Mountain Models Spook-E Micro Manual

Spook-E™ Micro

Micro Nostalgic R/C Electric Airplane

Spook-E™ Specifications

Wingspan: 23.53 in.

Length: 15.66 in.

Wing Area: 100 sq. in.

Weight (Ready to Fly): 1.8 oz.

Wing Loading: 2.6 oz. / sq. ft.

Version 1.0, April 9, 2012

WARRANTY

Mountain Models guarantees this kit to be free from any defects in both material and workmanship at the

time of purchase. This warranty does not cover ANY components or parts damaged by use or modification.

In no case shall Mountain Model’s liability exceed the original cost of the purchased kit. Mountain Models

reserves the right to modify or change this warranty without notice.

LIABILITY RELEASE

In that Mountain Models has no control over the final assembly or material used for final assembly, no

liability shall be assumed or accepted for any damage resulting from the use by the user of the final userassembled product. By the act of using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is

advised to return the kit immediately in new and unused condition.

THIS PRODUCT IS NOT INTENDED FOR CHILDREN 12 YEARS OF AGE OR YOUNGER.

WARNING: This product may contain chemicals known to the State of California to cause cancer and or

birth defects or other reproductive harm.

PRODUCT SUPPORT

This product has been designed to function properly and perform as advertised with the SUGGESTED power

system, speed control, and servos, as described in advertisements and in this manual. We do NOT support,

nor can Mountain Models assist in determining the suitability or use with any other electronics or hardware

not recommended by Mountain Models.

For the proper electronics to complete this model, replacement parts, and product assembly questions,

please contact Mountain Models online at www.MountainModels.com

Thank you for purchasing the Mountain Models Spook-E™ Micro. The Spook-E™ Micro is a micro model

designed with influence from the famous Spook, a classic vintake plane, to bring back that nostalgic feeling

of yesteryear, in an indoor electric package. The 23.5 inch Spook-E™ Micro is a super easy to build and

easy enough for a beginner to learn how to fly, with some friendly help.

The Spook-E™ was designed using a state of the art 3D CAD package, to allow for exceptional interlocking

parts design and fit. 3D design also allows us to provide clearer assembly images, without having to use

photos.

The Spook-E™ is built from self-jigging interlocking laser cut balsa and plywood parts. It's like a 3D jigsaw puzzle

with instructions. Although not needed for building, full size plans are included for reference. If the instructions are

read before hand and followed during the build, the Spook-E™ can be built up and ready to fly in only a few

evenings.

We think you’ll like the Spook-E™ and look forward to any feedback you might have.

Thank you,

Brian Eberwein

Mountain Models

2935 N Lynndale Drive

Appleton, WI 54914

www.mountainmodels.com

Phone: 920.840.6036

2

Before You Begin

Check to make sure that all of your parts are there and in good shape.

Parts List

Number

in Kit

Bundled Parts

1 Laser Cut Parts Sheets (6 Sheets )

2 Plan Sheets (11” x 17”)

1 These instructions of course!

Metal (on the back of the wood bundle)

1 0.020 x 18” Wire

1 0.020” x 12” Wire

1 1/32” x 12” landing gear wire

Bagged Parts

2 Wheels

1 1/16” Aluminum Tube

1 1/16” x 1” Shrink Tube

1 1/8” x 2-1/2” Dowel

6 #16 Rubber Bands

Description of Part

Building Materials and Tools You Will Need

• Smooth and FLAT work surface

• Wax paper or clear plastic wrap to protect the work surface

• Thin Cyanoacrylate (CA) glue

• Hobby knife with #11 blades

• Needle nose pliers

• Wire cutters

• Sanding block, 320 to 400 grit sandpaper

• Covering Iron

Finishing Materials You Will Need

• SoLite Covering (Do NOT use heavier covering!!!!!!!!!!!!)

(You can use a light weight tissue covering instead of SoLite)

• Double-Sided Foam Tape

• Hinge Tape (DuBro or Similar)

• Velcro to Mount Battery

Electronics You Will Need

• Power: ParkZone Motor/Gearbox (PKZ3624) for UM P-51/Sukhoi

• Prop: EFL9051 Ultra Micro 130mm x 70mm

• RX/ESC/Servo: ParkZone ‘Vapor’ PKZ3351 or Spektrum AR6400

• 1S-130 mAh LiPo

3

General Building Tips

• READ THE INSTRUCTIONS all the way through and study the plans BEFORE starting any

work on the model.

• PRE-SANDING: BEFORE removing any parts from the balsa sheets, use a sanding block

with 320 grit sandpaper and lightly sand the back of the balsa sheets. Our balsa suppliers

have been sending us wood that is over sized, so sanding the backs of the balsa sheets

reduces the thickness just slightly and removes any charring from the laser cutting process.

• Tape the plans to your nice clean work surface and cover it with wax paper or plastic wrap.

You want to keep your work surface clean and not glue the parts to the plans, right?

• Balsa is a lightweight and fragile wood, so you do need to be careful with it; however, you

will also need to use a little bit of force to make everything fit properly, so don’t be too

timid.

