Page 1

Operating Manual

motrona GmbH, Zeppelinstraße 16, DE - 78244 Gottmadingen, Tel. +49 (0) 7731 9332-0, Fax +49 (0) 7731 9332-30, info@motrona.de, www.motrona.de

touchMATRIX® Indicator IX350 / IX355

SSI indicator for absolute encoders, with touchscreen and graphic display

Product features:

Master or Slave operation with clock frequencies up to 1 MHz

For single turn and multi turn encoders with SSI formats from 10 … 32 Bit

Bright and high-contrast display with event-dependent color variations

Emulation of a 7-segment display inclusively icons and units

Intuitive and easy parameterization by plain text and touchscreen

5 V / 24 V auxiliary output for encoder supply

Linearization with 24 control points

Numerous features, e. g. scaling, bit blanking etc.

3.78 x 1.89 inch norm panel housing and IP65 protection

Available options:

IX350: Basic unit with SSI interface, 3 control inputs, 24 VDC encoder supply

IX355: Basic unit like IX350, with open-circuit monitoring, 5 / 24 VDC encoder supply

Option AC: Power supply 115 / 230 VAC

Option AO: 16 bit analog output, 4 control outputs, serial RS232 interface

Option AR: 16 bit analog output, 4 control outputs, serial RS485 interface

Option CO: 4 control outputs, serial RS232 interface

Option CR: 4 control outputs, serial RS485 interface

Option RL: 2 relay outputs

Options can be combined

Page 2

Ix350_02b_oi_e.doc / Mai-18 Page 2 / 50

Version:

Description:

IX350_01a_oi/cn/Jun-17

First Version

IX350_01b_oi/cn/Jul-17

First Revision

IX350_01c_oi/cn/Jul-17

Revision

IX350_02a_oi/cn/Nov-17

Expansion of the scale units

IX350_02b_oi/cn/Apr-18

Revision

IX350_02b_oi/cn/April-18

Expansion of the serial interface

Legal notices:

All contents included in this manual are protected by the terms of use and copyrights of motrona

GmbH. Any reproduction, modification, usage or publication in other electronic and printed media as

well as in the internet requires prior written authorization by motrona GmbH.

Page 3

Ix350_02b_oi_e.doc / Mai-18 Page 3 / 50

Table of content

1. Safety Instructions and Responsibility........................................................................... 4

1.1. General Safety Instructions .......................................................................................................... 4

1.2. Use according to the intended purpose ....................................................................................... 4

1.3. Installation .................................................................................................................................... 5

1.4. Cleaning, Maintenance and Service Notes ................................................................................. 5

2. Introduction ................................................................................................................... 6

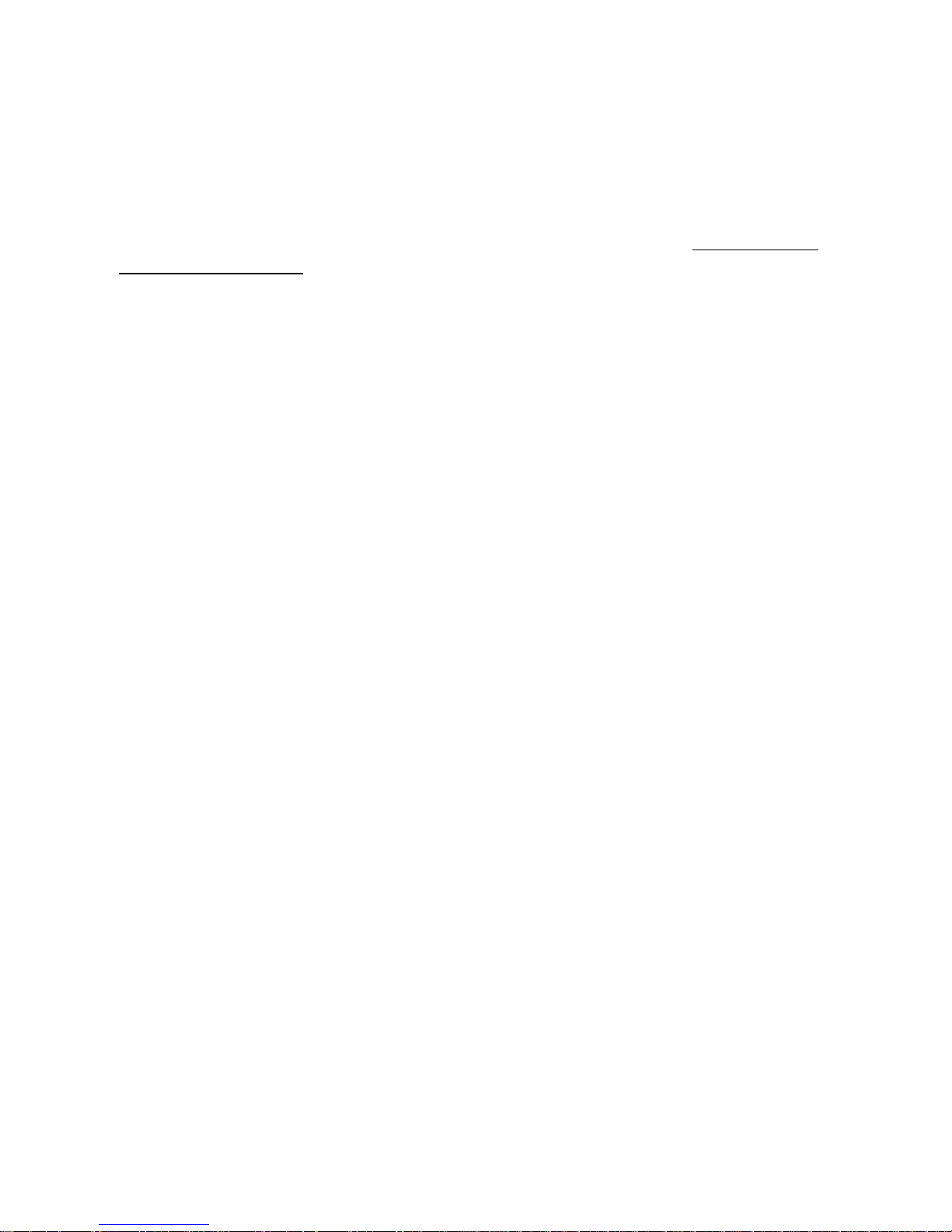

2.1. Operation mode ............................................................................................................................ 6

2.2. Function diagram .......................................................................................................................... 6

3. Electrical Connections ................................................................................................... 7

3.1. DC Power Supply .......................................................................................................................... 7

3.2. Auxiliary Voltage Output .............................................................................................................. 7

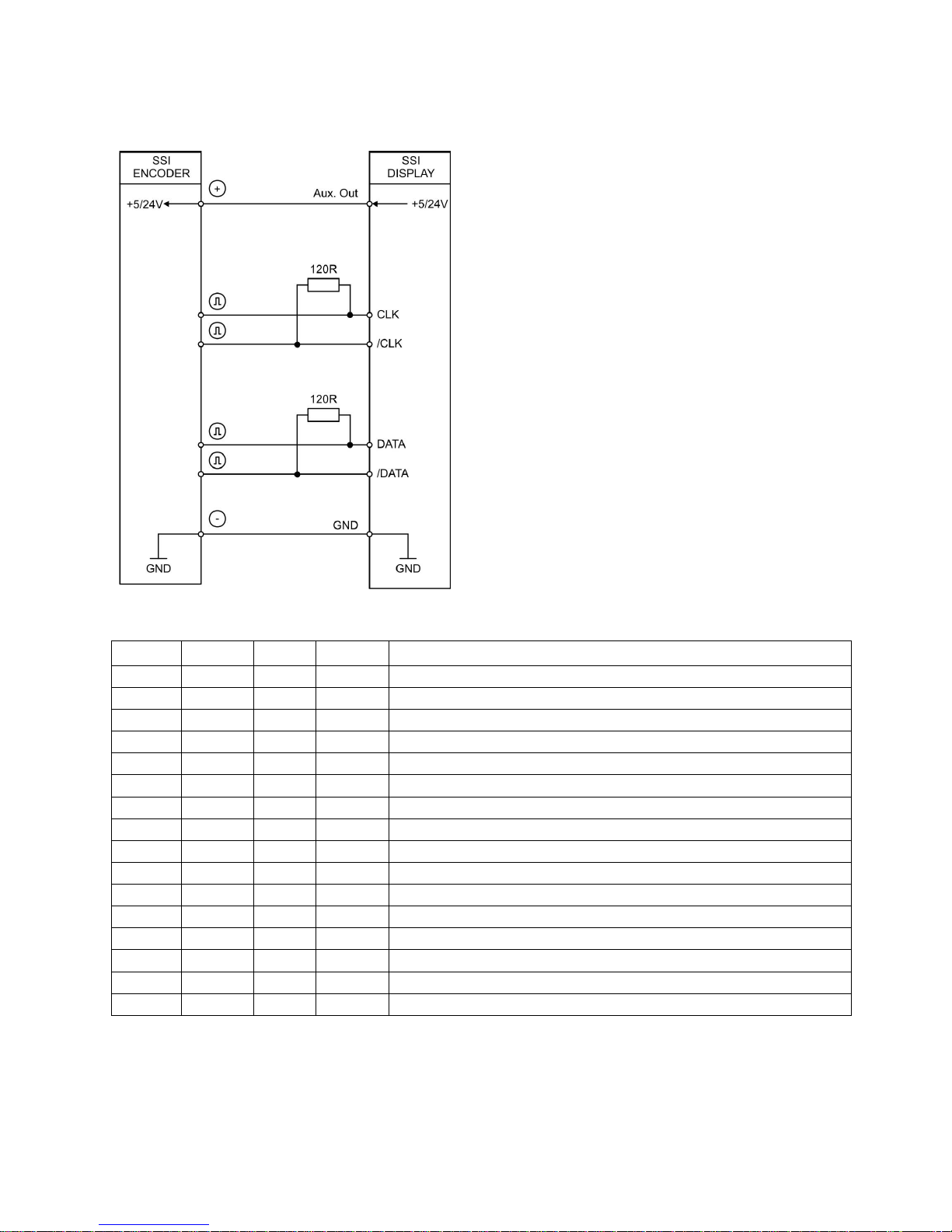

3.3. SSI-Inputs ..................................................................................................................................... 8

3.4. Control Inputs ............................................................................................................................. 10

3.5. Analog Output (Option AO/AR) .................................................................................................. 10

3.6. Serial interface (Option AO/AR/CO/CR) .................................................................................... 11

3.7. Control-Output (Option AO/AR/CO/CR) ..................................................................................... 11

3.8. AC Power supply (Option AC) ..................................................................................................... 12

3.9. Relay-Output (Option RL) ............................................................................................................ 12

4. Display and touch screen ............................................................................................ 13

4.1. Screen structure for parametrization ......................................................................................... 13

4.2. Screen structure in operation ..................................................................................................... 14

4.3. Error Message ............................................................................................................................ 15

5. Parameter / Overview-Menu Structure ........................................................................ 16

5.1. General Menu ............................................................................................................................. 18

5.2. SSI Properties ............................................................................................................................. 21

5.3. Preselection Values .................................................................................................................... 24

5.4. Preselection 1 Menu .................................................................................................................. 25

5.5. Preselection 2 Menu .................................................................................................................. 28

5.6. Preselection 3 Menu .................................................................................................................. 29

5.7. Preselection 4 Menu .................................................................................................................. 30

5.8. Serial Menu ................................................................................................................................ 31

5.9. Analog Menu .............................................................................................................................. 33

5.10. Command Menu ......................................................................................................................... 34

5.11. Display Menu.............................................................................................................................. 36

5.12. Linearization Menu ..................................................................................................................... 37

6. Appendix ..................................................................................................................... 38

6.1. Data readout via serial interface ............................................................................................... 38

6.2. Parameter / serial codes ............................................................................................................ 39

6.3. Linearization ............................................................................................................................... 43

6.4. Reading SSI-Value ...................................................................................................................... 45

6.5. Internal processing and calculation of SSI data ........................................................................ 46

6.6. Dimensions ................................................................................................................................. 48

6.7. Technical Specifications: ........................................................................................................... 49

Page 4

Ix350_02b_oi_e.doc / Mai-18 Page 4 / 50

1. Safety Instructions and Responsibility

1.1. General Safety Instructions

This operation manual is a significant component of the unit and includes important rules and hints

about the installation, function and usage. Non-observance can result in damage and/or impairment

of the functions to the unit or the machine or even in injury to persons using the equipment!

Please read the following instructions carefully before operating the device and observe all safety

and warning instructions! Keep the manual for later use.

A pertinent qualification of the respective staff is a fundamental requirement in order to use these

manual. The unit must be installed, connected and put into operation by a qualified electrician.

Liability exclusion: The manufacturer is not liable for personal injury and/or damage to property and

for consequential damage, due to incorrect handling, installation and operation. Further claims, due to

errors in the operation manual as well as misinterpretations are excluded from liability.

In addition the manufacturer reserves the right to modify the hardware, software or operation manual

at any time and without prior notice. Therefore, there might be minor differences between the unit

and the descriptions in operation manual.

The raiser respectively positioner is exclusively responsible for the safety of the system and

equipment where the unit will be integrated.

During installation or maintenance all general and also all country- and application-specific safety

rules and standards must be observed.

If the device is used in processes, where a failure or faulty operation could damage the system or

injure persons, appropriate precautions to avoid such consequences must be taken.

1.2. Use according to the intended purpose

The unit is intended exclusively for use in industrial machines, constructions and systems. Nonconforming usage does not correspond to the provisions and lies within the sole responsibility of the

user. The manufacturer is not liable for damages which have arisen through unsuitable and improper

use.

Please note that device may only be installed in proper form and used in a technically perfect

condition (in accordance to the Technical Specifications). The device is not suitable for operation in

explosion-proof areas or areas which are excluded by the EN 61010-1 standard.

.

Page 5

Ix350_02b_oi_e.doc / Mai-18 Page 5 / 50

1.3. Installation

The device is only allowed to be installed and operated within the permissible temperature range.

