SwitchBack Senior

SwitchBack Senior Specifications

Wingspan: 55.4 in.

Length: 41 in.

Wing Area: 597 sq. in.

Weight (Ready to Fly): 34 to 37 oz.

Wing Loading: 8.2 to 8.9 oz. / sq. ft.

Version 1.05, March 3, 2008

Thank you for purchasing the SwitchBack Sr. This plane is an aileron/elevator/rudder (full

house) setup, designed for the intermediate and higher pilot who wants a plane with

outstanding sport flying performance. Well… that and the SwitchBack groupie in all of us!

This kit is meant for beginner to intermediate builders and low-intermediate pilots (such as a

low wing aileron trainer) and on up for piloting experience.

We started with the original ever so popular SwitchBack, enlarged it by 50%, updated the

construction techniques, and slightly tweaked the design for an even better performing model

than the original.

Sincerely,

Brian Eberwein

sales@mountainmodels.com

Mountain Models guarantees this kit to be from defects in material and workmanship for the

original purchaser. Since we have no control over the assembly of the final model, we accept NO

liability for any damage or harm caused by the final product resulting from the user. By building

this kit, you accept sole responsibility and liability from its use.

If you, the original buyer are not prepared to accept the liability associated with the use of this

product, return the kit immediately in new and unused condition to us for a refund.

Mountain Models reserves the right to change or modify this warranty without notice.

WARRANTY

Mountain Models

PO Box 6815

Colorado Springs, CO 80934

www.mountainmodels.com

Phone: 719.630.3186

2

Before You Begin

Before you begin building your SwitchBack Sr., make sure that all the balsa sheets and

hardware are present in your kit. In the unlikely event that something is missing, please contact

us immediately and we will send it to you right away.

Make sure you read and understand all of the instructions thoroughly before beginning

assembly of this kit.

Additionally, you will need to have the following items. Check to make sure that all of your parts

are there and in good shape, and review a couple quick building tips to make this whole process

go quicker and easier.

Recommended Electronics:

• 3 ea. HS-81 Servos (2 x Ailerons, 1 x Elevator)

• 1 ea. HS-85 Servo (Rudder)

• 2 ea. 6” Servo extensions

• 1 ea. Y-Servo Connector (if using 1 channel for ailerons)

• 1 ea. Mini Receiver (6+ channel for using 2 aileron servos without Y-Connector)

• 1 ea. Scorpion 3008-32 Brushless Outrunner (or 200-300 watt equivalent)

• 1 ea. 3S-2000 LiPo Battery (or higher capacity)

• 1 ea. 35A Electronic Speed Control

Tools You Will Need:

• Smooth and FLAT work surface

• Plastic wrap or Wax paper to protect the work surface

• Thin and Thick Cyanoacrylate (CA) glue

• 5 to 10 Minute Epoxy

• Hobby knife with #11 blades

• Needle nose pliers

• Wire cutters

• Sanding block with 220, 320, and 400 grit sandpaper

• Sealing iron for applying the covering

• Soldering Iron

• Screwdrivers

Items for Finishing:

• 2 Rolls SoLite, Solar Film, or similar lightweight covering

• SolarTrim for adding details to your covering job

• Balsa Wood Filler, lightweight

3

Parts List:

• This Manual … If you do not have the manual you are holding, please call us. ☺

• Laser Cut Wood

• 2 ea. Red Pushrod Housings

• 2 ea. 1/16” x 24” Wire

• 2 ea. 1/16” x 12” Wire

• 1 ea. 0.047” x 9” Wire

• 2 ea. 0.060” x 24” Carbon Fiber Rod

• 2 ea. 1/8” Pre-Bent Landing Gear Wire

• Plastic Vac-Formed Canopy and Cowling

• Parts Bag

o 7 ea. 1/16” x 4” x 24” Balsa

o 4 ea. 1/16” x 3” x 24” Balsa

o 4 ea. 3/32” x 4” x 24” Balsa

o 4 ea. 1/8” x 4” x 24” Balsa

o 2 ea. 1/8” x 3” x 24” Balsa

o 2 ea. 3/16” x 4” x 24” Balsa

o 1 ea. 1/8” Plywood Sheet

o 2 ea. 1/8” Lt Plywood Sheet

o 1 ea. 1/16” Plywood Sheet

o 1 ea. 1/8” Plywood “loose” part

o 8 ea. EZ Hinges

o 4 ea. EZ Servo Connectors

o 8 ea. 4-40 T-Nuts

o 8 ea. 4-40 x 3/8” Machine Screws

o 2 ea. 10-32 T-Nuts

o 2 ea. 10-32 Nylon Bolts

o 2 ea. 2” DuBro Wheels

o 1 ea. 1” DuBro Tail Wheel

o 2 ea. 1/8” Wheel Collars

o 4 ea. Magnetic Washers

o 4 ea. Non-Magnetic Washers

o 4 ea. #2 Cowling Mounting Screws

o 3/16” x 5” Dowel

o Double Sided Velcro “Battery Seatbelt”

o 6” Sticky Backed Velcro

o 4 ea. Wire Ties

4

General Building Tips

• Balsa is a lightweight and fragile wood, so you do need to be careful with it; however,

you will also need to use a little bit of force to make everything fit properly, so don’t be

too timid.

• Join all of your pieces using thin CA (Cyanoacrylate) glue, unless we tell you otherwise.

In general, only a small amount of CA is necessary to glue parts together.

• Don’t remove any pieces from the balsa sheets until they’re ready to be used. That way,

parts won’t get mixed up or disappear.

• After you remove pieces from the balsa sheets, carefully remove any of the extra

material from where the piece was attached.

• Don’t over force your pieces together. If they aren’t going together properly, make sure

you have the right pieces and that they are oriented correctly.

• If you want to remove the charred edges caused by the laser cutting process, dampen a

cloth with bleach and gently rub the affected areas. Removing the char will not increase

the strength but will make it look better.

