Mouvex SLC1, SLC2, SLC3 Maintance Manual

SLC1 - SLC2 - SLC3

PUMPS

INSTRUCTIONS 1004-A00 e

Section 1004

Effective February 2013

Replaces January 2013

INSTALLATION

OPERATION

MAINTENANCE

Original instructions

Your distributor :

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact@mouvex.com - www.mouvex.com

3, Poruchik Nedelcho Bonchev Str., . 5,1528 Soa, Bulgaria

tel: +359 2 973 27 67

e-mail: oce@daisglobal.eu

2/32

T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e

1. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.1 Orientation of the pump ports . . . . . . . . . . . . . . . . . . .17

2.2 Direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.3 Protection of the installation and the pump . . . . . . . .17

2.4 Unit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3. USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.1 Noise level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.3 Dry running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.4 Stopping the pump . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.5 Bellows monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.6 Scrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4. CLEAN IN PLACE (CIP) & STERILISATION IN PLACE

(SIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.2 CIP circuit recommended . . . . . . . . . . . . . . . . . . . . . .21

4.3 Pumps arranged in series . . . . . . . . . . . . . . . . . . . . . .21

4.4 Pumps arranged in parallel . . . . . . . . . . . . . . . . . . . . .22

4.5 Successive cycles . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.6 Sterilisation In Place (SIP) . . . . . . . . . . . . . . . . . . . . .23

5. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.1 Necessary tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.2 Pump disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.3 Checking the cylinder/piston couple . . . . . . . . . . . . . .26

5.4 Reassembling the pump . . . . . . . . . . . . . . . . . . . . . . .26

5.5 Transmission disassembly/reassembly . . . . . . . . . . . .28

6. CHECKING THE BELLOWS . . . . . . . . . . . . . . . . . . . . . . .28

7. DRAINING THE BEARING . . . . . . . . . . . . . . . . . . . . . . .29

8. OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8.1 Bellows monitoring system . . . . . . . . . . . . . . . . . . . . .30

8.2 Bellows monitoring system ATEX . . . . . . . . . . . . . . . .30

9. STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

9.1 Short duration (≤ 1 month) . . . . . . . . . . . . . . . . . . . . .31

9.2 Long duration (> 1 month) . . . . . . . . . . . . . . . . . . . . .31

9.3 Restarting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

10. CERTIFICATE OF CONFORMITY . . . . . . . . . . . . . . . . .32

TABLE OF CONTENTS Page

ECCENTRIC DISC PUMP

MOUVEX PRINCIPLE

SAFETY INSTRUCTIONS, STORAGE, INSTALLATION AND MAINTENANCE

MODELS : SLC1 - SLC2 - SLC3

TECHNICAL CHARACTERISTICS

- Maximum pump speed : 1000 rpm

- Maximum running temperature :

* continuous . . . . . . . . . . . . . . . . . . . . . . . . . .110°C

* washing/rinsing/sterilisation . . . . . . . . . . . . .121°C

- Maximum suction pressure :

• In normal use, the suction pressure must be higher than the

required NPSH and less than 1,5 barg (21,7 psig).

• During pump CIP/SIP, the suction pressure must not

exceed 3 barg (43,5 psig).

• With pump stopped, the pressure must not exceed 6 barg

(87 psig).

- Acceptable maximal differential pressure :

• SLC1 . . . . . . . . . . . . . .16 bar* (232 psi)

• SLC2 . . . . . . . . . . . . . .10 bar* (145 psi)

• SLC3 . . . . . . . . . . . . . . .6 bar* (87 psi)

- Maximum pressure jacket : 5 barg (72,50 psig)

- Displacement :

• SLC1 . . . . . . . . . . . . . . .0,017 liter

• SLC2 . . . . . . . . . . . . . . .0,034 liter

• SLC3 . . . . . . . . . . . . . . .0,051 liter

- Volume :

• Suction . . . . . . . . . . . . . . .0,43 liter

• Discharge . . . . . . . . . . . . .0,16 liter

• Total . . . . . . . . . . . . . . . . .0,59 liter (0,036 US gallons)

* When the pump works with an inlet gauge pressure less than zero, the

maximum outlet pressure will be calculated as if the inlet pressure is

equal to zero.

This is a SAFETY ALERT SYMBOL

When you see this symbol on the product, or in the manual, look

for one of the following signal words and be alert to the potential for

personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

SAFETY INFORMATIONS

WARNING

CAUTION

DANGER

USED PRESSURE UNITS

Unit without suffix :

Differential pressure, for example, pressure difference between

equipment suction and discharge.

Unit with suffix

"a" :

Absolute pressure.

Unit with suffix

"g" :

Gauge pressure, given regarding to atmospheric pressure

(~101325 Pa, taken at 1 bar / 14,5 psi in this IOM).

