Motus M990T, M990TL, M995T, M995TL Service Manual

M990T, M990TL, M995T, M995TL

Treadmill

SERVICE MANUAL

This service manual is for use by Motus trained service providers only.

If you are not a Motus Trained Servicer, you must not attempt to service any Motus product.

Ver 0.2, Feb., 2007

ⓒ Motus Co., Ltd. All Rights reserved.

Unauthorized Reproduction and Distribution Prohibited By Law

1

Motus Treadmills M990T, M990TL, M995T and M995TL

Table of Contents

SECTION I TROUBLESHOOTING GUIDE

SECTION II HOW TO REPLACE & REPAIR GUIDE

General

SECTION III HOW TO REPLACE & REPAIR GUIDE,

Electronic PCB

SECTION IV ELECTRONIC PCB, CONNECTOR AND

CABLE OVERVIEW

APPENDIX EXPLODED VIEW

2

Motus Treadmills M990T, M990TL, M995T and M995TL

SECTION I

TROUBLESHOOTING GUIDE

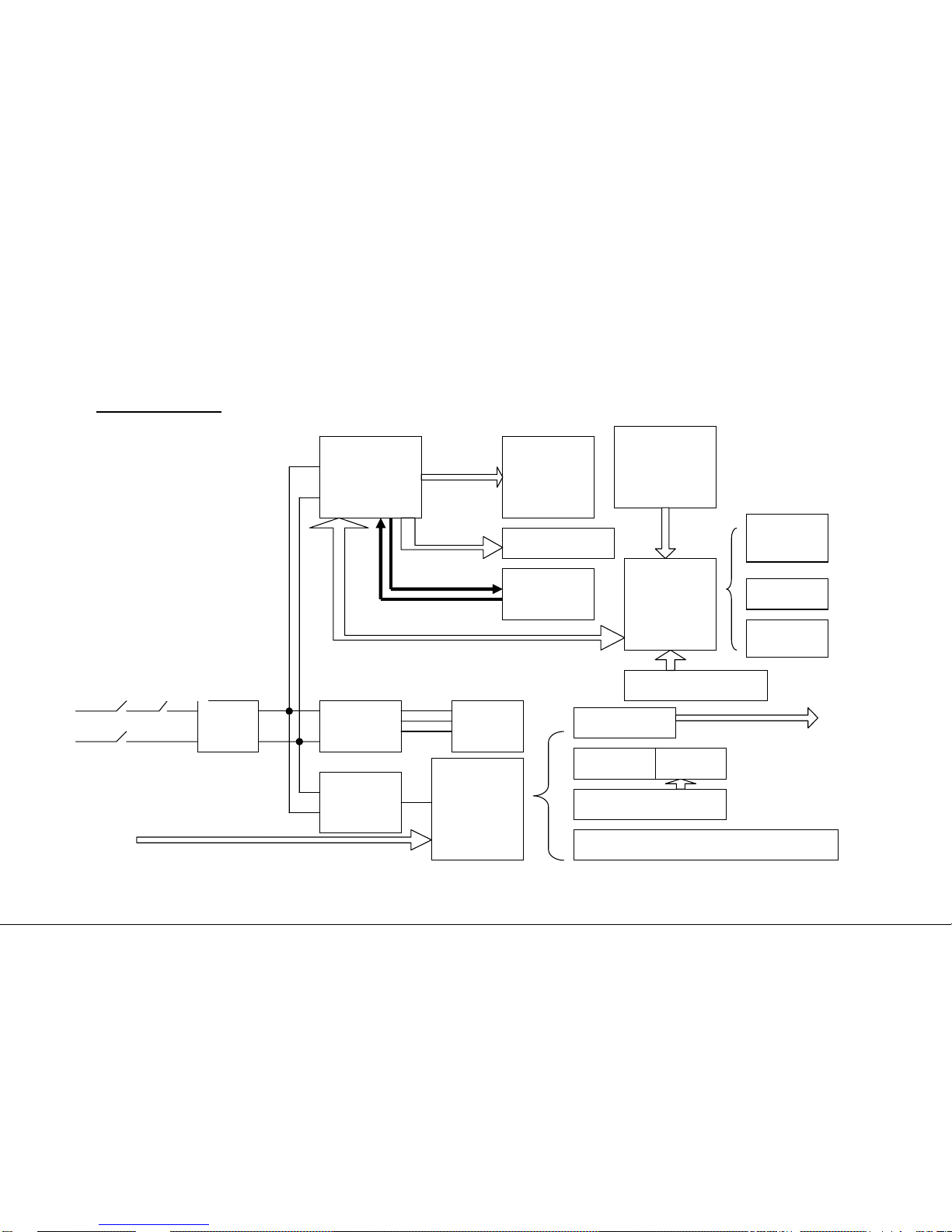

1.1 System Block Diagram

1.2 Troubleshooting Guide

1.3 Troubleshooting Guide for LCD

1.4 Protective Function & Display Code

1.5 Lubrication Guide

3

1.1 System Block Diagram

1) AC 220V/230V INPUT

U

V

W

Oil Pump Motor

A/D

PCB

Motor

Controller

(

Inverter

)

Drive

Motor

Lift/

Power Supply

PCB

Lift Motor

AC

220V/230V

Line

Filter

Transformer

LCD Power

Supply PCB

MPU PCB

(Main

Processing

Unit)

LCD Screen

LCD Lamp Inverter PCB

OSD Button PCB for Channel/Volume/Power-on

Touch -Sensitive

Key PCB (L/R)

Speed/Incline/

Start/Enter

Membrane Overlay Key

Emergency

Switch

CHR PCB

Wireless HR

PCB

Video & Audio Input

(Coaxial, RCA)

Back-Light

Audio Interface

Headphone Jack

Power ON/OFF

Switch

Circuit

Breaker

4

2) AC 100V/120V INPUT (USA, Japan)

AC 100V/120V

AC 230V/240V

U

V

W

Oil Pump Motor

A/D

PCB

Motor

Controller

(

Inverter

)

Drive

Motor

Lift

/Power Supply

PCB

Lift Motor

AC

100V/120V

Line

Filter

Transformer

LCD Power

Supply PCB

MPU PCB

(Main

Processing

Unit)

LCD screen

LCD Lamp Inverter PCB

OSD Button PCB for Channel/Volume/Power-on

Touch -Sensitive

Key PCB (L/R)

Speed/Incline/

Start/Enter

Membrane Overlay Key

Emergency

Switch

CHR PCB

Wireless HR

PCB

Video & Audio Input

(Coaxial, RCA)

