Mouvex C24 i, C36 i Maintance Manual

C24 i - C36 i

PUMPS

INSTALLATION

OPERATION

MAINTENANCE

INSTRUCTIONS 1001-C00 e

Section 1001

Effective November 2008

Replaces March 2008

Original instructions

Your distributor :

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact@mouvex.com - www.mouvex.com

2/21

NT 1001-C00 11.08 C24 i - C36 i e

ECCENTRIC PISTON PUMP

MOUVEX PRINCIPLE

SAFETY INSTRUCTIONS, STORAGE, INSTALLATION AND MAINTENANCE

C24 i - C36 i MODELS

Pump N° :

Commissioning date :

TECHNICAL CHARACTERISTICS

- Maximum pump speed : 460 rpm

- Maximum running temperature :

• PTFE L seals . . . . . . . . . . . . . . . . . . . . . . . . . . 80°C

• other seals :

* continuous . . . . . . . . . . . . . . . . . . . . . . . . . .100°C

* washing/rinsing/sterilisation . . . . . . . . . . . . .121°C

- Maximum suction pressure :

• In normal use, the suction pressure must be higher than the

required NPSH and less than 2 bar (29 psi).

• During CIP/SIP of the pump, the suction pressure must not

exceed 3 bar (43,5 psi).

• Pump stopped, the pressure must not exceed 6 bar (87 psi).

- Maximum differential pressure :

• C24 i . . . . . . .9 bar (130,5 psi)*

• C36 i . . . . . . .6 bar (87 psi)*

- Cylinder capacity :

• C24 i . . . . . . .0,946 litre

• C36 i . . . . . . .1,420 litre

- Informations about PTFE L seals :

• This seal is composed of fibreglass.

• CAUTION : This seal does not accept thermal shock

and Clean In Place.

* When the pump works with an inlet pressure less than zero, the maximum

outlet pressure will be calculated as if the inlet pressure is equal to zero.

1. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 Orientation of the pump ports . . . . . . . . . . . . . . . . . . . .7

2.2 Direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.3 Protection of the pump installation . . . . . . . . . . . . . . . .7

2.4 Hoisting devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5 Unit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3. UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.1 Noise level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3 Dry running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.4 Pump stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4. CLEAN IN PLACE (CIP) & STERILISATION IN

PLACE (SIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.2 CIP circuit recommended . . . . . . . . . . . . . . . . . . . . . .11

4.3 Pumps arranged in series . . . . . . . . . . . . . . . . . . . . . .11

4.4 Pumps arranged in parallel . . . . . . . . . . . . . . . . . . . . .12

4.5 Successive cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.6 Sterilisation In Place (SIP) . . . . . . . . . . . . . . . . . . . . .13

5. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.1 Necessary tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6. OPENING OF THE PUMP . . . . . . . . . . . . . . . . . . . . . . . .14