Pompe

P

asp

P

re

f

Psuc

Pdis

Pump

Example :

Psuc = -0,2 barg = 0,8 bara

Pdis = 8,8 barg = 9,8 bara

∆P = Pdis - Psuc = 9 bar

3/32

T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e

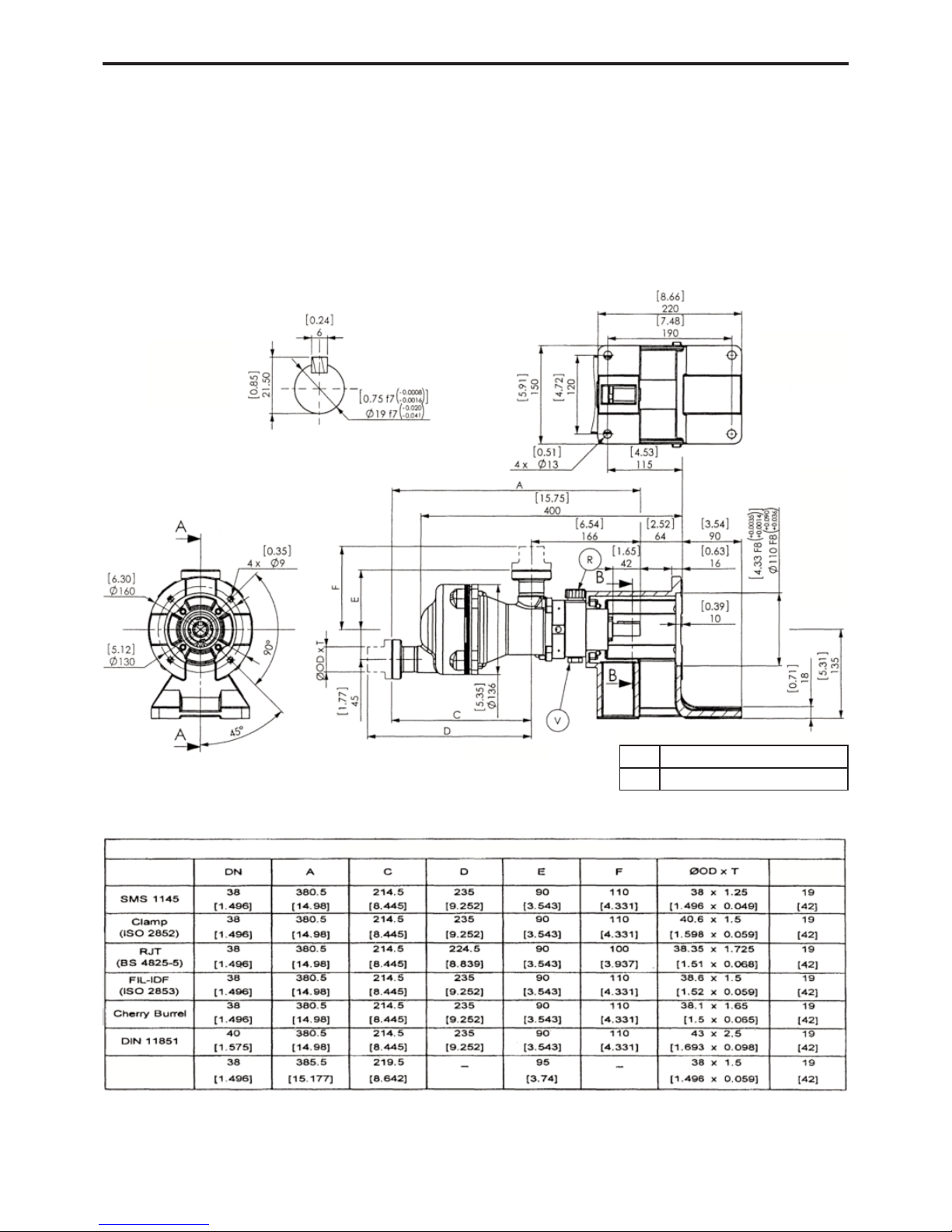

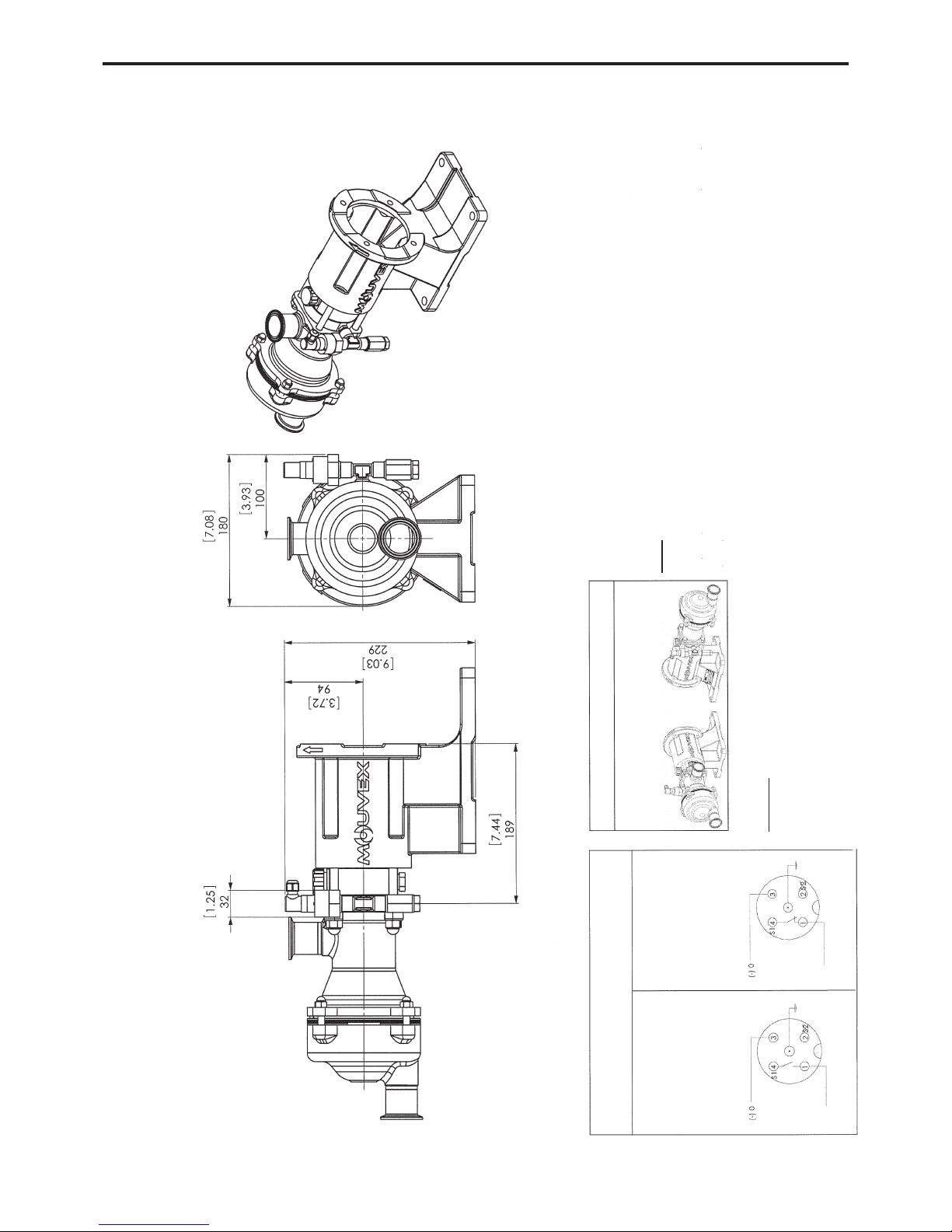

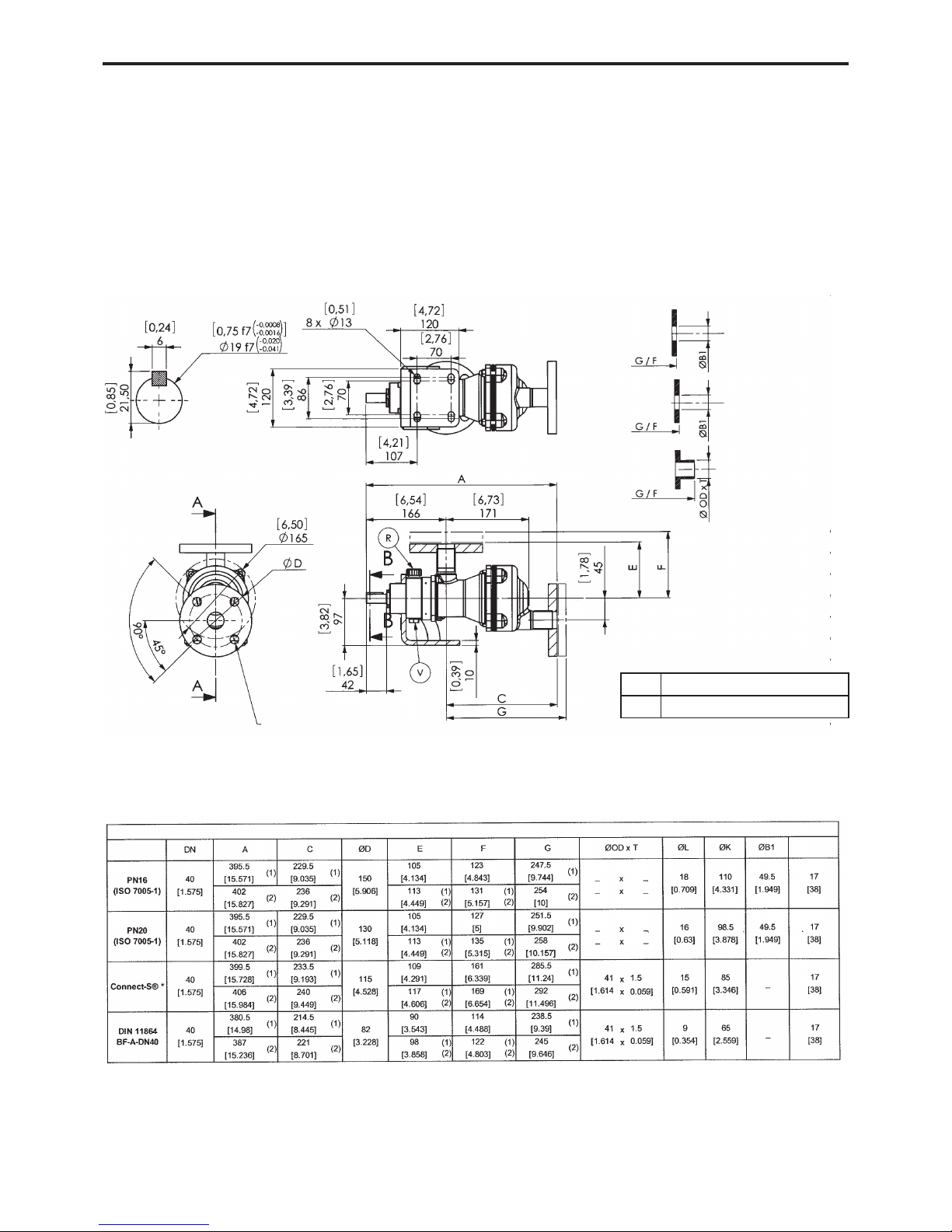

