Mouvex SLP25 i Maintance Manual

PUMPS

INSTRUCTIONS 1007-A00 e

Section 1007

Effective November 2011

Replaces March 2011

Original instructions

INSTALLATION

OPERATION

MAINTENANCE

Your distributor :

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact@mouvex.com - www.mouvex.com

SLP25 i S

ERIES

(manufactured from 2010 to 2013)

2/33

NT 1007-A00 11.11 SLP25 i series pumps e

VANE PUMPS

SAFETY, STORAGE, INSTALLATION AND MAINTENANCE INSTRUCTIONS

MODELS : SLP SERIES

SLP25 i

1. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 Pump selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Pipe diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.3 Piping assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

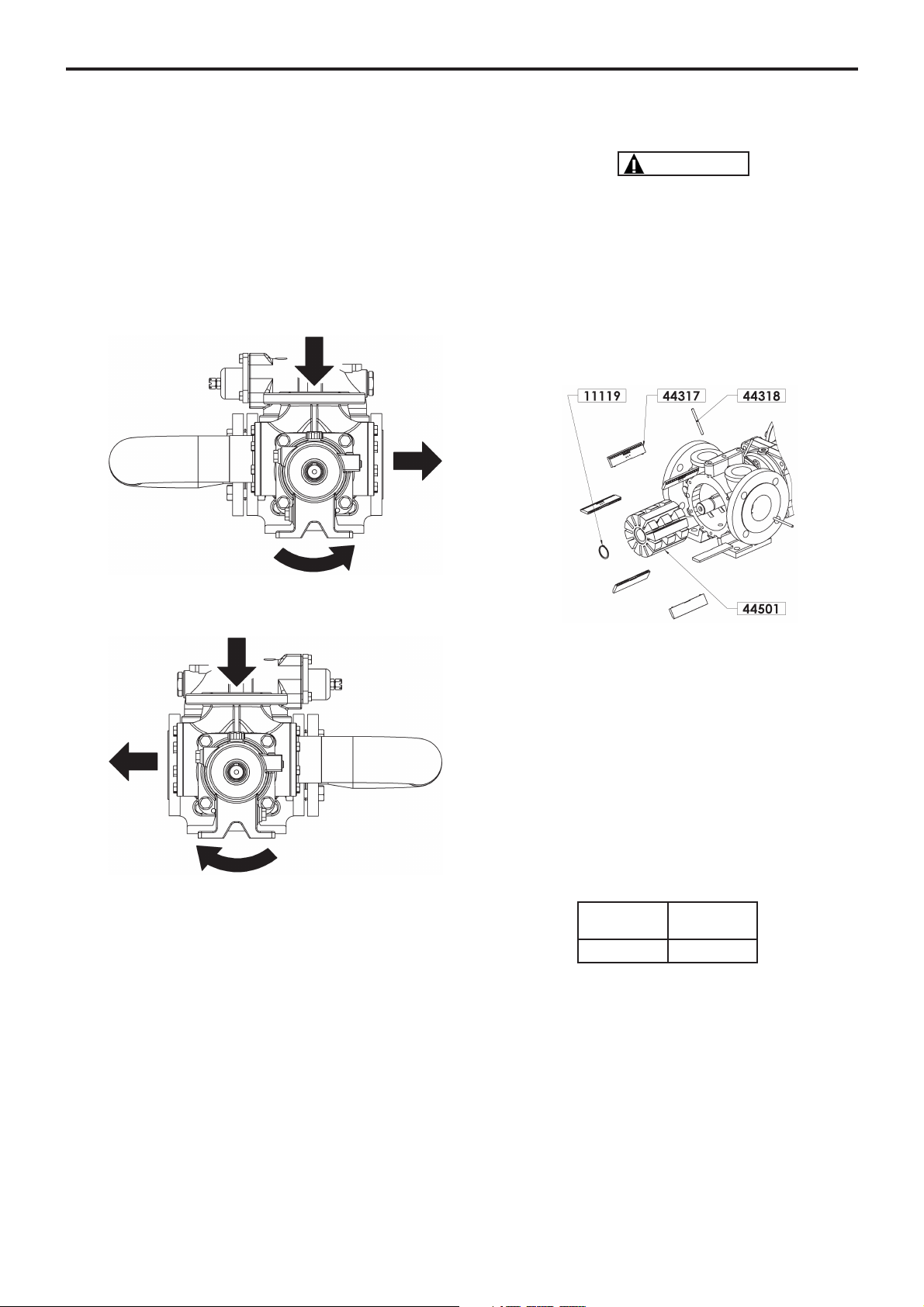

2.4 Direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5 Changing the direction of rotation . . . . . . . . . . . . . . . . .8

2.6 Protecting the installation against overpressure . . . . . .9

2.7 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.8 Hoisting devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.9 Installation of units . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.10 Alignment of motor/pump or reduction gearbox/pump

shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.11 Electric motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.12 Diesel engines drive . . . . . . . . . . . . . . . . . . . . . . . . .11

3. USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.1 Pumping hot or cold liquids . . . . . . . . . . . . . . . . . . . .12

