MovinCool Classic 10 Service Manual

SERVICE MANUAL

CLASSIC 10

SERIAL NUMBER FROM FEBRUARY 2011 (0211) TO PRESENT

DocID: 00G00089E

© 2012 DENSO SALES CALIFORNIA, INC.

All rights reserved. This book may not be reproduced or copied, in

whole or in part, without the written permission of the publisher . DENSO

SALES CALIFORNIA, INC. reserves the right to make changes without

prior notice.

trademarks of DENSO Corporation.

MovinCool®, Office Pro® and SpotCool® are registered

Table of Contents

Table of Contents

Operation Section

1. PRECAUTIONS FOR SAFETY

1.1 Foreword ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. SPECIFICATIONS

2.1 Exterior Dimension Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. CONSTRUCTION

3.1 Internal Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4. REFRIGERATION SYSTEM

3

4.1 Refrigeration System Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Capillary Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5 Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.7 High Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . 16

5. ELECTRICAL SYSTEM

5.1 Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Control Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 Compressor.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5 Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6 Temperature Thermistor. . . . . . . . . .

5.7 Drain Tank Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6. CONNECTION AND SETTING

6.1 Warning Signal Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Fire Alarm Control Panel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7. OPERATION

7.1 Operation of Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4

Table of Contents

Repair Section

8. TROUBLESHOOTING

8.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2 Self-Diagnostic Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.3 Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.4 Basic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.5 Compressor Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.6 Fan Motor Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.7 Capacitor Inspection ( For Fan Motor and Compressor ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.8 Full Drain Switch Inspection .

8.9 Thermistor Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . 45

8.10 Wiring Connection Inspection .

8.11 Refrigeration System Inspection .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9. DISASSEMBLY

9.1 Parts Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.3 Fan Motor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.4 Removal of Electrical Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.5 Full Drain Switch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10. REFRIGERATION SYSTEM REPAIR

10.1 Repair of Refrigeration System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.2 Removal of Refrigeration System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Charging the System with R-410A Refrigerant. . . . . . . . . .

10.4 Refrigerant Charging Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . 63

. . . . . . . . 69

11. REASSEMBLY

11.1 Reassembly of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

11.2 Compressor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Fan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11.4 Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . 71

. . . . . . . . 72

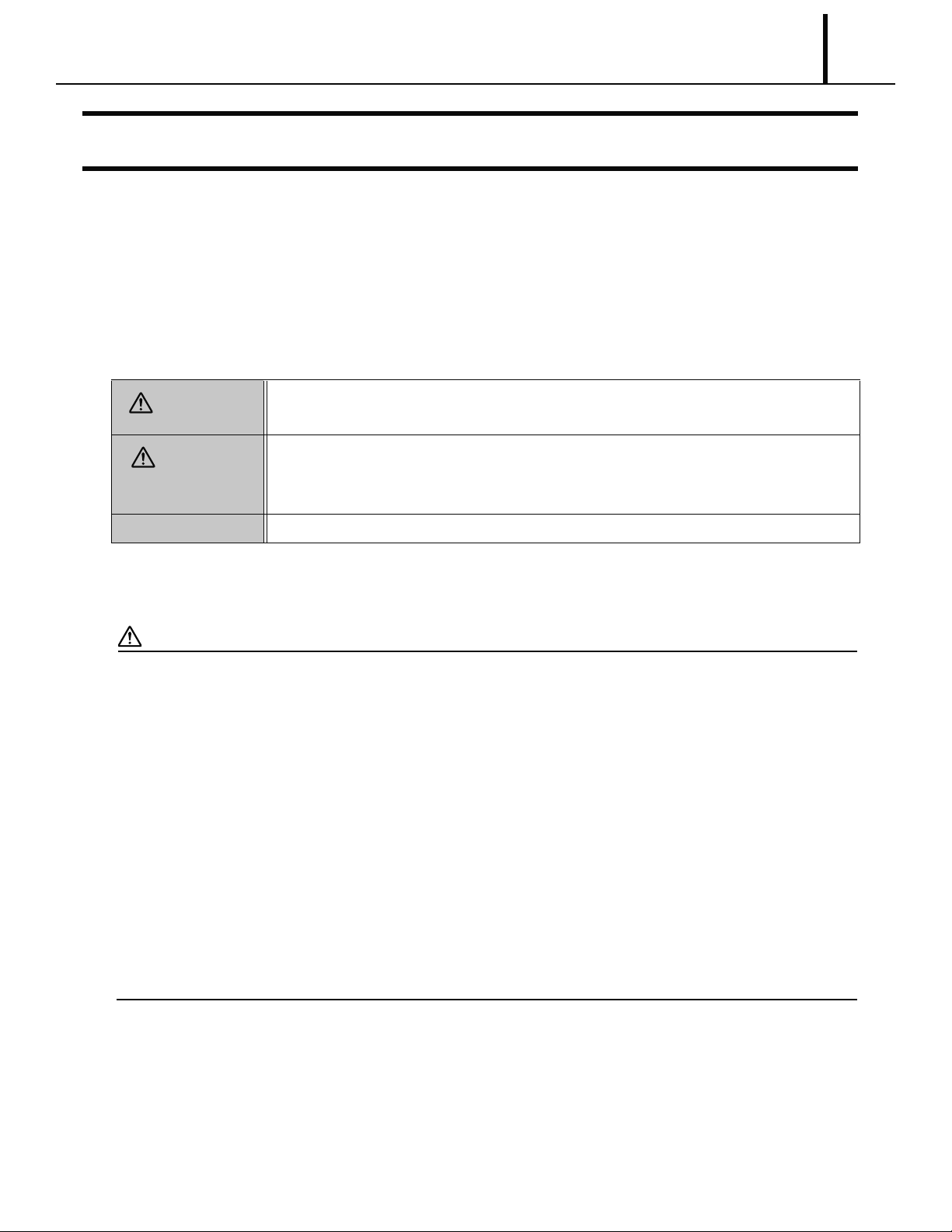

1. PRECAUTIONS FOR SAFETY

1.1 Foreword

• This manual has been published to service the MovinCool Classic 10. Please use this

service manual only when servicing this unit.

1.2 Definition of Terms

Operation Section

5

WARNING

CAUTION

NOTE Provides additional information that facilitates installation or unit operation.

Describes precautions that should be observed in order to prevent injury to

the user during installation or unit operation.

Describes precautions that should be observed in order to prevent damage to

the unit or its components, which may occur during installation or unit

operation if sufficient care is not taken.

1.3 General Precautions

WARNING

• All electrical work should only be performed by qualified electrical

personnel. Repair to electrical components by non-certified technicians may result in

personal injury and/or damage to the unit. All electrical components replaced must be

genuine MovinCool parts, purchased from an authorized reseller.

• When handling refrigerant, always wear proper eye protection and do not allow the

refrigerant to come in contact with your skin.

• Do not expose refrigerant to an open flame.

• The power supply for this unit should be a dedicated single outlet circuit with a UL

recognized short-circuit and ground-fault protective breaker to prevent electrical shock

from the unit.

• When brazing any tubing, always wear eye protection, and work only in a well ventilated

area.

6

Operation Section

2. SPECIFICATIONS

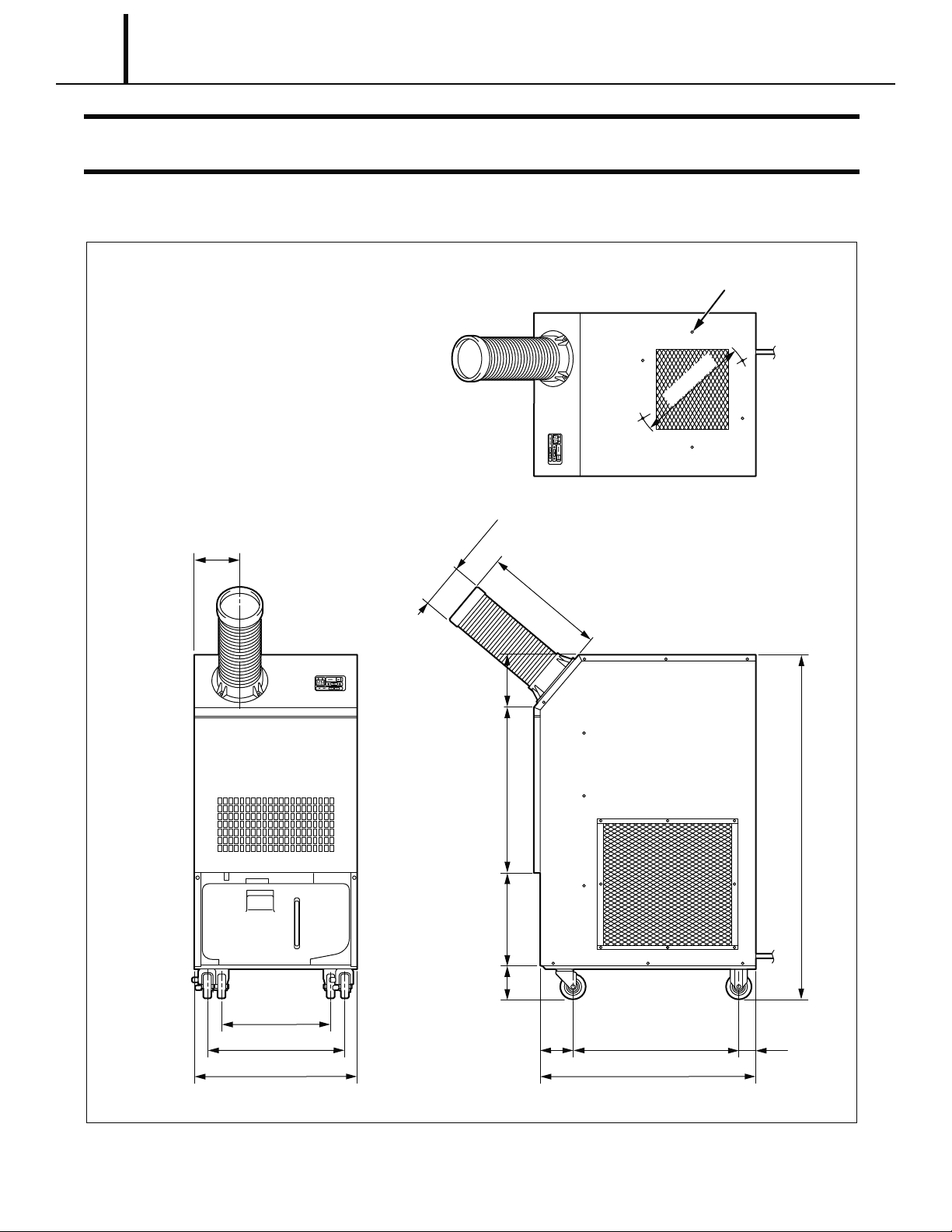

2.1 Exterior Dimension Diagram

6-M6

DIA. 13.8

5.5

DIA. 4.9

13.8

6.519.5

41.5

11.5

4.0

(Unit: inch)

13.0

16.5

19.3

20.7 8.11.3

25.6

ILL00548-00

2.2 Technical Specifications

p

g

g

(

)

p

p

)

p

(

g)

g

g

(

)

)

)

p

y

p

y

g

(

)

p

ITEM

Electronic Features O

Electrical Characteristics

Operating Voltage

e

Ran

Startin

FLA

Cooling Capacity and Power Consumption

Evaporator: 95 °F (35 °C), 60 %RH

Total Cooling Capacity

Condenser: 95 °F (35 °C), 60 %RH

Power Consum

Current Consum

EER

Compressor

Output

Evaporator

Air Flow

Motor Output*

Condenser

Air Flow

Motor Output*

Refrigerant

Refrigerant Control

Type

Amount

Signal Connection

Fire Alarm Input (Signal Type) •No-voltage contact input

Warning Signal Output

Power Cord

NEMA Plu

Gau

Configuration

e x Length

H × D × WnoisnemiD

Weight

Net

Shipping

Drain Tank Ca

Operating Condition Range

Maximum Duct Length

Sound Level*

acit

Inlet Air

Tem

erature

Cold Duct

2

With Condenser Duct

Without Condenser Duct

Safety Devices

Compressor Overload Protector

Fan Motor Overload Protector

Freeze Protection Thermistor

Full Drain Tank Switch

Automatic Restart

ressor Time Dela

Com

High Pressure Interruption*

Signal Input/Output

Control Devices

Temperature Control

• Specifications are subject to changee without notice.

