Page 1

OPERATION MANUAL

CM12

Unit Serial Number Range: 0211XXXXC12 to 0315XXXXC12

(From February 2011 to March 2015)

READ THIS MANUAL CAREFULLY FOR INSTRUCTIONS ON CORRECT

INSTALLATION AND USAGE, AND READ ALL SAFEGUARDS.

SECCIÓN EN ESPAÑOL

SECTION EN FRANÇAIS

AVAILABLE AT WWW.MOVINCOOL.COM

Page 2

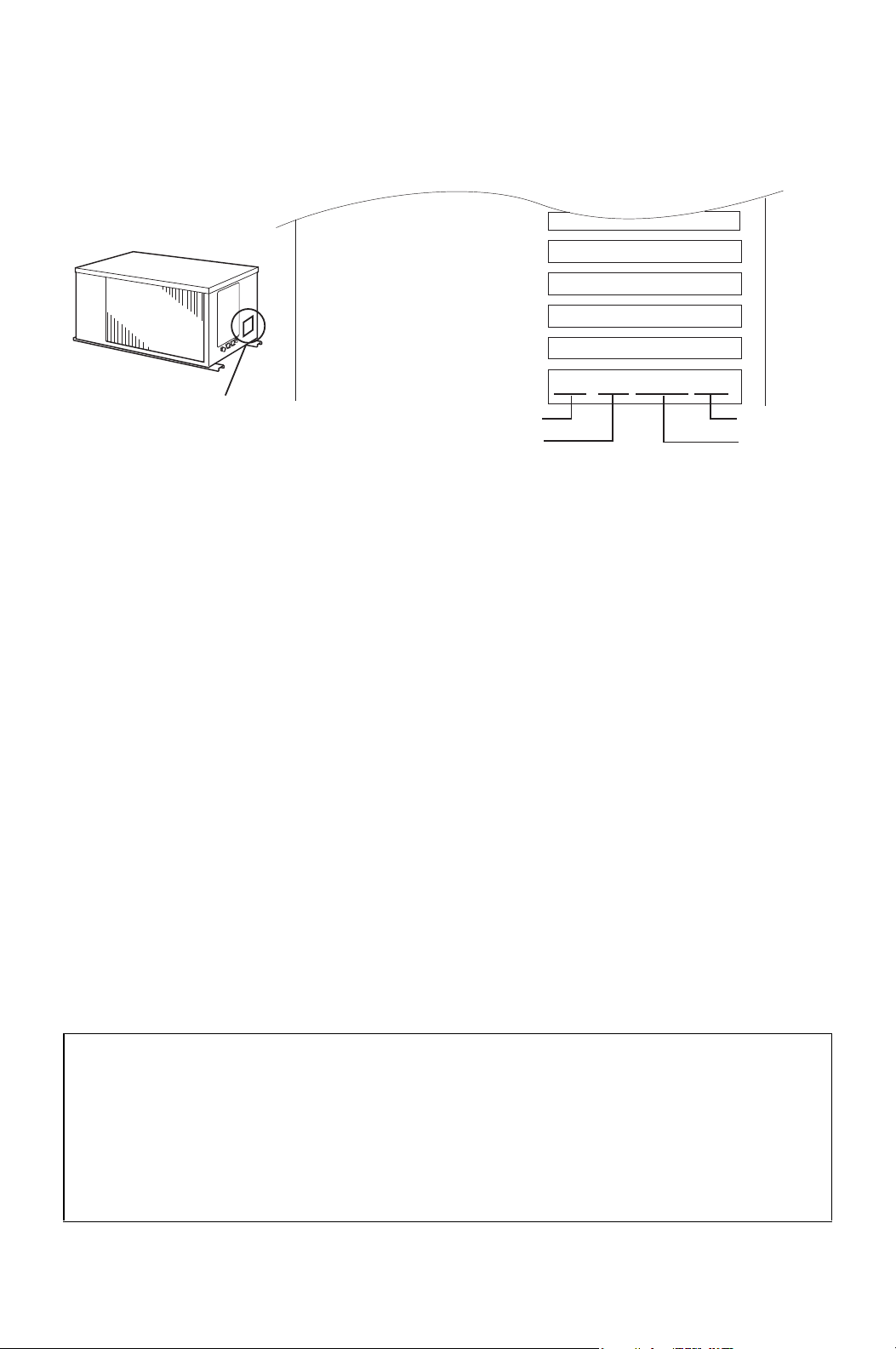

SERIAL NUMBER LOCATION AND IDENTIFICATION

Nameplate Label

COOLING AMPS. WITH PUMP

COMPR. OUTPUT

REFRIGERANT/TOTAL CHARGE

DESIGN PRESSURE LO/HI

PART NO./WEIGHT

Nameplate Label Position

SERIAL NO.

Month

Year

▲▲ XXXX ###

Model

Sequential

Number

© 2015 DENSO PRODUCTS AND SERVICES AMERICAS, INC.

All rights reserved. This book may not be reproduced or copied, in

whole or in part, without the written permission of the publisher.

DENSO PRODUCTS AND SERVICES AMERICAS, INC. reserves the

right to make changes without prior notice. MovinCool®, Office Pro®

and SpotCool® are registered trademarks of DENSO Corporation.