Assembly Instructions

Experienced builders may notice that this building order goes

against the “normal” building conventions. We have found that fewer pieces get mangled this

way, since you are building the stronger pieces first. For example, the tail feathers are at the

end of the build process instead of the beginning, so that they are less likely to get underfoot

(which seems to be a recurring problem) and are being built right before they are attached to

the fuselage and each other.

Section 1: Assembling the Fuselage

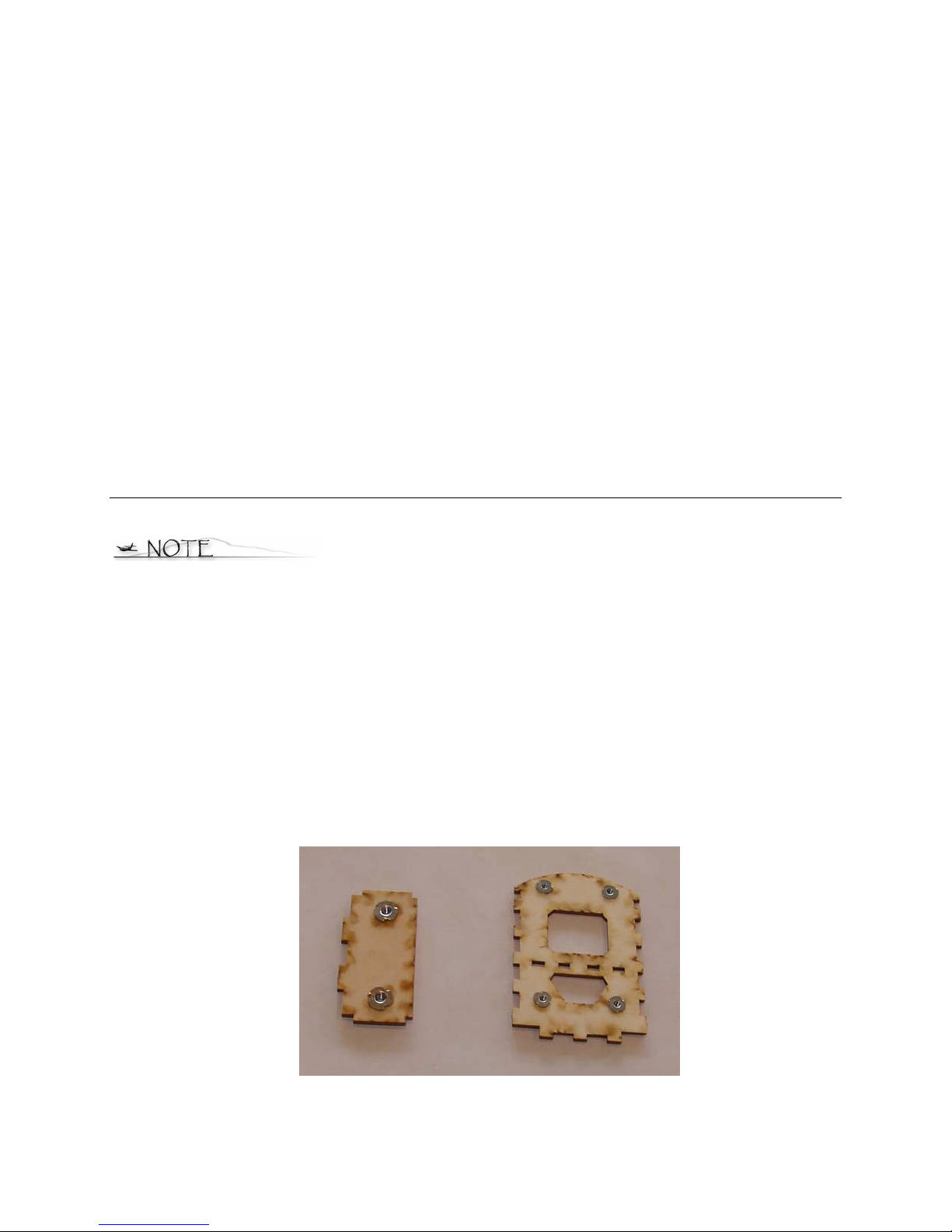

1. Press the 4-40 blind nuts into the front former and the 10-32 blind nuts into the fuselage wing

mount as shown below. There are 2 plywood circles on the sheet next to the wing mount.

These are to place behind the wing mount when installing the blind nuts so they don’t go into

your table. They are not glued into place. Make sure to install the blind nuts on the “dirty side”

of the parts. Secure the blind nuts with thin CA AFTER you are sure they are fully seated and

flat against the wood.

5

To remove the pieces, gently flex the balsa sheets until the pieces fall out.

You may find that you need to carefully trim the extra pieces of wood that

originally held the piece to the sheet.

