Mouvex HYDRIVE 2010A, HYDRIVE 2020A Instructions Manual

HYDRIVE 2010A - 2020A

INSTRUCTIONS 206-A00 e

Section 206

Effective October 2011

Replaces March 2011

INSTALLATION

OPERATION

MAINTENANCE

SAFETY

STORAGE

Original instructions

Your distributor :

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact@mouvex.com - www.mouvex.com

2/16

NT 206-A00 10.11 Hydrive e

1. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.1 Hydraulic circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.2 Mounting the HYDRIVE . . . . . . . . . . . . . . . . . . . . . . . .6

3.3 Hydraulic oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.4 Priming the system . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.5 Engaging Hydraulic Motor . . . . . . . . . . . . . . . . . . . . .10

3.6 Adjusting the relief valve . . . . . . . . . . . . . . . . . . . . . . .10

3.7 Setting HYDRIVE fan speed . . . . . . . . . . . . . . . . . . . .11

4. OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1 HYDRIVE pre-start up check list . . . . . . . . . . . . . . . .12

4.2 HYDRIVE operation . . . . . . . . . . . . . . . . . . . . . . . . . .12

5. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.1 Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . .13

5.2 Return filter replacement . . . . . . . . . . . . . . . . . . . . . .13

5.3 Fan replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .14

7. STORAGE CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . .15

8. SCRAPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

9. CERTIFICATE OF CONFORMITY . . . . . . . . . . . . . . . . . .16

TABLE OF CONTENTS Page

HYDRAULICS COOLERS

SAFETY, STORAGE, INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

MODELS : HYDRIVE 2010A & 2020A

Cooler N° :

Date of bringing into service :

NOTE :

Numbers in parentheses following individual parts indicate

reference numbers on the corresponding Parts Lists.

NOTICE :

The HYDRIVE MUST only be installed in systems which have been

designed by qualified engineering personnel. The system MUST

conform to all applicable local and national regulations and safety

standards.

This manual is intended to assist in the installation and operation of

the HYDRIVE and MUST be kept with the HYDRIVE.

HYDRIVE service shall be performed by qualified technicians ONLY.

Service shall conform to all applicable local and national regulations

and safety standards.

Thoroughly review this manual, all instructions and hazard warnings,

BEFORE performing any work on the HYDRIVE

Gloves shall be worn when handling sheet metal to avoid any risk of

injury.

Maintain ALL system and HYDRIVE operation and hazard warning

decals.