Please ensure an adequate ventilation and avoid all direct contact between the device and hot or

aggressive gases and liquids.

Before installation or maintenance, the unit must be disconnected from all voltage-sources. Further it

must be ensured that no danger can arise by touching the disconnected voltage-sources.

Devices which are supplied by AC-voltages must be connected exclusively by switches, respectively

circuit-breakers with the low voltage network. The switch or circuit-breaker must be placed as near as

possible to the device and further indicated as separator.

Incoming as well as outgoing wires and wires for extra low voltages (ELV) must be separated from

dangerous electrical cables (SELV circuits) by using a double resp. increased isolation.

All selected wires and isolations must be conform to the provided voltage- and temperature-ranges.

Further all country- and application-specific standards, which are relevant for structure, form and

quality of the wires, must be ensured. Indications about the permissible wire cross-sections for wiring

are described in the Technical Specifications.

Before first start-up it must be ensured that all connections and wires are firmly seated and secured

in the screw terminals. All (inclusively unused) terminals must be fastened by turning the relevant

screws clockwise up to the stop.

Overvoltage at the connections must be limited to values in accordance to the overvoltage category II.

For placement, wiring, environmental conditions as well as shielding and earthing/grounding of the

supply lines the general standards of industrial automation industry and the specific shielding

instructions of the manufacturer are valid. Please find all respective hints and rules on

www.motrona.com/download.html --> “[General EMC Rules for Wiring, Screening and Earthing]”.

1.4. Cleaning, Maintenance and Service Notes

To clean the front of the unit please use only a slightly damp (not wet!), soft cloth. For the rear no

cleaning is necessary. For an unscheduled, individual cleaning of the rear the maintenance staff or

assembler is self-responsible.

During normal operation no maintenance is necessary. In case of unexpected problems, failures or

malfunctions the device must be shipped for back to the manufacturer for checking, adjustment and

reparation (if necessary). Unauthorized opening and repairing can have negative effects or failures to

the protection-measures of the unit.

Page 6

Ix350_02b_oi_e.doc / Mai-18 Page 6 / 50

2. Introduction

The SSI display device is designed for panel mounting. It is universally applicable, with its intuitive

operation, the extensive features and options.

2.1. Operation mode

All functions are can be configured in the parameter menu.

The device can be set to one of the following operation modes:

• MASTER

- -The clock for the connected sensor is produced

- -The both clock terminals (CLK, / CLK) are configured as outputs in this case

• SLAVE

-The clock for the encoder is generated by an external device (the SSI master).

-The both clock terminals (CLK, / CLK) are configured as inputs in this case

2.2. Function diagram

Page 7

Ix350_02b_oi_e.doc / Mai-18 Page 7 / 50

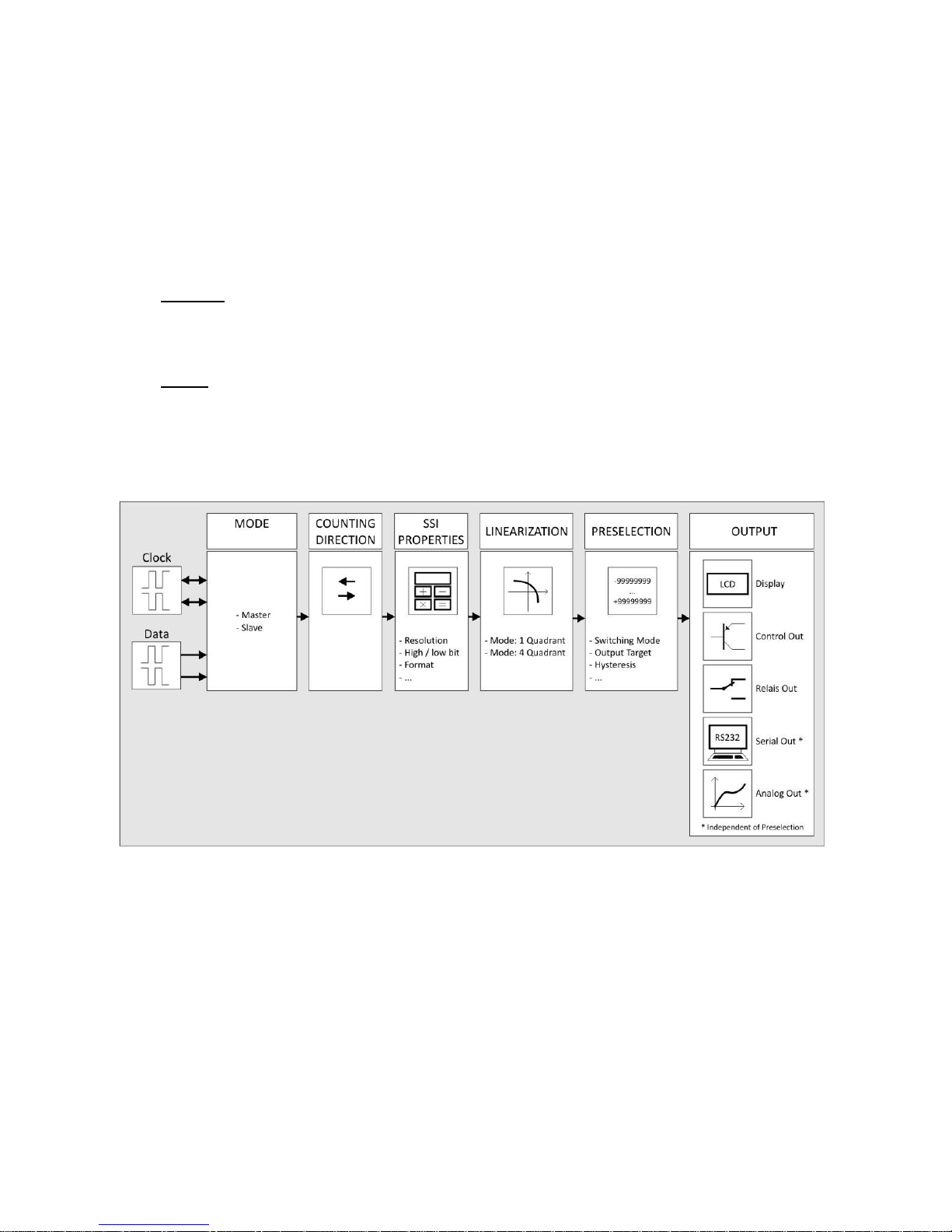

3. Electrical Connections

The terminal screws should be tightened with a slotted screwdriver (blade width 2mm).

3.1. DC Power Supply

The unit accepts DC supply from 18 to 30 V at the terminals 1 and 2. The power consumption depends

on the level of the supply voltage with approx. 100 mA and the additional current required at the

Auxiliary Voltage Output.

All GND terminals are internally interconnected.

3.2. Auxiliary Voltage Output

Terminal 3 and 4 provide an auxiliary output for supply of sensors and encoders.

The output voltage depends on the power supply.

DC version

AC version

The encoder voltage is approx. 1 V lower than

the power supply voltage at terminal 1 and 2

and should be loaded with max. 250 mA.

The encoder voltage is 24 VDC (± 15%) and

should be loaded with max. 150 mA up to 45

degrees Celsius. At higher temperature the

maximum output current is reduced to 80 mA.

At IX355 devices, the auxiliary voltages output is switchable from 24 VDC to 5 VDC.

Page 8

Ix350_02b_oi_e.doc / Mai-18 Page 8 / 50

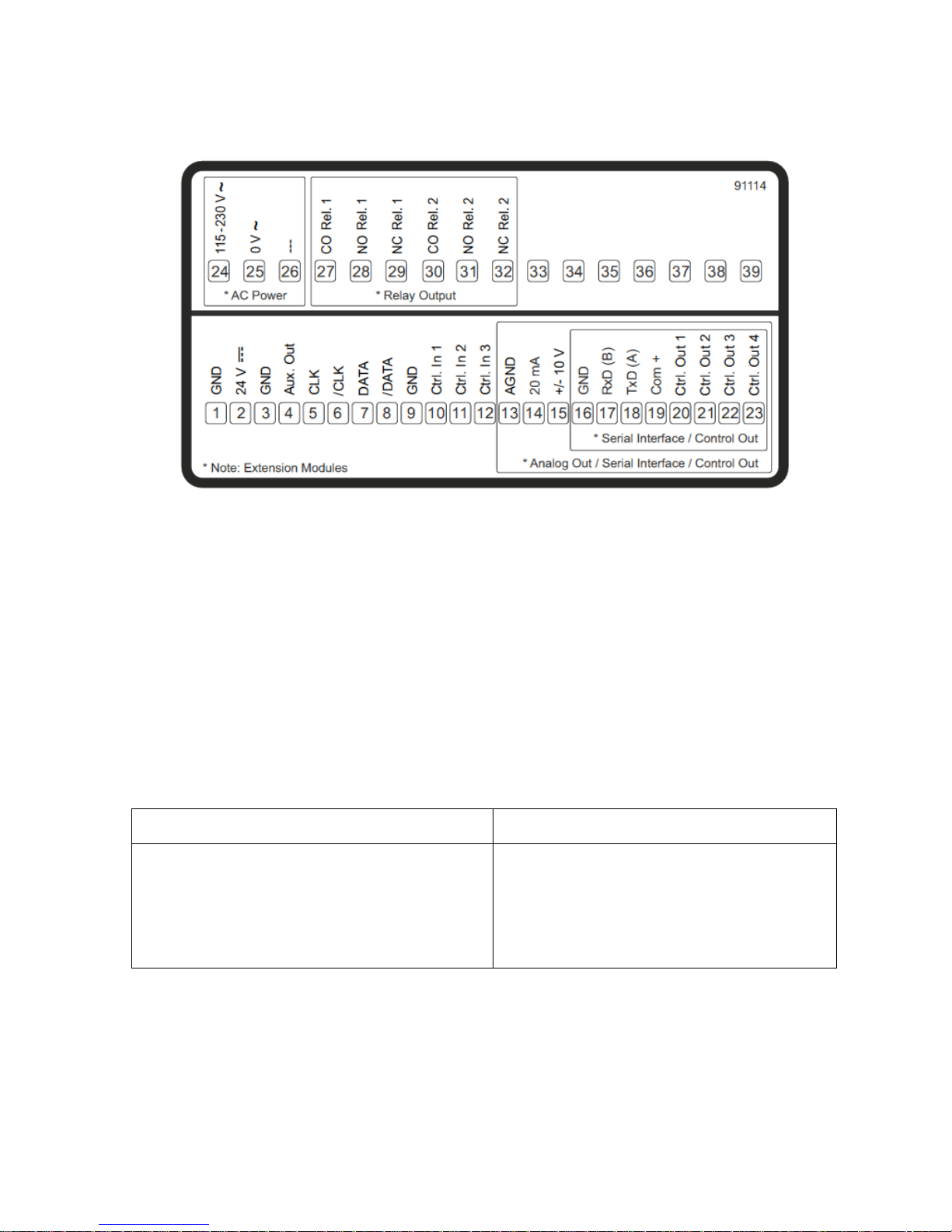

3.3. SSI-Inputs

At Terminal 5, 6, 7 and 8, the connection is available for SSI signals. The basic settings must be set in

the menu SSI PROPERTIES.

Wiring for MODE Master:

Wiring for MODE Slave:

Page 9

Ix350_02b_oi_e.doc / Mai-18 Page 9 / 50

Continuation „SSI-Inputs“:

The IX355 includes an open-circuit monitoring (only with termination, e.g. 120 ohm). In slave MODE,

CLK, /CLK and DATA, /DATA are monitored. In master MODE, only DATA, /DATA are monitored.

Error detection

/DATA

DATA

/CLK

CLK

Status

+ + + + Stable data

+ + + - Stable data (not guaranteed), no error detection

+ + - + Stable data (not guaranteed), no error detection

+ + - - Display value freezes, no error detection

+ - + + Error

+ - + - Error

+ - - + Error

+ - - - Error

- + + + Error

- + + - Error

- + - + Error

- + - - Error

- - + + Error

- - + - Error

- - - + Error - - - -

Error

If the encoder supply (GND or UB+) is demolished, an error is detected (regardless of CLK,/CLK,

data,/DATA.