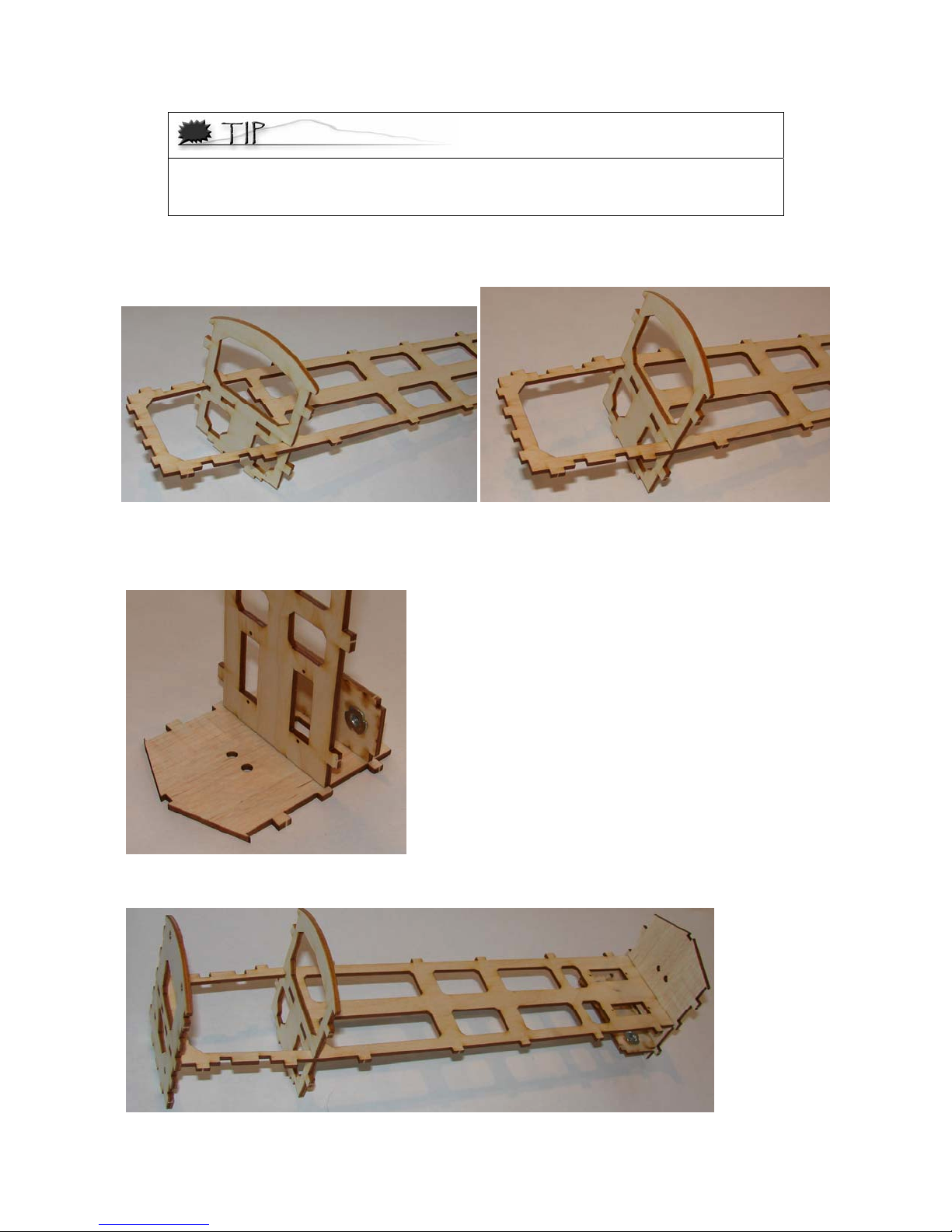

2. Slide the 1/8” Lt. Ply former into position on the 1/8” Plywood crutch as shown below. It is a

fairly tight fit, so work it back into position a little at a time. Do NOT glue them together yet.

3. Press the crutch from step 2 and the fuselage wing mount into the 1/8” balsa former as shown

below. Make sure the blind nuts are facing as they are in the image! It’s easiest to lay the

former on your table and press the crutch into the slots. Do NOT glue yet.

4. Press the crutch onto the 1/8” Lt Ply F1 as shown below. Nope, no glue here either.

6

5. Assemble the 1/8” balsa rear longerons as shown below. The parts fit best when you assemble

the top/bottom parts with one of the lasered sides up and the other down. Lay them on your

table as shown below so you make a LEFT and RIGHT side. Press the assembled 1/8” rear fuse

parts onto the 1/16” balsa rear parts as shown below. MAKE SURE you assemble them as

shown below, and not upside down! Also make sure that the parts are flush on one side.

Secure these parts with thin CA.

6. Assemble the rear parts to the front 1/8” fuselage parts, as shown below. Place only a couple

drops of thin CA at the joints. Between the front and rear fuselage parts.

7. Press the 3/32” balsa formers into the 1/16” balsa bottom as shown below. The “lasered” side

of the bottom goes “up” and the “lasered” sides of the formers face aft. MAKE Sure this is

right. Lightly tack the parts together with a couple drops of thin CA, AFTER you make sure

they are fully pressed into place.

7

8. Press the 1/8” fuselage sides onto the fuselage crutch as shown below. MAKE SURE that the

rear “flush” area of the 1/8” and 1/16” balsa parts is facing to the outside. Do NOT glue this

yet.

9. Set the assembly from step 7 on the table with the fuselage crutch assembly. Carefully slide

the rear /8” longerons into the slots in the formers. You may have to slightly bend and “crack”

the rear longerons where they attach to the front 1/8” balsa sides. You should end up with an

angle, rather than a curve at the joint with the 1/8” balsa former.

Be careful to keep your fingers as far away from the glue as possible; otherwise,

you might become a part of the model permanently. If you do get stuck, remove

yourself as carefully as possible, trying to avoid taking any of the wood with you.

Once separated, remove the CA glue from your fingers using nail polish remover or

acetone, making sure you wash your hands thoroughly when done.

10. Install the 1/16” balsa rear top part as shown in the image below. This part is somewhat

fragile until it is installed, so be careful when you are pressing it into place.

8

11. Weigh the fuselage down to the table to make sure it stays flat and straight and secure all the

joints with thin CA. ENSURE that the 1/16” balsa rear fuselage bottom is flush with the 1/8”

balsa longerons when you glue these together. Pull the sides together at the front of the fuse,

making sure they are fully pressed into the front former nd secure this area with thin CA.

12. Slide the 1/8” balsa part into place as shown below. Make sure it is flush with the sides and

secure with thin CA. This part is on the 1/8” balsa sheet with one of the fuse front sides.

13. Press the 1/16” balsa sides in place, with the “lasered” side to the inside of the fuselage. You

can use thick CA to glue these sides on, or you can use thin CA after they are on, making sure

they are fully pressed into place. Weights help make sure the sides are fully pressed into

place, as shown below.

