Mouvex S4C Installation Operation & Maintenance

S4C PUMP

INSTALLATION

OPERATION

MAINTENANCE

INSTRUCTIONS 1002-B00 e

Section 1002

Effective July 2019

Replaces February 2018

Original instructions

Your distributor :

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact.mouvex@psgdover.com - www.mouvex.com

WARRANTY :

S Series pumps are covered 24 months by warranty within the limits mentioned in our General Sales Conditions.

In case of a use other than that mentioned in the Instructions manual, and without preliminary agreement of MOUVEX,

warranty will be canceled.

2/15

NT 1002-B00 07 19 S4C Pump e

ECCENTRIC PISTON

MOUVEX PRINCIPLE

SAFETY, STORAGE, INSTALLATION AND MAINTENANCE INSTRUCTIONS

S4C MODEL

TECHNICAL CHARACTERISTICS

• Maximum speed : 750 rpm

• Range of acceptable temperature :

FKM :

* continuous.......................................0° C to 80°C

* washing / rinsing / sterilisation .....0° C to 121°C

• Acceptable pressure to the suction :

* minimum : - 0,4 barg (0,6 bara)

* maximum : 3,0 barg (4,0 bara)

• Acceptable maximal differential pressure : 6 bar*

• Cylinder capacity : 0,108 liter/rev.

* When the pump works with an inlet gauge pressure less than zero, the

maximum outlet pressure will be calculated as if the inlet pressure is

equal to zero.

1. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Installation design . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Orientation of the pump ports . . . . . . . . . . . . . . . . . . . .5

2.3 Direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4 Protection of the installation . . . . . . . . . . . . . . . . . . . . .6

2.5 Unit assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3. USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2 Dry running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.3 Scrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4. CLEAN IN PLACE (CIP) & STERILISATION IN PLACE

(SIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.1 Preamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.2 Cleaning Out of Place . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.3 Cleaning In Place . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.4 Sterilisation In Place (SIP) . . . . . . . . . . . . . . . . . . . . .10

5. ASSEMBLY / DISMANTLING . . . . . . . . . . . . . . . . . . . . . .11

5.1 Necessary tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.2 Opening the pump . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.3 Dismantling the transmission block . . . . . . . . . . . . . .12

5.4 Remounting the transmission block . . . . . . . . . . . . . .12

5.5 Remounting the pump . . . . . . . . . . . . . . . . . . . . . . . .12

6. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.1 Checking of parts . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.2 Checking of seals . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

7. STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

7.1 Short duration (≤ 1 month) . . . . . . . . . . . . . . . . . . . . .14

7.2 Long duration (> 1 month) . . . . . . . . . . . . . . . . . . . . .14

7.3 Restarting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

8. CERTIFICATE OF CONFORMITY . . . . . . . . . . . . . . . . . .15

TABLE OF CONTENTS Page

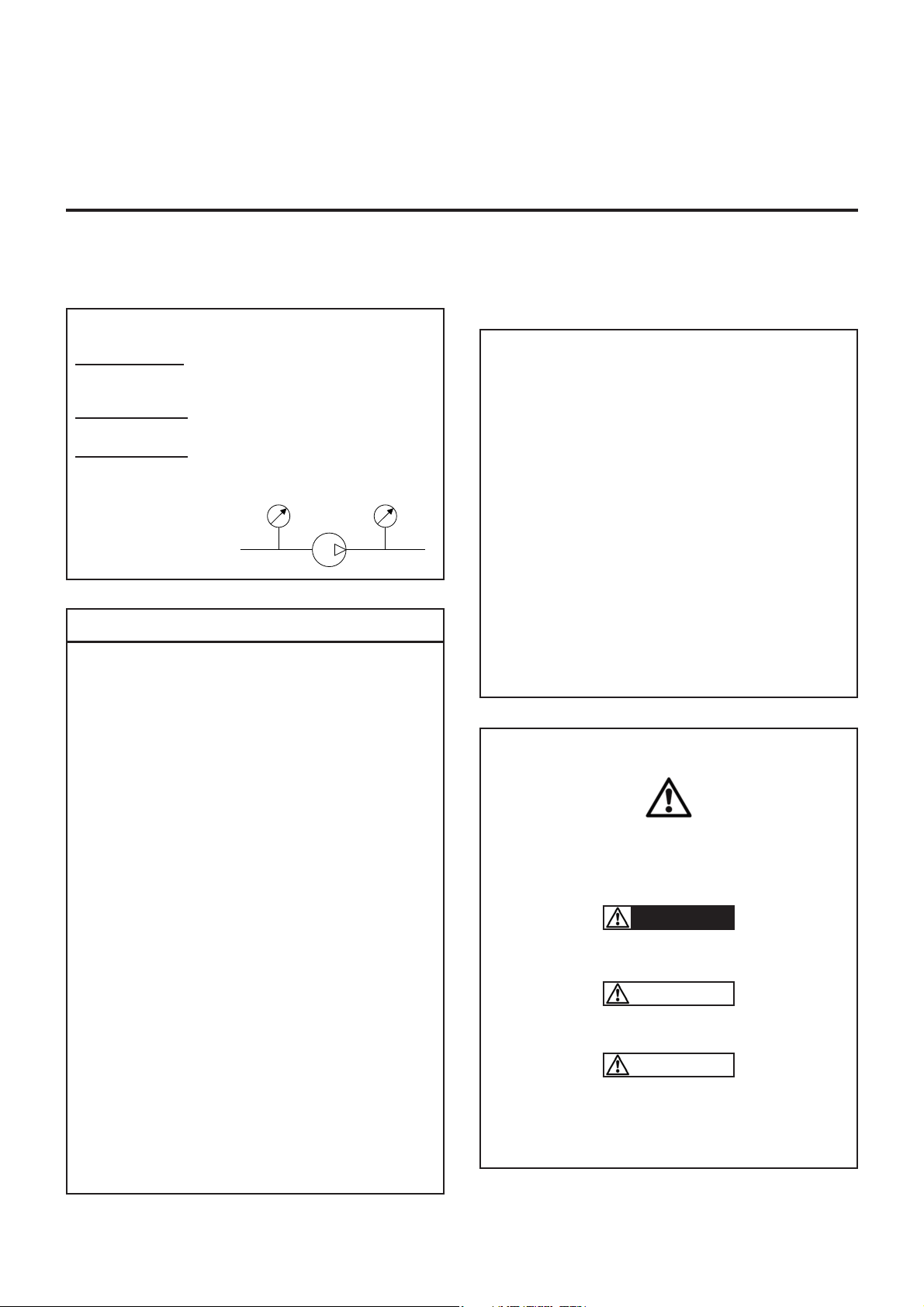

USED PRESSURE UNITS

Unit without suffix :

Differential pressure, for example, pressure difference between

equipment suction and discharge.

Unit with suffix

"a" :

Absolute pressure.

Unit with suffix

"g" :

Gauge pressure, given regarding to atmospheric pressure

(~101325 Pa, taken at 1 bar / 14,5 psi in this IOM).

P

P

f

Psuc

Pdis

Pump

Example :

Psuc = -0,2 barg = 0,8 bara

Pdis = 8,8 barg = 9,8 bara

∆P = Pdis - Psuc = 9 bar

Definition of safety symbols

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the product, or in the manual,

