DP 15 A

DP 30 A

User’s manual - Use and Maintenance

Descaling pumps

Notice technique - Utilisation et entretien

Pompes pour le détartrage

GB

F

Dear Customer, thank you for choosing a MOULDPRO descaling pump.

MANUAL

This manual is a safe guide for the use of the pump. Please read it carefully in all its parts before use.

This manual contains important information for the proper working and use of the equipment.

MOULDPRO reserve the right to introduce any future changes without notice or replacement.

PRELIMINARY INSPECTION

Upon receipt of the pump, take it out from the carton and check it is in perfect condition. Also check

that the data on the rating plate correspond to required ones. For any problem, immediately contact

the supplier specifying the kind of fault.

In case of doubts about the safety of the machine, do not use it.

DESCRIPTION

The pumps DP 15 A and DP 30 A are fitted with programmable automatic flow reverser. Particularly

recommended for difficult descaling treatments, they work in complete safety and autonomy enabling

the operator to carry out other works at the same time.

Vertical axis pumps with tank for descaling boilers by using specific non-acid restoring products.

The pumps are equipped with special fittings and valves to adjust the flows and purge the sludge, built

up by the operation, which is then rapidly removed.

Pumps are supplied ready to use, in strong carton boxes with related user’s manual.

Below are the main deposits which can be removed with these pumps:

- Scale deposits

- Calcium and silica deposits.

ENGLISH

3

CONTENTS

1 - REGULATIONS – CE MARK page 4

2 - THE ADVANTAGES OF THE PUMPS DP 15 A AND DP 30 A page 4

3 - TECHNICAL FEATURES page 5

4 - CUSTOMER SERVICE page 5

5 - USE page 5

6 - SAFETY INSTRUCTIONS page 7

7 - DESCALING CHEMICALS page 7

8 - EXPLODED VIEWS page 8

9 - DIRECTIONS FOR DISPOSAL page 10

10 - WARRANTY TERMS AND AFTER-SALE ASSISTANCE CONDITIONS page 10

4

1 - REGULATIONS – CE MARK

Declaration of Conformity

The pumps are in conformity with the following European Directives, Laws and Regulations:

Low Voltage Directive:

73/23/EEC

93/68/EEC

Electromagnetic Compatibility Directive:

89/336/EEC

92/31/EEC

93/68/EEC

93/97/EEC

Directives RoHS and WEEE:

02/98/EEC

02/96/EEC

03/108/EEC

QUALITY

MOULDPRO equipments are manufactured with high-quality acid-resistant materials and submitted to

severe operating tests.

Follow these instructions to avoid any operating and servicing problems.

