MovinCool CMW30 User Manual

OPERATION MANUAL

CMW30

Unit Serial Number Range: 0311XXXXCW3 to Present

(From March 2011 to Present)

READ THIS MANUAL CAREFULLY FOR INSTRUCTIONS ON CORRECT

INSTALLATION AND USAGE, AND READ ALL SAFEGUARDS.

SECCIÓN EN ESPAÑOL

SECTION EN FRANÇAIS

AVAILABLE AT WWW.MOVINCOOL.COM

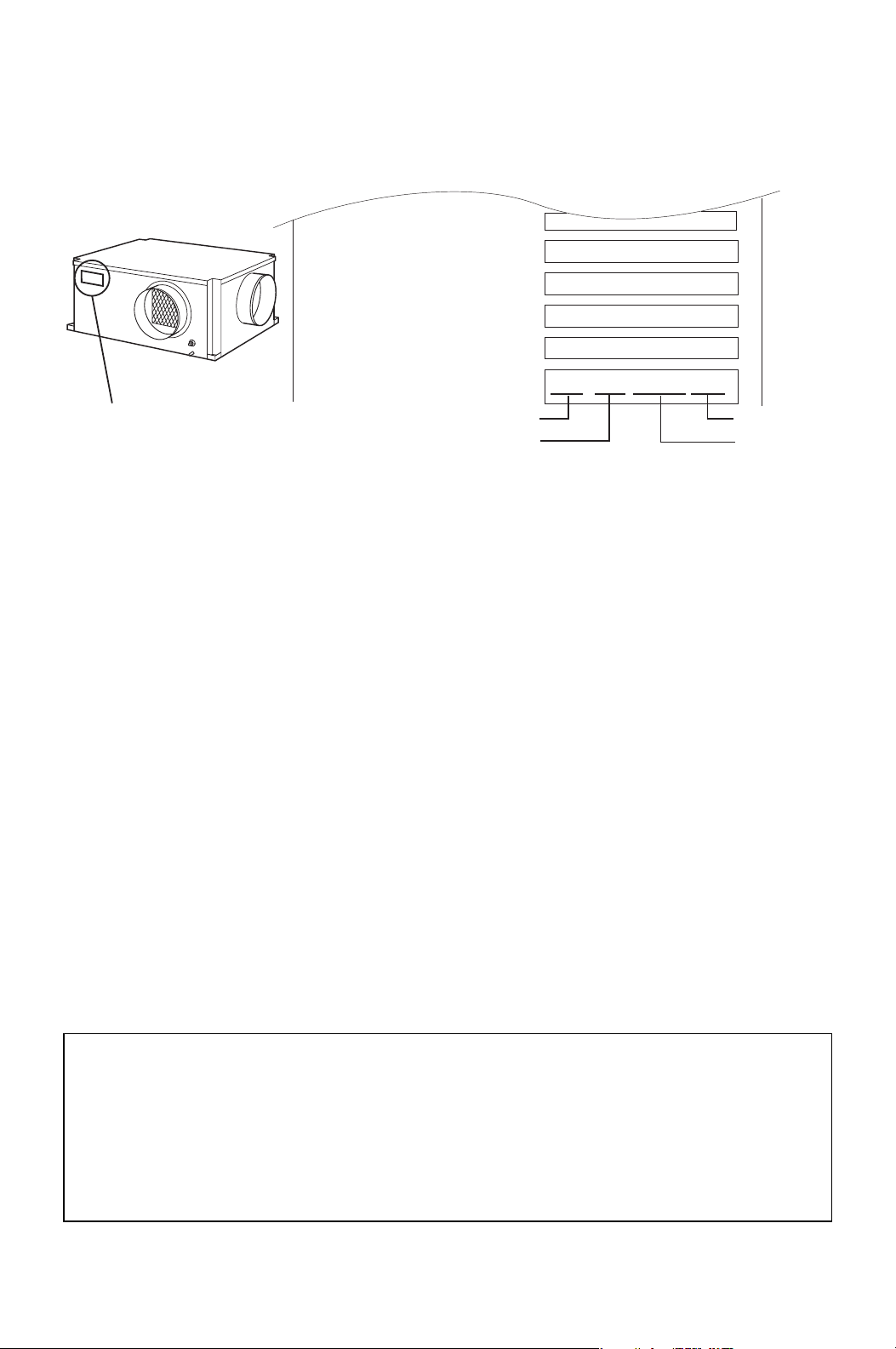

SERIAL NUMBER LOCATION AND IDENTIFICATION

Nameplate Label

COOLING AMPS. WITH PUMP

COMPR. OUTPUT

REFRIGERANT/TOTAL CHARGE

DESIGN PRESSURE LO/HI

PART NO./WEIGHT

Nameplate Label Position

SERIAL NO.

Month

Year

▲▲ XXXX ###

Model

Sequential

Number

© 2013 DENSO PRODUCTS AND SERVICES AMERICAS, INC.

All rights reserved. This book may not be reproduced or copied, in

whole or in part, without the written permission of the publisher.

DENSO PRODUCTS AND SERVICES AMERICAS, INC. reserves the

right to make changes without prior notice. MovinCool®, Office Pro®

and SpotCool® are registered trademarks of DENSO Corporation.

OPERATION MANUAL

CMW30

Table of Contents

SERIAL NUMBER LOCATION AND IDENTIFICATION ................................... 2

FOREWORD ...................................................................................................... 6

Definition of Terms................................................................................ 6

GENERAL WARNINGS & CAUTIONS..............................................................6

UNPACKING ...................................................................................................... 7

INVENTORY.......................................................................................................8

INSTALLATION ................................................................................................. 9

Unit Overview ........................................................................................ 9

Unit Dimensions and Clearance Requirement..................................10

Mounting CMW30 to Roof Structure.................................................. 11

Water Pipe Connection ....................................................................... 16

Drain Hose Connection....................................................................... 18

Packing Attachment ............................................................................21

Ducting With Typical Drop Ceiling..................................................... 21

Power Supply and Field Wiring Connection..................................... 22

DIP Switch Configuration and Setting...............................................24

Supplied Wall Mounted Controller Connection ................................ 26

Field-Supplied Millivolt Wall Thermostat Connection...................... 31

Warning Signal Connection (Output Signal)..................................... 34

Fire Alarm Connection (Input Signal)................................................ 35

FEATURES OF CMW30 .................................................................................. 37

FEATURES OF WALL MOUNTED CONTROLLER........................................ 37

OPERATION (Wall Mounted Controller ONLY) ............................................ 38

Control Panel ....................................................................................... 38

Standby Mode ...................................................................................... 41

Set Clock .............................................................................................. 41

Operate in COOL Mode ....................................................................... 42

Operate in FAN ONLY Mode ...............................................................43

Change Mode ....................................................................................... 43

Change Temperature Scale ................................................................ 43

Keypad Lock ........................................................................................ 43

Program Feature.................................................................................. 43

Program Setting ..................................................................................44

Select Program Sequence Number.................................................... 45

Set Start Time and Operation Mode................................................... 45

Set Stop Time ......................................................................................46

Exit Program Mode.............................................................................. 46

View Program ......................................................................................46

Edit Program ........................................................................................ 47

Delete Program .................................................................................... 47

Run and Stop Program ....................................................................... 47

Program Plan Sheet ............................................................................ 48

SELF-DIAGNOSTIC CODES & BUZZER PATTERN ...................................... 49

Self-Diagnostic Codes ........................................................................49

Buzzer Pattern ..................................................................................... 49

Table of Self-Diagnostic Codes.......................................................... 50

INSPECTION & MAINTENANCE..................................................................... 51

Cleaning Air Filters ............................................................................. 51

Ground Fault Breaker Testing............................................................ 51

Inspection of Water Lines and Connections..................................... 51

TROUBLESHOOTING ..................................................................................... 52

TECHNICAL SPECIFICATIONS...................................................................... 60

FOREWORD

Congratulations on purchasing the MovinCool air conditioner. This manual

explains how to assemble, install and operate the MovinCool CMW30 air

conditioning unit. Please read this operation manual thoroughly to familiarize

yourself with the features of the unit and to ensure years of reliable operation.

