MovinCool 24HFU Service Manual

SERVICE MANUAL

24HFU and 24HFU-1

DENSO SALES CALIFORNIA, INC.

REGISTERED TO ISO 9002

FILE NO. A5537

© 2000 DENSO SALES CALIFORNIA, INC.

All rights reserved. This book may not be reproduced or copied, in whole or in part, without the written permission

of the publisher. DENSO SALES CALIFORNIA, INC. reserves the right to make changes without prior notice.

MovinCool is a registerd trademark of DENSO CORPORATION.

DSCA P/N: LA990009-0205-E

(800) 264-9573 www.movincool.com

FOREWORD

This manual has been published to service the MovinCool 24HFU and 24HFU-1. Both the Model 24HFU and

24HFU-1 perform the same basic function, however the 24HFU-1 has additional features. Please use this service

manual in servicing Models 24HFU and 24HFU-1.

DEFINITION OF TERMS

WARNING

Describes precautions that should be observed in order to prevent injury to the user during installation or

unit operation.

CAUTION

Describes precautions that should be observed in order to prevent damage to the unit or its components,

which may occur during installation or unit operation if sufficient care is not taken.

NOTE

Provides additional information that facilitates installation or unit operation.

GENERAL PRECAUTIONS

WARNINGS:

• All electrical work if necessary, should only be performed by qualified electrical personnel. Repair to

electrical components by non-certified technicians may result in personal injury and/or damage to the unit.

All electrical components replaced must be genuine MovinCool, purchased from an authorized reseller.

• When handling refrigerant, always wear proper eye protection and do not allow the refrigerant to come in

contact with your skin.

• Do not expose refrigerant to an open flame.

• The proper electrical outlet for MovinCool units must be equipped with a “UL” approved ground-fault

breaker to prevent electrical shock from the unit.

• When brazing any tubing, always wear eye protection and brazing tubing in a well ventilated area.

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 2

GENERAL DESCRIPTION

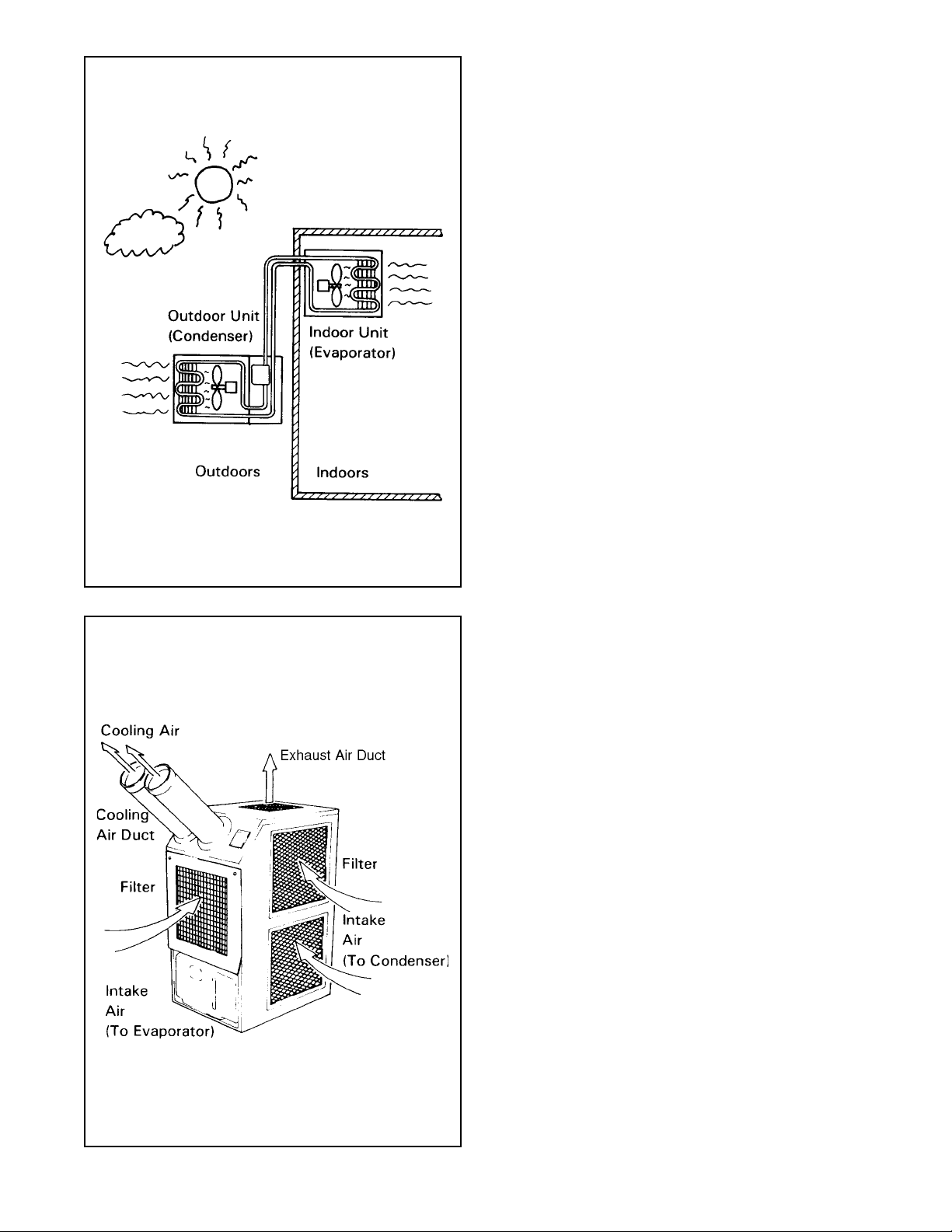

Generally speaking conventional air conditioners cool

the entire enclosed environment. They act as “heat

exchangers”, requiring an interior unit (evaporator) to

blow cool air into the interior and an exterior unit

(condenser) to exhaust exchanged heat to the outdoors. Unlike conventional air conditioners, the

MovinCool Spot Cooling System is a spot cooler which

directs cool air to particular areas or objects.

MovinCool Spot Cooling Systems have the following

features:

1-1. Compact Design

The innovative design of MovinCool has resulted

in one compact unit, replacing the need for two

separate units.

■ Conventional Air Conditioner

1-2. Easy Transportation and Installation

With the whole cooling system built into one

compact unit, MovinCool requires no piping and

can be easily transported and installed.

1-3. Energy Conservation

MovinCool is economical because it cools only

the area or objects which need to be cooled.