This is a SAFETY ALERT SYMBOL

When you see this symbol on the product, or in the manual, look

for one of the following signal words and be alert to the potential for

personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

SAFETY INFORMATIONS

WARNING

CAUTION

DANGER

3/16

NT 206-A00 10.11 Hydrive e

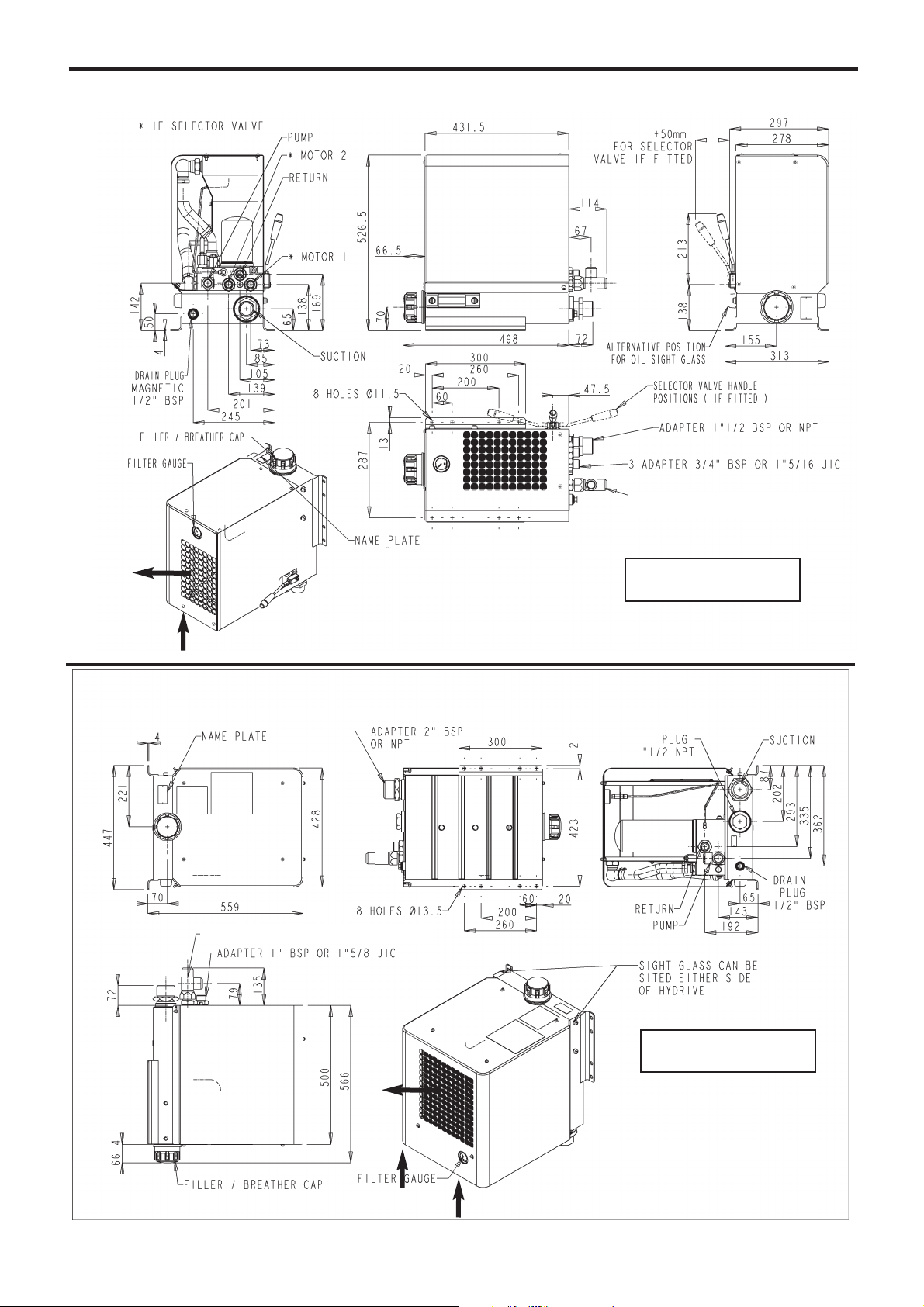

1. OVERALL DIMENSIONS

HYDRIVE 2010

HYDRIVE 2020

DISCHARGE

SUCTION

DISCHARGE

SUCTION

REVOLVING T 1”1/16 JIC M/F/M

REVOLVING T 1”5/16 JIC M/F/M

4/16

NT 206-A00 10.11 Hydrive e

2. TECHNICAL DATA

3. INSTALLATION

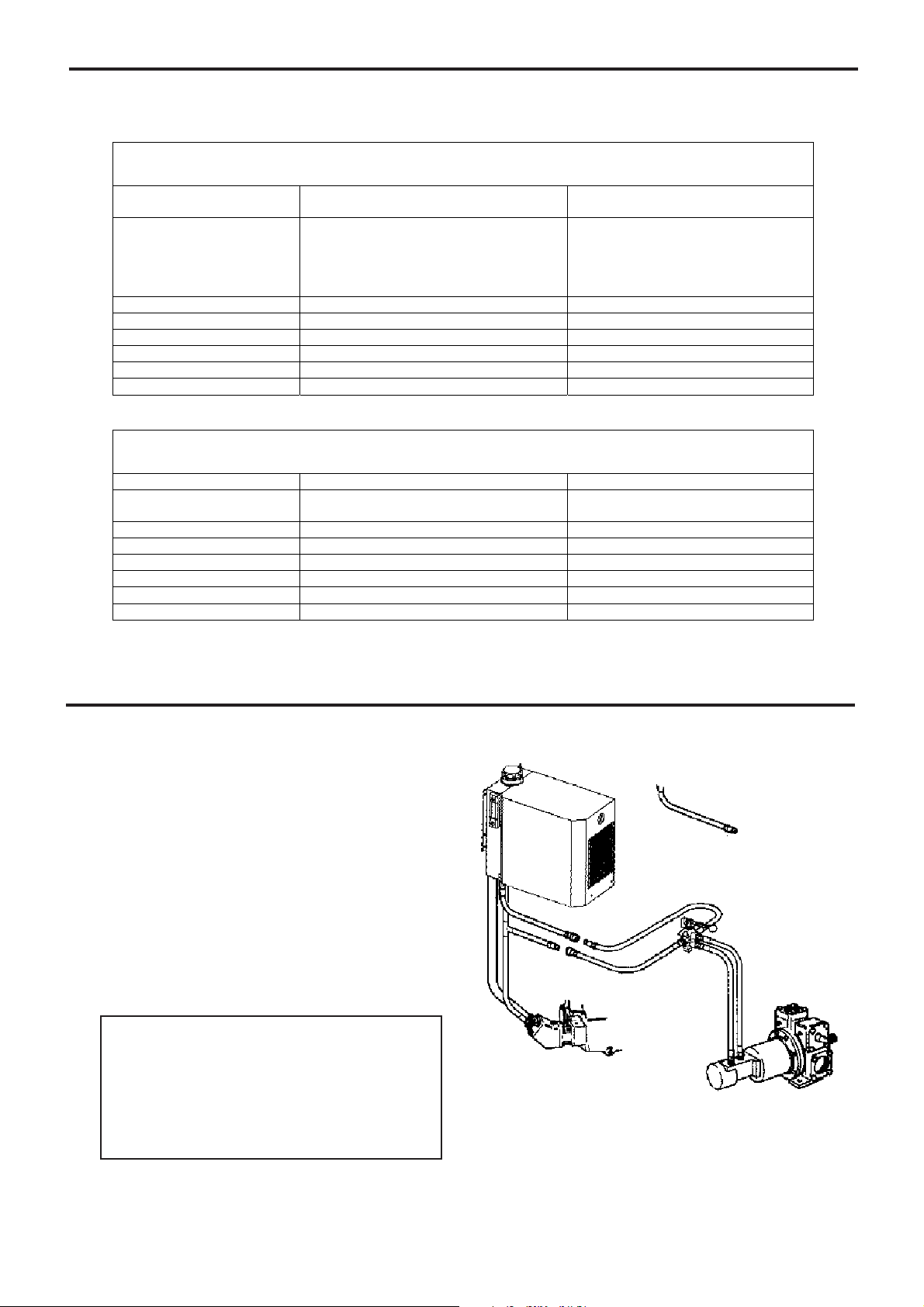

3.1 Hydraulic circuits

Figure 1 shows the hydraulic circuit for a single motor

drive system (without selector valve). If driving a motor

in both directions, install a directional control valve in the

circuit as shown (figure1).

The HYDRIVE is NOT suitable for use for systems using

tipping rams (hydraulic cylinders).

NOTE

Use bulkhead fittings to prevent any overstressing of the

hoses and connections between the tractor and trailer.

Figure 1

System layout without selector valve