Page 3

OPERATION MANUAL

CM12

Page 4

Table of Contents

SERIAL NUMBER LOCATION AND IDENTIFICATION ...................................2

FOREWORD ...................................................................................................... 5

Definition of Terms................................................................................ 5

GENERAL WARNINGS & CAUTIONS.............................................................. 5

INVENTORY....................................................................................................... 6

INSTALLATION ................................................................................................. 7

Unit Overview ........................................................................................ 7

Clearance Requirement ........................................................................ 8

Mounting the CM12 to a Roof Structure..............................................9

Power Supply Requirements.............................................................. 10

Service Panel Access ......................................................................... 10

Power Connection............................................................................... 11

Drain Hose Connection....................................................................... 11

Packing Attachment............................................................................ 13

Wall Thermostat Connection (Millivolt System ONLY) .................... 13

Warning Signal Connection (Output Signal)..................................... 14

Fire Alarm Control Panel Connection (Input Signal)........................ 15

DIP Switch Configuration and Setting...............................................15

Ducting With Typical Drop Ceiling..................................................... 16

FEATURES ...................................................................................................... 17

INSPECTION & MAINTENANCE.....................................................................

Cleaning Air Filters ............................................................................. 17

Cleaning Condenser Air Intake .......................................................... 17

Ground Fault Breaker Testing............................................................17

TROUBLESHOOTING ..................................................................................... 18

Buzzer Pattern ..................................................................................... 18

CM12: Installation Check Sheet ......................................................... 20

TECHNICAL SPECIFICATIONS...................................................................... 21

17

Page 5

FOREWORD

Congratulations on purchasing the MovinCool air conditioner. This manual

explains how to assemble, install and operate the MovinCool CM12 air

conditioning unit. Please read this operation manual thoroughly to familiarize

yourself with the features of the unit and to ensure years of reliable operation.

You may also find it useful to keep this operation manual on hand for reference.

Components and/or procedures are subject to change without prior notice.

Definition of Terms

WARNING: Describes precautions that should be observed in order

to prevent injury to the user during installation or unit operation.

CAUTION: Describes precautions that should be observed in order

to prevent damage to the unit or its components, which may occur

during installation or unit operation if sufficient care is not taken.

Note: Provides additional information that facilitates installation or unit operation.

GENERAL WARNINGS & CAUTIONS

1. All electrical work should only be performed by qualified electrical personnel.

Repair to electrical components by non-certified technicians may result in

personal injury and/or damage to the unit. All electrical components replaced

must be genuine MovinCool parts, purchased from an authorized reseller.

2. Disconnect power before any electrical installation.

3. Installation should be conducted by qualified technician only. DENSO and

DENSO affiliate are not responsible for injuries and/or damages caused by

improper installation.

4. Do not place water or any other liquid on the unit. This can cause damage to

the unit and increase the risk of electrical shock.

5. Do not sit or stand on the unit.

6. Do not place hands or any object in the cool air outlet or exhaust duct.

Touching the fan, which is rotating at a high speed, is very hazardous.

