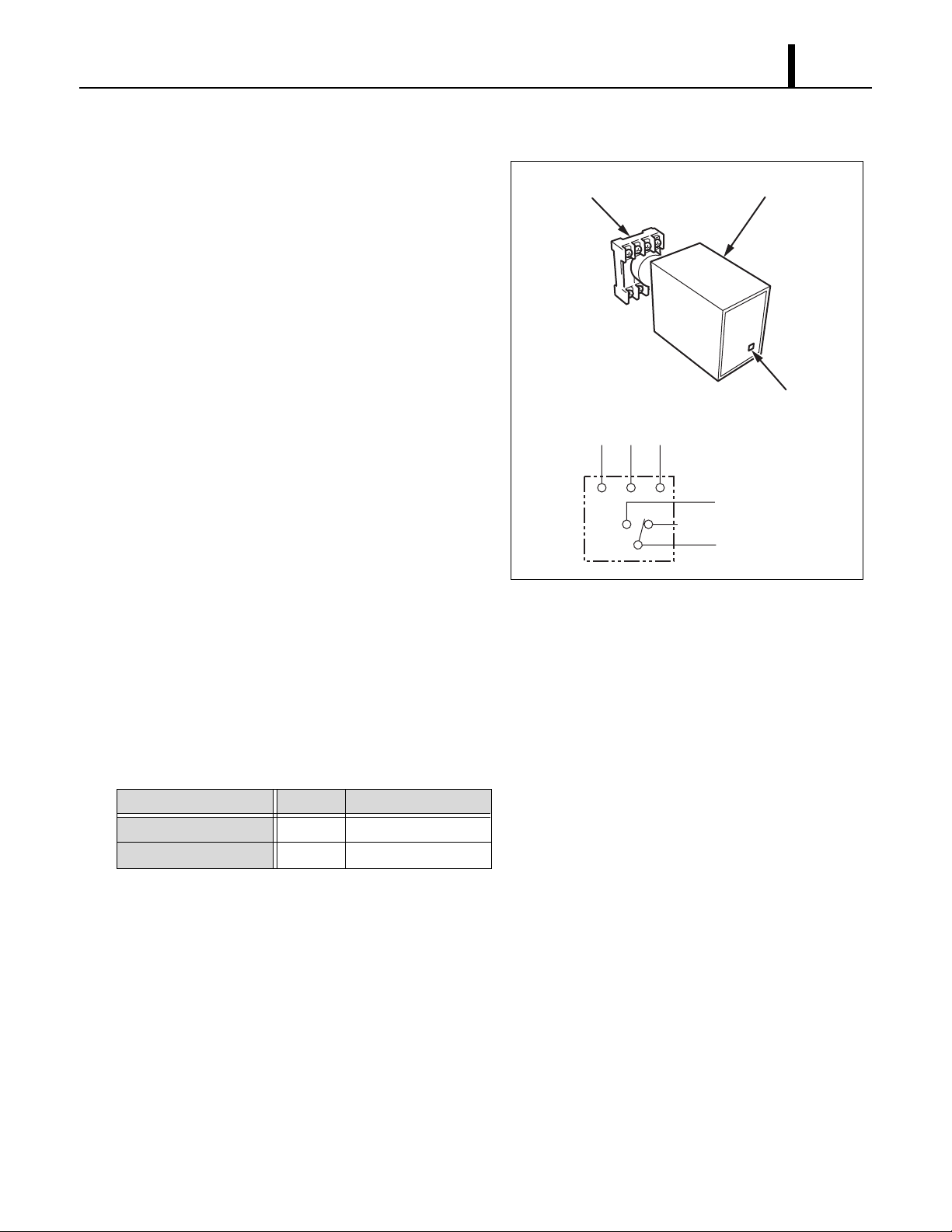

6.3 Transformer

• A dry-type transformer rated 5 KVA is equipped

within the unit to provide step down voltage

from 460 V single phase to 230 V single phase.

• The terminal connection of the primary side of

the transformer are labeled H1, H2, H3, and

H4. Terminals H2 and H3 are shorted together

to provide a series connection for 460 V

application. Terminals H1 and H4 are

connected to 460 V power source to supply

power to secondary side.

• T erminals X2 and X3 of the secondary side are

also shorted together to provide 230 V output

between terminals X4 and X1.

Specifications:

Distribution transformer

- Type: Dry type

- Rated VA: 5000 VA

Terminal Block

(Primary)

Coil

<Wiring Diagram>

Primary

(460 V)

Secondary

(230 V)

H1

Short Circuit

H3 H2 H4

Short Circuit

Terminal Block

(Secondary)

X1X2 X3X4

I001954

- Power Requirement: 1 PH, 60 Hz

- Primary Voltage: 460 V

- Secondary voltage: 230 V

6.4 Control Box

(1) Reverse Phase Protector

• The Reverse Phase Protector is operated at

nominal voltage of 440 VAC to 480 VAC.

The reverse phase protector is mounted on a

plug-in socket terminal block where it can

easily be plugged-in or removed during

service.

• The internal relay of a reverse phase protector

Terminal Block

Operation Section

23

Reverse Phase Protector

is energized and LED is on when the phase

sequence is correct. If the phases are reverse,

<Wiring Diagram>

RST

Power Source

LED

the out put relay will not energize.

3

45

• The reverse phase protector is reset

8

automatically upon correction of the fault.