You may also find it useful to keep this operation manual on hand for reference.

Components and/or procedures are subject to change without prior notice.

Definition of Terms

WARNING: Describes precautions that should be observed in order

to prevent injury to the user during installation or unit operation.

CAUTION: Describes precautions that should be observed in order

to prevent damage to the unit or its components, which may occur

during installation or unit operation if sufficient care is not taken.

Note: Provides additional information that facilitates installation or unit operation.

GENERAL WARNINGS & CAUTIONS

1. All electrical work should only be performed by qualified electrical personnel.

Repair to electrical components by non-certified technicians may result in

personal injury and/or damage to the unit. All electrical components replaced

must be genuine MovinCool parts, purchased from an authorized reseller.

2. Installation should be conducted by qualified technician only. DENSO and

DENSO affiliate are not responsible for injuries and/or damages caused by

improper installation.

3. Disconnect power before any electrical installation. Beware that some residual

voltage may remain in the unit immediately after the power is disconnected.

4. The power supply for this unit should be a dedicated single outlet circuit with

UL recognized short-circuit and ground-fault protective breaker.

5. Do not place water or any other liquid on the unit. This can cause damage to

the unit and increase the risk of electrical shock.

6. Do not sit or stand on the unit.

7. Do not place hands or any object in the cool air outlet or exhaust duct.

Touching the fan, which is rotating at a high speed, is very hazardous.

8. Do not operate the unit without water connection or without supplied water.

9. Unit connects to water supply and water leakage may cause damage to the

equipment directly under the unit. Do not mount the unit over a sensitive

equipment or a field supplied secondary drain pan may be required under the

unit.

6

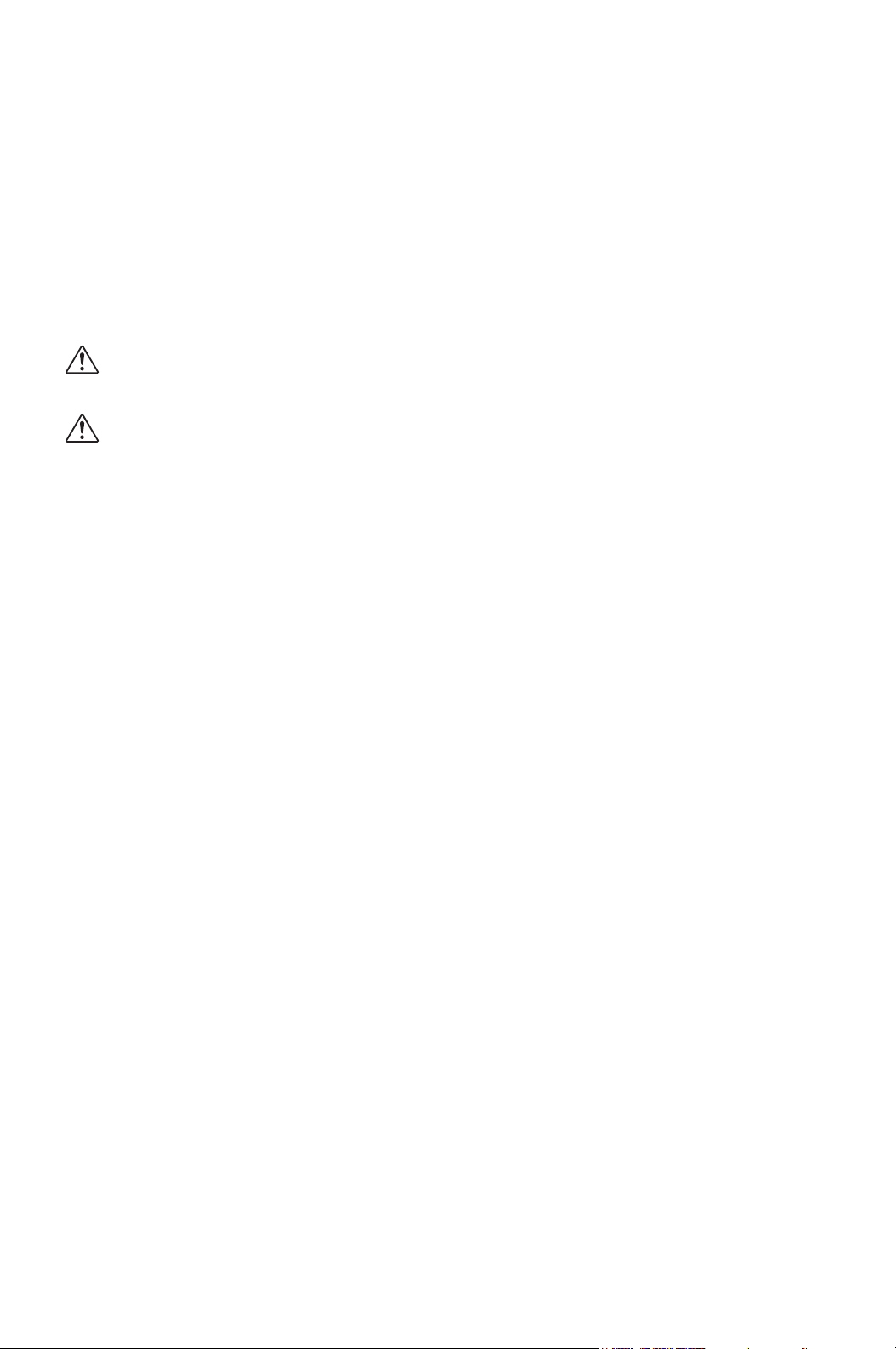

UNPACKING

Remove the package as shown below.

Note: The unit can be installed while the unit is on the pallet.

(See “Mounting CMW30 to Roof Structure” on page 11 to 13.)