Air Flow of MovinCool Spot Cooling System

■

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 3

CONSTRUCTION AND SPECIFICATIONS

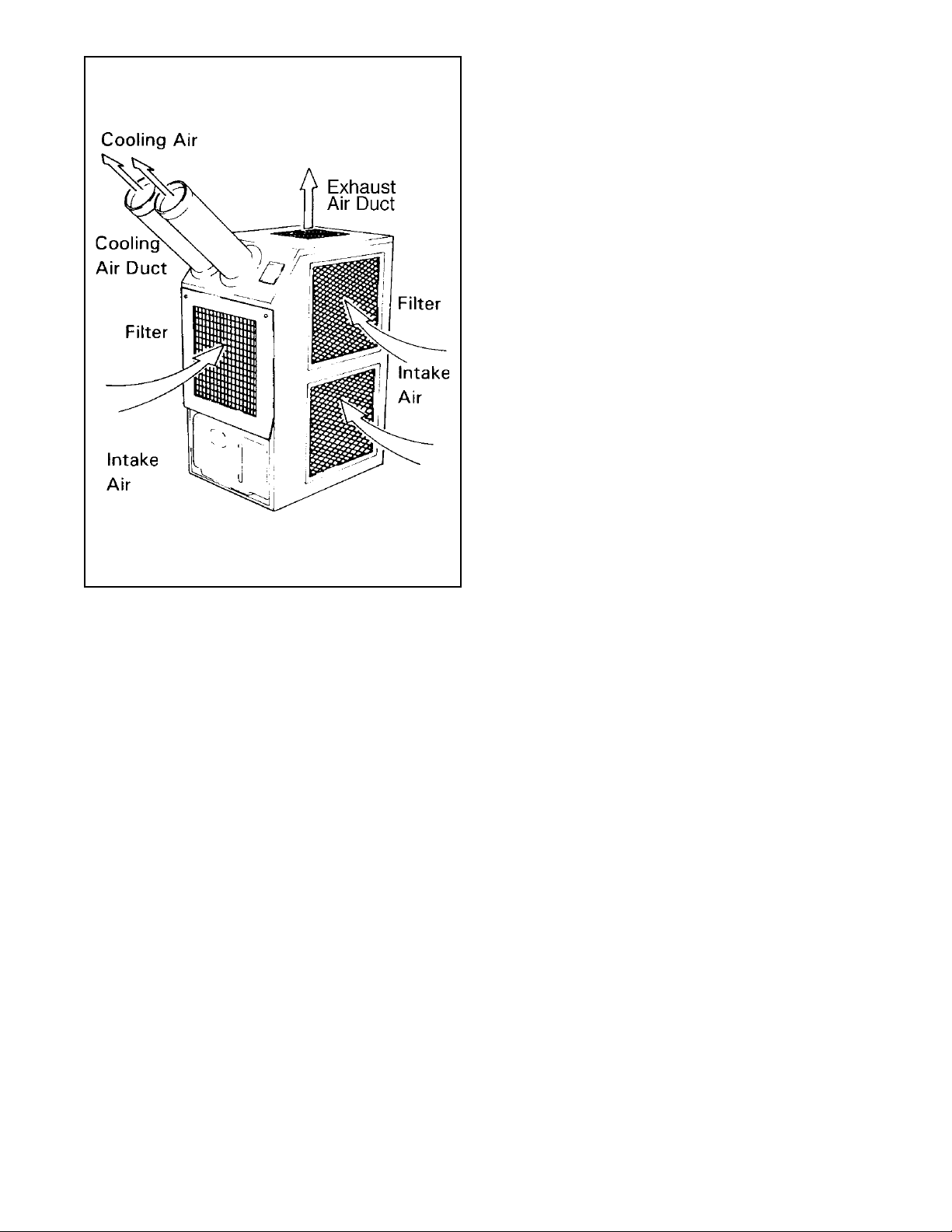

■ Construction of Models 24HFU & 24HFU-1

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 4

CONSTRUCTION AND SPECIFICATIONS

2-1. Basic Construction

The MovinCool Spot Cooling System is compact

in construction because the condenser and the

evaporator are enclosed in one unit. The interior

is divided into three sections. The upper front

face is equipped with the evaporator, while the

lower front face contains the drain tank. The

rear section contains the condenser, the compressor and the control box.

2-2. Air Flow

Air drawn from the right side face passes

through the condenser and extracts the heat.

This hot air is blown out through the upper

exhaust air duct. Air taken in from the front face

is cooled by the evaporator and then blown

through the cooling air duct which can be turned

in any direction. All the air inlets are provided

with filters, while the exhaust air duct is protected by wire mesh.

■ Air Flow

2-3. Compressor and Fans

The compressor is hermetically sealed. One

motor is used with two centrifugal fans to draw

air across the evaporator and condenser.

2-4. Drain Tank

The capacity of the drain tank is 5.3 gallons (20

liters). The unit is equipped with a full tank lamp

and a device to automatically stop the unit’s

operation when the drain tank reaches a level of

approximately 4.4 ± 0.5 gallons (16.5 ± 2 liters).

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 5

CONSTRUCTION AND SPECIFICATIONS

ITEM/MODEL 24HFU 24HFU-1

[Rating Condition] DB 35˚C WB 28.2˚C DB 35˚C WB 28.2˚C

95˚F 83˚F 95˚F 83˚F

RH 60% RH 60%

[Features]

Power frequency___________ (Hz) 60 60

Line voltage ______________ (Volt) Single phase 230 Single phase 230

Power consumption ________ (Kw) 3.1 3.1

Current consumption _______ (Amp) 14.0 14.0

Power factor ______________ (%) 96 96

Starting current ____________ (Amp) 62 62

Power wiring ______________ (AWG) 12 (3-core) 12 (3-core)

[Cooling Unit]

Cooling capability __________ (Kcal/h) 6,000 6,000

________________________ (Btu/h) 24,000 24,000

Cooling system Direct expansion Direct expansion

[Blower]

Type of fan Centrifugal fan Centrifugal fan

Condenser - Air flow ________ (ft

Evaporator - Air flow ________ (ft3/min) 706 706

Motor output ______________ (Kw) 0.55 0.55

[Compressor]

Type Hermetic scroll Hermetic scroll

Output___________________ (Kw) 1.6 1.6

Refrigerant type R-22 R-22

Refrigerant amount _________ (kg) 0.85 0.85

________________________ (lbs) 1.87 1.87

[Safety Device]

Compressor overload relay With With

Fan motor protector With With

Drain switch With With

Anti-freezing thermostat With With

High pressure switch With With

Restart relay - power interruption Without With

Time delay relay Without With

[Dimensions and Weight]

W x D x H ________________ (mm) 490 x 730 x 1200 490 x 730 x 1200

________________________ (inch) 19.3 x 28.7 x 47.2 19.3 x 28.7 x 47.2

Weight___________________ (kg) 107 107

________________________ (lbs) 235 235

[Operating Conditions]

Intake air temperature range 45˚C (113˚F), RH ≤50% 45˚C (113˚F), RH ≤50%

[Control Device]

Temperature control Without With

3

/min) 1,200 1,200

to 25˚C (77˚F), RH ≥50% to 25˚C (77˚F), RH ≥50%

■ Specifications

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 6

Specifications are subject to change without notice.

