Page 1

www.GenesisAutomationOnline.com

Series ZD / ZA / ZR 330 – 644

High Speed Position Counters and

Differential Counters with two Encoder Inputs

• Electronic counter series for high-end applications

• Two independent encoder inputs, each with channels A, /A, B, /B ,

1 MHz of counting capability and individual impulse scaling facility

• Selectable operating modes for fast position or event counter, summing counter,

differential counter, cutting length indicator, diameter calculator and more

• 4 preset levels with high-speed power transistor outputs

• RS232 interface and high-speed analogue output available, RS485 (only ZR)

• Choice of 6-decade display (15 mm, 0.56’’) or 8-decade display (10 mm, 0.36’’)

Operating Instructions

ZD340_07d_e.doc / Apr-17 Page 1 / 50

3046 Home Road. Powell, OH 43065 P: (740) 917-5781 F: (740) 917-5791 www.GenesisAutomationOnline.com Sales@GenesisAutomationOnline.com

Page 2

Safety Instructions

Version:

Description:

• This manual is an essential part of the unit and contains important hints about

function, correct handling and commissioning. Non-observance can result in

damage to the unit or the machine or even in injury to persons using the

equipment!

• The unit must only be installed, connected and activated by a qualified electrician

• It is a must to observe all general and also all country-specific and application-

specific safety standards

• When this unit is used with applications where failure or maloperation could cause

damage to a machine or hazard to the operating staff, it is indispensable to meet

effective precautions in order to avoid such consequences

• Regarding installation, wiring, environmental conditions, screening of cables and

earthing, you must follow the general standards of industrial automation industry

• - Errors and omissions excepted –

General instructions for cabling, screening and grounding can be found in the

SUPPORT section of our website http://www.motrona.com

ZD34001b/Mai06/hk/kk/af First edition

ZD34002a/Jul06/af/hk Extended modes of operation

ZD34003a/Aug06/hk Models ZA_xxx and models xx_330 included

ZD34003c/May06/af/hk Analogue output assignment, Preset calculation, Serial appendix

ZD34003d/Feb08/hk Motrona version with small corrections and modifications

ZD34005a/Sept08/hk Dual counter mode (mode 10), small corrections

ZD34005b/Dec08/hk Several amendments, additional clarifications

ZD34007a/Dec10/kk/hk Parameter "Display Update Time", correction of default values, amendments,

serial codes added to parameter lists

ZD34007b/Jan12/sm Additions for using Namur sensors and type definitions

ZD34007c/June12/pp Corrected images in chapter 1 and 7.2

ZD34007d/April17/cn Control Commands update

ZD340_07d_e.doc / Apr-17 Page 2 / 50

Page 3

Table of Contents

1. Available Models................................................................................................................4

2. Introduction.........................................................................................................................6

3. Electrical Connections.........................................................................................................7

3.1. Power Supply ...................................................................................................................9

3.2. Auxiliary Outputs for Encoder Supply..............................................................................9

3.3. Impulse Inputs for Incremental Encoders ........................................................................9

3.4. Control Inputs Cont.1 – Cont.4 ........................................................................................9

3.5. Switching Outputs K1 – K4............................................................................................10

3.6. Serial Interface ..............................................................................................................10

3.7. Fast Analogue Output ....................................................................................................10

4. Operating Modes of the Counter.......................................................................................11

4.1. “Single Mode” (Encoder 1 only): F07.062 = 0 ...............................................................12

4.2. “Sum Mode” (Encoder 1 + Encoder 2): F07.062 = 1 ......................................................13

4.3. Differential Mode (Encoder 1 – Encoder 2): F07.062 = 2 ..............................................14

4.4. Master Counter and Integrated Batch Counter: F07.062 = 3 ........................................15

4.5. Evaluation of the Real Cutting Length: F07.062 = 4 ......................................................16

4.6. Diameter Calculation with Winding Rolls: F07.062 = 5 ................................................17

4.7. Radius Calculation with Winding Rolls: F07.062 = 6 ....................................................18

4.8. Cut-to-Length Control Counter: F07.062 = 7 or 8 ..........................................................19

4.9. Monitor for Slip, Torsion, Skew Position, Shaft Fracture: F07.062 = 9.........................21

4.10. Dual Counter, Two Independent Counters for Encoders 1 and 2: F07.062 = 10 ..........22

5. Keypad Operation .............................................................................................................23

5.1. Normal Operation ..........................................................................................................23

5.2. General Setup Procedure...............................................................................................23

5.3. Direct Fast Access to Presets ........................................................................................24

5.4. Change of Parameter Values on the Numeric Level .....................................................25

5.5. Code Protection against Unauthorized Keypad Access ................................................26

5.6. Return from the Programming Levels and Time-Out Function ......................................26

5.7. Reset all Parameters to Factory Default Values ...........................................................26

6. Menu Structure and Description of Parameters ................................................................27

6.1. Summary of the Menu ...................................................................................................27

6.2. Description of the Parameters.......................................................................................30

6.3. Clarification of the Counter Setting Functions ..............................................................39

7. Appendix for models ZD 6xx and ZA 6xx ...........................................................................40

7.1. Relay Outputs.................................................................................................................40

7.2. Front Thumbwheel Switches .........................................................................................40

7.3. Specific Parameters for Units with Thumbwheel Switches .........................................41

8. Appendix: Serial Communication Details ..........................................................................43

8.1. Setup of the Counter by PC............................................................................................43

8.2. Automatic and Cyclic Data Transmission......................................................................44

8.3. Communication Protocol................................................................................................44

8.4. Serial Register Codes ....................................................................................................46

9. Specifications...................................................................................................................48

10. Dimensions....................................................................................................................... 49

ZD340_07d_e.doc / Apr-17 Page 3 / 50

Page 4

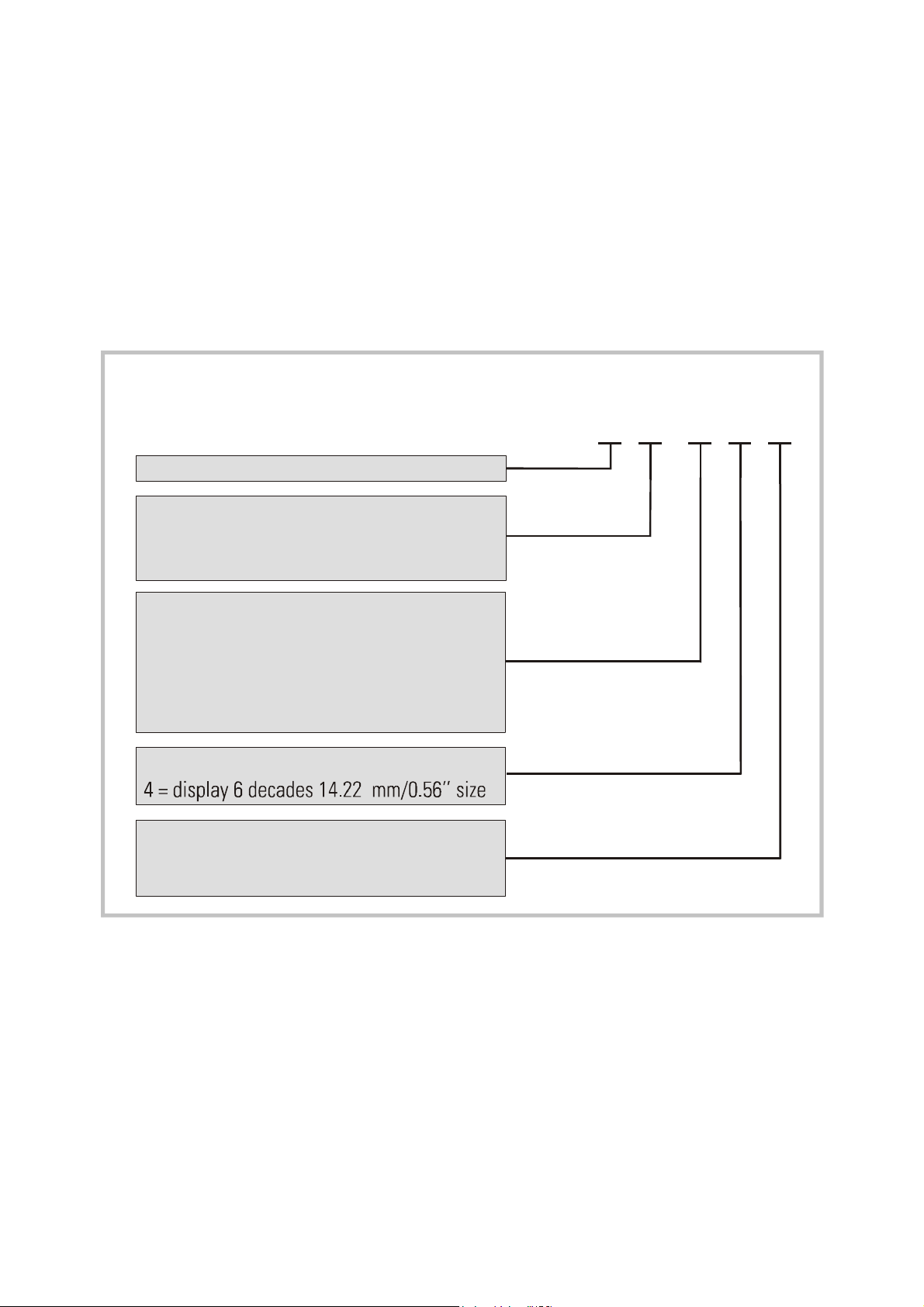

1. Available Models

2 = two thumbwheel sets (4 decade each)

4 = four thumbwheel sets (4 decade each)

ZD 330

The ZD, ZA and ZR counter series include a range of models with similar functions and

properties, but with different housings, displays and outputs.

ZA counters provide an additional high-speed analogue output which is not available with the

ZD or ZR models. However the ZR models have an additional RS485 interface, but otherwise all

details between ZD, ZA and ZR models are fully similar.

The following table explains the details of type designation and the possible options:

Z = electronic counter

D = display only, no analogue output

A = display and high-speed analogue output

R = display and RS-485 interface

3 = housing 96 x 48 mm (3.780 x 1.890’’)

and 4 high-speed transistor outputs

6 = housing 96 x 96 mm (3.780 x 3.780’’)

with 4 high-speed transistor outputs

and 4 relay outputs

3 = display 8 decades 9.15 mm/0.36’’ size

0 = no thumbwheel switches on front

ZD340_07d_e.doc / Apr-17 Page 4 / 50

Page 5

The following models are available:

ZD 330, ZA 330, ZR 330 ZD 340, ZA 340, ZR 340

ZD 630, ZA 630, ZR 630

ZD 632, ZA 632, ZR 632

ZD 640, ZA 640, ZR 640

ZD 642, ZA 642, ZR 642

ZD 634, ZA 634, ZR 634

ZD 644, ZA 644, ZR 644

Number and combination of front thumbwheels according to customer specification, see section 7.2

ZD340_07d_e.doc / Apr-17 Page 5 / 50

Page 6

2. Introduction

The counters of series ZD, ZA and ZR have been designed to close a gap with multiple counting

applications, which cannot be accomplished by the normal industrial electronic counters

available on the market.

A continual demand for increasing production speeds and higher precision at the same time

results in counting frequencies exceeding the conventional frequency range.

Particularly with fast running procedures it is most important to also have fast response of the

switching outputs or the analogue output.

Many applications require to evaluate the signals of two incremental measuring systems, and

to compare the results with respect to the sum or the difference or the ratio of the two

positions. This is e.g. necessary for calculation of diameters of winding rolls etc.

Still there exist applications where the use of traditional thumbwheel switches offers real

advantages compared to keypad and menu operations.

These are some of the reasons why the new counter series ZD, ZA and ZR have been designed.

• This manual at first provides all basic instructions for operation of the

counter models presented in the previous chapter

• For operation of relay outputs and thumbwheel switches (if applicable)

please observe the supplementary instructions given in the appendix

• For easy PC setup and PC communication with ZD and ZA counters, please

use our “OS32” operator software (free of charge, download from our

homepage www.motrona.com

• Where you like to have free serial access to the unit by PLC or IPC or by a

remote operator terminal, please observe the serial protocol details

described in our separate manual “Serpro”

• Subsequently the manual uses the expression ZD340 as a replacement for

all available models. However, statements are fully valid for the other

models too, except where especially remarked.