1. OVERALL DIMENSIONS

Pumps SLC1 - SLC2 - SLC3

with connections

Connections

* CAUTION : When welding the connections, the below should be protected.

Weight

kg [lb]

CROSS-SECTION A-A

CROSS-SECTION B-B

Filling / Breather

Draining

R

V

Smooth

end-fitting*

4/32

T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e

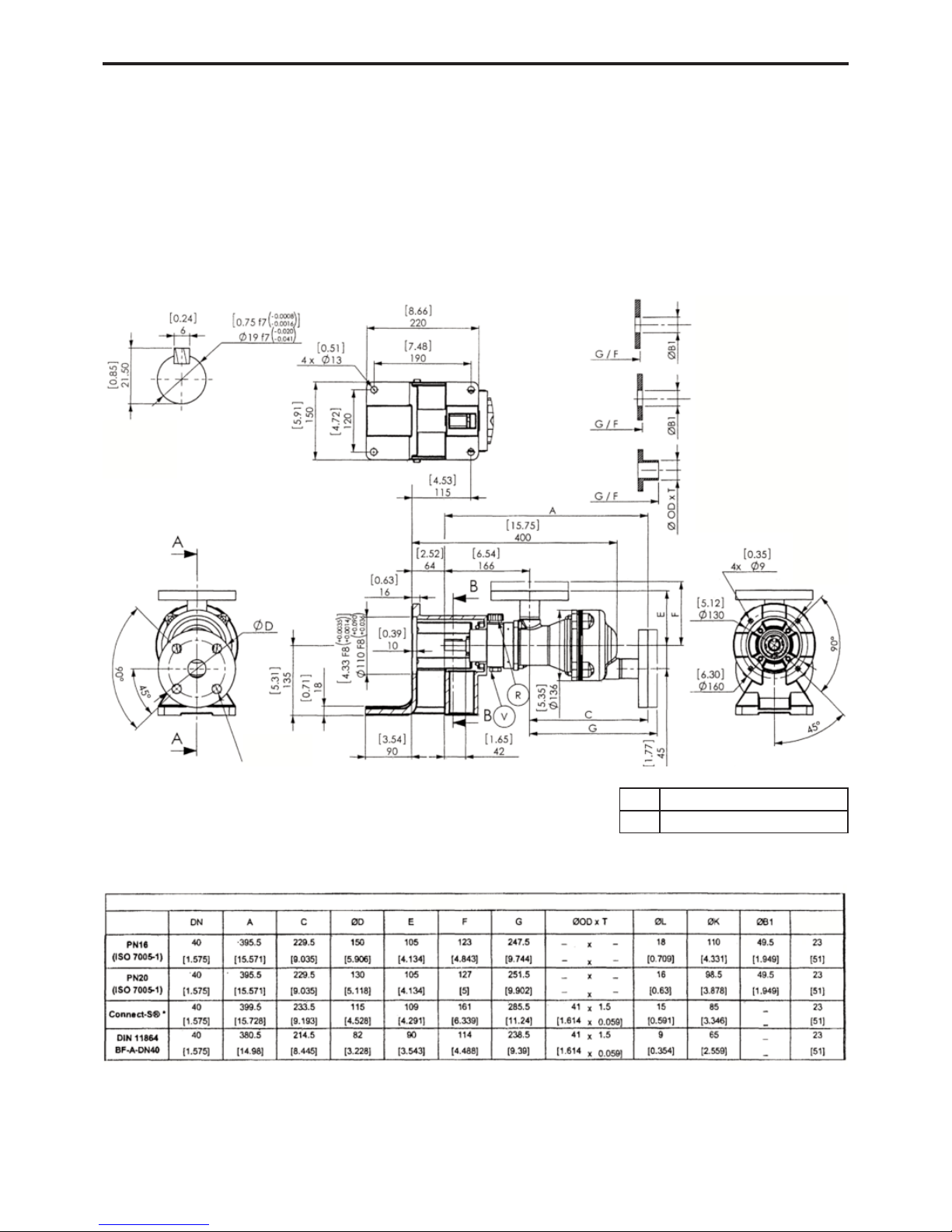

1. OVERALL DIMENSIONS (continued)

Pumps SLC1 - SLC2 - SLC3

with flanges

Flanges

PN16

Type 01

Fitted and welded pipe

PN20

Type 12B

Fitted and welded pipe

Others

Butt-welded pipe

* Connect-S®is a registered trademark owned by NEUMO.

