control – motion – interface

IX 345 - IX 348

SSI Indicators for Use with

Single-Turn or Multi-Turn SSI Encoders

motrona GmbH

Zwischen den Wegen 32

78239 Rielasingen - Germany

Tel. +49 (0)7731-9332-0

Fax +49 (0)7731-9332-30

info@motrona.com

www.motrona.com

IX 345: SSI display unit only

IX 346: SSI display unit with analogue output

IX 347: SSI display unit with two presets and outputs

IX 348: SSI display unit with serial interface RS232 and RS485

Clear LED display (15 mm / 0.59’’ size) with adjustable brightness

Master- or Slave operation with clock rates up to 1 MHz

Suitable for all SSI formats from 8 to 32 bits

Numerous supplementary functions like Linearization, Bit Blanking etc.

Operating Instructions

IX34510b_e.doc / Mrz-13 Page 1 / 43

Safety Instructions

Version:

Description:

This manual is an essential part of the unit and contains important hints about

function, correct handling and commissioning. Non-observance can result in

damage to the unit or the machine or even in injury to persons using the

equipment!

The unit must only be installed, connected and activated by a qualified electrician

It is a must to observe all general and also all country-specific and application-

specific safety standards

When this unit is used with applications where failure or maloperation could cause

damage to a machine or hazard to the operating staff, it is indispensable to meet

effective precautions in order to avoid such consequences

Regarding installation, wiring, environmental conditions, screening of cables and

earthing, you must follow the general standards of industrial automation industry

- Errors and omissions excepted –

General instructions for cabling, screening and grounding can be found in the

SUPPORT section of our website http://www.motrona.com

03b /af/hk//Feb 08 Range of PM-Factor, SSI zero position and preselection mode

1 / 2 increase to [-199999, 999999];

load on the current output max. 300 Ohm

07a = 08a/kk/hk/Apr.09 Extensions: Linearization, Activation of serial transmission

09a/kk/hk/Feb.10 Extension from 25 to 32 bits

10a/kk/hk/June.10 Missing encoder alarm, remote start of serial string

10b/af/nw/March 13 Correction of the basic parameter “Analogue Characteristics”

IX34510b_e.doc / Mrz-13 Page 2 / 43

Table of Contents

1. Terminal Assignment ................................................................................................... 4

1.1. Power Supply................................................................................................................................5

1.2. Aux. Voltage Output .....................................................................................................................5

1.3. Control Inputs A, B and C .............................................................................................................5

1.4. Adjustable Analogue Output (IX 346 only)...................................................................................6

1.5. Optocoupler (transistor) outputs (IX 437 only).............................................................................6

1.6. Serial RS232 / RS485 interface (IX 348 only) ..............................................................................7

2. How to Operate the Front Keys .................................................................................... 8

2.1. Normal display state ....................................................................................................................8

2.2. Selection and Setting of Parameters...........................................................................................9

2.3. Teach operation..........................................................................................................................10

2.4. Set all parameters to “Default“ .................................................................................................10

2.5. Code Locking of the Keypad.......................................................................................................10

3. The Operator Menu.................................................................................................... 11

3.1. Overview of Basic Parameters ...................................................................................................11

3.2. Overview of Operational Parameters.........................................................................................12

4. Setup Procedure......................................................................................................... 13

4.1. Basic Parameters........................................................................................................................13

4.2. Operational Parameters..............................................................................................................15

4.3. Additional Parameters for the Analogue Output (model IX 346)...............................................18

4.4. Additional Parameters for Preselections and Switching Outputs (model IX 347) ...................20

4.5. Additional Parameters for Units with Serial Interface (model IX 348).....................................22

5. Hints for Application .................................................................................................. 26

5.1. Master and Slave Operation ......................................................................................................26

5.2. Evaluation of Encoder Bits..........................................................................................................27

5.3. Scaling of the Display.................................................................................................................28

5.4. Basic Modes of Operation..........................................................................................................29

5.5. Testing Functions........................................................................................................................33

5.6. Error Messages...........................................................................................................................33

6. Special Functions....................................................................................................... 34

6.1. Linearization ...............................................................................................................................34

6.2. Manual Input or „Teaching“ of the Interpolation Points ...........................................................36

7. Technical Appendix.................................................................................................... 38

7.1. Dimensions .................................................................................................................................38

7.2. Technical Specifications.............................................................................................................39

7.3. Parameter-List ............................................................................................................................40

7.4. Commissioning Form ..................................................................................................................42

IX34510b_e.doc / Mrz-13 Page 3 / 43

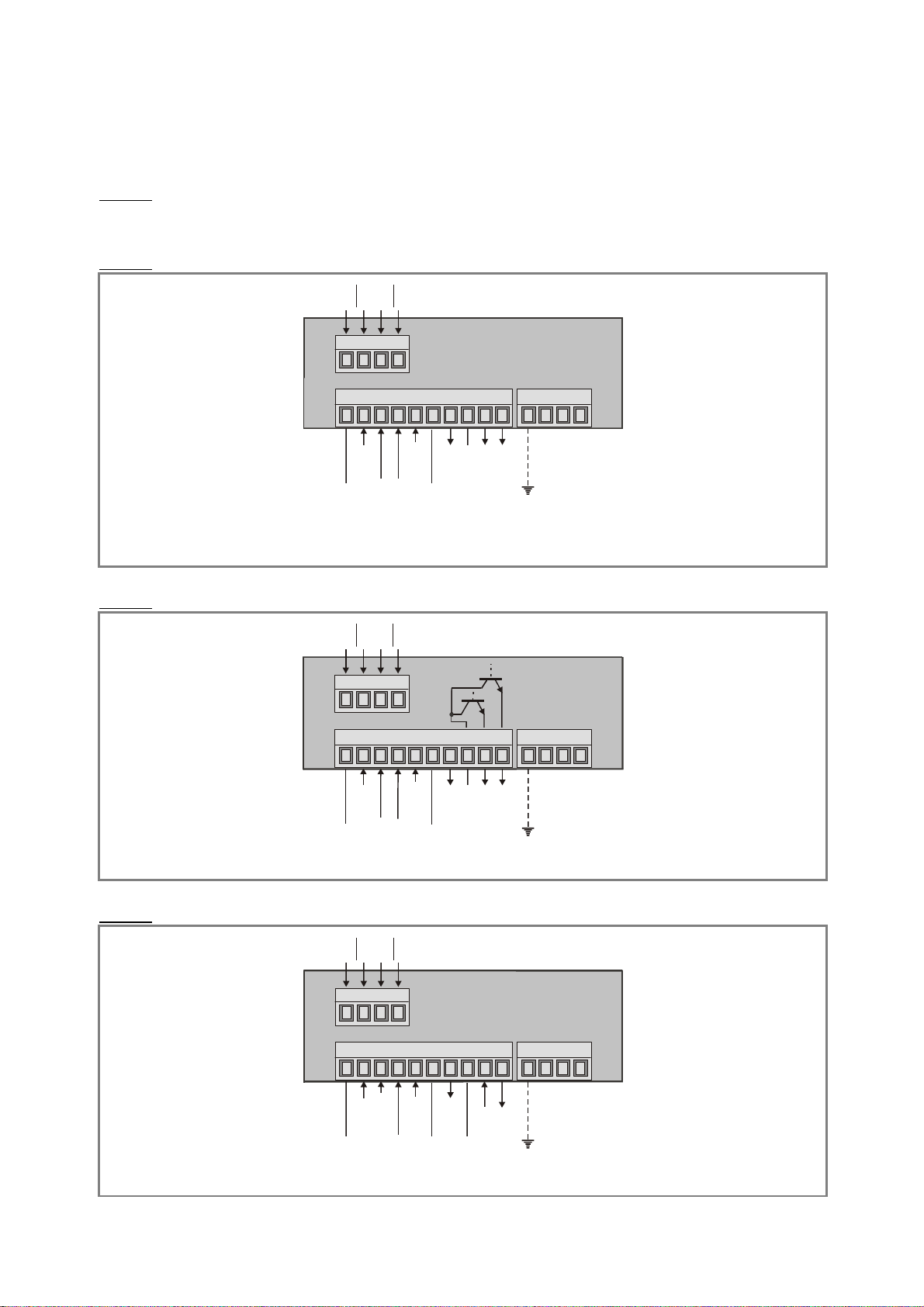

1. Terminal Assignment

10

C

L

KCL

KDA

T

D

A

T

10

GND

2

3

0

VAC11

5VA

C

0

V

ACC

LKC

LKD

ATD

A

T

10

CLK

CLK

DAT

DAT

IX 345: Display unit only

All connections are as shown below, except for terminals 8, 9 and 10 which are unconnected

IX 346: Display with analogue output

1 2 3 4

GND

230VAC

115 VAC

1 2 3 4 5 6 7 8 9

0 VAC

GND

17-30 VCD IN

Input A

Input B

Input C (Reset)

IX 347: Display with two presets and outputs

1 2 3 4

1 2 3 4 5 6 7 8 9

GND

17-30 VCD IN

Input A

Input B

Input C (Reset)

IX 348: Display with serial interface

GND

+24 VDC OUT

GND analogue

COM+

GND

+24 VDC OUT

PE

+/- 10 V analogue

0/4-20 mA analogue

OUT 1

OUT 2

PE

1 2 3 4

GND

230VAC

115 VAC

1 2 3 4 5 6 7 8 9

GND

Input B

Input C (Reset)

GND

+24 VDC OUT

17-30 VCD IN

InputA (transm.)

GND

PE

TxD / B (-)

RxD / A(+)

0 VAC

IX34510b_e.doc / Mrz-13 Page 4 / 43

1.1. Power Supply

The unit accepts DC supply from 17 V to 30 V when using terminals 1 and 2. The consumption

depends on the level of the supply voltage

(typical 130mA at 30V or 190mA at 17V, plus current taken from aux. output).

For AC supply the terminals 0 VAC, 115 VAC or 230 VAC can be used.

The total AC power is 7.5 VA.

The diagrams below show a dotted line for grounding to PE.

This connection is not really necessary, neither for safety nor for EMC. However, for some

applications, it may be desirable to ground the common potential of all signal lines.

When using this earthing option, please observe:

All terminals and potentials marked “GND“ will be earthed.