ZD340_07d_e.doc / Apr-17 Page 6 / 50

Page 7

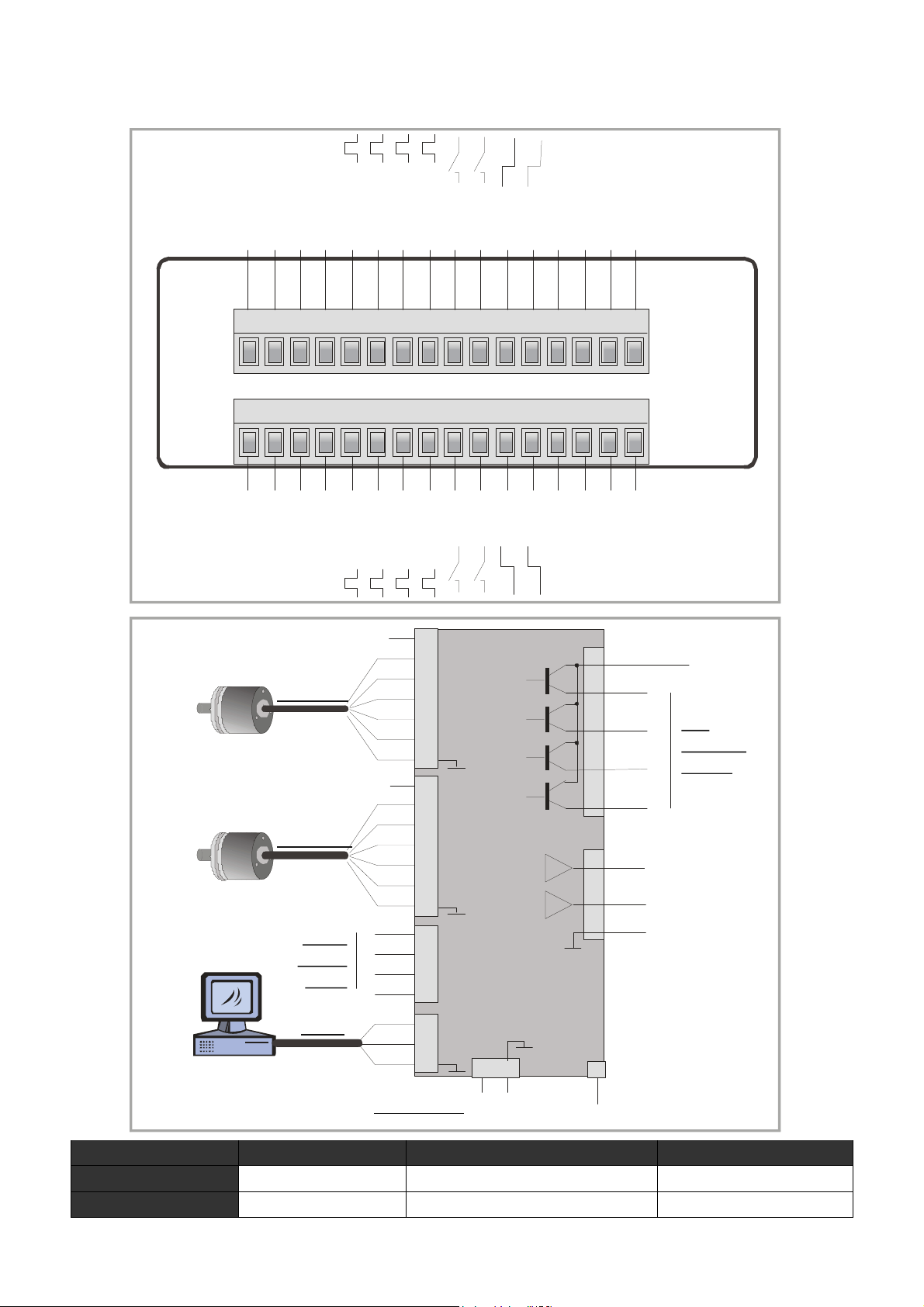

3. Electrical Connections

Series "

ZD"Series "

ZA"Series "

ZR"*) Interface 1:

*) Interface 2:

GND

GND

Encoder2 /A

Encoder2 /B

E ncoder1 /A

Encoder1 /B

RxD (RS232)

K4 out

PROG

Cont. 3

Interface 2*)

Interface 1*)

1 2 3 4 5 6 7 8 9 10

X1

17

18 19 20

X2

+Vin

+5,2V aux.out +5,2V aux. out

Encoder1*

*) Examp le shows wiring

for encod ers with 5 v olts

power supply and RS422

line drive r output

Encoder 2*

GND

+24V aux.out + 24V aux. out

Digital

Control

Inputs

RS232

21 22

Encoder 2 B

23

Encoder2 A

+24

+5

/A

+24

+5

/A

Cont1

Cont2

Cont3

Cont4

RxD

TxD

GND

11 12

24

25 26

Encoder1 B

Encoder1 A

19

18

A

24

8

B

23

/B

7

-

20

3

2

A

22

6

B

21

/B

5

-

4

28

27

12

11

14

30

31

27

K2 out

K1 out K3 out

17

1

13

28 29 30 31 32

Cont . 1

Cont. 2 Cont. 4

14

Com+ (K1-K4)

15 16

GND

T xD (RS232)

Co m+ (K1 - K4)

29

K1 out

26

K2 out

25

10

K3 out

9

K4 out

16

15

32

0V, GND

13

GND

Fast

transistor

outputs

Inte rface 2 *)

Inte rface 1 *)

+

-

Power supply

∼ ∼

24 V DC

24 V AC

PROG

- n.c. - Analogue output 0/4 - 20 mA RS 485, B (-)

- n.c. - Analogue output +/- 10 V RS 485, A (+)

ZD340_07d_e.doc / Apr-17 Page 7 / 50

Page 8

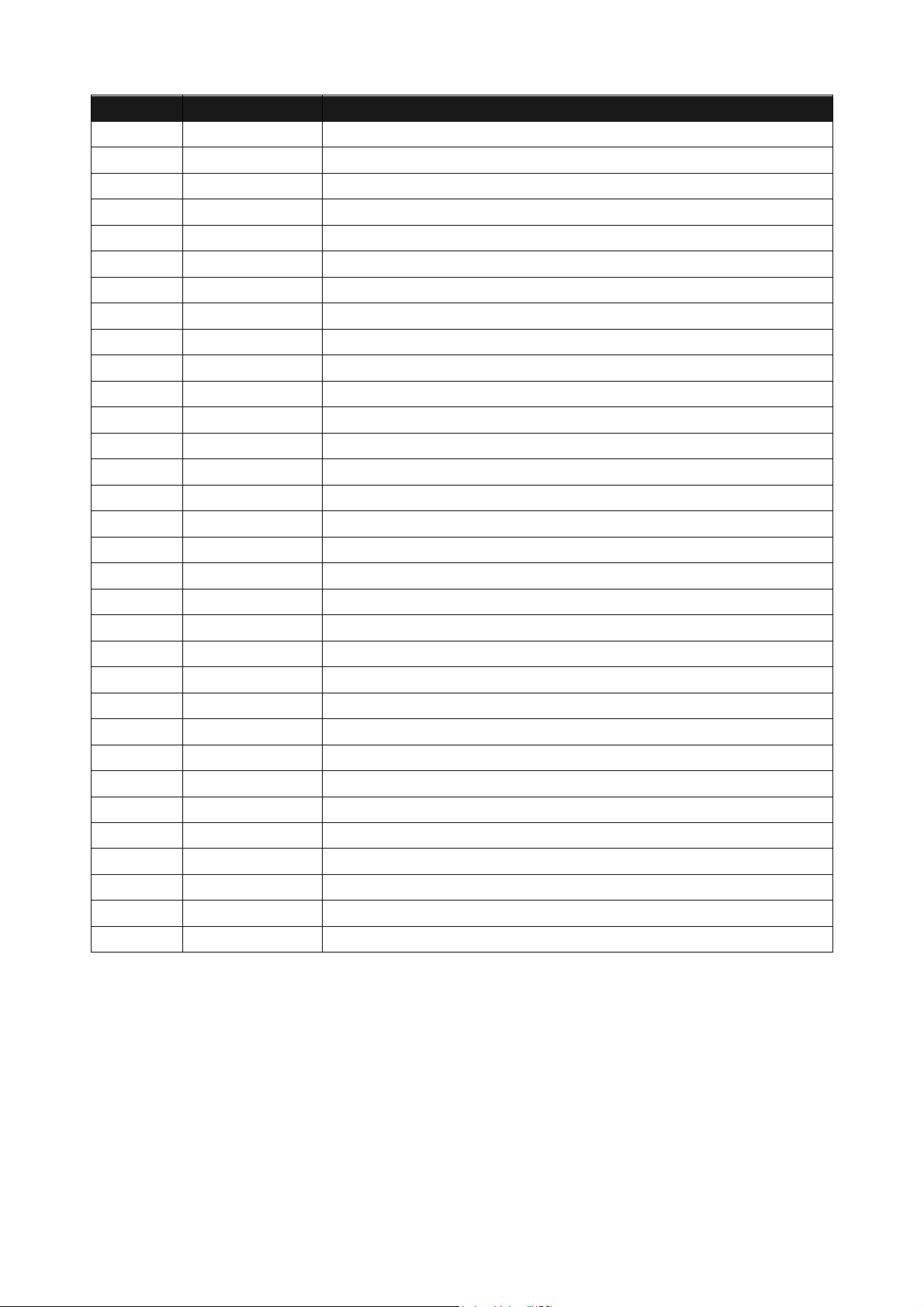

Terminal

Name

Function

01

GND

Common Ground Poten

tial (0V)

02

+5,2V out

Aux. output 5.2V/150 mA for encoder supply

03

+24V out

Aux. output 24V/120 mA for encoder supply

04

GND

Common Ground Potential (0V)

05

Encoder 2, /B

Encoder 2, channel /B (B inverted)

06

Encoder 2, /A

Encoder 2, channel /A (A

inverted)

07

Encoder 1, /B

Encoder 1, channel /B (B inverted)

08

Encoder 1, /A

Encoder 1, channel /A (A inverted)

09

K4 out

Output K4, transistor PNP 30 volts, 350 mA

10

K3 out

Output K3, transistor PNP 30 volts, 350 mA

11

Cont.4

Digital control input

12

Cont.3

Digital control input

13

(PROG)

(for download of new firmware only, not for general use)

14

RxD

Serial RS232 interface, input (Receive Data)

15

Ana.out 20 mA

Analogue current output 0

–

20 mA or 4

–

20 mA (optional)

16

Ana.out +/

-

10V

Analog

ue voltage output

-

10V … 0 … +10V (optional)

17

+Vin

Power supply input, +17

–

40 VDC or 24 VAC

18

+5,2V out

Aux. output 5,2V/150 mA for encoder supply

19

+24V out

Aux. output 24V/120 mA for encoder supply

20

GND

Common Ground Potential (0V)

21

Enc

oder 2, B

Encoder 2, channel B (non

-

inverted)

22

Encoder 2, A

Encoder 2, channel A (non

-

inverted)

23

Encoder 1, B

Encoder 1, channel B (non

-

inverted)

24

Encoder 1, A

Encoder 1, channel A (non

-

inverted)

25

K2 out

Output K2, transistor PNP 30 volts, 350

mA26K1 out

Output K1, transistor PNP 30 volts, 350 mA

27

Cont.2

Digital control input

28

Cont.1

Digital control input

29

Com+ (K1

-

K4)

Common positive input for transistor outputs K1

-K430

TxD

Serial RS232 interface, output (Transmit Data)

31

GND

Co

mmon Ground Potential (0V)

32

GND

Common Ground Potential (0V) for DC or AC power supply

*) 120 mA and 150 mA are per encoder, i.e. total maximum currents are 240 mA and 300 mA

ZD340_07d_e.doc / Apr-17 Page 8 / 50

Page 9

3.1. Power Supply

The ZD340 counter accepts both, a 17 – 40 volts DC power or a 24 volts AC power for supply

via terminals 17 and 1. The current consumption depends on the level of the input voltage and

some internal conditions; therefore it can vary in a range from 100 – 200 mA (aux. currents

taken from the unit for encoder supply not included).

3.2. Auxiliary Outputs for Encoder Supply

Terminals 2 and 18 provide an auxiliary output with approx. +5.2 volts DC (300 mA totally).