6.1 Assembly / Dismantling . . . . . . . . . . . . . . . . . . . . . . . .14

6.2 Checking of parts . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

7. ASSEMBLY OF CYLINDER/PISTON . . . . . . . . . . . . . . . .16

8. PROTECTION OF THE BELLOWS . . . . . . . . . . . . . . . . . .17

9. CHANGING THE LIP SEAL . . . . . . . . . . . . . . . . . . . . . . .18

10. CHANGING THE ORIENTATION OF THE PORTS . . . . .19

10.1 Discharge port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

10.2 Suction port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

11. DRAINING OF BEARING . . . . . . . . . . . . . . . . . . . . . . . .20

12. OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

12.1 Liquid detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

12.2 Bellows monitoring system . . . . . . . . . . . . . . . . . . . .21

SUMMARY Page

This is a SAFETY ALERT SYMBOL

When you see this symbol on the product, or in the manual, look

for one of the following signal words and be alert to the potential for

personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

SAFETY INFORMATIONS

WARNING

CAUTION

DANGER

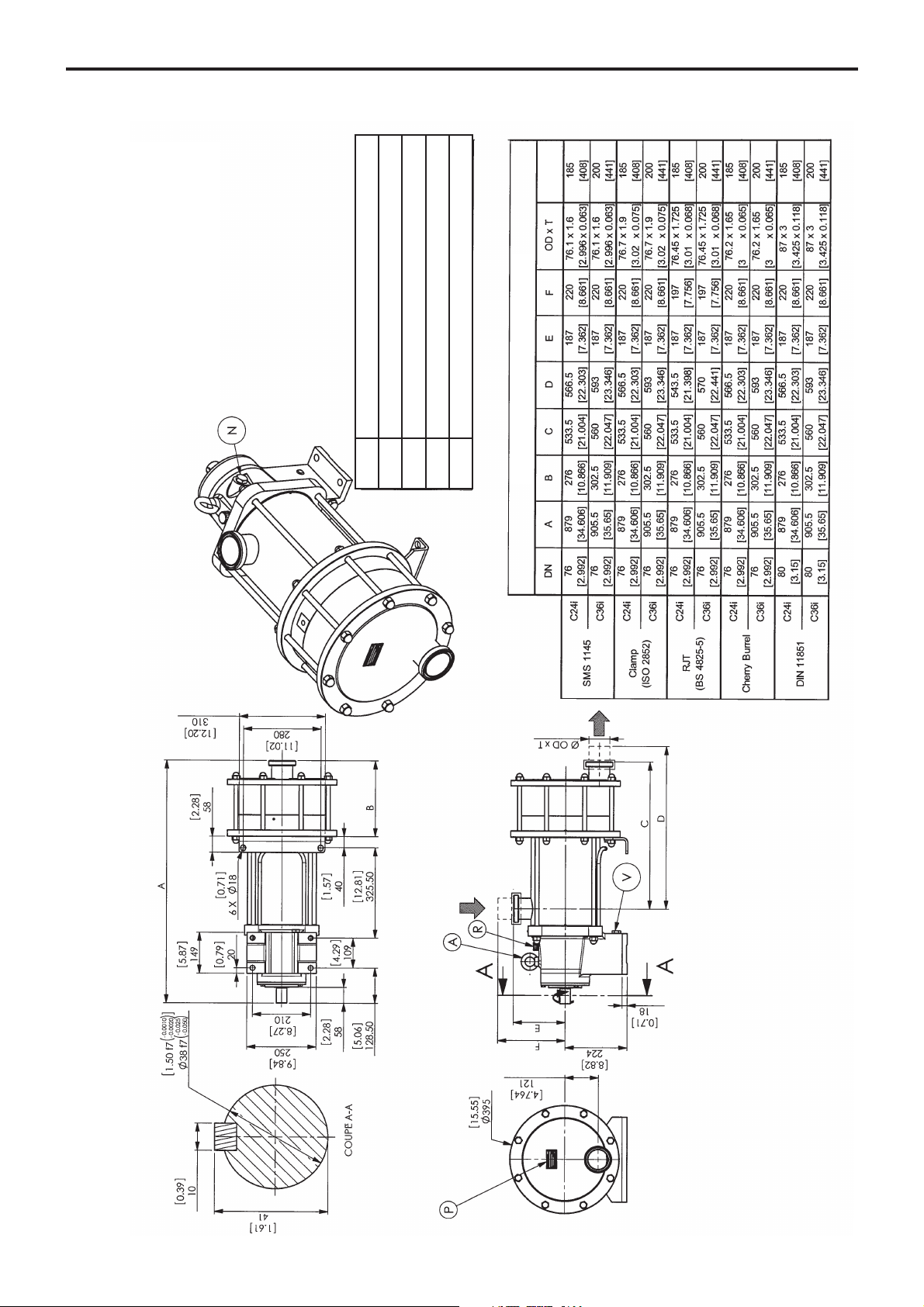

1. OVERALL DIMENSIONS

NT 1001-C00 11.08 C24 i - C36 i e

3/21

C24 i - C36 i

with connections

Lifting ring

Pump plate

Filling / Breather

Draining

Oil level

A

P

R

V

N

Weight

Connections

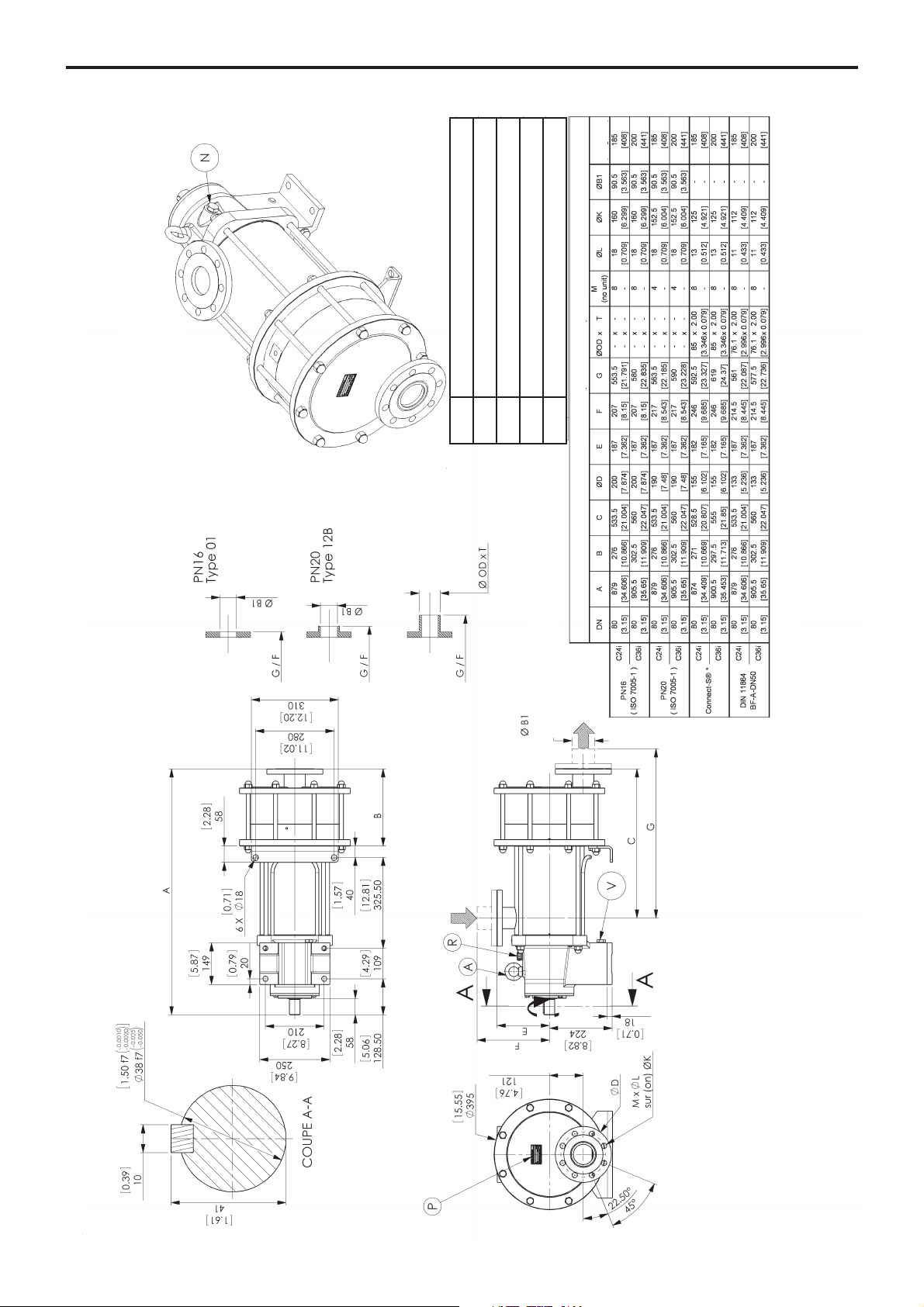

1. OVERALL DIMENSIONS (continued)

4/21

NT 1001-C00 11.08 C24 i - C36 i e

Lifting ring

Pump plate

Filling / Breather

Draining

Oil level

A

P

R

V

N

C24 i - C36 i

Flanges

Shrinked on and

welded pipe

Shrinked on and

welded pipe

Others

Butt welded piping

Companion flange drilling

Connect S-

®

is a registered trademark owned by NEUMO.