5

Page 6

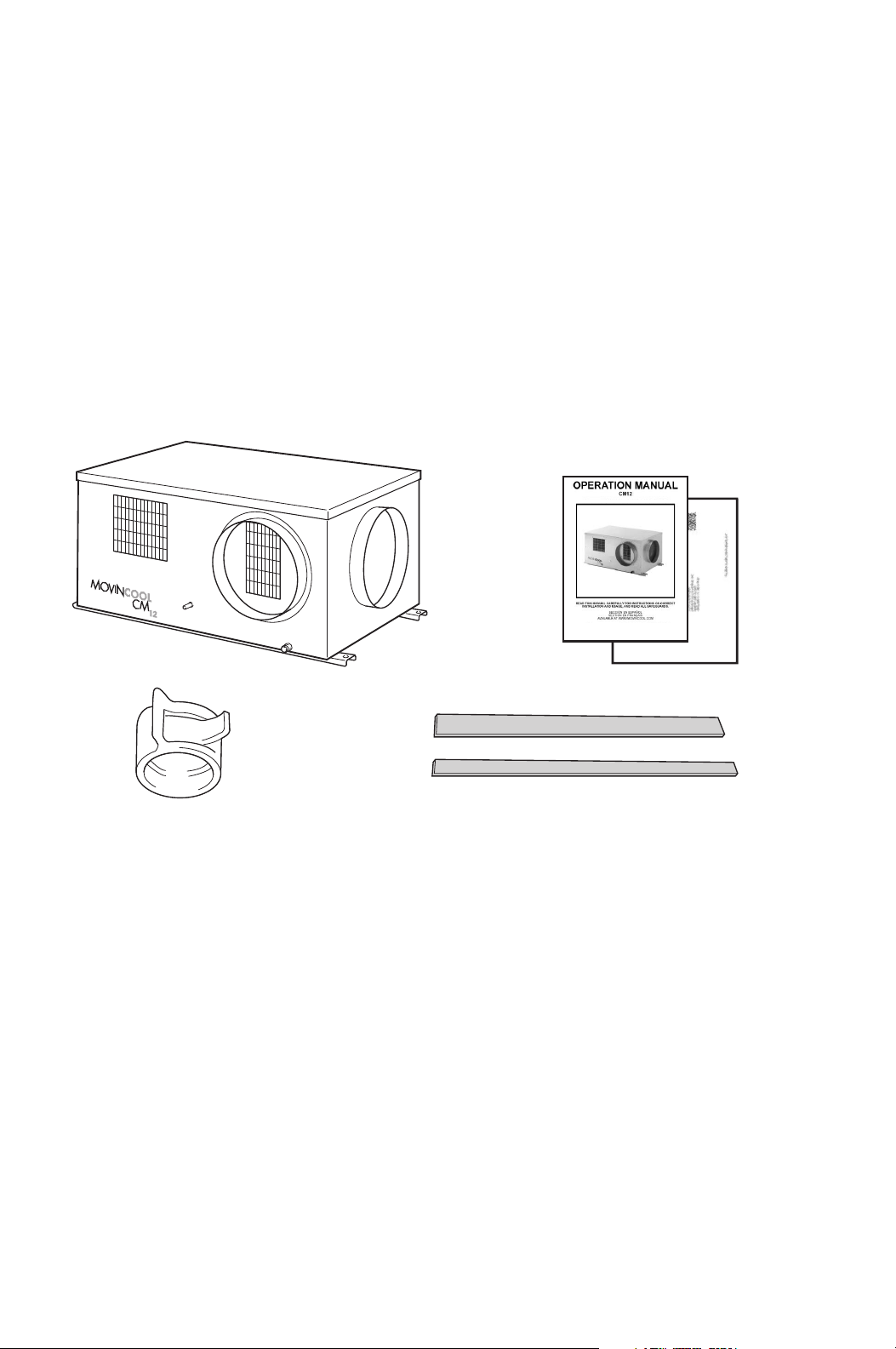

INVENTORY

CM12 UNIT OPERATION MANUAL /

PRODUCT REGISTRATION

CLIP

PACKING I (2.8 in x 32.0 in x 0.2 in)

PACKING II (1.0 in x 33.0 in x 0.2 in)

After unpacking your MovinCool unit, please check to make sure you have the

following items:

1. CM12 MovinCool Unit (1)

2. Operation Manual/Product Registration (1)

3. Clip (1)

4. Packing I (1)

5. Packing II (1)

Note: If any of these items were not included in the box or appear damaged,

please contact your MovinCool reseller for replacement.

6

Page 7

INSTALLATION

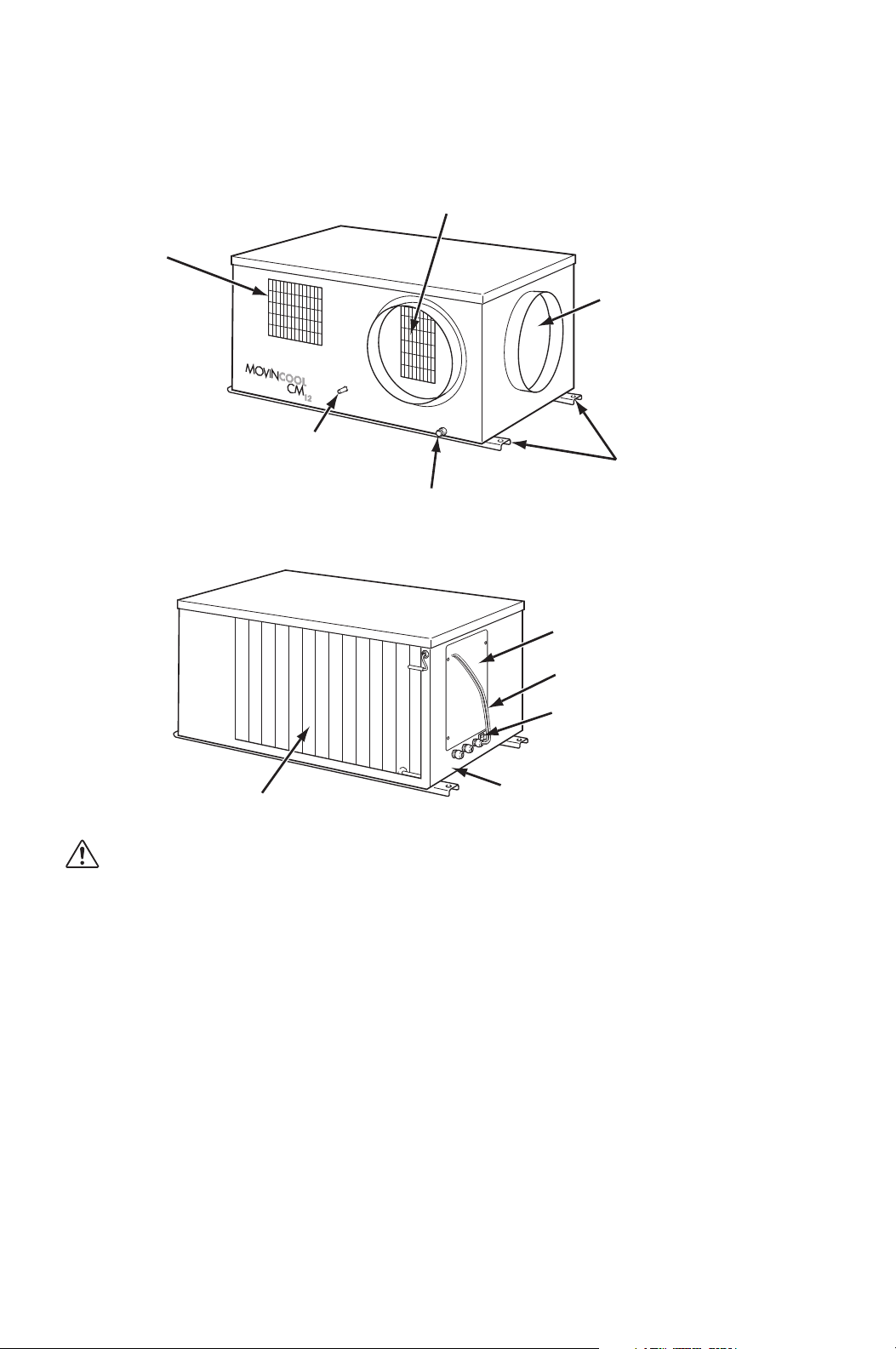

COLD AIR EXHAUST (10.0 in DIA. FLANGE)

DRAIN PIPE

FOR PUMP

CONDENSER (HOT)

AIR EXHAUST

EVAPORATOR (ROOM)

AIR INTAKE

(10.0 in DIA. FLANGE)

MOUNTING

BRACKETS

CONDENSATE PAN

DRAIN FOR MAINTENANCE

SERVICE PANEL

OVERRIDE (STOP)

SWITCH

POWER CORD

CONNECTION

CONDENSER AIR INTAKE

SIGNAL WIRE

Unit Overview

WARNING: Remove protective cardboard from condenser intake

after installation.