Terminals 3 and 19 provide an auxiliary output with approx. +24 volts DC (240 mA totally)

3.3. Impulse Inputs for Incremental Encoders

All input characteristics of the impulse inputs can be set by the parameter menu, for each of

the encoders separately. Depending on the application the unit can accept single channel

information (input A only) or quadrature information (A / B, 90°). The following settings are

possible:

• Symmetric input (differential) according to RS422 standard (min. differential voltage 1 V)

• TTL inputs at a level of 3.0 to 5 volts (differential, with inverted signal)

• TTL inputs at a level of 3.0 to 5 volts (single-ended) *)

• HTL signals at a 10 – 30 volts level

(alternatively differential with inverted signals A, /A, B, /B, or single-ended A, B only)

• Impulses from photocells or proximity switches etc. providing a HTL level (10 – 30 volts)

• Proximity switches according to NAMUR (2-wire) standard have an input level of 5,8V

respectively 19,4V. For a save crossover point set the threshold setting of the used input

to the value 200. *)

All encoder input lines are internally terminated by pull-down resistors ( 8,5 kΩ ).

Where encoders with pure NPN outputs are used, corresponding pull-up resistors must be

available inside the encoder or externally to ensure proper function (1 kΩ ... 3,3 kΩ).

3.4. Control Inputs Cont.1 – Cont.4

These inputs can be configured for various remote functions like Reset, Set, Latch, and Inhibit

or switch-over purpose.

All control inputs require HTL level. They can be individually set to either NPN (switch to -) or

PNP (switch to +) characteristics. For applications where edge-triggered action is needed, the

menu allows to set the active edge (rising or falling). Control inputs also accept signals with

Namur (2-wire) standard. For reliable operation the minimum pulse width on the control inputs

should be 50 µsec.

*) requires special settings of the threshold parameters, see “Special parameters F04”

ZD340_07d_e.doc / Apr-17 Page 9 / 50

Page 10

3.5. Switching Outputs K1 – K4

RS 232

RS 485

ZD340 provides four presets and outputs with programmable switching characteristics.

K1 – K4 are fast-switching and short-circuit-proof transistor outputs with a switching capability

of 5 – 30 volts / 350 mA each. The switching voltage of the outputs must be applied remotely

to the Com+ input (terminal 29)

3.6. Serial Interface

The serial RS232 and RS485 interface can be used for the following purposes:

• Set-up of the unit by PC (if desirable), by means of the OS32 PC software

• Change of parameters during operation

• Readout of actual counter or other values by PLC or PC

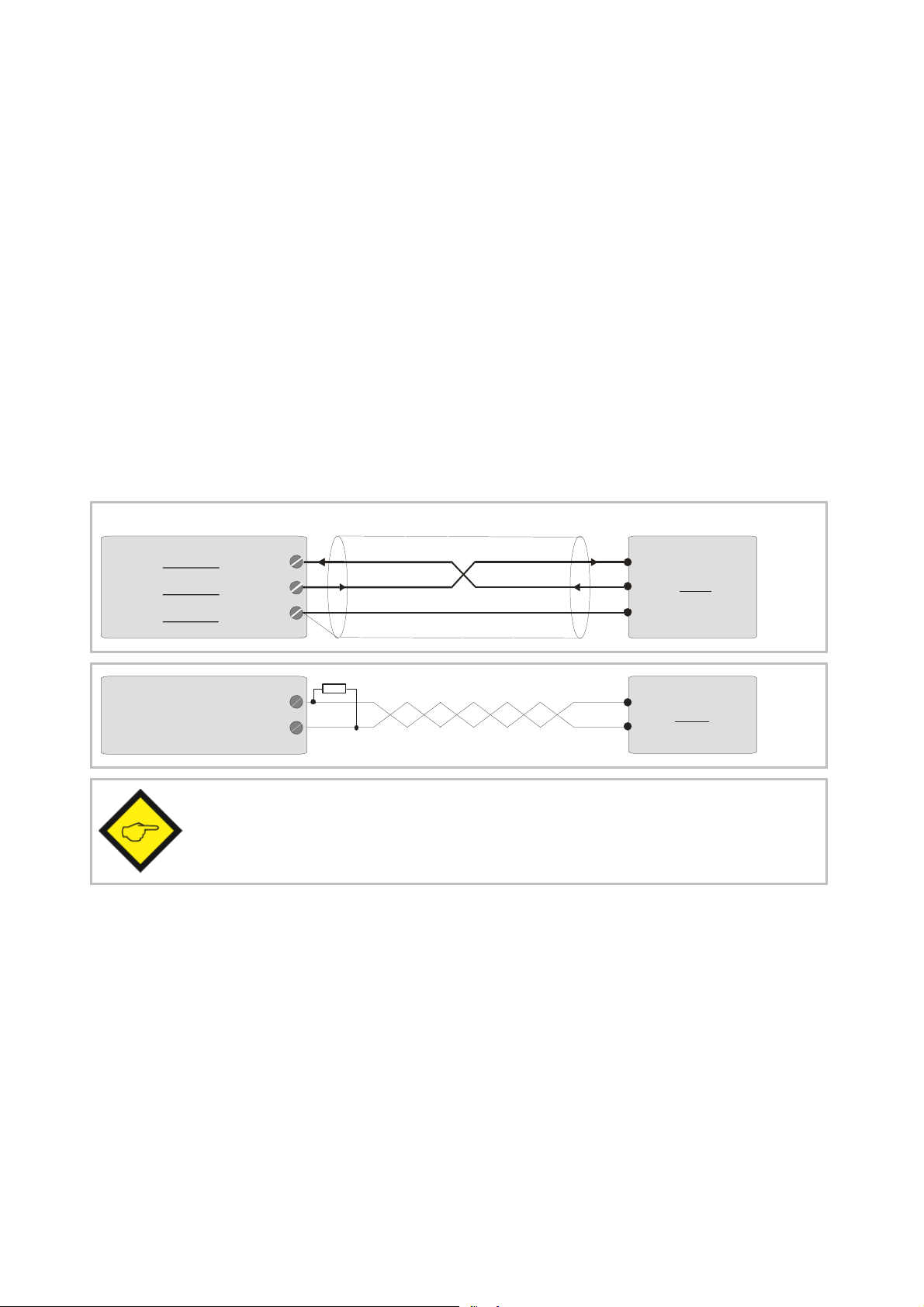

The figure below explains the connection between the ZD340 counter and a PC using the

standard Sub-D-9 serial connector, and the connection via RS485 terminals to a PLC.

For details of serial communication, please refer to section 10.

ZD 340

ZA 340

ZR 340

ZR 340

14

30

31

16

15

Where both, RS232 and RS485 interface are in use, you can communicate by the one or

by the other, but not by both interfaces at the same time

RxD RxD

TxDTxD

GND

Screen

A(+)

B(-)

2

PC

3

(Sub-D-9)

5

A

PLC

B

3.7. Fast Analogue Output

An analogue output is available with all ZA models, providing a voltage output of +/- 10 volts

(Load = 3 mA), and a current output of 0 – 20 mA or 4 – 20 mA (load = 0 – 270 Ohms). All output

characteristics like beginning of conversion range, output swing etc. are freely programmable

via menu. The response time of the analogue output is less than 1 msec. (time from encoder

event to analogue out). The resolution is 14 bits.

Please note that extensive serial communication with the unit may temporary increase the

analogue response time.

ZD340_07d_e.doc / Apr-17 Page 10 / 50

Page 11

4. Operating Modes of the Counter

Operating Mode

0

Single counter mode, encoder 1 only

1

Summing counter mode (encoder 1 + enc

oder 2)

2

Differential counter mode (encoder 1

-

encoder 2)

3

Master counter and batch counter

4

Display of the actual cutting length with cutting "on the fly" applications

5

Roll diameter calculation with winding rolls

6

Roll radius calculation with

winding rolls

7

Cut-to-length control (with deletion of residual errors)

8

Cut-to-length control (with consideration of residual errors)

9

Control of slip, torsion, skew position, shaft fracture etc.

10

Dual counter, two independent counters for encode

r 1 and encoder 2

•

For best survey, all parameters of the unit are arranged in 13 expedient groups, named

“F01” - “F13”. Depending on the application, only a few of these groups may be important,

while all other groups may be irrelevant for your specific application.

This section describes possible applications and operating modes of the counter.

The operation mode can be set under parameter group F07, parameter # F07.062.

The following counting functions are available:

Counter Function

F07.062

It is possible to cycle the display between the five reading modes shown in

the following function tables, by pressing one of the front keys or by using

one of the control inputs (you must have assigned the display scroll function

to one of the keys or the inputs under menu F06, to activate the scrolling of

the display). LEDs L1 and L2 indicate which of the values is actually displayed.

• Scrolling of the display from one reading mode to another will not affect the

function of the preselection outputs K1 – K4

• The analogue output (models ZA) can be assigned to any of the readings

accessible in the display, by a special parameter. Scrolling of the display from

one reading mode to another will not affect the analogue output.

• As far as the selected counter mode also allows reading out the minimum and

maximum values or the positions of the last change of direction, please note

that the unit latches these extreme values in time periods of 1 msec. only.

Therefore the display of memorized extreme positions may include some

inaccuracy with high counting frequencies (real extreme value may lie

between two records)

Full details about parameter arrangement and function can be found under section 6.

ZD340_07d_e.doc / Apr-17 Page 11 / 50

Page 12

All operating modes provide separate impulse scaling factors for each of the two

Display

L1 (red)

L2 (yellow)

1

Actual counter value

----2

Minimum value since last reset

blinking fast

--3Maximum value since last reset

--

blinking fast

4

Position of last change of direction (up and low)

blinking slow

--5Only lower poin

t of change of direction (F04.030 = 0)

--

blinking slow

encoders. Please observe that the display of the counter will only show whole

numbers (integers) whereas remainders will be carried in the background

Example: Differential Counter:

Encoder1

1000

Impulses

Impulse Scaling

Factor1

x 0,98765 minus

967,65000 - 2469,12000 = -1501 0,47000

Encoder2

2000

Impulses

Impulse Scaling

Factor2

x 1,23456

Display

Remainder

(background)

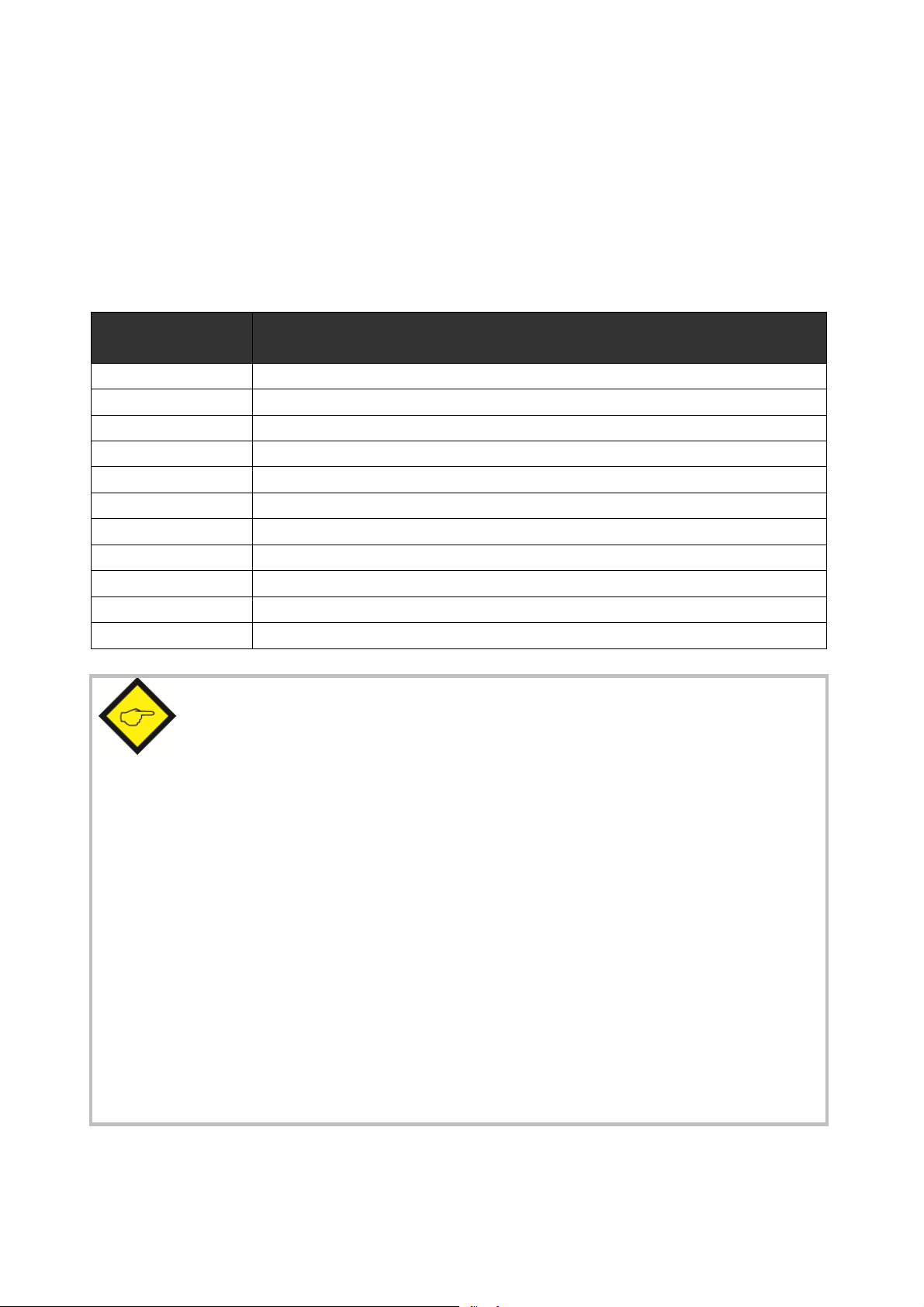

4.1. “Single Mode” (Encoder 1 only): F07.062 = 0

Only the inputs of encoder 1 are active, signals on the encoder 2 inputs will not be evaluated.