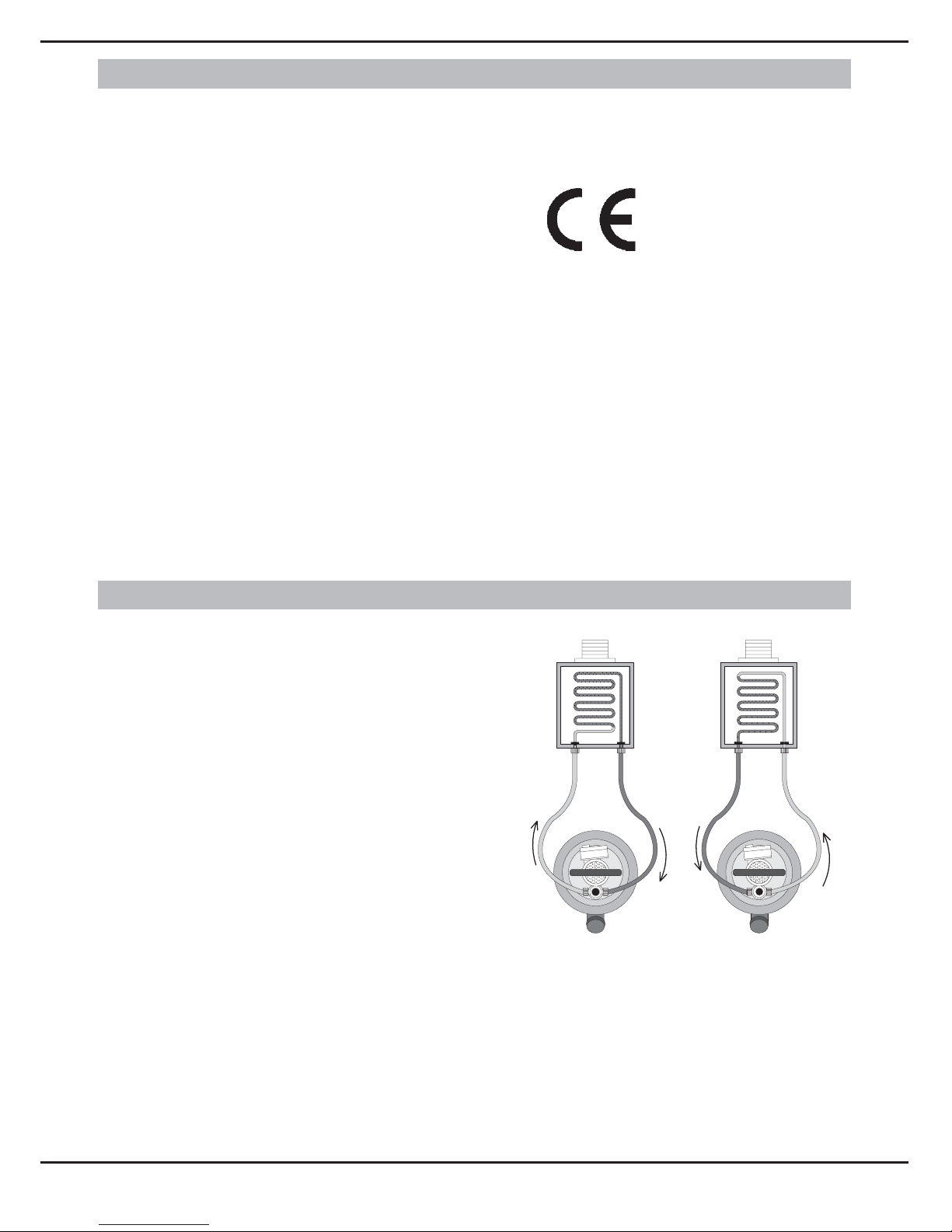

2 - THE ADVANTAGES OF THE PUMPS DP 15 A AND DP 30 A

Time and, above all, temperature increase make

calcium salts, usually present in water, precipitate in the

form of microcrystals and settle on metallic surfaces of

pipes, plant coils and heat exchangers, thus reducing

flow rate and thermal efficiency.

To restore the original plant performance it is necessary

to carry out a descaling with specific products and

equipments.

The automatic flow reverser device attacks scale on

both sides, thus making descaling particularly effective

and fast (as the normal dissolving action is combined

with the detachment in flakes of scale, which is made

friable by the double attack), even when pipes and

exchangers are almost totally obstructed.

Clockwise

circulation

Heat exchanger

Counterclockwise

circulation

ENGLISH

5

3 - TECHNICAL FEATURES

DP 15 A

Vertical axis pump

Motor 220 V - Hp 0,17

Degree of protection IP 54

Max. temperature 50° C

Flow rate 40* l/min.

Head 10* m

Fittings 1/2”

Tank capacity 15 l

Dimensions ø x H 35 x 48 cm

Weight Kg 6

DP 30 A

Vertical axis pump

Motor 220 V - Hp 0,45

Degree of protection IP 54

Max. temperature 50° C

Flow rate 90* l/min.

Head 20* m

Fittings 1/2”

Tank capacity 24 l

Dimensions ø x H 40 x 63 cm

Weight Kg 10,5

* Data referred to the pump body outlet.

4 - CUSTOMER SERVICE

For enquiries on spare parts, please specify serial number of pump (shown on product and

carton).

5 - USE

5.1 - HOW TO PREPARE THE PUMP AND CHECK THE SEAL

- Fill the tank with enough water to ensure that the pump rotor

housing is submerged during operation.

- Screw the outer ends of the flexible hoses securely to the

exchanger to be descaled.

- Connect the power cable to a single-phase 220 V power

supply.

- Switch on the pump and check the seal of the hose fittings on

the exchanger and on the pump. In case of leaks of liquid,

check hoses and fittings and replace the defective

components, if necessary.

- When seal is safe, switch off the pump.

- If necessary, add more descaling product by referring to the

dilution specified in the data sheet of the product.