REFRIGERANT SYSTEM

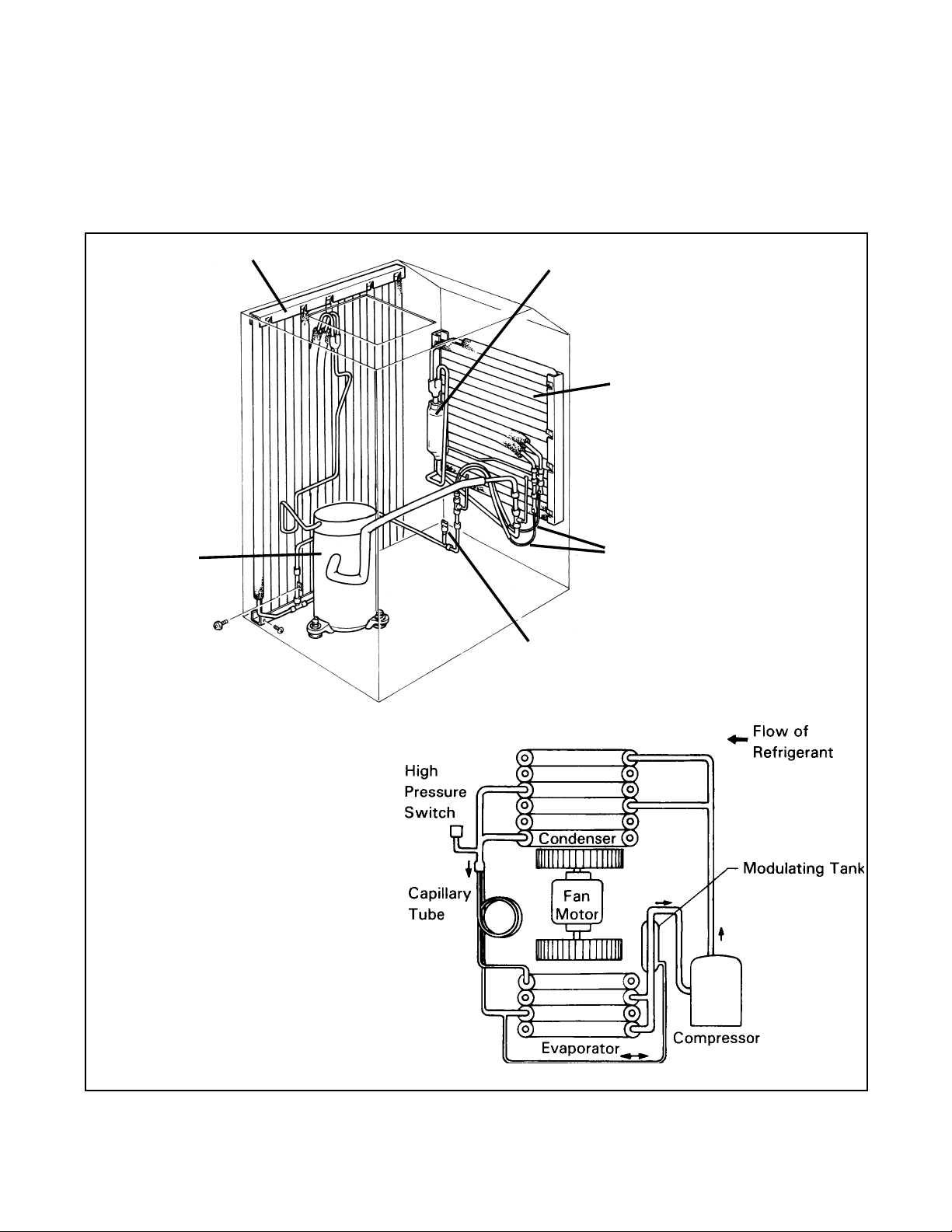

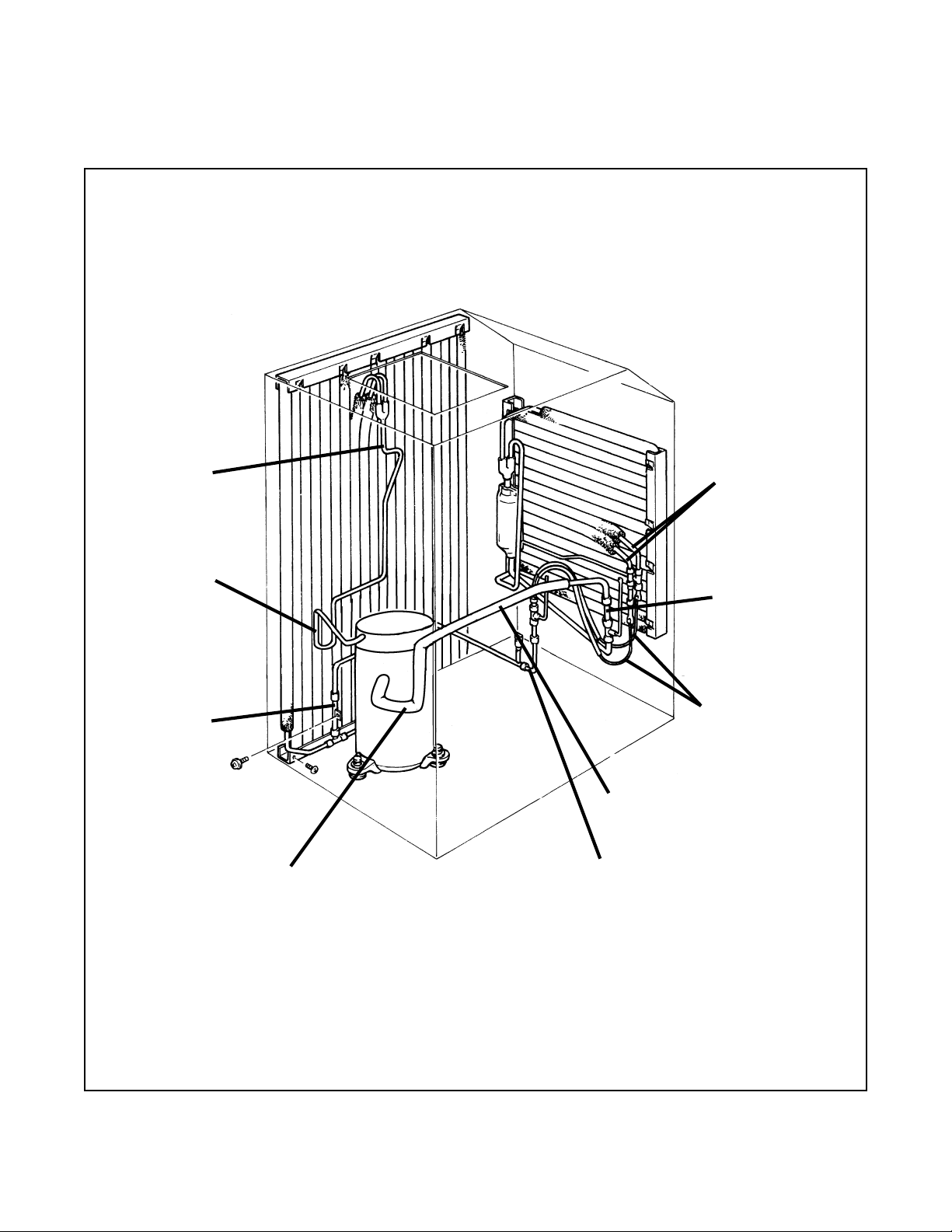

The component parts of the refrigerant system include the following:

• Compressor • Evaporator

• Condenser • High pressure switch

• Capillary tube • Modulating tank

These parts are all connected by copper piping. All the connections have been brazed.

Condenser

Compressor

Modulating Tank

Evaporator

Capillary T ube

High Pressure Switch

■ Refrigerant System

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 7

REFRIGERANT SYSTEM

3-1. Compressor

The compressor used for the unit is hermetically sealed. The compressor and the compressor motor are in

one casing.