Besides the actual counter value, the unit also records minimum and maximum values as well

as the last positions of change of direction.

All 4 presets are related to the actual counter value.

Only upper point of change of direction (F04.030 = 1)

or

Typical applications:

- fast preset counter

- position counter with m emorized

points of change of direction

- event counter, incrementing or decreme nting

1 2 3 4 5 6

Encoder 1

Cont.1

Reset, Preset, Inhibit etc.

Cont.4

ZD340_07d_e.doc / Apr-17 Page 12 / 50

Page 13

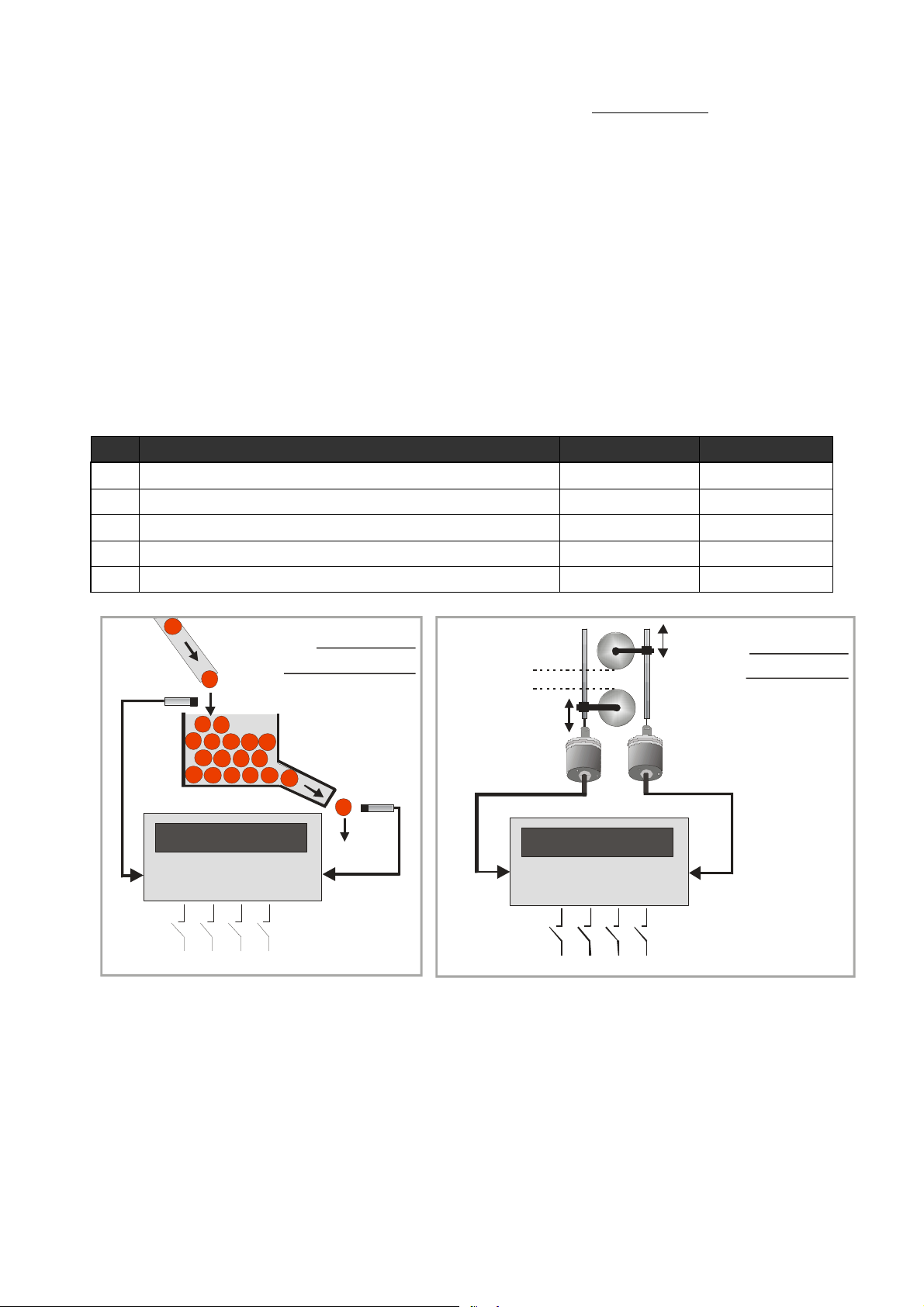

4.2. “Sum Mode” (Encoder 1 + Encoder 2): F07.062 = 1

Display

L1 (red)

L2 (yellow)

1

Actual sum encoder 1 + encoder 2

----2

Minimum value of the sum (since last reset)

blinking fast

--3Maximum value of the sum (since last reset)

--

blinking fast

4

Actual counter value of encoder 1 alone

blinking slow

--5Actual counter value of encoder 2 alone

--

blinking slow

Both inputs encoder 1 and encoder 2 are active. From both values the unit forms the sum, with

consideration of the individual encoder scaling factors. Where the encoder signal also provides

direction information, this information will be considered by a corresponding sign of the count.

Without direction information (channel A only) both encoder values will be added up. The final

result can once more be scaled into user-friendly engineering units by means of the special

scaling parameters in parameter group F07.

Besides the actual counter value and the sum, the unit also records minimum and maximum

values of the sum.

Presets K1 and K2 are related to the actual counter value of encoder 1 only.

Presets K3 and K4 are related to the actual sum result (encoder 1 + encoder 2)

1 2 3 4 5 6

+

Encoder 1

Cont.1

Reset, Pres et, Inhibit etc.

Encoder 2

Cont.4

Sum of two

event counts

+

s = s0 + s1 + s2

s0

Two-stage

hydraulic cylinder

1 2 3 4 5 6

Encoder 1

Reset, Preset, Inhibit etc.

Cont.1

s1

Encoder 2

Cont.4

s2

Sum of two

positions

ZD340_07d_e.doc / Apr-17 Page 13 / 50

Page 14

4.3. Differential Mode (Encoder 1 – Encoder 2): F07.062 = 2

Display

L1 (red)

L2 (yellow)

1

Actual difference encoder 1

-

encoder 2

----2

Minimum value of the differ

ence (since last reset)

blinking fast

--3Maximum value of the difference (since last reset)

--

blinking fast

4

Actual counter value of encoder 1 alone

blinking slow

--5Actual counter value of encoder 2 alone

--

blinking slow

Both inputs encoder 1 and encoder 2 are active. From both values the unit forms the difference,

with consideration of the individual encoder scaling factors.

Where the encoder signal also provides direction information, this information will be

considered by a corresponding sign of the count. Without direction information (channel A only)

encoder 1 will increment and encoder 2 will decrement the counter. The final result can once

more be scaled into user-friendly engineering units by means of the special scaling parameters

in parameter group F07.

Besides the actual counter value and the difference, the unit also records minimum and

maximum values of the difference.

Presets K1 and K2 are related to the actual counter value of encoder 1 only.

Presets K3 and K4 are related to the actual differential result (encoder 1 - encoder 2)

1 2 3 4 5 6

Encoder 1

Cont.1

+

Reset, Pres et, Inhibit etc.

Difference of

two event counts

Encoder 2

Cont.4

-

Gapw idth d = s1 - s2

d

s1

1 2 3 4 5 6

Encoder 1

Cont.1

Reset, Preset, Inhibit etc.

Encoder 2

C ont. 4

s2

Difference of

two positions

ZD340_07d_e.doc / Apr-17 Page 14 / 50

Page 15

4.4. Master Counter and Integrated Batch Counter: F07.062 = 3

Display

L1 (red)

L2 (yellow)

1

Actual counter value of batch counter

----2

Minimum value of batch counter (since last reset)

blinking fast

--3Maximum value of batch counter (since last reset

)--blinking fast

4

Actual counter value of master counter (encoder 1)

blinking slow

--5Actual counter value of batch counter

--

blinking slow

This counter mode can be used for cut-to lengths applications, cyclic production flows, packing

procedures etc. While the master counter takes care of the correct number of impulses per

product, the background batch counter counts the number of products produced.

This mode assumes that the automatic reset function has been activated for the master

counter, providing restart from zero every time the preset value has been reached.*)

Only the inputs of encoder 1 are active (master counter).

Every time the master counter reaches its preset value, it restarts from zero and the batch

counter increments by 1. ***)

The batch counter can be decremented by separate external signal, when one of the keys or

control inputs has been defined correspondingly. **)

Besides the master counter and the batch counter, the unit also records minimum and

maximum values of the batch count.

Presets K1 and K2 are related to the actual counter value of encoder 1.

Presets K3 and K4 are related to the actual value of the batch counter.

*) Example: If 500 impulses on encoder 1 are necessary for 1 product:

a. Set F01.000 to 500 (preset level 1)

b. Set F10.089 = 1.00 sec. (output pulse time K1)

c. Set F10.097 = 2 or 4 (automatic restart from 0)

**) Select parameter group F06 and assign the special command “13” to any of the keys or

control inputs for remote decrementing of the batch counter

***) As a matter of course the counting sense can also be reversed, i.e. the main counter

loads a preset value, counts down towards zero, increments the batch counter when

reaching zero and sets to the preset value again

ZD340_07d_e.doc / Apr-17 Page 15 / 50

Page 16

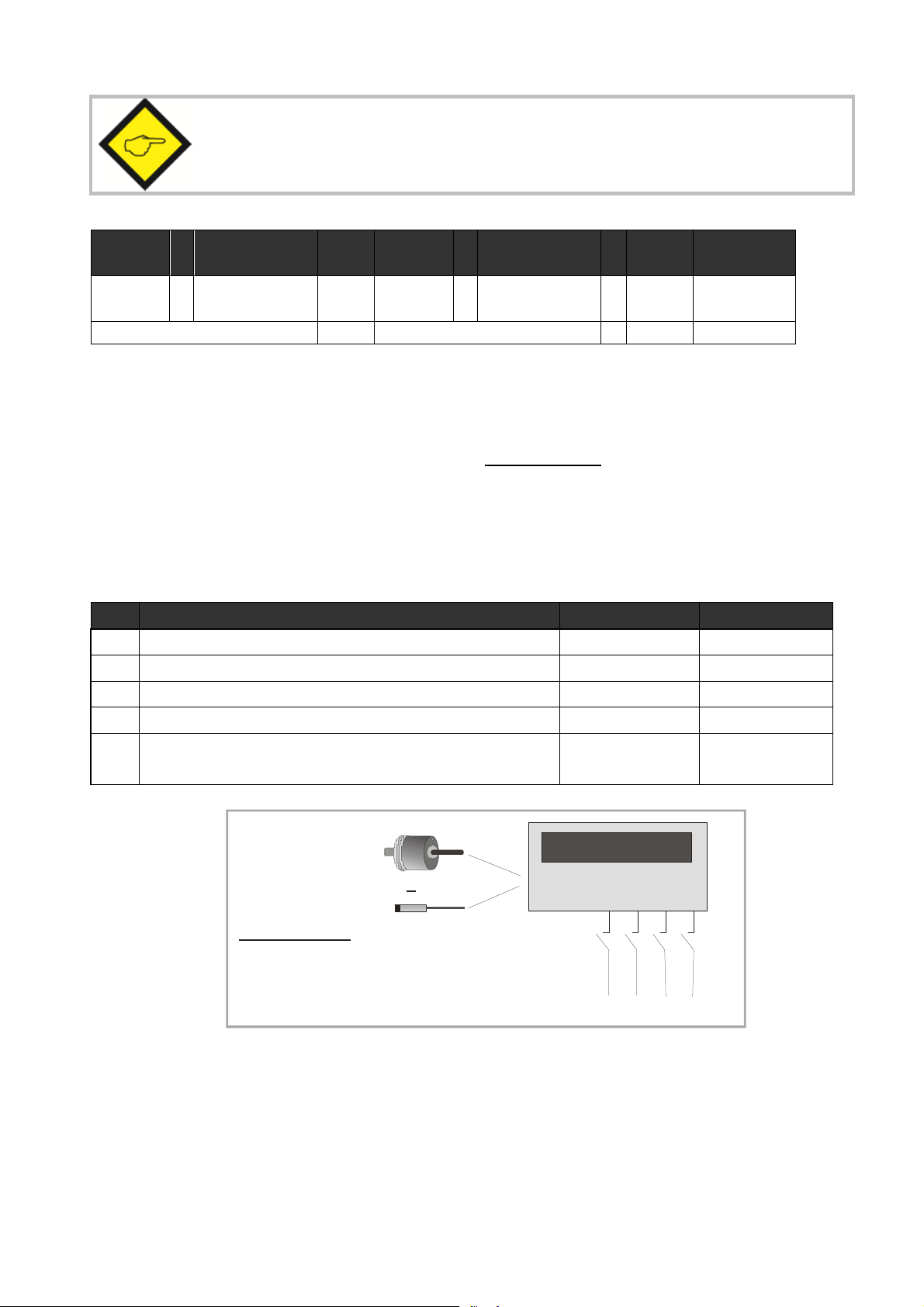

4.5. Evaluation of the Real Cutting Length: F07.062 = 4

Display

L1 (red)