6

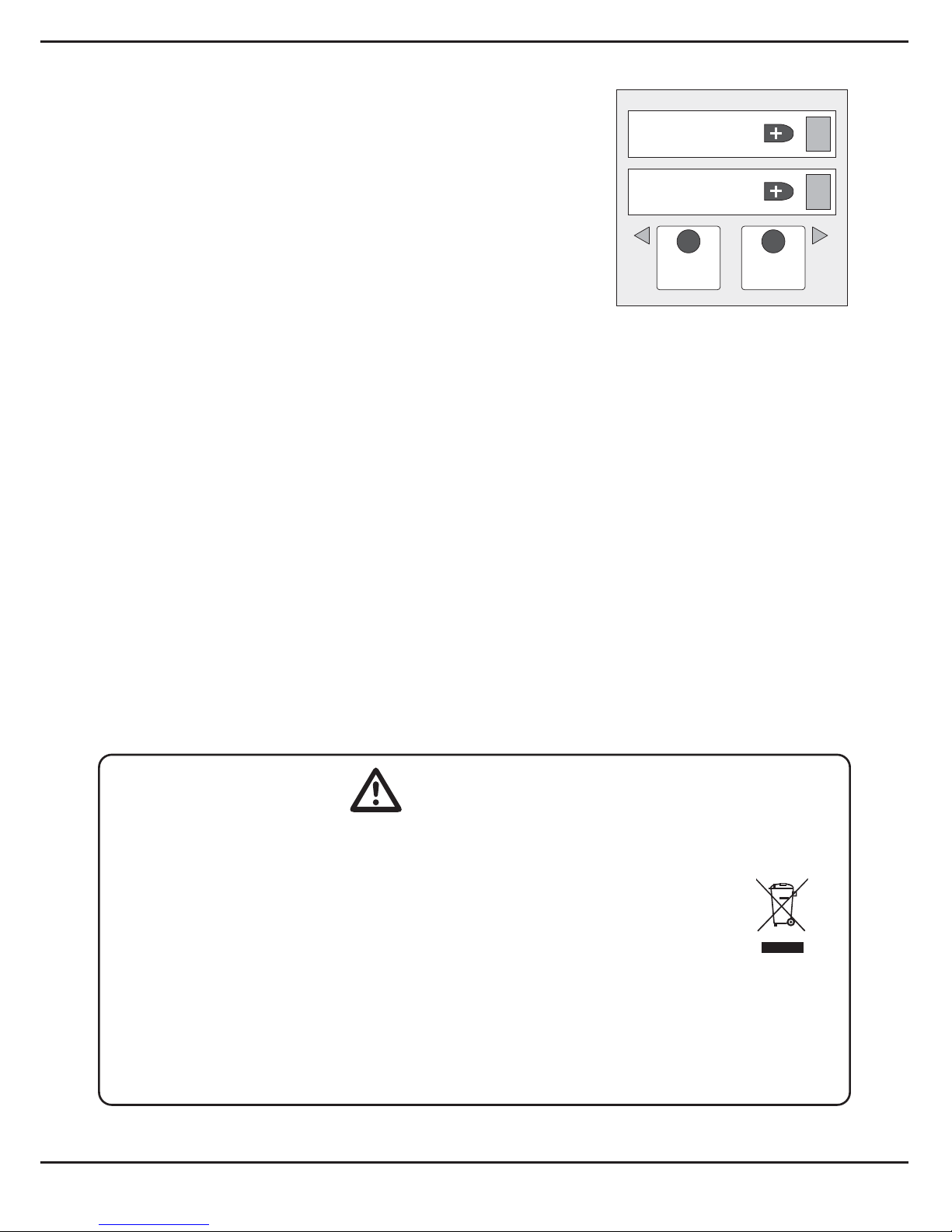

5.2 - PROGRAMMING

Switch on the pump.

When switching on, the led for “OPERATE HOURS” is blinking and

is on 0 (zero). Press keys DX (right) or SX (left) to start manual

mode; the value 1 will be displayed.

For automatic programming follow the instructions below:

1. By press key + “BACKFLOW INTERV. MIN” the value 1 will be

fixed on display; this means the flow reversion will be carried out

every minute.

2. To modify the value press once the key +, the value will start

blinking; only during this stage it is possible to increase the value

(up to 9) by pressing again key +. After 3 seconds the value is

confirmed.

3. The displayed value decreases as minutes go by. To know the actual value set at the beginning,

press key + for 1 second and the actual value will start blinking.

4. To modify the value for “OPERATE HOURS” please refer to steps 2 and 3 above.

5. During automatic operation, to operate in manual mode, press twice in succession keys SX and DX.

6. Once the time set on the display “OPERATE HOURS” is finished, the pump will stop and the display

will be blinking and indicate the value 0 (zero).

7. To restart the pump press keys DX or SX; the pump will start working in manual mode and the display

“OPERATE HOURS” will show the value 1.

Scale removal can be considered complete when bubbles no longer form in the return pipe and the

solution is still acidic.

5.3 - HOW TO CLEAN THE PUMP

After descaling REMOVE THE DESCALING LIQUID FROM THE TANK and wash out the pump by

circulating clean water through it for at least 10 minutes.

PRECAUTIONS

Only use “MOULDPRO” chemicals in order to ensure good working and avoid damaging the

equipments.

Once the lifetime of the pump has expired, do not dispose of it with household

waste. The pump must be recycled in authorized centres and can be assimilated

to a household appliance.

During handling lift the pump and do not drag it in order to avoid damages to the tank.

Temperature of the descaling solution must never exceed 50 °C.

Flexible hoses and fittings can be damaged in time; make sure to check the seal whenever

using the pump, as indicated in the pump preparation instructions.