Page 10

Ix350_02b_oi_e.doc / Mai-18 Page 10 / 50

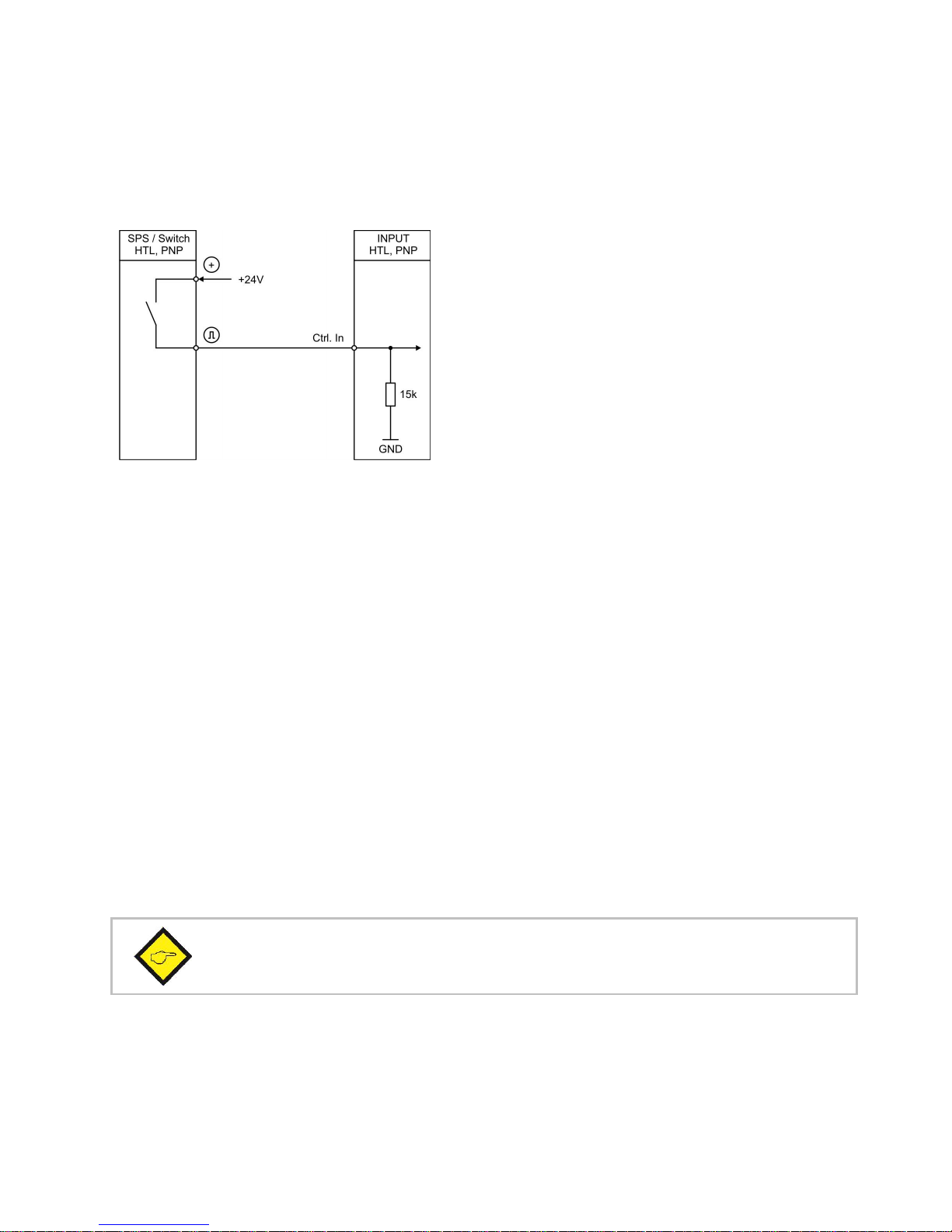

3.4 Control Inputs

The three control inputs at terminal 10, 11 and 12 have HTL PNP characteristics.

In the COMMAND MENU the programmable functions for the control inputs can be assigned.

Available functions are: reset the display value, display switching, locking the touch screen or release

the lock function of the control or relay outputs.

Wiring of the control inputs:

Unconnected PNP inputs are always “LOW” and unconnected NPN inputs are always “HIGH”.

All inputs are designed to receive impulses from electrical impulse sources.

Notice for mechanical switching contacts:

When exceptionally mechanical contacts are used, please connect an external capacitor between

GND (-) and the corresponding input (+). A capacity of 10 µF will reduce the input frequency to

20 Hz and miscounting due to contact bouncing will be eliminated.

3.4. Analog Output (Option AO/AR)

A 16 bit analog output is available at terminal 13 and 14 / 15

This output can be configured and scaled in the ANALOG MENU.

The following configuration is possible:

• Voltage output: -10 … +10 V

• Current output: 0 … 20 mA

• Current output: 4 … 20 mA

The analog output is proportional to the display value and is referenced to potential AGND.

AGND and GND are internally interconnected.

Important:

A parallel operation with voltage and current output at the analog output is not allowed.

Page 11

Ix350_02b_oi_e.doc / Mai-18 Page 11 / 50

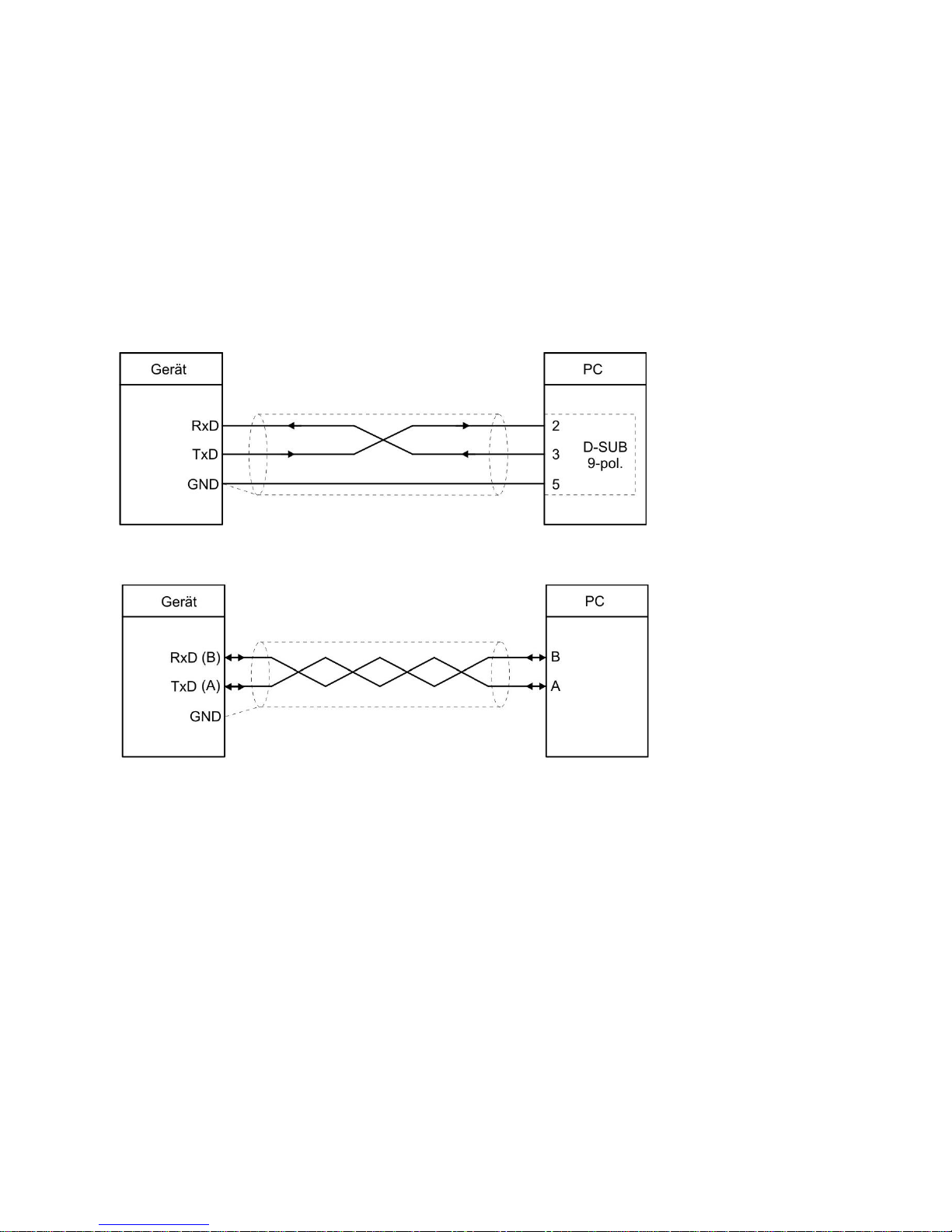

3.5. Serial interface (Option AO/AR/CO/CR)

A serial interface (RS232 or RS485) is available at terminal 16, 17 und 18.

This interface can be configured in the SERIAL MENU.

The serial interface RS232 or RS485 can be used:

for easy setup and commissioning of the units

to modify settings and parameters during operation

to read out internal states and actual measuring values by PC or PLC

The following drawing shows the connection to a PC by using a standard Sub-D-9 connector:

Connection of the RS232 interface:

Connection of the RS485 interface:

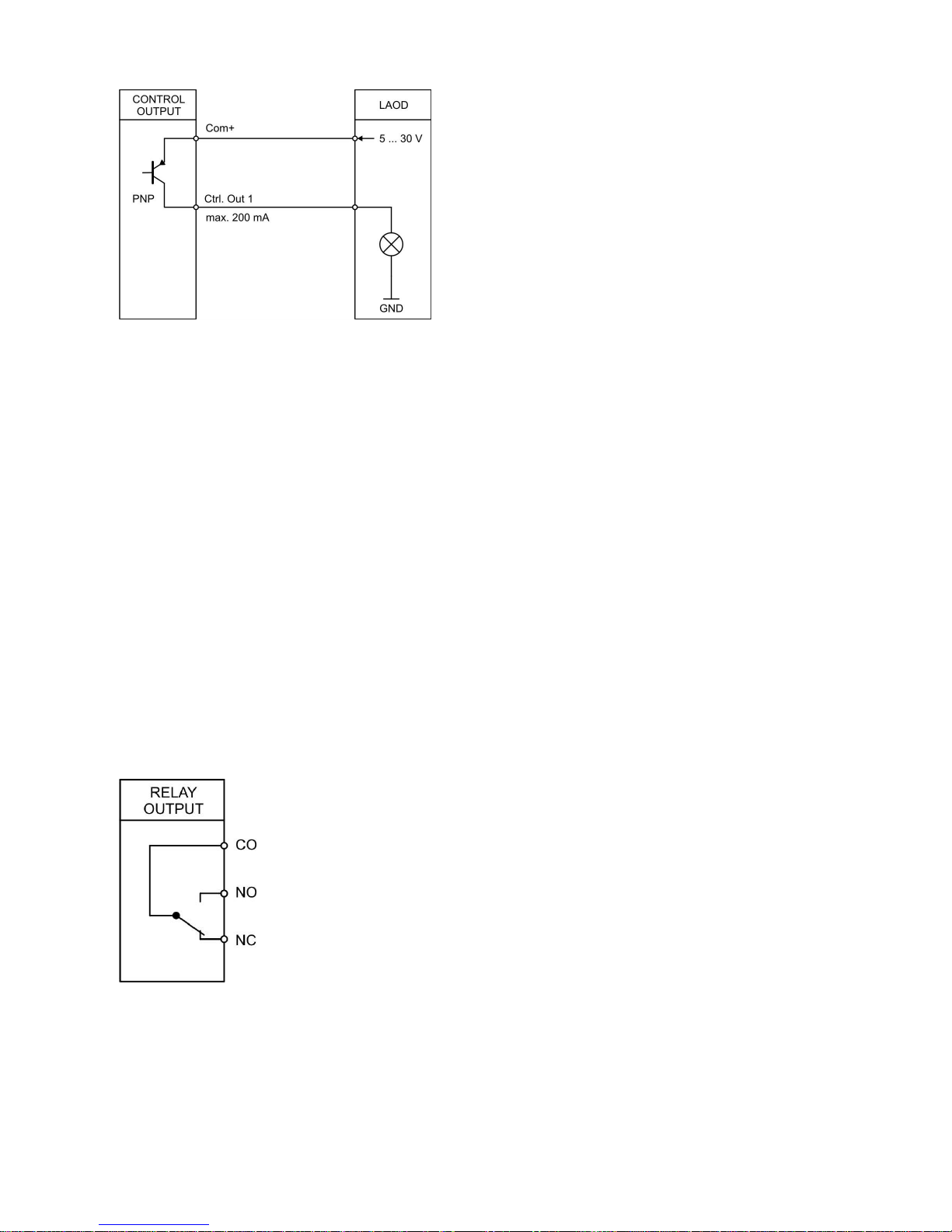

3.6. Control-Output (Option AO/AR/CO/CR)

Four control outputs are available at terminal 20, 21, 22 and 23.

Switching conditions can be set in the PRESELECTION MENU. The output Ctrl. Out1 – 4 are fast PNP

outputs with a switching capability of 5 – 30 Volt / 200 mA per channel. The switching states is

displayed (display with unit and status bar) as C1 … C4.

The switching voltage of the outputs must be applied to input terminal 19 (COM+).

In case of switching inductive loads it is advisable to use external filtering of the coils.

Page 12

Ix350_02b_oi_e.doc / Mai-18 Page 12 / 50

Wiring of the control-outputs:

3.7. AC Power supply (Option AC)

The unit accepts AC supply from 115 to 230 V at the terminals 24 and 25. The power consumption

depends on the level of the supply voltage with approx. 3VA and the additional current required at the

auxiliary voltage output.

Devices with option AC can also be supplied with a DC voltage between 18 and 30 VDC via Terminals

1 and 2.

3.8. Relay-Output (Option RL)

Two relay outputs with potential-free changeover contacts are available at terminal 27, 28, 28, 30, 31

and 32. Switching conditions can be set in the PRESELECTION MENU. The switching states are

displayed (display with unit and status bar) as K1 and K4.