< NOTE >

*1: One motor rotates both the evaporator and the condenser fans.

*2: Measured at 3 feet (1.0 m) from surface of the unit.

*3: For unit serial number from November 2011 (1111) to Present.

Max.

Min.

1

1

Power Interruption

Operation Section

7

SPECIFICATIONS

iDnoitare

ital Programmable

gniStnemeriuqeR egatloV le-Phase, 115 V, 60 Hz

127 V

104 V

A 34tnerruC

A 51eziS esuF dednemmoceR

9.7 A

A 34ARL

10000 Btu/h

2940 W

)W 0231( h/utB 0054yticapaC gnilooC elbisneS

Wk 50.1noit

A 7.9noit

9.5

% 49rotcaF rewoP

yratoR citemreHepyT

0.70 kW

niF etalProtaropavE fo epyT

naF lagufirtneCnaF fo epyT

265 CFM (451 m

3

/h

)aP 28( GWI 33.0erusserP citatS lanretxE .xaM

0.15 kW

niF etalPresnednoC fo epyT

naF lagufirtneCnaF fo epyT

740 CFM (1258 m

3

/h)

)aP 23( GWI 31.0erusserP citatS lanretxE .xaM

-

illary Tube

Ca

R-410A

1.43 lb

Contact resistance less than 100 ohm

•

0.65 k

2 A at 30 V (DC/AC) or less (resistive load)

5-15

14 AWG (3-core) × 10 ft (3.0 m)

19.4 × 26.5 × 41.5 in

(493 × 673 × 1054 mm)

156 lb (71 kg)

194 lb (88 kg)

5.0 gal (19 L)

HR% 05 ,)C° 04( F° 401.xaM

HR% 05 ,)C° 12( F° 07.niM

40 ft (12.2 m)

tf 06tcuD toH

18.3 m

55 dB (A

58 dB (A

Included

Included

Included

Included

Included

3

120 sec

Included

Included

Included

8

Operation Section

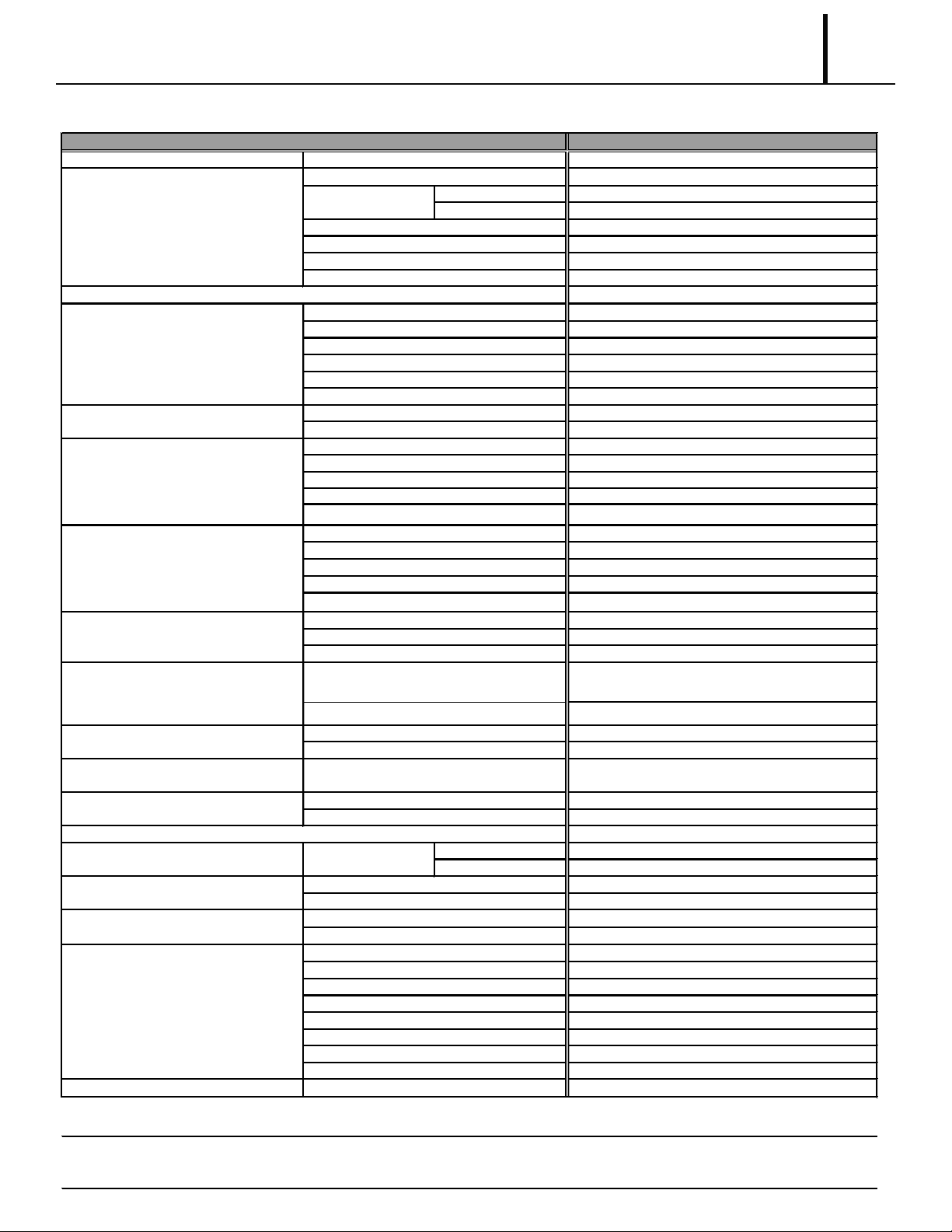

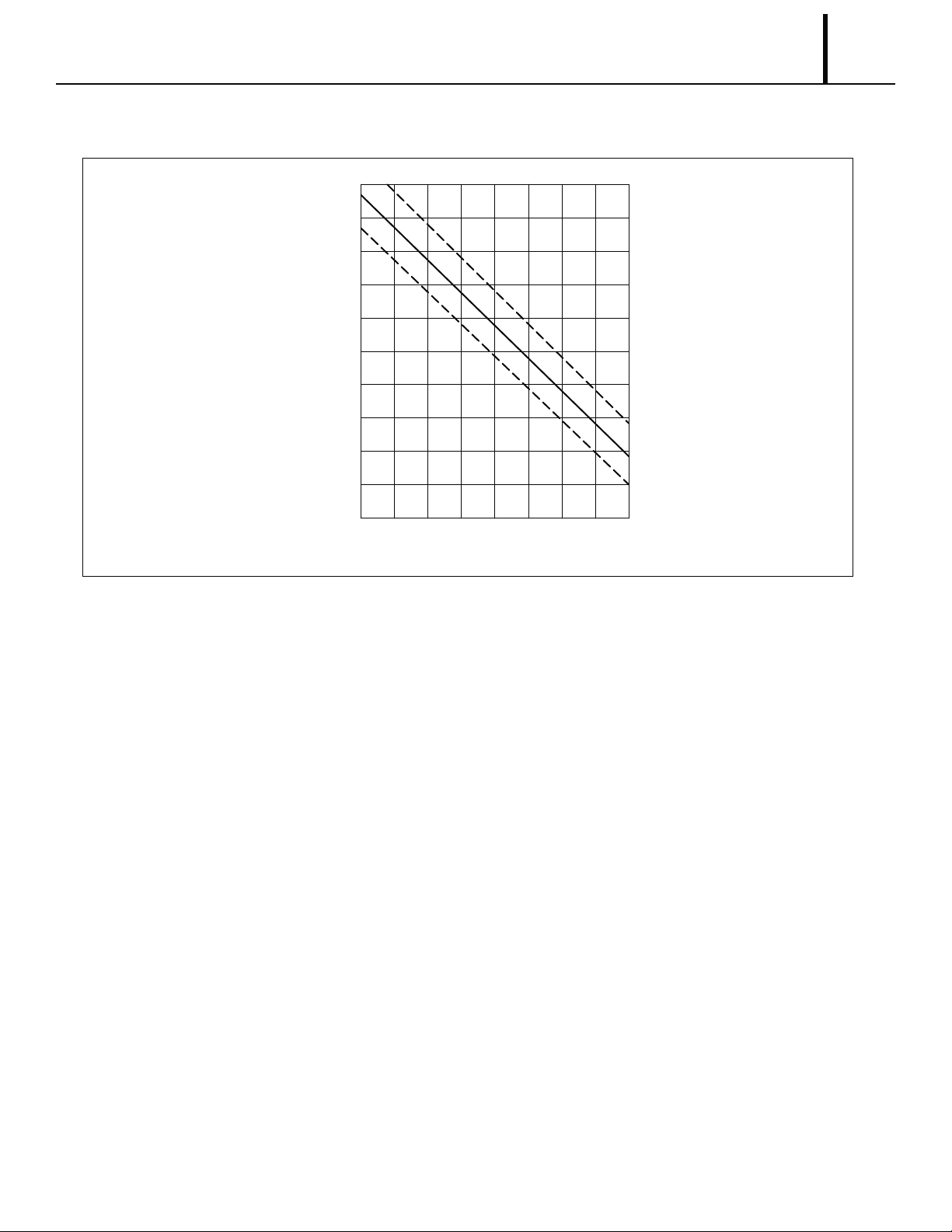

2.3 Characteristics

(1) Cooling capacity curve

13.9

Btu/hDry Bulb Temp. °F (°C)

3

11.9

9.9

7.9

Cooling Capacity. x10

6.0

104 (40)

95 (35)

86 (30)

77 (25)

(2) Power consumption curve

at 115 V

6859

(15) (20) (25) (30)

77 86

)C°( F° .pmeT bluB teW

ILL00563-00

1.2

1.1

1.0

0.9

Power Consumption. kWDry Bulb Temp. °F (°C)

