Page 1

Operating Manual

6890.5060, 6890.5061, 6890.5066, 6890.5067, 6890.5069

Monitor for speed, standstill and direction of rotation with incremental encoder signals

Available devices:

6890.5060: Monitor with 3 programmable output relays and 1 analog output

6890.5061: Monitor with 3 fast switching transistor outputs and 1 analog output

6890.5066: Monitor with 1 analog output only

6890.5067: Monitor with 3 programmable output relays only

6890.5069: Monitor with 3 fast switching transistor outputs only

Product features:

Compact and most versatile monitor series for control of

overspeed, underspeed, standstill and direction of rotation

Logical monitoring of remote motion enable signals

Universal inputs for connection to incremental encoders (TTL, RS422 or HTL),

proximity switches, photocells remote TTL signals

Extremely wide frequency range, operating from 0.1 Hz up to 1 MHz

Easy setup by means of four keys and LCD menu

All models include serial RS232 interface

motrona GmbH, Zeppelinstraße 16, DE - 78244 Gottmadingen, Tel. +49 (0) 7731 9332-0, Fax +49 (0) 7731 9332-30, info@motrona.com, www.motrona.com

Page 2

Version:

Description:

6890.5060_01b_af/kk/hk_07/07

First edition in English

6890.5060_02a_af/kk/hk_01/08

Commands “Force Relays” and “Freeze Relays” added

6890.5060_03a_af/hk_11/08

Command Monitor for remote enable signal

6890.5060_03b_pp_11/11

Chapter 6.2.2 “Encoder properties” replaced TTL by HTL

6890.5060_03c_pp_07/12

Hint: “Special Menu” is password protected (Chap. 6.2.5)

6890.5060_03d_pp_11/12

Changed “Setting Range” for parameter “Wait Time” (code A3)

6890.5060_04a_sn_12/12

Additional device 6890.5061 and 6890.5069

6890.5060_04b_hk/nw_04/13

Small corrections

6890.5060_04c_sn_06/14

Small corrections Analog-Menu

6890.5060_04d/ag_04/15

Small corrections Analog-Menu.

New chapter 1. “Safety Instructions and Responsibility”.

6890.5060_04e_ag / Aug-15

- Analog output 4.13 – hint: only V or mA can be used (not both together)

- Analog menu 7.2.7 – some hints and a setup example supplemented

- Some smaller corrections and modulations

6890.5060_05a_af / Okt-16

Parameter Analogue ABS added

Parameter Preselection Mode increased to 9

Legal notices:

All contents included in this manual are protected by the terms of use and copyrights of motrona GmbH. Any

reproduction, modification, usage or publication in other electronic and printed media as well as in the internet requires

prior written authorization by motrona GmbH.

6890_5060_05a_oi_e.doc / Mrz-21 Page 2 / 40

Page 3

Table of Contents

1. Safety Instructions and Responsibility ......................................................... 5

1.1. General Safety Instructions ................................................................................... 5

1.2. Use according to the intended purpose ................................................................ 5

1.3. Installation ............................................................................................................. 6

1.4. Cleaning, Maintenance and Service Notes ........................................................... 6

2. Introduction ................................................................................................. 7

3. Available Models ......................................................................................... 7

4. Electrical Connections ................................................................................. 8

4.1. 6890.5060 .............................................................................................................. 8

4.2. 6890.5061 .............................................................................................................. 9

4.3. 6890.5066 ............................................................................................................ 10

4.4. 6890.5067 ............................................................................................................ 11

4.5. 6890.5069 ............................................................................................................ 12

4.6. Power Supply ....................................................................................................... 13

4.7. Auxiliary Output for Encoder Supply ................................................................... 13

4.8. Impulse Inputs for Encoders and Sensors ........................................................... 13

4.9. Control Inputs ...................................................................................................... 13

4.10. Serial Interface .................................................................................................... 14

4.11. Relay Outputs K1 – K3 (6890.5060 and 6890.5067 only) .................................... 14

4.12. Transistor Outputs K1 – K3 (6890.5061 and 6890.5069 only) ............................. 14

4.13. Scalable Analog Output (6890.5060, 6890.5061 and 6890.5066 only) ............... 14

5. LCD Display and Keys ................................................................................ 15

6. Keypad Operation ...................................................................................... 16

6.1. Normal Operation ................................................................................................ 16

6.2. Keypad Interlock .................................................................................................. 16

6.3. General Setup Procedure .................................................................................... 17

6.4. Changing Parameters on the Setting Level ......................................................... 17

6.5. Return from the Menu, Time-Out Function ......................................................... 18

6.6. Reset all Parameters to Factory Default Values ................................................. 18

7. Menu Structure and Parameter Description ............................................... 19

7.1. Survey of Menus ................................................................................................. 19

7.2. Parameter Descriptions ....................................................................................... 20

7.2.1. Preselection’s ................................................................................................................20

7.2.2. Definitions for the Encoder or Speed Sensor ...............................................................20

7.2.3. Serial Readout Menu ....................................................................................................21

7.2.4. Special-Menu ................................................................................................................22

7.2.5. Key-Pad-Menu ...............................................................................................................22

7.2.6. Command-Menu............................................................................................................23

6890_5060_05a_oi_e.doc / Mrz-21 Page 3 / 40

Page 4

7.2.7. Analog-Menu ................................................................................................................24

7.2.8. Serial Menu ...................................................................................................................25

7.2.9. Switching –Menu..........................................................................................................27

7.2.10. Linear.-Menu .................................................................................................................31

7.2.11. Display –Menu ..............................................................................................................32

8. Example for Commissioning ....................................................................... 33

9. Appendix ................................................................................................... 35

9.1. Hints for Use of the Linearization Function ......................................................... 35

9.2. Data Readout via Serial Interface ....................................................................... 36

9.3. “Relay Action”, override relay states by programmed states ............................. 37

9.3.1. Override relay/output states by programmable ON / OFF states ................................37

9.3.2. Freeze the actual switching state of all relays ............................................................37

9.4. Monitoring of remote motion enable signals ...................................................... 38

9.4.1. Definition of a speed window ......................................................................................38

9.4.2. Assignment of a control input ......................................................................................38

9.4.3. Assignment of the control polarity ...............................................................................38

9.4.4. Setting of a Start-up delay time ...................................................................................38

9.4.5. Setting of an appropriate Standstill definition ............................................................38

10. Dimensions: ............................................................................................... 39

11. Technical Specifications ............................................................................ 40

6890_5060_05a_oi_e.doc / Mrz-21 Page 4 / 40

Page 5

1. Safety Instructions and Responsibility

1.1. General Safety Instructions

This operation manual is a significant component of the unit and includes important rules and

hints about the installation, function and usage. Non-observance can result in damage and/or

impairment of the functions to the unit or the machine or even in injury to persons using the

equipment!

Please read the following instructions carefully before operating the device and observe all

safety and warning instructions! Keep the manual for later use.

A pertinent qualification of the respective staff is a fundamental requirement in order to use

these manual. The unit must be installed, connected and put into operation by a qualified

electrician.

Liability exclusion: The manufacturer is not liable for personal injury and/or damage to property

and for consequential damage, due to incorrect handling, installation and operation. Further

claims due to errors in the operation manual as well as misinterpretations are excluded from

liability.

In addition the manufacturer reserve the right to modify the hardware, software or operation

manual at any time and without prior notice. Therefore, there might be minor differences

between the unit and the descriptions in operation manual.

The raiser respectively positioner is exclusively responsible for the safety of the system and

equipment where the unit will be integrated.

During installation or maintenance all general and also all country- and application-specific safety

rules and standards must be observed.

If the device is used in processes, where a failure or faulty operation could damage the system or

injure persons, appropriate precautions to avoid such consequences must be taken.

1.2. Use according to the intended purpose

The unit is intended exclusively for use in industrial machines, constructions and systems. Nonconforming usage does not correspond to the provisions and lies within the sole responsibility of

the user. The manufacturer is not liable for damages which has arisen through unsuitable and

improper use.

Please note that device may only be installed in proper form and used in a technically perfect

condition and in accordance to the Technical Specifications (see chapter 11).

The device is not suitable for operation in explosion-proof areas or areas which are excluded by

the EN 61010-1 standard.

6890_5060_05a_oi_e.doc / Mrz-21 Page 5 / 40

Page 6

1.3. Installation

The device is only allowed to be installed and operated within the permissible temperature range.

Please ensure an adequate ventilation and avoid all direct contact between the device and hot or

aggressive gases and liquids.

Before installation or maintenance, the unit must be disconnected from all voltage-sources.

Further it must be ensured that no danger can arise by touching the disconnected voltagesources.

Devices which are supplied by AC-voltages, must be connected exclusively by switches,

respectively circuit-breakers with the low voltage network. The switch or circuit-breaker must be

placed as near as possible to the device and further indicated as separator.

Incoming as well as outgoing wires and wires for extra low voltages (ELV) must be separated

from dangerous electrical cables (SELV circuits) by using a double resp. increased isolation.

All selected wires and isolations must be conform to the provided voltage- and temperatureranges. Further all country- and application-specific standards, which are relevant for structure,

form and quality of the wires, must be ensured. Instructions about the permissible wire crosssections for wiring are described in the chapter 11 “Technical Specifications”.

Before first start-up it must be ensured that all connections and wires are firmly seated and

secured in the screw terminals. All (inclusively unused) terminals must be fastened by turning the

relevant screws clockwise up to the stop.

Overvoltages at the connections must be limited to values in accordance to the overvoltage

category II.

For placement, wiring, environmental conditions, as well as shielding and earthing/grounding of

the supply lines, the general standards of industrial automation industry and the specific

shielding instructions of the manufacturer are valid. Please find all respective hints and rules on

www.motrona.com/download.html --> “[General EMC Rules for Wiring, Screening and Earthing]”.

1.4. Cleaning, Maintenance and Service Notes

To clean the front of the unit please use only a slightly damp (not wet!), soft cloth. For the rear no

cleaning is necessary. For an unscheduled, individual cleaning of the rear the maintenance staff

or assembler is self-responsible.

During normal operation no maintenance is necessary. In case of unexpected problems, failures

or malfunctions the device must be shipped back to the manufacturer for checking, adjustment

and reparation (if necessary). Unauthorized opening and repairing can have negative effects or

failures to the protection-measures of the unit.

6890_5060_05a_oi_e.doc / Mrz-21 Page 6 / 40

Page 7

2. Introduction

DZ = Function: Speed Monitor

DZ 260

26 = Housing with dimensions 72 x 91 mm

(2.835 x 3.583 ‘’), with LCD and keypad

0 = Analogue output + 3 relay outputs

1 = Anlaouge output + 3 transistor outputs

6 = Analogue output only

7 = Relay outputs only

9 = Transistor outputs only

This new series of monitors has been designed as control modules for mounting inside of electric

control cabinets. The units are suitable for speed monitoring of machines, signalling overspeed,

underspeed, zero motion and the direction of rotation. Units providing an analog output can

moreover be used for closed-loop control or feedback purpose within a control system.

Very special advantages of these new monitors are the wide frequency range, the extremely fast

response and the remarkable versatility with regard to possible input formats and programmable

monitoring functions.

3. Available Models

There are five models available, all with fully similar basic functions, but with different options

concerning the outputs.