• Do not remove any pieces from the balsa sheets until they’re ready to be used. That way,

parts won’t get mixed up or disappear.

• Do NOT glue anything until told to do so.

• Join all of your pieces using thin CA (Cyanoacrylate) glue, unless we tell you otherwise. In

general, only a small amount of CA is necessary to glue parts together.

• Don’t over force your pieces together. If they aren’t fitting together properly, make sure you

have the right pieces and that they are oriented correctly. If needed, you can lightly sand

the part to fit after making sure it is the correct part and oriented correctly. On balsa “tabs”,

you can “pinch” the wood with your fingers to get them to fit in slots. (The tabs might be

tighter some times, due to tolerances in wood thickness)

• If you want to remove the charred edges caused by the laser cutting process, lightly

dampen a cloth with bleach and gently rub the affected areas. Removing the char will not

increase the strength but will make it look better. It also keeps that dark edge from showing

under the lightweight coverings. You can also remove it by LIGHTLY sanding with 400 grit

sandpaper.

4

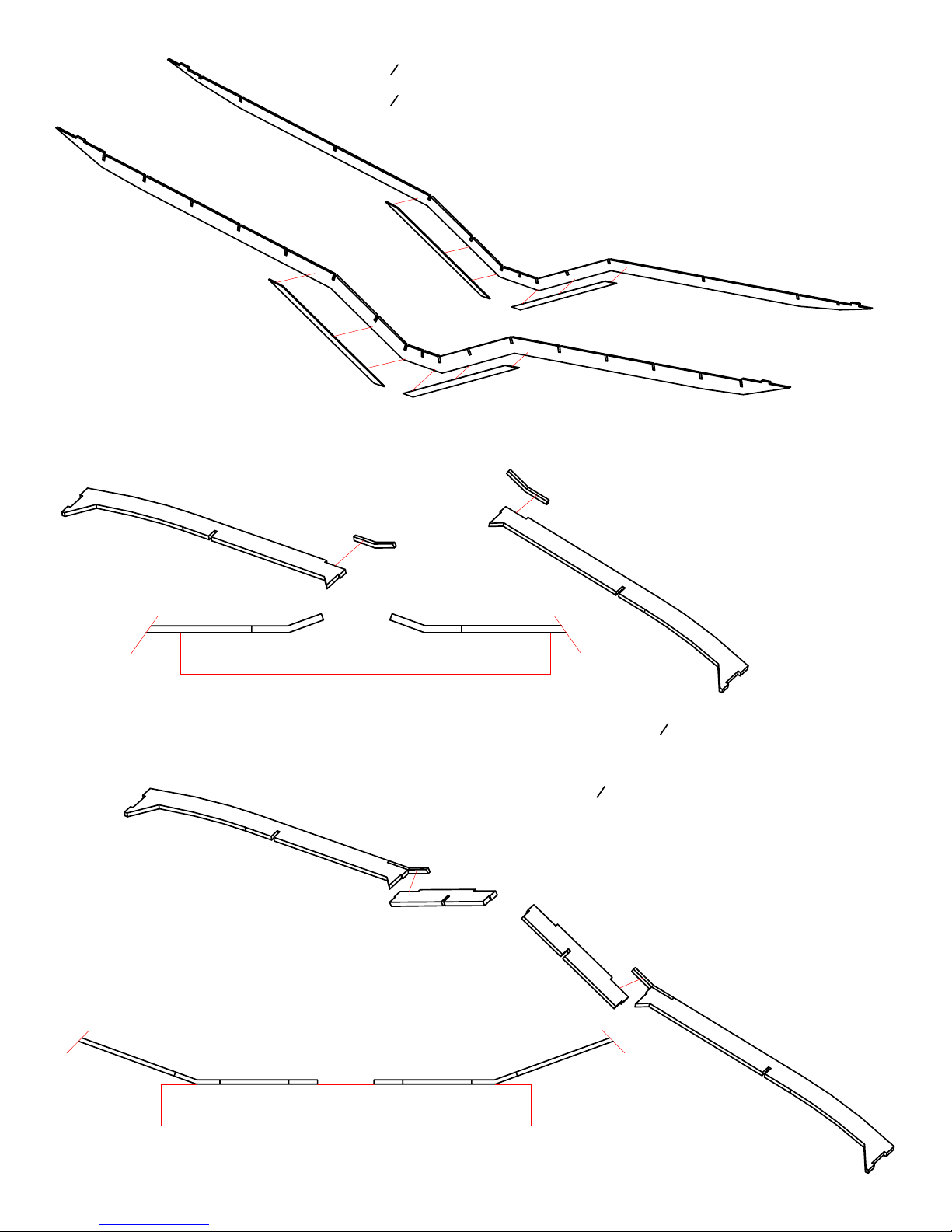

1. Join the

2. Join the

1

" balsa W1 and W1A parts together with thin CA, to make the main spar, W1.

16

1

" balsa W2 and W2A parts together with thin CA, to make the rear spar, W2.