7

Page 8

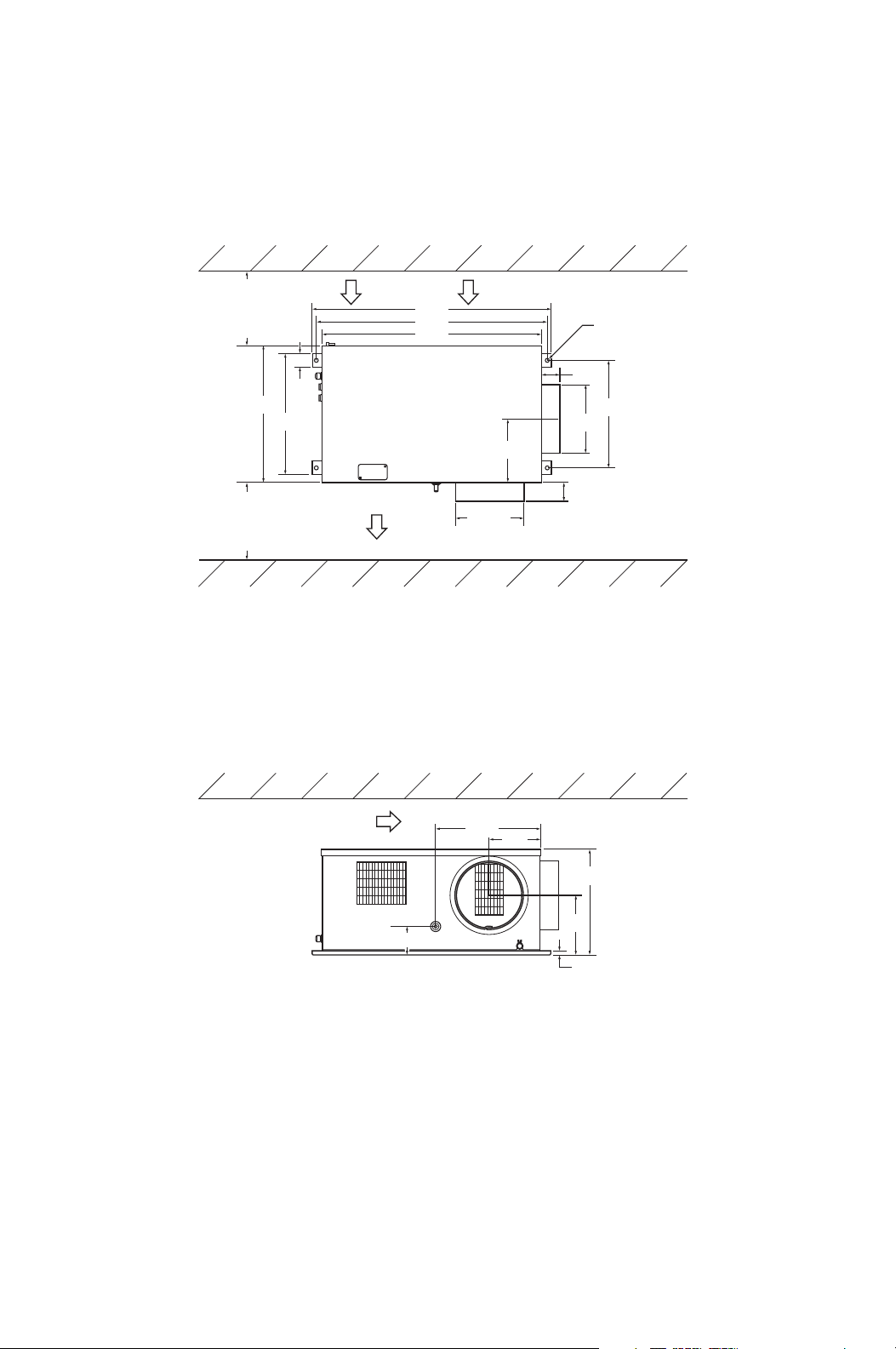

INSTALLATION (cont.)

WALL

All dimensions are in inches.

Unit Weight: 123 lb (56 kg)

WALL

CEILING

INTAKE

EXHAUST

Minimum

clearance

40.0 in

from wall

Minimum

clearance

40.0 in

from wall

Ø0.6

Ø10.0

15.3

7.5

15.8

4.1

8.7

17.6

19.9

34.8

33.6

32.0

15.7

2.7

2.8

0.6

Top of the unit should not contact

any building structure or object.

2.0

10.0

9.2

Clearance Requirement

8

Page 9

INSTALLATION (cont.)

1/2 in THREADED ROD

(MIN. 123 lb (56 kg) LOAD CAPACITY)

SEE MOUNTING DETAIL

VIBRATION ISOLATOR

(MIN. 123 lb (56 kg) LOAD CAPACITY)

1/2 in THREADED ROD

(MIN. 123 lb (56 kg)

LOAD CAPACITY)

1/2 in NUT

1/2 in WASHER

MOUNTING BRACKET

1/2 in WASHER

1/2 in NUT

1/2 in JAM NUT

Mounting the CM12 to a Roof Structure

WARNING: Be sure that the supporting roof structure is capable of

supporting the weight of the unit, mounting hardware and the

accessories (Roof structure should be capable to support four

times of total weight or more. Unit weight is 123 lb (56 kg).