CROSS-SECTION A-A

CROSS-SECTION B-B

4 x ØL on ØK

Weight

kg [lb]

Filling / Breather

Draining

R

V

5/32

T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e

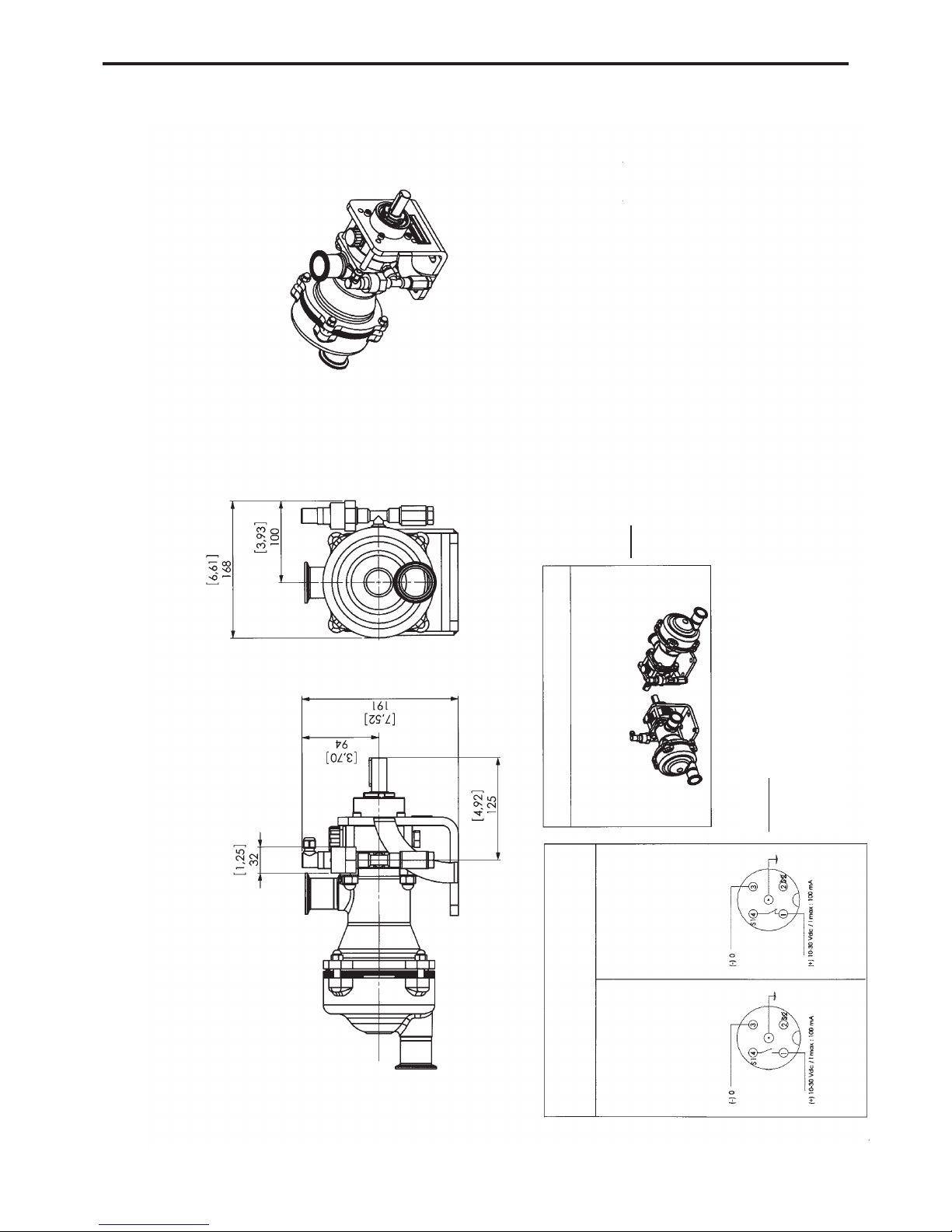

1. OVERALL DIMENSIONS (continued)

Pumps SLC1 - SLC2 - SLC3

with pressure switch

Standard pressure switch

Normal operation

Rupture detection

NOTE :

For the other dimensions, refer to the pump overall dimension drawing.

The detection bearings are adjusted in the plant and should not be modified.

The transmission may only be dismantled in the plant.