Please avoid multiple earthing, i.e. when you use a DC power supply where

the Minus is already connected to earth etc.

1.2. Aux. Voltage Output

Terminal 7 provides an auxiliary output of 24 VDC / 120 mA max. for supply of sensors and

encoders.

1.3. Control Inputs A, B and C

With models IX 348, input A is used to activate a serial transmission (rising edge, see 4.5.2).

Input B is not in use.

Input C operates as a Set / Reset input (static function, active "HIGH", see 5.3).

In the basic setup menu, the inputs can be configured to PNP (signal must switch to +) or to

NPN (signal must switch to -). This configuration is valid for all three inputs at a time.

The factory setting is always PNP.

Where NPN setting is used, please observe:

Open NPN inputs will always represent a logical HIGH state

Consequently, Input C has to be connected to GND externally to allow normal

operation. If unconnected, the unit would be kept in a continuous Reset state.

With models IX 348, also Input A must be tied to GND, and opening this connection will

generate a rising edge to start a serial transmission

Where your use 2-wire NAMUR type sensors, please select NPN, connect the negative

wire of the sensor to GND and the positive wire to the corresponding input.

IX34510b_e.doc / Mrz-13 Page 5 / 43

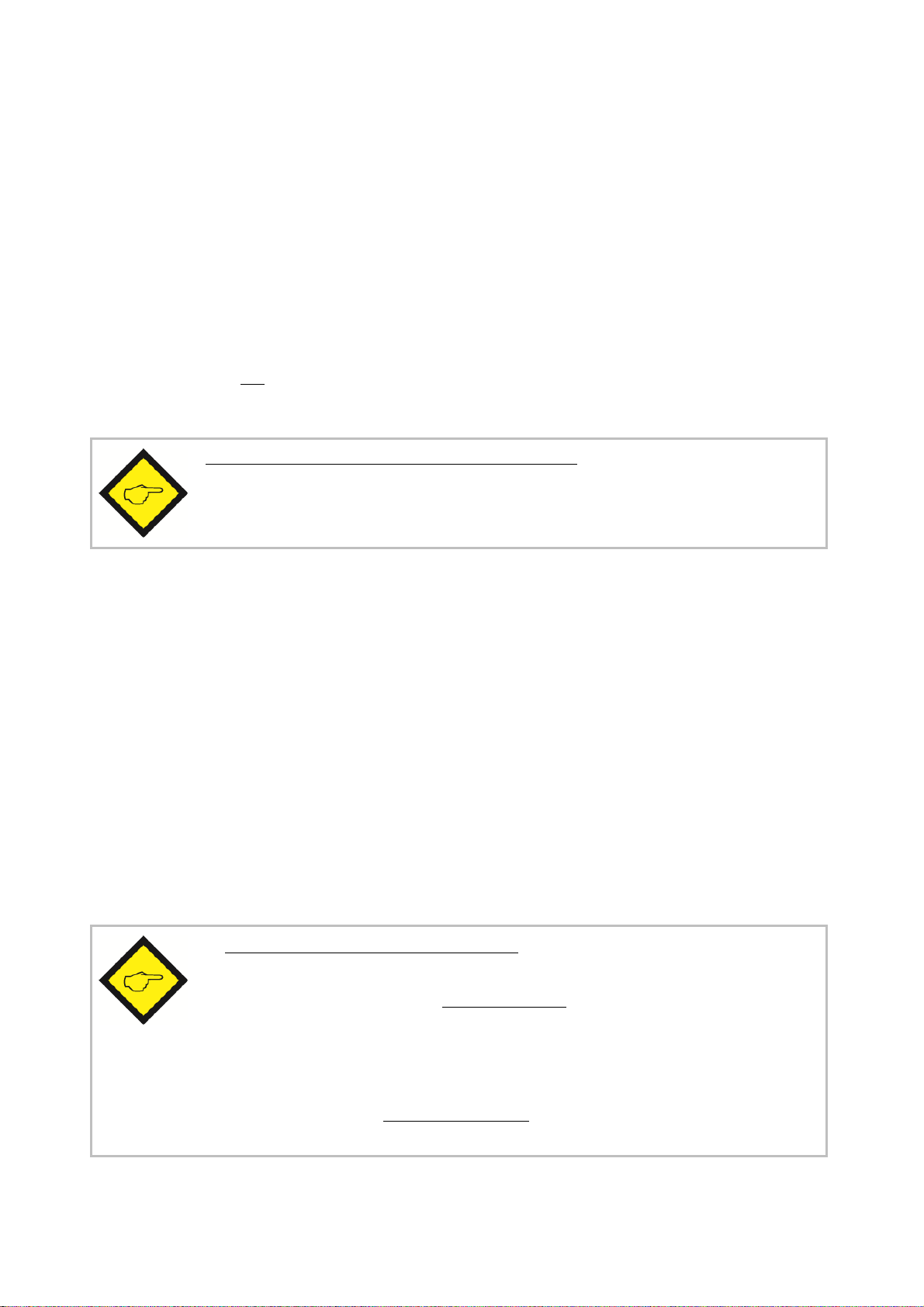

Typical input circuit of control input

PNP

GND

Input

+24V int.

NPN

Com+ (5 ... 35 V)

Output 1 (max. 150 mA)

Output 2 (max. 150 mA)

+24V int.

4,7k

Input

4,7k

GND GND

The minimum pulse duration on the Reset input (C) must be 5 msec.

1.4. Adjustable Analogue Output (IX 346 only)

A voltage output is available, operating in a range of 0 ... +10 V or –10 V ... +10 V according to

setting. At the same time, a current output 0/4 – 20 mA is available. Both outputs refer to the

GND potential and the polarity changes with the sign in the display. The outputs are

proportional to the display value and provide a 14 bits resolution.

The maximum current on the voltage output is 2 mA, and the load on the current output can

vary between 0 and max. 300 ohms.

The response time of the analogue output to changes of the encoder position is approx. 7 msec.

1.5. Optocoupler (transistor) outputs (IX 437 only)

The outputs provide programmable switching characteristics and are potential-free. Please

connect terminal 8 (COM+) to the positive potential of the voltage you like to switch

(range 5V....35V). You must not exceed the maximum output current of 150 mA. Where you

switch inductive loads, please provide filtering of the coil by means of an external diode.

The optocoupler outputs provide a response time of approx. 5 msec with resistive load.

Opto Opto

33 R

33 R

IX34510b_e.doc / Mrz-13 Page 6 / 43

1.6. Serial RS232 / RS485 interface (IX 348 only)

ON DIP

DIL-Switch

8

910RxD

TxD

GND

8

910A (+)

B (-)

235

RxD

RxD

TxD

TxD

GND

Screen

PC

(Sub-D-9)

Conn

ection of the RS232 interface

PLC

Connection of the RS485 interface

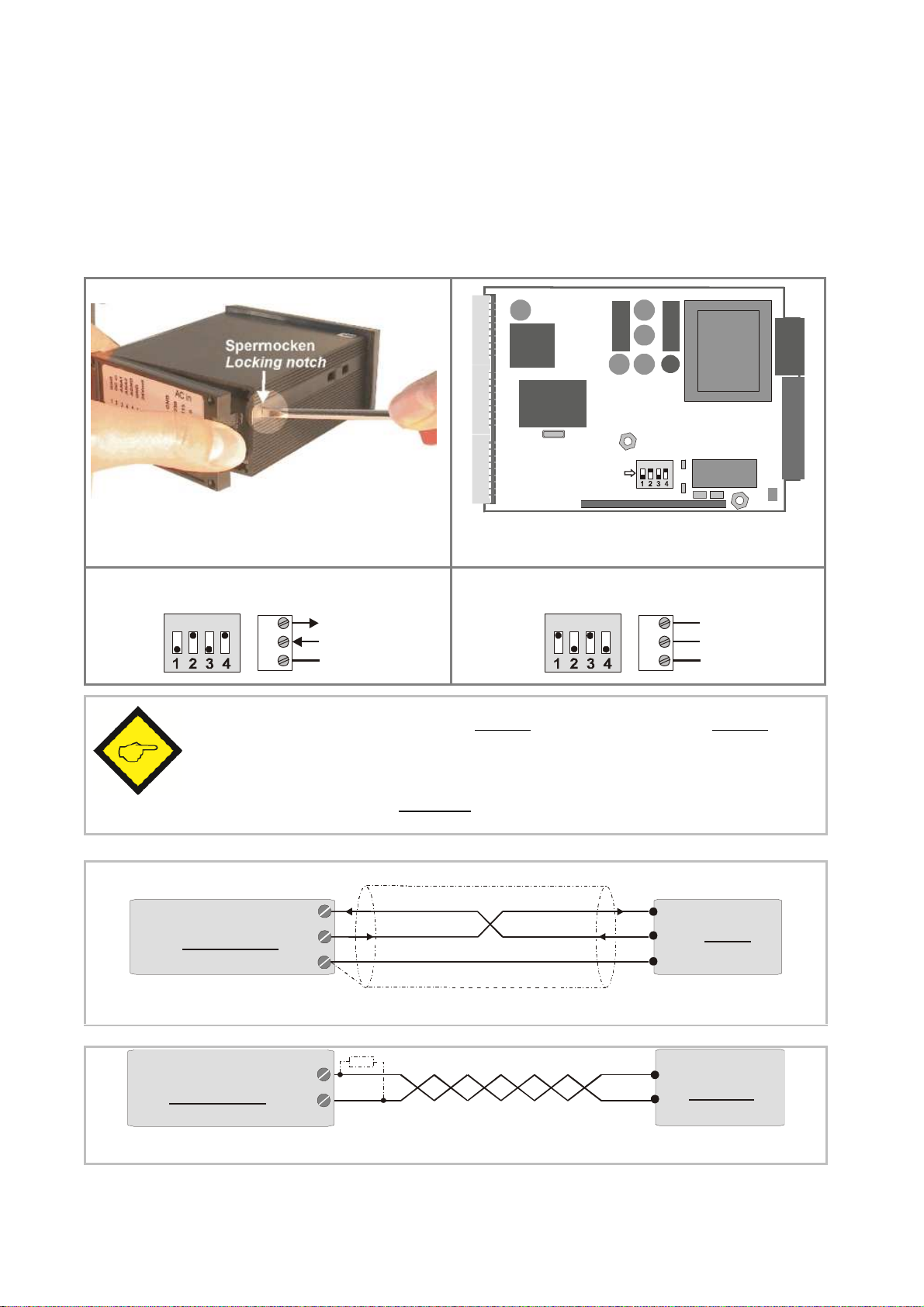

Ex factory the unit is set to RS232 communication. This setting can be changed to RS485

(2-wire) by means of an internal DIL switch. To access the DIL switch, you must remove the

screw terminal connectors and the backplane. Then pull the board to the rear to remove the

PCB from the housing.