¼” Steel plate cut to about 4” squares makes GREAT weights for building. They are

useful for many areas of building and are invaluable took in our shop. Call around

town and see if you can find a metal shop that might have some scrap they can cut

for you. You’ll love having these around. You can also use some 1” square aluminum

tube filled with lead shot and epoxy, bags of lead shot, and even a stack of old

magazines for weights.

9

14. Press the rear 1/16” sides into place with the “lasered” side of the part to the inside of the

fuselage, as shown below. BEFORE you glue anything, check to see if the pushrod exit slots

line up with the holes in the rear 3/32” former. If they don’t, you have the parts on the wrong

side. Secure the sides with thin CA.

15. Install the 3/16” rear spine into the formers as shown below. Make sure it is fully seated and

secure it with thin CA.

16. Press the 1/8” plywood landing gear supports into place as shown below. The “lasered” sides

should face to the inside of the fuselage. Clamp them, or otherwise make sure they are fully

pressed into place and against the sides while the glue is drying. If you’re fast, you can use

thick CA. If not, then use some 5 minute epoxy, spread thin.

10

17. Install the 1/8” Lt Ply part as shown below. MAKE SURE that the holes for the landing gear

wires match up with the landing gear supports from step 16. If the holes don’t line up, you will

NOT be able to install your landing gear. Now that would really be a pain, wouldn’t it? After it

is glued into place, install the 1/8” Lt Ply bottom as shown below, ONCE AGAIN, making sure

that the holes for the landing gear wire line up.

18. Install the 1/16” balsa rear deck, as shown below. Make sure that it lines up with the front of

the 3/16” spine. The deck sits on top of the inside 1/8” longerons and inside of the 1/16” balsa

sides. You’ll have to lightly bend the front of the 1/16” sheet to sit in the forward area.

19. Glue the MAGNETIC washers to the 1/8” Lt Ply canopy hold down plates, using the etched

circles for placement. Glue the canopy hold down plates in the fuselage as shown below.

11

20. Glue the 1/8” Lt Ply cowling mount parts into the front former as shown below.

21. Place some tape behind the second former to protect the fuselage sides. Sand the top front of

the fuselage sides to follow the curve of the front 2 formers. Line up the 1/16” top front balsa

sheet, so there is the same amount of material hanging off on each side. Lift up one side and

tack down with thick CA. Then glue the other side with thick CA as well. Sand the sides of the

front top sheet to be flush with the fuselage sides.

12

22. Glue in place the 1/16” plywood tail wheel wire support as shown below.

23. Install the Red pushrod housing through the holes in the aft 3 formers. They should come

forward of the front former by 1/8”. Secure them with thin CA and then trim them flush with

the fuselage sides where they exit in the rear.

24. Sand the forward part of the 1/8” balsa part, just aft of the rear former so it is flush with the

fuselage sides, as shown in the top right image.

25. Sand the front and rear bottom corners of the fuselage, round the top rear center, and round

the top of the fuselage sides where they meet the top rear deck. Test fit your canopy and

cowling to make sure you have rounded the corners enough for the parts to fit properly. Fill

any voids with lightweight filler and then lightly sand the entire fuselage with 320 grit and

then 400 grit sandpaper.