3.2 Pump full of liquid when stopped . . . . . . . . . . . . . . . .12

3.3 Noise level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.4 Starting-up the pump . . . . . . . . . . . . . . . . . . . . . . . . .12

3.5 Shutting down the pump . . . . . . . . . . . . . . . . . . . . . . .12

3.6 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.7 Scrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4. REQUIRED TOOLS AND TIGHTENING TORQUES . . . . .13

4.1 Necessary tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.2 Assembly torques . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5. OPENING AND CLOSING THE NON-DRIVE SIDE OF PUMP .14

5.1 Opening the base on the non-drive side . . . . . . . . .15

5.2 Checking the vanes . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.3 Changing the bushing . . . . . . . . . . . . . . . . . . . . . . . . .16

5.4 Closing the non-drive side base . . . . . . . . . . . . . . . . .16

6. OPENING AND CLOSING THE DRIVE SIDE BASE . . . . .17

6.1 Dismantling / reassembling connection manifold . . . .18

6.2 Dismantling / reassembling transmission . . . . . . . . . .18

6.3 Dismantling the adaptation unit base . . . . . . . . . . . . .19

6.4 Changing the bushing in the adaptation base . . . . . .20

6.5 Dismantling inlet manifold . . . . . . . . . . . . . . . . . . . . . .21

6.6 Dismantling / reassembling transmission square driver .21

6.7 Changing the transmission and/or hub nose seal . . .22

6.8 Reassembly of vanes and pushrods . . . . . . . . . . . . .22

7. BYPASS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

7.1 Bypass operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.2 Bypass orientation . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.3 Bypass inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.4 Bypass adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . .25

7.5 Obtaining the flow . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

7.6 Energy consumption . . . . . . . . . . . . . . . . . . . . . . . . . .25

7.7 Replacing the spring . . . . . . . . . . . . . . . . . . . . . . . . . .25

8. TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

8.1 Checking the bellows . . . . . . . . . . . . . . . . . . . . . . . . .27

8.2 Draining the bearing . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.3 Transmission oil level control . . . . . . . . . . . . . . . . . . .27

8.4 Changing lip seals . . . . . . . . . . . . . . . . . . . . . . . . . . .28

9. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

9.1 Checking the condition of vanes and the pushrods . .29

9.2 Checking the condition of friction bushings . . . . . . . .29

10. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . .30

11. CERTIFICATE OF CONFORMITY . . . . . . . . . . . . . . . . .33

SUMMARY Page

TECHNICAL SPECIFICATIONS

•

Construction I : Stainless steel

• Non-food grade pump

• Maximum pump speed : 1000 rpm

• Maximum differential pressure : 12 bar relative

• Maximum suction pressure : 1,5 bar relative

• Max admissible transmission torque : 135 Nm

Pump n° :

Date of bringing into service :