6890_5060_05a_oi_e.doc / Mrz-21 Page 7 / 40

Page 8

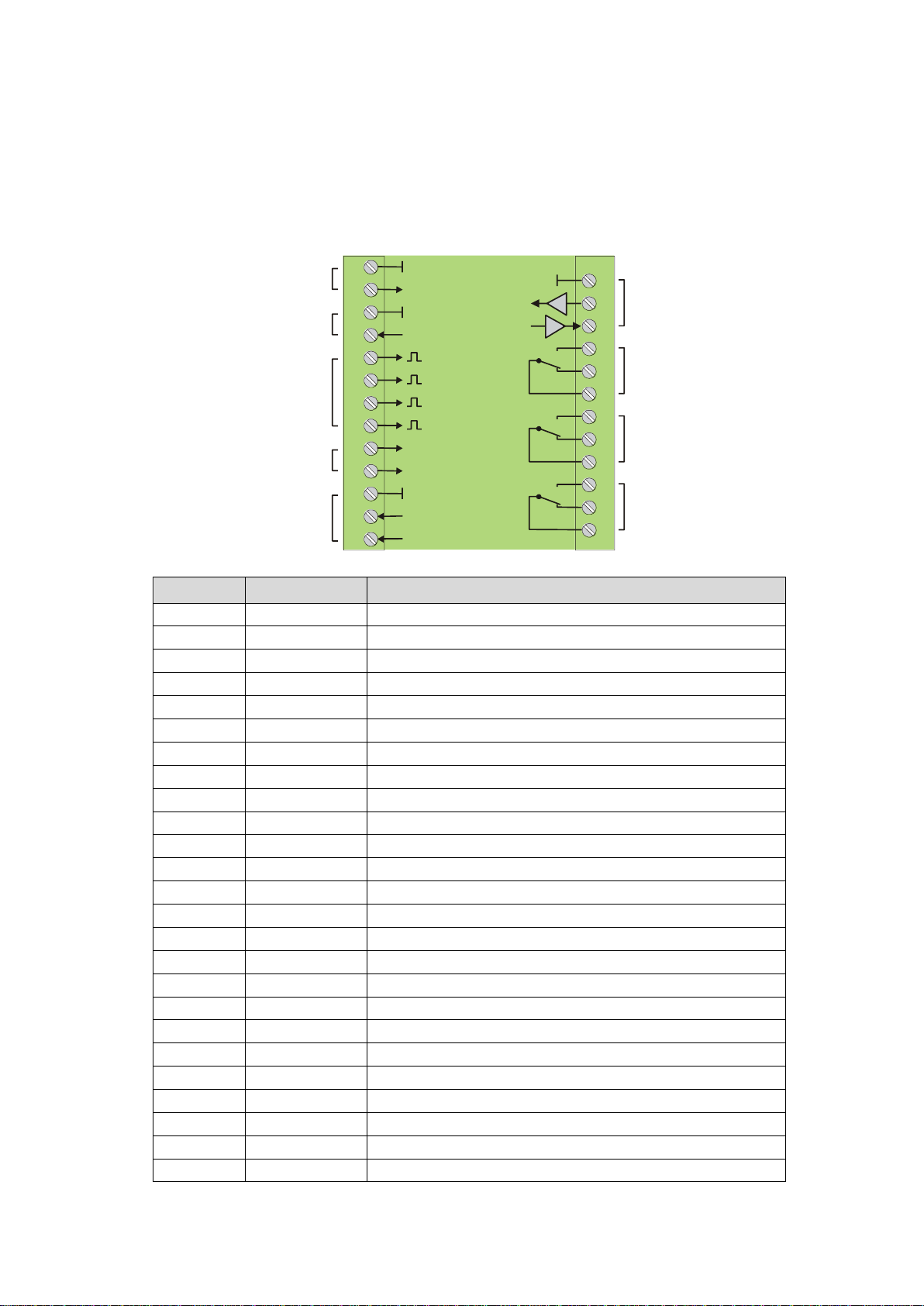

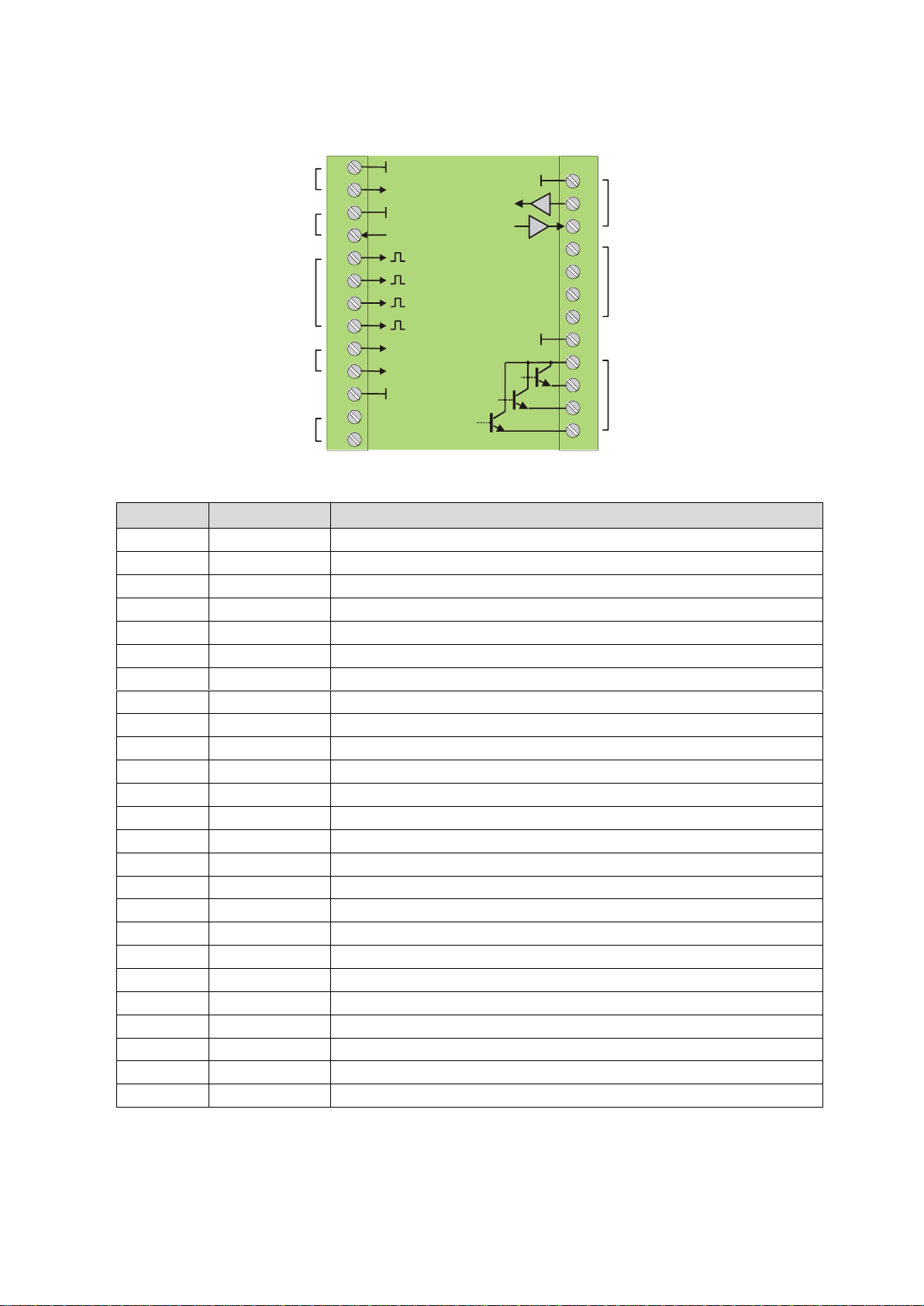

1

2

3

4

5

6

7

8

9

10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

GND (-)

GND

GND

GND

RxD

TxD

K1

K2

K3

+Power input

+5,2V

A

/A

B

/B

0 - 10 V

0/4 - 20 mA

Control 1

Control 2

Aux. Output

+5,2V

Impulse inputs

for encoders and

sensors

Power supply

17 - 30 VDC

Control

inputs

Analogue

output

Serial RS232interface

NO

NC

C

NO

NC

C

NO

NC

C

Relay K1

Relay K2

Relay K3

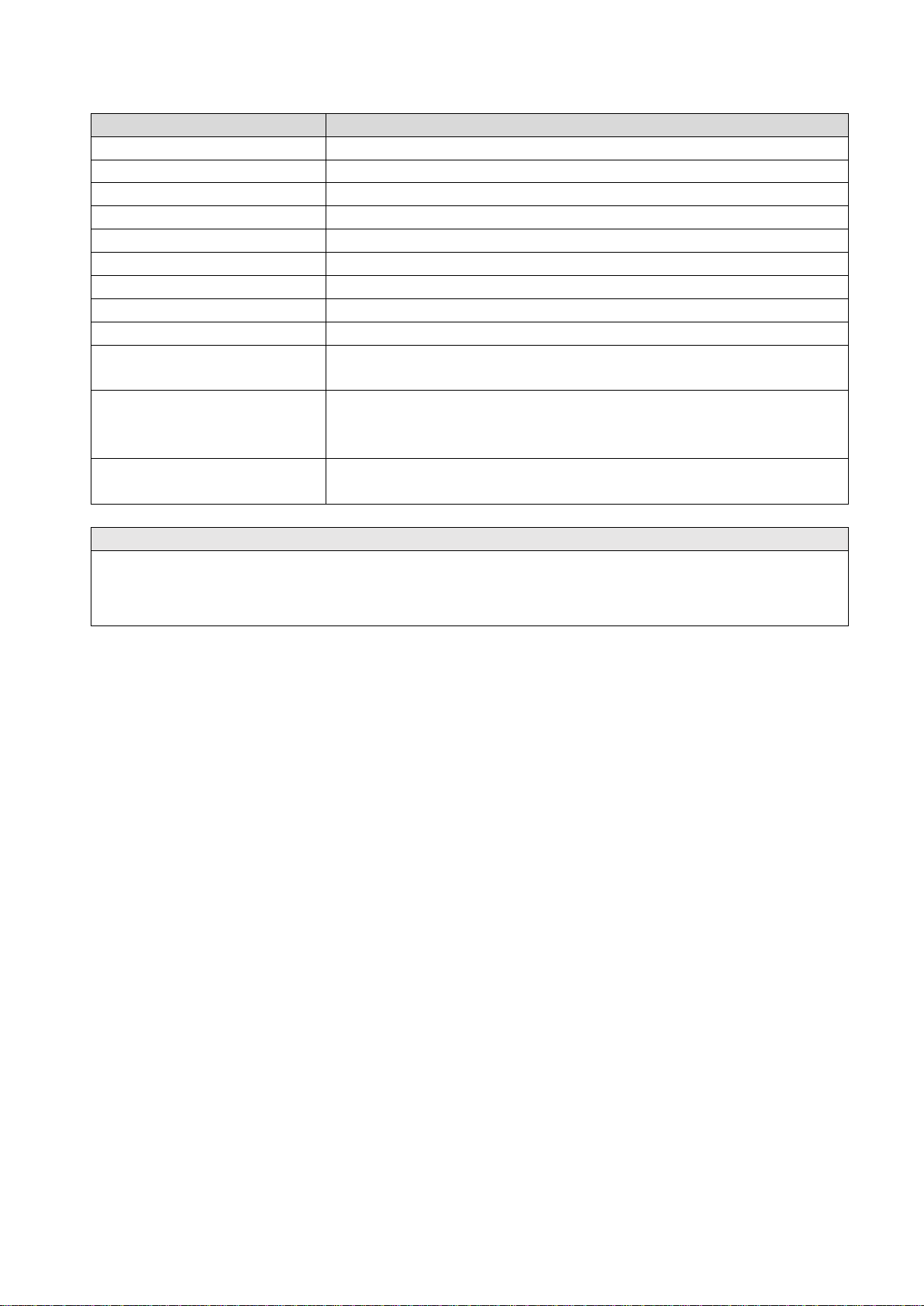

Terminal

Text

Function

01

GND

GND, common minus potential

02

Vin

Power input, +17 ... 30 VDC

03

GND

GND, common minus potential

04

+5,2V

Aux. output 5.2 V / 200 mA

05

A

Impulse input, channel A

06

/A

Impulse input, channel /A (=A inverted)

07

B

Impulse input, channel B

08

/B

Impulse input, channel /B (=B inverted)