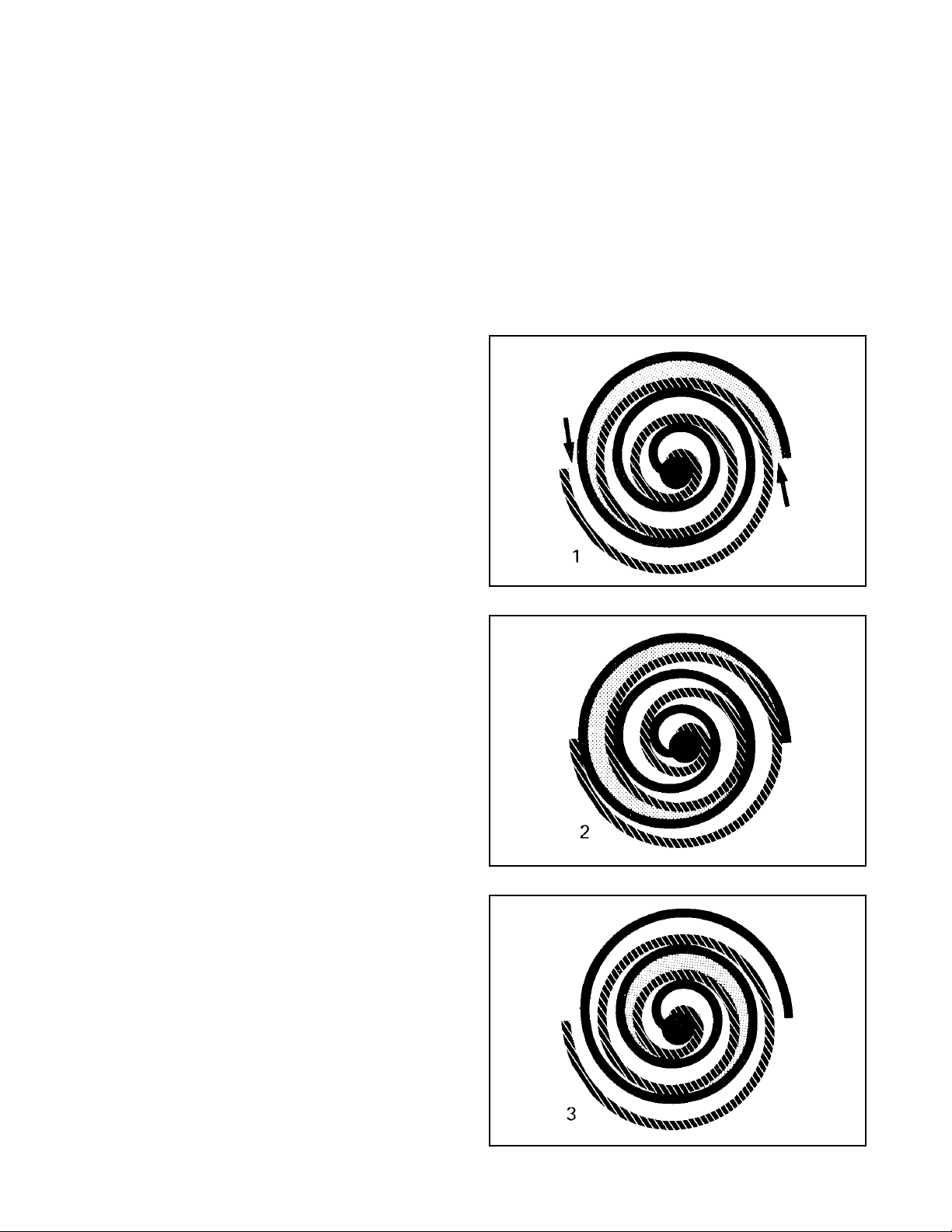

3-1-1. Compressor Theory of Operation

The scroll utilizes an involute spiral which, when matched with a mating scroll form, generates a

series of crescent-shaped gas pockets between the two members. During compression, one scroll

remains stationary (fixed scroll) while the other form (orbiting scroll) is allowed to orbit (but not rotate)

around the first form. As this motion occurs, the pockets between the two forms are slowly pushed to

the center of the two scrolls while simultaneously being reduced in volume. When the pocket reaches

the center of the scroll form, the gas, which is now at a high pressure, is discharged out of a port

located at the center. During compression, several pockets are being compressed simultaneously,

resulting in a very smooth process. Both the suction process (outer portion of the scroll members)

and the discharge process (inner portion) are continuous.

3-1-2. Compressor Operation

1) Compression in the scroll is created

by the interaction of an orbiting spiral

and a stationary spiral. Gas enters

the outer openings as one of the

spirals orbits.

2) The open passages are sealed off as

gas is drawn into the spiral.

3) As the spiral continues to orbit, the

gas is compressed into two increasingly smaller pockets.

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 8

REFRIGERANT SYSTEM

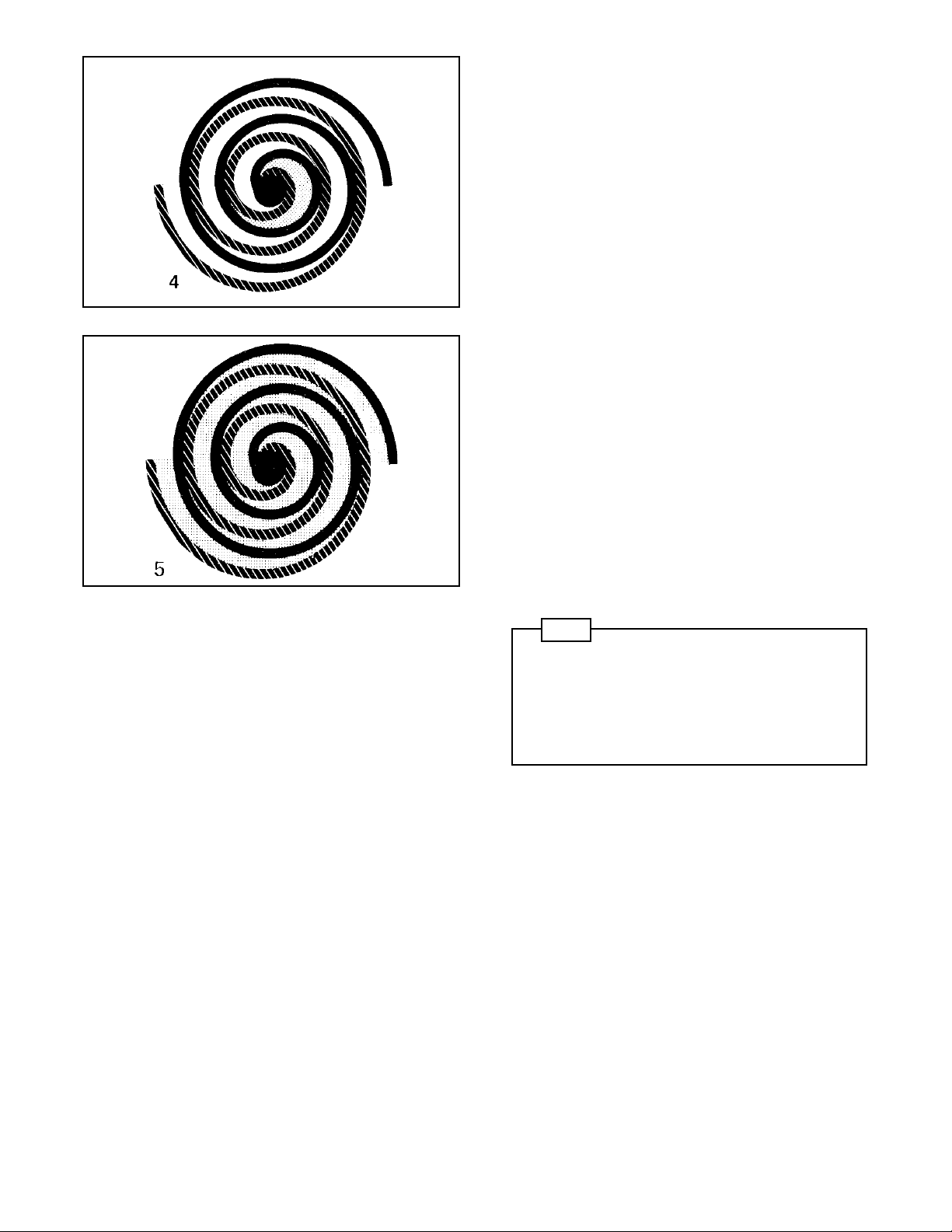

4) By the time the gas arrives at the

center port, discharge pressure has

been reached.