13

Section 2: Assembling the Wings

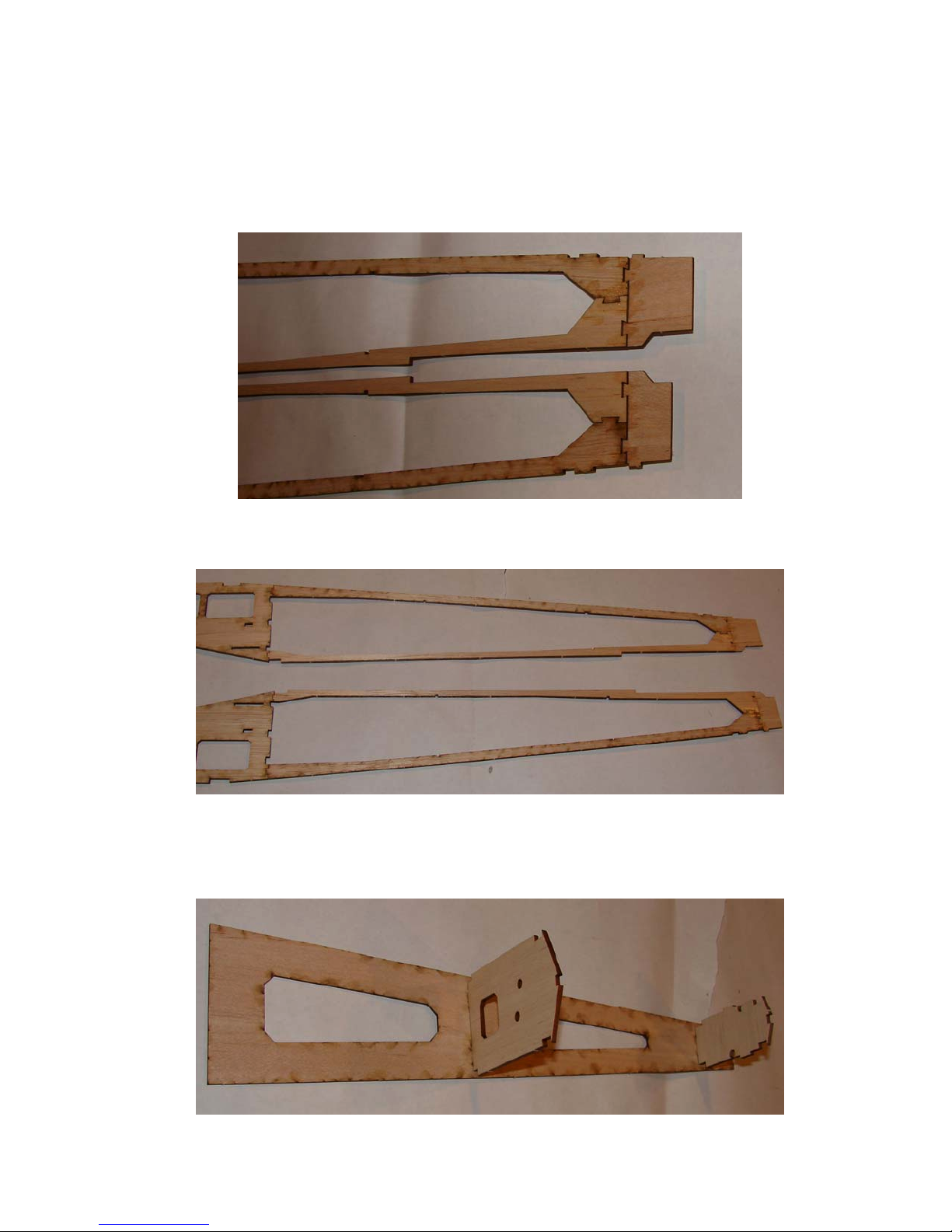

1. Assemble the 1/8” balsa spar as shown in the image below. Make sure the parts are fully

pressed together and secure with thin CA.

2. Insert the 1/8” center ribs and the 1/8” front half-ribs as shown in the image below. The 1/8”

ribs are on the sheet that had the front fuselage sides on it. They have 1 slot at the bottom

rear of the ribs. Do NOT glue them yet.

3. Insert the 1/8” plywood center front part into the ribs. Do this a little at a time. It will be

necessary to spread the full ribs out of the way while you slide it into place, as shown in the

above right image. After it’s fully seated into the ½ ribs, press the full ribs onto it. Do NOT

glue it yet.

4. Insert the 1/8” balsa rear ½ ribs into the spar as shown below, but do NOT glue them yet.

14

5. Press the 3/32” balsa servo wire guide into place between the rear half ribs.

6. Press the 1/8” balsa support into the rear ½ rib tabs as shown in the upper right image. You’ll

need to spread the back of the 1/8” full ribs to get the tabs on the part into the ribs.

7. Install the 1/8” Lt Ply rear center section as shown below. Make sure the center section is

square and secure the parts with thin CA. Glue the 2 1/8” balsa parts into place using thick CA

sh shown below, making sure that the bolt holes are lined up.

8. Press the 3/32” servo mounting area ribs into place. These ribs have slots in the bottom to

accept the servo mounting plate.

15

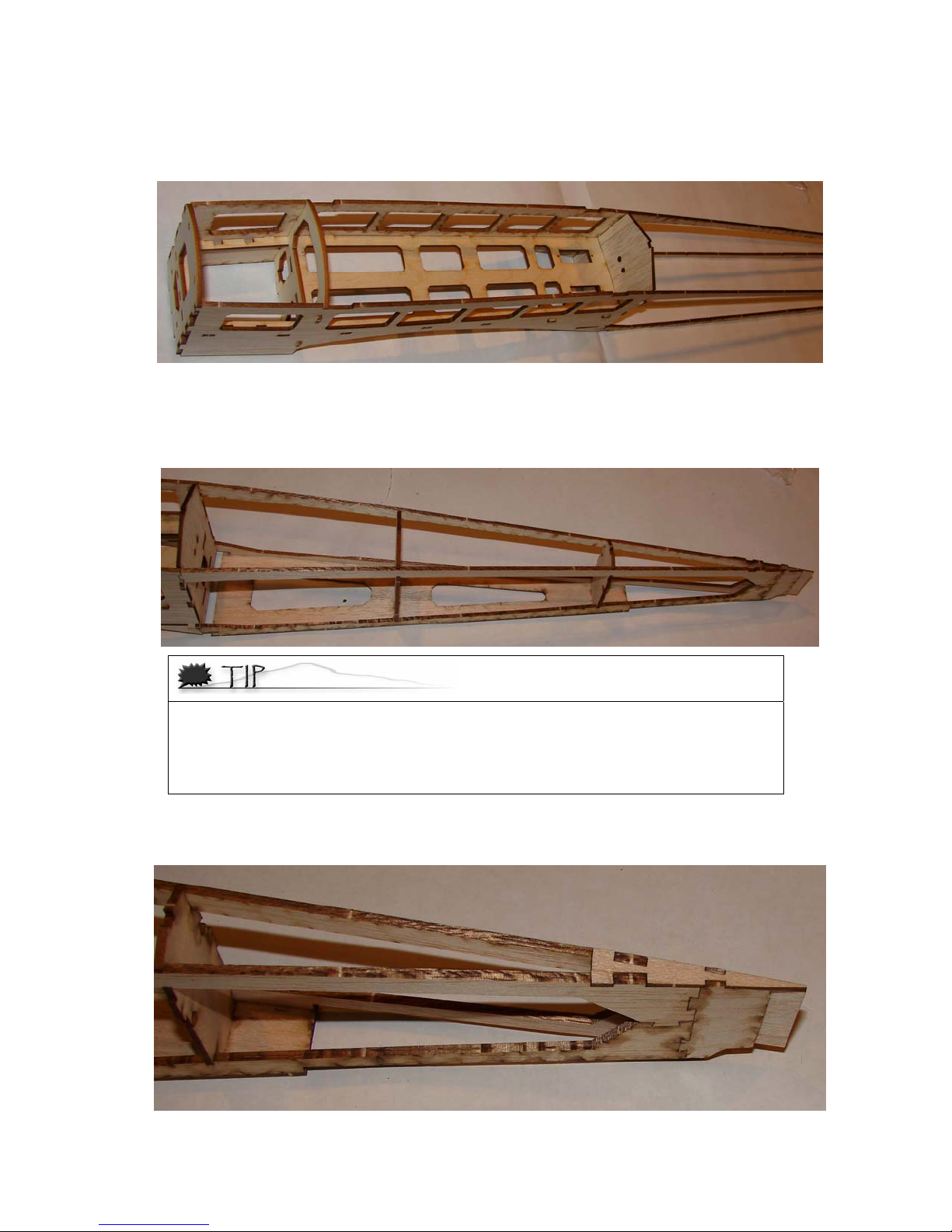

9. Insert the rest of the 3/32” balsa ribs onto the spar, making sure all of the ribs are pressed

fully in place.