L2 (yellow)

1

Last

actual cutting length (frozen)

----2

Minimum length (since last reset)

blinking fast

--3Maximum length (since last reset)

--

blinking fast

4

Actual background counter (live)

blinking slow

--5Last actual cutting length (frozen)

--

blinking slow

This mode uses encoder 1 as a length counter and encoder 2 is not active. All counting occurs

in the background and is not visible in the display. The counter gets started and stopped by

remote control signals, and the final counting result appears in the display (frozen) whilst the

counter already executes the next cycle in the background.

For remote start and stop signals the inputs Cont.1 and Cont.2 must be used, therefore these

inputs are no more available for other purpose. All assignments of the signals and the active

edges (rising or falling) can individually be set to match with the actual measuring situation.

Examples:

- use the rising edge of the Cont1 input to latch and reset, This will display your cutting

length as shown in the picture below.

- Use Cont1 to start the measuring cycle and Cont2 to stop and latch. This will display the

differential length between the two remote signals

- Use the same signal in parallel to Cont1 and Cont2. This e.g. allows to measure a gap or

distance between two products, while the remote signal is high (or low)

This mode is useful to get information about the actual cutting length with applications like

Rotary Cutters, Flying Shears and similar procedures. The automatic reset function is

automatically on in order to ensure that the next measuring cycle will restart at zero.

Besides the actual cutting length the unit also records the extreme length values (minimum and

maximum) of all cuts.

Presets K1 and K2 are related to the actual counter value of encoder 1 (live background

counter). Presets K3 and K4 are related to the real cutting lengths shown in the frozen display.

Therefore K3 and K4 can be used for quality sorting purpose (e.g. too short – good – too long)

Measuring of the

real cutting length

Measuring wheel

Cutting pulse

ZD340_07d_e.doc / Apr-17 Page 16 / 50

1 2 3 4 5 6

Encoder 1

Cont .1

Page 17

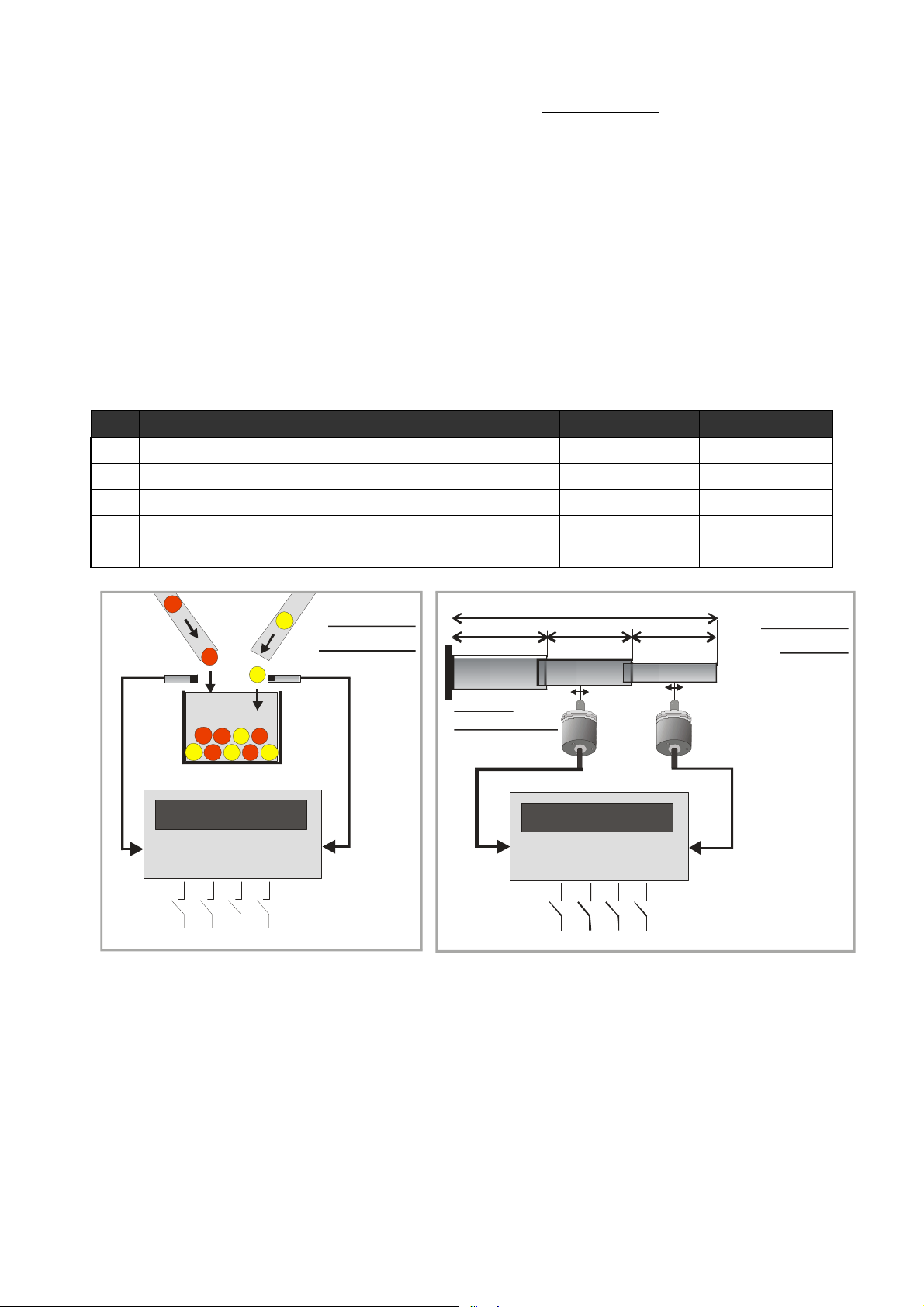

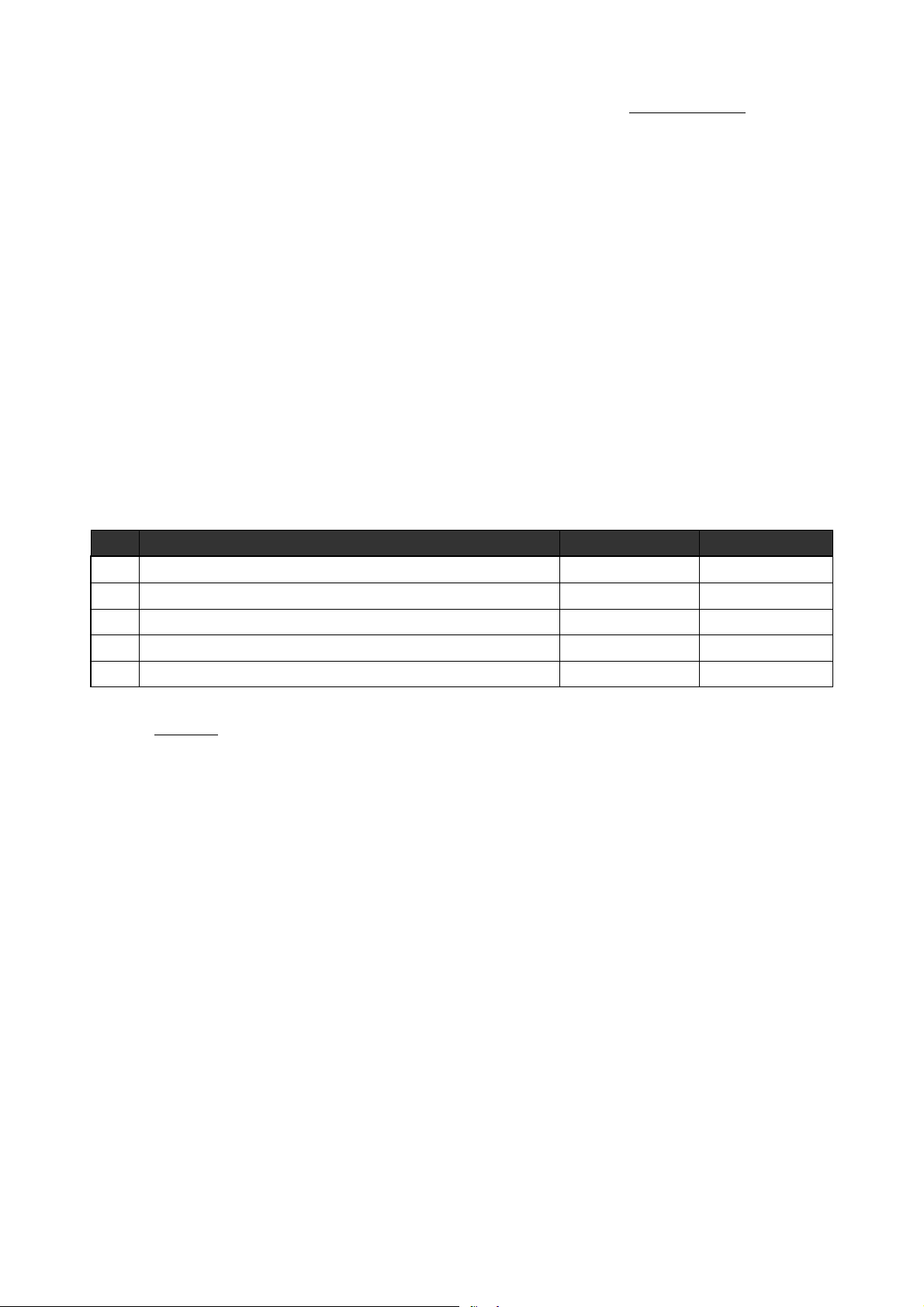

4.6. Diameter Calculation with Winding Rolls: F07.062 = 5

Display

L1 (red)

L2 (yellow)

1

Actual roll diameter

----2Minimum diameter (since last reset)

blinking fast

--3Maximum diameter (since last reset)

--

blinking fast

4

Actual value of the line counter

blinking slow

--5Last counting result of the line counter

--

blinking slow

With this mode encoder 1 receives line impulses from a measuring wheel or a feed roll of a

winder or unwinder application. Furthermore the counter needs one trigger impulse from the

rotation of the winding roll. From both signals the counter can calculate and display the actual

roll diameter. All counting occurs in the background and only updated diameter readings appear

in the display. Encoder 2 is not in use with this application.

The scaling parameters F07.066 and F07.067 are automatically set to the appropriate values

with this application. Parameter F07.068 allows setting a core diameter.

When set to zero, the display will show the full roll diameter.

When set to a core diameter, the display will show the remaining material diameter

(full diameter – core diameter).

Besides the total material length and the actual diameter the unit also records the extreme

diameter values (minimum and maximum) coming up during the process.

Presets K1 and K2 are related to the actual line counter of encoder 1 (total material length

under the measuring roll).

Presets K3 and K4 are related to the actual diameter value of the winding roll.

1 2 3 4 5 6

Encoder 1

feed roll

Cont.1

roll impulse

Calculation of the

diameter of a

winding roll

Display =

count / rev.