AC-switching capacity max 250 VAC/ max 3 A / 750 VA

DC-switching capacity max 150 VAC/ max 2 A / 50 W

Wiring of the relay outputs

Page 13

Ix350_02b_oi_e.doc / Mai-18 Page 13 / 50

4. Display and touch screen

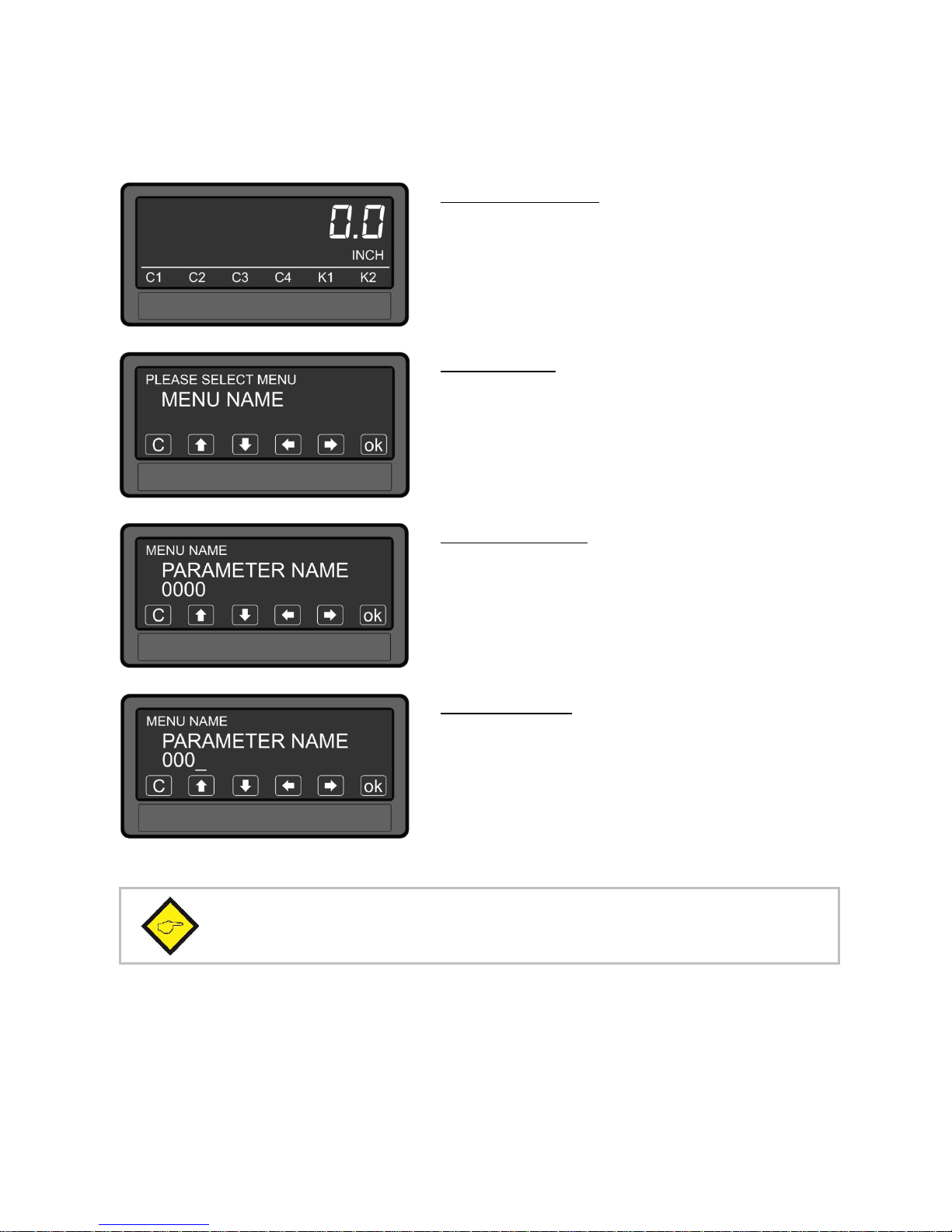

4.1. Screen structure for parametrization

The parameter menus and the parameters are described in chapter 5.

Start setup procedure:

To edit the parameters,

press the touchscreen for 3 seconds.

Menu selection:

Select the parameter menu via arrow buttons and

confirm with “OK”.

The menu selection can be terminated

with „C“.

Parameter selection:

Select the parameter via arrow buttons and confirm

with „OK“.

The parameter selection can be terminated with „C“.

Parameter editing:

Edit the parameter via arrow button up and down,

shift cursor via left and right and save with „OK“.

The parameter editing can be terminated with „C“.

Parameter changes becomes active only after closing the menu selection.

.

Page 14

Ix350_02b_oi_e.doc / Mai-18 Page 14 / 50

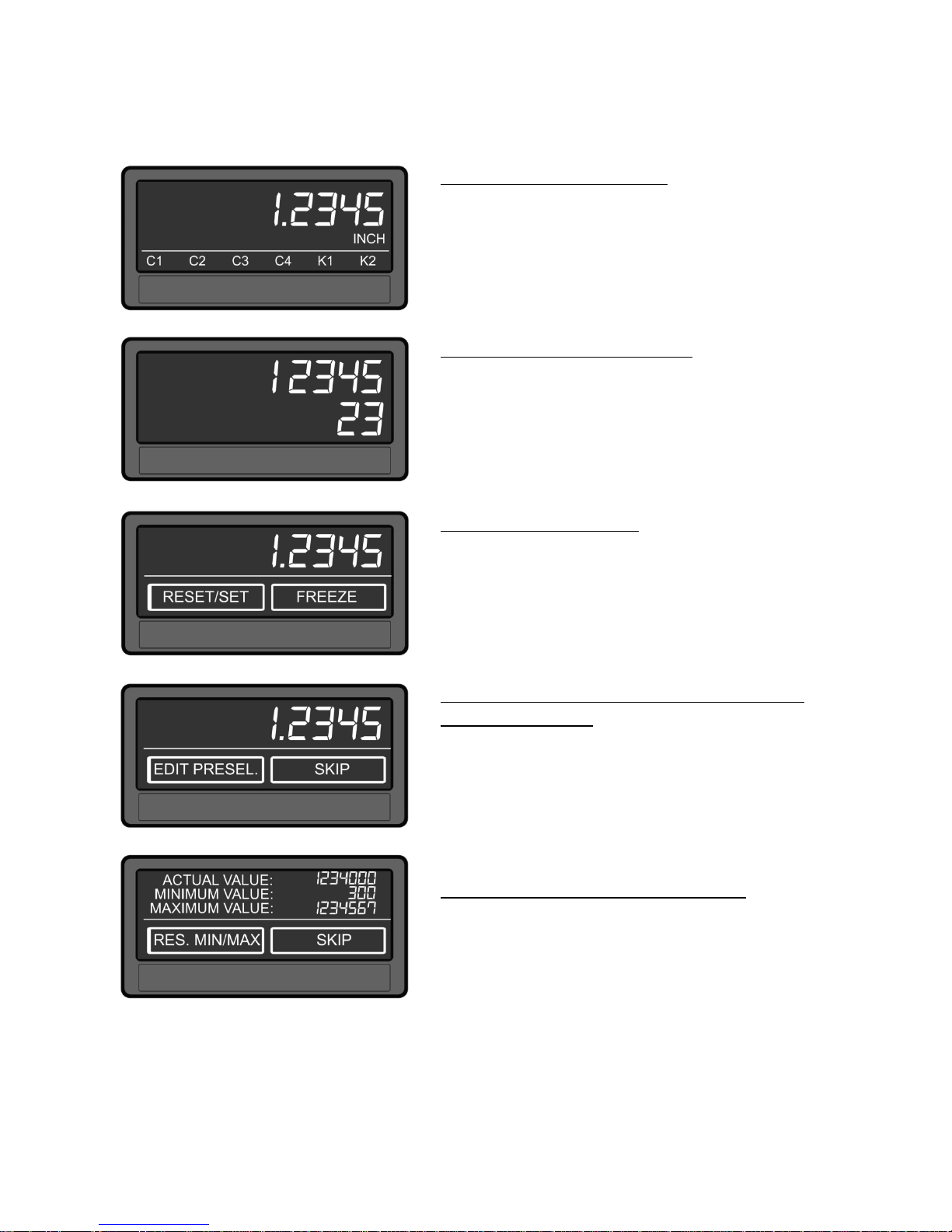

4.2. Screen structure in operation

The following displays are available during operation. Depending on the device version and the

selected operating mode, only certain representations are displayed.

Display with unit and status bar

To switch to the next display,

press the touch screen.

Control - or Relay status are only shown with Option

AO, CO, RL.

Display single and multi-turn value:

Display value for diagnostic purposes - raw data, no

influence on/by device functions.

To switch to the next display, press the top of the

screen.

Display with command keys

To switch to the next display, press the top of the

screen.

Display for quick start for enter preselection values

(PRESELECT VALUES)

To switch to the next display, press the top of the

screen or the “skip” button.

This is only possible with Option AO, CO, RL

Display with minimum and maximum value

To switch to the next display, press the top of the

screen or the “skip” button.

Page 15

Ix350_02b_oi_e.doc / Mai-18 Page 15 / 50

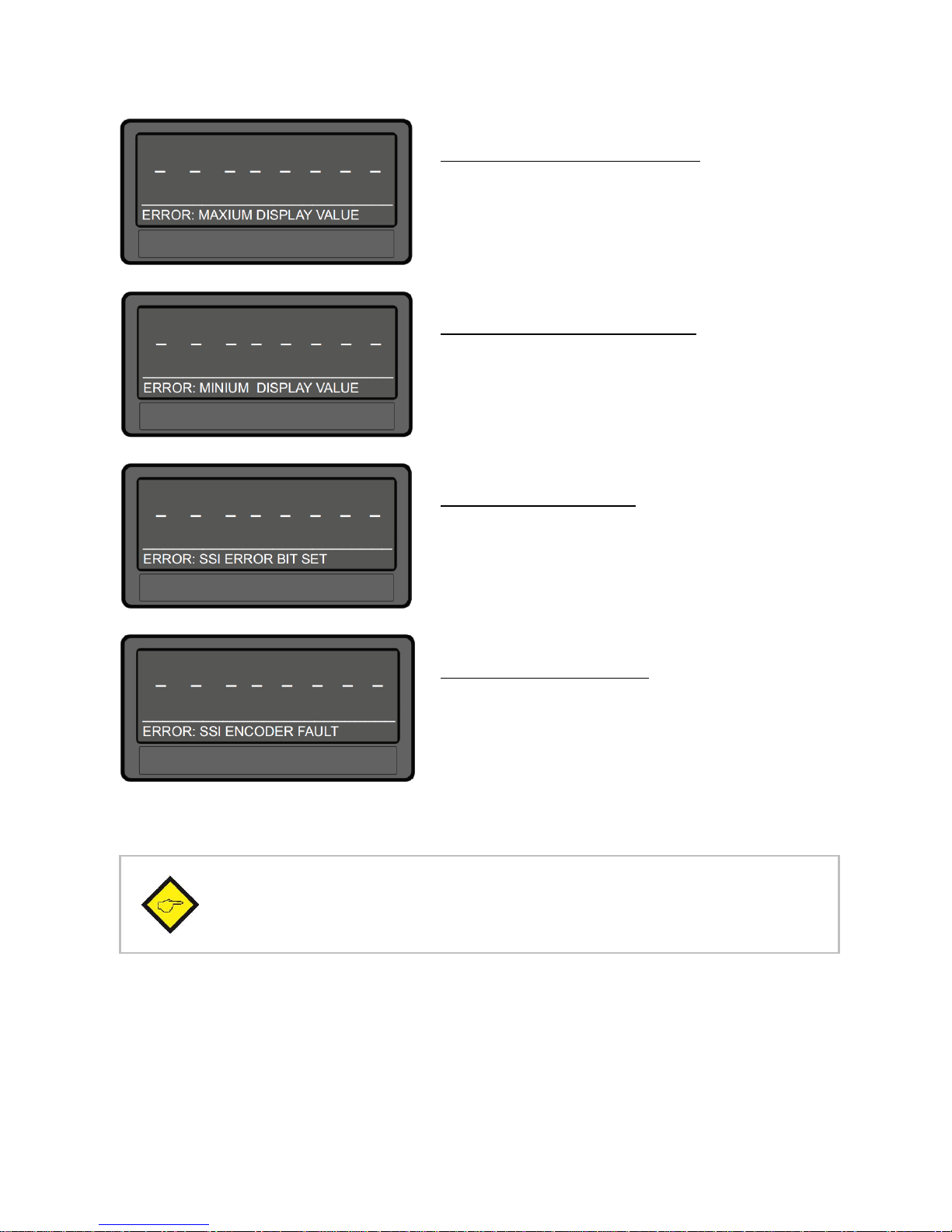

4.3. Error Message

ERROR: MAXIMUM DISPLAY VALUE

Display value is greater than + 99,999,999

ERROR: MINIMUM DISPLAY VALUE

Display value is less than-99,999,999

ERROR: SSI ERROR BIT SET

The error bit of the SSI encoder is set.

ERROR: SSI ENCODER FAULT

Encoder error (e.g. open-circuit) only at IX355

In case of error, the measurement result is set to 0.

With option AO, the analogue output is controlled with 0 V or 0 mA and with

option CO and AO the limit value monitoring is performed with the reference

value "0".

Page 16

Ix350_02b_oi_e.doc / Mai-18 Page 16 / 50

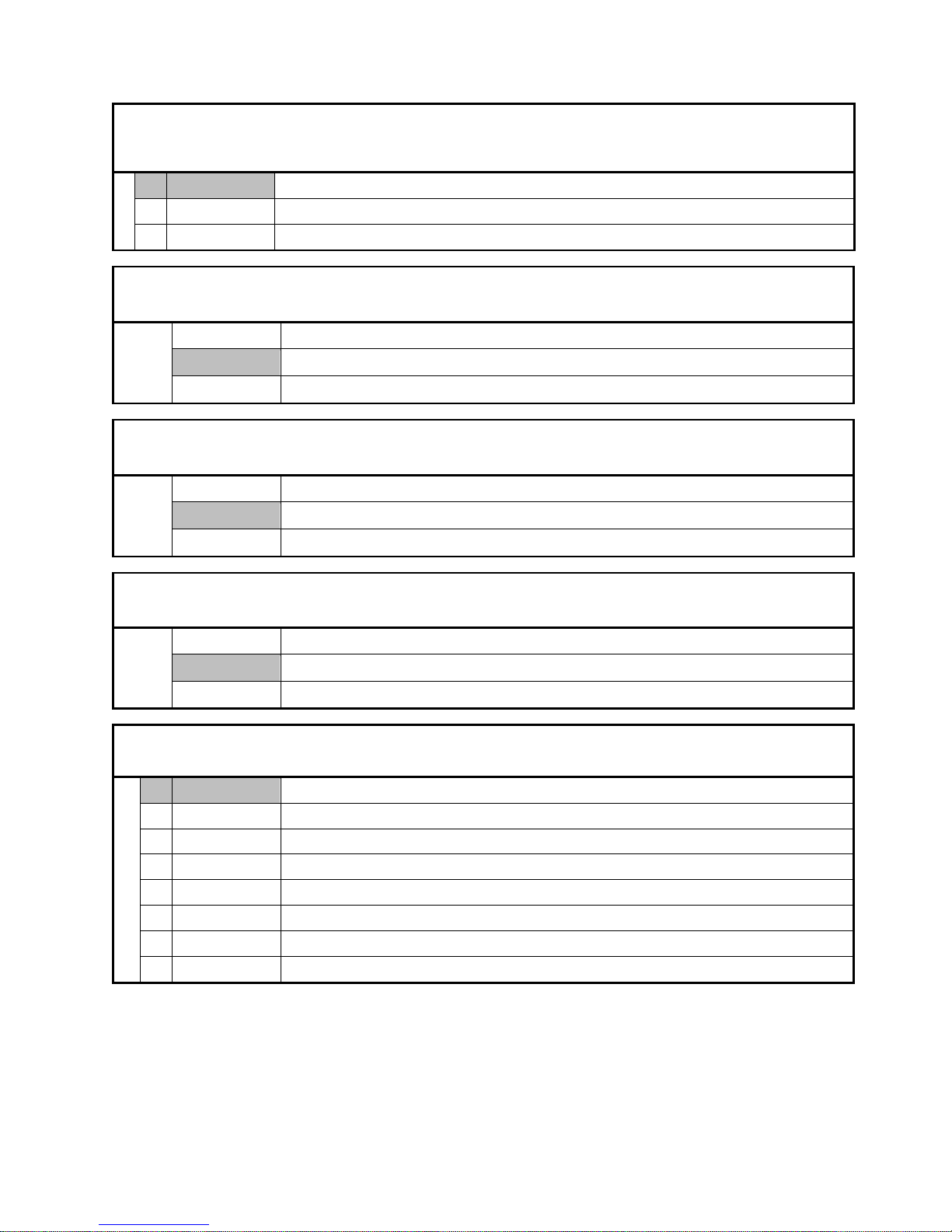

5. Parameter / Overview-Menu Structure

This section provides an overview of the menus and their parameters. The menu names are printed

bold and the associated parameters are listed under the menu name. Depending on the device version

and the selected operation mode, only the necessary menus / parameters are shown.