HYDRIVE

PTO

Pump

Hydraulic

pump

Non-spill couplings

Directional

control valve

“T” connector

fitting

NOTICE :

The HYDRIVE must only be installed in systems designed by qualified engineering personnel. System design must conform with all

applicable regulations and codes and must

provide warning of all system hazards.

HYDRIVE 2010A

Oil Flow Rate

Circuit pressure

2 possible versions :

170 bar

270 bar

Maximum pressure allowed

Fan speed 2800 rpm 2800 rpm

Return pressure 15 - 75 PSI 1 - 5 bar

Heat Dissipation 13.5 HP for 70°F temperature rise 10 kw for 40 °C Temperature rise

Fan Motor Flow 1.5 U.S GPM 5.5 l / min

Weight (Dry) 53 lbs 24 kg

Oil Tank Capacity 2.5 US Gallons 10 liters

15 - 32 US GPM 55 - 120 l / min

RV set @ :

2465 PSI

5639 PSI

3983 PSI

RV set @ :

170 bar

270 bar

280 bar

HYDRIVE 2020A

Oil Flow Rate 15 - 50 US GPM 55 - 190 l / min

Circuit pressure

Maximum pressure allowed

Fan speed 2800 rpm 2800 rpm

Return pressure 15 - 75 PSI 1 - 5 bar

Heat Dissipation 26 HP for 70°F temperature rise 20 kw for 40 °C Temperature rise