0.31416

ZD340_07d_e.doc / Apr-17 Page 17 / 50

Page 18

4.7. Radius Calculation with Winding Rolls: F07.062 = 6

Display

L1 (red)

L2 (yellow)

1

Actual roll radius

----2

Minimum radius (since last reset)

blinki

ng fast

--3Maximum radius (since last reset)

--

blinking fast

4

Actual value of the line counter

blinking slow

--5Last counting result of the line counter

--

blinking slow

With this mode encoder 1 receives line impulses from a measuring wheel or a feed roll of a

winder or unwinder application. Furthermore the counter needs one trigger impulse from the

rotation of the winding roll. From both signals the counter can calculate and display the actual

radius of the roll. All counting occurs in the background and only updated diameter readings

appear in the display. Encoder 2 is not in use with this application.

The scaling parameters F07.066 and F07.067 are automatically set to the appropriate values

with this application. Parameter F07.068 allows setting a core radius.

When set to zero, the display will show the full radius of the roll.

When set to a core radius, the display will show the remaining radius of the material

(full radius – core radius).

Besides the total material length and the actual radius the unit also records the extreme radius

values (minimum and maximum) coming up during the process.

Presets K1 and K2 are related to the actual line counter of encoder 1 (total material length

under the measuring roll).

Presets K3 and K4 are related to the actual radius value of the winding roll.

1 2 3 4 5 6

Encoder 1

feed roll

Cont.1

roll impulse

Calculation of the

radius of a

winding roll

Display =

count / rev.

0.62832

ZD340_07d_e.doc / Apr-17 Page 18 / 50

Page 19

4.8. Cut-to-Length Control Counter: F07.062 = 7 or 8

Preset

Function

Explanation

Thumbwheel 1

Tool Width

Compensates the cutting length setting by the

Thumbwheel 2

Cutting Length

Desired t

otal length of the piece to cut

Preset register

Pre-Stop

Anticipation distance where the speed changes

Preset register

Correction Stop

Correction of the ov

ershoot distance which the drive

The cut-to-length function described here requires the use of a counter model possessing at

least two front thumbwheel switches.

Modes 7 and 8 serve for control of cut-to-length applications with line drives providing a fast –

slow – stop speed profile. The table below explains which functions are assigned to the

thumbwheels and preset registers

width of the saw blade or cutting tool

F01.004

from high to low before reaching the final position.

(keypad entry)

F01.005

produces when changing from low speed to stop

(keypad entry)

Preselection registers K1 to K4 (F01.000 to F01.003) are not available for any settings, since this

application uses the same registers for calculations and intermediate results.

With operation mode F07.062 set to 7, the counter starts from zero and counts up until reaching

the value of “Cutting Length plus Tool Width”. With operation mode F07.062 set to 8, the start

signal presets the counter to the negative value of the Tool Width, from where the counter

counts up until it reaches “Cutting Length”

All other functions are fully similar with these two modes.

This mode provides display of the actual position only and also the analogue output (if

applicable) is assigned to the actual counter value.

Start command

1 2 3 4 5 6

En co der 1

ZD340_07d_e.doc / Apr-17 Page 19 / 50

Out2

Out3

Out4

Measuring wheel

En coder

A, B

Run command

Fast /Slow select

Rea dy to cu t

Page 20

The Start command can be assigned to any of the front keys or to or to any of the Control

Inputs, by attaching the RESET function to it (e.g. set parameter F06.052 to 1 to assign the Start

function to the ENTER key etc.). Also an automatic reset function with a timed output signal can

be used, in order to ensure automatic stepping of the cutting sequence without a remote start

signal.

The diagram below shows the switching states of outputs 2, 3 and 4 with respect to above

parameters. Output 1 must not be used with this application.

Cutting length

Tool width

Corr. Stop

Pre-stop

Output K2

(High speed)

Output K3

(Run signal)

Output K4

(Ready to cut)

Start

High speed Low speed Overshoot

The functions and switching characteristics shown above require the following parameter

settings:

F10.101 = 1 (preset counter to Preselections)

F10.090 = 0 (Output K2 static)

F10.098 = 1 (Output K2 active when count ≤ preset)

F10.091 = 0 (Output K3 static)

F10.099 = 1 (Output K3 active when count ≤ preset)

F10.092 = x (Output K4 static or dynamic according to need)

F10.100 = 0 (Output K4 active when count ≥ preset)

ZD340_07d_e.doc / Apr-17 Page 20 / 50

Page 21

4.9. Monitor for Slip, Torsion, Skew Position, Shaft Fracture:

Display

L1 (red)

L2 (yellow)

1

Differential count (encoder1

–

encoder2)

----2

Minimum difference (sin

ce last reset)

blinking fast

--

3

Maximum difference (since last reset)

--

blinking fast

4

Encoder 1 only

blinking slow

--5Encoder 2 only

--

blinking slow

F07.062 = 9

This counter mode is a special version of the Differential Counter described previously. As a

major difference, in this mode all four presets and outputs (K1 – K4) refer exclusively to the

differential count, and also a programmable slip function has been added.

Before forming the difference, each of the two encoder inputs is scaled individually according

to the setting of the impulse scaling factor. If applicable, the differential result can once more

be scaled to engineering units with use of the final scaling operands.

Since presets and outputs can be set to positive and negative values as well, it is also possible

to use the unit for simple synchronous control purpose of two drives, by temporary accelerating

or breaking one of the drives when lagging or leading the other. Typical examples are large

rolling gates or lifting ramps or gantry cranes, driven by several independent motors.

Some applications (e.g. with couplings) can accept (or even may require) a certain slip.

For slip control with adjustable slip parameters, an automatic timer function can be

programmed to reset the counters periodically.

Multi-purpose parameter F04.030 is used to set the reset cycle in seconds (00.0 = no automatic

reset, 99.9 = reset every 99.9 seconds)

Since with slip applications, where the automatic reset function is switched on, the real time

display of the counter may be very confusing, multi-purpose parameter F04.031 works to reduce

the update rate of the display

(0 = real-time display, 1 = 8 msec., 2 = 16 msec., 3 = 32 msec., 4 = 64 msec. etc.)

Besides the differential count, the display can be scrolled to indicate also the following values:

Encoder

1 2 3 4 5 6

Alert 1

Alert 4

Encoder

Motor

Encoder 1

Encoder 2

Control of Shaft and Gearbox Fracture

ZD340_07d_e.doc / Apr-17 Page 21 / 50

Page 22

4.10. Dual Counter, Two Independent Counters for Encoders 1 and 2:

Display

L1 (red)

L2 (yellow)

1

Main counter (encoder 1 or encoder 2)

----2

Minimum value of main counter (since last

reset)

blinking fast

--3Maximum value of main counter (since last reset)

--

blinking fast

4

Counter of encoder 1

blinking slow

--5Counter of encoder 2

--

blinking slow

Display

L1 (red)

L2 (yellow)

1

Counter of encoder 1

blinking slow

--2Counter of encoder 2

--

blinking slow

F07.062 = 10

Both encoder inputs operate fully independent one from the other, with individual scaling,

evaluation and display. Also each counter can be set or reset individually.

Both counters are treated equally, except with recording of minimum and maximum values.

With regard to this function one of the two counters has to be declared as the "main counter".

The unit will record the min/max values of the main counter only and no min/max values will be

available of the other counter.

Attribution of the main counter uses the Multi-Purpose Parameter 1 (F04.030)

F04.030 = 0 : Encoder 1 represents the main counter (default)

F04.030 = 1 : Encoder 2 represents the main counter

Presets K1 and K2 are always related to the main counter.

Presets K3 and K4 refer to the other of the two counters

With many applications it may be desirable to toggle the display only between encoder 1 and

encoder 2, without needing to pass over all the other values every time. Therefore the MultiPurpose Parameter 2 (F04.031) can be used to choose between one of the following two display

sequences:

F04.031 = 0 : Standard display sequence with all display values* (default)

F04.031 = 1 : Short display sequence to toggle between encoders 1 and 2 only

*) Units with analogue output (ZA series) will always generate the analogue signal

from one of the lines 1 to 5, according to assignment by parameter F08.079.

This is also valid when the short display sequence is used.

ZD340_07d_e.doc / Apr-17 Page 22 / 50

Page 23

5. Keypad Operation

PROG

UP

DOWN

ENTER

An overview of all parameters and explanations can be found under section 6.

The menu of the unit uses four keys, hereinafter named as follows:

P

Key functions depend on the actual operating state of the unit. Essentially we have to describe

three basic states:

• Normal operation

• General setup procedure

• Direct fast access to presets and set values

5.1. Normal Operation

In this mode the unit operates as a counter according to the settings defined upon setup. All

front keys may have customer-defined functions according to the specifications met in the

keypad definition menu F06 (e.g. scrolling of the display, Reset, Inhibit etc.)

5.2. General Setup Procedure

The unit changes over from normal operation to setup level when keeping the key down

for at least 2 seconds. Thereafter you can select one of the parameter groups F01 to F13.

Inside the group you can now select the desired parameter and set the value according to need.

After this you can either set more parameters or return to the normal operation.

The adjoining sequence of key operations explains how to change

Parameter number 052 of group F06 from the original value of 0 to 8

P

ZD340_07d_e.doc / Apr-17 Page 23 / 50

Page 24

Step

State

Key action

Display

Comment

00 Normal operation Counting

Display of the

Level:

Confirmation of F06.

Level:

F06.051…

Select parameter 052

Parameter 052 appears in

Level:

Setting has been modified

F06.052

Save the new setting

(8)08Level:

F06

Return to level parameter

Level:

Counting

Return to normal operation

Normal operation

01 > 2 sec. F01

Parameter group

02

03

04

05

06

07

09

10

Parameter group

Parameter numbers

Parameter values

Parameter numbers

Parameter groups

5 x F02 … F06 Select group # F06

F06.050

The first parameter of this

group is F06.050

2 x

F06.052

0

display, actual setting is 0

8 x 1 …. 8

from 0 to 8

groups

During the general setup procedure all counter activities remain

disabled. New parameter settings become active after return to

normal operation only.

5.3. Direct Fast Access to Presets

To get to the fast access routine, please press both

and

This will access the parameter group F01 right away. To change of the settings follow the same

procedure as already described above. Besides the advantage of direct access, the fundamental

difference to general setup is the following:

During the fast access procedure all counter functions remain fully active.

Access is limited to presets; no other parameters can be changed.

at the same time

ZD340_07d_e.doc / Apr-17 Page 24 / 50

Page 25

5.4. Change of Parameter Values on the Numeric Level

PROG

UP

DOWN

ENTER

Saves the actual value

Increments the

Decrements the

Shifts

the cursor (blinking

Step

Display

Key action

Comment

00102

4

Display of actual parameter setting, last

4 x

Scroll last digit down to 0

00102

0

Shift c

ursor to left

0010

2

0

2 x

Scroll highlighted digit down to 0

0010

0

0

Shift curser 2 positions left

00

1

000

Scroll highlighted digit down

to 0

00

0

000

Shift cursor left

000000

5 x

Scroll highlighted digit up to 5

050000

Shift cursor left

0

50000

2 x

Scroll highlighted digit up to 2

2

50000

Save new setting and return to the

The numeric range of the parameters is up to 6 digits with 6-decade models and up to 8 digits

with 8 decade models. Some of the parameters may also include a sign. For fast and easy

setting or these values the menu uses an algorithm as shown subsequently. During this

operation the front keys have the following functions:

P

shown in the display and

returns to the parameter

selection level

With signed parameters the left digit scrolls from 0 to 9 and then shows “–„ (negative) and

“-1“ (minus one). The example below shows how to change a parameter from the setting 1024

to the new setting 250 000 (using a 6 decade model).

This example assumes that you have already selected the parameter group and the parameter

number, and that you actually read the parameter value in the display.

Highlighted digits appear on colored background.

00

01

02

03

highlighted

(blinking) digit

highlighted

(blinking) digit

digit is highlighted

digit) one position to the

left, or from utmost left

to right

04

05

06

07

08

09

10

ZD340_07d_e.doc / Apr-17 Page 25 / 50

2 x

parameter number level

Page 26

5.5. Code Protection against Unauthorized Keypad Access

•

Parameter group F05 allows to define an own locking code for each of the parameter menus.

This permits to limit access to certain parameter groups to specific persons only.

When accessing a protected parameter group, the display will first show “CODE” and wait for

your entry. To continue keypad operations you must now enter the code which you have stored

before, otherwise the unit will return to normal operation again.

After entering your code, press the ENTER key and keep it down until the unit responds.

When your code was correct, the response will be “YES” and the menu will work normally.

With incorrect code the response will be “NO” and the menu remains locked.

5.6. Return from the Programming Levels and Time-Out Function

At any time the PROG key sets the menu one level up and finally returns to normal operation.