Menu / Parameter

GENERAL MENU

DISPLAY FORMAT

FACTOR

DIVIDER

ADDITIVE VALUE

DECIMAL POINT

SCALE UNITS

LINEARIZATION MODE

PIN PRESELECTION

PIN PARAMETER

FACTORY SETTINGS

Menu / Parameter

SSI PROPERTIES

MODE

ENCODER RESOLUTION

BIT PER REVOLUTION

DATA FORMAT

BAUD RATE

HIGHT BIT

LOW BIT

SSI OFFSET

DIRECTION

ROUND LOOP VALUE

SAMPLING TIME

ERROR BIT

ERROR POLARITY

ENCODER SUPPLY

Page 17

Ix350_02b_oi_e.doc / Mai-18 Page 17 / 50

Menu / Parameter

PRESELECTION VALUES

PRESELECTION 1

PRESELECTION 2

PRESELECTION 3

PRESELECTION 4

PRESELECTION 1 MENU

MODE 1

HYSTERESIS 1

PULSE TIME 1

OUTPUT TARGET 1

OUTPUT POLARITY 1

OUTPUT LOCK 1

START UP DELAY 1

EVENT COLOR 1

PRESELECTION 2 MENU

MODE 2

HYSTERESIS 2

PULSE TIME 2

OUTPUT TARGET 2

OUTPUT POLARITY 2

OUTPUT LOCK 2

START UP DELAY 2

EVENT COLOR 2

PRESELECTION 3 MENU

MODE 3

HYSTERESIS 3

PULSE TIME 3

OUTPUT TARGET 3

OUTPUT POLARITY 3

OUTPUT LOCK 3

START UP DELAY 3

EVENT COLOR 3

PRESELECTION 4 MENU

MODE 4

HYSTERESIS 4

PULSE TIME 4

OUTPUT TARGET 4

OUTPUT POLARITY 4

OUTPUT LOCK 4

START UP DELAY 4

EVENT COLOR 4

Menu / Parameter

SERIAL MENU

UNIT NUMBER

SERIAL BAUD RATE

SERIAL FORMAT

SERIAL INIT

SERIAL PROTOCOL

SERIAL TIMER

SERIAL VALUE

ANALOG MENU

ANALOG FORMAT

ANALOG START

ANALOG END

ANALOG GAIN

ANALOG OFFSET

COMMAND MENU

INPUT 1 ACTION

INPUT 1 CONFIG

INPUT 2 ACTION

INPUT 2 CONFIG

INPUT 3 ACTION

INPUT 3 CONFIG

DISPLAY MENU

COLOR

BRIGHTNESS

CONTRAST

SCREEN SAVER

UP-DATE-TIME

FONT

LINEARISATION MENU

P1(X)

P1(Y)

P2(X)

P2(Y)

…

…

P23(X)

P23(Y)

P24(X)

P24(Y)

Page 18

Ix350_02b_oi_e.doc / Mai-18 Page 18 / 50

5.1. General Menu

DISPLAY FORMAT

This parameter selects the Display Format. The corresponding decimal point will be set automatically by display

format 999999:59 or 9999:59:59.

0 99999999

Without format customization

1 999999:59

Display angle minutes / seconds

2 9999:59:59

Display in angle minutes : seconds

FACTOR

This parameter defines the factor.

-99999999

Smallest value

1

Default value

99999999

Highest value

DIVIDER

This parameter defines the divider.

-99999999

Smallest value

1

Default value

99999999

Highest value

ADDITIVE VALUE

This parameter defines the additive constant.

-99999999

Smallest value

0

Default value

99999999

Highest value

DECIMAL POINT

This value defines the position of the decimal point.

0

NO

No decimal point

1

0000000.0

Decimal point at the specified position

2

000000.00

Decimal point at the specified position

3

00000.000

Decimal point at the specified position

4

0000.0000

Decimal point at the specified position

5

000.00000

Decimal point at the specified position

6

00.000000

Decimal point at the specified position

7

0.0000000

Decimal point at the specified position

Page 19

Ix350_02b_oi_e.doc / Mai-18 Page 19 / 50

Continuation „General Menu“:

SCALE UNITS

This parameter defines the required engineering unit. This parameter does not affect the calculation of the display

value. The number of decimal places must be defined with the parameter DECIMAL POINT.

0

inch

Default

1

feet 2

mm 3

cm 4 m 5 Stueck

6 pcs 7

Grad 8

degree

9

Min:Sec

10

G:M:S

11 %

12

mbar

13

bar 14

psi 15

Pa 16

kPa 17 g

18

kg 19 t

20

lb 21

oz 22

ml 23 1

24

cm3 25

m3 26

gal

27

Edit Unit

A customized unit with up to 16 digits can be edited using this parameter.

Pressing the "OK" button opens the Edit Unit Menu.

A unit can be created using the arrow keys. (pressing and holding the arrow keys the

characters scroll fast).

The “OK” button saves the Edit Unit Menu. The “C” button closes the Edit Unit Menu.

! " # $ % & ' ( ) * + , - .

/

0 1 2 3 4 5 6 7 8 9 : ; < = > ? @ A B C D E F G H I J K L M N

O

P Q R S T U V W X Y Z [ \ ] ^ _ ` a b c d e f g h i j k l m n

o

p q r s t u v w x y z { | } ~

Page 20

Ix350_02b_oi_e.doc / Mai-18 Page 20 / 50

Continuation „General Menu“:

LINEARIZATION MODE

This parameter defines the linearization function. See chapter 6.1.

0

OFF

No linearization

1

1 QUADRANT

Linearization in the 1. quadrant

2

4 QUADRANT

Linearization in all 4 quadrants

PIN PRESELECTION

This parameter defines the PIN-code to lock the quick start of the menu PRESELECTION VALUE for entering the

preselection values. (Master PIN 6079).

This Lock function is only useful in conjunction with active lock function in PIN PARAMETER.

0000

No lock

… 9999

Access after entering PIN-Code 9999

PIN PARAMETER

This parameter defines the PIN-code for lock function of all parameters (master PIN 6079).

0000

No lock

… 9999

Parameterization of the unit after entering PIN-code 9999

FACTORY SETTINGS

0

NO

No default values are loaded

1

YES

Load default values of all parameters (grey marked default values)

Page 21

Ix350_02b_oi_e.doc / Mai-18 Page 21 / 50

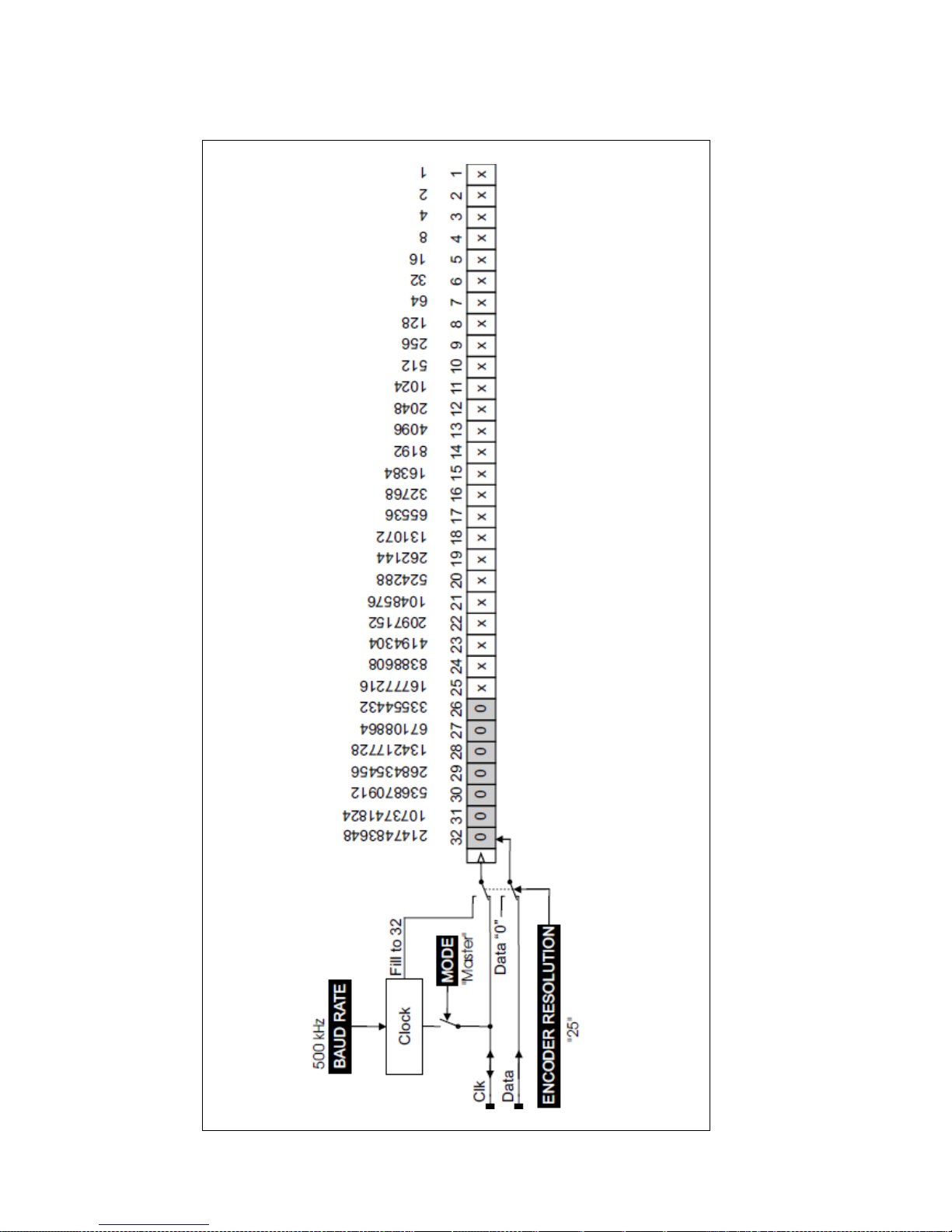

5.2. SSI Properties

MODE

SSI setting master mode or slave

0

MASTER

Master-Mode: Clock for SSI encoder comes from the device

1

SLAVE

Slave-Mode: Clock for SSI encoder comes from the external master.

ENCODER RESOLUTION

Resolution of the SSI encoder (total number of bits)

10

Smallest value

25

Default value

32

Highest value

BIT PER REVOLUTION

Bit revolution for singleturn

10

Smallest value

13

Default value

16

Highest value

DATA FORMAT

Setting the SSI code (binary or grey)

0

GRAY CODE

SSI-Code Gray

1

BINARY CODE

SSI-Code Binary

BAUD RATE

Clock frequency of SSI telegrams

0

2 MHZ

N.A.

1

1.5 MHZ

N.A.

2

1 MHZ

Clock frequency 1 MHz

3

500 KHZ

Clock frequency 500 kHz

4

250 KHZ

Clock frequency 250 kHz

5

100 KHZ

Clock frequency 100 kHz

Page 22

Ix350_02b_oi_e.doc / Mai-18 Page 22 / 50

Continuation „SSI Properties“:

HIGH BIT (for bit blanking)

Defines the highest evaluated bit (MSB) for bit blanking.

If all bits should be evaluated, HIGH BIT must be set to the given total number of bit.

01

Smallest value

25

Default value

32

Highest value

LOW BIT (for bit blanking))

Defines the lowest evaluated bit (MSB) for bit blanking.

If all bits should be evaluated, LOW BIT must be set to 01.

01

Smallest value

…

32

Highest value

SSI OFFSET

In the case of a reset/Set value command (via keyboard command, control input or PC user interface) The current

SSI position of the encoder is transferred to the parameter "SSI offset".

-99999999

Smallest value

0

Default value

99999999

Highest value

DIRECTION

Definition of the direction of rotation forward / backward

0

FORWARD

Forward

1

REVERSE

Backwards

ROUND LOOP VALUE

Defines the number of encoder steps when a round-loop function is desired.

0

Normal display of encoder data, round-loop function is turned off

…

99999999

Number of steps for the round-loop function

SAMPLING TIME (S)

Determines the read cycle for the SSI signal in the Master MODE

0.001

Minimum measurement time in seconds

0.010

Default value

9.999

Maximum measurement time in seconds

Page 23

Ix350_02b_oi_e.doc / Mai-18 Page 23 / 50

Continuation „SSI Properties“:

ERROR BIT

Defines the encoder monitoring and the error bit

0

No error bit available.

Review on connected sensor is turned off.