10. Sand Slide the 3/32” balsa leading edge support into place on the ribs on one side of the wing.

MAKE SURE you install it in the right direction. The side with 2 tabs goes toward the center of

the wing. Work a little bit at a time, pressing it just into the ribs along the wing, then start at

the center working out, pressing in further. Repeat until it is fully pressed into place.

11. Press the 3/32” balsa T.E. supports into the 1/8” trailing edge as shown below. The 3/32”

parts were next to the leading edges used in step 10. LOOK AT THE PARTS! One end has an

angle on the 1/8” parts, which goes toward the center section of the wing. Set them next to

each other so you make a LEFT and RIGHT side. The end of the 3/32” parts with the shorter

tab also goes toward the center section. Lightly tack these parts together with thin CA.

16

12. Press the parts from the previous step into place on the back of the ribs, as shown in the

image below. MAKE SURE that the angled end goes towards the center section and is on the

correct side. Press it into place a little bit at a time until all the ribs are fully seated and it is

plugged into the center 1/8” rib.

13. Press the outboard 1/8” balsa ribs into place. These are on the sheet with the canopy frame.

14. Slide the 1/16” plywood spars into place as shown in the images below. Note that the top and

bottom spars are different shapes. Make sure they are flush with the spar and glue them in

place with thin CA after they are in position.

17

15. Slide the 1/16” leading edge parts onto the wing as shown. Work a little at a time along the

wing, until it is fully seated against the leading edge support and the ribs. PAY ATTENTION to

these parts. The ends of the outboard parts have an angle to them to match the dihedral

angle of the wing. These ends go towards the center. Add the center 1/16” part as well.

16. Slide the 3/16” leading edge parts onto the wing as shown below. Make sure they are all fully

pressed in place and lightly tack with thin CA.

17. MAKE SURE that the wing panels are straight and all parts are fully seated and lined up. After

you are SURE, secure all parts with CA, double checking as you go to make sure the parts are

still seated before you add the glue to an area.

18. Install the top center wing sheeting. The front of the wing sheeting rests on the 1/16” leading

edge part, and in front of the 3/16” leading edge part. Secure with thin CA. Repeat for the

bottom center wing sheeting.

18

19. Test fit the bottom right wing sheeting and weigh down the wing as shown. Weigh the wing

down and secure the sheeting along the back of the spar with thin CA. Pick up the wing and

glue the rest of the lower sheeting into place along the front. The sheeting rests on top of the

1/16” leading edge and in front of the 3/16” leading edge parts. Make sure that the sheeting is

fully pressed onto the tabs on the ribs and sits flush with the 3/16” leading edge part.

20. Weigh down the right side of the wing and make sure it is straight and flat. Test fit the top

wing sheeting. Start by gluing down the front of the sheeting with thin CA, with the back

sitting up slightly, as shown in the image below.

21. You can glue the back of the sheeting with thick CA (if you’re fast), or white glue. If you use

white glue, weigh down the sheeting while it dries to make sure you get a good bond.

22. Repeat steps 19 to 21 for the Left side of the wing.

19

23. Glue the 3/32” wing tip supports in place as shown in the image below. The shorter of the 2

goes on towards the rear. Secure lightly with thin CA after making sure they are fully pressed

into place. Make sure you make a left and right version. Put these in place on the wing tips as

shown in the second image, making sure they are pressed fully into place and secure them to

the wing with thin CA.

24. Install the 1/16” plywood servo mounts in the wing as shown below, using thick CA. Glue in

the 1/8” balsa servo mount doublers on the inside of the wing on top of the plywood mounts

with thick CA.

25. Sand the leading edge to finish the airfoil shape. DO NOT NICK THE plywood wing mounts in

the center section. Wrapping these with tape while sanding is a good idea. A good

approximation on where to sand is by starting out sanding tangent to the wing sheeting at the

back and go down to the front tabs. Then gently round off the tab area of the leading edge.

Sand the leading edge at the tips to match the wing tips. It will look like the next image when

you are done.

20

26. Sand down the rear center section balsa blocks for the wing bolts to match the rib profile on

either side of them. Laying some tape on the ribs will help keep you from sanding into the ribs

themselves.

27. Lightly sand the entire wing with 320 and 400 grit sandpaper. The smoother the sanding job,

the better the covering will look.

28. It is a VERY GOOD IDEA to run a string from the servo box up through the servo wire hole in

the center of the wing, so you can fish the servo wire out the wing after it is covered. Tape the

string in place just to the inside so you can get to it after cutting out the holes in the covering.

Section 3: Assembling the Ailerons

1. Build both ailerons at the same time to make sure you make a LEFT and RIGHT aileron.

2. Press the 3/32” aileron ribs into the 1/16” aileron sheet as shown below. The center ribs are

made up of a 1/16” balsa rib between 2 of the 3/32” ribs. Do NOT glue them in place yet.

3. Press the 1/16” top front part in place as shown below. Make sure the aileron is flat and

secure the parts in place with thin CA.

21

4. Assemble the 3/32” aileron leading edge parts together as shown. ENSURE that they are

straight and fully secured, using weights or rulers, and secure with thin CA.

5. Glue the aileron leading edge in place on the aileron as shown. Make sure it is FLAT and

STRAIGHT, weighing it down while it is glued.

6. Trim the Carbon Fiber rods to length and glue them to the trailing edge of the ailerons with

thick CA. Keep your aileron flat while you are doing this or you’ll end up with a permanent

warp!

7. When done, you should have a LEFT and RIGHT aileron as shown.

22

Section 4: Assembling the Stabilizer, Elevator, Vertical Fin, and, Rudder

8. Press the parts together as shown. After the parts are assembled and flat, secure each joint

with a drop or 2 of thin CA.