This is a SAFETY ALERT SYMBOL

When you see this symbol on the product, or in the manual, look

for one of the following signal words and be alert to the potential for

personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

SAFETY INFORMATIONS

WARNING

CAUTION

DANGER

3/33

NT 1007-A00 11.11 SLP25 i series pumps e

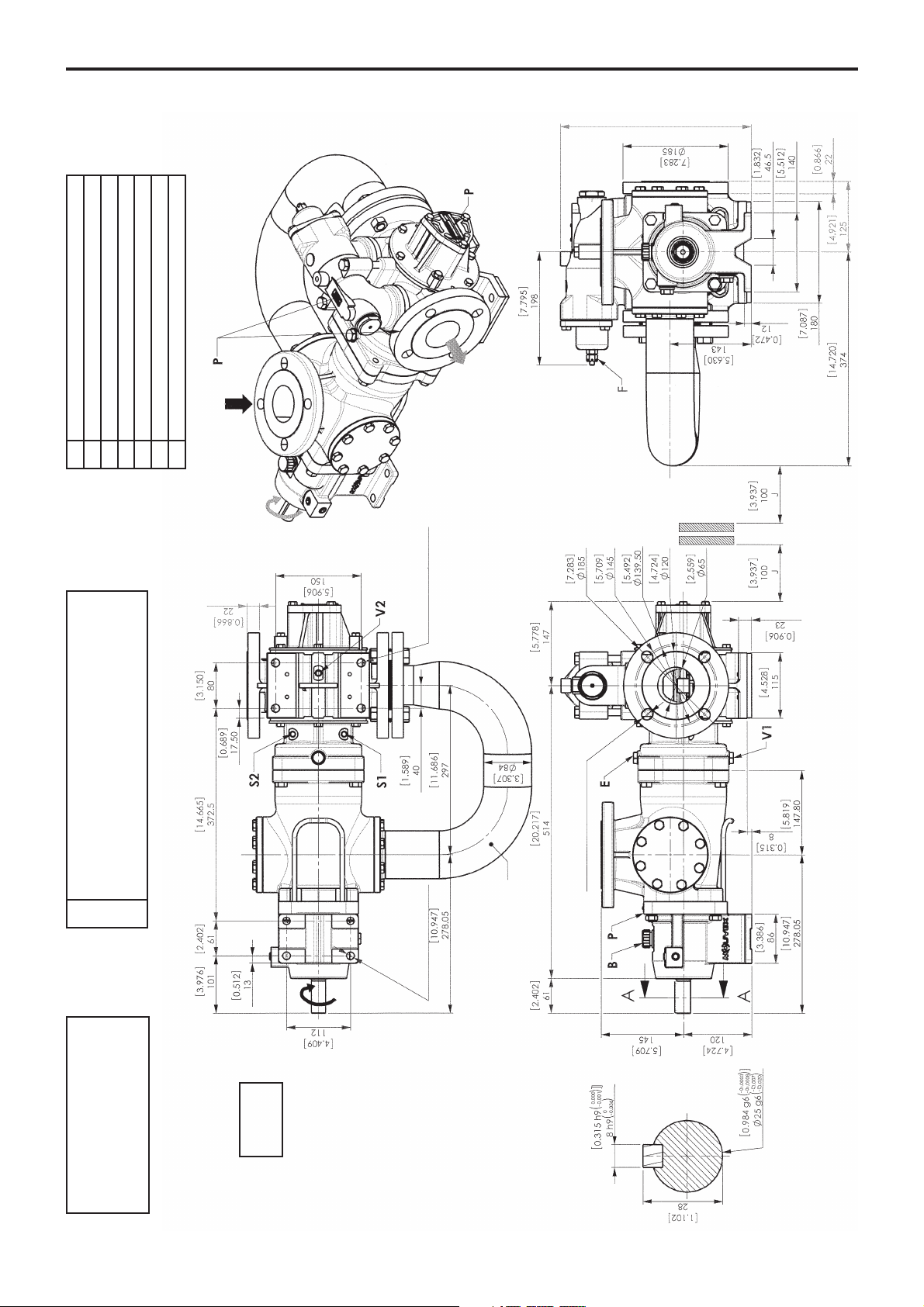

1. OVERALL DIMENSIONS

S1

S2

Temperature limiter device position

- Drilling Ø 8

- Always side of connecting manifold

S1 : outlet to the right*

S2 : outlet to the left*

4 holes Ø 13.5 [0.531]

Weight :

84 kg

2 x 4 holes Ø 18 [0.709]

at 90° (PN 16/20)

SLP25 i

4 holes Ø 14 [0.551]

335 with bypass

282 without bypass

Connecting manifold

* View from motor side

B

Plug (filling, breather)