…

32

Position of the error bits to be evaluated

Review on connected sensor is turned on.

ERROR POLARITY

Defined the polarity of the error bit in the case of an error

0

Bit is low in the case of an error

1

Bit is high in the case of an error

ENCODER SUPPLY (available only at IX355)

This parameter defines the output voltage of the auxiliary output (aux out)

0

24VDC SUPPLY

24 VDC encoder supply

1

5VDC SUPPLY

5 VDC encoder supply

Page 24

Ix350_02b_oi_e.doc / Mai-18 Page 24 / 50

5.3. Preselection Values

This menu is used to set the preselection values or the switching points.

The preselection values / switching points are always referred to the display value.

This menu is only available for devices with option CO, AO or RL.

PRESELECTION 1

Preselection / switching point 1

-99999999

Smallest value

1000

Default value

+99999999

Highest value

PRESELECTION 2

Preselection / switching point 2

-99999999

Smallest value

2000

Default value

+99999999

Highest value

PRESELECTION 3

Preselection / switching point 3

-99999999

Smallest value

3000

Default value

+99999999

Highest value

PRESELECTION 4

Preselection / switching point 4

If the BATCH MODE is active, the batch counter is compared with the preselection value 4.

-99999999

Smallest value

40000

Default value

+99999999

Highest value

Page 25

Ix350_02b_oi_e.doc / Mai-18 Page 25 / 50

5.4. Preselection 1 Menu

This function is only available for devices with option CO, AO or RL.

MODE 1

Switching conditions for preselection 1. Output/ relay/ display switches under the following conditions:

0

|RESULT|>=|PRES|

Absolute value of the display value is greater or equal absolute value of

PRESELECTION 1

With HYSTERESIS 1 not equal 0 the following switching condition is

applied:

Display value >= PRESELECTION 1 ON,

Display value < PRESELECTION 1 – HYSTERESIS 1 OFF

1

|RESULT|<=|PRES|

Absolute value of the display value is less or equal absolute value of

PRESELECTION 1 (start-up suppression (START UP DELAY) is advisable)

With HYSTERESIS 1 not equal 0 the following switching condition is

applied:

Display value <= PRESELECTION 1 ON,

Display value > PRESELECTION 1 + HYSTERESIS 1 OFF

2

|RESULT|=|PRES|

Absolute value of the display value is equal absolute value of

PRESELECTION 1

A range (Preselection +/- ½ Hysteresis) can be defined and monitored in

conjunction with the hysteresis.

With HYSTERESIS 1 not equal 0 the following switching condition is

applied:

Display value > PRESELECTION 1 + ½ HYSTERESIS 1 OFF,

Display value < PRESELECTION 1 - ½ HYSTERESIS 1 OFF

3

RESULT>=PRES

Display value is greater or equal PRESELECTION 1, e.g. overspeed

With HYSTERESIS 1 not equal 0 the following switching condition is

applied:

Display value >= PRESELECTION 1 ON,

Display value < PRESELECTION 1 – HYSTERESIS 1 OFF

4

RESULT<=PRES

Display value is less or equal PRESELECTION 1, e.g. underspeed

(start-up suppression (START UP DELAY) is advisable)

With HYSTERESIS 1 not equal 0 the following switching condition is

applied:

Display value <= PRESELECTION 1 ON,

Display value > PRESELECTION 1 + HYSTERESIS 1 OFF

5

RESULT=PRES

Display value is equal PRESELECTION 1. A range (Preselection +/- ½

Hysteresis) can be defined and monitored in conjunction with the hysteresis.

With HYSTERESIS 1 not equal 0 the following switching condition is

applied:

Display value > PRESELECTION 1 + ½ HYSTERESIS 1 OFF,

Display value < PRESELECTION 1 - ½ HYSTERESIS 1 OFF

6

RES>=PRES-TRAIL

Trailing PRESELECTION 1:

Display value is greater or equal PRESELECTION 2 – PRESELECTION 1

ON,

PRESELECTION 1 is the trailing value from PRESELECTION 2

7

ERROR SET

Error message for device errors

Page 26

Ix350_02b_oi_e.doc / Mai-18 Page 26 / 50

Continuation „Preselection 1 Menu“:

HYSTERESIS 1

This parameter defines the switching hysteresis of the switch-off point for preselection 1

0

No switching hysteresis

…

99999

Switching hysteresis of 99999

PULSE TIME 1 (S)

Duration of output pulse for the switching condition of preselection 1

0,000

No output pulse (static signal)

…

60,000

Pulse duration of 60 seconds

OUTPUT TARGET 1

Assignment of an output or relay for the switching condition of preselection 1.

If more than one switching condition is assigned to one output / relay, the output is set when at least one

switching condition is true

0

NO

No assignment

1

CTRL OUT 1

Switching condition assigned to “Ctrl. Out 1”

2

CTRL OUT 2

Switching condition assigned to “Ctrl. Out 2”

3

CTRL OUT 3

Switching condition assigned to “Ctrl. Out 3”

4

CTRL OUT 4

Switching condition assigned to “Ctrl. Out 4”

5

RELAY 1

Switching condition assigned to “Rel. 1”

6

RELAY 2

Switching condition assigned to “Rel. 2”

OUTPUT POLARITY 1

Polarity for the switching condition of preselection 1

0

ACTIVE HIGH

Switching condition is true Active „HIGH“

1

ACTIVE LOW

Switching condition is true Active „LOW“

OUTPUT LOCK 1

Latch for the switching condition of preselection 1

0

NO

No latch for preselection

1

YES

Latch for preselection (command LOCK RELEASE will clear latch)

Page 27

Ix350_02b_oi_e.doc / Mai-18 Page 27 / 50

Continuation „Preselection 1 Menu“:

START UP DELAY 1 (S)

Start-up suppression for the switching condition of preselection 1. Time to start the monitoring function.

This adjustment is only valid for the switching condition |RESULT|<=|PRES| or RESULT<=PRES and mode SPPED

and PROCESS TIME.

(Start Up Delay 3 and 4 have an automatic start up suppression).

0.000

No start-up suppression

…

60.000

Start-up suppression in seconds

EVENT COLOR 1

Event-depending change of the display color for the switching condition of preselection 1.

EVENT COLOR 1 has the lowest priority. EVENT COLOR 2 … 4 are allowed to overwrite this color change.

0

NO CHANGE

No color change.

1

CHANGE TO RED

Color change to red

2

CHANGE TO GREEN

Color change to green

3

CHANGE TO YELLOW

Color change to yellow

Page 28

Ix350_02b_oi_e.doc / Mai-18 Page 28 / 50

5.5. Preselection 2 Menu

MODE 2

Switching conditions for preselection 2., see chapter PRESELECTION 1 MENU (except the trailing value)

see chapter PRESELECTION 1 MENU

6

RES>=PRESTRAIL

Trailing preselection 2:

Display value is greater or equal to PRESELECTION 1 – PRESELECTION 2 ON,

PRESELECTION 2 is the trailing preselection from PRESELECTION 1.

HYSTERESIS 2

This parameter defines the switching hysteresis of the switch-off point for preselection 2.

See chapter PRESELECTION 1 MENU.

PULSE TIME 2 (S)

Duration of output pulse for the switching condition of preselection 2.

See chapter PRESELECTION 1 MENU.

OUTPUT TARGET 2

Assignment of an output or relay for the switching condition of preselection 2.

See chapter PRESELECTION 1 MENU.

OUTPUT POLARITY 2

Polarity for the switching condition of preselection 2.

See chapter PRESELECTION 1 MENU.

OUTPUT LOCK 2

Latch for the switching condition of preselection 2.

See chapter PRESELECTION 1 MENU.

START UP DELAY 2 (S)

Start-up suppression for the switching condition of preselection 2.

See chapter PRESELECTION 1 MENU.

(Start Up Delay 3 and 4 have an automatic start up suppression).

EVENT COLOR 2

Event-depending change of the display color for the switching condition of preselection 2.

See chapter PRESELECTION 1 MENU.

Page 29

Ix350_02b_oi_e.doc / Mai-18 Page 29 / 50

5.6. Preselection 3 Menu

MODE 3

Switching conditions for preselection 3., see chapter PRESELECTION 1 MENU (except the trailing value)

See chapter PRESELECTION 1 MENU

6

RES>=PRESTRAIL

Trailing preselection 3:

Display value is greater or equal to PRESELECTION 4 – PRESELECTION 3 ON,

PRESELECTION 3 is the trailing preselection from PRESELECTION 4.

HYSTERESIS 3

This parameter defines the switching hysteresis of the switch-off point for preselection 3.

See chapter PRESELECTION 1 MENU.

PULSE TIME 3 (S)

Duration of output pulse for the switching condition of preselection 3.

See chapter PRESELECTION 1 MENU.

OUTPUT TARGET 3

Assignment of an output or relay for the switching condition of preselection 3.

See chapter PRESELECTION 1 MENU.

OUTPUT POLARITY 3

Polarity for the switching condition of preselection 3.

See chapter PRESELECTION 1 MENU.

OUTPUT LOCK 3

Latch for the switching condition of preselection 3.

See chapter PRESELECTION 1 MENU.

START UP DELAY 3

Start-up suppression for the switching condition of preselection 3.

Time to start the monitoring function.

This adjustment is only valid for the switching condition |RESULT|<=|PRES| or RESULT<=PRES and mode SPPED

and PROCESS TIME. (Start Up Delay 1 and 2 have a time-dependent start up suppression).

0

OFF

No start-up suppression

1

AUTO

Automatic start up suppression,

Until the preselection value / switching point is exceeded for the first time.

EVENT COLOR 3

Event-depending change of the display color for the switching condition of preselection 3.

See chapter PRESELECTION 1 MENU.

Page 30

Ix350_02b_oi_e.doc / Mai-18 Page 30 / 50

5.7. Preselection 4 Menu

If the BATCH MODE is active, the batch counter is compared with the preselection value 4.

MODE 4

Switching conditions for preselection 4., see chapter PRESELECTION 1 MENU (except the trailing value)

See chapter PRESELECTION 1 MENU

6

RES>=PRES-TRAIL

Trailing preselection 4:

Display value is greater or equal to PRESELECTION 3 – PRESELECTION 4 ON,

PRESELECTION 4 is the trailing preselection from PRESELECTION 3.

HYSTERESIS 4

This parameter defines the switching hysteresis of the switch-off point for preselection 4.

See chapter PRESELECTION 1 MENU.

PULSE TIME 4 (S)

Duration of output pulse for the switching condition of preselection 4.

See chapter PRESELECTION 1 MENU.

OUTPUT TARGET 4

Assignment of an output or relay for the switching condition of preselection 4.

See chapter PRESELECTION 1 MENU.

OUTPUT POLARITY 4

Polarity for the switching condition of preselection 4.

See chapter PRESELECTION 1 MENU.

OUTPUT LOCK 4

Latch for the switching condition of preselection 4.

See chapter PRESELECTION 1 MENU.

START UP DELAY 4

Start-up suppression for the switching condition of preselection 4. See chapter PRESELECTION 3 MENU.

(Start Up Delay 1 and 2 have a time-dependent start up suppression).

0

OFF

No start-up suppression

1

AUTO

Automatic start up suppression,

Until the preselection value / switching point is exceeded for the first time.

EVENT COLOR 4

Event-depending change of the display color for the switching condition of preselection 4.

See chapter PRESELECTION 1 MENU.

Page 31

Ix350_02b_oi_e.doc / Mai-18 Page 31 / 50

5.8. Serial Menu

This menu defines the basic settings of serial interface.

This function is only available for devices with option CO or AO.

UNIT NUMBER

This parameter defines serial device addresses. The addresses between 11 and 99 can be assigned to the

devices. Addresses with zero are not allowed, there are used as broadcast addresses.

11

Smallest address

… 99

Highest address

SERIAL BAUD RATE

This parameter defines the serial baud rate

0

9600

9600 baud

1

19200

19200 baud

2

38400

38400 baud

SERIAL FORMAT

This parameter defines the bit data format.

0

7-EVEN-1

7 data Parity even 1 Stop

1

7-EVEN-2

7 data Parity even 2 Stops

2

7-ODD-1

7 data Parity odd 1 Stop

3

7-ODD-2

7 data Parity odd 2 Stops

4

7-NONE-1

7 data no Parity 1 Stop

5

7-NONE-2

7 data no Parity 2 Stops

6

8-EVEN-1

8 data Parity even 1 Stop

7

8-ODD-1

8 data Parity odd 1 Stop

8

8-NONE-1

8 data no Parity 1 Stop

9

8-NONE-2

8 data no Parity 2 Stops

SERIAL INIT

This parameter defines the baud rate for the initialization to the user interface OS6.0. With settings larger than

9600 the initialization time can be reduced.

0

NO

Initialization with 9600 baud. Then the device operates with the value selected by the

user.

1

YES

Initialization with the baud rate set by SERIAL BAUD RATE. Then the device operates

with the value selected by the user.

Page 32

Ix350_02b_oi_e.doc / Mai-18 Page 32 / 50

Continuation „Serial Menu“:

SERIAL PROTOCOL

Determines the sequence of characters send, when using the serial output for cyclic data transmission under time

control (xxxxxxx = value SERIAL VALUE).

Setting „1“ removes the unit address from the string which allows a slight faster transmission cycle.

0

Transmission report = Unit No., +/-, data, LF, CR

1 1 +/- X X X X X X X LF

CR

1

Transmission report = +/-, data, LF, CR

+/- X X X X X X X LF

CR

SERIAL TIMER (S)

This register determines the cycle time in seconds for cycling transmission of SERIAL VALUE when using the serial

output. (On a serial request, the cycling transmission is stopped for 20 s)

0,000

All cyclic transmission is switched off. The unit will send data upon a serial request or with

command SERIAL PRINT.

…

60,000

Cycle time in seconds.

SERIAL VALUE

This parameter defines the value to be transmitted.