09

Control 2

Control input with programmable function

10

Control 1

Control input with programmable function

11

GND

GND, common minus potential

12

+10V Out

Analog output 0 ... 10 V

13

20mA out

Analog output 0 ... 20 mA

14

GND

GND, common minus potential

15

RXD

Serial RS232 interface, data input

16

TXD

Serial RS232 interface, data output

17

K1NO

Relay 1, normally open contact

18

K1NC

Relay 1, normally closed contact

19

K1C

Relay 1, common contact

20

K2NO

Relay 2, normally open contact

21

K2NC

Relay 2, normally closed contact

22

K2C

Relay 2, common contact

23

K3NO

Relay 3, normally open contact

24

K3NC

Relay 3, normally closed contact

25

K3C

Relay 3, common contact

4. Electrical Connections

4.1. 6890.5060

6890_5060_05a_oi_e.doc / Mrz-21 Page 8 / 40

Page 9

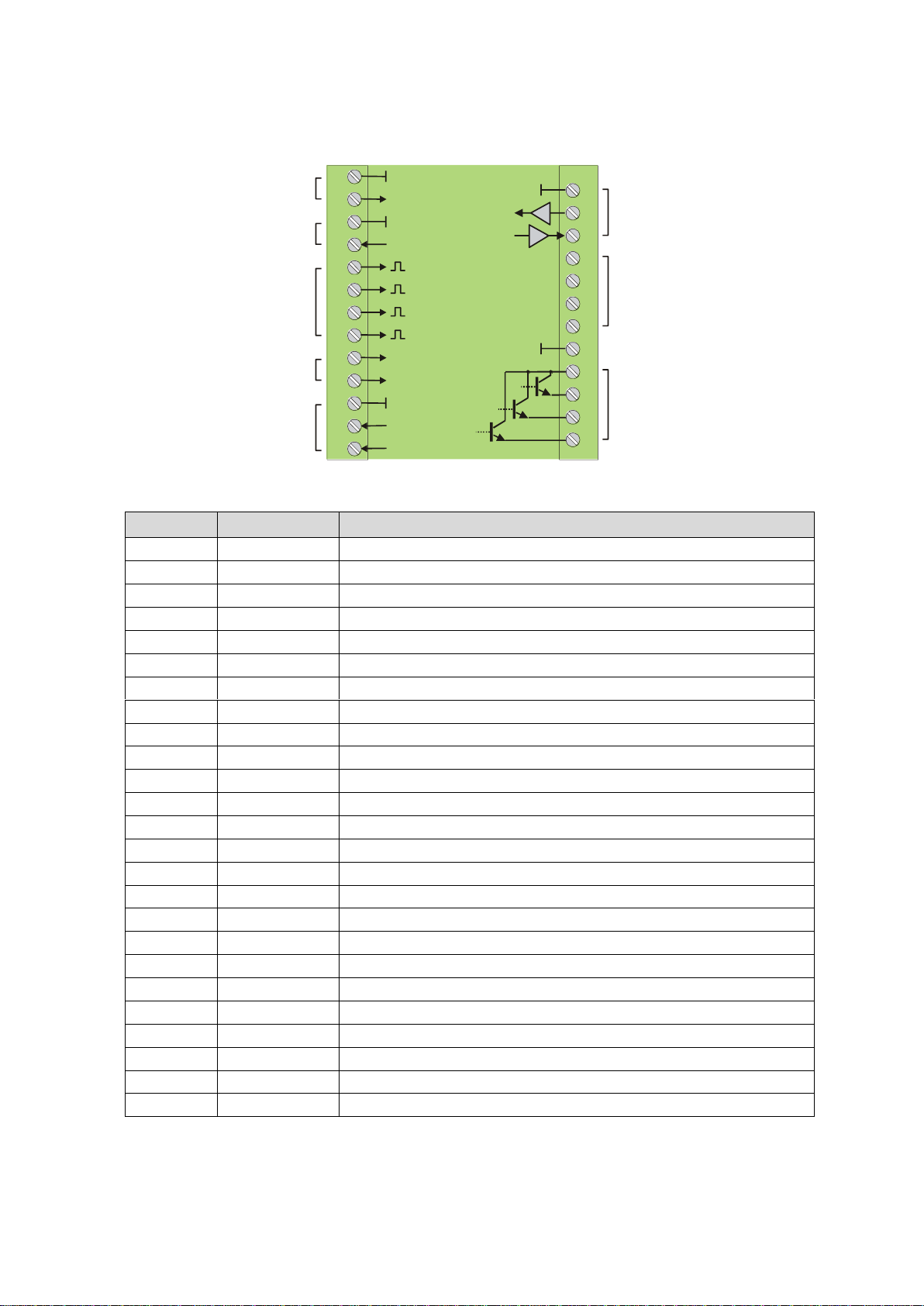

1

2

3

4

5

6

7

8

9

10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

GND (-)

GND

GND

GND

RxD

TxD

+Power supply

+5,2V

A

/A

B

/B

0 - 10 V

0/4 - 20 mA

Control 1

Control 2

Aux. output

+5,2V

Impulse inputs

for encoders and

sensors

Power supply

17 - 30 VDC

Control

inputs

Analogue

output

Serial RS232interface

Com + (5-30 V/DC)

GND

NC

K1 out

K2 out

K3 out

Terminal

Text

Function

01

GND

GND, common minus potential

02

Vin

Power input, +17 ... 30 VDC

03

GND

GND, common minus potential

04

+5,2V

Aux. output 5.2 V / 200 mA

05

A

Impulse input, channel A

06

/A

Impulse input, channel /A (=A inverted)

07

B

Impulse input, channel B

08

/B

Impulse input, channel /B (=B inverted)

09

Control 2

Control input with programmable function

10

Control 1

Control input with programmable function

11

GND

GND, common minus potential

12

+10V Out

Analog output 0 ... 10 V

13

20mA out

Analog output 0 ... 20 mA

14

GND

GND, common minus potential

15

RXD

Serial RS232 interface, data input

16

TXD

Serial RS232 interface, data output

17

NC

Not connected

18

NC

Not connected

19

NC

Not connected

20

NC

Not connected

21

GND

GND, common minus potential

22

Com +

Common positive input for transistor outputs K1-K3

23

K1 out

Output K1, transistor PNP 30 V, 350 mA

24

K2 out

Output K2, transistor PNP 30 V, 350 mA

25

K3 out

Output K3, transistor PNP 30 V, 350 mA

4.2. 6890.5061

6890_5060_05a_oi_e.doc / Mrz-21 Page 9 / 40

Page 10

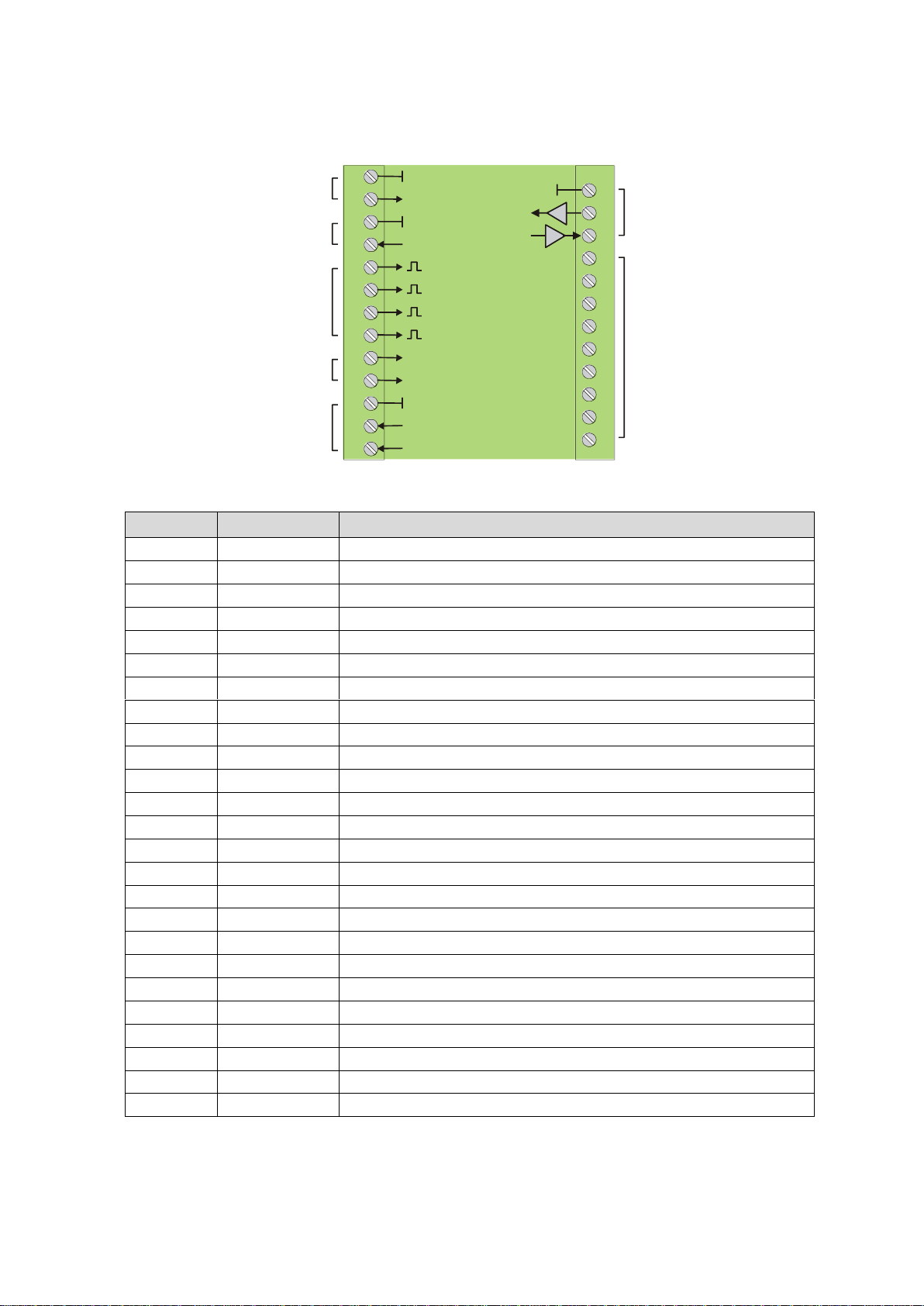

1

2

3

4

5

6

7

8

9

10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

GND (-)

GND

GND

GND

RxD

TxD

+Power supply

+5,2V

A

/A

B

/B

0 - 10 V

0/4 - 20 mA

Control 1

Control 2

Aux. Output

+5,2V

Impulse input

for encoders and

sensors

Power supply

17 - 30 VDC

Control

inputs

Analogue

output

Serial RS232interface

NC

Terminal

Text

Function

01

GND

GND, common minus potential

02

Vin

Power input, +17 ... 30 VDC

03

GND

GND, common minus potential

04

+5,2V

Aux. output 5.2 V / 200 mA

05

A

Impulse input, channel A

06

/A

Impulse input, channel /A (=A inverted)

07

B

Impulse input, channel B

08

/B

Impulse input, channel /B (=B inverted)