E

Inlet tube vent

F

Bypass setting

J

Space for dismantling

P

Pump plate

V1

Inlet tube drain

V2

Pump drain

4/33

NT 1007-A00 11.11 SLP25 i series pumps e

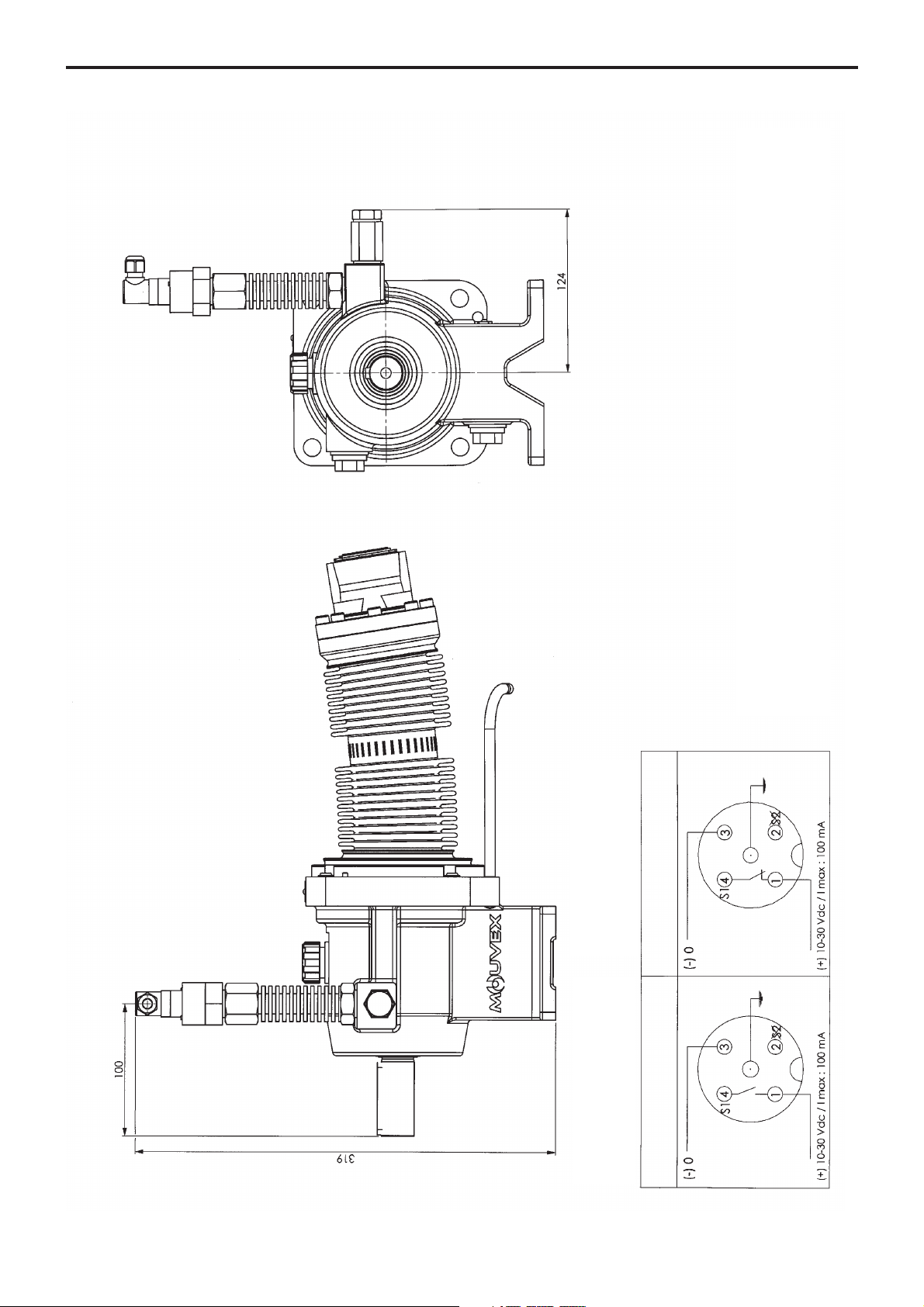

1. OVERALL DIMENSIONS (continued)

NOTA :

Adjustments of the detection levels are made in the factory and must not be modified.

For other dimensions, refer to pump overall dimension drawing.

The transmission may only be dismantled in the factory.

CAUTION :

WRONG CONNECTION MAY

DESTROY THE SENSOR.

Connection diagram

Connector

Do not use S2

Normal operation

Rupture detection

Bellows monitoring system (pressure switch)