Back-Light

Audio Interface

Headphone Jack

Power ON/OFF

Switch

Circuit

Breaker

Boost

Transformer

5

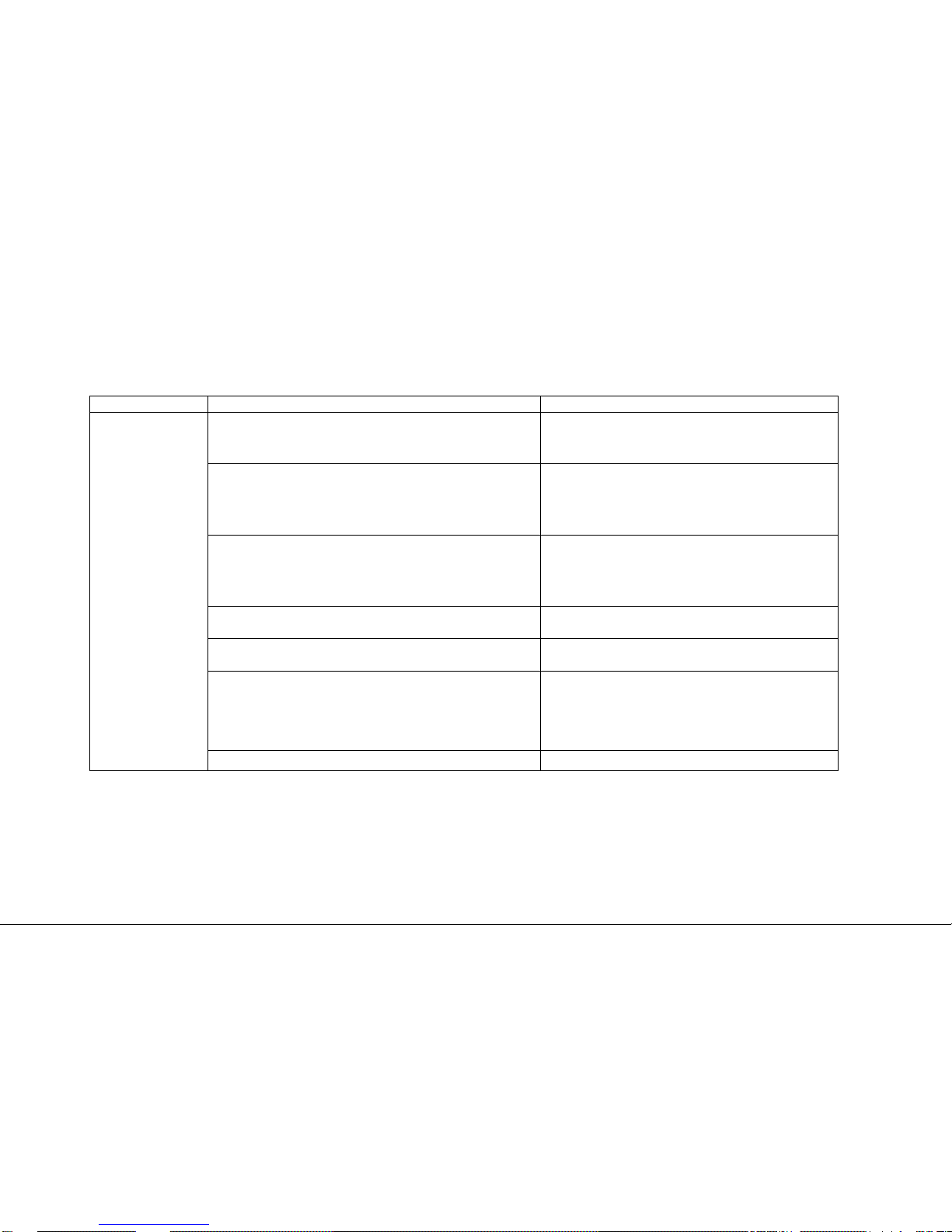

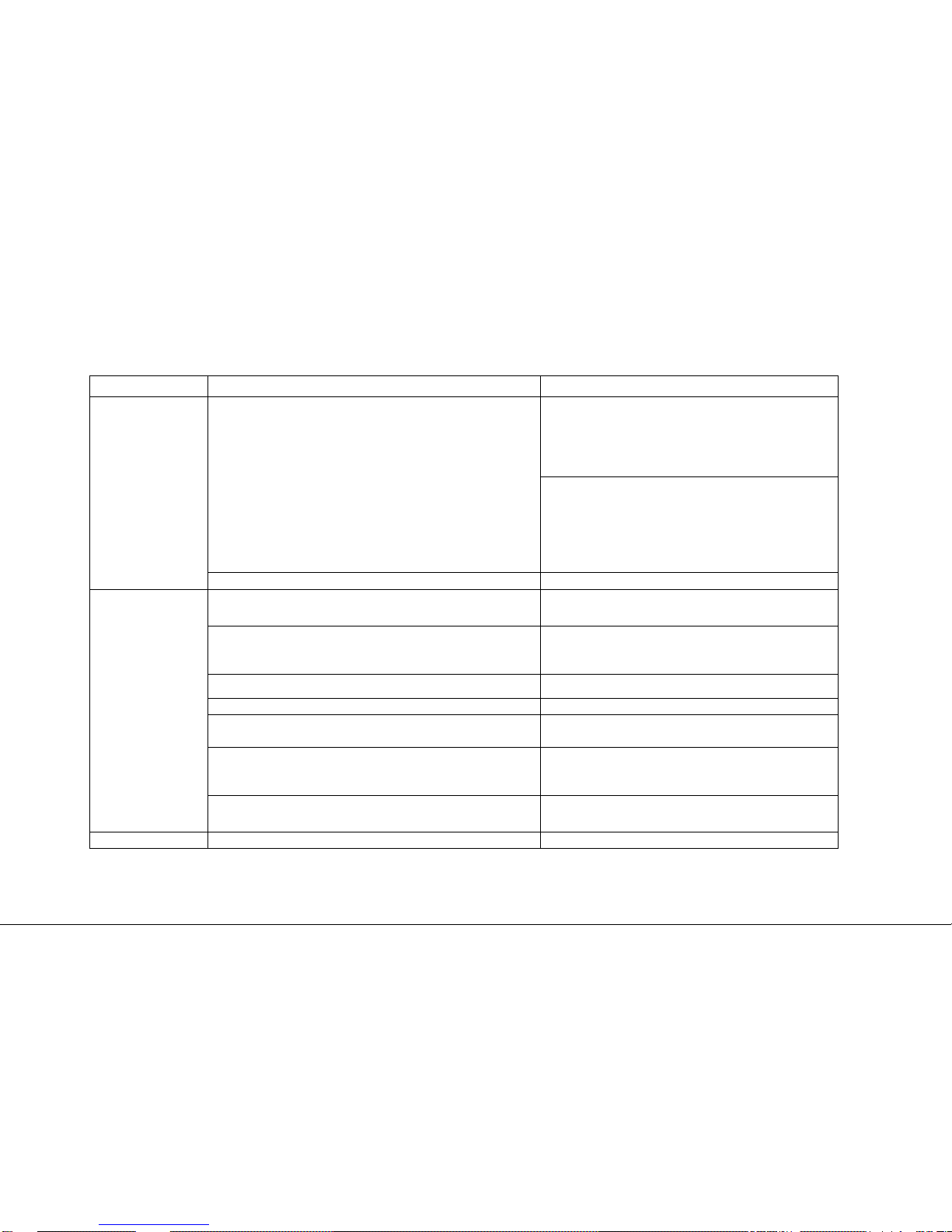

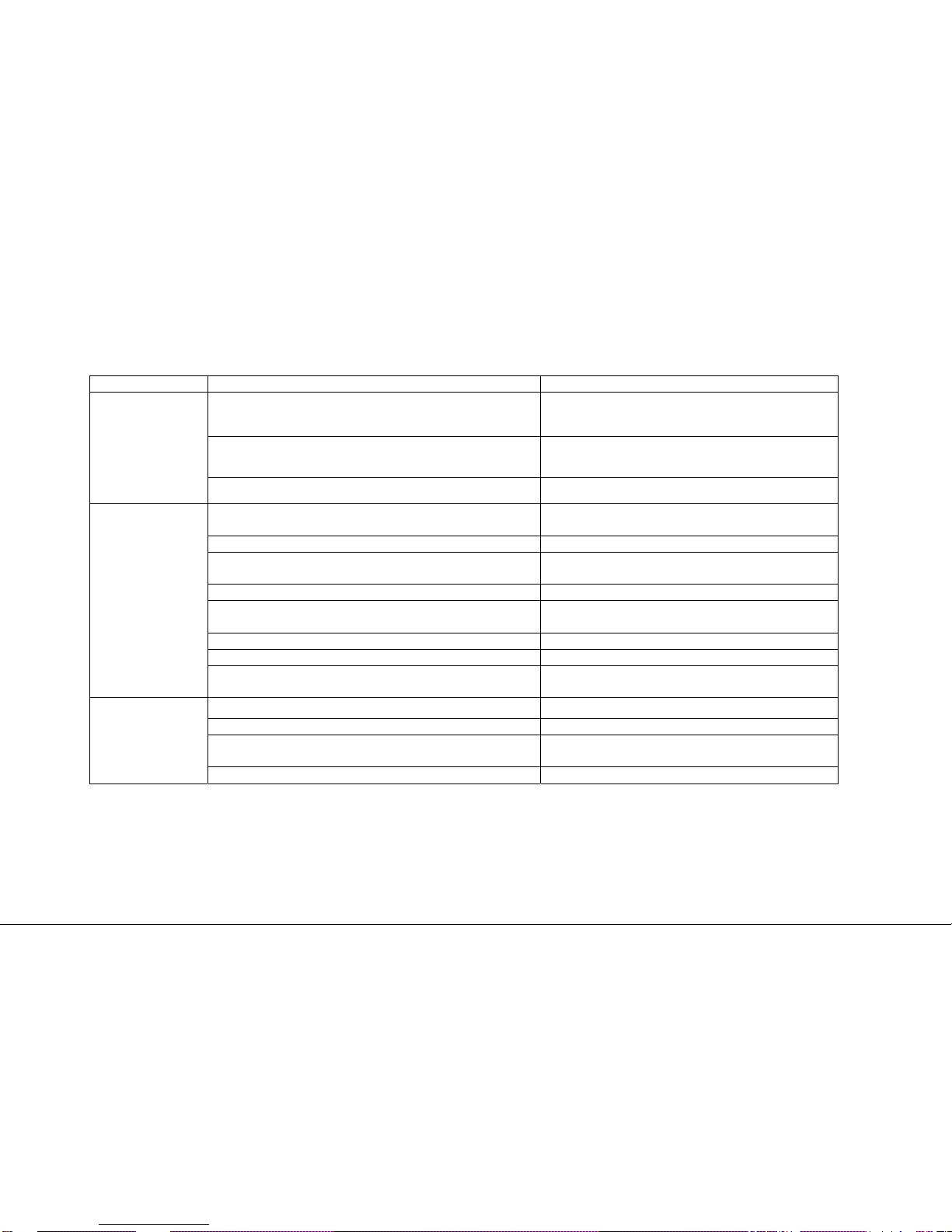

1.2 Troubleshooting Guide

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Line voltage is not present at treadmill.

Check the main circuit breaker and wall outlet voltage at

the Facility.

If wall outlet voltage is present, then replace line cord.

Circuit breaker on the rear of the Treadmill Is tripped.

(Countries using 220V or 230V Supply Voltage)

If tripped, a white button has popped out. Press the white

button to reset the circuit breaker after eliminating the

cause of the trip. The circuit breaker is located next to

power ON/OFF switch on the outside of the treadmill.

Power-on switch with built-in circuit breaker is tripped.

(US/Canada market or Japan market using 100V or 120V

Supply Voltage)

In the United States, Canada and Japan, circuit breaker

is combined with power ON/OFF switch. If tripped, the

switch is turned to OFF position. Turn the switch on after

eliminating the cause of the trip. Replace it if necessary

Power-on Switch is damaged.

Replace Power-on Switch if the output voltage of Power

Switch is not present.

Defective Line Filter.

Replace Line Filter if the output of Line Filter is not

present.

Electronic components of Lift/Power Supply PCB are damaged.

Disconnect CN3 cable at Lift/Power Supply PCB and

then measure the voltage between pin 2 and pin 1.

Measure the voltage between pin 2 and pin 3. The

voltage should be 5VDC. If there is no voltage, replace

the PCB.

No power to

treadmill console

Fuses 1, 2 on Lift/Power Supply PCB are blown. Replace Fuses or the PCB.

6

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Disconnect CN6 (3-pin connector) on MPU PCB

(M990T/M995T) and then measure the voltage between

pin 2 and pin 1 at the cable. Measure the voltage

between pin 2 and pin 3 at the cable. If there is no

voltage, replace the cable.

Defective wire harness

Disconnect CN1 (3-pin connector) on MPU

(M990TL/M995TL) and then measure the voltage

between pin 2 and pin 1 at the cable. Measure the

voltage between pin 2 and pin 3 at the cable. If there is

no voltage, replace the cable. If the cable is normal,

secure the connector firmly.

No power to

treadmill console

Defective MPU PCB Replace MPU PCB.

Due to normal protective function.

(E□□ is displayed on Console Display.)

Refer to

“Protective Function & Display Code”

Magnetic switch for emergency stop is not firmly attached.

Mount magnetic switch in position.

If it is in position, adjust the position of magnetic sensor

under properly or replace it if necessary.

Emergency Push Button Switch is locked. Unlock it by rotating clockwise.

Insufficient power source Plug treadmill into a dedicated 20-amp circuit.

Unstable power connection.

Find unstable connection at electrical outlet and at

treadmill

RS485 connection for communication is loose.

If the Console display is normal, check the electrical

connection between MPU of Console and Motor

Controller under motor hood is firm.

Striding belt does not

move or treadmill

pauses randomly

3-pin connectors at MPU of Display Console or Lift/Power

Supply PCB are not secure.

Check the connection is secure.