INTERVALLO INVERS. MIN.

UMKEHRINTERVALL MIN.

BACKFLOW INTERV. MIN.

FUNZIONAMENTO ORE

FUNKTIONIEREN STUNDEN

OPERATE HOURS

SX DX

MANUAL

BLOCK

MANUAL

BLOCK

ENGLISH

7

6 - SAFETY INSTRUCTIONS

- Avoid using the pump in rooms where there are liquids, gases, flammable powders or with risk of

explosion.

- Before plugging in the pump to the outlet, make sure the switch is off.

- The outlet must be suitable for the plug of the pump. Do not use non CE-marked defective outlets.

- Use (CE) approved extensions, only if necessary.

- Do not use plug adapter. Do not carry out any modifications to the plug nor to the electrical cable.

- Pump shall always kept in perfect efficiency.

- During maintenance operations, check the switch is off and the plug is not connected.

- All maintenance operations must be carried out by the authorized Technical Assistance Service.

- Only use MOULDPRO original spare parts.

- Do not carry out any modifications to the pump if not authorized by MOULDPRO Technical

Department (ask for written authorization).

- Keep children and unauthorized persons away from the pump.

- Keep the pump out of reach of children and unauthorized persons.

- Do not use the pump if tired or under the effect of alcohol, medicines or drugs.

- When using the pump, wear overalls, do not wear jewellery, keep hair away from the pump.

- When handling descaling liquids, be very careful. It is necessary to use Individual Protection

Equipment (IPE).

7 - CHEMICALS

Copper Steel Stainless

Aluminium

Brass Tin Light

Galvanised

steel alloys iron

DESCALING CHEMICALS

REMOVER LIQUID ••

Concentrated descaling liquid

with powerful reaction for

systems and heat exchangers.

REMOVER PLUS LIQUID ••

Concentrated descaling liquid

(non-fuming), with degreasing

action, for systems and heat

exchangers.

REMOVER PLUS POWDER •••••

Concentrated descaling powder

(non-corrosive, non-fuming) for

systems and heat exchangers.

NEUTRALIZING CHEMICALS

NEUTRALIZER ••••••••

Neutralizing powder to remove

residual acidity after descaling

systems and heat exchangers.

Also suitable for neutralizing

descaling chemicals after use,

thus making it possible to

drain them.

8

70

90

91

30

2

24

1

10

27

31

47

64

26

14

33

18

17

19

71

74

72

73

69

68

4

6

7

45

9

20

12

5

8

13

15

23

1. Metal handle

2. Motor 220/50

4. Brass nut 6 MA

5. Blind nut 16 M

6. Circlip

7. Arnite washer

8. O-Ring for rotor/ impeller

9. PP bolt 12 MA

10. Flange + pump body

12. Shaft sleeve

13. PP rotor/ impeller

14. Bulkhead

15. Rotor cover in PP

17. PP bolt 8 MA

18. Bolt 6 MA

19. Tank

20. O-ring, bolt M 12

23. Tank cap

24. O-Ring for motor flange

26. O-Ring for rotor cover

27. Fairlead for flange

30. Transparent hose m. 2x2 +

hose fitting 1/2”

31. Ring nut 3/4”

33. O-Ring for rotor/ impeller bolt

45. O-Ring for reverser butterfly valve

47. Pipe fitting 3/4” x 16

64. Elbow 3/4”

68. Electronic card

69. Keyboard

70. Motor fan cover

71. Motor fan

72. Seal bearing

73. Switch

74. Motor flange

90. Thread adaptors

91. Hose end fitting 1/2”

8 - EXPLODED VIEWS AND SPARES DIAGRAMS

DP 15 A

P.S..: For enquiries on spare parts, please specify always if needed for the model DP 15 A.

ENGLISH

9

DP 30 A

P.S.: For enquiries on spare parts, please specify always if needed for the model DP 30 A.

70

90

91

30

2

24

1

10

27

31

47

64

26

14

33

18

17

19

71

74

72

73

69

68

4

6

7

45

9

20

12

5

8

13

15

23

1. Metal handle

2. Motor 220/50

4. Brass nut 6 MA

5. Blind nut 16 M

6. Circlip

7. Arnite washer

8. O-Ring for rotor/ impeller

9. PP bolt 12 MA

10. Flange + pump body

12. Shaft sleeve

13. PP rotor/ impeller

14. Bulkhead

15. Rotor cover in PP

17. PP bolt 8 MA

18. Bolt 6 MA

19. Tank

20. O-ring, bolt M 12

23. Tank cap

24. O-Ring for motor flange

26. O-Ring for rotor cover

27. Fairlead for flange

30. Transparent hose m. 2x2 +

hose fitting 1/2”

