Mouvex Typhon II, 20R, 13R, 30R, 15L Maintance Manual

...

OPERATION

MAINTENANCE

SAFETY

TYPHON II

SCREW COMPRESSORS

INSTRUCTIONS 1401-G00 e

Section 1401

Effective October 2018

Replaces February 2016

Original instructions

This Instructions only contains bare shaft machine information.

It is imperative to have in complement the accessories instructions, also the parts list before

installing the equipment.

Your distributor :

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact@mouvex.com - www.mouvex.com

WARRANTY :

TYPHON II screw compressors are covered 24 months by warranty within the limits mentioned in our General Sales Conditions. The use of

the BSC3 oil carries our warranty from 24 to 36 months. In case of a use other than that mentioned in the Instructions manual, and without

preliminary agreement of MOUVEX, warranty will be canceled.

20R/30R 13R/15L - 19R22L 20R/30R SAE4

2/16

NT 1401-G00 10 18 TYPHON II e

MOUVEX TRUCK SCREW COMPRESSOR

SAFETY, OPERATION AND MAINTENANCE INSTRUCTIONS

MODEL : TYPHON II

REMARKS :

MOUVEX truck screw-type compressors MUST be installed in systems designed by qualified personnel. The installation MUST be in

compliance with local standards, national regulations and rules of

safety.

This manual is designed to permit installation and commissioning of MOUVEX truck screw-type compressors and MUST

accompany the compressor.

Maintenance of MOUVEX screw-type compressors must ONLY be

carried out by qualified technicians. This maintenance must meet

local and national standards as well as all safety regulations.

Read this manual, including all instructions and warnings, in

full BEFORE any use of MOUVEX compressors.

Do not remove the warning and use label stickers that are

found on the compressors.

1. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .4

2. GENERAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . .8

2.3 Operating ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3. MULTIPLIER 13R/15L - 19R/22L . . . . . . . . . . . . . . . . . . .11

3.1 Cross-section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 Multiplier mounting . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4. USE OF COMPRESSOR . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1 Lubricant recommendations . . . . . . . . . . . . . . . . . . . .14

4.2 Filling of lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.4 Starting-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.1 Maintenance schedules . . . . . . . . . . . . . . . . . . . . . . .16

5.2 Compressor oil change procedure . . . . . . . . . . . . . . .16

5.3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

TABLE OF CONTENTS Page

ADDITIONAL DOCUMENTATION

The table below gives the list of instructions in addition

to this central instruction :

TYPHON II

application

Instructions

Spare parts

list

20R/30R - SAE NT 1401-Q00 PL 1401-Q02

13R/15L - 19R/22L NT 1401-Q00 PL 1401-Q01

DDIC - DDNC NT 1401-R00 PL 1401-R01

LS DDNC NT 1401-W00 PL 1401-W01

Torque limiter NT 1401-B00 PL 1401-Q01

Check and relief valve NT 1401-E00 PL 1401-Q01

Oil cooler NT 1401-AC00 PL 1401-Q01

Definition of safety symbols

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the product, or in the manual,

look for one of the following signal words and be alert to the

potential for personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

DANGER

WARNING

CAUTION

3/16

NT 1401-G00 10 18 TYPHON II e

SAFETY CHECK LIST

1. Before operating the compressor, ensure the vessel to which the

compressor is connected is certified to withstand the pressure and

/or vacuum produced.

2. Verify adequately sized relief valves have been fitted to protect the

vessel. Do not use solvents or inflammable products for cleaning

the pipelines and the accessories.

3. Gas/air mixtures which are potentially volatile/explosive must not be

introduced or allowed to be introduced into the compressor.

4. All pressure vessel and piping connected to the compressor must

be isolated and in a safe operating condition.

5. Operators should wear ear protection when operating truck mounted compressors.

6. There are components within the compressor of sufficient weight

to cause injury if mishandled. Use proper lifting devices as necessary.

7. Where necessary, this equipment should be grounded to control

static electricity.

8. The temperature of the air leaving the compressor is elevated

above ambient due to air compression. Check that the elevated

temperatures do not adversely affect the product and any material

used in design of the system. Attach clearly marked warning signs

to warn of potentially hot surfaces on the compressor, piping and

accessories which will burn if touched.