look for one of the following signal words and be alert to the

potential for personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

DANGER

WARNING

CAUTION

asp

Pompe

re

3/15

NT 1002-B00 07 19 S4C Pump e

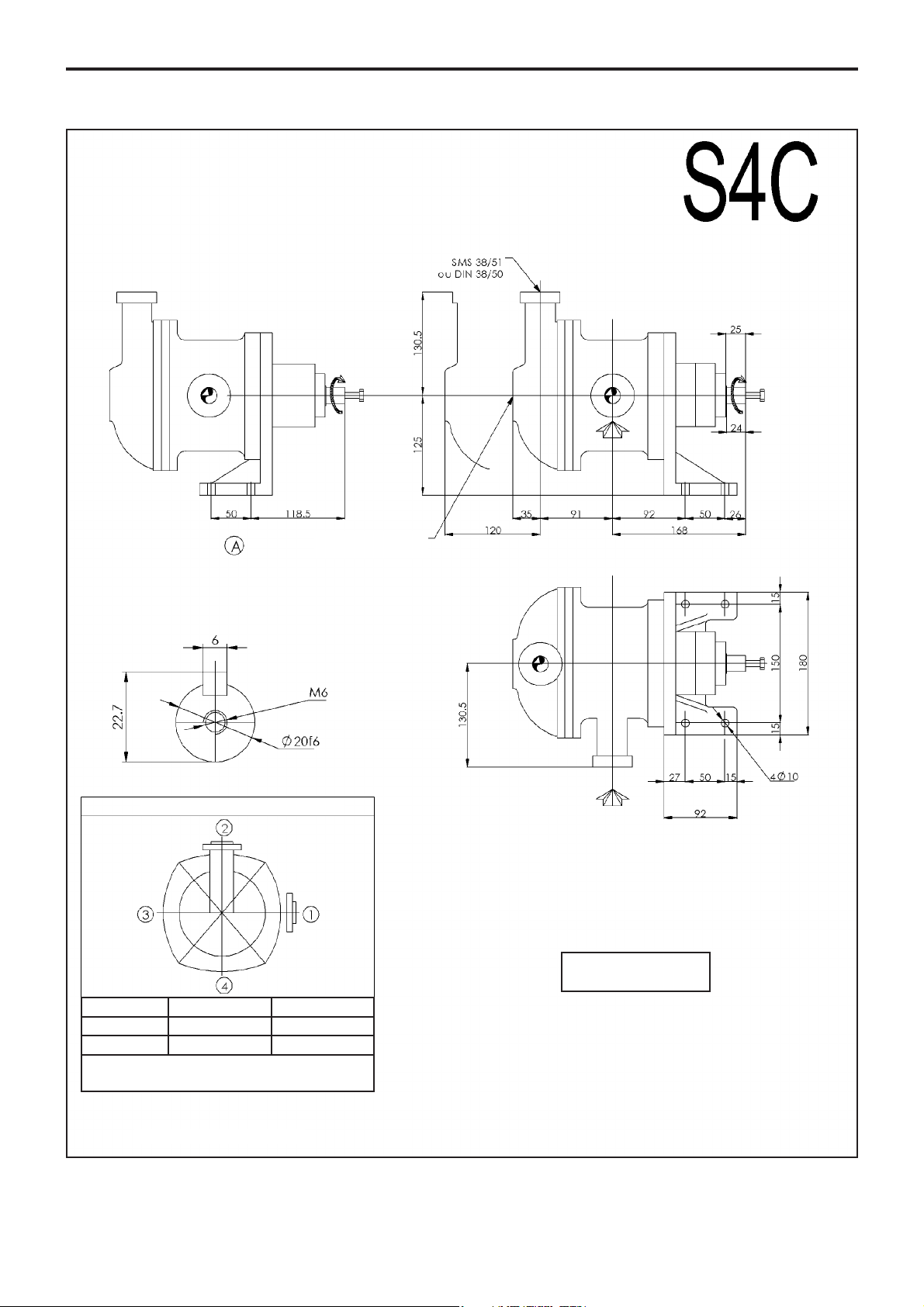

1. OVERALL DIMENSIONS

Pump plate

POSITION OF THE ORIFICES

Dimensions in millimetres

Weight : 23,5 kg

Orifices Connection Standards

Suction 1 - 2 - 3 - 4 1

Discharge 1 - 2 - 3 - 4 2

This position of the mounting bracket does not permit

orientation of the discharge in position 4.