16

3. Glue the plywood W1R spar reinforcements onto W1, with thick

CA. BE SURE to align them properly, as shown on the plans.

4. Glue the plywood W2R spar reinforcements onto W2, with thick CA.

BE SURE to align them properly, as shown on the plans.

W10

W2R

W1

W1R

W22

W22W10 W10W22

TABLE

W2

W2R

W1R

W22

W10

W9

TABLE

5. Glue the plywood W22 parts onto the

a LEFT and RIGHT as shown, with thick CA. Place the "dirty" side

3

" balsa W10 parts, making

32

of W10 "up".

6. READ THIS STEP!! Glue the

assembly, with thick CA. BE SURE to align them properly, and

3

" balsa W9 parts onto the W10/W22

32

make a LEFT and RIGHT. THE ENGRAVED TEXT ON W9 goes AWAY

from the W22 parts.

W9

W9

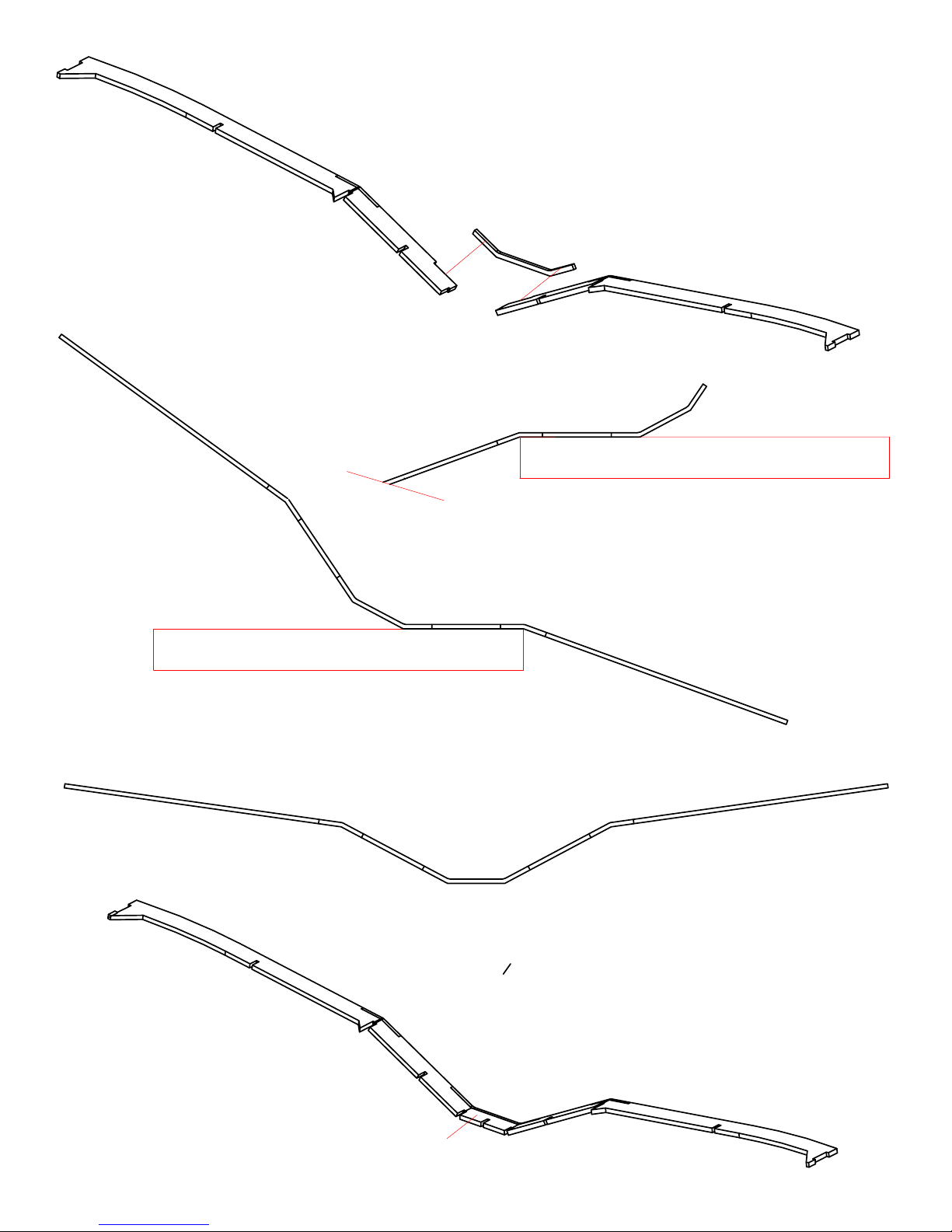

W9

7. Glue the plywood W21 brace onto one of the assemblies from the

previous step, with the long part of the W10/W9 assembly hanging

off the table.

8. Glue on the other assembly, as shown.

W9

W21

TABLE

W21

W9

W9

W21

TABLE

9. Glue the

W8

3

" balsa W8 part onto the W21 brace with thick CA.

32

Loading...

Loading...