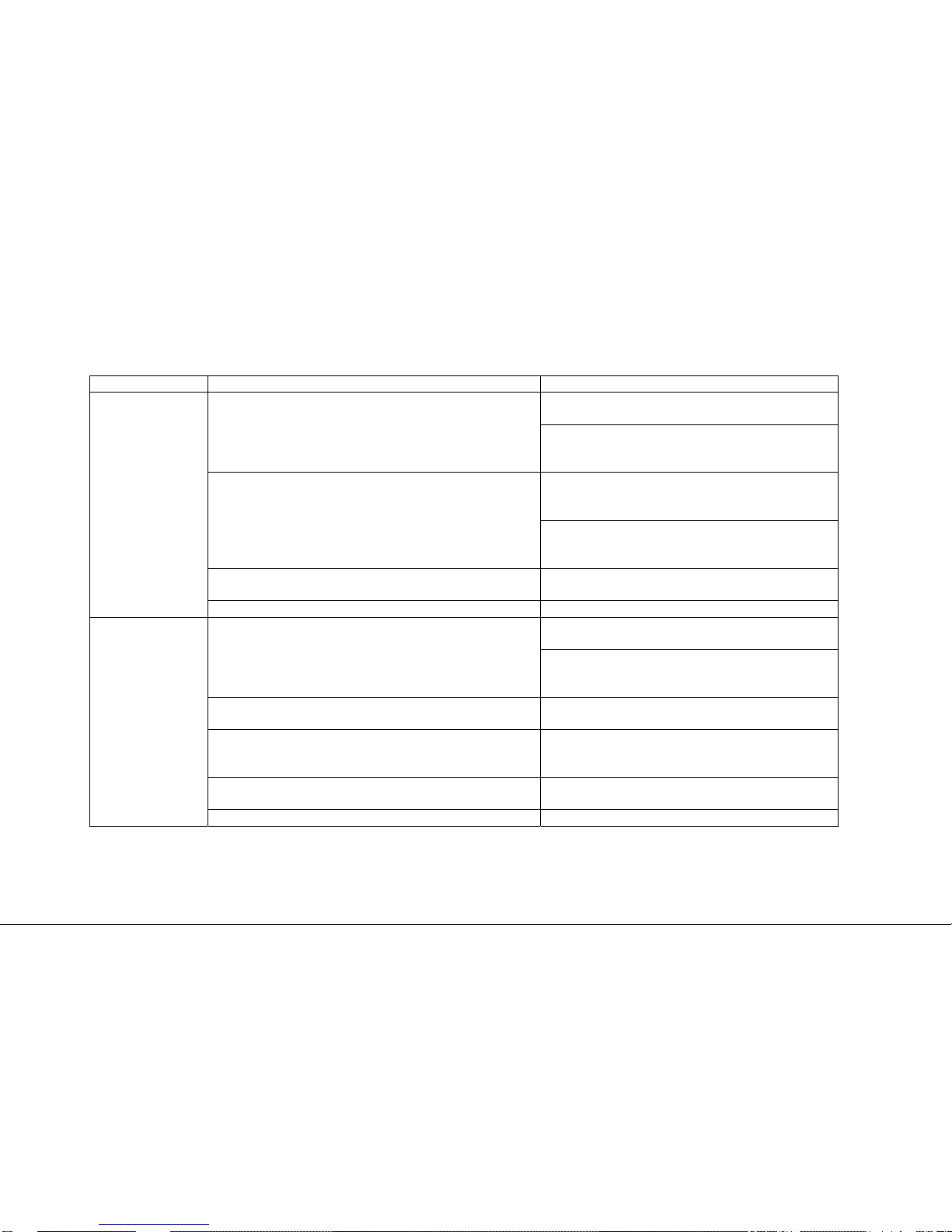

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

7

Power-on switch is unstable or defective. Replace power-on switch.

If the voltage between pin 2 and pin 1 at CN1 on MPU

PCB (M990T/M995T) is under 4.8V, replace Lift/Power

Supply PCB.

Supply voltage to MPU PCB is too low.

If the voltage between pin 2 and pin 1 at CN6 on MPU

PCB (M990T/M995T) is under 4.8V, replace Lift/Power

Supply PCB.

Check the connection between CN3 on Lift/Power

Supply PCB and CN1 (M990TL/M995TL) on MPU PCB

is connected firmly.

Treadmill pauses

Randomly and then

Program Profile

Window of Console

start displaying from

the beginning as if

Power-on Switch is

turned on.

Unstable cable connection.

Check the connection between CN3 on Lift/Power

Supply PCB and CN6 (M990T/M995T) on MPU PCB is

connected firmly.

The deck laminate worn through or the underside of striding belt

became hard or glossy.

Replace belt and deck.

(Refer to section “How to replace Striding Belt”, “How to

replace Deck”)

Manual lubrication is not sufficient.

Check if the lubrication is proper by pushing striding belt

backward using your feet while holding front handlebar

after turn OFF the treadmill. If insufficient, apply

lubrication.

Maximum speed is

reduced

Automatic lubrication system does not work.

Check if the lubrication is proper by pushing striding belt

backward using your feet while holding front handlebar

after turn OFF the treadmill. If insufficient, apply

lubrication.

Verify lubricant tank is not empty, or lubrication system

works well.

8

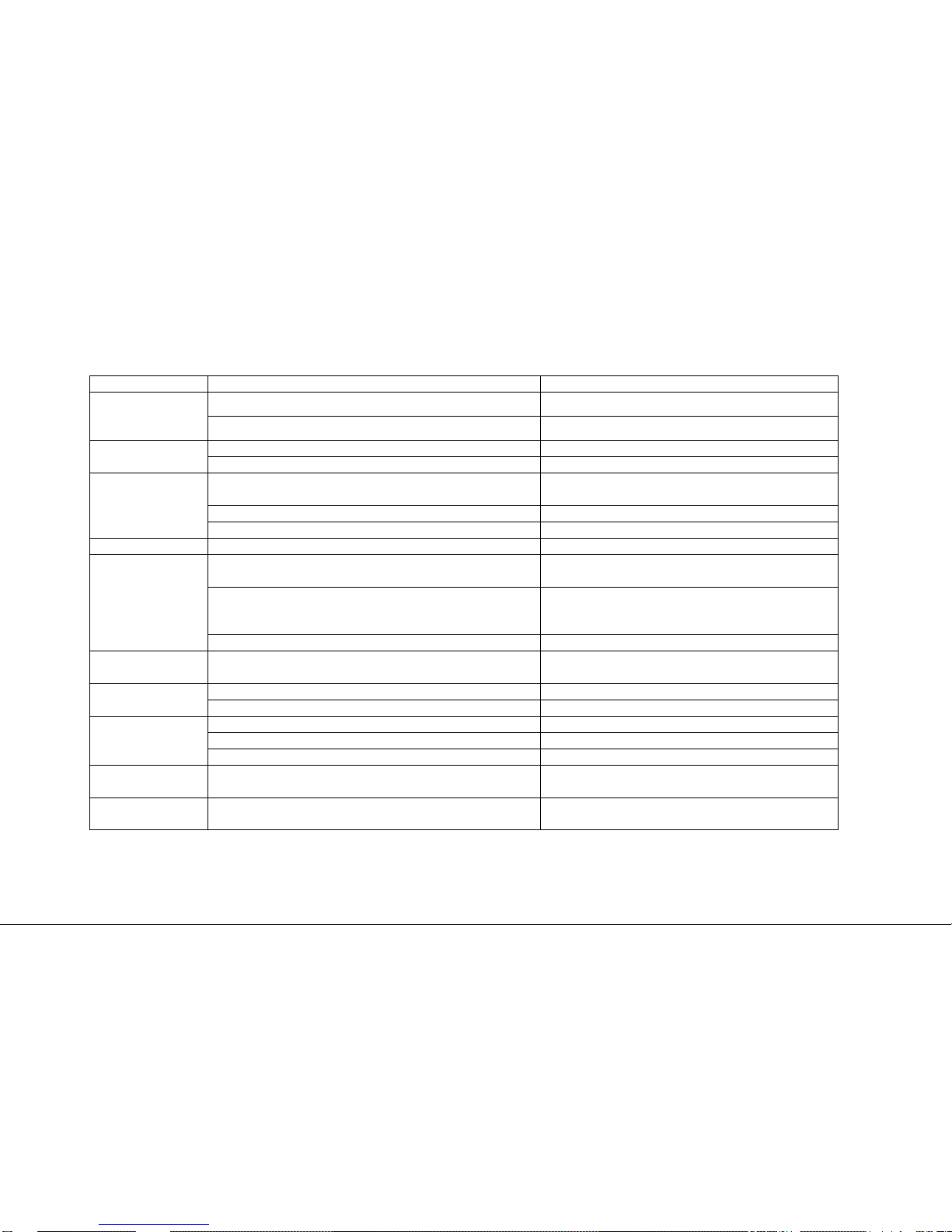

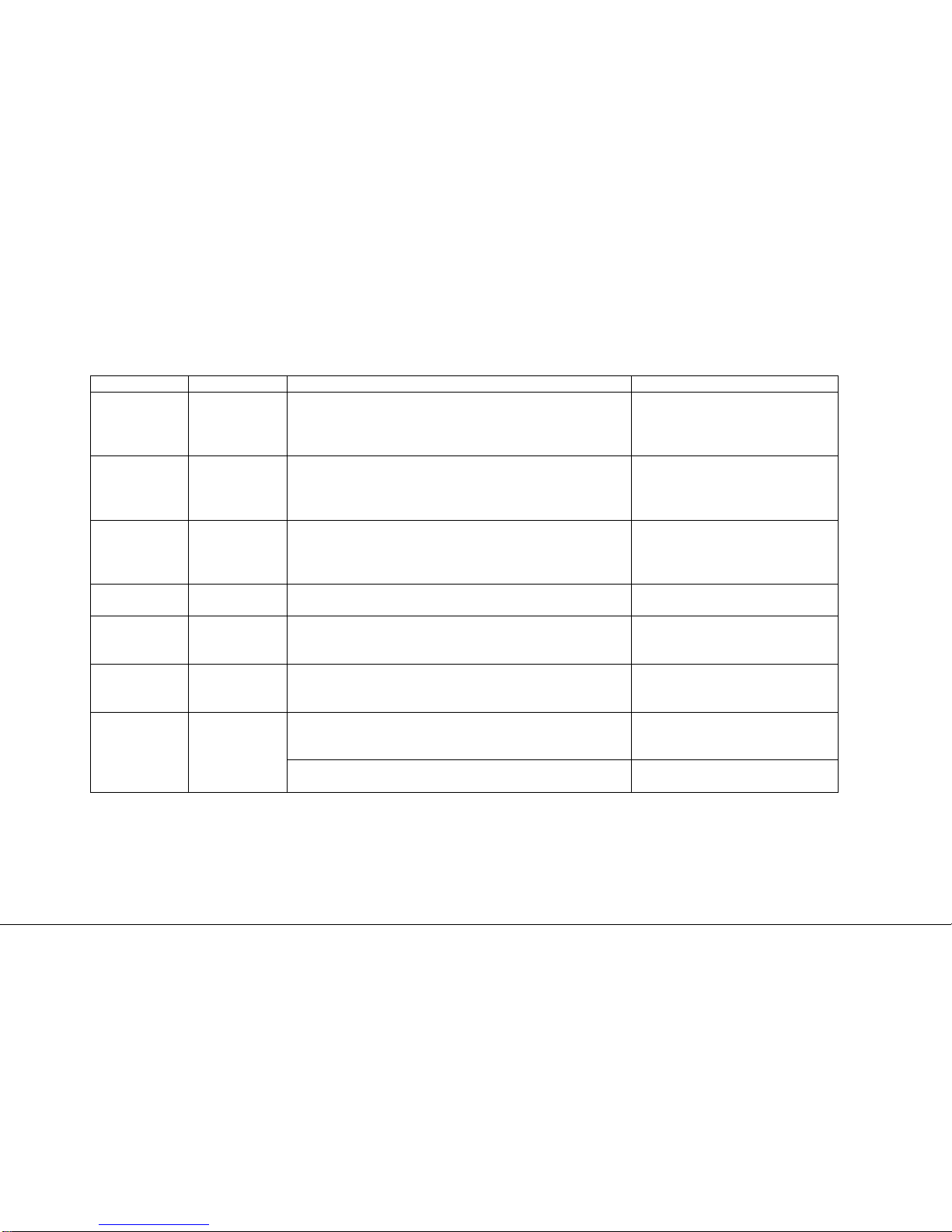

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

If all 3 lamps on Start/Stop, Speed Down and Speed UP

do not light up, replace the Touch-Sensitive Key PCB.

Touch-Sensitive Buttons does not work.