Pump weight : add 0,45 kg for the pressure switch.

CAUTION :

Incorrect connection can lead to :

- a flammability risk,

- ineffective monitoring,

- possible damage to the sensor.

lf the suction port is in position 1 :

The transmission is rotated by 180° and the detection

system is installed on the right (as seen from the shaft

end).

(+) 10-30 Vdc / I max : 100 mA

(+) 10-30 Vdc / I max : 100 mA

6/32

T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e

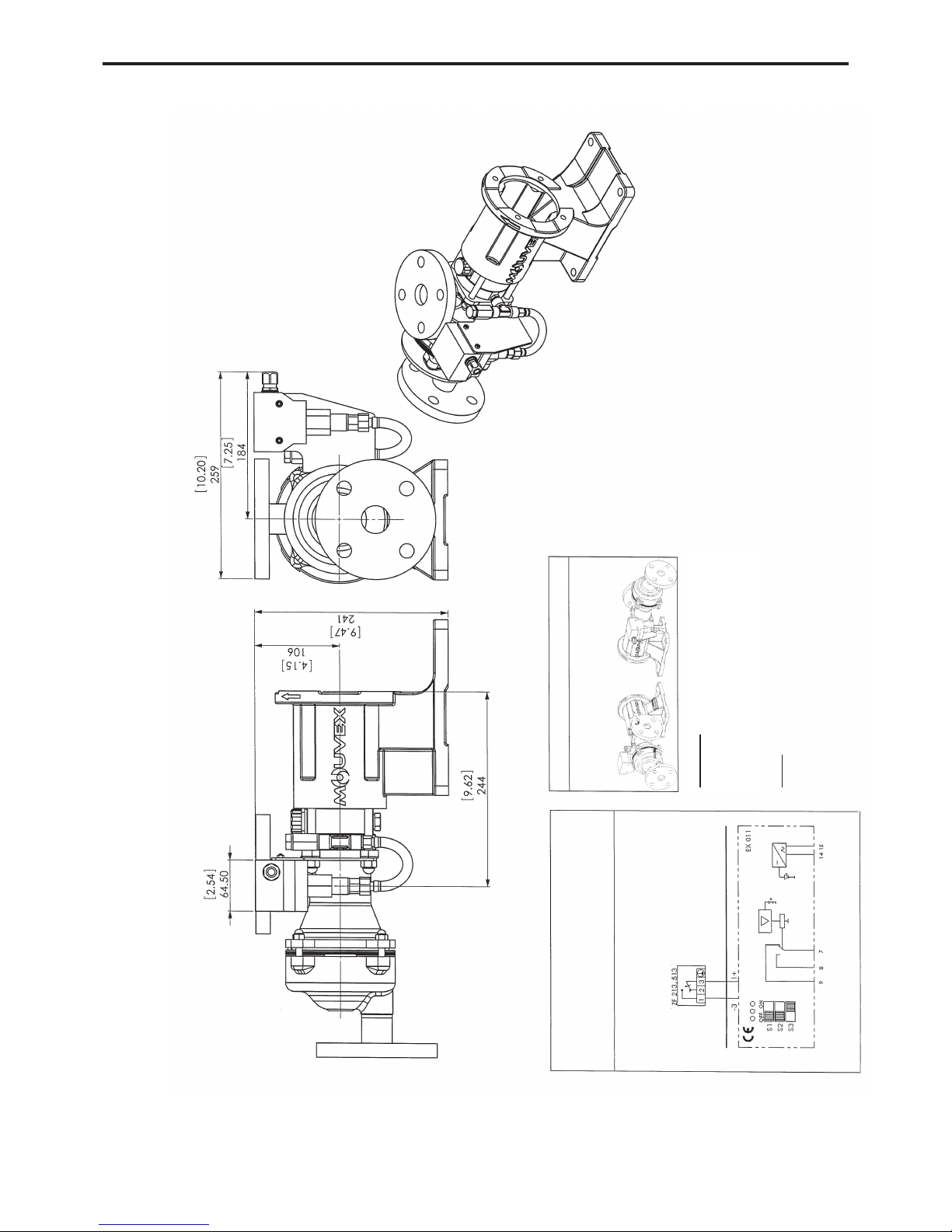

Pumps SLC1 - SLC2 - SLC3

with ATEX pressure switch

ATEX pressure switch

With falling pressure 3-2 opens.

NOTE

:

For the other dimensions, refer to the pump overall dimension drawing.

The detection bearings are adjusted in the plant and should not be modified.

The transmission may only be dismantled in the plant.

Pump weight : add 1 kg for the ATEX pressure switch.

CAUTION :

Incorrect connection can lead to :

- a flammability risk,

- ineffective monitoring,

- possible damage to the sensor.

lf the suction port is in position 1 :

The transmission is rotated by 180° and the detec-

tion system is installed on the right (as seen from

the shaft end).