23

9. Cut the 3/16” dowel to 4-1/8”. Slightly roughen the dowel with some 220 grit sandpaper for a

better glue bond. Join the elevator halves with the dowel using 5 minute epoxy.

10. Lightly sand each side of the tail parts with 320 and 400 grit sandpaper.

11. Sand a 45 degree “V” in the hinge side of the rudder. It will look something like the image

below.

12. Sand a 30 to 45 degree bevel in the horizontal stab for the hinge line.

13. Sand round the outside edges of the vertical, rudder, stab, and elevators. It looks a lot better

round, instead of leaving it squared off.

Shaping the Tail Wheel Wire and Attaching it to the Rudder

Needle nose pliers work pretty well to shape the wire.

1. Bend the 0.047” wire as shown below. This drawing is to scale.

2. Cut one of the CA hinges in half lengthwise. Wrap one piece of it around the landing gear wire

as shown. Use some plastic wrap or wax paper over the hinge and squeeze it together with

some needle nose pliers to make sure it stays as thin as possible.

24

3. You do NOT attach the tail wheel until the rudder is attached to the vertical fin after covering

and hinging the rudder to vertical. Drill a hole in the rudder for the wire to press into and cut a

slot in the rudder for the hinge that is attached to the tail wheel wire. Slightly indent the balsa

rudder where the rest of the wire rests. Press the wire into place and secure it with thick CA.

Use some thin CA on the hinge material to make sure it is properly adhered to the rudder.

Section 5: Assembling the Canopy

You are going to assemble and attach the canopy base, which once in place will be used to hold

the plastic canopy in place.

1. Position the 1/8” balsa cross braces in the canopy base. Press the 4 magnets into the holes,

making sure they are flush on the “lasered” side of the canopy base. Glue in the magnets with

thin and thick CA.

2. Trim the canopy plastic so you have about 1/8” to 3/16” overhand on the front, back, and

sides of the fuselage.

3. Set the canopy frame in the fuselage and the canopy over it. You’ll need to slightly sand the

front sides of the frame so the canopy sits properly on it. Do this a little at a time until you

have a good fit. Slightly roughen up the inside of the canopy sides where the balsa meets it so

you can get a good glue bond.

4. Set some plastic wrap in the fuselage canopy area to keep you from gluing the canopy base to

the fuselage. Set the canopy frame in place and glue the canopy to the canopy frame using

Canopy Glue or 5-minute epoxy. Do NOT use CA to glue the plastic. CA would make it brittle.

25

Section 6: Covering

Covering the SwitchBack Sr.

Determine what material you’ll use to cover, we recommend using Solite or SolarFilm covering

material since it is extremely lightweight and won’t crush the balsa when shrinking. Please refer

to the instructions that came with your covering for details on how to cover if you haven’t done

it before.

Following your covering material instructions, cover the pieces in this order:

Do not shrink the covering until both sides of each part are covered. This reduces your

chances of twisting the surfaces.

• Wings (Trim out covering for servos and servo wires

• Fuselage (Cut out the aft bottom lightening hole for an air exit)

• Ailerons

• Tail Feathers

• Control Horns (Looks a LOT better than leaving them uncovered!)

Cutting the Slits for the CA Hinges

You need to cut slits into the tail feathers and ailerons to allow for the CA hinges to be

attached.

• Cut the rest of the CA hinges in half, lengthwise . Cut 1/2” wide slits into the ailerons,

wings, stabilizers, elevator, and rudder. The slits in the tails should be exactly

centered into the thickness of the wood. The rudder gets 3 hinges; one ¼” down

from the top, one just above the rudder horn slot, and one ½ way between the other 2.

The elevators/stab get 2 hinges per side, one about ½” in from the tips, and one 1bout

½” away from the dowel. The ailerons get 3 hinges each, one about 1” in from each end,

and one in the middle. For the aileron slits, cut them in the ailerons first and then lay

out the ailerons to see where the corresponding slits need to go into the rear of the

wing.

Section 7: Installing the Tail Feathers

For this step, you are going to install the horizontal stabilizer, elevator, the vertical

stabilizer and the rudder to the fuselage.

Attaching the Horizontal Stabilizer

• You need to remove some of the covering on the horizontal stabilizer so that you can

securely attach it to the fuselage. Set the stabilizer onto the bottom of the fuselage,

making sure it is centered on the fuselage. Mark the elevator to show where you need to

trim the covering. You need to remove the covering so you get a strong balsa to balsa

glue joint. Use a sharp blade and try not to cut into the balsa itself.

• Make sure the stab is centered on the fuselage and flat with the bottom of the fuselage

and glue it in place with 5 minute epoxy or thick CA.

26

Installing the Elevator

• Install the CA hinges into the slots in the stabilizer and slide the elevator onto the CA hinges,

so half of the hinge is in each part. Move the elevator through its full range of motion and then

secure the hinges by placing a few drops of thin CA on both sides of the hinges at the hinge

line. Keep flexing the elevator to keep the CA from gluing the covering of each part together.

Attaching the Vertical Stabilizer and Installing the Rudder

• Run a bead of thick CA along the top of the fuselage sides where the vertical stabilizer

will rest, and position the vertical stabilizer, making sure that the rear of the stabilizer

lines up with the rear of the fuselage and that it’s perpendicular to the elevator. Hold in

place until the CA sets. (See image at top of page)

• Position the three hinges into their slots on the rudder. Slide the tail wheel wire though the

hole in 1/16” plywood part on the back bottom of the fuselage. Maneuver the rudder so that

one by one, the hinges can be lined up and slid into the slots in the vertical stabilizer.

• Glue the hinges into place with thin CA as you did with the elevator and stab.

Attaching the Ailerons

Attach the ailerons to the wing using the same method you used to attach the tail feathers. You

will use 3 half CA hinges per aileron.

aileron when you are attaching them to the wings. The aileron control pockets need to face

down.