SL MECH D 135

5/33

NT 1007-A00 11.11 SLP25 i series pumps e

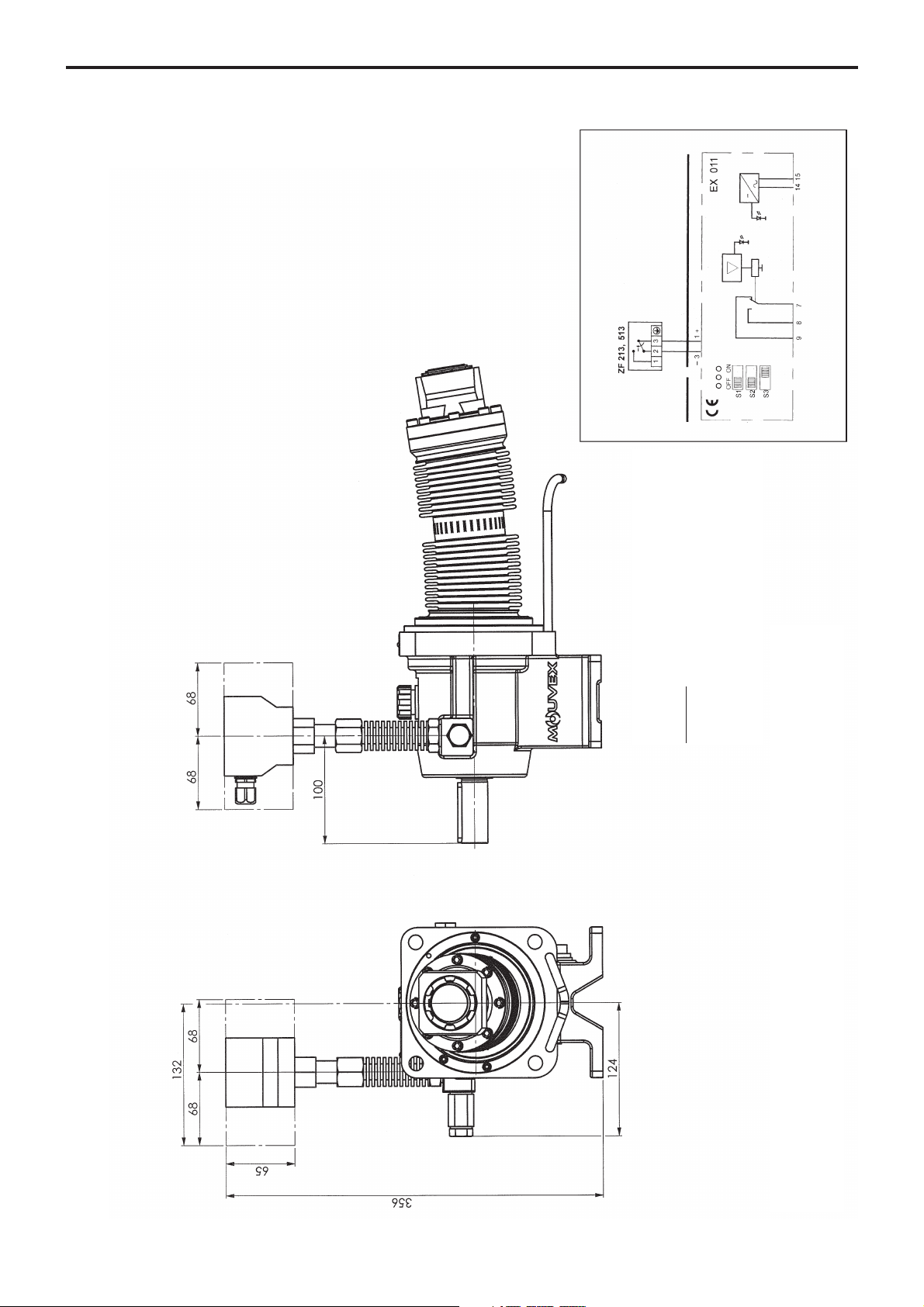

1. OVERALL DIMENSIONS (continued)

NOTA :

Adjustments of the detection levels are made in the factory and must not be modified.

For other dimensions, refer to pump overall dimension drawing.

The transmission may only be dismantled in the factory.

Bellows monitoring system (ATEX pressure switch)

SL MECH D 135

When the pressure drops, 3-2 opens.

CAUTION :

Wrong connection may :

- create a fire risk,

- make monitoring ineffective

- damage the sensor

Connection diagram

Ex-free Zone

Ex-Zone 1 or 2, 21 or 22

Supply

voltage

Outlet

Yellow

Green

Microswitch

6/33

NT 1007-A00 11.11 SLP25 i series pumps e

1. OVERALL DIMENSIONS (continued)

NOTA :

Adjustments of the detection levels are made in the factory and must not be modified.

For other dimensions, refer to pump overall dimension drawing.

The transmission may only be dismantled in the factory.

Double wall transmission with pressure gauge

SL MECH D 135

2.1 Pump selection

To obtain expected performance from MOUVEX series

SLP pump, regarding both performance and durability, it

is essential that the type of pump, its rotation speed and

the materials used in its construction are suitably determined in accordance with the pumped liquid and the installation and operating conditions.

OOur technical departments are at your disposal any

time for all necessary informations.

2.2 Pipe diameter

To obtain optimum conditions of use, it is important to check

the following recommendations regarding the sizing of

pipes :

• The pipe diameter will be determined depending on

their length and the flow and viscosity of liquid pumped,

so that pressure losses stay within the admissible limits

for the motor-driven pump unit. It is therefore difficult to

give general and precise instructions. However, it is

never a disadvantage to over-dimension pipe diameters, especially for the section on the inlet side.

• In the case of thin liquids and the piping on the discharge

side,one can generally allow a diameter equal to the

pump ports and a larger diameter for the piping on the

inlet side, if the value for the inlet power of the pump is

negative or especially high.

• For viscous liquids, special attention should be paid to

determining the pipe diameters. Indeed, the variation in

pressure loss is proportional to the viscosity and inversely proportional to the diameter exponent 4. A slight

reduction in the pipe diameter could therefore have

serious consequences on the pump’s operating conditions.

Our Technical Services are always available to provide you

with precise data if you give them accurate information

or, even better, the installation drawings.

2.3 Piping assembly

In order to achieve the best operating conditions, it is

important to take account of the following recommendations regarding piping assembly :

• The positioning of the pump in the transfer or recycling

circuit should always be chosen so as to reduce the

height and length of the piping as much as possible.

• Wherever possible, siphons and reverse slopes shouldbe avoided in the inlet piping.

• Particular care needs to be taken with the sealing on

the inlet side to prevent air entering.

• Pipe elbows must always have a large radius (more

than 3 times the diameter of the pipes) and must not be

mounted too close to the pump flanges (min. recommended distance : 10 times the pipe diameter), on both

the inlet and discharge sides.

• The pipes are supported and aligned with the pump so

as to avoid generating stress on the pump flanges.

Non-compliance with this instruction can lead to deformation of pump parts, misalignment of bearings and

accelerated material wear, even causing parts to break.

• For ease of any adjustments and checks, it is recommended that pressure tapping ports to which pressure/vacuum gauges may be fitted, are provided as close

as possible to the pump’s suction and discharge ports

(preferably at a distance of less than 5 times the pipe

diameter).

• If the suction head is especially high or if you want to

prevent the pipes emptying at shutdown, you can install

a foot valve. This should have a large diameter so as

not to generate additional pressure loss.

• We recommend placing valves as close as possible to

the pump ports to avoid having to drain the entire system

each time maintenance is carried out. These valves

should have the same diameter as the pipes and preferably be full bore models.

• All steps should be taken to prevent foreign bodies

from entering the pump (the use of a filter at the pump

intake is therefore strongly recommended).

• Before installing new pipes or tanks, check that they

are carefully cleaned to remove waste from welding,

rust, etc. which when carried through by the liquid

could cause deterioration to the pump.

• The pipes should be designed to allow thermal expansion/contraction (the use of flexible couplings or expansion loops is therefore recommended).