Weight

1. OVERALL DIMENSIONS (continued)

5/21

NT 1001-C00 11.08 C24 i - C36 i e

NOTE :

For the other sides, see the specific overall dimension plan for the connection.

Maximum jacket pressure : 8 bar (116 psi)

Maximum jacket temperature : FKM and FEP encapsulated FKM seals : 180°C.

JACKET CONNECTION 1" B.S.P.F

The entry connection may be connected to one or two points.

STEAMLIQUID

The outlet connection may be connected to one or two points.

If it is done at 1 point, purge the air at the second point.

CAUTION :

The pumped product must not exceed the maximum temperature of the pump.

FOR ATEX PUMPS, SEE INSTRUCTIONS NR 1050.

C24 : 867.50 - C36 : 900

8 (plug)

C24 i - C36 i

with heating jacket

1. OVERALL DIMENSIONS (continued)

6/21

NT 1001-C00 11.08 C24 i - C36 i e

Bellows monitoring system

C24 - C36

NOTA :

Setting of detecion levels is done in factory and do not have to be modified.

For other dimensions, report to pump dimensional drawing.

The dismantling of the transmission could be done only in factory.

CAUTION :

A BAD CONNECTION CAN DESTROY THE SENSOR.

Wiring diagramm

Connector

Do not use S2

Normal operation

Leakage detection

7/21

NT 1001-C00 11.08 C24 i - C36 i e

The C Series pump is a selfpriming volumetric PD pump.

Therefore, the pump must not run on a circuit with a closed

valve. This is valid both for the suction circuit and for the

discharge circuit.

2.1 ORIENTATION OF THE PUMP PORTS

The suction and discharge ports may be oriented in

various positions.

If the ports positions needs to be changed at any time,

see the corresponding paragraph.

2.2 DIRECTION OF ROTATION

An arrow situated on the bearing housing indicates the

correct direction of rotation.

When looking at the shaft, the rotation will be clockwise.

When looking at the front cover, the direction of rotation

will be anti-clockwise.

Verification of the correct rotation direction : Turn the

pump the wrong way is not dangerous for the pump.

2.3 PROTECTION OF THE PUMP INSTALLATION

• For ease of maintenance, it is a good idea to place isolation valves before and after the pump. The sizing of

these valves must correspond to the diameter of the

pipes.

• Before any start-up, during operation or complete stopping of the pump, make sure the valves are open

.

• During stop periods, with the pump full of product,

either the suction or discharge circuit must be left open

to enable expansion or contraction of the pumped product through reheating or cooling. If this instruction is

not complied with, The bellows may be damaged and

lead to premate failure.

• The bearing must be ventilate at all times, therefore the

breather mounted on the bearing must be re-used.

Never put the bung on

.

• In case of flodded suction, it is possible to install a liquid

detector in the place of the transmission breather (see

§ OPTIONS). This detector will enable the user to be

informed in the case of failure of the bellows. In the

case of detection, the installer must make sure the

pump is stopped and the isolating valves are closed.

Non compliance with this instruction can lead to the

pumped product being spilt outside the pump.

• It is possible to have a puncture detection system with

double-walled bellows : an inert gas is maintained under

pressure between the 2 walls and said pressure is permanently monitored. A signal is dispatched immediately

should a wall become punctured (see § OPTIONS).

• The stop time may lead to cooling of the product in the

pump and therefore to an increase in viscosity. If this is

the case, we recommend re-starting the pump at a

speed adapted to this new viscosity (starting pump).

Once the product arrives in the pump at the installation

definition temperature, the pump may run at the speed

specified for this application.

NOTICE

C-Series pumps remains drainable whatever

position is chosen for the inlet port, but the

outlet port must be at the bottom (position 4)

to keep the self-draining capability.

2. INSTALLATION

POSSIBLE POSITIONS

SUCTION

DISCHARGE

Loading...

Loading...