Be sure to securely anchor the top ends of the suspension rods. Make sure all nuts

are tight. Be sure to follow all applicable codes.

The CM12 unit is usually mounted above the ceiling and must be securely

mounted to the roof structure. The ceiling support of the existing building may

require reinforcements.

Use field-supplied threaded 1/2 inch suspension rods, washers, nuts and vibration

isolators.

The recommended clearance between ceiling grids and building the structural

member is the unit height plus 3.0 inch (76 mm).

ALL MOUNTING HARDWARE FIELD PROVIDED

Install the four field-supplied rods by

suspending them from suitable

building structure members. Locate

the rods so that they will align with

four mounting holes in the mounting

bracket that are part of the unit

base.

WARNING: Wear gloves to

Tightening torque for nuts: 3.02

avoid injury during

installation.

ft•lbf (4.1 N•m)

CAUTION: Make sure the

unit is level (must be less

than 2° incline).

9

Page 10

INSTALLATION (cont.)

CIRCUIT BREAKER WITH

GROUND-FAULT PROTECTIVE

FUSE 20 A MAX.

RTG

RTG

TERMINAL BLOCK OF CM12

GROUND TERMINAL

Power Supply Requirements

• The CM12 requires a single-phase 115 V, 60 Hz power supply to operate.

• The power supply should be a dedicated single outlet circuit with a UL approved

short-circuit and ground fault protective breaker with a fuse size of 20 A maximum.

Service Panel Access

1. Access service panel by

removing 4 screws.

Tightening torque for screw: 1.10

ft•lbf (1.5 N•m)

2. Remove the service panel.

10

Page 11

INSTALLATION (cont.)

POWER CORD

DRAIN PIPE

CONDENSATE PAN

DRAIN FOR MAINTENANCE

Power Connection

Connecting Power Supply to Unit

The following are recommended wire sizes

and electrical ratings:

• Cord Type: SJT (3 wires) or

equivalent

• Wire Gauge: 14 AWG

• Voltage Rating: 300 V minimum

• Heat Resistance: 140 °F (60 °C)

1. Remove service panel from the right

side of CM12 unit.

2. Route power cord wires through the

opening of the left grommet connector located below service panel. Tighten

the grommet connector at about 0.15 ft•lbf (0.2 N•m) torque.

3. Connect the neutral wire (white color label “R”) to the center screw connection

of terminal block. Tighten screw at about 0.96 ft•lbf (1.3 N•m) torque.

T

G

R

4. Connect the line wire (black color label “T”) to the left screw connection of

terminal block. Tighten screw at about 0.96 ft•lbf (1.3 N•m) torque.

5. Connect the ground wire (green color label “G”) to brass screw located below

terminal block. Tighten screw at about 0.96 ft•lbf (1.3 N•m) torque.

WARNING: All electrical work, if necessary, should only be

performed by qualified personnel. Repair to electrical components

by non-certified technicians may result in personal injury and/or

damage to the unit.

Drain Hose Connection

The CM12 is equipped with an internal

condensation removal pump. Maximum lift

is 4 feet (1.2 m).

1. Use the provided 1/2 inch (13 mm)

female connection on the unit for the

evaporator coil condensate drain. The

drain line must be located so it will not

be exposed to freezing temperatures.

The drain should be the full size of the

drain connection. (Connect the drain

hose to the condensation drain or the janitor closet.)

2. A 1/2 inch (13 mm) ID (5/8 inch (16 mm) OD), PVC tubing is required for the

drain. Insulate the drain hose; condensation may occur during humid

conditions. (Field supplied material)

11

Page 12

INSTALLATION (cont.)

RED STOPPER

MAX. 3 ft

(0.9 m)

MAX. 4 ft (1.2 m)

1/4 inch (6 mm)

PER FOOT

OR MORE

Drain Hose Connection (cont.)

1. Plug in the 1/2 inch (13

mm) drain hose with the

lose clip into the drain

pipe. Make sure the hose

is all the way in and flush

with the grommet.

2. Position the clip to the top

of the drain pipe near the

unit as shown.

3. Pull out the red stopper and

secure hose. Make sure

there are no kinks or bends.

When using the gravity

drain, make sure the hose

is connected as a decline.

Note: Do not use more than 4 feet (1.2 m) of drain hose vertically. This is maximum

lift of the condensation pump.

To insure proper drainage, locate the drain hose to the highest vertical position, no

more than 4 feet (1.2 m) high, and run the hose to the drain, run the drain hose on

a downward slope at a minimum rate of 1/4 inch (6 mm) per foot.

Check following items:

1. No kinks or bends on the drain hose

2. No trap in the drain hose

3. The end of the drain hose should be highter than the water level at the drain

4. No dripping from the drain hose at the clamping area

DRAIN HOSE ARRANGEMENT

SLOPE

ABOVE

DRAIN

CM12

NO TRAP

TO DRAIN HOSE

When uninstalling the unit, empty the drain pan by draining out the water through

the drain pan drain pipe.

WATER

12

CM12

NO TRAP

NO POOL

Page 13

INSTALLATION (cont.)

Wall Thermostat

Connector Name

CM12 WIRES

Label Name Color

Function

RC

Y

G

G1

RC

Y

G

G1

Brown

Red

Orange

Yellow

Common

Cool On/Off

Fan On/Off

Fan Hi/Lo

Packing Attachment

Apply include “Packing I” (provided) and

“Packing II” (provided) to the cold air outlet

flange to prevent condensation in high

humidity environments.