09

Control 2

Control input with programmable function

10

Control 1

Control input with programmable function

11

GND

GND, common minus potential

12

+10V Out

Analog output 0 ... 10 V

13

20mA out

Analog output 0 ... 20 mA

14

GND

GND, common minus potential

15

RXD

Serial RS232 interface, data input

16

TXD

Serial RS232 interface, data output

17

NC

Not connected

18

NC

Not connected

19

NC

Not connected

20

NC

Not connected

21

NC

Not connected

22

NC

Not connected

23

NC

Not connected

24

NC

Not connected

25

NC

Not connected

4.3. 6890.5066

6890_5060_05a_oi_e.doc / Mrz-21 Page 10 / 40

Page 11

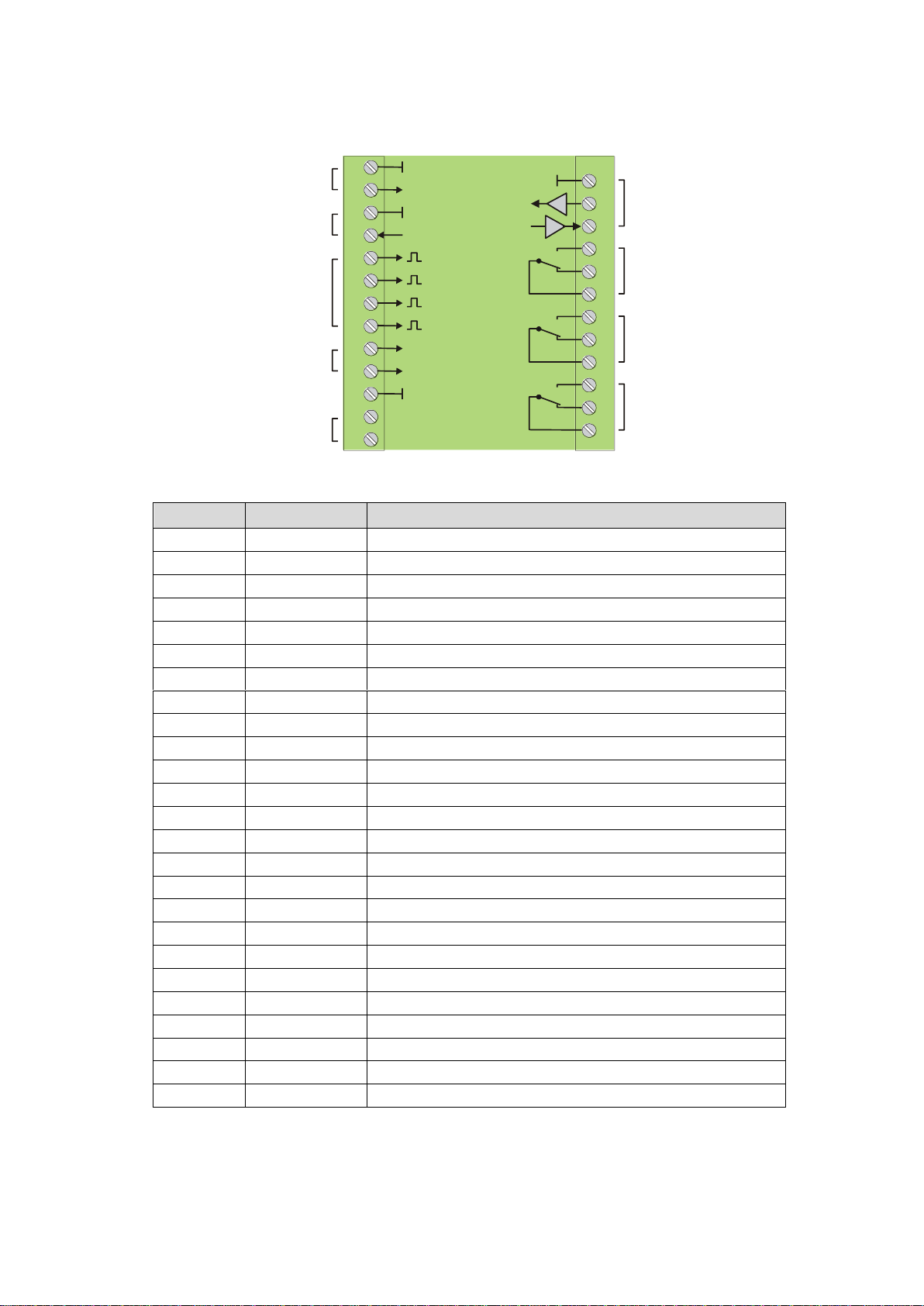

1

2

3

4

5

6

7

8

9

10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

GND (-)

GND

GND

GND

RxD

TxD

K1

K2

K3

+Power supply

+5,2V

A

/A

B

/B

Control 1

Control 2

Aux. output

+5,2V

Impulse inputs

for encoders and

sensors

Power supply

17 - 30 VDC

Control

inputs

NC

Serial RS232interface

NO

NC

C

NO

NC

C

NO

NC

C

Relay K1

Relay K2

Relay K3

Terminal

Text

Function

01

GND

GND, common minus potential

02

Vin

Power input, +17 ... 30 VDC

03

GND

GND, common minus potential

04

+5,2V

Aux. output 5.2 V / 200 mA

05

A

Impulse input, channel A

06

/A

Impulse input, channel /A (=A inverted)

07

B

Impulse input, channel B

08

/B

Impulse input, channel /B (=B inverted)

09

Control 2

Control input with programmable function

10

Control 1

Control input with programmable function

11

GND

GND, common minus potential

12

NC

Not connected

13

NC

Not connected

14

GND

GND, common minus potential

15

RXD

Serial RS232 interface, data input

16

TXD

Serial RS232 interface, data output

17

K1NO

Relay 1, normally open contact

18

K1NC

Relay 1, normally closed contact

19

K1C

Relay 1, common contact

20

K2NO

Relay 2, normally open contact

21

K2NC

Relay 2, normally closed contact

22

K2C

Relay 2, common contact

23

K3NO

Relay 3, normally open contact

24

K3NC

Relay 3, normally closed contact

25

K3C

Relay 3, common contact

4.4. 6890.5067

6890_5060_05a_oi_e.doc / Mrz-21 Page 11 / 40

Page 12

1

2

3

4

5

6

7

8

9

10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

GND (-)

GND

GND

GND

RxD

TxD

+Power supply

+5,2V

A

/A

B

/B

Control 1

Control 2

Aux. output

+5,2V

Impulse inputs

for encoders and

sensors

Power supply

17 - 30 VDC

Control

inputs

NC

Serial Rs232interface

Com + (5-30 V/DC)

GND

NC

K1 out

K2 out

K3 out

Terminal

Text

Function

01

GND

GND, common minus potential

02

Vin

Power input, +17 ... 30 VDC

03

GND

GND, common minus potential

04

+5,2V

Aux. output 5.2 V / 200 mA

05

A

Impulse input, channel A

06

/A

Impulse input, channel /A (=A inverted)

07

B

Impulse input, channel B

08

/B

Impulse input, channel /B (=B inverted)

09

Control 2

Control input with programmable function

10

Control 1

Control input with programmable function

11

GND

GND, common minus potential

12

NC

Not connected

13

NC

Not connected

14

GND

GND, common minus potential

15

RXD

Serial RS232 interface, data input

16

TXD

Serial RS232 interface, data output

17

NC

Not connected

18

NC

Not connected

19

NC

Not connected

20

NC

Not connected

21

GND

GND, common minus potential

22

Com +

Common positive input for transistor outputs K1-K3

23

K1 out

Output K1, transistor PNP 30 V, 350 mA

24

K2 out

Output K2, transistor PNP 30 V, 350 mA

25

K3 out

Output K3, transistor PNP 30 V, 350 mA

4.5. 6890.5069

6890_5060_05a_oi_e.doc / Mrz-21 Page 12 / 40

Page 13

4.6. Power Supply

The units require a DC supply from 17 to 30 V which must be applied to terminals 1 and 2.

Depending on the input voltage level and internal states, the power consumption may vary and

lies in a range of about 70 mA with a 24 V input (plus encoder currents taken from the auxiliary

voltage output).

4.7. Auxiliary Output for Encoder Supply

Terminals 4 and 3 provide a +5.2 VDC / 200 mA auxiliary output for supply of encoders and

sensors.

4.8. Impulse Inputs for Encoders and Sensors

The setup menu of the unit allows individual setting of the desired characteristics of the signal

inputs. According to the application the units will accept single-channel signals (input A only with

no direction information) as well as dual channel signals A/B including information of the

direction of rotation. The following input formats and levels are acceptable:

symmetric differential input with RS422 format A, /A, B, /B

asymmetric (single-ended) TTL levels (A and/or B only without inverted channels)

HTL level 10 ... 30 V, alternatively differential (A, /A, B, /B) or single-ended

(A and B only, without inverted channels)

Signals from proximity switches or photocells providing HTL level (10 ... 30 V)

NAMUR (2-wire) signals

4.9. Control Inputs

Two programmable control inputs allow the assignment of functions like remote start-up-delay,

reset of relay lock, hardware interlock of the keypad and similar.

Both inputs provide PNP characteristics and require HTL level. Also it is possible to set the control

function to "active LOW" or "active HIGH".

For evaluation of dynamic events the desired "active edge" can be set (rising or falling edge)

6890_5060_05a_oi_e.doc / Mrz-21 Page 13 / 40

Page 14

4.10. Serial Interface

2

3

5

RxD RxD

TxDTxD

GND

Screen

PC

DZ 260

DZ 261

DZ 266

DZ 267

DZ 269

15

(Sub-D-9)

16

14

Important note: “voltage out” and “current out” must not be used together.

Please do never connect mA and V simultaneously!

The serial RS232 interface in general may be used

for easy setup and commissioning of the units (with use of the OS32 operator software)

to change settings and parameters by PC or PLC during the operation

to read out internal states and actual measuring values by PC or PLC

The subsequent drawing shows how to link the monitor with a PC, using the standard

9-pin SUB-D-9 connector

4.11. Relay Outputs K1 – K3 (6890.5060 and 6890.5067 only)

The units provide three programmable relay outputs (all dry changeover), providing a switching

capability of 30 V / 2 A DC or 125 V / 0.6 A AC or 230 V / 0.3 A AC. Both, switching

characteristics and monitoring function may be programmed for each of the relays individually.

4.12. Transistor Outputs K1 – K3 (6890.5061 and 6890.5069 only)

The units provide three outputs with programmable switching characteristics.

K1 – K3 are fast-switching and short-circuit-proof transistor outputs with a switching capability of

5 ... 30 V / 350 mA each. The switching voltage of the outputs must be applied remotely to the

Com+ input (terminal 22). Both, switching characteristics and monitoring function may be

programmed for each of the outputs individually.

4.13. Scalable Analog Output (6890.5060, 6890.5061 and 6890.5066 only)

The units provide a voltage output with a +/-10 V range (max. load 2 mA) and a current output

with ranges 0 / 4 ... 20 mA (burden 0 – 270 Ohm), however only one of the two can be used at a

time. Beginning and end of the desired conversion range can be set by the operator menu (see

section 7.2.7). The common potential of both outputs refers to GND.

The total resolution is 14 bits. A settling time of approx. 200 µs. is required. The overall response

time of the analog outputs primarily depends on the selected Sampling Time setting. After

volatile jumps of the input signal, the analog outputs may need up to two Sampling Time cycles

(plus 200 µsec.) to stabilize.

6890_5060_05a_oi_e.doc / Mrz-21 Page 14 / 40

Page 15

Actual speed value

Input frequency, scaled in user units

+156.5 Hz

I: LH O: COO +47 %

Analogue output (not with DZ267, DZ269)

Actual output level in % of full scale

O: Outputs (not with DZ266)

Actual switching states of relays/transistor outputs

(Rel1, Rel2, Rel3)/(out1, out2, out3)

C = Closed, O = Open

I: Inputs

Actual logical state of inputs

(Control1, Control2)

L = Low, H = High

5. LCD Display and Keys

The units provide a back-lit LCD display with 2 lines at 16 characters each, and four keys for setup

and command control.

During the setup procedure the LCD display indicates the menu with all parameter texts and the

set values of the parameters.

During normal operation, the LCD display indicates the following information:

The "Display Menu" allows free scaling of the speed measuring values and the speed-related

parameters to any kind of engineering units.

6890_5060_05a_oi_e.doc / Mrz-21 Page 15 / 40

Page 16

PROG

UP

DOWN

ENTER

Stage

Protected

Range

Protection

by

Key Operations

Change of Parameters

Commands

1

---

---

permitted

permitted

2

Menu

Password upon

activation of menu

Protection of selectable parts of the menu

via password

permitted

3

Keyboard

Hardware-Latch 1

interlocked

permitted

Hardware Latch 2

All functions interlocked

Using the Hardware Latch function may accidentally cause a total locking of all

functions, when the Control Inputs characteristics have been set inauspiciously.

In this exceptional case you can release the key functions again by either

a) applying the correct logical state (High or Low) to the inputs

b) or resetting the parameters to their default values (see section 6.6)

c) or change the parameters being responsible for the locking by PC

P

6. Keypad Operation

A summary of all parameters and a detailed description of parameter functions is available under

section 6.

For all operation, the units provide four keys which subsequently will be named as shown below:

The key functions depend on the actual operating state of the units. Basically we have to

distinguish between Normal Operation and Setup Operation

6.1. Normal Operation

While in normal operation state, the units monitor the speed according to the selected

operational parameters and settings. Each of the front keys provides the command functions as

attached to it upon setup in the "Command Menu"

6.2. Keypad Interlock

There is a 3-stage conception to protect the keys against unauthorized changes of the

configuration respectively against activation of commands.

The "Key Pad" menu allows to define an individual password for each group of parameters. This

function can be used to provide individual access rights to different operators. Upon access to an

interlocked section the unit asks for the corresponding password. If the correct password is not

entered in time, the unit denies access and automatically returns to normal operation.