4/15

NT 1002-B00 07 19 S4C Pump e

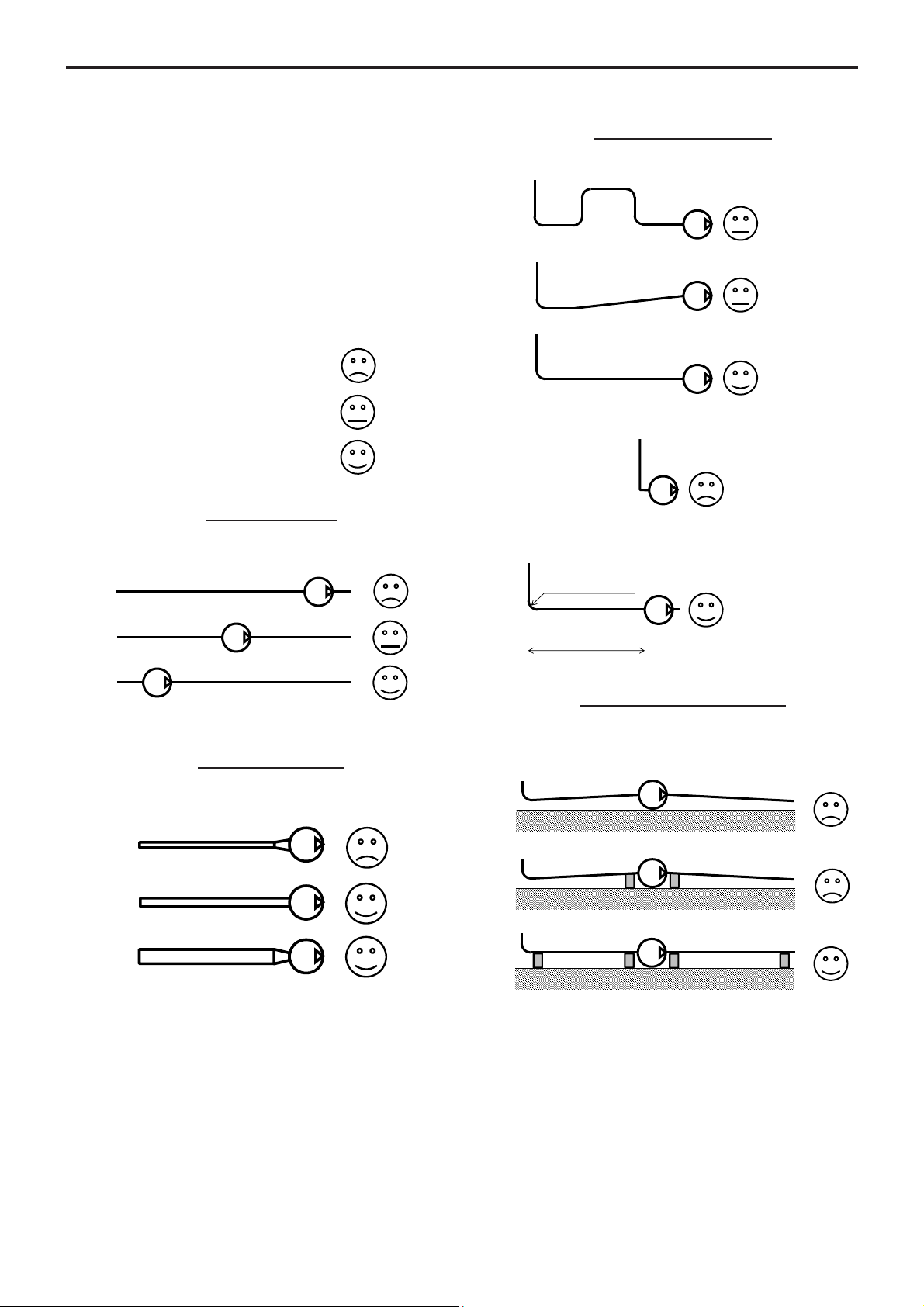

2.1 Installation design

2.1.1 Pump

To obtain the service expected from a MOUVEX pump,

regarding both performance and longevity, it is vital that

the type of pump, its speed and the materials used for its

construction are determined as a function of the pump

output, its installation and operating conditions.

You can contact our Technical Services at any time to

ask for the information you require.

2.1.2 Pipe

Suction pipe length

Length should be as short as possible.

Suction pipe diameter

Diameter must be at least equal to pump port diameter

and even more if required by pumping conditions.

Suction pipe configuration

Check tightness to avoid accidental air intake.

--------------------------------------------------------------------

Pipe alignment and supporting

Pump must not support piping nor endure stress resulting from piping weight or dilatation effects. For latters,

expansion loops should be included.