Connection diagram

Ex-free Zone

Ex-Zone 1 or 2, 21 or 22

Microswitch

Supply voltageOutput

Yellow

Green

1. OVERALL DIMENSIONS (continued)

7/32

T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e

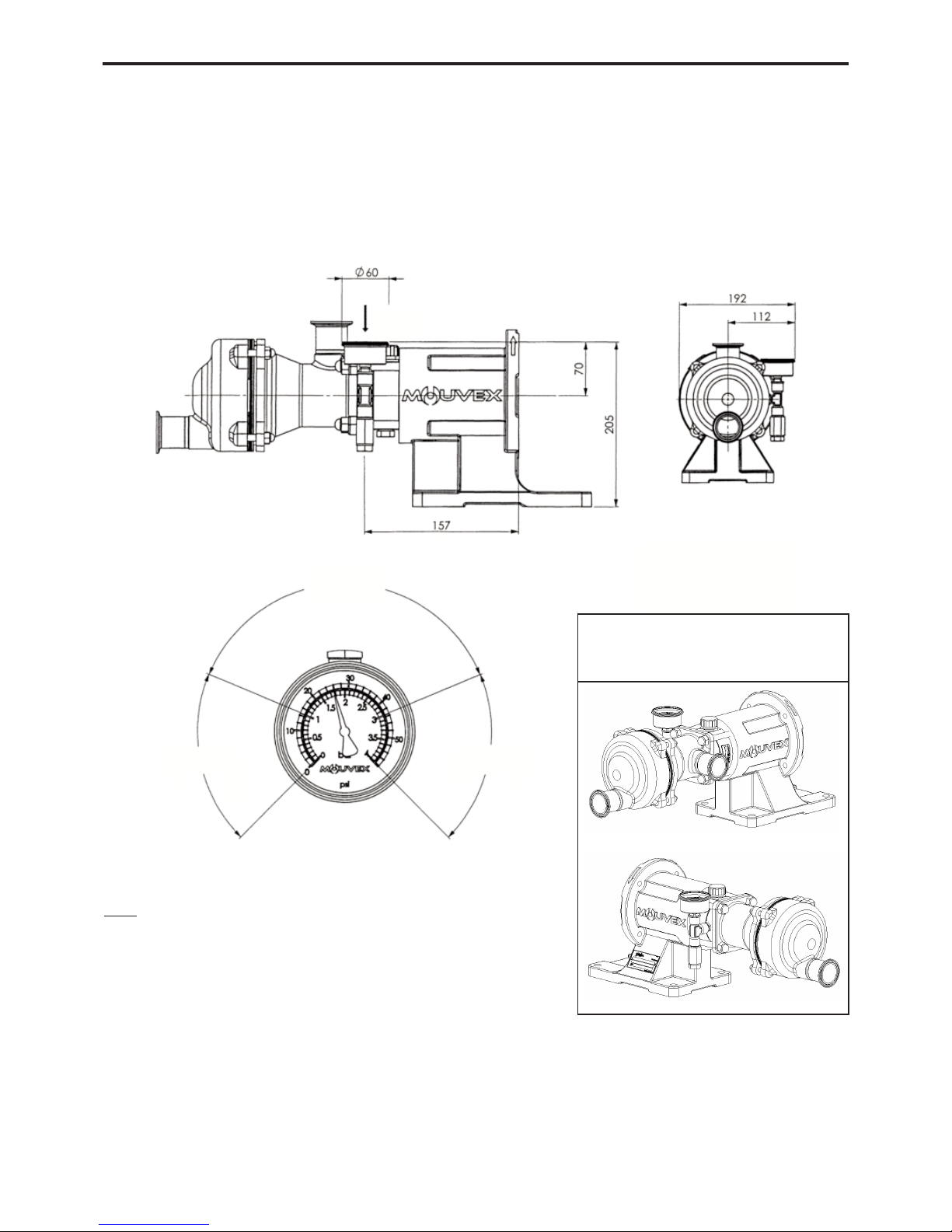

1. OVERALL DIMENSIONS (continued)

Pumps SLC1 - SLC2 - SLC3

with pressure gauge

Green zone

Red zone

Red zone

View F

NOTE :

For the other dimensions, refer to the pump overall dimension drawing.

The detection bearings are adjusted in the plant and should not be modified.

The transmission may only be dismantled in the plant.

Weight added to the pump : 0,5 kg

View F

If the suction port is in position 1 :

The transmission is rotated by 180° and the detection system

is installed on the right (as seen from the shaft end).