Removal of the back plane Location of the DIL switch

ON

RS232:

ON

RS485:

GND

Never set DIL switch positions 1 and 2 or DIL switch positions 3 and 4 to

“ON” at the same time!

After setting the switch, shift the print carefully back to the housing and

avoid damage of the front pins for connection to the front keypad plate.

9

IX 348

10

8

IX 348

IX34510b_e.doc / Mrz-13 Page 7 / 43

10

9

A(+)

B(-)

A(+)

B(-)

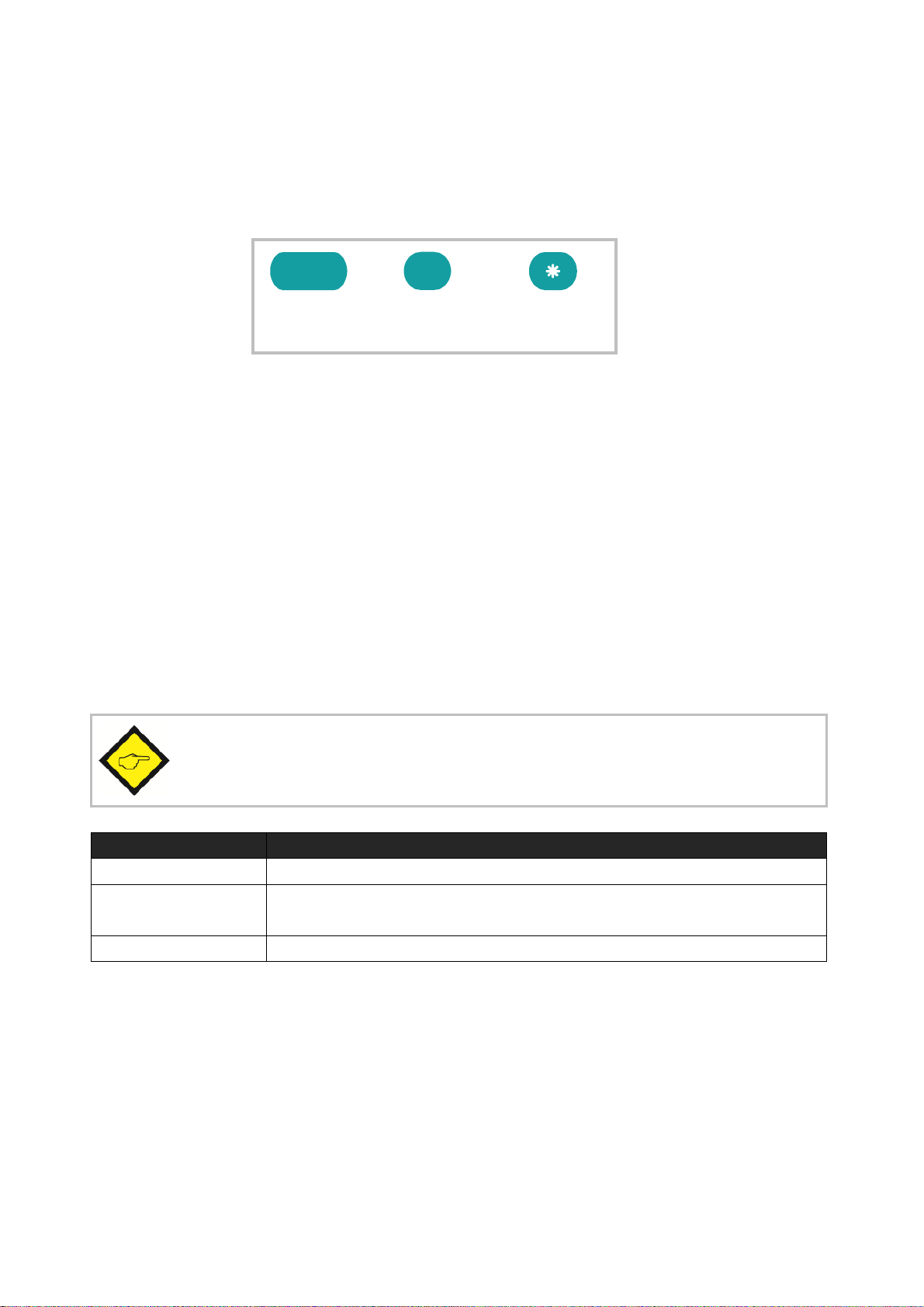

2. How to Operate the Front Keys

ENTER

SET

Cmd

Change over to

Key ope

ration

Basic setup

Keep

ENTER

and

SET

down simultaneously for 3 seconds

Operational

Keep

ENTER

down for 3 seconds.

Teach operation

Keep

Cmd

down for 3 seconds

For setup and other operations the unit uses three front keys which subsequently will be

denominated as follows:

(Input)

The functions of the keys are depending on the actual operating state of the unit.

The following three operating states apply:

Normal display state

Setup state

a.) Basic setup

b.) Operational parameter setup

Teach operation

(Setting)

(Command)

2.1. Normal display state

You can only change over to other operation states while the unit is in the

normal display state.

parameter setup

The Cmd key is only used to execute the Teach procedure with linearization. For more details

please refer to sections 6.1 and 6.2.

IX34510b_e.doc / Mrz-13 Page 8 / 43

2.2. Selection and Setting of Parameters

2.2.1. How to select a parameter The ENTER key will scroll through the menu. The SET key allows to select the corresponding

item and to change the setting or the numeric value. After this, the selection can be stored by

ENTER again, which automatically changes over to the next menu item.

2.2.2. How to change parameter settings With numerical entries, at first the lowest digit will blink. When keeping the SET key

continuously down, the highlighted digit will scroll in a continuous loop from 0 … 9 , 0 … 9.

After releasing the SET key, the actual value will remain and the next digit will be highlighted

(blink). This procedure allows setting of all digits to the desired values. After the most

significant digit has been set, the low order digit will blink again and you can do corrections if

necessary.

With signed parameters, the high order digit will scroll from “0” to "9" (positive) followed by

“-“ and "-1" (negative)

2.2.3. How to store settings To store the actual setting, press the ENTER key, which will also automatically scroll forward

the menu.

At any time the unit changes from programming mode to normal display operation, when you

keep the ENTER key down again for at least 3 seconds.

2.2.4. Time-out function A “time-out” function will automatically conclude every menu level, when for a break period of

10 seconds no key has been touched. In this case, any changes which have not been confirmed

by ENTER yet would remain unconsidered.

IX34510b_e.doc / Mrz-13 Page 9 / 43

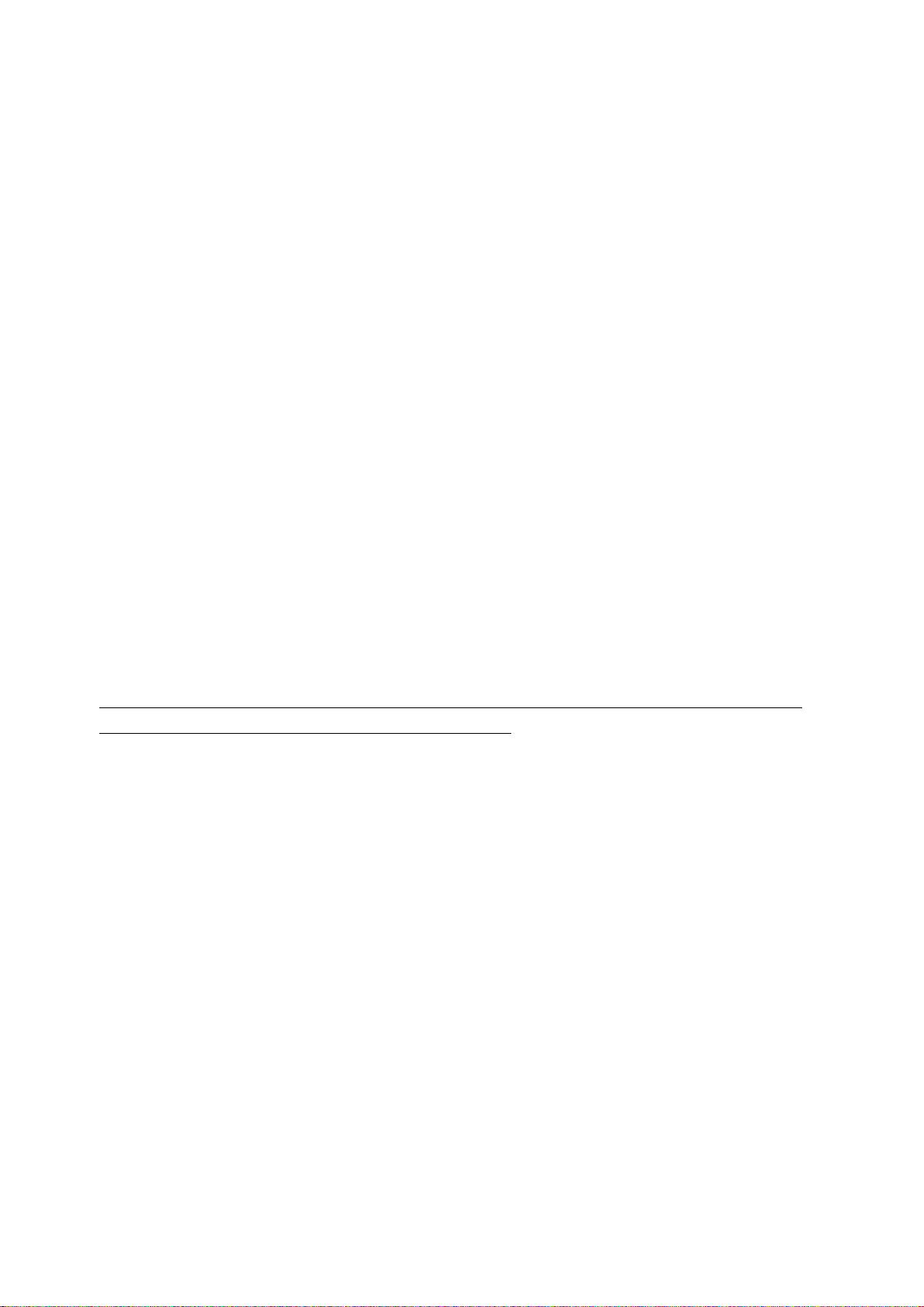

2.3. Teach operation

Key

Function

Cmd will store the display value to the register and will change over to the

The Time-out function will be switched off during all Teach operations

ENTER will conclude or abort any Teach operation in progress

SET function is fully similar to normal set-up operation

next interpolation point.