The hardware latch function can be activated and deactivated by one of the Control Inputs, or by

means of serial access to the corresponding locking register.

6890_5060_05a_oi_e.doc / Mrz-21 Page 16 / 40

Page 17

Key

Menu Level

Parameter Level

Setting Level

PROG

Save settings and return

to normal operation

Return to Menu Level

Check entry, store result,

then go back to Parameter

Level

UP

Switch over to next menu

Select next parameter

Increment the highlighted

digit or scroll the setting

upwards

DOWN

Go back to previous menu

Select previous parameter

Decrement the highlighted

digit or scroll the setting

downwards

ENTER

Switch over to the

Parameter Level of the

current menu

Switch over to

Setting Level

Shifts the highlighted digit

one position to the left, or

from utmost left to utmost

right

6.3. General Setup Procedure

To change over from normal operation to the setup state, please keep down the PROG key for at

least 2 seconds. After this the menu appears and you can select one of the menu groups.

Inside each group you can select the desired parameter and edit the setting according to need.

After this you are free to edit more parameters, or to return to normal operation.

The function of the different keys during setup is shown in the table below.

6.4. Changing Parameters on the Setting Level

With signed parameters, the front digit can only be changed between „+“ (positive) and „-„

(negative). The subsequent example explains how to change a parameter from originally 1024 to

a new value of 250 000.

The example assumes that you are already on the Setting Level, i.e. you have already selected

the corresponding parameter and read its actual value on the display. Highlighted (blinking) digits

are marked by background colour and indicate the cursor position.

6890_5060_05a_oi_e.doc / Mrz-21 Page 17 / 40

Page 18

No.

Display

Key action

Comment

00

001024

The actual value 1024 is displayed, with

the last digit blinking

01

4 x

Change last digit to 0

02

001020

Shift cursor to left

03

001020

2 x

Change highlighted digit to 0

04

001000

2 x

Shift curser to left by 2 positions

05

001000

Change highlighted digit to 0

06

000000

Shift cursor to left

07

000000

5 x

Change highlighted digit to 5

08

050000

Shift cursor to left

09

050000

2 x

Change highlighted digit to 2

10

250000

Save new setting and return to

Parameter Level

Power the unit down

Press

and

simultaneously

Switch power on with both keys held down

When execute this action, please be aware that all parameter settings

will be lost and the whole setup procedure must be repeated!

6.5. Return from the Menu, Time-Out Function

At any time the PROG key changes the Menu by one level backwards or fully back to the normal

operation mode. The menu also switches automatically one level backwards, every time when for

10 seconds no key has been touched (Time-Out-Function).

6.6. Reset all Parameters to Factory Default Values

If applicable, the whole set of parameters can be reset to factory default values (e.g. because a

code for the keypad interlocking has been forgotten, or because the unit does no more work

correctly for reasons of bad settings). All default values are indicated in the following parameter

tables.

To execute this Reset procedure, you have to take the following steps:

6890_5060_05a_oi_e.doc / Mrz-21 Page 18 / 40

Page 19

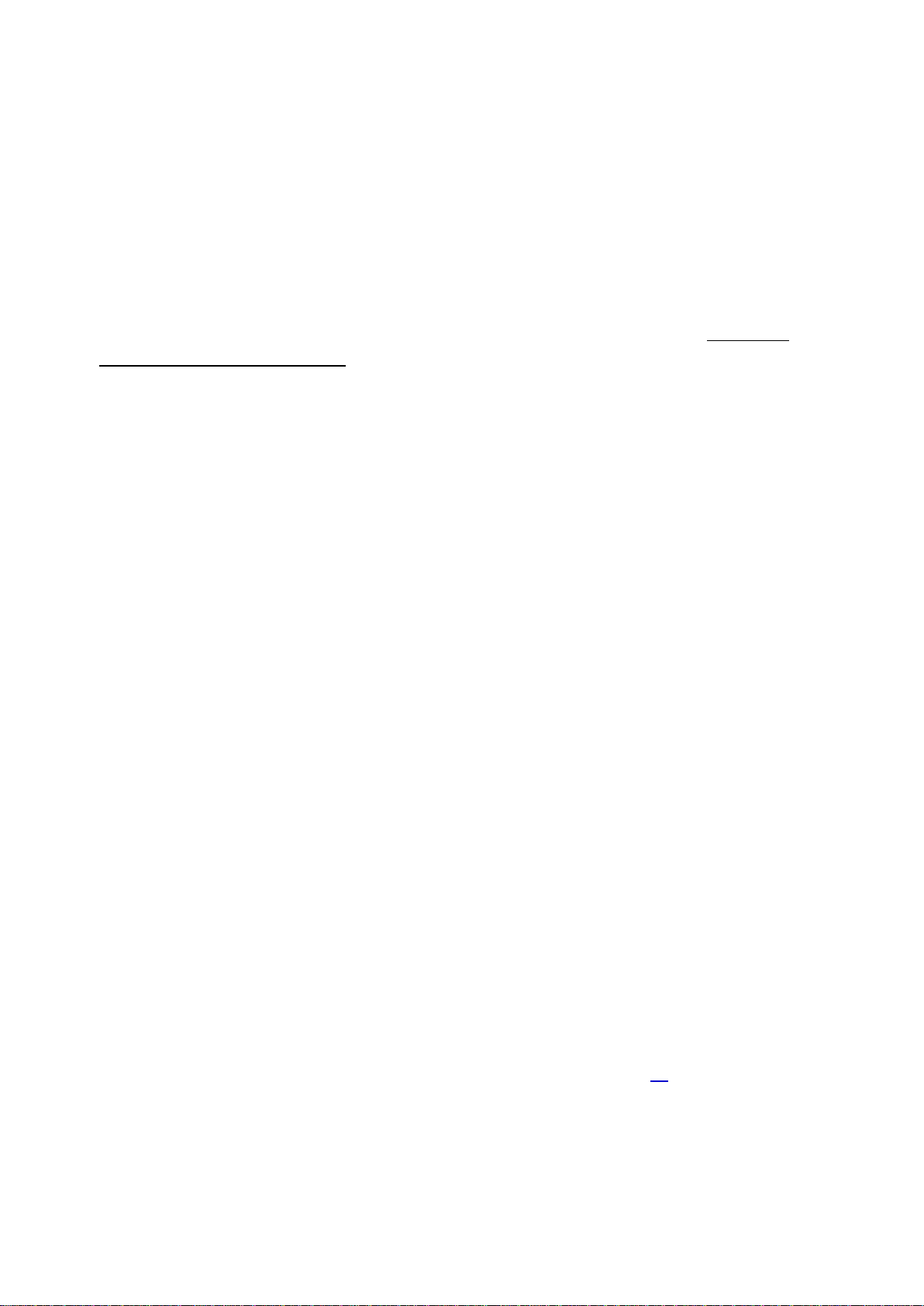

Preselect.-Menu*

Encoder-Menu

Ser.Readout Menu

Special-Menu

Preselection 1

Encoder Proper

Multiplier

Linear Mode**

Preselection 2

Direction

Divider

Freq. Control

Preselection 3

Sampling Time

Offset

Input Filter

Wait Time

Filter

Set Value

Key-Pad-Menu

Command-Menu

***

Analog-Menu**

Serial-Menu

Protect Menu M01

Key Up Func.

Analogue Format

Unit Number

Protect Menu M02

Key Down Func.

Analogue Start

Serial Baud Rate

Protect Menu M03

Key Enter Func.

Analogue End

Serial Format

… Input 1 Config.

Analogue Swing

Serial Protocol

Protect Menu M09

Input 1 Func.

Analogue Offset

Analogue ABS

Serial Timer

Protect Menu M10

Input 2 Config.

Register Code

Protect Menu M11

Input 2 Func.

Switching-Menu*

Linear.-Menu**

Display-Menu

Pulse Time 1

P1(x)

Up-Date-Time

Pulse Time 2

P1(y)

Display Mode

Pulse Time 3

P2(x)

Encoder Factor

Hysteresis 1

P2(y)

Multiplier

Hysteresis 2

..

Hysteresis 3

P14(x)

Preselect Mode 1

P14(y)

Preselect Mode 2

P15(x)

Preselect Mode 3

P15(y)

Output Polarity

Start up Mode

Start up Relay

(*) not relevant with 6890.5066

(**) not relevant with 6890.5067, 6890.5069

(***) partially inactive with 6890.5066

Lock Relay

Standstill Time

7. Menu Structure and Parameter Description

All parameters are combined to groups, arranged in several menus. Settings are only necessary

for parameters which are really relevant for the individual application.

7.1. Survey of Menus

This section provides an overview of the menus and their assignments to the different functions

of the units. The menu names are printed bold, and associated parameters are arrayed directly

under the menu names.

Menu texts are in English language, according to the presentation on the LCD display

6890_5060_05a_oi_e.doc / Mrz-21 Page 19 / 40

Page 20

Preselection parameters are not relevant for model 6890.5066

Preselection Menu

Code

Setting Range

Default

Preselection1

Switching point of relay 1/ out 1 (engineering units)

„00“

-1 000 000.0 ... +1 000 000.0

100.0

Preselection2

Switching point of relay 2/ out 2 (engineering units)

„01“

-1 000 000.0 ... +1 000 000.0

200.0

Preselection3

Switching point of relay 3/ out 3 (engineering units)

„02“

-1 000 000.0 ... +1 000 000.0

300.0

Encoder-Menu

Code

Setting Range

Default

Encoder Proper

Encoder properties

„A0“

0 … 11

0

0

A/B/90° quadrature, RS422 or HTL differential

1

A/B/90° quadrature, single-ended, HTL NPN*

2

A/B/90° quadrature, single-ended, HTL PNP

3

A/B/90° quadrature, single-ended, TTL level

4

A=Impulse, B=direction, RS422 or HTL differential

5

A=Impulse, B=direction, single-ended, HTL NPN*

6

A=Impulse, B=direction, single-ended, HTL PNP

7

A=Impulse, B=direction, single-ended, TTL level

8

Channel A only, RS422 or HTL differential

9

Channel A only, single-ended, HTL NPN*

10

Channel A only, single-ended, HTL PNP

11

Channel A only, single-ended, TTL level

Direction

Definition of the direction of rotation with quadrature encoders

„A1“

0, 1

0

0

forward when A leads B

1

forward when B leads A

(*) With settings HTL / NPN the input terminals are connected to the power supply voltage of

the unit (+24 V) via internal pull-up resistors. For this reason it is advisable to first set the

encoder properties correctly, prior to connecting TTL encoders to the unit.

Setting HTL / NPN is also suitable for use with NAMUR (2-wire) proximities.

(connect the positive wire of the sensor to the input terminal and the negative wire to GND)

7.2. Parameter Descriptions

7.2.1. Preselection’s

These parameters assign the desired switching points to the relays/outputs. The preselection’s

use the same engineering units as the display of the actual speed (see Display-Menu).

7.2.2. Definitions for the Encoder or Speed Sensor

6890_5060_05a_oi_e.doc / Mrz-21 Page 20 / 40

Page 21

Encoder-Menu

Code

Setting Range

Default

Sampling Time

Internal time base for sampling of the input frequency (sec.)

„A2“

0.001..9.999

0.001

Wait Time

Time to wait before unit detects zero speed (sec.)

Impulse distances greater than this time will be takes as zero

„A3“

0.01..9.99

1.00

Filter

Digital filter for smoothing of unstable frequencies

„A4“

0..7

0

0

Filter off

(very fast response to frequency changes)

1

Τ (63%) = 1,9 msec. with Sampling Time = 1msec.

2

Τ (63%) = 3,8 msec. with Sampling Time = 1msec.

etc.

7

Τ (63%) = 122 msec. with Sampling Time = 1msec.

(very slow response to frequency changes)

Set Value

Fixed frequency set value for encoder simulation (Hz)

(see also "Command"-Menu)

„A5“

-1 000 000.0 ...