31. Ring nut 3/4”

33. O-Ring for rotor/ impeller bolt

45. O-Ring for reverser butterfly valve

47. Pipe fitting 3/4” x 16

64. Elbow 3/4”

68. Electronic card

69. Keyboard

70. Motor fan cover

71. Motor fan

72. Seal bearing

73. Switch

74. Motor flange

90. Thread adaptors

91. Hose end fitting 1/2”

10

9 - DIRECTIONS FOR DISPOSAL

In accordance with the WEEE directive 2002/96/EC on waste electrical and

electronic equipment, the pump, when no longer used, shall be disposed of in a

RAEE – WEEE collection centre authorized for disposal of waste electrical and

electronic equipment, or directly contact your dealer.

10 - WARRANTY TERMS AND AFTER-SALE ASSISTANCE CONDITIONS

MOULDPRO guarantee that the equipments sold are free from designing, manufacturing and material

defects, under normal operating conditions and according to the directions contained in the instructions manual supplied with the equipment.

In compliance with the directive 1999/44/CE valid in the EEC countries, the warranty rights apply only

to the purchaser.

MOULDPRO, placed in Baltorpbakken 10, DK - 2750 Ballerup - Denmark, guarantee the equipments

against any conformity defects appearing within 24 (twenty-four) months from the purchase date, even

when warranty operations have been carried out during this period, if only proved by a document.

The warranty covers all components of the equipment and provides for the repairing or, if necessary,

the free replacement of those parts that, according to your Dealer, have conformity defects.

The warranty does not cover the aesthetic parts and the parts subject to wear and tear, nor does it

cover all damages or failures whose cause is not due to the manufacturer, such as: transport, wrong

installation or maintenance, tampering, sudden changes of electric voltage and/or hydraulic pressure,

thunderbolts, corrosions, excess of humidity, accidental bumps or events beyond our control.

The warranty is valid only if the equipments have been installed, used and properly maintained according to all directions supplied by MOULDPRO in the instructions manual attached to the equipment.

Should any conformity defects of the product be found during the warranty period, the Customer shall

notify the Dealer to agree upon the terms of repairing and/or replacing of the product.

FRANÇAIS

11

Cher Client, nous vous remercions d’avoir choisi une pompe détartreuse MOULDPRO .

NOTICE TECHNIQUE

Cette notice représente un guide sûr pour l’utilisation de cette pompe MOULDPRO, il est donc

nécessaire de bien en lire chaque partie avant de les utiliser.

Cette notice contient des informations importantes pour un fonctionnement et une utilisation corrects

de ces appareils.

MOULDPRO se réserve le droit d’apporter des modifications sans obligation de préavis ni de

remplacement.

CONTROLES PRELIMINAIRES

Au moment de la livraison, sortir la pompe de l’emballage et en vérifier l’intégrité. Vérifier que les

inscriptions sur l’étiquette correspondent aux caractéristiques choisies. En cas d’anomalie, contacter

immédiatement le fournisseur et lui signaler la nature des défauts. En cas de doutes sur la sécurité de

l’appareil, ne pas l’utiliser.

DESCRIPTION

Les pompes DP 15 A et DP 30 A sont pourvues d’inverseur de flux automatisé programmable, et sont

recommandées pour le détartrage difficile. Elles travaillent en complète autonomie et sécurité en

permettant à l’utilisateur d’effectuer plusieurs opérations à la fois.

Pompes à axe vertical avec réservoir pour le détartrage des chaudières par l’intermédiaire de produits

spécifiques détartrants non acides.

Les pompes sont pourvues de raccords spéciaux avec vannes pour régler les flux et effectuer

rapidement la vidanges des boues formées à la suite de l’intervention.

Les pompes sont fournies dans des cartons robustes avec la notice d’instructions prêtes à l’emploi.

Synthèse des dépôts éventuels qui peuvent être éliminés grâce à ces pompes :

- incrustations calcaires

- incrustations de calcium et de silice.

12

INDEX

1 - NORMES - MARQUE CE page 13

2 - LES AVANTAGES DES POMPES DP 15-30 A page 13

3 - CARACTERISTIQUES TECHNIQUES page 14

4 - SERVICE ASSISTANCE CLIENTS page 14

5 - UTILISATION page 14

6 - INSTRUCTIONS POUR LA SECURITE page 16

7 - PRODUITS DETARTRANTS page 16

8 - VUES ECLATEES page 17

9 - INSTRUCTIONS POUR L’ELIMINATION page 19

10 - CONDITIONS DE GARANTIE ET ASSISTANCE APRES VENTE page 19

FRANÇAIS

13

1 - NORMES-MARQUE CE

Déclaration de conformité

Ces pompes sont conformes aux Directives, Lois et Règlements européens.