The same step occurs automatically via the time-out function, when during a period of 10

seconds no key has been touched.

Termination of the menu by automatic time-out will not store new settings, unless they have

already been stored by the PROG key after editing.

5.7. Reset all Parameters to Factory Default Values

Upon special need it may be desirable to set all parameters back to their original factory

settings (e.g. because you have forgotten your access code, or by too many change of settings

you have achieved a complex parameter state). Default values are indicated in the parameter

tables shown later.

To reset the unit to default, please take the following steps:

•

•

Switch power off

Press and simultaneously

Switch power on while you keep down both keys

Where you decide to take this action, please note that all parameters and

settings will be lost, and that you will need to run a new setup procedure

again.

ZD340_07d_e.doc / Apr-17 Page 26 / 50

Page 27

6. Menu Structure and Description of Parameters

Group

Function

Group

Function

F01

Preselection values

F02

Definitions for encoder 1

000

Preselection K1

010

Encoder properties

001

Preselection

K2

011

Edge count select x1, x2, x4

002

Preselection K3

012

Counting direction up/down

003

Preselection K4

013

Impulse scaling Factor

004

Preset value encoder 1

014

Multiple count factor

005

Preset value encoder 2

015

Round

-

loop cycle definition

F03

Definitions for encoder 2

F04

Special functions

018

Encoder properties

026

Digital input filters

019

Edge count select x1, x2, x4

027

Power down memory

020

Counting direction up/down

028

Input threshold 1

021

Impulse scaling Factor

029

Input threshold 2

022

Multiple count factor

030

Multi

-

purpose parameter (1)

023

Round

-

loop cycle definition

031

Multi

-

purpose parameter (2)

F05

Keypad protection codes

F06

Key commands and control inputs

033

F01

050

Key UP

034

F02

051

Key D

OWN

035

F03

052

Key ENTER

036

F04

053

Input Cont.1, switching characteristics

037

F05

054

Input Cont.1, assignment of function

038

F06

055

Input Cont.2, switching characteristics

039

F07

056

Input Cont.2, assignment of function

040

F08

057

Inpu

t Cont.3, switching characteristics

041

F09

058

Input Cont.3, assignment of function

042

F10

059

Input Cont.4, switching characteristics

043

F11

060

Input Cont.4, assignment of function

044

F12

045

F13

All parameters are arranged in a reasonable order of functional groups (F01 to F13)

You must only set those parameters which are really relevant for your specific application.

Unused parameters can remain as they actually are.

6.1. Summary of the Menu

This section shows a summary of the parameter groups, with an assignment to the functional

parts of the unit.

ZD340_07d_e.doc / Apr-17 Page 27 / 50

Page 28

ZD340_07d_e.doc / Apr-17 Page 28 / 50

Group

Function

Group

Function

F07

Basic settings

F08

Analogue output definitions (ZA only)

062

Mode of operation

074

Output current or voltage

063

Decimal point encoder 1

075

Start value of conversion

064

Decimal point encoder 2

076

End value of conversion

065

Decimal point c

ombined <1,2>

077

Output swing

066

Multiplication factor <1,2>

078

Zero offset

067

Division factor <1,2>

079

Assignment of the Analogue Output

068

Display offset <1,2>

069

Brightness of LED display %

070

Display Update Time

F09

Seri

al communication

F10

Switching features and presets

081

Serial device address

089

K1 (static or pulse)

082

Baud rate

090

K2 (static or pulse)

083

Data format

091

K3 (static or pulse)

084

Serial protocol selection

092

K4 (static or pulse)

085

Time

r for auto

-

transmission

093

Hysteresis K1

086

Serial code for transmission

094

Hysteresis K2

095

Hysteresis K3

096

Hysteresis K4

097

Preselection mode K1

098

Preselection mode K2

099

Preselection mode K3

100

Preselection mode K4

101

Preset mode

102

Output polarity

103

Sign of thumbwheel switch (ZD6...)

104

Thumbwheel assignment

105

Start

-

up Inhibit for Outputs

106

Calculation of trailing preselections

Page 29

F11

Mode of Linearisation

F12

Table of

Linearisation Counter 1

F11.108

Linearisation mode counter 1

F12.114

First interpolation point (x1 value)

F11.109

Linearisation mode counter 2

F12.115

First interpolation point (y1 value)

etc.

--------

>

F12.144

Last interpolation point (x16 val

ue)

F12.145

Last interpolation point (y16 value)

F13

Table of Linearisation Counter 2

F13.146

First interpolation point (x1 value)

F13.147

First interpolation point (y1 value)

etc.

--------

>

F13.176

Last interpolation point (x

16 value)

F13.177

Last interpolation point (y16 value)

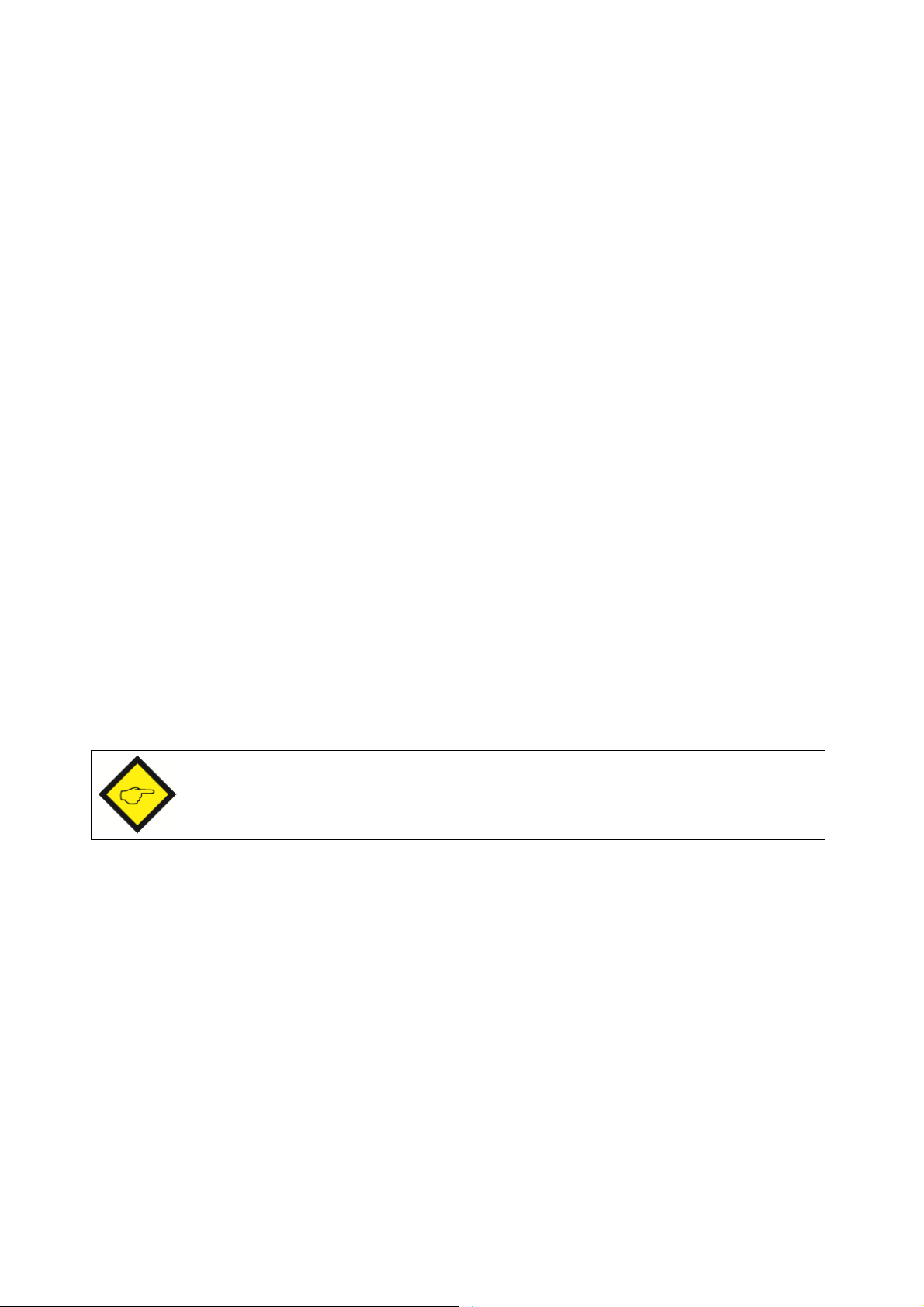

The following schematics shows how in principle the parameter blocks are assigned to the

various elements and functions of the counter.

Digita l

Contro l

Inputs

F10

F08

K1 out

K2 out

K3 out

K4 out

+/-10V

20 mA

Encoder 1

Encoder 2

RS232

Cont1

Cont2

Cont3

Cont4

F02

F03

F06

F07

F11F12F13

123456

up

dn

P

F05 F06

ENT

F01

F09

Where you find highlighted indications in the following parameter listings,

this indicates that the setting range depends on the model and is 6 digits

with 6 decade models and 8 digits with 8 decade models

Fast

Switch ing

Out puts

Fast

An alogue

Ou tputs

(optio nal)

ZD340_07d_e.doc / Apr-17 Page 29 / 50

Page 30

6.2. Description of the Parameters

F01

Range

Default

Ser.000

Preselection K1

-

199 999

-

999 999

1 000

00

001

Preselection K2

-

199 999

-

999 999

2 000

01

002

Preselection K3

-

199 999

-

999 999

3 000

02

003

Preselection K4

-

199 999

-

999 999

4 000

03

004

Preset value encoder 1

-

199 999

-

999 999

000 000

04

Upo

n internal or external command the encoder 1

005

Preset value encoder 2

-

199 999

-

999 999

000 000

05

Upon internal or external command the encoder 2

F02Range

Default

Ser.

010

Encoder properties

0 … 3

1A00=

Differential signals A, /A, B, /B (2 x 90°)

1=

HTL signals A, B (2 x 90°) single

-

ended

2=

Differential signals A, /A for count *)

3=

HTL signal A (single

-

ended) for count

011

Edge counting

0 … 2

0A10=

Simple (x1)

1=

Double (x2)

2=

Full quadrature (x4)

012

Counting direction

0 … 1

0A20=

Up when A leads B

1=

Down when A leads B

013

Impulse scaling factor

0.00001

-

9.99999

1.00000

A3

Multiplier for input impulses

014

Impulse multiplier

001-99

001A4Multiple count of every impul

se

015

Round

-

loop cycle

0-999 999

0A50=

Unlimited counting range

xxx

Round

-

loop operation in a range 0

-

xxx

6.2.1. Preselections and presets

counter will set to this value

counter will set to this value

6.2.2. Definitions for encoder 1

*)

Differential signals B, /B to indicate static

direction (if available)

HTL signal B (single-ended) to indicate static

direction (if available)

*) Applies for any kind of differential signals, no matter if RS422 or TTL level or HTL level

ZD340_07d_e.doc / Apr-17 Page 30 / 50

Page 31

6.2.3. Definitions for encoder 2

F03

Range

Default

Ser.

018

Encoder properties

0 … 3

1A80=

Differential signals A, /A, B, /B (2 x 90°) *)

1=

HTL signals A, B (2 x 90°) single

-

ended

2=

Differential signals A, /A for count *)

3=

HTL signal A (single

-

ended) for count

019

Edge counting

0 … 2

0A90=

Simple (x1)

1=

Double (x2)

2=

Full quadrature (

x4)

020

Counting direction

0 … 1

0B00=

Up when A leads B

1=

Down when A leads B

021

Impulse scaling factor

0.00001

-

9.99999

1.00000

B1

Multiplier for input impulses

022

Impulse multiplier

001-99

001

B2

Multiple count of every im

pulse

023

Round

-

loop cycle

0-999 999

0B30=

Unlimited counting range

xxx

Round

-

loop operation in a range 0

-

xxx

F04

Range

D

efault

Ser.

026

Digital input filter

0 … 3

0B6027

Power

-

down memory

0-10B70=Off. Counter resets to zero after power down

1=

On. Counter stores last counting result

028

Trigger threshold for encoder1 inputs **)

30 … 250

166B8029

Tri

gger threshold for encoder2 inputs **)

30 … 250

166B9030

Multi

-

purpose parameter, function depending on

0 … 999

0C0031

Multi

-

purpose parameter, function depending on

0 … 999

0

C1

Differential signals B, /B to indicate static

direction (if available)

HTL signal B (single-ended) to indicate static

direction (if available)

*) Applies for any kind of differential signals, no matter if RS422 or TTL level or HTL level

6.2.4. Special functions

application as shown under 4.1, 4.9, 4.10, 6.3

application as shown under 4.9, 4.10

**) Must be set to the default value (166) with any kind of input signals, except if exceptionally single-

ended TTL signals should be used. Only in this case setting 35 is required.