• If there is danger of the liquid freezing or solidifying, it

must be possible to drain the piping by installing taps

at the low points and air vents at the high points.

7/33

2. INSTALLATION

NT 1007-A00 11.11 SLP25 i series pumps e

2.4 Direction of rotation

• In its standard configuration, the SLP series MOUVEX

pump is supplied as non reversible and with anticlockwise rotation.

NOTE :

ALL VIEWS IN THIS INSTRUCTION MANUALSHOW PARTS IN

THE STANDARD DIRECTION OF ROTATION.

The rule for the discharge side and the direction of rotation is as follows :

• For anticlockwise rotation (standard), the discharge

should be on the right side of the pump.

• For clockwise rotation, the discharge should be on the

left side of the pump.

In all cases, suction is from the top.

Operation in the opposite direction from that designed

for the pump is authorised nonetheless for a maximum

duration of 5 minutes as long as it remains below the

pressure limits (1,5 bar at the bellows).

The direction of rotation may be reversed :

• On request at the time the order is placed. In this case

the pump will be supplied with clockwise rotation.

• Or manually, referring to the following §.

2.5 Changing the direction of rotation

REGARDLESS OF THE INTERNAL DESIGN OF THE PUMP, THE

DIRECTION OF ROTATION SHOULD NOT BE CHANGED UNTIL

THE PUMP HAS COME TO A COMPLETE STOP, HAS COOLED

DOWN AND HAS BEEN DRAINED.

• Dismantle the connection manifold (see § DISMANTLING

/ASSEMBLING THE CONNECTION MANIFOLD).

• Dismantle the relief valve (see § ORIENTATION OF

BYPASS).

• Change the position of the rotor, the vanes and the

pushrods (for a pump with pushrods) : see § OPENING

AND CLOSING THE PUMP ON THE NON-DRIVE SIDE.

• Remove the vanes 44317 and the pushrods 44318.

• This may be carried out by removing the vanes 44317

horizontally and then the pushrods 44318 using a

screwdriver and pushing them to one of the pump outlet

ports.

• Follow the same procedure for the other vanes 44317.

• Remove the circlips 11119 (BE CAREFUL not to

scratch the shaft).

• Remove the rotor 44301, turn it over and re-assemble

it so that the rotor pushrods 44301 match up with the

holes in the shaft 44501.

• Place a suitable screw at the end of the shaft to pull it

and reveal the circlip groove.

• Replace the circlips 11119 taking care not to scratch the

shaft 44501.

• Re-assemble the vanes 44317 and the pushrods 44318

facing the correct direction (see § VANE CHECKS).

• Re-assemble the bypass facing the correct direction

(see § DIRECTION OF BYPASS).

• Re-assemble the connection manifold on the correct

side (see § DIRECTION OF ROTATION).

Screw

SLP25 M8

CAUTION

8/33

2. INSTALLATION (continued)

NT 1007-A00 11.11 SLP25 i series pumps e

2.6 Protecting the installation against overpressure

To protect the installation from any overpressure, the

use of a pressure relief safety device is recommended.

The standard pump is supplied fitted with a single internal relief valve to protect the system in one operating

direction. Its orientation therefore depends on the operating direction of the pump (refer to § RELIEF VALVE).

It is also possible to order the following option :

• Without relief valve

: the pump then has no other inbuilt

safety device. In this case, the pump must be protected

(for example with a pressure switch) to reduce any

overpressure.

If the rotation of the pump is to be used in both directions, (whatever the operating conditions), it is recommended to use a device that protects the pump from

overpressure when rotating in both directions (pressure

switch, etc.).

2.7 Cleaning

As the pumps are well-greased when supplied, it may be

necessary to clean them before starting them up.

They may be cleaned either by circulating an appropriate liquid or by dismantling the pump and carefully cleaning the internal parts (in which case, refer to § relating

to pump maintenance).