Directive Basse Tension:

73/23/EEC

93/68/EEC

Directive Compatibilité Electromagnétique:

89/336/EEC

92/31/EEC

93/68/EEC

93/97/EEC

Directive RoHS et WEEE:

02/98/EEC

02/96/EEC

03/108/EEC

QUALITE

Nos appareils sont construits avec des matériaux antiacides de la meilleure qualité et sont soumis à

des tests rigoureux de fonctionnement.

La maintenance et le fonctionnement ne créent aucun problème si l’on respecte ces instructions.

2 - LES AVANTAGES DE LA POMPE DP 15 A ET DP 30 A

Avec l’augmentation de la température, le temps

passant, les sels de calcium qui se trouvent

normalement dans l’eau précipitent sous forme de

microcristaux et se déposent sur les surfaces

métalliques des tuyaux, des serpentins, des

installations et échangeurs de chaleur avec diminution

consécutive du débit et du rendement thermique.

Pour rétablir les prestations d’origine des installations il

faut effectuer un détartrage avec des produits et des

appareils spécifiques.

Le dispositif Inverseur de flux automatique permet

d’attaquer les incrustations des deux cotés, en rendant

la désincrustation particulièrement rapide (en plus de

l’action de dissolution normale, on a un effet de

décollement du calcaire sous forme d’écailles devenu

friable à la suite de la double attaque subie) et efficace,

même en présence de tuyaux et d’échangeurs

quasiment bouchés.

Circulation

dans le sens horaire

Echangeur de chaleur

Circulation

dans le sens antihoraire

14

3 - CARACTERISTIQUES TECHNIQUES

DP 15 A

Pompe à axe vertical

Moteur 220 V - Hp 0,17

Degré de protection IP 54

Température max. 50° C

Débit 40* l/min.

Hauteur d’élévation 10* m

Raccords 1/2”

Capacité réservoir 15 l

Dimensions ø x H 35 x 48 cm

Poids Kg 6

DP 30 A

Pompe à axe vertical

Moteur 220 V - Hp 0,45

Degré de protection IP 54

Température max. 50° C

Débit 90* l/min.

Hauteur d’élévation 20* m

Raccords 1/2”

Capacité réservoir 24 l

Dimensions ø x H 40 x 63 cm

Poids Kg 10,5

* Données se référant à la sortie de pompe

4 - SERVICE ASSISTANCE CLIENTS

A chaque fois que vous appelez il faut spécifier le N° de matricule de la pompe (reporté sur le

produit et sur la boite d’emballage)

5 - MODE D’EMPLOI

5.1 - PREPARATION DE LA POMPE ET VERIFICATION DE L’ETANCHEITE

- Remplir le réservoir avec la quantité d’eau nécessaire pour

maintenir le corps de la pompe submergé pendant le

fonctionnement.

- Visser les bouts des tuyaux flexibles à l’échangeur à détartrer

- Brancher le câble d’alimentation à une prise de courant 220

V monophasé

- Mettre en marche la pompe grâce à l’interrupteur et contrôler

la tenue des raccords sur l’échangeur et sur la pompe. En

cas de pertes liquides vérifier l’intégrité des raccords et des

tuyaux et pourvoir au remplacement des pièces abimées.

- Quand l’étanchéité est sure éteindre la pompe.

- Ajouter avec précaution la quantité d’acide nécessaire pour

le détartrage en se référant à la dilution spécifiée sur la fiche

technique du produit.

FRANÇAIS

15

5.2 - PROGRAMMATION

Mettre en marche la pompe grâce à l’interrupteur.

Au moment de l’allumage le voyant lumineux “FONTIONNEMENT

HEURES” clignote sur le 0; en appuyant sur les touches DX ou SX

la pompe s’enclenchera en mode manuel et la valeur 1 s’affichera

sur l’écran.

Pour la programmation en mode automatique suivre les phases

suivantes:

1. En appuyant sur la touche + “INTERVALLE INVERS.MIN” la

valeur 1 est affichée cela signifie que l’inversion de flux se produit

toutes les minutes.

2. Pour modifier la valeur il faut appuyer une fois la touche +, cette

valeur commencera à clignoter et seulement pendant cette

phase en appuyant encore sur + cette valeur pourra être augmentée ( jusqu’à 9). Trois secondes

après cette valeur est confirmée.

3. La valeur sur l’afficheur se met à jour en décroissant. Pour connaitre la valeur imposée au début

appuyer sur la touche + pendant une seconde, la valeur se mettra à clignoter.

4. Pour modifier la valeur du “FONCTIONNEMENT HEURES” voir 2. et 3. ci dessus.

5. Pendant le fonctionnement en mode automatique, pour passer au mode manuel, il suffit d’appuyer

deux fois de suite sur les touches SX et DX.