5) Actually, during operation, all six gas

passages are in various stages of

compression at all times, resulting in

nearly continuous suction and discharge.

NOTE

Upon compressor shut-off, the compressor may

run backward for a moment or two until internal

pressures equalize. This has no effect on compressor durability but may cause an unexpected

sound after the compressor is turned off and

should not be diagnosed as a malfunction.

3-2. Condenser

The condenser is a heat exchanger whose

copper tubes are covered with thin aluminum

projections called spine fins. Heat is given off

and absorbed by air being pulled across the

condenser fins by the centrifugal fan and then

expelled through the exhaust air duct.

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 9

REFRIGERANT SYSTEM

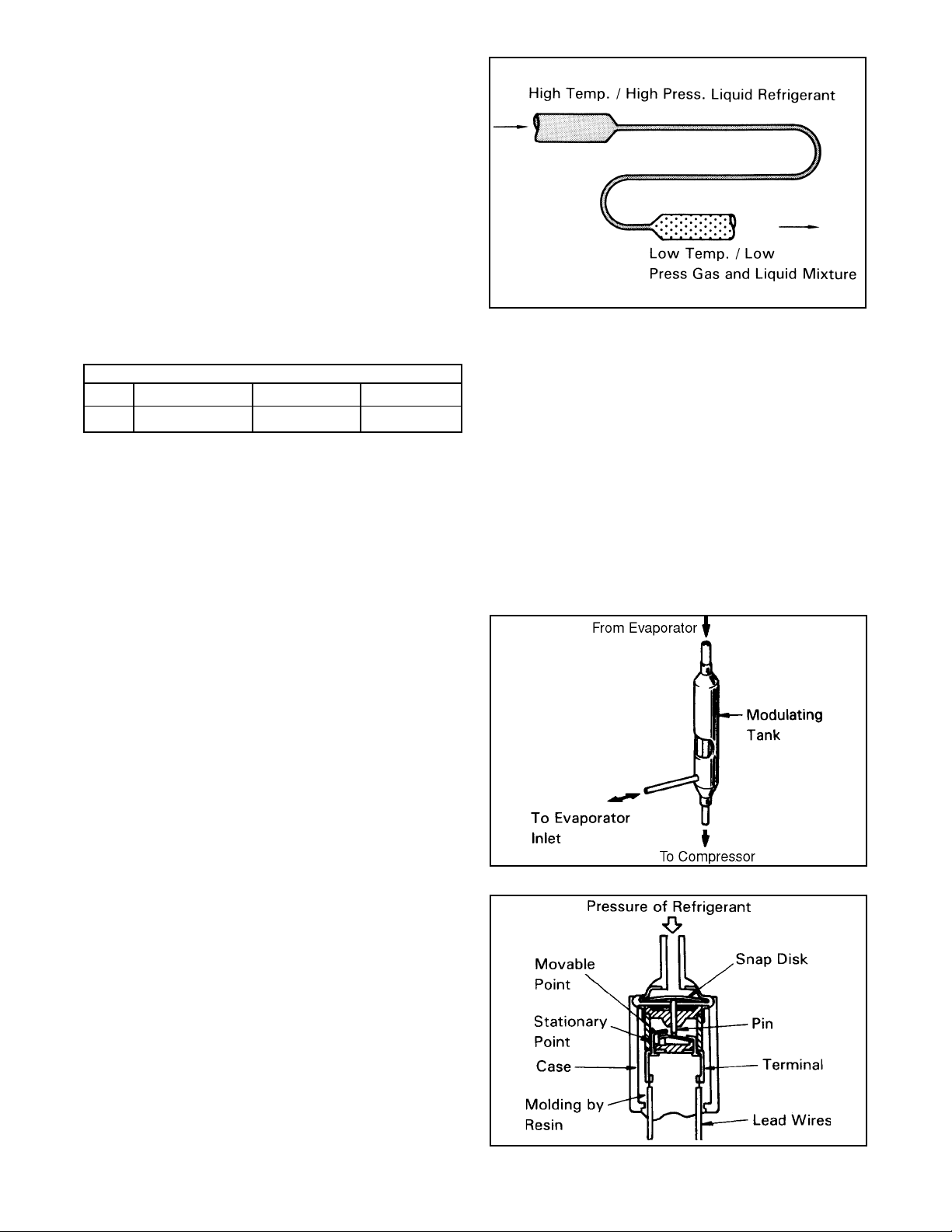

3-3. Capillary Tube

The capillary tube is a long thin tube and its line

flow resistance serves as an expansion valve.

The length and the inner diameter of the capillary tube are determined according to the

capacity of refrigeration system, operating

conditions and the amount of refrigerant.

The capillary tube causes the high pressure,

high temperature liquid refrigerant sent from the

condenser to expand rapidly as the refrigerant is

sprayed out through the fixed orifice in the

capillary tube. As a result, the temperature and

state of the refrigerant become low and mistlike, and therefore it evaporates easily.

Capillary Tube Dimensions

Qty Purpose of Use I.D. (mm) Length (mm)

1 For cooling ∅1.5 ± 0.05 540

3-4. Evaporator

The evaporator, like the condenser, is a heat

exchanger covered with spine fins. Heat is

removed from the air being pulled across the

evaporator by the centrifugal fan and the

resulting cool air is expelled through the cooling

air ducts.

■ Capillary Tube

3-5. Modulating Tank

The modulating tank consists of a copper pipe

and tank sections, each being separated from

the other. The pipe connects to the evaporator

outlet at one end and to the compressor at the

other; the tank connects to the evaporator inlet.

The modulating tank is covered with insulation to

reduce thermal effects of ambient temperature.

It varies the quantity of refrigerant in the refrigerating cycle for optimum operating condition; it

stores part of refrigerant under light load and

delivers additional refrigerant to the cycle under

heavy load.

3-6. High Pressure Switch

The high pressure switch prevents the condenser and compressor from being damaged by

excessively high pressure in the high pressure

line of the refrigeration cycle. The switch is

normally closed. The snap disk responds to

variations in pressure and, if pressure is abnormally high, the snap disk moves down to push

the pin down, causing the internal contacts to

open. This generates a signal to open the

auxiliary relay.

Possible causes of this trouble include:

(1) The condenser air filter is dirty, restricting

air flow.

(2) The condenser blower is defective.

■ Modulating Tank

■ High Pressure Switch

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 10

REFRIGERANT SYSTEM

Condenser

Inlet Pipe

Compressor

Discharge

Pipe

Condenser

Outlet Pipe

Compressor Suction

Pipe (insulated)

Evaporator

Inlet Pipe

Evaporator

Outlet Pipe

Capillary T ube

Connecting Pipe

(evaporator to compressor)

Connecting Tube

(condenser to capillary tube)