9. Mounting of the compressor must be correctly engineered and the

compressor must be properly secured. Refer to the Compressor

Mounting section of this manual.

NOTICE :

MOUVEX COMPRESSORS ARE DESIGNED TO PRODUCE COMPRESSED AIR. NOT TO PUMP GASES, LIQUIDS, POWDERS OR

CONDENSATES THOUGH THE COMPRESSOR. TO DO SO WOULD

VOID THE WARRANTY.

LIFTING POINTS :

The compressor can be picked up from underneath to be

transported.

Discharge flanges threads can be used to install a lifting lug

in order to transport the compressor.

WARNING

IT IS IMPERATIVE TO APPLY THE

TRUCK PARKING BRAKE AND TO

BLOCK THE WHEELS BEFORE ANY

INTERVENTION DUE TO RISKS OF

SERIOUS BODILY INJURIES OR PROPERTY DAMAGE.

Hazardous machinery

can cause severe

personal injury or

property damage.

WARNING

CONTENTS OF THE COMPRESSOR,

TANK, PIPING, AND FILTERS COULD

BE HAZARDOUS TO HEALTH.

TAKE ALL NECESSARY PRECAUTIONS

WHEN PERFORMING COMPRESSOR

SERVICE OR MAINTENANCE.

Hazardous or toxic

fluids can cause

serious injury.

CAUTION

COMPRESSOR, PIPING AND ACCESSORIES WILL BECOME HOT DURING

OPERATION AND CAN CAUSE SERIOUS

PERSONAL INJURY.

Extreme heat can

cause injury or

property damage.

WARNING

COMPRESSING GASES INTO A VESSEL CONTAINING FLAMMABLE OR

EXPLOSIVE GASES OR COMPRESSING

FLAMMABLE OR EXPLOSIVE GASES,

CAN CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

Hazardous fluids

can cause fire,

serious personal injury

or property damage.

WARNING

FAILURE TO INSTALL ADEQUATELY

SIZED PRESSURE RELIEF VALVE(S)

CAN CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

THE NOISE EMITTED BY WORKING

MOUVEX SCREW COMPRESSOR

CAN BE HIGHER THAN 80 DBA.

THE END USERS MUST USE, WHEN

NECESSARY THE APPROPRIATE

EAR PROTECTIONS. FAILURE TO

WEAR HEAR PROTECTIONS IN

AREAS WHERE THE NOISE IS

HIGHER THAN 80 DBA CAN LEAD TO

PERMANENT BODY DAMAGE.

A loud noise can

cause permanent

body damage.