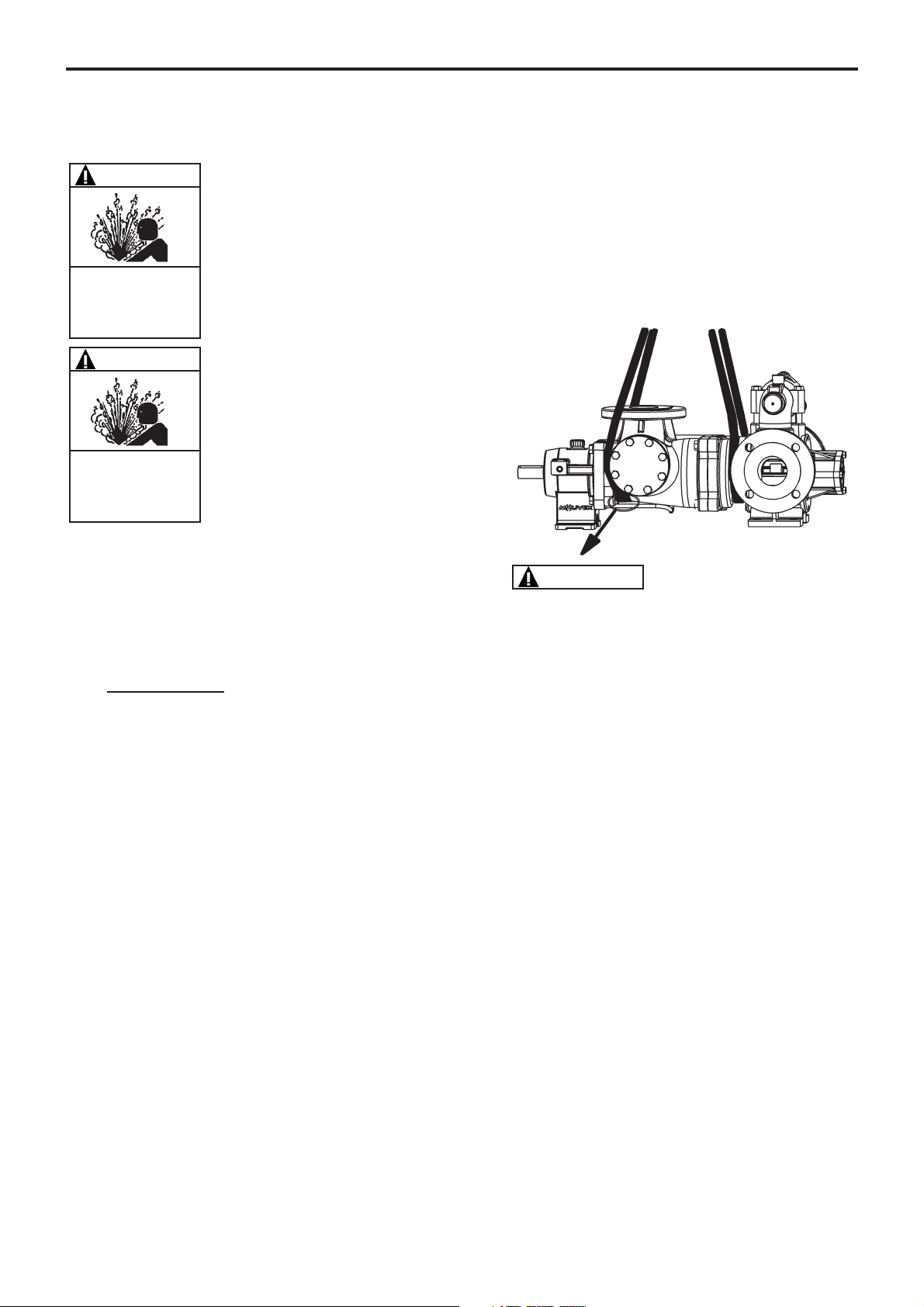

2.8 Hoisting devices

Hoisting points :

The strap must pass between the cradle and the

manifold.

• Use straps designed for the weight of the pump (see

overall dimension drawing).

WARNING

FAILURE TO INSTALL ADEQUATELY

SIZED PRESSURE RELIEF VALVE(S)

CAN CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

Hazardous pressure

can cause

personal injury

or property damage.

INCORRECT SETTINGS OF THE PRESSURE

RELIEF VALVE CAN CAUSE PUMP

COMPONENT FAILURE, PERSONAL

INJURY, AND PROPERTY DAMAGE.

WARNING

Hazardous pressure

can cause

personal injury

or property damage.

9/33

2. INSTALLATION (continued)

NT 1007-A00 11.11 SLP25 i series pumps e

10/33

2. INSTALLATION (continued)

2.9 Installation of units

The correct seating of a unit is essential for ensuring

smooth operation and longevity. The base must be flat,

level and sufficiently resistant to absorb stresses caused

by the motor-driven pump without being distorted

(concrete blocks must conform to the BAEL 91 standard).

Where the unit is fastened using anchor lugs or bolts, it

must be wedged carefully to prevent any distortion of the

chassis when tightening the bolts. Distortion of the chassis could cause prejudicial stress to the pump and the

drive device and put the coupling out of alignment, causing vibrations, noise and premature wear. Check that

the chassis is clear of the floor and off the support

plates.

Where the chassis is a one-piece unit in folded sheet

metal, it is recommended to leave a clear horizontal

space of around 50 cm between one end of the chassis

and the other to allow access to the locking nuts on the

pump, the reduction gearbox and the motor. In all cases,

the space around the pump unit should allow enough

room for dismantling the pump (refer to the overall

dimension drawing at the beginning for details of these

distances).

The chassis is equipped with an earth connection that

must be used to protect personnel and equipment.

The mounting base of the vane pump body and the

pump bearing are not on the same level (see § OVERALL DIMENSIONS). Different wedging must therefore

be used for these two bases.