For details of the Teach procedure see section 6.2.

2.4. Set all parameters to “Default“

At any time you can return all settings to the factory default values.

The factory default settings are shown in the parameter listings in section 6.

When you decide to set all parameters to „default“, please be aware that all

previous settings will be lost and you will need to do the whole set-up

procedure once more

To execute the „Default“ setting function:

Power the unit down.

Press the ENTER key.

Power the unit up again while the ENTER key is kept down

2.5. Code Locking of the Keypad

When the code locking of the keypad has been switched on, any key access first results in

display of

To access the menu you must press the key sequence

within 10 seconds, otherwise the unit will automatically return to the normal display mode.

IX34510b_e.doc / Mrz-13 Page 10 / 43

3. The Operator Menu

IX 345

IX 346

IX 347

IX 348

The menu provides one section with “Basic Parameters” and another section with “Operational

Parameters”. On the display you will only find those parameters which have been enabled by

the basic settings. E.g. when the Linearisation Functions have been disabled in the basic setup, the associated linearization parameters will also not appear in the parameter menu.

All parameters, as good as possible, are designated by text fragments. Even though the

possibilities of forming texts are very limited with a 7-segment display, this method has proved

to be most suitable for simplification of the programming procedure.

The subsequent table shows the general structure of the whole menu only.

Detailed descriptions of all parameters will follow in section 4.

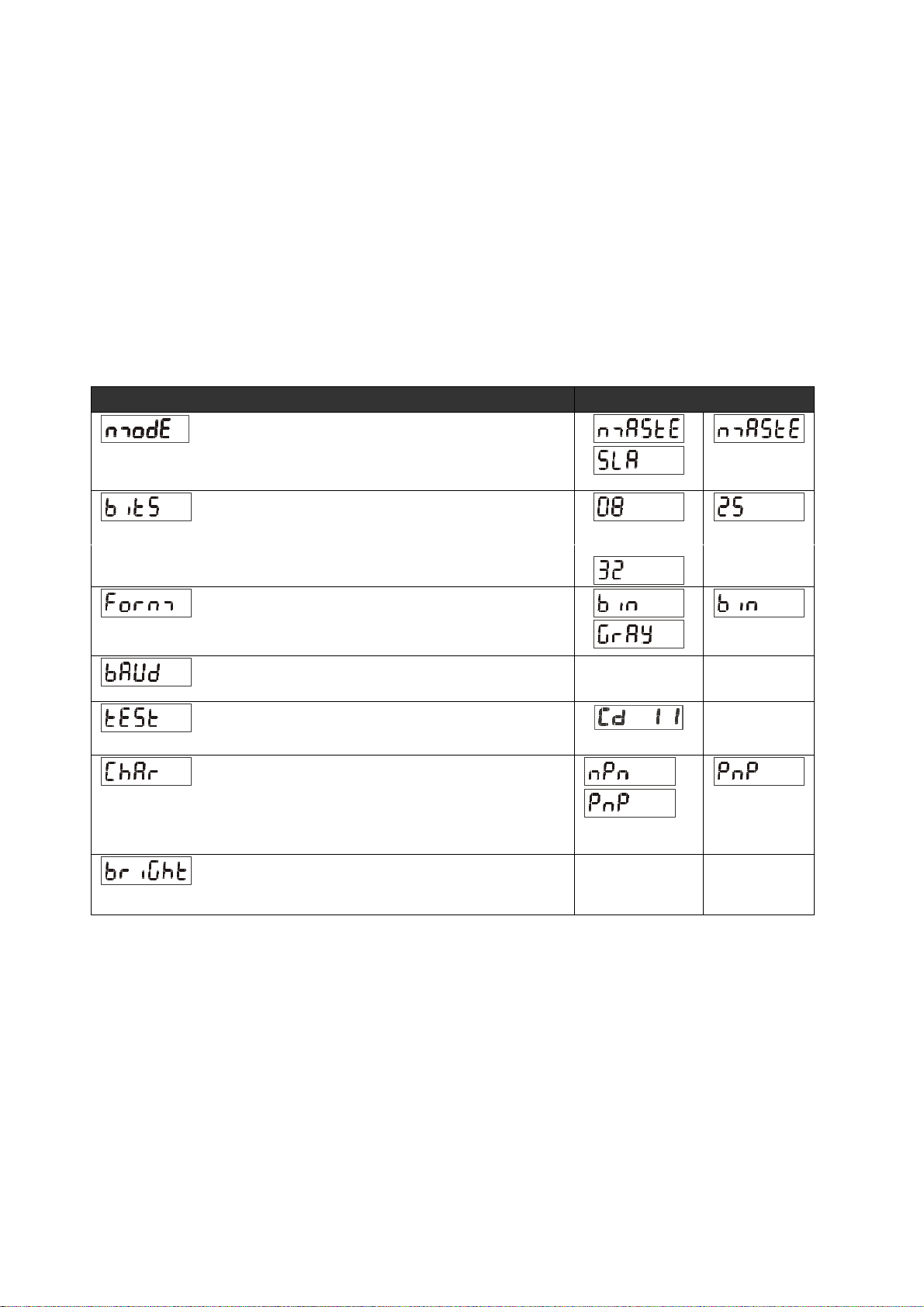

3.1. Overview of Basic Parameters

SSI_Mode SSI_Mode SSI_Mode SSI_Mode

SSI_Bits SSI_Bits SSI_Bits SSI_Bits

SSI_Format SSI_Format SSI_Format SSI_Format

SSI_Baud Rate SSI_Baud Rate SSI_Baud Rate SSI_Baud Rate

SSI_Test SSI_Test SSI_Test SSI_Test

Characteristics Characteristics Characteristics Characteristics

Brightness Brightness Brightness Brightness

Code Locking Code Locking Code Locking Code Locking

Linearization Mode Linearization Mode Linearization Mode Linearization Mode

Analogue Characteristics Preselection_Mode 1 Ser_Unit_Nr

Analogue Offset Preselection_Mode 2 Ser_Format

Analogue Gain Hysteresis 1 Ser_Baudrate

Hysteresis 2

IX34510b_e.doc / Mrz-13 Page 11 / 43

3.2. Overview of Operational Parameters

IX 345

IX 346

IX 347

IX 348

Preselection 1

Preselection 2

M-Factor M-Factor M-Factor M-Factor

D-Factor D-Factor D-Factor D-Factor

P-Factor P-Factor P-Factor P-Factor

Decimal point Decimal point Decimal point Decimal point

Display Display Display Display

Hi_Bit (MSB) Hi_Bit (MSB) Hi_Bit (MSB) Hi_Bit (MSB)

Lo_Bit (LSB) Lo_Bit (LSB) Lo_Bit (LSB) Lo_Bit (LSB)

Direction Direction Direction Direction

Error Error Error Error

Error_Polarity Error_Polarity Error_Polarity Error_Polarity

Round Loop Round Loop Round Loop Round Loop

Time Time Time Time

Reset Reset Reset Reset

Zero Position Zero Position Zero Position Zero Position

Analogue Begin Ser_Timer

Analogue End Ser_Mode

Ser_Value

P01_X *) P01_X *) P01_X *) P01_X *)

P01_Y*) P01_Y*) P01_Y*) P01_Y*)

P16_X *) P16_X *) P16_X *) P16_X *)

P16_Y *) P16_Y *) P16_Y *) P16_Y *)

*) appears only when Linearization has been enabled in the Basic Menu

IX34510b_e.doc / Mrz-13 Page 12 / 43

4. Setup Procedure

Menu

Setting Range

Default

SSI-Bits

SSI-Format:

SSI-Baud Rate

SSI Test

Characteristics

*)

Brightness

For better understanding the following sections 4.1 and 4.2 explain settings for the display only.

Model-specific settings for Analogue Output, Preselections and Serial Link will be explained

separately, later.

4.1. Basic Parameters

The subsequent settings are of unique nature and must only be made upon the very first setup.

The basic setup selects the desired operation mode of the unit, the input characteristics

PNP/NPN and the desired brightness of the LED display.

SSI-Mode

Setting of Master Mode or Slave Mode

For details see section 5.1

Bit length of the SSI string

For more details see section 5.2

Setting of the SSI code (Binary or Gray)

SSI Self test functions (see 5.5.)

Switching characteristics of the Reset input

NPN: switch to "-" *)

PNP: switch to "+"

Brightness of the 7-segment LED display

*) Please observe hints given in chapter 1.3

.....

0.1 ... 1000.9

kHz

etc.

20%, 40%, 60%

80% and 100%

100.0

kHz

100%

IX34510b_e.doc / Mrz-13 Page 13 / 43

Menu

Setting Range

Default

Code Locking

Interlock of keypad access (see 2.5)

Linearization Mode

no: Keypad accessible at any time

All: Keypad interlock for all functions

P-Free: Keypad interlock except for Preselection

Settings Pres 1 und Pres 2 (model IX 347)

For details please see 6.1 und 6.2.

no: Linearization is switched OFF *)

1-qua: Linearization settings for the positive range

only (negative values will appear as a mirror).