0.8

104 (40)

95 (35)

86 (30)

77 (25)

68

(25)

(20) (30) (35)

at 115 V

77

86 95

)C°( F° .pmeT bluB teW

ILL00564-00

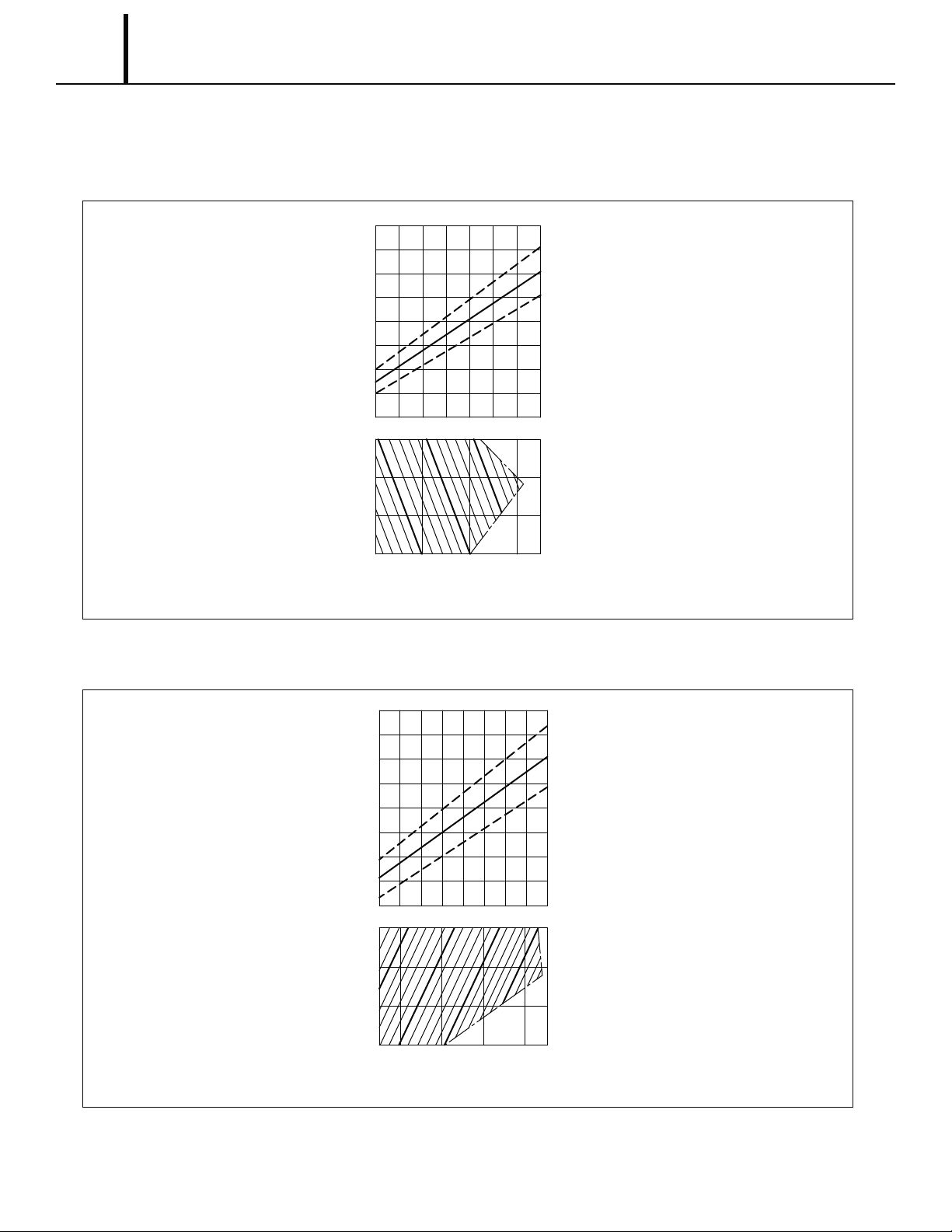

(3) Cool air temperature difference curve

27.0 (15)

25.2 (14)

23.4 (13)

(Delta-T) °F (°C)

21.6 (12)

19.8 (11)

18.0 (10)

16.2 (9)

14.4 (8)

12.6 (7)

Between Inlet and Outlet

Temperature Difference

at 115 V

Operation Section

9

40 50 60 70

Relative Humidity. %

ILL00565-00

10

Operation Section

3. CONSTRUCTION

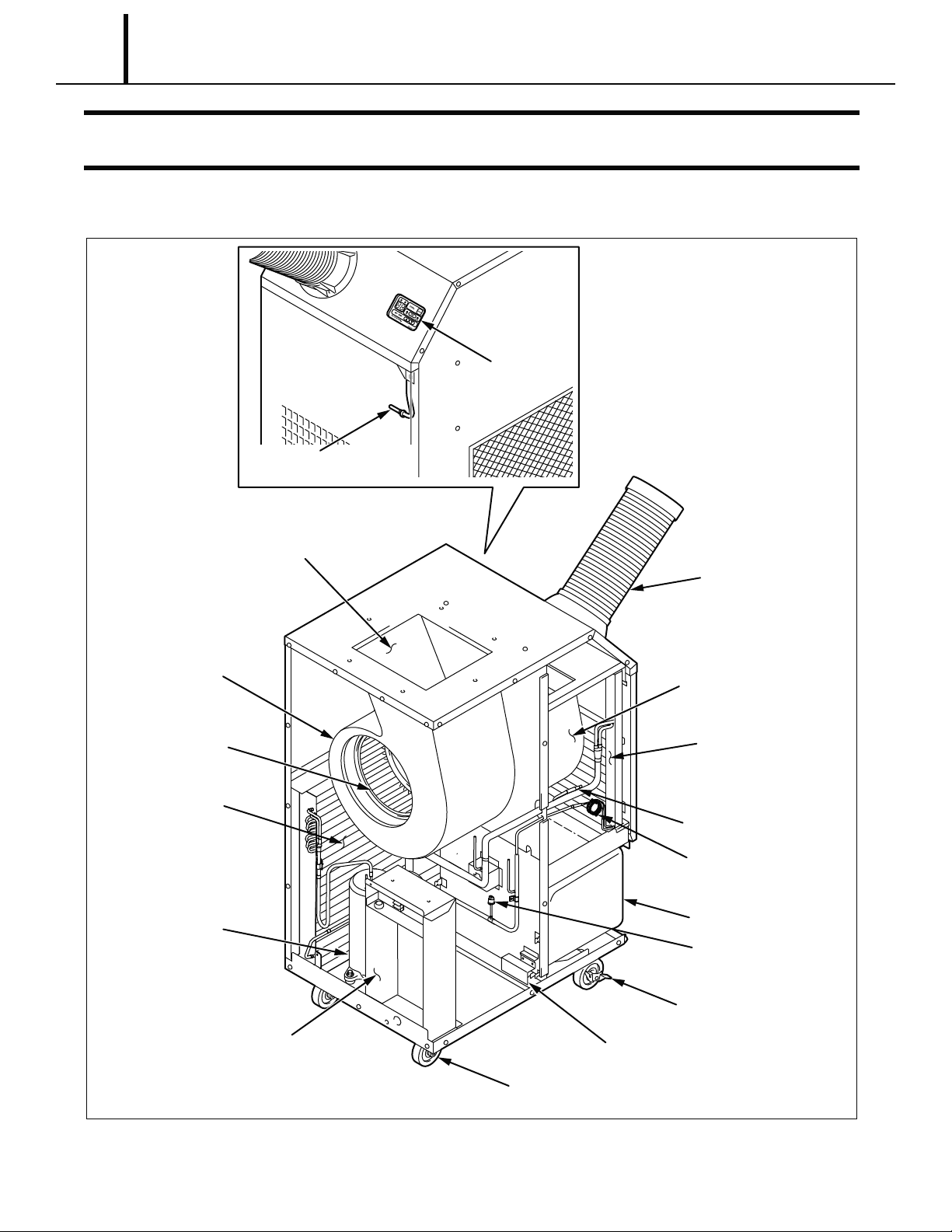

3.1 Internal Structure

Room Thermistor (RTS)

Control Panel

Housing for

Condenser Fan

Condenser Fan

and Motor

Condenser

Compressor and

Accumulator

Condenser Air Outlet

Cooling Air Duct

Housing for

Evaporator Fan

Evaporator

Freeze Protection

Thermistor (CTS)

Capillary Tube

Drain Tank

High Pressure Switch

Control Box

• Relay Board

• Capacitor

Locking Swivel Caster

(Front)

Full Drain Switch

Caster (Rear)

ILL00549-00

Operation Section

4. REFRIGERATION SYSTEM

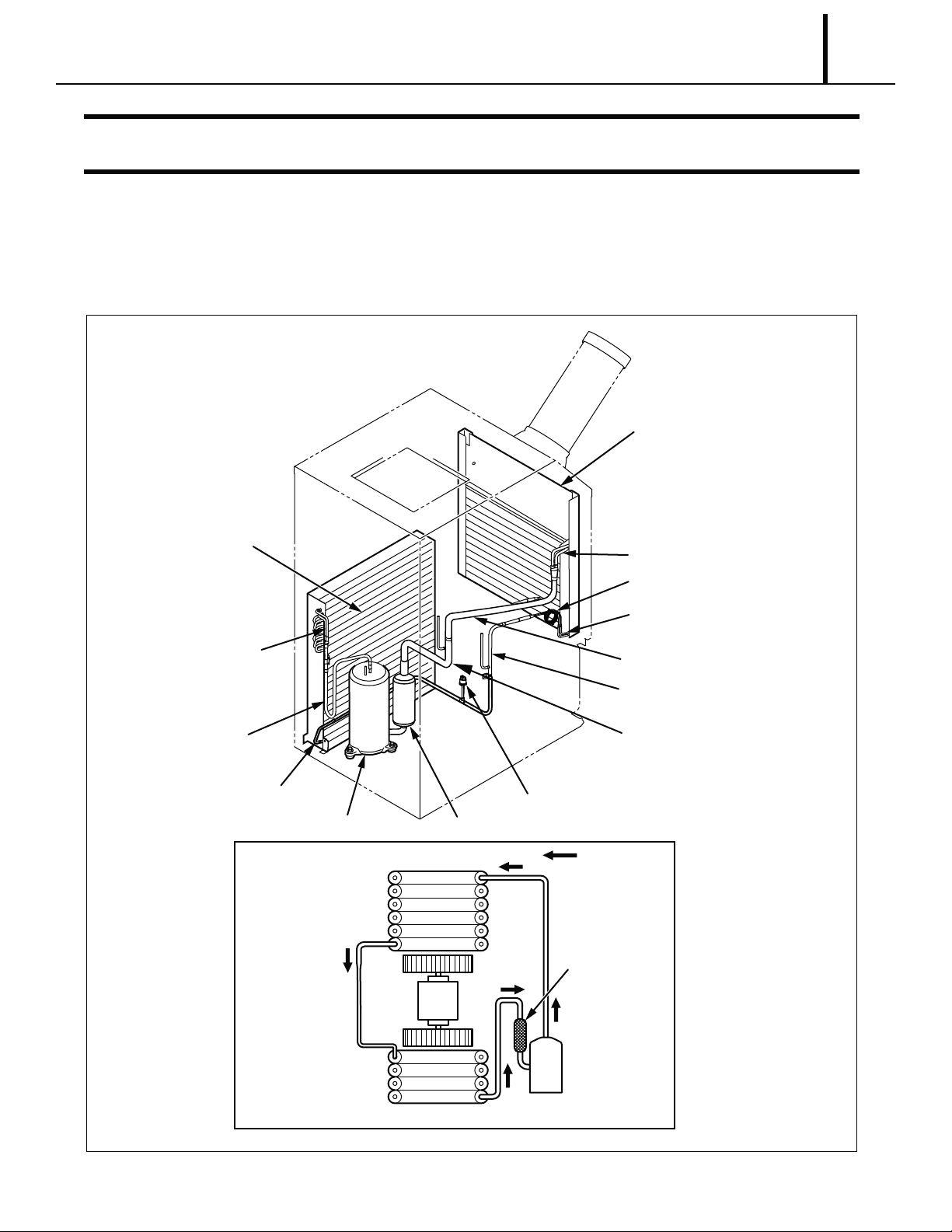

4.1 Refrigeration System Construction

The component parts of the refrigeration system include the following:

• Compressor, Evaporator, Condenser, Accumulator, Capillary tube, High Pressure Switch.