If a lamp on Start/Stop, Speed Down or Speed UP does

not light up any more than before pressing each button,

replace the Touch-Sensitive Key PCB.

Check the connection between CN4 on Lift/Power

Supply PCB and CN2 (M990TL/M995TL) on MPU PCB

is exact or connected firmly.

Unplugged or defective cables.

Check the connection between CN4 on Lift/Power

Supply PCB and CN3 (M990TL/M995TL) on MPU PCB

is exact or connected firmly.

Unplugged or defective cable

Check the cable from the incline motor is connected

firmly to CN20 on Lift/Power Supply PCB.

Incline is not

adjusted by InclineUp or Incline-Down

Button.

Lift/Power Supply PCB is damaged. Replace Lift/Power Supply PCB.

If all 3 lamps on Start/Stop, Speed Down and Speed UP

do not light up, replace the Touch-Sensitive Key PCB.

Touch-Sensitive Buttons does not work.

If a lamp on Start/Stop, Speed Down or Speed UP does

not light up any more than before pressing each button,

replace the Touch-Sensitive Key PCB.

Unplugged or defective cable

Check the cable from the Drive motor is connected firmly

to the terminal of Motor Controller..

RS485 connection for communication is loose.

If the Console display is normal, check the electrical

connection between MPU of Console and Motor

Controller under motor hood is firm.

3-pin connectors at MPU of Display Console or Lift/Power

Supply PCB are not secure.

Check the connection is secure.

Speed is not

adjusted by Speed-

Up or Speed-Down

Button.

Motor Controller or MPU PCB is defective. Replace Motor Controller or MPU PCB if necessary.

9

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Touch-Sensitive Key PCB is affected by some noise. Replace the Touch-Sensitive Key PCB.

Treadmill changes

Speed or Incline on

its own.

Sweat or water over the buttons. Remove sweat or water.

Touch-Sensitive Key PCB is affected by some noise. Replace the Touch-Sensitive Key PCB. Treadmill shuts

down on its own.

Sweat or water over the buttons. Remove sweat or water.

Loose ribbon connection.

Verify the ribbon connection is firmly inserted into the

corresponding socket of MPU PCB.

Defective Membrane Overlay Key. Replace Membrane Overlay Key.

Membrane Overlay

Key is not

responding when

depressed.

Defective MPU PCB. Replace MPU PCB.

Oil leakage Too much amount of lubrication. Reduce the amount to be lubricated.

Uneven floor surface

Level or balance treadmill. (Refer to section “Level

Adjustment”)

Striding belt tension or tracking adjustment is needed.

Align striding belt by using belt adjustment bolt after

Level Adjustment is done.

(Refer to section ”Striding belt alignment”)

Striding belt drifts off

center

Worn striding belt. Replace striding belt.

Striding belt slips

during footfall.

Belt tension is loose.

Adjust the belt tension.

(Refer to section ”Belt Tension adjustment”)

High friction between deck and striding belt. Lubrication is needed between deck and striding belt. Loud groaning on

footfall

Foreign objects. Remove any debris or objects under striding belt.

Drive Motor Belt may be worn or damaged. Replace Drive Motor Belt.

Drive Motor Belt tension is loose. Adjust the tension.

Squeaking noise

under motor hood

Foreign objects on the groove of the belt. Remove any debris or objects on the groove of the belt.

Knocking sound

from deck.

Deck is not fixed. Tighten Deck by using the bolt to fix DECK.

Electrostatic

discharge

The underside of Striding belt is worn away. Replace the striding belt.

10

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Electromagnetic interference from television sets, cell phones,

refrigerator, or motor driven exercise equipment.

Keep the treadmill away from the probable cause until

the heart rate readings are accurate.

RF energy source from another chest straps.

Keep another chest strap away more than 1 meter until

the heart rate readings are accurate.

Heart rate reading is

abnormally high or is

displayed even when

Chest Strap or

Contact Heart Rate

sensors are not in

use.

Contact Heart Rate cables are pinched at handle bars. Replace damaged cables.

Chest strap electrodes are not wet enough to sense accurate

heart rate.

Dampen the Chest strap electrodes with tap waters.

The distance between cardio equipments are too close. Maintain the distance more than 30 cm.

Chest strap electrodes are out of monitoring range.

Make sure the chest strap is within 60cm from Wireless

HR PCB.

Chest strap battery is discharged. Replace chest strap or the battery.

Chest strap electrodes are not laid flat or horizontally across

your skin.

Make sure the chest strap electrodes lies flat and

horizontally across your skin.

Faulty chest strap. Replace chest strap.

Faulty Wireless HR PCB. Replace Wireless HR PCB.

Heart rate reading

using wireless chest

strap is erratic or not

displayed

Defective cable or bad connection between Wireless HR PCB

and MPU PCB.

Check the cable and connection is no problem.

Faulty CHR PCB. Replace CHR PCB

Dirty handlebar sensors. Wipe stainless steel sensors with a clean soft cloth.

Defective cable or bad connection between CHR PCB and MPU

PCB.

Check the cable and connection is no problem

Contact Heart Rate

reading is erratic or

not displayed.

User may have an unusual heart rate condition. Let different user grasp sensors to detect any variances.

11

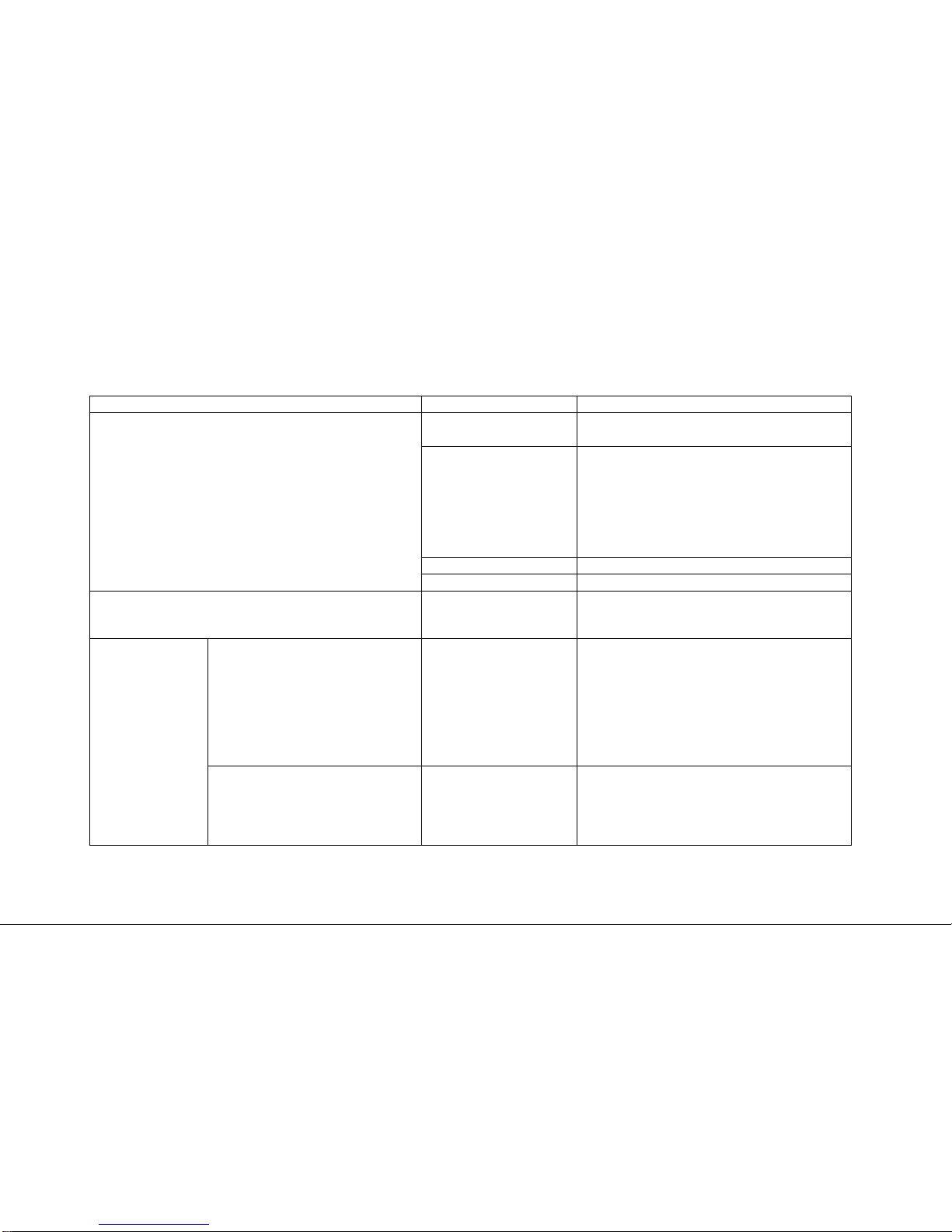

1.3 Troubleshooting Guide for LCD

Symptom/Condition PROBABLE CAUSE CORRECTIVE ACTION

Air/cable setting is not

correct

Follow the set up procedures in LCD manual.

TV signal source is not

supplied.

- Check if the TV signal source is correctly supplied

to A/D PCB from external source.

- Make sure the cable is properly secure.

- If external TV signal is correct, try to connect the

coaxial cable directly to the internal connector in AD

PCB of Console to check whether the internal

cables are wrong or not.

75 ohm coaxial cable is bad. Replace 75 ohm coaxial cable.

Snow and noise are scattering on LCD screen. Any picture is

not found even though channel-up button or channel-down

button is pressed.

A/D Board is damaged. Replace A/D Board with new one.

LCD screen is uniformly white

Internal cable connection is

loose or disconnected.

Check if the connection between LCD screen and

A/D Board is tight.. In other word, LVDS cable

shown in picture.

When LCD power is turned on by

pressing TV on/off, “VIDEO”, “S-VIDEO”

or “ANALOG” appears temporarily and

then disappears on the left upper corner

of LCD screen.

TV mode is not set-up.

1) Whenever you press Volume down button, words

are displayed in following order on the left upper

corner of LCD screen.

“ANALOG”=>”VIDEO”=>”S-VIDEO”=>”TV”

2) Press the button until “TV” is displayed.

3) As soon as “TV” is displayed, snow and noise will

be scattering on LCD screen or any picture will be

captured.

LCD screen is dark

or black.

When LCD power is turned on by

pressing TV on/off, “VIDEO”, “S-VIDEO”

or “ANALOG” is NOT displayed on the

left upper corner of LCD screen.

LCD Power Supply has a

problem. Power Supply is

used for supplying 12 VDC

to LCD Overlay Bezel

Assembly.

Check if LCD Power supply is normally operated or

its LED lamp is turned on.

If LED is off,

z replace Power Adapter.

If LED is on,

12

z tighten midpoint (LCD Power Supply side)

& endpoint(A/D Board side) connection.

z or make sure the voltage of end point is

DC 12 volt.

The cable related to LCD

Lamp Inverter is loose in

either side.

Check if the connection is secure.

TV on/off button is wrong or

stuck.

Replace OSD Button Board.

A/D Board is damaged. Replace A/D Board.

LCD Lamp inverter is

damaged.

Replace LCD Lamp inverter.