6. Une fois terminé le temps imposé sur l’afficheur “ FONCTIONNEMENT heures” la pompe s’arrête et

l’afficheur clignote en indiquant la valeur 0.

7. Pour faire repartir la pompe il suffit d’appuyer sur les touches DX ou SX la pompe commencera à

travailler en mode manuel et sur l’afficheur “FONCTIONNEMENT HEURES” la valeur 1 sera

indiquée.

Le détartrage sera considéré terminé quand il n’ya aura plus de formation de bulles dans le tuyau de

retour et la solution est encore acide.

5.3 - NETTOYAGE DE LA POMPE

Une fois terminé le détartrage ENLEVER LE LIQUIDE ANTITARTRE DU RESERVOIR et effectuer un

lavage en faisant circuler de l’eau propre pendant 10 minutes minimum.

PRECAUTIONS

Pour garantir un bon fonctionnement et pour éviter des dommages aux appareils utiliser

exclusivement les détartrants « MOULDPRO ».

Une fois terminée la durée de la pompe, ne pas la jeter à la poubelle . La pompe

devra être transportée dans un centre autorisé pour le recyclage et elle est

considérée un électroménager.

Pendant la manutention soulever la pompe en évitant de la faire glisser pour éviter tout

dommage au réservoir.

La solution détartrante ne doit jamais dépasser la température de 50°C.

Les flexibles et les raccords peuvent s’abimer au cours du temps, prendre soin de vérifier à

chaque utilisation la tenue comme cela est indiqué dans les instructions de préparation de la

pompe.

INTERVALLO INVERS. MIN.

UMKEHRINTERVALL MIN.

BACKFLOW INTERV. MIN.

FUNZIONAMENTO ORE

FUNKTIONIEREN STUNDEN

OPERATE HOURS

SX DX

MANUAL

BLOCK

MANUAL

BLOCK

16

6 - INSTRUCTIONS POUR LA SECURITE

- Eviter l’utilisation de la pompe dans un environnement où se trouvent des liquides, gaz et poudres

inflammables ou à risque d’explosions.

- Avant de brancher la fiche à la prise électrique, s’assurer que l’interrupteur soit éteint.

- La prise de courant doit être adaptée à la fiche de la pompe. Ne pas utiliser de fiches défectueuses

ou non conformes aux normes CE.

- Si cela est nécessaire, utiliser des rallonges homologuées (CE)

- Ne pas employer d’adaptateurs pour prise. Ne pas apporter de modifications à la prise, ni au câble

électrique.

- La pompe doit être maintenue en parfaite efficience

- Durant les interventions de maintenance, contrôler que l’interrupteur est éteint et que la fiche est

débranchée.

- Les interventions de maintenance doivent être effectuées exclusivement par le personnel spécialisé

- Utiliser uniquement les pièces de rechange originales MOULDPRO

- Ne pas apporter de modifications à la pompe si elles n’ont pas été préalablement autorisées par

MOULDPRO ( demander une autorisation écrite)

- Garder la pompe hors de la portée des enfants et des personnes externes.

- Ne pas utiliser la pompe en cas de fatigue, sous l’effet de l’alcool, de médicaments ou de drogues.

- Lors de l’utilisation de la pompe, utiliser une combinaison de travail, ne pas utiliser de bijoux et

garder les cheveux attachés.

- La manipulation de liquides désincrustants demande une grande attention.

- Il faut utiliser les dispositifs de protection individuels (DPI)

7 - PRODUITS CHIMIQUES

Cuivre Acier Acier Aluminium Laiton Etain Alliages Zingués

inox légers

PRODUITS DETARTRANTS

REMOVER LIQUID ••

Détartrant liquide concentré à

action énergique pour les

installations et les échangeurs.

REMOVER PLUS LIQUID ••

liquide détartrant concentré

( non fumigatoire) action

dégraissante pour les

installations et les échangeurs.

REMOVER PLUS POWDER •••••

Détartrant en poudre concentré

( non corrosif, non fumigatoire)

pour les installations

et les échangeurs.

PRODUITS NEUTRALISANTS

NEUTRALIZER ••••••••

Poudre neutralisante pour

l’élimination de l’acidité résiduelle

après la désincrustation des

installations et des échangeurs.

Elle peut être aussi utilisée

comme neutralisant pour les

solutions détartrantes en

permettant la décharge directe

à l’égout.