The parts above are all connected by copper piping with brazed connections.

Evaporator

11

Condenser

Condenser

Inlet Pipe

Compressor

Discharge Pipe

Condenser

Outlet Pipe

Compressor

Capillary

Tube

Accumulator

Condenser

Fan

Motor

Evaporator Outlet Pipe

Capillary Tube

Evaporator inlet Pipe

Connecting Pipe

(Evaporator to Compressor)

Connecting Pipe

(Condenser to Capillary Tube)

Compressor Suction Pipe

High Pressure Switch

Flow of

Refrigerant

Accumulator

Evaporator

Compressor

ILL00550-00

12

Operation Section

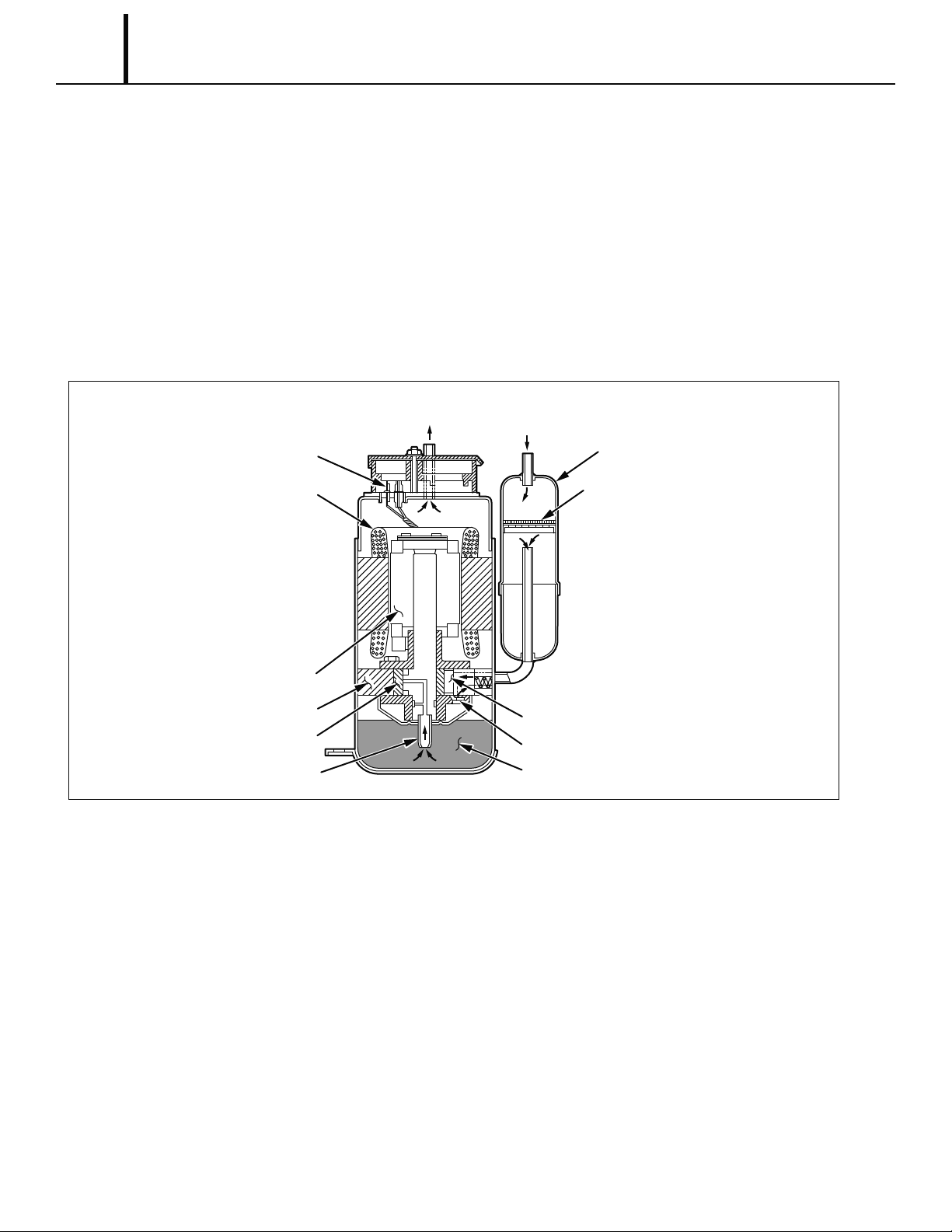

4.2 Compressor

• The compressor used for the unit is hermetically sealed. The compressor and the compressor

motor are in one casing.

(1) Compressor construction

• The construction of a rotary type compressor is divided into two mechanisms; the drive

mechanism (compressor motor), and the compression mechanism (compressor). When the

rotor shaft of the motor (drive mechanism) turns, the roller (compression mechanism) rotates to

compress the refrigerant.

Terminal

Stator

Rotor

Cylinder

Roller

Lubricator

To Condenser

From Evaporator

Accumulator

Strainer

Blade

Discharge Valve

Oil

I001675

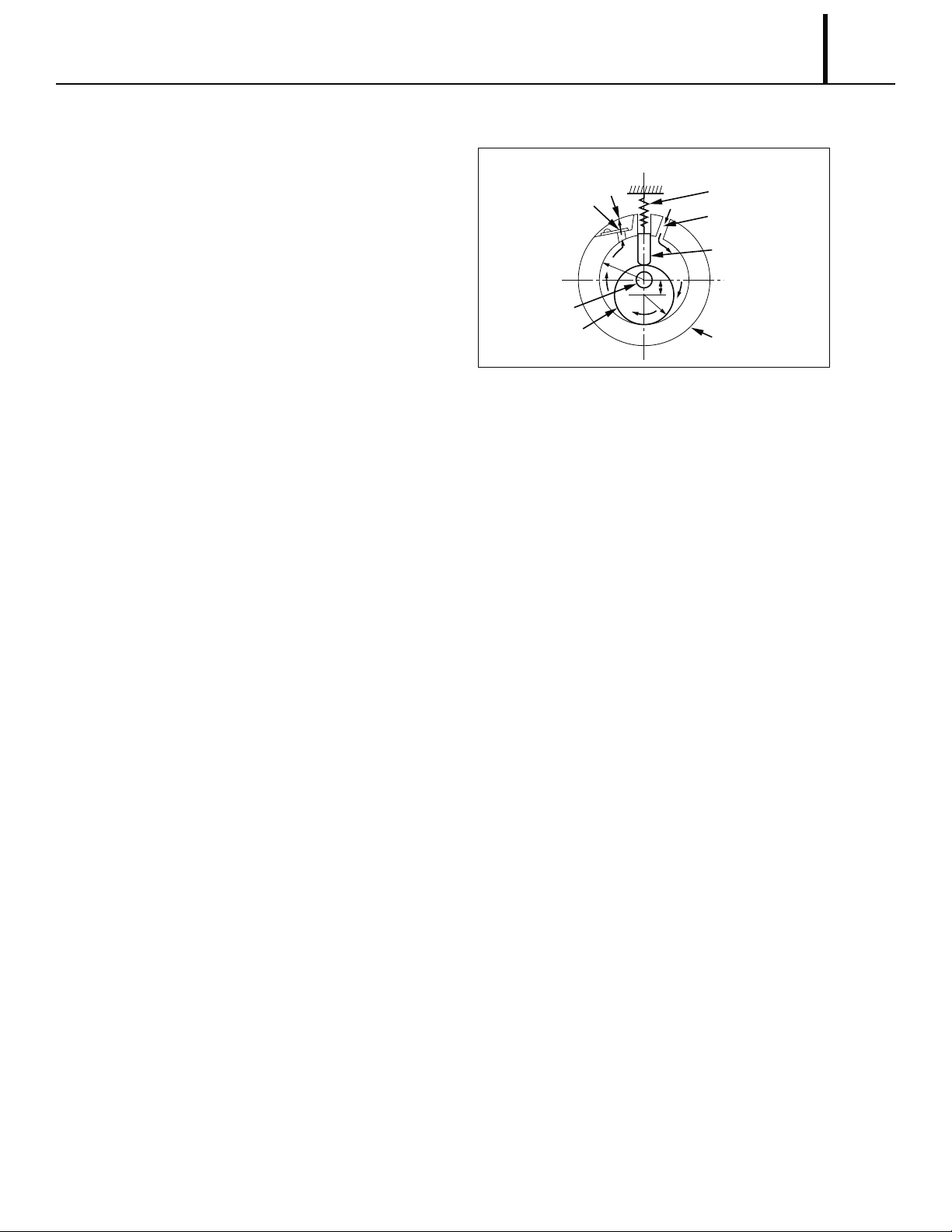

(2) Basic compressor operation

Operation Section

13

• The roller (compression mechanism) is set

eccentrically with a certain distance given from

the axis of the center of the cylinder. A spring

loaded blade is mounted on the cylinder. The

Discharge

Discharge

Valve

Hole

Spring

Suction

Hole

Blade

roller turns to compress the refrigerant in the

space between the cylinder and eccentrically

mounted roller. The blade is in contact with the

roller by means of spring force. The blade

Shaft

Roller

Cylinder

I000510

partitions the space between the suction side

and the discharge side to keep compressed refrigerant from returning to the suction side. There

is no suction valve. The discharge valve is designed not to open until the pressure of the

refrigerant within the cylinder reaches or exceeds discharge side pressure. As a result, the

discharge valve prevents the backward flow of re

frigerant gas.