Setting

Code

Register contents

0

:0

Measurement Result

1

:1

SSI Data

2

:2

SSI Single

3

:3

SSI Rev

4

:4

SSI Dir Result

5

:5

SSI Mask Result

6

:6

Minimal Value

7

:7

Maximal Value

8

:8

SSI Set Result

9

:9

SSI Data

Page 33

Ix350_02b_oi_e.doc / Mai-18 Page 33 / 50

5.9. Analog Menu

This menu defines the basic settings of the analog output.

This function is only available for devices with option AO.

ANALOG FORMAT

This parameter defines the output characteristics. The analogue output is proportional to the display value.

With setting ANALOG FORMAT (-10 … +10 V) in MODE COUNTER the polarity of the analog output depends on

the polarity of the display value.

0

-10…10V

-10 … +10 V

1

0…20MA

0 … 20 mA

2

4…20MA

4 … 20 mA

ANALOG START

This parameter defines the start value of the analog conversion. This start value is corresponding to the display

value for an analog output of 0 V or 0/4 mA.

-99999999

Smallest start value

0

Default value

+99999999

Highest start value

ANALOG END

This parameter defines the end value of the analog conversion. This end value is corresponding to the display

value for an analog output of (+/-) 10 V or 20mA.

-99999999

Smallest end value

10000

Default Wert

+99999999

Highest end value

ANALOG GAIN (%)

This parameter defines the zero offset of the analog output. The ANALOG GAIN is the maximum modulation of

the analog output in % terms given up to (+/-) 10 V or 20 mA.

E.g. 102,00 results in an offset of 10.2 V / 20.4 mA from reaching the ANALOG START value

E.g. 95,00 results in an offset of 9.5 V / 18 mA from reaching the ANALOG END value

0,00

Smallest end value

100,00

Default Wert

110,00

Highest end value

ANALOG OFFSET (%)

This parameter defines the zero offset of the analog output.

E. g. 0.20 results in an offset of 0.02 V or 0.04 mA from reaching the ANALOG START value

-99,99

Smallest offset

0

Default value

+99,00

Highest offset

Page 34

Ix350_02b_oi_e.doc / Mai-18 Page 34 / 50

5.10. Command Menu

INPUT 1 ACTION (function Input 1)

This parameter defines the function of the input “Ctrl. In 1”.

0

NO

No function

1

RESET/SET VALUE

Transfer of the current SSI position to the SSI offset parameter

(d) (s)

2

FREEZE

Freeze actual display value

(s)

3

KEY LOCK

disable touch screen

(s)

4

LOCK RELEASE

Loosen locking of all outputs / relay

(d)

5

RESET MIN/MAX

Reset of the min. / max. values

(d) (s)

6

SERIAL PRINT

Sending of serial data, see parameter SERIAL VALUE

(d)

7

TEACH PRESEL. 1

Current display value is stored as PRESELECTION 1

(d)

8

TEACH PRESEL. 2

Current display value is stored as PRESELECTION 2

(d)

9

TEACH PRESEL. 3

Current display value is stored as PRESELECTION 3

(d)

10

TEACH PRESEL. 4

Current display value is stored as PRESELECTION 4

(d)

11

SCROLL DISPLAY

Display switching (see display in operation mode)

(d)

12

CLEAR LOOP TIME

Release all latched switching conditions

13

START PRESELECT

N.A. 14

ACTIVATE DATA

N.A. 15

STORE DATA

N.A. 16

TESTPROGRAM

N.A.

17

SET RED COLOR

The display lights up red. The color can be changed by the eventdependent color switching in the PRESELECTION 1... 4

(d)

18

SET GREEN COLOR

The display lights up green. The color can be changed by the eventdependent color switching in the PRESELECTION 1... 4

(d)

19

SET YELLOW COLOR

The display lights up yellow The color can be changed by the eventdependent color switching in the PRESELECTION 1... 4

(d)

(s) = static switching (level evaluation)

INPUT CONFIG must be set to active LOW / HIGH

(d) = dynamic switching (edge evaluation)

INPUT CONFIG must be set to RISING/FALLING EDGE

Page 35

Ix350_02b_oi_e.doc / Mai-18 Page 35 / 50

Continuation „Command Menu“:

INPUT 1 CONFIG

This parameter defines the switching characteristics of the input “Ctrl. In 1”.

0

ACTIVE LOW

Active at „LOW“ (static)

1

ACTIVE HIGH

Active at „HIGH“ (static)

2

RISING EDGE

Activate at rising edge

3

FALLING EDGE

Activate at falling edge

INPUT 2 ACTION

This parameter defines the function of the input “Ctrl. In 2”.

See parameter INPUT 1 ACTION.

INPUT 2 CONFIG

This parameter defines the switching characteristics of the input “Ctrl. In 2”.

See parameter INPUT 1 CONFIG.

INPUT 3 ACTION

This parameter defines the function of the input “Ctrl. In 3”.

See parameter INPUT 1 ACTION.

INPUT 3 CONFIG

This parameter defines the switching characteristics of the input “Ctrl. In 3”.

See parameter INPUT 1 CONFIG.

Page 36

Ix350_02b_oi_e.doc / Mai-18 Page 36 / 50

5.11. Display Menu

Parameter changes become active only after closing the menu selection.

COLOR

This parameter defines the display color.

Event-depending change of the display color by a switching condition is possible (see PRESELECTION 1…4 MENU)

Event-depending changes are only available for devices with option CO, AO or RL.

0

RED

Red display

1

GREEN

Green display

2

YELLOW

Yellow display

BRIGHTNESS (%)

This parameter defines the brightness of the display in percent

10

Min. brightness

90

Default value

100

Max. brightness

CONTRAST

This parameter defines the viewing angle.

0

Viewing angle from top

1

Viewing angle from centre

2

Viewing angle from bottom

SCREEN SAVER (S)

This parameter defines the time in seconds until the display is switched off, after the last touch action.

A new touch action will activate the display again.

0

No switch off

… 9999

Longest time to switch off

UP-DATE-TIME (S)

This parameter defines the update time in seconds of the display only.

0,005

Shortest update time

0,1

Default value

9,999

Longest update time

FONT

This parameter defines the setting of the font style.

0

Standard

1

Font 1

Page 37

Ix350_02b_oi_e.doc / Mai-18 Page 37 / 50

5.12. Linearization Menu

The linearization function is defined in this menu. This menu will only be showed, if the

LINEARIZATION MODE in GENERAL MENU is selected.

Linearization description and examples are shown in the appendix.

P1(X) … P24(X)

X-coordinate of the linearization point.

This value representing the display value which the unit show in the display without linearization.

-99999999

Smallest X-coordinate

0

Default value

+99999999

Largest X-coordinate

P1(Y) … P24(Y)

Y-coordinate of the linearization point

This is the display value, which the unit should show in the display with linearization.

E.g. P2(X) is replaced by P2(Y).

-99999999

Smallest Y-coordinate

0

Default value

+99999999

Largest Y-coordinate

Page 38

Ix350_02b_oi_e.doc / Mai-18 Page 38 / 50

6. Appendix

6.1. Data readout via serial interface

All codes shown in the parameter SERIAL VALUE are available for serial readout by PC or PLC. For

communication the monitors use the Drivecom Protocol according to ISO 1745. All protocol details can

be found in our manual SERPRO which is available for download from our homepage

www.motrona.com.

To request for a data transmission you must send the following request string to the converter:

EOT

AD1

AD2

C1

C2

ENQ

EOT = control character (Hex 04)

AD1 = unit address, High Byte

AD2 = unit address, Low Byte

C1 = register code, High Byte

C2 = register code, Low Byte

ENQ = control character (Hex 05)

The following example shows the request string for readout of the actual input frequency of a monitor

(Code=1) from a unit with unit address 11:

ASCII-Code:

ASCII-Code:

EOT

1

1

: 1 ENQ

Hex-Code:

Hexadecimal:

04

31

31

3A

31

05

Binary-Code:

Binary:

0000

0100

0011

0001

0011

0001

0011

1010

0011

0001

0000

0101

After a correct request, the unit will respond:

STX

C1

C2

xxxxx

ETX

BCC

STX = control character (Hex 02)

C1 = register code, High Byte

C2 = register code, Low Byte

xxxxx = readout data

ETX = control character (Hex 03)

BCC = block check character

Page 39

Ix350_02b_oi_e.doc / Mai-18 Page 39 / 50

6.2. Parameter / serial codes

#

Menu

Name

Serial Code

Min

Max

Default

0

GENERAL MENU

DISPLAY FORMAT

0 0 2 0 1

GENERAL MENU

FACTOR

1

-99999999

99999999

1

2

GENERAL MENU

DIVIDER

2

-99999999

99999999

1

3

GENERAL MENU

ADDITIVE VALUE

3

-99999999

99999999

0

4

GENERAL MENU

DECIMAL POINT

4 0 7

0

5

GENERAL MENU

SCALE UNITS

5 0 28

0

6

GENERAL MENU

LINIARIZATION MODE

6 0 2

0

7

GENERAL MENU

PIN PRESELECTION

7 0 9999

0

8

GENERAL MENU

PIN PARAMETER

8 0 9999

0

9

GENERAL MENU

FACTORY SETTINGS

9 0 1

0

10

GENERAL MENU

-

10 0 0

0

11

GENERAL MENU

-

11 0 0

0

12

GENERAL MENU

-

12 0 0

0

13

GENERAL MENU

-

13 0 0

0

14

SSI PROPERTIES

MODE

14 0 1

0

15

SSI PROPERTIES

ENCODER

RESOLUTION

15

10

32

25

16

SSI PROPERTIES

BIT PER REVOLUTION

16

10

16

13

17

SSI PROPERTIES

DATA FORMAT

17 0 1

0

18

SSI PROPERTIES

BAUD RATE

18 0 5

3

19

SSI PROPERTIES

HIGH BIT

19 1 32

25

20

SSI PROPERTIES

LOW BIT

20 1 32

1

21

SSI PROPERTIES

SET VALUE

21

-99999999

99999999

0

22

SSI PROPERTIES

DIRECTION

22 0 1

0

23

SSI PROPERTIES

ROUND LOOP VAUE

23

0

99999999

0

24

SSI PROPERTIES

SAMPLING TIME (S)

24

1

9999

10

25

SSI PROPERTIES

ERROR BIT

25 0 32

0

26

SSI PROPERTIES

ERROR POLARITY

26 0 1

0

27

SSI PROPERTIES

ENCODER SUPPLY

27 0 1

0

28

SSI PROPERTIES

-

28 0 0

0

29

SSI PROPERTIES

-

29 0 0

0

30

PRESELECTION VALUES

PRESELECTION 1

A0

-99999999

99999999

1000

31

PRESELECTION VALUES

PRESELECTION 2

A1

-99999999

99999999

2000

32

PRESELECTION VALUES

PRESELECTION 3

A2

-99999999

99999999

3000

33

PRESELECTION VALUES

PRESELECTION 4

A3

-99999999

99999999

4000

34

PRESELECTION 1 MENU

MODE 1

A4 0 9

0

35

PRESELECTION 1 MENU

HYSTERESIS 1

A5

0

99999

0

36

PRESELECTION 1 MENU

PULSE TIME 1 (S)

A6

0

60000

0

37

PRESELECTION 1 MENU

OUTPUT TARGET 1

A7 0 6

1

38

PRESELECTION 1 MENU

OUTPUT POLARITY 1

A8 0 1

0

39

PRESELECTION 1 MENU

OUTPUT LOCK 1

A9 0 1

0

40

PRESELECTION 1 MENU

START UP DELAY 1 (S)

B0

0

60000

0

41

PRESELECTION 1 MENU

EVENT COLOR 1

B1 0 3

0

42

PRESELECTION 1 MENU

-

B2 0 0

0

43

PRESELECTION 1 MENU

-

B3 0 0

0

Page 40

Ix350_02b_oi_e.doc / Mai-18 Page 40 / 50

Continuation „Parameterliste“:

#

Menu

Name

Serial Code

Min

Max

Default

44

PRESELECTION 2 MENU

MODE 2

B4 0 9

0

45

PRESELECTION 2 MENU

HYSTERESIS 2

B5

0

99999

0

46

PRESELECTION 2 MENU

PULSE TIME 2 (S)

B6

0

60000

0

47

PRESELECTION 2 MENU

OUTPUT TARGET 2

B7 0 6

2

48

PRESELECTION 2 MENU

OUTPUT POLARITY 2

B8 0 1

0

49

PRESELECTION 2 MENU

OUTPUT LOCK 2

B9 0 1

0

50

PRESELECTION 2 MENU

START UP DELAY 2 (S)

C0

0

60000

0

51

PRESELECTION 2 MENU

EVENT COLOR 2

C1 0 3

0

52

PRESELECTION 2 MENU

-

C2 0 0

0

53

PRESELECTION 2 MENU

-

C3 0 0

0

54

PRESELECTION 3 MENU

MODE 3

C4 0 9

0

55

PRESELECTION 3 MENU

HYSTERESIS 3

C5

0

99999

0

56

PRESELECTION 3 MENU

PULSE TIME 3 (S)

C6

0

60000

0

57

PRESELECTION 3 MENU

OUTPUT TARGET 3

C7 0 6

3

58

PRESELECTION 3 MENU

OUTPUT POLARITY 3

C8 0 1

0

59

PRESELECTION 3 MENU

OUTPUT LOCK 3

C9 0 1

0

60

PRESELECTION 3 MENU

START UP DELAY 3

D0 0 1

0

61

PRESELECTION 3 MENU

EVENT COLOR 3

D1 0 3

0

62

PRESELECTION 3 MENU

-

D2 0 0

0

63

PRESELECTION 3 MENU

-

D3 0 0

0

64

PRESELECTION 4 MENU

MODE 4

D4 0 9

0

65

PRESELECTION 4 MENU

HYSTERESIS 4

D5

0

99999

0

66

PRESELECTION 4 MENU

PULSE TIME 4 (S)

D6

0

60000

0

67

PRESELECTION 4 MENU

OUTPUT TARGET 4

D7 0 6

4

68

PRESELECTION 4 MENU

OUTPUT POLARITY 4

D8 0 1

0

69

PRESELECTION 4 MENU

OUTPUT LOCK 4

D9 0 1

0

70

PRESELECTION 4 MENU

START UP DELAY 4

E0 0 1

0

71

PRESELECTION 4 MENU

EVENT COLOR 4

E1 0 3

0

72

PRESELECTION 4 MENU

-

E2 0 0

0

73

PRESELECTION 4 MENU

-

E3 0 0

0

74

SERIAL MENU

UNIT NUMBER

90

11

99

11

75

SERIAL MENU

SERIAL BAUD RATE

91 0 2

0

76

SERIAL MENU

SERIAL FORMAT

92 0 9

0

77

SERIAL MENU

SERIAL INIT

9~ 0 1

0

78

SERIAL MENU

SERIAL PROTOCOL

E4 0 1

0

79

SERIAL MENU

SERIAL TIMER (S)

E5

0

60000

0

80

SERIAL MENU

SERIAL VALUE

E6 0 3

0

81

SERIAL MENU

-

E7 0 0

0

82

ANALOG MENU

ANALOG FORMAT

E8 0 2

0

83

ANALOG MENU

ANALOG START

E9

-99999999

99999999

0

84

ANALOG MENU

ANALOG END

F0

-99999999

99999999

10000

85

ANALOG MENU

ANALOG GAIN %

F1

0

11000

10000

86

ANALOG MENU

ANALOG OFFSET %

F2

-9999

9999

0

87

ANALOG MENU

-

F3 0 0

0

88

ANALOG MENU

-

F4 0 0

0

Page 41

Ix350_02b_oi_e.doc / Mai-18 Page 41 / 50

Continuation „Parameterliste“:

#

Menu

Name

Serial Code

Min

Max

Default

89

COMMAND MENU

INPUT 1 ACTION

F5 0 22

0

90

COMMAND MENU

INPUT 1 CONFIG.