PACKAGE

UNIT

PALLET

MOUNTING HOLES

ILL00251-00

7

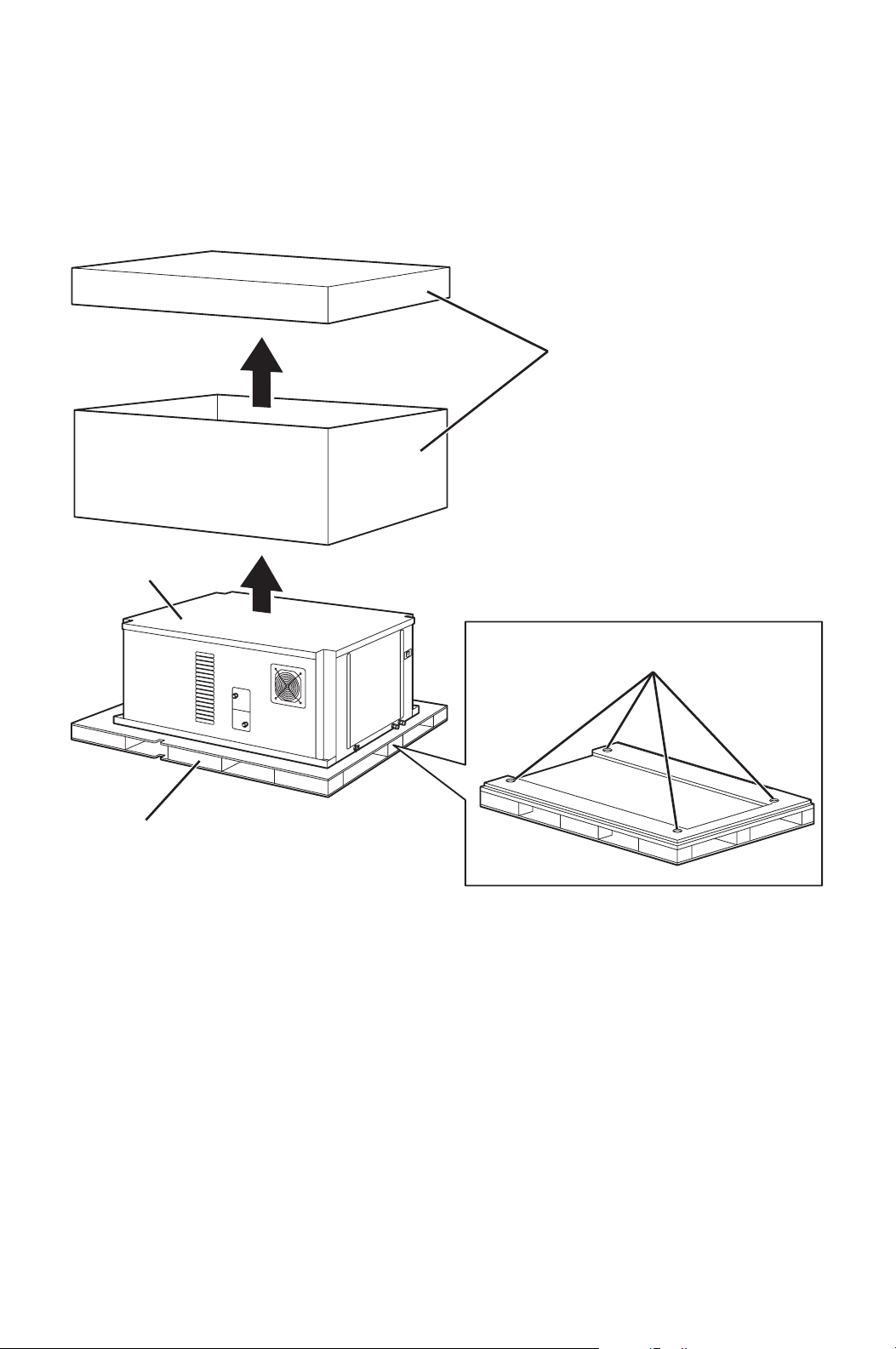

INVENTORY

After unpacking your MovinCool unit, please check to make sure you have the

following items:

1. CMW30 MovinCool Unit (1)

2. Operation Manual/Product

Registration (1)

3. Clip (1)

4. Packing (1)

Note: If any of these items were not included in the box or appear damaged,

please contact your MovinCool reseller for replacement.

CMW30 UNIT WALL MOUNTED CONTROLLER

5. Vibration Isolator (4)

6. Wall Mounted Controller (1)

7. Shield Wire (1)

8. Screw (4)

CLIP

VIBRATION ISOLATOR

SHIELD WIRE FOR WALL

MOUNTED CONTROLLER (12 ft)

SCREW FOR WALL

MOUNTED CONTROLLER

OPERATION MANUAL /

PRODUCT REGISTRATION

PACKING (1.8 × 43.9 × 0.2 in)

8

ILL00252-00

INSTALLATION

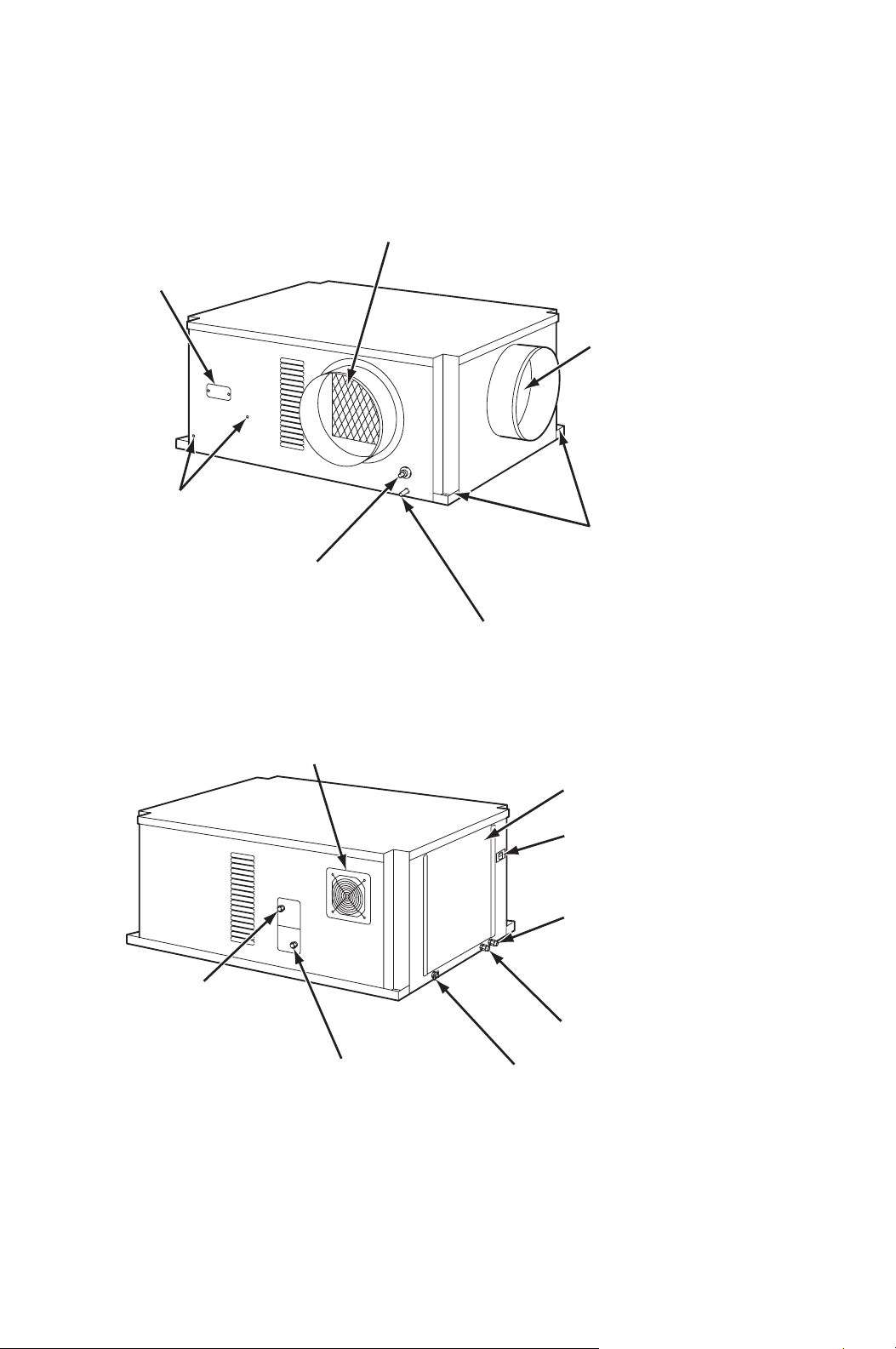

Unit Overview

COOL AIR EXHAUST

CONNECTION FOR

OPTIONAL

CONDENSATE PUMP

FIXING POSITION FOR

OPTIONAL

CONDENSATE PUMP

DRAIN PIPE FOR PUMP

(12.0 in. DIA. FLANGE)

EVAPORATOR (ROOM)

AIR INTAKE

(14.0 in. DIA. FLANGE)

MOUNTING HOLES

AC FAN MOTOR

WATER OUTLET

(3/4 in NPT FEMALE)

CONDENSATE PAN DRAIN

FOR GRAVITATIONAL DRAIN/MAINTENANCE

WATER INLET

(3/4 in NPT FEMALE)

ILL00253-00

SERVICE PANEL

STOP SWITCH

WALL MOUNTED

CONTROLLER/MILLIVOLT

WALL THERMOSTAT

WIRE INLET

SIGNAL WIRE INLET

POWER CORD INLET

ILL00254-00

9

INSTALLATION (cont.)