LCD Back Light is damaged. Replace LCD screen.

The connector or cable is

bad.

Replace the connector or cable

Channels or sound does not change

Button to change channels

or sound does not work.

Replace the button, OSD Button Board or harness

related to it.

Air/cable setting is not

correct

Follow the set up procedures in LCD manual.

Faulty headphones Replace headphones

No sound

Faulty headphone jack

assembly.

Replace Audio Interface Board or headphone jack.

13

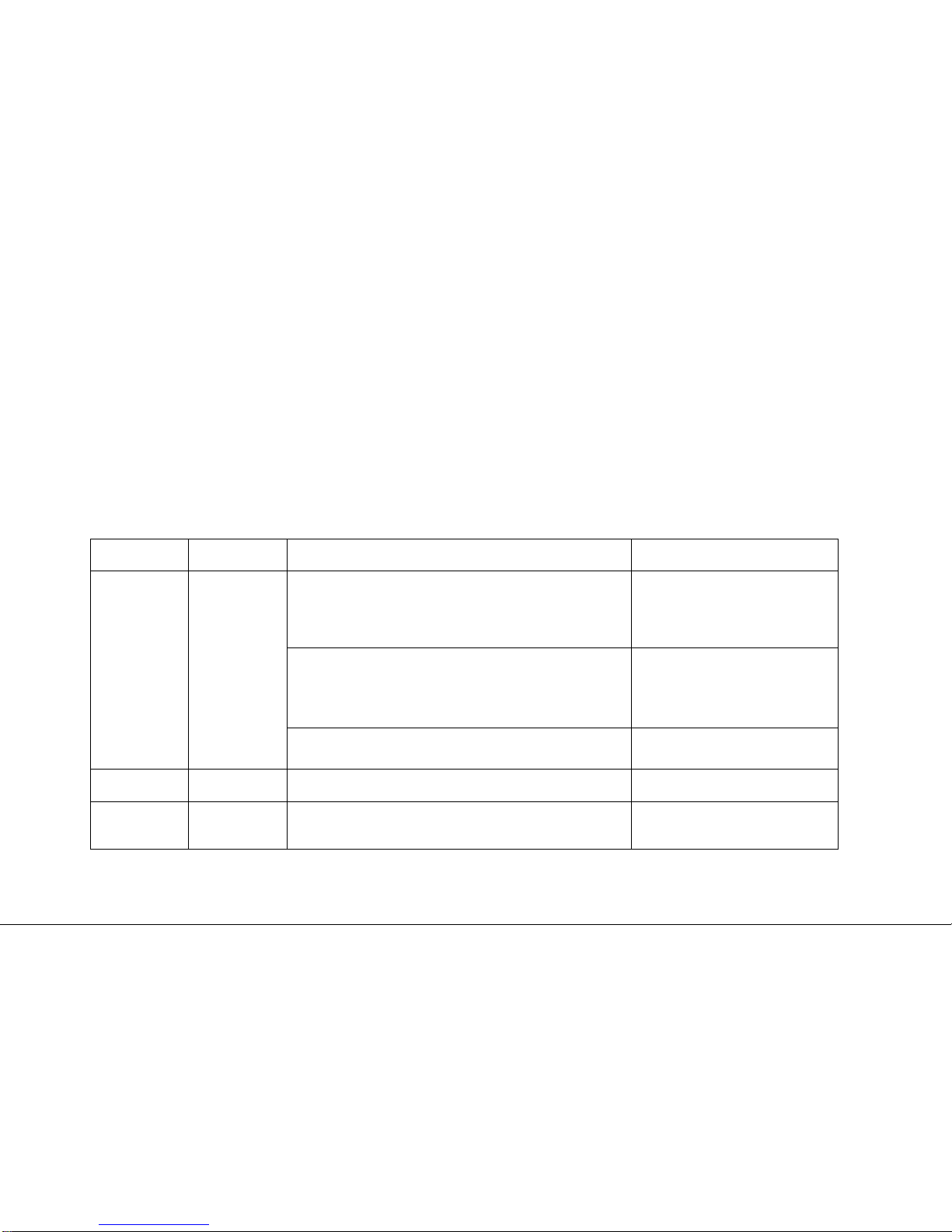

1.4 Protective Function & Display Code

If a treadmill stops suddenly, it means a protective function works properly. This is normal function to protect the treadmill. As the result of

protective function, a code indicating the cause of error is displayed on the display console or the display panel of Motor Controller (or Motor

Inverter) which is located under motor hood. Motor is driven directly by Motor Controller according to the command from the console.

If this protective function occurs, turn off the treadmill and then turn on the treadmill after 20 seconds even though the cause is eliminated. Even

though the cause is eliminated, the treadmill stop due to protective function will remain unsolved if you turn on the treadmill within 20 seconds after

turning off the treadmill.

Display

Code

Protective

Function Name

PROBABLE CAUSE or DESCRIPTION CORRECTIVE ACTION

Excessive current flows in Motor Controller. In other word, the

Motor Controller output current exceeds the rated current by more

than approximately 180%.

- The load is in abnormal condition like impact load.

- Reduce impact load or lubricate

between belt and deck

- A main circuit element is defective.

- The output is short

- Replace Motor Controller with new

one. - - Check the cables and wires

between motor and Motor Controller

are loose or if there is any short

between wires.

E04 Overcurrent

Overheated Motor Controller caused by worn or damaged belt and

deck.

Replace the deck or belt.

E05 Overload

An excessive load is applied to motor, which is judged by

detecting Motor Controller output current.

- Lubricate between belt and deck

E07 Overvoltage

Unexpected high voltage is detected at DC voltage of Motor

Controller.

- Input voltage of Motor Controller is too high.

- Check the input voltage fluctuates

abnormally.

- Don’t push the striding belt backward

14

- Regenerative energy from motor is too much. compulsorily by foot.

E60

Communication

Error

- External noise

- Trouble in internal memory due to or high temperature.

- Cable connection between MPU and Motor Controller

- Replace Motor Controller cable with

new one

- Replace Motor Controller with new

one

E09 Low voltage

Unexpected low voltage is detected at DC voltage of Motor

Controller.

- Input voltage of Motor Controller is too low.

- Instantaneous power failure

- Check the input voltage to treadmill.

- Connect the treadmill to dedicated

circuit.

- Supply stable power to treadmill

E34

Short-circuited

output

Excessive current flows in Motor Controller when the output of

Motor Controller is short

- Check the cables and wires between

motor and Motor Controller are loose

or if there is any short circuit between

wires.

E08 EEPROM

Trouble in internal EEPROM due to high temperature. A lot of

parameters are saved in the EEPROM.

- Make a service call.

E12

Tripped out due

to external input

signal

Failure caused intentionally by input terminal. It is not

implemented in the treadmill.

Replace the Motor Controller

E14 Ground fault trip

Grounding protection when an Motor Controller output line

dropped to earth. Current leaks from an output cable or the motor

to ground.

- Check the cables and wires from

Motor Controller are dropped to the

earth

The temperature of power module in Motor Controller is too high.

- Ambient temperature is too high.

- Do not place heat generating device

near the treadmill.

E21 Temperature trip

Overheated Motor Controller caused by worn or damaged belt and

deck.

Replace the deck or belt.

15

1.5 Lubrication Guide

Basically, initial lubrication is performed at factory, but the oil could be dried during transportation or stock in your warehouse.

As soon as you complete installing, please lubricate and then make sure that oil is enough or not as below.

1) Turn off treadmill.

2) Push the striding belt backward using your feet while holding the front handle bar or side handle bar.

3) You can judge whether the friction is enough or not by feeling the smooth move of the belt. Lubrication is needed if the belt is not pushed well.

z Lubricant prevents the belt and deck from being damaged by frictional heat, which extends life span of the deck and belt.

z Use the lubricant provided by Motus only. KF54 silicone fluid made from Shin-Etsu Chemical Co. Ltd.

How to manage automatic lubrication system (M990T, M990TL)

A certain amount of oil is lubricated automatically every lubrication interval which is preset at Manager Mode. Default lubrication amount and

lubrication interval are set up to, for instance, 30cc and 500km, respectively, which can be set at Manager Mode. Therefore, it is recommended that

fitness club manger set up the lubrication amount and interval according to club condition.

A volume of lubricant tank is about 270cc, and if residual amount of oil is less than 20%, the warning SYMBOL is displayed on the screen with a

beep. At that time, fill the tank as instructions below.

1) Turn OFF the treadmill and open motor hood.

2) Open the cap of oil tank by turning it with hand.

3) Fill the empty tank fully with the oil provided by Motus. Keep in mind that automatic lubrication system doesn’t work properly if oil is not filled full.

4) Close the cap of oil tank and put the motor hood in place.

5) Turn ON the treadmill. Message indicating oil lack will be still displayed on the screen with the beep.

6) To input “finishing oil-filling”, press buttons in the order as below.

16

‘INCLINE ▽’ -> ‘INCLINE △’ -> ‘SPEED ▽’ -> ‘SPEED △’ -> ‘ENTER’

Keep in mind that this step must be done after filling the tank fully.

7) The warning SYMBOL and beep disappears.

How to inject lubricant manually (M995T, M995TL)

To judge proper lubrication timing, you can feel the friction intensity by pushing the striding belt backward using your feet while holding the front

handle after turn OFF the treadmill.

1. Fill the lubricator with the oil Motus provided.

2. The conduction hole for the lubrication is at the right corner on the front of the treadmill as shown in the picture.

3. Insert the pipe tip of the lubricant to the end through the conduction hole to spread out the lubricant on the center of the belt.

4. Inject the lubricant into the conduction hole by squeezing the lubricator about 20 times under the belt speed of 4km.

The amount of 30 cc is recommended.

5. To spread out the lubricant all round on the belt, operate the treadmill for a few minutes.

6. Lubricate more than twice a month.

How to eliminate warning beep & symbol requiring lubrication (M995T, M995TL)

Although lubricant is not injected automatically, lubrication interval can be set up at Manager Mode, for instance, 500km. If the interval is too short or

long, you can adjust the interval at Manager Mode. Warning beep & symbol every lubrication interval makes you easy to lubricate without any need

to consider lubrication timing.

To reset the warning beep and symbol after completing manual lubrication, press buttons in the order as below.

‘INCLINE ▽’ -> ‘INCLINE △’ -> ‘SPEED ▽’ -> ‘SPEED △’ -> ‘ENTER’

The warning beep and SYMBOL disappear.

17

Numeric value 5 in management mode means interval of 500 km. If you exercise on treadmill at 8km/h for 10 hours a day, total distance a day is

80km and the warning beep and symbol appears every 6.25 days corresponding to 500 divided by 80.

The speed (8km/h) and workout duration for a day (10 hours) depend on the numbers of the users or utilization rate ay Gym.