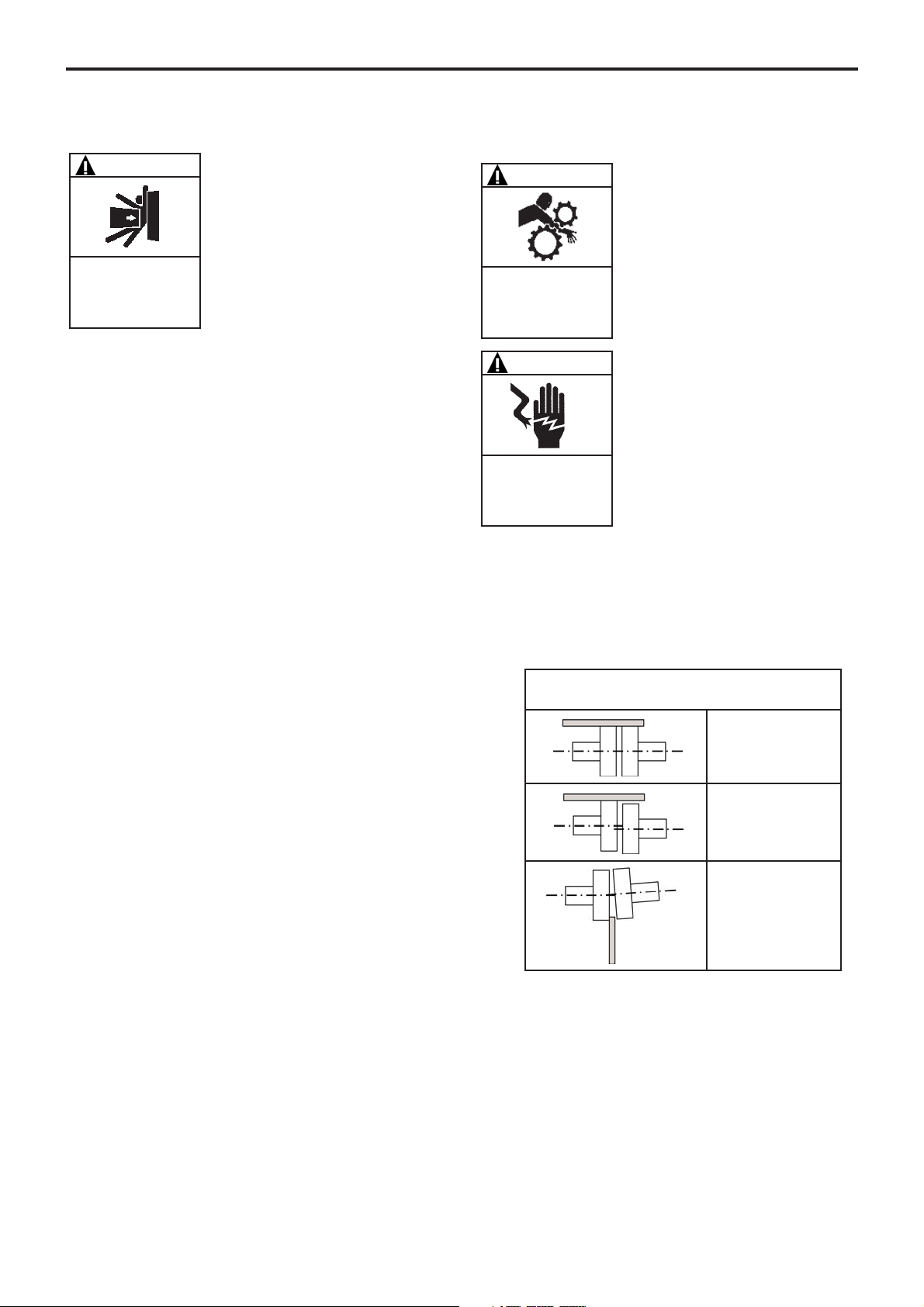

2.10 Alignment of motor/pump or reduction

gearbox/pump shafts

The motor and pump shafts are accurately aligned in the

factory before dispatch, but they must be checked automatically upon arrival and realigned if necessary. To align

the coupling and the shaft, use a straight edge to check

the offset and thickness gauges for angular misalignment.

The 3 figures below illustrate the operation and show the

admissible deviations :

It is important to check the alignment at each stage of

installation to ensure that no stresses are caused to the

unit or the pump :

• after fixing to the base.

• after attaching piping.

• after pump has operated at normal operating temperature.

Reminder :

The coupling must not be relied on to compensate for a

misalignment.

NEVER START A UNIT IF THE COUPLING ALIGNMENT IS

INCORRECT. THIS WILL INVALIDATE OUR WARRANTY.

Make this check for 4 points :

up - down - left - right

Correct

Out-of-parallelism

Angular defect

(maximum : 1°)

DISCONNECT THE ELECTRICITY SUPPLY

BEFORE ANY MAINTENANCE OPERATION.

WARNING

Dangerous voltage.

Can cause

injury and death.

OPERATION WITHOUT THE SHAFT

PROTECTOR CAN CAUSE SERIOUS

PERSONAL INJURY, MAJOR PROPERTY

DAMAGE, OR DEATH.

WARNING

Do not operate

without guard

in place.

BE CAREFUL WITH THE WEIGHT OF

THE PARTS WHEN THEY ARE BEING

REMOVED.

WARNING

The weight ot the parts can

be dangerous and may

provoke bodily injuries or

material damages.

NT 1007-A00 11.11 SLP25 i series pumps e

Loading...

Loading...