4-qua: Linearization over the full numeric range

*) The menu will not display any further linearization parameters

IX34510b_e.doc / Mrz-13 Page 14 / 43

4.2. Operational Parameters

Menu

Setting Range

Default

M-Factor *):

D-Factor *):

P-Factor *):

Decimal Point

Display:

Hi Bit **):

Lo Bit **):

Multiplying factor for the SSI value

(after consideration of possible bit blanking)

Dividing factor for the SSI value

(after consideration of possible bit blanking)

-9.999 … 9.999 1.000

0.001 … 9.999 1.000

This signed value will be added to the SSI result

(after consideration of possible bit blanking)

Setting according to the decimal formats shown in

the display

Display mode of the unit

norm: regular scaling of the display

359.59: Angular display format 359° 59' with use of

the Round Loop Function

Bit Blanking Function: Defines the highest bit for

evaluation. To evaluate all encoder bits this

parameter has to be set to the total number of bits

according to setting

-199999

…

999999

000000

00000.0

...

0.00000

norm

359.59

1 … 32 25

1 … 31 1

00000.0

norm

0

Bit Blanking Function: Defines the lowest bit for

evaluation. To evaluate all encoder bits this

parameter has to be set to "01"

*) Scaling details are explained under 5.3

**) For more details about Bit Blanking see 5.2

IX34510b_e.doc / Mrz-13 Page 15 / 43

Menu

Setting Range

Default

Direction

Parameter to negate the SSI value, resulting in

Error:

Error

-

Polarity *):

Round Loop

Time

reversal of the direction of the encoder count.

riGht: ascending values with forward motion

LEFt:: decreasing values with forward motion

riGht

LEFt

riGht

(please refer to 5.6)

Defines the control of presence of an encoder and

the location of the Error Bit in case of error.

00: No error bit available

Control of presence of an encoder is off

01: No error bit available

Control of presence of an encoder is on

>01: Location of the error bit

Control of presence of an encoder is on

Defines the polarity of the Error Bit in case of error.

0: Error Bit is Low in case of error

1: Error bit is High in case of error

When an error occurs, „Err-b“ appears on the display.

The same function can also be used to monitor the Power Failure Bit of an encoder

(mostly called „PFB“).

Defines the number of encoder steps per revolution

with use of the Round Loop Function (see 5.4.2).

0 ... 32 0

0

1

0 ... 999999 0

0

0: Normal display of the encoder data, no

Round Loop Function

>0: Number of steps per Round Loop Cycle

Sets the update cycle of the display (and of the

analogue output or the switching outputs where

applicable). The fastest possible update time is

3 msec. respectively one telegram length including 4

pause clocks. With Slave operation the next update

will occur when the unit synchronizes again to the

Master pause following to the expiration of the

update time.

0.000 ... 1.009

sec

0.01 sec

IX34510b_e.doc / Mrz-13 Page 16 / 43

Menu

Setting Range

Default

Reset

A Reset command is available to store the actual SSI

Zero Position:

*)

P01_X

**)

Linearization Point 1_X

P01_Y

Linearization Point 1_Y

…

P16_X

Linearization Point 16_X

P16_Y

Linearization Point 16_Y

position to register „Zero Position“. As a result, the

display value will become zero at the actual encoder

position, and all further operation will refer to this

new datum point. The zero position remains

memorized also after power-down.

no: Reset function disabled

Front: Reset function by the front SET key

E_tErn: Reset function by the remote Reset input

FR u E: Reset via key and remote input

-199999

Defines the zero position of the display. When you

set this parameter to e.g. "1024", the unit will

display zero when the encoder position is 1024.

Zero Position can be set directly via keypad or by

means of an external Reset command.

X value of the first interpolation point.

Y value of the first interpolation point.

X value of the 16. interpolation point.

Y value of the 16. interpolation point.

*) Please observe that Parameter P_Fac will cause an additional displacement of the zero position

**) Parameters P01_X to P16_Y appear only when the linearization has been enabled in the basic menu

...

999999

-199999

... 999999

-199999

... 999999

-199999

... 999999

-199999

... 999999

0

999999

999999

999999

999999

IX34510b_e.doc / Mrz-13 Page 17 / 43

4.3. Additional Parameters for the Analogue Output

Menu

Setting Range

Default

Analogue Characteristics

Analogue Offset:

Analogue Gain

:

Menu

Setting Range

Default

Analogue

-

Begin

Analogue

-

End

(model IX 346)

The following additional settings for the analogue output appear in the Basic Menu:

You can set the following output options:

+/- 10 V (bipolar),

0 - 10 V (positive only),

4 - 20 mA

0 - 20 mA.

With setting +/-10 Volts the polarity of the output

voltage will follow the sign in the display

-9,999..+9,999 0,000

Set this parameter to 0 when you expect your

analogue signal to start with 0 V (or 0 mA / 4 mA

respectively). Where another zero definition is

desired it can be set by this parameter. Setting of

e.g. 5.000 will already produce 5 volts with the

output in zero state.

00,00..99,99 10,00

Parameter to set the analogue output swing. Setting

10.00 will allow full swing of 10 V or 20 mA, setting

8.00 will reduce the swing to 8 V or 16 mA.

The following Operational Parameters provide scaling of the analogue output:

-199999...999999 0

Start value of the analogue conversion range

-199999...999999 100000

End value of the analogue conversion range

By means of these two parameters any window of the whole display range can be mapped onto

the analogue output.

IX34510b_e.doc / Mrz-13 Page 18 / 43

The subsequent example shows how to convert the display range from 1400 to 2000 into an

1000

2000

3000

4000

5000

SSI Display Value

AnalogueOutput

analogue signal of 2 - 10 volts.

Volts

10

8

6

4

2

A-ChAr = 0 - 10 V AnAbEG = 1400

OFFSEt = 2.000 AnAEnd = 2000

GAin = 8.00

All settings refer to the scaled values shown in the display of the unit,

and not to the original SSI encoder data

IX34510b_e.doc / Mrz-13 Page 19 / 43

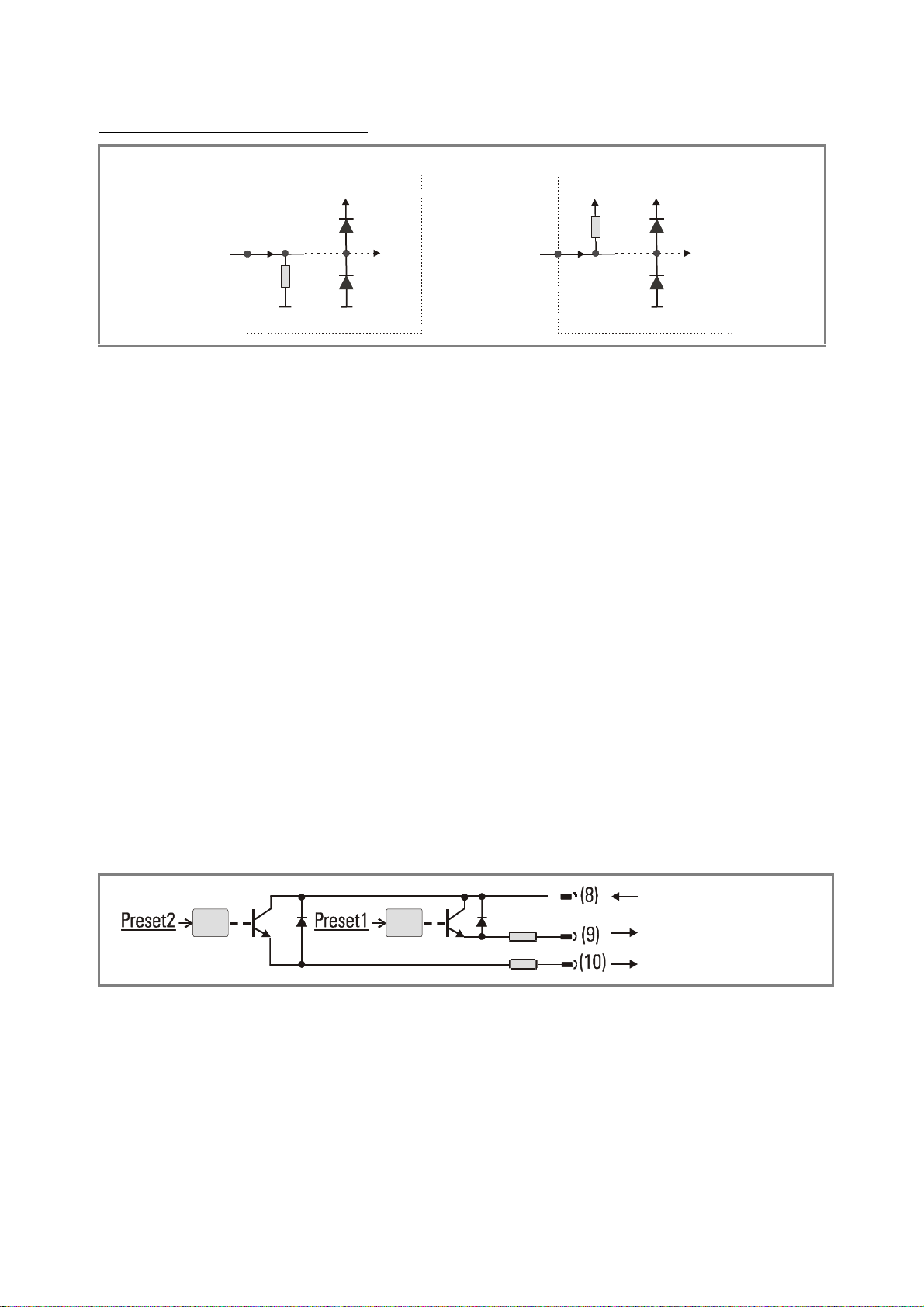

4.4. Additional Parameters for Preselections and Switching Outputs

Menu

Default

HYSt 1

Hysteresis 1

HYSt 2

Hysteresis 2

(model IX 347)

The following additional settings for the Preselections appear in the Basic Menu:

Switching Characteristics of Output 1

Greater/Equal. Output to switch statically ON

when Display Value ≥ Preselection1

Lower/Equal. Output to switch statically ON

when Display Value ≤ Preselection1

Greater/Equal. Output to switch dynamically ON

when Display Value ≥ Preselection1

(timed output pulse) *)

Lower/Equal. Output to switch dynamically ON

when Display Value ≤ Preselection1

(timed output pulse) *)

Switching Characteristics of Output 2

See above, but Preselection2

See above, but Preselection2

See above, but Preselection2

See above, but Preselection2

Output to switch statically ON when

Display Value ≥ Preselection1 – Preselection2 **)

Output to switch dynamically ON when

Display Value ≥ Preselection1 – Preselection2 **)

Adjustable hysteresis for output 1

Setting range 0 ... 99999 display units

Adjustable hysteresis for output 2

Setting range 0 ... 99999 display units

*) Timed output pulses have a fixed duration of 500 msec (factory adjustable only)

**) Trailing Preset to generate an anticipation signal with a fixed distance to the main signal

0

0

IX34510b_e.doc / Mrz-13 Page 20 / 43

The following Operational Parameters provide setting of the switching thresholds:

Menu

Setting Range

Default

Preselection 1:

P

reselection 2:

Preselection

GE=Greater/Equal

Display Value

Preselection

LE=Lower/Equal

Hysteresis

Display

Meaning

Both outputs are actually OFF

Both outputs are actually ON

Output 1 is ON

Output 2 is OFF

Output 1 is OFF

Output 2 is ON

-199999..