18

Motus Treadmills M990T, M990TL, M995T and M995TL

SECTION II

HOW TO REPLACE & REPAIR GUIDE

General

2.1 How to Stabilize the Treadmill

2.2 How to Align Striding Belt

2.3 How to Adjust Striding Belt Tension

2.4 How to Adjust Motor Drive Belt Tension

2.5 How to Replace the Rear Roller

2.6 How to Replace the Front Roller

2.7 How to Replace the Striding Belt

2.8 How to Replace the Motor Drive Belt

2.9 How to Replace the DECK

2.10 How to Replace Drive Motor

2.11 How to Replace the Incline Motor

2.12 How to Replace the Oil Pump

2.13 How to Replace the Contact Heart Rate Sensor

19

2.1 How to Stabilize the Treadmill

Two front casters and two adjustable rear feet (or stabilizing leg) support the weight of both the

treadmill and a user exercising on it. The rocking motion or striding belt misalignment may be

caused when one of them is not resting on the floor.

1) Check if the treadmill is even on a solid and flat

surface. A BUBBLE LEVEL can be used to ensure

proper leveling. Determine which foot is not resting on

the floor.

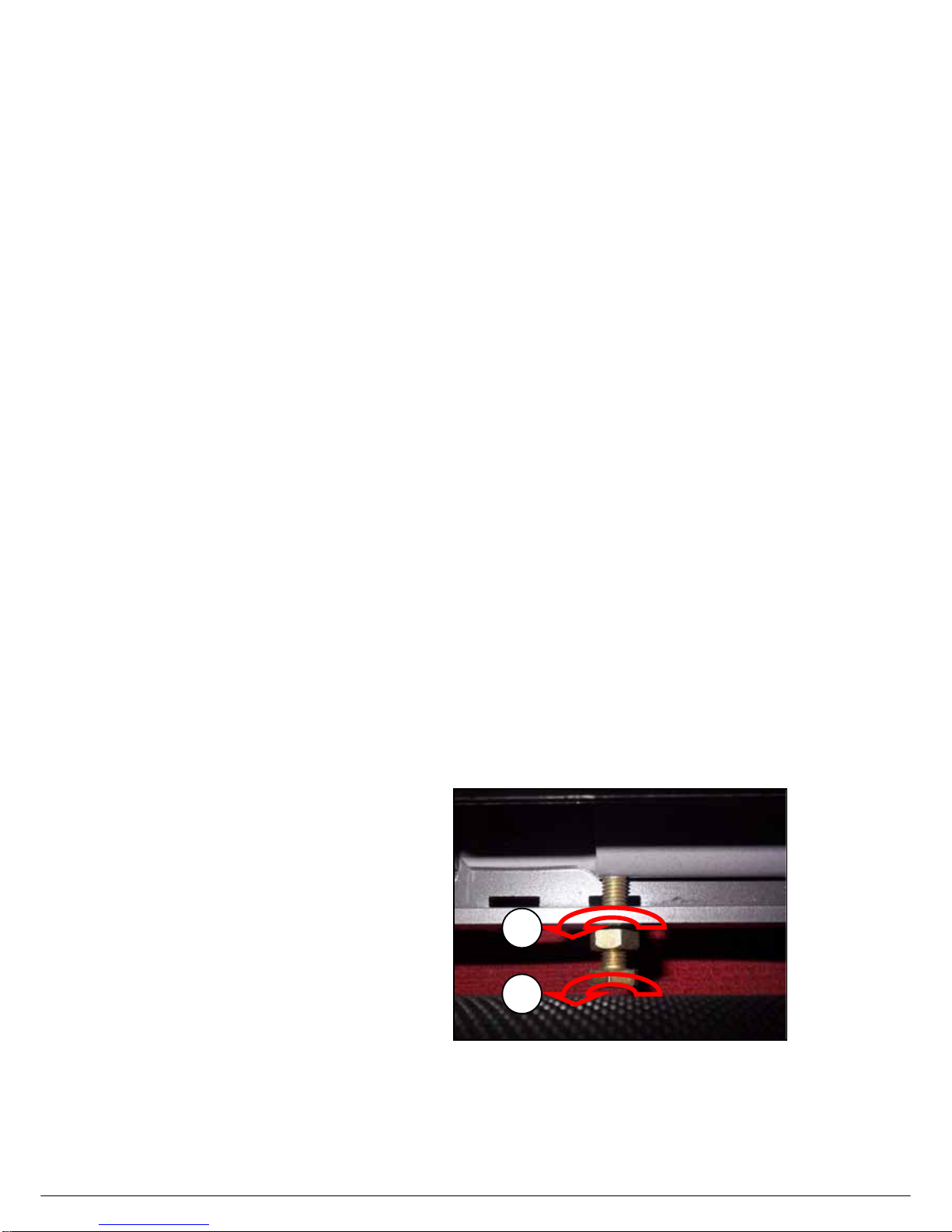

2) Loosen the nut on the top of adjustable foot by

turning it clockwise.

3) Once the nut is loosened, turn adjustable foot with

hand until the rocking motion ceases.

4) After leveling, turn the nut counterclockwise and

tighten it.

Note: Adjusting height must be done while rear

side of treadmill is lifted up. Do not adjust more than 1/4 of entire adjustable rear foot’s

height.

20

2.2 How to Align Striding Belt

The belt is properly aligned at the factory before shipment. However, while delivering or

exercising, the belt can be misaligned from the original center position. The correct alignment or

striding belt is critical to the smooth operation of the treadmill.

2.2.1 When the belt is off center to either right direction or left direction

1) Level and stabilize the treadmill prior to any alignments or tracking adjustments.

* The belt may move off center by using the treadmill on uneven surface.

2) Turn on the treadmill and then check if the belt drifts off center or not while treadmill is

operated with the speed of 5km/h for a few minutes.

3) Turn off the treadmill after keeping in mind whether the belt is off center to which direction, left

or right.

4) Make sure the striding belt has completely stopped.

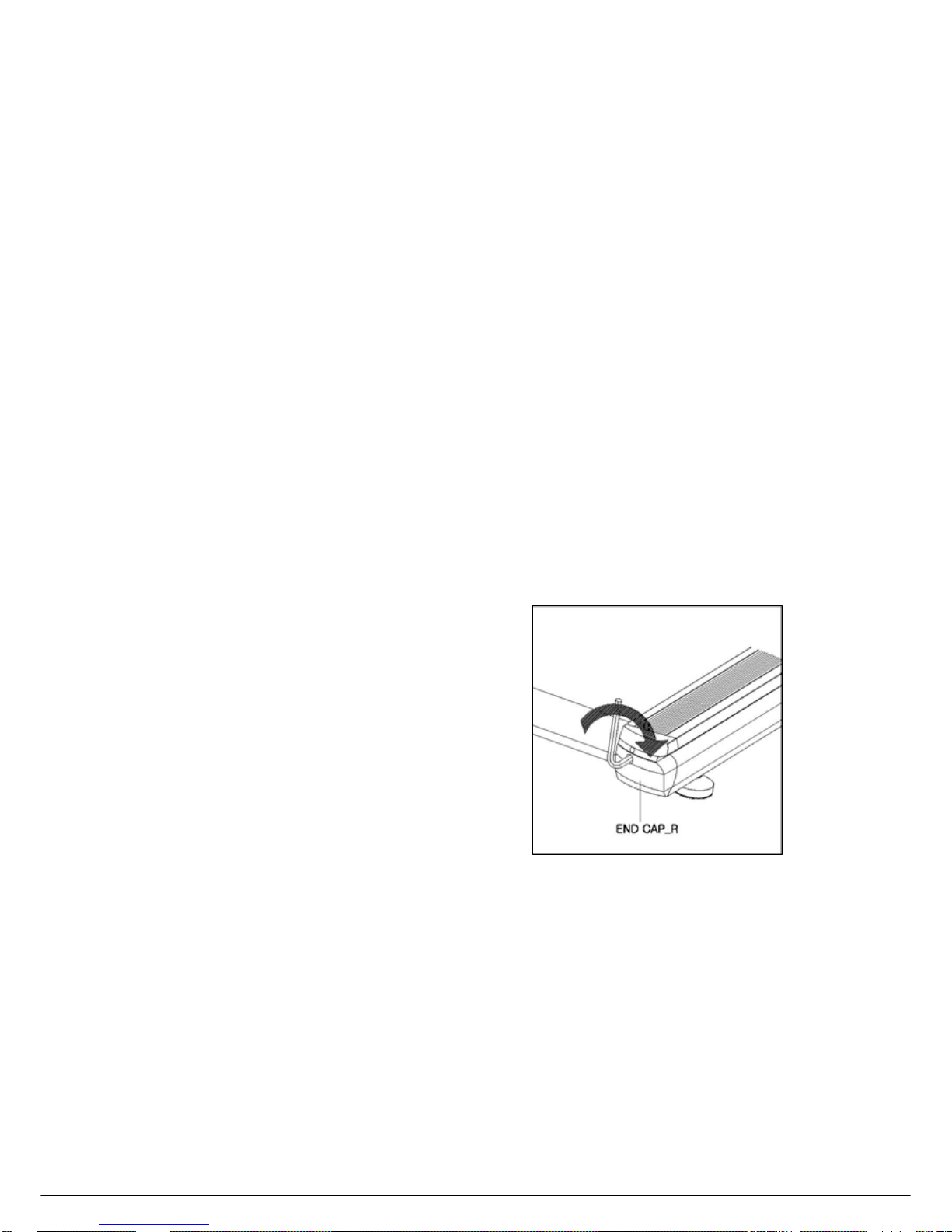

5) Find the right belt tensioning bolt in the rear end cap of the treadmill.

Make tracking adjustments using the 10 mm hex key

wrench provided as shown.

z If the belt is off center to the right, turn the right

adjusting bolt 1/4 turn clockwise, which brings the

striding belt back to the left.

z If the belt is off center to the left, turn the right

adjusting bolt 1/4 turn counterclockwise, which

brings the striding belt back to the right.

Note: Do not turn the adjusting bolt more than 1/4

at a time. Over-tightening the bolt can damage the

treadmill. Do not exceed one full turn of the adjusting bolts in either direction.

6) Turn ON the treadmill, press START/STOP, and then operate the treadmill with the speed of

5km/h.

7) Observe the striding belt for a few minutes. The belt should be centered on the deck.

8) If you need additional alignment, repeat step 2) through 7) of this procedure until the belt is

properly aligned.

CAUTION: If you hear any chafing, the belt is not center-aligned or the belt appears to be

21

getting damaged, stop the treadmill and contact authorized local dealer.