1. Release the liner on Packing I and

apply to outside flange cylinder of the

ring as shown.

2. Release the liner on Packing II and

apply to edge of Packing II as shown.

PACKING I

PACKING II

Wall Thermostat Connection (Millivolt System ONLY)

Preparation for Wall Thermostat Connection

1. Use with a single stage wall thermostat.

Thermostat type: Millivolt System

2. Set the wall thermostat to cooling system mode, since most wall thermostats

are designed for both heating and cooling.

3. Prepare the wire harness for connection from the unit to the thermostat. The

recommended wire size is:

Wire Type: Thermostat cable / Solid wire 16 ~ 26 AWG

4. Identify the thermostat connectors labeled G, G1, Y, and RC.

G (Fan On/Off), G1 (Fan Speed Hi/Lo), Y (Cooling On/Off) and RC (Cooling

Transfer - Common)

Connecting Thermostat to CM12 Unit

13

Page 14

INSTALLATION (cont.)

CM12 UnitThermostat

(Millivolt System)

Orange Wire

G

Y

RC

G1

Red Wire

GYWRCRHOB

Brown Wire

Yellow Wire

Remove Factory-Installed Jumper

Use only with thermostat that has

Fan Hi-Lo Speed control.

Note: Use thermostat that is compatible with millivolt system. Do not connect

thermostat to AC power source.

5. Install the wall thermostat to the proper location inside the room where it can

be conveniently accessed. Do not install the wall thermostat where unusual

heating condition may occur (i.e. hot stove, hot pipe, fireplace, direct sunlight,

and etc.)

Most thermostats provide these basic functions:

Fan Mode: On / Auto (Select the desired fan mode)

System: Cool / Heater (Select Cool only)

Warning Signal Connection (Output Signal)

The CM12’s controller is equipped with a warning signal output relay type (FormC, normal open dry contact), which can be used to monitor the failure condition.

Relay contactor is closed when the following condition has occurred:

a. Condensation Overflow

b. Temperature Sensor fails

c. Cooling Function fails

The relay output contactor is rated 5 A at 30 VDC or 5 A at 250 VAC (resistive

load), and it is compatable with various warning devices such as alarm speakers,

light indicators, and etc.

Connecting Warning Signal From CM12

1. Connect the warning device to CM12 signal wires label L+ and L-.

2. Use recommended warning signal wire size from 16 AWG to 26 AWG for a

solid wire, or 16 AWG to 22 AWG for a stranded wire.

14

Page 15

INSTALLATION (cont.)

1234

NO

“OFF” POSITION

250V 5A

OUTPUT: 12.6V-0.37A

GA09301-G ST

INPUT: 230V 115V 0

CN01

CN15CN16CN14CN02CN03CN04

CN17

CN25

CN23 CN22 CN21

4

3

52CH

RTSCTSODS

SW2

4-POSITION DIP SWITCH

Fire Alarm Control Panel Connection (Input Signal)

The CM12’s controller is equipped with a normal open input signal, which can be

connected directly from the fire alarm control panel. When receiving the signal

from the fire alarm control panel, the unit turns off and does not turn back on until

power source is reset or turns the wall thermostat off and on.

Connecting Fire Alarm Control Panel to CM12

1. Connect the fire alarm signal wires to CM12 signal wires label E+ and E-.

2. Use recommended fire alarm signal wire size from 16 AWG to 26 AWG for a

solid wire, or 16 AWG to 22 AWG for a stranded wire.

DIP Switch Configuration and Setting

The CM12’s controller is equipped with a 4-position DIP switch, which defaults in

the OFF position. The DIP switch can be set to configure the following functions:

a. When the switch position #1 is ON, the evaporator and condenser fan

motor turn on. This function is used for test purposes and verification.

b. When switch position #2 is ON, the compressor, evaporator and condenser

fan motor turn on. This function is used for test purposes and verification.

c. When switch position #3 is ON, the compressor delay timer function is

disabled.

15

d. When switch position #4 is ON, the buzzer sound function is disabled.

Page 16

INSTALLATION (cont.)

Ducting With Typical Drop Ceiling

RETURN GRILL WITH FILTER REQUIRED

CONDENSER

INTAKE

CONDENSER

EXHAUST

2 ft x 2 ft,

T-bar diffuser

with 10.0 in flange

COOL AIR SUPPLY

(EVAPORATOR)

10.0 in insulated

flexible duct

(6 ~ 10 ft each)

2 ft x 2 ft,

T-bar return

grill with 10.0 in

flange and filter

ROOM AIR

INTAKE

Use a 10.0 inch diameter insulated duct with low friction and air resistance.

The duct should be bent in a large radius. If the bending radius is less than 15.0

inch (381 mm), then use vanes or guides to reduce air resistance.

Make sure the ducts are secured in order to absorb vibration from the unit.

Avoid bending the duct suddenly and have air ducts travel in a strait line for

improved performance.

• Following filed supplied hardware requires:

• Insulated 10.0 inch diameter ducts

• Return air grill with filter for evaporator air intake

• Diffuser for cold air

• Maximum external static pressure, 0.40 IWG (100 Pa) for evaporator duct and

grills

CAUTION: Do not operate CM12 without the filter installed on the

return air grill.

16

Page 17

FEATURES

CM12 Features

• Built-in condensation removal pump

• Built-in mounting bracket

• Built-in flange for supply and return air (room air) - 10.0 inch diameter, 2.8 inch

deep cylinder for easy installation

• Fire alarm control panel connection with automatic shut off

• Automatic shut off and warning signal output and alarm for

• Condensation Overflow

• Unit Failure (no cooling)

• Temperature Sensor Failure

INSPECTION & MAINTENANCE

Cleaning Air Filters

The air filter on the evaporator return grill should be checked weekly for dust

buildup.