+1 000 000.0

0

Serial Readout Menu

Code

Setting Range

Default

Multiplier

„A8“

-9.9999 … +9.9999

+1.0000

Divider

„A9“

0.0000 … 9.9999

0.0000

Offset (absolute term)

„B0“

-99999999 … +99999999

0

Readout (:8) = Basic Value x

Multiplier

Divider

+ Offset

The definition of the "Basic Value" occurs in the "Analog Menu" and is also available

for the 6890.5067 units without analog output

the ratio Multiplier / Divider must never be greater than 15 000

Setting "Divider" to zero will skip the rescaling procedure, resulting in a shorter

response time with all functions of the unit

7.2.3. Serial Readout Menu

An actual value proportional to the input frequency can be read out via serial link, accessing the

serial readout register (code :8 ). As a Basic Value this register uses the scaling set for the analog

output, i.e. a range from 0 to 10 000 units corresponding to 0 - 100,00 % of the full scale output

(see section 7.2.7 "Analog Menu"). This readout can still be rescaled to user-friendly engineering

units, using the following parameters:

More details about serial communication can be found in the appendix.

6890_5060_05a_oi_e.doc / Mrz-21 Page 21 / 40

Page 22

Special-Menu

Code

Setting Range

Default

Linear Mode

Programmable linearization for Basic Value and Analog Output

„B3“

0..2

0

0

Linearization off

1

Linearization range 0 V … +10 V

2 Linearization range -10 V … +10 V

Freq. Control

Defines behaviour and response of the unit to sudden interruptions of

the input frequency.

This parameter must only be changed in very special cases and under

special instruction of an motrona engineer.

Otherwise please use always the default setting "2"!

„B4“

0..2

2

Input Filter

Digital filter for limitation of the input frequency

„B5“

0..3

0

0

Filter off, the full range of frequency will be evaluated

1

Filter to cut frequencies higher than 500 kHz

2

Filter to cut frequencies higher than 100 kHz

3 Filter to cut frequencies higher than 10 kHz

Using the Input Filter will cause wrong frequency measurement when you use the unit with

frequencies higher than indicated above.

Key-Pad-Menu (Passwords for menu groups)

Code

Setting Range

Default

Protect Menu 01 (Preselect.-Menu)

„C0“

0..999999

0

Protect Menu 02 (Encoder-Menu)

„C1“

Protect Menu 03 (Ser.Readout.-Menu)

„C2“

0 = no interlock

Protect Menu 04 (Special-Menu) a)

„C3“

6079

Protect Menu 05 (Key-Pad-Menu)

„C4“

1 – 999 999 =

Protect Menu 06 (Command-Menu)

„C5“

password for the

Protect Menu 07 (Analog-Menu)

„C6“

corresponding

Protect Menu 08 (Serial-Menu)

„C7“

group

Protect Menu 09 (Switching-Menu)

„C8“

Protect Menu 10 (Linear-Menu)

„C9“

Protect Menu 11 (Display-Menu)

„D0“

7.2.4. Special-Menu

7.2.5. Key-Pad-Menu

a) This menu is protected by the password 6079 due to factory setting. After entry of the

password please press the Enter button at least 2 seconds.

6890_5060_05a_oi_e.doc / Mrz-21 Page 22 / 40

Page 23

Command-Menu (assignment of functions)

Code

Setting Range

Default

Key Up Func.

Supplementary command function of the UP key

„D7“

0..9

0

0

no function

1

Activation of a serial data transmission

2

Force programmed relay/output states / freeze (a)(c)

3

Frequency simulation according to parameter "Set Value"

4

Freeze actual input frequency

5

Remote start-up-delay function (a)

6

Release lock of relay 1 (a)

7

Release lock of relay 2 (a)

8

Release lock of relay 3 (a)

9

Release lock of all relays 1-3 (a)

Key Down Func.

Supplementary command function of the DOWN key (see UP)

„D8“

0..9

0

Key Enter Func.

Supplementary command function of the ENTER key (see UP)

„D9“

0..9

0

Input 1 Config.

Switching characteristics of input „Control1“

„E0“

0..3

0

0

Static low

1

Static High

2

Dynamic, rising edge

3

Dynamic, falling edge

Input 1 Func.

Control function of input „Control1“

„E1“

0..12

0

0

no function

1

Activation of a serial data transmission

2

Force programmed relay/output states / Freeze (a)(c)

3

Frequency simulation according to parameter "Set Value"

4

Freeze actual input frequency

5

Remote start-up-delay function (a)

6

Release lock of relay 1/transistor output 1 (a)

7

Release lock of relay 2/transistor output 2 (a)

8

Release lock of relay 3/transistor output 3 (a)

9

Release lock of all relays 1-3/output 1-3 (a)

10

Interlock for parameter access via keypad (b)

11

Total keypad interlock (b)

12

Command monitor for remote motion enable signal

Input 2 Config. (see Input 1 Config.)

„E2“

0..3

0

Input 2 Func. (see Input 1 Func.)

„E3“

0..12

0

7.2.6. Command-Menu

(a) these parameters are not relevant for model 6890.5066.

(b) see section 6.2 (c) see section 9.3 (d) see section 9.4

6890_5060_05a_oi_e.doc / Mrz-21 Page 23 / 40

Page 24

Analog-Menu (settings for analog outputs)

Code

Setting Range

Default

Analogue Format

Output format and range of the analog output

„E6“

0..3

0

0 -10 V to +10 V

1 0 V to +10 V

2 4 mA to 20 mA

3 0 mA to 20 mA

Analogue Start *)

Start value (engineering units) for 0 V resp. -10 V or 0 mA / 4 mA

Please note: „Analog Start“ represents the value, where the

analog output should start with 0 V. )*

… see example below

„E7“

- 1000000.0

… + 1000000.0

+0000000.0

Analogue End

End value (engineering units) for 10 V or 20 mA

„E8“

- 1000000.0

… + 1000000.0

+0001000.0

Analogue Swing

Max. output value (1.00 = 10 V or 20 mA)

Example: adjustment for a limitation to 8 V = 00.80

„E9“

0 ... 10.00

01.00

Analog Offset

Shift of the zero position (mV)

„F0“

-9999 ... 9999

0000

Analogue ABS

Only positive voltage values are displayed.

Please note: Independent of the parameters Analogue Start and

Analogue End, only positive values are displayed. At normal

case (Analogue ABS=0) the displayed voltage value is for

example -1,234V. If Analogue ABS=1, in this case 1,234V would

be displayed.

„F1“

0 ... 1

0

The settings above are at the same time used to generate the Basic Value 0 - 10 000

(corresponding to 0 - 100,00 %), which finally can be read out from the serial register

with access code :8 (see 7.2.3)

7.2.7. Analog-Menu

*) Example: If a display range of -250 to +250 must output a proportional analog range

from -10 V to +10 V, the “Analog Start” parameter must be set to 0 and the “Analog End”

value to +250.

6890_5060_05a_oi_e.doc / Mrz-21 Page 24 / 40

Page 25

Serial -Menu (Configuration of the serial link)

Code

Setting Range

Default

Unit Number (Serial device address)

A unit number between 11 and 99 can be assigned to each unit.

The address must not contain any zeros (0) since these addresses are

reserved for collective addressing of several units.

„90“

11 ... 99

11

Serial Baud Rate (Transmission speed)

„91“

0..6

0

0=

9600 Baud

1=

4800 Baud

2=

2400 Baud

3=

1200 Baud

4=

600 Baud

5=

19200 Baud

6=

38400 Baud

Serial Format (Format of transmit data)

„92“

0 ... 9

0

0=

7 Data, Parity even, 1 Stop

1=

7 Data, Parity even, 2 Stop

2=

7 Data, Parity odd, 1 Stop

3=

7 Data, Parity odd, 2 Stop

4=

7 Data, no Parity, 1 Stop

5=

7 Data, no Parity, 2 Stop

6=

8 Data, Parity even, 1 Stop

7=

8 Data, Parity odd, 1 Stop

8=

8 Data, no Parity, 1 Stop

9=

8 Data, no Parity, 2 Stop

7.2.8. Serial Menu

Serial transmissions will operate in either the “PC Mode“ or in “Printer Mode“.

With “PC-Mode“, the unit receives a request string and responds with a corresponding data

string. For details of the protocol see separate description “SERPRO“.

With “Printer Mode“ the unit sends data without any request and under Timer control as

described subsequently.

As soon as the unit receives a character, it automatically switches over to PC Mode and operates

according to protocol. When for a period of 20 sec. no character has been received, the unit

switches automatically back to “Printer Mode“ and starts cyclic data transmission again.

6890_5060_05a_oi_e.doc / Mrz-21 Page 25 / 40

Page 26

Serial -Menu (Configuration of the serial link)

Code

Setting Range

Default

Serial Protocol

Determines the sequence of characters sent, when you use the serial

output for cyclic data transmission under timer control

(xxxxxxx is the measuring value transmitted).

„F3“

0 ... 1

0

0=

Transmission = Unit Nr. – Data, LF, CR

1=

Transmission = Data, LF, CR

Setting "1" removes the unit address from the string which allows a

slightly faster transmission cycle.

Unit No.

0: 1 1 +/- X X X X X X

LF

CR

1: +/- X X X X X X

LF

CR

Serial Timer

This register determines the cycle time in seconds for cyclic

transmission when the Printer Mode is switched on.

With setting “0” all cyclic transmission is switched off and the unit will

only send data upon request (PC mode).

„F4“

0 ... 9.99

0

Register Code

Serial access code of the register which, in Printer Mode, should be

transmitted with every cycle. The most important registers are shown

below.

Setting

Code

Register contents

7

:7

Actual analog output value

10000 = 10 V = 20 mA

8

:8

User-defined readout value

(see 7.2.3)

9

:9

Frequency detected on the input

(Scaling is 0.1 Hz)

11

;1

Actual LCD display value

„F5“

0 ... 19

(:0) … (;9)

8

6890_5060_05a_oi_e.doc / Mrz-21 Page 26 / 40

Page 27

These parameters are not relevant for model 6890.5066.

Indications | f | mean that only the absolute value of the frequency is considered. With all other

indications, frequencies are categorically signed (+ with forward and - with reverse)

Switching -Menu (Switching characteristics of relays/outputs)

Code

Setting Range

Default

Pulse Time 1 Rel.1: Duration of timed output, sec. (0=static)

„F8“

0 ... 9.99

0

Pulse Time 2 Rel.2: Duration of timed output, sec. (0=static)

„F9“

0 ... 9.99

0

Pulse Time 3 Rel.3: Duration of timed output, sec. (0=static)

„G0“

0 ... 9.99

0

Hysteresis 1 Rel.1: Switching Hysteresis (engineering units)

„G1“

0 ... 99999.9

0

Hysteresis 2 Rel.2: Switching Hysteresis (engineering units)

„G2“

0 ... 99999.9

0

Hysteresis 3 Rel.3: Switching Hysteresis (engineering units)

„G3“

0 ... 99999.9

0

Preselect Mode 1 (switching operation for relay 1/output 1)

„G4“

0..9

0

0

|f| >= |Preselection| (catch*)

1

|f| <= |Preselection| with start-up-delay (catch*)

2

|f| == |Preselection| with start-up-delay (catch*)

3

Standstill (f=0) after expiration of standstill time

4

f >= Preselection (catch*)

(also suitable for signalization of forward direction)

5

f <= Preselection (catch*)

(also suitable for signalization of reverse direction)

6

f == Preselection (catch*)

7

Relay/output signals "forward" when a positive frequency (f > 0)

is detected. This information disappears upon detection of

"standstill"

8

Relay/output signals "reverse" when a negative frequency (f < 0)

is detected. This information disappears upon detection of

"standstill"

9

f > (Preselection + Hysteresis) or f < (Preselection – Hysteresis)

with start-up suppression and latch *)

The parameter Preselection forms the center, the hysteresis

specifies the area around.

Preselect Mode 2 (switching operation for relay 2/output 2)

see Preselection Mode 1

„G5“

0..8

0

Preselect Mode 3 (switching operation for relay 3/output 3)

see Preselection Mode 1

„G6“

0..8

0

7.2.9. Switching –Menu

*) The corresponding relay/output can be used with catch operation, when a catch function has been

assigned to it under parameter „Lock Relay“.