F6 0 3

2

91

COMMAND MENU

INPUT 2 ACTION

F7 0 22

0

92

COMMAND MENU

INPUT 2 CONFIG.

F8 0 3

2

93

COMMAND MENU

INPUT 3 ACTION

F9 0 22

0

94

COMMAND MENU

INPUT 3 CONFIG.

G0 0 3

2

95

COMMAND MENU

-

G1 0 0

0

96

COMMAND MENU

-

G2 0 0

0

97

COMMAND MENU

-

G3 0 0

0

98

COMMAND MENU

-

G4 0 0

0

99

COMMAND MENU

-

G5 0 0

0

100

DISPLAY MENU

COLOR

G6 0 2

0

101

DISPLAY MENU

BRIGHTNESS %

G7

10

100

90

102

DISPLAY MENU

CONTRAST

G8 0 2

1

103

DISPLAY MENU

SCREEN SAVER (S)

G9

0

9999

0

104

DISPLAY MENU

UP-DATE-TIME (S)

H0

5

9999

100

105

DISPLAY MENU

FONT

H1 0 1

0

106

DISPLAY MENU

-

H2 0 0

0

107

DISPLAY MENU

-

H3 0 0

0

108

DISPLAY MENU

-

H4 0 0

0

109

LINEARIZATION MENU

P1(X)

H5

-99999999

99999999

0

110

LINEARIZATION MENU

P1(Y)

H6

-99999999

99999999

0

111

LINEARIZATION MENU

P2(X)

H7

-99999999

99999999

0

112

LINEARIZATION MENU

P2(Y)

H8

-99999999

99999999

0

113

LINEARIZATION MENU

P3(X)

H9

-99999999

99999999

0

114

LINEARIZATION MENU

P3(Y)

I0

-99999999

99999999

0

115

LINEARIZATION MENU

P4(X)

I1

-99999999

99999999

0

116

LINEARIZATION MENU

P4(Y)

I2

-99999999

99999999

0

117

LINEARIZATION MENU

P5(X)

I3

-99999999

99999999

0

118

LINEARIZATION MENU

P5(Y)

I4

-99999999

99999999

0

119

LINEARIZATION MENU

P6(X)

I5

-99999999

99999999

0

120

LINEARIZATION MENU

P6(Y)

I6

-99999999

99999999

0

121

LINEARIZATION MENU

P7(X)

I7

-99999999

99999999

0

122

LINEARIZATION MENU

P7(Y)

I8

-99999999

99999999

0

123

LINEARIZATION MENU

P8(X)

I9

-99999999

99999999

0

124

LINEARIZATION MENU

P8(Y)

J0

-99999999

99999999

0

125

LINEARIZATION MENU

P9(X)

J1

-99999999

99999999

0

126

LINEARIZATION MENU

P9(Y)

J2

-99999999

99999999

0

127

LINEARIZATION MENU

P10(X)

J3

-99999999

99999999

0

128

LINEARIZATION MENU

P10(Y)

J4

-99999999

99999999

0

129

LINEARIZATION MENU

P11(X)

J5

-99999999

99999999

0

130

LINEARIZATION MENU

P11(Y)

J6

-99999999

99999999

0

131

LINEARIZATION MENU

P12(X)

J7

-99999999

99999999

0

132

LINEARIZATION MENU

P12(Y)

J8

-99999999

99999999

0

133

LINEARIZATION MENU

P13(X)

J9

-99999999

99999999

0

134

LINEARIZATION MENU

P13(Y)

K0

-99999999

99999999

0

135

LINEARIZATION MENU

P14(X)

K1

-99999999

99999999

0

136

LINEARIZATION MENU

P14(Y)

K2

-99999999

99999999

0

Page 42

Ix350_02b_oi_e.doc / Mai-18 Page 42 / 50

Continuation „Parameterliste“

#

Menu

Name

Serial Code

Min

Max

Default

137

LINEARIZATION MENU

P15(X)

K3

-99999999

99999999

0

138

LINEARIZATION MENU

P15(Y)

K4

-99999999

99999999

0

139

LINEARIZATION MENU

P16(X)

K5

-99999999

99999999

0

140

LINEARIZATION MENU

P16(Y)

K6

-99999999

99999999

0

141

LINEARIZATION MENU

P17(X)

K7

-99999999

99999999

0

142

LINEARIZATION MENU

P17(Y)

K8

-99999999

99999999

0

143

LINEARIZATION MENU

P18(X)

K9

-99999999

99999999

0

144

LINEARIZATION MENU

P18(Y)

L0

-99999999

99999999

0

145

LINEARIZATION MENU

P19(X)

L1

-99999999

99999999

0

146

LINEARIZATION MENU

P19(Y)

L2

-99999999

99999999

0

147

LINEARIZATION MENU

P20(X)

L3

-99999999

99999999

0

148

LINEARIZATION MENU

P20(Y)

L4

-99999999

99999999

0

149

LINEARIZATION MENU

P21(X)

L5

-99999999

99999999

0

150

LINEARIZATION MENU

P21(Y)

L6

-99999999

99999999

0

151

LINEARIZATION MENU

P22(X)

L7

-99999999

99999999

0

152

LINEARIZATION MENU

P22(Y)

L8

-99999999

99999999

0

153

LINEARIZATION MENU

P23(X)

L9

-99999999

99999999

0

154

LINEARIZATION MENU

P23(Y)

M0

-99999999

99999999

0

155

LINEARIZATION MENU

P24(X)

M1

-99999999

99999999

0

156

LINEARIZATION MENU

P24(Y)

M2

-99999999

99999999

0

Serial codes of commands:

Serial Code

Command

54

RESET/SET

55

FREEZE DISPLAY

56

TOUCH DISABLE

57

CLR LOCK

58

CLR MIN MAX

59

SERIAL PRINT

60

TEACH PRES 1

61

TEACH PRES 2

62

TEACH PRES 3

63

TEACH PRES 4

64

SCROLL_DISPLAY

65

CLEAR LOOP TIME

66

START PRESELCETION

67

ACTIVATE DATA

68

STORE EEPROM

69

TESTPROGRAMM

Page 43

Ix350_02b_oi_e.doc / Mai-18 Page 43 / 50

6.3. Linearization

The linearization function of this unit allows converting a linear input signal into a non-linear

developing (or vice versa). There are 24 programmable x/y coordinates available, which can be set in

any desired distance over the full conversion range. Between two coordinates, the unit uses linear

interpolation. Therefore it is advisable to use more coordinates in a range with strong curves and only

a few coordinates where the curvature is less.

7.

To specify an individual linearization curve, the parameter LINEARISAZATION MODE must be set to

either 1 QUADRANT or 4 QUADRANT (see following diagram).

8.

The parameters P1(X) to P24(X) are used to specify the coordinates on the x-axis. These are the

measuring values that the unit normally would generate according to the actual input signal.

9.

Now enter the attached values to parameter P1(Y) to P24(Y). These are the values that the unit will

generate instead of the x- values, i.e. P5(Y) replaces P5(X) etc.

The X-Coordinates must use continuously increasing settings, i.e. P1(X) must have the lowest and

P24(X) must have the highest setting. If the measured value is bigger than the last defined X-value,

the corresponding Y-value is displayed.

Mode: 1 Quadrant:

Mode: 4 Quadrant:

P1(X) must be set to zero. Linearization is only

defined in the positive range and the negative

range will be mirrored symmetric to central

point.

P1(X) can also be set to a negative value. If the

measured value is smaller than P1(X), P1(Y) is

displayed.

Page 44

Ix350_02b_oi_e.doc / Mai-18 Page 44 / 50

Application Example:

The picture below shows a watergate where the opening is picked up by means of an incremental

encoder. We would like to display the clearance of the gate "d", but the existing encoder information

is proportional to the angular information φ.

Page 45

Ix350_02b_oi_e.doc / Mai-18 Page 45 / 50

6.4. Reading SSI-Value

The received data is always filled to 32 bit data length.

Page 46

Ix350_02b_oi_e.doc / Mai-18 Page 46 / 50

6.5. Internal processing and calculation of SSI data

Checking the e

rror bit:

Data Conversion

: Grey

Code

-binary

Data splitting: Bit

per revolution and

number of revolutions

Checking the direction

of rotation

Page 47

Ix350_02b_oi_e.doc / Mai-18 Page 47 / 50

Continuation „Internal processing and calculation of SSI data”

Evaluation of the bit

blanking

Considering SSI

Offset

Calculation Display

Value

Page 48

Ix350_02b_oi_e.doc / Mai-18 Page 48 / 50

6.6. Dimensions

Page 49

Ix350_02b_oi_e.doc / Mai-18 Page 49 / 50

6.7. Technical Specifications:

Technical Specifications:

Connections:

Connector type:

screw terminal, 1.5 mm² / AWG 16

Power supply (DC):

Input voltage:

Protection circuit:

Consumption:

Fuse protection:

18 … 30 VDC

reverse polarity protection

approx. 150 mA (unloaded)

extern: T 0.5 A

Power supply (AC):

(Option AC)

Input voltage:

Power consumption:

Fuse protection:

115 / 230 VAC (60/50 Hz)

approx. 5 VA (unloaded)

extern: T 0.1 A

Encoder supply:

DC version:

AC version:

24 VDC (approx. 1 V lower than the power supply

voltage),max 250 mA

24 VDC (± 15%), (max 150 mA until 45°C / 80 mA by

more than 45°C)

Encoder supply:

(IX355)

DC version:

AC version

24 VDC (approx. 1 V lower than the power supply

voltage), max 250 mA or 5 VDC (± 15%), max. 250 mA

24 VDC (± 15%) (max 150 mA until 45°C / 80 mA by more

than 45°C)

or 5 VDC (± 15%), max. 250 mA)

SSI interface:

Number (channels):

Configuration:

Format:

Frequency:

Resolution:

Load:

1 (Clock, /Clock, Data, /Data)

Master or Slave

Binary or Gray code

Max. 1 MHz

10 … 32 Bit

Max. 2 mA / Ri > 10 kOhm / 47 pF

Control inputs:

Number of inputs:

Format:

Frequency:

Load:

3

HTL, PNP (10 … 30 V)

Max. 10 kHz

Max. 2 mA / Ri > 15 kOhm / 470 pF

Analog output:

(Option AO/AR)

Configuration:

Voltage output:

Current output:

Resolution:

Accuracy:

Reaction time:

current or voltage operation

-10…+10 V (Low 0 …3 V, High 9 …30 V)

0/4 … 20 mA (burden: max. 270 Ohm)

16 Bit

± 0,1 %

< 150 ms

Control outputs:

(Option AO/AR/CO/CR)

Number of outputs:

Format / level:

Output current:

Reaction time:

4

5 … 30 V (depends on the Com+ voltage), PNP

Max. 200 mA

< 1 ms

Relay outputs:

(Option RL)

Number of outputs:

Configuration:

AC-Switching capacity:

DC-Switching capacity:

Reaction time:

2

potential free changeovers

Max. 250 VAC / 3 A / 750 VA

Max. 150 VDC / 2 A / 50 W

< 20 ms

Page 50

Ix350_02b_oi_e.doc / Mai-18 Page 50 / 50

Serial interface:

(Option

AO/AR/CO/CR)

Format (Option A0/CO):

Format (Option AR/CR)

Baudrate:

RS232

RS485

9600, 19200 or 38400 baud

Display:

Type:

Display range:

Digit height

Color:

Operation:

LCD (backlight)

8 digits plus sign (-99999999 … 999999999)

13 mm height

red / green / yellow (switchable)

resistive touchscreen

Housing:

Material:

Mounting:

Dimensions (w x h x d):

Cut out (w x h):

Protection class:

Weight:

ABS, UL 94 V-0

panel cut out

96 x 48 x 116 mm /

3.78 x 1.89 x 4,56 inch

91 x 44 mm / 3.58 x 1.69 inch

IP65 (front), IP20 (rear)

approx. 200 g

Ambient

temperature:

Operation:

Storage:

-20 °C … +60 °C resp. -4 … 140 °F

-25 °C … +70 °C resp. -13 … 158 °F

Conformity and

standards:

EMC 2004/108/EC:

LV 2006/95/EC

RoHS 2011/65/EU:

EN 61000-6-2, EN 61000-6-3, EN 61000-6-4

EN 61010-1

EN 50581

Loading...

Loading...