Unit Dimensions and Clearance Requirement

All dimensions are in inches.

Unit Weight: 236 lb (107 kg)

WALL

Minimum

clearance

5.0 inch

from wall

31.5

29.8

45.4

43.7

DIA. 0.6

3.9

Minimum

clearance

20.0 inch

from wall

Top of the unit should not contact

any building structure or object.

DIA. 12.0

WALL

CEILING

14.4

14.4

16.0

3.9

DIA. 14.0

6.5

10

0.6

20.0

10.7

4.0

ILL00255-00

INSTALLATION (cont.)

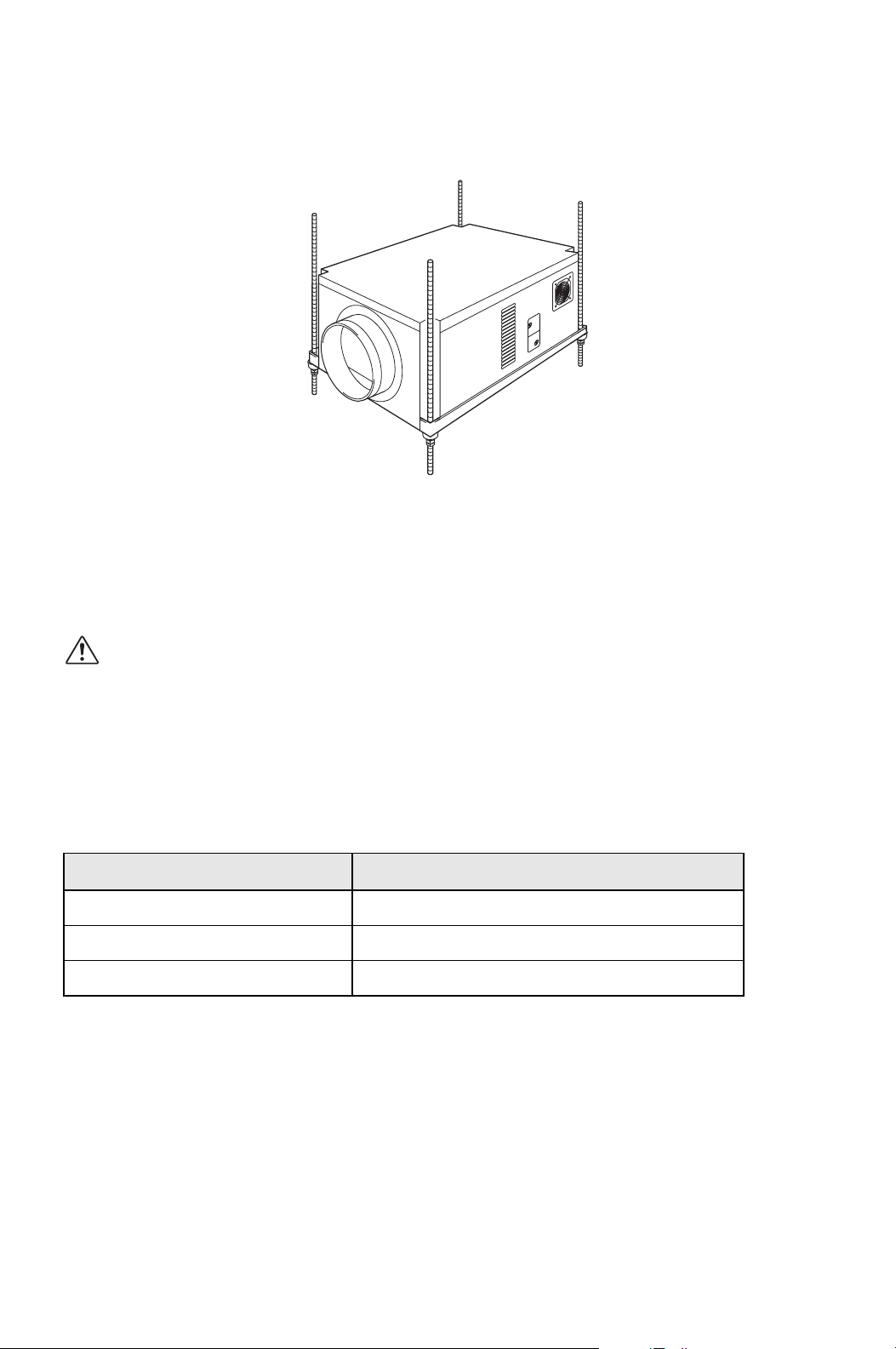

Mounting CMW30 to Roof Structure

ILL00256-00

Be sure to securely anchor the top ends of the suspension rods. Make sure all nuts

are tight. Be sure to follow all applicable codes.

The unit is usually mounted above the ceiling and must be securely mounted to

the roof structure. The ceiling support of the existing building may require

reinforcements.

WARNING: Make sure the supporting roof structure is capable of

supporting the weight of the unit, mounting hardware and the

accessories. Roof structure should be able to support four times of

total weight or more. Unit weight is 236 lb (107 kg).

The recommended clearance between ceiling grids and building structural

member is the unit height plus 3.0 inch (76 mm).

All mounting hardware except vibration isolators is field supplied.

Use the following hardware.

Hardware (Quantity) Size

Threaded suspension rod (4) 1/2 in (Min. 236 lb (107 kg) load capability)

Nut (12) 1/2 in

Washer (4) 1/2 in

11

INSTALLATION (cont.)

Mounting CMW30 to Roof Structure (cont.)