8/32

T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e

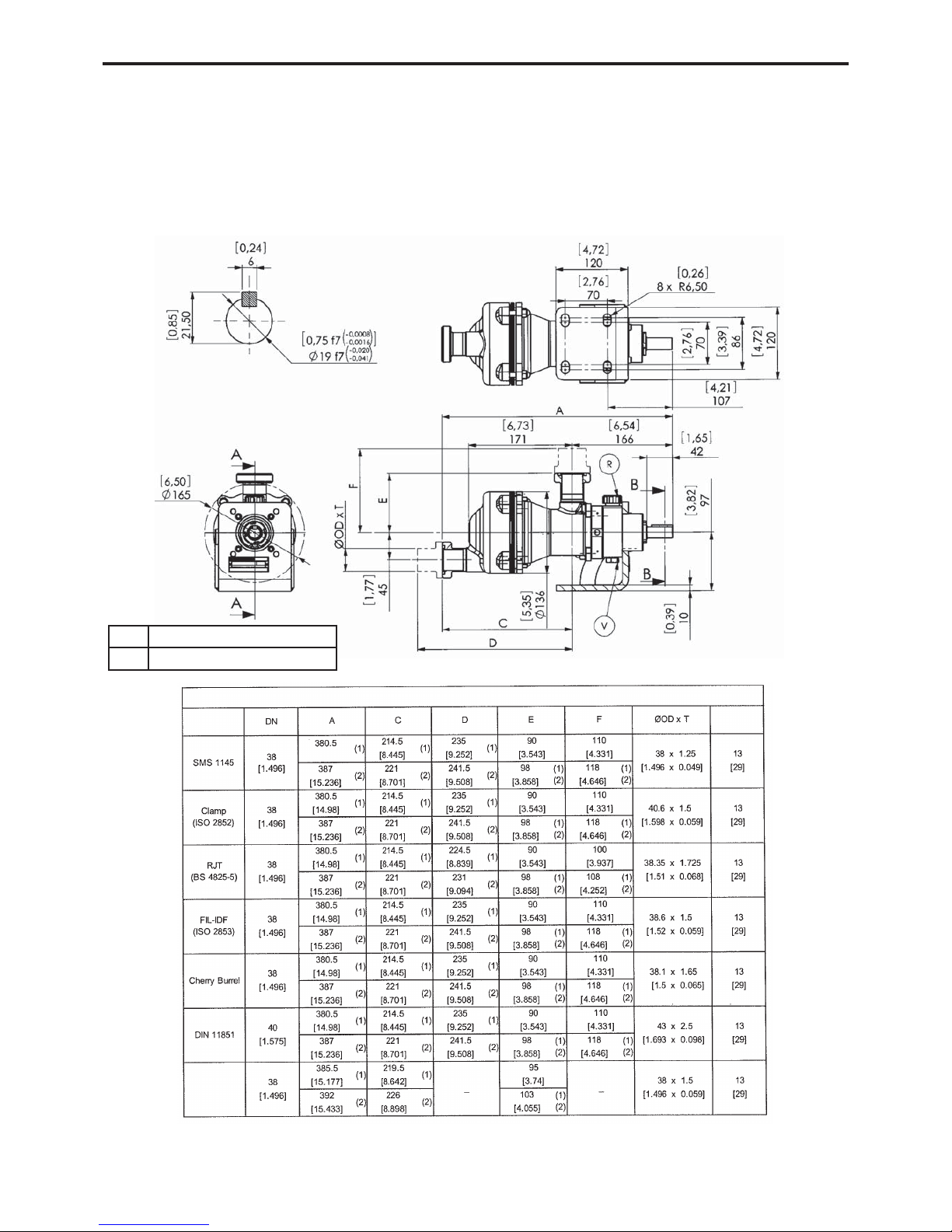

Pumps SLC1 - SLC2 - SLC3

Bended bracket with connections

Connections

* CAUTION : When welding the connections, the below should be protected.

Weight

kg [lb]

CROSS-SECTION A-A

CROSS-SECTION B-B

Filling / Breather

Draining

R

V

Smooth

end-fitting*

(1) C1 interchangeable option

(1)+(2) C2 interchangeable option

1. OVERALL DIMENSIONS (continued)

9/32

T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e

Pumps SLC1 - SLC2 - SLC3

Bended bracket with flanges

PN16

Type 01

Fitted and welded pipe

PN20

Type 12B

Fitted and welded pipe

Filling / Breather

Draining

R

V

Flanges

Others

Butt-welded pipe

* Connect-S®is a registered trademark owned by NEUMO.

CROSS-SECTION A-A

CROSS-SECTION B-B

Weight

kg [lb]

(1) C1 interchangeable option

(1)+(2) C2 interchangeable option

1. OVERALL DIMENSIONS (continued)

4 x ØL on ØK

10/32

T 1004-A00 02.13 Pumps SLC1 - SLC2 - SLC3 e

1. OVERALL DIMENSIONS (continued)

Pumps SLC1 - SLC2 - SLC3

Bended bracket with pressure switch

Standard pressure switch

Normal operation

Rupture detection

NOTE :

For the other dimensions, refer to the pump overall dimension drawing.

The detection bearings are adjusted in the plant and should not be modified.

The transmission may only be dismantled in the plant.

Pump weight : add 0,45 kg for the pressure switch.

CAUTION :

Incorrect connection can lead to :

- a flammability risk,

- ineffective monitoring,

- possible damage to the sensor.

lf the suction port is in position 1 :

The transmission is rotated by 180° and the detection

system is installed on the right (as seen from the shaft

end).

(+) 10-30 Vdc / I max : 100 mA

(+) 10-30 Vdc / I max : 100 mA

Loading...

Loading...