14

Operation Section

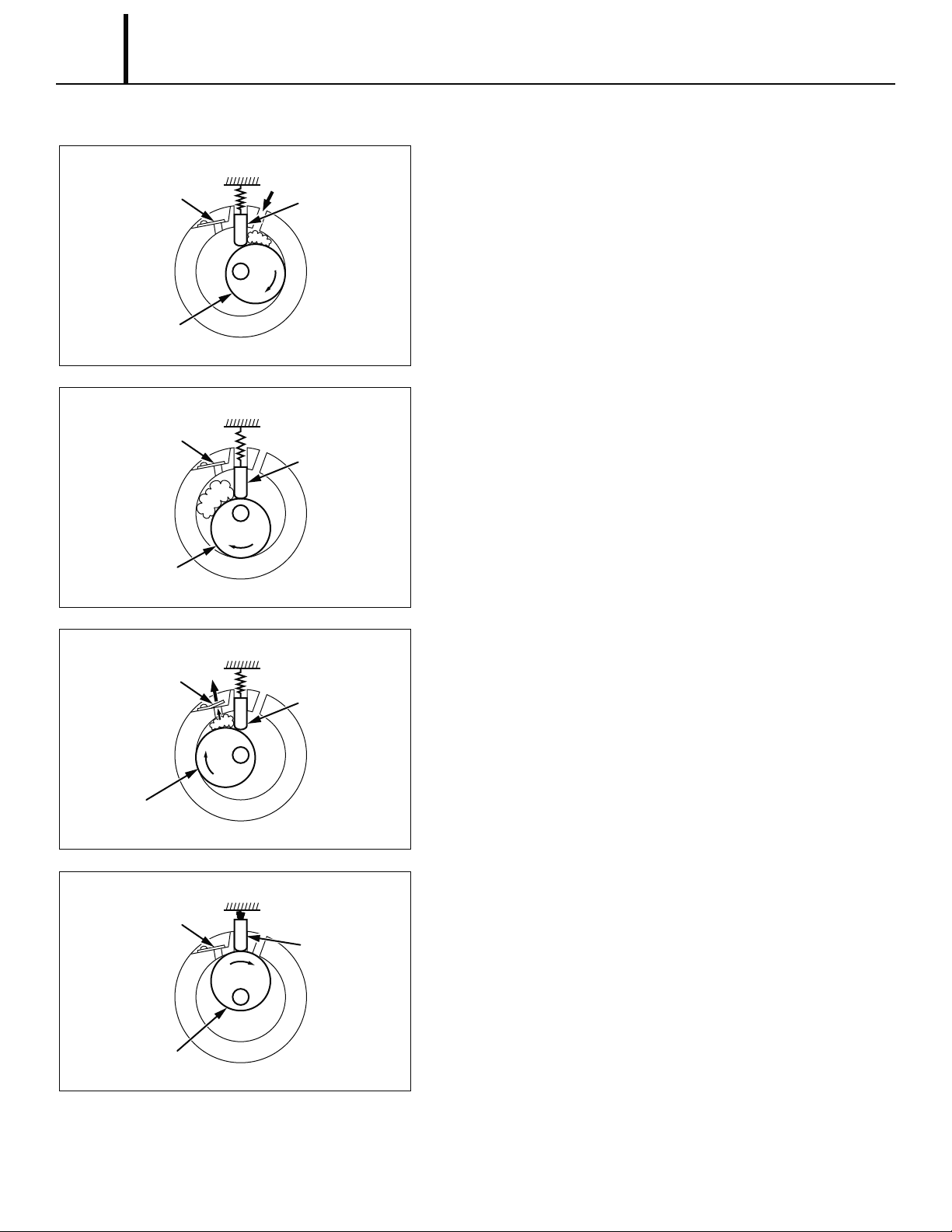

(3) Operation

1) Start of compression

Discharge

Valve

Roller

Discharge

Valve

Roller

Blade

Blade

1) The cylinder is filled with low pressure gas.

2) Since pressure in the discharge chamber is

higher than in the cylinder, the discharge

valve is kept closed.

I001676

2) Suction and compression

1) The pressure in the cylinder increases

gradually.

2) Refrigerant suction begins on the suction

side of the cylinder.

3) The discharge valve remains closed.

I001677

Discharge

Roller

Discharge

Roller

Valve

Valve

Blade

Blade

I001678

I001679

3) Discharge

1) The pressure in the cylinder exceeds that in

the discharge chamber, and the discharge

valve opens.

2) On the suction side, refrigerant suction

continues.

4) Completion of compression

1) When compression is completed, all of the

refrigerant has been drawn from the suction

chamber.

2) Operation then returns to step 1) (Start of

compression) and the above process of

suction and compression continues

repeatedly in succession.

(4) Compressor lubrication

• The lubrication system is comprised of a

Operation Section

15

hollow shaft, an oil scraper mounted at the end

face, hollow shaft, a shaft journal (shaft

bearing), and the lubrication groove for the

shaft journal. The lubrication groove is wider

than the oil hole. When the shaft turns, oil is

Hollow Shaft

Cylinder

Eccentric Shaft

Roller

scraped upward by the oil scraper along the

inside diameter of the hollow shaft. The oil is

fed through the oil hole by centrifugal force,

then supplied to the lubrication groove for each

shaft journal, lubricating the bearing. In this

lubrication system, oil enters into each bearing

Oil Feed Groove

Oil Hole

Oil Scrapper

separately and returns to the oil reservoir.

This system effectively prevents bearing temperature increases, and offers high reliability.

In addition, the specially treated shaft journal keeps the bearing from being damaged during

high temperature operation.

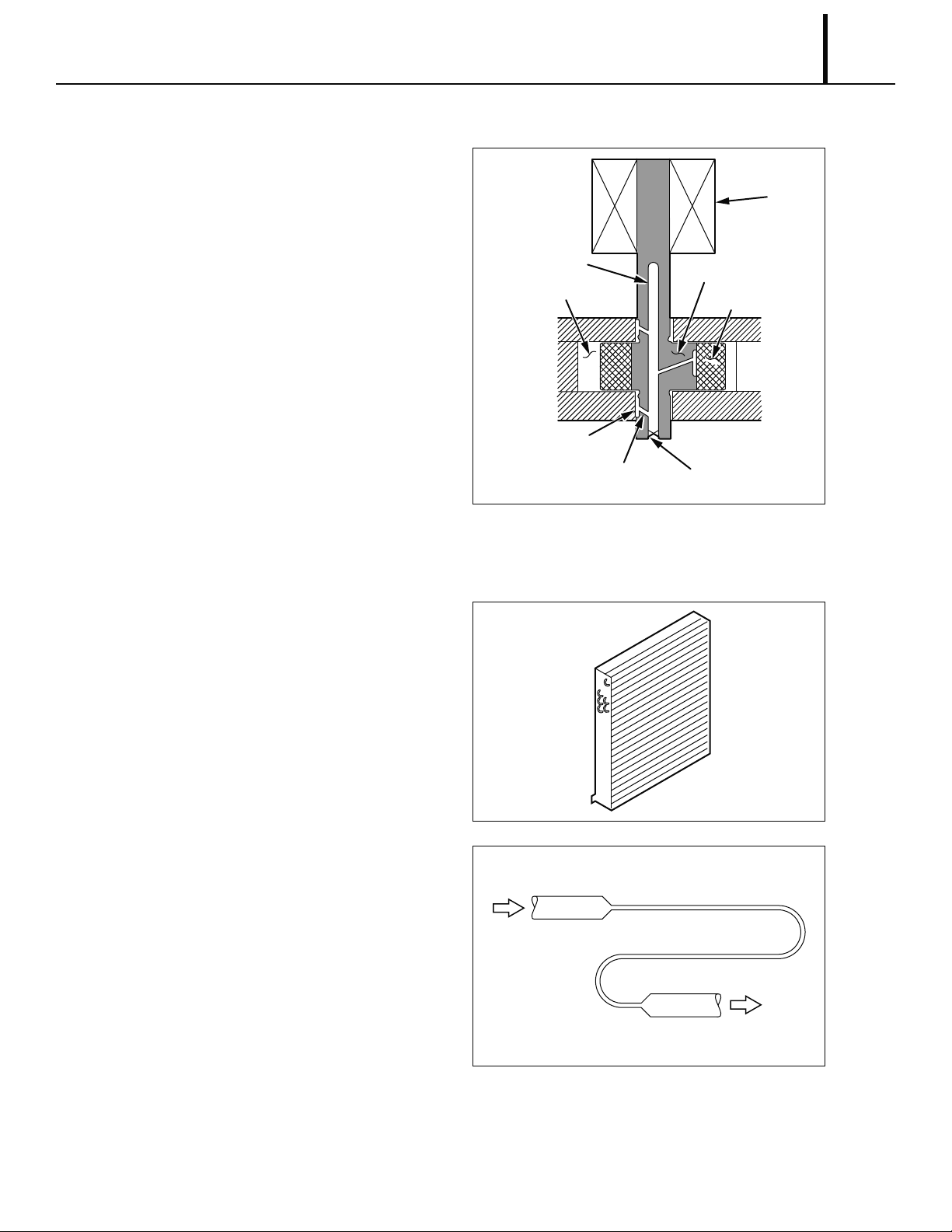

4.3 Condenser

Rotor

I001680

• The condenser is a heat exchanger with

copper tubes that are covered with thin

aluminum projections called plate fins.

• Heat is given off and absorbed by air being

pulled across the condenser fins by the

centrifugal fan and then expelled through the

exhaust air duct.

ILL00551-00

4.4 Capillary Tube

High Temp./High Pressure

• The capillary tube is a long thin tube that

utilizes line flow resistance as an expansion

valve. The length and the inner diameter of the

capillary tube are determined according to the

capacity of the refrigeration system, operating

conditions, and the amount of refrigerant. The

high pressure, high temperature liquid

refrigerant sent from the condenser expands rapidly as the refrigerant is sprayed out through

the fixed orifice in the capillary tube. As a result, the temperature and state of the refrigerant

becomes low and mist-like, and therefore evaporates easily.