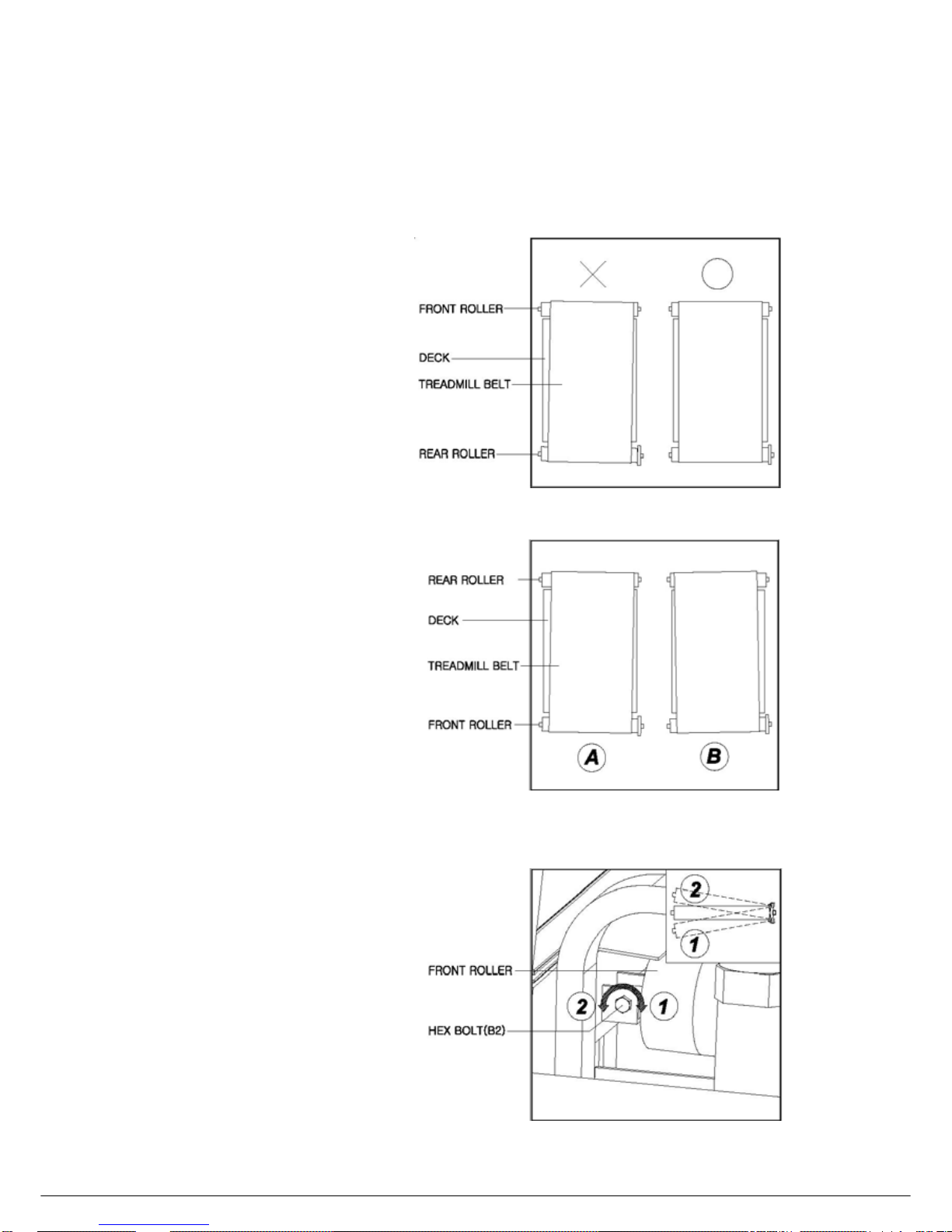

2.2.2 When the belt is diagonally tilted

When the Striding Belt is diagonally

tilted as shown, the Front Roller (F4)

needs to be aligned by following

steps.

1) Turn off the unit power at the

switch and then unplug the line cord

at wall outlet.

2) Remove three Motor Cover

screws (B20) and then lift the cover

(T1) out from between the upright Supports.

3) Turn the Hex Bolt (B2) in either

direction to compensate for the tilted

Striding Belt.

When the Striding Belt is tilted as

shown in A), turn the Hex Bolt (B2)

by 1/4 turn in the direction of (1).

When the Striding Belt is tilted as

shown in B), turn the Hex Bolt (B2)

by 1/4 turn in the direction of (2).

Note: Make adjustments in 1/4

turn.

The position of the Front Roller to be changed by the direction of the Hex Bolt (B2) is indicated

in the figure.

4) Re-assemble the Motor Cover in

the reverse order of removal and

make sure that the Striding Belt is

properly aligned after turning on the

unit power and operating it with the

speed of 5km/h for a few minutes..

5) Repeat this adjustment until the

Striding Belt is properly aligned.

22

2.3 How to Adjust Striding Belt Tension

Belt tension is properly adjusted before delivery. However, while exercising for a long time, the

tension can be loose. Belt tension is adjusted by moving the position of rear roller using the belt

tensioning bolt of END CAP.

Note: it is very important to keep belt’s tension constant to avoid belt slips during footfall

for user’s safety.

1) Turn on the treadmill, press START/STOP, and then operate the treadmill with the speed of

4km/h. Walk on the treadmill. Tightly grip the front handlebar and apply force with feet on the

striding near the motor cover against the moving direction. If the belt slips, do steps from 2). If it

does not slip, the tension is proper.

2) Stop the treadmill for a safety during adjustment and prepare 10mm wrench

Do not adjust tension while treadmill is in operation.

Warning: If you adjust the belt tension when the treadmill is in operation, it is very

dangerous because sleeve or a part of body may be caught in roller or belt.

3) Locate the two belt tensioning bolts in the end caps on each rear side of the treadmill as

shown, which enables to adjust belt tension. When turning this bolt, a position of roller moves

back and forth. To move

backward the roller, turn the

bolts clockwise. To move

forward the roller, turn the

bolts counterclockwise.

4) Put 10mm wrench into

the hole of the Right End

Cap as shown and then turn

the wrench 1/4 turn

clockwise.

5) Put 10mm wrench into the hole of the Left End Cap as shown and then turn the wrench 1/4

turn clockwise. Equal amount of rotations should be performed on right tensioning bolt and left

tensioning bolt. If not so, the belt is off center to either right direction or left direction.

6) Repeat steps 1) through 5) until the belt no longer slips.

Do not exceed one full turn of the adjusting bolts in either direction. Over-tightening of the bolts

may over stretch and damage the striding belt or roller bearings.

If the belt continues to slip in spite of the belt tension adjustment, verify that Drive Motor Belt

can be the cause of the slip.

23

2.4 How to Adjust Motor Drive Belt Tension

The tension of Motor Drive Belt (M3, Poly-V Belt) can be loosened by a long time use and it can

cause a slip between The Drive Motor Pulley and Motor Drive Belt. The tension is corrected by

adjusting the mounting position of the Drive Motor (M1).

Do the steps below while referring to the following Exploded Views in Appendix.

A.1 M990T

B.1 MAIN BODY_FRONT A

C.1 MAIN BODY_REAR

1) Stop the treadmill after lifting up the unit at maximum by operating Incline Motor.

2) Turn off the unit power at the switch at the state of the treadmill lifted-up and then unplug the

line cord at wall outlet.

3) Remove three bolts (B20) and then lift Motor Cover (T1) out from between the upright

Supports.

4) Loosen four nuts (N2) securing the Drive

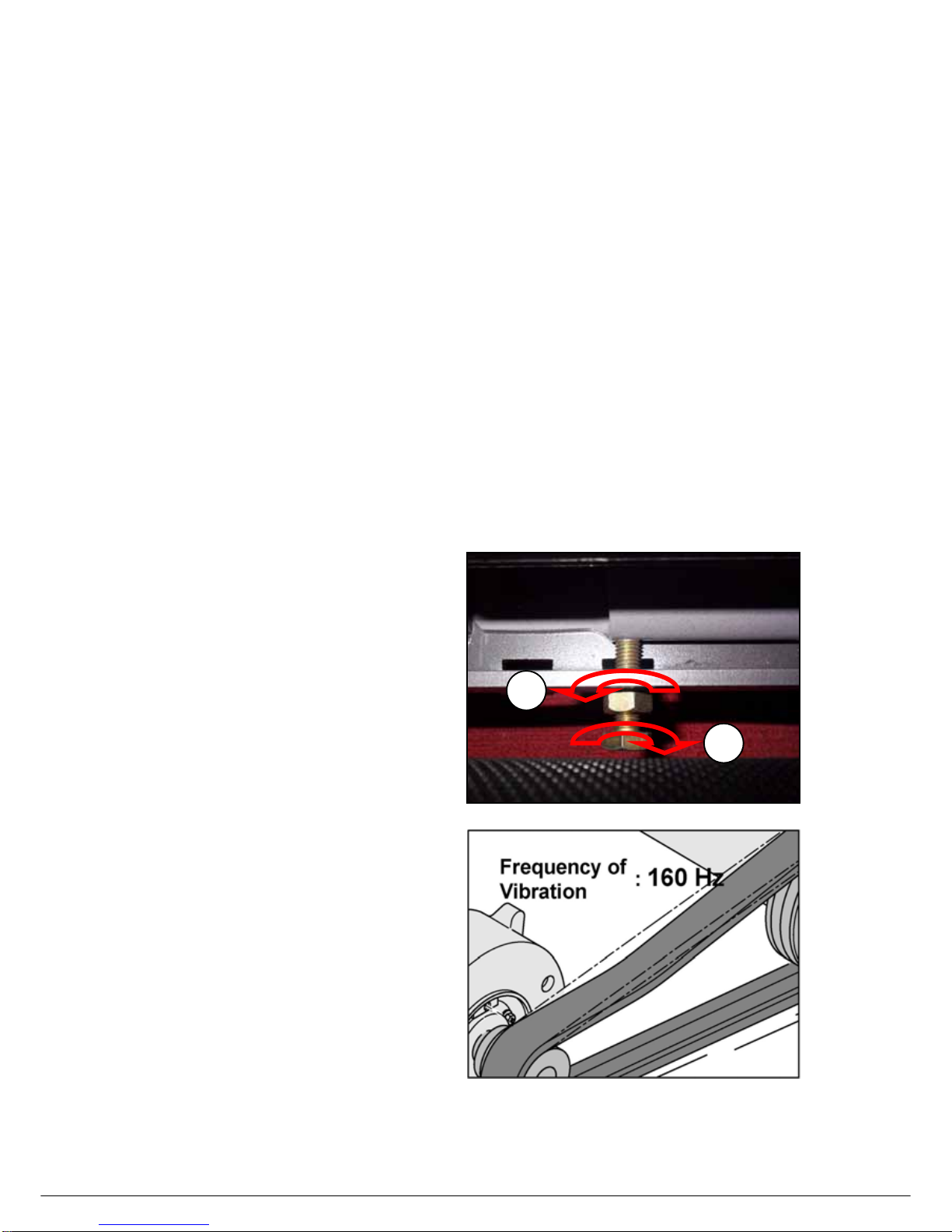

Motor (M1) by one or two turns to allow the

Drive Motor to be moved by the Tension

Bolt (B7).

5) Turn the nut (N3) in the direction of arrow

‘1” to allow adjusting the tension on the

Drive Motor Belt by using the Tension Bolt

(B7).

6) Turn the Tension Bolt (B7) in 1/4 turn in

the direction of arrow ”2” to move the Drive

Motor (M1) toward the outside of the unit,

and then measure the tension of the Belt..

Note: One turn of the Tension Bolt makes

the Drive Motor move by 1.5 mm. Keep in

mind that tightening the Tension Bolt too

much can damage the internal bearings

of the Drive Motor or Front Roller.

7) When the tension reaches 160 Hz,

secure two nuts (N2) diagonally.

Note: It is desirable to set the tension to

150Hz before tightening two nuts (N2)

24

because tightening two nuts (N2) increases the tension of the Motor Drive Belt.