■ Refrigerant System Piping

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 11

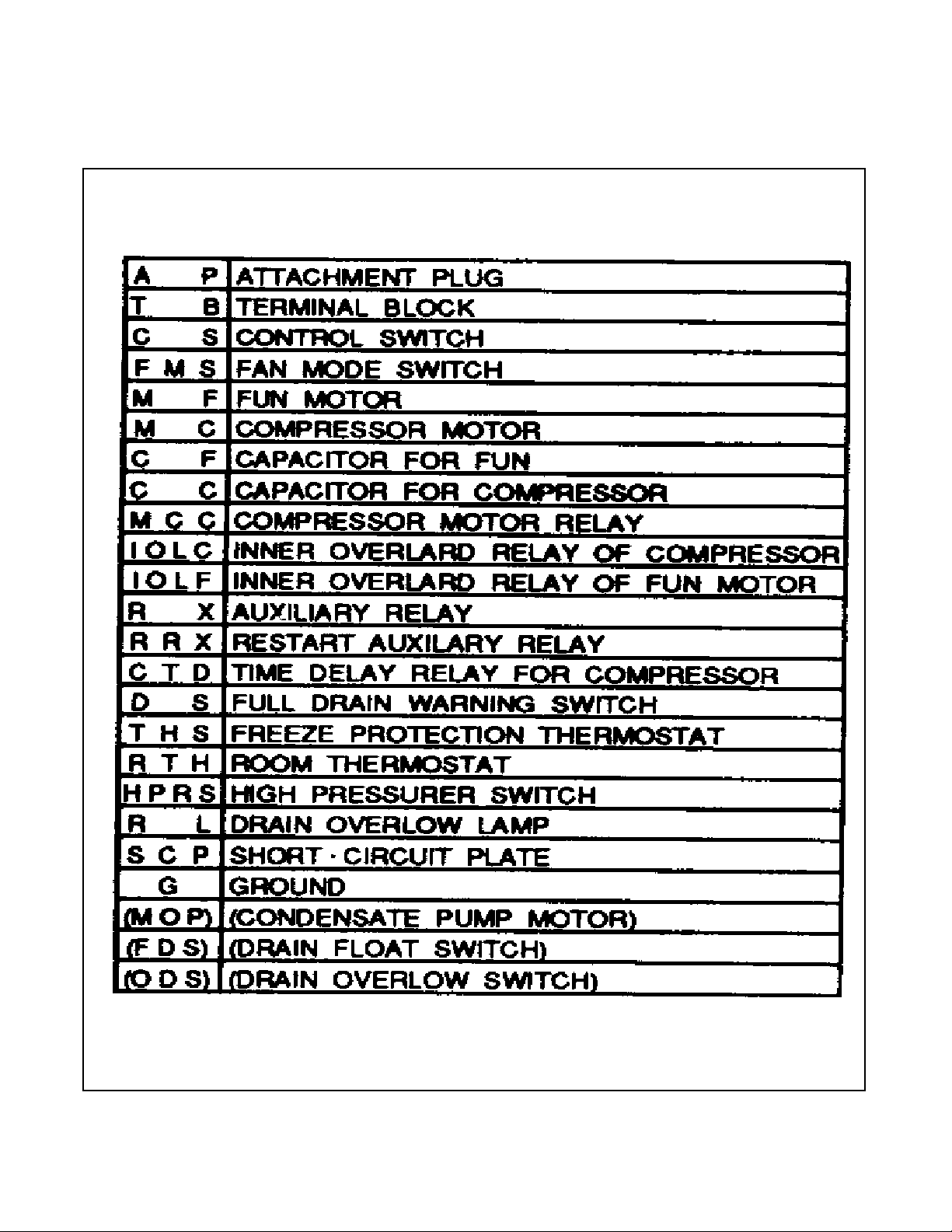

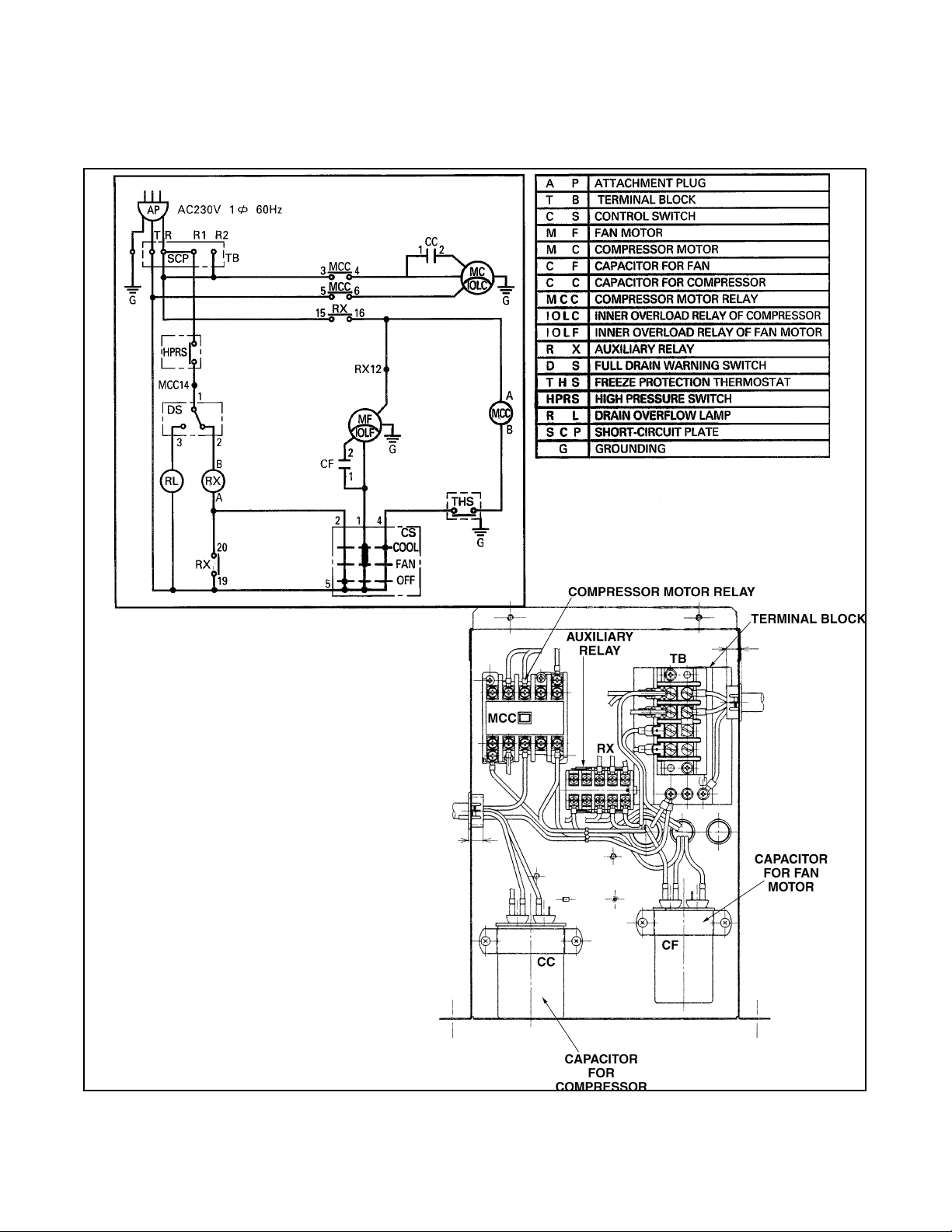

ELECTRICAL SYSTEM • 24HFU

24HFU

■ Electrical System and Control Box for Model 24HFU

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 12

ELECTRICAL SYSTEM • 24HFU

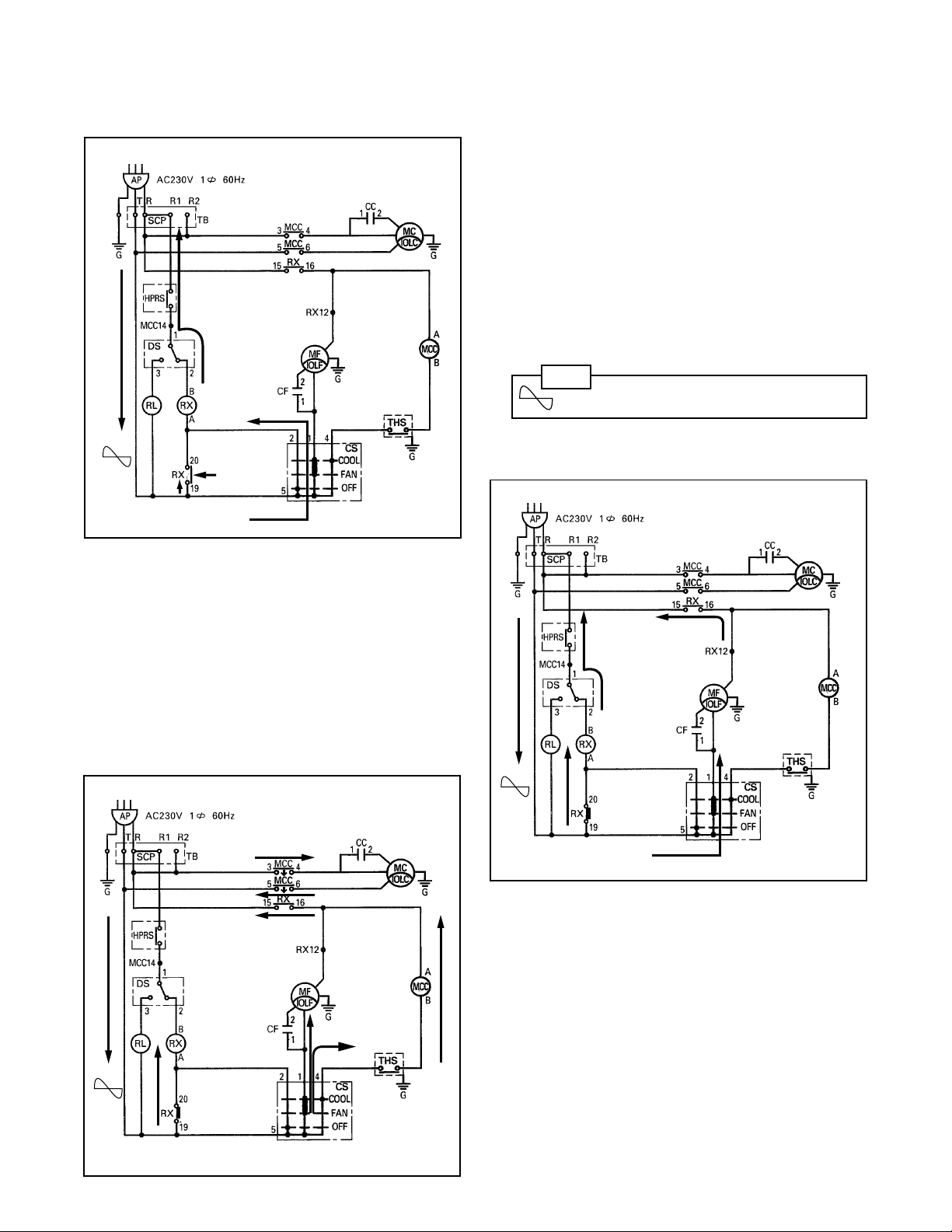

4-1. Basic Operation of MovinCool Modelp 24HFU Electrical Circuit

The three basic modes of operation are as follows:

■ Operation in “OFF” position

2) Control Switch in “FAN” position:

a. Current also flows through the control

switch (CS) to the fan motor (MF).

b. Current flows through the contact (termi-

nals 19 and 20) of the auxiliary relay and

its coil, and remains closed.

1) Control Switch in “OFF” position:

a. Current flows through terminals 5 and 2

of the control switch (CS) and to the coil

of the auxiliary relay (RX). (A and B.)

b. Two contacts (RX) of the auxiliary relay

are closed by electromagnetic force. The

closed contact RX (terminals 19 and 20)

allows current to flow directly to the

auxiliary relay coil and hold the contact in

a closed position.

NOTE

Symbol indicates alternating current.

■ Operation in “FAN” position