Make sure that you pay attention to which is the left and right

27

Section 8: Attaching the Control Horns

Next, you are going to attach all of the control horns, you will need:

• 1 Elevator control horn

• 1 Rudder control horn

• 2 Aileron control horns

Insert the control horns into their appropriate pocket. The Rudder control horn goes on the

RIGHT side and the elevator horn goes on the LEFT side. Left and right is as if you were

sitting in the cockpit looking forward. After checking to make sure that they’re aligned

properly, glue them into place with thin CA.

Section 9: Installing the Servos and Control Rods

1. The tail feather servo holes in the plywood crutch are sized for HS81 size servos.

2. Place the servos in the holes with the control horns towards the front of the fuselage. Screw

the servos into place and then remove the screws and servos. Flow some thin CA into where

the servo screws screw holes to strengthen the wood, creating tough “threads”. Allow the glue

to dry completely and then reinstall the servos and screws. Do not over-tighten the screws.

3. Do the same procedure for the aileron servos. The control horn ends should be facing towards

the ailerons. You’ll need to thread the servo wires with extensions through the wing. Place a

strip of tape around the connectors to keep it from coming unplugged.

28

4. Put an EZ Servo connector in each of the servo control horns.

5. Place Z-Bends in the ends of each of the 2 - 24” and 2 - 12” 1/16” diameter wires.

6. Place the Z-bend ends of the 12” wires into the plywood aileron control horns.

7. Slide the aileron servo horn EZ Connector onto the wire and then onto the servo. With the

aileron neutral, secure the control rod in the EZ Connector with the screw.

8. Trim off extra wire about 1-4” on the other side of the EZ connector.

9. Thread the 24” 1/16” wire through the pushrod housings with the Z-Bend in the front fuselage

area.

10. Install an EZ Connector on the plywood elevator and rudder control horns.

11. Slide the control wire through the EZ connector on the plywood control horn. Place the Z-Bend

through the servo control horn and place the control horn onto the servo.

12. With the control surfaces neutral, install and tighten the EZ Connector screw.

13. Trim off the extra wire about ¼” behind the EZ Connector.

29

Section 10: Landing Gear

• Slide the landing gear into the holes on the bottom front fuselage.

• Place a bend in the end of the wire ties and thread them up though the bottom and then

back out on the other side. Pull them tight and trim off the extra, as shown in the image

below.

• Slide the wheels onto the main gear and secure them with the Wheel Collars and set

screws.

• Slide the tail wheel onto the tail wire and secure it with some drops of thick CA on the

end of the wire. BE CAREFUL not to get CA in the wheel itself.

30

Section 11: Installing the Motor

We recommend a brushless motor rated for around 200 to 300 watts. The prototypes flew

outstanding on the Scorpion 3008 and 3S at around 250 watts.

! Installing the Motor

1. You will want to glue the mounts together with epoxy, rather than CA. Epoxy can handle the

vibration of a slightly out of balance propeller better than CA can.

2. Assemble the motor mount as shown in the photos. Make sure the parts are seated properly

to ensure the thrust angles are correct. All the parts are 1/8” Lt. Ply except for the 1/16”

plywood front doubler. The front parts have holes for the Scorpion motors. There are

additional ones marked with an X to help alignment if you are using a different brand motor.

3. Bolt the motor to the mount using the supplied 4-40 x 3/8” screws.

4. Bolt the motor mount to the firewall using 4-40 x 3/8” screws and the #4 washers.

31

Section 12: Attaching the Receiver and Speed Controller

! Attaching the Receiver

• The receiver is attached within the fuselage, in front of the servos. Use adhesive Velcro

and attach it to the ply crutch. Connect the servos and ESC to the receiver, following the

guides on the receiver itself.

! Attaching the ESC

• The speed controller can be attached behind the motor on the motor mount with wire

ties, or placed inside the fuselage.

Section 13: Finishing the Kit

Well, you’re almost there…the end is in sight; just a few more steps and you can go flying,

assuming the weather is cooperating.

Attaching the Nose Cowl

1. Trim the cowling from the plastic sheet. The easiest way to do this is to use sandpaper from

the back inside.

2. Trim out a hole in the front so the motor shaft can come through. Also trim out the cowling

vent in the front to allow air to flow through, cooling the motor, ESC, and battery.

3. Place the cowling on the front fuselage and use the 4 - #2 screws to fasten the cowling to the

cowling mounts.

Attaching the Wing

• Place the wing into the fuselage and secure it in place with the 10-32 nylon bolts.

Attaching the battery

1. The battery mount is the front section of the plywood crutch.

2. Determine approximately where the battery will need to be placed to establish your CG. Cut

the rough side of the Velcro strip down to 4 1/2" in length, and attach it to the top of the

battery mount so that it’s centered on the battery’s position.

3. Attach the soft side of the Velcro strip to the bottom of your battery pack.

4. After you attach the battery pack onto the mount, run the 6” double-sided Velcro strip

underneath the battery mount, around the top of the battery pack, and then secure it to itself

snugly. This acts as a seatbelt, holding the battery pack securely in place.

Typically, losing your battery in mid-flight is a bad thing…a very bad thing…

32

Setting the Throws

You need to adjust your radio trim so that the elevator, rudder, and ailerons are all level. The

throws are listed as total travel, and are as follows:

Low Rates High Rates

Ailerons

Elevator

Rudder

1” Full 45 degrees

1” ~45 degrees

2” As much as you can get

Setting the Center of Gravity

The Center of Gravity (CG) will affect how the airplane recovers from a nose up or nose down

condition (pitch stability). With the CG too far forward, the plane will be quite stable, but

require a lot of up elevator to fly level. This will result in an increased low end speed. On the

other hand, too far back and the plane will be hard to control, requiring constant input to keep

the plane flying straight and level. Start with the CG about 3-5/8” back from the leading

edge of the wing. Use this as a starting point. You can slowly move it back as you get more

comfortable with the plane.

33

Loading...

Loading...