Clean or replace air filter on a weekly basis. If the unit is used in a dusty

environment, more frequent cleaning may be required.

A dirty air filter can reduce the air output, resulting in a decrease in cooling

capacity.

Cleaning Condenser Air Intake

Inspect and remove dust buildup on the condenser air intake of the unit with a

vacuum cleaner periodically to prevent insufficient cooling.

Ground Fault Breaker Testing

The ground fault breaker should be tested at least once a month.

17

Page 18

TROUBLESHOOTING

PATTERN 1

(Internal thermistor failure)

PATTERN 4

(Fire alarm signal input)

PATTERN 2

(Pump or drain problem)

PATTERN 3

(Refrigeration system

problem)

ON

OFF

ON

OFF

ON

ON

OFF

0.5 sec

0.5 sec

0.5 sec

4 sec

4 sec

1 sec

Buzzer Pattern

18

Page 19

TROUBLESHOOTING (cont.)

Check the following items before calling your MovinCool reseller or a qualified

technician.

CONDITION POSSIBLE CAUSE REMEDY

Unit does not

operate

Insufficient Cooling /

Unit operation

interrumpted

frequently.

1. Power supply is off Check circuit breaker.

2. Power interruption Unit will turn on automatically

when power back (Some

thermostats require reset).

3. Blockage of air duct Check duct for any blockages or

excessive kinks in ducting.

4. Turn off signal input Check for turn off signal input (fire

alarm control panel).

5. Override (Stop) switch is

active

6. Battery ran out on

thermostat

1. Blockage of Condenser air

intake or outlet in the ceiling

2. Dirty Surface of Condenser

Core

3. Dirty / Blocked filters Clean / replace air filter.

4. Excessive evaporator air

ducting

Ensure the switch is in

“OPERATE” position.

Change battery.

Check any blockages in the

ceiling.

Clean surface of Condenser Core.

Evaporator ducting should not

exceed 10 feet (3.0 m) and bend

radius should be larger than twice

of duct diameter.

Beeping / Alarm

coming from unit and

unit stops.

(Buzzer sound

pattern indicated on

page 18.)

5. Blockage of Condenser air

intake or outlet in the ceiling

6. Outside of operating range Use within operating temperature

1. Internal thermistor failure

(Sound pattern 1)

2. Pump or drain problem

(Sound pattern 2)

3. Refrigeration system

problem (Sound pattern 3)

4. Receiving fire alarm signal

input (Sound pattern 4)

Remove the blockage.

range.

Replace internal thermistor.

Check for drain connection and

blockage, kink or bend on drain

hose. (See “Drain Hose

Connection” on page 11.)

Turn off power source and contact

your MovinCool reseller or a

qualified technician.

Reset power source or turn the

wall thermostat off and on.

If conditions persist after the above actions have been taken, turn the unit off,

disconnect the power and contact your MovinCool reseller or a qualified technician.

19

Page 20

TROUBLESHOOTING (cont.)

CM12: Installation Check Sheet

ITEMS

Installation Unit Check and make sure all screws are tight and

unit is secured in place.

Check and make sure inlet / outlet air exhaust

are clear without blockage.

Wiring Check and make sure the unit is properly

connected to the dedicated circuit breaker.

Check and make sure all wiring are properly

connected and secured.

Check and make sure ground wire is tighten

and secured.

DIP Switch Setting Check and make sure all DIP switches

located on relay board are set to “OFF”

positions.

Before Test

Operation

Test

Operation

Drain Hose

Connection

Grill Installation Check and make sure that grill is secured and

Wall Thermostat Check and make sure wall thermostat is

Other Remove card board on condenser inlet side.

Maintenance Switch Check and make sure override switch located

Check Operation

with Wall

Thermostat

Abnormal Noise Check and observe abnormal noise during

Check and make sure that drain hose

provided with heat insulator to prevent

condensation on hose surface.

properly installed.

connected properly to unit.

below maintenance’s panel is at “OPERATE”

position before test operation.

Set wall termostat to Fan On or Fan Only

mode to confirm fan only mode operation.

Set wall thermostat to Fan Auto or Cool mode

operation. During cool mode operation, check

and cinfirm cooling operation after delay timer

is expired. (Note: Delay timer vary from 2 ~ 5

min depending on thermostat model used.)

Blowing/Cooling operation.

Drain During cooling operation, check and observe

condensation drip through normal drainage

path.

Air Leakage Check for air leakage from duct and duct

connection.

20

Page 21

TECHNICAL SPECIFICATIONS

ITEM SPECIFICATIONS

Electronic Features Control Millivolt Thermostat

(Field supplied)

Electrical Characteristics Voltage Requirement Single-Phase, 115 V, 60 Hz

Operating

Voltage Range

Max. 127 V

Min. 104 V

Recommended Fuse Size 15 A

Cooling Capacity and Power Consumption

*1

*1

*1

*1

10,500 Btu/h (3,090 W)

7,200 Btu/h (2,100 W)

1.23 kW

11.2 A

Evaporator: 80 °F (27 °C),

50 %RH

Condenser: 95 °F (35 °C),

50 %RH

Total Cooling Capacity

Sensible Cooling Capacity

Power Consumption

Current Consumption

EER 8.5

*1

*1

*1

*1

9,300 Btu/h (2,730 W)

7,000 Btu/h (2,040 W)