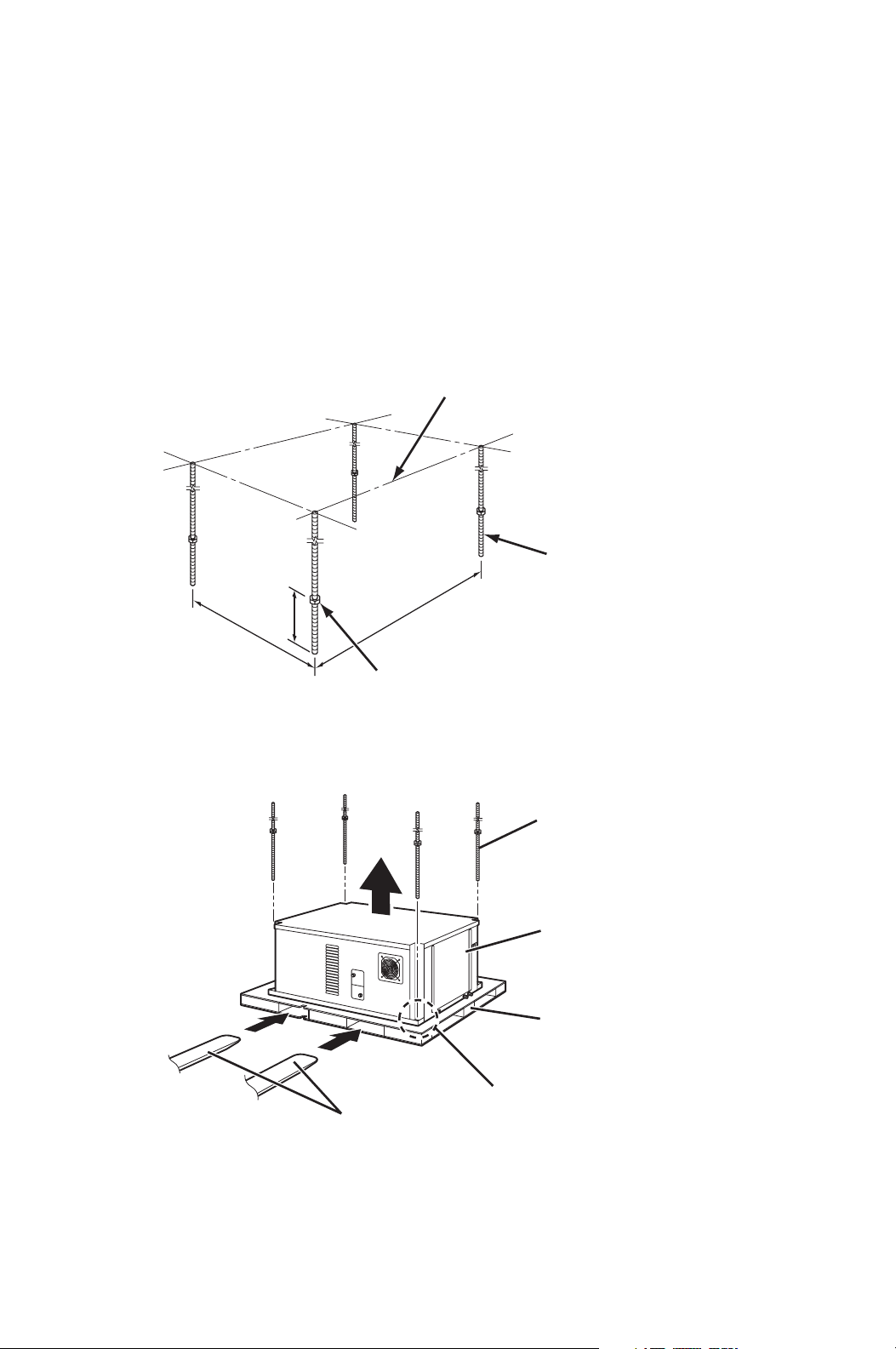

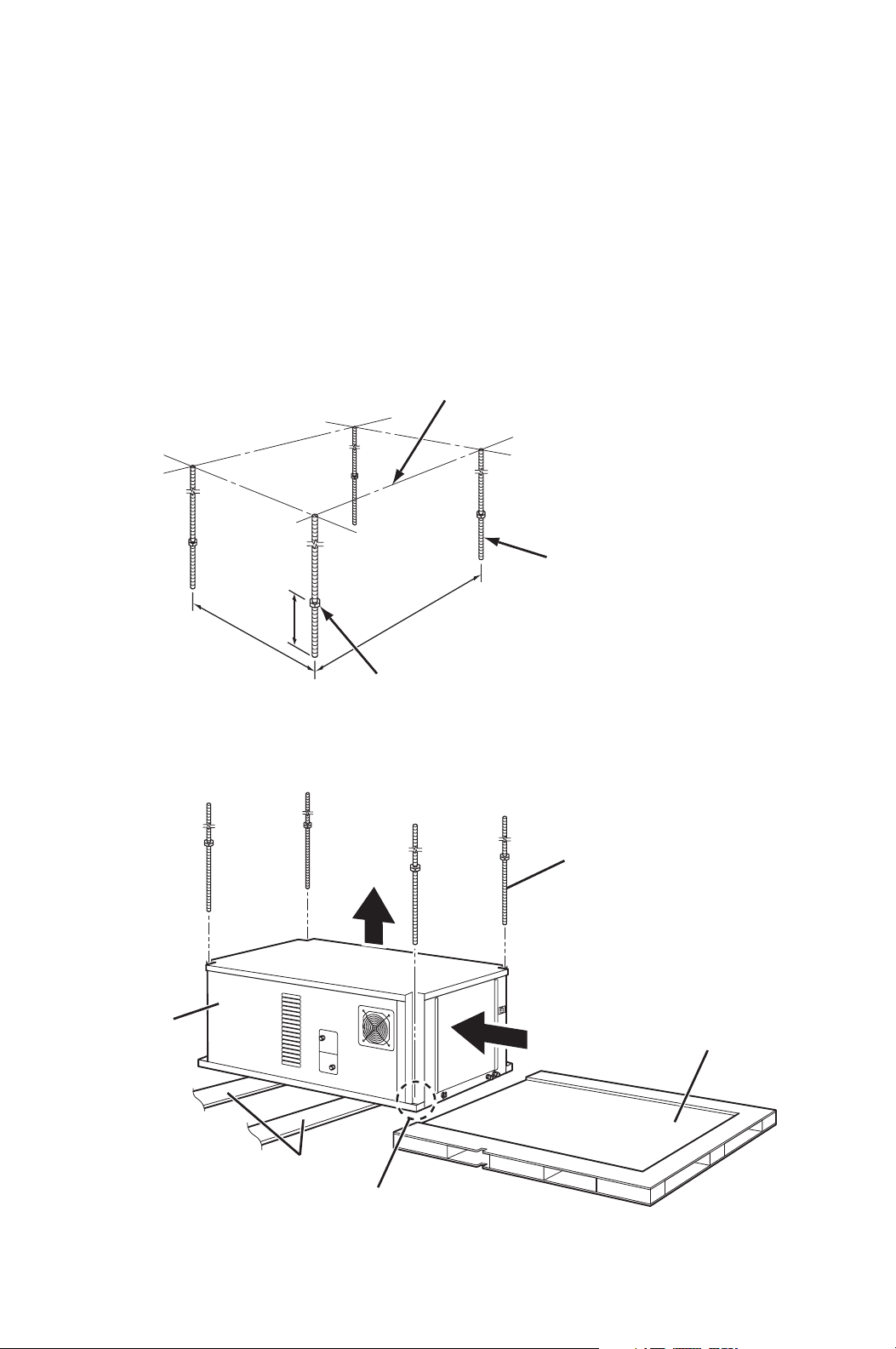

Example of Mounting with Pallet

1. Install four (4) suspension rods by suspending them from suitable building

structure members. Locate the rods so that they will align with four mounting

holes that are part of the unit base. Make sure to securely anchor the top ends

of the suspension rods and tighten all nuts.

2. Insert four (4) nuts (top) to the suspension rods before mounting the unit (12.0

inch minimum height from the bottom end of the suspension rods).

ROOF STRUCTURE

12.0 in

Min.

29.8 in

43.7 in

NUT (top)

3. Locate the rods so that they will align with four mounting holes. Enter the lifts

into pallet openings. Slowly lift up the unit with the pallet.

THREADED

SUSPENSION ROD

ILL00257-00

SUSPENSION ROD

UNIT

PALLET

LIFTS

MOUNTING HOLE

ILL00258-00

12

INSTALLATION (cont.)