Liquid Refrigerant

Low Temp./Low Pressure

Gas and Liquid Mixture

I001887

16

Operation Section

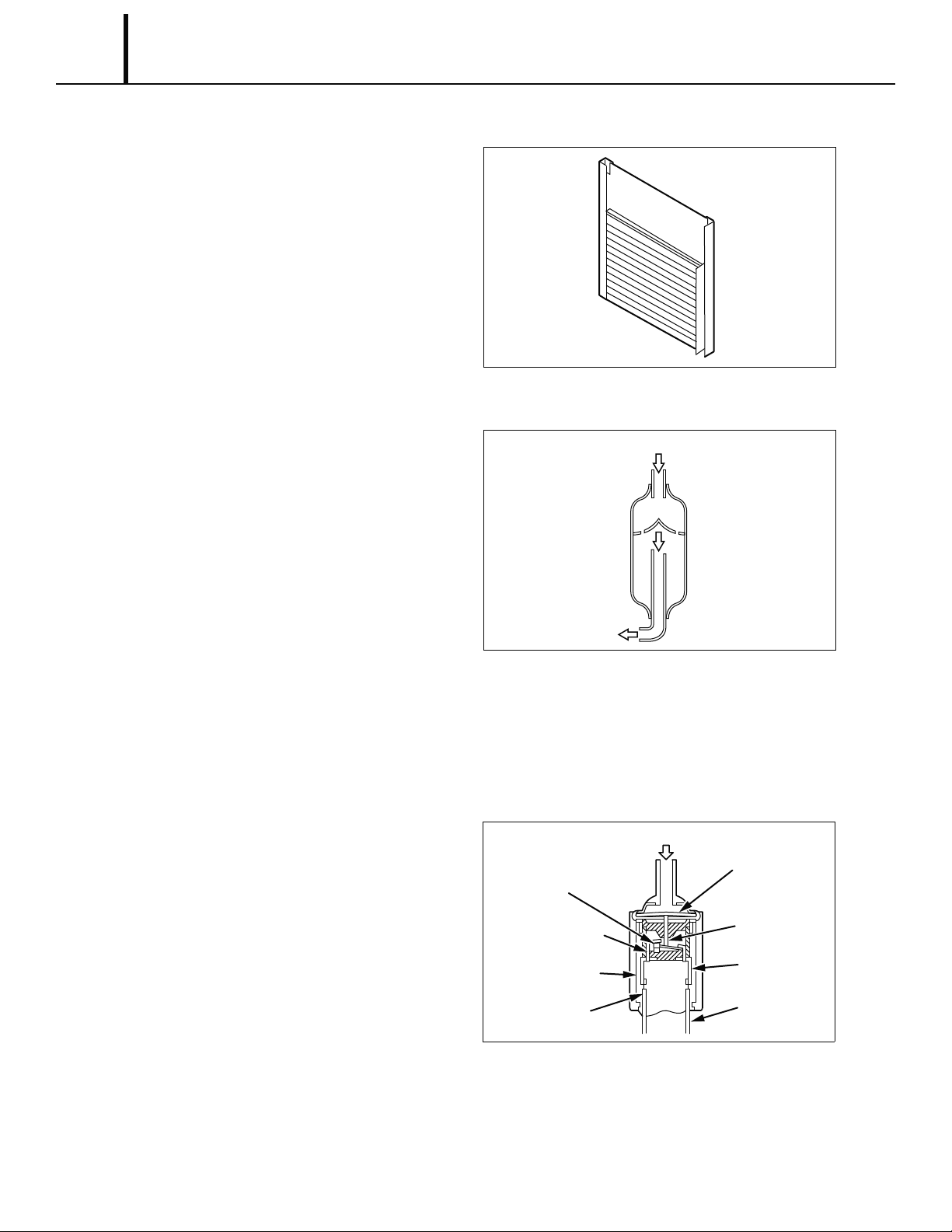

4.5 Evaporator

• The evaporator is a heat exchanger covered

with plate fins. Heat is removed from the air

being pulled across the evaporator by the

centrifugal fan. The resulting cool

expelled through the cooling air ducts.

4.6 Accumulator

• The accumulator is mounted on the suction

gas piping between the evaporator and the

compressor. The accumulator separates the

liquid refrigerant from the gas refrigerant,

allowing only the gas refrigerant to enter the

compressor. In the accumulator, suction gas is

led into a cylindrical vessel where the speed of

the gas is decreased. This process separates

the refrigerant contained in the gas by the force

air is

ILL00552-00

From Evaporator

To Compressor

I000514

of gravity, causing the refrigerant to accumulate at the bottom of the vessel. As a result, the

compressor is protected from possible damage caused by liquid refrigerant intake.

4.7 High-Pressure Switch

• The high-pressure switch prevents the

condenser and compressor from being

damaged by excessive high pressure in the

Movable Point

high-pressure line of the refrigeration cycle.

The switch is normally closed. The snap disk

Stationary Point

responds to the variations in pressure and, if

pressure is abnormally high, the snap disk

moves down to push the pin down, causing the

Molding by Resin

internal contacts to open. This interrupts the

ground signal at the relay board which turns the compressor off.

Pressure of Refrigerant

Snap Disk

Pin

Case

Terminal

Lead Wires

I001768

Operation Section

5. ELECTRICAL SYSTEM

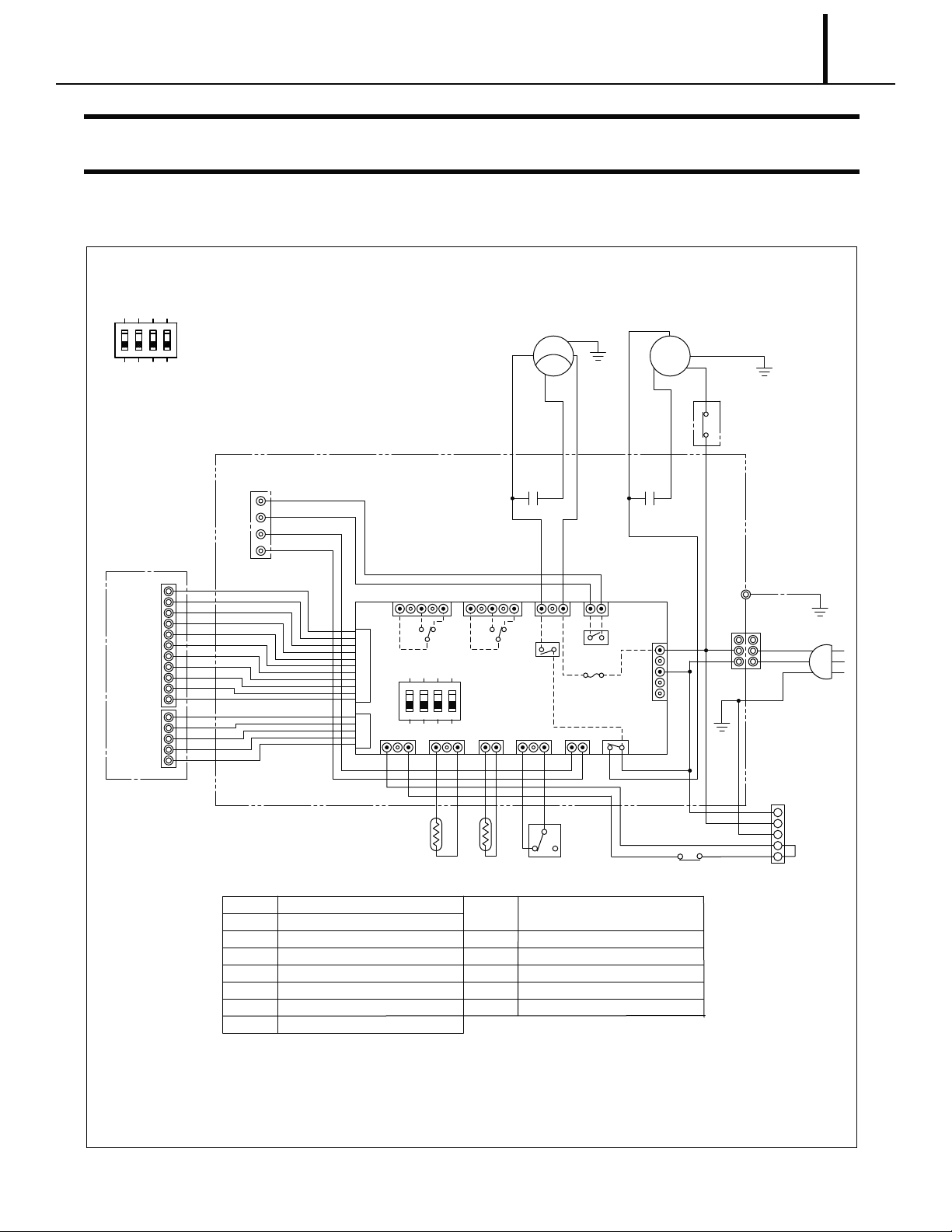

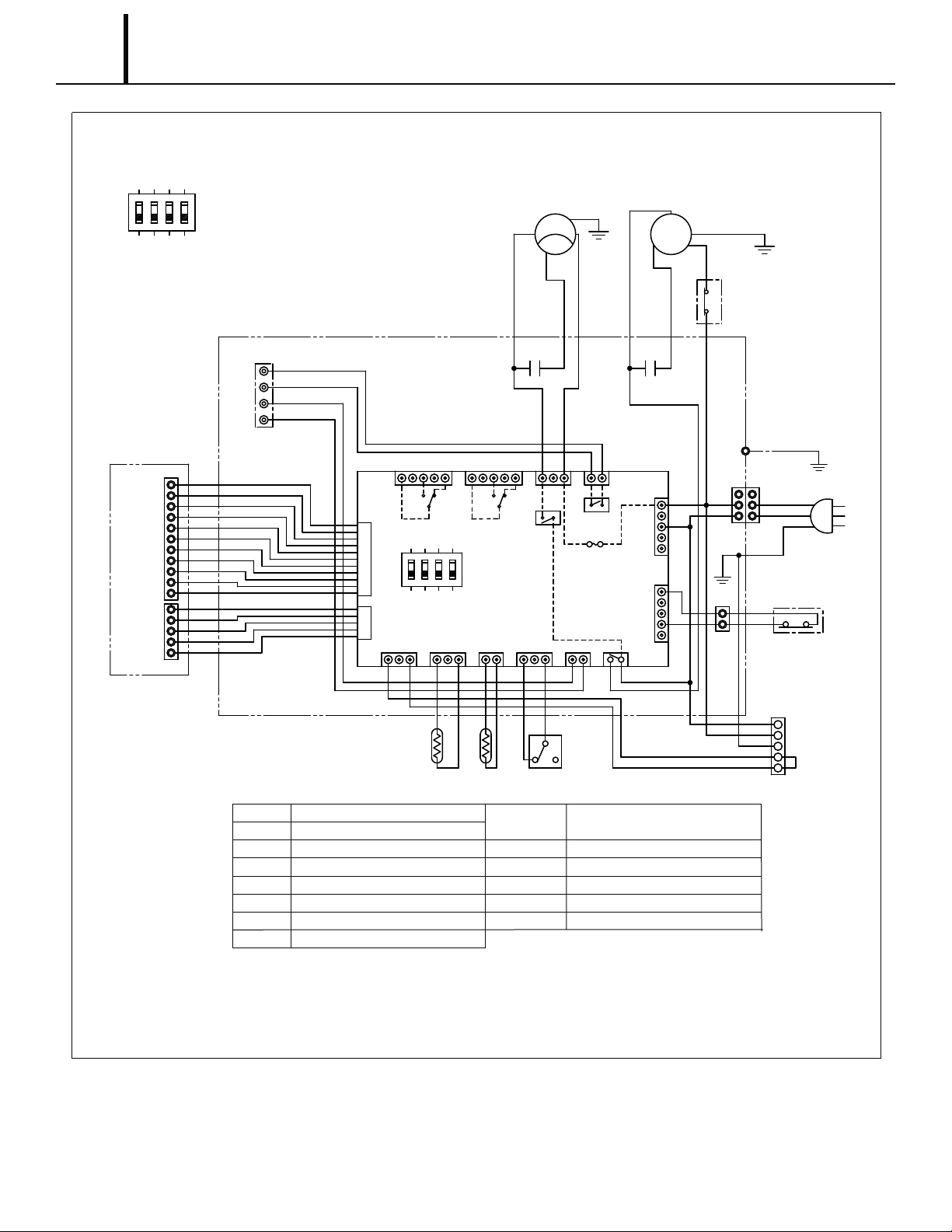

5.1 Circuit Diagram

For Unit Serial Number from February 2011 (0211) to October 2011(1011)