■ Operation in “COOL” position

3) Control Switch in “COOL” position:

a. The contacts of the auxiliary relay remain

closed as mentioned in step 2) b.

b. Current flows to the fan motor (MF).

c. Current also flows to the anti-freezing

thermostat (THS) contact, to the coil of

the relay for the compressor motor

(MCC) (A and B) and the auxiliary relay

contacts.

d. Two contacts of the relay for the com-

pressor motor (MCC) are closed by the

electromagnetic force. Current then

flows to the compressor motor (MC).

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 13

ELECTRICAL SYSTEM • 24HFU

4-2. Control Box

4-2-1. Capacitor

The capacitor is used to boost power

output to the fan motor and the compressor at start-up.

The specifications of each capacitor are

shown below.

Capacitor Registrant Voltage Capacitance

(Volt) (mF)

For fan motor 440 12.5

For compressor 370 40

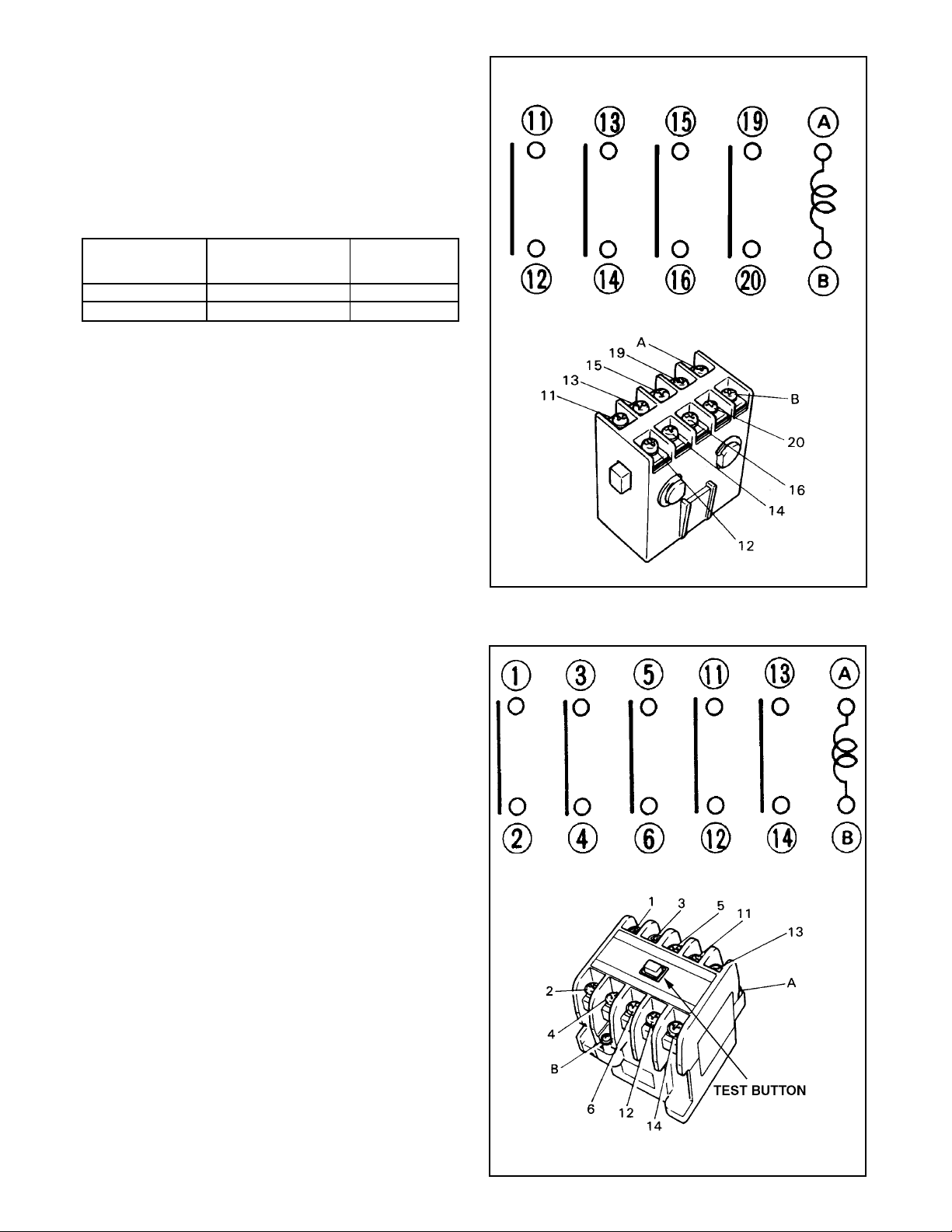

4-2-2. Auxiliary Relay

This auxiliary relay is normally closed

when the unit is in operation (FAN or

COOL), and supplies power to the compressor relay and the fan motor. In the

following cases, however, the relay opens

to interrupt power to the compressor and

the fan motor.