Fan Motor Flow 2.2 U.S GPM 8.2 l / min

Weight (Dry) 77 lbs 35 kg

Oil Tank Capacity 4.5 US Gallons 17 liters

RV set @ 3675 PSI

4978 PSI

RV set @ 253 bar

350 bar

5/16

NT 206-A00 10.11 Hydrive e

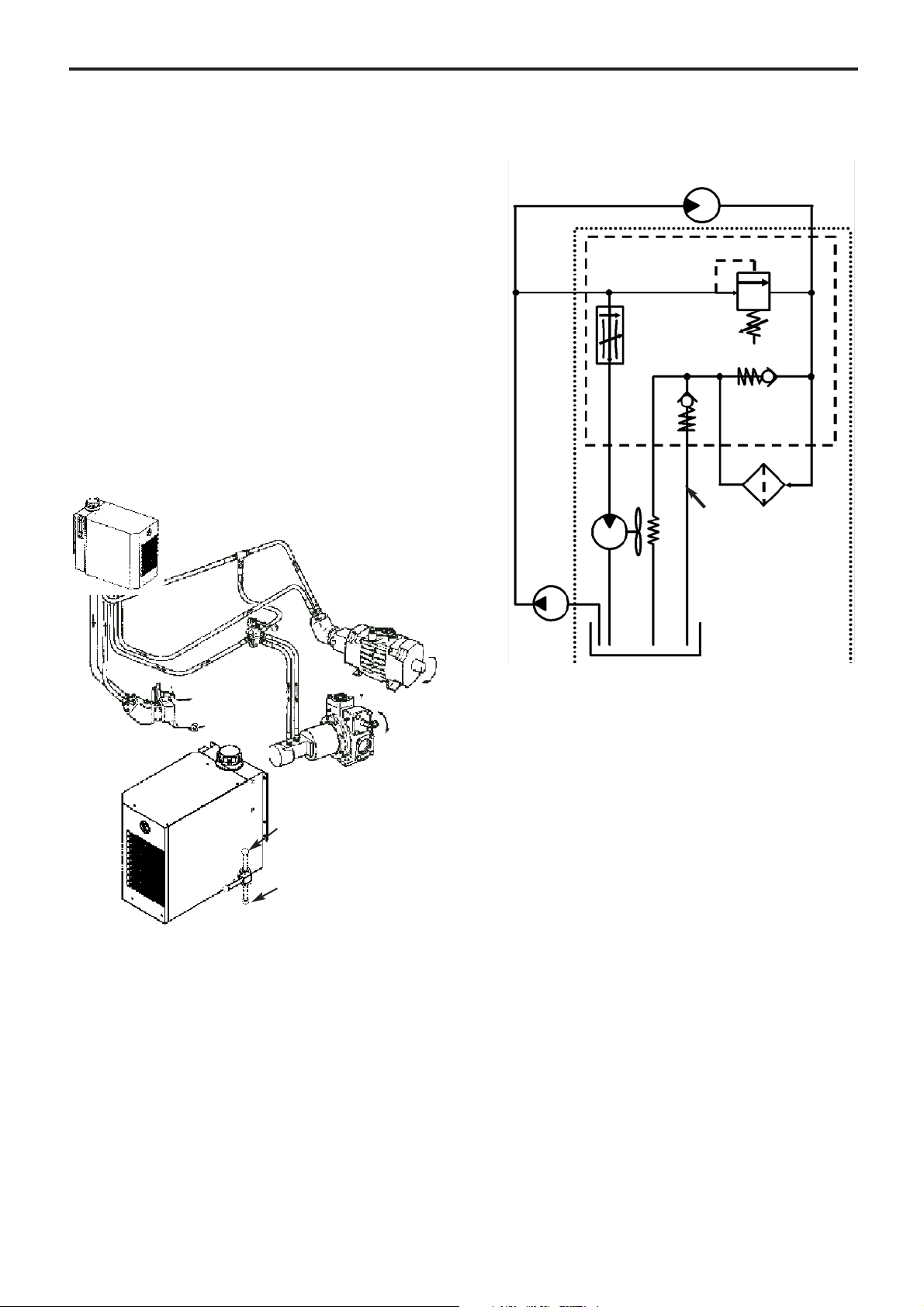

3. INSTALLATION (continued)

There are 2 versions of the HYDRIVE 2010, standard version

and selector valve version. (NOTE : Use a remote on / off

valve on hydraulic systems using the hydrive 2010 without

the selector valve).

The selector version features a manually operated spool

valve so that the high pressure oil (from the hydraulic pump)

can be switched between two possible hydraulic motors

(Motor 1 & Motor 2). The valve can also be set to neutral position with the system unloaded, and the oil returning back to

the tank.

The selector version is designed for tanker applications

where both a compressor and pump may be installed on a

vehicle but operated separately. HYDRIVES are NOT suitable for use with hydraulic cylinders.

The selector valve is NOT available for the HYDRIVE 2020

model.

The HYDRIVE 2010 is not designed for use with 2 motors

running simultaneously unless the system is designed to

allow multi motor operation.

3.1.1 STANDARD HYDRIVE 2010A & 2020A

HYDRAULIC CIRCUIT

1. Adjustable relief valve

2. Fan speed control valve

3. Return line filter

4. Fan motor

5. Filter by-pass valve

6. Oil cooler radiator

7. Fan

8. System pressure gauge point

(not accessible for the 2010)

9. Return pressure gauge point

NOTES

THE DRIVEN MACHINE, PUMP OR COMPRESSOR, WILL START AUTOMATICALLY WHEN THE HYDRAULIC PUMP IS ENGAGED UNLESS A

REMOTE ON/OFF CONTROL VALVE IS INSTALLED IN THE SYSTEM.

A cold start bypass protects the cooler and quickly warms the

oil to its normal working temperature.

Direction

valve

Compressor

(Motor 1)

Pompe (Motor 2)

Figure 2

HYDRIVE 2010 with selector valve

Motor 1

Motor 2

HYDRIVE

Hydraulic

pump

Oil tank

Suction

line

High pressure line

1

3

4

5

6

7

8

9

Hydraulic

pump

Return line

Cold start

bypass

Valve block

Loading...

Loading...