17

Dip Switch

ON

OFF (Default)

2

3

14

#1 : ON: Fan Stop Mode (Fan Auto)

OFF: Fan Operate Mode (Fan On)

#2 : N/A

#3 : N/A

#4 : ON: The Buzzer Sound Disabled

TB2

LL+

E-

On Board

Controller

CB

CN9

11

1

5

1

CN8

E+

Control Box

Output Signal

Fine Alarm

Input

CN23

CN25

1

11

CN17

1

5

13

520D1520D2

Dip Switch

1ON234

CN13

CN12

CN11

13 3

1

CN22

2

12

11521135

52ID

CN16

1

MF

IOLF

CN21

52CT

F1

CN15 52CM

1243

R

G

CN24

MC

SC

CCCF

1

2

RB

T1

COM

R

115V

5

CN01

G

OLC

1

2

Ground (G)

T

R

TB1

G

CN

AP

AC115V

1PHASE

60Hz

TB1 Terminal Block1

TB2 Terminal Block2

RB Relay Board

MF Fan Motor

MC Compressor Motor

CF Capacitor for Fan Motor

CC Capacitor for Compressor

OLC Overload Protector

CTS

RTS Drain Tank SW

CN Connector for Option

Drain Pump

CTS Freeze Protection Thermistor

RTS Room Thermistor

G Ground

CB Control Board

HPRS High Pressure Switch

HPRS

Jumper

Line

ILL00553-00

18

Operation Section

For Unit Serial Number from November 2011 (1111) to Present

Dip Switch

ON

OFF (Default)

2

3

14

#1 : ON: Fan Stop Mode (Fan Auto)

OFF: Fan Operate Mode (Fan On)

#2 : N/A

#3 : N/A

#4 : ON: The Buzzer Sound Disabled

MF

IOLF

R

G

MC

S

C

OLC

1

2

G

On Board

Controller

CB

TB2

Output Signal

LL+

EE+

Fine Alarm

Input

CN9

11

1

5

1

CN8

Control Box

CN23

CN25

1

11

CN17

14

1

CN13

1

520D1520D2

Dip Switch

ON

2

3

CN11

CN12

1

3

3

CTS RTS Drain Tank SW

CF

12 1

11521135

CN22

CN21

52ID

CN165CN15

312

12

1

52CT

F1

CN24

52CM

4 3

COM

115V

CC

RB

1

5

CN01

1

5

CN03

2

Ground (G)

T

R

CN-HP

T

R

TB1

G

CN-PUMP

HPRS

AP

AC115V

1PHASE

60Hz

Jumper

Line

TB1 Terminal Block1

TB2 Terminal Block2

RB Relay Board

MF Fan Motor

MC Compressor Motor

CF Capacitor for Fan Motor

CC Capacitor for Compressor

OLC Overload Protector

CN-PUMP

CTS

RTS

G

CB

HPRS

Connector for Option

Drain Pump

Freeze Protection Thermistor

Room Thermistor

Ground

Control Board

High Pressure Switch

ILL00554-00

Operation Section

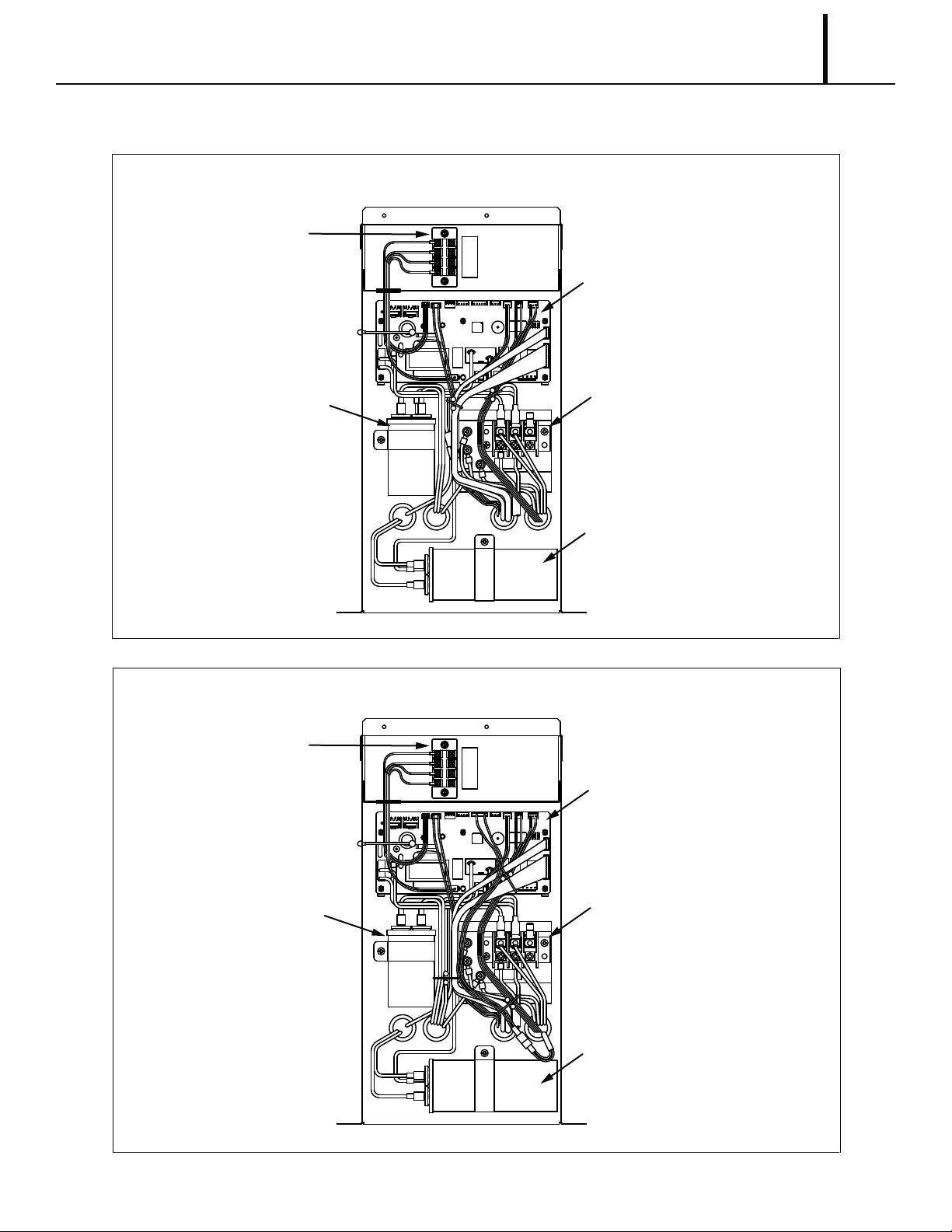

5.2 Control Box

For Unit Serial Number from February 2011 (0211) to October 2011 (1011)

19

T B 2 : T erminal Block2

CF:Capacitor for

Fan Motor

E+

EL+

L-

RB:Relay Board

TB1:Terminal Block 1

CC:Capacitor for Compressor

ILL00559-00

For Unit Serial Number from November 2011 (1111) to Present

T B 2 : T erminal Block2

CF:Capacitor for

Fan Motor

E+

EL+

L-

RB:Relay Board

TB1:Terminal Block 1

CC:Capacitor for Compressor

ILL00555-00

20

Operation Section

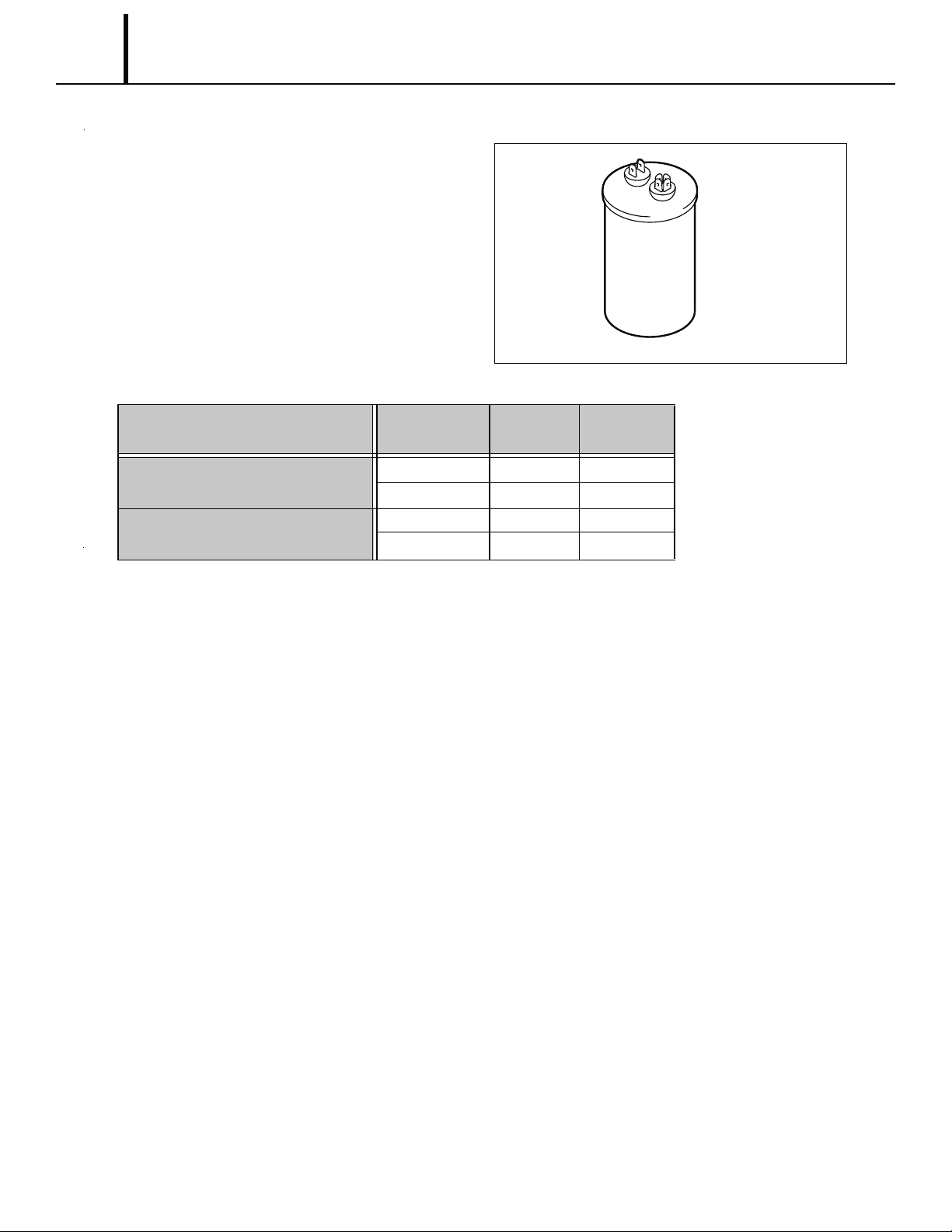

(1) Capacitor

• The capacitor is used to improve the rotational

power of the fan motor and compressor at

startup. The specification for each capacitor is

shown below.