Specifications:

- Rated Line Voltage: 440/480 V

to J2

(Normally Closed)

2

to TB1 R1

1

- Rated Output: 8 A resistive at 240 V

- Mounting: Plug-in socket (8 pin, octal plug)

(2) Capacitors

• The capacitors are used to temporarily boost the power output available to the fan motor at

start-up.

• The specifications of each capacitor are listed below:

Capacitor Application Voltage Rating Capacitance

Evaporator Fan Motor 440 VAC 15 µF

Condenser Fan Motor 370 VAC 25 µF

I001955

24

Operation Section

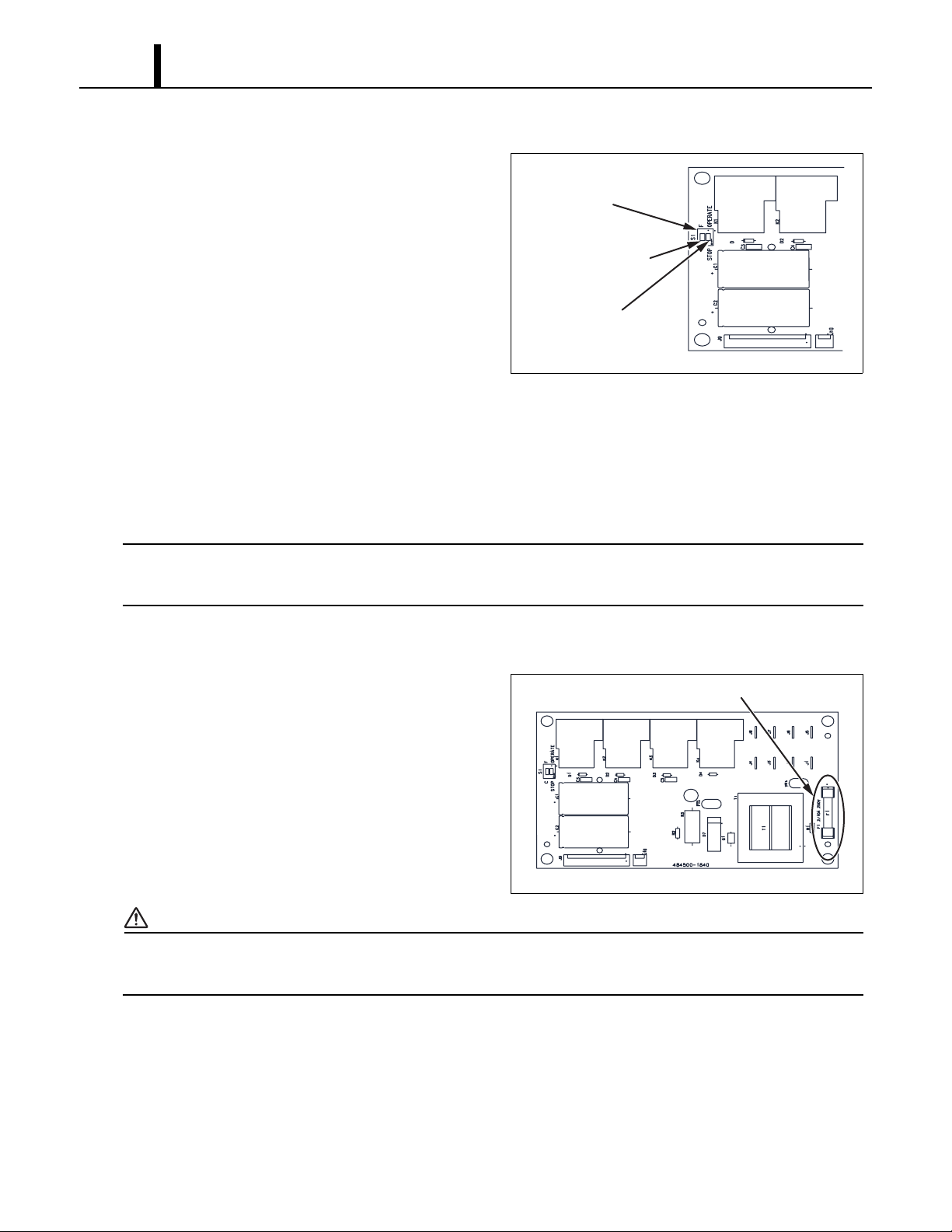

(3) Relay board

• The relay board receives signals and outputs

<Dip Switch>

from the control board that contains a

microprocessor. The relay board contains the

Dip Switch

compressor, fan on and fan mode (speed)

relays.

• It also contains a step-down transformer that

converts the line voltage (230 VAC) to 12 V.

• This 12 V is then converted from AC to DC and

Temperature Scale

Display Switch

(°C⇔°F)

Fan Mode Control

Switch

(STOP⇔OPERATE)

I001772

used for relay coil activation. The 12 V (DC)

power is sent to the control panel assembly where it is further reduced to 5 V for the system logic.

• The relay board also contains the DIP switch.

• The DIP switch is used to change the fan mode operation from stop to operate and change both

the set point and room temperature display from Fahrenheit to Celsius.

< NOTE >

The relay board must be serviced as a complete assembly. It has only one serviceable

component, the fuse. (see below)

(4) Relay board fuse

• This fuse provides protection against damage

to the step-down transformer. It must be

replaced with the exact type of fuse or an

equivalent.

Specifications:

- 2/10 A, 250 V

<Relay Board>

Fuse

CAUTION

Failure to use the exact type of fuse could result in damage to the unit and/or to components. It

could also void the warranty of the unit.

I001773

Loading...

Loading...