8) Measure the Tension again. If the tension is lower than 155Hz or higher than 165Hz, re-

adjust the tension 4 through 8) until it reaches 155Hz to 165Hz.

9) When the tension reaches 160 Hz, tighten the nut (N3) securing the Tension Bolt (B7).

10) Tighten remaining two nuts (N2) diagonally.

11) Make sure that the nut (N3) securing the Tension Bolt (B7) is tightened.

12) Re-assemble remaining parts in the reverse order of removal.

25

2.5 How to Replace the Rear Roller

Do the steps below while referring to the following Exploded Views in Appendix.

A.1 M990T

B.1 MAIN BODY_FRONT A

C.1 MAIN BODY_REAR

1) Turn off the unit power at the switch and then unplug the line cord at wall outlet.

2) Remove three Motor Cover screws (B20) and then lift the cover(T1) out from between the

upright Supports.

3) Remove one bolt (B18) inside the left End Cap on the rear side of the unit and then remove

END CAP_L (F10) from the unit.

Remove one bolt (B18) inside the right End Cap on the rear side of the unit and then remove

END CAP_R(F11) from the unit.

4) Pull out two NONSLIP_PVC (F9) toward the rear side of the unit, which are inserted into the

left NONSLIP_TOP (F8) /NONSLIP SIDE_L(F6) and the right NONSLIP_TOP(F8)/NONSLIP

SIDE_R (F7).

5) Remove eight bolts (B13) and then remove the left NONSLIP_TOP (F8) /NONSLIP

SIDE_L(F6) and the right NONSLIP_TOP(F8)/NONSLIP SIDE_R(F7).

6) Remove two bolts (B1) and then remove REAR ROLLER (F5) out under the Striding Belt.

7) Install a new Rear Roller in the reverse order of disassembly.

8) Refer to “How to Align Striding Belt” and “How to Adjust Striding Belt Tension”.

26

2.6 How to Replace the Front Roller

Do the steps below while referring to the following Exploded Views in Appendix.

A.1 M990T

B.1 MAIN BODY_FRONT A

C.1 MAIN BODY_REAR

1) Stop the treadmill after lifting up the unit at maximum by operating Incline Motor.

2) Turn off the unit power at the switch at the state of the treadmill lifted-up and then unplug the

line cord at wall outlet.

3) Remove three bolts (B20) and then lift Motor Cover(T1) out from between the upright

Supports.

4) Remove one bolt (B18) inside the left End Cap on the rear side of the unit and then remove

END CAP_L (F10) from the unit.

5) Remove one bolt (B18) inside the right End Cap on the rear side of the unit and then remove

END CAP_R (F11) from the unit.

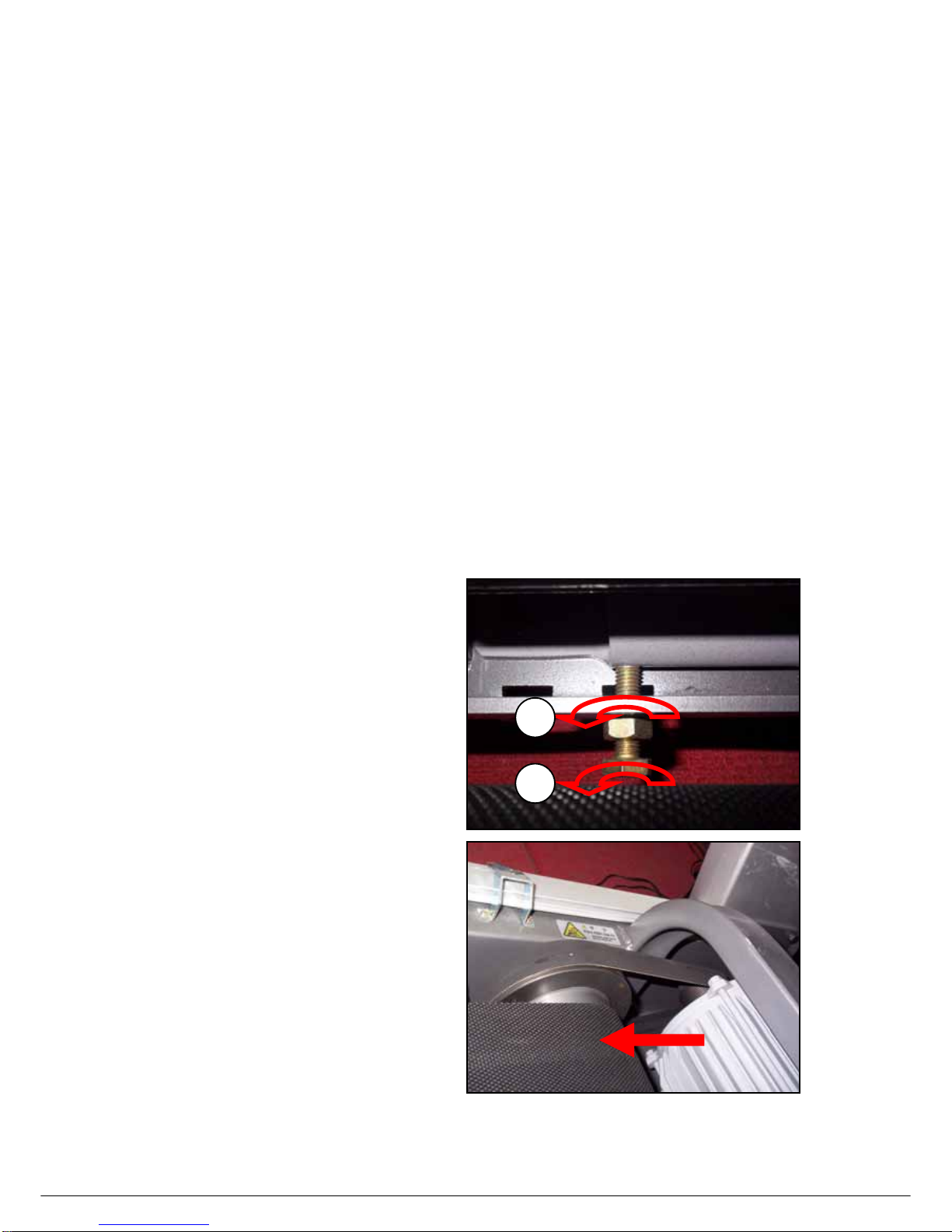

6) Loosen two bolts (B1) by turning it

counterclockwise to slacken the Striding

Belt enough to allow side-to-side movement

of the FRONT ROLLER (F4).

Count the number of rotations when

loosening the bolts (B1) for re-tensioning

the Striding Belt.

7) Loosen the nut (N3) securing Tension

Bolt (B7) for the Drive Motor Belt (M3) using

spanner as shown in arrow mark 1.

9) Loosen the Tension Bolt (B7) for the

Drive Motor Belt (M3) as indicated in arrow

mark 2 to allow the movement of the Drive

Motor (M1).

10) Loosen four nuts (N2) securing the

Drive Motor (M1) by one or two turns to

allow the Drive Motor to be moved by the

Tension Bolt (B7).

11) M o ve the D r ive Mo tor (M1) toward the

FRONT ROLLER to slacken the Drive Motor

27

Belt (POLY-V BELT).

12) Remove two bolts (B16, B2) securing the FRONT ROLLER (F4) and then remove the

FRONT ROLLER out from the left side of the frame, through the underside the Striding Belt.

Remove the DRIVE BELT (M3) out and save for a new Front Roller.

13) Install the new Front Roller and the Drive Motor Belt into position and secure in place with

the mounting bolt (B16, B2). Adjust the Front Roller to be in parallel with the Rear Roller and the

Drive Motor by using the right side bolt (B2).

14) Make sure that the Motor Drive Belt (M3) is positioned on the grooves of the Front Roller

Pulley and the grooves of the Drive Motor Pulley.

15) Adjust the Motor Drive Belt Tension while referring to “How to Adjust Motor Drive Belt

Tension”.

16) Install the REAR ROLLER and other parts in the reverse order of disassembly.

17) Refer to “How to Align Striding Belt” and “How to Adjust Striding Belt tension”.

28

2.7 How to Replace the Striding Belt

Do the steps below while referring to the following Exploded Views in Appendix.

A.1 M990T

B.1 MAIN BODY_FRONT A

C.1 MAIN BODY_REAR

1) Stop the treadmill after lifting up the unit at maximum by operating Incline Motor.

2) Turn off the unit power at the switch at the state of the treadmill lifted-up and then unplug the

line cord at wall outlet.

3) Remove three bolts (B20) and then lift Motor Cover (T1) out from between the upright

Supports.

4) Remove one bolt (B18) inside the left End Cap on the rear side of the unit and then remove

END CAP_L (F10) from the unit.

Remove one bolt (B18) inside the right End Cap on the rear side of the unit and then remove

END CAP_R (F11) from the unit.

5) Pull out two NONSLIP_PVC (F9) toward the rear side of the unit, which are inserted into the

left NONSLIP_TOP (F8)/NONSLIP SIDE_L (F6) and the right NONSLIP_TOP (F8)/NONSLIP

SIDE_R (F7).

6) Remove eight bolts (B13) and then remove the left NONSLIP_TOP (F8)/NONSLIP SIDE_L

(F6) and the right NONSLIP_TOP (F8)/NONSLIP SIDE_R (F7).

7) Remove two bolts (B1) and then remove REAR ROLLER (F5) out under the Striding Belt.

8) Loosen the nut (N3) securing Tension Bolt (B7) for the Drive Motor Belt (M3) using spanner

as shown in arrow mark “1”.

9) Loosen the Tension Bolt (B7) for the

Drive Motor Belt (M3) as indicated in

arrow mark “2” to allow the movement of

the Drive Motor (M1).

10) Loosen four nuts (N2) securing the

Drive Motor (M1) by one or two turns to

allow the Drive Motor to be moved by the

Tension Bolt (B7).

11) Move the Drive Motor (M1) toward the

FRONT ROLLER to slacken the Drive

Motor Belt (POLY-V BELT).

12) Remove two bolts (B16, B2) securing the FRONT ROLLER (F4) and then remove the

29

FRONT ROLLER out from the left side of the frame, through the underside the Striding Belt.

Remove the DRIVE BELT (M3) out and save for a new Front Roller.

13) Remove the eight mounting bolts (B13) and then remove the DECK (F2).

14) Position a new Striding Belt (F3) onto the center of the frame inside unit and then install the

saved DECK (F2) by tightening the eight mounting bolts (B13).

15) Install the new Front Roller and the Drive Motor Belt into position and secure in place with

the mounting bolt (B16, B2). Adjust the Front Roller to be in parallel with the Rear Roller and the

Drive Motor by using the right side bolt (B2).

16) Make sure that the Motor Drive Belt (M3) is positioned on the grooves of the Front Roller

Pulley and the grooves of the Drive Motor Pulley.

17) Adjust the Motor Drive Belt Tension while referring to “How to Adjust Motor Drive Belt

Tension”.

18) Install the REAR ROLLER and other parts in the reverse order of disassembly.

19) Refer to “How to Align Striding Belt” and “How to Adjust Striding Belt tension”.

Loading...

Loading...