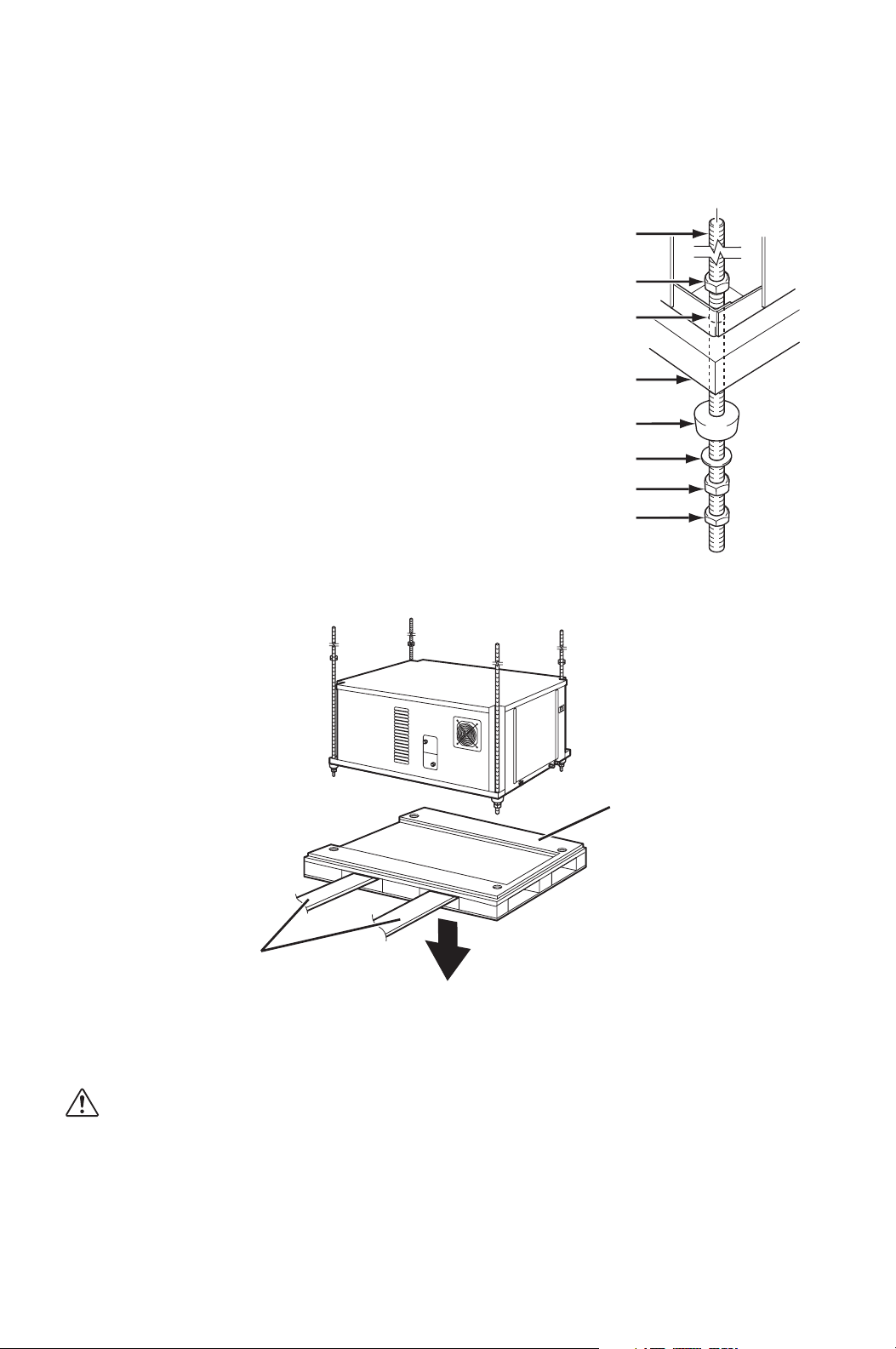

Mounting CMW30 to Roof Structure (cont.)

Example of Mounting with Pallet (cont.)

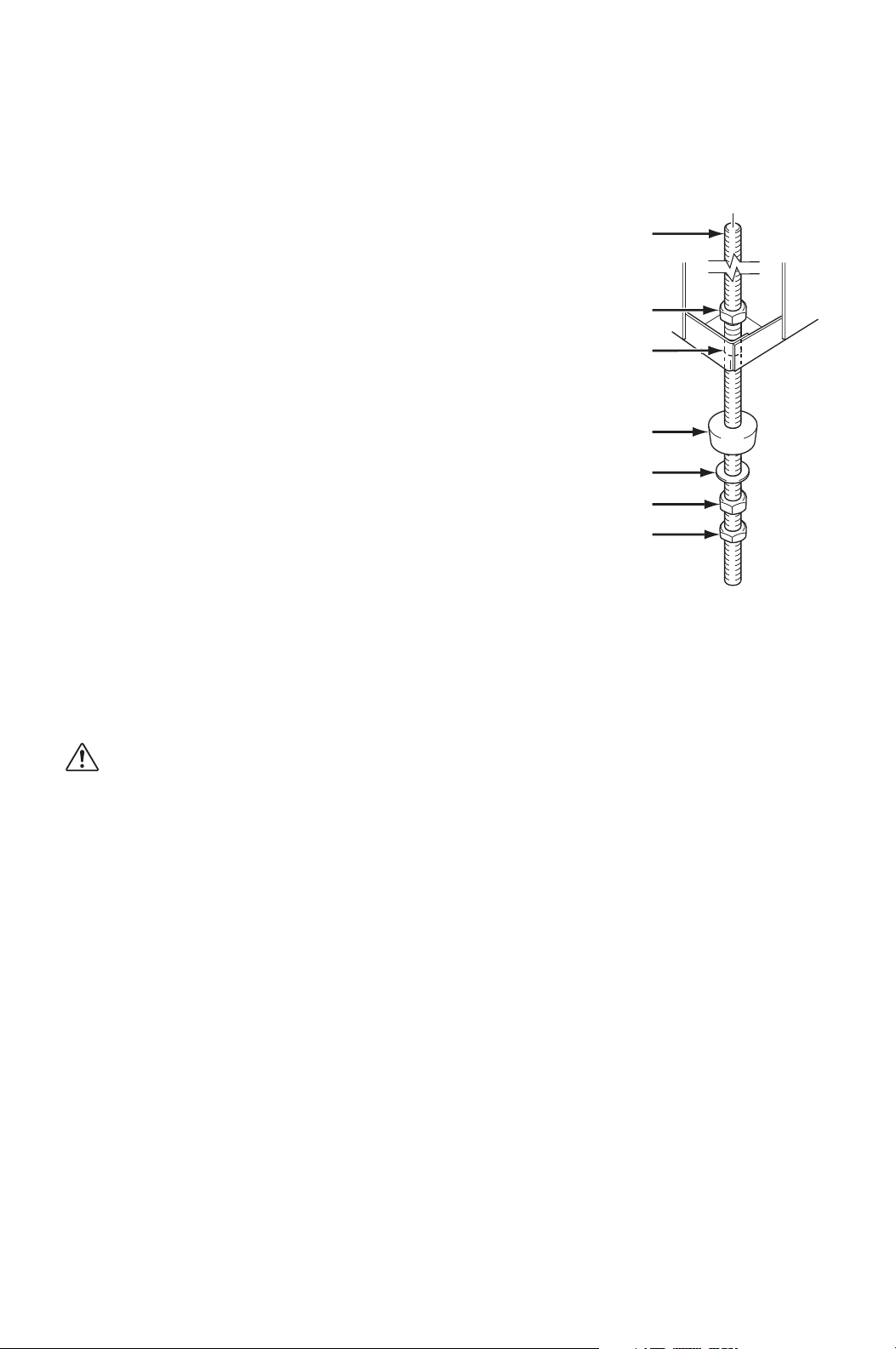

4. Insert the suspension rods

through the mounting holes of

unit and pallet. Then install

vibration isolators, washers,

nuts (middle) and jam nut

(bottom) to be same level for

all four mounting positions.