999999

-199999..

999999

10000

5000

The direction of the Hysteresis effect depends on the setting of the switching characteristics.

With the settings „GE“ or „LE“ the following switch points will result:

Hysteresis

Hysteresis effect with "Greater / Equal"

Display Value

Hysteresis effect with "Lower / Equal"

It is possible to check up on the actual switching state of the outputs at any time.

For this, just tap on the ENTER key shortly.

The display will then show for the next two seconds one of the following information:

IX34510b_e.doc / Mrz-13 Page 21 / 43

4.5. Additional Parameters for Units with Serial Interface

Menu

Setting Range

Default

(model IX 348)

The following additional settings for serial communications appear in the Basic Menu:

Unit Number

You can assign any unit number between

11 and 99. The address must however not contain a

“0“ because such numbers are reserved for collective

addressing of several units.

Serial Data Format

The first character indicates the number of data bits.

The second character specifies the Parity Bit

„Even“, "Odd“ or no Parity Bit.

The third character indicates the number of Stop Bits.

0..99 11

Baud Rate

The following Baud Rates can be set for

communication:

IX34510b_e.doc / Mrz-13 Page 22 / 43

The following Operational Parameters provide configuration of the serial interface:

Menu

Setting Range

Default

Serial Timer:

Setting 0,000 allows manual activation of a serial data

transmission at any time. All other settings specify the cycle

time for automatic transmission, when the interface is set to

"Printer Mode"

Between two transmission cycles the unit will allow a pause

depending on the baud rate. The minimum cycle times for

timer transmissions are shown in the table.

Baud Rate Minimum Cycle Time [ms]

600 384

1200 192

2400 96

4800 48

9600 24

19200 12

38400 6

Serial Mode:

PC: Operation according to communication profile

(see 4.5.1)

Print1: Transmission of string type 1 (see 4.5.2)

Print2: Transmission of string type 2 (see 4.5.2)

0,000

0,010 sec

…

9.999 sec

0,100 sec

Serial Register-Code:

Specifies the register code of the data to be transmitted.

The most important register codes are:

Register S-Code ASCII Description

Original SSI

Value

SSI Value 113 ; 3 Encoder data after

Display

value

111 ; 1 Direct encoder data

Bit Blanking

101 : 1 Value with full scaling

as it appears in the

display

100

...

120

101

IX34510b_e.doc / Mrz-13 Page 23 / 43

4.5.1. PC-Mode

EOT

AD1

AD2

C1C2ENQ

EOT = Control Character (Hex 04)

ASCII

-

Code:

EOT11:1

ENQ

Hex:

0431313A3105Binary:

0000 0100

0011 0001

0011 0001

0011 1010

0011 0001

0000 0101

STXC1C2

x x x x x x x

ETX

BCC

STX = Control Character (Hex 02)

Communication with PC - Mode allows free readout of all parameters and registers of the unit.

The subsequent example shows the details of communication for serial readout of the actual

display value.

The general string to initiate a request has

the following format:

AD1 = Unit Address, High Byte

AD2 = Unit Address, Low Byte

C1 = Register Code, High Byte

C2 = Register Code, Low Byte

ENQ = Control Character (Hex 05)

Example:

Request string for readout of the actual display data from a unit with serial address No. 11:

With a correct request the unit will

respond with the adjoining response

string. Leading zeros will be suppressed.

BCC provides a „Block Check Character“,

formed by Exclusive-OR of all characters

from C1 through ETX.

C1 = Register Code, High Byte

C2 = Register Code, Low Byte

x x x x x = Data (display value)

ETX = Control Character (Hex 03)

BCC = Block Check Character

With inaccurate request strings the unit would only respond "STX C1 C2 EOT" or just "NAK".

IX34510b_e.doc / Mrz-13 Page 24 / 43

4.5.2. Printer Mode

„S-mod“

Transmission String Type

Space

Sign

Data

Line

Carriage

+/-XXXXXXLF

CR

Sign

Data

Carriage

+/-XXXXXXCR

Cyclic (timed)

Set the Serial Timer to any value

0.010 sec.

Manual activation of

Set the Serial Timer to 0.000.

The Printer Mode allows cyclic or manual activation of transmissions of the specified register

data. The corresponding register can be specified by means of parameter „S-Code“.

Another parameter named „S-mod“ allows selection between two different string types:

„Print1“

feed

return

„Print2“

return

The mode of activation of serial transmissions can be determined as follows:

≥

transmissions:

Select the desired string type by parameter "S-mod"

transmissions

After exit from the menu the transmissions will start automatically

Select the desired string type by parameter "S-mod"

After exit from the menu a transmission can be activated at any time

- by shortly pressing the ENTER key or

- by a rising edge to Control Input A

IX34510b_e.doc / Mrz-13 Page 25 / 43

5. Hints for Application

CLK

7 (+24V out)

SSI Encoder

SSI Indicator

Screen

DAT

DAT

SSI Indicator with Slave Operation

DAT

SSI Indicator

1000,0 kHz

888,0 kHz

800,0 kHz

7

27,0 kHz

666,0 kHz

615,0 kHz

571,0 kHz

533,0 kHz

500,0 kHz

470,0 kHz

444,0 kHz

421,0 kHz

400,0 kHz

380,0 kHz

363,0 kHz

347,0 kHz

333,0 kHz

320,0 kHz

307,0 kHz

296,0 kHz

285,0 kHz

275,0 kHz

266,0 kHz

258,0 kHz

250,0 kHz

5.1. Master and Slave Operation

Set register “Mode” to position “Master” when the unit should generate the clock signal for

the encoder. In this case the clock terminals (CLK) are configured as clock outputs.

(+24V)

Clock-

Clock+

DataData+

GND

(optional)

CLK

6 (GND)

SSI Indicator with Master Operation

When your encoder receives already its clock from another device and the unit should only

“listen” to the communication, then set register “Mode” to “Slave”. In this case, both clock

terminals (CLK) are configured as inputs.

Remote Master

+

Clock+

Clock-

SSI Encoder

ClockClock+

DataData+

-

Data+

Data-

Screen

CLK

CLK

DAT

6 (GND)

Set registers “Bits”, “Format” and “Baud” according to the encoder you use.

You are free to set any baud rate in a range from 0.1 kHz to 1000.0 kHz. For technical reasons

however, in the upper frequency range, the unit itself in master mode can only generate one of

the following Baud rates accurately:

IX34510b_e.doc / Mrz-13 Page 26 / 43

With Master operation, therefore other settings will result in generation of the next upper or

Requested

Usable Bits

lower value according to above list. With all settings <250.0 kHz the error between set rate and

generated rate becomes negligible.

It is mandatory to set the Baud rate also with Slave operation. In this case, however, the

setting serves only to determine the pause time for correct synchronization (pause is detected

after 4 clock cycles). The unit automatically synchronizes with every remote clock signal within

the specified Baud rate range.

5.2. Evaluation of Encoder Bits

This chapter explains the correlation between the Basic Parameter „BitS“ and the Operational

Parameters „Hi bit“ and „Lo bit“. The example below uses an encoder with 16 bits.

Unused Bits may be blanked out according to individual need

Whenever the number of bits (clock cycles) requested from the SSI Master is higher

than the real number of encoder bits, all excessive Bits must be blanked by

corresponding setting of parameters „Hi_bit“ and „Lo_bit“.

Basic Settings:

In general, parameter „BitS“ will always be set according to the real resolution of the encoder

(i.e. "BitS" = 16 with a 16 bit encoder). In this normal case the SSI telegram will not contain any

excessive bits.

With some applications (e.g. with Slave operation) it may however happen that the Master

transmits more clock cycles than the number of encoder bits (e.g. 21 clocks with a 16 bit

encoder). In such a case the master would always request 21 bits from the encoder, where the

encoder itself responds with 16 usable bits only, followed by 5 waste bits. These 5 excessive

bits must be blanked.

All standard SSI telegrams start with the most significant bit (MSB) and close with the least

significant bit (LSB). Unusable waste bits (X) will follow at the tail end. To blank these bits out,

in our example we would have to set „Hi bit“ to 21 and „Lo bit“ to 6 for proper evaluation of the

encoder information.

Hi Bit

Lo Bit

Bits (Clocks)

(encoder)

IX34510b_e.doc / Mrz-13 Page 27 / 43

21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 X X X X X

5.3. Scaling of the Display

M-Factor

D-Factor

P-Factor

Under consideration of the scaling parameters which have been described previously, the final

display value of the unit results from

DISPLAY [Encoder SSI Data] [0-Position]

= - x

{ }

Encoder SSI data are always positive only. Where also negative values should be

indicated, this can be achieved by corresponding setting of the parameters

„0-Position“ or „P-Factor“

The LED display provides 6 decades. For this reason all parameter settings (including

0-Position) are also limited to a maximum range of 6 decades. SSI encoders with a

resolution of more than 19 bits will however generate SSI data with more than 6

decades. In such a case it can become difficult to set the 0-Position and the other

scaling parameters while the mechanical encoder position is in the overflow zone

(the unit would insistently display "overflow").