ILL00561-00

Model Capacitor

For unit serial number from February

2011 (0211) to March 2011 (0311)

For unit serial number from April

2011 (0411) to Present

Rated

Voltage

For Fan Motor 450 V 16 μF

For Compressor 450 V 55 μF

For Fan Motor 250 V 25 μF

For Compressor 450 V 55 μF

Capacitance

Operation Section

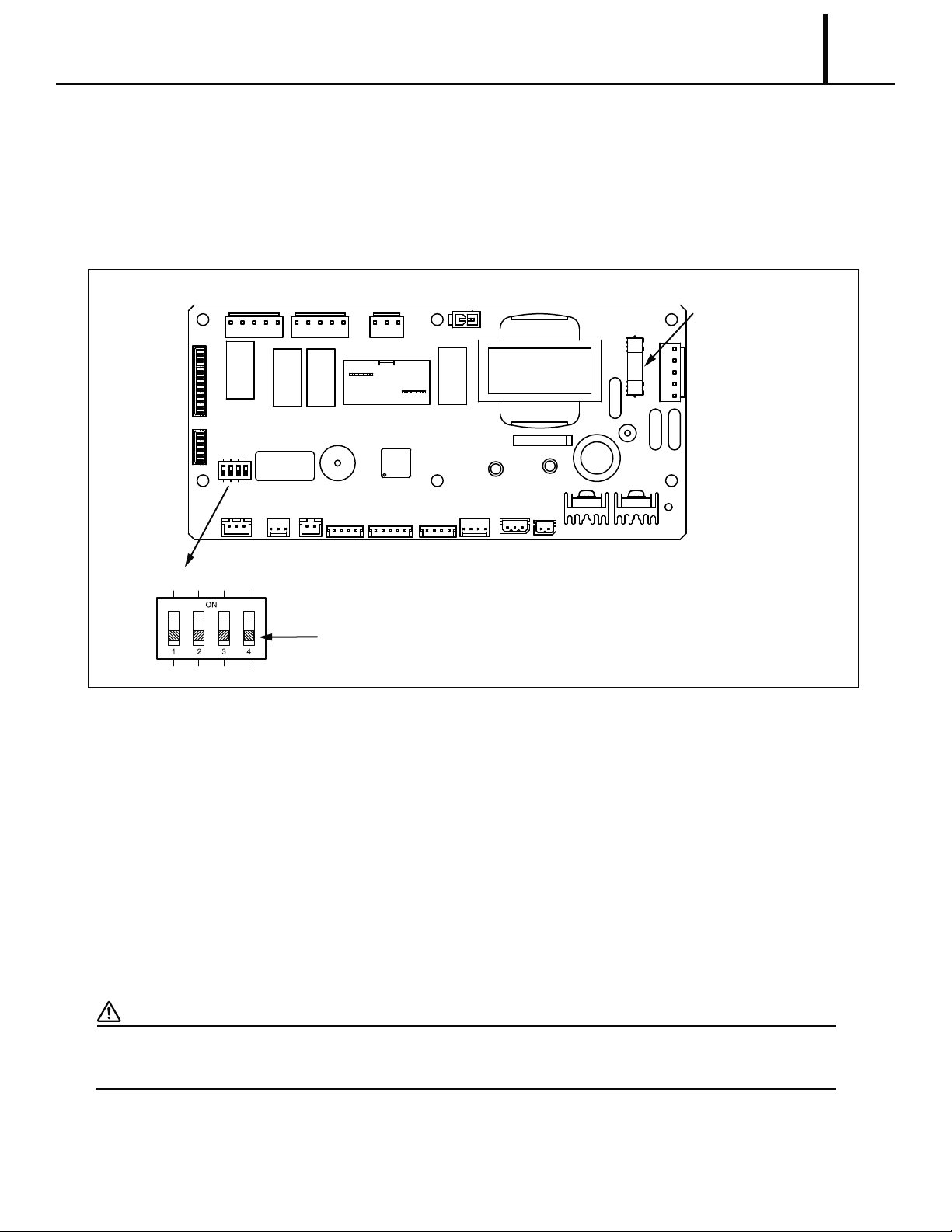

(2) Relay board

• The relay board contains the dip switch, the compressor and fan relays, and a step-down

transformer that reduces the line voltage from 115VAC to approx. 14 VAC. This voltage is

then rectified from 14 VAC to 12 VDC and used for relay coil activation. The 12 VDC voltage

is sent to the control panel assembly, and further being reduced to 5 V for the system logic.

21

CN23

CN25

CN17

CN12CN13

4-Position Dip Switch

CN04CN11

“OFF” Position

1) Power supply requirements

CN21CN22

CN24

Relay Board Fuse (5A)

CN01

CN15CN16CN14CN02CN03

ILL00556-00

• This unit requires a single-phase 115 V, 60 Hz power supply.

2) Relay board fuse

• The relay board fuse is the only serviceable component on the relay board assembly. This fuse

provides protection against damage to the step-down transformer. The fuse must be replaced

with the exact same part, or a suitable equivalent.

Specifications:

- 5 A, 250 VAC

CAUTION

Failure to use the exact same fuse may result in damage to the unit and/or components, and will

also void the unit warranty.

22

*1

Operation Section

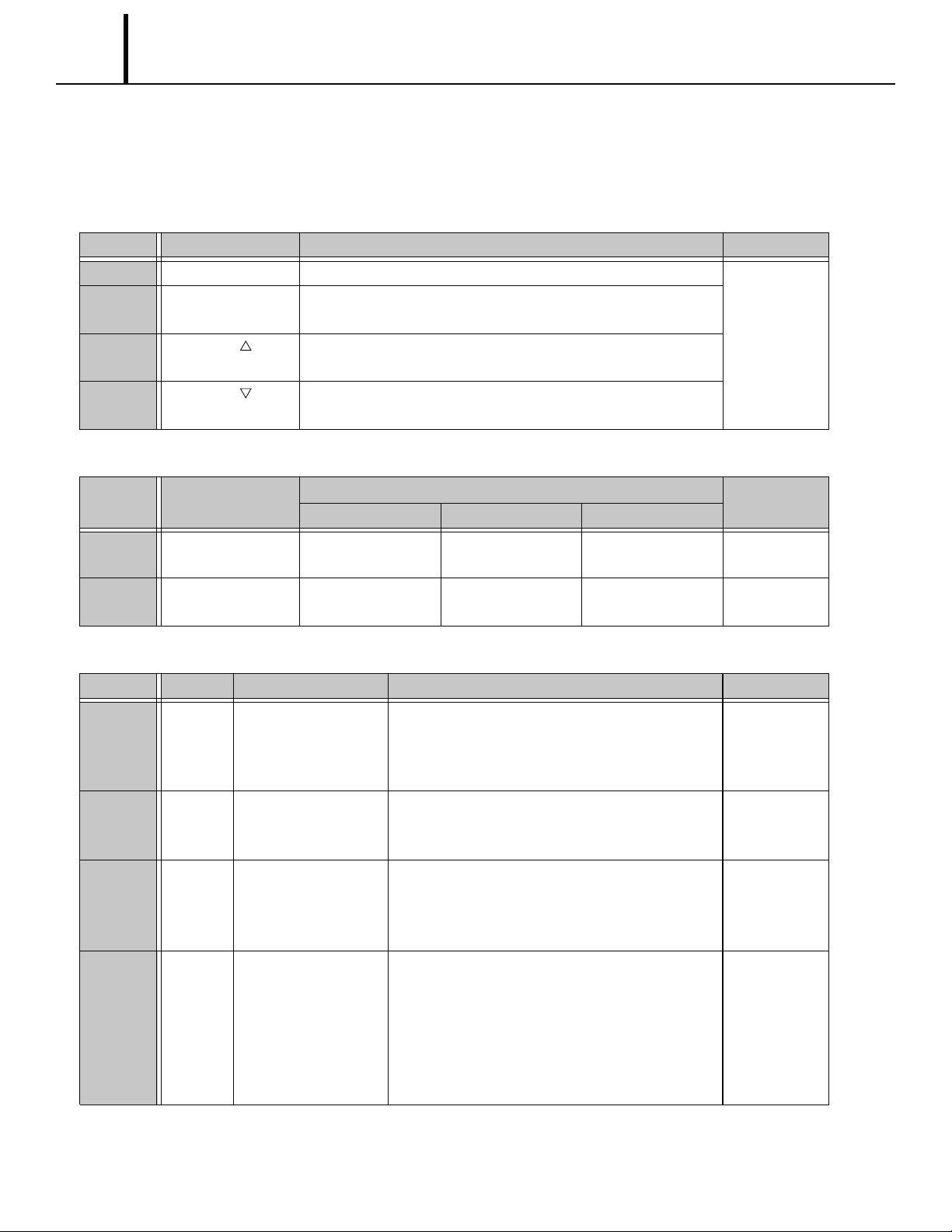

3) Input signal

• The relay board receives inputs from the control panel, sensors, and external devices to perform

device control.

Control Panel Input

Symbol Indication Function Connector

SW1 ON/OFF Button On/off control for unit operation. Turns the unit on and off.

SW2 FAN Button

SW3

SW4

SET TEMP

Button

SET TEMP

Button

Changes the fan control mode between continuous and automatic

on/off control.

Increases the set temperature.

Decreases the set temperature.

CN17

Sensor Input

Symbol Type

RTS Room Thermistor

CTS

Freeze Protection

Thermistor

Characteristic “Short” Detection “Open” Detection

5 k ohm at 77 °F

(25 °C)

5 k ohm at 77 °F

(25 °C)

Specification

181 °F (83 °C) or

more

181 °F (83 °C) or

more

-29 °F (-34 °C) or

less

-29 °F (-34 °C) or

less

Connector

CN11

CN12

External Input Signal Specification

Symbol Signal Specification Function Connector

On: Activates “Defect control”

(Contact: Normally open)

LED shows “AL”, Output signal “ON”

On board buzzer sound

CN15

AUX2

Fire

Alarm

Input

On: Between 10 to 20

mA at DC12 V

(Off: No signal)

TANK

FULL S/W

AUX1

HPRS

*1 : For unit serial number from November 2011 (1111) to Present

Tank Full

Switch

External

Pump

Failure

High

Pressure

Switch

On: Between 10 to 20

mA at DC12 V

(Off: No signal)

On: Between 10 to 20

mA at DC12 V

(Off: No signal)

On: Between 0.4 to 1.0

mA at DC 5V

(Off: No signal)

Off: Activates “Defect control”

LED shows “FL”, Output signal “ON”

Off:

1) From 1 to 180 seconds - Compressor stops.

2) After 180 seconds - Compressor stops.

LED shows “AS”, Output signal turns “ON”

(Contact: Normally closed)

Off: Activates “Defect control”

(Contact: Normally closed)

1) Activates 3 times in 24 hours:

LED shows blinking “HP”.

2) Activates 10 times in 24 hours:

LED shows “HP”, Output signal “ON”

CN16

CN13

CN03

Loading...

Loading...