FRANÇAIS

17

70

90

91

30

2

24

1

10

27

31

47

64

26

14

33

18

17

19

71

74

72

73

69

68

4

6

7

45

9

20

12

5

8

13

15

23

1. Poignée métallique

2. Moteur 220/50

4. Ecrou en laiton 6 MA

5. Frette borgne M16

6. Bague de retenue

7. Rondelle en Arnite

8. Joint pour turbine

9. Vis en PP 12b MA

10. Bride + corps pompe

12. Tuyau pour arbre

13. Turbine en PP

14. Cloison

15. Bouchon filtre en PP

17. Vis 8 MA en PP

18. Vis M6

19. Réservoir

20. Joint vis 12 M

23. Bouchon réservoir

24. Joint bride moteur

26. Joint bouchon filtre

27. Porte-câble pour bride

30. Tube transp. mt 2x2 + racc. 1/2”

31. Bague 3/4”

33. Joint vis turbine

45. Joint pour papillon inverseur

47. Raccord 3/4” x 16

64. Coude 3/4”

68. Carte électronique

69. Clavier

70. Couvre-hélice de ventilation

pour moteur

72. Palier d’étanchéité

73. Interrupteur

74. Bride moteur

90. Réductions

91. Raccord terminal 1/2”

8 - VUE ECLATEE

DP 15 A

N.B.: pour le choix des pièces de rechange spécifier toujours le modèle DP 15 A

18

DP 30 A

N.B.: pour le choix des pièces de rechange spécifier toujours le modèle DP 30 A

70

90

91

30

2

24

1

10

27

31

47

64

26

14

33

18

17

19

71

74

72

73

69

68

4

6

7

45

9

20

12

5

8

13

15

23

1. Poignée métallique

2. Moteur 220/50

4. Ecrou en laiton 6 MA

5. Frette borgne M16

6. Bague de retenue

7. Rondelle en Arnite

8. Joint pour turbine

9. Vis en PP 12b MA

10. Bride + corps pompe

12. Tuyau pour arbre

13. Turbine en PP

14. Cloison

15. Bouchon filtre en PP

17. Vis 8 MA en PP

18. Vis M6

19. Réservoir

20. Joint vis 12 M

23. Bouchon réservoir

24. Joint bride moteur

26. Joint bouchon filtre

27. Porte-câble pour bride

30. Tube transp. mt 2x2 + racc. 1/2”

31. Bague 3/4”

33. Joint vis turbine

45. Joint pour papillon inverseur

47. Raccord 3/4” x 16

64. Coude 3/4”

68. Carte électronique

69. Clavier

70. Couvre-hélice de ventilation

pour moteur

72. Palier d’étanchéité

73. Interrupteur

74. Bride moteur

90. Réductions

91. Raccord terminal 1/2”

FRANÇAIS

19

9 - INSTRUCTIONS POUR L’ELIMINATION

Selon les la directive WEEE 2002/96/EC sur les déchets électriques et

électroniques, lorsque la pompe n’est plus utilisée elle devra être éliminée dans un

centre de stockage des déchets RAEE – WEEE autorisé pour l’élimination des

déchets électriques et électroniques, ou bien contacter directement votre

revendeur.

10 - CONDITIONS DE GARANTIE ET D’ASSISTANCE APRES-VENTE

MOULDPRO garantit que les produits vendus sont exempts de défauts de conception, de fabrication

ou de vices inhérents aux matériaux utilisés, dans les conditions d’utilisation normales et selon les

instructions reportées dans cette notice technique fournie avec ce produit.

MOULDPRO ayant siège à Baltorpbakken 10, DK - 2750 Ballerup - Denmark,, garantit ses propres

appareils contre tous défauts de conformité se manifestant dans les 24 mois à partir de la date d’achat,

même dans le cas où des interventions de garantie aient été effectuées durant cette période du

moment qu’elle soit prouvée par un document fiscal ou équivalent.

La garantie couvre toutes les parties composant l’appareil et inclut la réparation, ou si nécessaire le

remplacement, gratuit des pièces qui, selon l’avis de l’Assistance technique présente des défauts de

conformité.

La garantie ne couvre pas les parties esthétiques ou les parties qui sont sujettes à l’usure. Elle ne

couvre pas non plus tous les dommages ou les pannes dues à des causes non imputables au

producteur, par exemple transport, mauvaise installation ou manutention, écarts de tension électriques

et/ou de pression hydrauliques, coups de foudre, corrosion, excès d’humidité, chocs ou causes de

force majeure.

La garantie est valable à condition que durant l’installation, utilisation ou manutention, toutes les

indications fournies par MOULDPRO avec le produit aient été respectées.

Si des défauts de conformité du produit pendant la période de garantie devaient se présenter, le Client

doit s’adresser à la structure d’assistance compétente pour des accords sur les modalités de

réparation et/ou de remplacement du produit.

Mouldpro Aps - Baltorpbakken 10 DK - 2750 Ballerup - Denmark

Phone: +45 7020 3131 Fax: +45 7020 3151

www.mouldpro.com info@mouldpro.com

ZCA.016.21 REV. 00/11

Loading...

Loading...