6890_5060_05a_oi_e.doc / Mrz-21 Page 27 / 40

Page 28

Switching -Menu (Switching characteristics of the relays/outputs)

Code

Setting Range

Default

Output Polarity (Relay/output active „on“ or active „off“ *)

Parameter with binary interpretation

„G7“

0..7

0

0

all Relays are energized when the assigned event occurs

1

Relay 1/transistor output 1 inverted

2

Relay 2 transistor output 2 inverted

3

Relay 1&2 transistor output 1&2 inverted

4

Relay 3 transistor output 3 inverted

5

Relays 1&3 transistor output 1&3 inverted

6

Relays 2&3 transistor output 2&3 inverted

7

All relays inverted

Start-up Mode

Start-up-delay after power-up and after standstill

„G8“

0..10

0

0

No start-up-delay

1

Start-up-delay 1 second

2

Start-up-delay 2 seconds

3

Start-up-delay 4 seconds

4

Start-up-delay 8 seconds

5

Start-up-delay 16 seconds

6

Start-up-delay 32 seconds

7

Start-up-delay 64 seconds

8

Start-up-delay 128 seconds

9

Automatic delay until to first overstepping of the set value

10

Start-up-delay by remote signal

Start up Relay / Switching Output

Assignment of a start-up-delay function to the relays/outputs

„G9“

0..7

0

0

No start-up-delay for any of the relays

1

Relay 1/transistor output 1 provides start-up-delay

2

Relay 2/transistor output 2 provides start-up-delay

3

Relays 1&2/transistor output 1&2 provide start-up-delay

4

Relay 3/transistor output 3 provides start-up-delay

5

Relays 1&3/transistor output 1&3 provide start-up-delay

6

Relays 2&3/transistor output 2&3 provide start-up-delay

7

All relays provide start-up-delay

*) Active "on" means the relay/output will be energized upon occurrence of the assigned event.

Active "off" means the relay/output will be de-energized upon occurrence of the assigned event.

6890_5060_05a_oi_e.doc / Mrz-21 Page 28 / 40

Page 29

Switching -Menu (Switching characteristics of the relays/outputs)

Code

Setting Range

Default

Lock Relay /Switching Output

Assignment of a catch function to the relays *)

„H0“

0..15

0

0

No catch function for any of the relays

1

Relay 1/output 1 with catch (release by key/control input)

2

Relay 2/output 2 with catch (release by key/ control input)

3

Relays 1&2/output 1&2 with catch (release by key/control input)

4

Relay 3/output 3 with catch (release by key/control input)

5

Relays 1&3/output 1&3 with catch (release by key/control input)

6

Relays 2&3/output 2&3 with catch (release by key/control input)

7

all Relays/outputs with catch (release by key/control input)

815

similar to 0 - 7, but catch to release by key/by control input and

automatically upon standstill

Standstill Time

Time setting for standstill definition

A time of xx.xx seconds after detection "zero input frequency" the unit

signals "standstill" and re-activates the start-up-delays

„H1“

0..99.99

0

Relay / Switching Output Action (for more details see section 9.3)

Selection of the relays/transistor outputs of which the switching state

should be overridden by key command or remote command (nonselected relays will continue normally)

„K8“

0…8

0

0

No relay/transistor output selected

1

Relay 1/transistor output 1

2

Relay 2/transistor output 2

3

Relays 1 & 2/transistor output 1&2

4

Relay 3/transistor output 3

5

Relays 1 & 3 /transistor output 1&3

6

Relays 2 & 3/transistor output 2&3

7

All relays/transistor outputs selected

8

Freeze actual switching state of all relays/transistor outputs

*) According to parameter settings, the catch situation can be released by either pressing one of the front

keys or by a remote control signal or automatically upon detection of standstill (see "Command menu").

6890_5060_05a_oi_e.doc / Mrz-21 Page 29 / 40

Page 30

Switching -Menu (Switching characteristics of the relays/outputs)

Code

Setting Range

Default

Action Polarity (for more details see section 9.3)

Desired override state of the corresponding relays/transistor outputs

(parameter is out of function when “Relay Action” is set to “8”)

„K9“

0…7

0

Setting

Relay/out K1

Relay/out K2

Relay/out K3

0 0 0 0 1 1 0 0 2 0 1 0 3 1 1 0 4 0 0 1 5 1 0 1 6 0 1

1

7 1 1

1

0 = Coil of the relay is de-energized – transistor output off.

1 = Coil of the relay is energized – transistor output on

6890_5060_05a_oi_e.doc / Mrz-21 Page 30 / 40

Page 31

Linear.-Menu

(Interpolation points for linearization)

Code

Setting Range

Default

P1(x) % Interpolation point 1, original value

„H2“

-100.000...100.000

100.000

P1(y) % Interpolation point 1, substitute value

„H3“

P2(x) etc.

„H4“

P2(y) etc.

„H5“

P3(x)

„H6“

P3(y)

„H7“

P4(x)

„H8“

P4(y)

„H9“

P5(x)

„I0”

P5(y)

„I1”

P6(x)

„I2”

P6(y)

„I3”

P7(x)

„I4”

P7(y)

„I5”

P8(x)

„I6”

P8(y)

„I7”

P9(x)

„I8”

P9(y)

„I9”

P10(x)

„J0“

P10(y)

„J1“

P11(x)

„J2“

P11(y)

„J3“

P12(x)

„J4“

P12(y)

„J5“

P13(x)

„J6“

P13(y)

„J7“

P14(x)

„J8“

P14(y)

„J9“

P15(x)

„K0“

P15(y)

„K1“

P16(x)

„K2“

P16(y)

„K3“

7.2.10. Linear.-Menu

6890_5060_05a_oi_e.doc / Mrz-21 Page 31 / 40

Page 32

Display -Menu

Code

Setting Range

Default

Up-Date-Time

Update time of the LCD display (seconds)

„K4“

0.05...1.00

0.10

Display Mode

Scaling of the unit's engineering units and the actual LCD display

„K5“

0..4

0

0

Hz

1

kHz (switch points and analog output remain in Hz)

2

RPS (revolutions per second) = f / Encoder Factor (*)

3

RPM (revolutions per minute) = 60 x f / Encoder Factor (*)

4

Customer-specific units set by Encoder-Factor und Multiplier

Display = f x Multiplier / Encoder Factor (*)

Encoder Factor number of impulses per revolution “ppr”

(with Display-Modes 2 – 4 only)

„K6“

1..99999

1

Multiplier Impulse multiplier (with display-Mode 4 only)

Display = f x Multiplier / Encoder Factor

„K7“

1..200

1

7.2.11. Display –Menu

*) f = Input frequency in Hz

With display modes 2 – 4 also the switching point settings will use the same engineering units

as set for the display

6890_5060_05a_oi_e.doc / Mrz-21 Page 32 / 40

Page 33

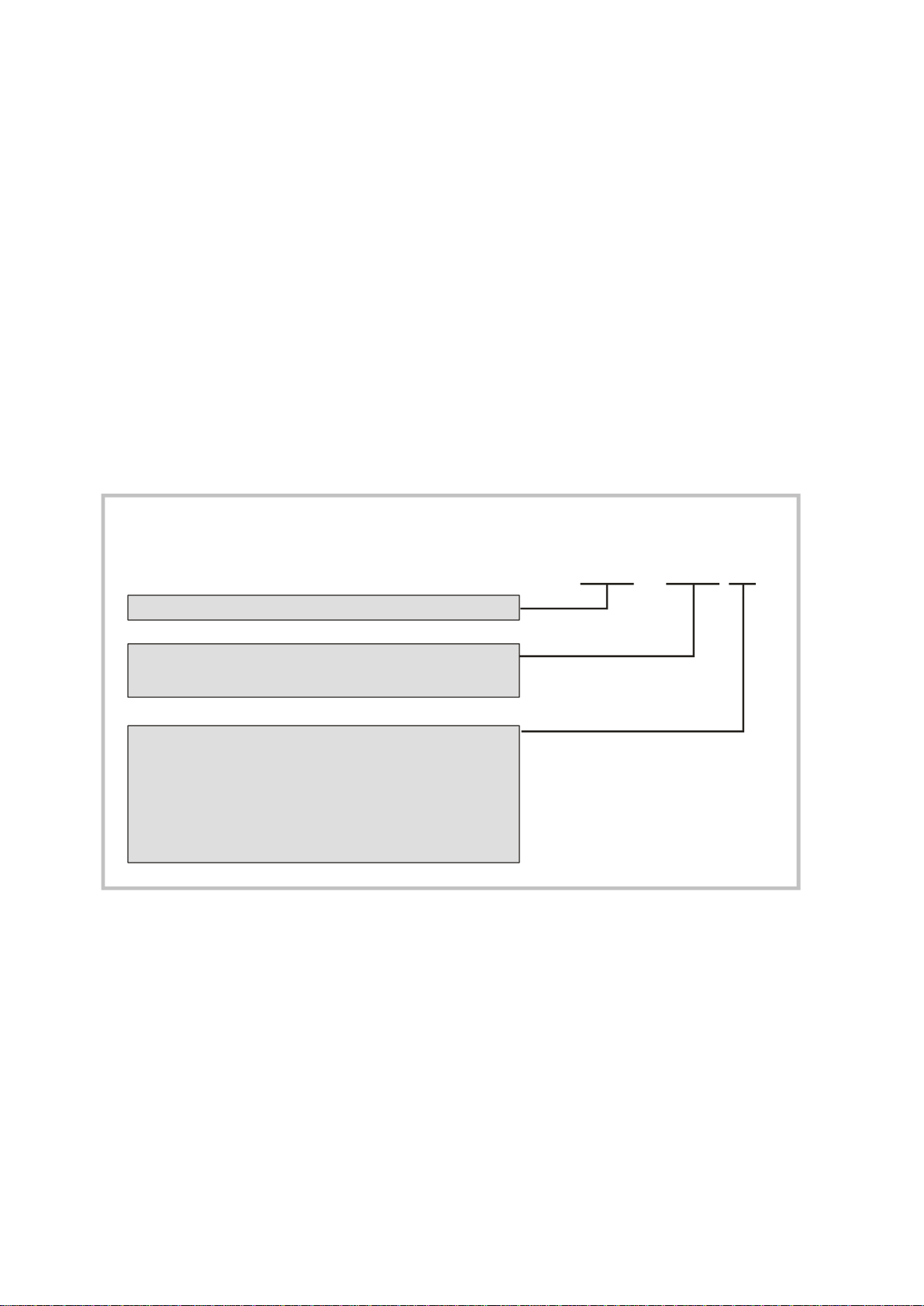

1 2 3 4 5 6 7 8 9 10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

GND (-)

GND

GND

GND

RxD

TxD

K1

K2

K3

+power in

+5,2V

A

/A

B

/B

0 - 10 V

0/4 - 20 mA

Control 1

Control 2

NO

NC

C

NO

NC

C

NO

NC

C

Relay K1

(standstill)

Relay K2

(underspeed forw. + rev.)

Relay K3

(overspeed, forward only)

A

B

+

+

2 x NAMUR

+24V

forward rotation

reverse rotation

0

Rel.1: Standstill

Rel.2: Underspeed

(pulsed output)

Rel.3: Overspeed

(forward roation only)

-100 +100

+300

8. Example for Commissioning

The following example is to explain setup and commissioning of the units with a typical

application.

A tooth wheel with 32 teeth should be monitored with respect to speed and standstill

For speed pick-up we use two proximity switches "Namur-type", which for detection of the

direction of rotation are mechanically displaced to generate an impulse offset

Relay 1 should signal "standstill" when one second after detection of "zero frequency" no

further input impulse has been registered

Relay 2 should generate a timed output pulse of 0.3 seconds when the speed drops below

100 RPM in either forward or reverse direction.

Relay 3 should switch on and catch when, with forward direction only, the speed exceeds

300 RPM. With reverse direction relays 3 should not respond at all

Release of the relay 3 catch state should be possible by either a positive signal applied to

input "Control1", or by activating the ENTER key.

6890_5060_05a_oi_e.doc / Mrz-21 Page 33 / 40

Page 34

Nr,

Menu

Parameter

Value

Function

1

Preselect Menu

Preselection1

Preselection2

Preselection3

--100

300

unimportant (relay 1 is used for standstill)

Switching point for "underspeed"

Switching point for "overspeed"

2

Encoder Menu

Encoder Proper.