5. Slowly lower the pallet with the lifts.

SUSPENSION ROD

NUT (top)

MOUNTING HOLE

PALLET

VIBRATION ISOLATOR

WASHER

NUT (middle)

JAM NUT (bottom)

ILL00259-00

PALLET

LIFTS

ILL00260-00

6. Make sure the unit is level.

Level must be less than 2° incline.

If the unit is not level, align the nut (middle) to level.

CAUTION: If level is more than 2° incline, condensation water

leakage may occur.

7. Tighten the jam nut (bottom).

Tightening torque for jam nut: Approx. 3.02 ft•lbf (4.1 N•m)

8. Tighten the nut (top) by hand until it is secured against the base frame.

13

INSTALLATION (cont.)

Mounting CMW30 to Roof Structure (cont.)

Example of Mounting without Pallet

1. Install four (4) suspension rods by suspending them from suitable building

structure members. Locate the rods so that they will align with four mounting

holes that are part of the unit base. Make sure to securely anchor the top ends

of the suspension rods and tighten all nuts.

2. Insert four (4) nuts (top) to the suspension rods before mounting the unit (12.0

inch minimum height from the bottom end of the suspension rods).

ROOF STRUCTURE

12.0 in

Min.

29.8 in

43.7 in

NUT (top)

3. Locate the rods so that they will align with four mounting holes. Slide the unit

from the pallet onto the lifts. Slowly lift up the unit.

UNIT

THREADED

SUSPENSION ROD

ILL00257-00

SUSPENSION ROD

PALLET

LIFTS

MOUNTING HOLE

ILL00261-00

14

INSTALLATION (cont.)

Mounting CMW30 to Roof Structure (cont.)

Example of Mounting without Pallet (cont.)

4. Insert the suspension rods

through the mounting holes of

the unit. Then install vibration

isolators, washers, nuts

(middle) and jam nut (bottom) to

be same level for all four

mounting positions.

SUSPENSION ROD

NUT (top)

MOUNTING HOLE

VIBRATION ISOLATOR

WASHER

NUT (middle)

JAM NUT (bottom)

ILL00356-00

5. Slowly lower the lifts.

6. Make sure the unit is level. Level must be less than 2° incline. If the unit is

not level, align the nut (middle) to level.

CAUTION: If level is more than 2° incline, condensation water

leakage may occur.

7. Tighten the jam nut (bottom).

Tightening torque for jam nut: Approx. 3.02 ft•lbf (4.1 N•m)

8. Tighten the nut (top) by hand until it is secured against the base frame.

15

INSTALLATION (cont.)

Water Pipe Connection

WARNING: Before wiring the unit, connect the water line to the unit.

To avoid electrical shock, make sure that there is no water splashed

onto the electrical box.

CMW30 unit is equipped with two female 3/4 inch NPT (National Pipe Thread)

connectors for water connections. Two water pipes with 3/4 inch NPT Male

connectors and proper insulators are required for field installation.

Connecting Water Pipes

1. Remove the caps from the NPT connectors on the rear side of the unit.

Note: Small residues of water may drip from the NPT connectors when the caps

are first removed.

2. Apply teflon tape to the NPT male connectors.

3. Connect the threaded water pipes or pipes with the NPT male connectors to

the NPT female connectors on the unit. Hold the wrench A tightly so that the

pipe on the unit is not deformed, then tighten the connector with the wrench B.

CAUTION: Use proper size wrenches.

WRENCH B

WRENCH A

ILL00332-00

16

INSTALLATION (cont.)

Water Pipe Connection (cont.)

Connecting Water Pipes (cont.)

4. Make sure the water inlet and outlet of the unit and water source are

connected, and there is no water leakage.

CAUTION: Supply water pressure limitation is maximum 150 psi

(1,034 kPa). Do not use the unit with water which contains a high

corrosive factor.

5. Attach the insulators to the water pipes and connectors to prevent

condensation.

ILL00333-00

CAUTION: If the insulators are not attached properly, condensation

may occur.

Note:

1. Service shut-off valves and drain plugs are recommended to be installed at the

water supply and return lines for routine field service or emergency service.

The drain plugs are used to drain the remaining water in the system. The shutoff valves and drain plugs should have a minimum pressure rating of 150 psi

(1,034 kPa). The drain plugs should be connected between the shut-off valves

and the unit.

2. When supply water quality is poor, filters that can be easily serviced should be

placed in the water supply line.

17

INSTALLATION (cont.)

Drain Hose Connection

The CMW30 is equipped with an

internal condensation removal pump

with maximum head lift of 4 feet (1.2 m).

1. Use the provided 1/2 inch (13 mm)

male connection on the unit for the

evaporator coil condensate drain.

The drain line must be located so it

will not be exposed to freezing

temperatures. The drain should be

the full size of the drain connection.

(Connect the drain hose to the

condensation drain or the janitor closet.)

2. PVC tubing (1/2 inch (13 mm) for ID, 5/8 inch (16 mm) for OD) is required for

the drain. Insulate the drain hose. Condensation may occur during humid

conditions.

Note: PVC tubing and insulation material are field supplied.