Not recommended

To be avoided if possible

Recommended

2. INSTALLATION

R=3xDminimum

L=10xDminimum

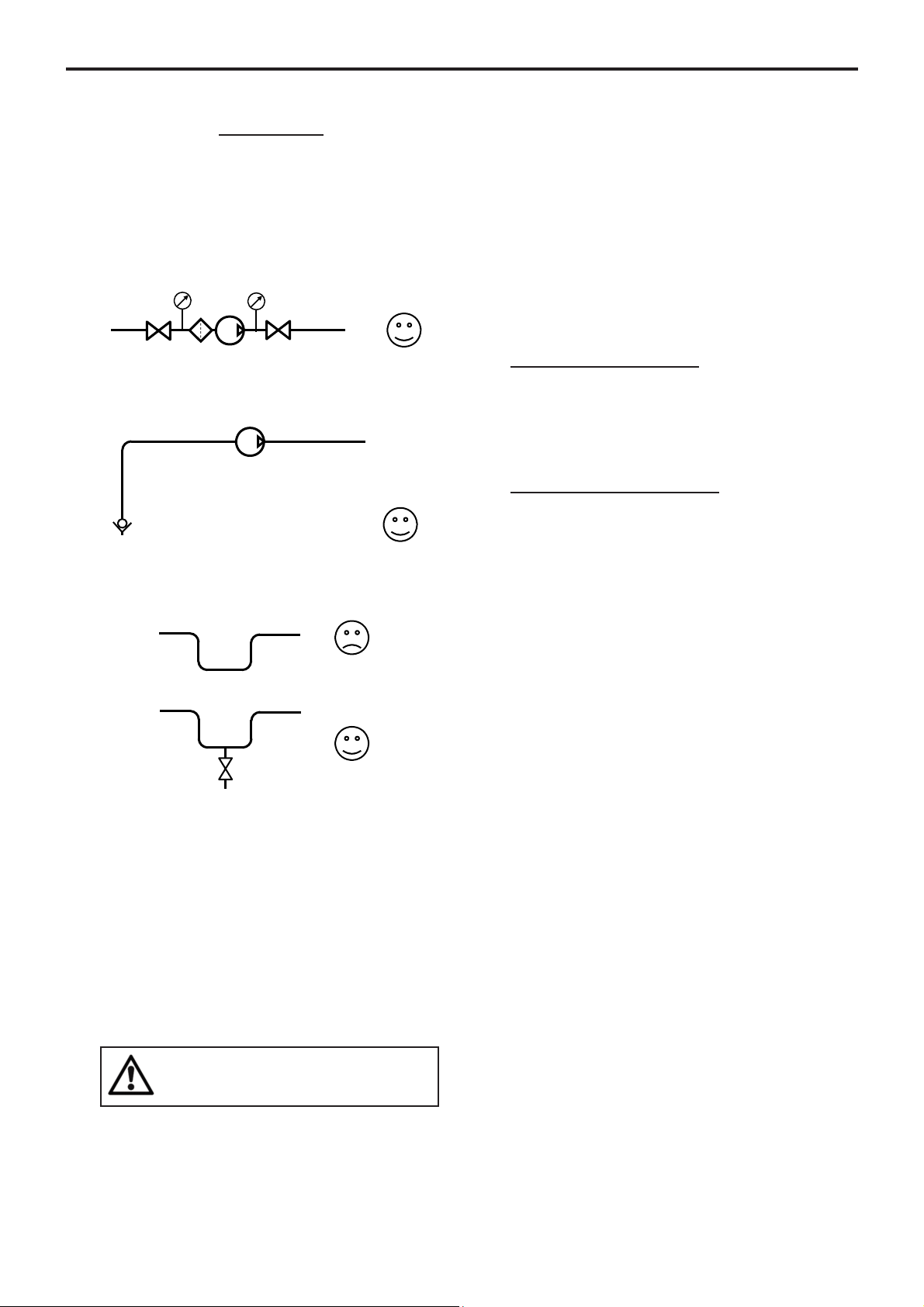

Pipe equipment

• Place valves close to the pump to avoid draining pipe

during maintenance operations. Preferably select full

bore ball or butterfly valves.

Pressure connections on pump suction and discharge

are recommended for settings and controls.

Make sure piping, vessels valves and other installation

devices are carefully cleaned before mounting.

• MOUVEX pumps are self priming. However, if line

emptying should be avoided and/or if suction lift is high,

a foot valve can be added.

• If pumped liquid presents a risk of in pipe solidification

and potential dilatation, low points on the pipe should

be avoided or equipped with drain valve.

• If installation is heated, it must be designed so that fluid

dilatation can evacuate through piping. Therefore fluid

contained in piping must be heated before fluid contained

in the pump. Also check that a heated pump is not isolated by closed valves.

The S Series pump is a selfpriming volumetric PD pump.

Therefore, the pump must not run on a circuit with a closed

valve. This is valid both for the suction circuit and for the

discharge circuit.

For hoses fitting on pump suction or discharge, a hose

whip restrain device must be installed to limit the whip or

travel of the pressurized hose at start up, or in case the

hose breaks free.

2.2 Orientation of the pump ports

The suction port and the discharge port may be oriented

in various positions (see overall dimensions plan).

If the port positions need to be changed at the time of

installation, see the corresponding §.

The suction port may be oriented the top, the right or the

left. Unless otherwise specified, the equipment is delivered with the suction port the right (for an observer facing

the back of the pump).

The discharge port may be oriented at any angle around

the pump's horizontal axis.

To orient the suction port

(cf. § DISMANTLING THE PUMP) :

Unscrew the 4 screws 002 at the back of the pump

mounting braket 001. Orient the pumps’ suction port

101 to the desired position. Screw back the 4 screws

002 at the back of the pump mounting braket 001.

To orient the discharge port :

Unscrew the 4 nuts 106 then remove the base 401.

Orient the base 401 to the desired position. Tighten the

nuts 106.

2.3 Direction of rotation

The S4C pump only has one rotation direction (the pump

not being reversible), clockwise (observer facing the

back of the pump).

When connecting the motor, make sure, by observing the

shaft, that the motor is turning in the correct direction.

An incorrect rotation direction will not damage the pump

but it will not allow the unit to pump product.

WARNING: SEVERE PERSONAL INJURY OR

PROPERTY DAMAGE CAN CAUSE FROM

WHIPPING HOSES.

2. INSTALLATION (continued)

5/15

NT 1002-B00 07 19 S4C Pump e

Loading...

Loading...