Wait Time

=1

=5,00

A/B/90°, HTL / NPN for two displaced Namur sensors

Frequencies < 0,2 Hz are considered as "0"

3

Command

Menu

Key Enter Func.

Input 1 Config.

Input 1 Func.

=7

=1

=7

ENTER key to release the relay 3 catch

Function of "Control1" input is static HIGH

"Control1" input to release the relay 3 catch

4

Switching

Menu

Pulse Time 1

Pulse Time 2

Pulse Time 3

Presel. Mode1

Presel. Mode2

Presel. Mode3

Output Polarity

Start-up Mode

Start-up Relay

Lock Relay

Standstill Time

=0

=0.30

=0

=3

=1

=4

=0

=0

=0

=4

=1.00

Relay 1 static

Relay 2 timed output 0.3 seconds

Relay 3 static

Relay 1 energizes after lapse of standstill time

Relay 2 energizes when absolute value underpasses

Relay 3 energizes with positive overstepping only

All relays with non-inverted function (energize)

No start-up-delay function

No relay assignment to start-up-delay

Relay 3 to operate with catch function

Standstill output 1 second after detection of

"frequency = 0"

(i.e. 6 seconds after the last input pulse)

5

Display Menu

Display Mode

Encoder Factor

Multiplier

=3

=32

=1

Engineering units are RPM

Tooth wheel generates 32 pulses per revolution

No specific impulse scaling

The table below shows the setup procedure for an application according to the previous example.

Parameters which are not mentioned are optional, but not relevant for this function.

6890_5060_05a_oi_e.doc / Mrz-21 Page 34 / 40

Page 35

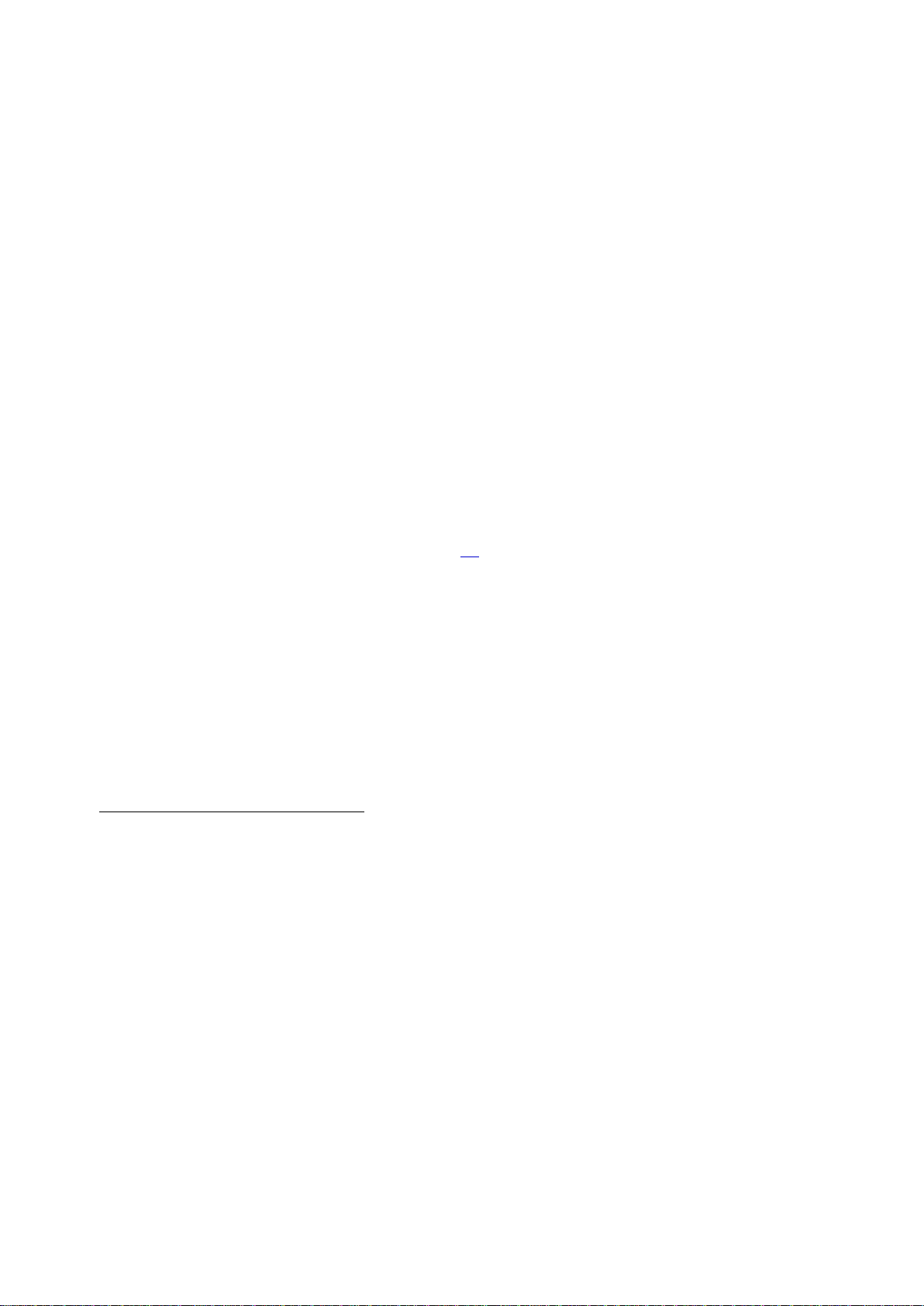

x-registers must use continuously increasing settings, i.e. P1(x) must

have the lowest and P16(x) must have the highest setting

All entries use a percental format of xx.xxx% full scale.

Setting 000.000 % means zero output and setting 100.000 % means

full scale output.

With Linearisation Mode set to 1, it is a must to set P1(x) to 0 % and

P16(x) to 100 %. Linearisation is defined in the positive range only

and the negative range will be a mirror image of the positive range

with reference to zero.

With Linearisation Mode set to 2, it is a must to set P1(x) to –100 %

and P16(x) to +100 %. This enables the user to set curves which are

not symmetric to the zero position.

x

y

P1(x)= 0%

P1(y)=10%

Linearisation Mode = 1

x

y

Linearisation Mode = 2

P1(x)= -100%

P1(y)= 95%

P8(x)= 0%

P8(y)= 80%

P16(x)=+100%

P16(y)= -60%

*)

P16(x)=100%

P16(y)= 80%

*) Output mode = 0

9. Appendix

9.1. Hints for Use of the Linearization Function

The linearization function of these units allow to convert a linear input frequency into a non-linear

developing, which can be indicated on the LCD display and which is also available as analog

signal or as serial data, for further processing.

There are 16 programmable x/y coordinates available, which can be set in any desired distance

over the full conversion range. Between two coordinates, the unit uses linear interpolation.

Therefore it is advisable to use more coordinates in a range with strong curves and only a few

coordinates where the curvature is less.

To specify an individual linearization curve, the „Linearisation Mode“ register must be set to

either 1 or 2.

The registers P1(x) to P16(x) are used to specify the coordinates on the x-axis. These are the

measuring values that the unit normally would generate according to the actual input frequency.

These settings must be in % of full scale.

Now enter the attached values to registers P1(y) to P16(y). These are the values that the unit will

generate instead of the x- values, i.e. P2(y) will substitute P2(x) etc.

6890_5060_05a_oi_e.doc / Mrz-21 Page 35 / 40

Page 36

EOT

AD1

AD2

C1

C2

ENQ

EOT = control character (Hex 04)

AD1 = unit address, High Byte

AD2 = unit address, Low Byte

C1 = register code, High Byte

C2 = register code, Low Byte

ENQ = control character (Hex 05)

ASCII Code:

EOT 1 1 : 9

ENQ

Hex Code:

04

31

31

3A

39

05

Binary Code:

0000 0100

0011 0001

0011 0001

0011 1010

0011 1001

0000 0101

STX

C1

C2

x x x x x x x

ETX

BCC

STX = control character (Hex 02)

C1 = register code, High Byte

C2 = register code, Low Byte

xxxxx = readout data

ETX = control character (Hex 03)

BCC = block check character

9.2. Data Readout via Serial Interface

All register codes shown in the "Serial Menu" are available for serial readout by PC or PLC. For

communication the monitors use the Drivecom Protocol according to ISO 1745. All protocol details

can be found in our manual SERPRO_2a.doc which is available for download from our homepage

www.motrona.com.

To request for a data transmission you must send the following request string to the converter:

The following example shows the request string for readout of the actual input frequency of a

monitor (code :9) from a unit with unit address 11:

After a correct request, the unit will respond:

For all further details see SERPRO_2a.doc.

6890_5060_05a_oi_e.doc / Mrz-21 Page 36 / 40

Page 37

Action

Parameter settings

1

Assign the Override Command to key “UP”

Key Up Func. = 2

2

Select relays/outputs K1 and K3

Relay Action = 5

3

Set the desired switching state of the

relays/outputs (both de-energized)

Action Polarity = 2

Action

Parameter settings

1

Assign the Freeze command to input “Control1”

Input 1 Func. = 2

2

Set the input to “Active High” characteristics

Input 1 Config = 1

3

Assign the “Freeze relays” function to the input

Relay Action = 8

These commands will override the switching states of the selected relays/outputs. All

relays/outputs will immediately return to the actual control state after removing the

override command. All internal measuring and control cycles will continue normally.

To use these functions, please set the corresponding key and input characteristics to

static operation only, since dynamic (edge-triggered) operation would make no sense

9.3. “Relay Action”, override relay states by programmed states

Models providing relay outputs allow to temporary change the actual relay states according to a

programmable ON / OFF pattern, or to temporary freeze the actual switching states. These

override functions can be activated by either touching a front key or by a remote command.

9.3.1. Override relay/output states by programmable ON / OFF states

Parameter “Relay Action” allows to select which of the relays/outputs should be affected by the

override action. Parameter “Action Polarity” provides setting of the desired “ON / OFF” pattern»

(see section 7.2.9, “Switching Menu”). The desired way of activation this override command can

be set by the “Command-Menu” (see 7.2.6).

Application example:

You would like to temporary de-energize relays K1 and K3 by touching the key “UP”, whilst relay

K2 should continue to function normally.

9.3.2. Freeze the actual switching state of all relays

This function will temporary freeze all relays in their actual state for the duration where you press

a key or apply a remote command. During the freeze period the relays will no more follow any

changes of the input frequency

Application example:

You would like to freeze all relays by applying a “High” signal to input “Control1”

6890_5060_05a_oi_e.doc / Mrz-21 Page 37 / 40

Page 38

The command monitor uses always the same relay/transistor output to which the

underspeed function has been assigned.

It is important to set a time higher than the Start-up delay time!

While the command monitor function is active, you can see an indicator box in the

PI/PO column of the PC screen. The "Command Monitor" box shines blue when the

motion command is in "Disable" state.

9.4. Monitoring of remote motion enable signals

The unit provides a special "Command Monitor" function for logical control of a motion enable

signal and the resulting response of the system. In addition to the normal monitoring functions

this mode is suitable to generate alarm outputs under any of the following conditions:

motion is disabled, but still the system moves

motion is enabled, but the system does not move at all (mechanical deadlock), or the

system does not reach the scheduled speed within an expected time (overload)

the motion command changes over from "enable" to "disable" but the system does not come

down to standstill within an expected time

The following parameter settings will activate the Command Monitor function:

9.4.1. Definition of a speed window

The application requires one of the relays to operate in overspeed mode (Preselect Mode = 0) and

another relay to operate in underspeed mode (Preselect Mode = 1). This will define a window for

the expected speed under regular motion conditions (see 7.2.9)

9.4.2. Assignment of a control input

One of the two control inputs has to be set to the control function "12" to activate the monitoring

of the command. This input must be connected to the remote Enable/Disable signal (see

parameters "Input Function" under 7.2.6)

9.4.3. Assignment of the control polarity

Parameter "Input Config" provides setting of the input polarity as follows:

Input Config = 0 => Motion disabled (stop) corresponds to input level "LOW"

Motion enabled (run) corresponds to input level "HIGH"

Input Config = 1 => Motion disabled (stop) corresponds to input level "HIGH"

Motion enabled (run) corresponds to input level "LOW"

9.4.4. Setting of a Start-up delay time