DRAIN PIPE

CONDENSATE PAN DRAIN

FOR GRAVITATIONAL

DRAIN/MAINTENANCE

ILL00262-00

ILL00263-00 ILL00264-00

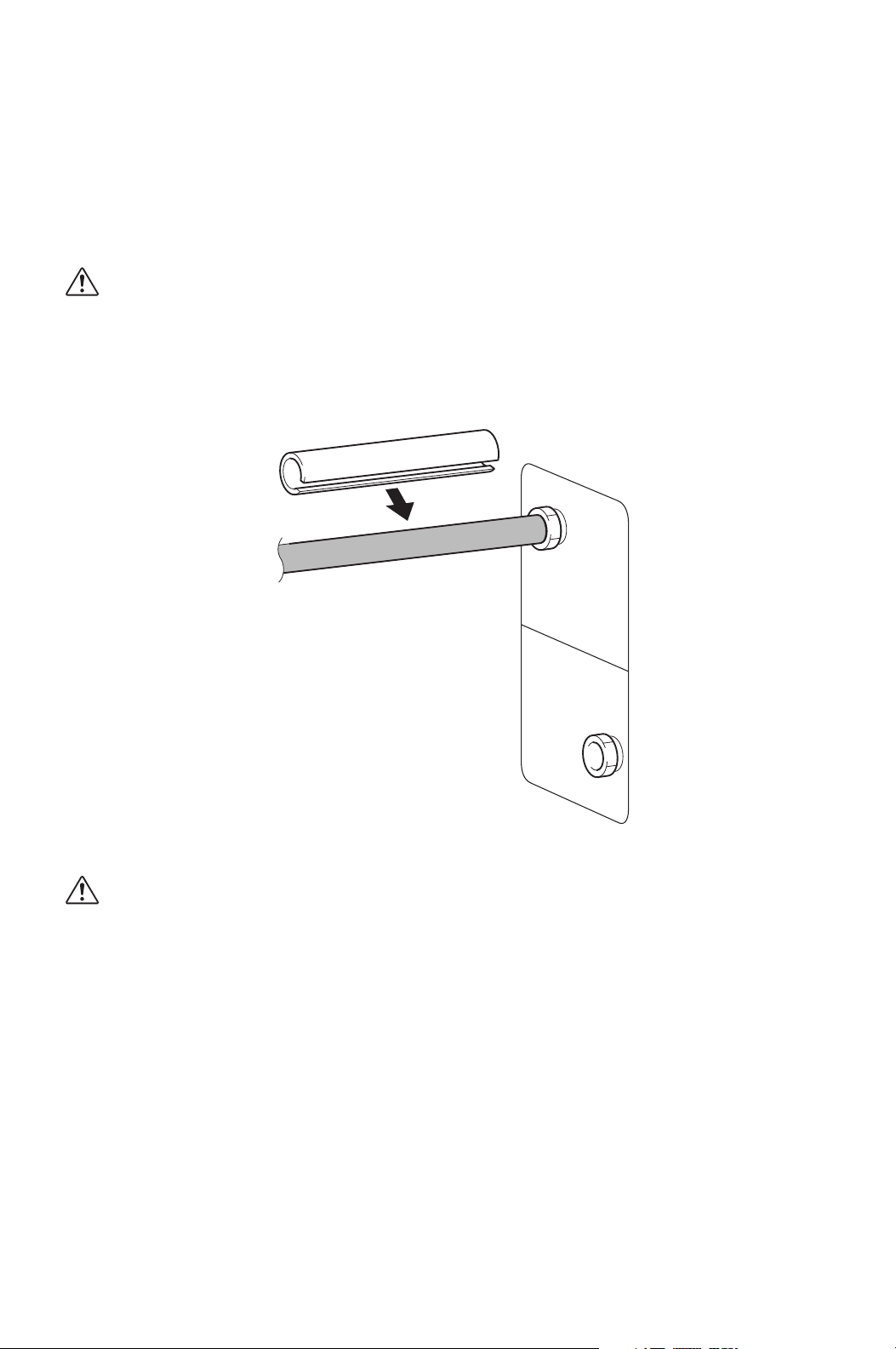

1. Plug in the 1/2 inch (13

mm) drain hose with the

supplied clip into the drain

pipe. Make sure the hose

is all the way in and flush

with the grommet.

2. Position the clip to the top

of the drain pipe near the

unit as shown.

STOPPER

3. Pull out the stopper and

secure hose. Make sure

there are no kinks or bends.

When using the gravity

drain, make sure the hose

is connected as a decline.

ILL00265-00

Note: Do not use more than 4 feet (1.2 m) of drain hose vertically. This is maximum

lift of the condensation pump.

3. To insure proper drainage, locate the drain hose to the highest vertical position,

no more than 4 feet (1.2 m) high, and run the hose to the drain on a downward

slope at a minimum rate of 1/4 inch (6 mm) per foot.

MAX. 3 ft

(0.9 m)

MAX. 4 ft (1.2 m)

1/4 in (6 mm)

PER FOOT

OR MORE

ILL00266-00

18

INSTALLATION (cont.)

Drain Hose Connection (cont.)

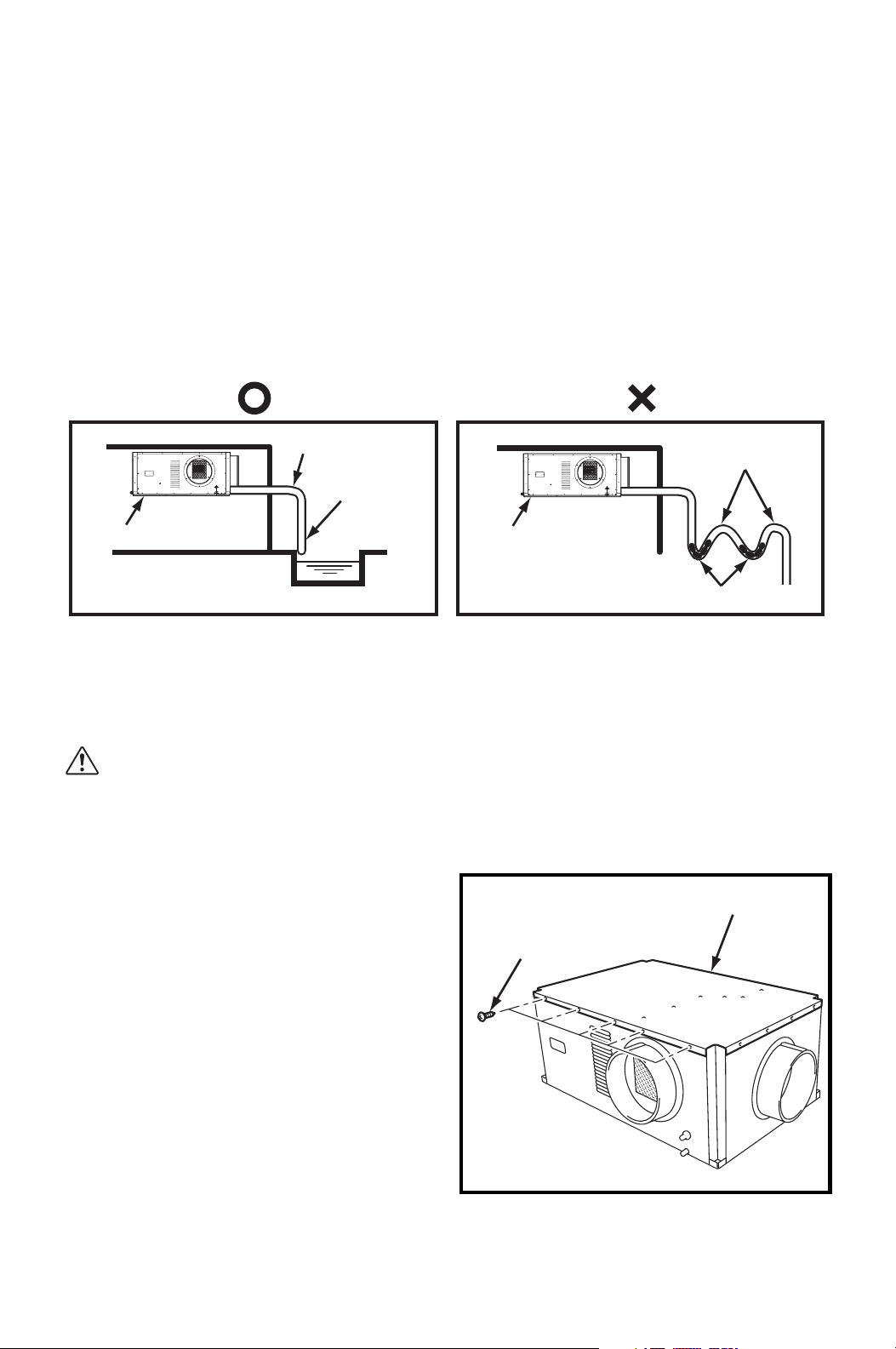

4. Check the following items.

• No kinks or bends on the drain hose

• No trap in the drain hose

• The end of the drain hose should be higher than the water level at the drain

• No dripping from the drain hose at the clamping area

• When uninstalling the unit, empty the drain pan by draining out the water

through the condensate pan drain pipe.

UNIT

NO TRAP

TO DRAIN HOSE

SLOPE

ABOVE

DRAIN

WATER

UNIT

NO TRAP

NO POOL

ILL00267-00

For the gravitational drain, power connection to the internal condensation removal

pump must be disconnected. Follow the procedures shown below.

CAUTION: The condensate water will drain out from the drain pipe

of the condensate pan if the internal condensation removal pump

connector is not disconnected.

1. Disconnect power.

2. Remove five (5) screws from the top

panel.

TOP PANEL

SCREWS (5)

19

ILL00344-00

Loading...

Loading...