To avoid this kind of problem with encoders of more than 19 bits, we recommend to

use the Bit Blanking Function and evaluate 19 bits only

Where later you intend to use the "Round Loop" function, it is mandatory to blank all

unused bits.

Remote Reset/Set commands via keyboard or external input will overwrite the

current value of parameter „0-Position“ by the actual SSI position of the encoder.

Therefore, in the formula above, the content between the brackets { } will become

zero and the unit will display the same value as set to parameter „P-Factor“. This

scaling is also automatically stored to the Flash Prom for full data retention in powerdown state

+/-

IX34510b_e.doc / Mrz-13 Page 28 / 43

5.4. Basic Modes of Operation

M-Factor

:

1.000

Direction

:0D-Factor

:

1.000

Error

:

xxxP-

Factor

:0Error P

:

xxx

Decimal Point

:

000000

Round

-

Loop

:0Display

:0Time

:

xxx

Hi bit

:

Reset

:noLo bit

:0-

Position

:

0

5.4.1. Normal SSI display Normal operation provides calculation of the display value from the SSI encoder data and the

settings of the scaling factors. Negative values can be achieved by corresponding setting of the

zero-position, or by inversion of the direction bit.

To set the unit up without problem, it is best to use the following sequence of steps:

Set all basic registers according to the encoder type you use, as shown in section 4.1.

For better comprehension, use first all initial settings as shown in the list

(xxx = according to need)

see 5.2 and 5.3 *)

*) Please evaluate 19 bits only to avoid overflow

These settings ensure that the unit displays the pure SSI encoder information at first.

Move your encoder now from a “lower” position towards a “higher” position according

to your own definition of "low" and "high". When also the display changes from lower to

higher values, your own definition of directions matches with the encoder definition. If

not, change the setting of “Direction” from “0” to “1” now to receive the desired sense

of direction (changes after further parameter settings may cause different results) **)

Set the desired zero position, either by entering the numeric value to the “0-Position”

register, or by using the Reset function as described previously. Your zero definition will

divide the range into a positive and a negative zone.

At this time you are free to set all other registers according to your needs.

The subsequent drawings show the principle of evaluation with use of a 13 bit single turn

encoder, with the direction bit set to either “0” or to “1”, and with the zero position register

set to “1024” **)

**) Subject of correct sequence with parameter settings

IX34510b_e.doc / Mrz-13 Page 29 / 43

8192

Course of display with positive counting direction

Course of display with negative counting direction

7168

1024

Original encoder signal

Encoder 13Bit

Direction = 0

0-Position = 1024

Display

o

0

0-PoS = 1024

8192

1024

o

0

0-PoS = 1024

45

45

o

Original encoder signal

o

180 degrees

360

o

Encoder 13Bit

Direction = 1

0-Position = 1024

o

o

o

360180 degrees

-7168

IX34510b_e.doc / Mrz-13 Page 30 / 43

Display

5.4.2. Round-Loop Function

Round

-

Loop operation with 2048 steps / revolution when using of a 13 bit encoder

This mode of operation is used frequently with rotating round tables or similar applications,

where the absolute encoder information is only used for a limited and repeating range of the

encoder (like one revolution of the table, which must not at the same time mean one revolution

of the encoder shaft). The Round-Loop Function never uses any negative display values.

The Round-Loop Function allows assigning a programmable number of encoder steps to one full

360º rotation of the table. To avoid miscounting when passing the mechanical overflow of the

encoder range, the total encoder resolution should be an integer multiple of the number of

steps for one loop.

For setup, please proceed first like shown under section 5.4.1.

Then set register “r-LooP” to the number of steps corresponding to one revolution of the table.

You are free to scale the display to any engineering units desired, by setting the scaling factors

correspondingly.

Where you like to scale your display with the angular display format 359º59’, just change the

“Display” register from “0” to “359,59”. This will also automatically disable the general scaling

factors.

The subsequent diagram shows the round loop function with a 13 bit encoder, where one table

revolution corresponds to 2048 encoder steps and where the zero position is set to 1024.

8192

Original encoder signal

Round-Loop display

2048

1024

0 360

180

r-LooP = 20480-PoS = 1024

Encoder 13Bit

Direction = 0

0-Position = 1024

r-Loop = 2048

degrees

IX34510b_e.doc / Mrz-13 Page 31 / 43

5.4.3. Operation with Zero-Crossing

Overflow suppression w

ith a 13 bit SSI encoder

Master: bits 17 - 32

Slave: bits 01 - 16

As a special advantage, the round-loop mode can be used to bypass the mechanical encoder

overflow position, because in this mode the unit continues with steady operation, even while

the SSI encoder signal passes the mechanical overflow position from maximum to zero.

This feature can help to avoid mechanical adjusting of the encoder zero position with many

applications, when no other means for the mechanical zero definition is available.

In general the Reset input will be used to define the zero position. The following picture

explains the details of operation.

8192

Original encoder signal

Display

3500

Overflow

Encoder: 13 Bit

Direction = 0

r-LooP = 6000

0-PoS = 3500

o

0

0-PoS = 3500

r-LooP = 6000

360

o

degrees

5.4.4. Splitting of SSI Encoder Information into Two Separate Displays The Bit Blanking Function also allows to distribute one SSI telegram to two different SSI

indicator units. As a typical application the figure below shows how to separate the angular

information within one turn and the number of turns with a 16 x 16 Multiturn Encoder.

Multiturn SSI

16 + 16 = 32 Bit

(number of turns)

Parameters:

Bits = 32

HiBit = 32

LoBit = 17

(angular position)

Parameters:

Bits = 32

HiBit = 16

LoBit = 01

IX34510b_e.doc / Mrz-13 Page 32 / 43

5.5. Testing Functions

Menu

Selection

Text

Description

Cd (Clock

-

and data wiring test):

Cd (Clock

-

and data function test):

Menu

Description

The test menu can be accessed while doing the basic set up, as shown in section 4.1. Most of

these tests are for factory use only, but the following tests may also be helpful for the user:

When the wiring of clock line and data line is ok,

the display shows “Cd 11”. Display of “Cd 10”

means that the clock line is o.k. but the data wires

are false (wrong polarity) and "Cd 01" indicates a

problem with the clock lines.

With master mode, only the data lines are subject

of this test.

The next test generates clock and data signals and

feeds them directly into the rear terminals.

Therefore please remove the encoder connection.

“Cd iO” says that clock and data interface are all

right. and all other displays indicate a problem

with the SSI interface circuit.

5.6. Error Messages

The unit can detect and display the errors shown below. If you find an error message, please

check again the encoder wiring and the settings of all SSI-relevant parameters.

Overflow:

The selected SSI Baud Rate is too high.

Please set lower rate.

Error-bit: the error bit or the power failure bit of the encoder (PFB) is set

Error-time-out: with Slave mode, during the last 0.6 seconds (plus wait time setting)

the unit did not receive any valid data.

Error-Format: with Slave mode, a telegram with too short length has been received.

Missing encoder (1): right after power-up the unit detects that all SSI telegrams are

empty (all bits = 1)

Missing encoder (2): during normal operation the unit detects that regular SSI

telegrams are suddenly followed by empty telegrams (all bits = 1)

IX34510b_e.doc / Mrz-13 Page 33 / 43

6. Special Functions

y

xyLinearization Mode = 4_quA

P1(x)= -1000

6.1. Linearization

This function allows converting a non-linear input signal into a linear presentation or viceversa. There are 16 interpolation points available, which can be freely arranged over the whole

measuring range in any distance. Between two points the unit automatically will interpolate

straight lines.

It is advisable to set many points into areas with strong bending, and to use only a few points

in areas with little bending. „Linearisation Mode“ has to be set to either „1-quA“ or „4-quA“ to

enable the linearization function (see subsequent drawing).

Parameters P01_x to P16_x select 16 x- coordinates, representing the display values which the

unit would normally show in the display. With parameters P01_y to P16_y you can specify,

which values you would like to display instead of the corresponding _x values.

This means e.g. that the unit will replace the previous P02_x value by the new P02_y value.

With respect to the consistency of the linearization, the x- registers have to use continuously

increasing values, e.g. the x- registers must conform to the constraint

P01_X < P02_X < … < P15_X < P16_X.

Independent of the selected linearization mode, the possible setting range of all registers

P01_x, P01_y,…, P16_x, P16_y is always -199999 … 999999

With measuring values lower than P01_x the display will always be P01_y

With measuring values higher than P16_x, the display will always be P16_y.

P1(x)= 0

*)

*) Mirror of positive range

P1(y)= 0

Linearization Mode = 1_quA

P16(x)= 1000

P16(y)= 800

P1(y)= 900

P8(x)= 0

P8(y)= 750

x

P16(x)= +1000

P16(y)= - 600

IX34510b_e.doc / Mrz-13 Page 34 / 43

Application Example:

d

φ

(1-cos )

SSI Encoder

Display value

P01_xP0

5_xP1

6_x

SSI Data ( )

The picture below shows a Watergate where the opening is picked up by means of an SSI

encoder. We would like to display the clearance of the gate "d", but the existing encoder

information is proportional to the opening angle φ.

P16_y

Display (d)

d = d

0

φ

P15_y

P07_y

P05_y

P03_y

P01_y

φ

P03_x

P07_x

P15_x

IX34510b_e.doc / Mrz-13 Page 35 / 43

6.2. Manual Input or „Teaching“ of the Interpolation Points

Interpolation points to form the linearization curve can be entered one after another, using the

same procedure as for all other numeric parameters. This means you will enter all parameters

P01_x to P16_x and P01_y to P16_y manually by keypad.

During manual input of interpolation points the unit will not examine the settings

P01_x to P16_x. Therefore the operator is responsible for observation of the constraint

P01_X < P02_X < … < P15_X < P16_X.

In many cases it should however be much more convenient to use the Teach function.

For this we need to move the SSI encoder, step by step, from one interpolation point to the

next. Every time we enter the desired display value by keypad.

How to use the Teach Function:

Please select the desired range of linearization (see 4.1).

Hold down the “Cmd” key for 3 seconds, until the display shows “tEACh”. Now the unit

has switched over to the Teach mode. To start the teach procedure please press again

“Cmd” within the next 10 seconds. The display will then show “P01_X”.