ZD340_07d_e.doc / Apr-17 Page 31 / 50

Page 32

6.2.5. Keypad protection codes

F05

Range

Default

Ser.

033

Protected group F01

0C3034

Protected group F02

0C4035

Protected group F03

0C5036

Protected group F04

6079

C6

037

Protected group F05

0C7038

Protected group F06

0C8039

Protected group F07

0C9040

Protected group F08

0D0041

Protected group F09

0D1042

Protected group F10

0D2043

Protected group F11

0D3044

Protected group F12

0D4045

Protected group F13

0

D5

F06Range

Default

Ser.

050

Function assignment to key „UP“

0 … 14

0E00=

No function

1=

Reset counter 1 (encoder 1) and read **)

2=

Reset counter 2 (encoder 2) and read **)

3=

Reset counter 1 a

nd counter 2 and read **)

4=

Set counter 1 to Set Value 1 *)

**)5=Set counter 2 to Set Value 2 *)

**)6=Set both counters to Set Value *)

**)7=Inhibit counter 1 and read **)

8=

Inhibit counter 2 and read **)

9=

Read front

thumbwheels (models 6xx only) **)

10=

Start serial transmission

11=

Reset minimum/maximum records

12=

Scroll actual display

13=

Special command (depends on counter mode)

14=

n.a.

051

Function assignment to key „DOWN“

0 … 14

0E1See key „UP“

052

Function assignment to key „ENTER“

0 … 14

0E2See key „UP“

6.2.6. Key commands and control input definitions

0 = no protection

1 – 999 999 =

Protection code

for the actual

group

(Clears also points of change of direction)

*) Parameter F10.101 defines the source of the Set Value (see 6.3)

**) “Read” refers to models 6xx with thumbwheel switches only. See appendix.

ZD340_07d_e.doc / Apr-17 Page 32 / 50

Page 33

F06

(conti

nued)

Range

Default

Ser.

053

Switching characteristics of input „Cont.1“

0 … 7

0

E3

0= NPN (switch to -) function active LOW

054

Function assignment to input „Cont.1“

0 … 14

0

E4

**)

**)

**)

055

Switching characteristics of input „Cont.2“

0 … 7

0

E5

056

Function assignment to input „Cont.2“

0 … 14

0

E6

057

Switching characteristics of input „Cont.3“

0 … 7

0

E7

058

Function assignment to input „Cont.3“

0 … 14

0

E8

059

Switching characteristics of input „Cont.4“

0 ... 3

0

E9

060

Function assignment to input „Cont.4“

0 … 14

0

F0

1= NPN (switch to -) function active HIGH

2= NPN (switch to -) rising edge

3= NPN (switch to -) falling edge

4= PNP (switch to +), function active LOW

5= PNP (switch to +), function active HIGH

6= PNP (switch to +), rising edge

7= PNP (switch to +), falling edge

0= No function

1= Reset counter 1 (encoder 1) and read **)

(Clears also points of change of direction)

2= Reset counter 2 (encoder 2) and read **)

3= Reset counter 1 and counter 2 and read **)

4=

Set counter 1 to Set Value 1 *)

5=

Set counter 2 to Set Value 2 *)

6=

Set both counters to Set Value *)

7= Inhibit counter 1 and read **)

8= Inhibit counter 2 and read **)

9= Read only **)

10= Start serial transmission

11= Reset minimum/maximum records

12= Scroll actual display

13= Special command (depends on counter mode)

14= Hardware keypad interlock

See „Cont.1“ (F06.053)

See „Cont.1“ (F06.054)

See „Cont.1“ (F06.053)

See „Cont.1“ (F06.054)

0 =

= NPN (switch to -), active LOW

1 =

= NPN (switch to -), active HIGH

2 =

= PNP (switch to +), active LOW

3 =

= PNP (switch to +), active HIGH

See „Cont.1“ (F06.054)

Unconnected NPN inputs are always HIGH (internal pull-up resistor)

Unconnected PNP inputs are always LOW (internal pull-down resistor)

*) Parameter F10.101 defines the source of the Set Value (see 6.3)

**) “Read” refers to models 6xx with thumbwheel switches only. See appendix.

static switching

functions only

ZD340_07d_e.doc / Apr-17 Page 33 / 50

Page 34

6.2.7. Basic settings

F07

Range

Default

Ser.

062

Operation mode of the counter

0 … 10

0

F2

063

Decimal point position of encoder 1

0 … 5

0F3064

Decimal point position of encoder 2

0 … 5

0F4065

Decimal point position combined <1&2>

0 … 5

0

F5

066

Scaling factor for combined va

lues <1&2>

0.0001

–

9.9999

1.0000

F6

067

Divider for combined values

*

0.0000

–

9.9999

0F7068

Offset value for combined values

-

199999

-

999999

0F8069

Brightness of the 7

-

segment LED display

0 … 4

0

F9

070

Display Update Time (sec.)

0.005

-

9.999

0.005

G0

F08

Range

Default

Ser.

074

Output format

0 … 3

0

G4

075

Beginning of the conversion range

-

199999

-

999999

0G5Display value to generate 0 volts or 0/4 mA

076

End of the conversion range

-

199999

-

999999

10 000

G6

Display value to generate 10 volts or 20 mA

077

Analogue output swing (1000 = 10 V or 20 mA)

0 … 1000

1000

G7

078

Analogue zero offset (mV, zero displacement)

-

10000

-

10000

0G8079Analogue output assignment

0 … 4

G9

0= „Single“, encoder 1 only

1= „Sum“, encoder 1 + encoder 2

2= „Differential“, encoder 1 – encoder 2

3= Master counter and batch counter

4= Measuring of real cutting length

5= Calculation of roll diameters

6= Calculation of roll radius

7= Cut-to-length control

8= Cut-to-length control

9= Slip-, torsion- skew position monitor

10= Dual counter, independent counters 1 and 2

0= 100% of maximum brightness

1= 80% of maximum brightness

2= 60% of maximum brightness

3= 40% of maximum brightness

4= 20% of maximum brightness

6.2.8. Analogue output definitions (ZA models only)

0= Voltage – 10 V… + 10 V

1= Voltage 0 ….. +10 V

2= Current 4 – 20 mA

3= Current 0 – 20 mA

(according to lines 1 – 5 of the display scrolling function)

*) Setting 0,0000 will skip the whole recalculation and therefore speed up the cycle time

ZD340_07d_e.doc / Apr-17 Page 34 / 50

(Line1) … (Line5)

Page 35

6.2.9. Serial communication parameters

F09

Range

Defau

lt

Ser.

081

Serial device address (unit number)

11 … 99

1190082

Serial baud rate

0 … 6

0910=

9600 Baud

1=

4800 Baud

2=

2400 Baud

3=

1200 Baud

4=

600 Baud

5=

19200 Baud

6=

38400 Baud

083

Serial data form

at

0 … 9

0920=

7 Data, Parity even, 1 Stop

1=

7 Data, Parity even, 2 Stop

2=

7 Data, Parity odd, 1 Stop

3=

7 Data, Parity odd, 2 Stop

4=

7 Data, no Parity, 1 Stop

5=

7 Data, no Parity, 2 Stop

6=

8 Data, Parity even,

1 Stop

7=

8 Data, Parity odd, 1 Stop

8=

8 Data, no Parity, 1 Stop

9=

8 Data, no Parity, 2 Stop

084

Serial protocol select *)

0 … 1

1H10=

Transmission = Unit Nr.

–

Data, LF, CR

1=

Transmission = Data, LF, CR

085

Serial ti

mer (sec.) for timer transmissions *)

0.000 … 99.999

0H2086

Serial register code of the transmit parameter *)

0 … 19

14

H3

F10

Range

Default

Ser.

089

Pulse t

ime (sec.) output K1 (0 = static output)

0.00 … 9.99

0.00

H6

090

Pulse time (sec.) output K2 (0 = static output)

H7

091

Pulse time (sec.) output K3 (0 = static output)

H8

092

Pulse time (sec.) output K4 (0 = static output)

H9

093

Switching hyster

esis K1 (display units) *)

0 … 9999

0I0094

Switching hysteresis K2 (display units) *)

I1

095

Switching hysteresis K3 (display units) *)

I2

096

Switching hysteresis K4 (display units) *)

I3

*) for more details please see appendix in section 8

6.2.10. Switching characteristics and presets

*) The switching point equals to the preset value and the return point is displaced by the hysteresis setting

ZD340_07d_e.doc / Apr-17 Page 35 / 50

Page 36

F10

Range

Default

Ser.

097

Switching characteristics K1

0 … 5

0I40=

active with display

≥

preselection

1=

active with display

preselection

Remark

:

2=

active with display

preselection, 0

counter.

3=

active with display

preselection,

4=

active with display

preselection, 0

counter

5=

active with display

preselection,

098

Switching characteristics K2 (see K1, F10.097)

0 … 5

0I5099

Switching characteristics K3 (see K1, F10.097)

I6

100

Switching characteristics K4 (see K1, F10.097)

I7

101

Set value of the counter

0 … 1

0I80=

Set value = Preset (1 or. 2)

1=

Set value = Preselection K1 or K2

102K1–

K4 outputs N.C or N.O *)

0 … 15

0I9K1=

binary value 1

K2=

binary value 2

Example

: Setting

K3=

binary value 4

K4=

binary value

8

Bit = 0: Output switches ON when active (N.O.) *)

Bit = 1: Output switches OFF when active (N.C.) *)

103

Sign of thumbwheel switches (models ZD6xx only)

0J0104

Thumbwheel switch assignment (models ZD6xx only)

0Q1105

Start

-

up Inhibit of timed K1

-

K4 outputs

0Q2106

Switch point calculation with trailing preselections

0 … 3

0

Q3

≤

≥

→

Remaining errors are cancelled

≤

Set→counter. Remaining errors are cancelled

≥

→

Remaining errors added to following cycle

≤

Set→counter

Remaining errors added to following cycle

≥ and ≤ refer to

positive values

and are inversely

with negative

values

after power-up

0: K1=>K1, K2=>K2, K3=>K3, K4=>K4

1: K1=>K1, K1-K2=>K2, K3=>K3, K4=>K4

2: K1=>K1, K2=>K2, K3=>K3, K3-K4=>K4

3: K1=>K1, K1-K2=>K2, K3=>K3, K3-K4=>K4

Example: if set to “1” the K2 switching point would be

substituted by the difference K1 - K2 (i.e. F00.000 - F00.001)

*) N.O. means “normally open”, saying that the corresponding output is normally switched

OFF and will switch on when the assigned event happens.

9 means that K1

and K4 operate

N.O. and K2 and

K3 operate N.C *)

see appendix

see appendix

0 = pulses enabled

1 = pulses disabled

*) N.C. means “normally closed”, saying that the corresponding output is normally switched

ON and will switch off when the assigned event happens

ZD340_07d_e.doc / Apr-17 Page 36 / 50

Page 37

6.2.11. Parameters for Linearisation

F11

Modes of Linearisation

Range

Default

Ser.

108

Mode of linearization for counter 1 (encoder 1)

0–2

0J1109

Mode of li

nearization for counter 2 (encoder 2)

0–2

0J2F12

Table of linearization for counter 1 (encoder 1)

Range

Default

Ser.

114

First interpolation point, (x0, original value)

J7

115

First interpolation point, (y0, replacement value)

J8

116

Second interpolation point (x1, original value)

-

199999

-

999999

0J9117

Second interpolation point (y1, replacement value)

K0

etc.

---->144

Last interpolation point, (x15, original value)

M7

145

First interpolation point, (y15, repla

cement value)

M8

F13

Table of linearization for counter 2 (encoder 2)

Range

Default

Ser.

146

First interpolation point, (x0, original value)

M9

147

First interpolation point, (y0, replacement value)

N0

148

Second interpolation point (x1, origina

l value)

-

199999

-

999999

0

N1

149

Second interpolation point (y1, replacement value)

N2

etc.

---->176

Last interpolation point, (x15, original value)

P9

177

Last interpolation point, (y15, replacement value)

Q0

0 = Linearisation off

1 = Linearisation is defined for the numeric range

from 0 to +999 999 only and negative values

will appear as a mirror of the positive values

2 = Linearisation is defined over the full range from -

199 999 to +999 999

0 = Linearisation off

1 = Linearisation is defined for the numeric range

from 0 to +999 999 only and negative values

will appear as a mirror of the positive values