SAFETY DATA

4/16

NT 1401-G00 10 18 TYPHON II e

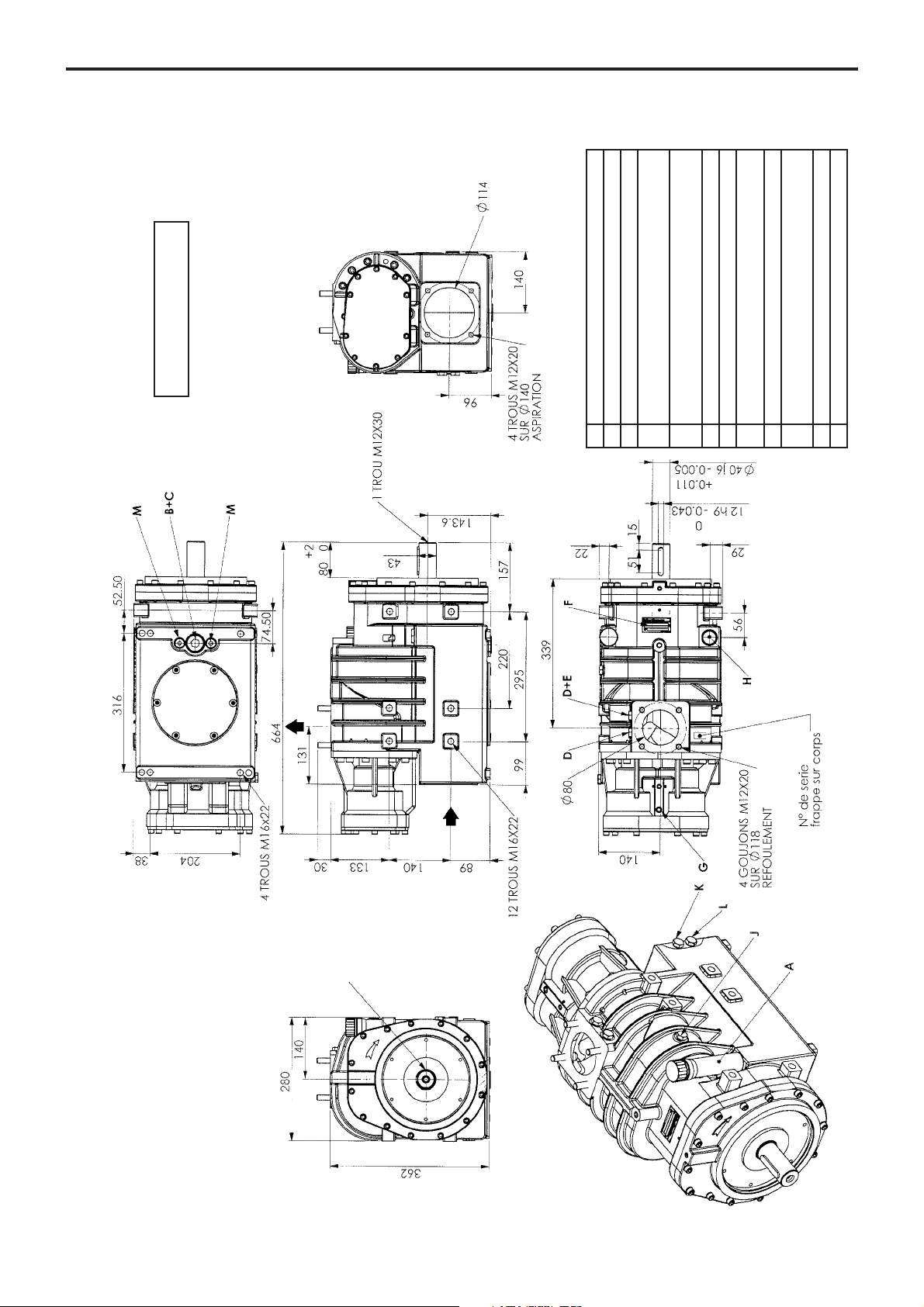

20R - 30R

1. OVERALL DIMENSIONS

A Jauge d’huile / Oil gauge

B

Filtre à huile / Oil filter

C

Vidange / Draining cap

D

Contrôle pression refoulement G1/4”

Outlet pressure control G1/4”

E

Contrôle T° refoulement G1/4”

Outlet T° control G1/4”

F

Plaque signalétique / Identification plate

G Prise pression huile / Oil pressure plug

H

Bouchon 3/4 (pour montage jauge d’huile à droite)

3/4 cap (for right oil gauge installation)

J

Prise vitesse G1/4” / Speed control G1/4”

K

Contrôle pression aspiration G1/4”

Inlet pressure control G1/4”

L Contrôle T° aspiration G1/4” / Inlet T° control G1/4”

M Bouchon magnétique G3/8” / Magnetic plug G3/8”