With respect to the consistency required for linearization, all parameters from P01_X to

P16_Y will first be overwritten by suitable initial values. Initial values for „P01_X“ and

„P01_Y“ are -199999 and all other values will start with 999999.

Press once more “Cmd” to display the actual encoder position. Then move the encoder

to the first of the desired interpolation points

When you read the x-value of your first interpolation point in the display, press “Cmd”

again. This will automatically store the actual display value to the P01_x register. For

about 1 second you will read “P01_y “ on the display, followed by the same reading

again that has been stored previously

This display value now can be edited like a regular parameter, and you can change it to

the desired P01_y value

When you read the desired P01_y value in your display, store it by pressing “Cmd”

again. This will automatically cycle the display to the next interpolation point P02_x.

IX34510b_e.doc / Mrz-13 Page 36 / 43

Once we have reached and stored the last interpolation points P16_x/y, the routine will

restart with P01_x again. You are free to double-check your settings once more or to

make corrections.

To conclude the Teach procedure, keep ENTER down for about 2 seconds. In the display

you will read “StOP” for a short time, and then the unit returns to the normal operation.

At the same time all linearization points have been finally stored.

The unit will examine the constraint valid for the x-values of interpolation points. Every

interpolation point must be higher than its preceding point. Where this constraint is

breached, all 6 decimal points will blink automatically as a warning. Pressing the CMD key

will not store the illegal value, but result in an error text "E.r.r.-.L.O."

To exit the teach mode again, you have the following two possibilities:

1. Press the enter key for 2 seconds. On the display you will read “StOP” for a short time,

and then the unit will switch back to the normal mode.

2. Just do nothing. After 10 seconds the unit will switch back to the normal mode

automatically.

In both cases the parameters of linearization P01_X to P16_Y will not change.

IX34510b_e.doc / Mrz-13 Page 37 / 43

7. Technical Appendix

110,0 (4.331’’)

44,0(1.732)

48,0(1.890)

7.1. Dimensions

96,0 (3.780’’)

9,0 (.345)

8,0

(.315)

10,0

(.394)

129,0 (5.079)

140,5 (5.531)

91,0 (3.583)

Panel cut out: 91 x 44 mm (3.583 x 1.732’’)

IX34510b_e.doc / Mrz-13 Page 38 / 43

7.2. Technical Specifications

Supply voltage AC : 115/230 V (+/- 12.5 %)

Supply voltage DC : 24 V (17 – 30 V)

Consumption (without sensor) : 17 V: 190 mA, 24 V: 150 mA, 30 V: 120 mA

AC Power : 7.5 VA

Aux. output for encoder : 24 VDC, +/- 15%, 120 mA (with AC and DC supply)

Control Inputs : 3 inputs, A, B, C (PNP/NPN/Namur)

Input currents : 5.1 mA / 24 V (Ri = 4,7 kOhm)

Input level HTL : Low: 0 ... 2 V, High: 9 ... 35 V

SSI input frequency range : 100 Hz – 1 MHz

Min. pulse duration for Reset : 5 msec

Analogue output (IX 346) : 0/4 ... 20 mA (max. 300 ohms), 0...+/-10 V (max. 2 mA)

Resolution : 14 Bits + Sign

Accuracy : 0.1%

Serial interface (IX 348) : RS 232 / RS 485, 600 to 38 400 bauds

Ambient temperature : Operation: 0° - 45°C ( 32 – 113°F)

Storage: -25° - +70°C (-13 – 158°F)

Housing : Norly UL94 – V-0

Display : 6 decades, LED, high- efficiency orange, 15 mm (0.59’’)

Protection class : Front IP65, Rear IP20

Terminal cross section : Signals max. 1.5 mm², AC power max. 2.5 mm²

Switching outputs (IX 347) : PNP, max. 35 volts, max. 150 mA

Conformity and Standards : EMC 2004/108/EC: EN 61000-6-2

EN 61000-6-3

LV 2006/95/EC: EN 61010-1

IX34510b_e.doc / Mrz-13 Page 39 / 43

7.3. Parameter-List

Min

-

Max

-

Default

-

Ser.

NPN / PNP

CHAr

0111005Brightness

briGht

0401006Code Locking

Code

0201007SSI-Mode

modE

0101000SSI-Bits

bitS0832252001

SSI-Format

Form

0101002SSI-

Baudrate

bAUd

0.1

1000.9

100.0

5103

SSI-Test

tESt

0201004M-Factor

mFAc

-

9.999

+9.999

1.000

+/-4308D-

Factor

dFAc

0.001

9.999

1.000

4309P-

Factor

PFAc

-

199999

+999999

0+/-6010Decimal Point

dPoint

0501011Display

diSPLA

0101012Hi_Bit MSB

Hi_bit

132252013Lo_Bit LSB

Lo_bit

13112014Direction

dir0101015

Error Bit

Error

03202016Error Polarity

ErrorP

0101017Round Loop

r-looP

0

999999

06018Wait Time

timE

0.000

1.009

0.010

4319

Reset

FE

rES0301020

Zero Positionn

0-PoS-199999

+999999

0+/-6021Preselection 1

PrES 1

-

199999

+999999

10000

+/-6027

Preselection 2

PrES 2

-

199999

+999999

5000

+/-6028

Presel. Mode 1

CHAr 1

03010

29

Presel. Mode 2

CHAr 2

0501030Hyst

eresis 1

Hyst1

0

99999

05036Hysteresis 2

Hyst2

0

99999

05037Analogue Begin

An-bEG-199999

999999

0+/-6031Analogue End

An-End-199999

999999

100000

+/-6032

Analogue Mode

A-CHAr

0301033Offset

OFFSEt

-

9,999

+9,999

0,000

+/-4334

Gain

GAin

00,00

99,99

10,00

4235

Denomination Text

Value

Value

Value

Positions Characters

Code

IX34510b_e.doc / Mrz-13 Page 40 / 43

Denomination Text

Min

-

Max

-

Default

-

Ser.

Ser. Format

S-Form

0901092Baud Rate

S-bAUd

0601091Ser. Address

S-Unit

099112090Ser. Timer

S-tim109999

1004338

Ser. Mode

S-mod

0201039Register

-

Code

S-CodE

100

120

1013040Linear. Mode

LinEAr

02010D2Linear. Point 1

P01_H

-

199999

999999

999999

+/-60A0

P01_Y

-

199999

999999

999999

+/-60A1

Linear. Point 2

P02_H

-

199999

999999

999999

+/-60A2

P02_Y

-

199999

999999

999999

+/-60A3

Linear. Point 3

P03_H

-

199999

999999

999999

+/-60A4

P03_Y

-

199999

999999

999999

+/-60A5

Linear. Point 4

P04_H

-

199999

999999

999999

+/-60A6

P04_Y

-

199999

999999

999999

+/-60A7

Linear. Point 5

P

05_H

-

199999

999999

999999

+/-60A8

P05_Y

-

199999

999999

999999

+/-60A9

Linear. Point 6

P06_H

-

199999

999999

999999

+/-60B0

P06_Y

-

199999

999999

999999

+/-60B1

Linear. Point 7

P07_H

-

199999

999999

999999

+/-60B2

P07_Y

-

199999

999999

999999

+/-60B3

Linear. Point 8

P08_H

-

199999

999999

999999

+/-60B4

P08_Y

-

199999

999999

999999

+/-60B5

Linear. Point 9

P09_H

-

199999

999999

999999

+/-60B6

P09_Y

-

199999

999999

999999

+/-60B7

Linear. Point 10

P10_H

-

199999

999999

999999

+/-60B8

P10_Y

-

199999

999999

999999

+/-60B9

Linear. Point 11

P11_H

-

199999

999999

999999

+/-60C0

P11_Y

-

199999

999999

999999

+/-60C1

Linear. Point 12

P12_H

-

199999

999999

999999

+/-60C2

P12_Y

-

199999

999999

999999

+/-60C3

Linear. Point 13

P13_H

-

199999

999999

999999

+/-60C4

P13_Y

-

199999

999999

999999

+/-60C5

Linear. Point 14

P14_H

-

199999

999999

999999

+/-60C6

P14_Y

-

199999

999999

999999

+/-60C7

Linear. Point 15

P15_H

-

199999

999999

999999

+/-60C8

P15_Y

-

199999

999999

999999

+/-60C9

Linear. Point 16

P16_H

-

199999

999999

999999

+/-60D0

P16_Y

-

199999

999999

999999

+/-60D1

Value

Value

Value

Positions Characters

Code

IX34510b_e.doc / Mrz-13 Page 41 / 43

7.4. Commissioning Form

Date Software:

Operator: Serial Number:

General Setting: SSI-Mode: SSI-Bits:

SSI-Format: SSI-Baud Rate (kHz):

SSI-Test:

Characteristics: Brightness

Code Locking: Linearization Mode:

Model IX 346 Output Char.: Analogue Offset:

Analogue Gain:

Model IX 347 Presel. Mode 1 Presel. Mode 2:

Hysteresis 1 Hysteresis 2:

Model IX 348 Serial Unit Nr: Serial Format:

Serial Baud Rate:

Display-Parameters M-Factor: Decimal Point:

D-Factor: Display:

P-Factor:

SSI-Special: SSI-High bit: (MSB): SSI-Error bit:

SSI-Low bit: (LSB): SSI-E-Bit Polarity

SSI-Direction:

SSI-Round Loop: SSI-Reset Function:

SSI-Gap Time: SSI-Offset:

Zusatz-Parameter:

Model IX 346 Analogue Begin: Analogue End:

Model IX 347 Preselection 1: Preselection 2:

Model IX 348 Serial Timer: Serial Printer Mode:

Serial Register Code:

IX34510b_e.doc / Mrz-13 Page 42 / 43

Linearization

P1(x): P1(y): P9(x): P9(y):

P2(x): P2(y): P10(x): P10(y):

P3(x): P3(y): P11(x): P11(y):

P4(x): P4(y): P12(x): P12(y):

P5(x): P5(y): P13(x): P13(y):

P6(x): P6(y): P14(x): P14(y):

P7(x): P7(y): P15(x): P15(y):

P8(x): P8(y): P16(x): P16(y):

IX34510b_e.doc / Mrz-13 Page 43 / 43

Loading...

Loading...