• When the drain tank is filled with water.

(Drain switch OFF.)

• When the high pressure becomes

excessively high. (High pressure switch

OFF.)

When current flows across A and B,

terminals 11 and 12, 13 and 14, 15 and

16, 19 and 20 conduct.

■ Circuit of Auxiliary Relay

■ Auxiliary Relay

Specifications:

Rated Voltage AC 240V

Rated current 15 amps

UL Listed File No. E1 12482

4-2-3. Compressor Relay

The compressor relay is closed when the

unit is operating in COOL mode, and

supplies power to the compressor. However in the following cases, the relay

opens to cut off power to the compressor.

• When the auxiliary relay is opened.

(Drain switch OFF or high pressure

switch OFF.)

• When the evaporator has frosted.

(Thermostat OFF.)

Specifications:

Rated Voltage AC 230V

Rated Current 30 amps

UL Listed File No. E43028

■ Circuit of Compressor Relay

■ Compressor Relay

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 14

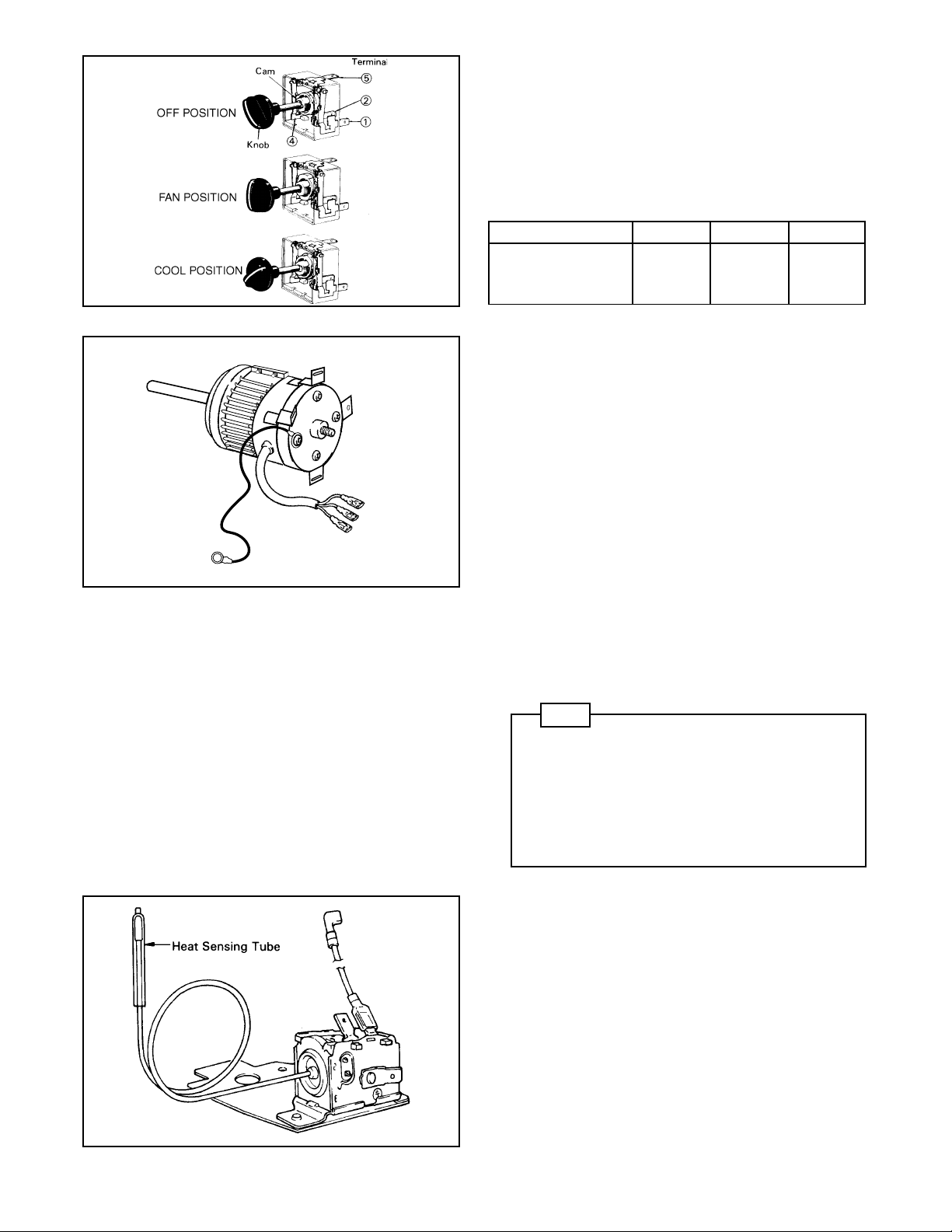

■ Control Switch

■ Fan Motor

CF1

CF2

RX12

ELECTRICAL SYSTEM • 24HFU

4-3. Control Switch

The control switch is employed to start or stop

operation. This switch is a 250V, 20A rating

rotary type (3-position). The switching positions

are OFF-FAN-COOL. Each contact is switched

by the cam uniting with the shaft.

Switch Terminals OFF FAN COOL

(5) - (2) Conduct OFF OFF

(5) - (1) OFF Conduct OFF

(5) - (4) OFF Conduct Conduct

4-4. Fan Motor

The fan motor is a single phase, induction type

motor which drives fans on the evaporator side

and the condenser side at the same time.

Specifications:

Rated Voltage AC 230V

Rated Output 552 Watts

UL Listed File No. E49807

4-5. Compressor Motor

The compressor motor is a single phase motor

and is contained within the same housing as the

compressor.

Specifications:

Rated Voltage AC 230V

Rated Output 1600 Watts

■ Thermostat

NOTE

An internal overload relay is used to protect the

compressor motor and fan motor. This relay is

built into the compressor motor and fan motor and

will interrupt the flow of current when there is an

overcurrent situation or if abnormally high

temperature builds up in the compressor motor or

fan motor.

4-6. Anti-freezing Thermostat

If the evaporator has frosted, the thermostat

contacts open to stop the compressor and the

unit continues to operate on “FAN” mode. Once

the evaporator has defrosted, the contacts close

to restart the compressor and the unit operates

in “COOL” mode. The thermostat heat sensing

tube is mounted at the evaporator outlet tube

and is insulated from surrounding air by heat

insulating material. The thermostat contacts are

opened at -1.5˚C and closed at +14.5˚C.

MOVINCOOL 24HFU / 24HFU-1 SERVICE PAGE 15

Loading...

Loading...