20R

30R

Poids / Weight : 143 kg

5/16

NT 1401-G00 10 18 TYPHON II e

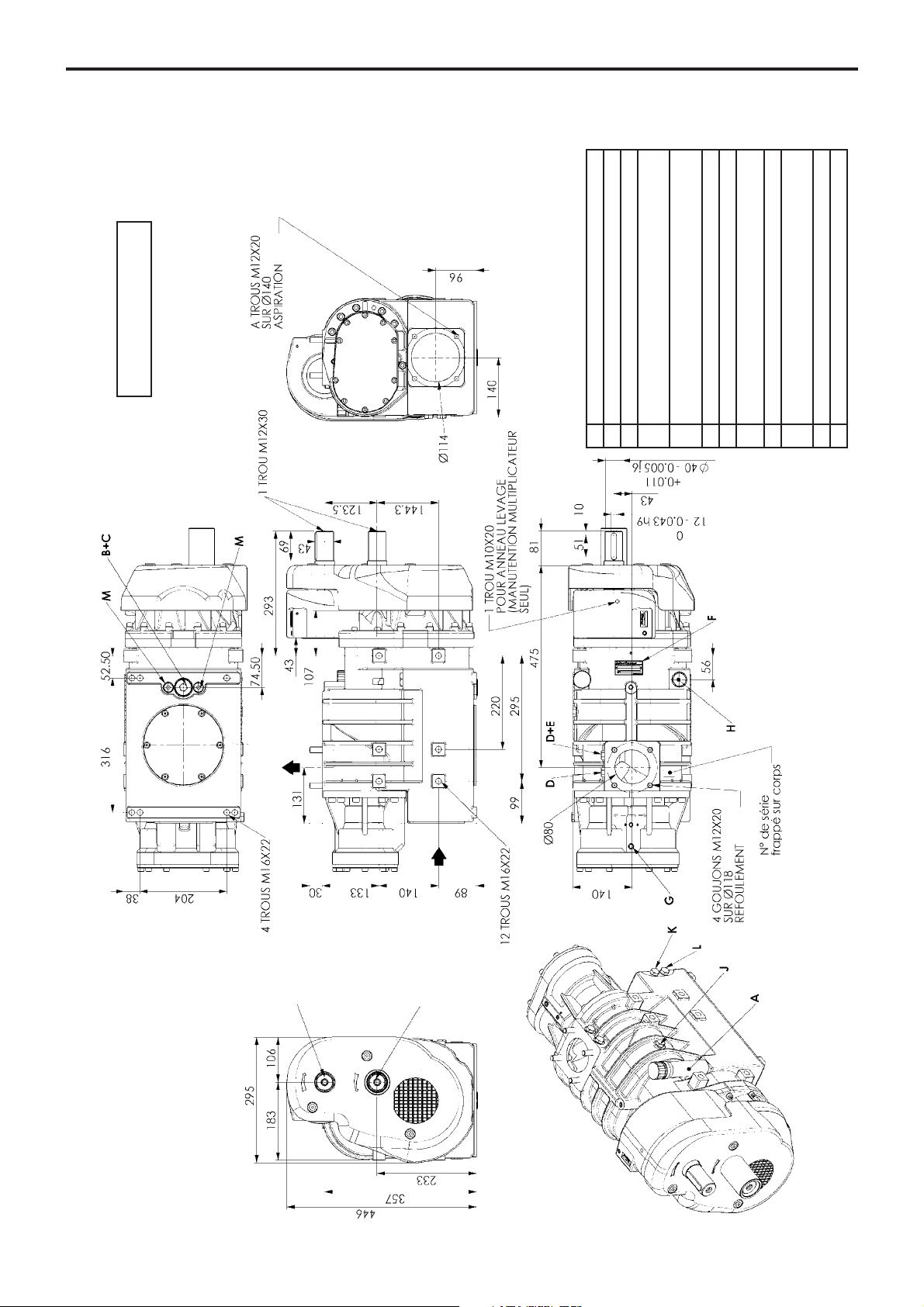

1. OVERALL DIMENSIONS (continued)

13R/15L - 19R/22L

13R

19R

15L

22L

Poids / Weight : 173 kg

A Jauge d’huile / Oil gauge

B

Filtre à huile / Oil filter

C

Vidange / Draining cap

D

Contrôle pression refoulement G1/4”

Outlet pressure control G1/4”

E

Contrôle T° refoulement G1/4”

Outlet T° control G1/4”

F

Plaque signalétique / Identification plate

G Prise pression huile / Oil pressure plug

H

Bouchon 3/4 (pour montage jauge d’huile à droite)

3/4 cap (for right oil gauge installation)

J

Prise vitesse G1/4” / Speed control G1/4”

K

Contrôle pression aspiration G1/4”

Inlet pressure control G1/4”

L Contrôle T° aspiration G1/4” / Inlet T° control G1/4”

M Bouchon magnétique G3/8” / Magnetic plug G3/8”

Loading...

Loading...