1.22 kW

11.1 A

Evaporator: 72 °F (22 °C),

50 %RH

Condenser: 95 °F (35 °C),

50 %RH

Total Cooling Capacity

Sensible Cooling Capacity

Power Consumption

Current Consumption

EER 7.6

Compressor Type of Compressor Hermetic Rotary

Evaporator Type of Fan Centrifugal Fan

Air Flow High

Low

324 CFM (550 m

228 CFM (390 m

Max. External Static Pressure 0.16 IWG (40 Pa)

3

3

/h)

/h)

Condenser Type of Fan Centrifugal Fan

Air Flow

High

Low

700 CFM (1,190 m

370 CFM (630 m

Max. External Static Pressure 0.12 IWG (30 Pa)

Refrigerant Type R-410A

Amount 1.59 lb (0.72 kg)

Dimension W x D x H Without Flange

and Mounting

Bracket

With Flange

and Mounting

Bracket

32.0 x 19.9 x 15.2 in

(813 x 505 x 386 mm)

34.8 x 22.7 x 15.8 in

(884 x 577 x 401 mm)

Weight Net 123 lb (56 kg)

21

3

3

/h)

/h)

Page 22

TECHNICAL SPECIFICATIONS (cont.)

ITEM SPECIFICATIONS

Condensate Pump

Capacity

Operating Condition

Range

Maximum Duct Length

Maximum Sound Level

*2

Pump Rate 5.0 gal/h (19 L/h)

Max. Head 4 ft (1.2 m)

Evaporator Air

Inlet

Condenser Air

Inlet

*3

Cold Duct 20 ft (6.1 m)

Hot Duct 10 ft (3.0 m)

*4

High 52 dB (A)

Low 52 dB (A)

Max. 95 °F (35 °C), 50 %RH

Min. 65 °F (18 °C), 50 %RH

Max. 113 °F (45 °C), 50 %RH

Min. 65 °F (18 °C), 50 %RH

• Specifications are subject to change without notice.

Note:

*1: With two 6-foot (1.8 m) ducts containing one 90° bend each, supply grill and

return grill with filter [0.16 IWG (40 Pa) external static pressure] on high fan

speed.

*2: When ambient temperature is lower than 65 °F (18 °C), operation may be

interrupted due to anti-freeze protection activation.

*3: Confirm pressure drop of duct, grills, and filter with manufacture’s

specifications.

*4: Measured at 3 feet (1.0 m) under the ceiling with evaporator duct and ceiling

tile.

22

Page 23

WARRANTY STATEMENT

DENSO PRODUCTS AND SERVICES AMERICAS, INC. ("DENSO") warrants its

MOVINCOOL Products only to the extent stated in its official written warranties. Unless

otherwise specifically provided in writing by DENSO, DENSO warrants to the original end-user

that the products shall be free of defects in materials or workmanship and will function in

accordance with DENSO's published specifications under ordinary intended use and service

for a period listed below beginning from the date of purchase on the invoice to the end-user:

CM12 Warranty: 2 Years on the Unit and 3 Years on the Compressor with warranty registration

OR 1 Year on the Unit and 3 Years on the Compressor for unregistered units.

DENSO shall, at its sole discretion, repair or replace any defective product covered by this

warranty. Such remedy shall be end-user's sole remedy with respect to any particular defect

in the products.

This warranty does not cover defects or malfunctions which result from causes beyond

DENSO's control, including, without limitation, (i) unusual physical or electrical stress; (ii)

accident, neglect, abuse, misuse or other abnormal use; (iii) failure to perform routine

maintenance in accordance with DENSO's recommended procedures; (iv) normal wear and

tear; (v) repairs or attempted repairs by an unauthorized person; (vi) modifications or

alterations to the products; (vii) use with parts or devices not supplied or approved by

DENSO; (viii) improper installation or service; (ix) shipping damage to any units or spare

parts during shipping. This includes and is not limited to compressors, evaporators and

condenser coils. This warranty shall extend only to the original end-user and shall be void if

any labels or other identifying marks permanently affixed to products when shipped by

DENSO are removed, altered, defaced or obliterated.

TO THE EXTENT PERMITTED BY LAW, THIS WARRANTY, AS LIMITED HEREIN, SHALL

BE IN LIEU OF AND EXCLUSIVE OF ALL OTHER WARRANTIES, EITHER EXPRESSED

OR IMPLIED, ON THE PART OF DENSO PRODUCTS AND SERVICES AMERICAS, INC.,

OR DENSO CORPORATION, WHETHER ARISING FROM LAW, COURSE OF DEALING,

USAGE OF TRADE, OR OTHERWISE, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS OF A PARTICULAR

PURPOSE OR ANY LIABILITY FOR COMMERCIAL LOSSES BASED UPON

NEGLIGENCE OR MANUFACTURER'S STRICT LIABILITY. EXCEPT AS EXPRESSLY

PROVIDED HEREIN, NEITHER DENSO PRODUCTS AND SERVICES AMERICAS, INC.,

NOR DENSO CORPORATION WILL, IN ANY EVENT, BE LIABLE FOR LOST PROFITS,

COSTS OF PROCESSING, INJURY, GOODWILL, OR ANY OTHER CONSEQUENTIAL

DAMAGES OF ANY KIND ARISING FROM BREACH OF THIS WARRANTY.

DENSO PRODUCTS AND SERVICES AMERICAS, INC. reserves the right to make

changes without prior notice. MovinCool®, Office Pro® and SpotCool® are registered

trademarks of DENSO Corporation.

PURCHASE DATE:

SERIAL NUMBER:

Page 24

P/N: 484007-3433EN Fourth Issue: March 2015

Loading...

Loading...